Bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation construction method

A technology for prestressed pipe piles and composite foundations, which is used in infrastructure engineering, sheet pile walls, buildings, etc., and can solve the problem that the treatment method of large-scale weak foundation cannot fully meet the requirements, the depth of the pile body is too deep, and the construction machinery is cumbersome. Field and other problems, to achieve the effect of convenient pile quality inspection, reduction of post-construction settlement, and guaranteed pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

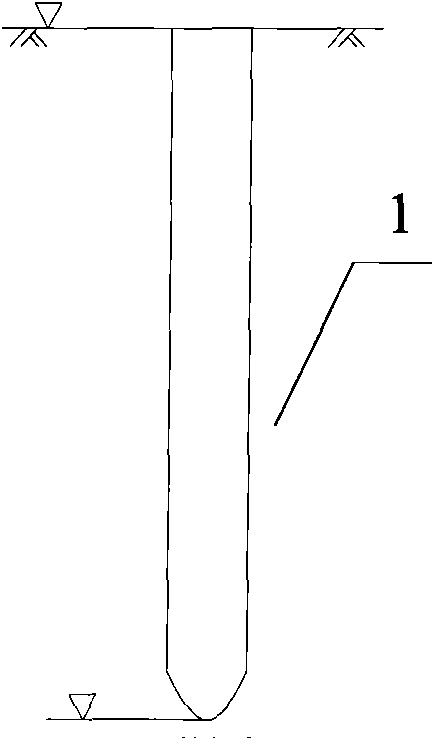

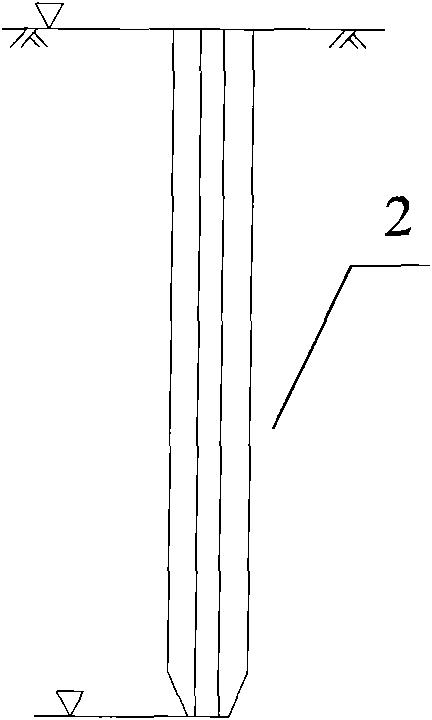

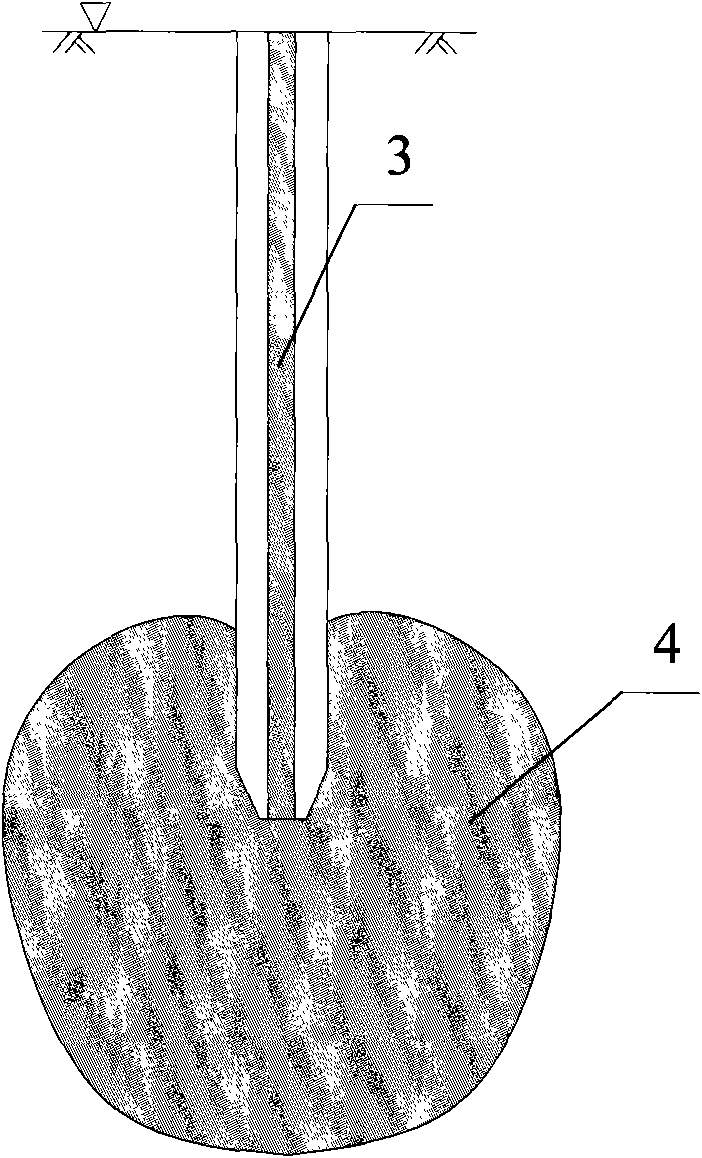

[0020] The specific construction steps of the construction method of the small-diameter prestressed pipe pile composite foundation by grouting and expanding the bottom are further described below in conjunction with the attached drawings:

[0021] (1) Pile sinking in place by a small pile driving machine: ① According to the characteristics of the site soil and the form of the building, the reinforcement depth of the weak soil foundation is determined to be 6.0m, and the prefabricated pipe pile length is 6.0m, the outer diameter is 150mm, and the wall thickness is 50mm; ② Luoyang shovel Prefabricated holes with a diameter of 90mm and a depth of 4.0m to reduce the difficulty of driving prefabricated tubular piles;

[0022] (2) Preparation of grout for grouting: ① Use No. 42.5 clot-free, non-damp ordinary Portland cement or slag cement; ② Dry cement and non-polluted water are prepared according to the designed water-cement ratio to achieve fluidity with a water-cement ratio of 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com