Patents

Literature

201results about How to "Guarantee the pile quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

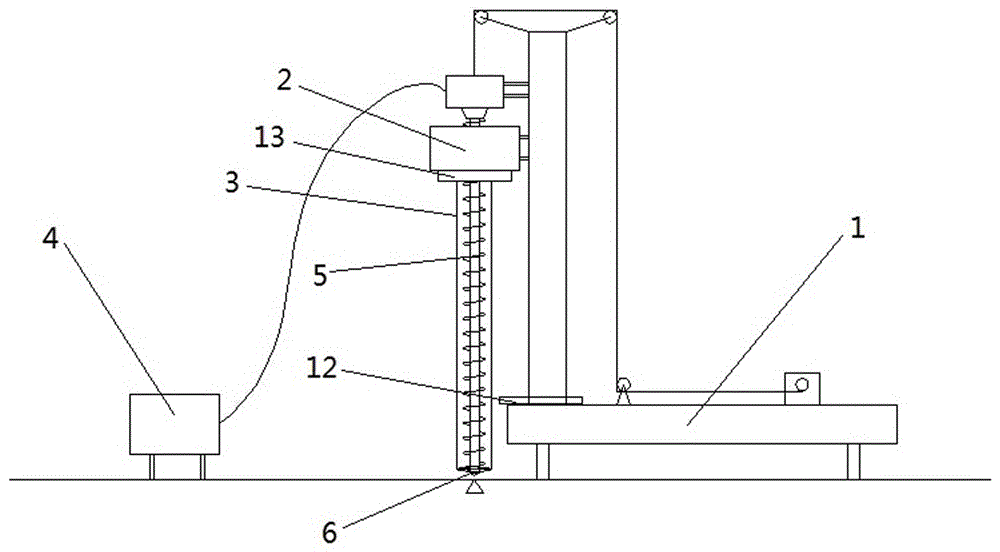

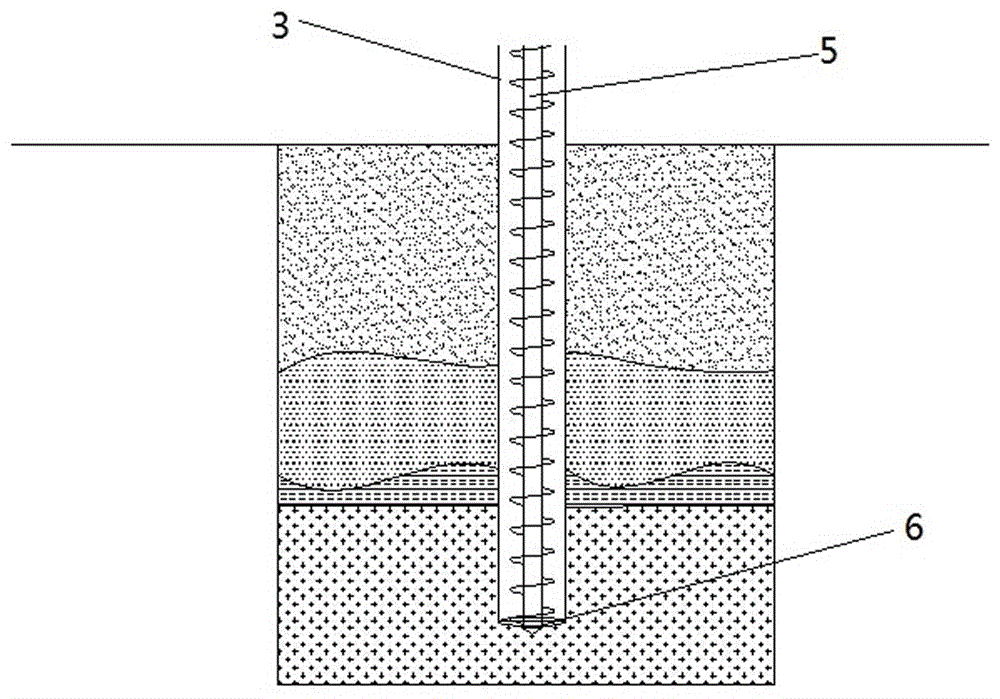

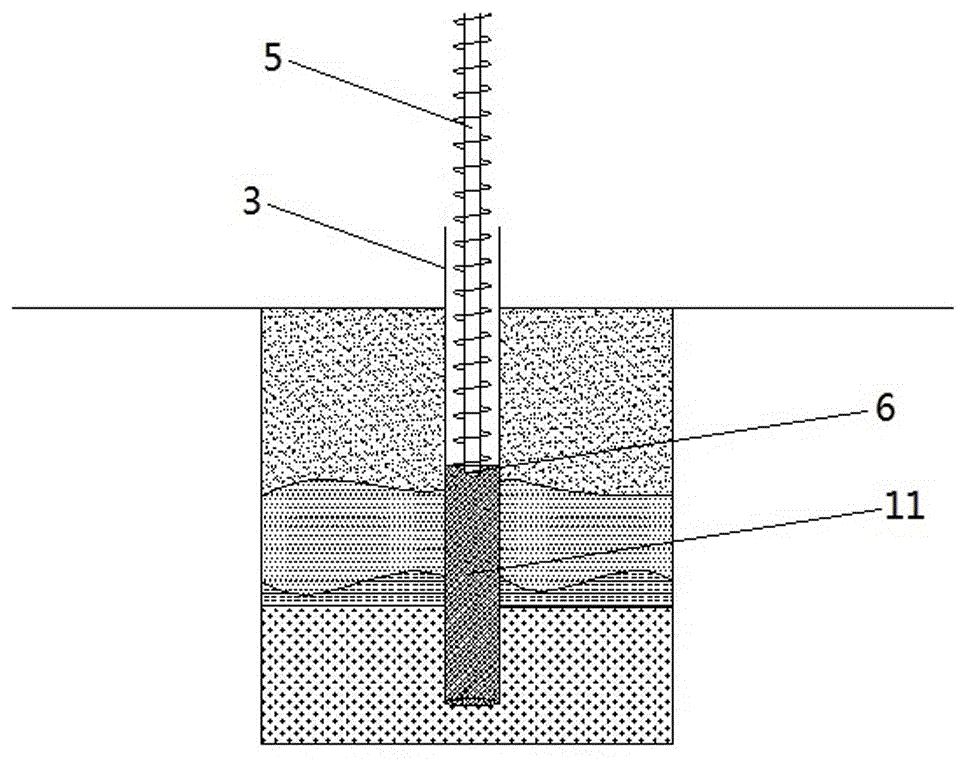

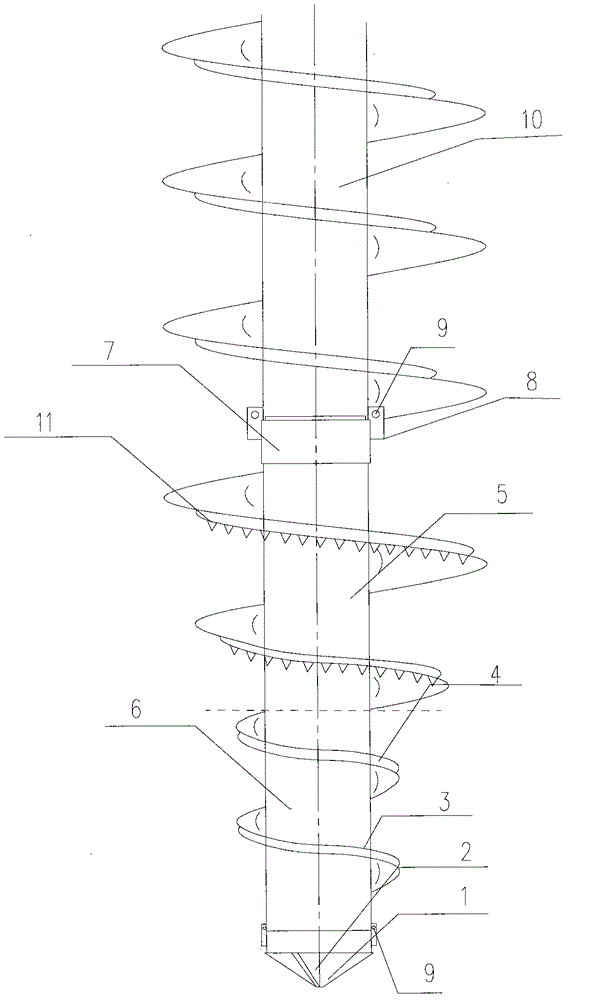

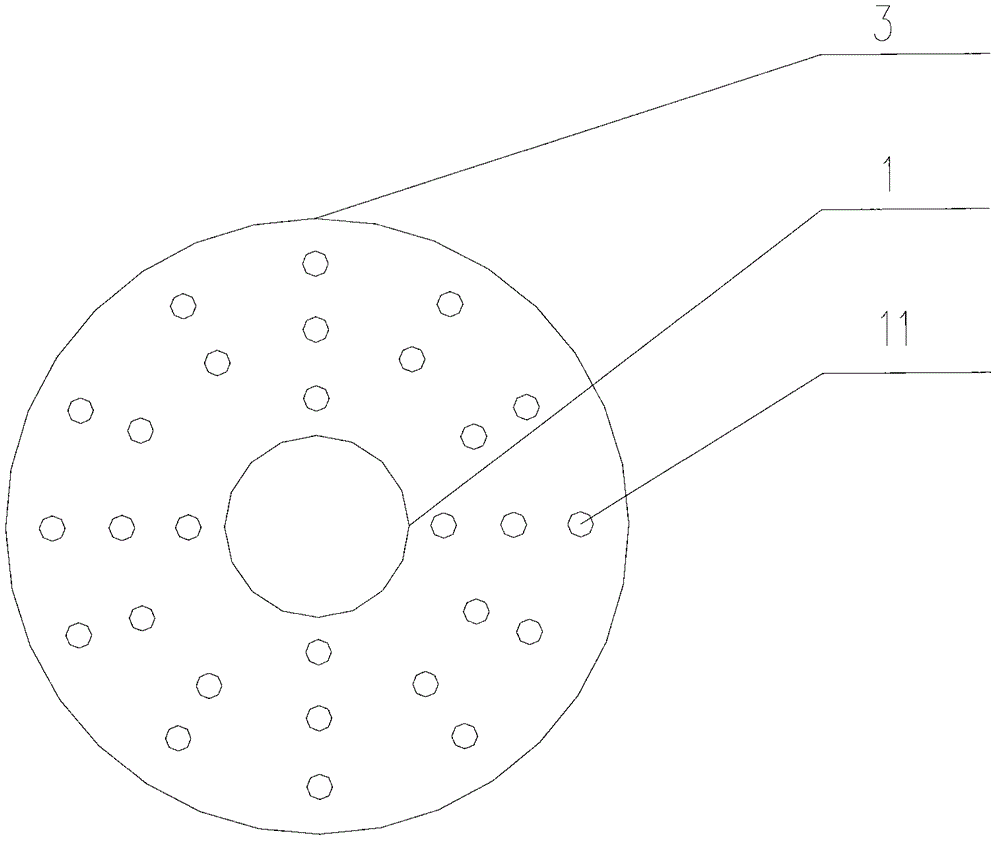

Molding device and molding method for long spiral extruding rock-entering cast-in-place pile

ActiveCN102535445AReasonable structural designEasy to operateDrill bitsDrilling rodsDevice formForming processes

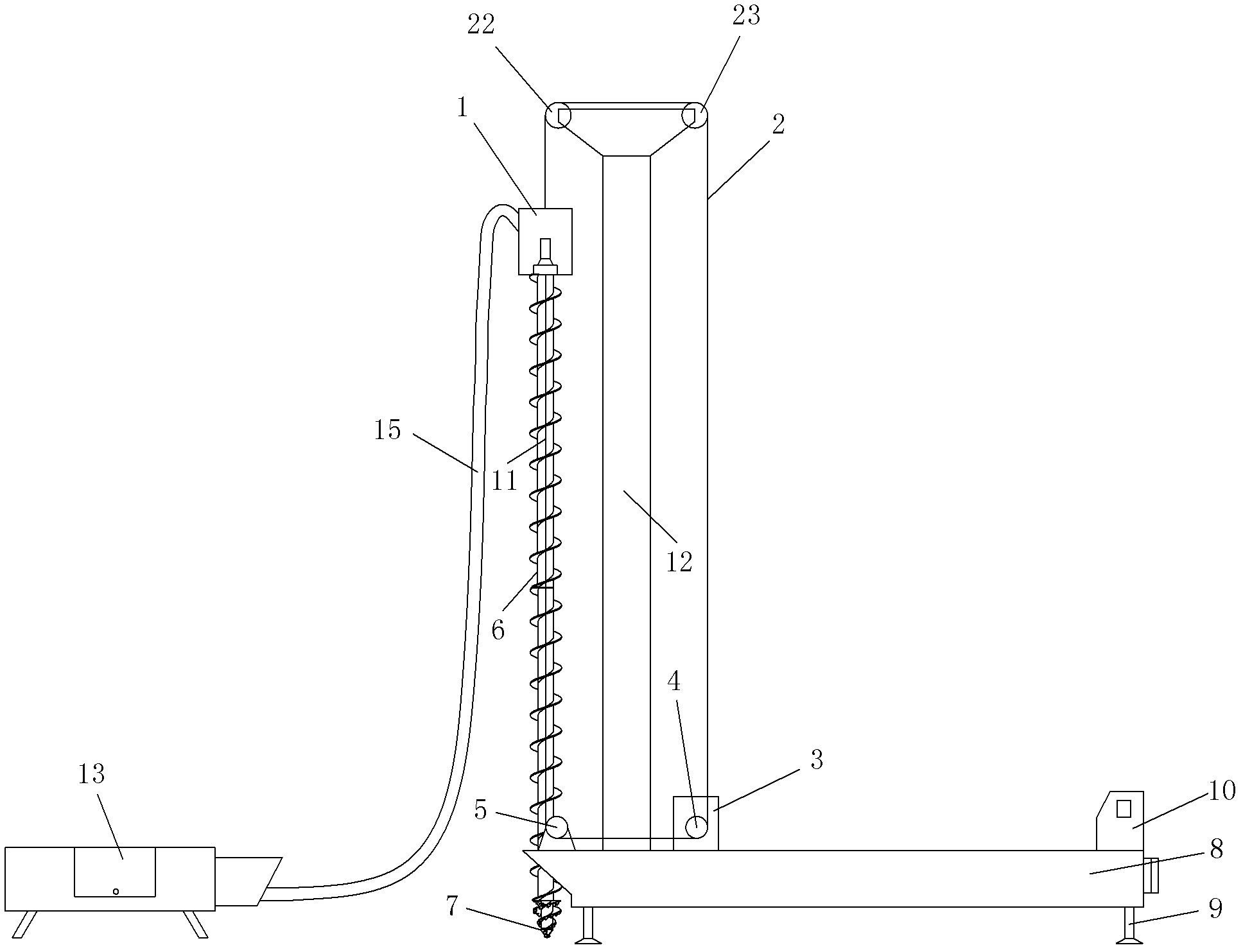

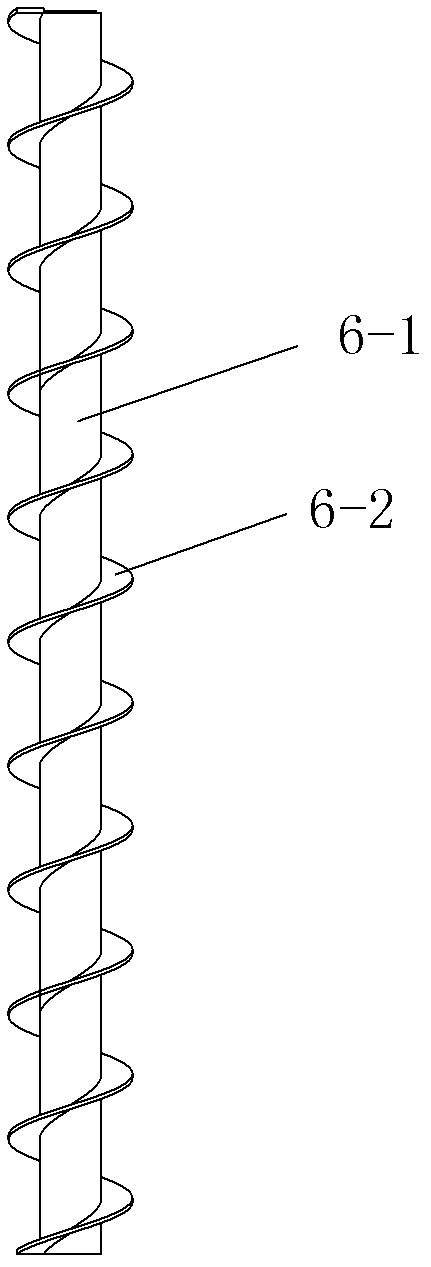

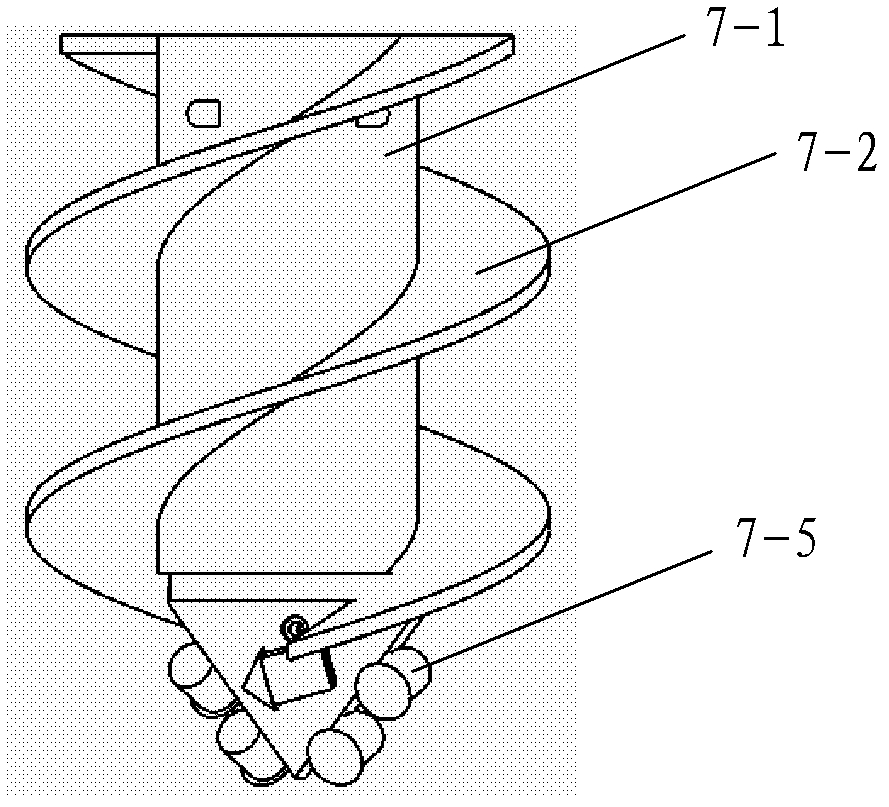

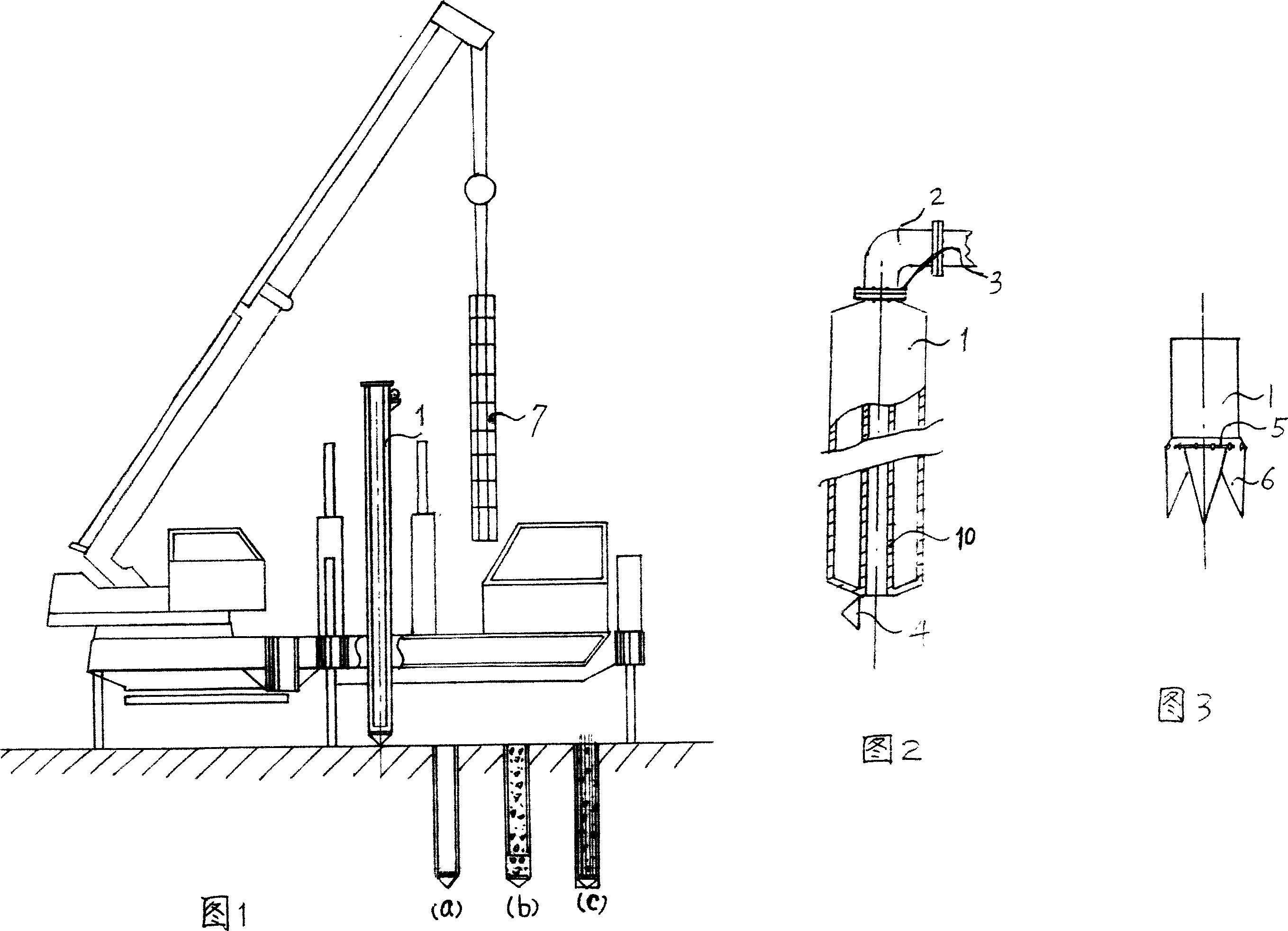

The invention discloses a molding device and a molding method for a long spiral extruding rock-entering cast-in-place pile. The molding device comprises a drilling device formed by assembling a drill stem and a drill arranged at the bottom of the drill stem coaxially, a lowering / lifting system, an electric rotating driving mechanism for driving the drilling device to rotate continuously, a slip casting device for grouting casting slip into molded drill holes continuously to form bored piles when the lowering / lifting system lifts the drill stem, a drilling depth / lifting height detecting unit, a pumping flow detecting unit, a controller and a parameter input unit connected with the controller. The molding method includes: 1 setting initial parameters; 2 drilling; 3 further processing after drilling is in place; and 4 lifting the drill and slip-casting simultaneously. The molding device and the molding method are reasonable in design, easy to use and operate, high in automation, easy in molding process, easy in controlling of pile quality, wide in application range and capable of solving a plurality of problems in the existing molding devices and molding methods for the long spiral extruding rock-entering cast-in-place pile.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

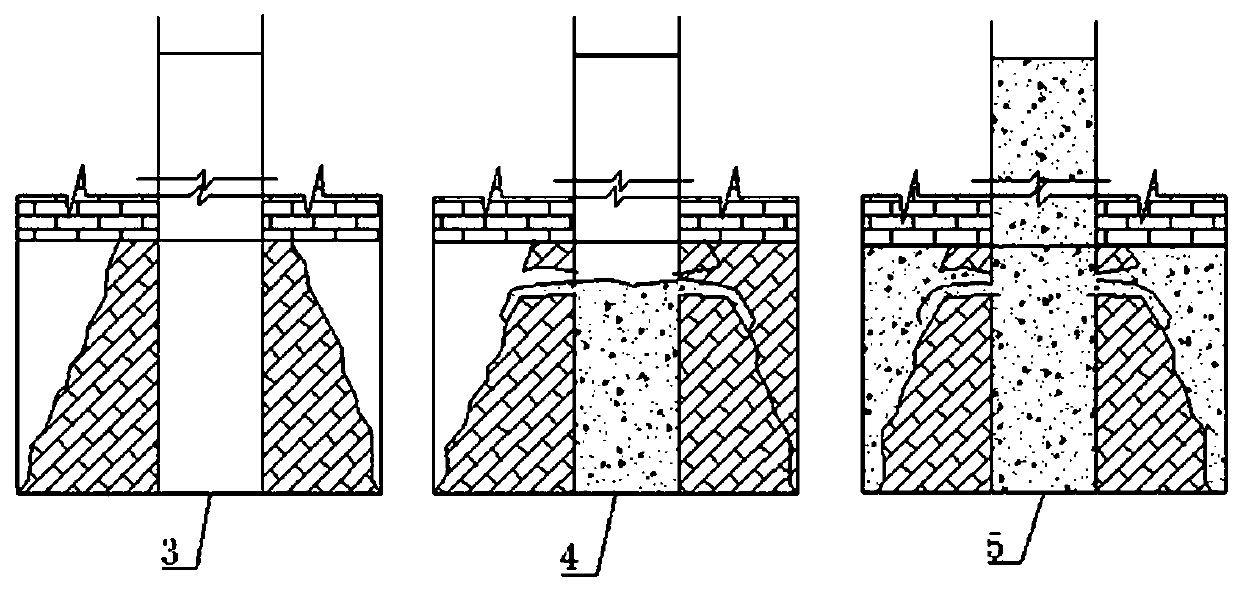

Construction method of pile foundations of bridge karst caves in karst area

ActiveCN110230309ASafe and effective constructionAccelerate the progress of hole formingBridge erection/assemblyBulkheads/pilesPunchingKarst

The invention discloses a construction method of pile foundations of bridge karst caves in a karst area. The construction method comprises the following steps: punching and karst cave treatment are conducted, and punching and karst cave treatment are carried out repeatedly till holes are formed finally; and karst cave treatment specifically comprises the steps of type identification and treating methods, wherein type identification is that before drilling starting, in the process of drilling and in the process of pouring, the types of the karst caves are judged according to the vertical depthand whether fillers exist or not, and the treating methods comprise pretreatment before construction, treatment during drilling and treatment in the process of concrete pouring. The different treatingmethods are adopted for the different karst caves, thus construction of the pile foundations of the karst caves is safer and more effective, and the purposes of accelerating the hole forming progress, ensuring the pile forming quality and saving the construction cost are achieved.

Owner:中建新疆建工土木工程有限公司

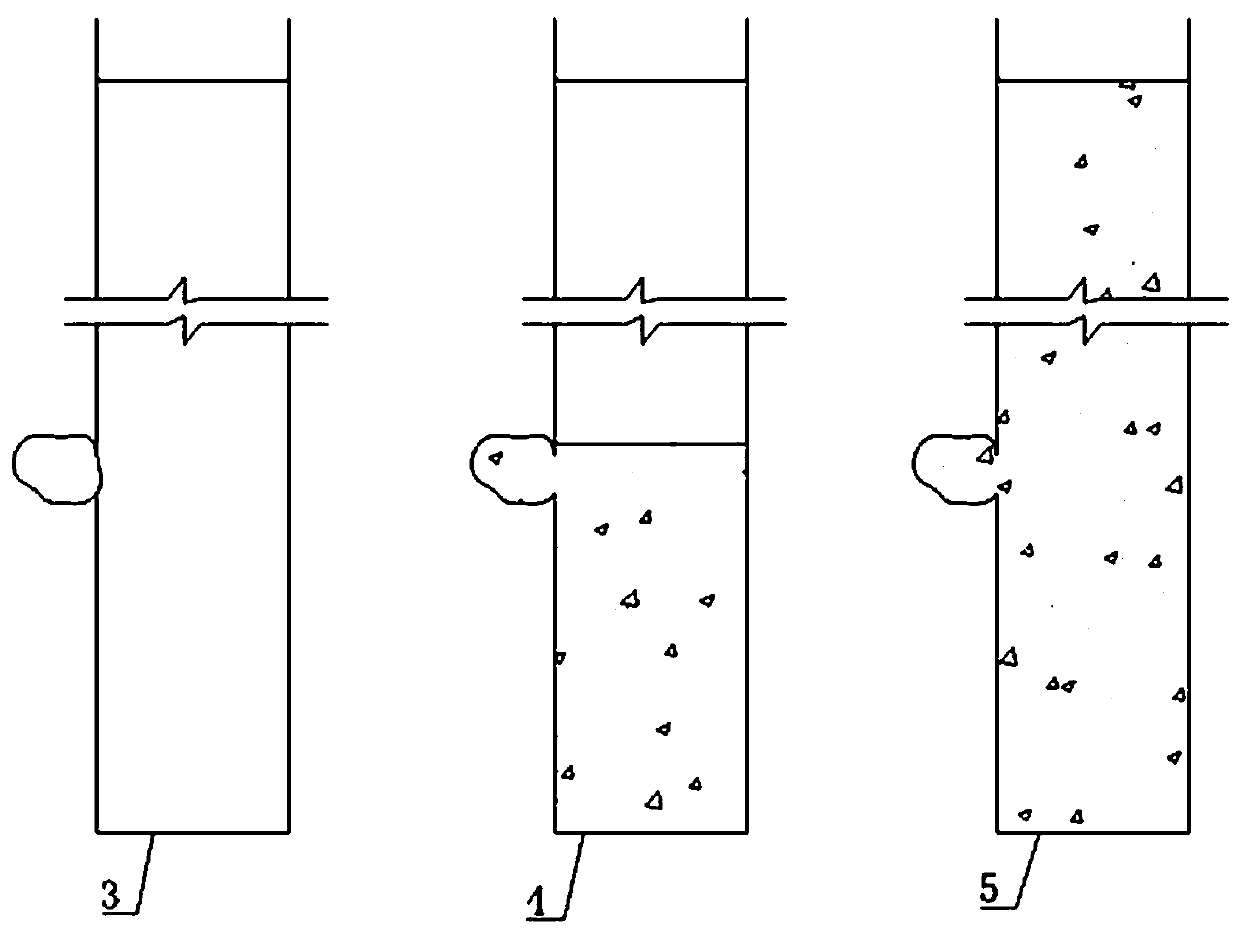

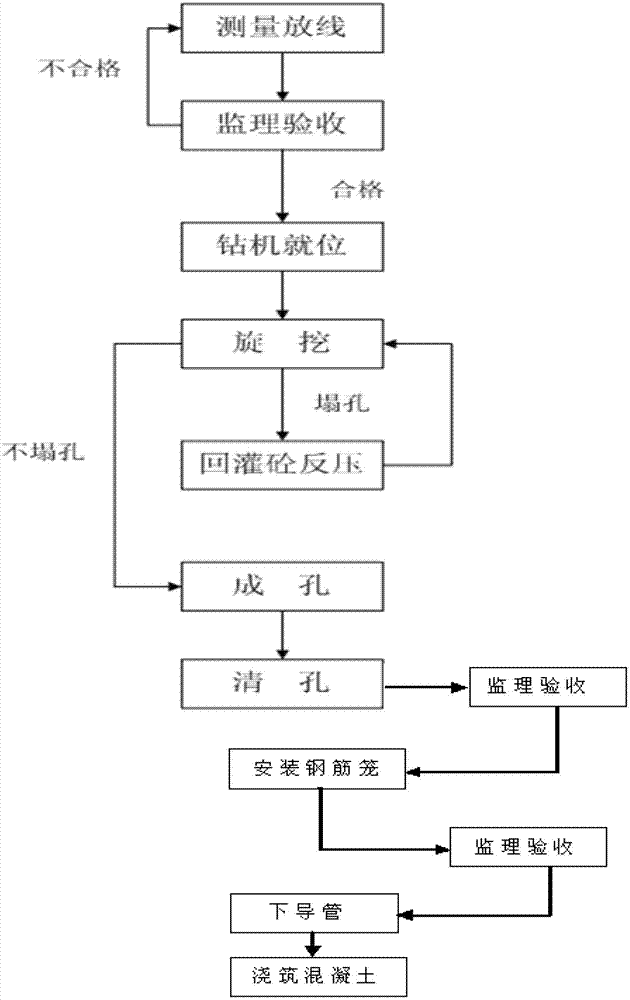

Large-diameter rotary digging pile construction technology for ultra-deep dumped unconsolidated soil bodies

ActiveCN102758430ASolve the pile problemSimple structureDirectional drillingBulkheads/pilesCounter pressureLower grade

The invention discloses a large-diameter rotary digging pile construction technology for ultra-deep dumped unconsolidated soil bodies, wherein low grade concrete is reinjected in a hole collapse section for countering pressure in the rotary digging pile construction process, so that the collapse of soil bodies around a pile hole is prevented; after the concrete is finally solidified and reaches a certain strength, the peripheral soil bodies are solidified, and a rotary digging operation is carried out in site for excavating soil, so that the reinjected concrete forms a protective wall; and the operations are carried out in circles till the hole is formed. The large-diameter rotary digging pile construction technology disclosed by the invention is a construction technology capable of carrying out large-diameter rotary digging pile construction on the unconsolidated soil bodies.

Owner:中建五局第三建设有限公司 +1

Construction method of ultra-long bored concrete pile with large-diameter casing combination

ActiveCN103603342AIncrease the number of reusesReduce frictionBulkheads/pilesGuide tubeFriction force

The invention relates to a construction method of an ultra-long bored concrete pile with large-diameter casing combination. Construction of bore forming of a pile foundation is completed by means of combination of multiple casings; the gap between every two steel casings is backfilled by sand; a reinforcement cage is hung in the most inside steel casing; concrete pouring is completed section by section through guide ducts; the most inside steel casing is pulled out after concrete pouring of the pile body is completed; then, other steel casings are pulled out so that construction of the bored concrete pile is completed. By the construction method, problems such as drilling difficulty, severe abrasion of the steel casings, proneness of pipe burying and pile breakage which are caused by overhigh friction force between the steel casings and the surrounding soil can be solved. The construction method has the advantages of deep bore, high speed, guaranteed construction quality and the like.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

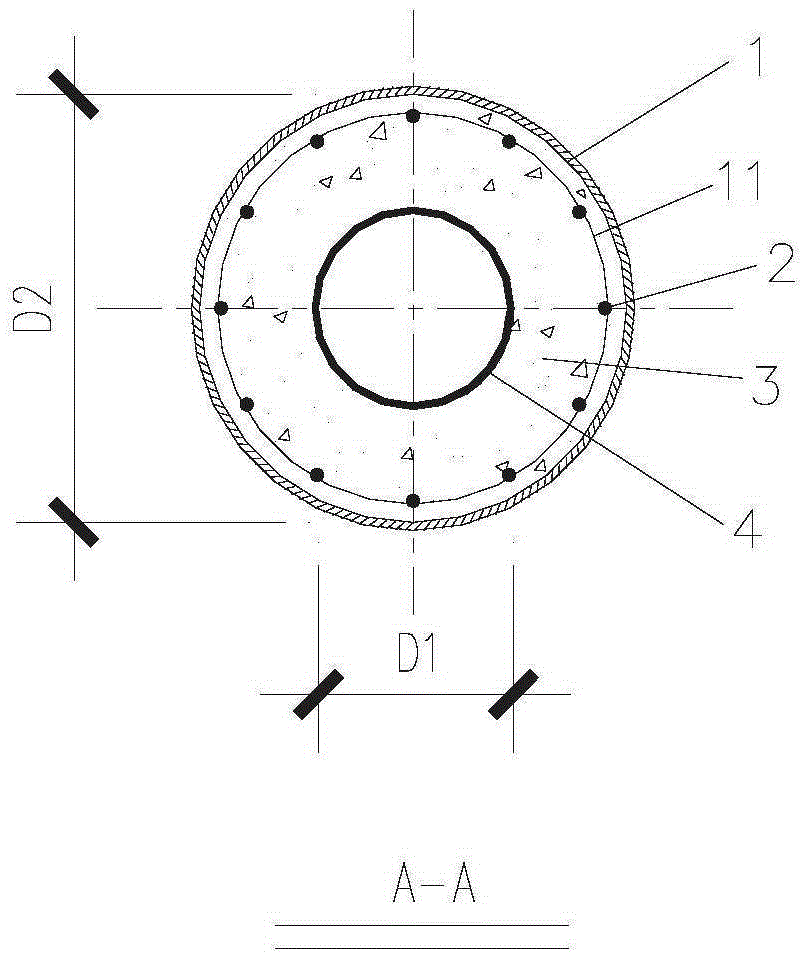

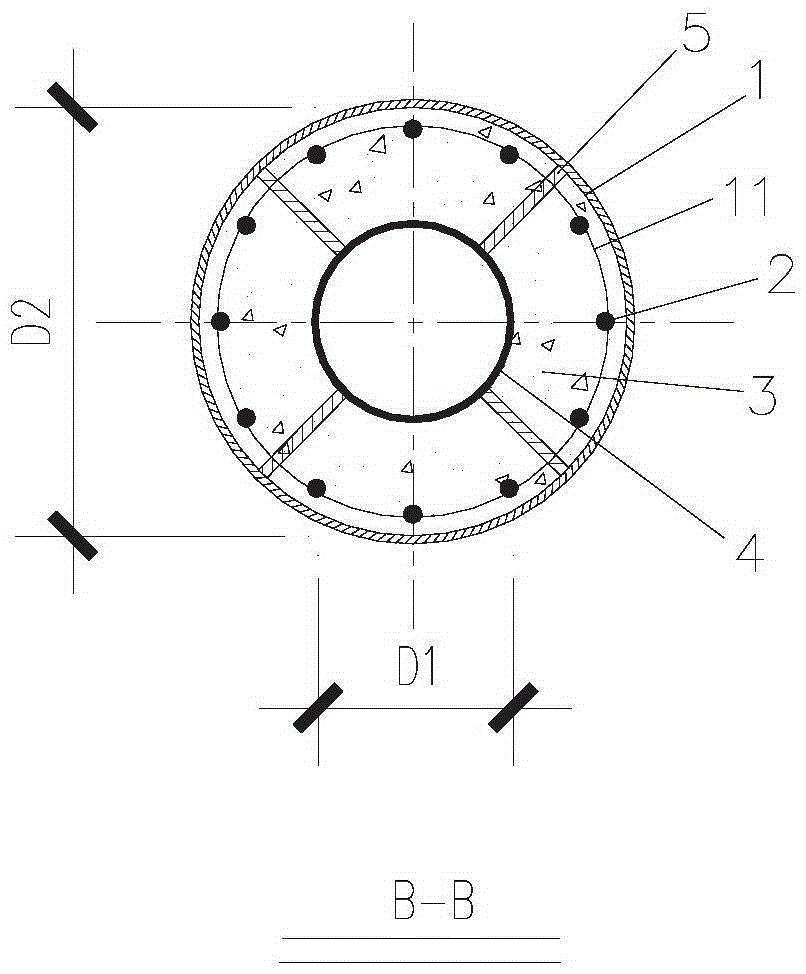

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

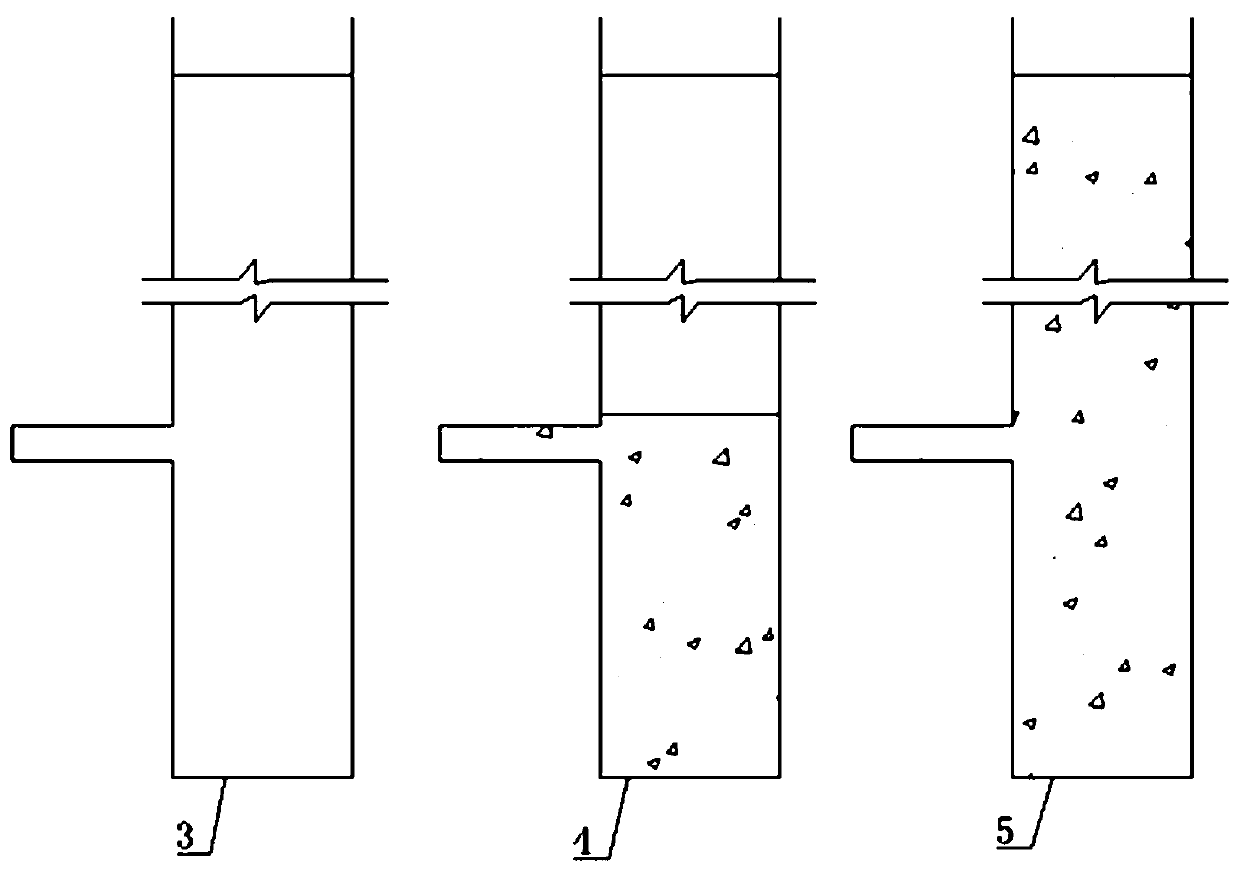

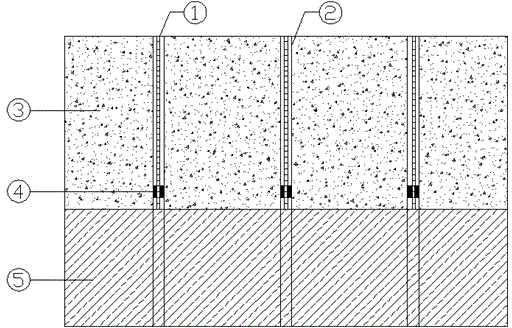

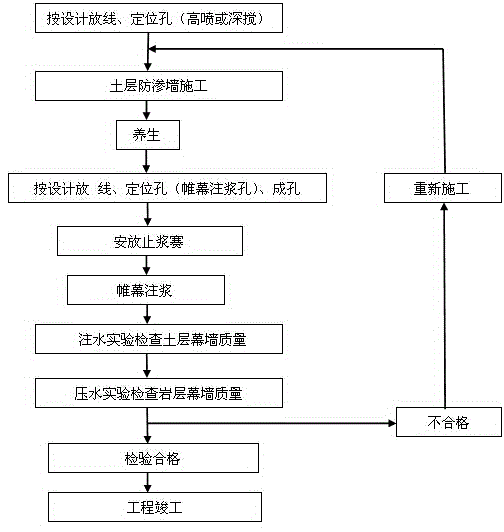

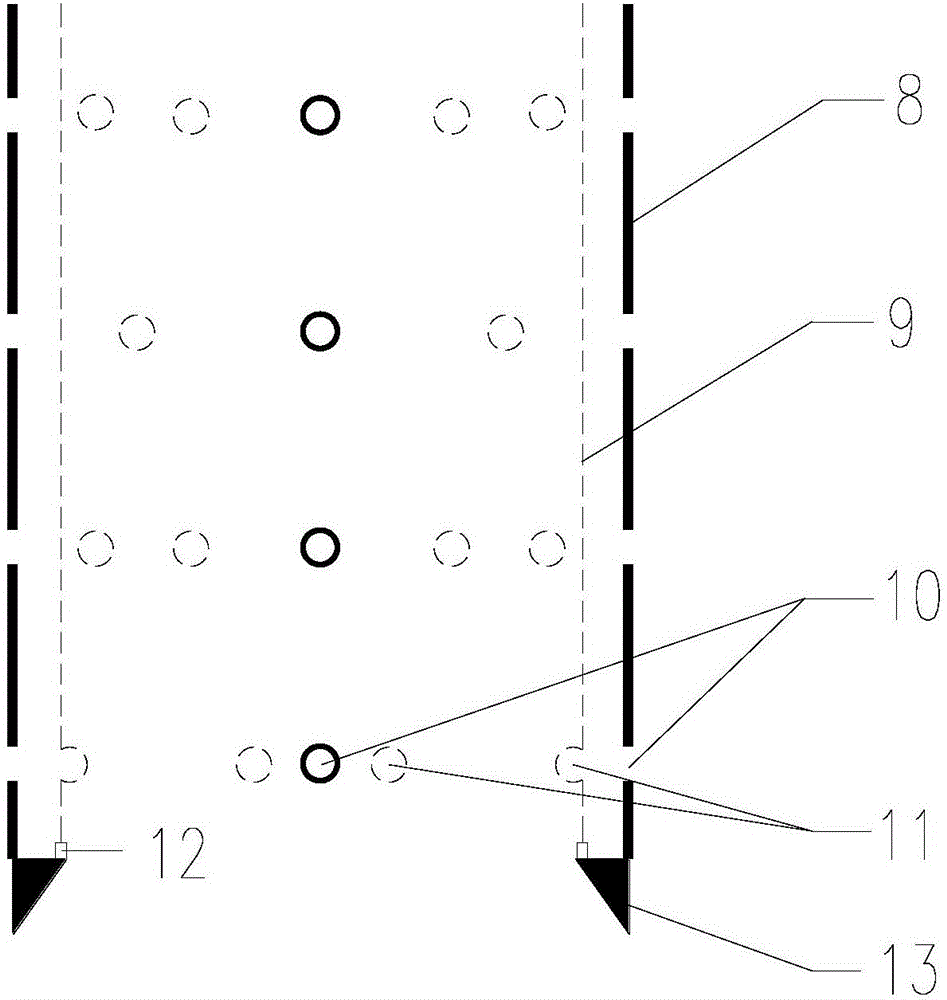

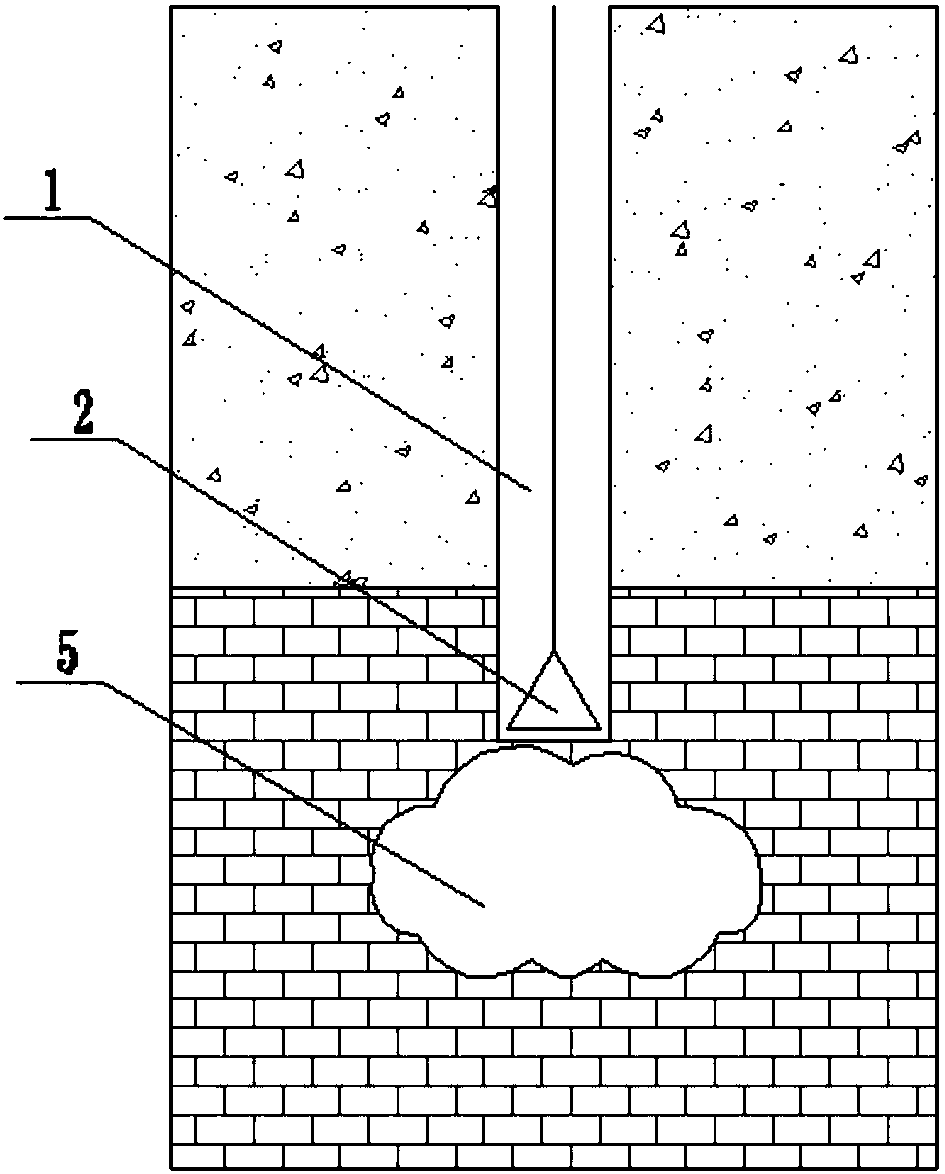

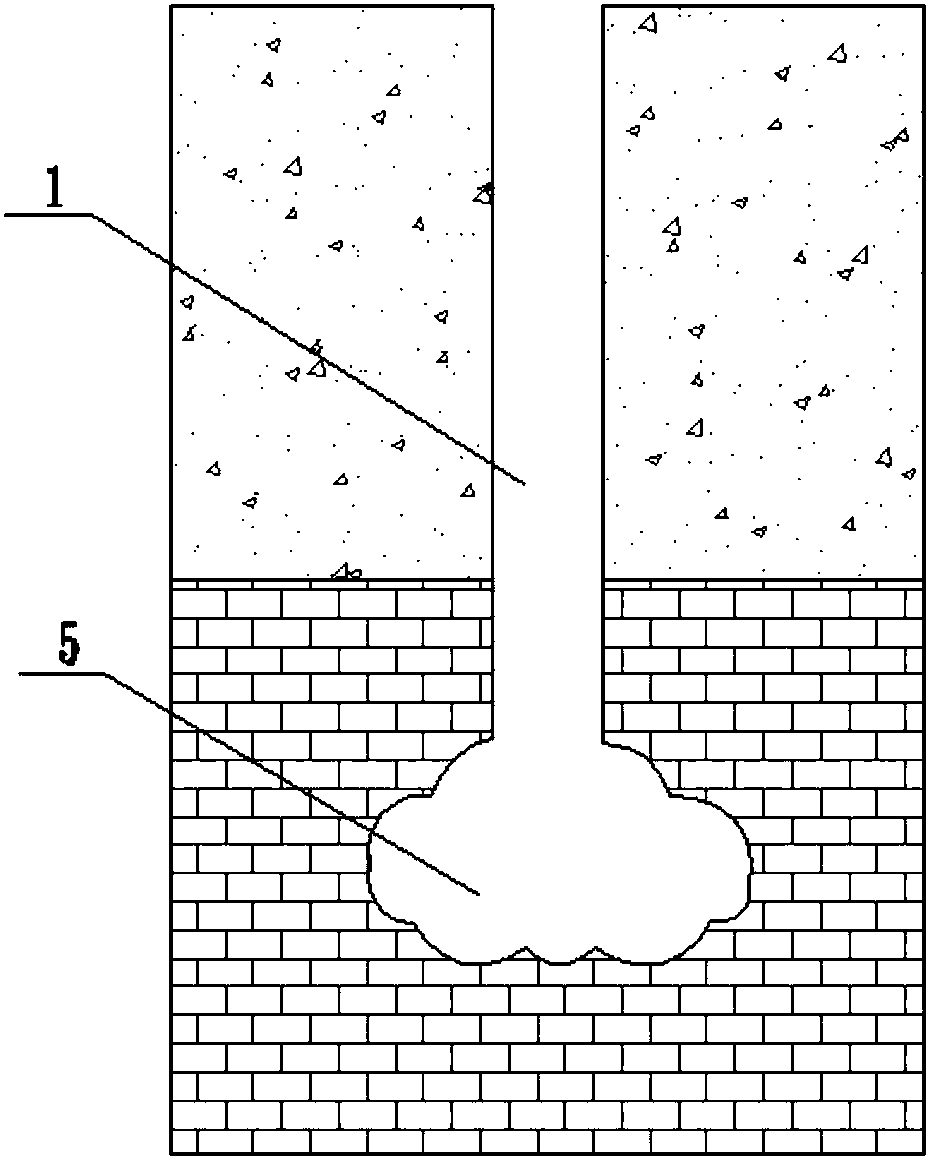

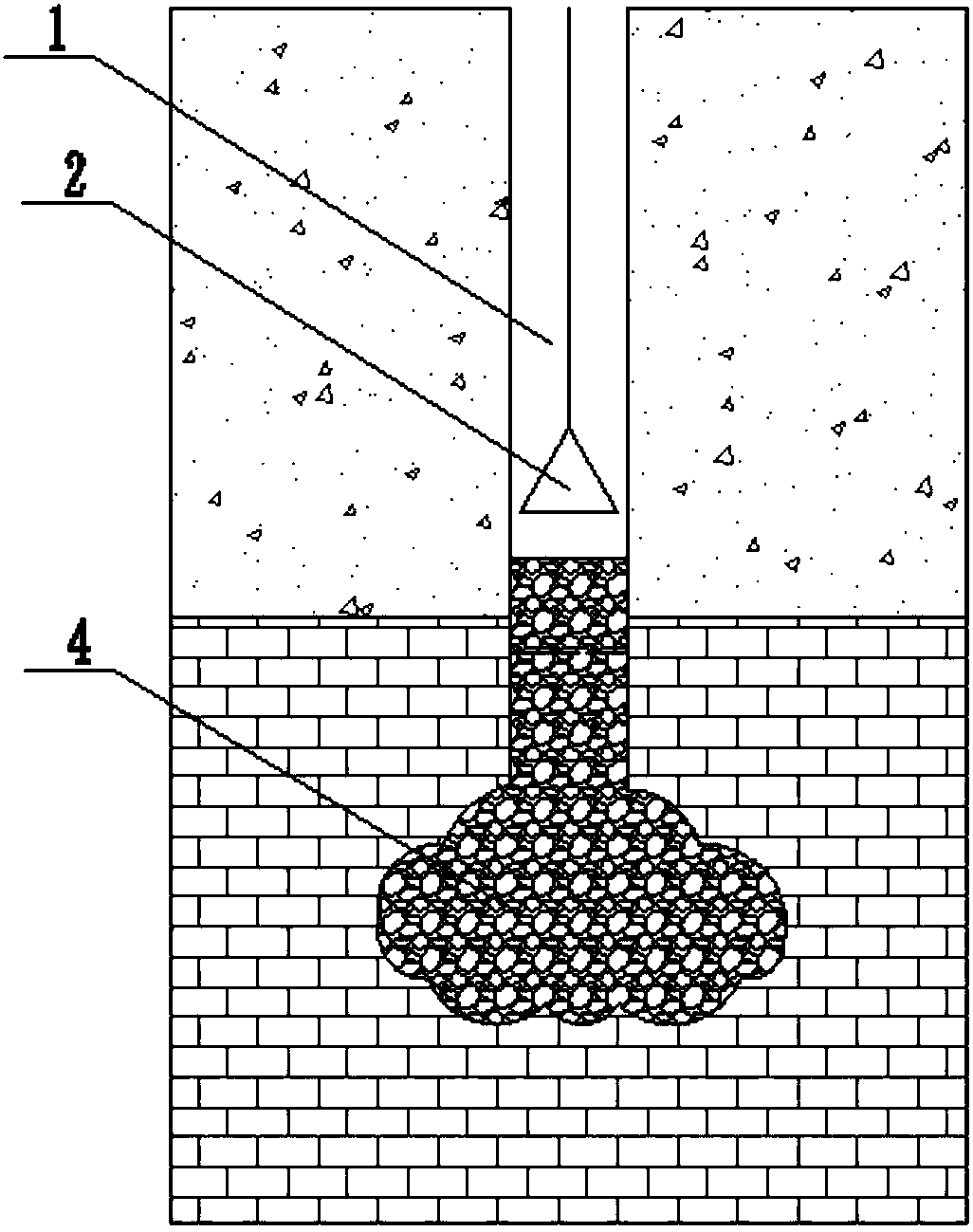

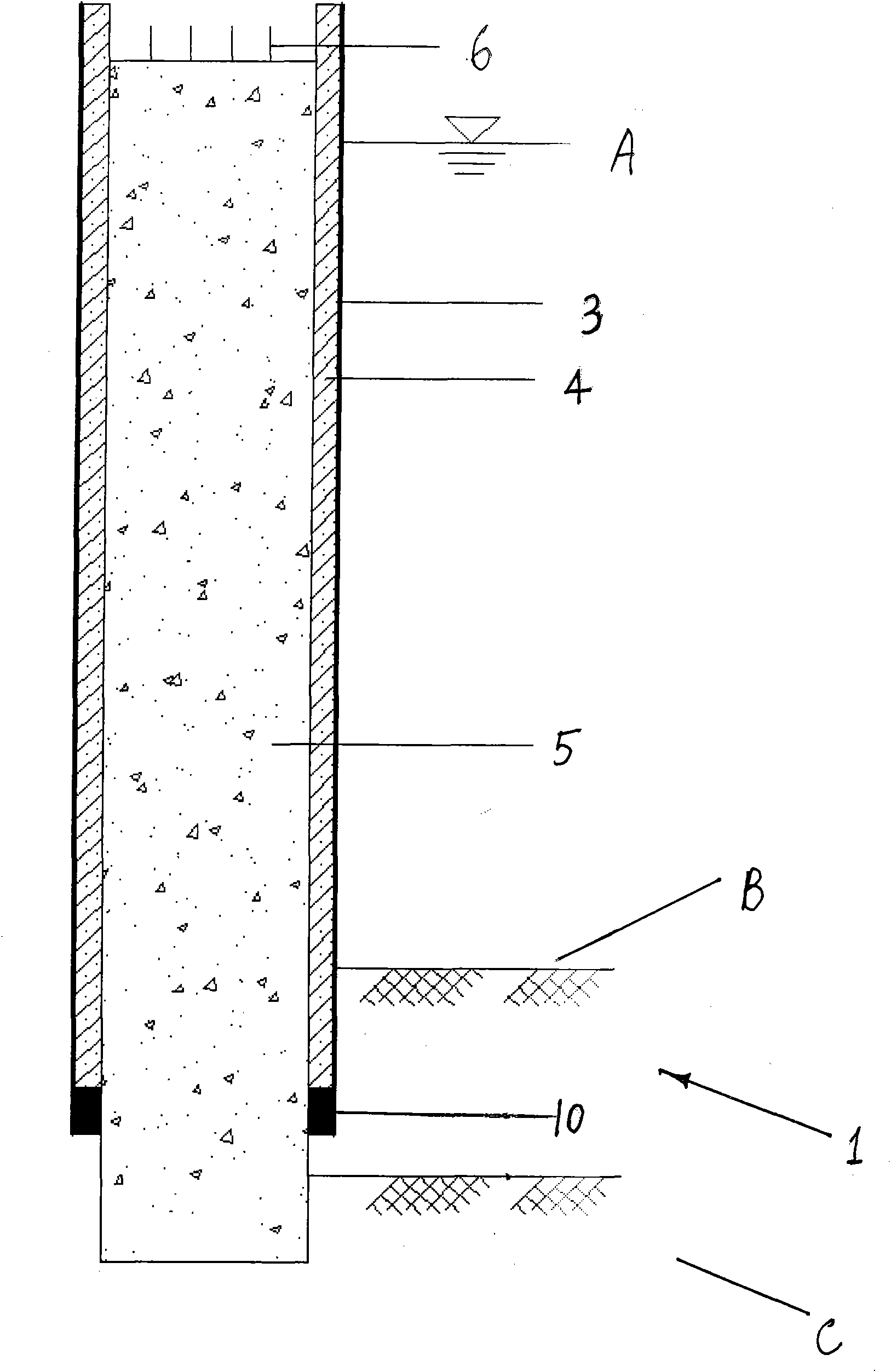

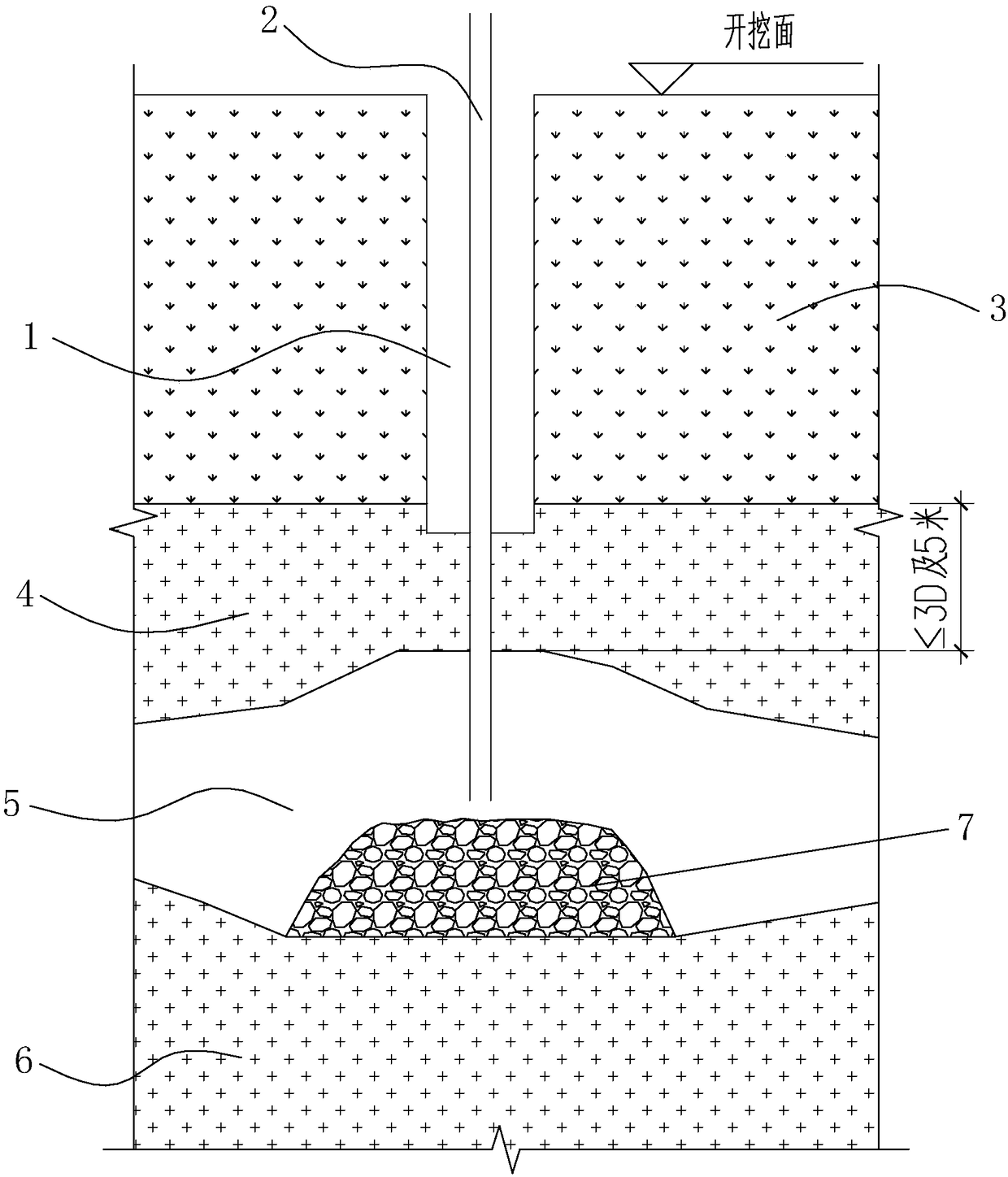

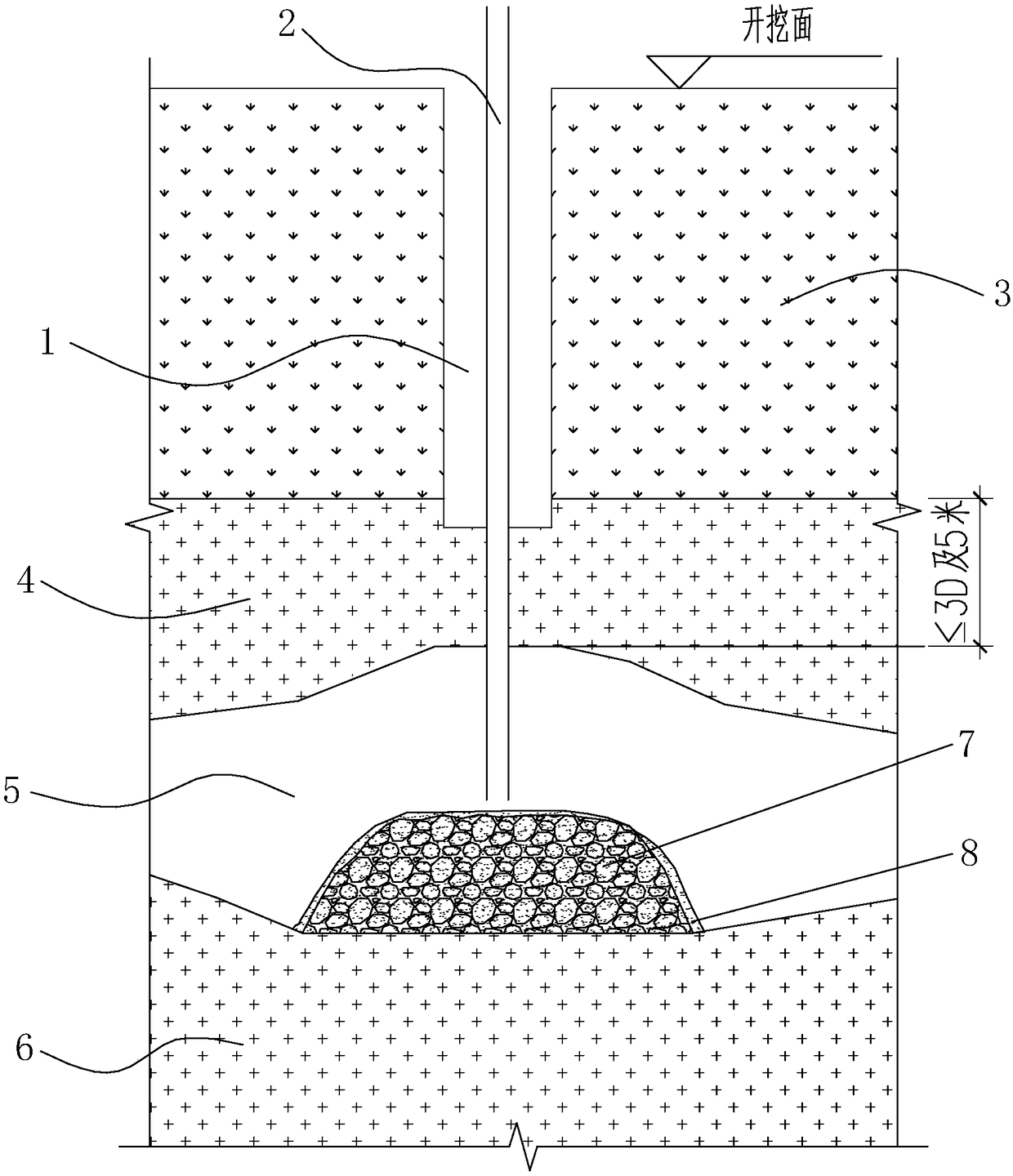

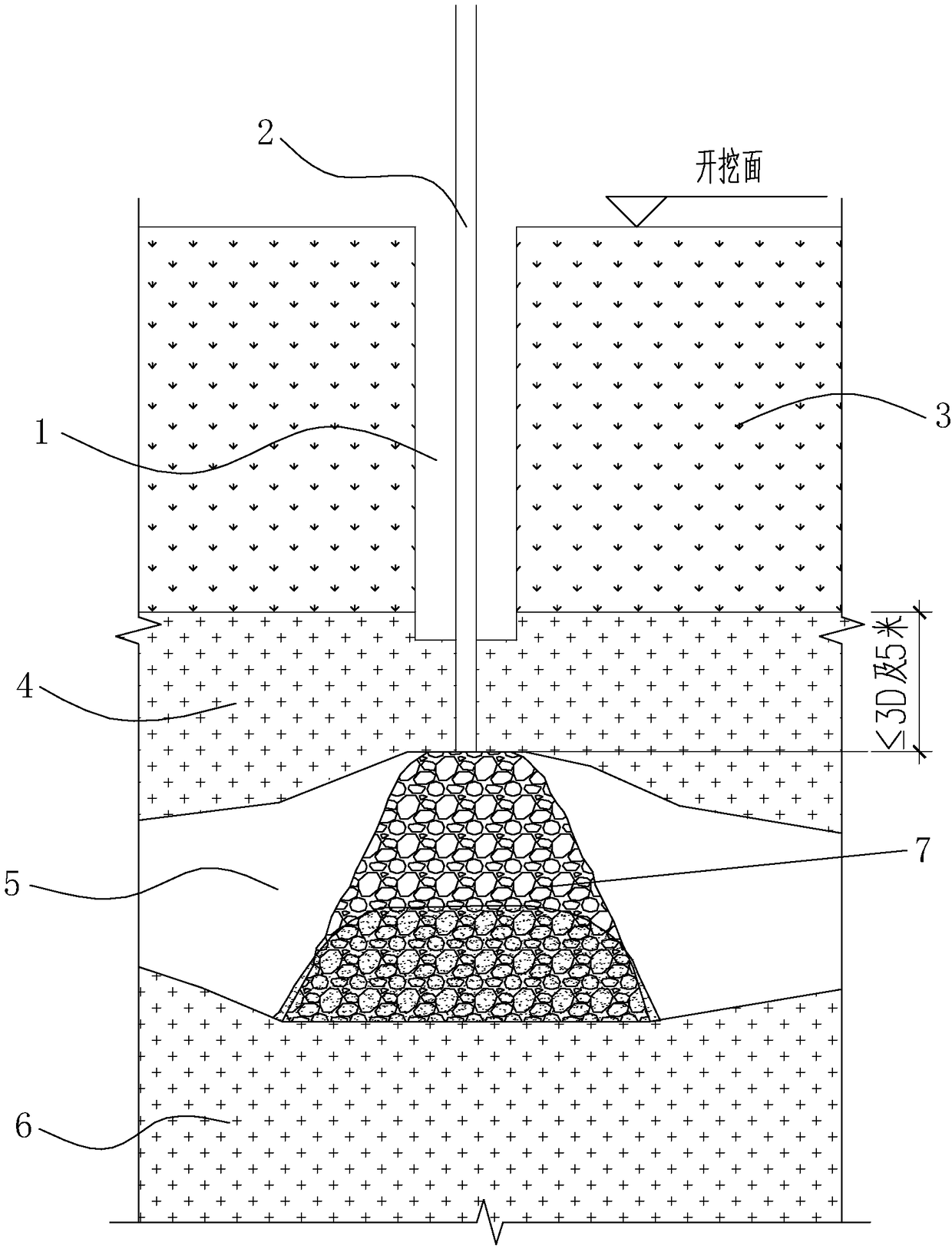

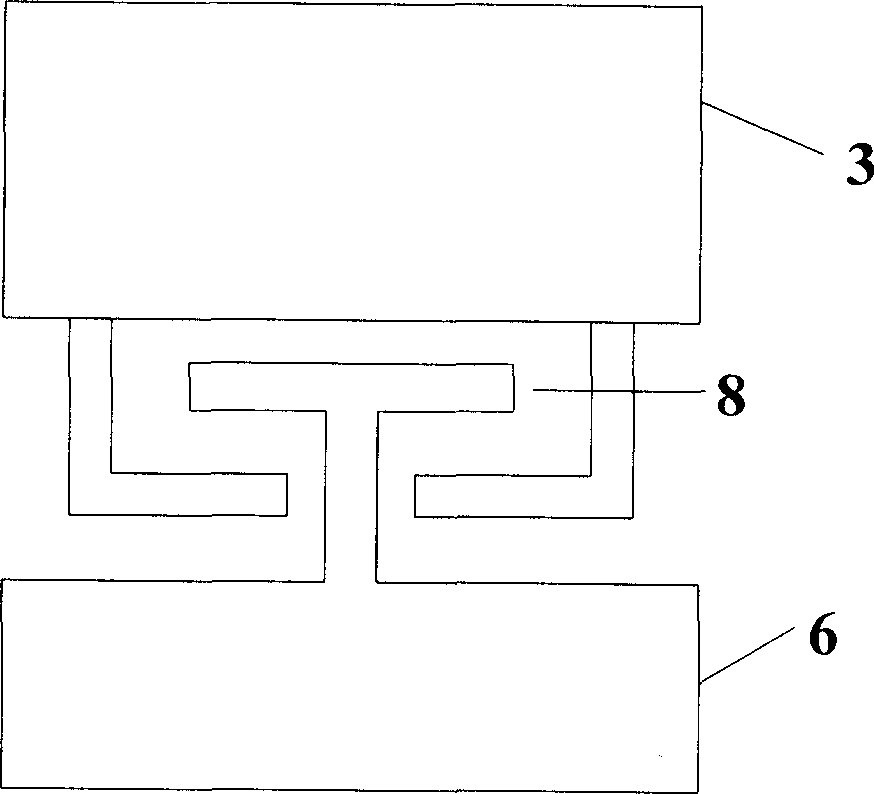

Method for forming complete seepage prevention curtain in two media of rock and soil

ActiveCN104141314AApplicable to a wide range of strataImprove construction qualityBulkheads/pilesGeomorphologyEarth surface

The invention discloses a method for forming a complete seepage prevention curtain in two media of rock and soil. High spray pile construction or deep stirring pile construction is carried out on an upper soil layer to form an upper soil layer seepage prevention curtain wall (3); rock layer curtain grouting holes (2) are drilled in the top of the formed upper soil layer seepage prevention curtain wall (3) according to the hole distance and hole depth designed in rock curtain grouting to a waterproof rock layer; rock layer curtain grouting pipes (1) are sleeved with grouting hole grout block plugs (4), the grouting hole grout block plugs (4) are inserted into the rock layer curtain grouting holes (2), the curtain grouting work is completed through the rock layer curtain grouting pipes (1) according to rock grouting standard requirements, and therefore a lower rock layer waterproof curtain wall (5) is formed in a lower rock layer, and finally a complete vertical seepage prevention curtain wall from the soil layer to the rock layer is formed. According to the seepage prevention curtain constructed and completed through the method, underground water can be effectively prevented from streaming in the lower rock layer of the earth surface, the formed wall quality completely meets the environmental protection requirements of current mine lots and plants, construction speed is high, and the cost is low.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

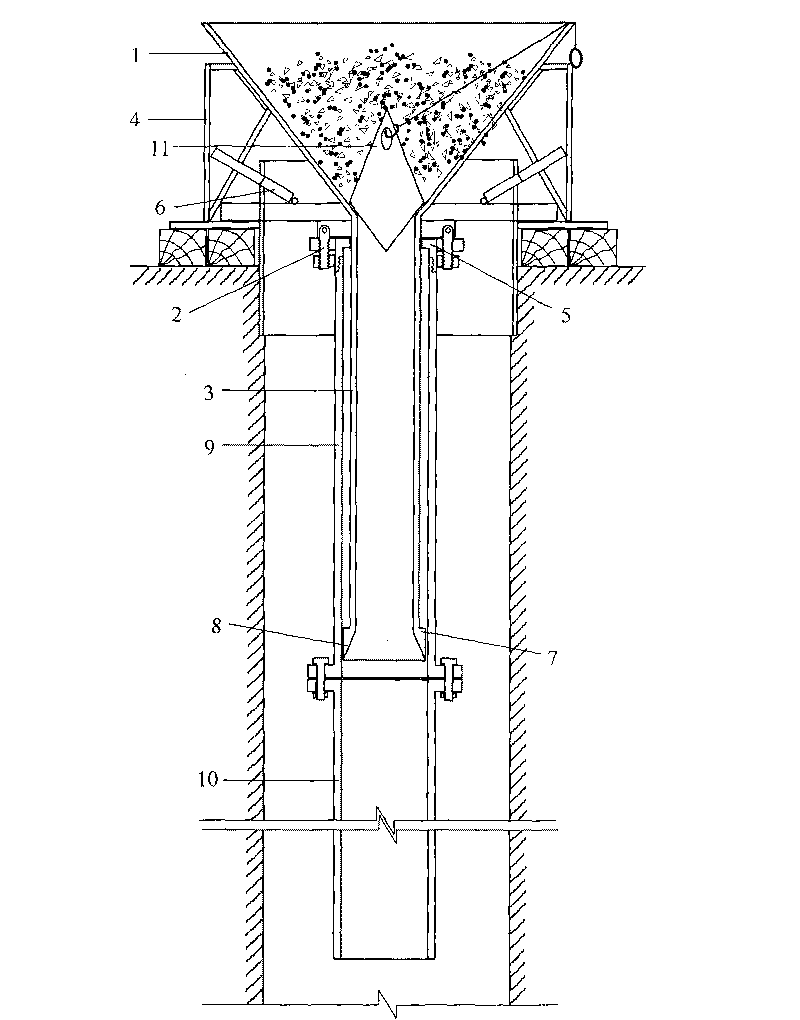

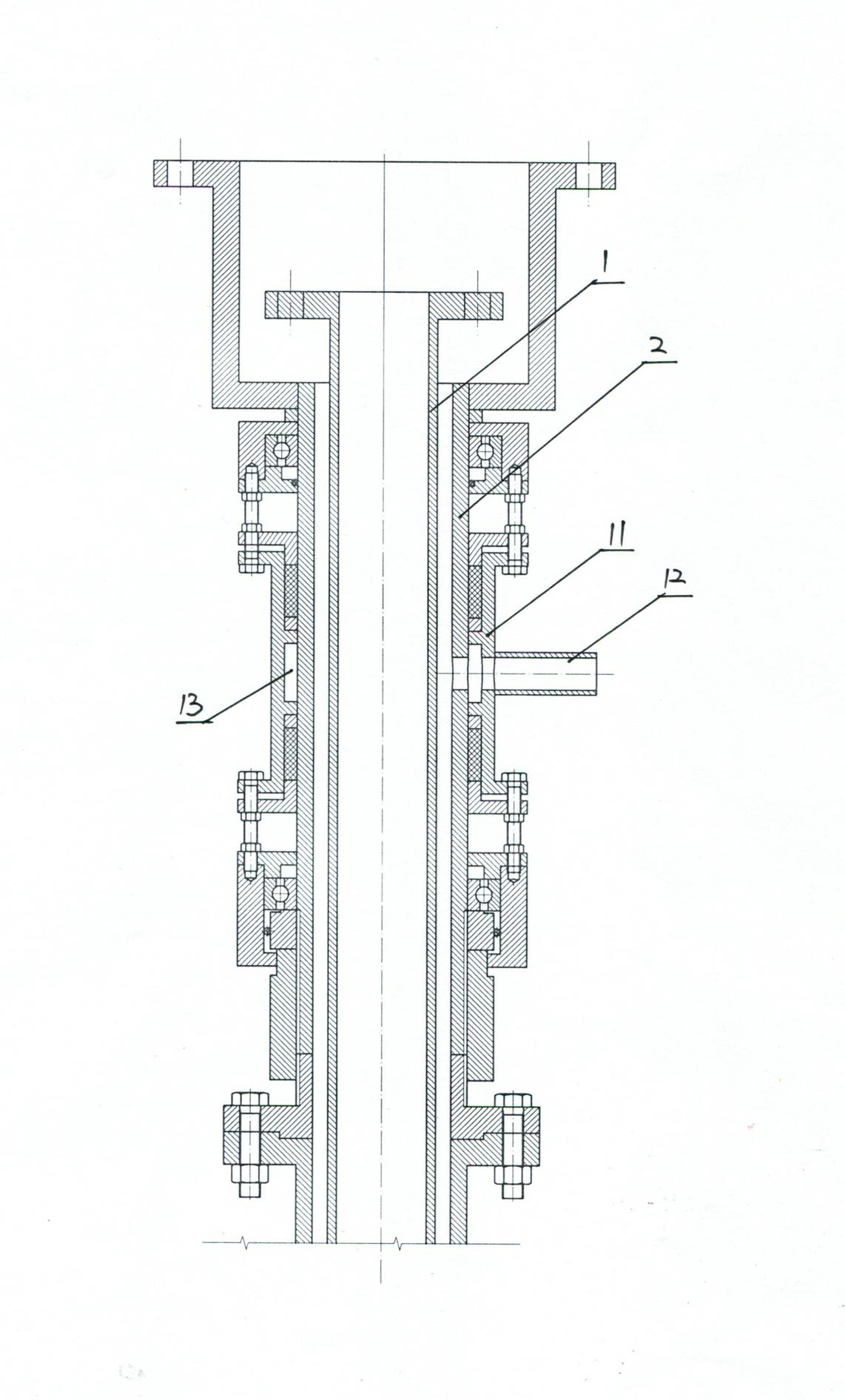

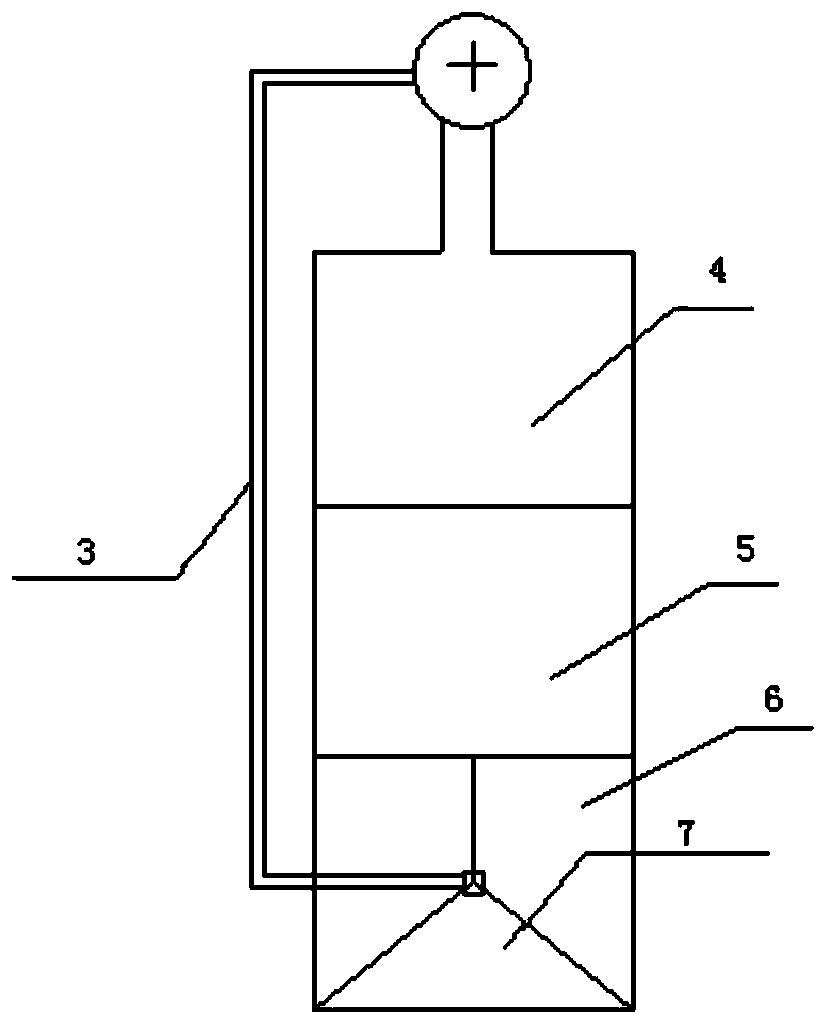

Feeding device of pouring pile underwater concrete and pouring method thereof

InactiveCN101725148AIncrease active pressureSolve the problem that is not easy to fallFoundation engineeringSlurryGuide tube

The invention belongs to the field of building construction, in particular to a feeding device of pouring pile underwater concrete and a pouring method thereof. The device comprises a hopper, a hopper frame, a sleeve pipe, a guide pipe and a hopper plug. The feeding device is characterized in that the lower end of the hopper is provided with the lining guide pipe; fixed bolts are arranged outside a lower port of the hopper; the upper end of the sleeve pipe is provided with a seal cap; bolt grooves are arranged outside the seal cap and respectively correspond to the fixed bolts outside the hopper in position; two folio valves are arranged on a clamping cover and sleeved at the lower port of the outer edge of the seal cap during working; the sleeve pipe is connected with the guide pipe by a flange; and the hopper plug is an iron plug of which both ends are in cone shapes. Compared with the traditional method for reducing the resistance of concrete in a pile and the slurry protecting wall on the concrete in the guide pipe just by lifting the guide pipe in a limited way, the invention greatly improves the active pressure of pouring concrete in the guide pipe, effectively solves the problem of difficult falling of the concrete, improves the pouring speed, ensures the molded pile quality and has obvious economic and comprehensive benefits.

Owner:DALIAN AERBIN GROUP

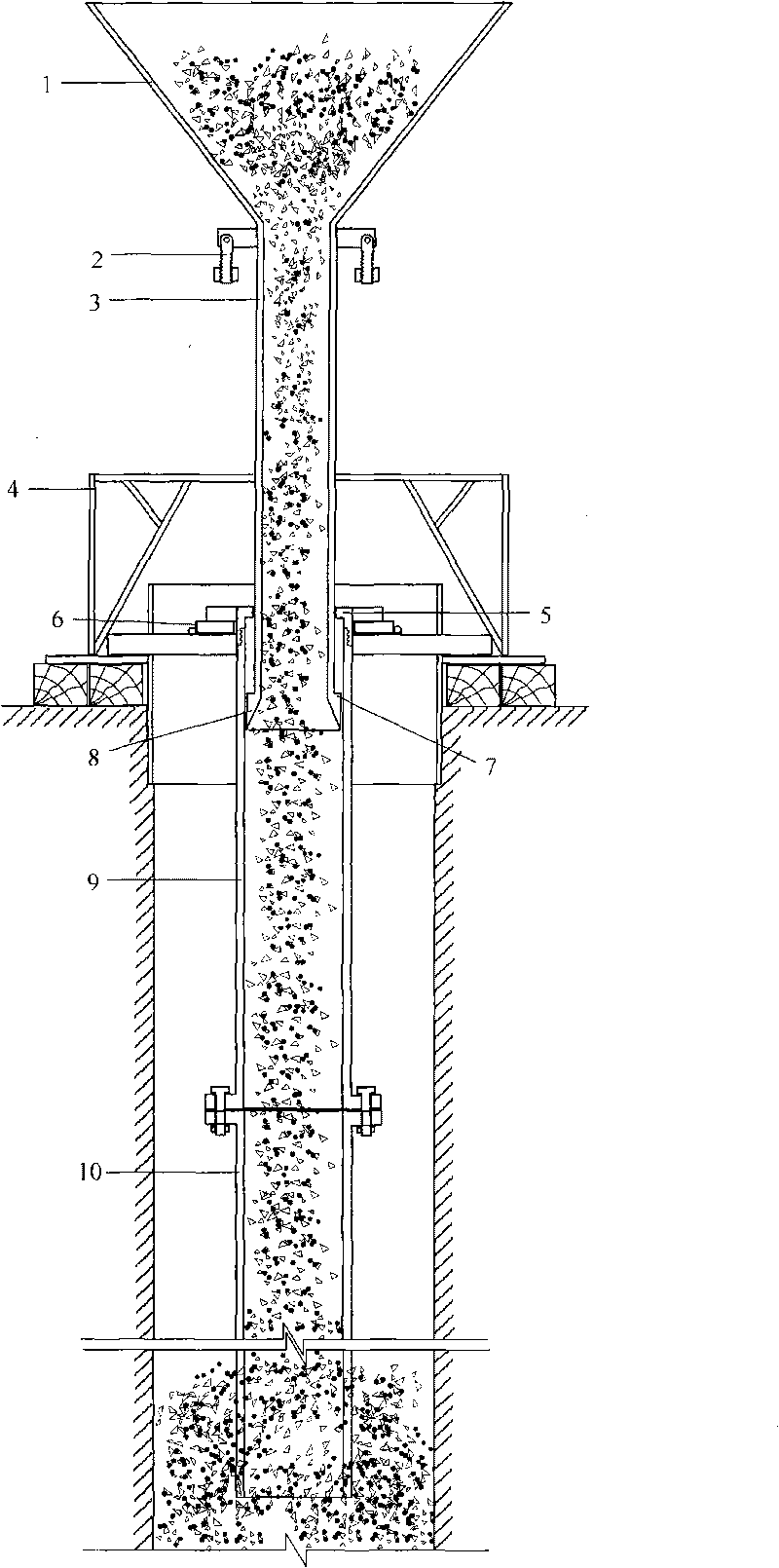

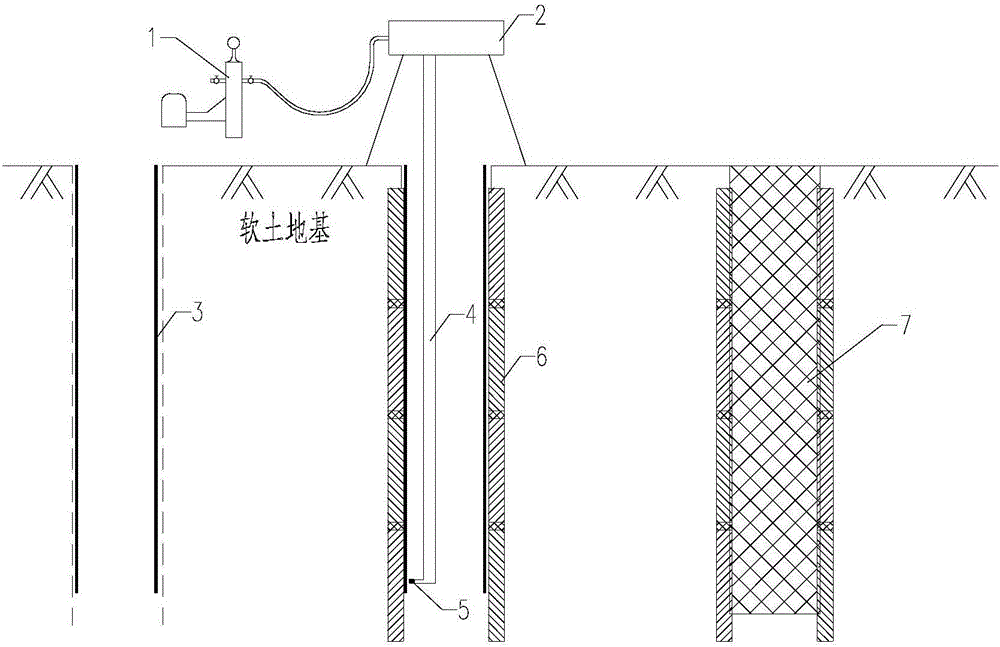

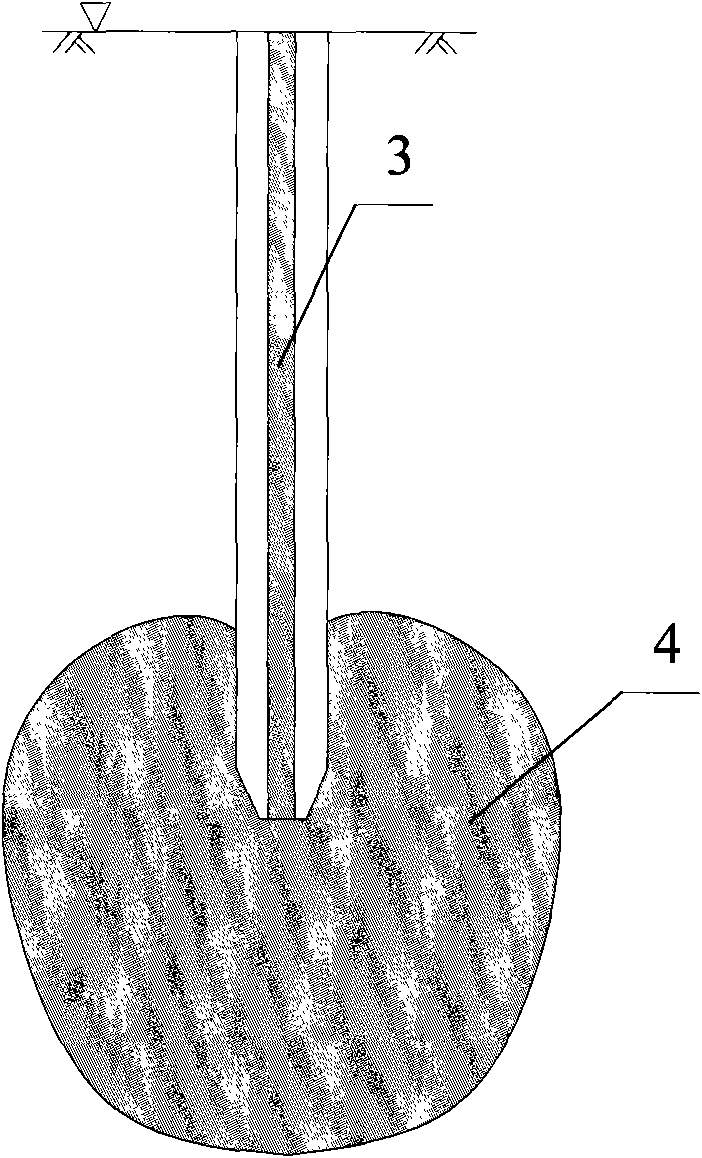

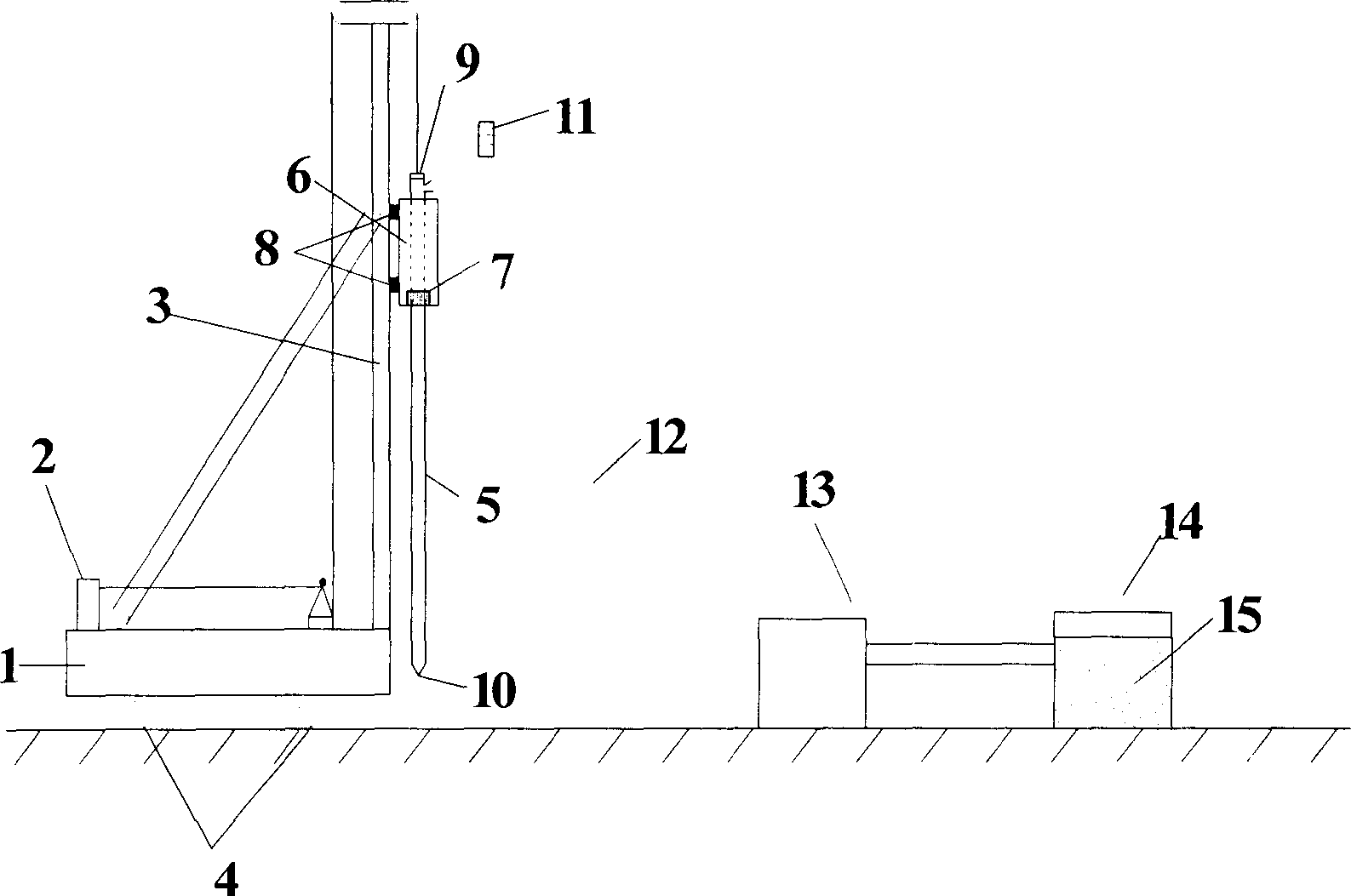

Equipment and method for improving bearing capacity of cast-in-place pile under soft soil foundation condition

The invention belongs to the field of foundation engineering and relates to equipment and method for improving a bearing capacity of a cast-in-place pile under a soft soil foundation condition. The equipment comprises a cement paste pumping device, an injection grouting pipe position control device, am injection grouting pipe and a rotatable three-directional nozzle, wherein the injection grouting pipe is arranged on the injection grouting pipe position control device and the position of the injection grouting pipe in a pile hole of the cast-in-place pile through the injection grouting pipe position control device; the cement paste pumping device is connected with the rotatable three-directional nozzle through the injection grouting pipe; the rotatable three-directional nozzle is used for carrying out slurry spraying work on an injection grouting reinforcing region in the pile hole of the cast-in-place pile. The equipment and method for improving the bearing capacity of the cast-in-place pile under the soft soil foundation condition, provided by the invention, are simple in structure and are convenient to control and implement; soft soil at the periphery of a pile body is reinforced by adopting an injection grouting manner and the strength of a soil body is improved, so that the aims of guaranteeing the pile forming quality of the cast-in-place pile under the soft soil foundation condition and improving the friction resistance of a pile foundation side and a total bearing capability are realized.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation construction method

The invention discloses a bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation construction method for processing a small-area / narrow-range deep mucky soil or soft clay foundation, which is characterized in that: by utilizing the high bearing capacity and pile-bottom concrete reinforced and enlarged ends of bottom-grouting-enlarged small-diameter prestressed tubular piles, the bottom-grouting-enlarged small-diameter prestressed tubular piles effectively reduce diameters of pile bodies of the conventional prestressed tubular piles, reduce the buried depths of the pile bodies, and are arranged in a plane at a proper pile spacing to achieve micro shallow and dense pile group effect and achieve shallow soft field soil composite foundation reinforcement effect. The method has the advantages that: on bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation, the small-diameter prestressed tubular piles are used to compact the surrounding soil to transfer load, and grouting and reinforcement of pile bottoms are performed to improve the end bearing capacity, so that a shallow pile-based composite foundation is formed. Compared with a normal large-area soft soil foundation composite foundation processing method and a prestressed tubular pile foundation method, the method has the characteristics of simple process, high construction speed, miniature construction equipment, material saving and low cost.

Owner:HOHAI UNIV

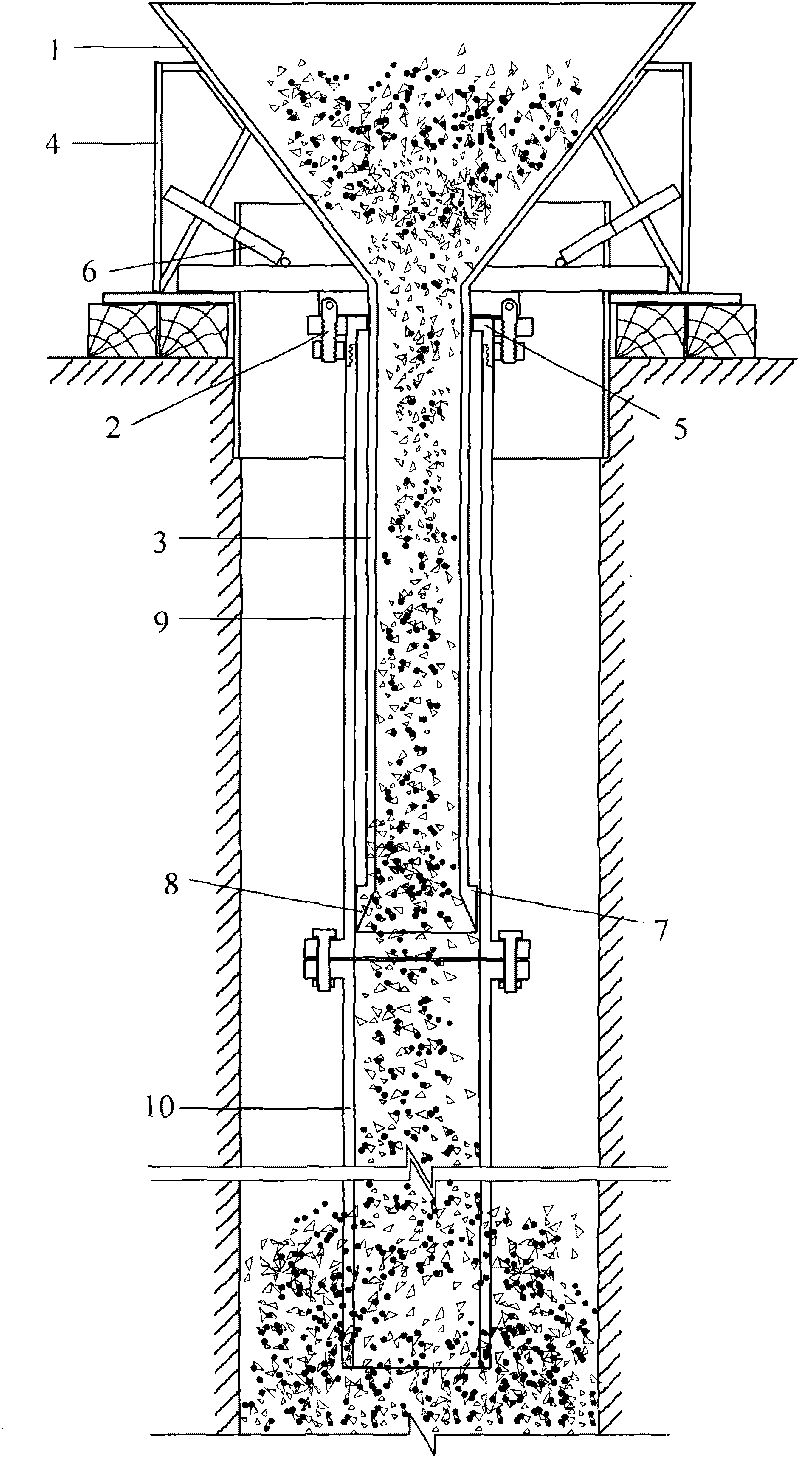

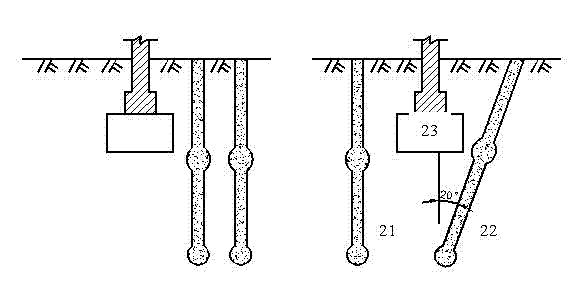

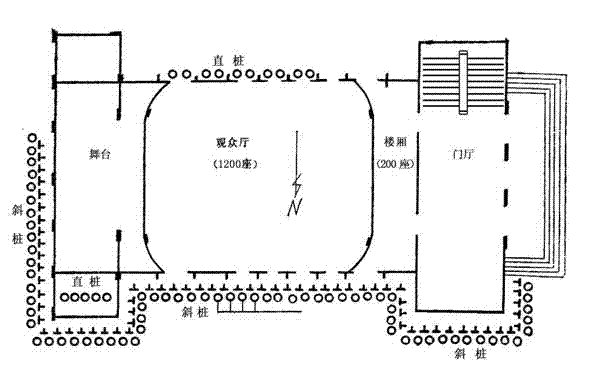

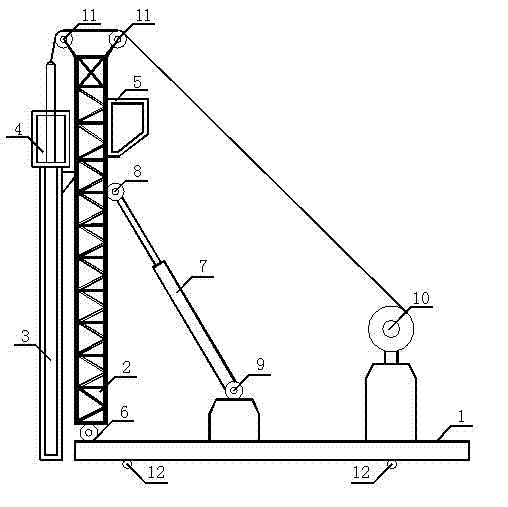

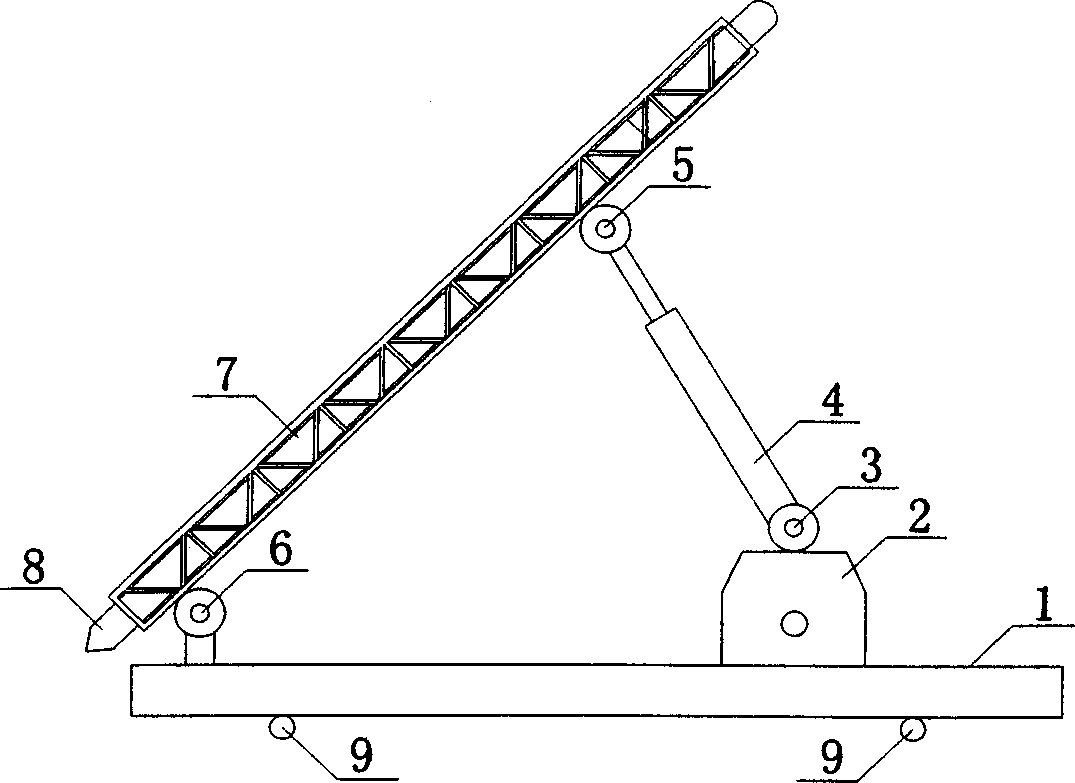

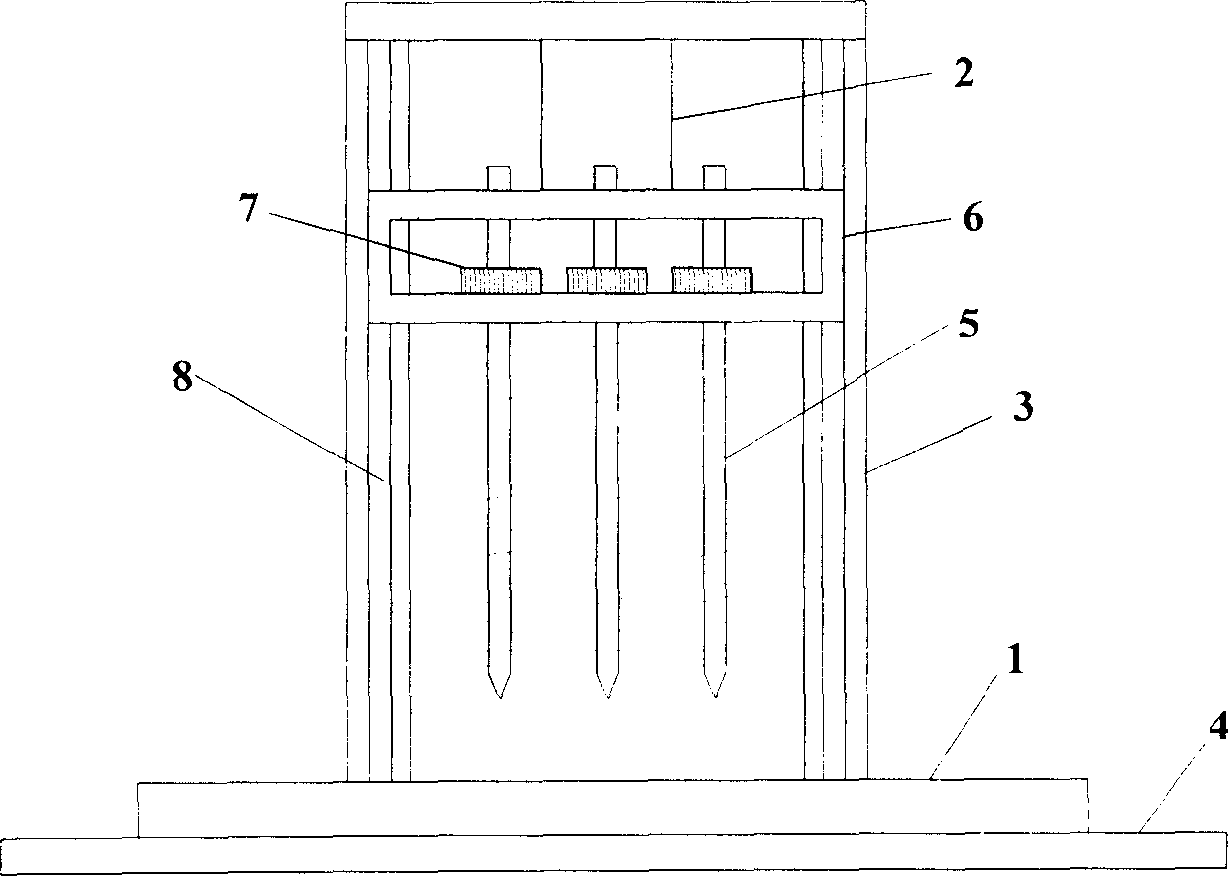

Given force variable stiffness discrete material pile ramming and expanding machine and application thereof

InactiveCN102392447AMeet the trait requirementsFast reinforcement effectBulkheads/pilesSoil preservationVariable stiffnessElectricity

The invention relates to a given force variable stiffness discrete material ramming and expanding machine which comprises a chassis, a traveling part, a control system, a hoist system, a portal steel frame and a pile pipe ramming and expanding system. The pile pipe ramming and expanding system comprises a straight-through ramming hammer head, a hammer cushion and inner and outer sleeve pile pipes. The portal steel frame for supporting and stabilizing the inner and outer sleeve pile pipes is arranged on the chassis. A telescopic pull rod for controlling a piling angle is also connected onto the portal steel frame. The hoist system comprising lifting inner and outer pile pipes, a lifting straight-through ramming hammer head and a lifting vibrator part and the control system comprising an electric motor and an electrohydraulic linking and illuminating device are also arranged on the chassis. The straight-through ramming hammer head is positioned at the upper part of double layers of pile pipes in the sleeve structure. The given force variable stiffness discrete material ramming and expanding machine not only can be used for piling a multi-section enlarged head discrete material flexible pile, but also can be used for piling a concrete rammed and expanded rigid pile. The machine can be suitable to be applied to piling of a new construction, an extension project, a reconstruction project and the engineering for treating pathological accidents on weak or poor foundations such as interlayer soft clay, loose fine sandy soil, plain fill, miscellaneous fill, collapsed loess and the like.

Owner:苏州予力再生建材有限公司 +1

Karst cave treating method suitable for pile foundation construction in karst area

InactiveCN107794915AAffect the carrying capacityPrevent burialBulkheads/pilesSoil preservationKarstEngineering

In order to overcome the adverse effects of pile foundation construction in karst area, reduce the cost of the pile foundation construction and simplify the process of the pile foundation construction, the invention provides a karst cave treating method suitable for the pile foundation construction in karst area. The karst cave treating method suitable for the pile foundation construction in karstarea, which is provided by the invention, comprises the steps of when encountering a karst cave during the pile foundation construction, squeezing rubble and clay into the karst cave, filling the karst cave with the rubble and the clay by utilizing a pile hammer, prepressing and compacting. The karst cave is filled with the rubble and the clay and a support is provided for the pile hammer, so that the situation that the pile hammer deflects for lack of support cannot happen during hammering; in addition, the situation that the bearing capacity of pile foundation is affected for lack of a force transferring layer cannot happen.

Owner:上海市建工设计研究总院有限公司

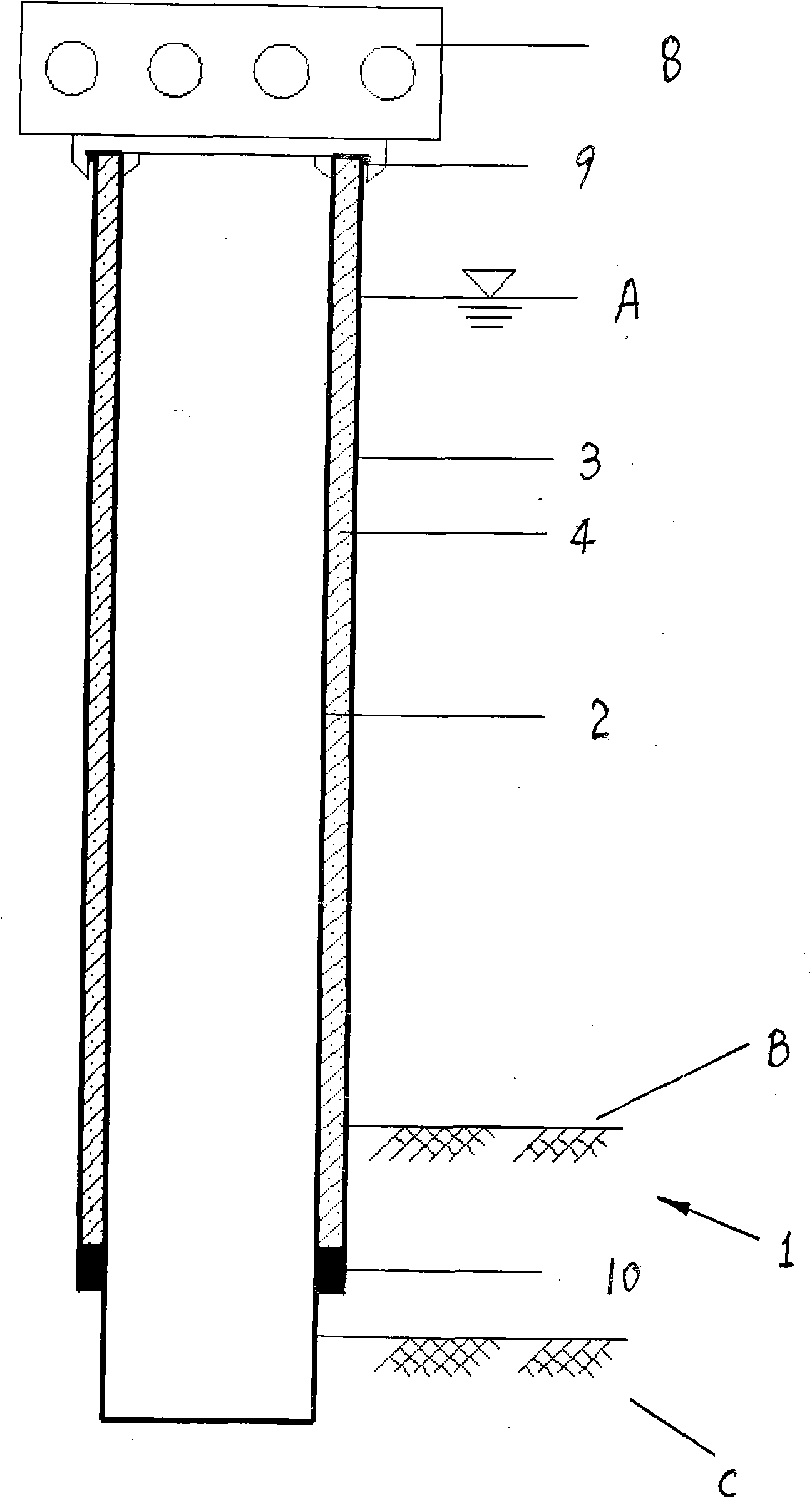

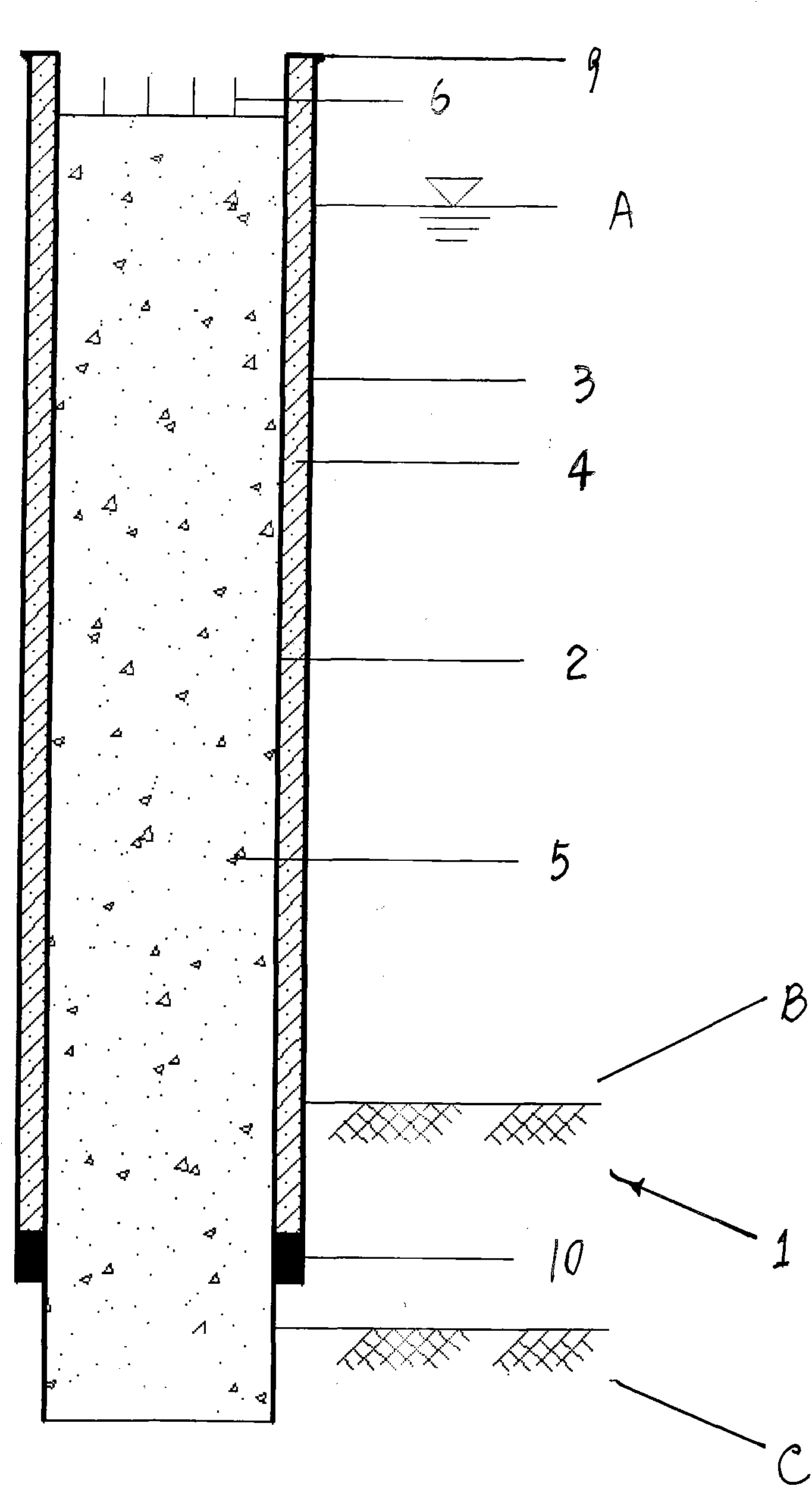

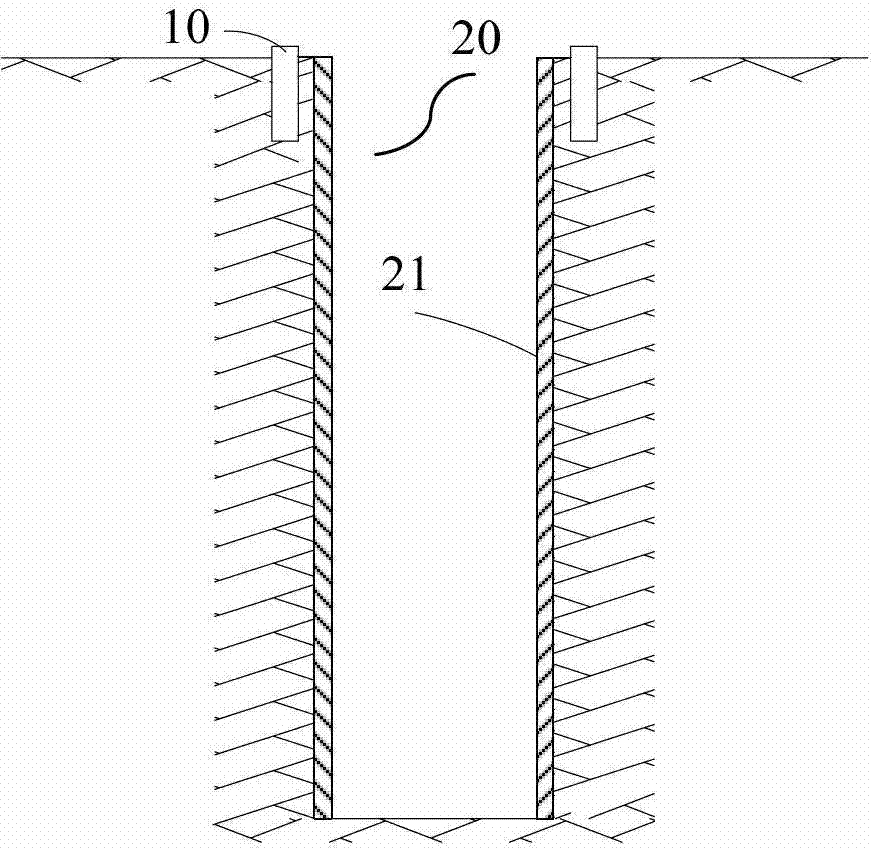

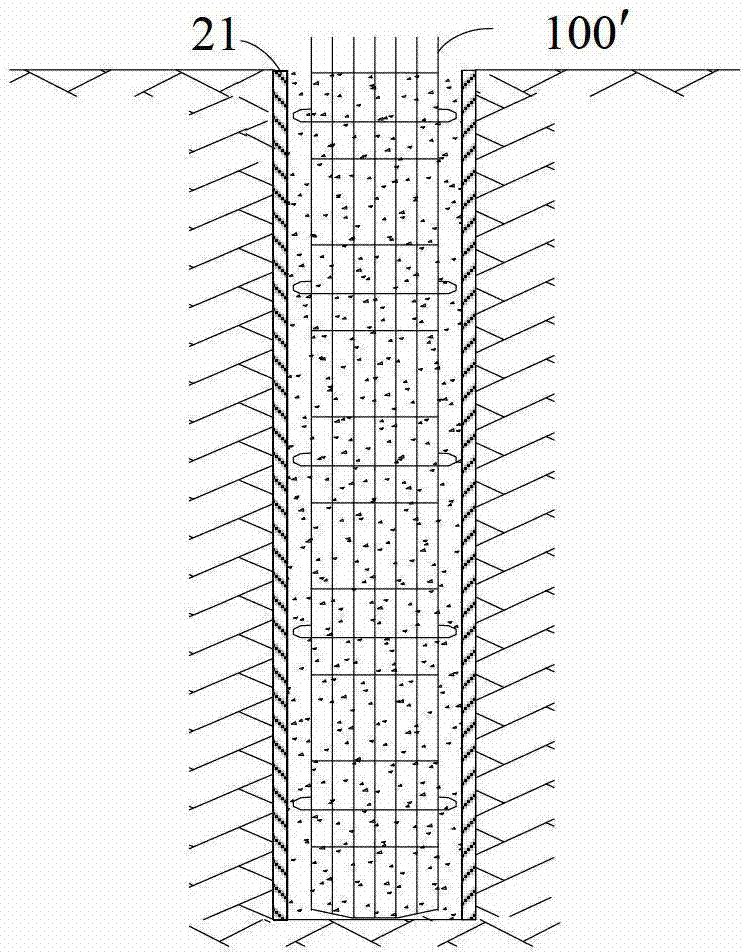

Construction method of concrete filling piles

ActiveCN102080374AGuarantee the pile qualityReduce construction costsBulkheads/pilesUnderwaterFilling materials

The invention aims at providing a construction method of concrete filling piles for recovering sleeves, and the method is used for recycling sleeves of a die for pouring the concrete when the concrete is poured underwater, and greatly saving the construction cost. The construction method of the concrete filling piles comprises the following steps: a) embedding two nested and homocentric inner and outer sleeves in aground base; forming a filling material for concrete pouring molds between the inner and outer sleeves; fetching earth in the inner sleeve and forming pile holes; b) pouring the concrete in the inner sleeve; c) pulling out the inner sleeve before the poured concrete is initially congealed, and forming the molds of the poured concrete by the filling material; and d) pulling out the outer sleeve after the poured concrete is initially congealed.

Owner:MCC COMM CONSTR GRP CO LTD

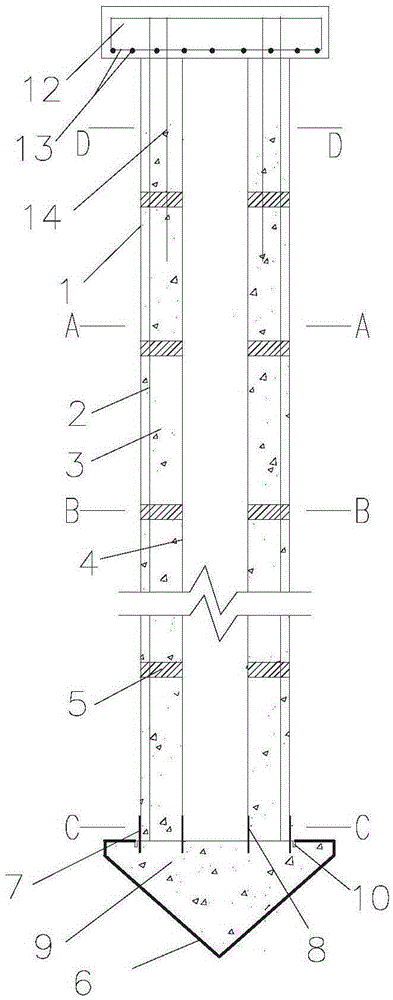

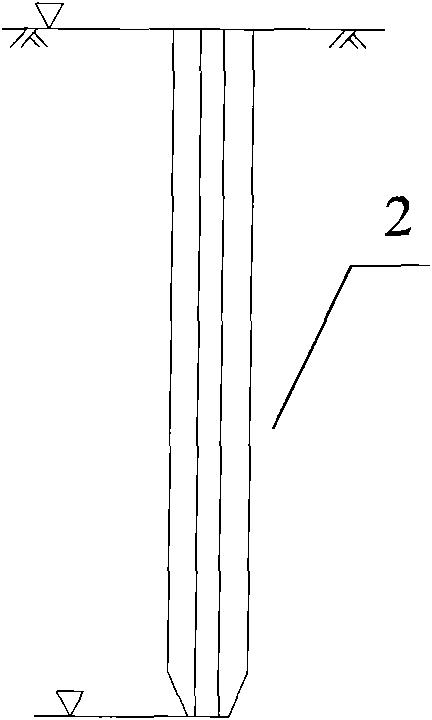

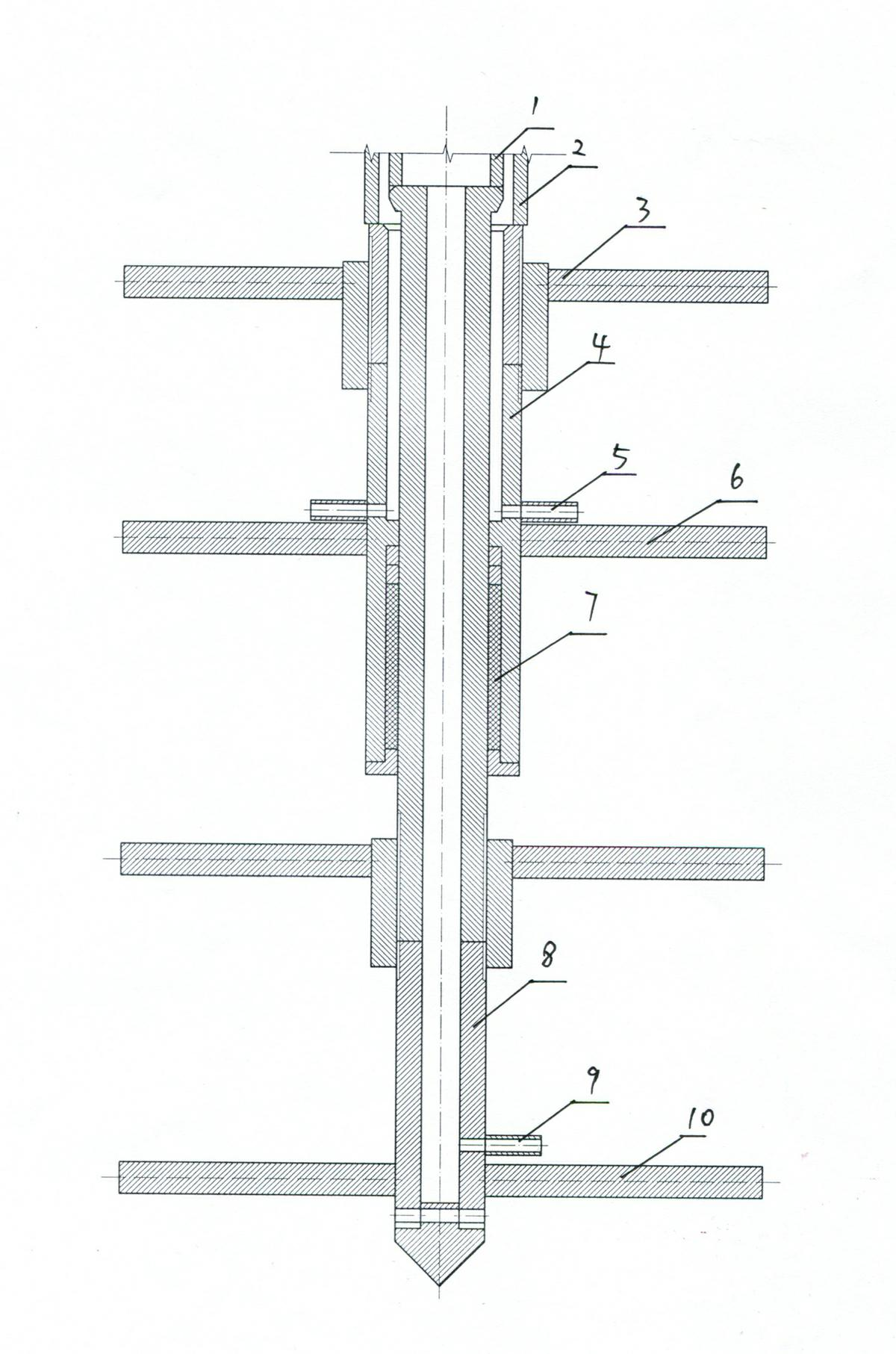

Double-pipeline drill bit for cast-in-place stiffening core composite pile

InactiveCN105064330ASimple construction processShorten the construction periodDrill bitsDrilling rodsCement slurryStructural engineering

The invention relates to a double-pipeline drill bit for a cast-in-place stiffening core composite pile. The double-pipeline drill bit comprises an opening / closing blade, a core pile molding protective drum, a cutting blade and a hollow drill pipe, wherein the opening / closing blade is hinged to the bottom end of the hollow drill pipe, and is controlled to be opened or closed through a magnet; the core pile molding protective drum is arranged at the bottom of the hollow drill pipe, and is slidingly connected with the hollow drill pipe through a dowel pin; a cutting blade cutting soil body is arranged at the outer side of the core pile molding protective drum, and provides acting force for vertical sliding of the protective drum; the cutting blade is arranged outside the hollow drill pipe; double pipelines are arranged in the hollow drill pipe; a cement slurry nozzle is arranged at the bottom of the hollow drill pipe; the lower end of a cement slurry pipeline is communicated with the cement slurry nozzle, and the upper end is externally connected with a pumping device for injecting cement slurry; and the lower end of a hollow part of the hollow drill pipe is communicated with the opening / closing blade, and the upper end is connected with the pumping device for filling concrete. The drill bit can be applied to a conventional cement mixing pile machine to omit the pile machine customization cost, realizes once molding of the cast-in-place stiffening core composite pile to simplify the pile forming process, and guarantees the coaxiality of a peripheral pile and a core pile to achieve reliable pile forming quality.

Owner:建设综合勘察研究设计院有限公司 +2

Static pressure pipe pile settling construction technique

The static pressure immersed tube pile constructing process includes the following steps: hoisting the immersed tube with pile tip and setting in place, pressing the immersed tube into ground with one static pressure piling machine while detecting whether to have the pile tip reaching the bearing stratum until reaching the required bearing pressure, and pouring concrete with the concrete pump while lifting the immersed tube gradually until the poured concrete reaches the design elevation. The in-situ high pressure concrete pouring piling process has the features of easy control, concentrated construction jobs, less environment interference, no pollution, high piling quality and low material loss.

Owner:夏传清

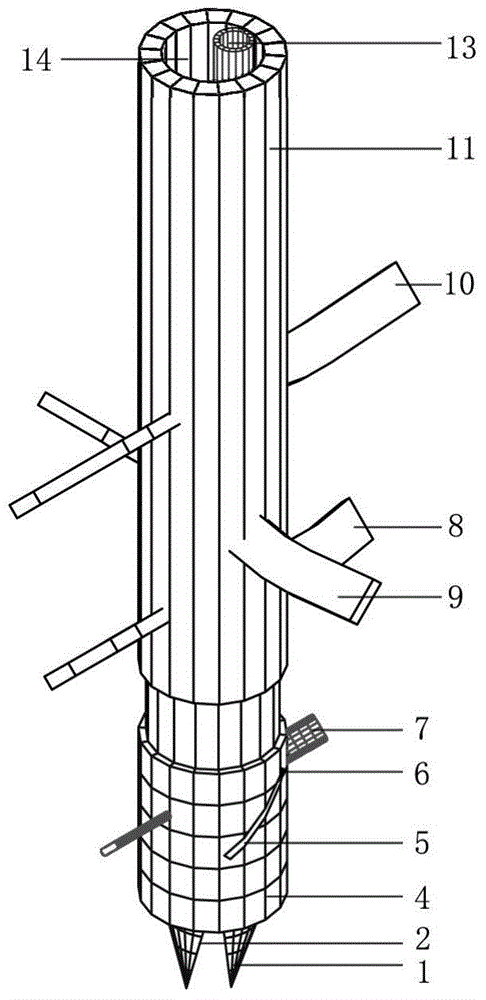

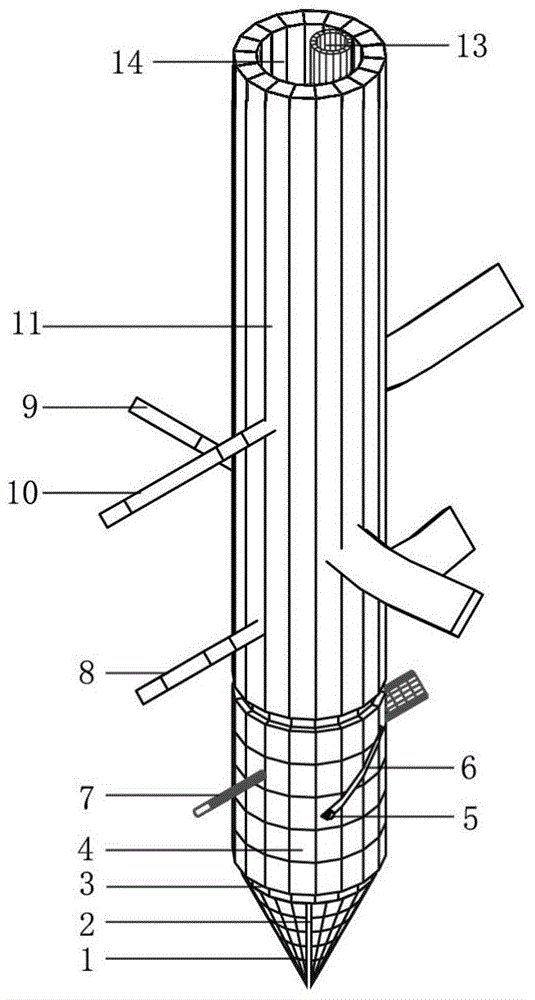

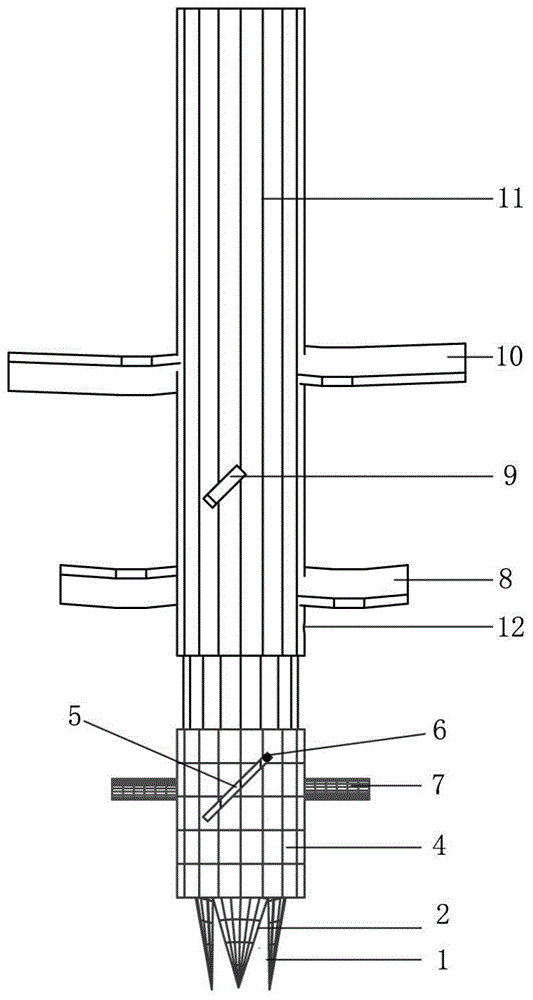

Drilling tool for two-way soil-cement mixed pile

ActiveCN102505683AGuarantee the pile qualityNot easy to blockBulkheads/pilesWater contentSpray nozzle

The invention relates to a drilling tool for a two-way soil-cement mixed pile. The drilling tool comprises an inner drilling rod, an outer drilling rod, an inner drilling bit and an outer drilling bit, wherein a water gas injection device is arranged at the upper part of the outer drilling rod, a cavity between the outer drilling rod and the inner drilling rod is set as a channel enabling water gas to descend, a water gas injection spray nozzle is arranged in the position of an outer drilling core pipe above a lower layer of mixing blades of the outer drilling head, the water gas injection spray nozzle is provided with a spray pipe which is arranged perpendicular to the outer drilling core pipe, spray ports are arranged at the two ends of the spray pipe, a valve cavity is arranged in the middle of the spray pipe, a floating spherical valve core is arranged in the valve cavity, and the middle of the valve cavity is connected with the outer drilling core pipe through a connecting pipe. When a pile is made of cement flour, the quality problem of the pile formed at the upper part due to low water content in a crust layer on the earth surface can be solved by water injection; when the pile is made of cement grout, the quality problem of the pile formed at the deep part due to the lack of dry curing at the deep part of the file can be solved by gas injection; the full pile length pile quality of the two-way soil-cement mixed pile can be ensured; and simultaneously, the drilling pipe is less prone to pipe blockage and can increase the mixing times of the cement flour or the cement grout which is sprayed out and greatly improve construction efficiency.

Owner:江苏盛泰建设工程有限公司

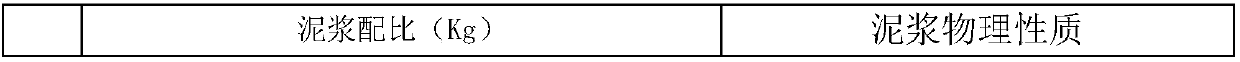

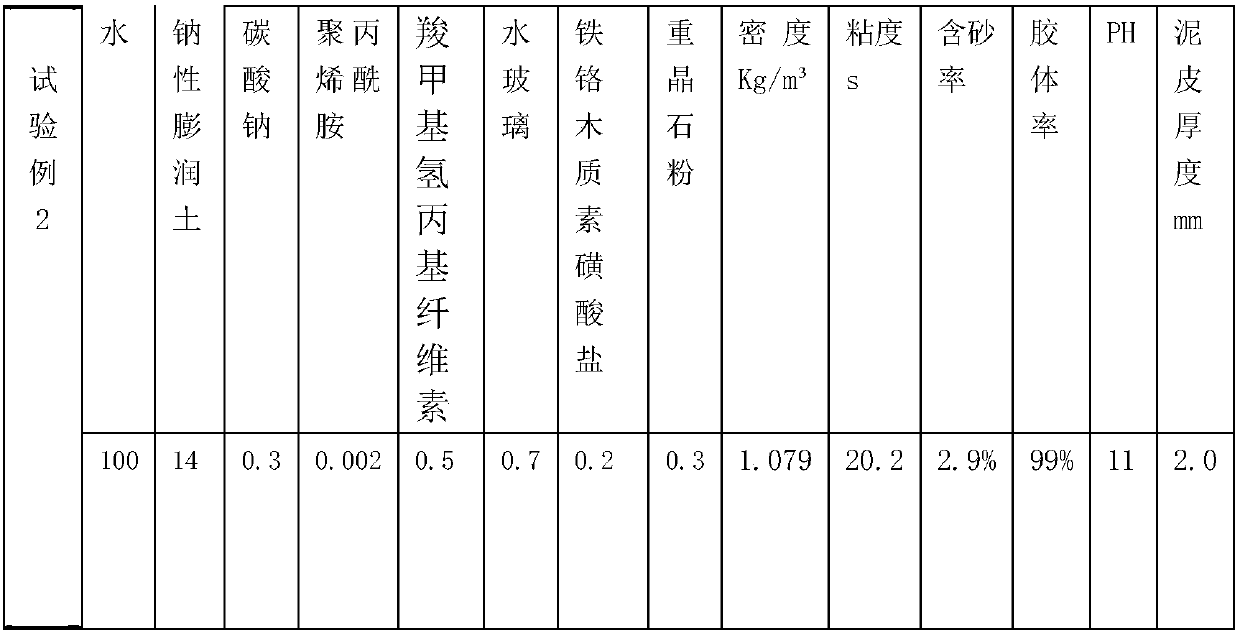

Alluvial plain karst developing district drilling pile formation wall protection mud and preparation method thereof

InactiveCN107739597AReduce construction riskMake up for technical defects in drillingDrilling compositionSodium BentoniteKarst

The invention discloses alluvial plain karst developing district drilling pile formation wall protection mud which is prepared from the components in parts by mass: 100 parts of water, 6-10 parts of clay, 5-14 parts of sodium bentonite, 0.2-0.3 part of sodium carbonate, 0.002-0.005 part of polyacrylamide, 0.5-0.6 part of carboxymethyl hydroxypropyl cellulose, 0.6-0.9 part of water glass, 0.1-0.3 part of ferric chromium lignin sulfonate, 0.1-0.3 part of barite powder and 0.25-0.5 part of potassium humate. The mud prepared by the invention is suitable for an alluvial plain karst developing district drilling pile formation technology and lowers the probability of occurrence of safety accidents of drilling pile formation. A result of interaction of the mud and a stratum is changed by changingthe performance index of the mud, so that the safety coefficient of construction is increased, and the technical defect of drilling a complex strata is made up.

Owner:SHENYANG POLYTECHNIC UNIV

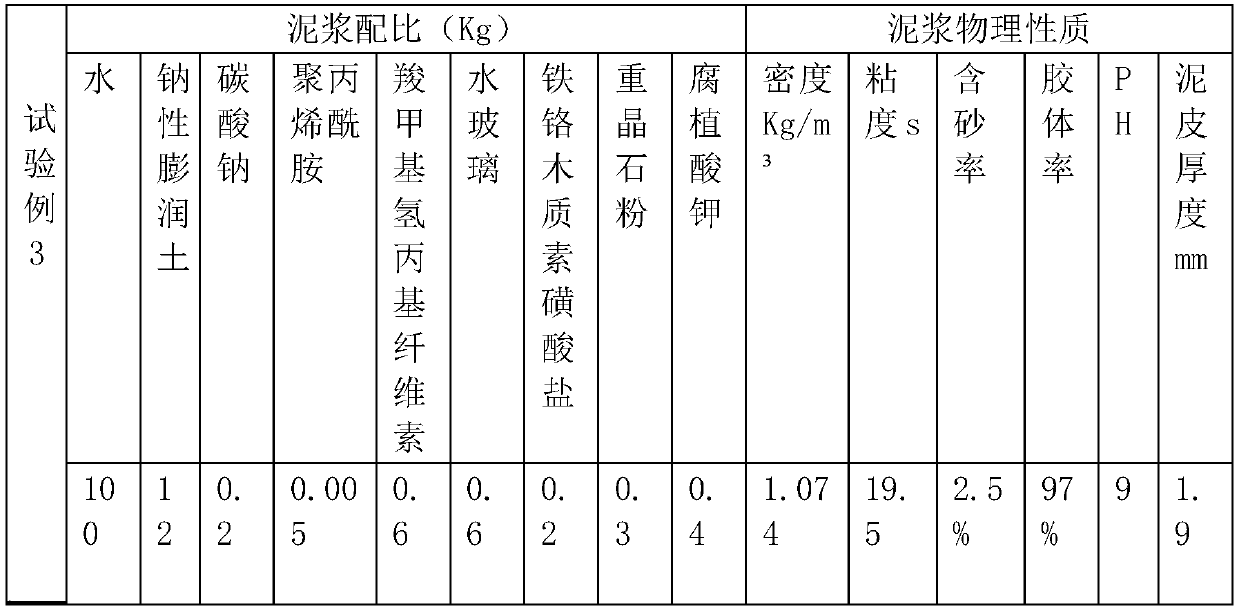

Concrete grouting construction method and device for implementing same

The invention discloses a concrete grouting construction method and a device for implementing the same. The device comprise a plurality of tremies of which one ends extend into underwater concrete in a grouting slot; a blanking hopper is arranged at the top end of each tremie; a slag pumping pipe is arranged in the grouting slot; and the bottom end of the slag pumping pipe is positioned at a position which is 1-2 meters away from the surface of the underwater concrete. According to the concrete grouting construction method and the construction device, slurry above the surface of the underwater concrete is pumped through the slag pumping pipe in a concrete pouring process, and concrete is poured in the pumping process, so that the quality of underwater concrete is prevented from being damaged by the slurry above the surface of the underwater concrete, and the piling quality of the underwater concrete is effectively ensured; and the method and the device can be applied to the field of building construction.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Construction method of medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile

The invention relates to a construction method of a medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile. The construction method comprises the steps that surveying and setting-out are conducted for determining a pile position, and a long spiral drilling machine is made to be aligned to the pile position; the long spiral drilling machine is started, and a spiral drill rod and a drill bit are driven to conduct rotary drilling vertically downwards; a medium-hole vibrating hammer is started at the same time to drive a pile casing to follow up vertically downwards to a preset pile end depth; the spiral drill rod idles, so that residue soil at the bottom is discharged; the drill rod is lifted, concrete is poured into a pile hole while the spiral drill rod is lifted, and concrete pouring is stopped after the spiral drill rod is lifted to a preset height; after concrete pouring is completed, the pile casing is left in the pile, the long spiral drilling machine is removed out of the pile hole, and a steel bar insertion device and a steel reinforcement cage are inserted into the poured concrete together by means of a crane while being vibrated; and after the steel reinforcement cage is inserted to a preset depth, the steel rib insertion device is pulled out, the pile casing is completely pulled out, and the cast-in-situ pile is solidified and formed. The construction method of the medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile has the advantages that the quality of the cast-in-site pile is high, construction is safe, the cost is low, the speed is high, environmental friendliness is achieved, and results are practical.

Owner:HENAN JINYUAN FOUND ENG CO LTD

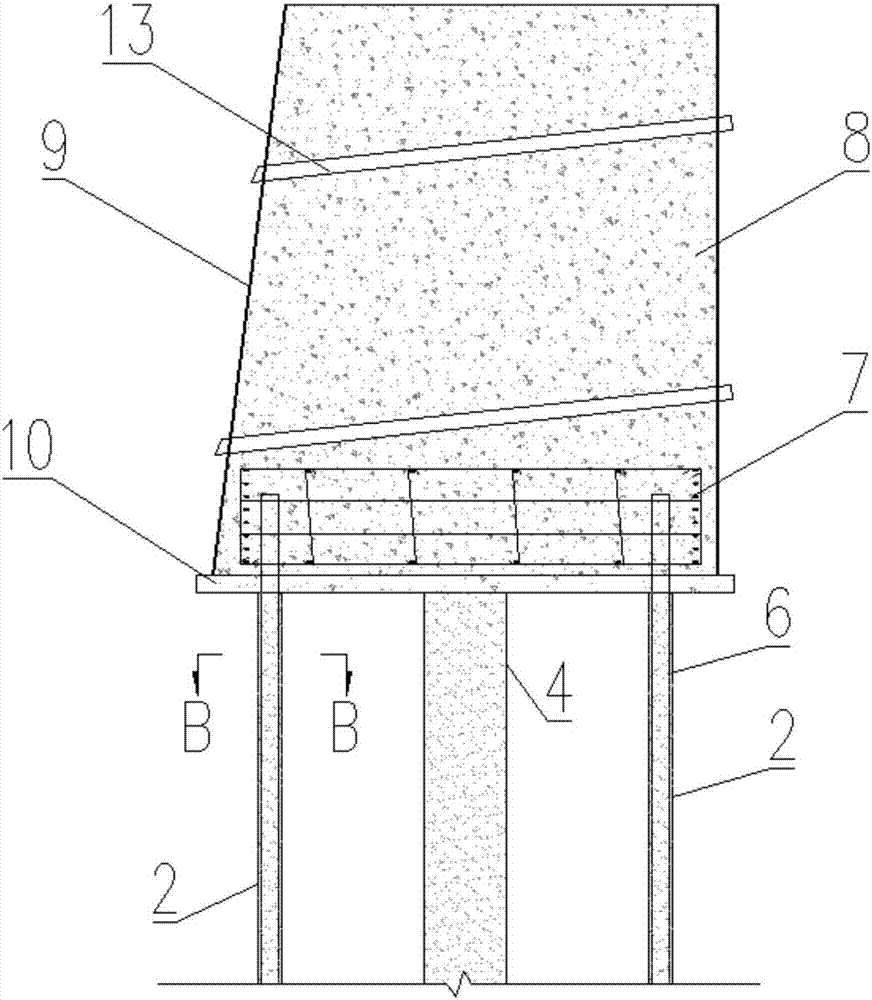

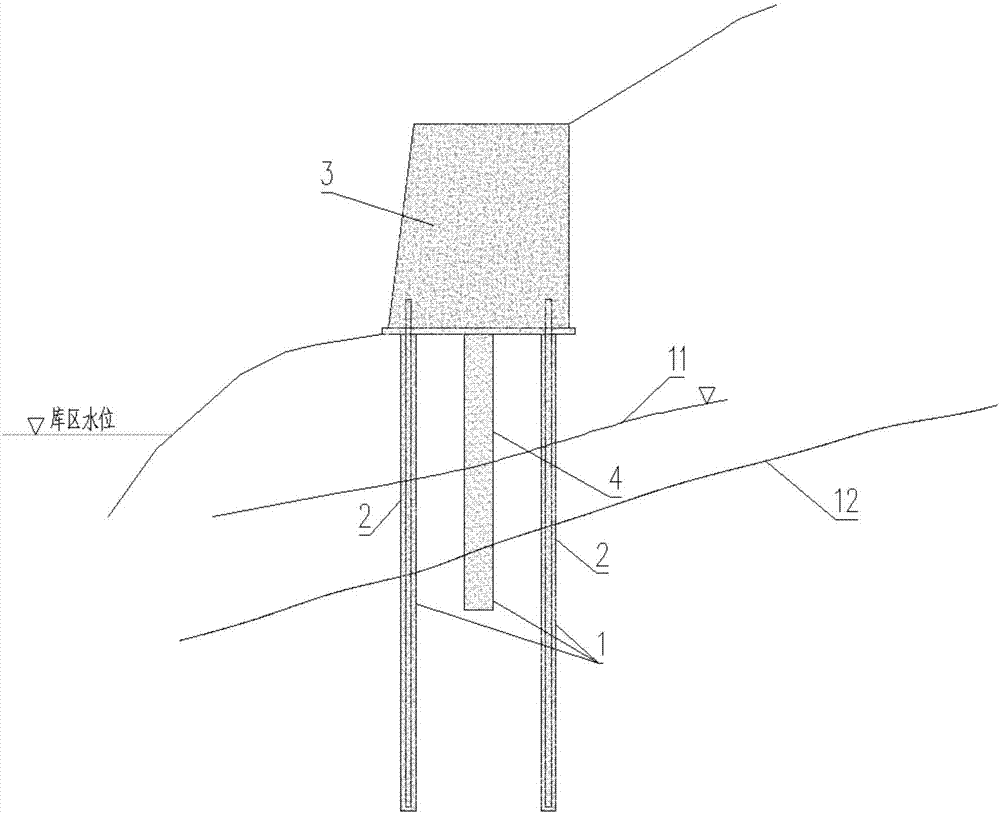

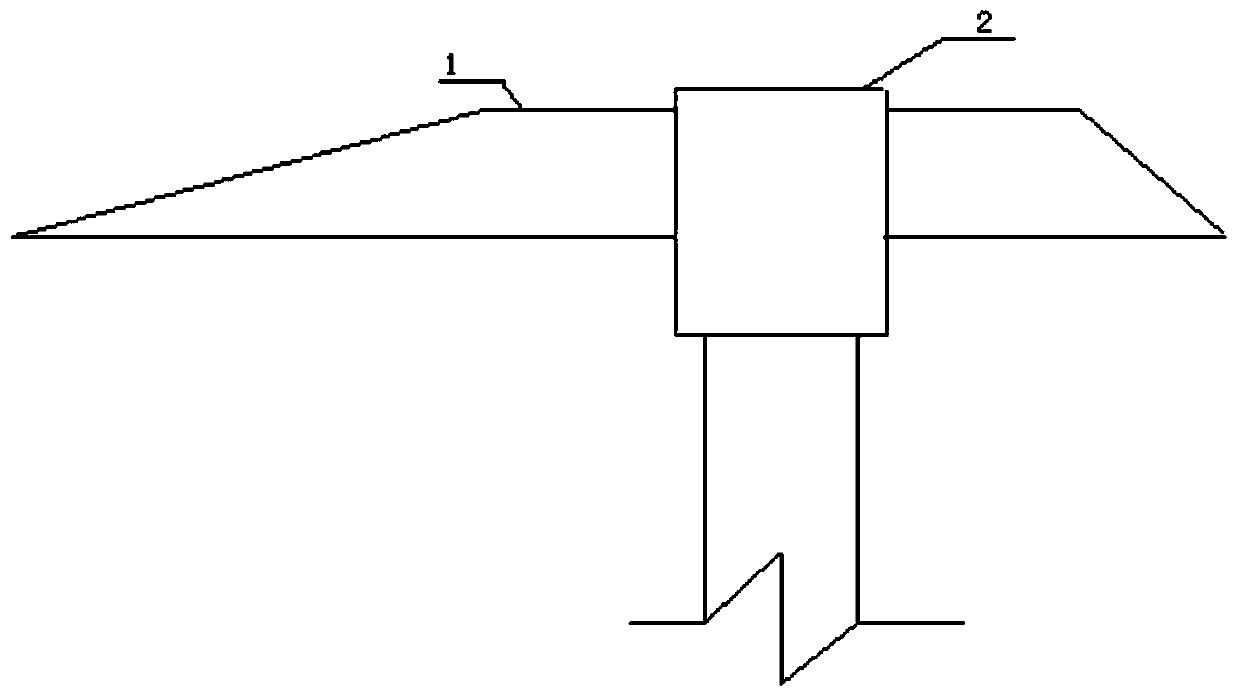

Composite anti-sliding pile wall retaining structure suitable for reservoir bank slope and construction method

PendingCN107503362AMeet the requirements of anti-skid stabilityImprove integrityArtificial islandsExcavationsRetaining wall

The invention relates to a composite anti-sliding pile wall retaining structure suitable for a reservoir bank slope and a construction method. The structure comprises an anti-sliding pile group and a retaining wall; the anti-sliding pile group is vertically arranged between the retaining wall and the reservoir bank slope face and supports the retaining wall, the upper end of the anti-sliding pile group and the bottom end of the retaining wall are fixedly connected, the lower end of the anti-sliding pile group stretches downwards and is embedded in an anti-sliding stratum below a reservoir bank slope sliding band; the anti-sliding pile group is embedded in the anti-sliding stratum below the reservoir bank slope sliding band, the anti-sliding stability needs can be met, the pile top gravity type concrete retaining wall manner is adopted, the lower grouting type anti-sliding pile group and the pile peripheral soil are integrated, and the anti-sliding pile group and the upper gravity type retaining wall are connected to form the composite anti-sliding pile wall. Integrality is good, space effect is optimized structurally, and stress is more reasonable.

Owner:WUHAN MUNICIPAL ENG DESIGN & RES INST

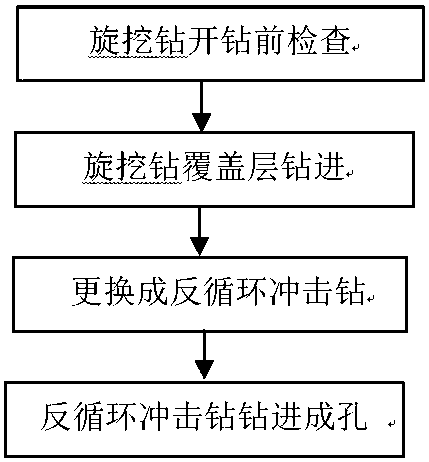

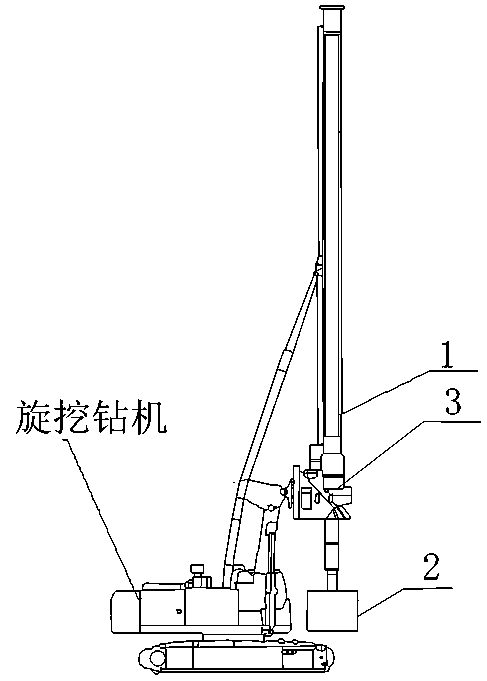

Rapid hole-forming construction method of large-diameter deep hole pile foundation under karst geology

InactiveCN111594041AEasy to moveAvoid drilling difficulties, low efficiency and other problemsDrilling drivesFlushingKarstEconomic benefits

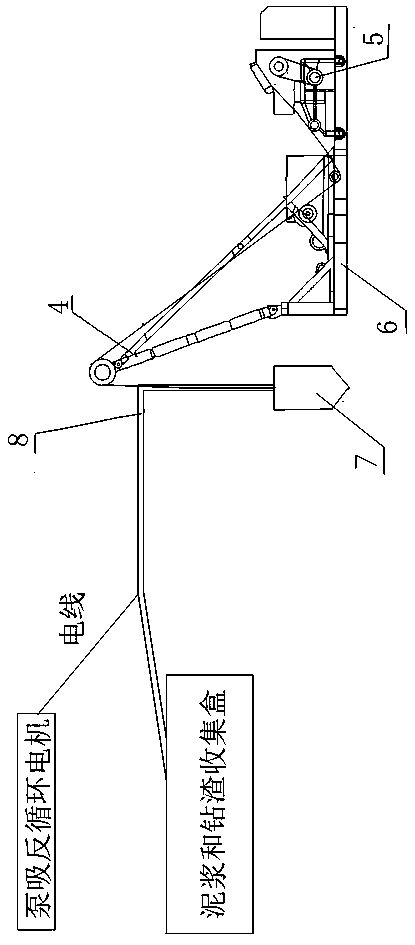

The invention discloses a rapid hole-forming construction method for a large-diameter deep hole pile foundation under karst geology. 'Rotary drill and reverse circulation impact drill' combined relaydrilling is performed, a rotary drill rapidly performs drilling construction of a covering layer, and a reverse circulation impact drill is used for relay construction when a karst geological layer isdrilled. The combined construction process gives full play to the advantages of the two kinds of drills under the situations of different geological conditions and hole depths, the advantages are complemented with each other, and the construction efficiency and economic benefits of the large-diameter deep hole pile foundation under the karst geology are improved. Drilling of single drilling equipment is converted into combined drilling of the two different kinds of drilling equipment, the construction progress of the pile foundation is greatly accelerated under the condition of ensuring the hole-forming quality of the pile foundation, meanwhile, environmental friendliness is better achieved, civilized construction is facilitated, input of personnel and mechanical equipment is reduced, andthe good economic benefits are generated.

Owner:THE 5TH ENG MBEC

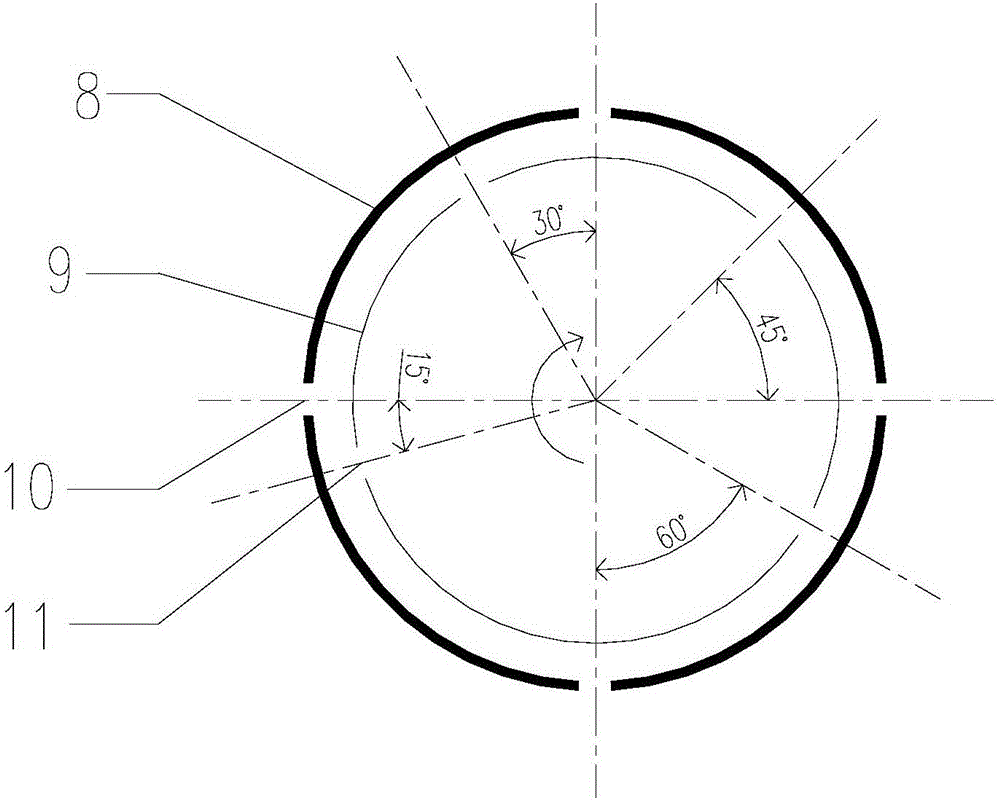

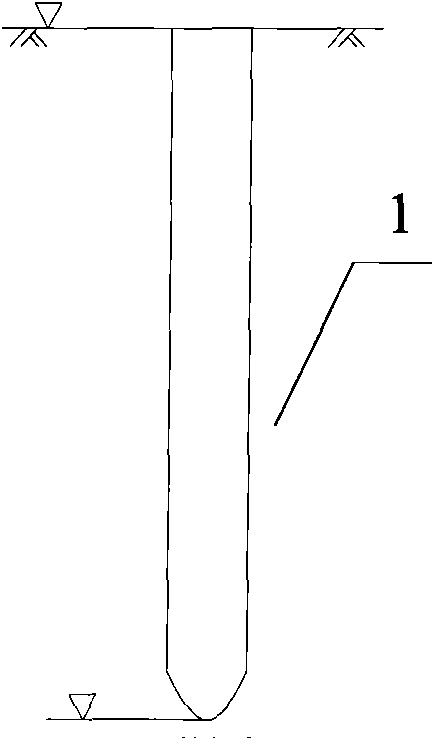

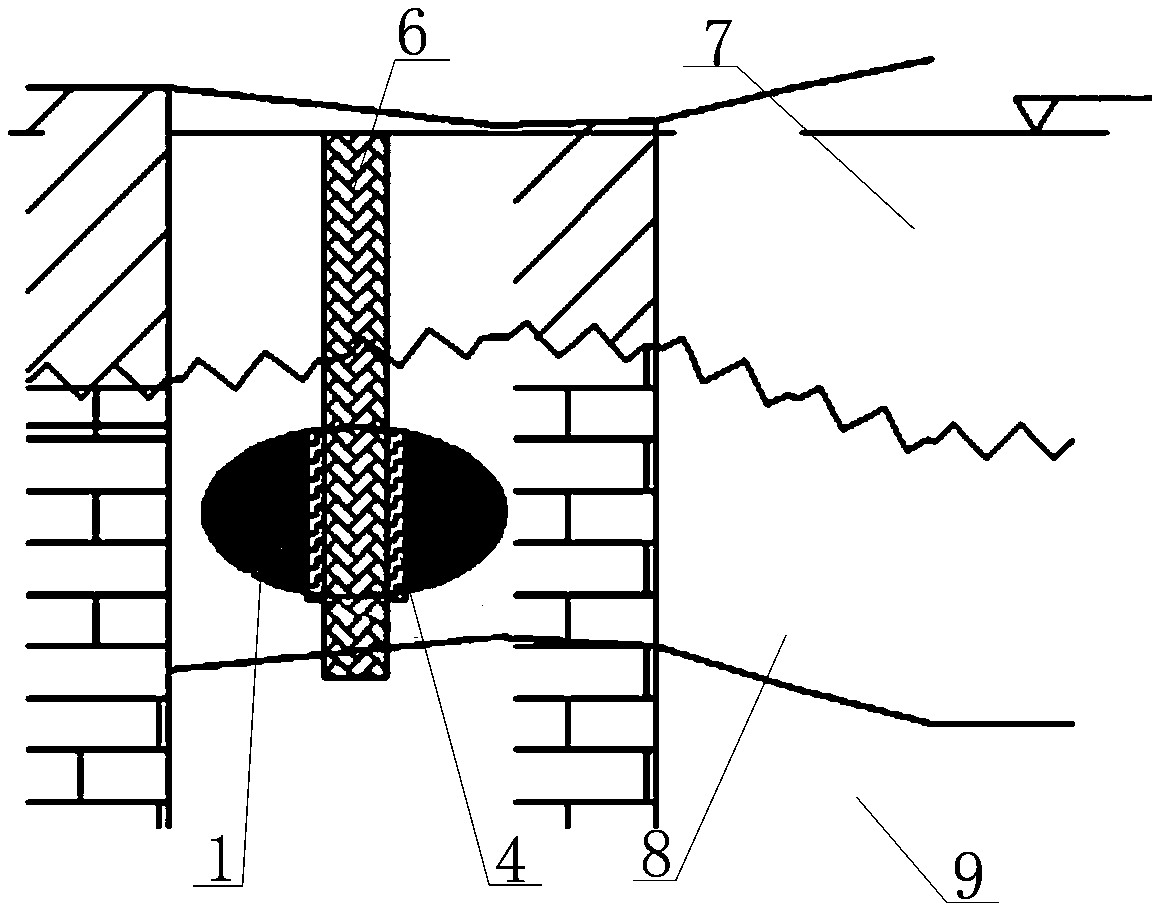

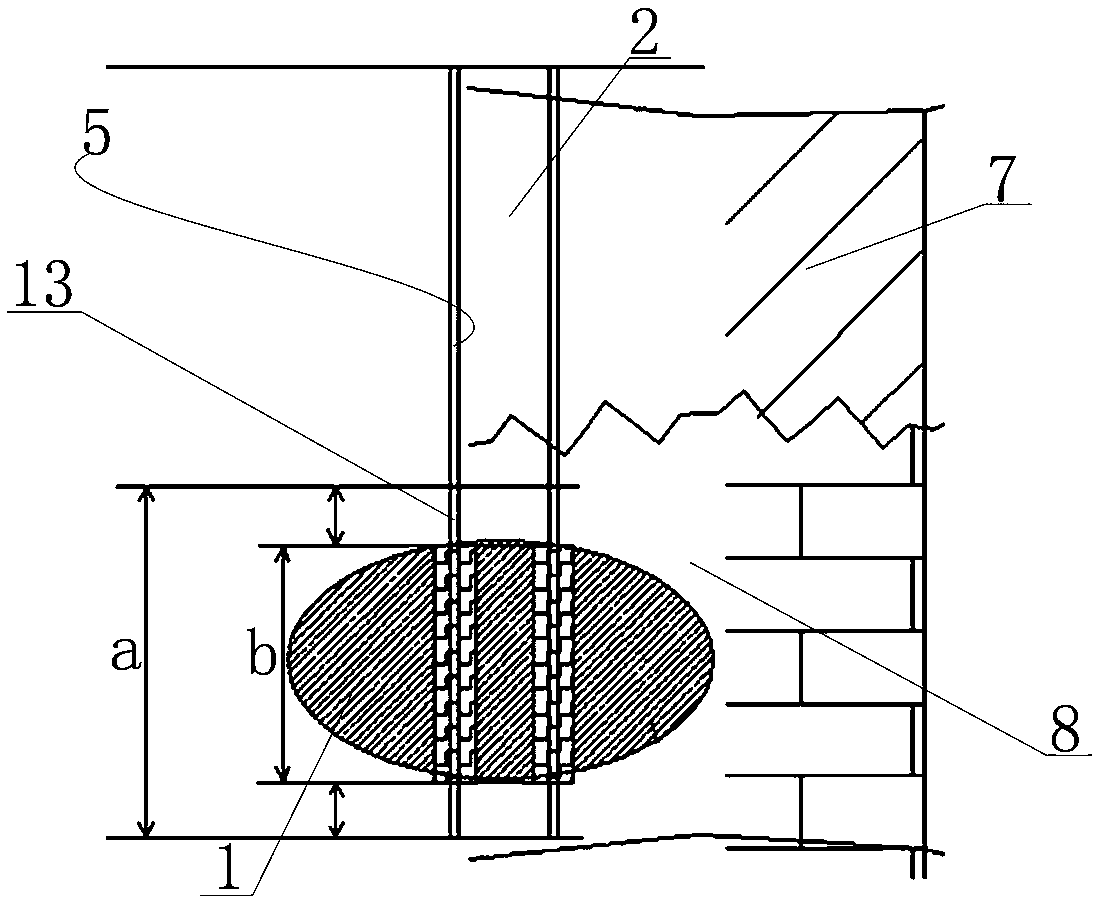

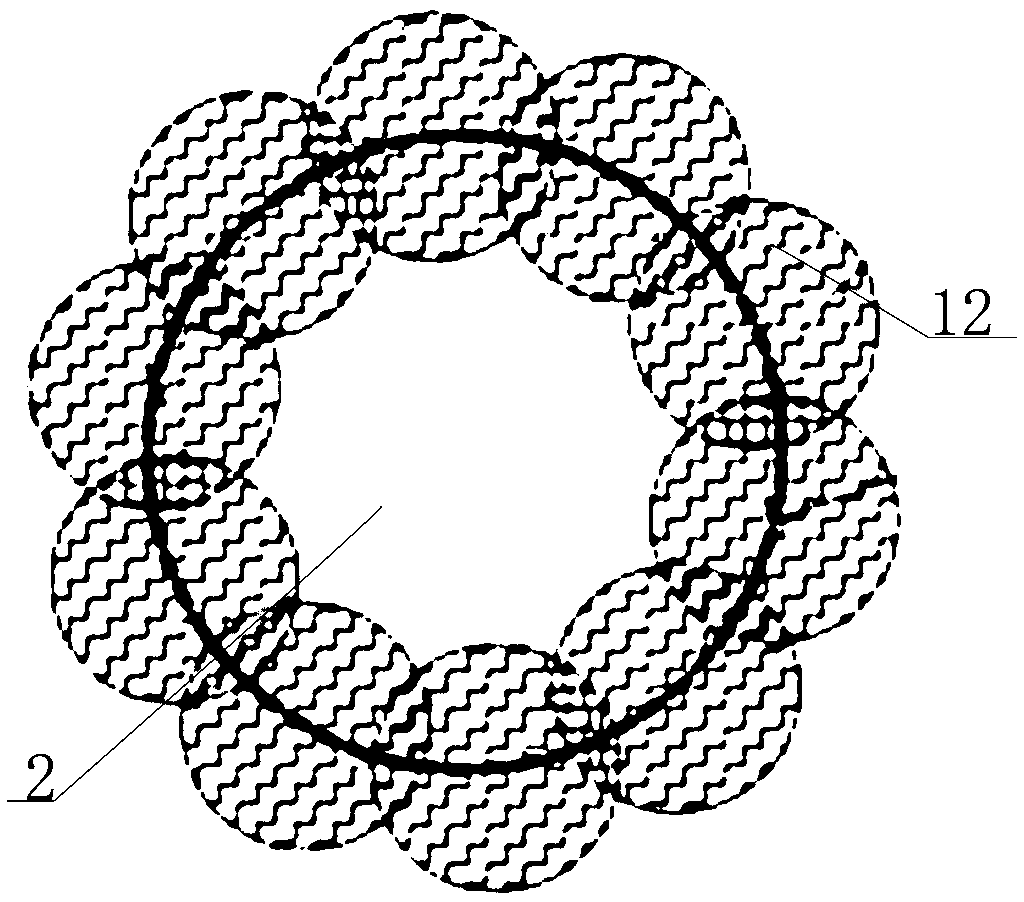

Engineering pile in karst cave geology and pile forming process

PendingCN108265706ASide wall stabilizationGuarantee the pile qualityBulkheads/pilesStructure of the EarthKarst

The invention relates to an engineering pile in karst cave geology and a pile formation process. The lower part of the engineering pile passes through the geological layer, a cave is positioned in thegeological layer, the engineering pile passes through the karst cave and extends into anupper layer soil body; a circle of jet grouting pile reinforcing body is arranged on the outer wall of the engineering pile in the karst cave in a supporting way; the reinforcing body has a centrosymmetric structure; the cross section of the jet grouting pile reinforcing body is formed by a plurality of minorarcs which are connected with each other end to end; the geological layer sequentially comprises a limestone layer, a fractured rock layer and the upper layer soil body from bottom to top; the cave ispositioned in the fractured rock layer. The engineering pile in the cave geology and the pile forming process have the characteristics of being safe and applicable, and the like, having very good practical and promotional values, and producing good economic benefit after being widely popularized and applied.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

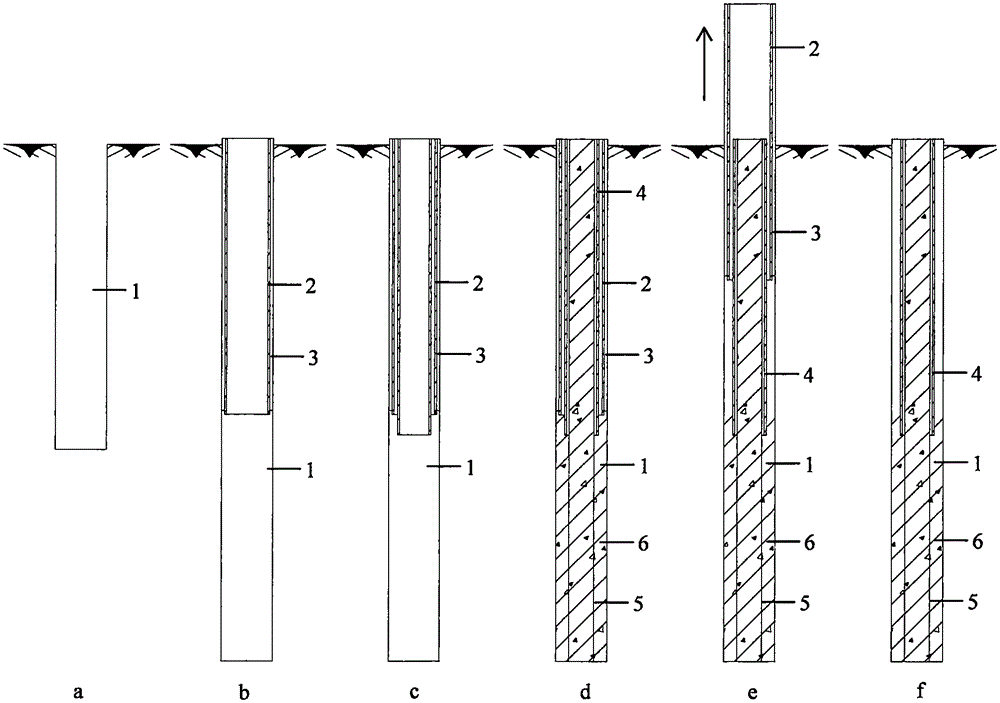

Double-protective barrel impact pile-forming method at silt rock soil layer

InactiveCN106381869AReduce the difficulty of pilingImprove piling efficiencyBulkheads/pilesSoil horizonMaterials science

The invention relates to a double-protective barrel impact pile-forming method at a silt rock soil layer. The method is characterized in that after holes are formed in the silt rock soil layer through impact, steel outer protective barrels are buried inside the holes in a sleeving manner; after the holes are cleaned, steel inner protective barrels are embedded inside the steel outer protective barrels; and after pile bodies inside the steel inner protective barrels are constructed, the steel outer protective barrels are pulled out. According to the double-protective barrel impact pile-forming method, the hole forming difficulty of a mixed soil layer of rock and flow plastic silt can be effectively reduced, the pile forming efficiency is improved, the pile forming quality of pile body concrete and durability of the pile bodies are guaranteed, and the quality problems like diameter shrinkage and collapse of the pile bodies due to the fact that the protective barrels are pulled out are avoided.

Owner:浙江省东阳第三建筑工程有限公司

Force-given effect flexible stake composite presser for groundsill and its uses

InactiveCN1884717AFast reinforcement effectEasy to handleBulkheads/pilesSoil preservationElectricityControl system

The invention relates to a flexible pile composite foundation compress machine, formed by chassis, stabilize leg, walking device, compress tube, pile support, angle control flexible drawing rod, hydraulic system formed by hydraulic device and oil tube, control system formed by motor, hydraulic electric linkage and lighting device, and weight, wherein the chassis is arranged with pile support, support pile support and angle control flexible drawing rod, which are connected via pins or bolts; another end of flexible drawing rod is connected to the pile support via pin or bolt; the compress support and relative fixing pile support form compress part; and the hydraulic system is formed by compress tube jack, oil pump and oil tube; the hydraulic output of hydraulic system is fixed on the pile support and connected to the compress tube, to extend and contract the compress tube, to form hole in soil and compress pile.

Owner:NANJING UNIV OF TECH +1

Diameter-variable drill bit of long-spiral drill

InactiveCN104533297AEasy to driveRealize pilingDrilling rodsConstructionsPetroleum engineeringDrill bit

Provided is a diameter-variable drill bit of a long-spiral drill. A lip-shaped locating ring which has the role of axial locating and is connected with a hollow runner of the long-spiral drill is arranged at the top of the drill bit. A long-spiral drill pipe is connected with screws through fixing lugs on both sides of the lip-shaped locating ring. The part above the middle of a drill core is a diameter-variable cutting section drill core, and the screw blade of the part becomes gradually bigger in the upward direction. The part below the middle of the drill core is a guiding section drill core, wherein the blade diameter is unchanged. The drill core is provided with the screw blade, the front end of the screw blade is provided with cutting edges, the screw blade of the cutting section is provided with cutting teeth, a drill bit point is arranged at the bottom of the drill bit, the drill bit point is provided with a main cutting tool, and the top of the main cutting tool is connected with the drill core through the fixing lugs on both sides of the lip-shaped locating ring and retaining screws. The diameter-variable drill bit of the long-spiral drill is especially suitable for the construction of lock-joint pile waterproof curtains with pre-guide holes and the construction of other long-spiral piles with pre-guide holes, and effectively solves the problems that the pile-body perpendicularity deviation and the pile position deviation are large in the long-spiral construction.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

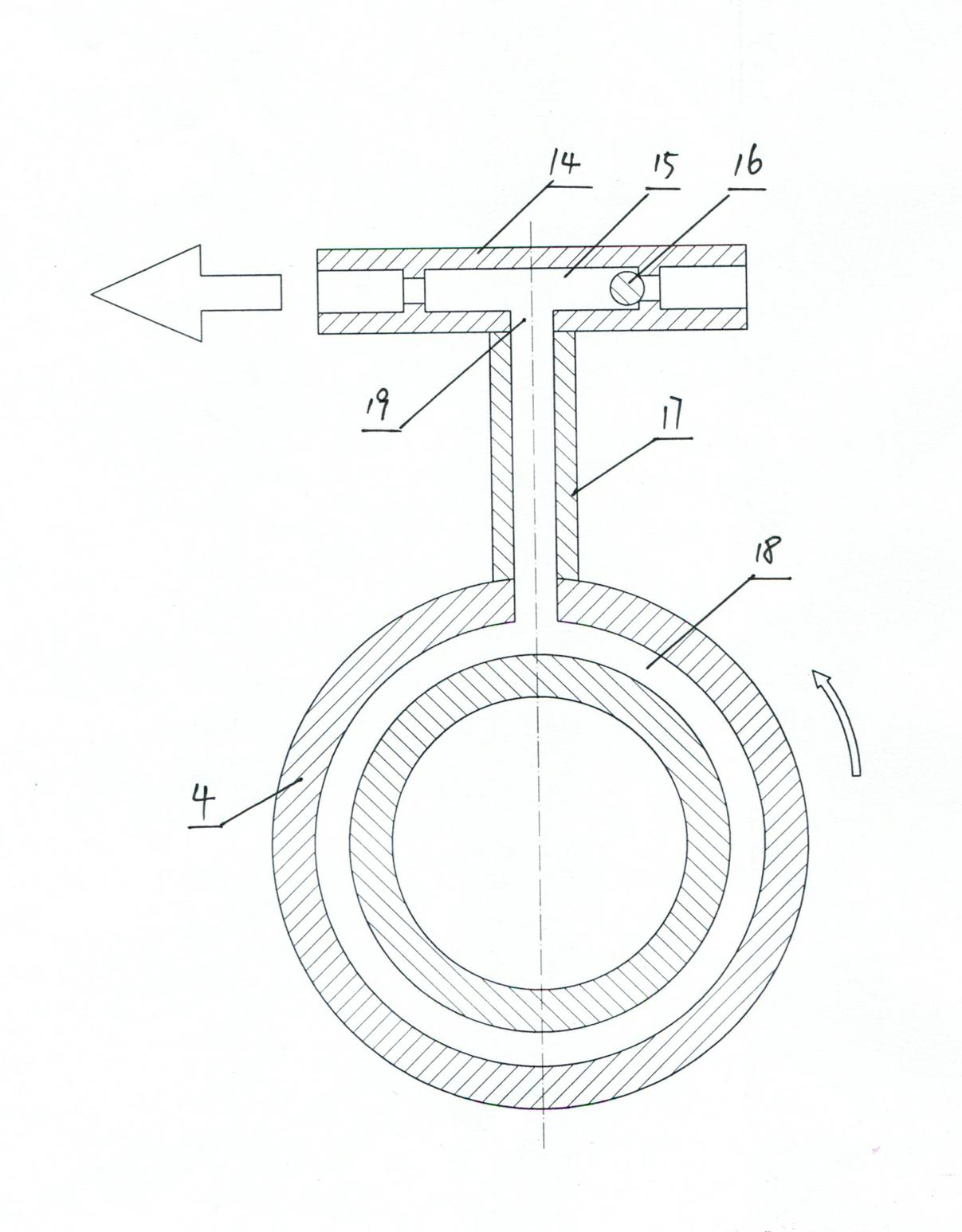

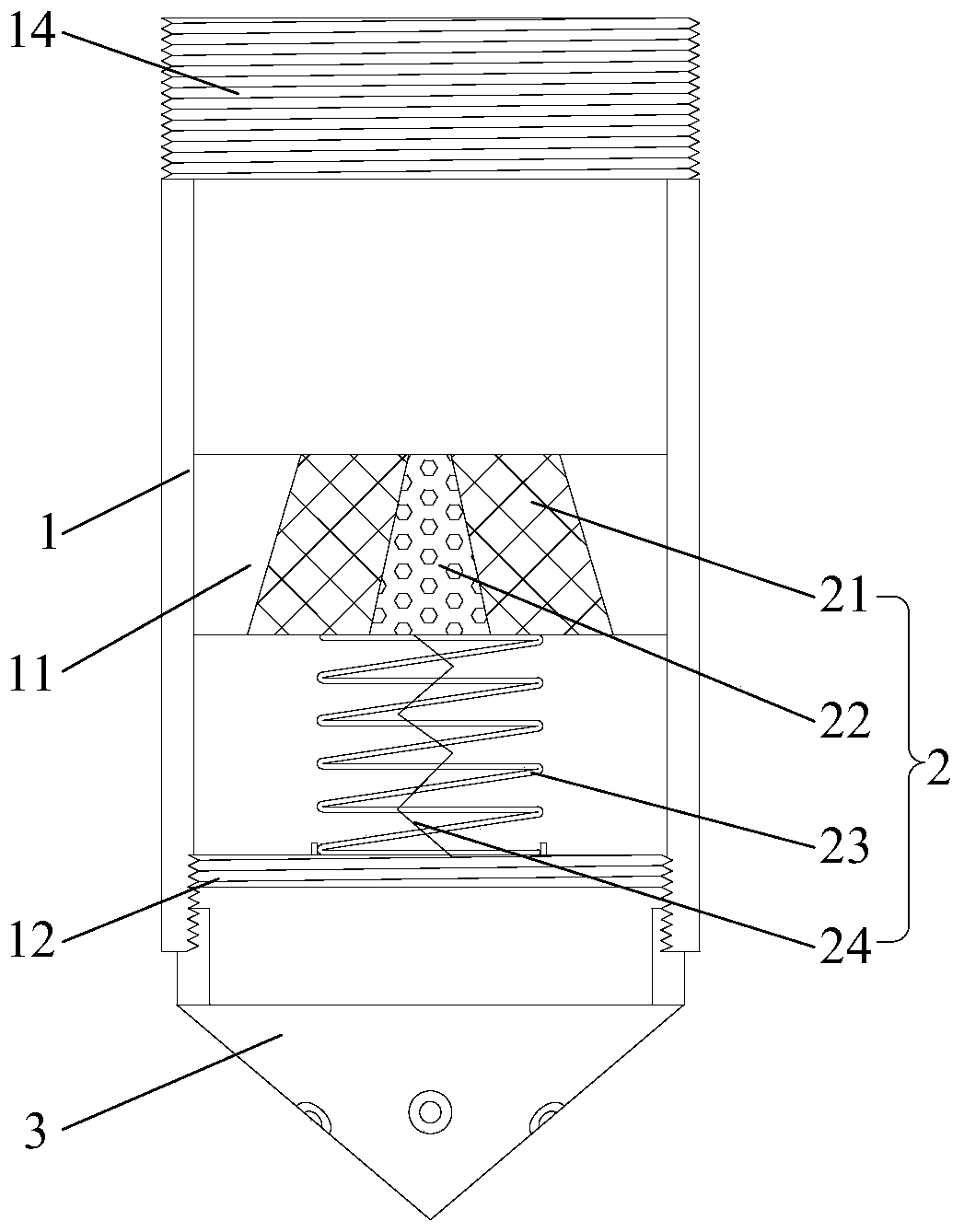

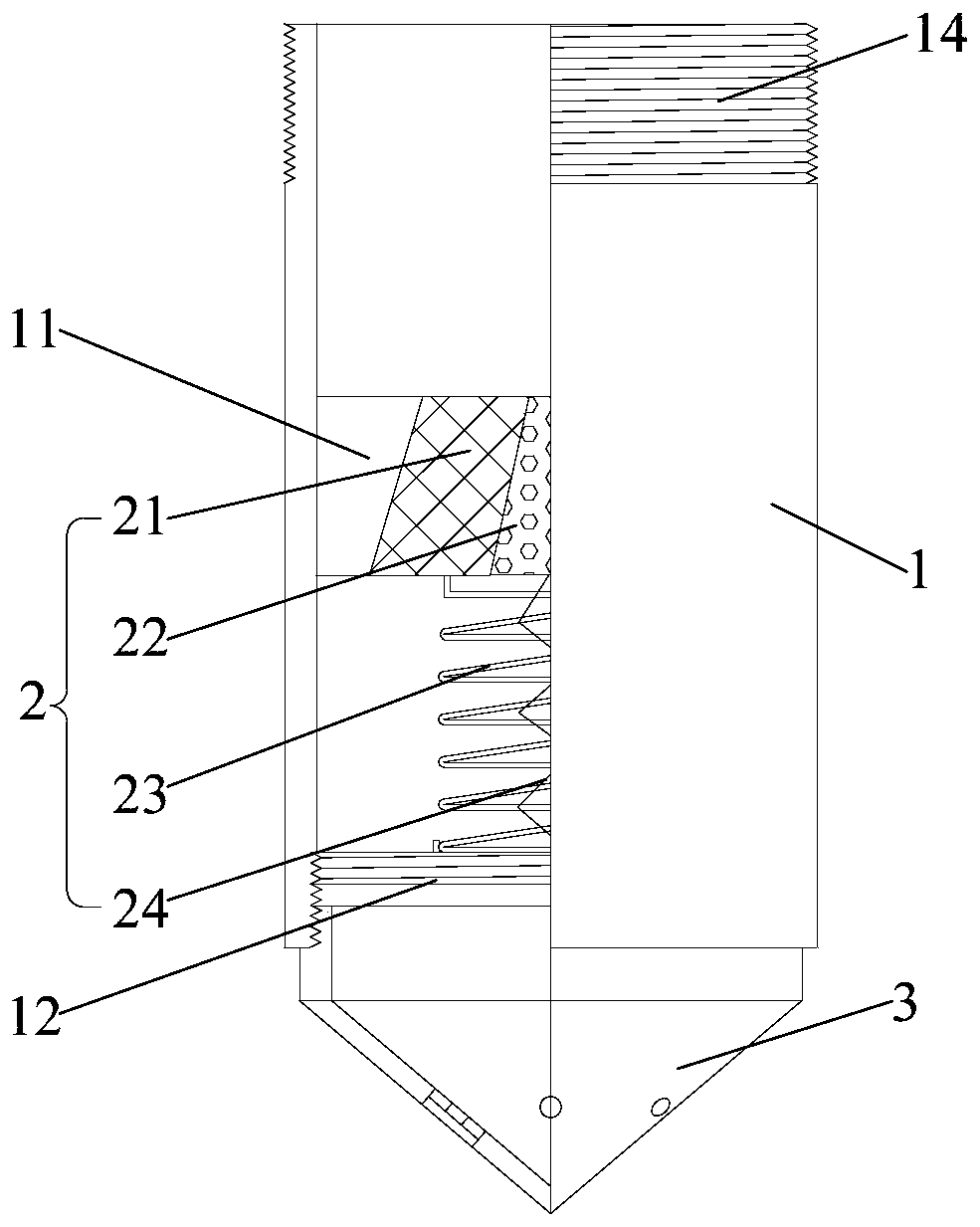

Pile end grouting spray head

PendingCN110499765AConstruction safetyEfficient constructionFoundation engineeringArchitectural engineeringPiston

The invention provides a pile end grouting spray head. The pile end grouting spray head comprises a grouting pipe, an adjusting assembly and a grouting head, wherein a baffle and a base are connectedin the grouting pipe in the grouting direction in a spaced mode; the baffle is provided with a first grout outlet hole, and the base is provided with grout passing holes; the adjusting assembly can bemovably arranged in the first grout outlet hole; the adjusting assembly comprises at least two pistons arranged in a sleeving mode from inside to outside in sequence; the pistons are connected with the base through corresponding elastic parts, and the elastic force of the elastic parts connected with the corresponding pistons increases progressively in sequence from inside to outside; the grouting head is connected to the grout outlet end of the grouting pipe and is provided with grouting holes. Through the pile end grouting spray head provided by the invention, under the condition that grouting pressure meets the using requirement, the first grout outlet hole can be opened smoothly to complete grouting operation. The pile end grouting spray head can adjusting the grout flow according tothe grouting pressure to ensure that the grout flow meets the using requirement.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

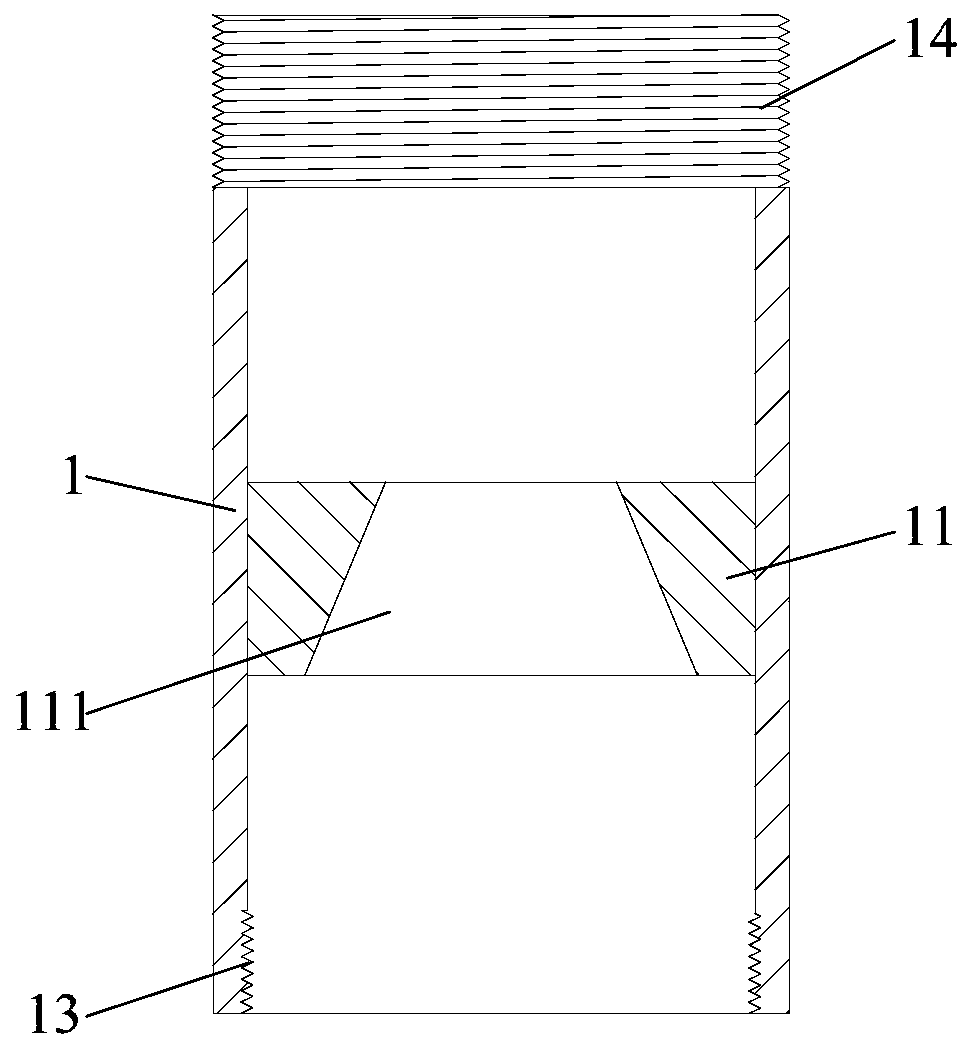

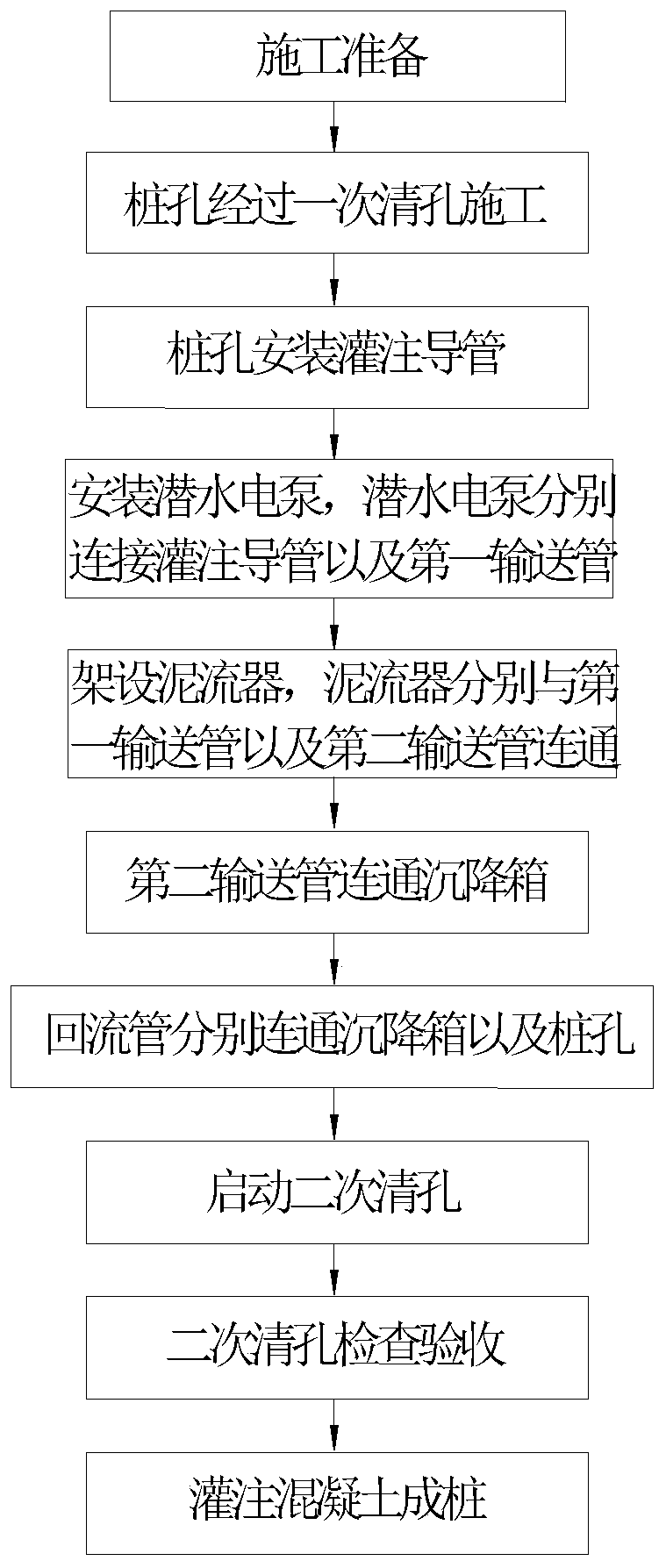

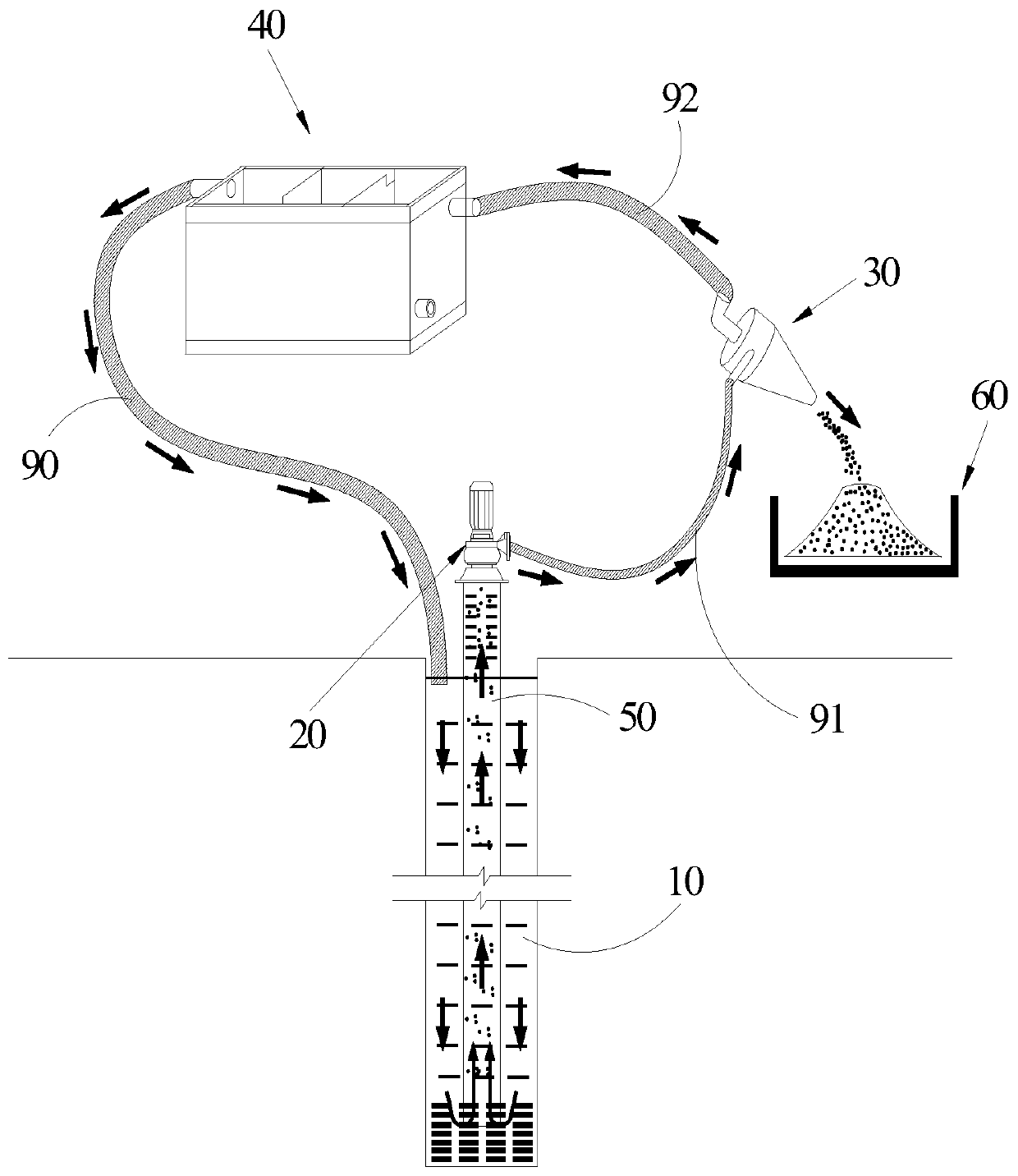

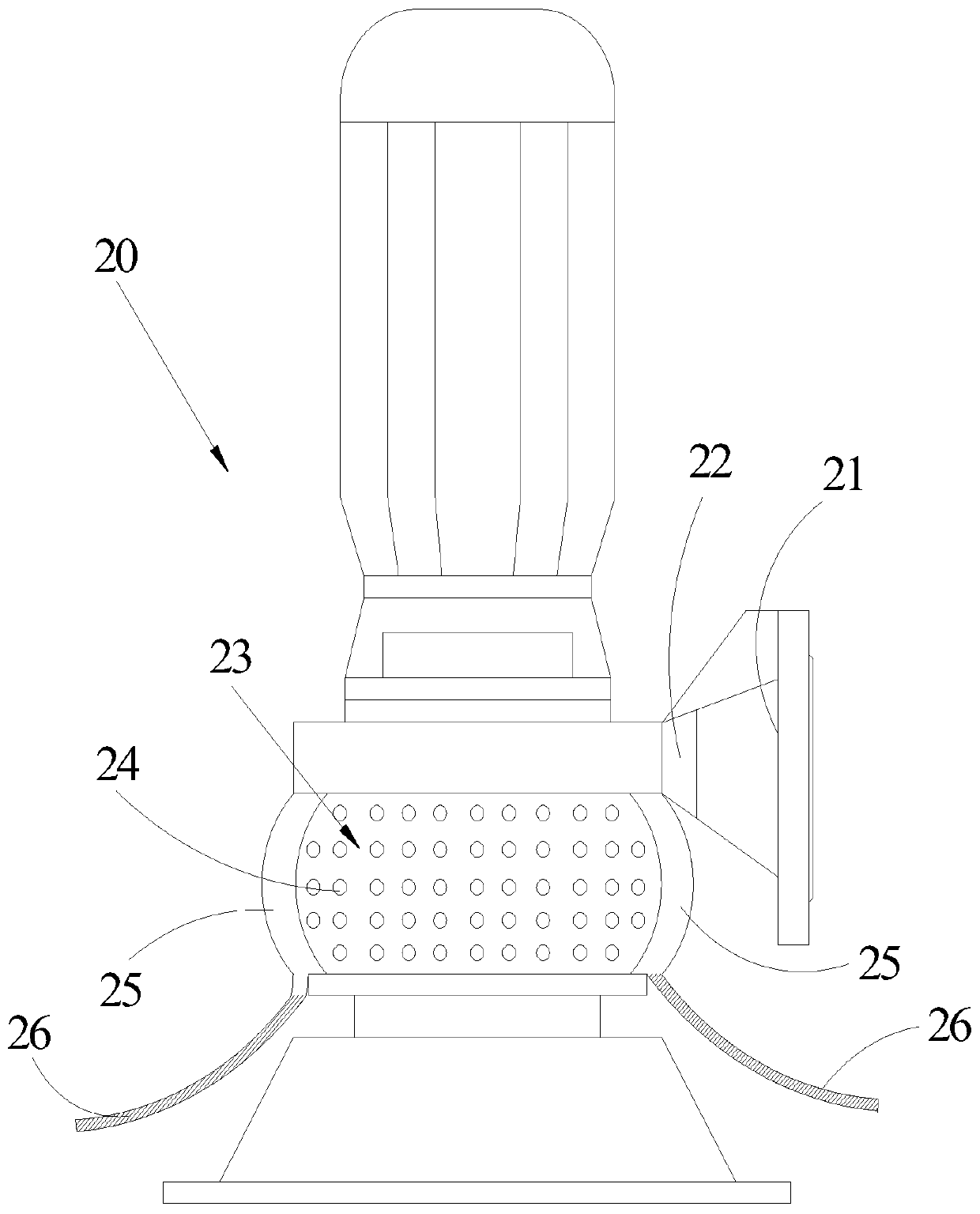

Secondary hole clearing method of cast-in-place pile

The invention relates to the technical field of cast-in-place pile secondary hole clearing, and discloses a secondary hole clearing method of a cast-in-place pile. A pile hoe passing through one-timehole clearing, a submersible electric pump, whirlcone, and a settling box are included, the method includes the following steps that (1) the submersible electric pump is mounted; (2) the whirlcone iserected; (3) the whirlcone separates small particle slurry and large particle slurry, the large particle slurry is discharged from a slag-drip opening, and the small particle slurry overflows from anoverflow outlet through a second transporting pipe to the settling box; (4) a return pipe communicates with the pile hole, and high-quality thick liquid flows back to the pile hole through the returnpipe; and (5) the submersible electric pump and slurry whirlcone are started. The submersible electric pump and whirlcone are used, the weight is light, connection is convenient, loads applied to a platform by second hole clearing construction is lowered, safety and reliability are realized, the hole clearing efficiency is high, the adverse effect of hole collapse caused by hole clearing for a long time is avoided, the quality of pile forming is guaranteed, in addition, hole clearing time is short, the slurry using amount is small, and second hole clearing construction of the cast-in-place pile of an over water work platform is met.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

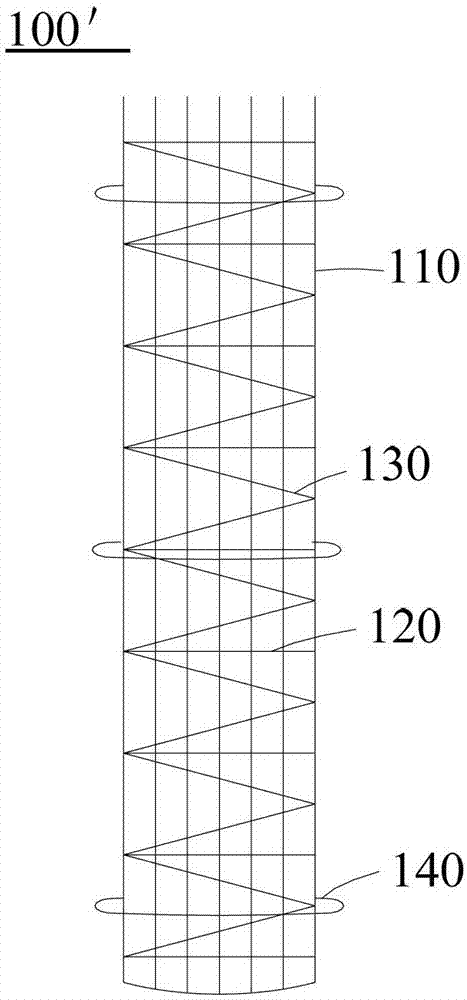

Steel reinforcement cage for filling pile and filling pile construction method using steel reinforcement cage

ActiveCN103114575AGuarantee the pile qualityEliminate potential safety hazardsBulkheads/pilesEngineeringSlurry

The invention provides a steel reinforcement cage for a filling pile and a filling pile construction method using a steel reinforcement cage. The steel reinforcement cage for the filling pile comprises a cage body, at least one anti-scour protective hoop and a plurality of grounting pipes. Each anti-scour protective hoop is arranged on a pre-arranged position outside the cage body, encircles the cage body, and comprises a steel reinforcement framework encircling and fixed on a pre-arranged position outside the cage body, a fine mesh wire net fixed on the steel reinforcement framework, and a slurry layer coated on the fine mesh wire net fine mesh wire net. The plurality of grounting pipes are fixed outside the cage body and extend along the lengthwise direction of the cage body, and slurry outlets of the grounting pipes expose outside each anti-sour protective hoop. In the construction process of the filling pile by using the steel reinforcement cage, anti-sour protective hoops on the steel reinforcement protective hoop ensure that water on an underwater layer can not directly generate scour on concrete in the filling pile. Furthermore, the grounting pipes on the steel reinforcement cage fill slurry between the anti-scour protective hoops and a pile hole wall, and accordingly water seams are plugged by the slurry, and the pile hole wall is strengthened.

Owner:MCC COMM CONSTR GRP CO LTD

Strengthening and reinforcing mountain piling construction method for underground pile foundation cavern

The invention discloses a strengthening and reinforcing mountain piling construction method for an underground pile foundation cavern. The strengthening and reinforcing mountain piling construction method comprises the steps that (1), advanced drilling is conducted, specifically, the cavern situation of a site is displayed according to survey data of a project, advanced drilling is conducted before pile forming, and the advanced drilling depth should be drilled till the cavern situation below the pile bottom is proven; (2), hole forming is conducted, specifically, a pile hole is formed in thedesign elevation of the pile bottom; (3), deep drilling is conducted, specifically, a miniature steel pipe is drilled to the cavern bottom; (4), mountain piling is conducted, specifically, mountain piling comprises dredging, discharging for stacking and filling, grouting for consolidation and re-inspection; and (5), pile forming is conducted, specifically, the miniature steel pipe penetrates through a filler pile to be driven to the cavern bottom, a made steel reinforcement cage is put into the pile hole, pile body concrete is poured into a pile, and construction is completed. According to thestrengthening and reinforcing mountain piling construction method, the harm of the underground pile foundation cavern can be safely, quickly, economically, thoroughly and effectively treated, the construction safety and the pile forming quality of the project pile are guaranteed, and the bearing capacity and anti-deformation requirements of the structure are met.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

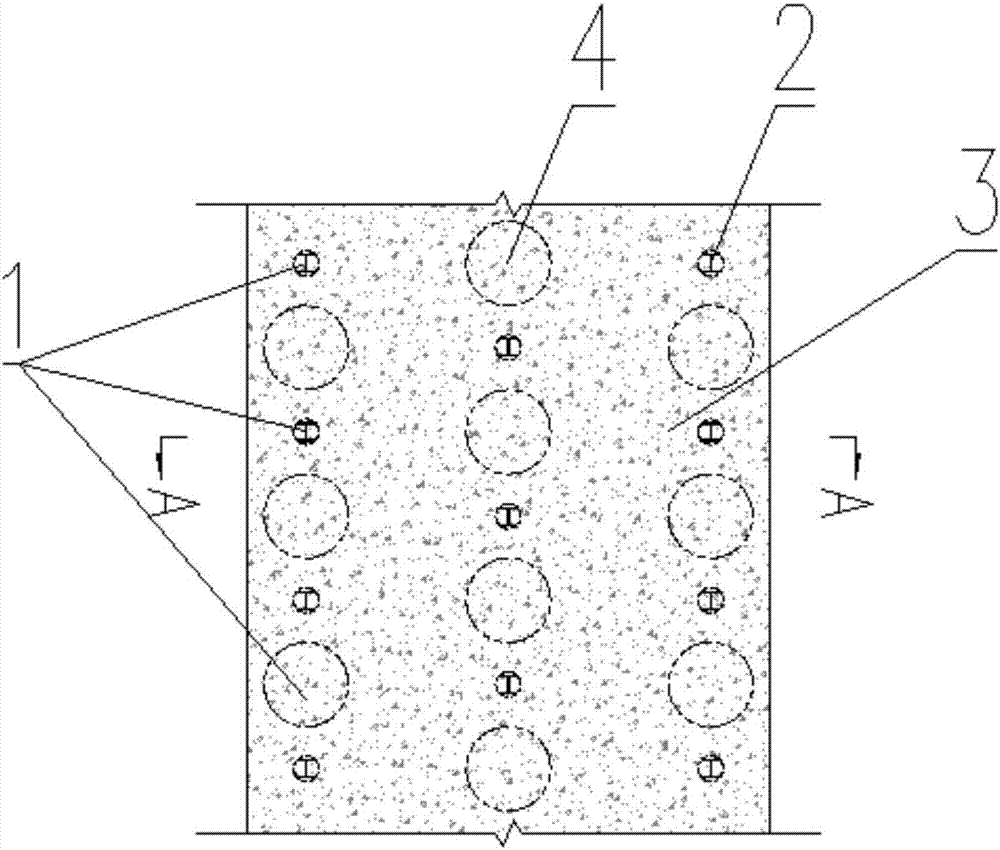

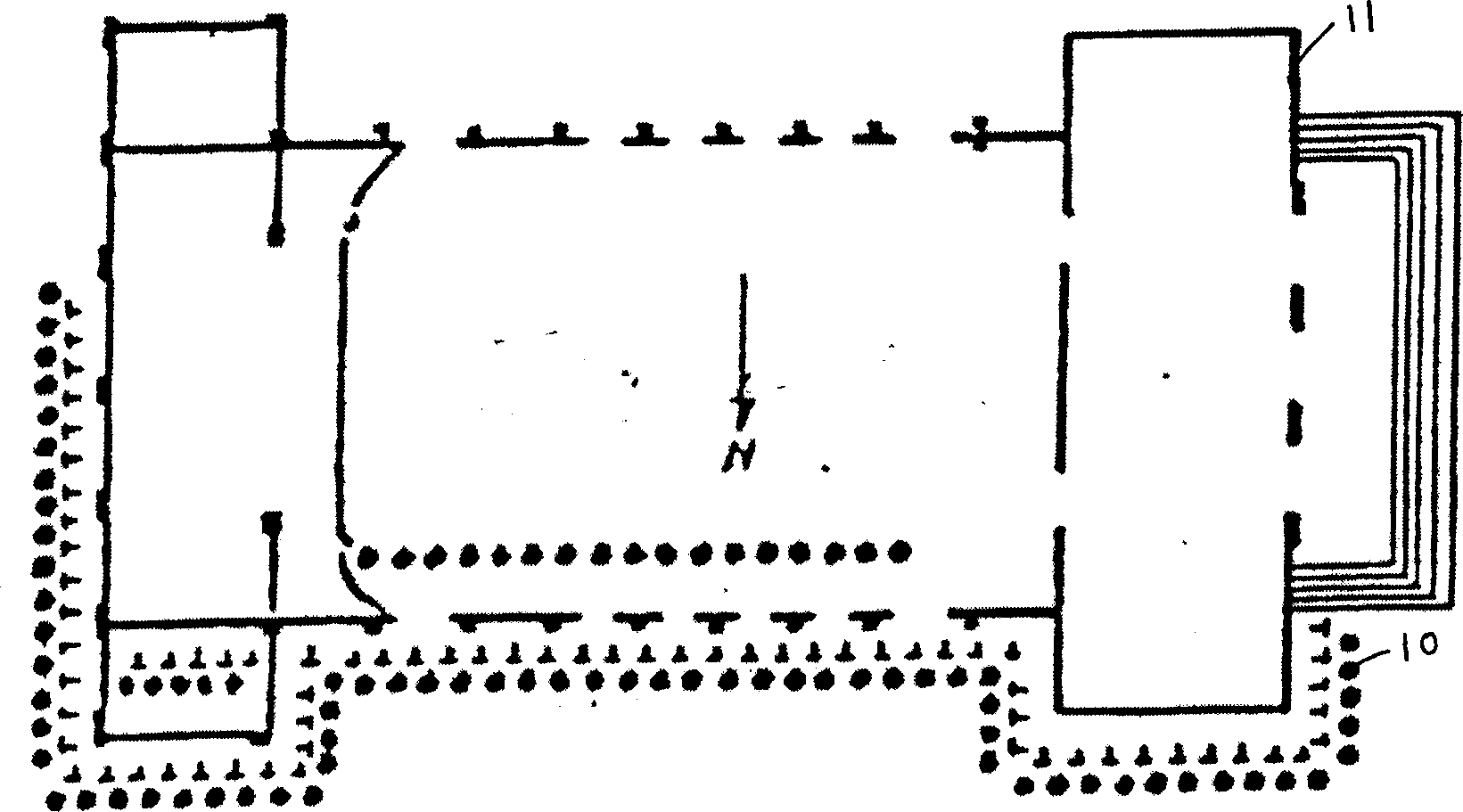

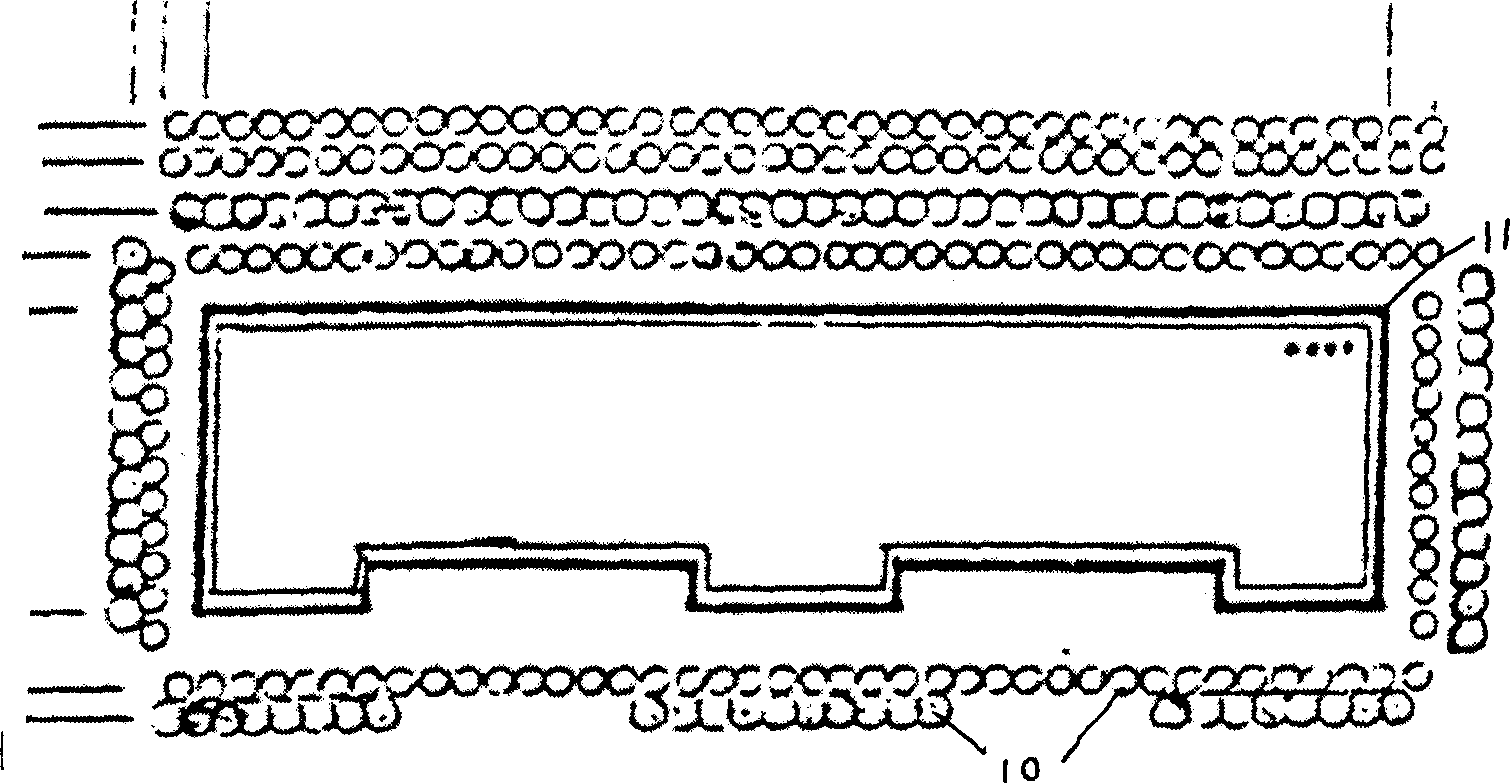

Multiple head small diameter long screw drilling wall forming machine

InactiveCN1900430AImprove adaptabilityGuarantee the pile qualityDamsArtificial islandsPower unitDrill bit

The present invention relates to a multithread minor diameter long auger drilling wall forming machine. Said invention adopts portal shaped piledriver side-by-side set at least auger stems, lower end set drill, top connected with spacer, spacer slip connection with portal shaped piledriver, spacer set rotating power unit, auger stem connected with rotating power unit, auger stem being hollow in middle part, connected with concrete delivery pipe, guideway set below the chassis. Said invention solves uneven soil stirring, weak intensity, inefficiency etc shortage.

Owner:HOHAI UNIV

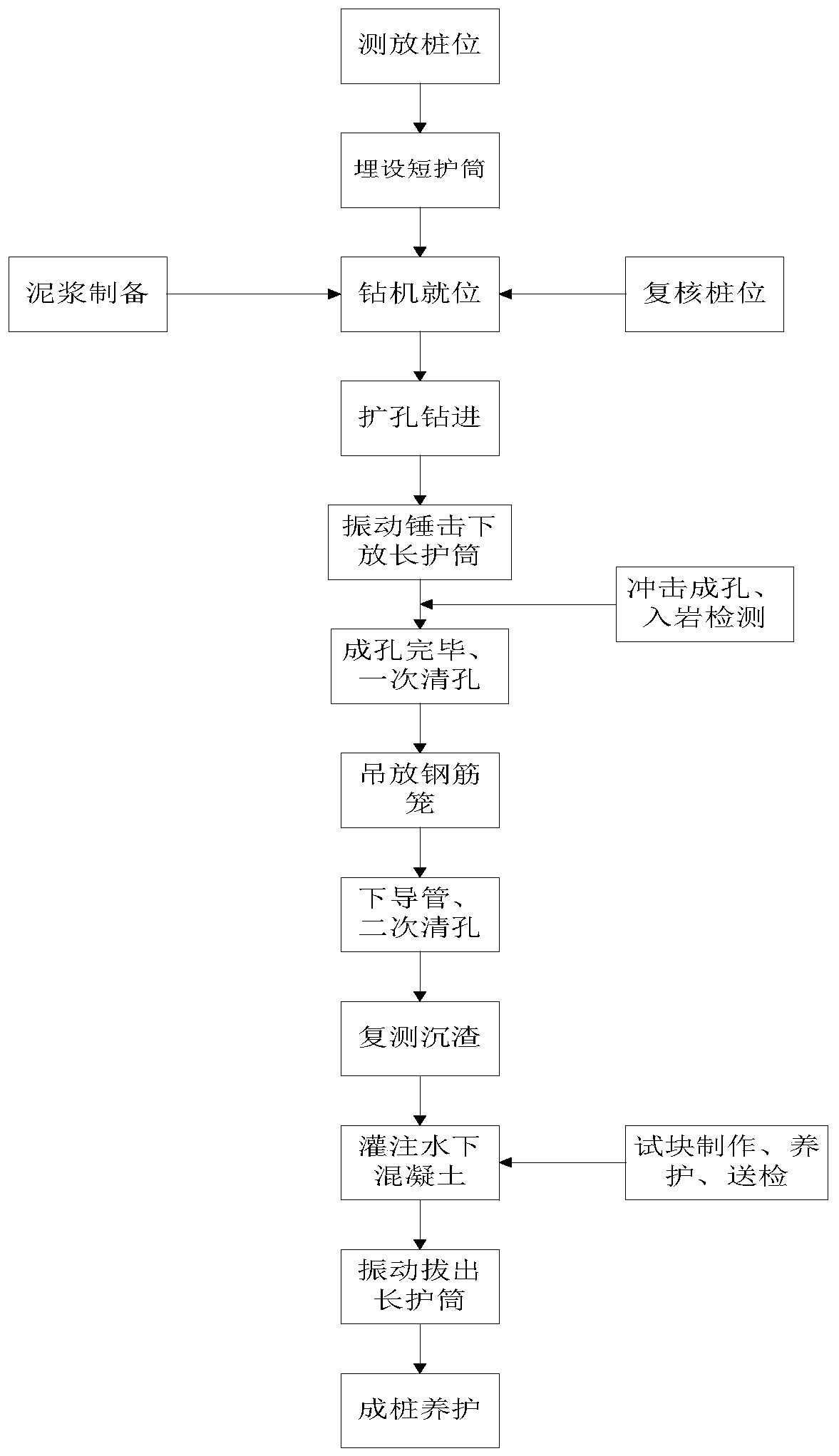

Construction method of long protective tube impact-cone concrete pile in ultra-thick silt area

InactiveCN110106872AAccelerate return on investmentGuarantee the pile qualityBulkheads/pilesSludgeRebar

The invention discloses a construction method of a long protective tube impact-cone concrete pile in an ultra-thick silt area, and relates to the technical field of impact-cone concrete pile construction. Above a sludge soil layer, a chopping bit with the diameter larger than 200mm of the pile diameter is adopted for chambering drilling and mud wall protection pore-forming, a sludge layer is entered, a long protective tube protective wall is adopted, a crawler crane is matched with vibration hammer hydraulic pliers to vibrate a long protective tube to perform sludge layer drilling, the sludgelayer is broken through, a chopping bit in line with the pile diameter is replaced to drilling and complete pore-forming, when punching reaches the design-required depth into rock clear, a hole is cleaned, a steel bar cage is lifted to designed elevation after the hole is cleaned, pile-forming construction is organized, concrete is poured, a guide tube is laid, the concrete is continuously pouredto above the designed pile top elevation 800-1000 mm, pulling out of the long protective tube and concrete replenishment of a pile body are organized, and pile-forming work is completed.

Owner:CHINA CONSTR EIGHTH ENG DIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com