Tailing cemented and filled retaining wall device under mine

A technology for cementing filling and retaining walls, which is used in filling materials, safety devices, mining equipment, etc., can solve the problems of complex construction process of reinforced flexible retaining walls, affecting the construction speed and quality of retaining walls, and difficult to guarantee the quality. Good effect, good water filtration effect, fast erection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

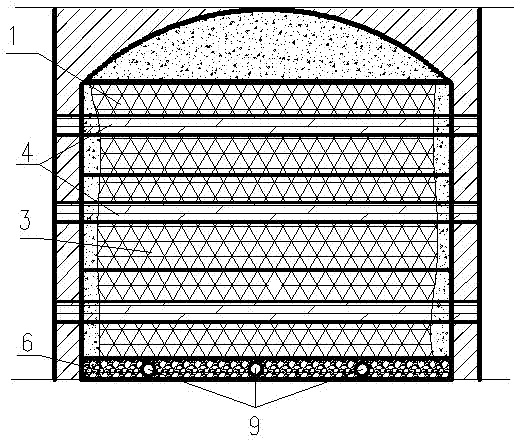

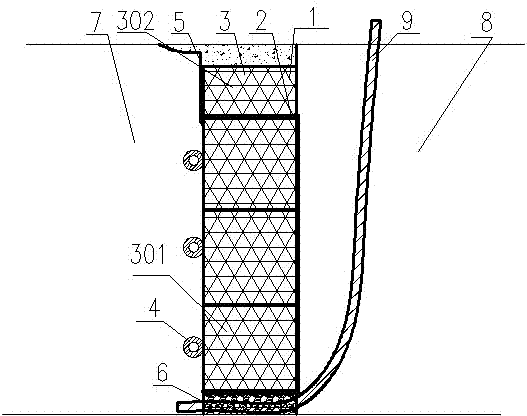

[0014] Such as figure 1 Shown: a retaining wall device for cemented filling of mine tailings, including a roadway, a wall 1, and three to five dewatering pipes 9 ( figure 1 shown in three); wall 1 separates the roadway into stope 8 and stope outside 7; wall 1 includes filter cloth 2, several layers of gabion cages 3 arranged according to the upper and lower layers and several retaining walls Crossbar 4; Gabion net box 3 is filled with excavation waste rock, and the particle size of excavation waste rock is 100-200mm; The lower gabion net box 3 is provided with a concrete foundation 6, and several dewatering pipes 9 are arranged in the concrete foundation 6 to dehydrate The water outlet port of the pipe 9 is located outside the stope 7, the water inlet port is located at the stope 8, and the filter cloth 2 is laid on the outer surface of several layers of gabion cages 3 located at the stope 8; Layers are arranged and fixed outside the several layers of gabion cages 3 outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com