Catalyst tremie pipe

A catalyst and feeding tube technology, applied in the field of reactors, can solve the problems of fan-shaped tube or central tube being squeezed and deformed by the catalyst, the flow pattern of catalyst particles deviating from plug flow, and the low utilization rate of the effective volume of the reactor. Small catalyst flow dead zone, large practical value and economic significance, and the effect of improving effective volume utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

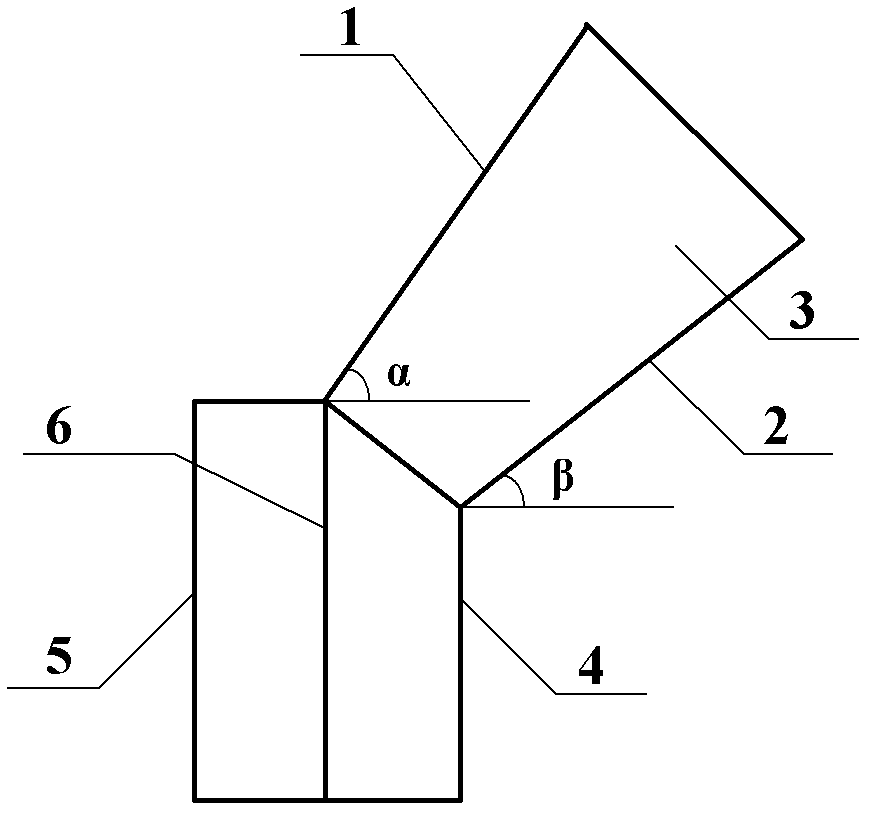

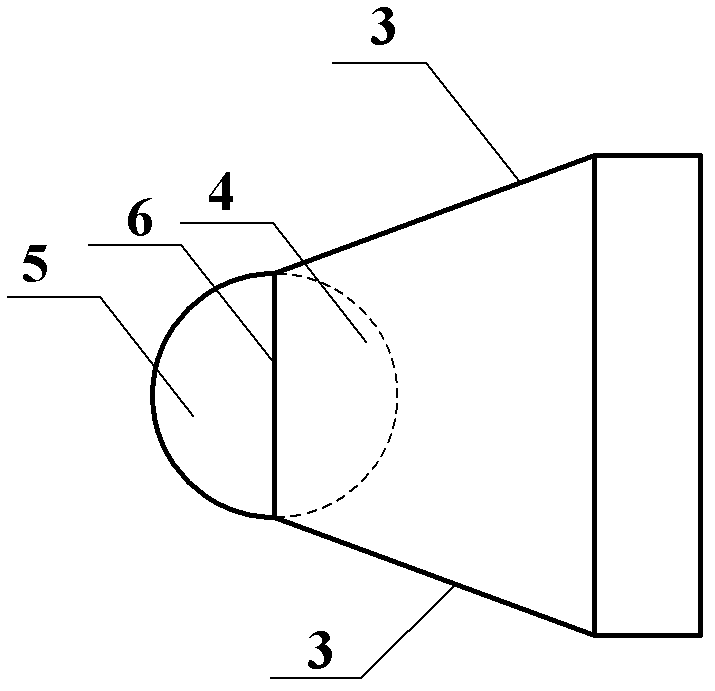

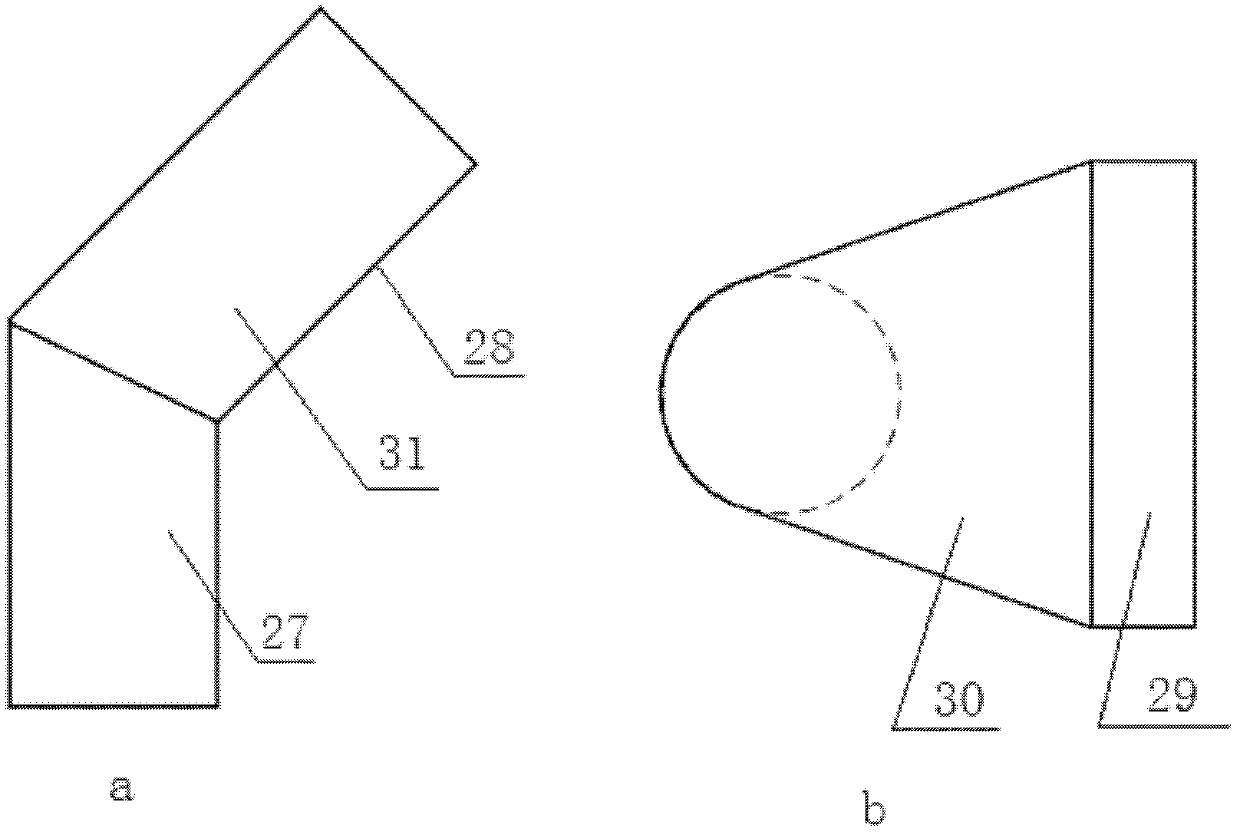

[0034] Such as figure 1 and figure 2 As shown, the catalyst feeding pipe of the present invention includes a guide tube and a side port, and a partition 6 is arranged in the guide tube, and the partition 6 is perpendicular to the cross section of the guide tube and divides the guide tube into side ports to guide The flow tube 4 and the center interface guide tube 5; the side interface guide tube 4 communicates with the side interface. Both ends of the side interface guide tube 4 and the center interface guide tube 5 are not closed. The cross section of the guide tube is circular, and the cross sections of the side interface guide tube 4 and the central interface guide tube 5 are both semicircular. The catalyst feeding pipe is symmetrical along a plane perpendicular to the partition 6 and passing through the central axis of the partition 6 . A port of the side interface away from the side interface guide tube 4 is higher than the mouth of the central interface guide tube 5...

Embodiment 2

[0041] Such as Figure 6 As shown, the present invention adopts the moving bed methanol-to-olefins radial reactor of the r-type catalyst feeding pipe in Example 1, and the reactor is composed of an upper head 11, a cylindrical reactor shell 12 and a bottom head 13. Reactor outer shell. A gas inlet pipe 14 and a gas outlet pipe 15 are provided on the outer casing of the reactor, wherein the gas inlet pipe 14 is arranged on the upper head 11 . A central pipe 16 coaxial with the reactor cylinder 12 is arranged on the central axis of the reactor cylinder 12 , and the gas outlet pipe 15 communicates with the central pipe 16 . A plurality of fan-shaped tubes 17 are uniformly arranged on the inner wall of the reactor cylinder 12, and 20 r Type catalyst feed pipe 25 (such as figure 1 and figure 2 shown). The annular space 18 between the central pipe 16 and the fan-shaped cylinder 17 is filled with catalyst, which is a catalyst flow channel. When the gas flow form is centripeta...

Embodiment 3

[0049] The present invention adopts the continuous catalytic reforming radial reactor of the r-type catalyst feeding pipe in embodiment 1, except that the moving bed methanol-to-olefins radial reactor adopted in embodiment 2 is replaced by a continuous catalytic reforming radial reaction Device, other structures are all the same as embodiment 2.

[0050] The structure of the above-mentioned continuous catalytic reforming radial reactor and its components, except that the catalyst feeding pipe 25 adopts the r-type catalyst feeding pipe in Embodiment 1, all the other parts are conventional parts, and the arrangement of the catalyst feeding pipe 25 The method, the operation process of the reactor, and the operating conditions are also conventional methods or conditions, so only the above brief description is given.

[0051] The catalyst feeding pipes 25 used in Embodiment 1, wherein, the number of catalyst feeding pipes 25 is 8, and the plate thickness is 5mm. The ratio of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com