Patents

Literature

85 results about "Tremie" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

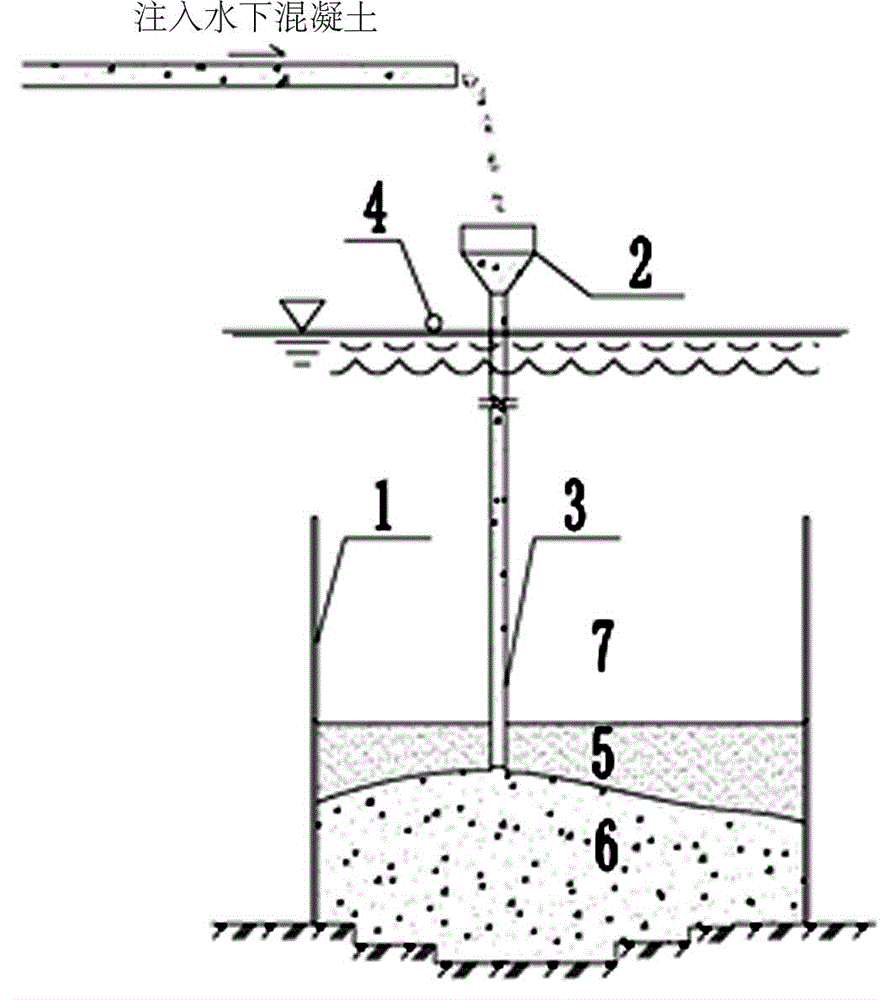

A tremie is a watertight pipe, usually of about 250mm inside diameter (150 to 300 mm), with a conical hopper at its upper end above the water level. It may have a loose plug or a valve at the bottom end. A tremie is used to pour concrete underwater in a way that avoids washout of cement from the mix due to turbulent water contact with the concrete while it is flowing. This produces a more reliable strength of the product. Common applications include the following.

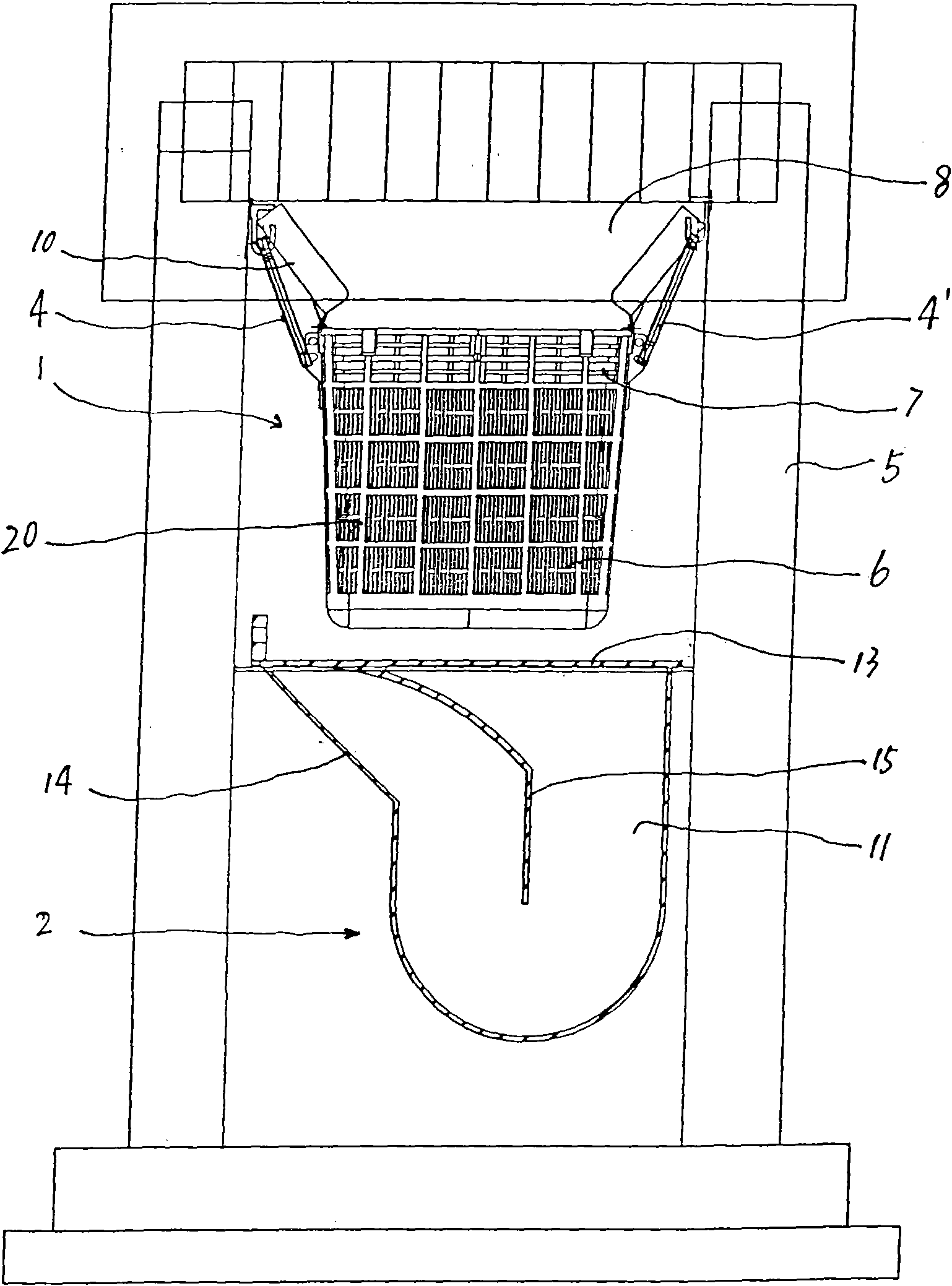

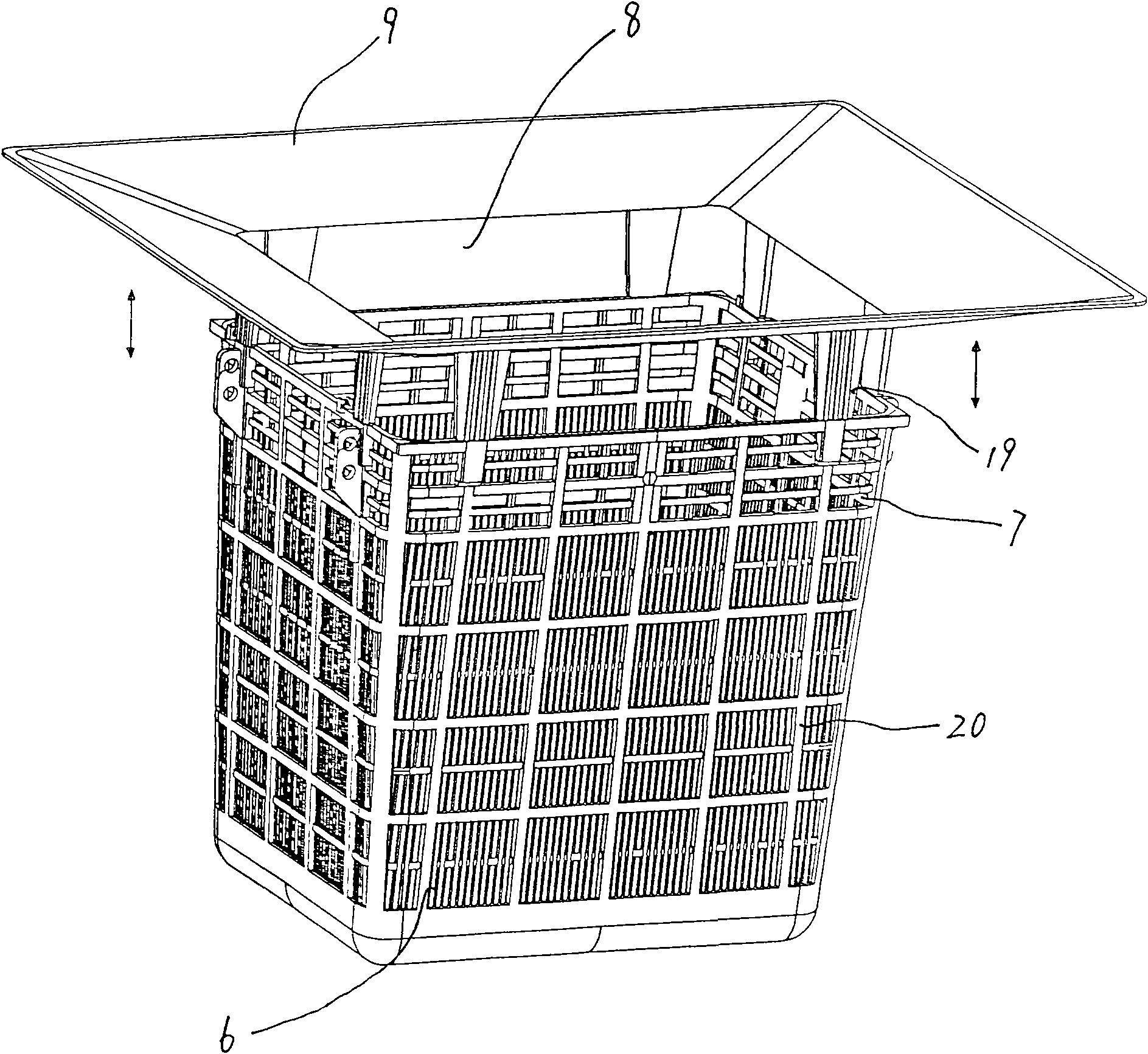

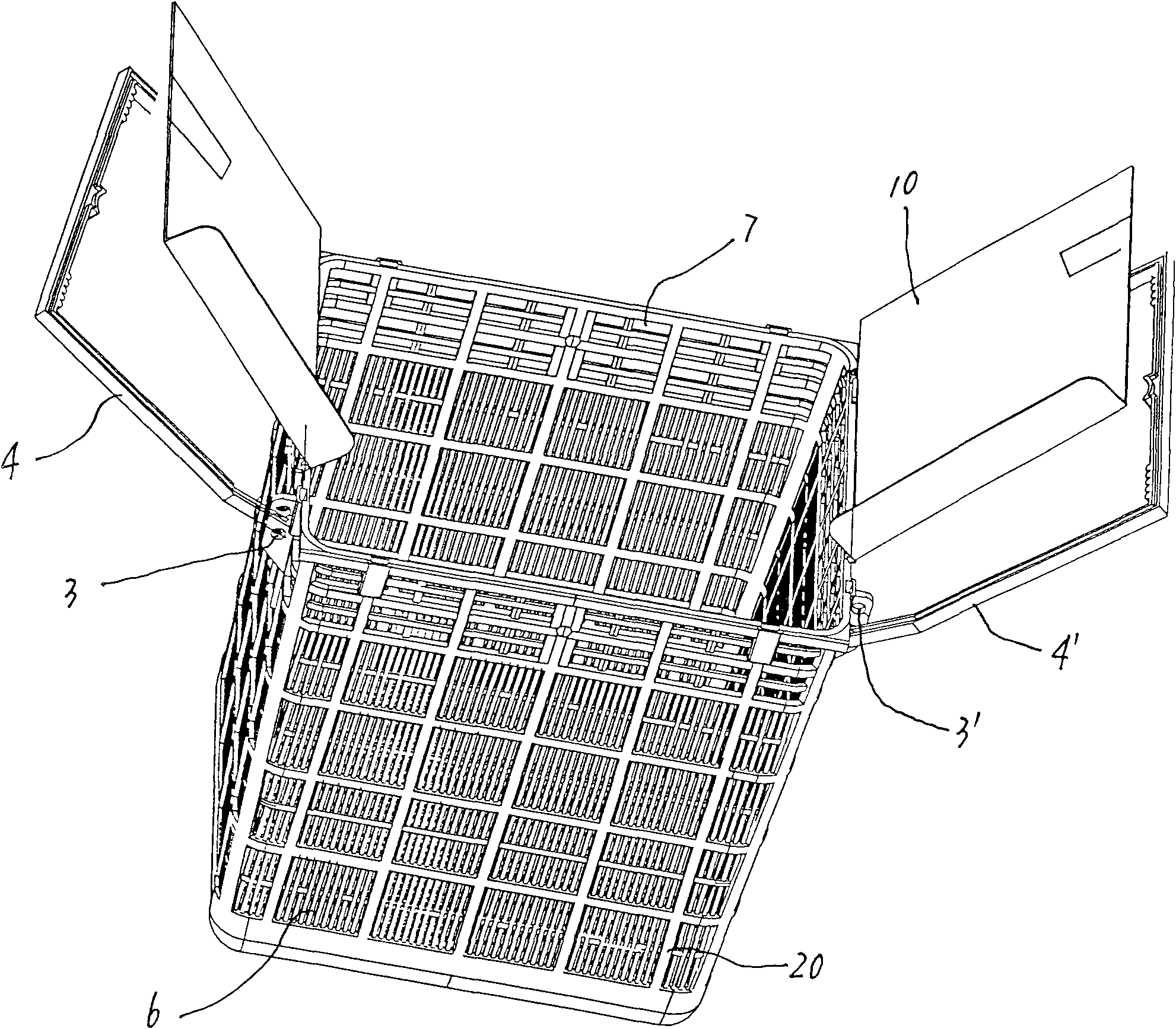

Device for intercepting and deodorizing waste at road gully

The invention discloses a device for intercepting and deodorizing waste at a gully; a solid waste intercepting device is arranged at a gully wall chamber, a deodorizing device is arranged at the lower part of the solid waste intercepting device, the solid waste intercepting device is a grating type framework with an opening at the upper end thereof, the grating type framework hangs at a fixed stainless steel hanger of the inner wall of the gully wall chamber by two handles at the two sides thereof, filtering areas with uniform density are respectively arranged at the middle and lower part of the lateral side of the grating type framework, a flooded zone is arranged at the upper part of the lateral side thereof, a drainage area is arranged at the upper part of the flooded zone, a tremie-type priming frame or a tremie-type priming frame is connected on the grating type framework; the deodorizing device is a water-holding bent deodorizing water seal or a self equilibrating turnover plate water seal. Considering the defect of complex structure of the existing solid waste treatment device, the invention provides a solid waste intercepting and deodorizing device featuring simple structure and low cost. As the device is simple in structure, convenient in both installation and use, thus being beneficial for promotion and popularization.

Owner:上海天予实业有限公司

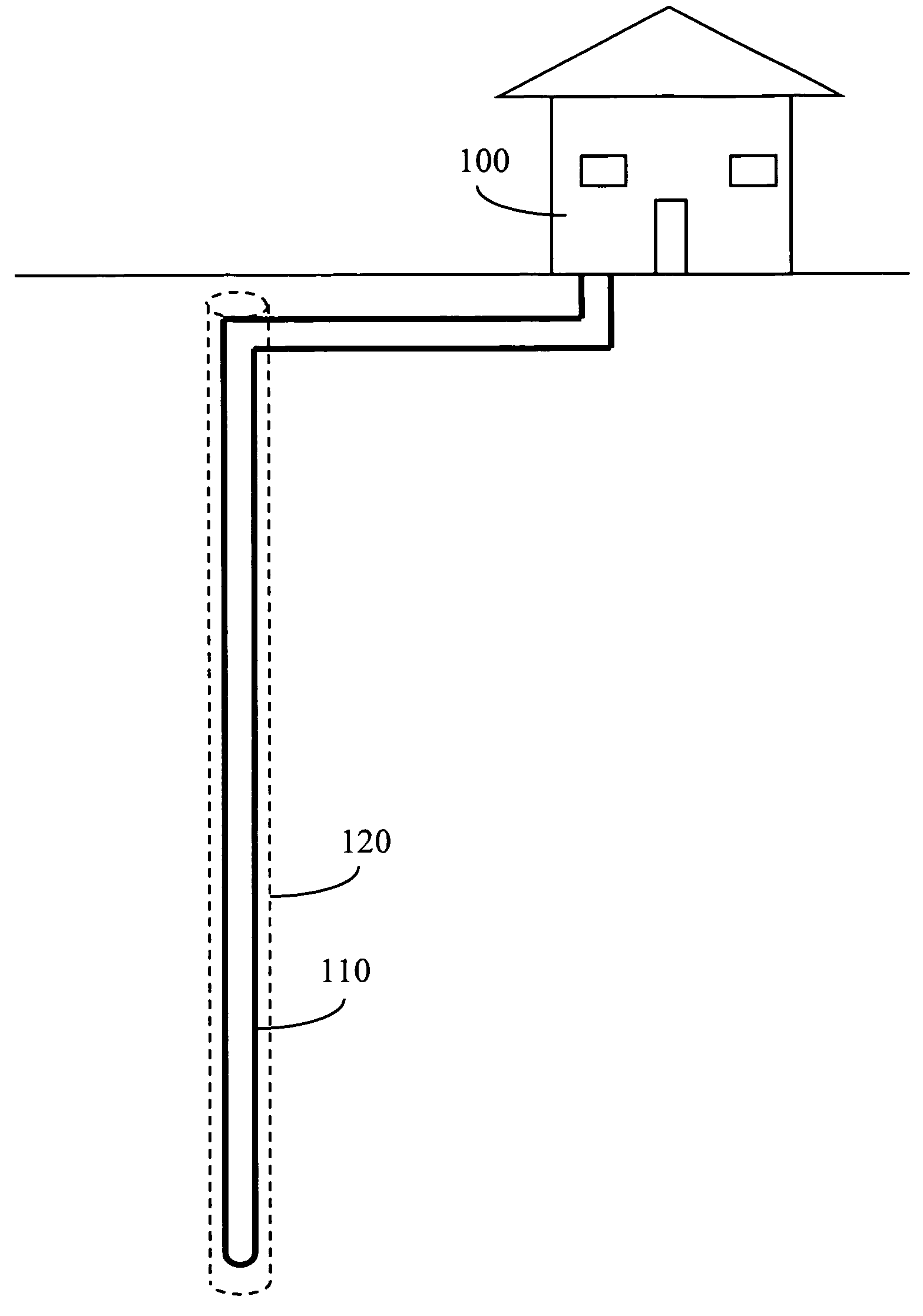

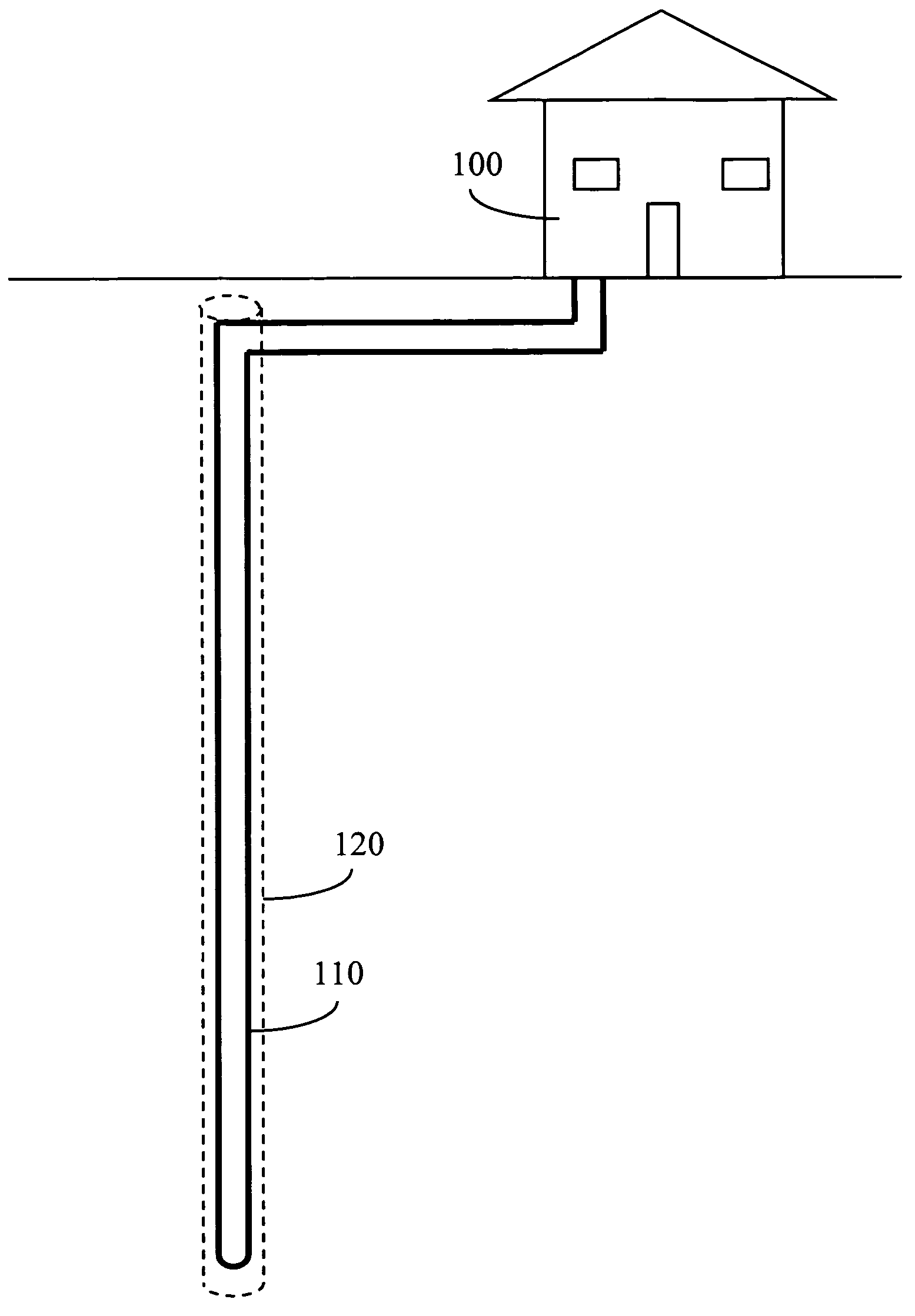

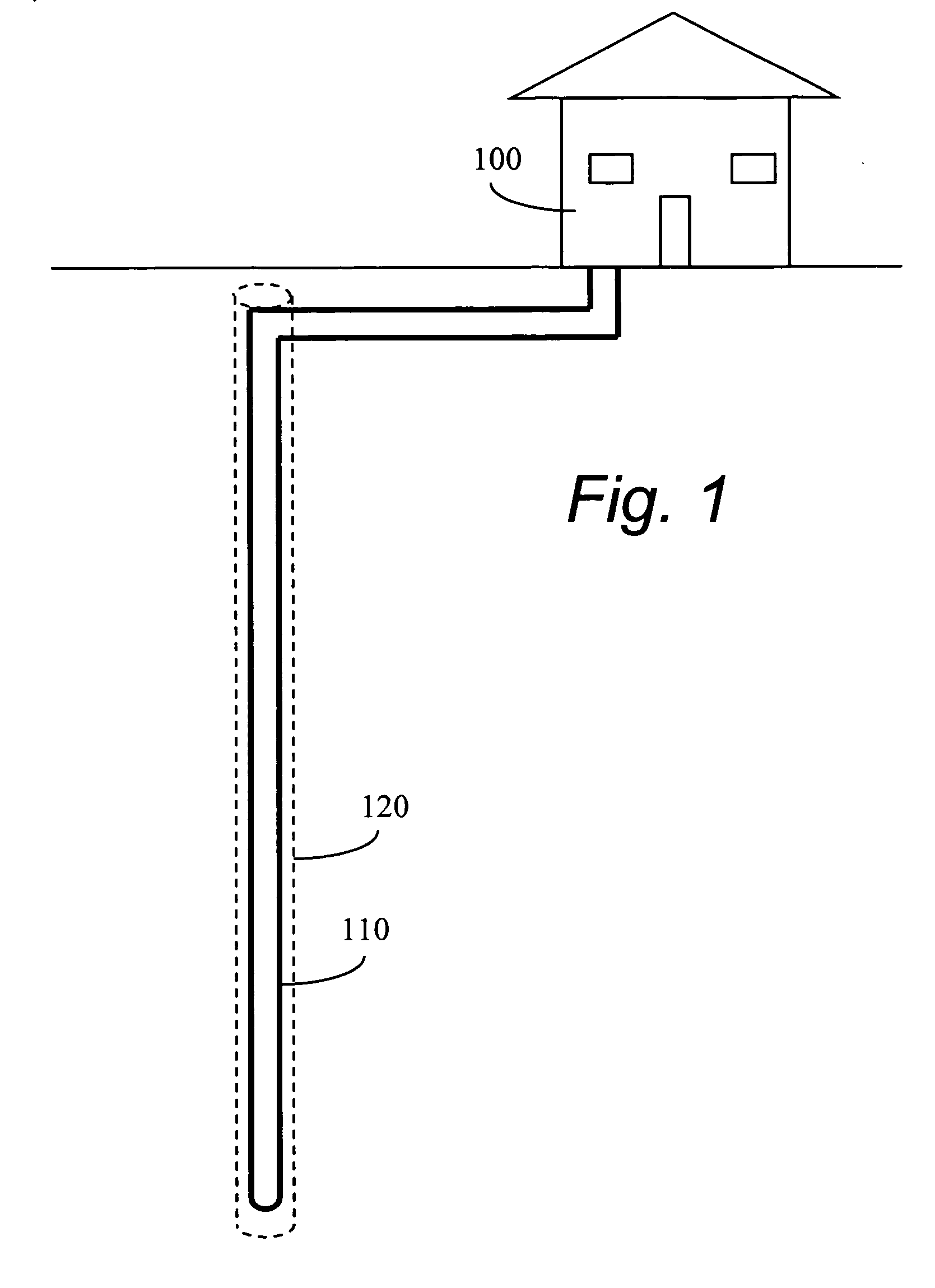

Geothermal pipe weight

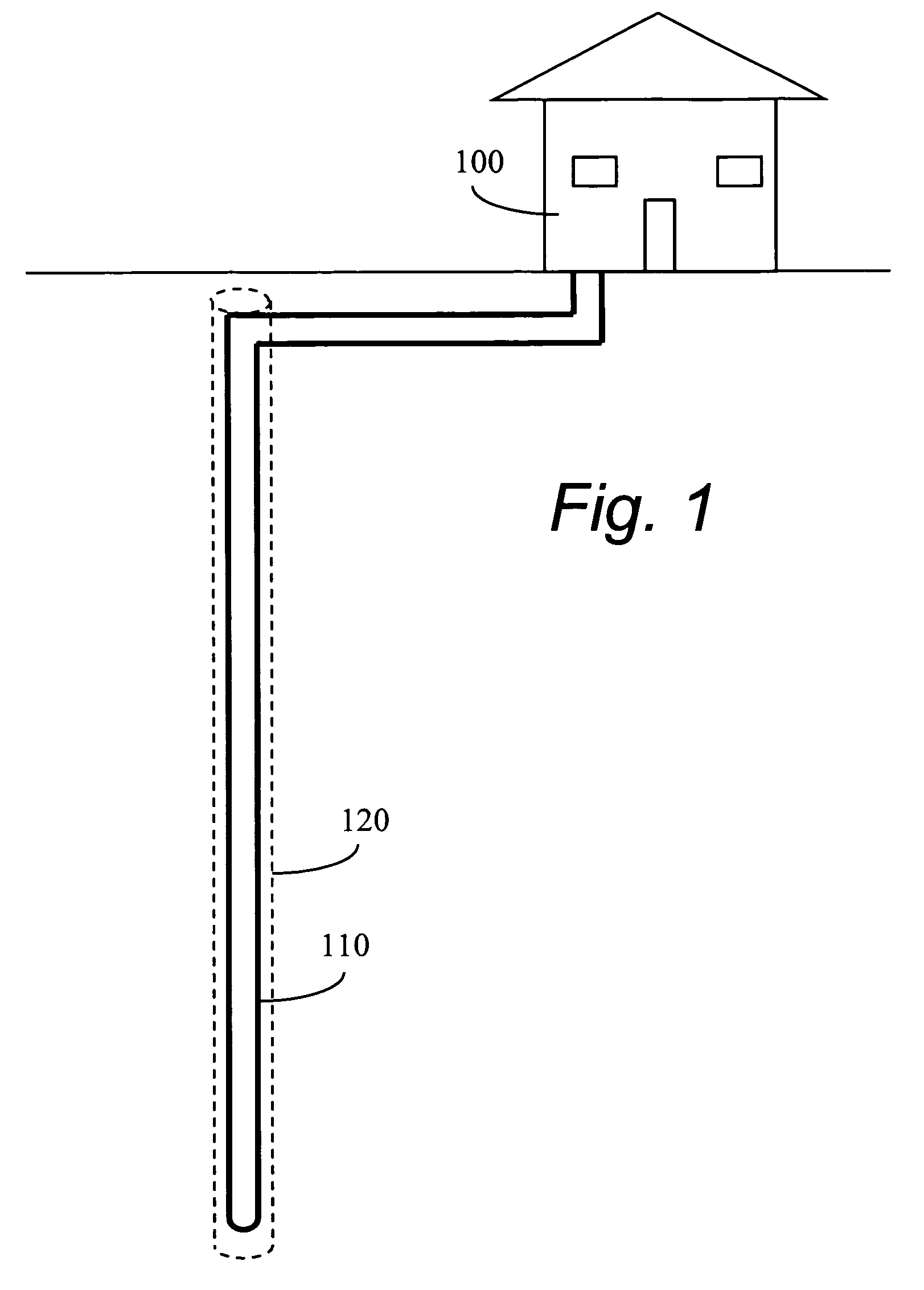

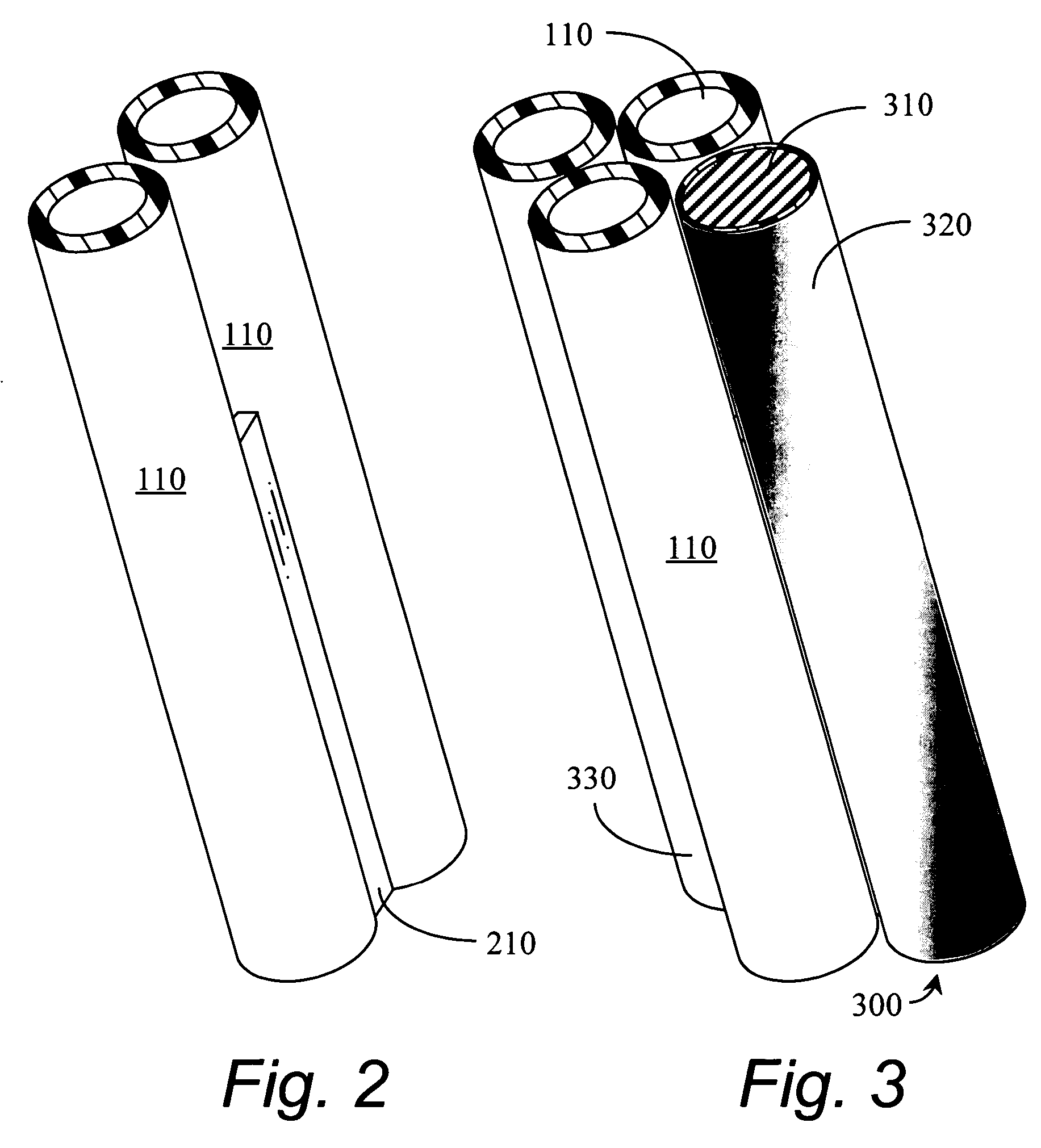

InactiveUS7213649B2Curvature may be reduced or even eliminatedWork hardHeat pumpsDrilling rodsGeothermal heatingTremie

A method and apparatus for adding rigidity and weight to the piping used in geothermal wells for ground-source heat pumps enhances insertion of the piping into the wells. The weight used must be approved by appropriate organizations such as the DNR, NSF, and / or EPA, or similar, for contact with the ground water. Concrete and coated iron or steel are examples of such weights. A system for assembling the pipes, weight, and a tremie pipe for insertion is disclosed. The weighting system may also help maintain straightness in the geothermal piping for ease of inserting the piping into the vertical well.

Owner:MCNAIR EDWARD F +1

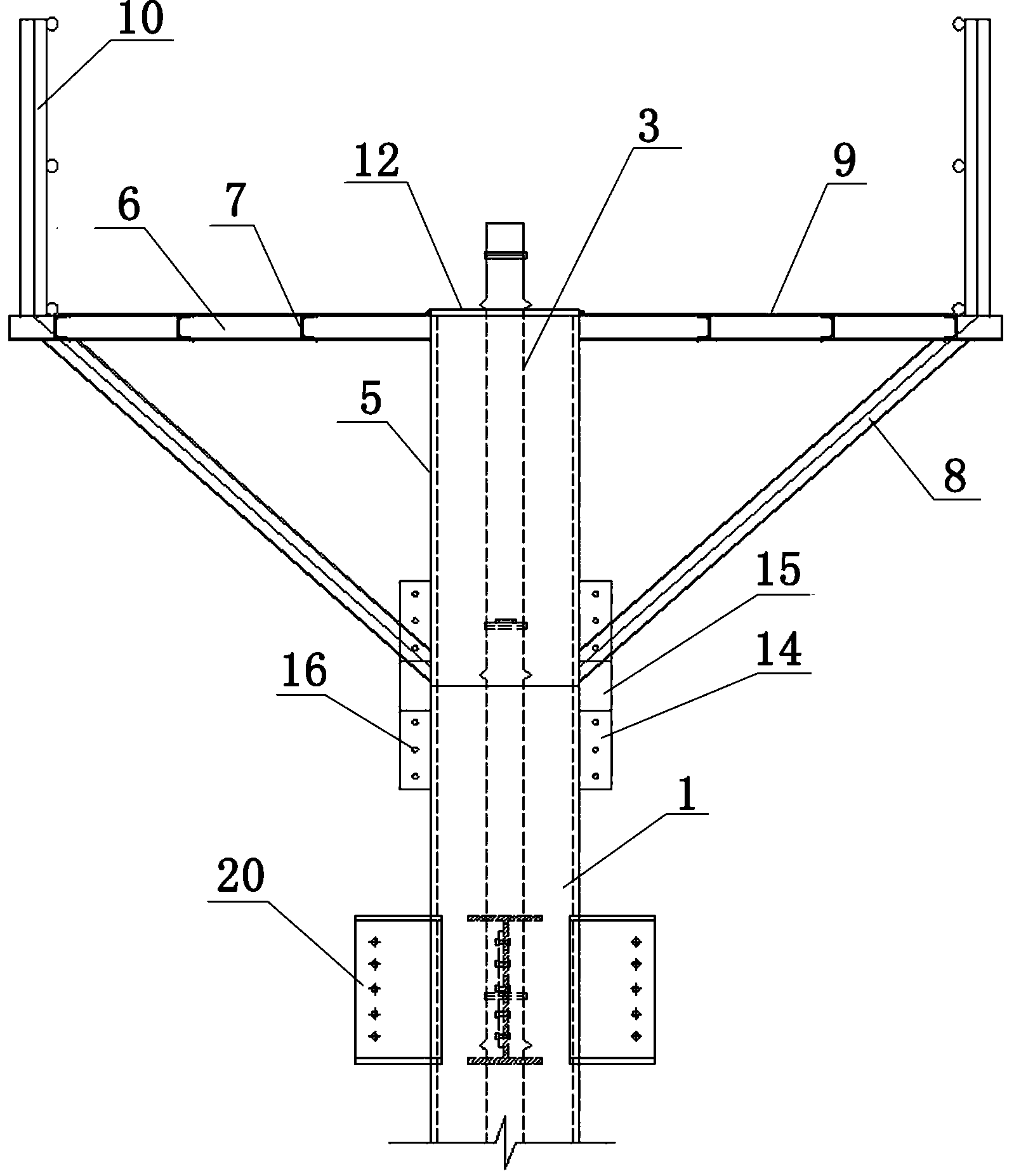

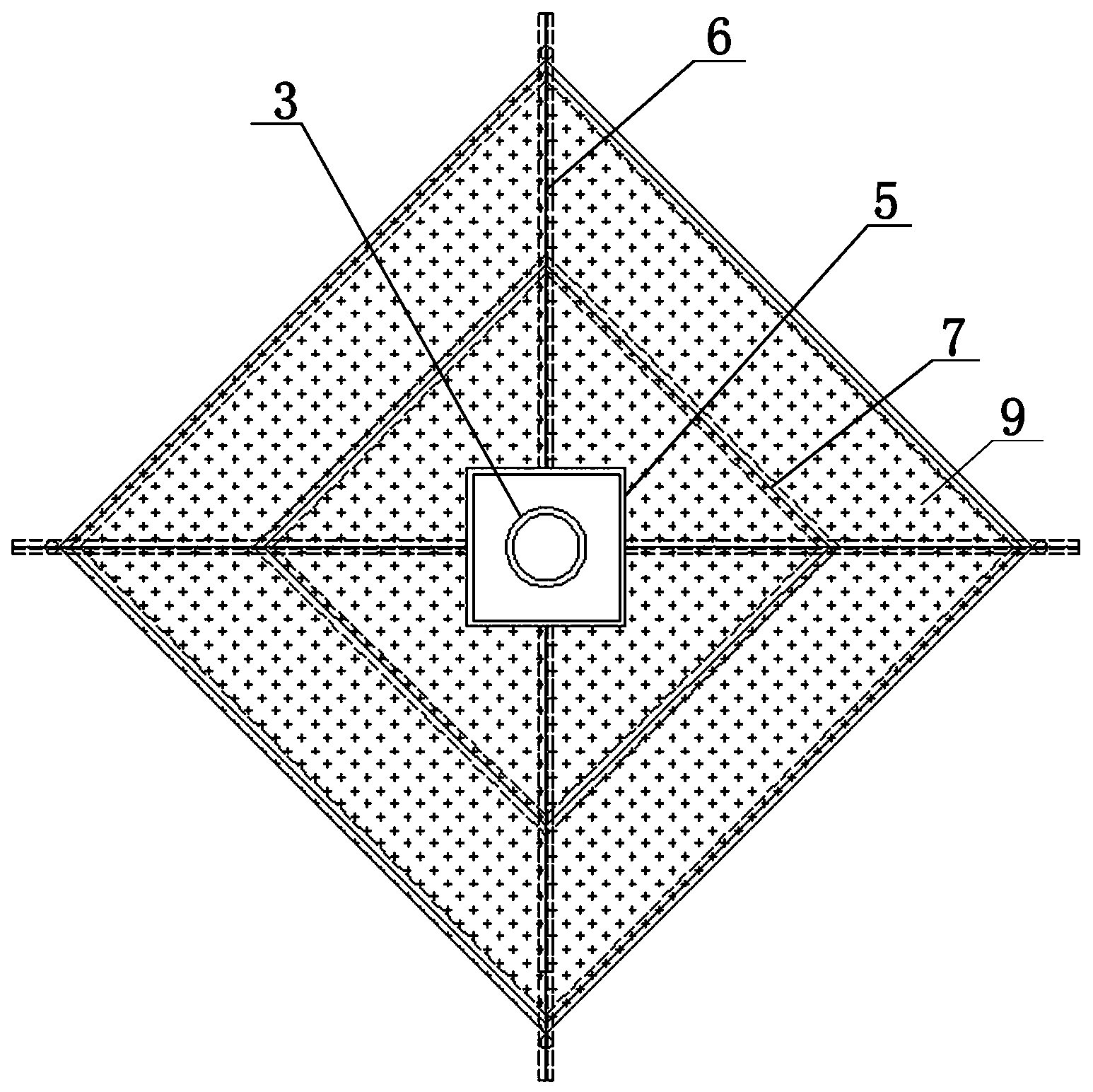

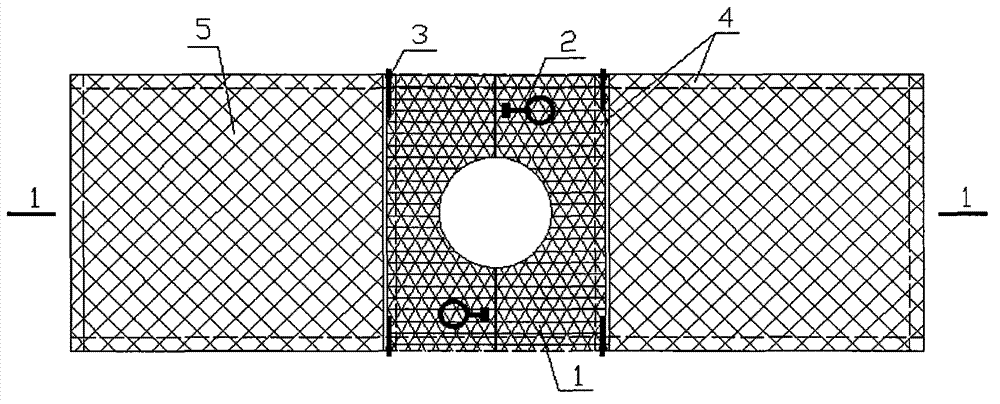

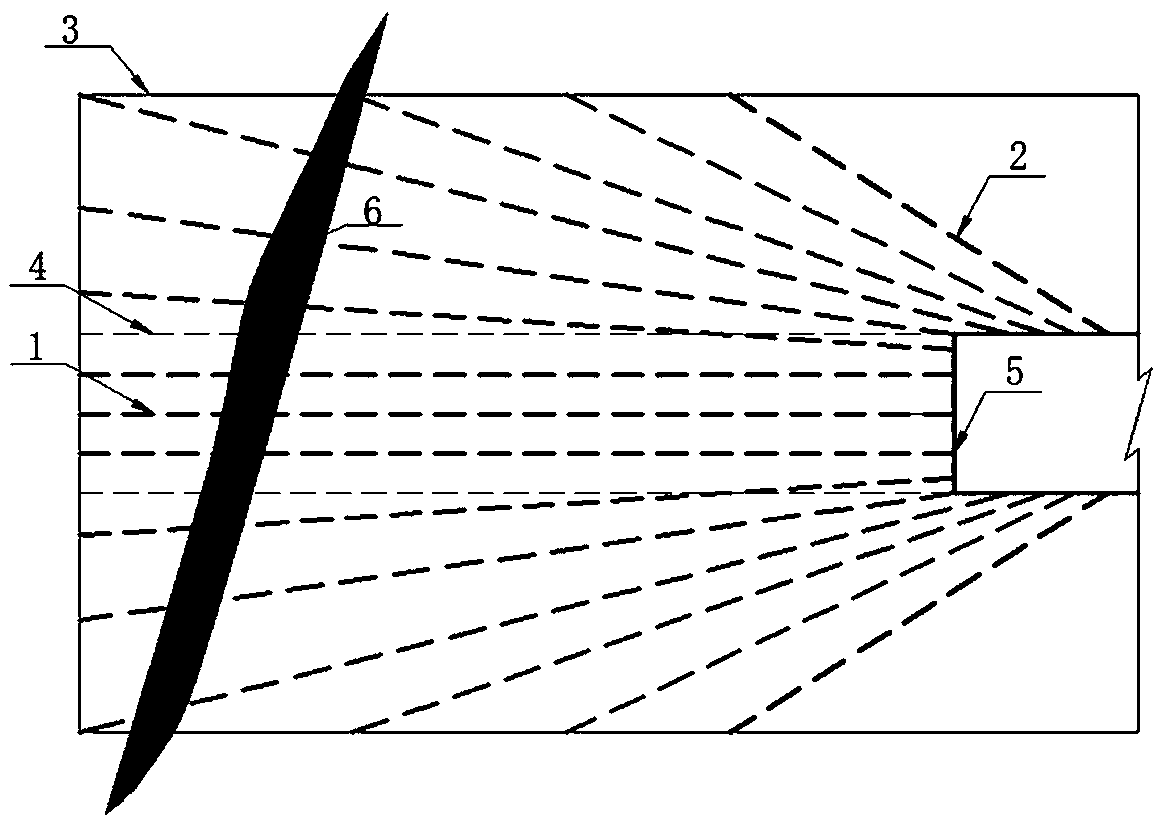

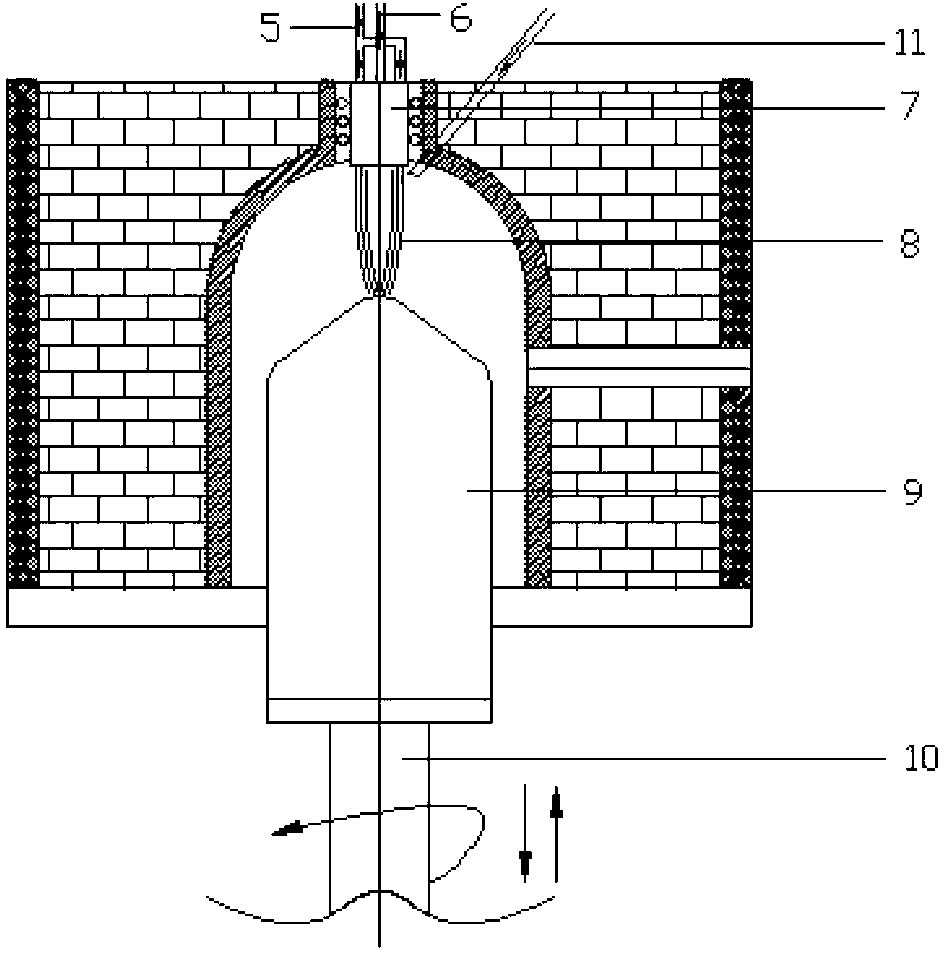

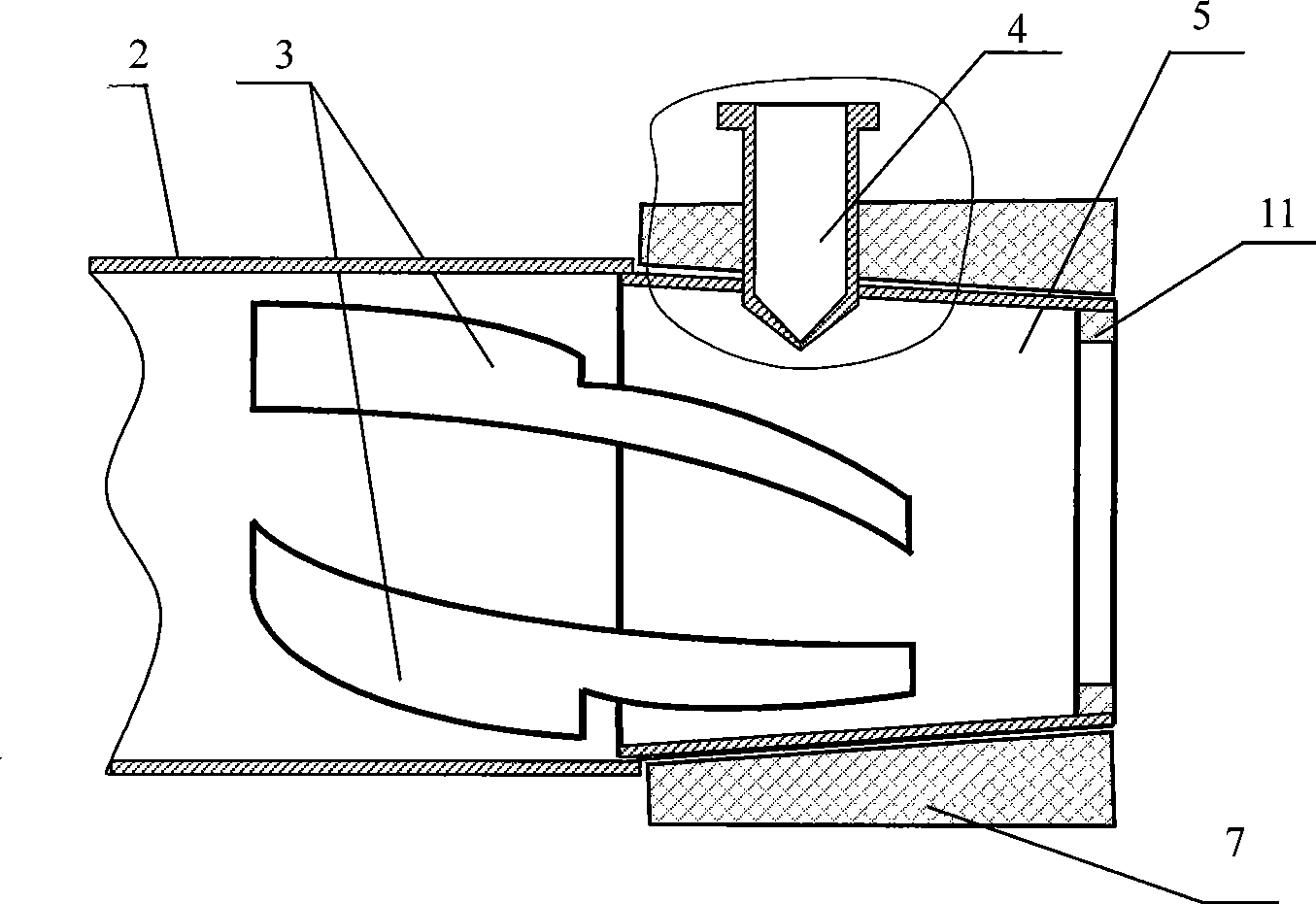

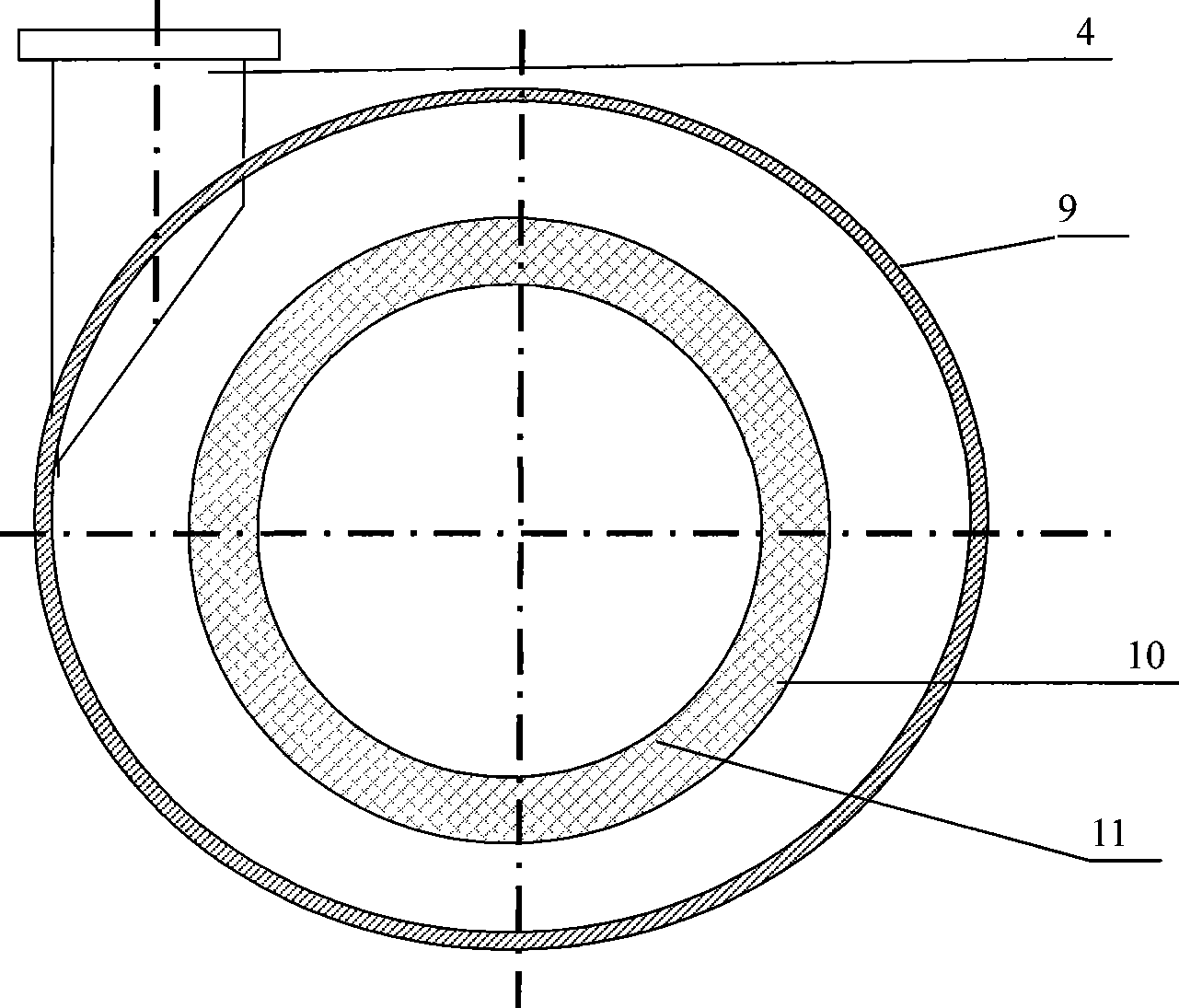

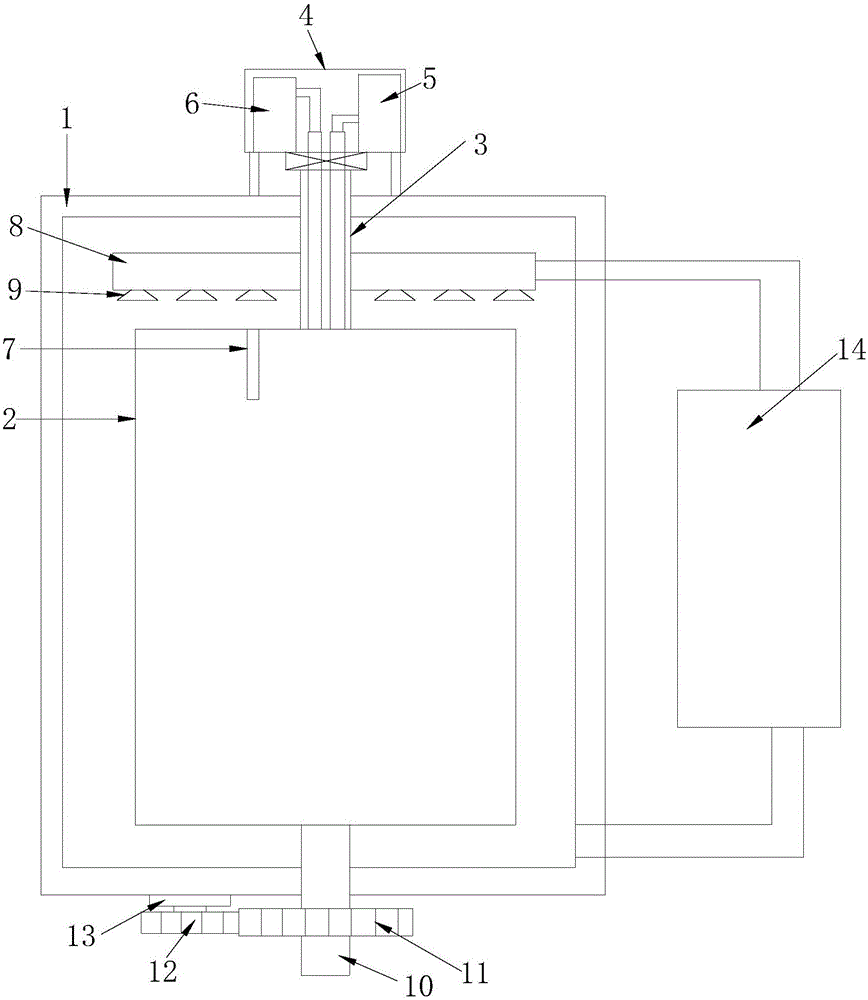

Concrete pouring device and method for ultrahigh steel pipe concrete column tremie method

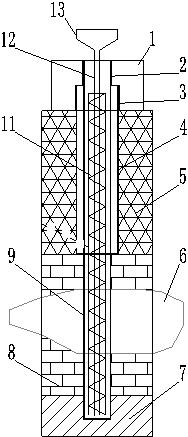

InactiveCN103470046AControl the amount of concreteReduce cloggingBuilding material handlingBuilding support scaffoldsTremieMaterials science

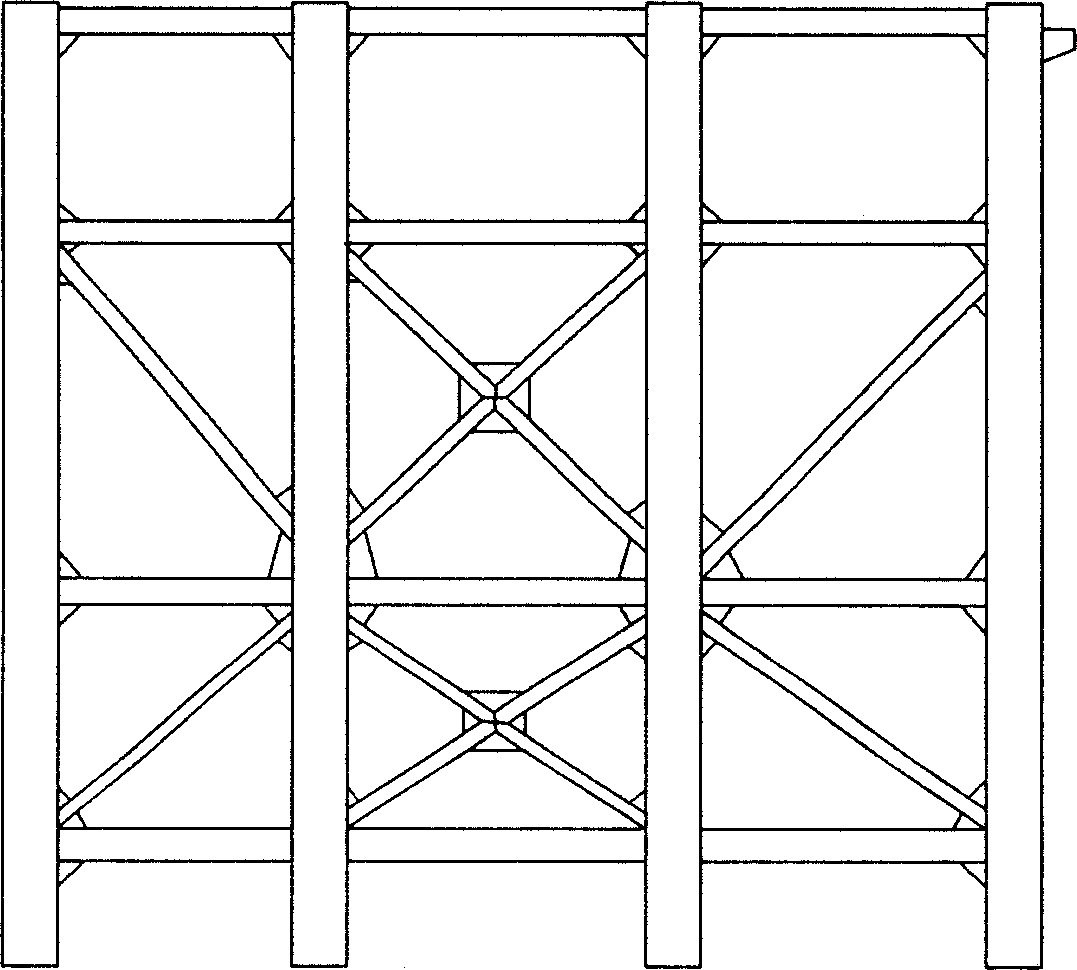

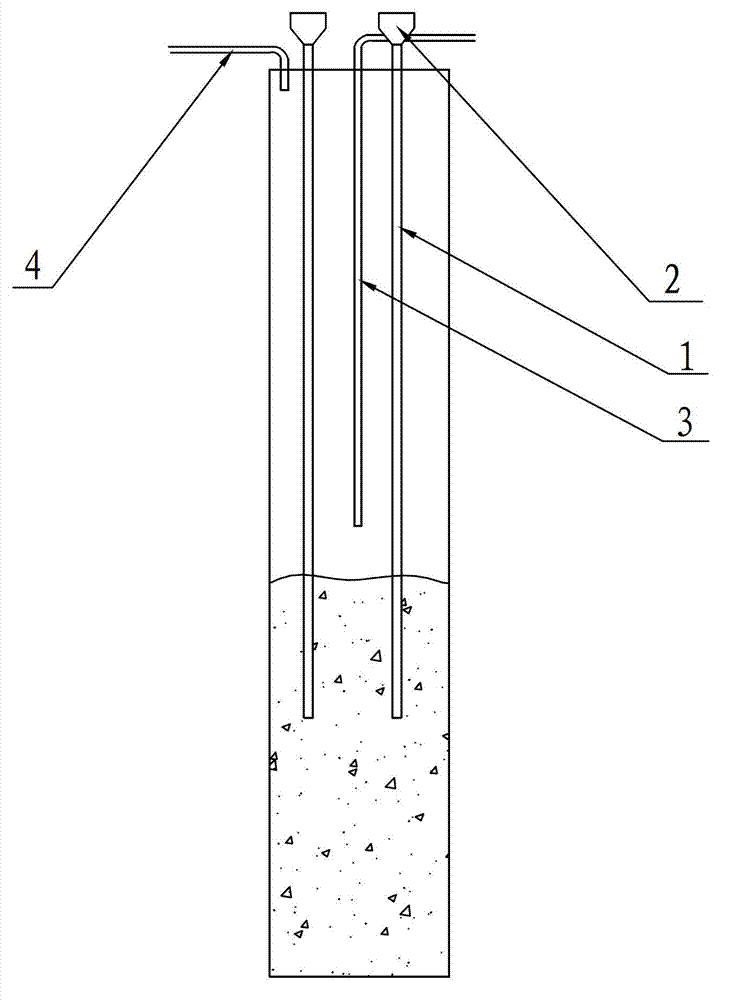

The invention relates to a concrete pouring device and a concrete pouring method for an ultrahigh steel pipe concrete column tremie method. Inner baffles are arranged at intervals in a steel pipe. Pouring holes are formed in the middle parts of the inner baffles. Air vents are distributed on the peripheries of the inner baffles. The device comprises a column top movable platform which is connected onto the top of the steel pipe, a guide pipe which is inserted into the steel pipe, and a feeding hopper which is connected onto the upper part of the guide pipe. The column top movable platform consists of a joint steel pipe 5, a main beam, a secondary beam, diagonal bracings, a steel plate and a guardrail. Two clamping plates which can be upwards turned over are connected at the mouth of the top of the joint steel pipe through hinges. Guide pipe clamping mouths which are used for positioning the guide pipe are formed in the middles of the two clamping plates. The bottom of the joint steel pipe is fixedly connected with the steel pipe. The guide pipe is formed by sections in connecting way. The guide pipe is downwards inserted into the steel pipe through the joint steel pipe. The concrete pouring device and the concrete pouring method for the ultrahigh steel pipe concrete column tremie method have the advantages that the one-step pouring height can reach 29m, the requirement on the construction period and process can be met, the concrete column is detected as acceptable through ultrasonic detection, the pouring quality is reliable and the device and the method are particularly suitable for the pouring construction of ultrahigh steel pipe concrete with dense baffle holes.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

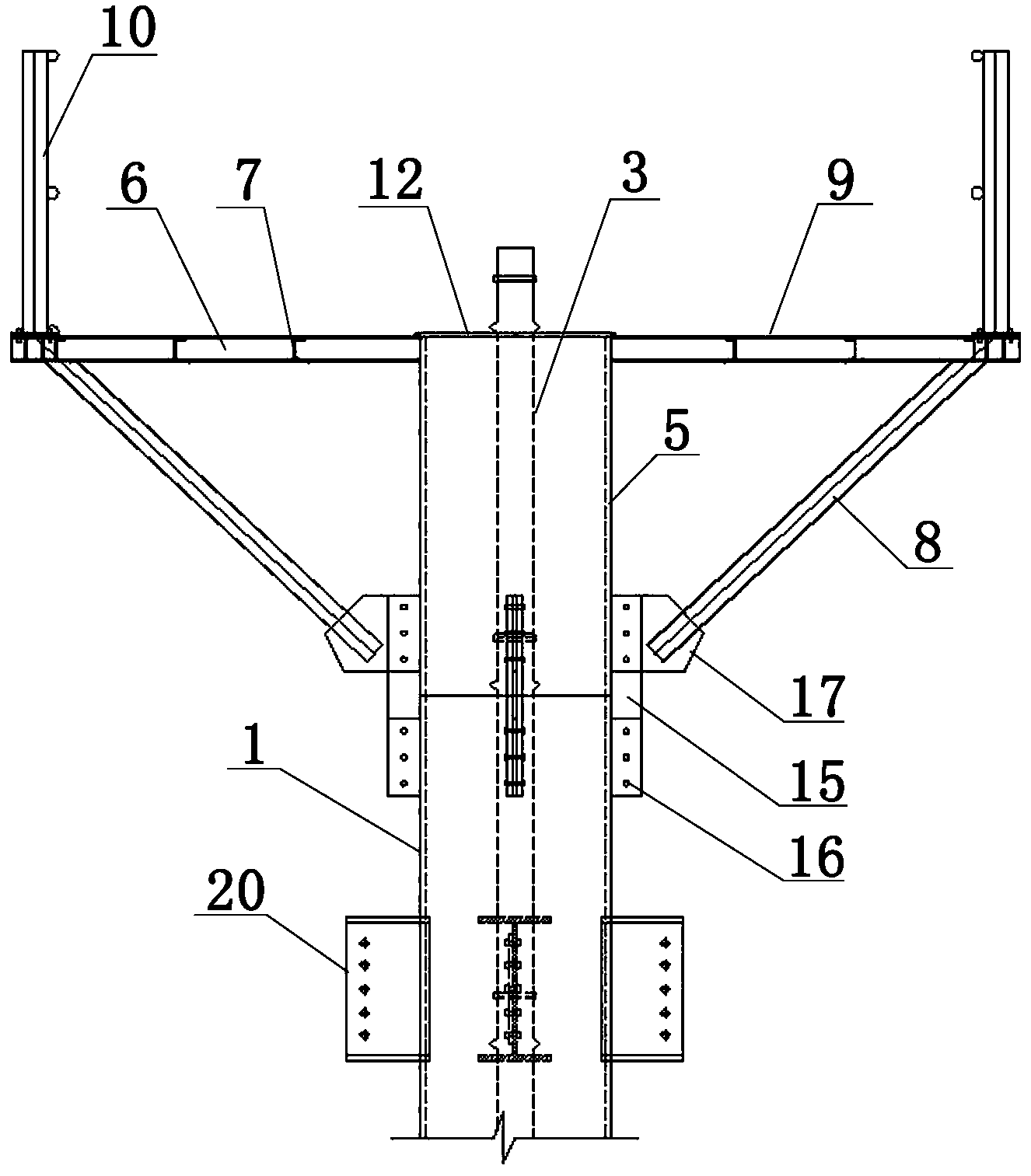

Tool type operating platform for pile foundation tremie extension

InactiveCN102828513AEasy to fixSimple and efficient operationFoundation engineeringTremieEngineering

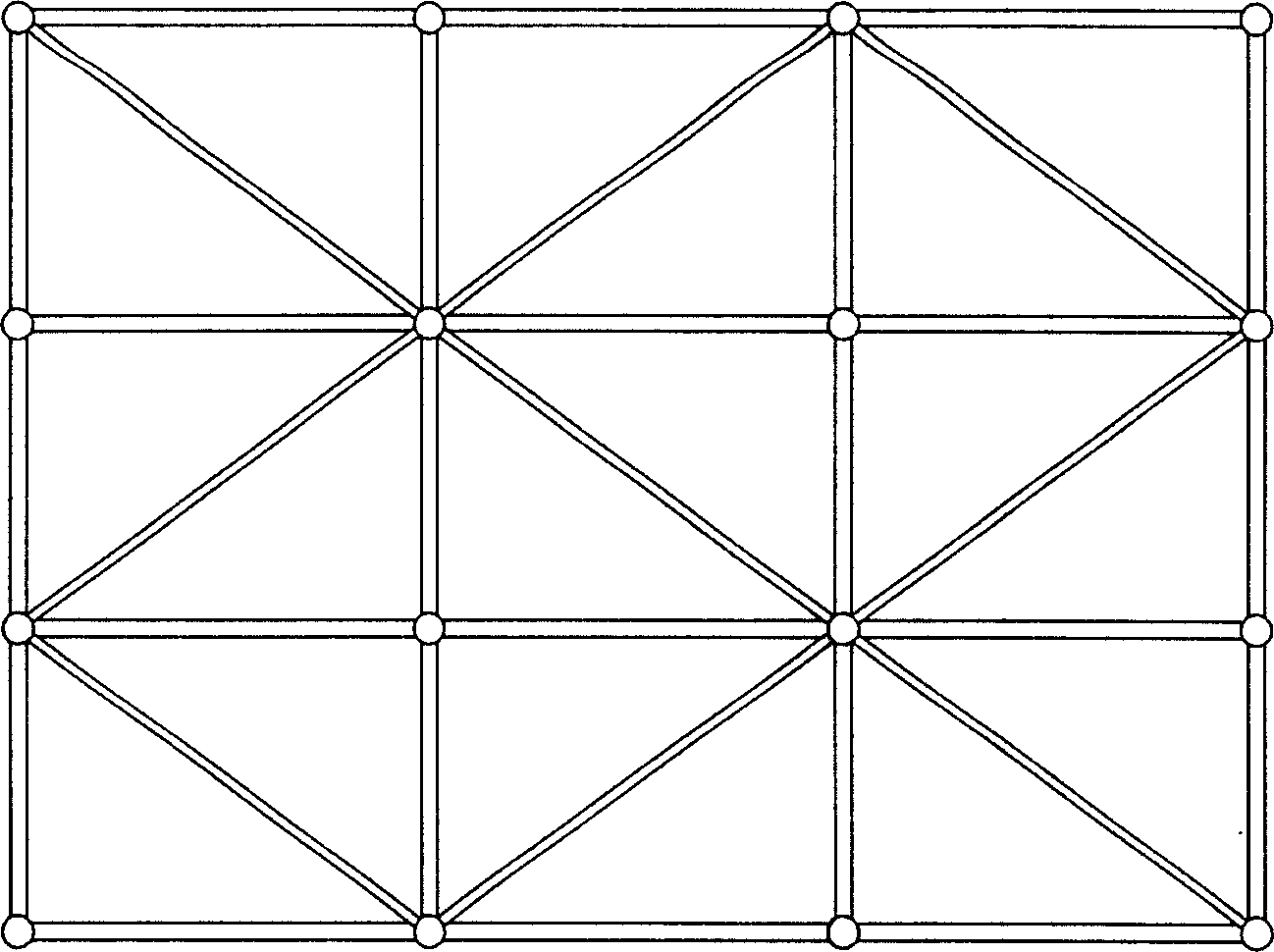

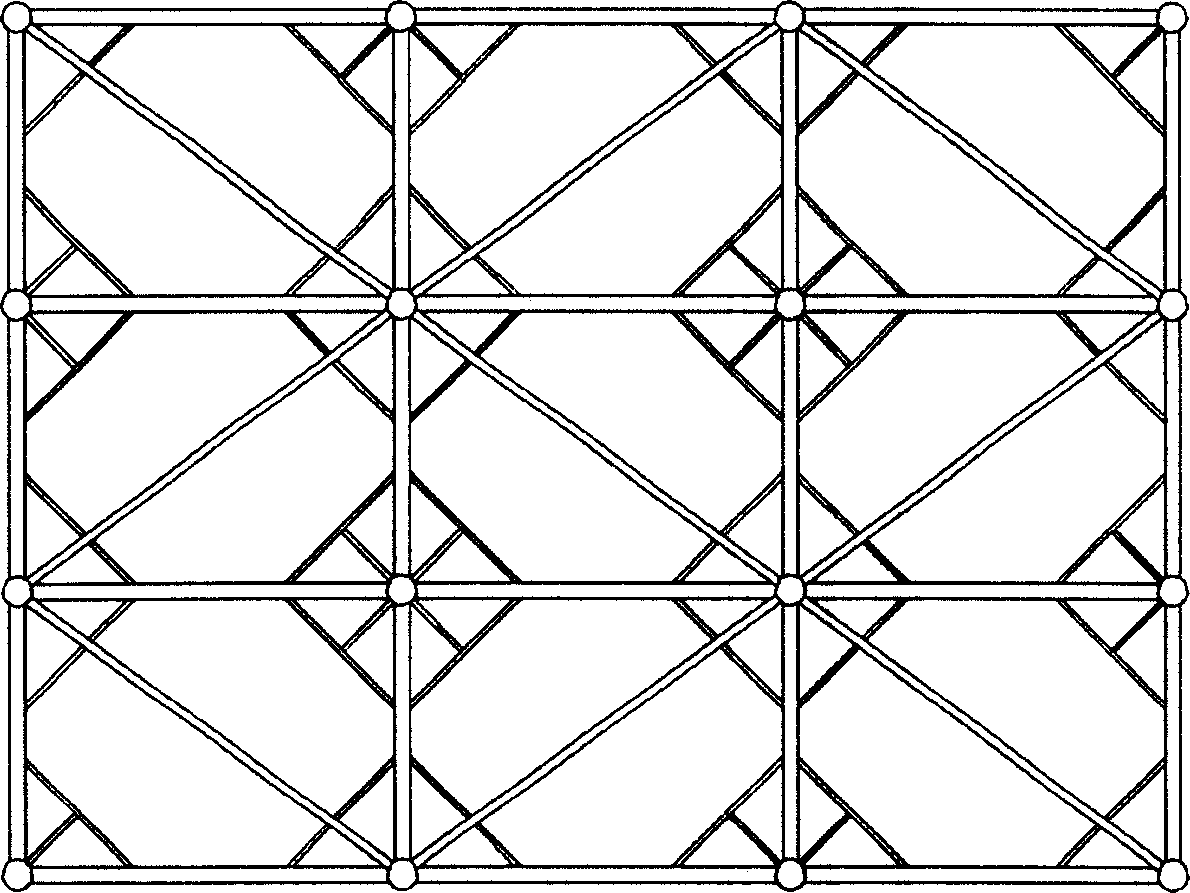

The invention discloses a tool type operating platform for pile foundation tremie extension. The tool type operating platform for pile foundation tremie extension is characterized by comprising an operating platform body and a movable door plate, the operating platform body is formed by fixing channel beams and two anti-skid steel plates, the channel beams form a frame in the shape of three stacked square blocks, and the two anti-skid steel plates are fixed on two sides of the channel beam frame. The movable door plate is composed of two high-strength steel plates, circular pull rings and pin shafts, the outer side edge of each high-strength steel plate is connected with the middle of the channel beam frame through the pin shafts, each pull ring is fixed on the top face of each high-strength steel plate, and semicircles are arranged at inner side contact edges of the two high-strength steel plates to jointly form a circular hole for a tremie to pass through. The tool type operating platform is convenient and efficient to operate and simple and stable in tremie fixation during tremie extension and underwater concrete construction and demolishing, and is recyclable and reusable at various cast-in-place pile heads with different diameters.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Tremie frame for marine bridge construction and platform construction process of tremie frame method

InactiveCN1676758AShort offshore construction timeShorten the construction periodArtificial islandsBridge erection/assemblyTremieGuide tube

A pipe shelf and the construction technique of flat roof based on it used to the construction of the bridge on the sea. Each main body comprises sixteen one-meter diameter steel pipes, every neighboring two pipes jointed together by the 0.4-meter diameter horizontal pipes and 0.328-meter diameter slash pipes. A sink against board set to the bottom 1.5 meters, it used to the construction technique of the flyover on the sea. The concrete process of the construction contains make and transport of the pipe shelf, sink and orientation of the pipe shelf, set of the orientation stake, fixed connection of the stake and the pipe shelf and the installation of the top structure of the flat floor. The pipe shelf of the invention act as the horizontal support of the whole flat as well as the orientation measure and the operation flat of the flat stake's base., and also have the strongpoint that it has the short time construction on the sea, can shorten the deadline of the project heavily, change the single stake orientation to the whole orientation, reduce the cumulate error between the stakes, can assure the stability of stakes, has the good whole pressed and can easy guarantee the quality and the safety.

Owner:SHANGHAI FOUND ENG GRP

Mechanical matched construction method for full fracture surfaces and micro steps of IV and V stage weak surrounding rocks of tunnel

ActiveCN111997622AFast constructionImprove working accuracyUnderground chambersHydro energy generationTremieFracture (geology)

Owner:CHINA RAILWAY 19TH BUREAU GRP SECOND ENG CO LTD +1

Method for building riprap levee island wall of offshore artificial island by large box barge

InactiveCN101597896AUndisturbedSpeed upArtificial islandsCargo handling apparatusTremieEngineering

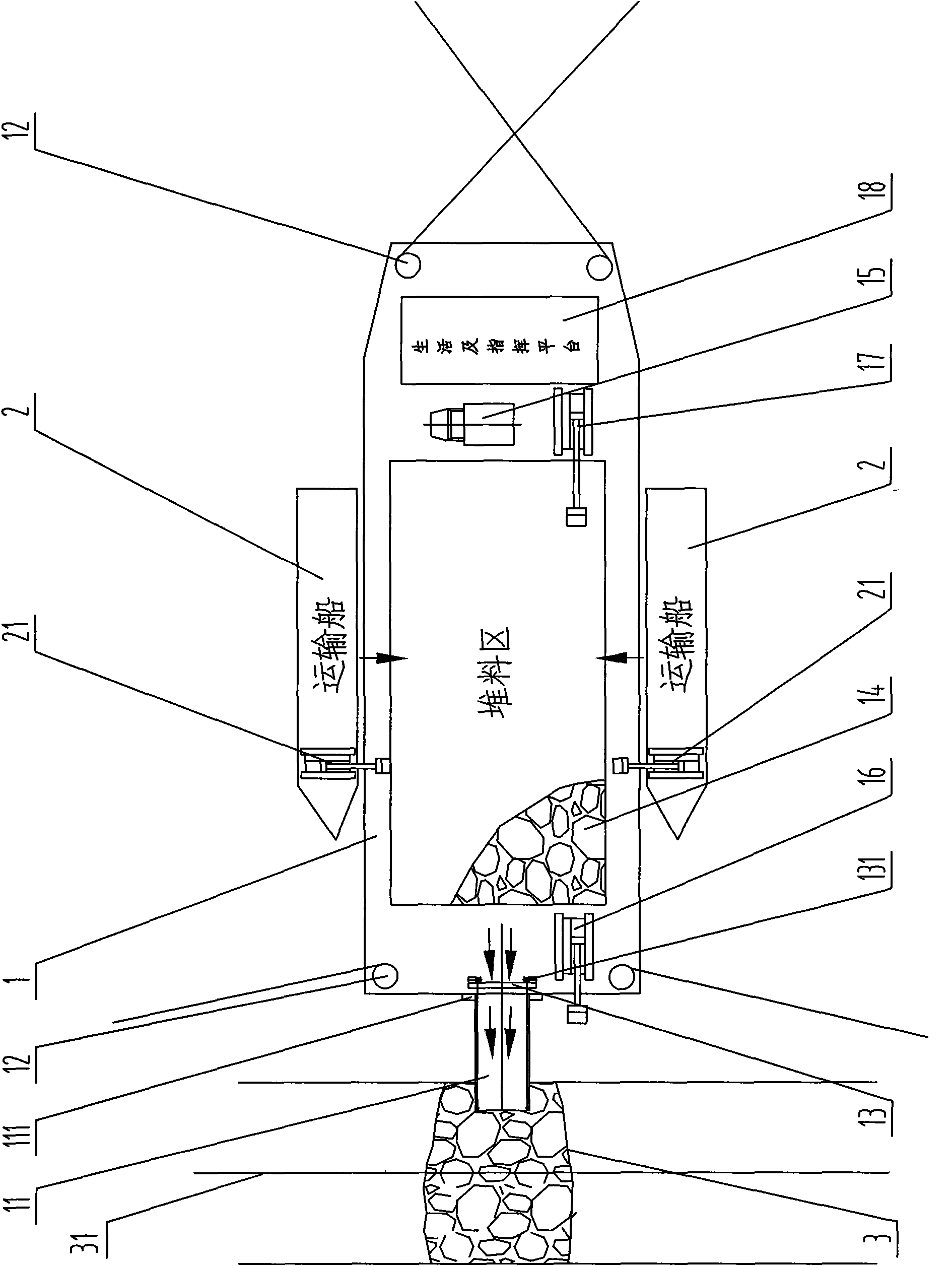

The invention discloses a method for building riprap levee island wall of an offshore artificial island by a large box barge, comprising the following steps: (1) remodeling a large box barge; (2) dragging the large box barge to an area for building the riprap levee island wall of the offshore artificial island to facilitate the longitudinal centerline to be vertical to the axis of the riprap levee island wall of the offshore artificial island; (3) respectively parking transport ships at the both sides of the large box barge to unload stone material to the large box barge; (4) with excavators and waggon tremie riprap construction stone material piling platform of the large box barge provided, facilitating the large box barge to be driven to the stone piling platform by steel butt straps to riprap and deal with the slopes to build a section of riprap levee, repeating the process so as to facilitate the riprap levee island wall to move forward section by section to be formed and finally completed. In the invention, the on-water construction of the island wall of the offshore artificial island is transformed into onshore advance, thus reducing influence of stormy weather on the construction and greatly accelerating construction speed of the artificial island.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

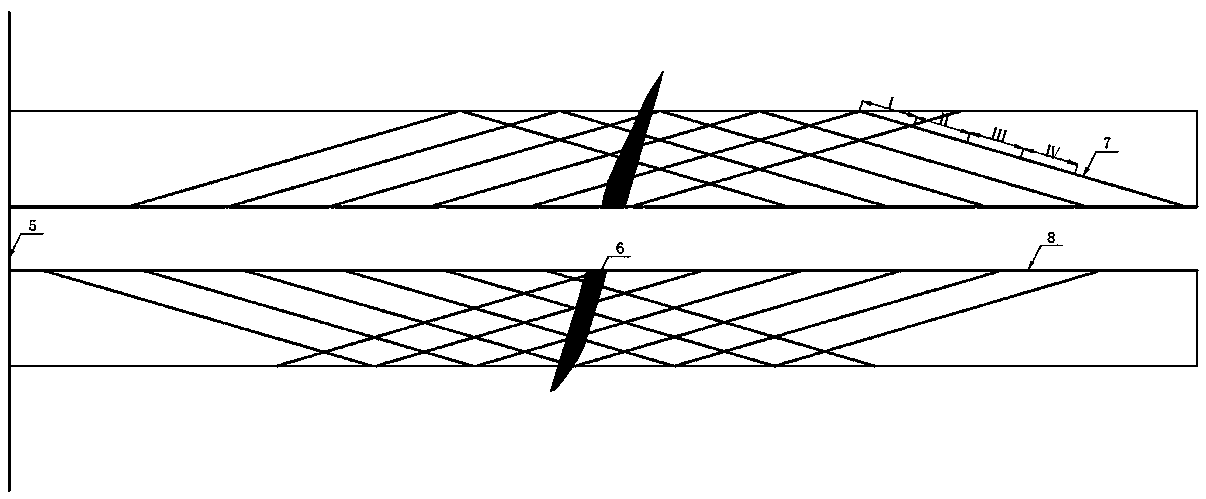

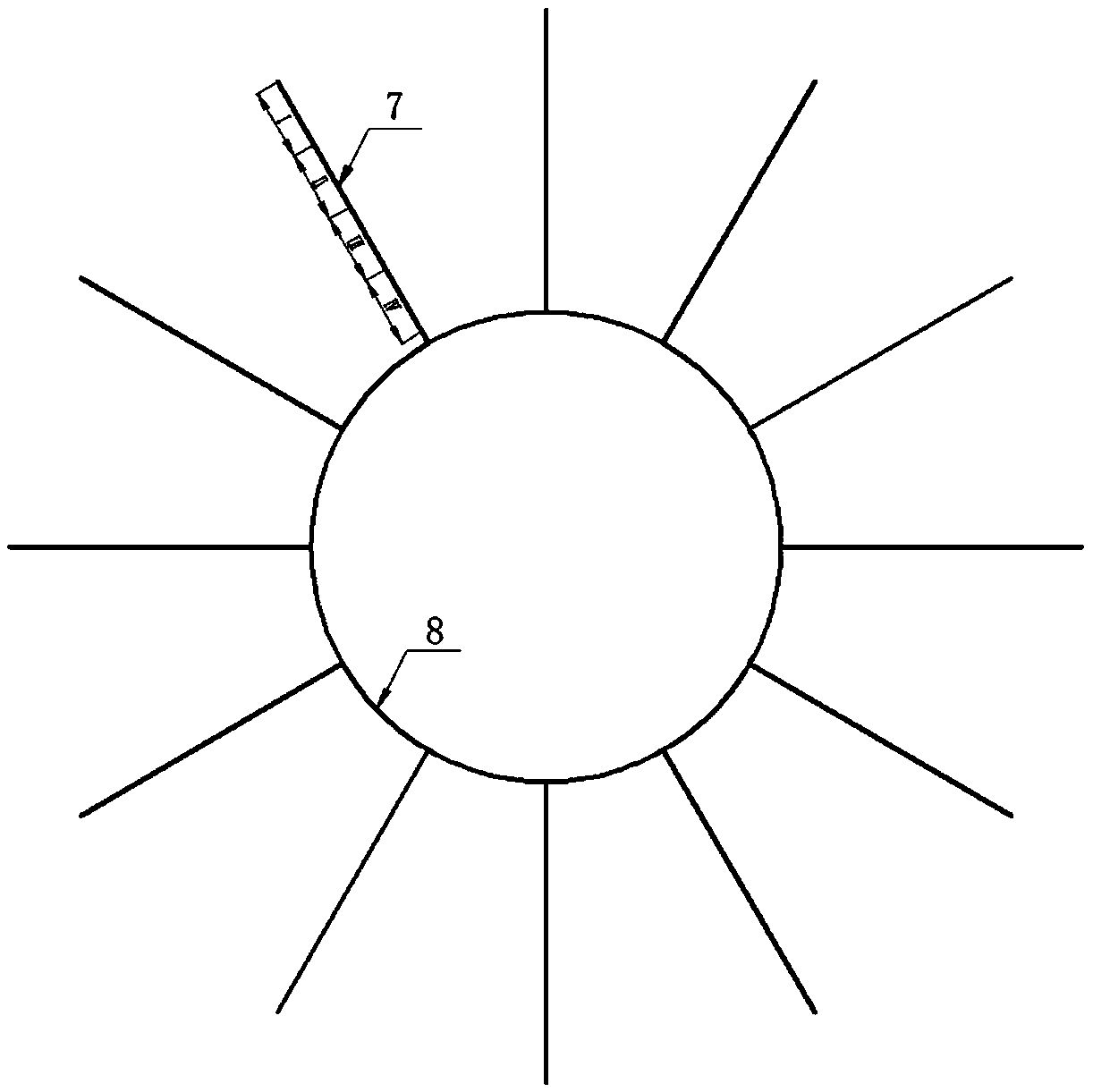

Deep-hole backward grouting and water-blocking construction method for igneous rock water-rich fault

InactiveCN110735653ALarge crack openingStrong penetrating powerUnderground chambersMaterial fill-upSoil scienceTremie

The invention discloses a deep-hole backward grouting and water-blocking construction method for an igneous rock water-rich fault. An advance exploratory drilling technology is adopted to prove a fracture zone of the water-rich fault, after deep-hole backward advanced pre-grouting and primary water blocking, tunneling construction is quickly conducted to pass through the fracture zone of the fault, and in a tunnel area of a water-rich section, full-face deep-hole backward little tremie grouting and secondary water blocking is adopted. According to the characteristics that the fracture zone ofthe igneous rock fault is large in fracture aperture and high in connectivity, the deep-hole backward grouting method is adopted to change the way that a little tremie conducts segmented grouting at the positions of grouting holes from far to near in the order of I, II, III, IV......, the grout on the upper stage is deposited and solidified to achieve an enhancing effect on deposition and solidification of the grout on the next stage, finally, cracks are sufficiently filled with the grout, the water-blocking aim is achieved, the problem that in the prior art, igneous rock tunnel construction is conducted to pass through the water-rich fault, water is difficult to block is solved, and the full-face deep-hole backward grouting method is provided for the difficulty of grouting and water blocking in the process that tunnel construction is conducted to pass through the fracture zone of the water-rich fault in the igneous rock.

Owner:TAIYUAN UNIV OF TECH

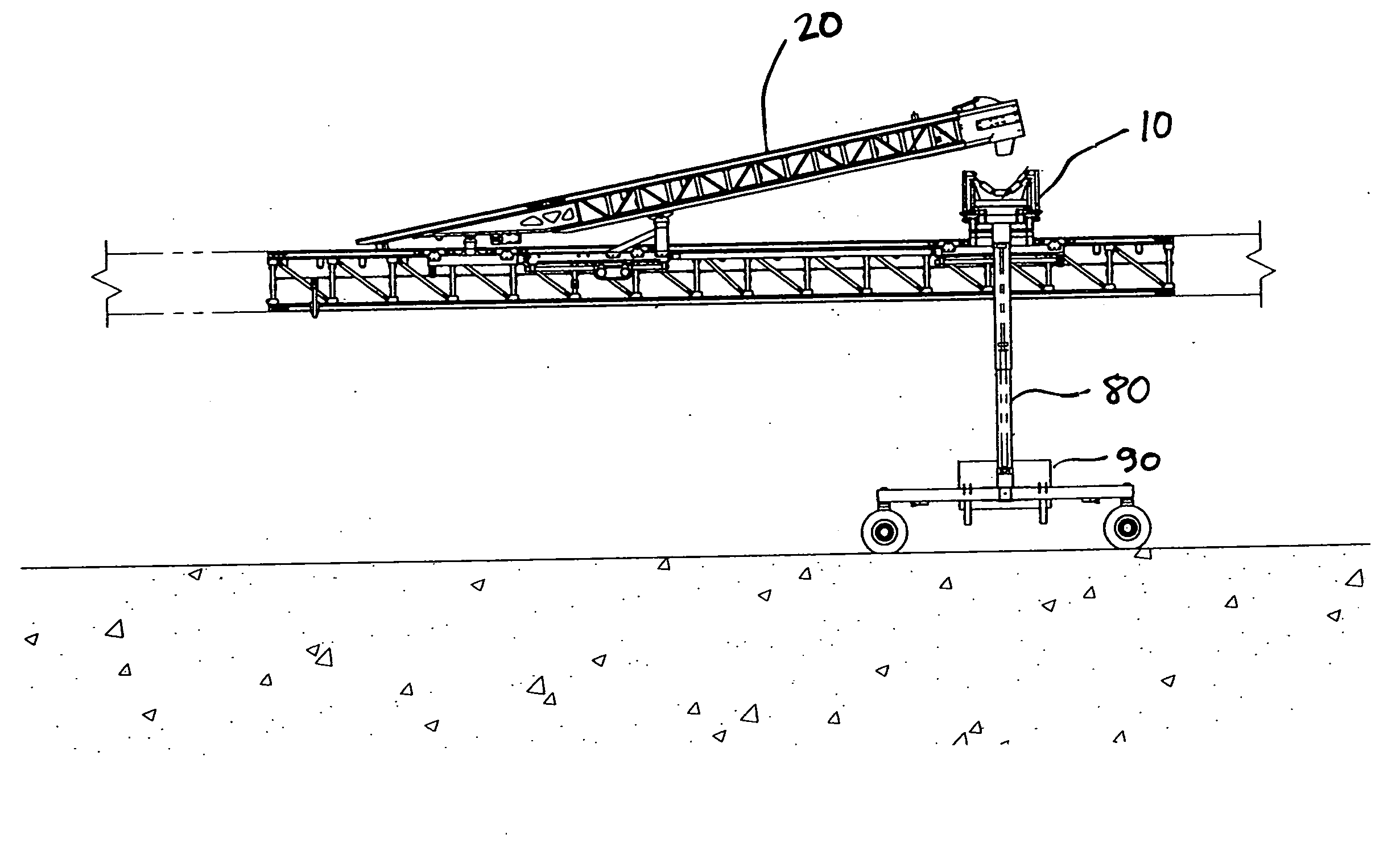

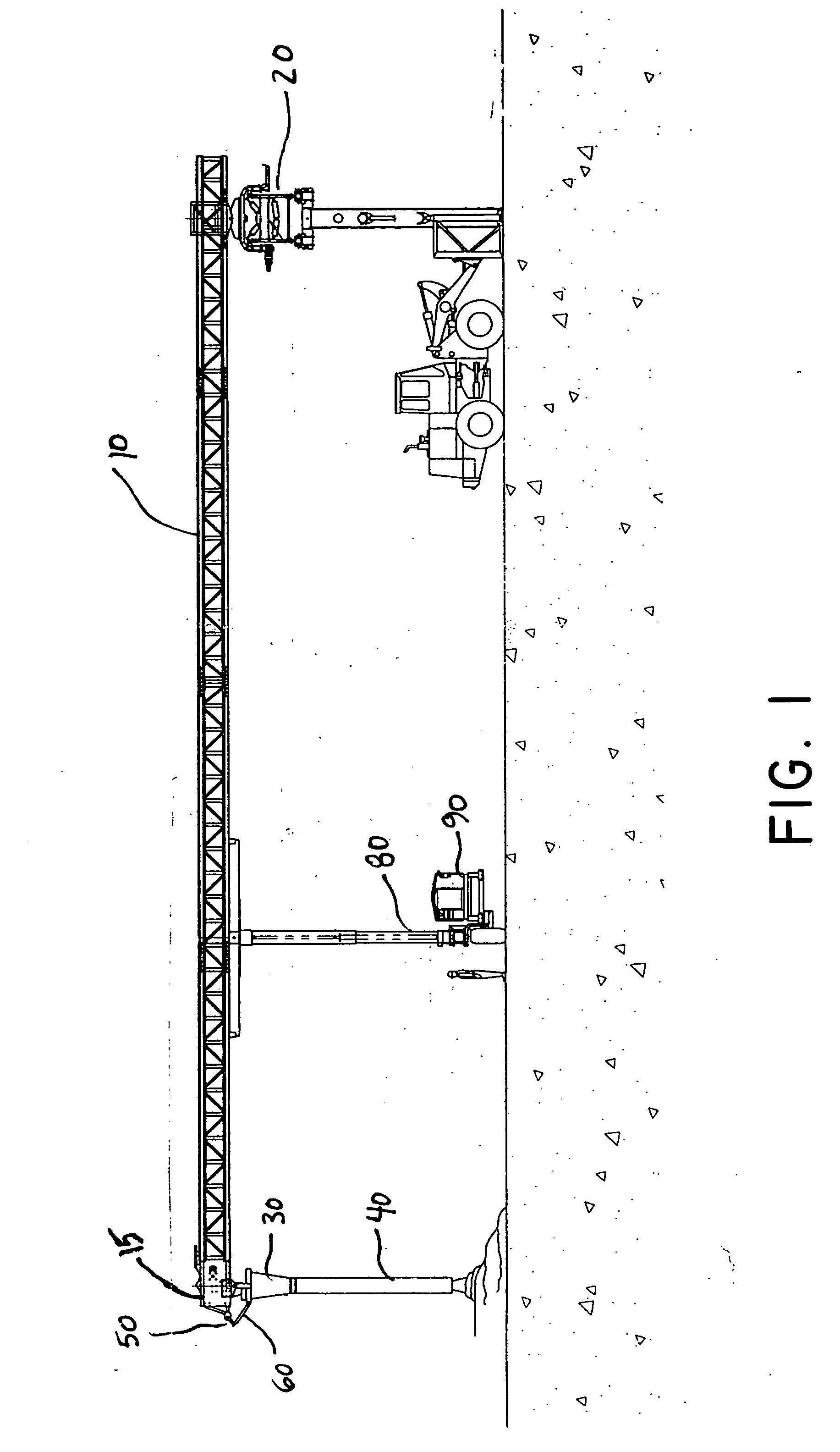

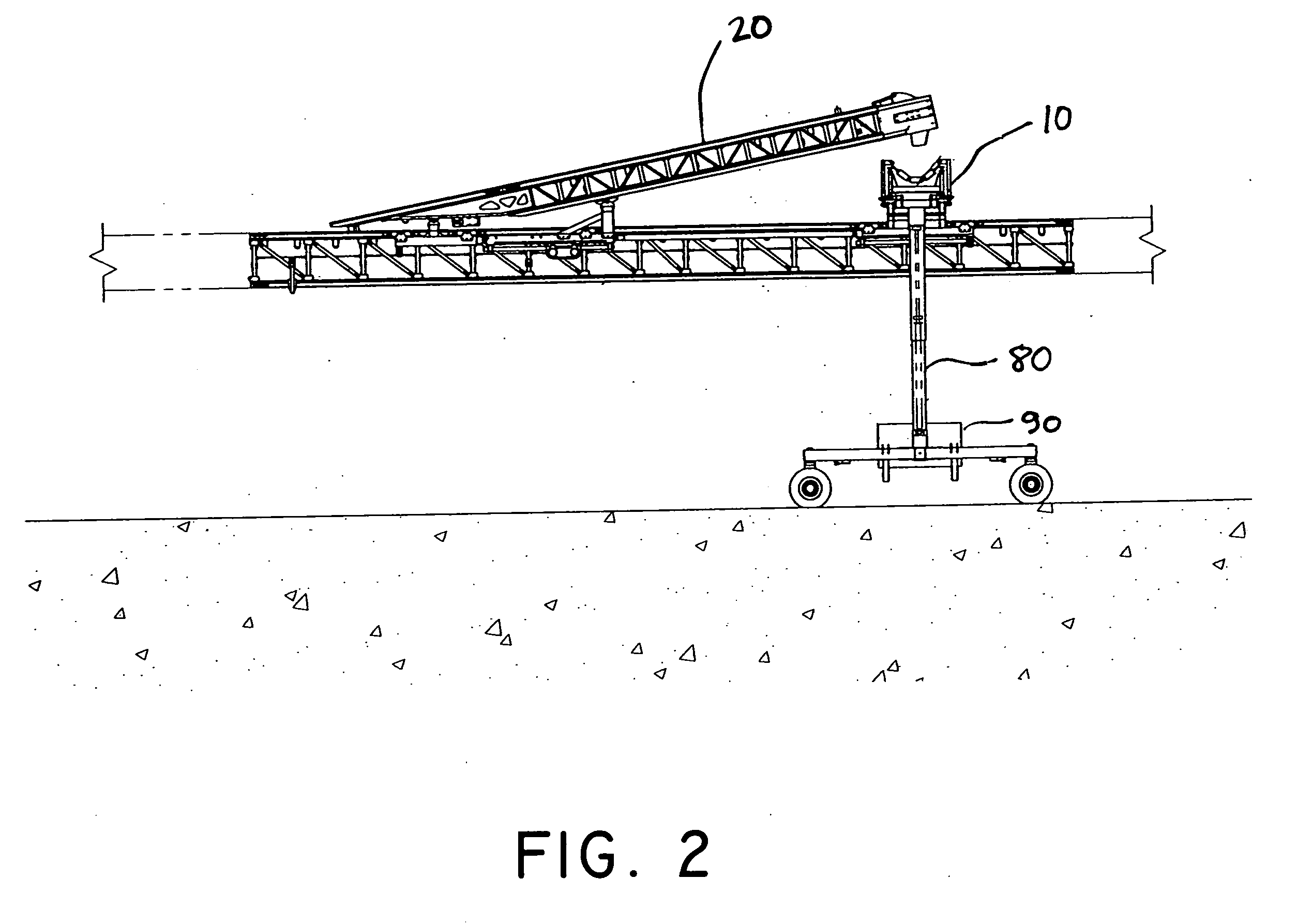

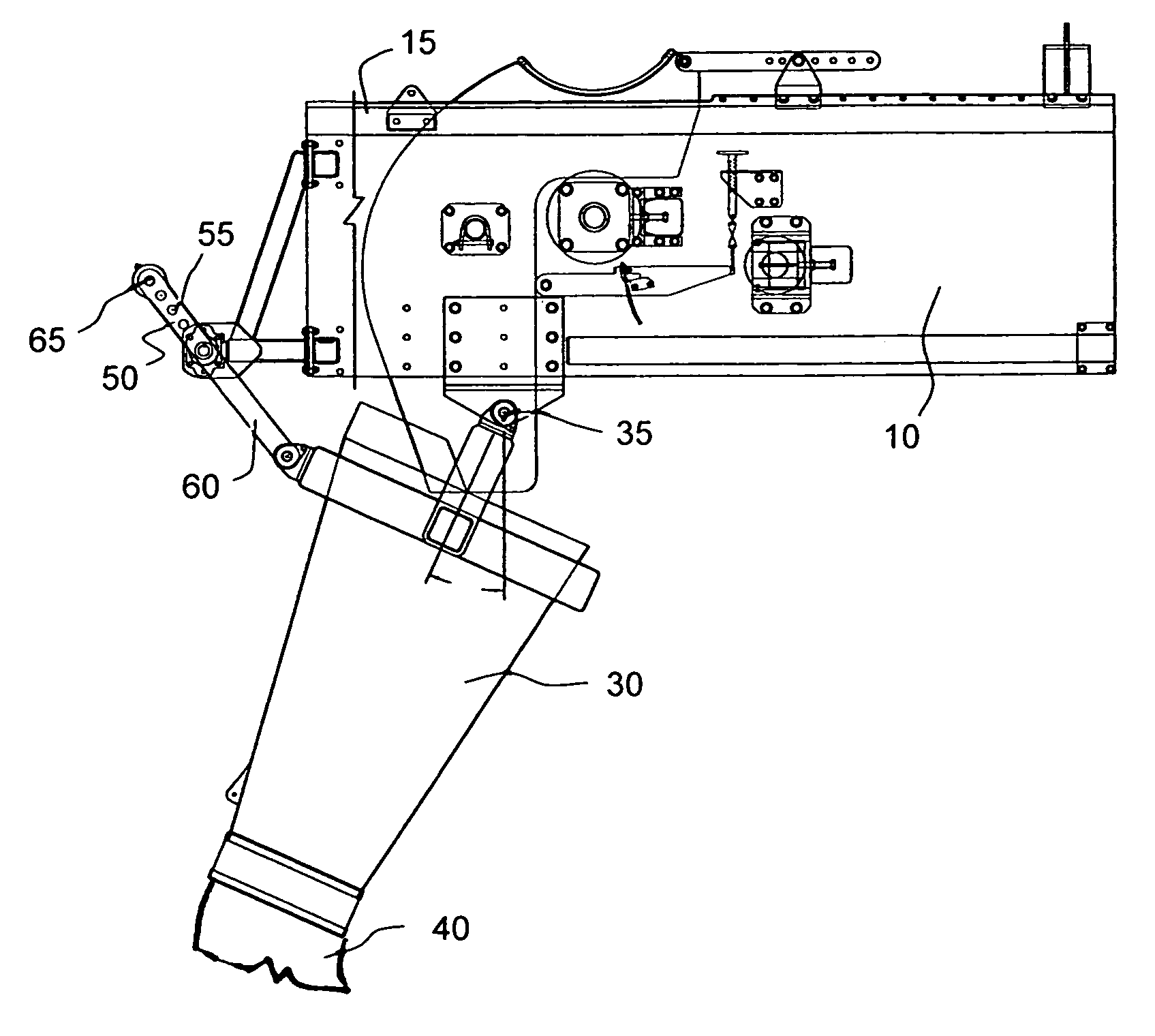

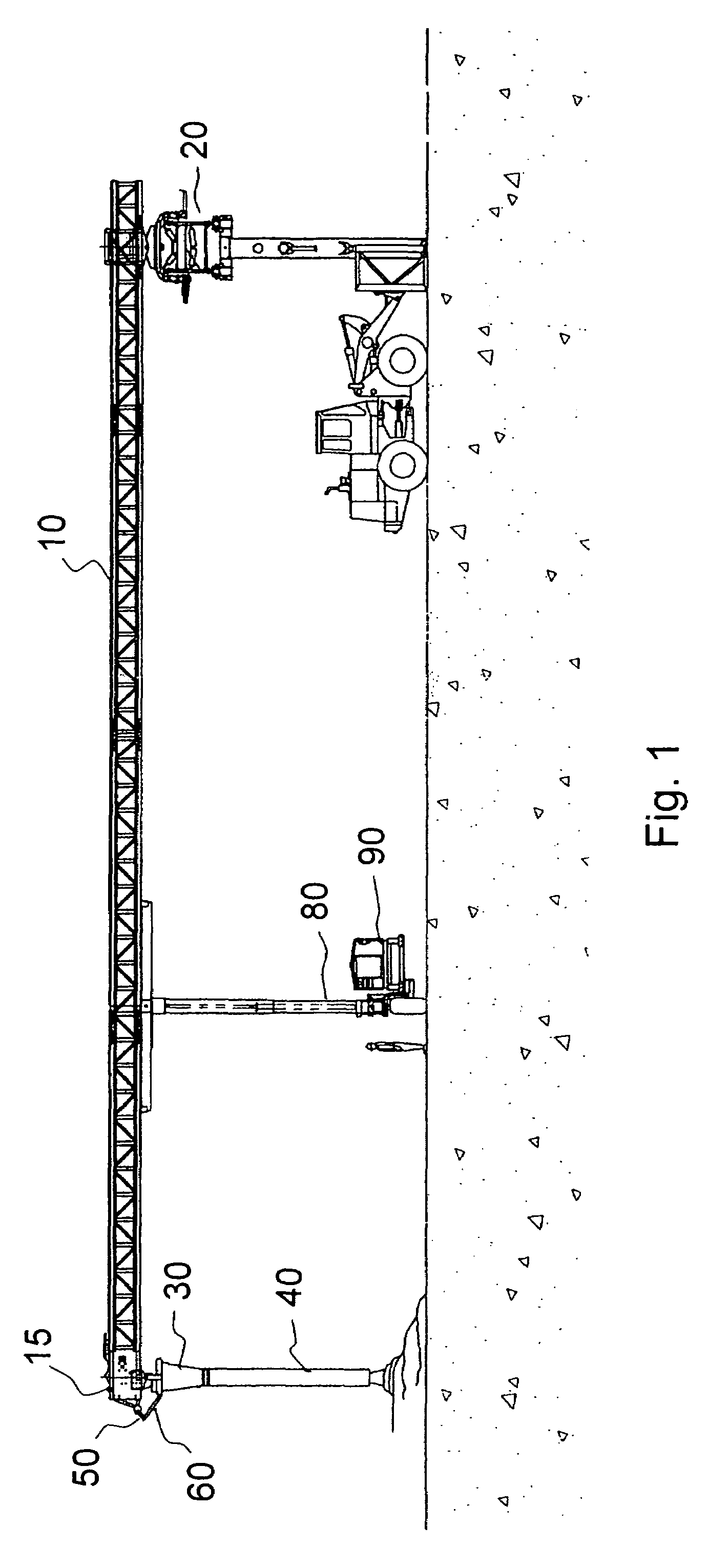

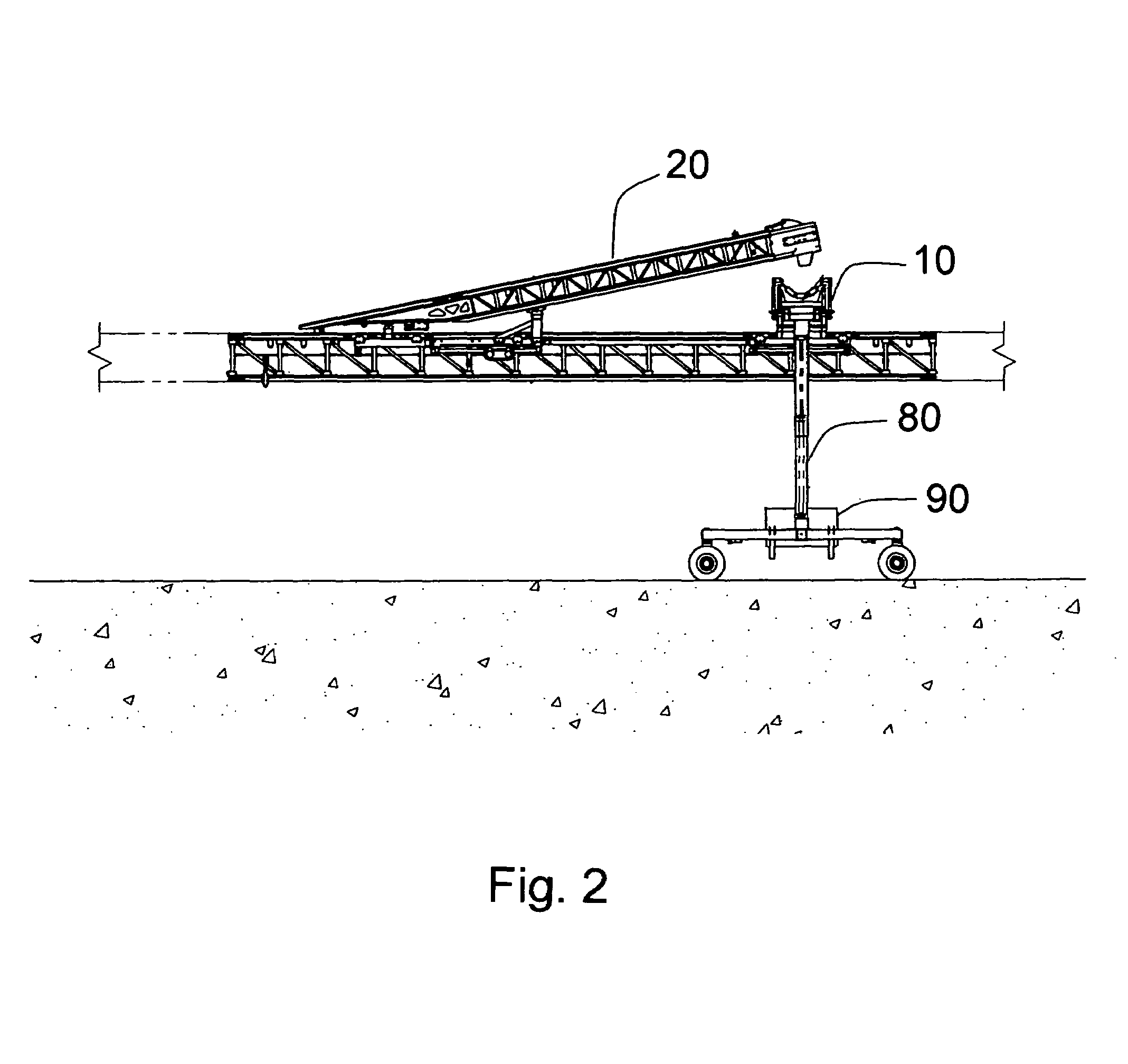

Conveyor discharge device

A device for spreading aggregate material from a discharge conveyor onto a work surface includes a tremie attached relative to the discharge conveyor and a flexible hose connected to the tremie. A crank connected between the tremie and the discharge conveyor permits adjustment of a frequency and an amplitude of the tremie to provide a desired windrow of material on the surface. A distal end of the discharge conveyor is preferably moveable relative to a supply of material to further optimize the desired windrow of material.

Owner:ROTEC INDS

Construction method for tremie guiding pouring inside steel pipe column

InactiveCN103216102APouring fully denseNo sinkingBuilding material handlingTremieUltimate tensile strength

The invention provides a construction method for tremie guiding pouring inside a steel pipe column, and relates to the technical field of construction of pouring concrete inside the steep pipe column of high-rise buildings. After the steel pipe column is erected, cement is poured from bottom to top layer by layer. The construction method for tremie guiding pouring inside the steel pipe column is characterized in that a plurality of inner clapboards are respectively fixed inside the steel pipe column, a through hole used for allowing a tube to insert is formed in the center of each clapboard, in the process of pouring, the tube is inserted in the steel pipe column, the outlet end of the tube is located between two adjacent inner clapboards, vibration is conducted after pouring of the steel pipe column between the two adjacent inner clapboards is finished, and then the tube is lifted upwards, and pouring of a steel pipe column between a former set of two adjacent inner clapboards is conducted. The construction method for tremie guiding pouring inside the steel pipe column has the advantages of improving pouring quality of cement inside the steel pipe column, increasing whole intensity of a steel structure, and saving funds. The phenomena that the measures that the steel pipe column is scraped or the cement inside the steel pipe column is reinforced are adopted due to the fact that incompact quality of the cement inside the steel pipe column and insufficient intensity is eliminated.

Owner:JIANGSU HUAJIANG CONSTR GROUP

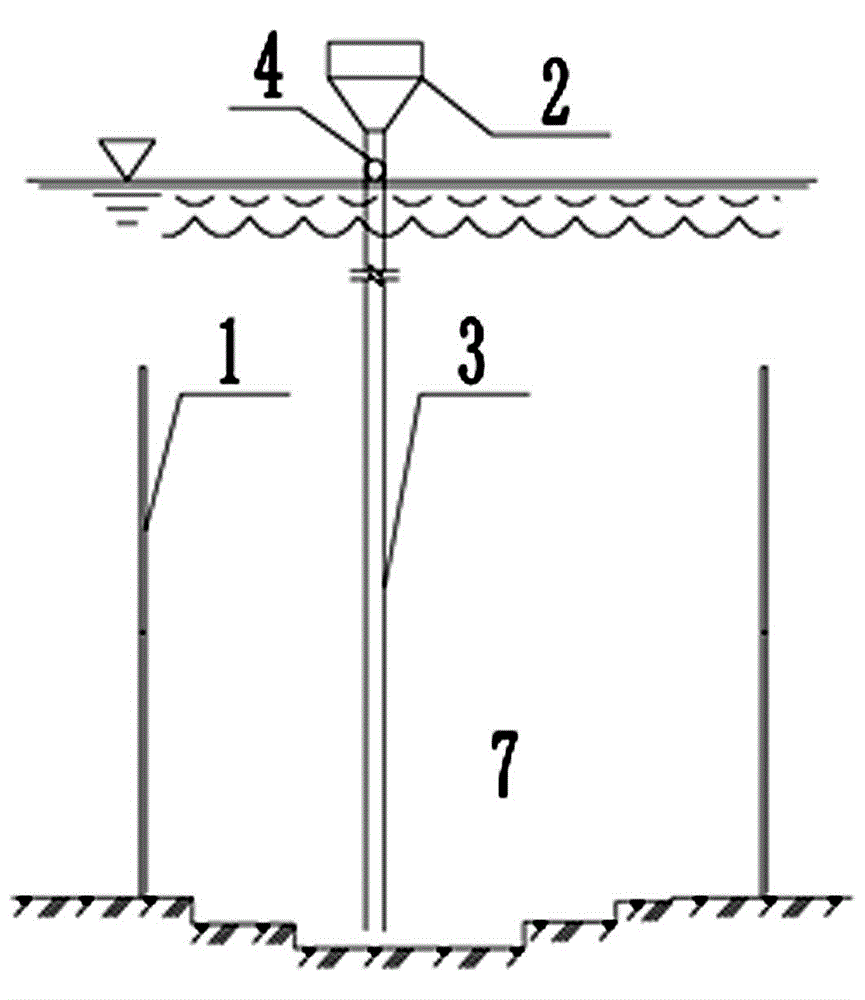

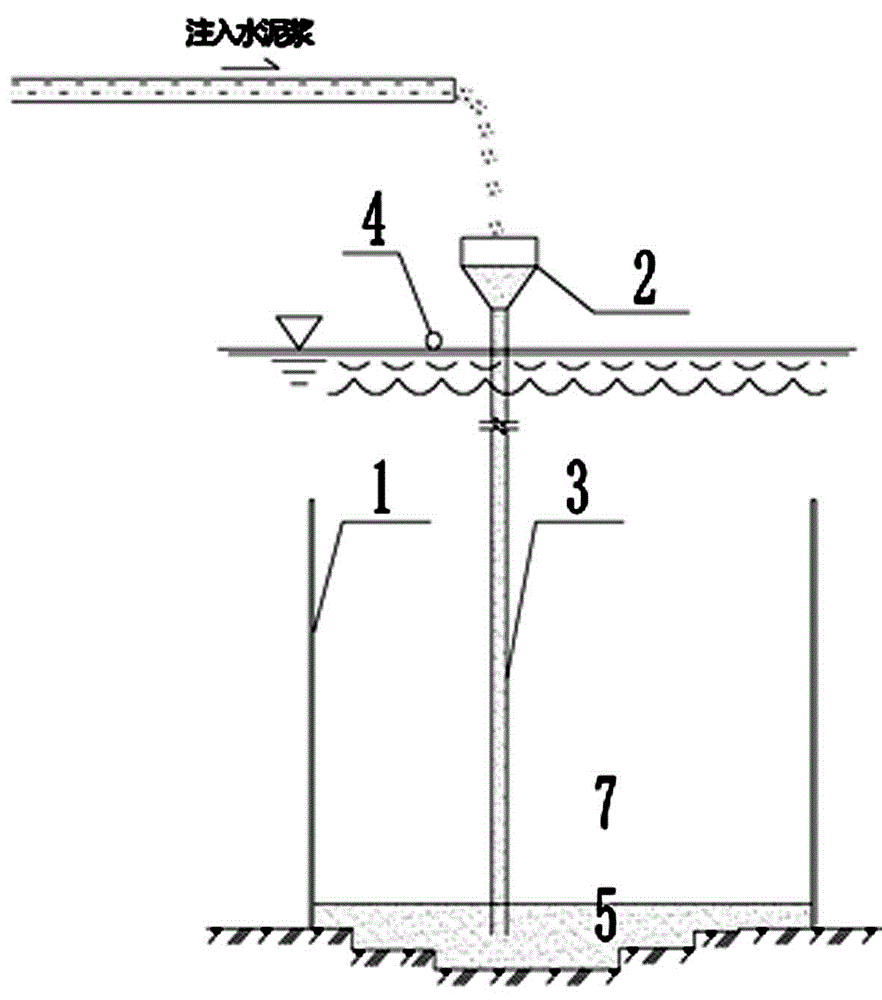

Underwater separating type concrete pouring constructing method

The invention provides an underwater separating type concrete pouring construction method. The method is characterized in that cement paste is introduced as a medium layer during underwater pouring, so that concrete, cement paste and water can be automatically layered under the gravity effect, and as a result, the concrete can be separated from environmental water all the time; in addition, a tremie can horizontally move in the cement paste, and concrete can be vibrated underwater, so that the underwater pouring constructing quality is improved. According to the method, the medium layer prepared from cement paste is high in mobility, dispersion resistance and homogeneity, and the separating effect is achieved through the specific gravity characteristics of the medium layer, so that the concrete under underwater pouring can be vibrated without widely directly contacting with environmental water, and as a result, the underground pouring quality can be improved; large-placed area and large size general underground water pouring construction can be achieved; the process is simple, the construction quality is greatly improved, and the construction cost is greatly decreased.

Owner:THREE GORNAVIGATION AUTHORITY

Concrete grouting construction method and device for implementing same

The invention discloses a concrete grouting construction method and a device for implementing the same. The device comprise a plurality of tremies of which one ends extend into underwater concrete in a grouting slot; a blanking hopper is arranged at the top end of each tremie; a slag pumping pipe is arranged in the grouting slot; and the bottom end of the slag pumping pipe is positioned at a position which is 1-2 meters away from the surface of the underwater concrete. According to the concrete grouting construction method and the construction device, slurry above the surface of the underwater concrete is pumped through the slag pumping pipe in a concrete pouring process, and concrete is poured in the pumping process, so that the quality of underwater concrete is prevented from being damaged by the slurry above the surface of the underwater concrete, and the piling quality of the underwater concrete is effectively ensured; and the method and the device can be applied to the field of building construction.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Preparation method of low-hydroxyl solid quartz steelyard weight

The invention relates to a preparation method of a low-hydroxyl solid quartz steelyard weight and belongs to the field of quartz glass melting technology. A plasma device, instead of a hydrogen and oxygen flame burner in the traditional gas-refining equipment for fabrication of steelyard weights, is used as a heat source in the invention. Quartz powders are delivered into the plasma device or into a flame area through a tremie pipe and then will be sprayed on a quartz glass target holder. A constant distance between the target surface and the plasma flame front is maintained through an uniform rotation and a descending motion of the quartz target holder. Powders can be placed in the area with the highest temperature all along. Therefore, powders are continuously melted and then will be cooled into a solid glass steelyard weight. The quartz steelyard weight prepared in the invention is characterized by the high purity, the low hydroxyl content, the high softening point, the good heat resistance performance, the high strength or the like in combination with traditional gas-refined steelyard weights. It can be widely applied in high-tech fields with all kinds of requirements for high-performance quartz products.

Owner:久智光电子材料科技有限公司 +1

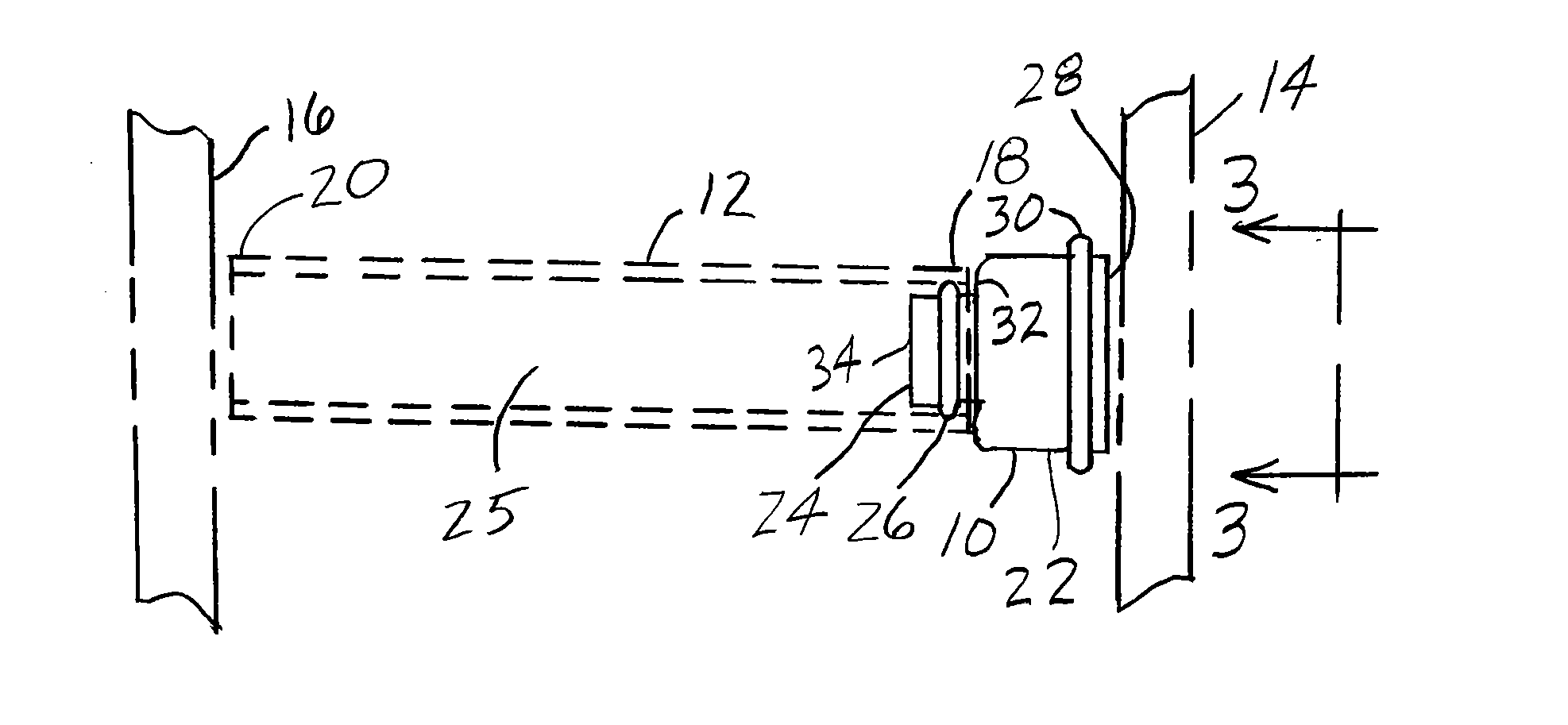

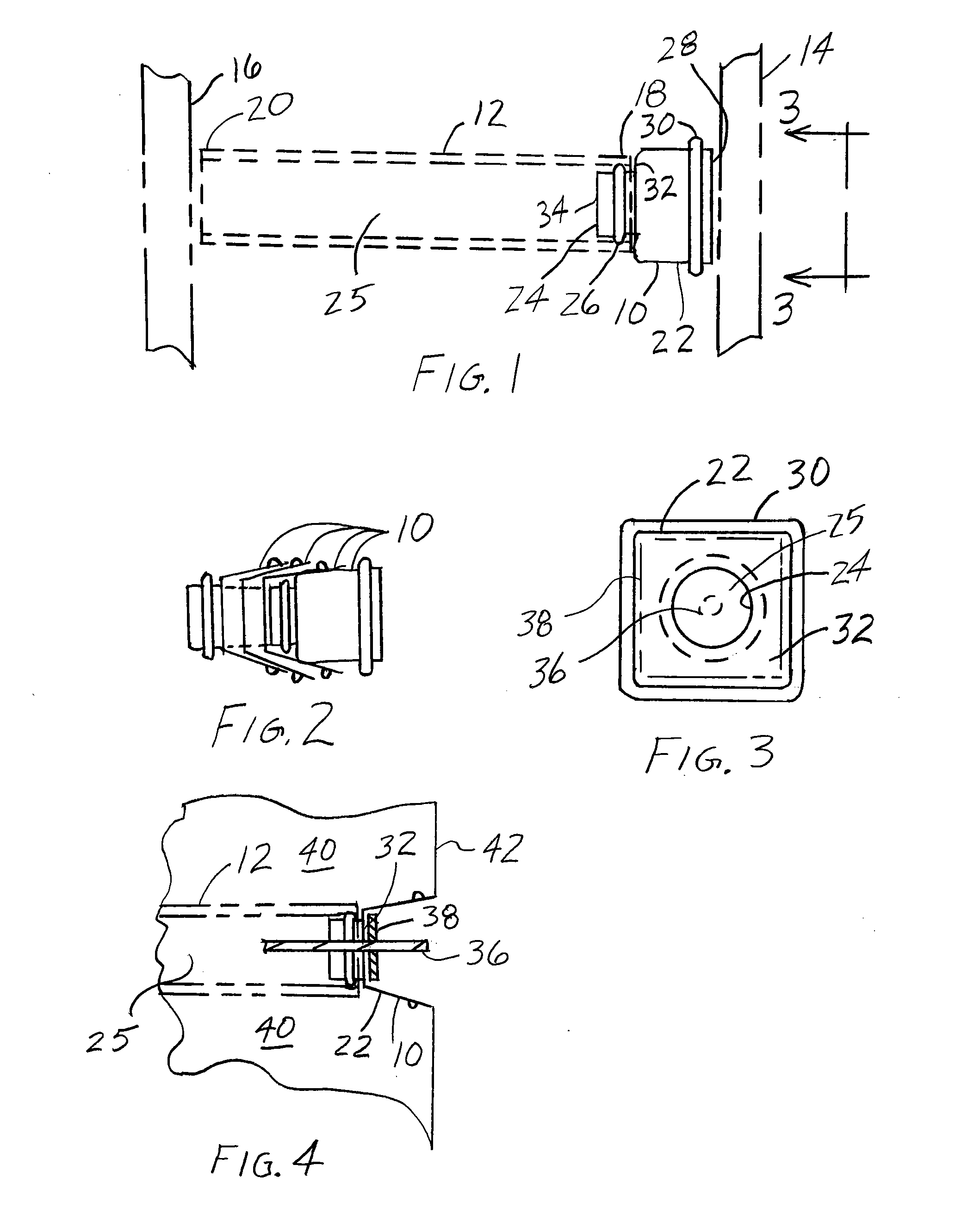

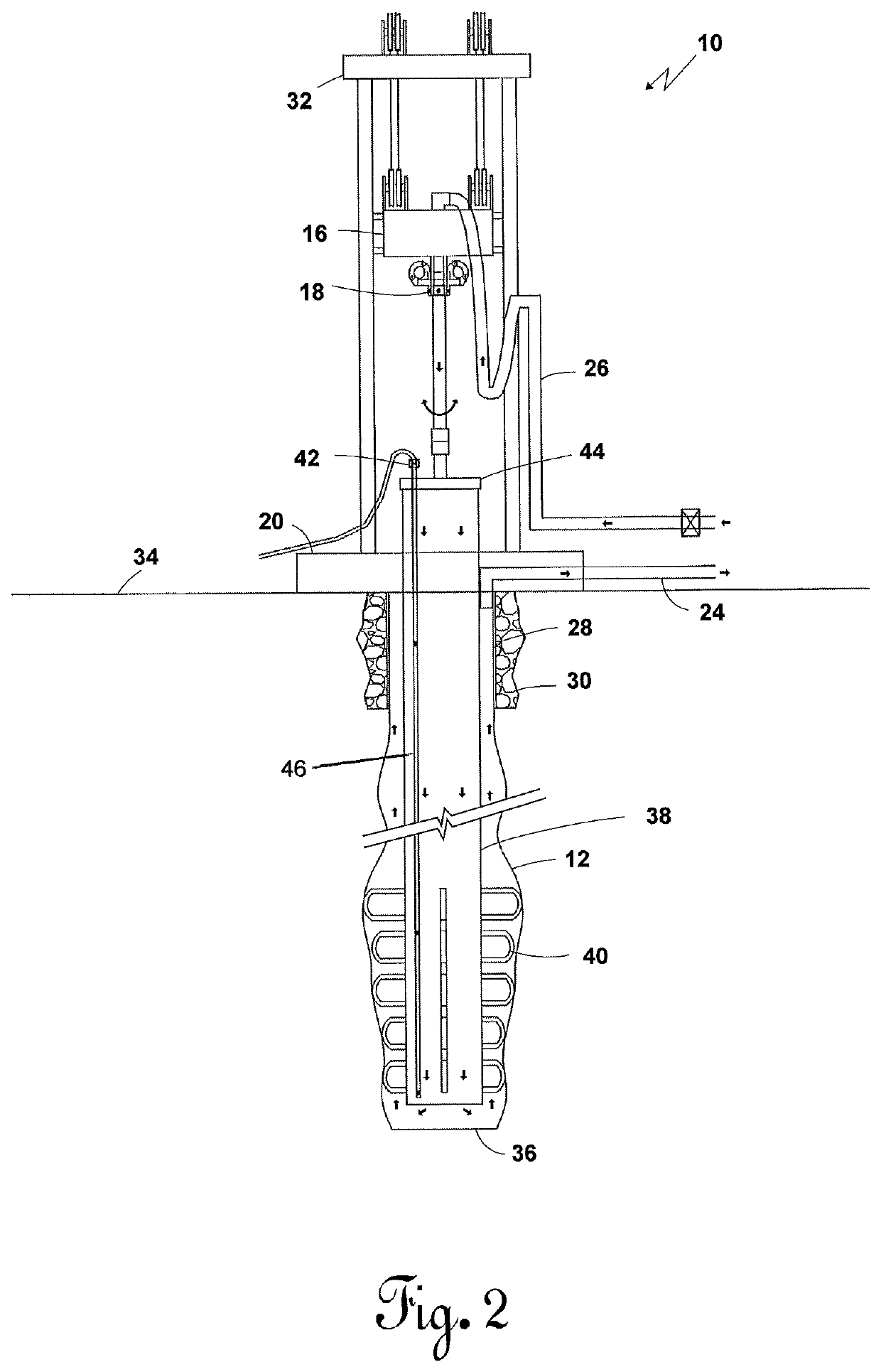

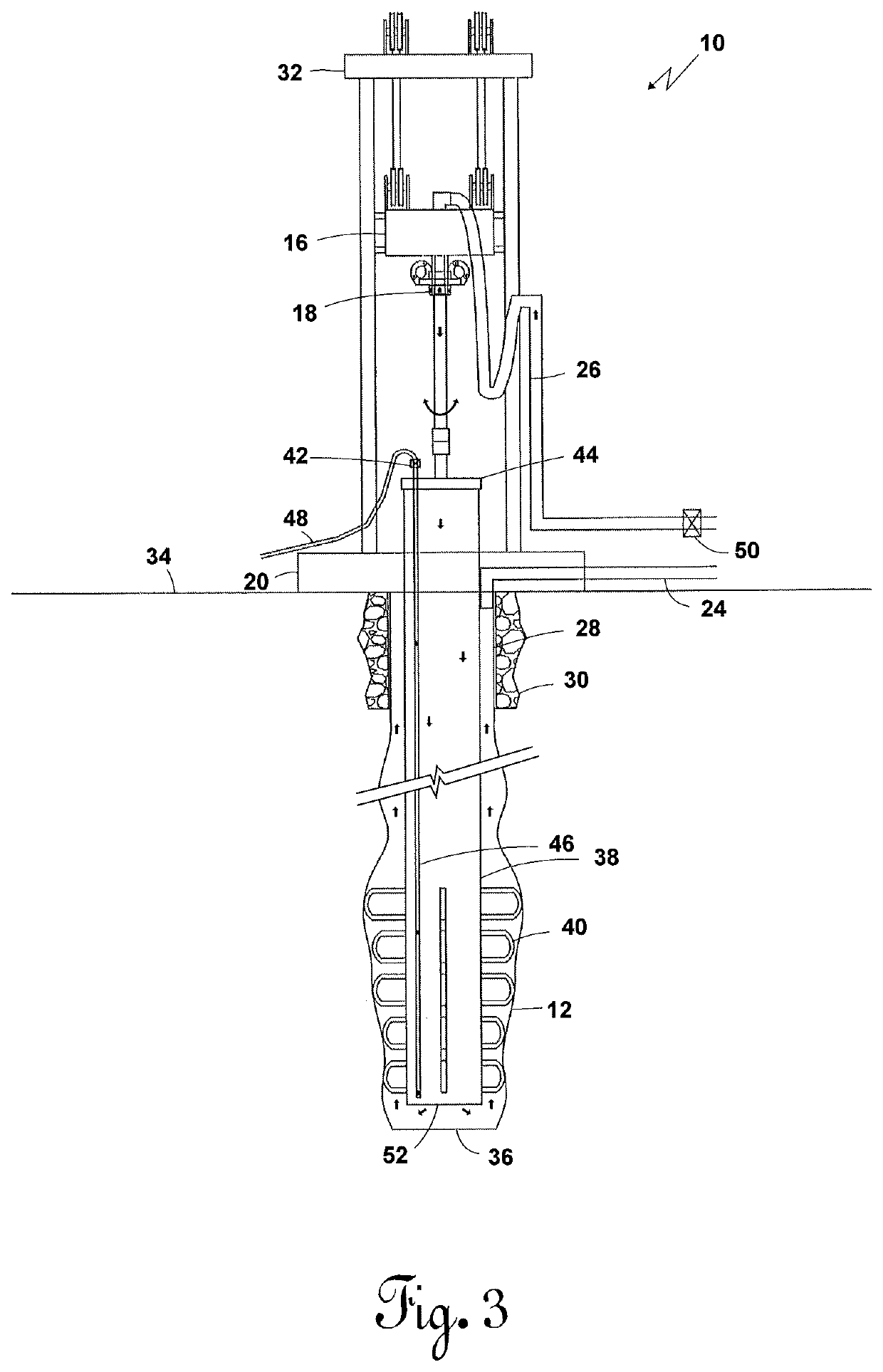

Geothermal pipe weight

A method and apparatus for adding rigidity and weight to the piping used in geothermal wells for ground-source heat pumps enhances insertion of the piping into the wells. The weight used must be approved by appropriate organizations such as the DNR, NSF, and / or EPA, or similar, for contact with the ground water. Concrete and coated iron or steel are examples of such weights. A system for assembling the pipes, weight, and a tremie pipe for insertion is disclosed. The weighting system may also help maintain straightness in the geothermal piping for ease of inserting the piping into the vertical well.

Owner:MCNAIR EDWARD F +1

Conveyor discharge device

A device for spreading aggregate material from a discharge conveyor onto a work surface includes a tremie attached relative to the discharge conveyor and a flexible hose connected to the tremie. A crank connected between the tremie and the discharge conveyor permits adjustment of a frequency and an amplitude of the tremie to provide a desired windrow of material on the surface. A distal end of the discharge conveyor is preferably moveable relative to a supply of material to further optimize the desired windrow of material.

Owner:ROTEC INDS

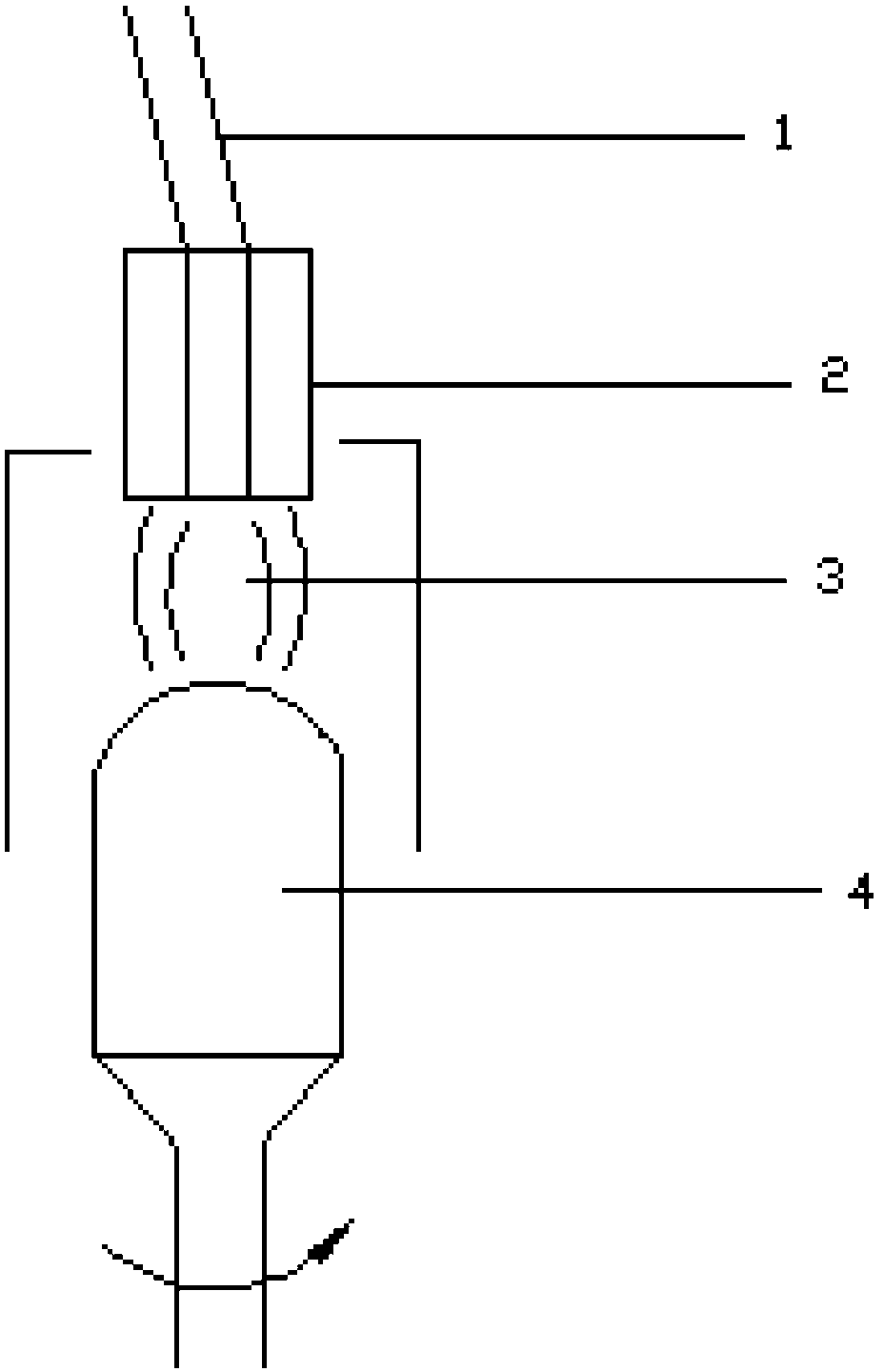

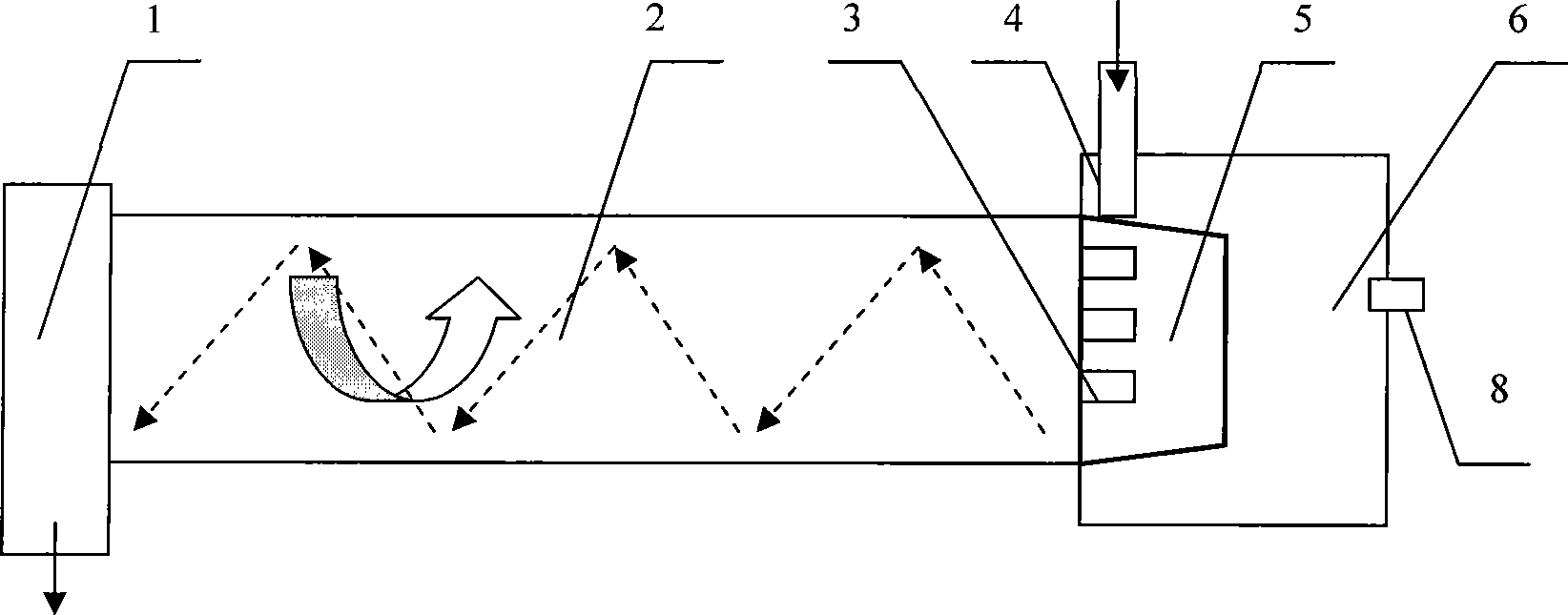

Feeding apparatus of cylinder drier

ActiveCN101430162ASolve the problem of entering the running cylinderSolve the problem of feeding methodDrying machines with non-progressive movementsCombustion chamberTremie

The invention relates to a feeding apparatus of a cylindrical drier. The feeding apparatus is characterized by being arranged between a combustion chamber and a rotary kiln cylinder of the cylindrical drier, being coaxially linked with the combustion chamber and the cylinder, and comprising a tremie pipe, a fixed cylinder and inclined stirring plates; the fixed cylinder is a coniform flaring cylinder and fixed in the combustion chamber; the big end of the fixed cylinder extends into the cylinder in a suspension manner, and the small end of the fixed cylinder is provided with an annular blocking ring; the tremie pipe is vertically arranged on a tangent line of the fixed cylinder from the top down, and the tangential direction is identical with the rotation direction of the cylinder; the inclined stirring plates take arc strip plate shape; one end of the inclined stirring plates is fixed on the inner surface of the cylinder, and the other end extends into the fixed cylinder slantwise and is suspended at the tremie pipe; the number of the inclined stirring plates is four or more, and the inclined stirring plates are evenly arranged on the inner surface of the cylinder in the radial direction. The feeding apparatus can ensure normal continuous feeding of materials into the cylindrical kiln of the cylindrical drier, and has the advantages of no easy adhesion and blocking, no need of cooling water jacket and long service life.

Owner:ZHUZHOU SMELTER GRP

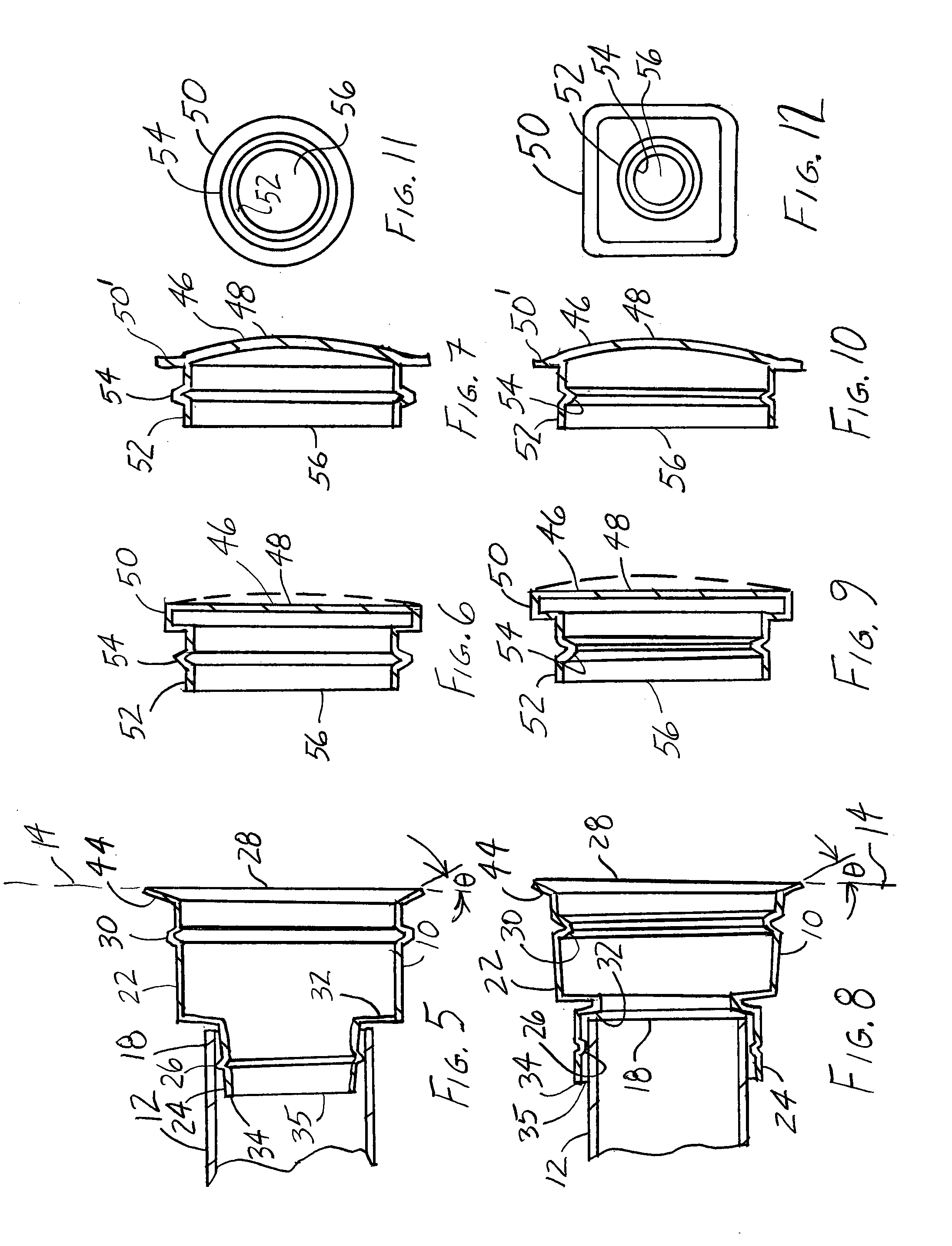

Concrete conduit members

Owner:HIGH CONCRETE GROUP

Steel casing lead hole type pile planting construction technology

The invention discloses a steel casing lead hole type pile planting construction technology. The steel casing lead hole type pile planting construction technology comprises the steps: firstly, determining a pile position and a pile position center line underwater; secondly, performing slope bedding and slope flattening construction for the pile position preliminarily by centering on the pile position center line; thirdly, further performing construction for the pile position after slope bedding and slope flattening in the second step are completed so as to form a lead hole for holding a steel casing; fourthly, hoisting the steel casing, subjecting the steel casing to pile sinking to enable the steel casing to be in the lead hole, and guaranteeing that a center line of the steel casing is consistent with the pile position center line; fifthly, performing pile planting construction through a frost boil hole formed in the bottom of the steel casing by the aid of a tremie method, and guaranteeing that a riverbed rockface has concrete with a certain thickness while the lead hole is filled with concrete. The steel casing lead hole type pile planting construction technology has the advantages that lead hole depth, hole bottom flatness, hole bottom sediments and pile sinking deviation are controlled, the pile planting construction technology can adapt to complicated geological conditions, construction procedures are reduced, input of ship and machine equipment, personnel and platform materials is reduced, construction progress is accelerated, and cost is saved economically.

Owner:CHINA STATE CONSTR HARBOR CONSTR

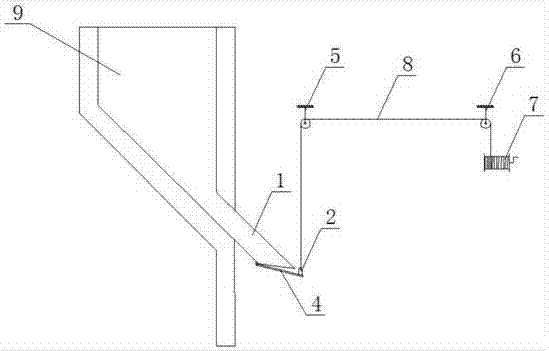

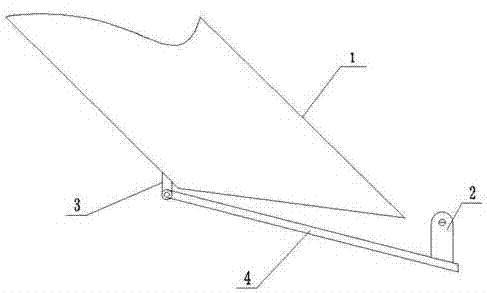

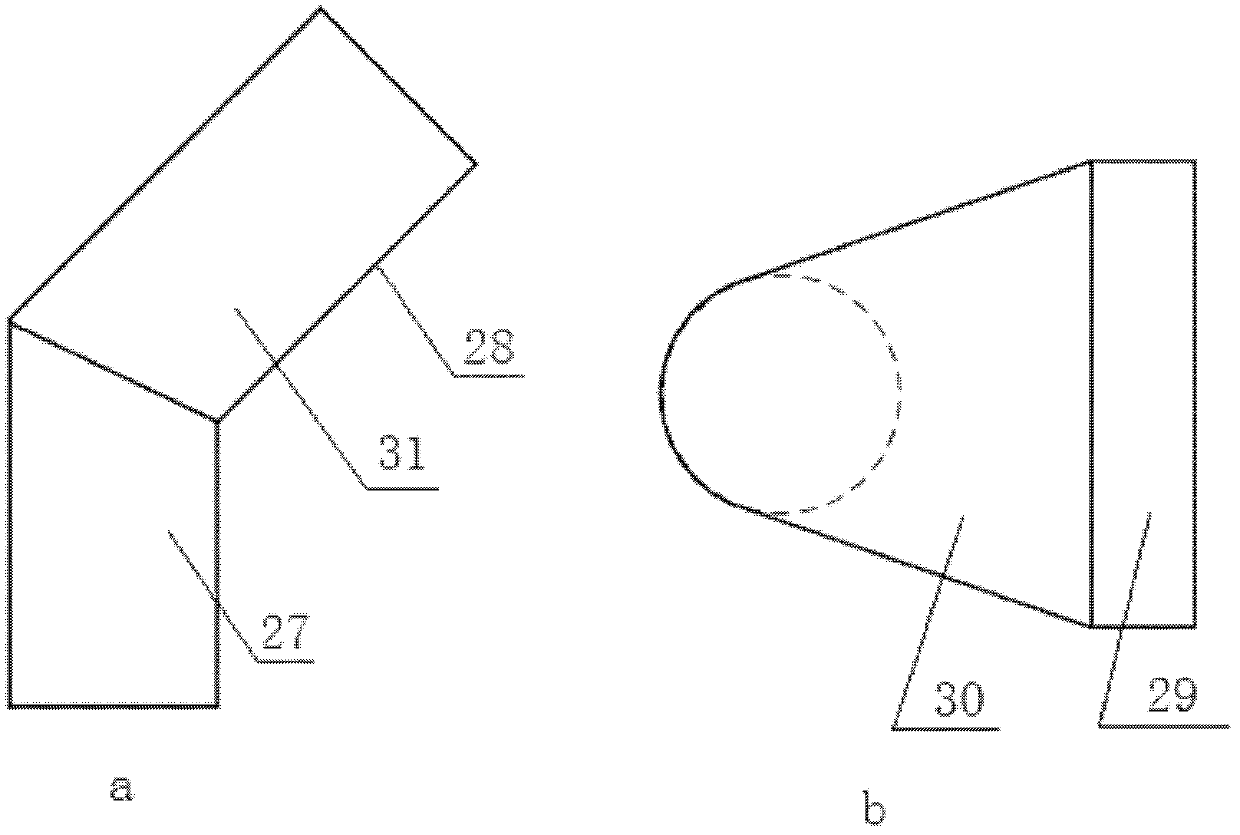

Alligator nozzle type long-distance manual control dump valve

ActiveCN103486320ASimple structureLive productionOperating means/releasing devices for valvesLarge containersWinding machineTremie

The invention discloses an alligator nozzle type long-distance manual control dump valve. The alligator nozzle type long-distance manual control dump valve comprises a valve body and a pulley group, wherein the valve body comprises a valve body, a lifting lug, a connecting piece and a lower jaw plate, and the connecting piece is fixed on the lower part of the valve body; the rear end of the lower jaw plate is connected with the valve body in a rotating manner, the lifting lug is fixed on the front end of the lower jaw plate, and the pulley group comprises a first pulley, a second pulley, a winding machine and a shaft line; the initiating end of the shaft line is fixed on the winding machine in a winding manner, and the tail end of the shaft line is fixedly connected with the lifting lug; the winding machine and the valve body are matched to use through the shaft line, the first pulley and the second pulley. The alligator nozzle type long-distance manual control dump valve provided by the invention has the beneficial effects that the structure of the valve is simple, the main body of the valve body directly utilizes a stock bin tremie pipe, the valve is beneficial for field fabrication, and the material is saved; due to the adoption of the scheme, field operation of an operator is not required, an operational condition is improved, the labor intensity is lightened, the valve is adjusted to open and close at any time to control the baiting, so that the operating efficiency is improved.

Owner:青岛磊鑫混凝土有限公司

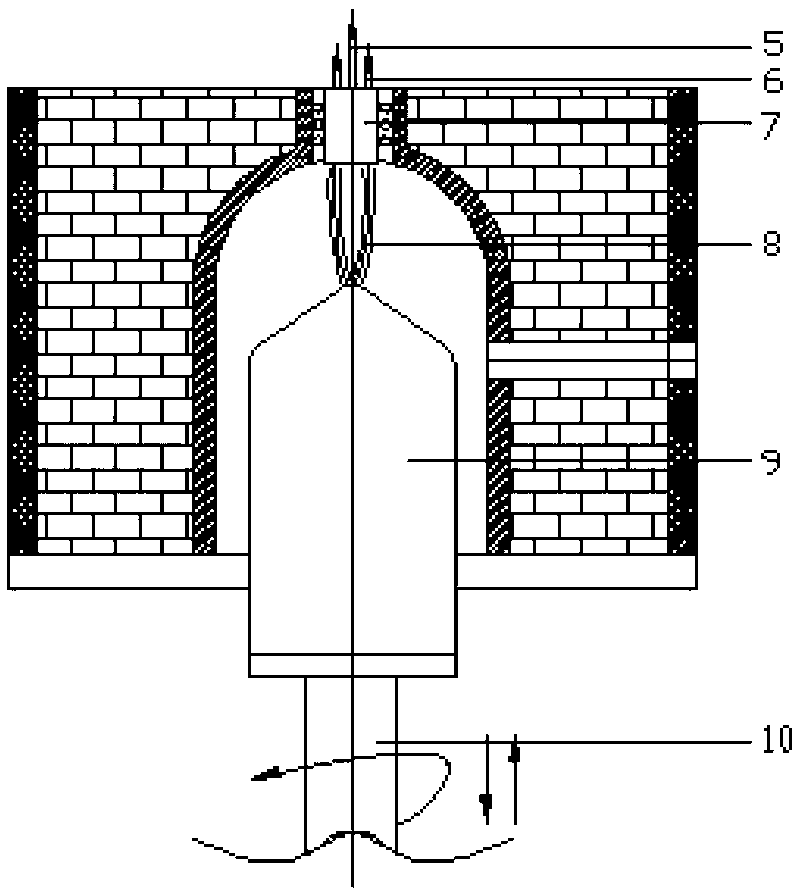

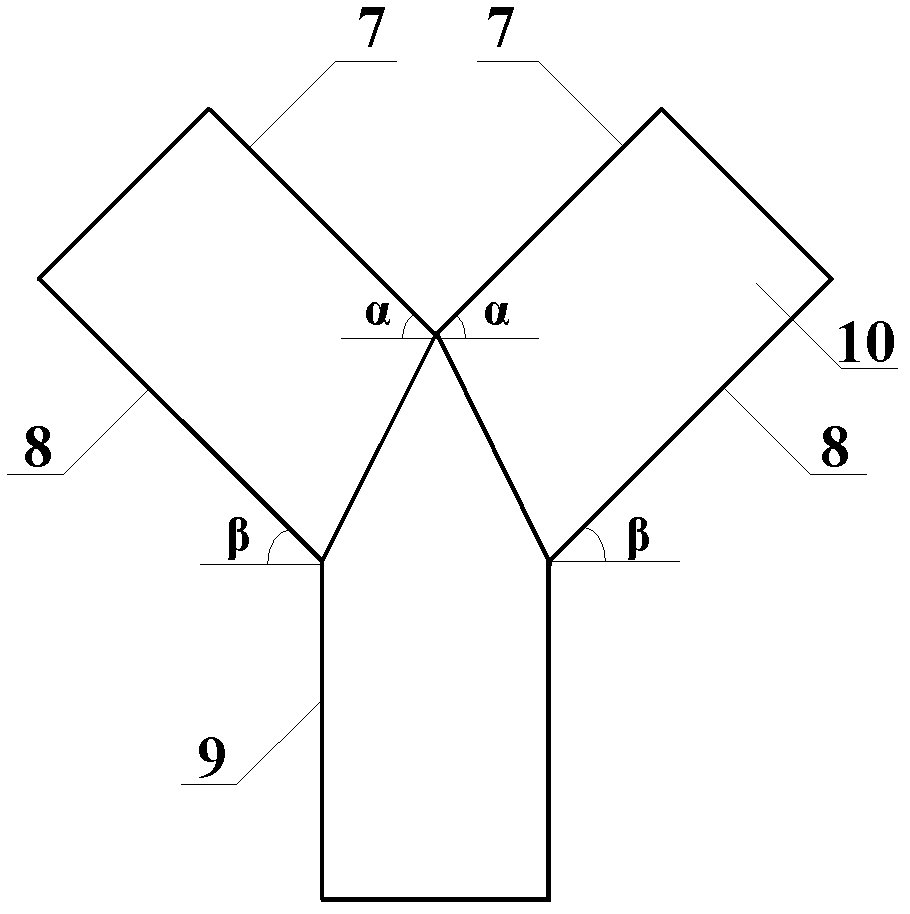

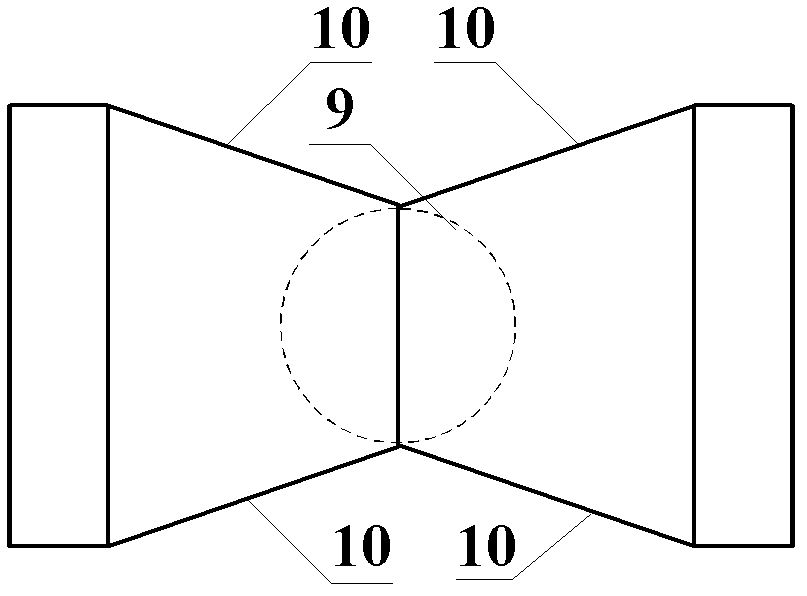

Catalyst tremie pipe

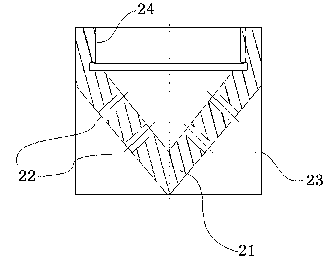

InactiveCN103285782AReduce stagnation dead zoneReasonable structureChemical/physical processesCatalytic reformingTremie

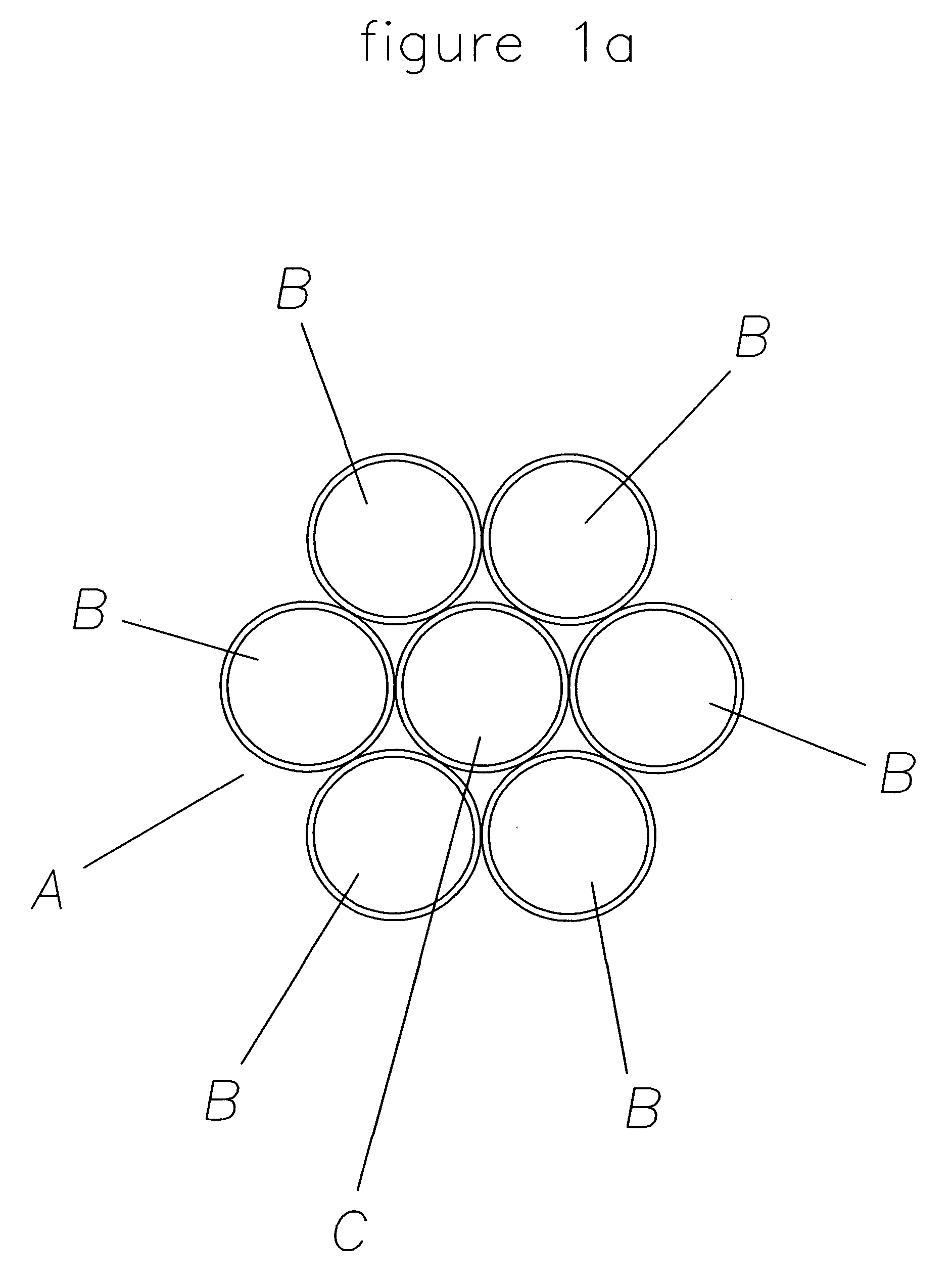

The invention discloses a catalyst tremie pipe which comprises a guide shell and two side ports, wherein the two side ports are respectively communicated with the same port of the guide shell and arranged symmetrically. The catalyst tremie pipe disclosed by the invention can reduce the influence of the wall attachment effect on the reactor wall surface, can obviously reduce the catalyst flow dead zone in the reactor, enhances the effective volume utilization ratio of the reactor, enables the catalyst stream type to be more approximate to the piston flow, and is especially suitable for a moving bed radial reactor for preparation of olefine from methanol, catalytic reforming or any other production process.

Owner:ZHEJIANG UNIV

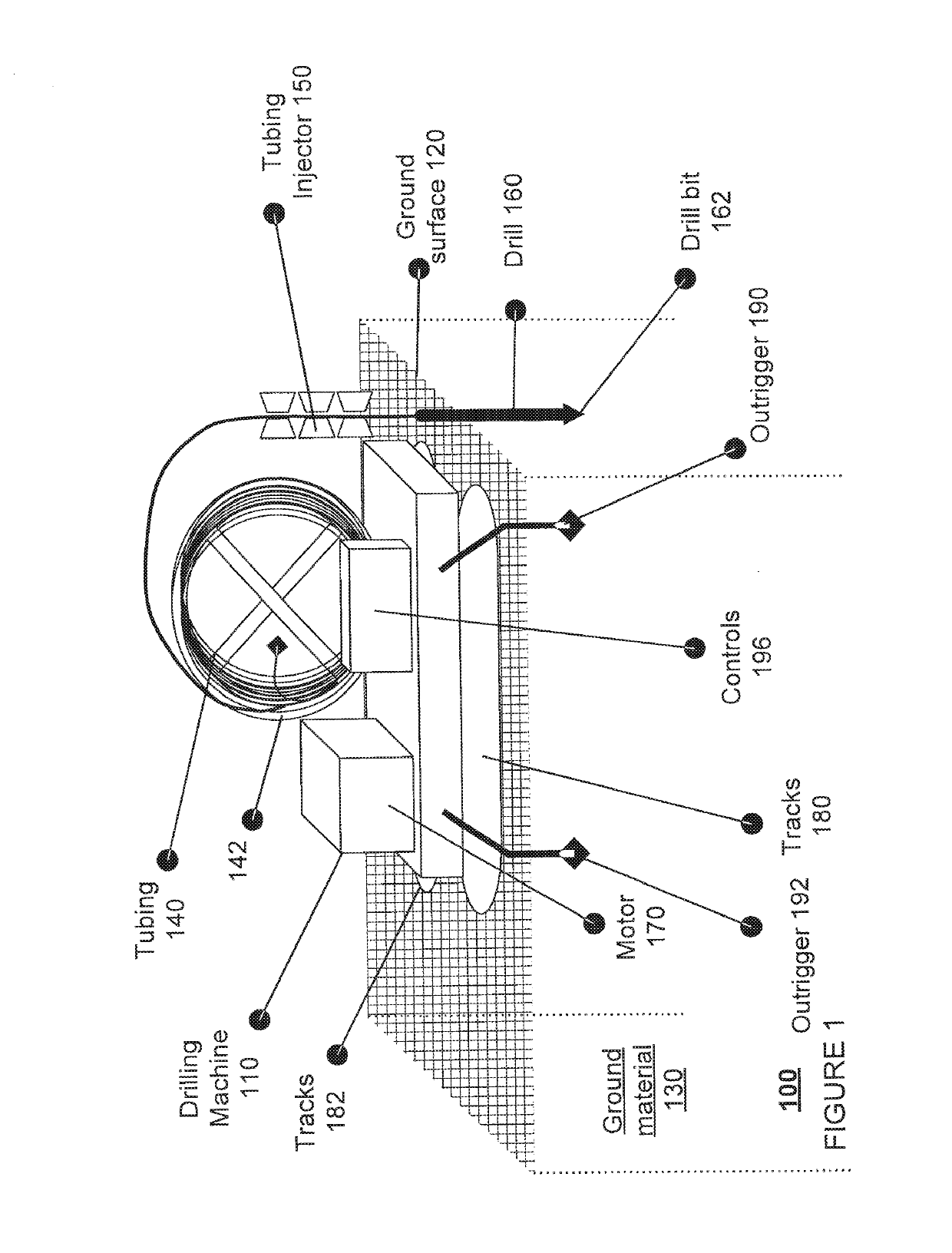

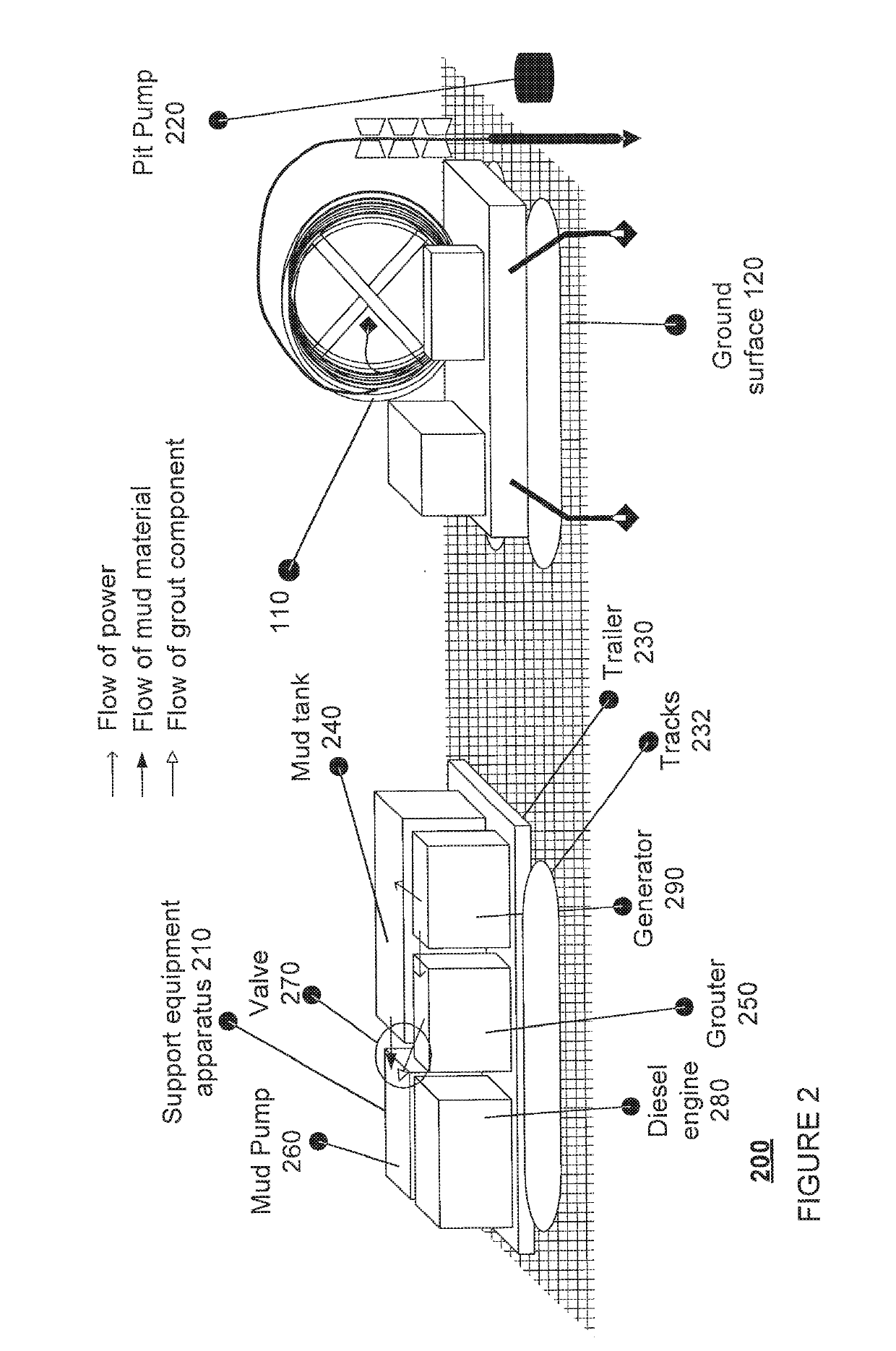

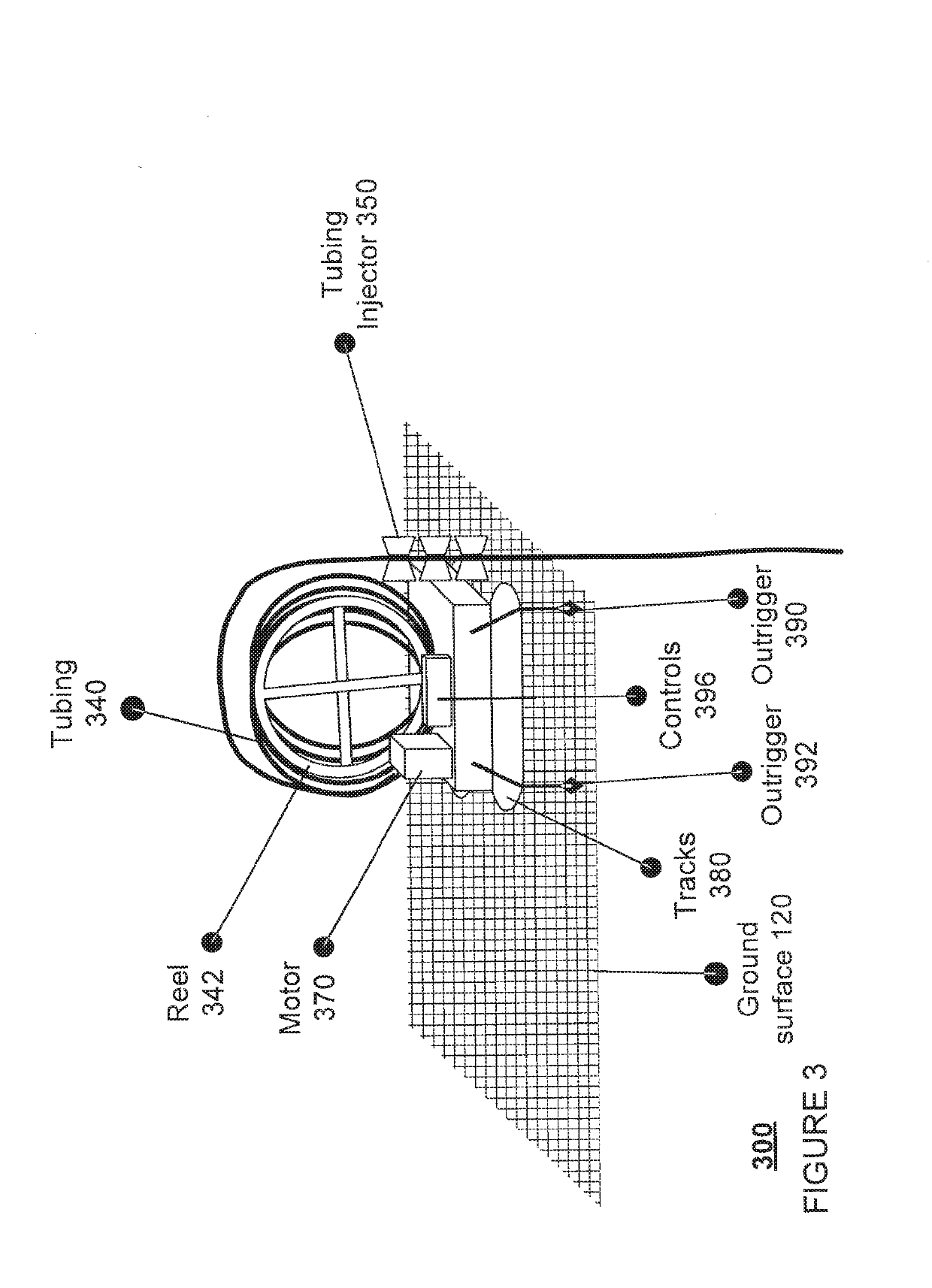

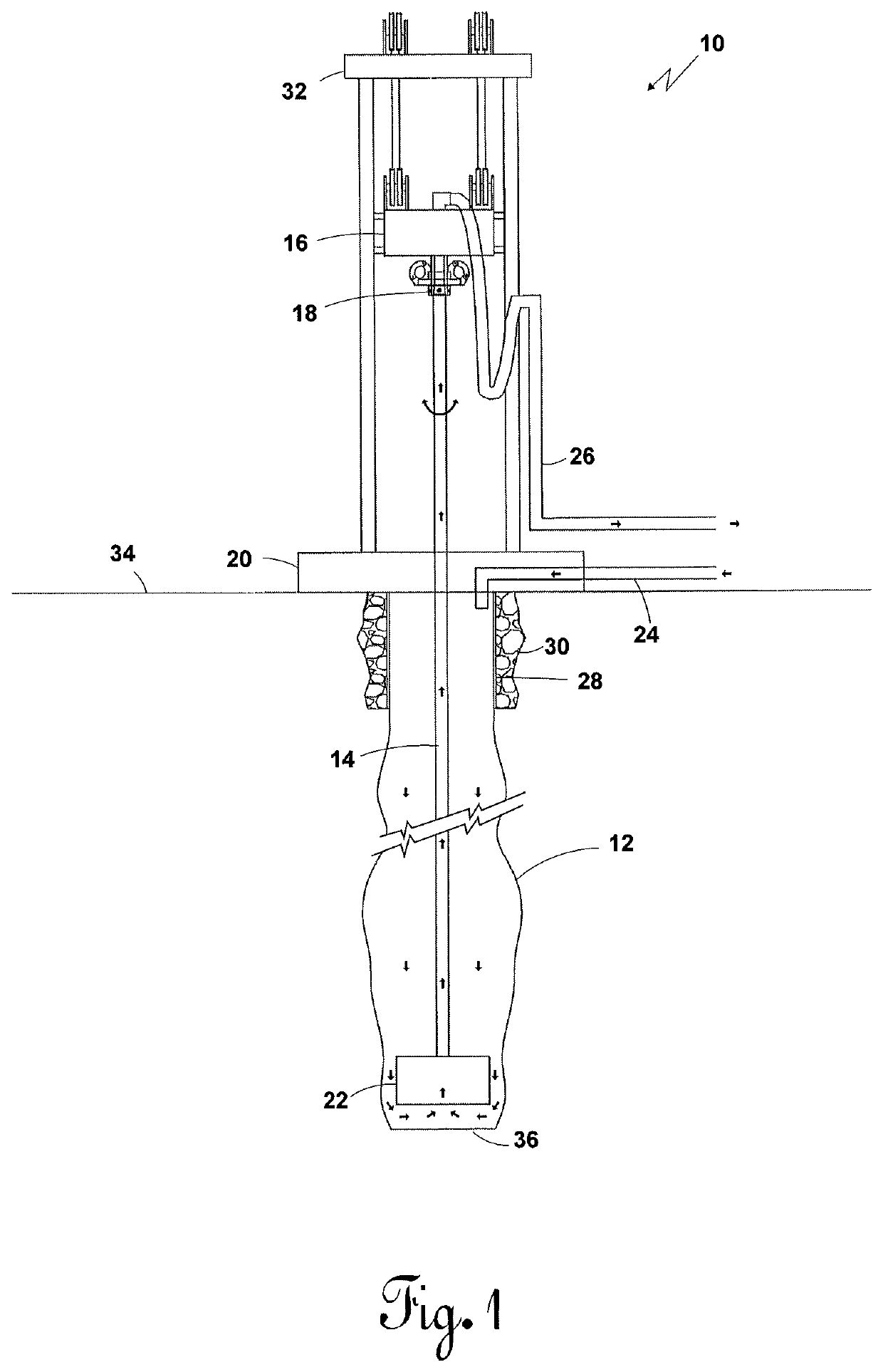

Installation Of Ground Loops For Geothermal Heating And/Or Cooling Applications

In order to install a ground loop for a geothermal heating and / or cooling system in ground material, a drilling machine having a drill bit connected to an end of first tubing may be used to create an borehole in the ground material. After the borehole is created, grout may be pumped into the borehole through the first tubing as the first tubing is removed from the borehole. This allows the borehole to be grouted from the bottom towards the top. Thereafter, second tubing may be inserted into the grout in order to create the ground loop. This eliminates the need for a “tremie” pipe to insert the ground loop and pump grout into the borehole, while still allowing for the borehole to be grouted from the bottom towards the top to reduce the likelihood of voids.

Owner:DANDELION ENERGY INC

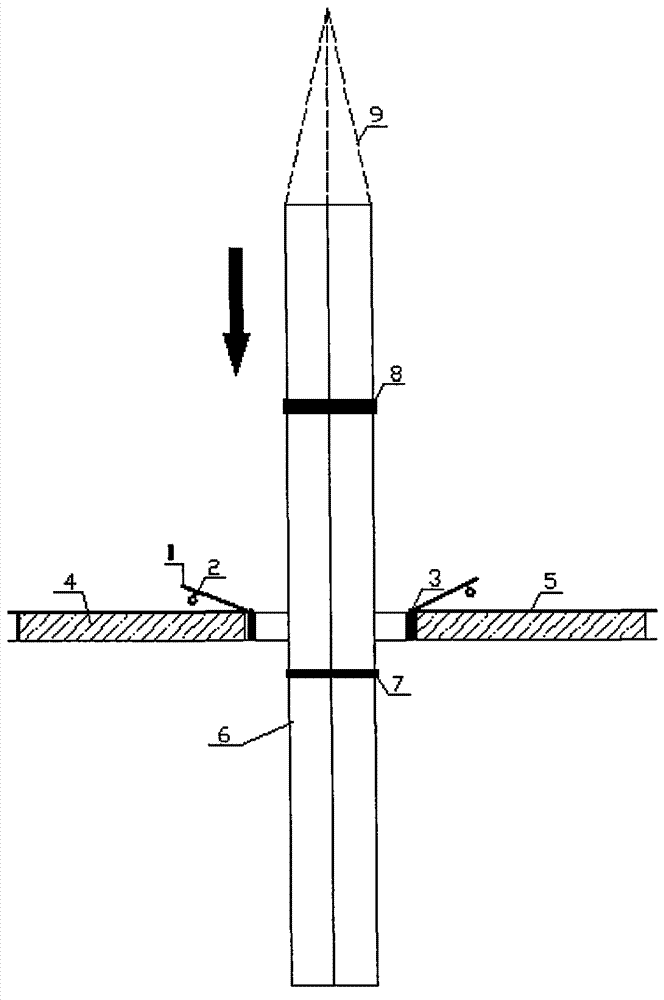

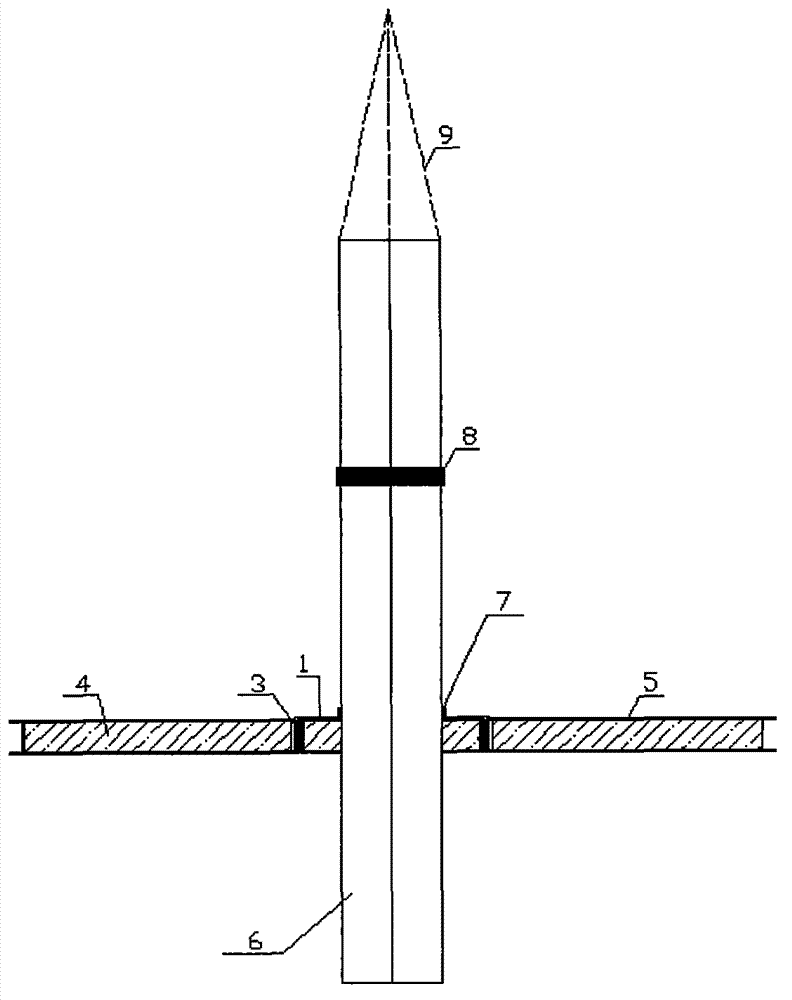

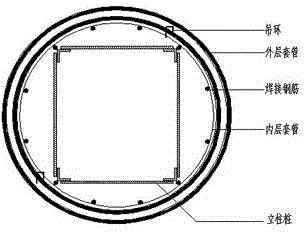

Double-casing-pipe full-circle-swinging erect column pile construction method

InactiveCN105274984AReduce torqueSolve the problem of elevation dropBulkheads/pilesTremieEngineering

The present invention discloses a double-casing-pipe full-circle-swinging erect column pile construction method. The method comprises the steps of positioning a pile machine, pressing an inner casing pipe dowards, forming holes in the inner casing pipe; cleaning up barriers, hanging and welding steel reinforcement cages, hanging latticed columns at the edge of an inner casing pipe tube, placing tremies, lifting out inner and outer casing pipes and backfilling with coarse sand. The construction method provided by the present invention is suitable for various complicated soil textures, is short in pile-forming time, and can solve the problem of lowering of top elevation of steel columns, the sinkage of the steel columns is controlled within an error allowable range, and the pile-forming quality is ensured.

Owner:ZHONGTIAN CONSTR GROUP

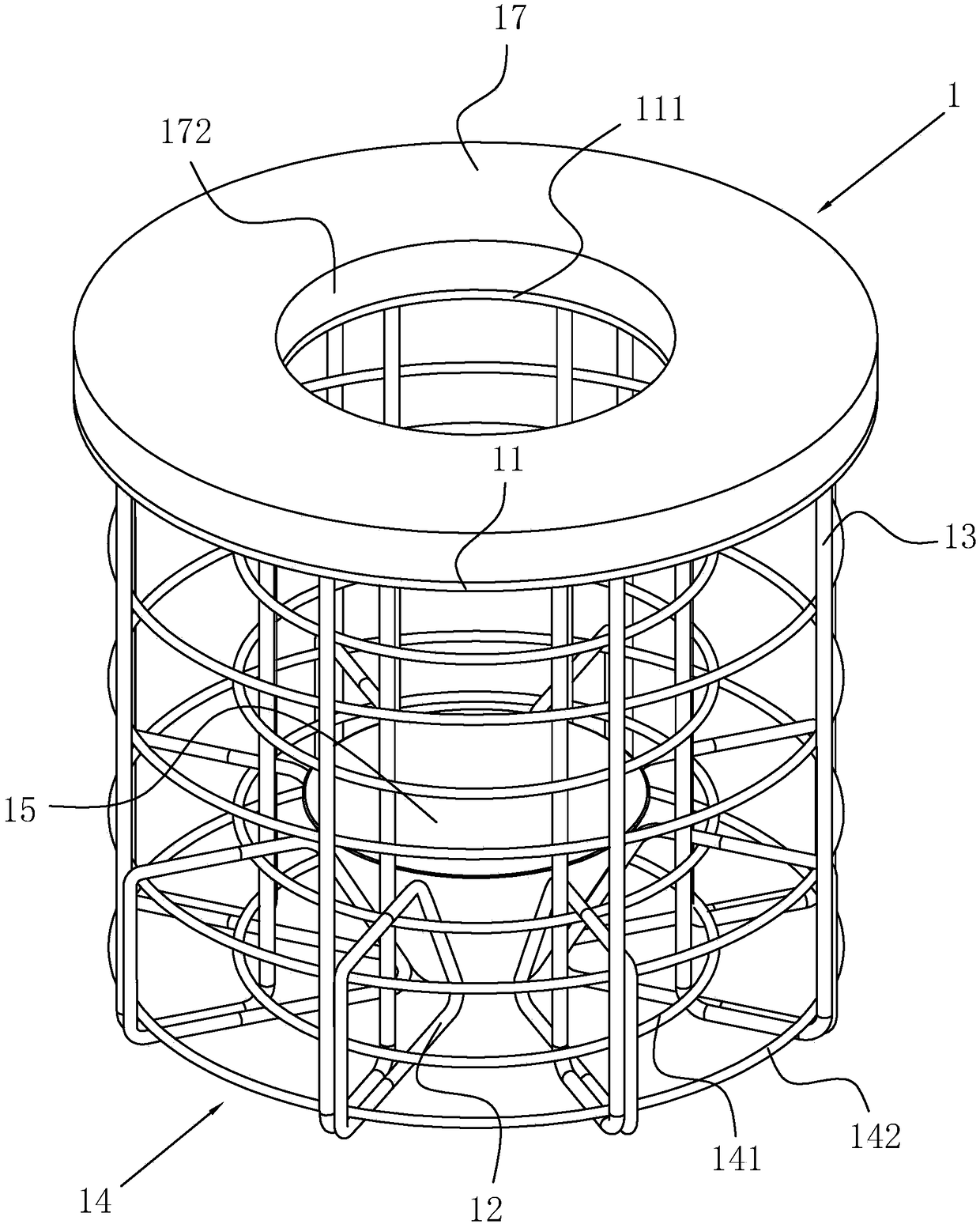

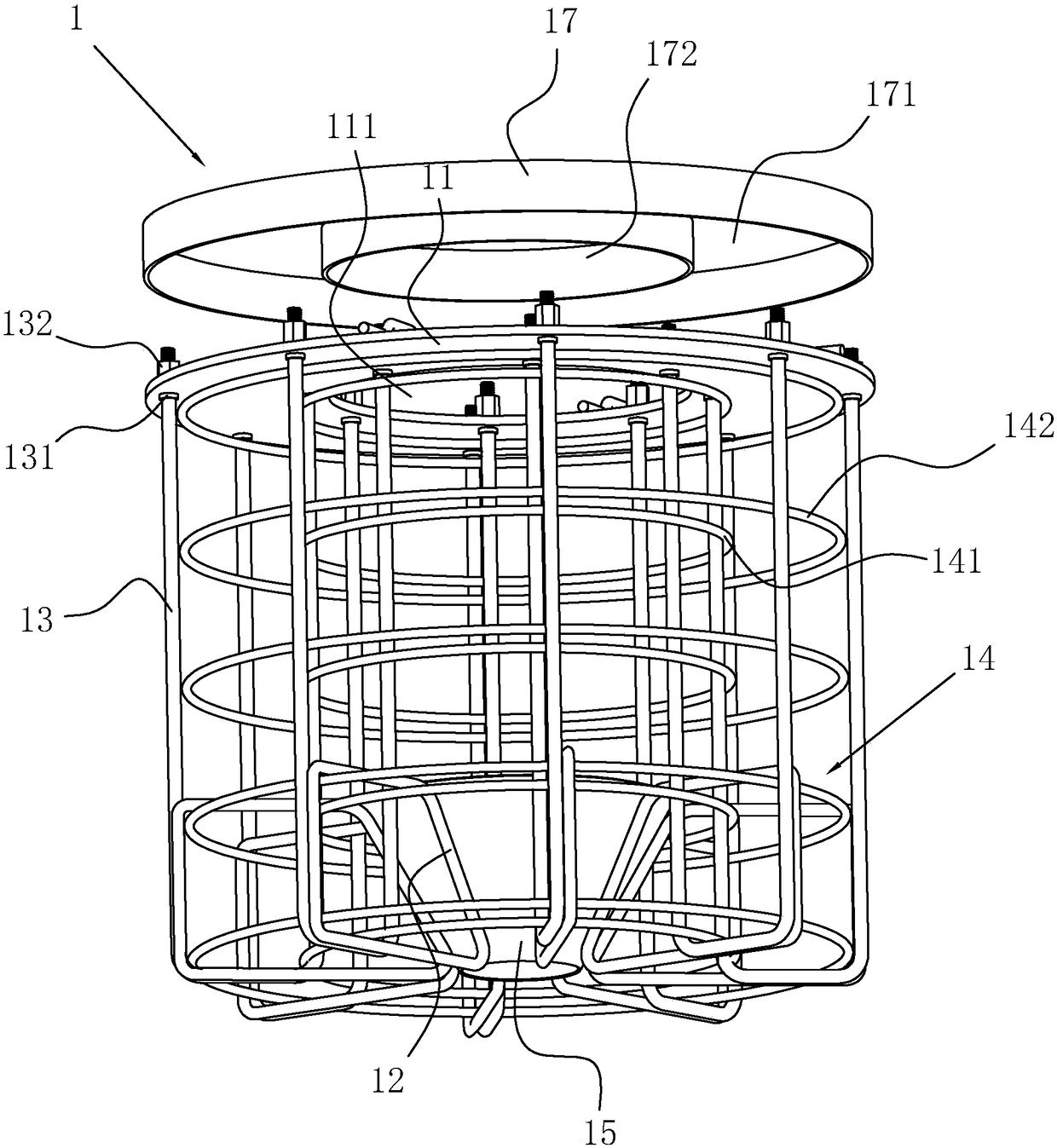

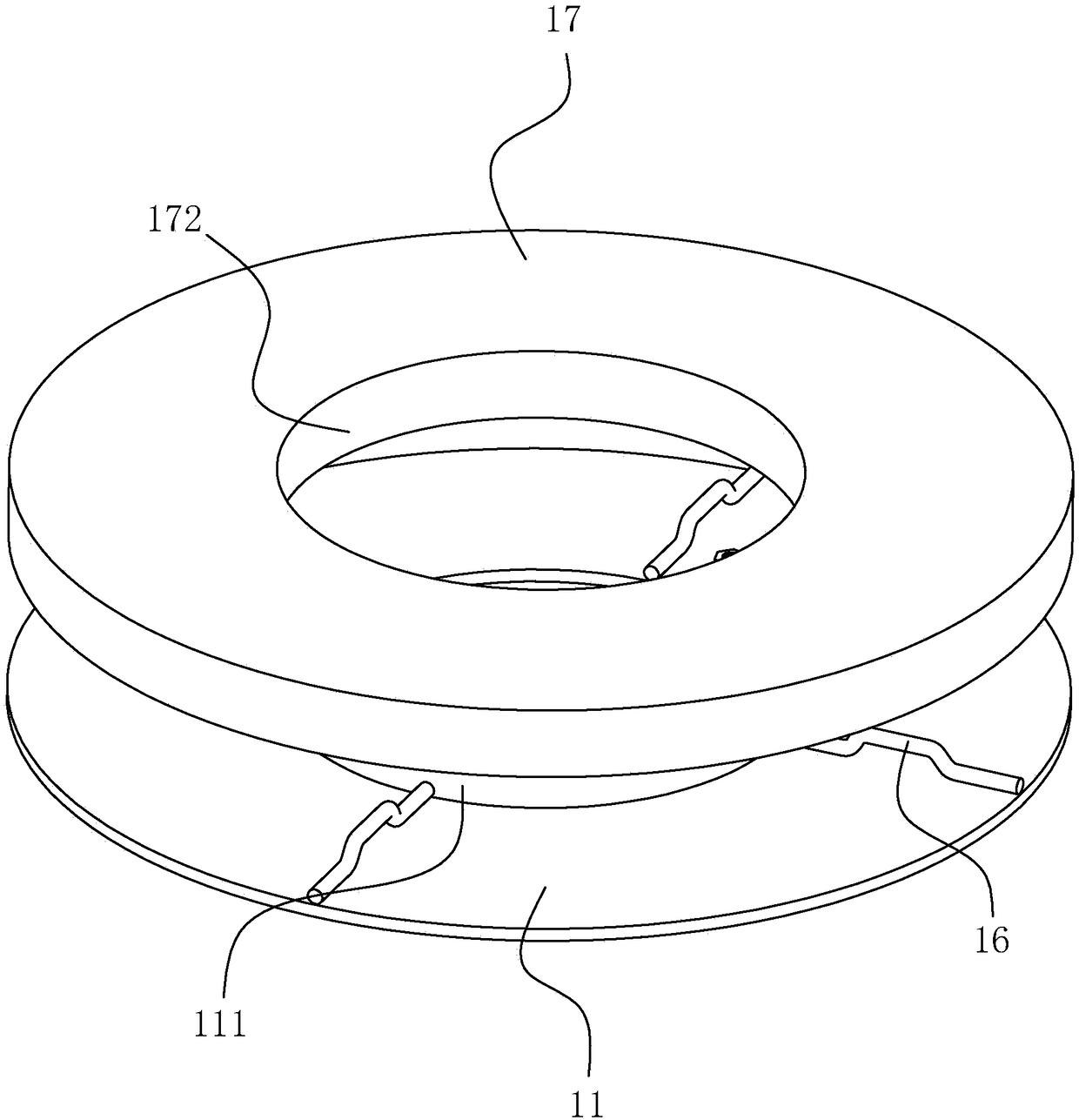

Medical crystallization kettle

InactiveCN106390509AEasy to achieve rotary condensation crystallizationHigh speedSolution crystallizationHeat exchange cooling cystallizationTremieCoupling

The invention discloses a medical crystallization kettle, relating to the technical field of medical appliances. The inside of the kettle body is provided with a crystallization chamber; the upper end of the crystallization chamber is provided with an upper penetration pipe; the upper end of the upper penetration pipe is mounted on the bottom of a mounting tank through a sealed bearing seat; the inside of the mounting tank is respectively provided with a raw material bin and a vacuum apparatus; a discharge pipe of the raw material bin is connected with a feed pipe inside the upper penetration pipe; a suction pipe of the vacuum apparatus is connected with a suction pipe inside the upper penetration pipe through a quick coupling; a lower penetration pipe penetrates through the lower end of the kettle body through a seal sleeve, and is provided with a master gear; the master gear meshes with a matched gear; the matched gear is mounted on the rotating shaft of a drive motor; and the inside of the lower penetration pipe is provide with a tremie pipe. The medical crystallization kettle can conveniently implement rotary condensation crystallization, has the advantages of high speed and time saving, and is convenient to use and simple to operate.

Owner:ZHENGZHOU TONGXIN CHUANGYUAN BIOLOGICAL SCI &TECH

Cementing casing in a large diameter mud drilled well

ActiveUS10494896B1High speedRemove excessive wall cake, heavy mudConstructionsCleaning apparatusTremieWell drilling

A method of cementing casing in a large diameter mud drilled well is shown. A drilling rig turns drill pipe with sufficient down pressure being applied to a drill bit to drill a large diameter borehole. Initially drilling mud flows down the annulus between the drill pipe and borehole, then back up the drill pipe. An air pressure line in the drill pipe creates a suction at the drill bit. Direction of flow of drilling mud is reversed when the drill pipe is replaced with casing. Cuttings and heavy mud are removed from the borehole by bi-directionally rotating a casing while reciprocating up and down near a bottom of the borehole. When the desired mud weight and viscosity is reached, mud flow is stopped and cement is applied through a tremie tube.

Owner:YOUNGQUIST BROS INC

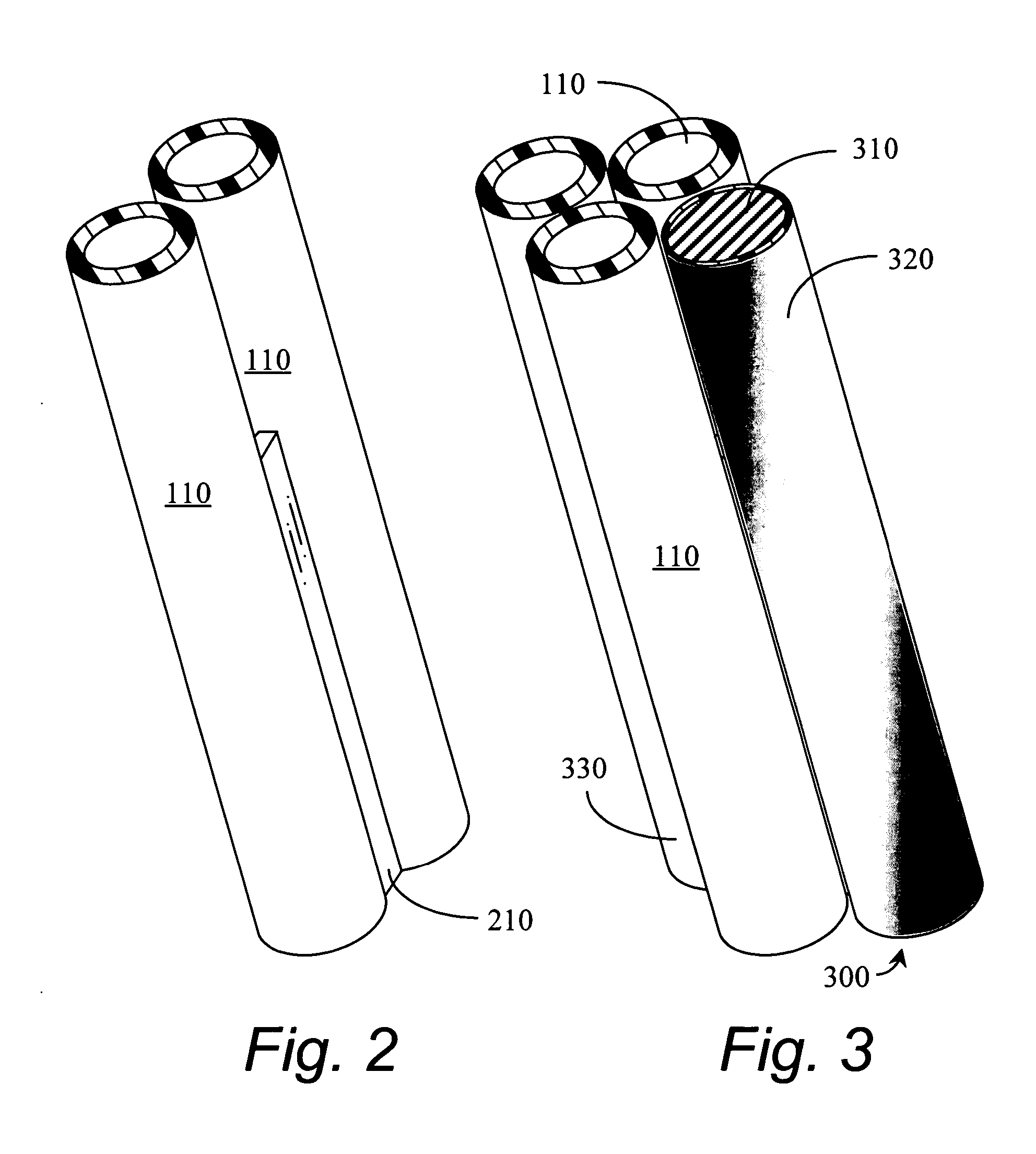

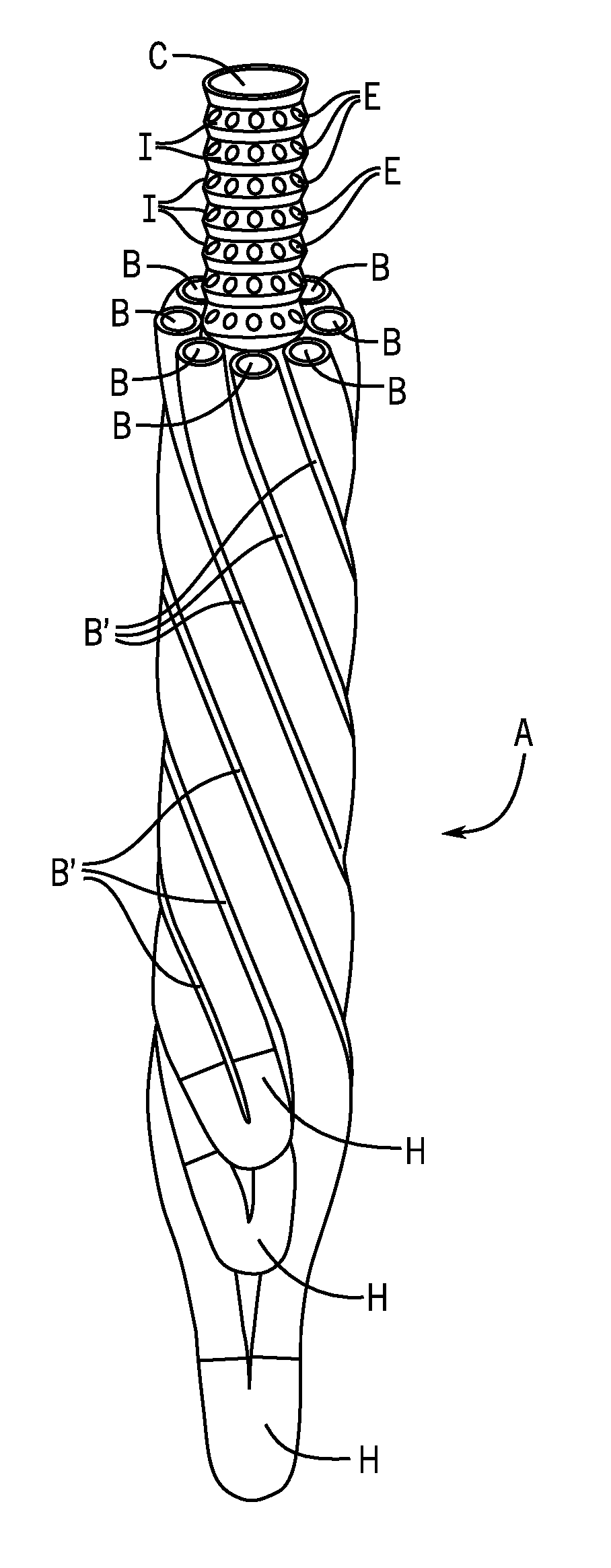

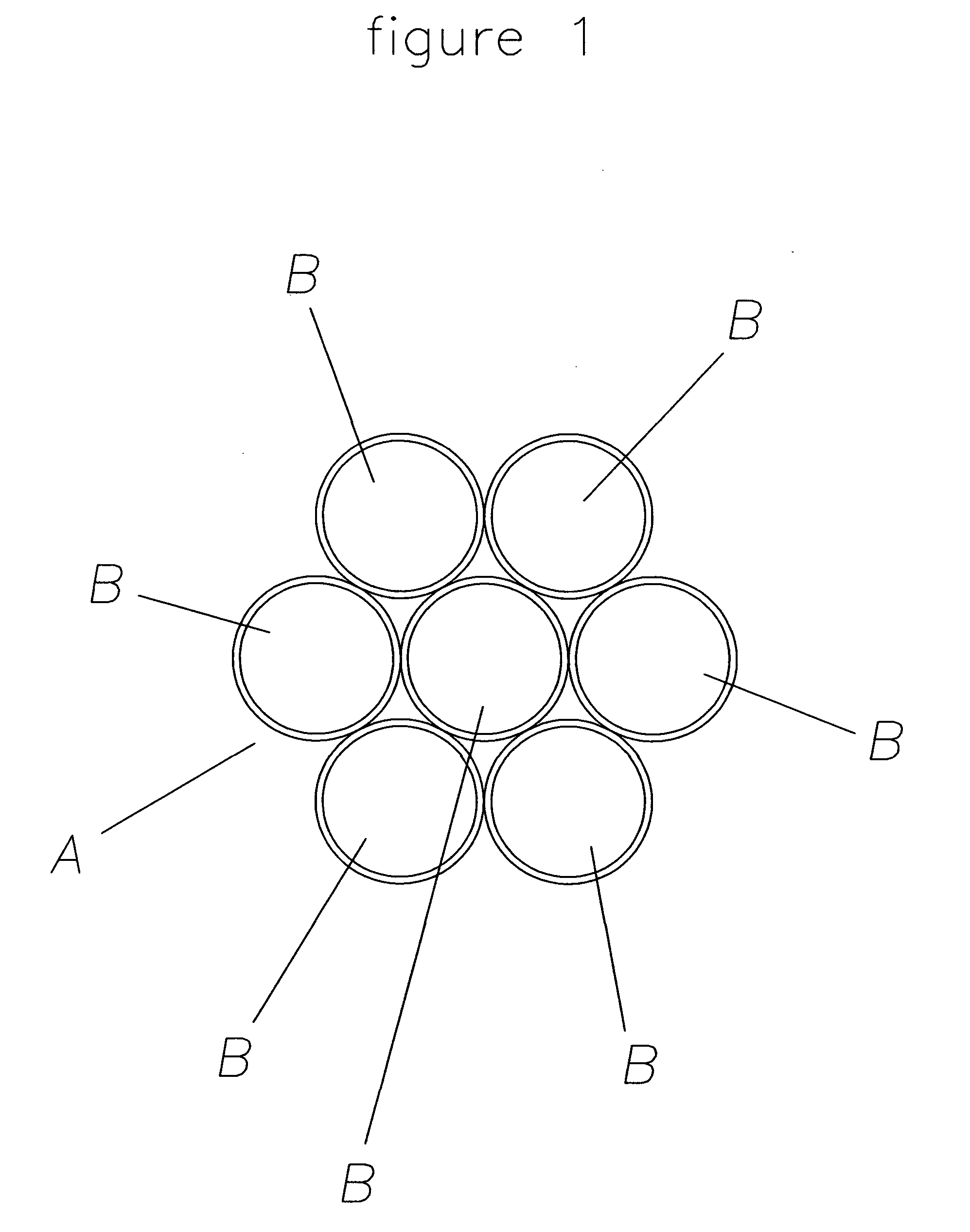

Twisted conduit for geothermal heating and cooling systems

The present invention relates to a conduit for use in a geothermal heating and cooling system wherein said conduit comprises 2 or more pipes, wherein said 2 or more pipes are twisted together, wherein further that said 2 or more twisted pipes are twisted around a central pipe, further provided that the functions of said central pipe include, but are not limited to, serving as a conduit for a tremie pipe, serving as a support pipe, serving as an insulating pipe or serving as a tremie pipe.

Owner:JENSEN ROBERT

Pile head breaking and cutting device for bridge cast-in-place pile and using method

The invention provides a pile head breaking and cutting device for a bridge cast-in-place pile, and relates to the field of cast-in-place piles. The device comprises a breaking and cutting device body, wherein the breaking and cutting device body comprises a cover plate which is arranged in a disc shape, a plurality of vertically-arranged breaking ribs are arranged at the bottom end of the cover plate around the axis of the cover plate at intervals, and the breaking ribs are arranged in a frame structure. The invention further provides a using method of the pile head breaking and cutting device for the bridge cast-in-place pile. The using method comprises the following steps that S1, the breaking and cutting device body is coaxially placed at the top end of a reinforcement cage; S2, the cast-in-place pile is cast by adopting a tremie method; S3, when concrete is initially set, a protecting cover is taken off, and a lifting device is used for pulling lifting ribs to enable the whole breaking and cutting device body to be pulled away from the cast-in-place pile; and S4, when the concrete is finally set, a pile head is broken from an initial position of the breaking and cutting devicebody. The device and the method aim to solve the problems that in the prior art, the pipe head of the cast-in-place pile is difficult to break, and the cost is relatively high. According to the device and the method, the breaking and cutting device body arranged at the top of the reinforcement cage is taken out when the concrete is initially set, so that the strength of the pile head is reduced,the construction personnel can conveniently break down the pile head, and the cost is reduced.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

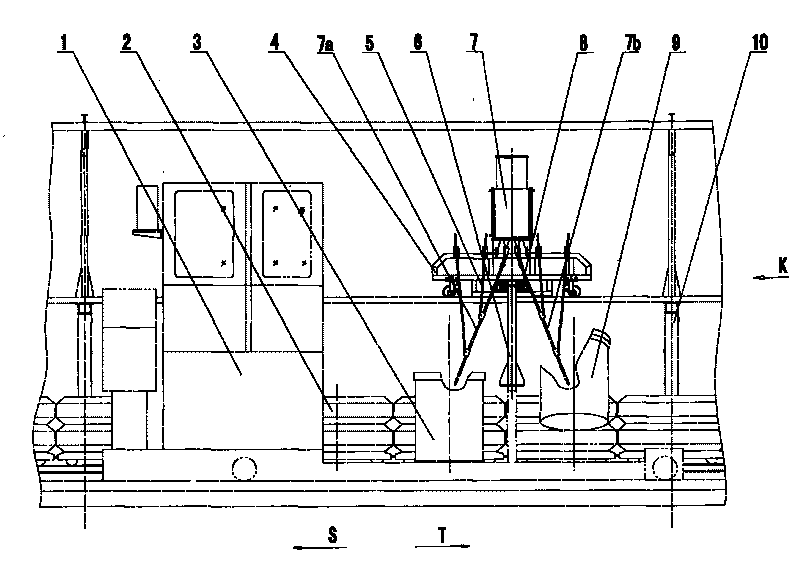

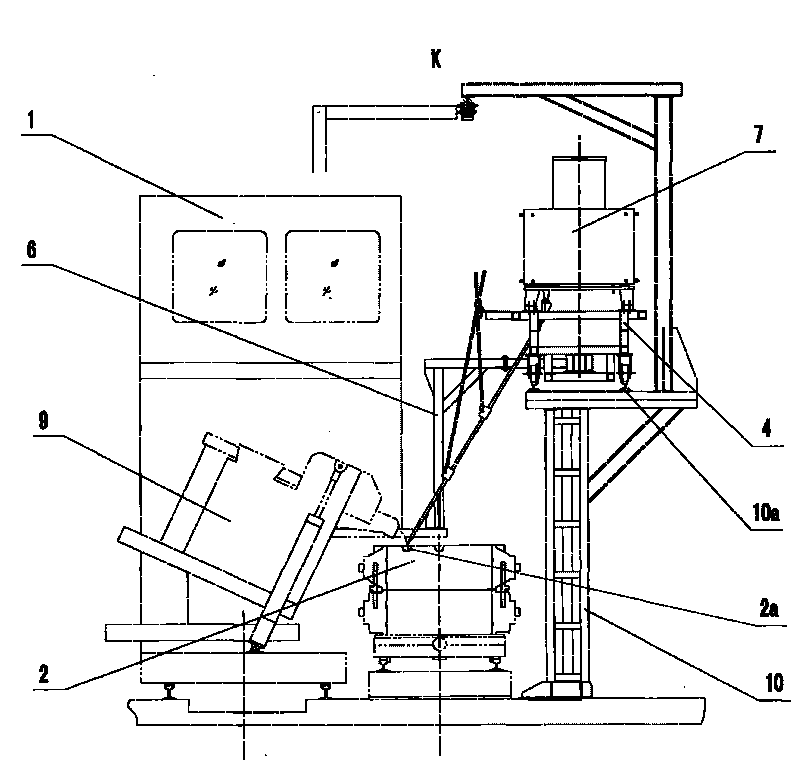

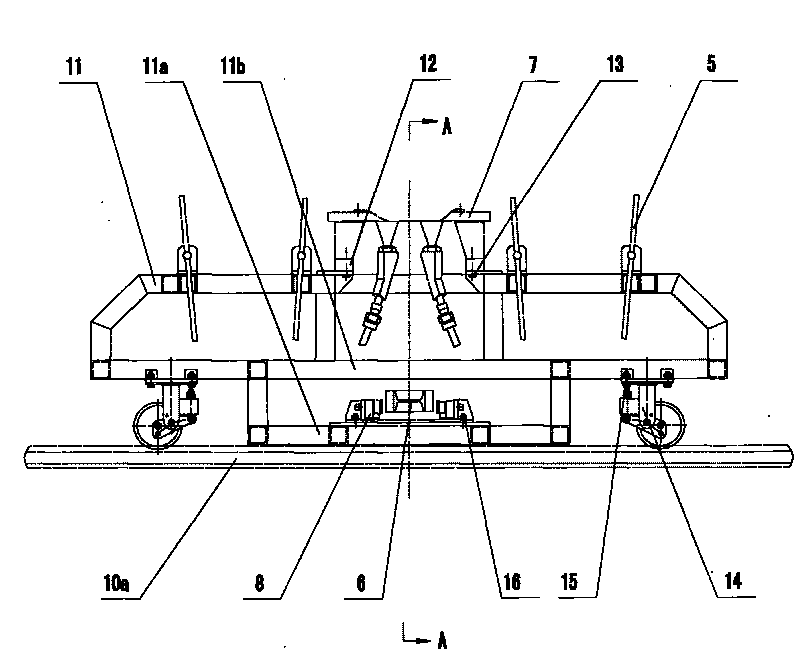

Method for configuring double-tube metal-stream inoculation device on double-station tilting type casting machine

InactiveCN101745609AAvoid the impact of work performanceSatisfy the needs of breeding with the flowDouble tubeTremie

The invention discloses a method for configuring double-tube metal-stream inoculation device on double-station tilting type casting machine, which belongs to the field of machinofacture. A double-tube metal-stream inoculation device (7) is arranged on the upper part of a damping trolley (4); the outlets of a tremie pipe (7a) and another tremie pipe (7b) are correspondingly arranged on the pouring gates (2a) of the sand boxes (2) approaching to a first casting station and a second casting station on the double-station tilting type casting machine; the bottom part at one end of a reversely 'L'-shaped shifting fork component is fixedly connected with a supportable part on the casting machine; a cantilever at the other end stretches into the body framework of the damping trolley (4); the method for configuring double-tube metal-stream inoculation device on double-station tilting type casting machine can effectively solve the problems of site installation of the double-tube metal-stream inoculation device as well as moving together with the casting machine; but also can solve the problem of vibration distribution brought by running of the casting machine, tilling casting of pouring ladle as well as unfairness and uncleanness of running orbital plane, and can meet the demand of implementing metal-stream inoculation on the casting machine.

Owner:CHINA YITUO GROUP

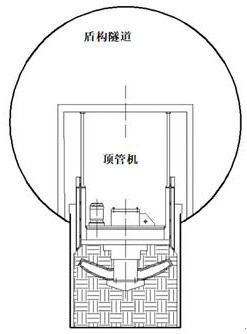

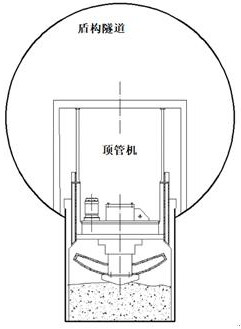

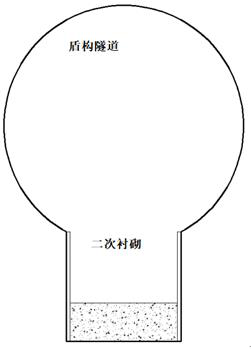

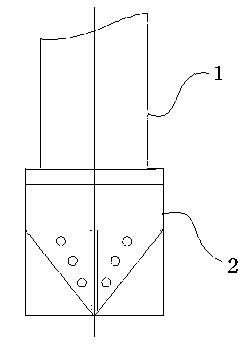

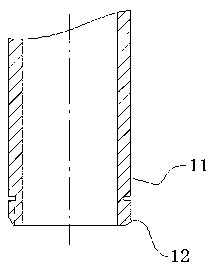

Vertical shaft bottom sealing method for mechanized construction in tunnel

ActiveCN112228091AReduce in quantitySolve the problem of high water pressure in deep ground and difficult bottom sealingUnderground chambersTunnel liningTremieArchitectural engineering

The invention discloses a vertical shaft bottom sealing method for mechanized construction in a tunnel, and belongs to the technical field of tunnel vertical shaft bottom sealing construction. After apipe jacking machine in a vertical shaft carries out tunneling to a set depth, concrete is poured into the front of a cutterhead through a concrete guide pipe pre-arranged on a cutterhead center shaft on the pipe jacking machine, concrete is poured, meanwhile, the cutterhead is withdrawn before rotating, the withdrawing speed of the cutterhead is matched with the amount of poured concrete, and itis guaranteed that underground water does not destroy a mud film and rushes into a mud water bin of the pipe jacking machine; and the vertical shaft is constructed through a mechanical method, underground resources can be effectively saved, construction is completed in narrow working space, the lowest point of a tunnel longitudinal slope does not need to be considered for contact channels, setting can be achieved according to the maximum interval of specification requirements, and the number of the contact channels is reduced. In addition, the bottom sealing method can solve the problems thatdeep underground water pressure is large and bottom sealing is difficult, and guarantees are provided for construction of a built-in pump house.

Owner:BCEG CIVIL ENG

Screw-on disposable underwater concrete conduit head

InactiveCN103195065ASolving Perfusion Quality ChallengesEasy to processFoundation engineeringTremieScrew thread

A screw-on disposable underwater concrete conduit head comprises a section of special conduit (1) and a steel tapered conduit head (2), and the steel tapered conduit head (2) can be in threaded connection with the special conduit. The upper portion of the special conduit is identical to an existing tremie concrete conduit in diameter, and the end of the lower portion of the conduit is provided with an external thread. The tapered conduit head is a steel structure component with a cylindrical upper portion and a conical lower portion, an inner ring of the upper cylindrical structure is provided with an internal thread, matched with the conduit end, of the tapered conduit head, 3-4 steel plate blades are uniformly distributed on the outer periphery of a conduit head cone along a cone bus, and an air hole is drilled at the conical position of the conduit head. The screw-on disposable underwater concrete conduit head solves the problem that underwater concrete pouring quality is affected severely due to the fact that faults in an underwater concrete pouring process occur for a long time or cannot be processed after occurred, and also solves the special process problems of probability that conduits need to be added during construction and the like, and is applicable to tremie concrete.

Owner:EAST CHINA JIAOTONG UNIVERSITY

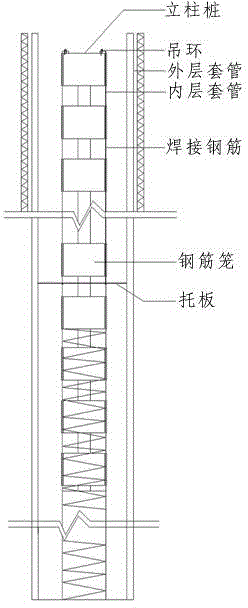

Double-casing-pipe double-drive full-rotation type pile forming device and technology

InactiveCN111749231AMeet the construction depthSimple on-site construction workDrilling rodsDrilling casingsTremieKarst

The invention discloses a double-casing-pipe double-drive full-rotation type pile forming device. A double-casing-pipe double-drive full-rotation drilling machine, an upper clamp sheet, a lower clampsheet, an outer casing pipe, an inner casing pipe and a steel bar cage are included. The lower clamp sheet and the outer casing pipe are connected together, the outer casing pipe can be downwards pressed to penetrate through a refilling layer through forward rotation, and the outer casing pipe can be pulled out of the refilling layer through reverse rotation. The upper clamp sheet and the inner casing pipe are connected together, the inner casing pipe can be downwards pressed to penetrate through strong weathered rock and a karst cave to enter a bearing stratum moderately-weathered limestone layer through forward rotation, and the inner casing pipe can be pulled out through reverse rotation. The steel bar cage is arranged at the middle positions of the outer casing pipe and the inner casing pipe, a concrete guide pipe is arranged at the middle position of the steel bar cage and can be lowered and hoisted along the center position of the steel bar cage, and a funnel is fixedly connectedto the upper end of the concrete guide pipe. By means of the double-casing-pipe double-drive full-rotation type pile forming device, the ultra-long pile construction depth can be achieved, the hole forming efficiency can be greatly improved, the hole forming depth can reach 120 m, and the problems that in deep refilling layer karst development areas and other complex stratums, the pile length islimited, and the pile forming efficiency is too low are solved.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com