Static pressure pipe pile settling construction technique

A technology of construction technology and technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of frequent maintenance, construction noise disturbing residents, increase of engineering quantity, etc., to achieve concentrated construction workload, small construction environment interference, Guarantee the effect of pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

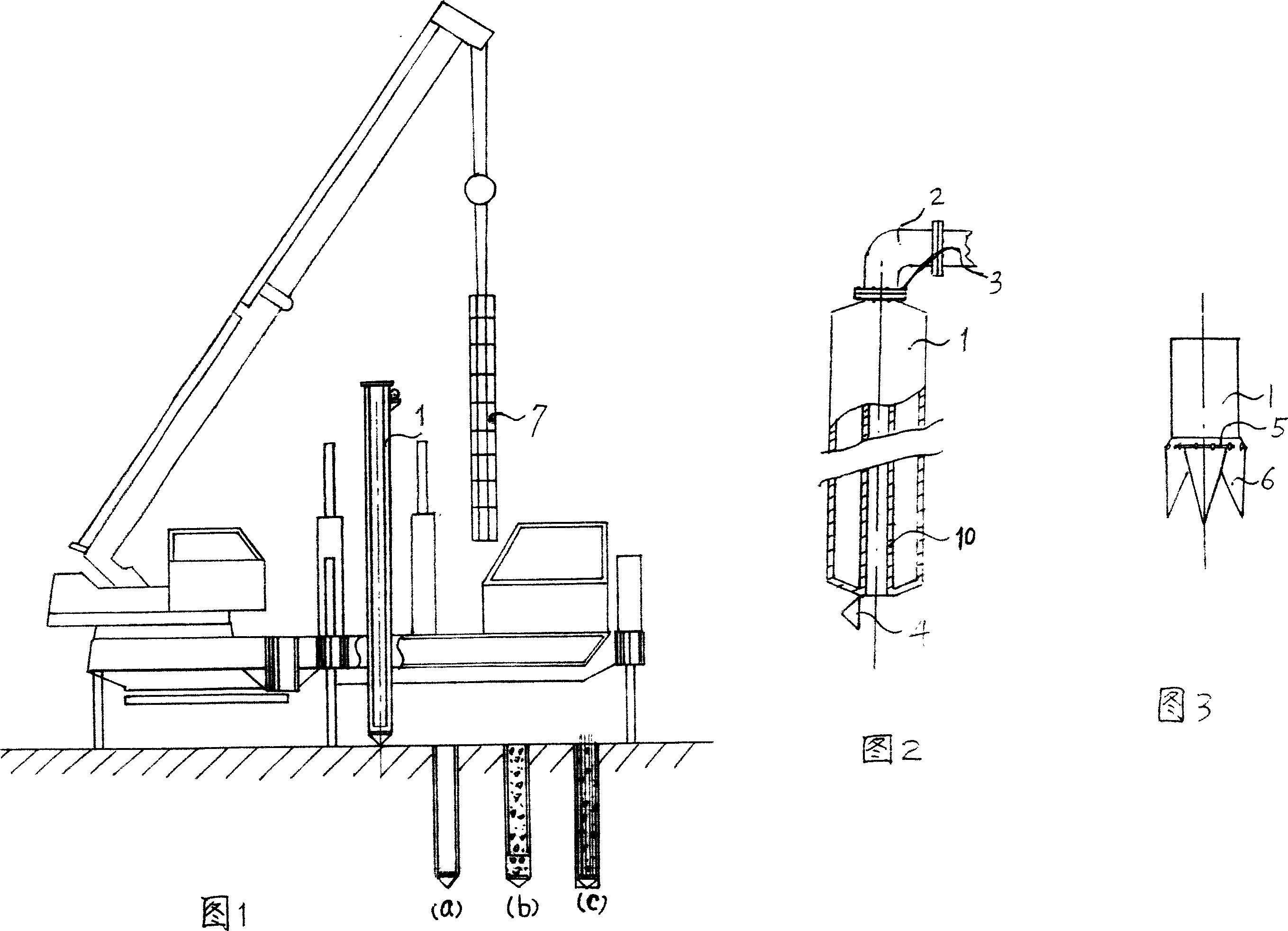

[0010] The construction method of the static pressure sinking pile provided by the patent application of the present invention uses the sinking structure as follows: the upper end is provided with a connecting flange 3 communicating with the concrete high-pressure conveying pipeline 2, and the lower end is hinged with a connecting flange 3 which is used when injecting high-pressure concrete. The pile point 4 that high pressure pressure opens. The immersed tube implementing the construction process method of the present invention can be an existing general-purpose seamless thick-walled steel pipe, and the lower end of the immersed tube is hinged with a valve pile point 4; the immersed tube structure as shown in Figure 2 can also be used, and the immersed tube A double-layer casing structure is adopted, that is, a core tube 10 is coaxially arranged in the immersed tube, and the lower end of the core tube is hinged to set a pile tip 4, and the tube layer space between the core tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com