Mini-type non-cooling plasma jet igniter

A plasma, non-cooling technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

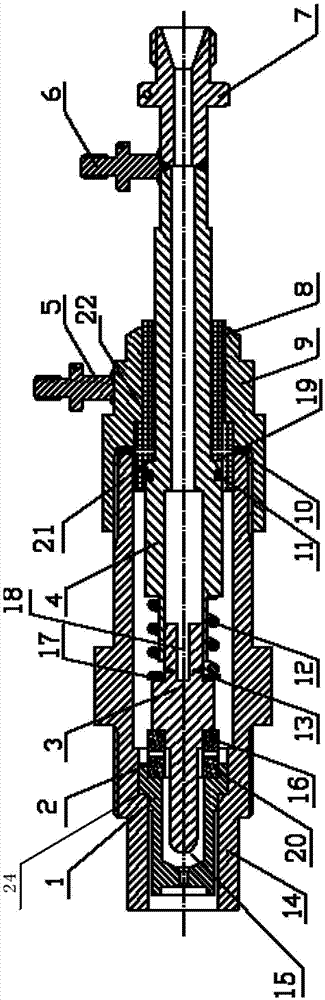

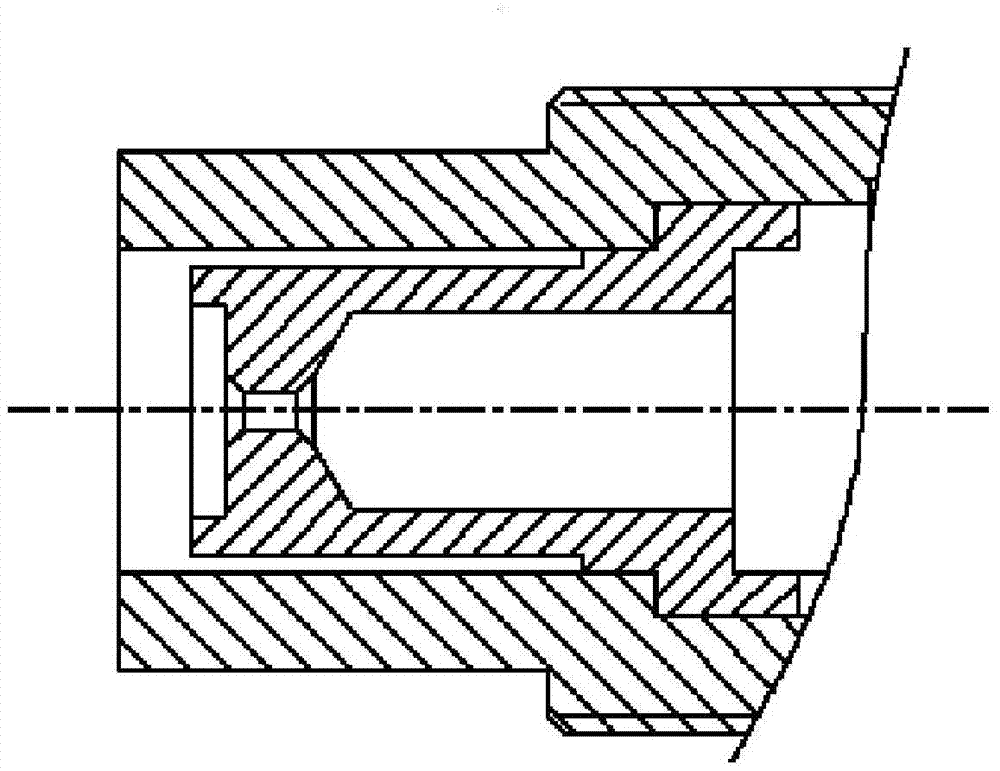

[0030] As shown in FIG. 3, the small uncooled plasma jet igniter of the present invention includes a cathode 3, an anode 1, a cyclone 2, a casing, an anode terminal 5, a cathode terminal 6, a spring 12, a cathode terminal rod 4 and The ceramic ring 8, the tail of the anode 1 is provided with a blind hole 15, the inner wall of the tail of the anode 1 is provided with a first inner ring groove 20; the cathode 3 includes a cathode head, a middle part and a cathode tail, and the diameter of the middle of the cathode is larger than that of the head and tail. The outer wall of the front end of the middle of the cathode is provided with a first annular shoulder 16; the outer wall of the cathode tail is provided with a second annular shoulder 17, the end of the cathode tail is provided with a through slot 18 inward, and the center of the cathode connecting rod is provided with an air channel The cathode terminal is divided into a cathode terminal head and a cathode terminal tail, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com