Patents

Literature

96results about How to "Reduce flow dead zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

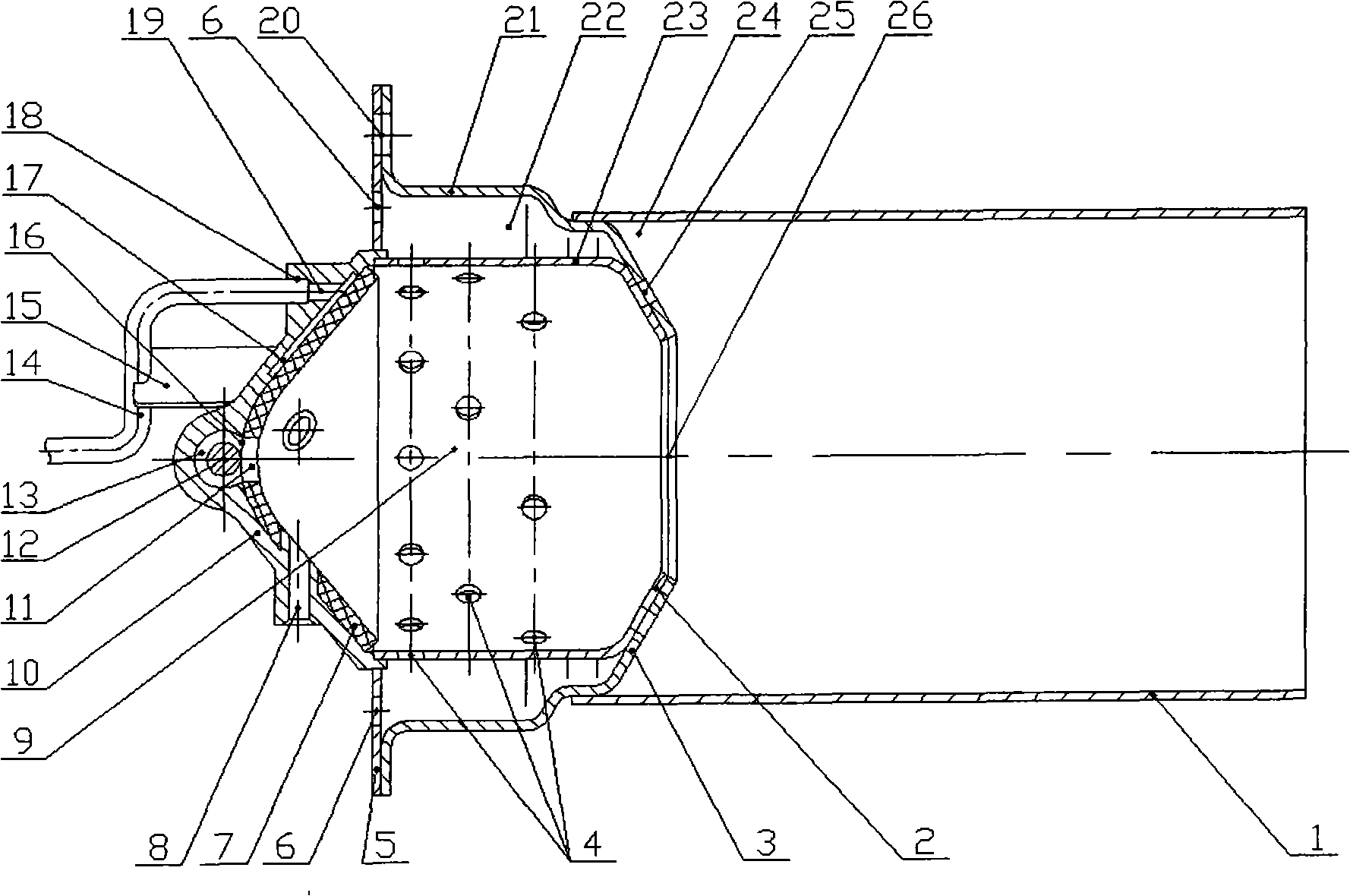

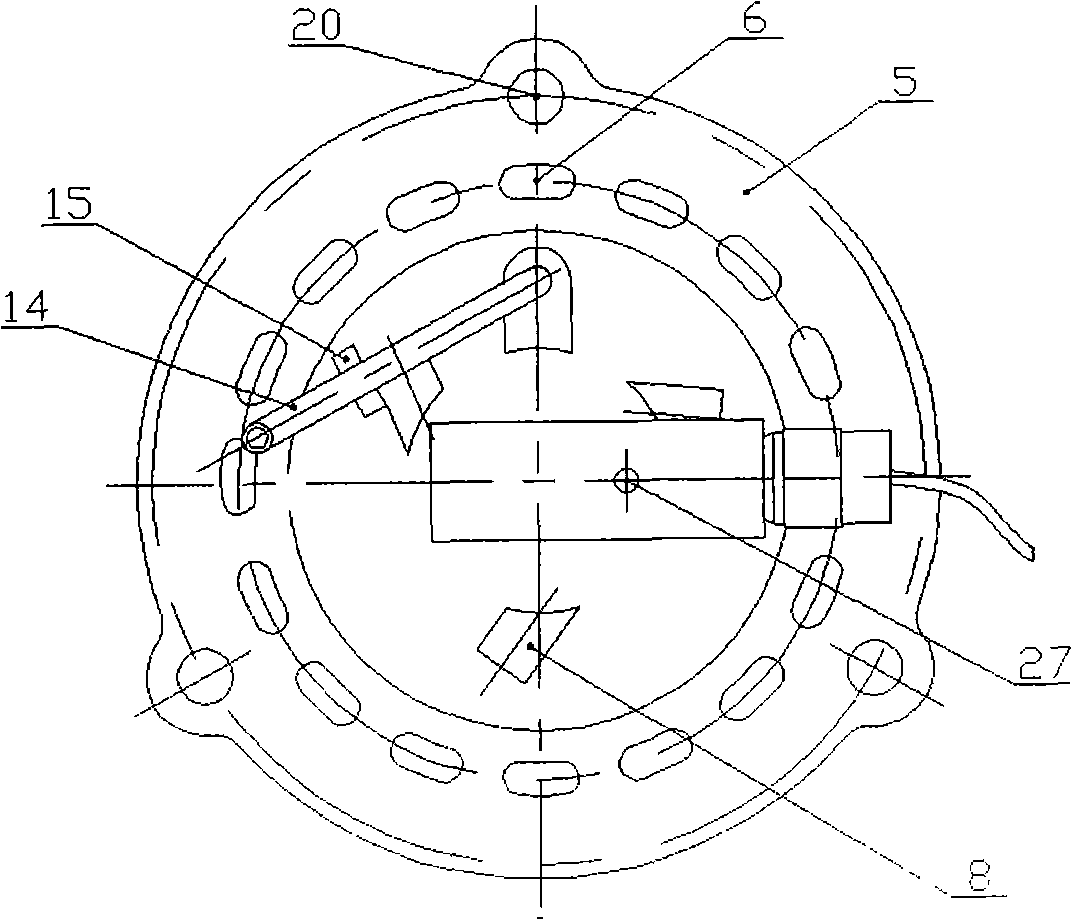

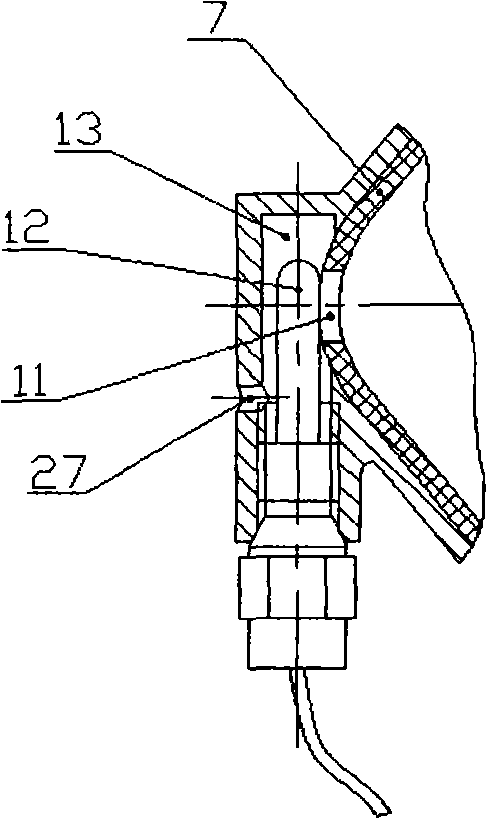

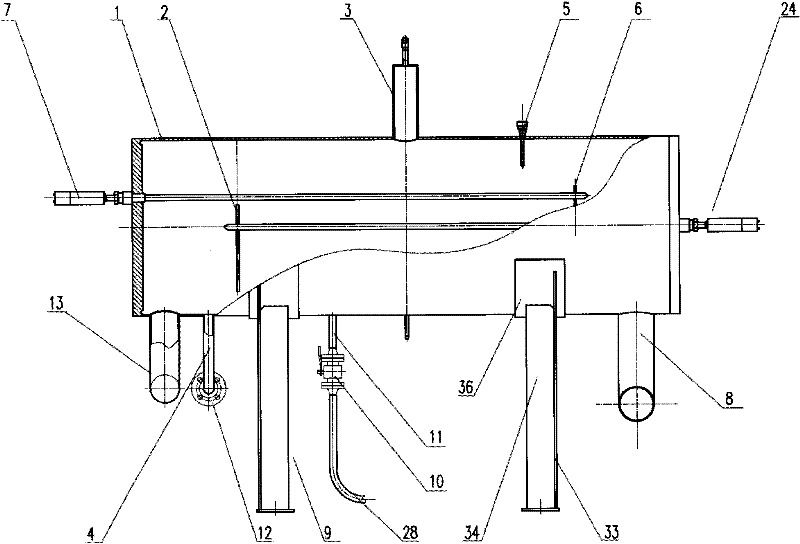

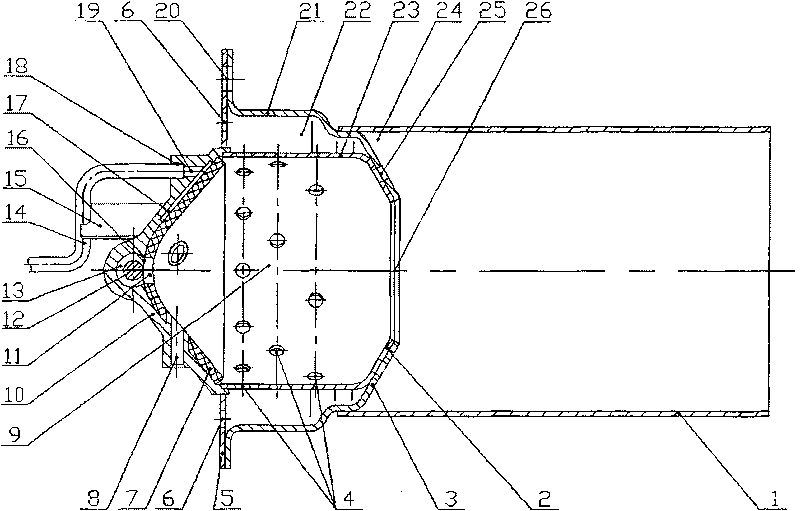

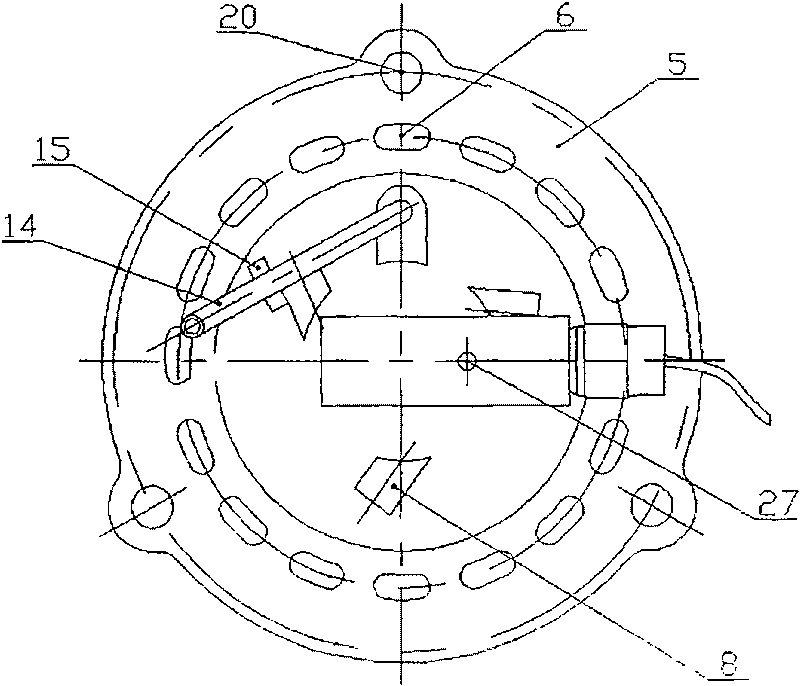

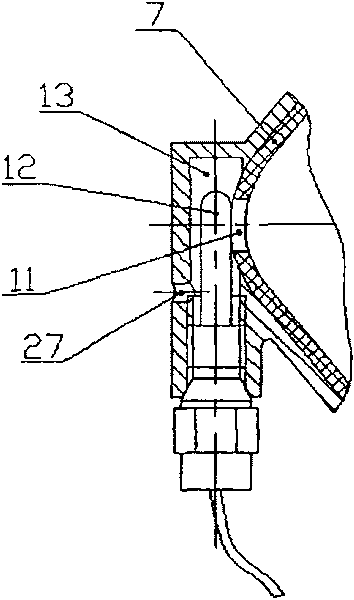

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922AEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

Coarse ring-free aluminum alloy bar and preparation method thereof

InactiveCN106011564AReduce shear deformationReduce material flow dead zoneShearing deformationCrystallite

The invention discloses a coarse ring-free aluminum alloy bar. The coarse ring-free aluminum alloy bar is prepared from the following components in percentage by weight: 0.62 to 0.7 percent of Si, 0.3 to 0.4 percent of Fe, 0.2 to 0.35 percent of Cu, 0.1 to 0.15 percent of Mn, 0.9 to 0.98 percent of Mg, 0.15 to 0.25 percent of Cr, 0.25 percent of Zn, 0.06 to 0.13 percent of Ti and the balance of Al. According to the coarse ring-free aluminum alloy bar disclosed by the invention, the addition range of Cr and Mn elements is strictly controlled on the basis of 6061 aluminum alloy specified in the national standard GB / T3191-2010, and the Cr and Mn elements have a function of inhibiting grain expansion in the aluminum alloy; the temperatures of a die, a cast ingot and an extrusion container can be controlled during a follow-up extrusion process, so that the shear deformation of a material during extrusion is reduced; an arc-shaped die bearing is adopted, so that the material flowing dead zone of an extrusion die is reduced; by using the produced 6061 aluminum alloy bar, a coarse ring cannot be fundamentally seen, the mechanical performance of a material and the oxidation performance of a product are greatly increased, the color of the material is consistent after an anode is oxidized, and the coarse ring-free aluminum alloy bar has no defects of piebaldness and the like.

Owner:无锡海特铝业有限公司

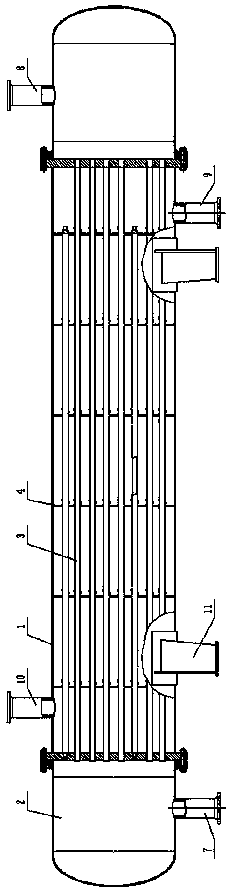

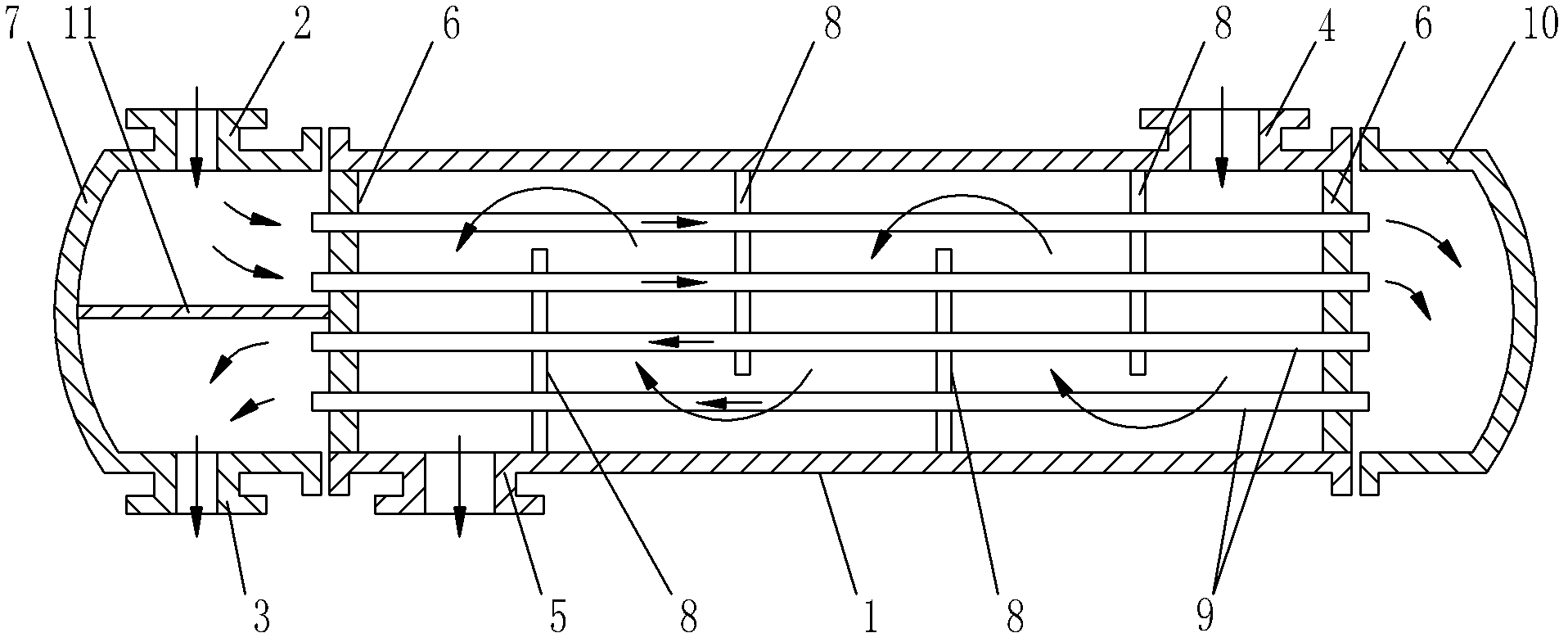

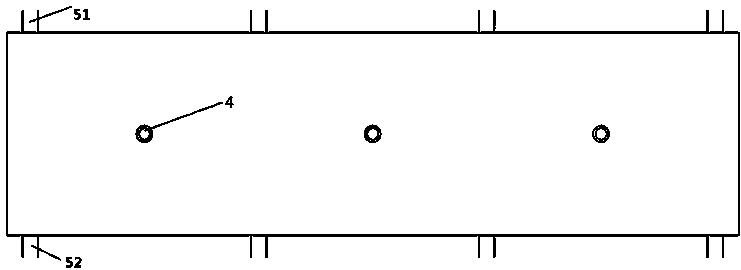

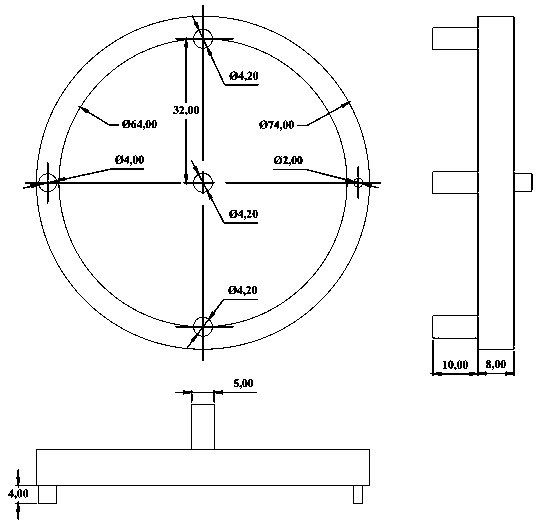

Shell-and-tube heat exchanger with rotary jet-flow baffle plates

InactiveCN103353245AFlow form is reasonableIncrease the circulation areaChemical industryHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The invention relates to a shell-and-tube heat exchanger with rotary jet-flow baffle plates, in particular to a shell-and-tube heat exchanger used for heat exchanging between two fluid media in the fields such as nuclear energy, power, oil refining, chemical engineering and petrochemical engineering. The shell-and-tube heat exchanger with the rotary jet-flow baffle plates is simple and reasonable in structure, capable of effectively reducing flow resistance, enlarging the flow area, improving turbulence effect, and reducing shell side dead zones, and high in heat exchanging efficiency. According to the technical scheme, the shell-and-tube heat exchanger with the rotary jet-flow baffle plates comprises a shell body and tube boxes arranged on the two ends of the shell body, a tube side fluid inlet is formed in the tube box at one end of the shell body, a tube side fluid outlet is formed in the tube box at the other end, a shell side fluid inlet and a shell side fluid outlet are formed in the shell body, heat exchanging tubes and the baffle plates are arranged inside the shell body, a plurality of through holes are formed in each baffle plate, the heat exchanging tubes are perpendicular to the baffle plates and penetrate through the baffle plates, and a plurality of jet-flow pieces are arranged in each through hole of each baffle plate. The shell-and-tube heat exchanger with the rotary jet-flow baffle plates is mainly used for heat exchanging between fluid media.

Owner:TAIYUAN UNIV OF TECH

Immersed self-flow-interfering shell-and-tube-type heat exchanger

ActiveCN110631301AEnhanced perturbation strengthImprove heat transfer effectIndirect heat exchangersModifications using liquid coolingTemperature controlPlate heat exchanger

The invention provides an immersed self-flow-interfering shell-and-tube-type heat exchanger. The heat exchanger comprises a shell, a liquid distribution device, a self-flow-interfering device and a liquid collection device; a cooling liquid inlet and a cooling liquid outlet are formed in the shell; the cooling liquid inlet communicates with the liquid distribution device; the liquid distribution device communicates with the self-flow-interfering device; the liquid collection device is located on the upper part of the shell and below the liquid surface of cooling liquid; the liquid collection device communicates with the cooling liquid outlet; the cooling liquid enters the shell sequentially through the cooling liquid inlet, the liquid distribution device and the self-flow-interfering device, and flows out of the cooling liquid outlet through the liquid collection device; a heat source is immersed in the cooling liquid in the shell; and the liquid distribution device comprises a liquiddistribution mother tube which communicates with the cooling liquid inlet. The immersed self-flow-interfering shell-and-tube-type heat exchanger is controlled through liquid outlet temperature, so that the effects of automatic controlling and energy saving are realized; the interfering strength of a cooling liquid flowing field in the shell is enhanced; and the heat exchanging efficiency is improved.

Owner:SHANDONG UNIV

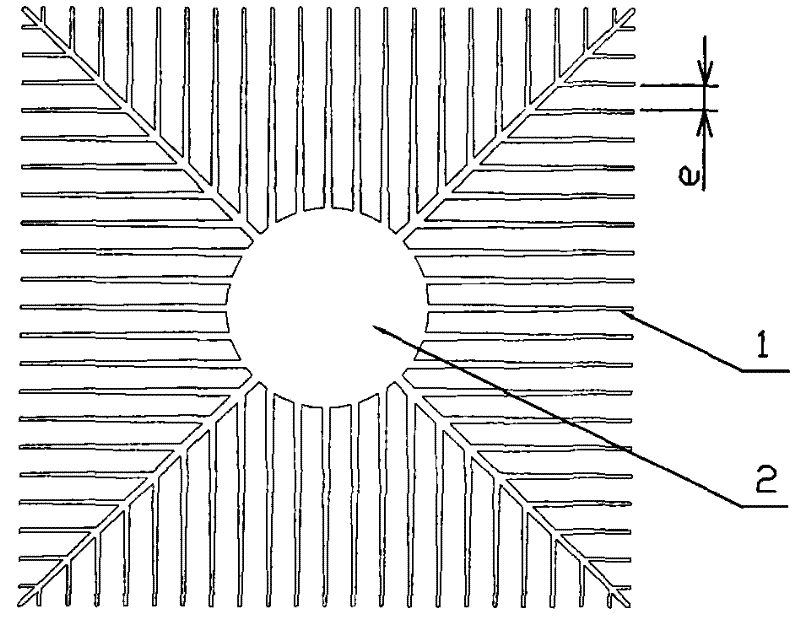

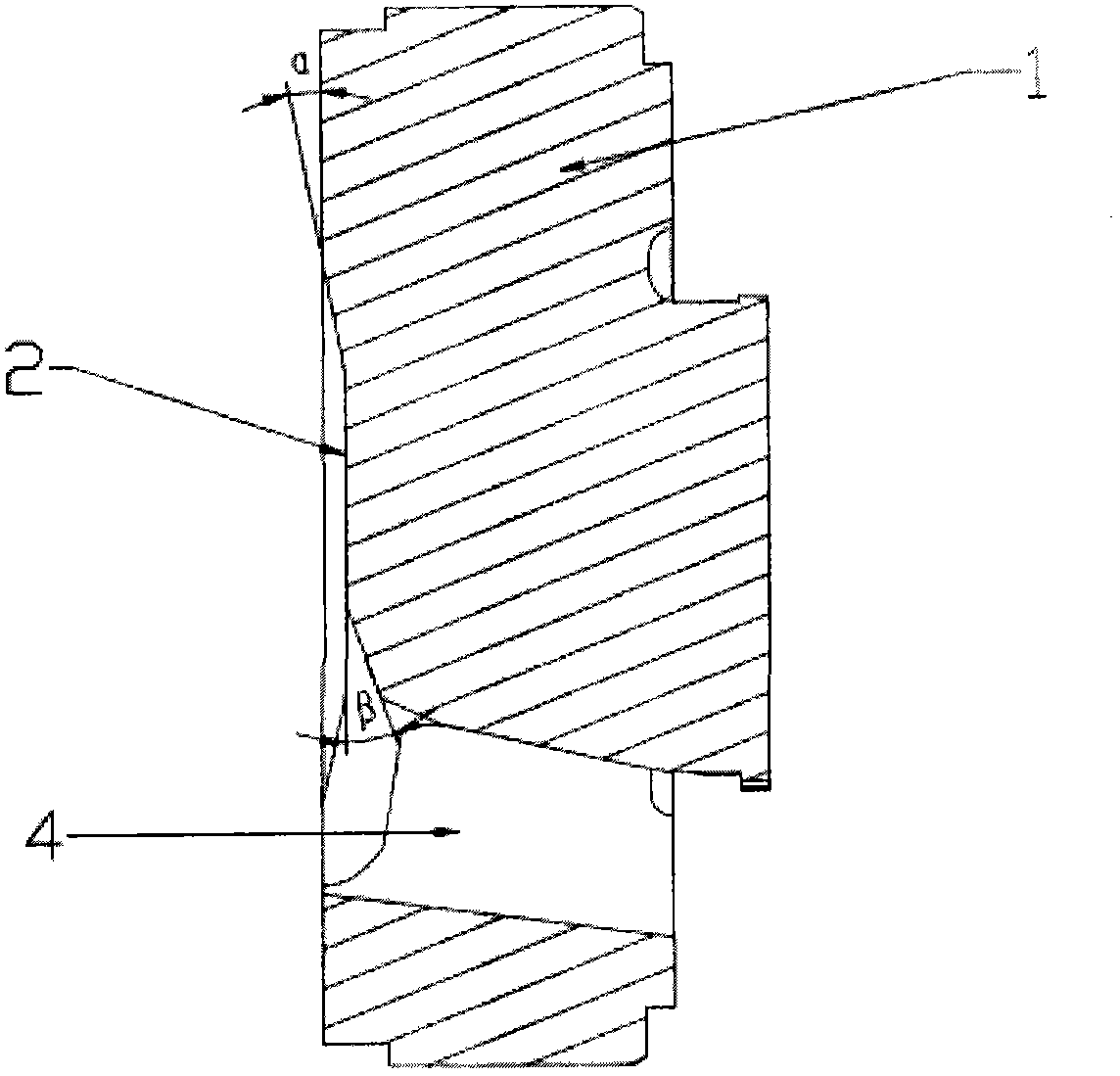

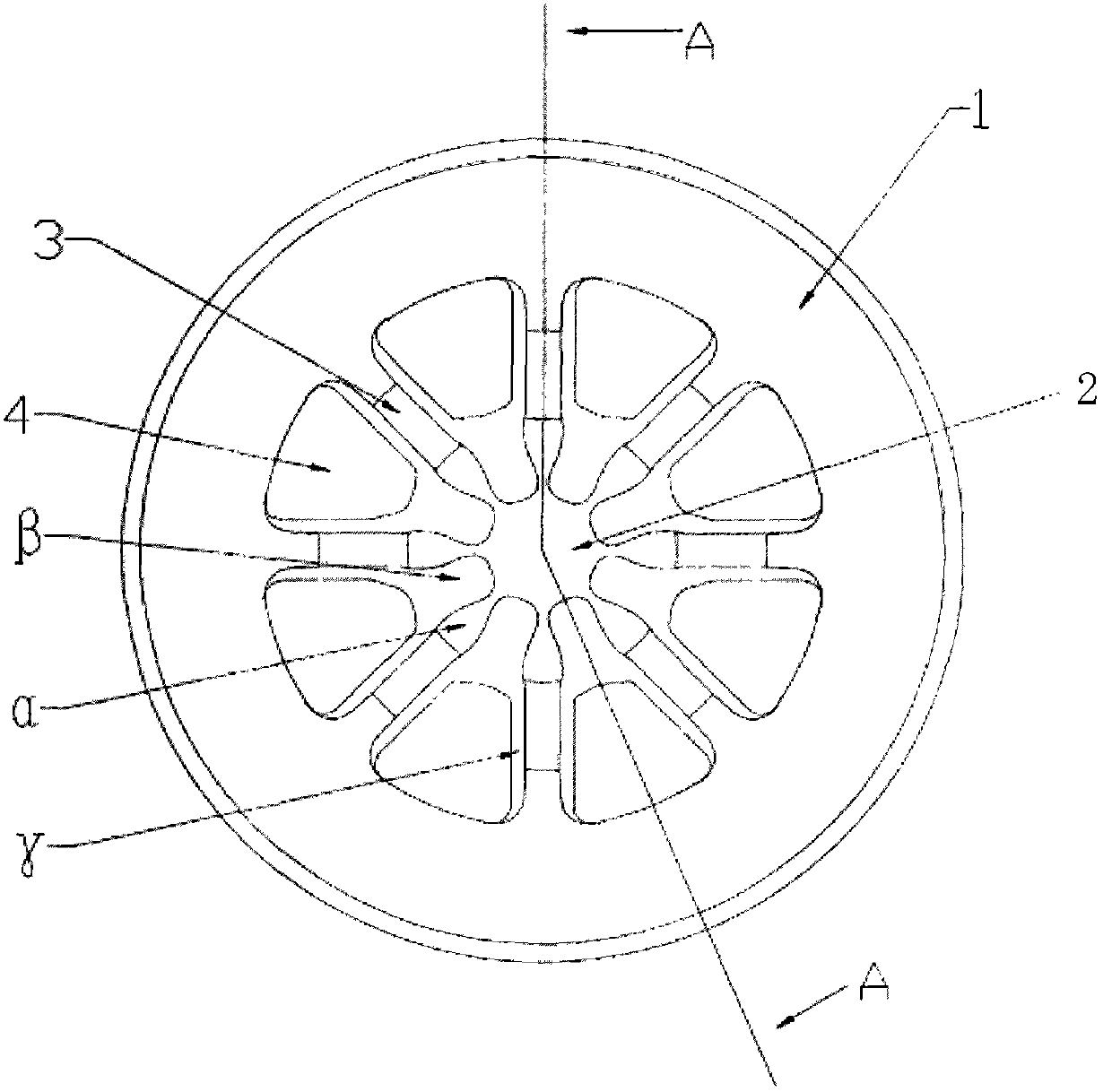

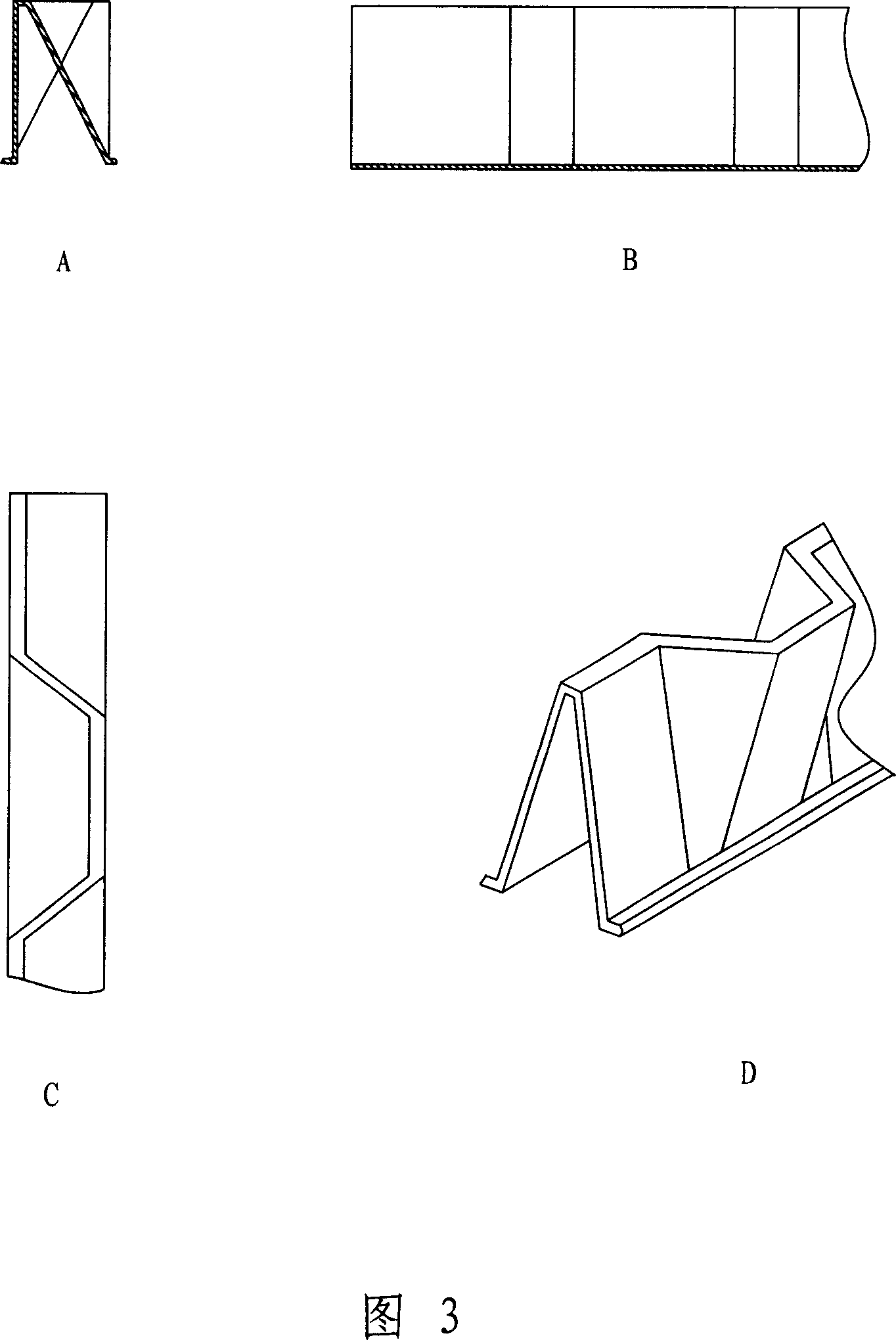

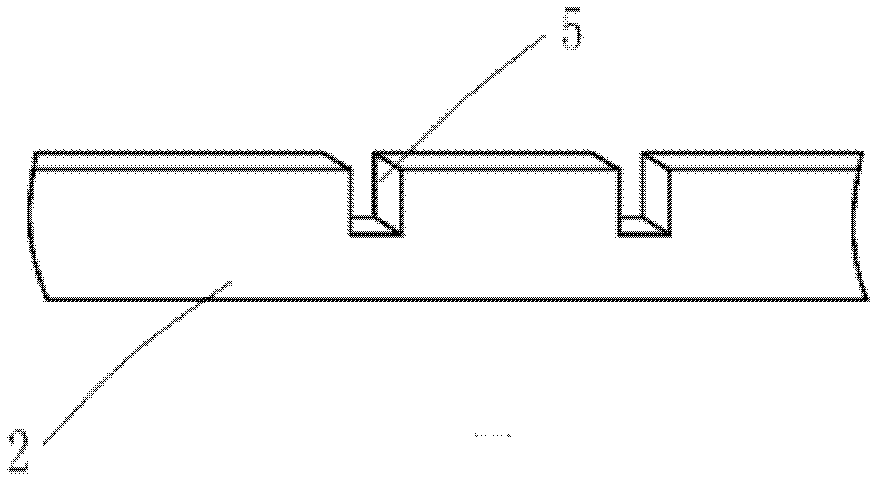

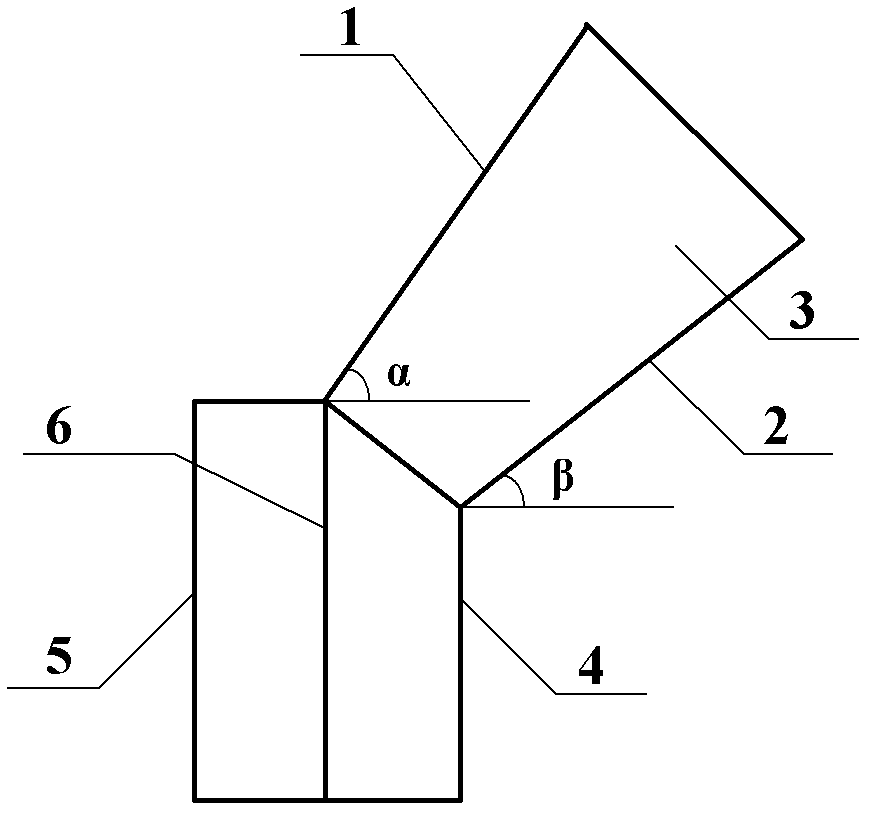

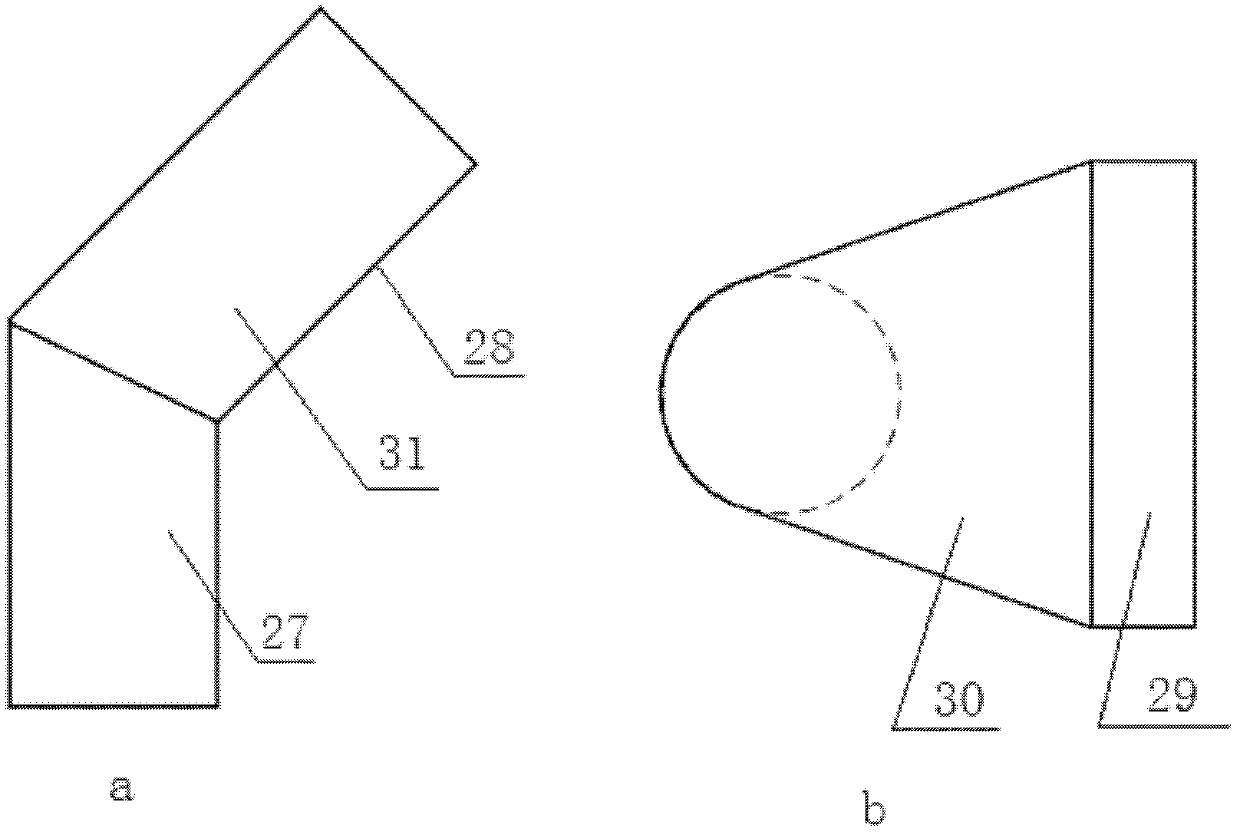

Multistage-welding-chamber extrusion mould used for producing aluminium sections and production technology of the aluminium sections

InactiveCN103599956AUniform velocity distributionImprove mold strengthExtrusion diesWeld seamAluminium

The invention discloses a multistage-welding-chamber extrusion mould used for producing aluminium sections. The extrusion mould comprises an upper mould and a lower mould. The upper mould comprises a guide plate. The guide palate is provided with a plurality of flow distribution bridges. A plurality of flow distribution holes are formed among the plurality of the flow distribution bridges. The extrusion mould is characterized in that intersections of the flow distribution bridges are lower than a material feeding surface around to form recessed surfaces; slopes are disposed between the flow distribution bridges and the recessed surfaces on the material feeding surface for transition to form first pressure-relief angles; flow distribution hole and feeding openings in the recessed surfaces form second pressure-relief angles; two sides of the flow distribution bridges form third pressure-relief angles; the lower end of the guide plate is provided with multistage welding chambers communicated with the flow distribution holes; and the multistage welding chambers are disposed below the material feeding surface of the lower mould. The invention also discloses an extrusion technology for producing the aluminium sections by the extrusion mould. The multistage-welding-chamber extrusion mould can effectively control metal flow, and therefore the speed distribution in the section of the aluminium sections is uniform, the thickness of the mould is increased relatively, the mould intensity is enhanced, the stage of the welding chambers is increased, the welding pressure increases gradually, and the quality and the surface of the welding seams are improved.

Owner:东莞市东联铝业有限公司

Solid State Lighting

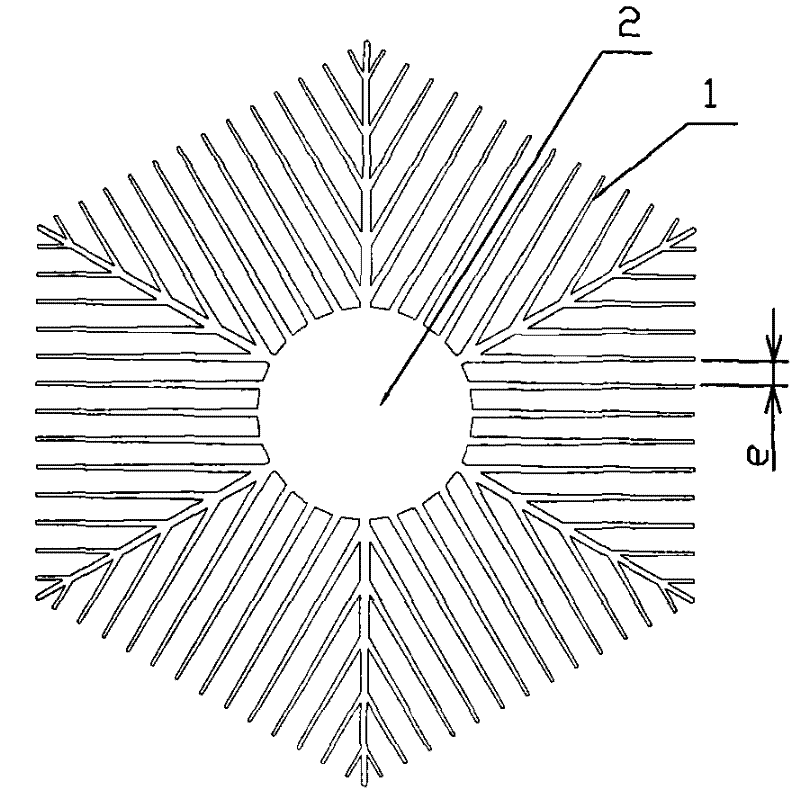

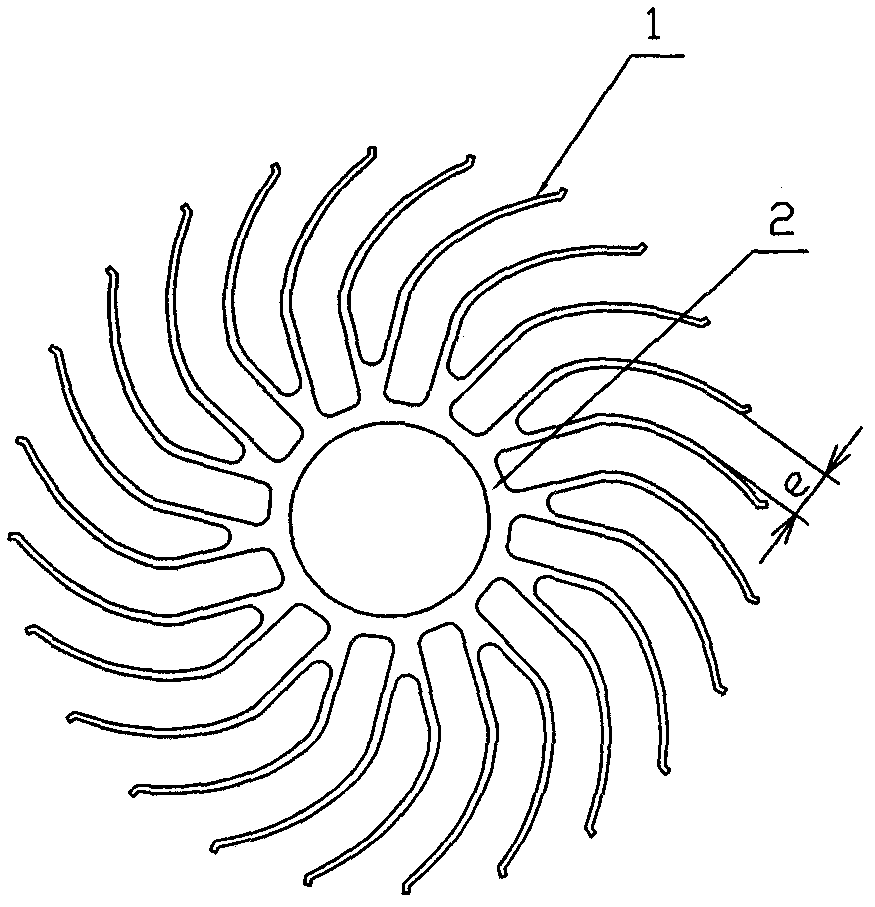

InactiveCN102287686AReduces severe performance degradation issuesLow costPoint-like light sourceLighting heating/cooling arrangementsHeat conductingCooling effect

The present invention discloses a solid state lamp, comprising an LED light source and a heat sink, the LED light source is provided in the distal end of the heat conducting column, wherein the heat sink uses a sunflower structure with ribs projecting from the side of the heat conducting column, mainly characterized in that the ribs are opened with airflow grooves perpendicular to the axis and penetrating through the circumferential ring, wherein the depth of the deepest airflow groove is greater than half the rib length, the airflow groove has a width of not less than 2mm, and the average height of the short rib is less than five times the average rib gap; the averaged rib length on the heat sink is greater than10mm. The present invention solves the problems of poor air circulation and serious deterioration in heat dissipation efficiency when the heat sink axis level is transversely placed. The present invention also discloses an LED bulb having optimal structure size and the new structure to enable efficacies of lower cost and higher cooling effect.

Owner:深圳市秦博核芯科技开发有限公司

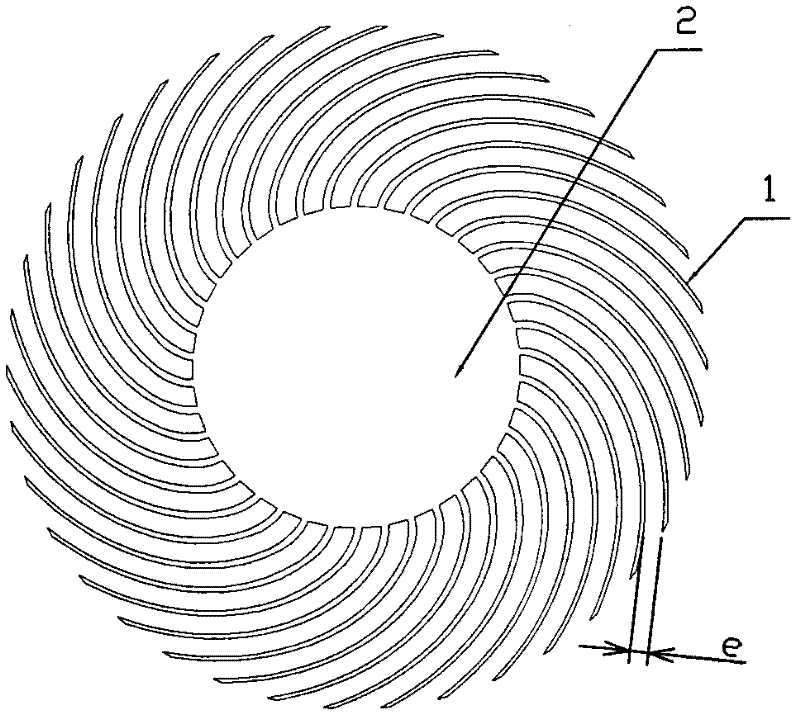

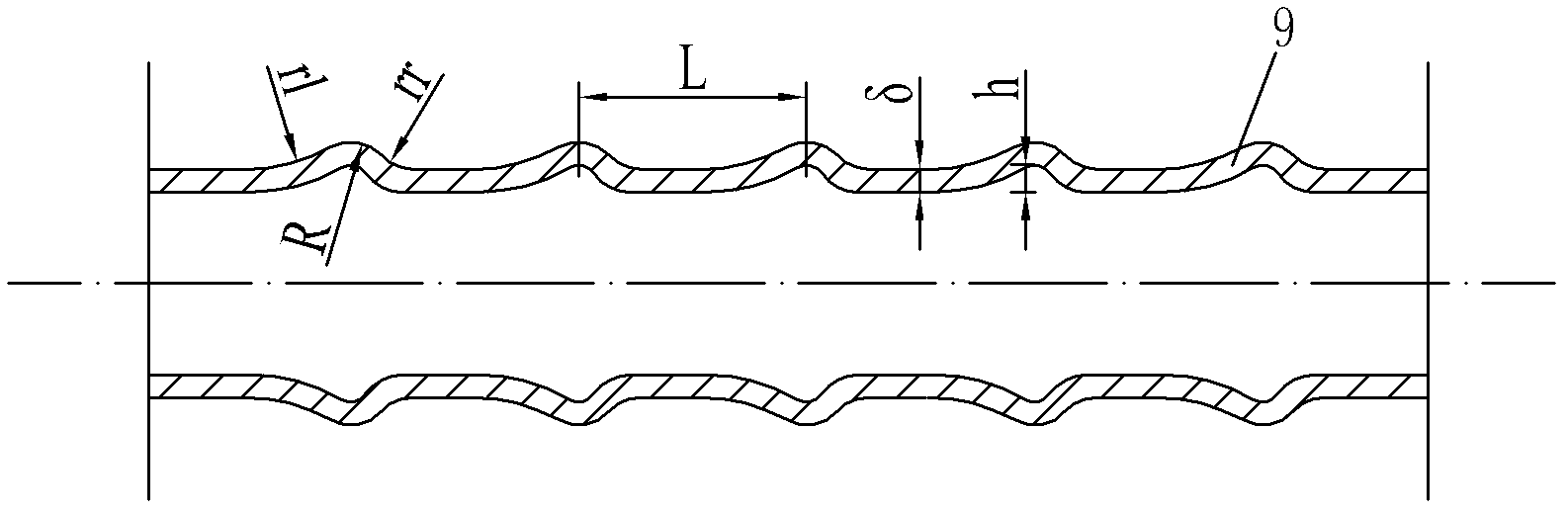

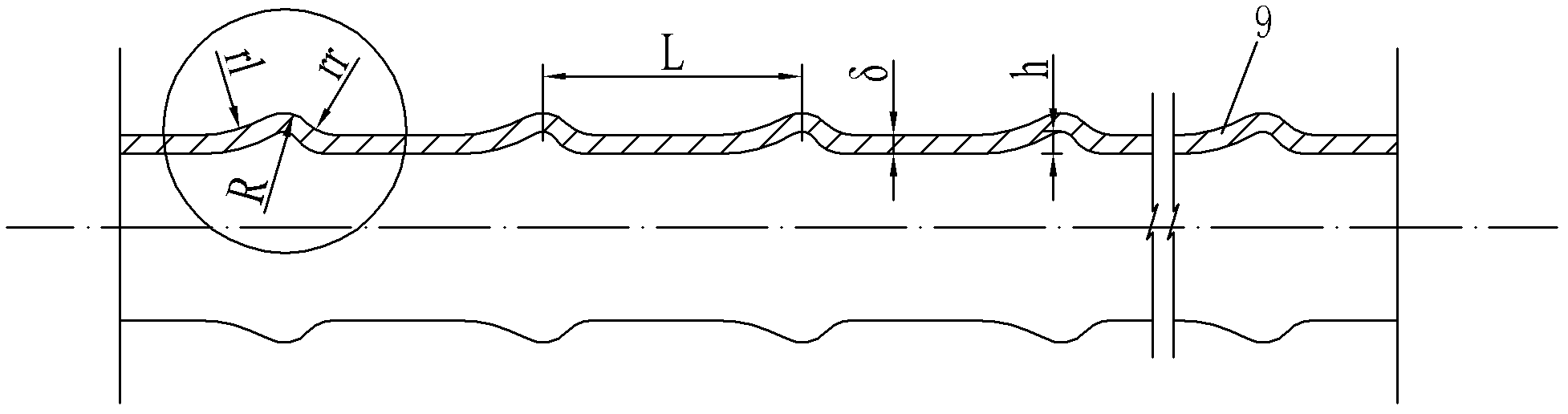

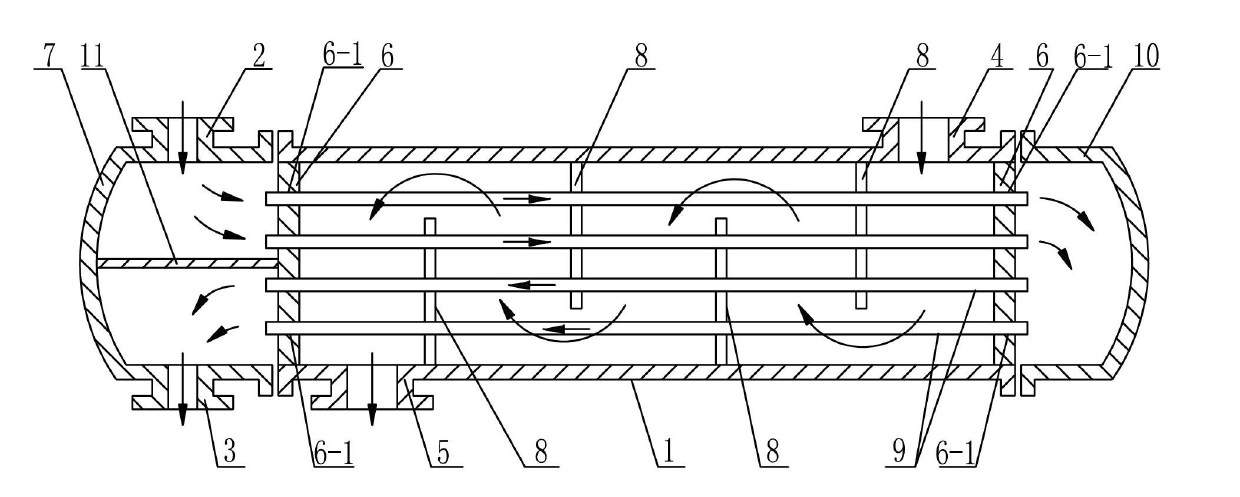

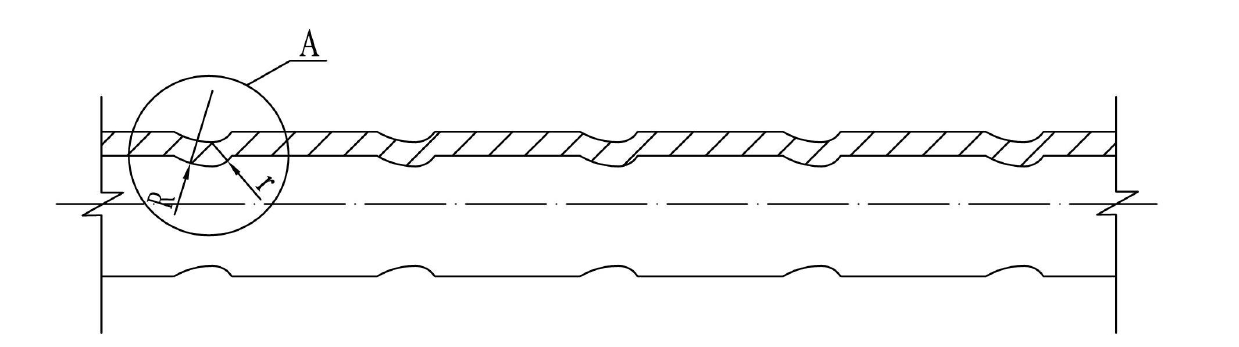

Convex asymmetric corrugated tube heat exchanger

ActiveCN102278907AReduce flow dead zoneSpeed up the flowTubular elementsPlate heat exchangerHeat transfer efficiency

The invention discloses an external-convex-type asymmetrical wave node pipe heat exchanger, and relates to a wave nod pipe heat exchanger for solving problems that the comprehensive heat transfer efficiency is low for the existing wave node pipe heat exchanger, the heat exchanger can not applied to gas-steam heat exchange, and the in-service detection is difficult. Each heat exchange pipe (9) provided by the invention is an external-convex-type asymmetrical wave node pipe; the curvature radius (rr) of the outer side wall, positioned on the circular arc surface of an going flow side, of the external-convex-type asymmetrical wave node pipe is less than the curvature radius (r1) of the outer side wall, positioned at the circular arc surface of an incoming side, of the external-convex-type asymmetrical wave node pipe; the curvature radius (R) of the external circular arc surface of a circular arc protrusion of the external-convex-type asymmetrical wave node pipe is 5mm; the distance (L) between two adjacent circular arc protrusions on the external-convex-type asymmetrical wave node pipe is 40mm-50mm; the top depth (h) of the circular arc protrusions of the external-convex-type asymmetrical wave node pipe is 2mm-4mm; and the wall thickness (delta) of the external-convex-type asymmetrical wave node pipe is 2mm-3mm. The heat exchanger provided by the invention is especially suitable for the gas-steam heat exchange.

Owner:HARBIN INST OF TECH

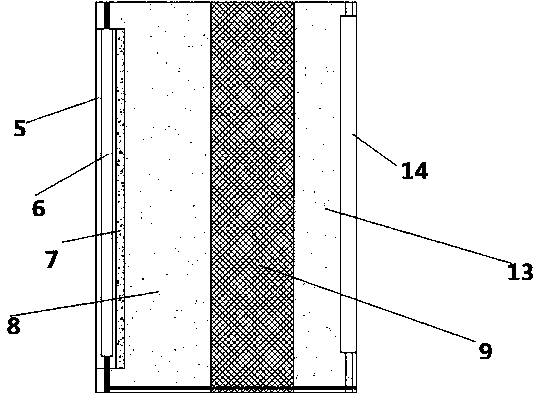

Prefabricated wall, building and construction component management system thereof

ActiveCN111561068ATo regulateImprove rational utilization efficiencyGeometric CADSolar heating energySolar air collectorInsulation layer

The invention provides a prefabricated wall, a building and a construction component management system thereof. The prefabricated wall includes a transparent board, a preheating tube, a heat insulating layer, an outer bearing wall, an thermal insulation layer, an inner bearing wall, and a ventilation component; the transparent board, the preheating tube and the heat insulating layer are arranged on the outer surface of the outer bearing wall, the transparent board is arranged on the outside of the preheating pipe, the heat insulating layer is arranged on the inner side of the preheating pipe,and the thermal insulation layer is installed between the outer bearing wall and the inner bearing wall; the ventilation component is arranged on the inner surface of the inner bearing wall; the upperentrance of the ventilation component is connected to a solar collector; the preheating tube enters the wall from the upper part of the wall; the lower part of the wall is a closed structure; the preheating tube is provided with branches, and the branch entrance extends into the room inside the wall; and the lower entrance is provided with a fan. The invention provides a new solar air-conditioning building wall located at the bottom of the building, which achieves the air conditioning effect and improves the utilization degree and utilization efficiency of solar energy.

Owner:QINGJIAN GRP CO LTD

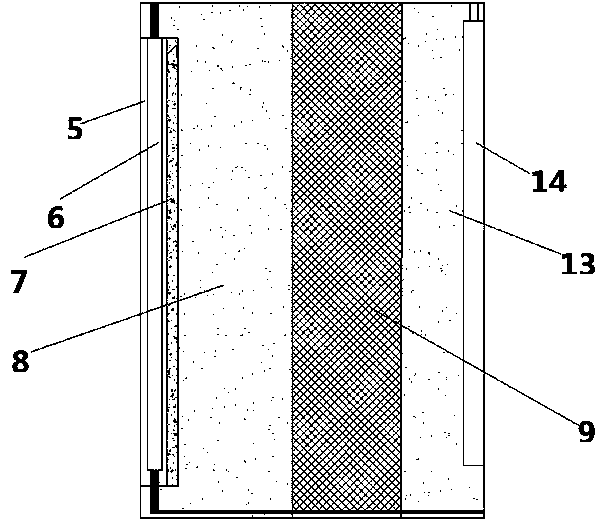

Assembled wall body, building and construction process control system of building

ActiveCN111549930ATo regulateImprove utilizationSolar heating energyWallsControl systemArchitectural engineering

The invention provides an assembled wall body, a building and a construction process control system of the building. The solar assembled building wall body comprises a bottom wall body and non-bottomwall bodies which are assembled, wherein the bottom wall body is arranged at the bottom of the wall body, one non-bottom wall body is assembled at the upper part of the bottom wall body, and another non-bottom wall body is assembled at the upper part of the non-bottom wall body, so that the solar assembled building wall body is formed. The invention provides the novel assembled building wall body.Two assembled wall bodies are respectively arranged at the bottom and the non-bottom part. Through the assembly of the assembled wall body, through the arrangement of transparent plates, preheating pipes and other devices, air entering a heat collector can be preheated first, the air conditioning effect is achieved, and the reasonable utilization efficiency of solar energy is improved.

Owner:青建集团股份公司 +1

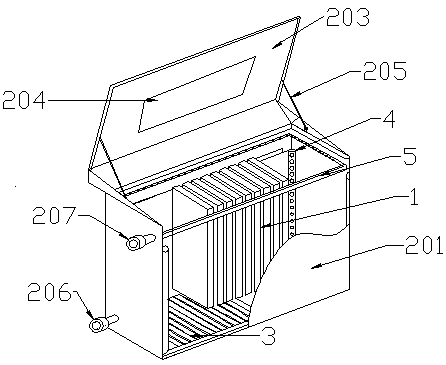

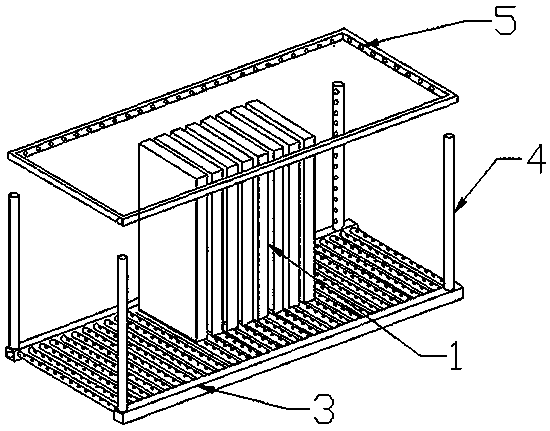

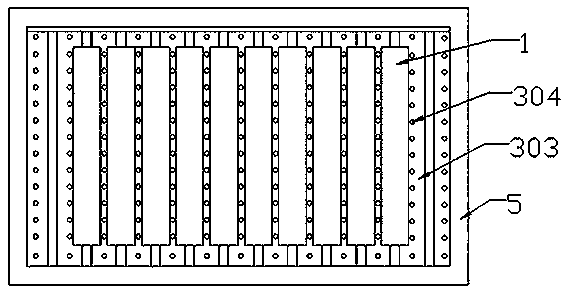

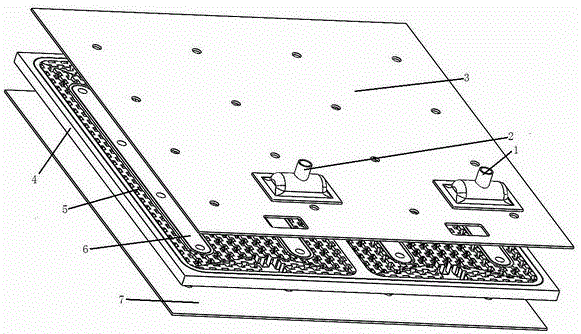

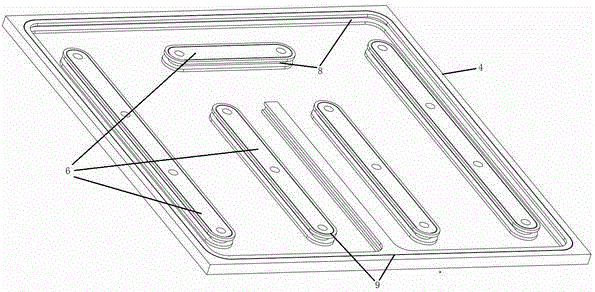

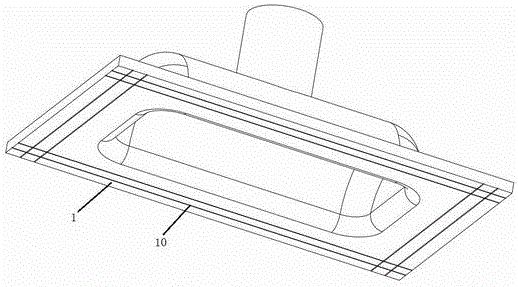

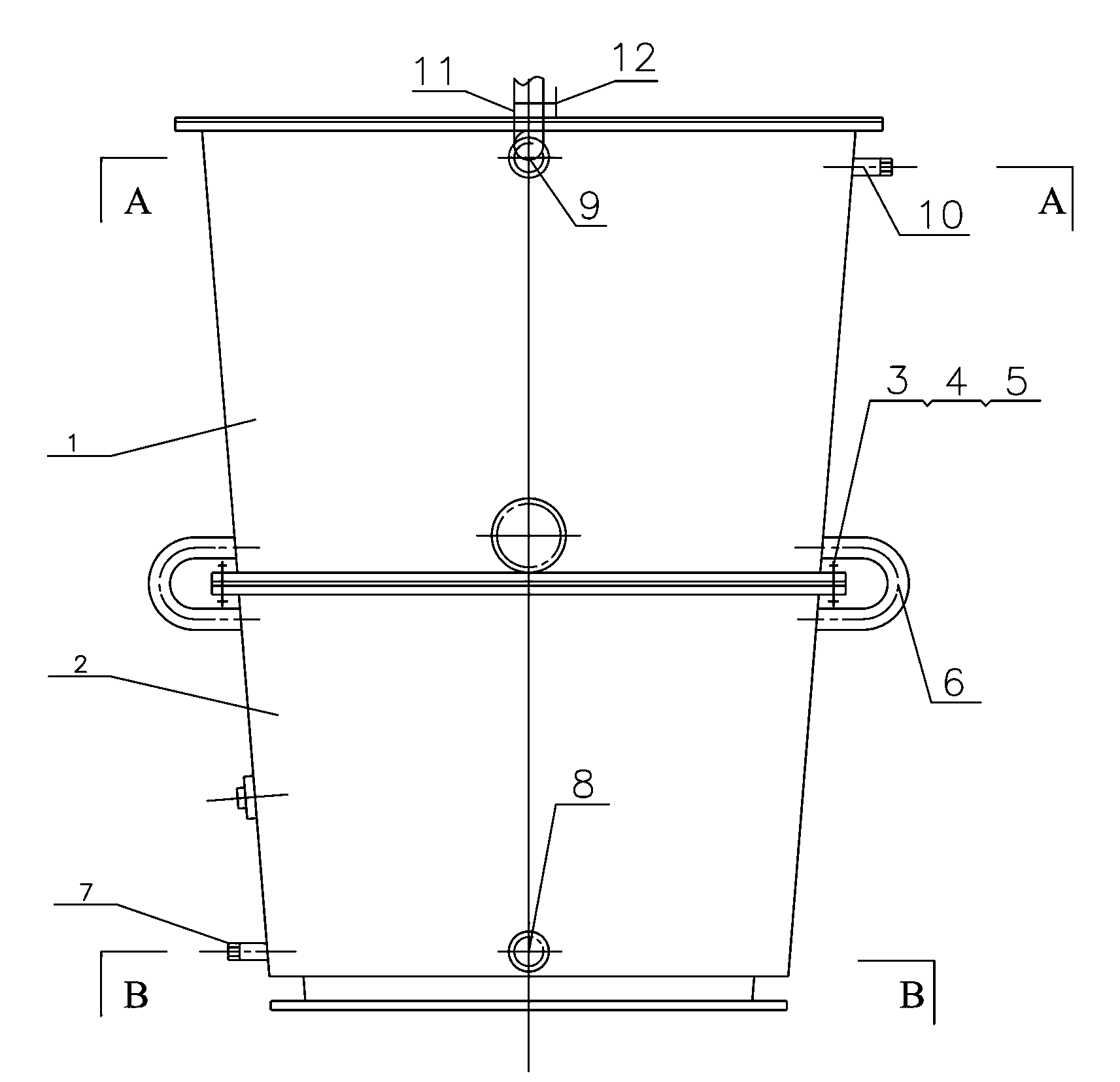

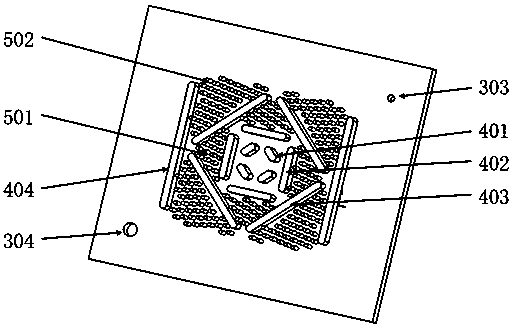

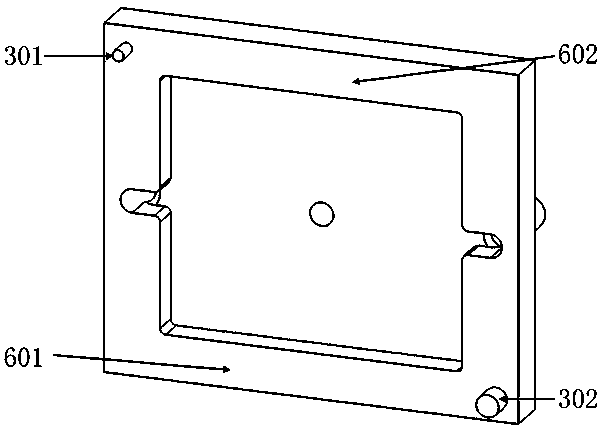

Liquid-cooling cold plate

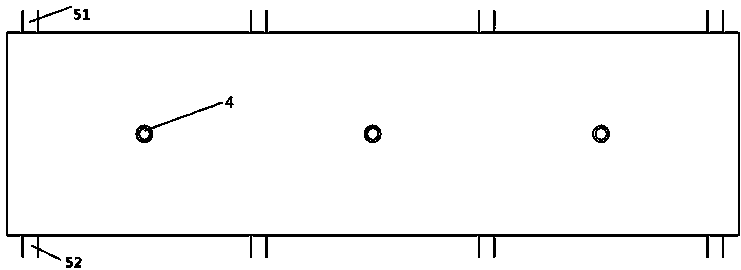

ActiveCN105682431AImprove temperature uniformityReduce flow dead zoneCooling/ventilation/heating modificationsEngineeringCold plate

The invention discloses a liquid-cooling cold plate, which comprises a liquid inlet connector, a liquid outlet connector, an upper cover plate, frame strip seal, fins, pad blocks and a bottom board, wherein the pad blocks and the fins are arranged in the frame strip seal; the upper cover plate and the bottom board are connected to the two sides of frame strip seal through vacuum brazing to form a sealed heat exchange cavity; the two sides of the pad blocks are connected with the upper cover plate and the bottom board through vacuum brazing respectively; the liquid inlet connector and the liquid outlet connector are connected with the upper cover plate through vacuum brazing; and the inner side surface of the frame strip seal or / and the outer side surfaces of the pad blocks contacted with a heat exchange medium are respectively provided with a groove. The liquid-cooling cold plate is simple in structure, low in cost, high in heat exchange efficiency, good in brazing process, high in welding finished product rate, more beautiful in appearance, small in flow dead zone and good in temperature uniformity.

Owner:XINXIANG TEMEITE HEAT TRASFER EQUIP CO LTD

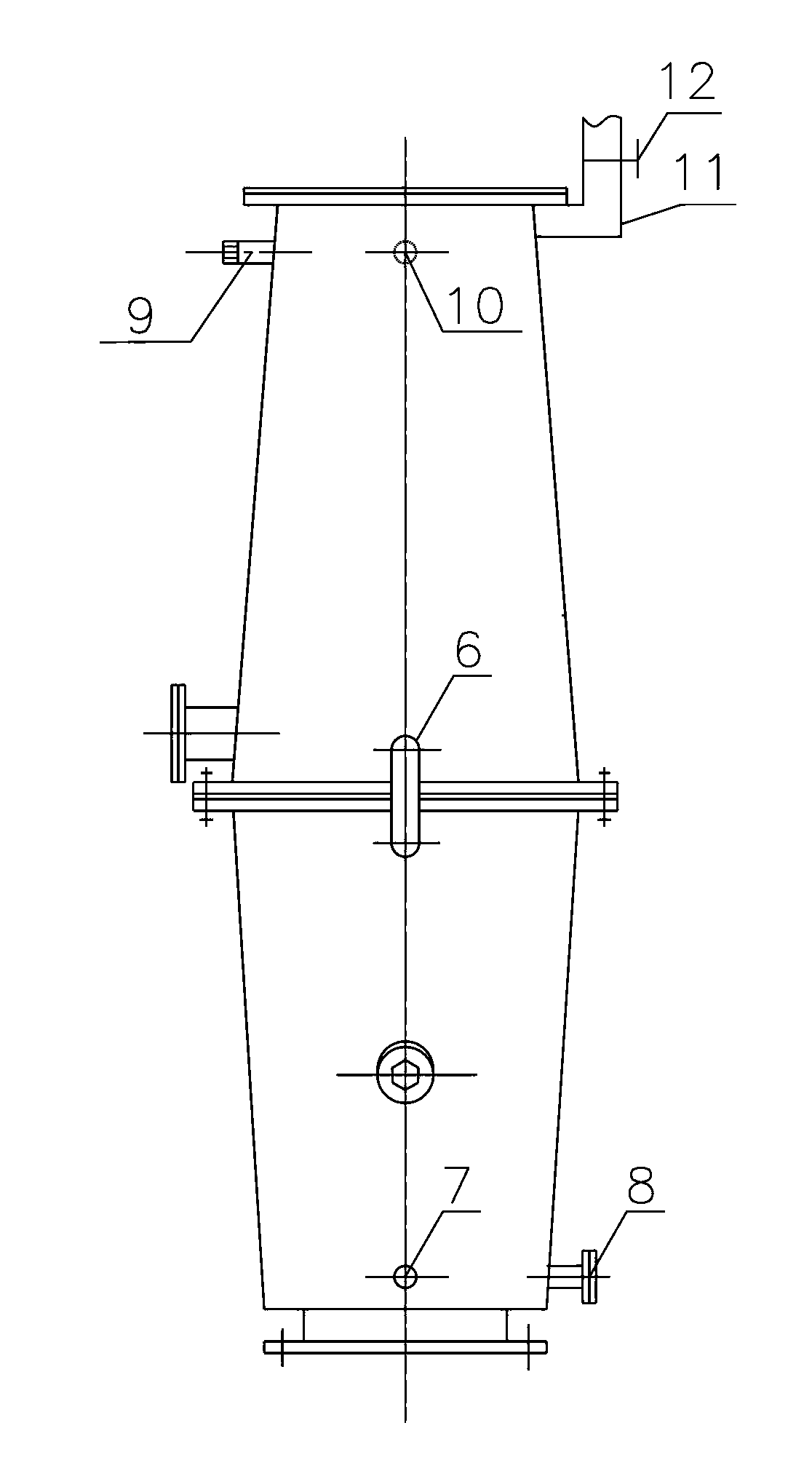

Cooling water jacket of pot type calcining furnace

InactiveCN103256818ASave installation spaceIncrease layout spaceFurnace coolingWater vaporCooling effect

The invention relates to a cooling water jacket of a pot type calcining furnace. The cooling water jacket is structurally composed of an upper water jacket and a lower water jacket, the upper water jacket is of a structure with a narrower bottom and a wider top, the lower water jacket is of a structure with a wider top and a narrower bottom, a water outgoing pipe I and a water outgoing pipe II are arranged on the upper portion of the upper water jacket, a water incoming pipe I and a water incoming pipe II are arranged on the lower portion of the lower water jacket, the lower portion of the upper water jacket and the upper portion of the lower water jacket are communicated through a connecting pipe, and the connecting pipe is arranged outside the upper water jacket and the lower water jacket. The cooling water jacket of the pot type calcining furnace has the advantages that mounting space of a furnace bottom is saved, steam girder arrangement space of the furnace bottom is increased, and maintenance of the cooling water jacket is facilitated; heat exchange area is greatly increased through the structure with narrower top and bottom and a wider middle than conventional structures, and cooling effect is more excellent; by the arrangement, cooling water can flow smoothly, flowing dead areas of the cooling water can be reduced, and cooling effect can be greatly improved; and an exhausting device is mounted, so that vaporized steam in the cooling water jacket can be exhausted smoothly, material cooling effect is guaranteed, and the service life of the cooling water jacket is prolonged.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

High-efficiency scaling turbolator ring pipe frame and heat exchanger with same

InactiveCN103278037AReduce flow dead zoneIncrease the effective heat transfer areaStationary tubular conduit assembliesHeat transfer modificationPhysicsEngineering

Owner:GUANGDONG OCEAN UNIVERSITY

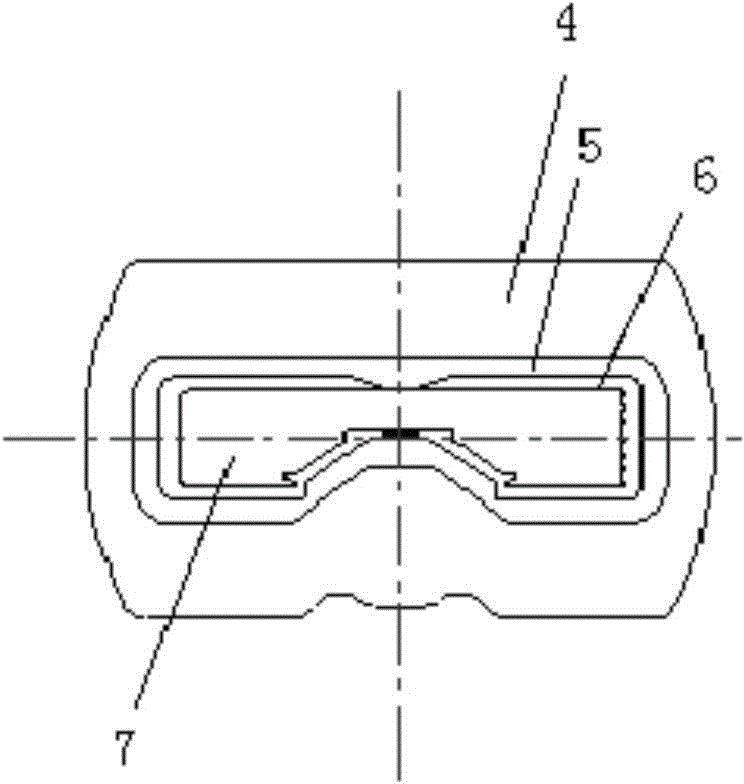

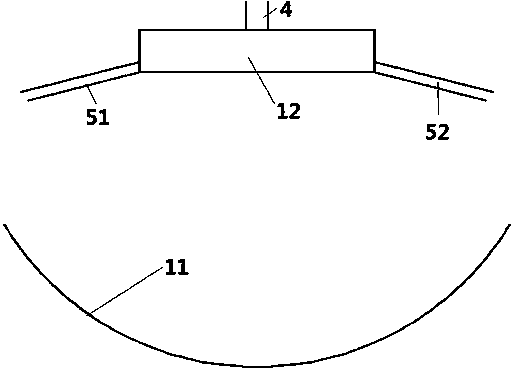

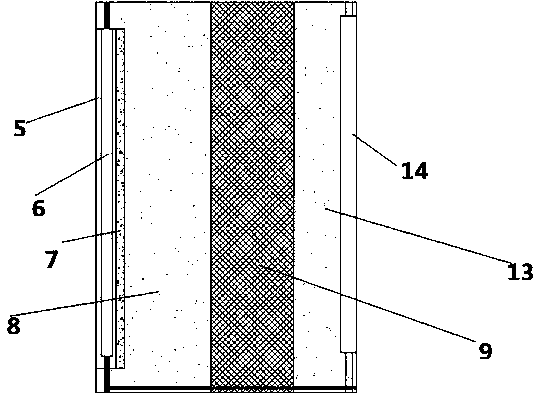

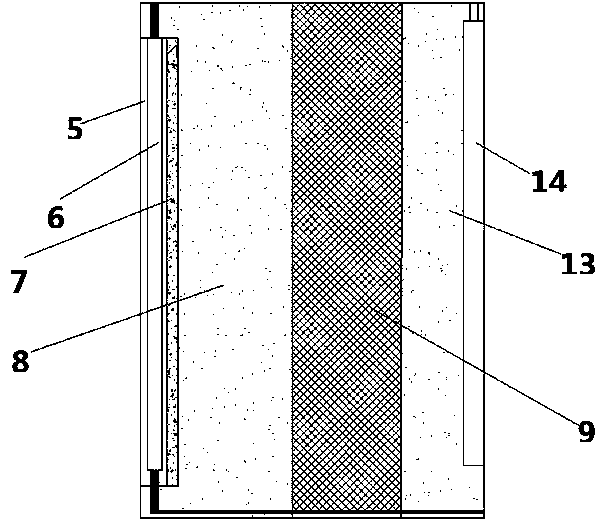

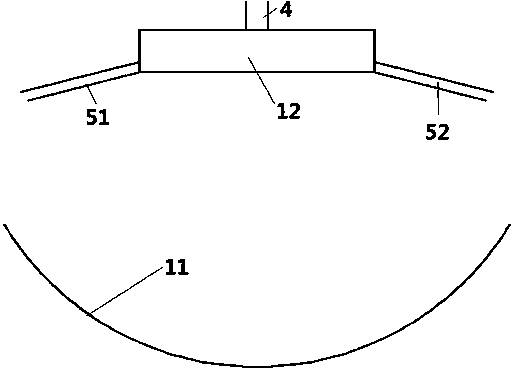

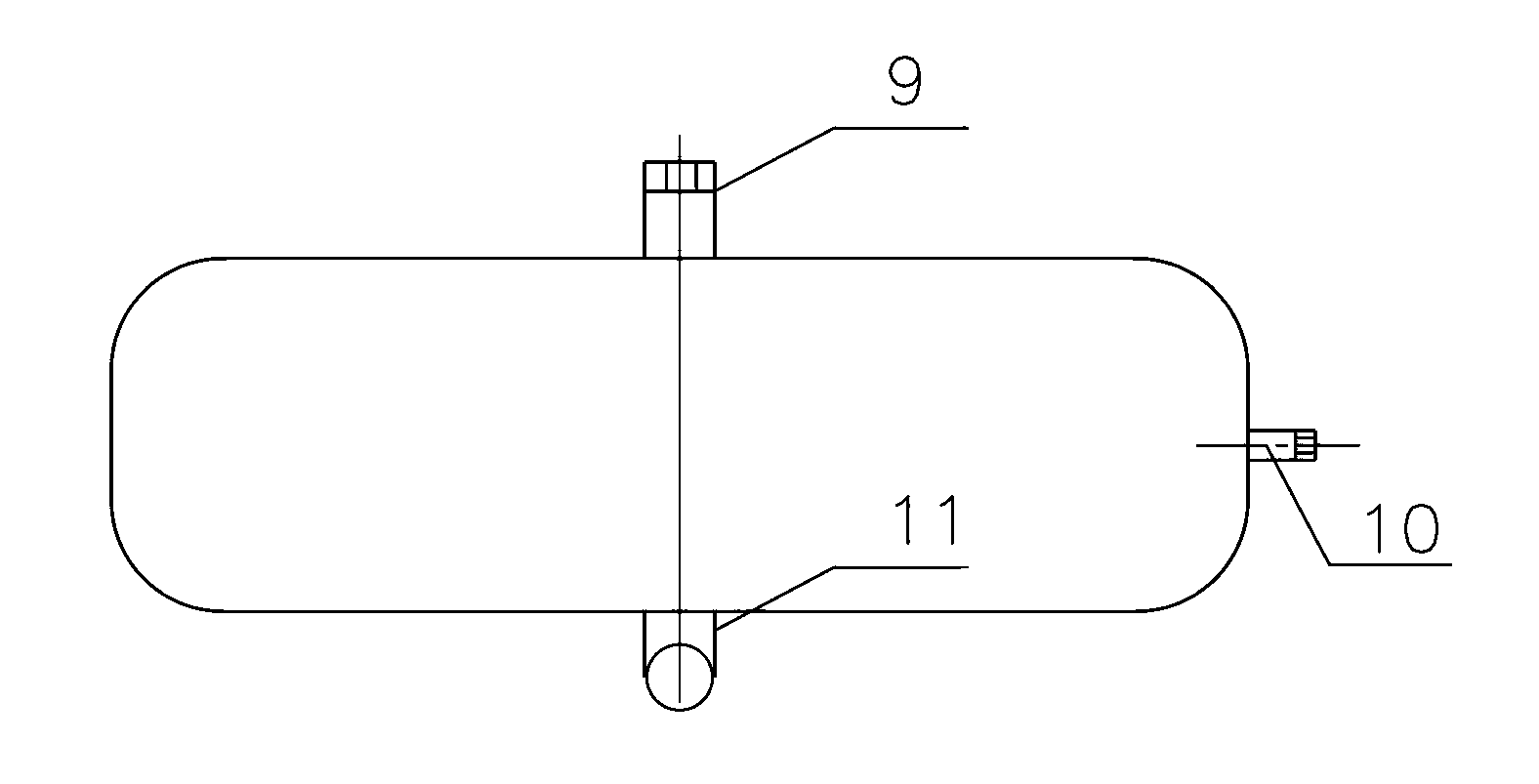

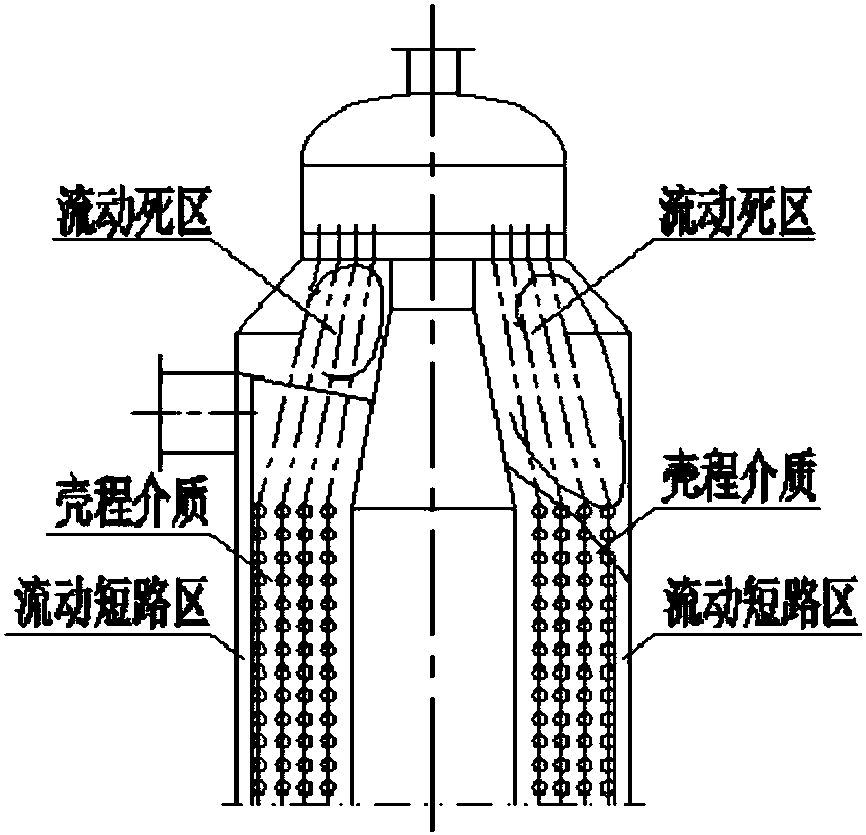

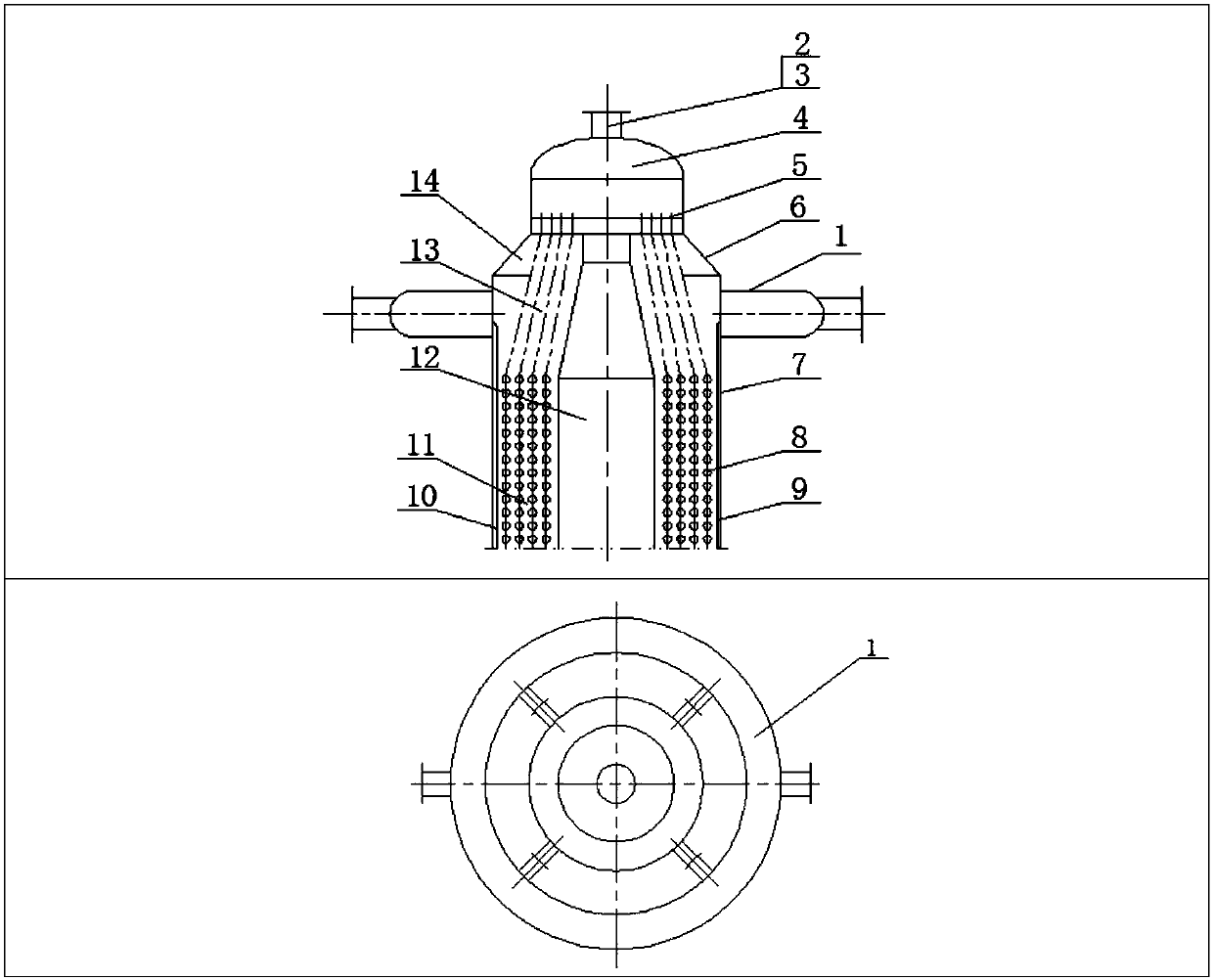

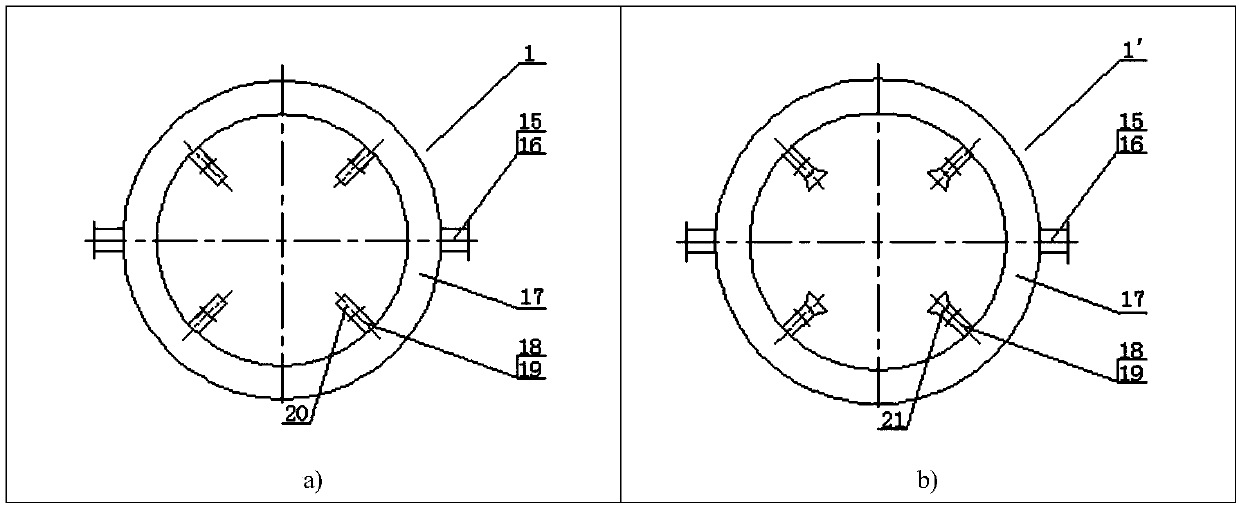

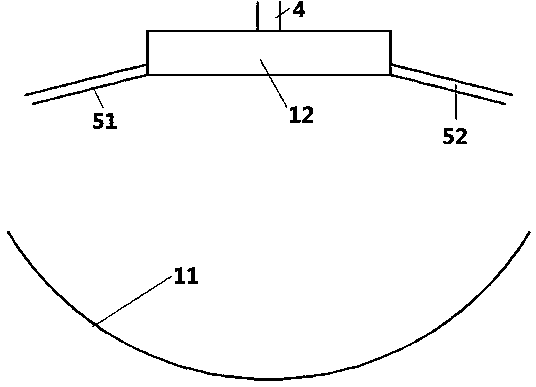

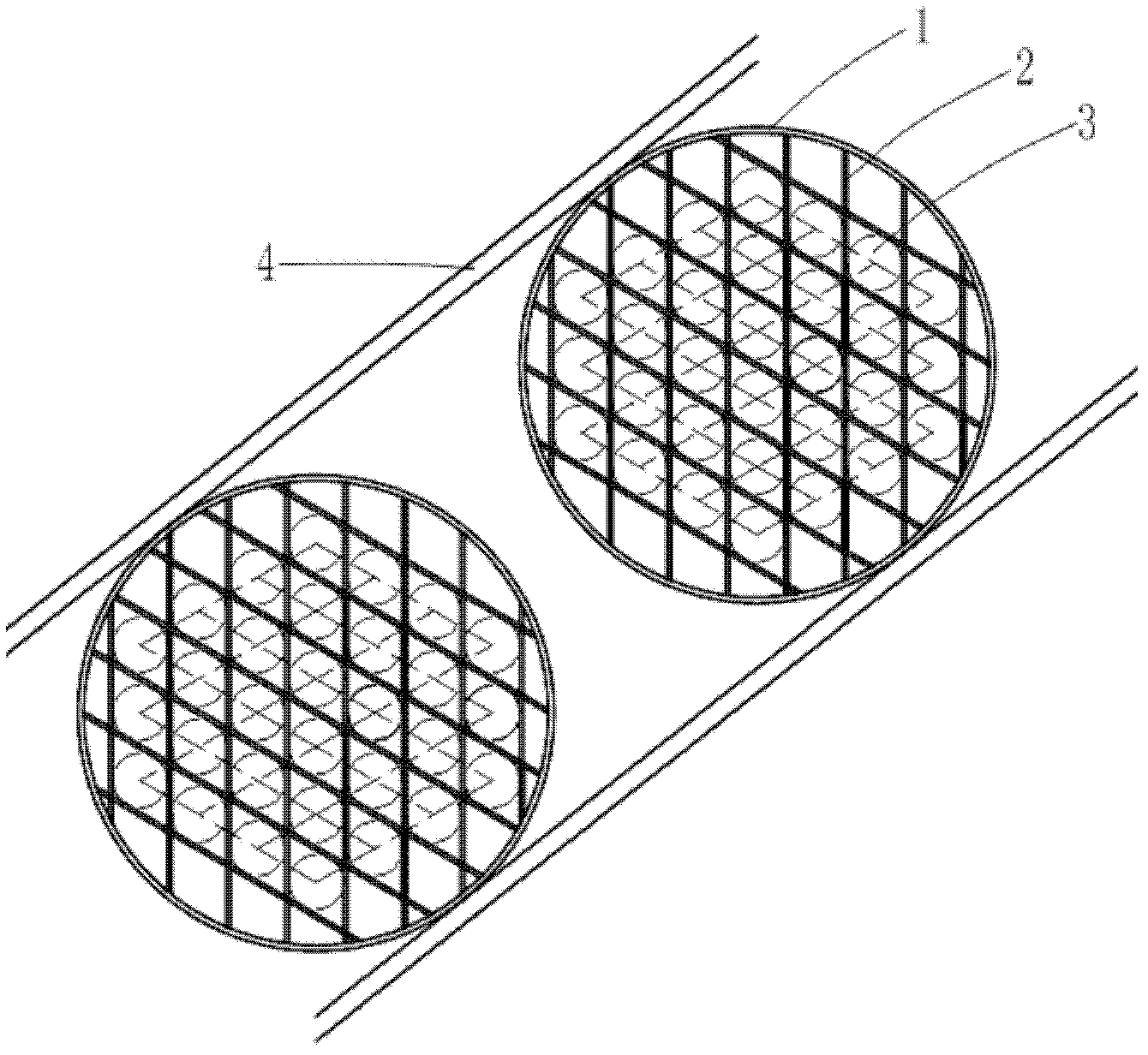

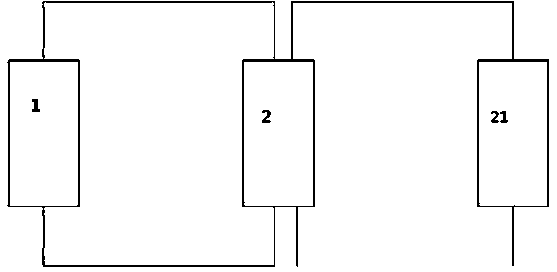

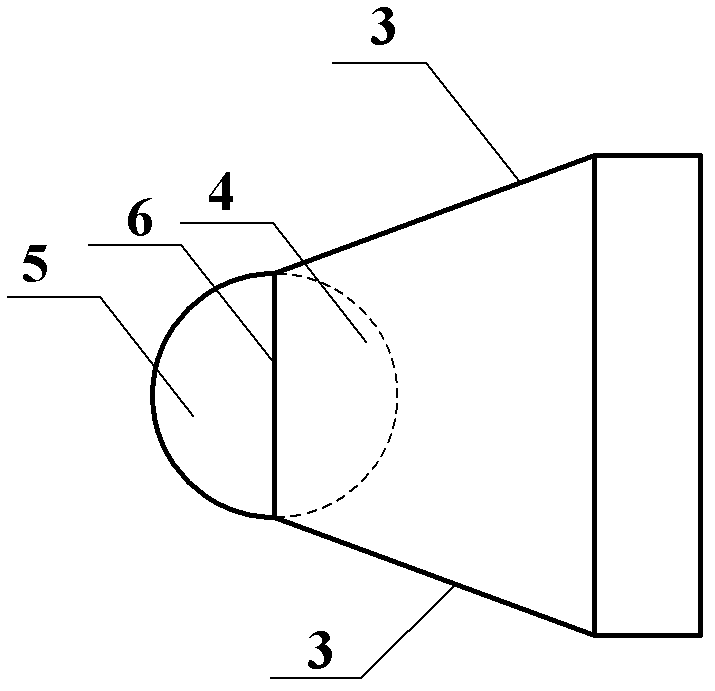

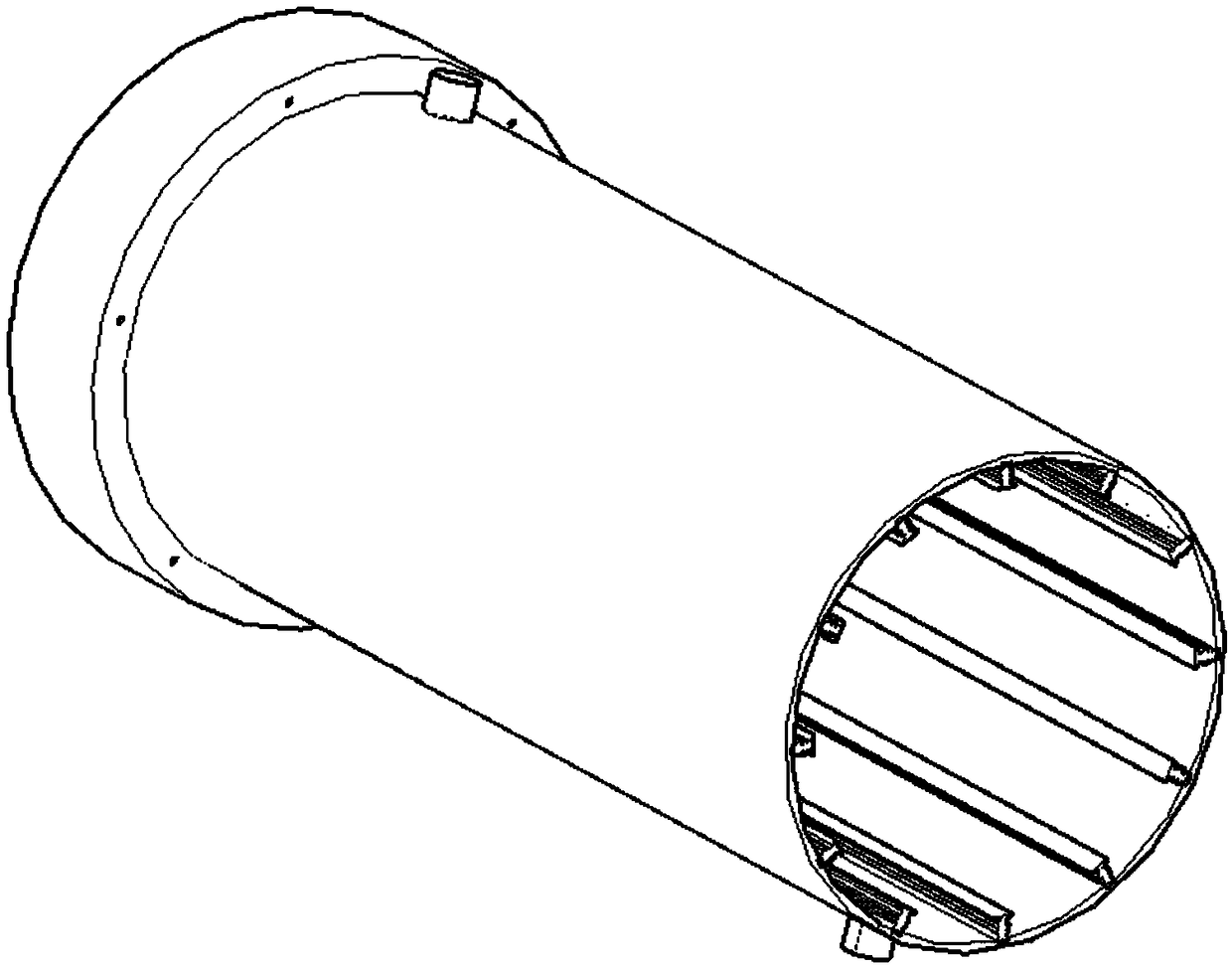

Winding tube type heat exchanger with circular tube flow guider and inner lining barrel device

InactiveCN108225051ASpeed up the flowReduce flow dead zoneHeat exchanger casingsStationary tubular conduit assembliesStraight tubeEngineering

The invention discloses a winding tube type heat exchanger with a circular tube flow guider and an inner lining barrel device. The winding tube type heat exchanger comprises a tube box (4), a tube plate (5) and a shell pass barrel body (7), and the winding tube type heat exchanger is characterized in that the annular tube flow guider (1) is mounted on the outer side of the shell pass barrel body(7) corresponding to a straight tube transitional area (13); on one hand, the annular tube flow guider (1) communicates with a reaction medium, and on the other hand, the annular tube flow guider (1)uniformly conveys the medium into the straight tube transitional area (13) through multiple channels; simultaneously / or, the inner lining barrel (10) is mounted in a barrel body, corresponding to a winding tube heat exchange area (11), of the inner part of the shell pass barrel body (7); the upper end of the inner lining barrel (10) is hermetically connected with an inner wall of the shell pass barrel body (7); and a channel into which the medium enters is reserved between the lower end of the inner lining barrel (10) and the inner wall of the shell pass barrel body (7). According to the winding tube type heat exchanger disclosed by the invention, a flowing dead area of an entrance part of a shell pass medium is reduced, a flowing area of the shell pass medium is widened, a flowing gap isreduced, flowing short-circuit of the shell pass medium is effectively improved, an effective utilization ratio of the heat exchange area of the winding tube type heat exchanger is increased, and theoverall heat exchange efficiency of the heat exchanger is also obviously improved.

Owner:NANJING UNIV OF TECH

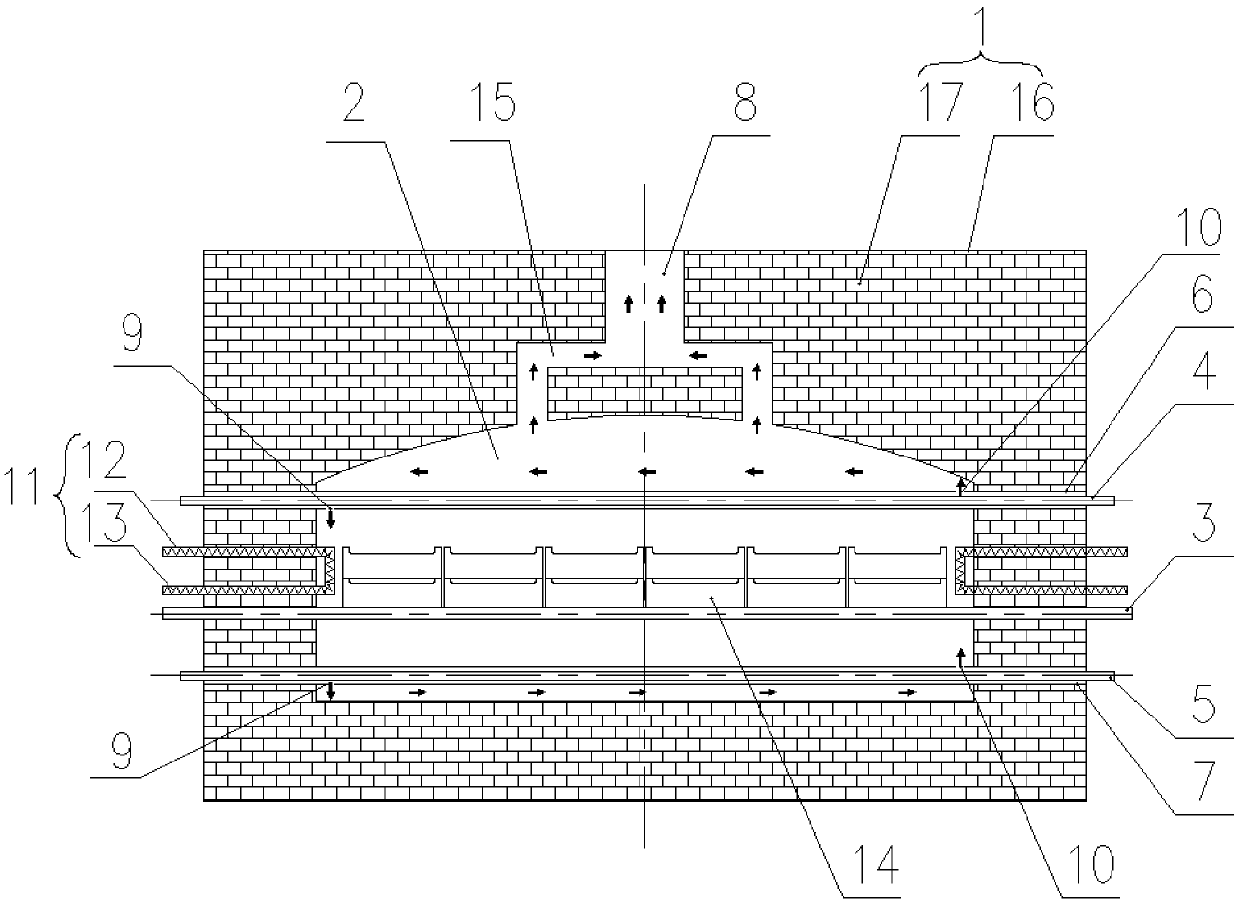

Roller way sintering furnace with uniform hearth temperature

The invention discloses a roller way sintering furnace with uniform hearth temperature. The roller way sintering furnace comprises a furnace body and a hearth, wherein a transmission roller way, an upper heating element and a lower heating element are arranged in the hearth, the upper heating element and the lower heating element are arranged above and below the transmission roller way correspondingly, the upper heating element is correspondingly provided with an upper protective sleeve, the lower heating element is correspondingly provided with a lower protective sleeve, and the top of the furnace body is provided with an exhaust port. One end of the upper protective sleeve is provided with at least one first air inlet hole, the other end of the upper protective sleeve is provided with atleast one second air inlet hole, one end of the lower protective sleeve is provided with at least one first air inlet hole, the other end of the lower protective sleeve is provided with at least onesecond air inlet hole, the first air inlet holes are the same in size and orientation, the second air inlets are the same in size and orientation, the orientations of the first air inlet holes are opposite to the orientations of the second air inlet holes, and the orientations are all located in the vertical face of the hearth. Uniformity of the flow field and the temperature inside the hearth canbe improved, and the comprehensive performance of sintered products is ensured.

Owner:湖南烁科热工智能装备有限公司

Ventilation system using solar energy and building thereof

ActiveCN110986239ATo achieve the effect of purifying the airReduce flow dead zoneSolar heating energyMechanical apparatusFresh airDust control

The invention provides a ventilation system using solar energy and a building thereof. The cold source comprises air, and the air is heated and then conveyed into building rooms, thereby forming an air supply system. The ventilation system further comprises a filtering module which is used for filtering the inlet air, the filtering module is arranged in an air inlet channel, and a primary effect filter, an electrostatic precipitator, an activated carbon filter and a high efficiency filter are sequentially arranged in the filtering module; the primary effect filter is one or more of non-woven fabric, nylon net, fluffy fiberglass felt, plastic net or metal mesh; the electrostatic precipitator comprises an electrostatic dust removal section, the electrostatic dust removal section comprises two stages, the two stages are a first stage and a second stage in the air flow direction, and the electric field strengths of the first stage and the second stage are different; and the material of thehigh efficiency filter is one or more of PP filter paper, glass fiber paper and PET filter paper. The invention provides a fresh air system, the fresh air system is provided with the novel filteringmodule, and the effect of purifying air can be achieved.

Owner:青建集团股份公司 +1

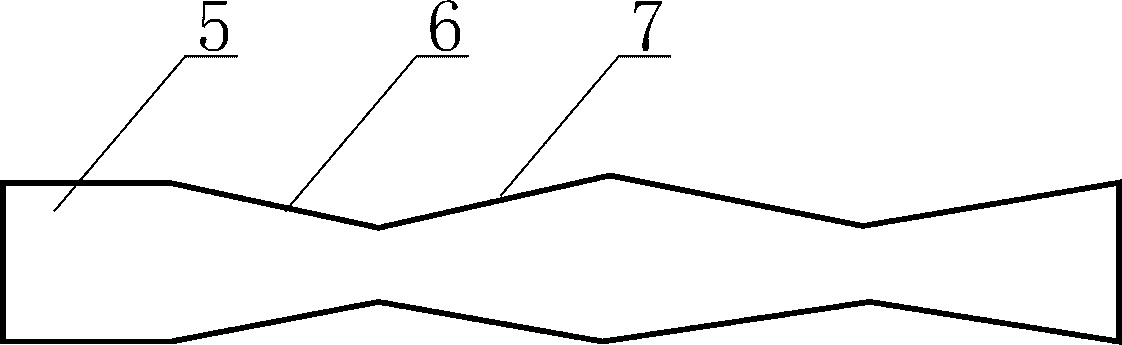

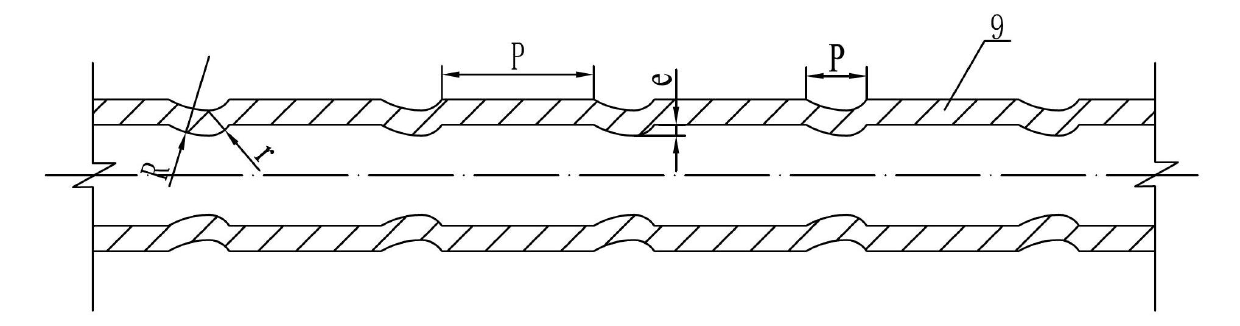

Asymmetric retractable transverse slot pipe heat exchanger

InactiveCN102636054AReduce flow dead zoneSpeed up the flowStationary tubular conduit assembliesTubular elementsProcess equipmentEngineering

The invention relates to a transverse slot pipe heat exchanger, in particular to an asymmetric retractable transverse slot pipe heat exchanger, which belongs to the technical field of heat exchanging process equipment and aims at solving the problems of low comprehensive heat transfer efficiency and being inapplicable to gas-steam heat exchanging in the existing transverse slot pipe heat exchanger. Each heat exchanging pipe is an asymmetric retractable transverse slot pipe; the curvature radius of an arc surface of the inside wall of the asymmetric retractable transverse slot pipe located at a flowing away side is less than that of an arc surface of the inside wall of the asymmetric retractable transverse slot pipe located at an incoming flow side; the width of an opening of a ringlike slot arranged on the asymmetric retractable transverse slot pipe is at a range of 6-10mm; the height of a bead of the ringlike slot arranged on the asymmetric retractable transverse slot pipe is at a range of 0.6-1.1mm; and the wall thickness of the asymmetric retractable transverse slot is at a range of 2-3mm. The transverse slot pipe heat exchanger provided by the invention is applicable to the industrial field, and is particularly applicable to the gas-steam heat exchanging.

Owner:HARBIN INST OF TECH

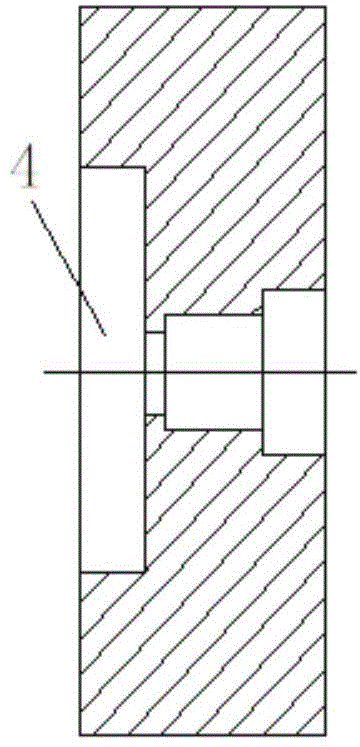

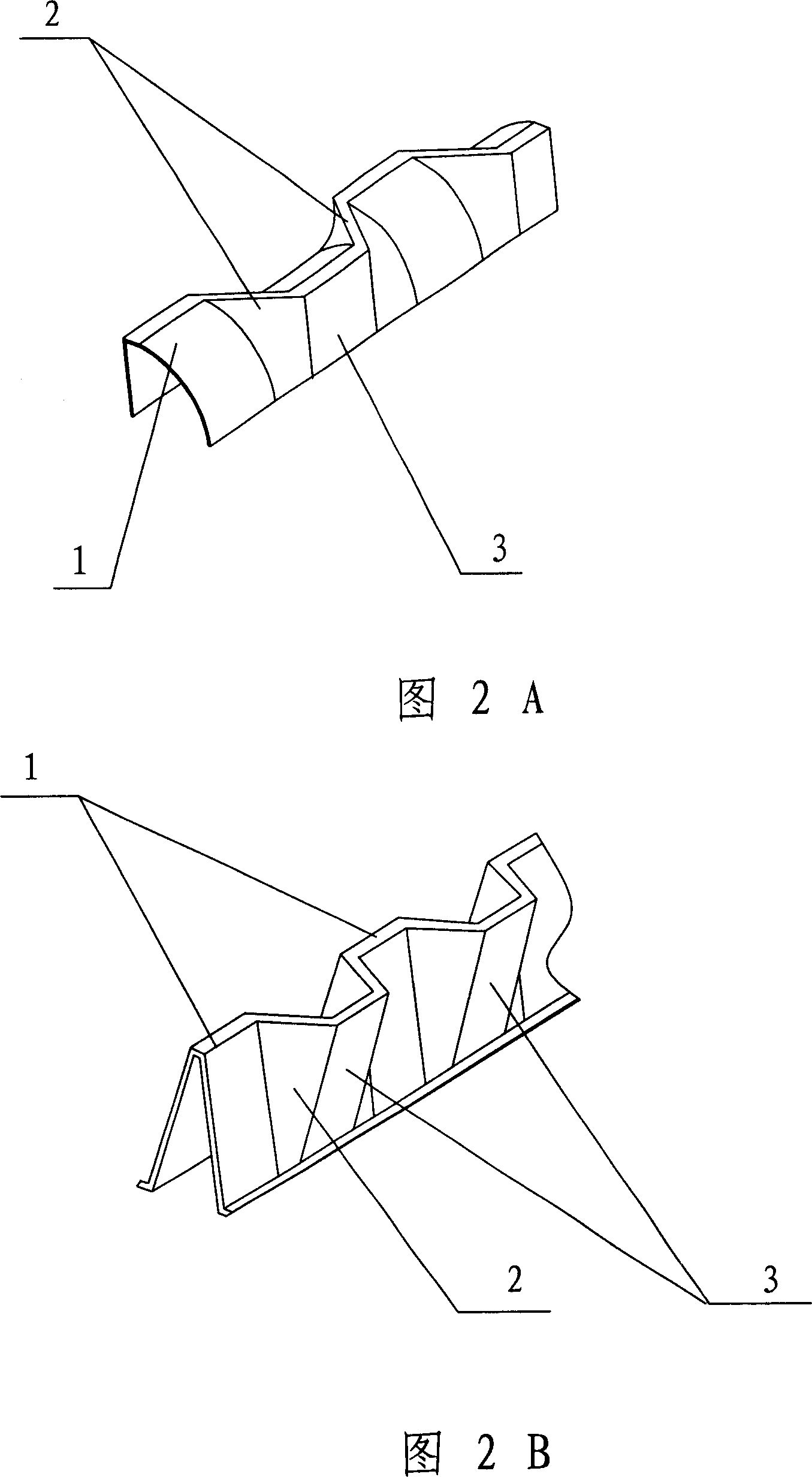

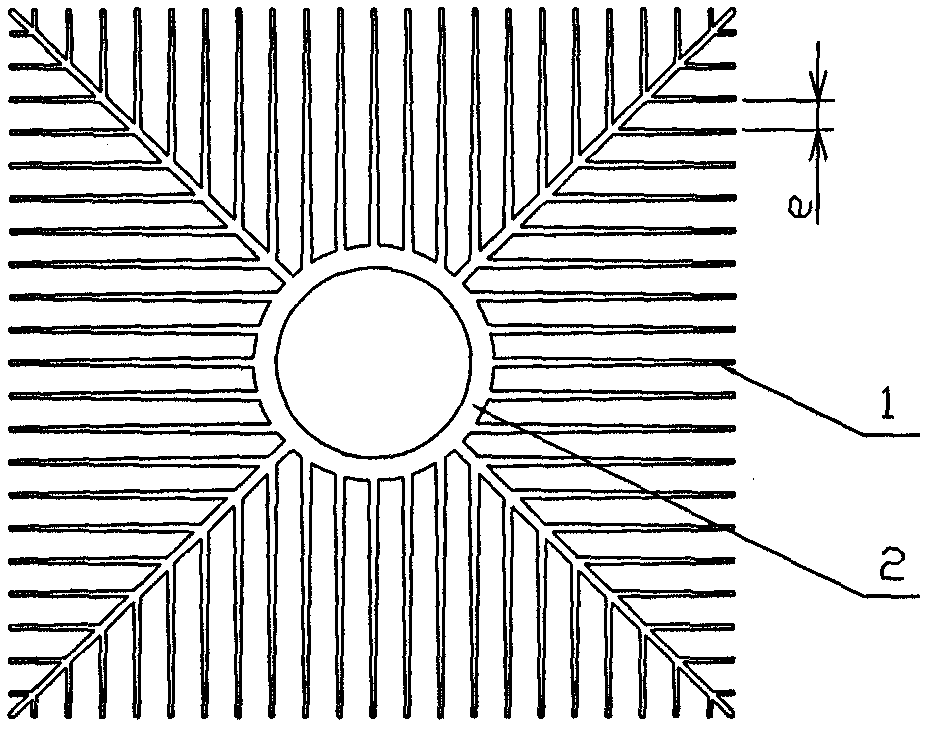

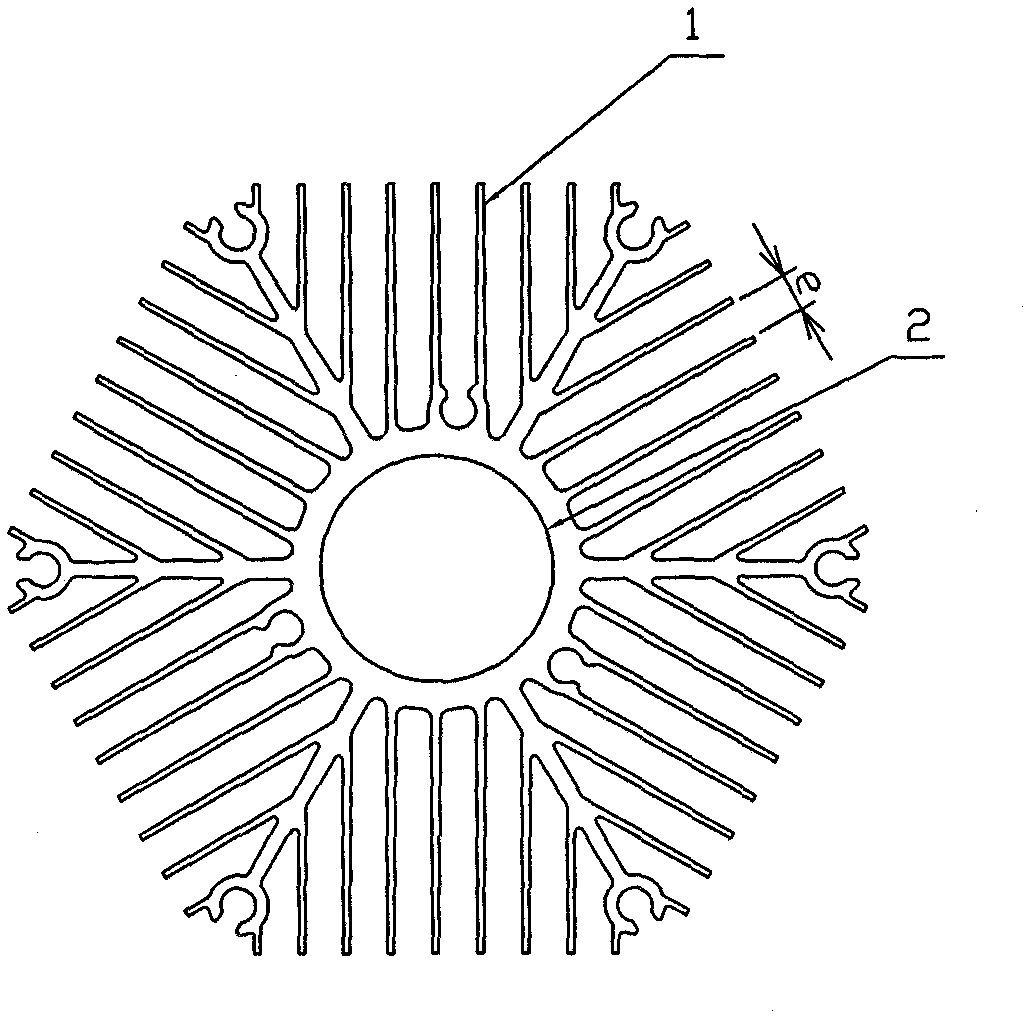

Extruding mould

ActiveCN102806243AImprove liquidityImprove the forceExtrusion diesChinese charactersCarrying capacity

The invention relates to an extruding mould which comprises an upper mould and a lower mould, wherein flow-splitting bridges having a shape of Chinese character 'Mi' are distributed on a feeding surface of the upper mould; uniform flow-splitting holes are formed between the flow-splitting bridges; a crossing part of the flow-splitting bridges is lower than the peripheral feeding surface, thereby forming a concave surface; the flow-splitting bridges on the feeding surface and the concave surface are transited through an inclined angle, thereby forming a first pressure-reducing angle; a second pressure-reducing angle is arranged at a feeding port of the flow-splitting hole on the concave surface; and third pressure-reducing angles are arranged on the two sides of the flow-splitting bridges. According to the extruding mould, the flow-splitting bridges are reasonably arranged and the flow-splitting bridges and the feeding surface are designed in an optimized form, so that the remaining flowing dead area is reduced, the load-carrying capacity of the mould is improved and the service life of the mould is prolonged.

Owner:GUANGDONG HAOMEI ALUMINUM

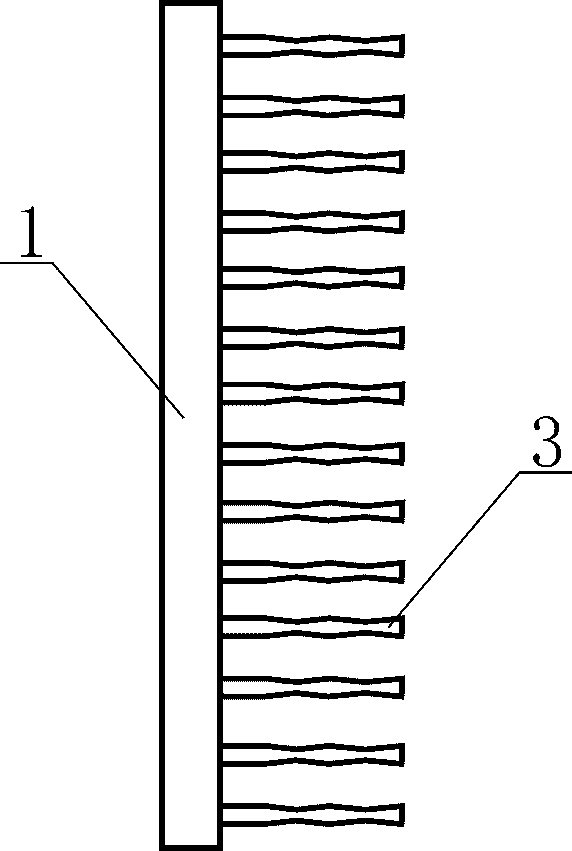

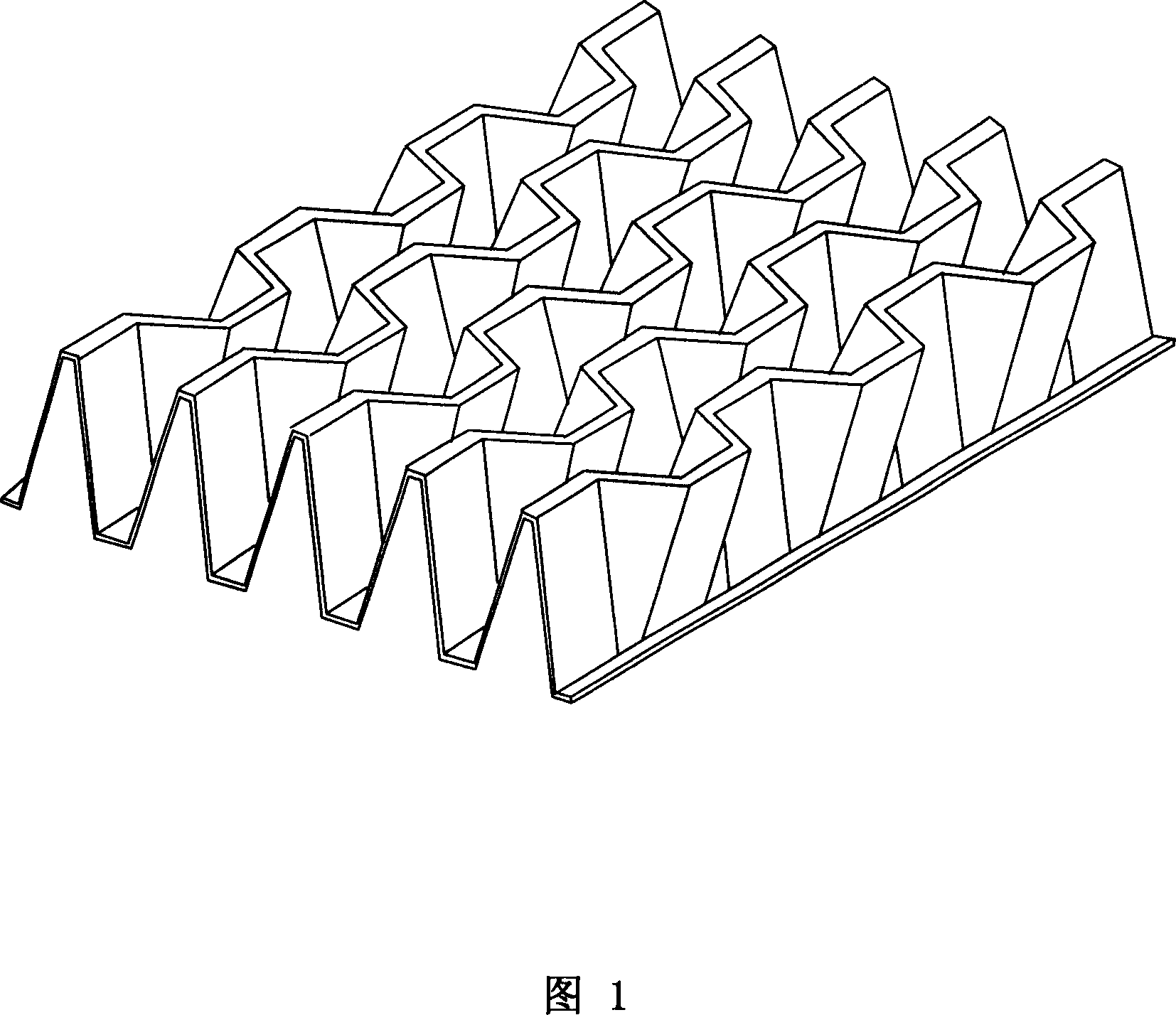

Chaos fin and plate-fin heat exchanger comprising the same

InactiveCN1963372AIngenious ideaEasy to processSemiconductor/solid-state device detailsHeat transfer modificationEngineeringTransitional phase

The chaotic fin tube comprises a fin tube unit which is made of several units of direct current phase, transitional phase and twisted direct current phase, with same geometrical appearance of the direct current phase and the twisted direct current phase within each unit, axially symmetrical rounding the transitional phase center perpendicular to the bottom. The cross section of the direct current phase and the twisted direct current phase takes on geometrical shapes, which ensures the two dimensional change on the cross section and the twisted change along the third shaft of the liquid. The plate-fin heat exchanger comprises seals, clapboard, and chaotic fins made by multi fins longitudinally and horizontally connected. Ingenious in design, simple in processing, it exchanges heat based on chaotic principle, having better effect than that of the laminar flow and lower pressure drop compared with onflow. Liquids have better status than the current flow channel, with less dead corner, fine mixing efficiency and greatly reducing the opportunity of flow channel block.

Owner:ZHENGZHOU UNIV

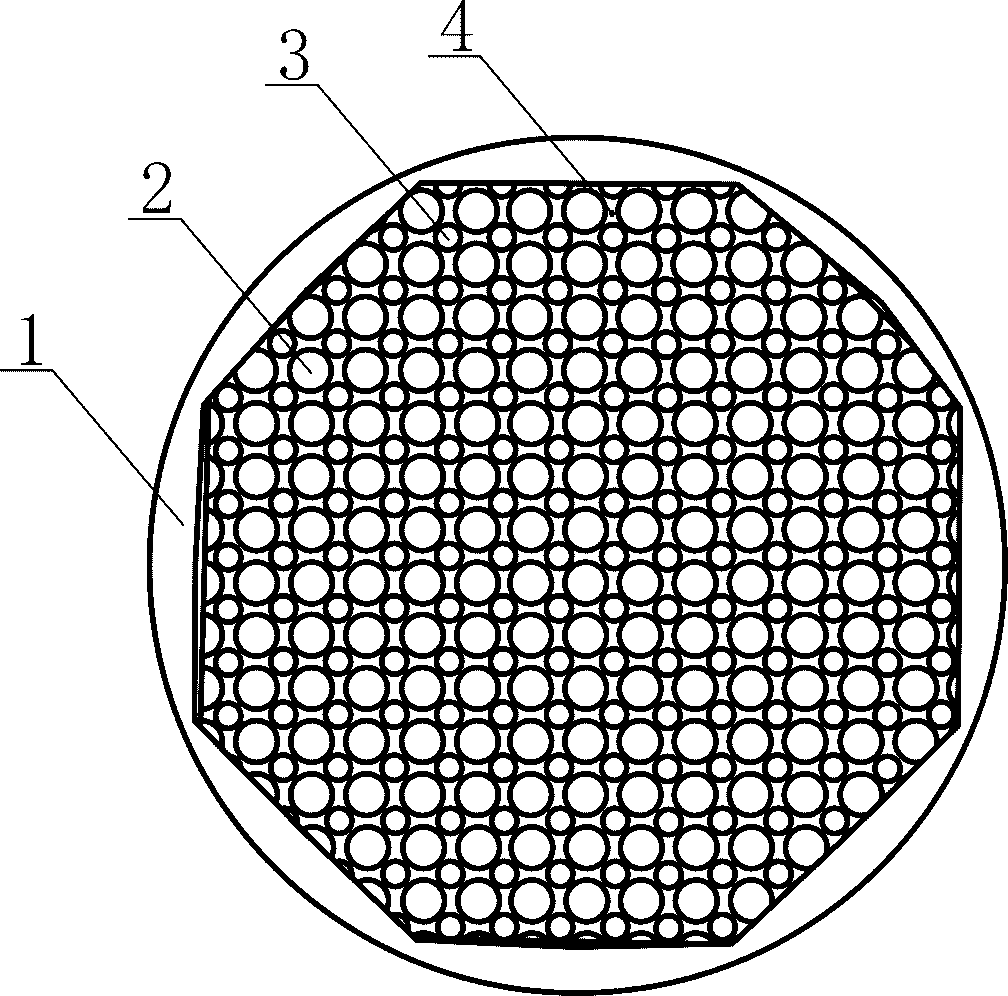

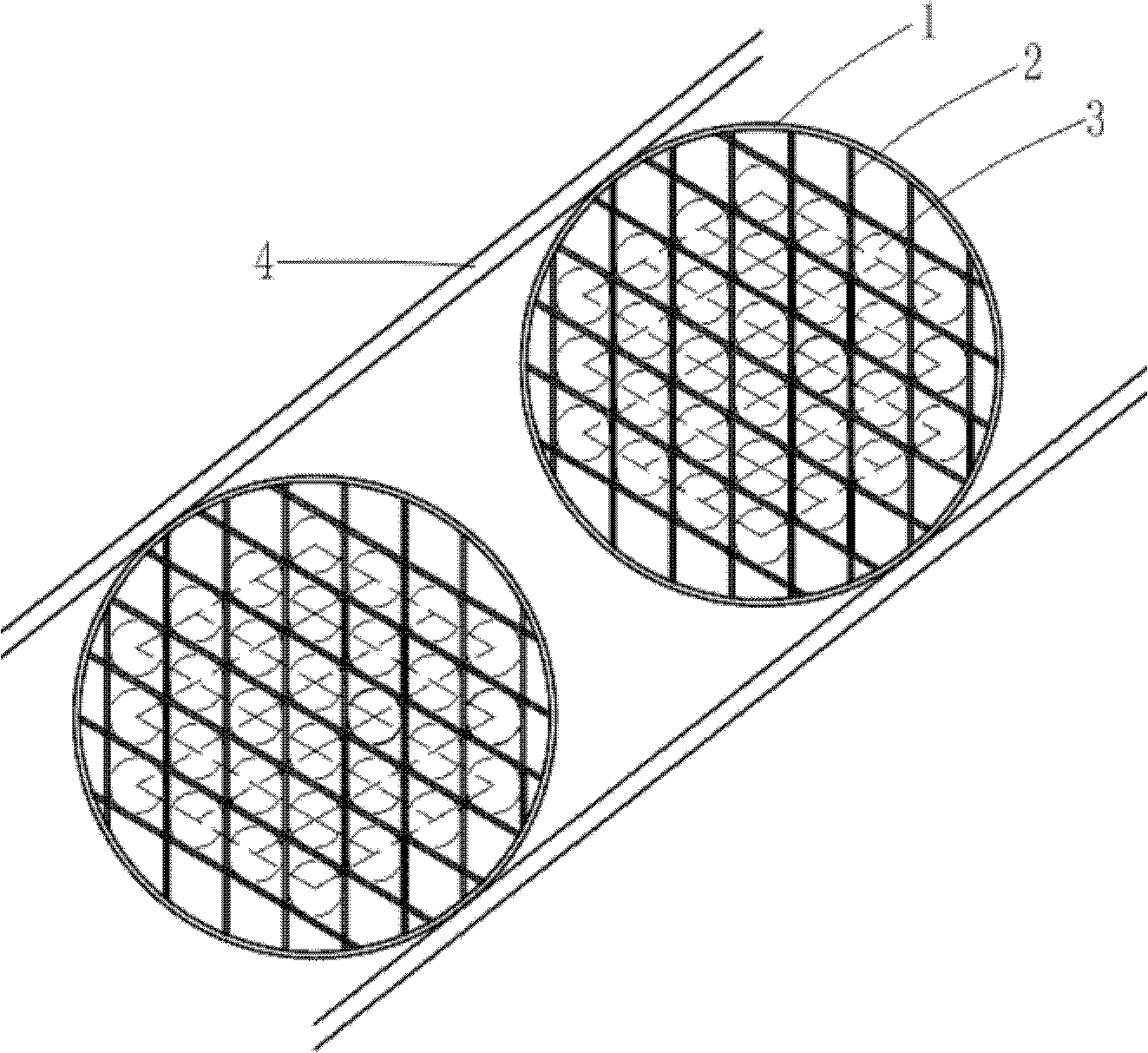

Grid type supporting baffling device of shell-and-tube heat exchanger

InactiveCN102564206AStable supportReduce resistanceHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The invention discloses a grid type supporting baffling device of a shell-and-tube heat exchanger, which comprises supporting limiting rings fixedly connected with the inner wall of a heat exchanger shell. A plurality of grid plates are connected in a crossed manner in each supporting limiting ring to form a porous grid, heat exchange tubes penetrate through holes of each grid, outer walls of the heat exchange tubes closely contact with inner walls of the holes, and two ends of each grid plate are fixedly connected with the inner wall of the corresponding supporting limiting ring. By the aid of the grid type supporting baffle device, heat transfer efficiency can be effectively improved, resistance loss of a shell pass is reduced, vibration of the heat exchange tubes is avoided, and the service life of equipment is prolonged.

Owner:HEFEI GENERAL MACHINERY RES INST

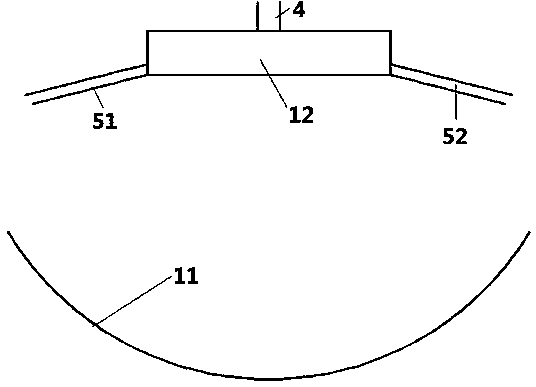

Solar system, heating and ventilating system and building roof with solar system

ActiveCN111306812AReduce flow dead zoneImprove temperature uniformitySolar heating energyRoof covering using slabs/sheetsThermodynamicsHeat flow

The invention provides a solar system, a heating and ventilating system and a building roof with the solar system. The solar system comprises a collector. The collector comprises heat collecting pipesand a reflecting mirror. The heat collecting pipes are flat pipes. The lower flat surfaces of the flat pipes are opposite to the reflecting surface of the reflecting mirror. Each flat pipe comprise abottom plate on the lower side and an upper cover on the upper side, wherein the upper cover and the bottom plate are assembled together to form a cavity of the flat pipe, and fluid flows in the cavity. Each bottom plate comprises a plurality of heat exchange area. Each heat exchange area comprises vertical plates and column ribs. The novel solar system is developed, and a flow guide structure isarranged in a cold plate of each heat exchange area, so that a refrigerant flowing dead area is effectively reduced, and the thermal homogeneity of a hot flow surface is further improved; and by means of the column ribs, the disturbance to the flow field is enhanced, the heat exchange area is expanded, and heat exchange can be easily reinforced.

Owner:QINGJIAN GRP CO LTD +1

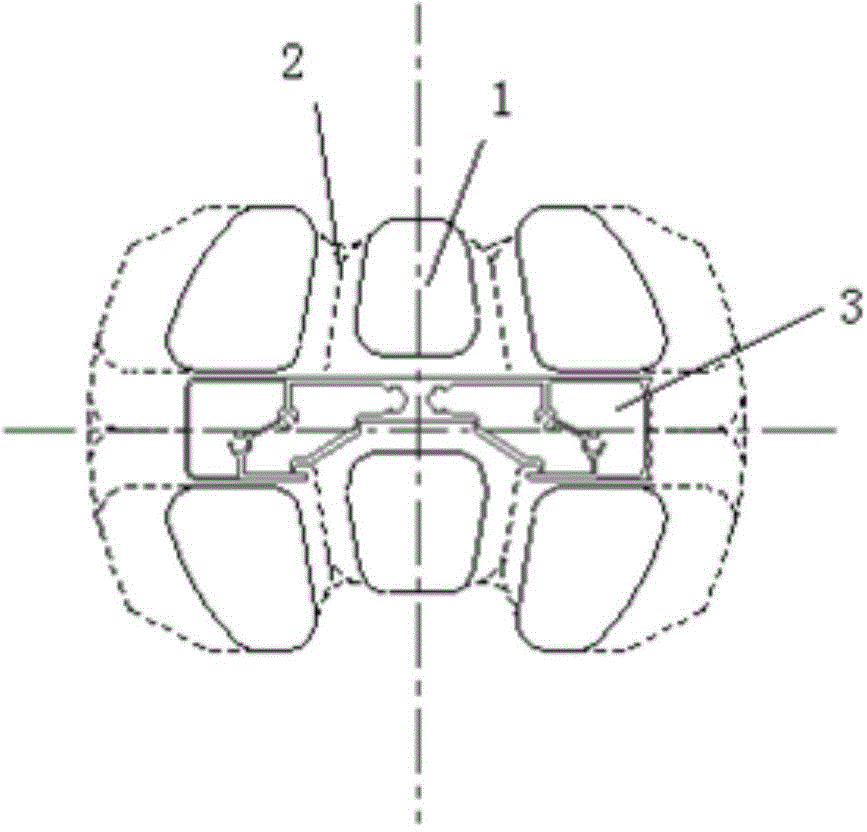

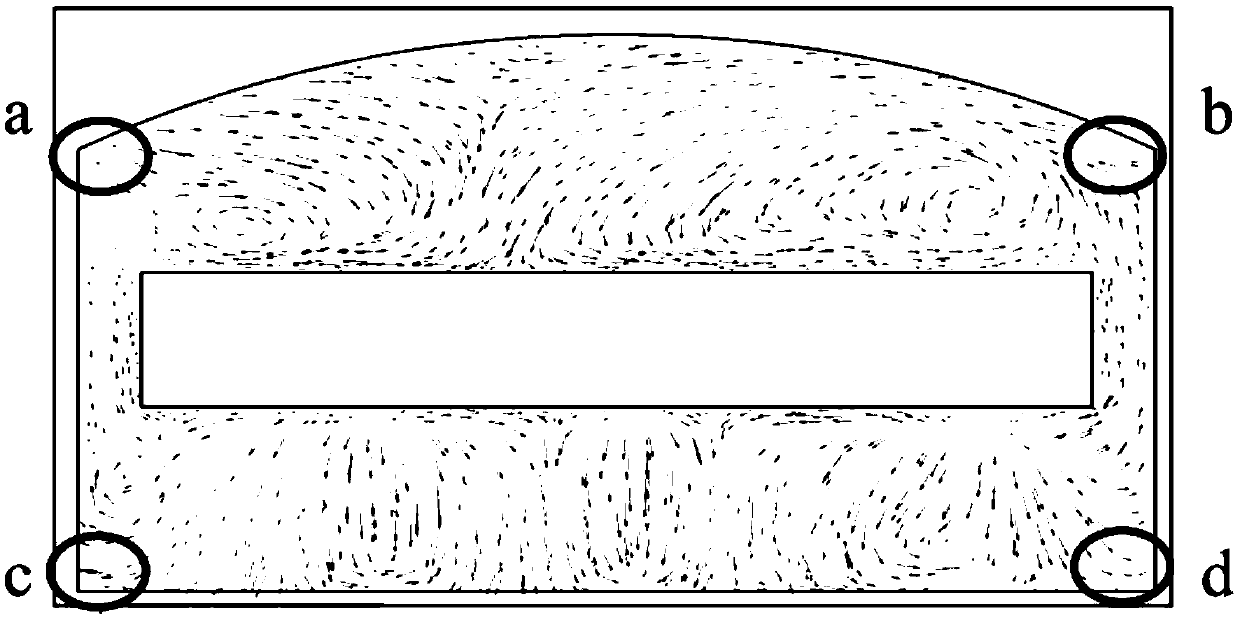

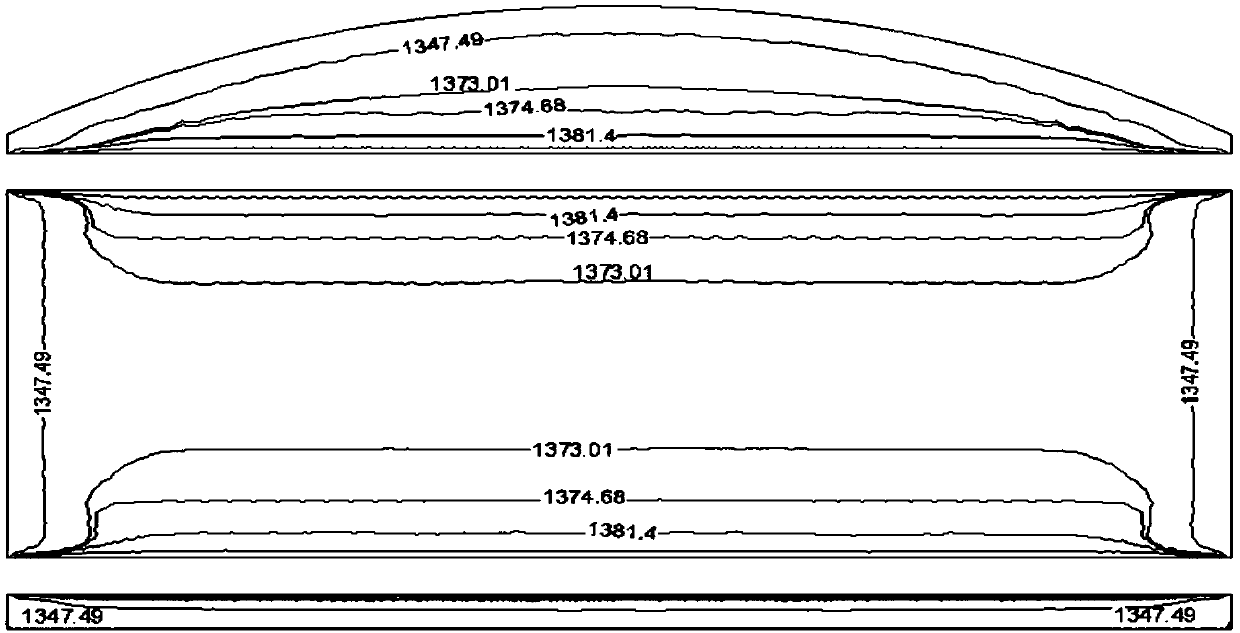

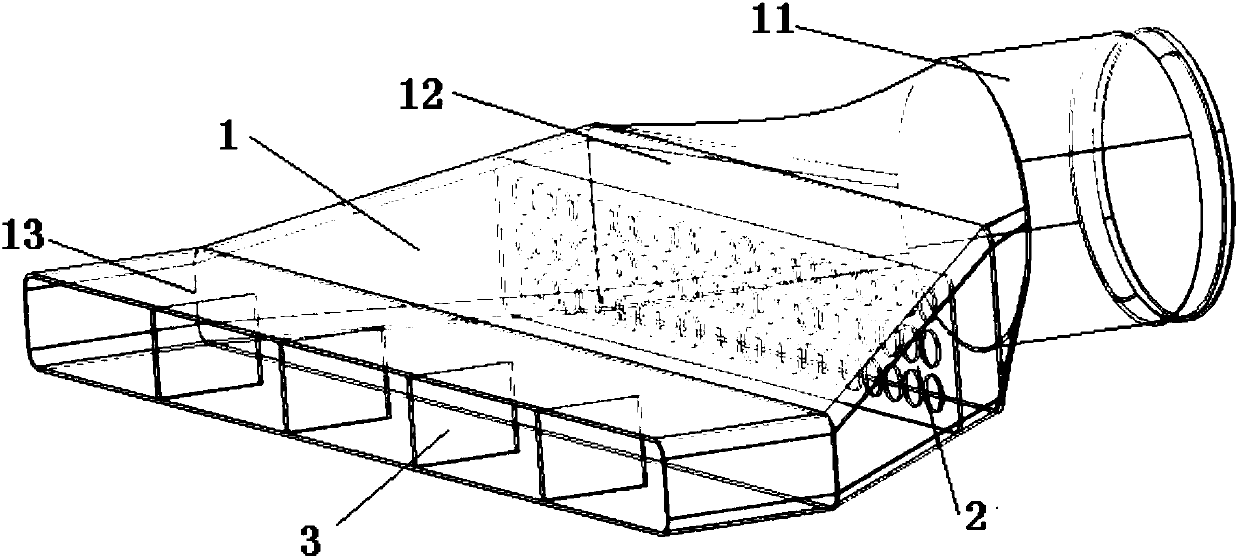

An air outlet structure of a passenger cabin of a civil aircraft

InactiveCN109250121AImprove flow field distributionPromote circulationAir-treatment apparatus arrangementsAirplaneJet aeroplane

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

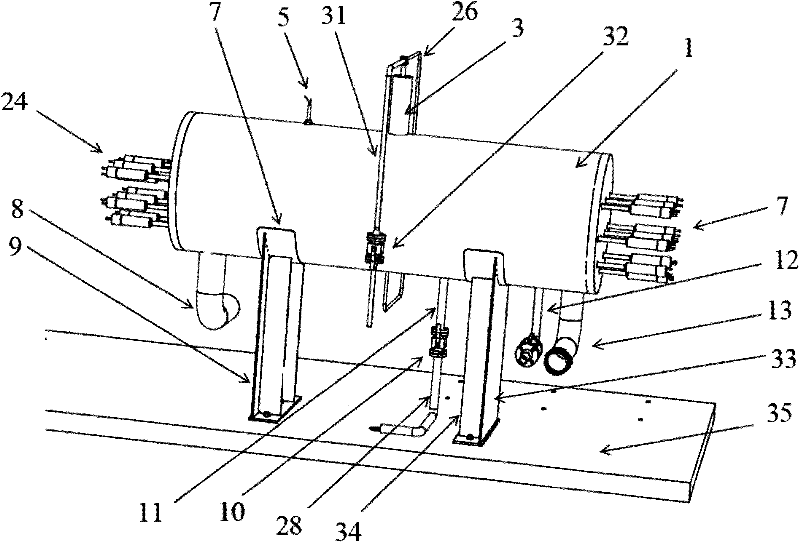

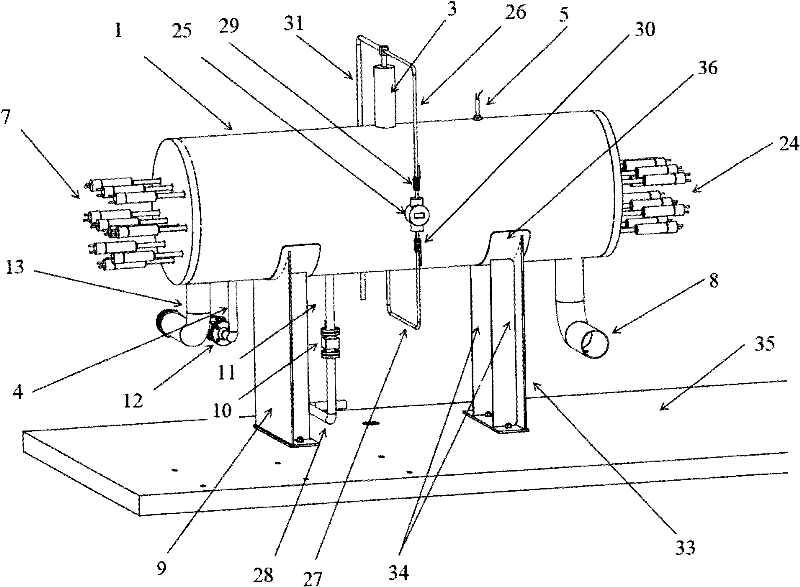

High power density electric heating water tank for secondary pre-service hydraulic pressure test of steam generator

ActiveCN102192586AIncrease heating powerRapid Heat Flux DistributionWater heatersElectricityEngineering

The invention belongs to an electric heating water tank, particularly relates to a high power density electric heating water tank for secondary pre-service hydraulic pressure test of a steam generator, which comprises a cylinder, an electric heater, a water inlet pipe and a water outlet pipe; the heating end of the electric heater is located inside the cylinder, the water inlet pipe is arranged at one end of the bottom of the cylinder, and the water outlet pipe is arranged at the other end of the bottom of the cylinder. The water tank has smaller volume, high heating power and high thermal efficiency and can realize quick temperature rise of a secondary shell of the steam generator.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922BEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

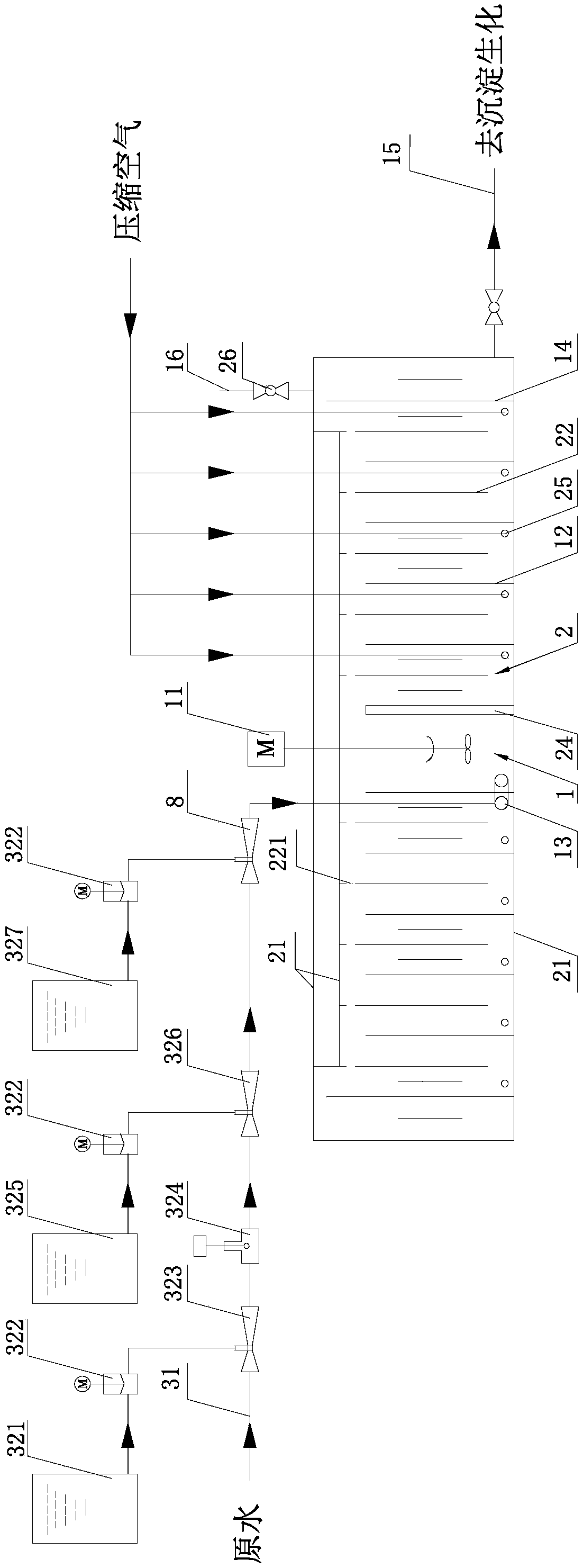

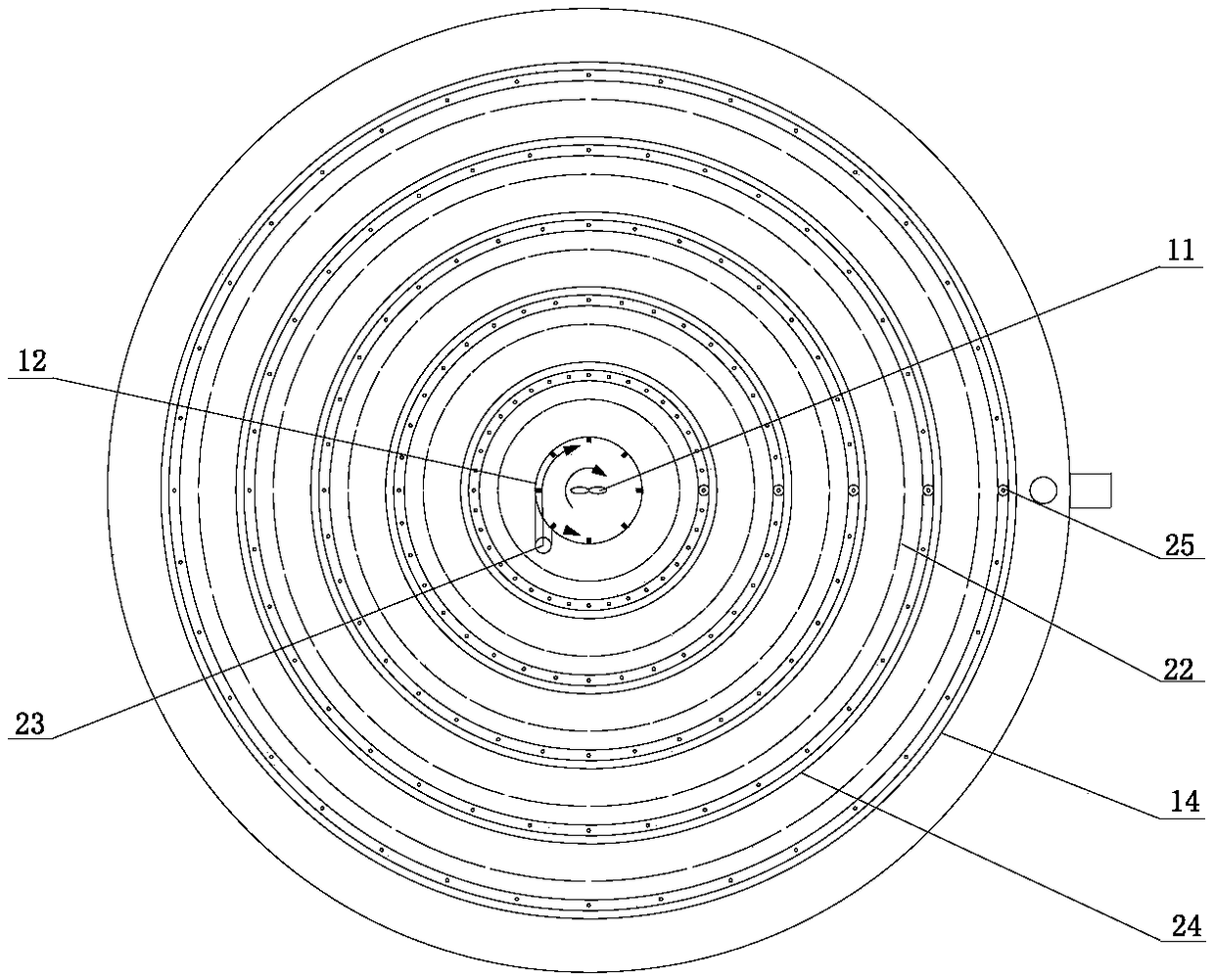

Baffled Fenton oxidation reactor and organic wastewater treatment method

ActiveCN108689475AMixing helpsIncreased turbulenceWater/sewage treatment apparatusWater/sewage treatment by oxidationFenton reactionFenton oxidation

The invention relates to a baffled Fenton oxidation reactor and an organic wastewater treatment method. The baffled Fenton oxidation reactor comprises a chemical mixing area, a baffled reaction area ,and four pipeline connectors, the chemical mixing area and the baffled reaction area are sequentially arranged from the inside to the outside of concentric sleeves, wherein the bottom central area isprovided with a wastewater inlet, a series of compressed air connectors are arranged on the bottom of the reaction area, and a drain outlet and an exhaust outlet are arranged at a position far from the center. The organic wastewater treatment method comprises the following steps: after wastewater is filtered and pH is regulated, metering pumps quantitatively add FeSO4 solution and H2O2 solution in sequence into a water inlet pipeline by means of a jet device to get into the reactor, an aerator is switched on, the mixed wastewater gets into the chemical mixing area in a tangential feeding manner, and rapidly spirals upwards along the internal wall of the barrel under the action of an agitating pump, the disturbance and turbulence of the wastewater are further intensified by fin baffles, and thereby the uniform mixing of the wastewater and chemical is promoted; in the baffled reaction area, and the mixed wastewater passes through in the form of plug flow, carries out rapid Fenton reaction, and flows out of the reactor via a downflow weir.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Light-emitting diode (LED) optical engine and LED illuminating lamp

InactiveCN103032721AReduces severe performance degradation issuesLow costPoint-like light sourceElectric circuit arrangementsEngineeringHeat sink

The invention provides a light-emitting diode (LED) optical engine which is a standard module of an LED illuminating device and can be conveniently realized. The LED optical engine comprises an LED light source (3) and cooling fins, wherein the cooling fins form a sunflower-shaped structure. The LED optical engine is mainly characterized in that the cooling fins (1) are respectively provided with cross flow grooves (5); each cooling fin is divided into a plurality of short fins (4), so that the problems that the ventilation performance is poor and the heat dissipation performance seriously worsens when axes of the cooling fins are horizontally arranged are solved. The LED light source (3) and an external power supply are connected by adopting a splicing structure, so that assembly and maintenance are convenient. The invention also provides an LED bulb lamp with an optimized structure size and a novel structure, and thus, lower manufacturing cost and a higher heat dissipation effect can be realized.

Owner:秦彪

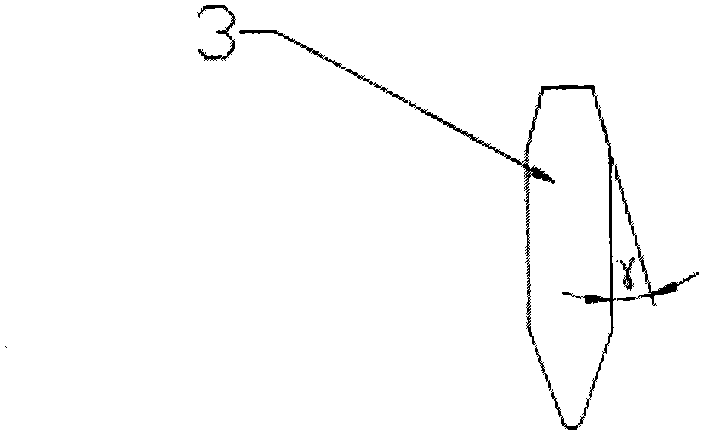

Catalyst tremie pipe

InactiveCN103285788AReduce stagnation dead zoneReduce flow dead zoneChemical/physical processesCatalytic reformingTremie

The invention discloses a catalyst tremie pipe which comprises a guide shell and a side port, wherein a partition is arranged in the guide shell; the partition divides the guide shell into a side port guide shell and a central port guide shell; and the side port guide shell is communicated with the side port. The catalyst tremie pipe disclosed by the invention can reduce the influence of the wall attachment effect on the reactor wall surface, can obviously reduce the catalyst flow dead zone in the reactor, enhances the effective volume utilization ratio of the reactor, enables the catalyst stream type to be more approximate to the piston flow, and is especially suitable for a moving bed radial reactor for preparation of olefine from methanol, catalytic reforming or any other production process.

Owner:ZHEJIANG UNIV

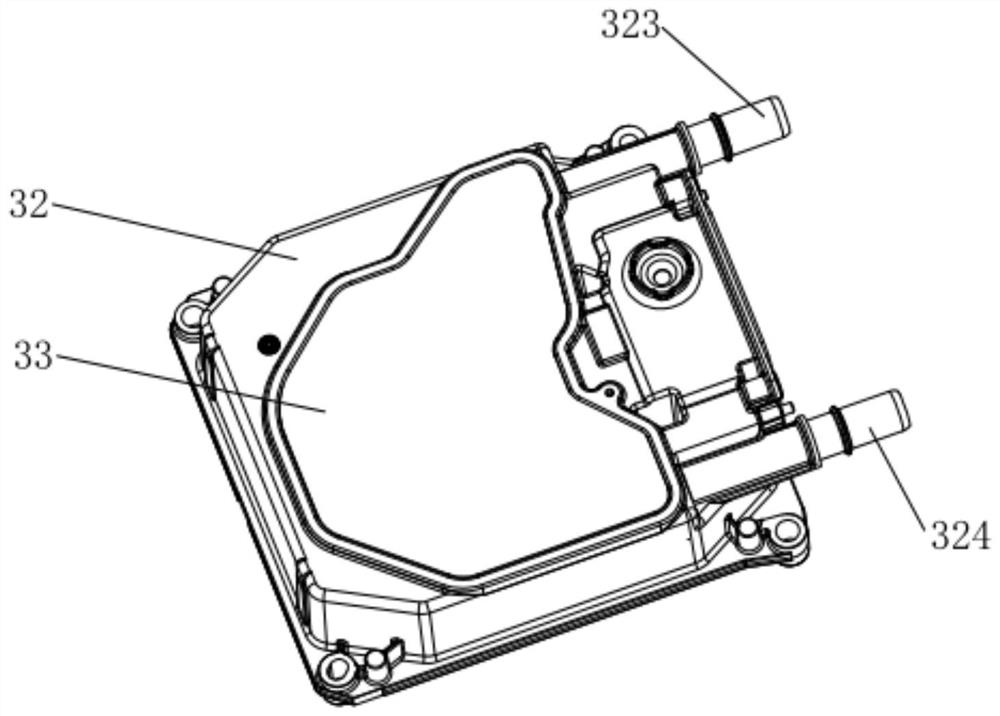

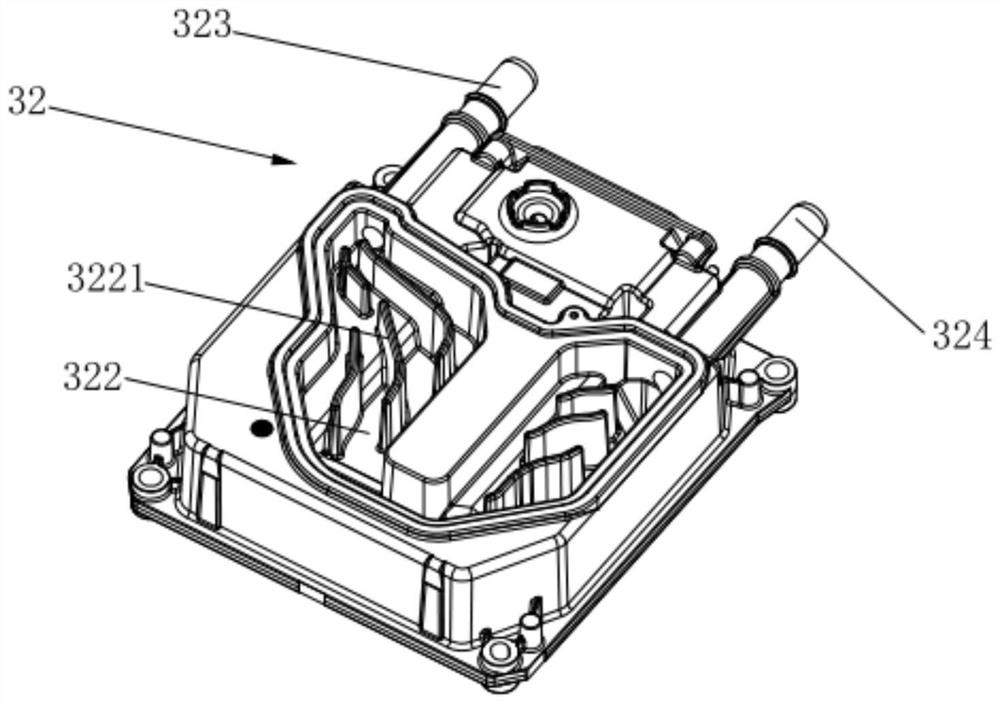

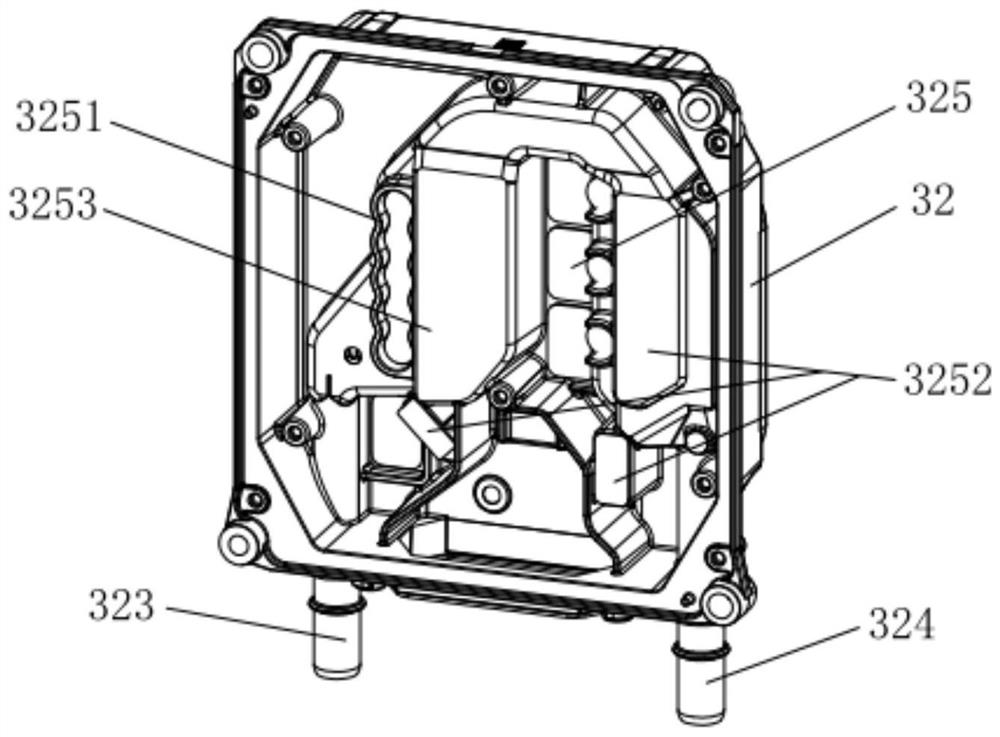

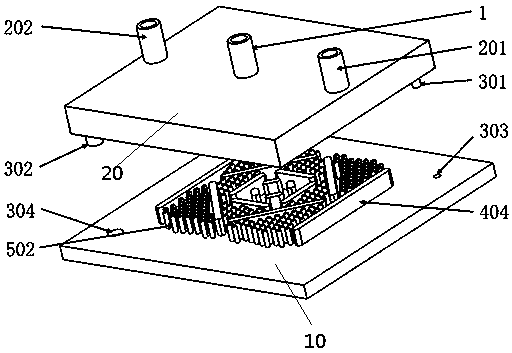

Cooling device of power converter and power converter

PendingCN112423569AAvoid separate settingsReduce flowCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsWater flowEngineering

The invention discloses a cooling device of a power converter and the power converter, and belongs to the technical field of power converters. The cooling device of the power converter comprises a shell and a lower cover plate, a communication groove and a mounting cavity are formed in the shell, openings of the communication groove and the mounting cavity face opposite directions, and a flow guide rib is arranged on the communication groove to separate the communication groove; the lower cover plate is arranged on the shell, the lower cover plate and the communication groove form a waterway channel, and a diversion rib divides the waterway channel into shunting channels. The power converter comprises the cooling device of the power converter. According to the cooling device of the power converter and the power converter, the diversion rib is arranged in the communication groove to reduce a cooling liquid flowing dead zone, and a heat dissipation part is arranged in the mounting cavity, so that heat conduction between the to-be-cooled element and the waterway channel is improved, and the cooling efficiency is improved.

Owner:SHANGHAI VALEO AUTOMOTIVE ELECTRICAL SYST

Design method of water-cooled tube plate type heat exchanger

ActiveCN110793370AEstimated heat dissipationEstimated pump power consumptionIndirect heat exchangersDesign optimisation/simulationEngineeringMechanical engineering

The invention provides a design method of a water-cooled tube plate type heat exchanger. The heat exchanger comprises a base plate and a cover plate, the cover pate and the base plate are assembled together to form a fluid space, the base plate is provided with baffles and cylindrical fins, the baffles comprise the first baffle located at the center of the base plate, the second baffle surroundingthe first baffle and the third baffle surrounding the second baffle, and a nusselt number and other formulas are designed through parameters. According to the design method, through a large number ofresearches, the structure of the heat exchanger is simulated, the nusselt number and other formulas of the structure are determined for the first time, and the heat dispersion performance and pump power consumption of a water-cooled plate can be estimated by the formulas.

Owner:SHANDONG UNIV

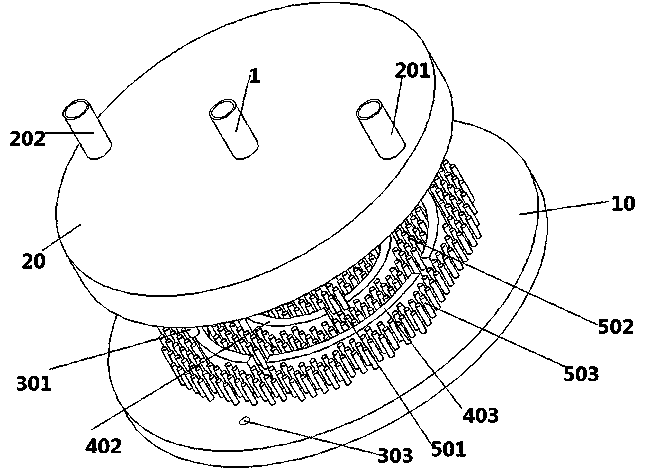

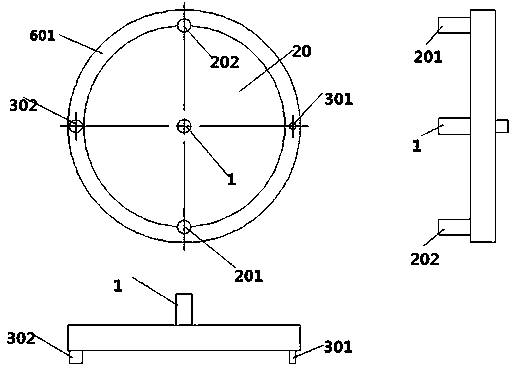

Circular-structure plate heat exchanger for controlling flow by comparing adjacent temperatures

ActiveCN111336844AAffect operationMeet heat transfer needsHeat exchanger casingsHeat transfer modificationData connectionPlate heat exchanger

The invention provides a circular-structure plate heat exchanger for controlling flow by comparing adjacent temperatures. The circular-structure plate heat exchanger comprises a base plate and a coverplate, the base plate and the cover plate are of a circular structure, the cover plate and the base plate are assembled together to form a circular cavity, cooling fluid flows in the cavity, an inletis formed in the center of the cover plate, and a temperature sensor is arranged on the outer wall face of the base plate; the temperature sensor is in data connection with the controller, and the controller automatically controls the fluid flow of the inlet according to the data of the temperature sensor; and the controller extracts the temperature data according to the time sequence, the temperature difference of the temperature data is obtained by comparing the temperature data of the adjacent time periods, and the controller automatically controls the fluid flow of the inlet according tothe temperature difference. According to the circular-structure plate heat exchanger for controlling flow by comparing the adjacent temperatures, the situation that heat exchange and heat dissipationcannot be conducted in time due to too much or too little heat exchange fluid is avoided, and it is avoided that the temperature of a heat source is too high or too low to affect operation of the heatsource.

Owner:SHANDONG UNIV

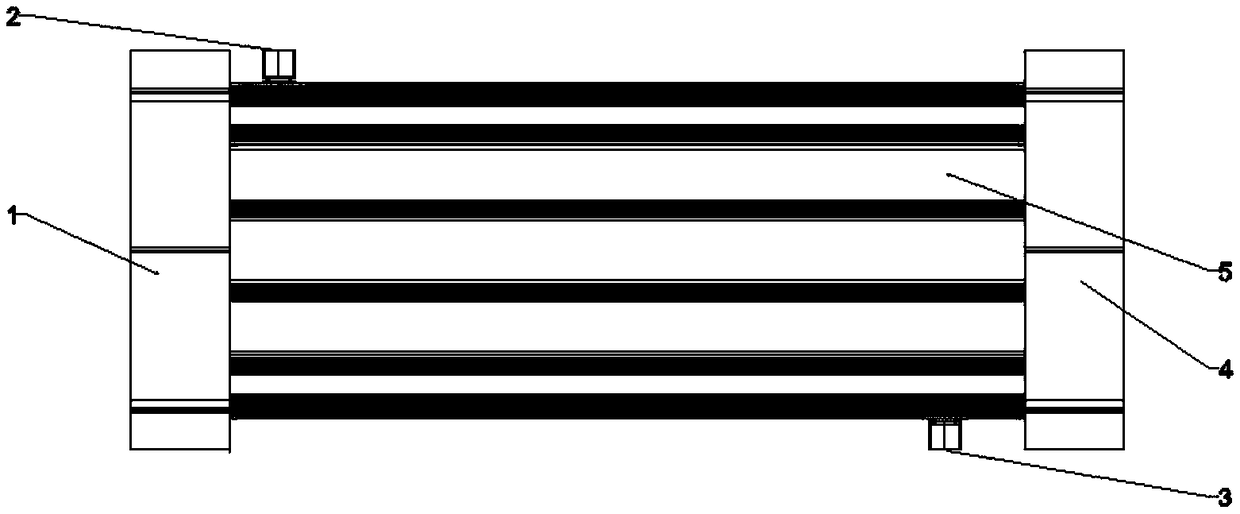

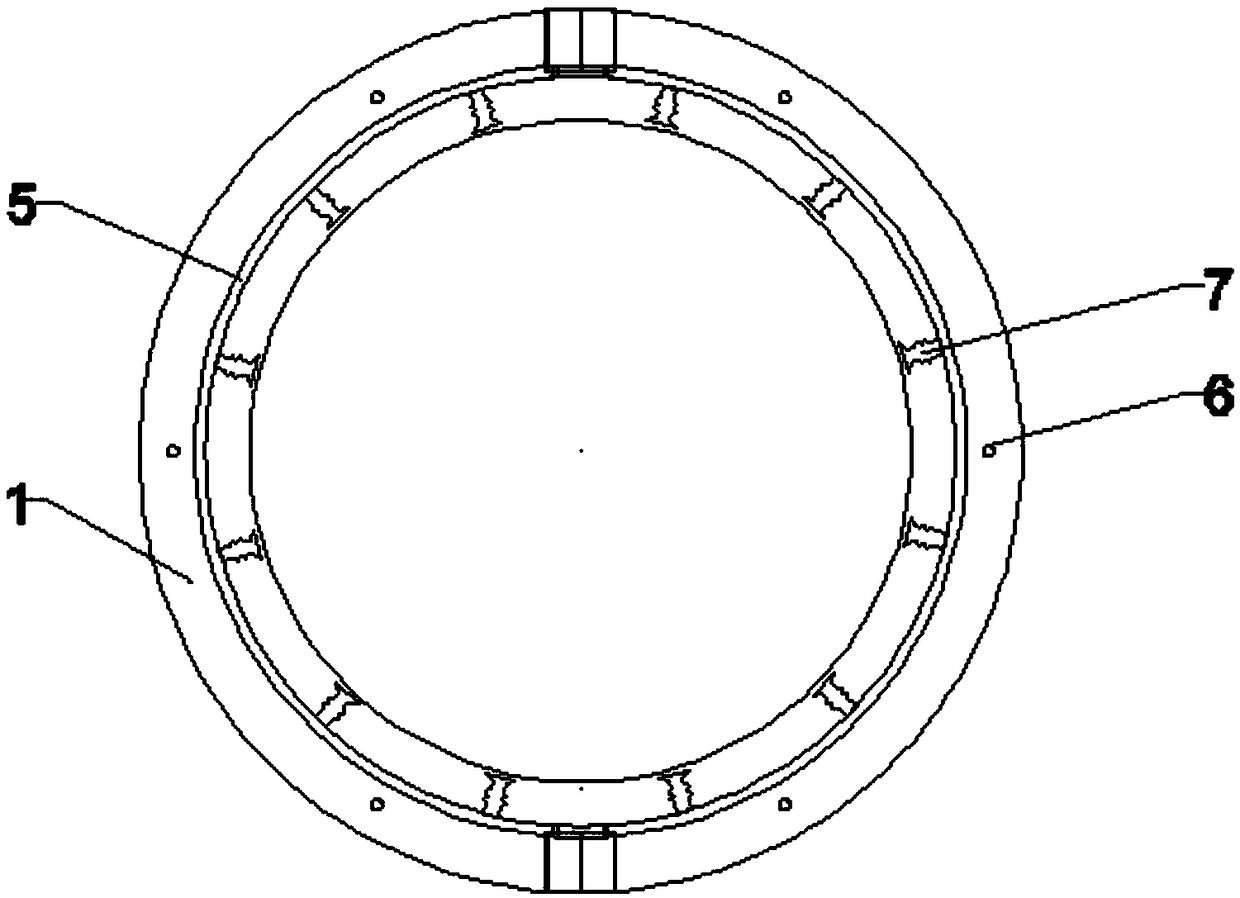

Launcher barrel cooling water jacket based on turbulent flow blades

ActiveCN109029067AIncrease cooling areaReduce flow dead zoneVentillation systemsWater deliveryEngineering

The invention provides a launcher barrel cooling water jacket based on turbulent flow blades. The launcher barrel cooling water jacket comprises a water jacket body, a water inlet and a water outlet.The water jacket body is tubular and is fixed to a launcher barrel. The water inlet and the water outlet are located in the upper and lower wall faces of the two ends of the water jacket body correspondingly. A plurality of T-shaped water delivery blades are arranged on the inner wall of the water jacket body in the circumferential direction. Each T-shaped water delivery blade is in a strip shapeand is arranged in the axial direction of the water jacket body. According to the launcher barrel cooling water jacket, the barrel can be cooled efficiently in the continuous shooting process of a launcher.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com