Patents

Literature

343results about How to "Improve pile quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

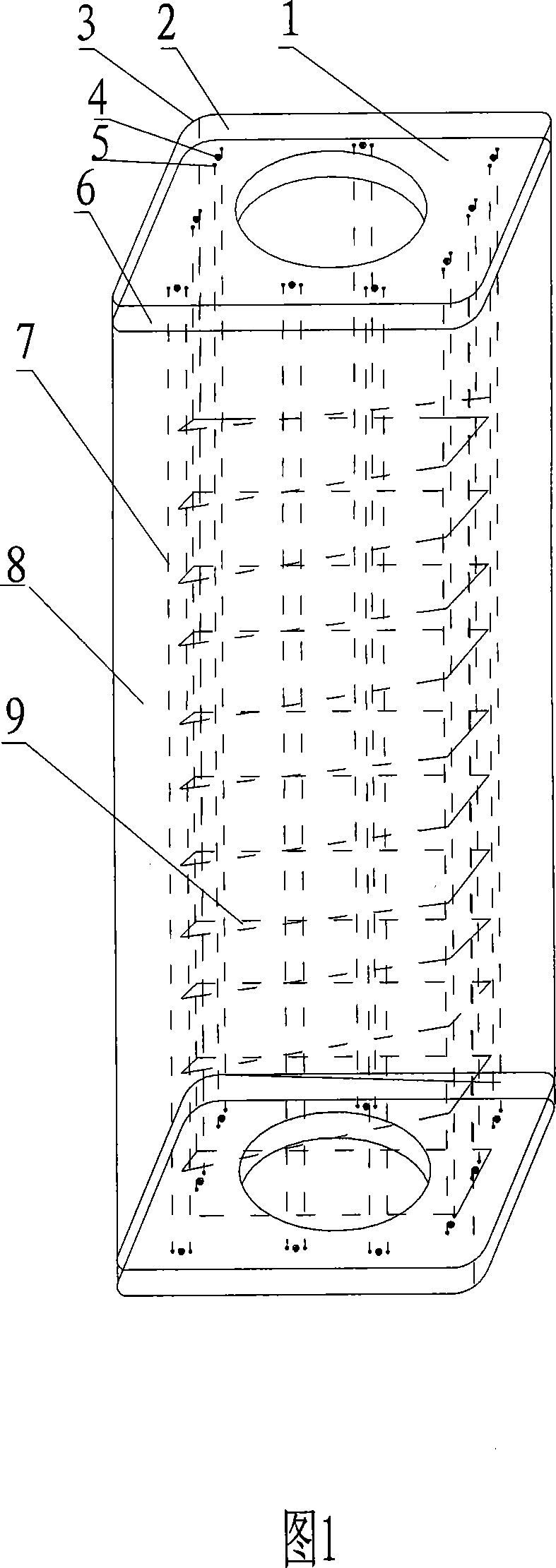

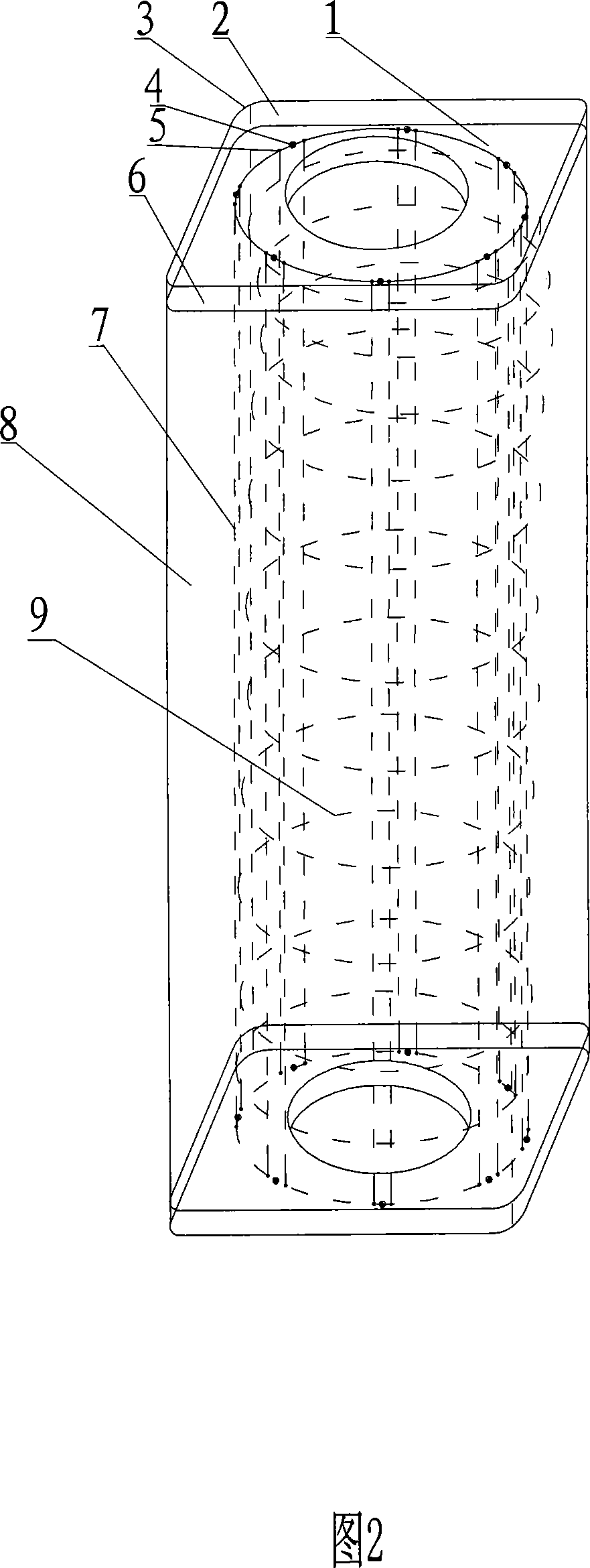

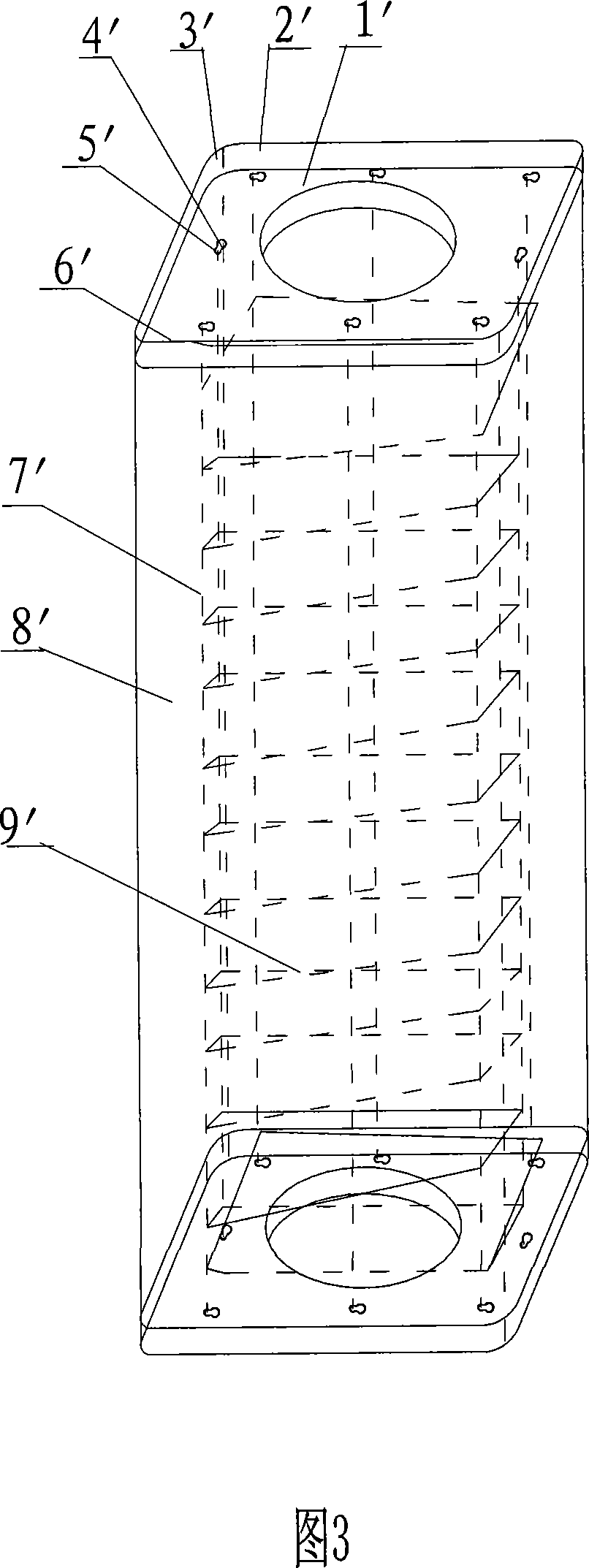

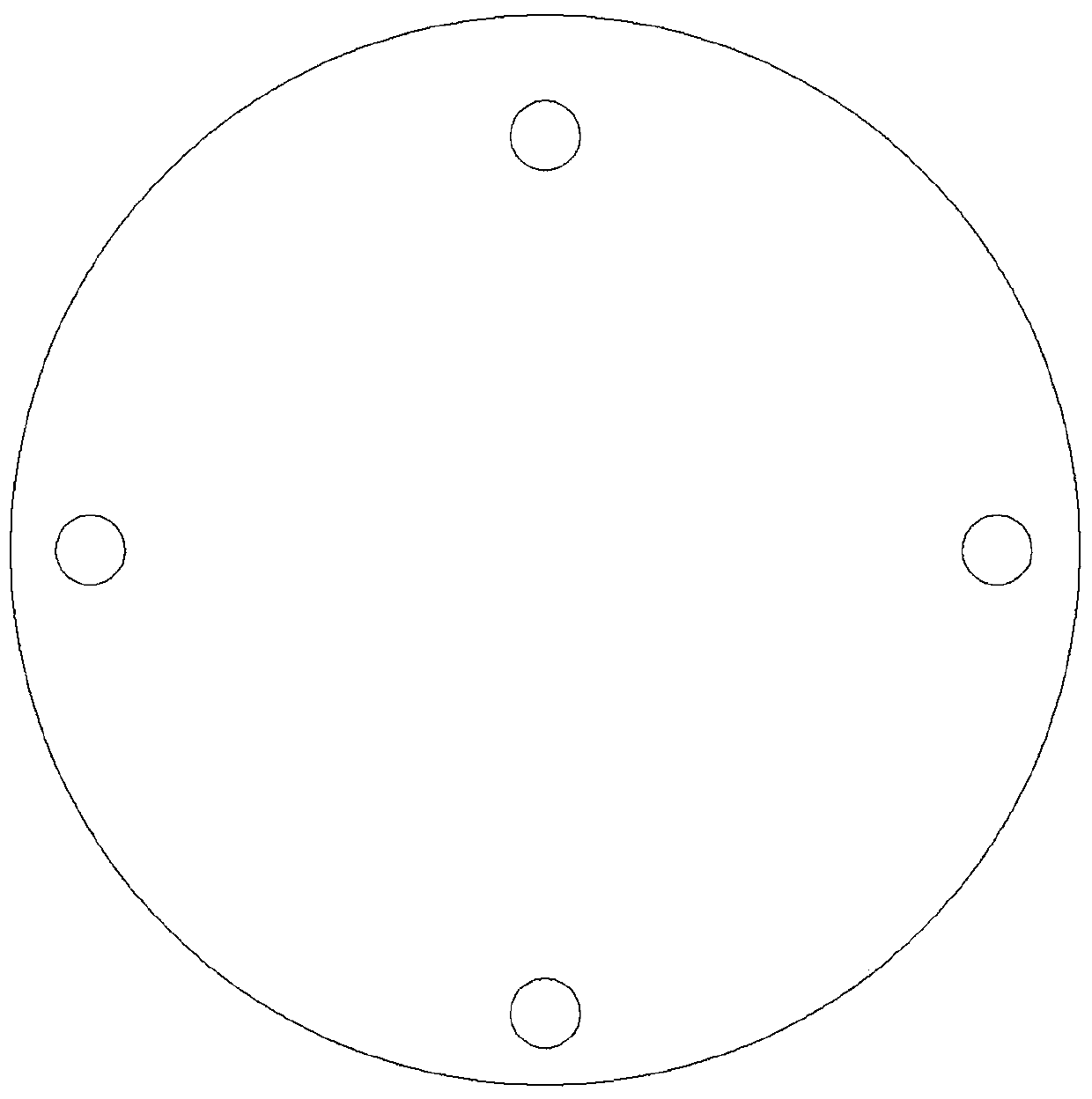

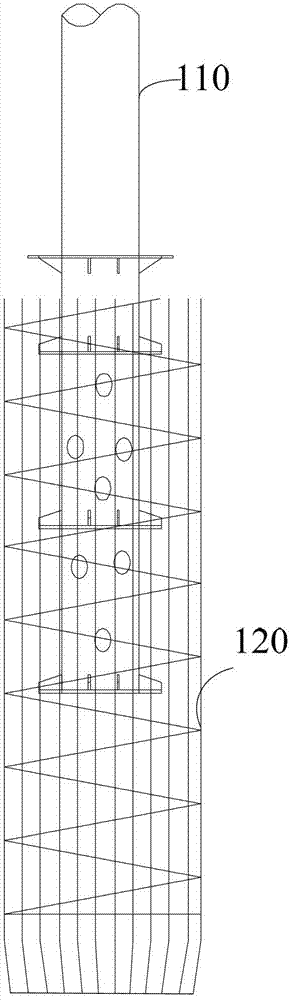

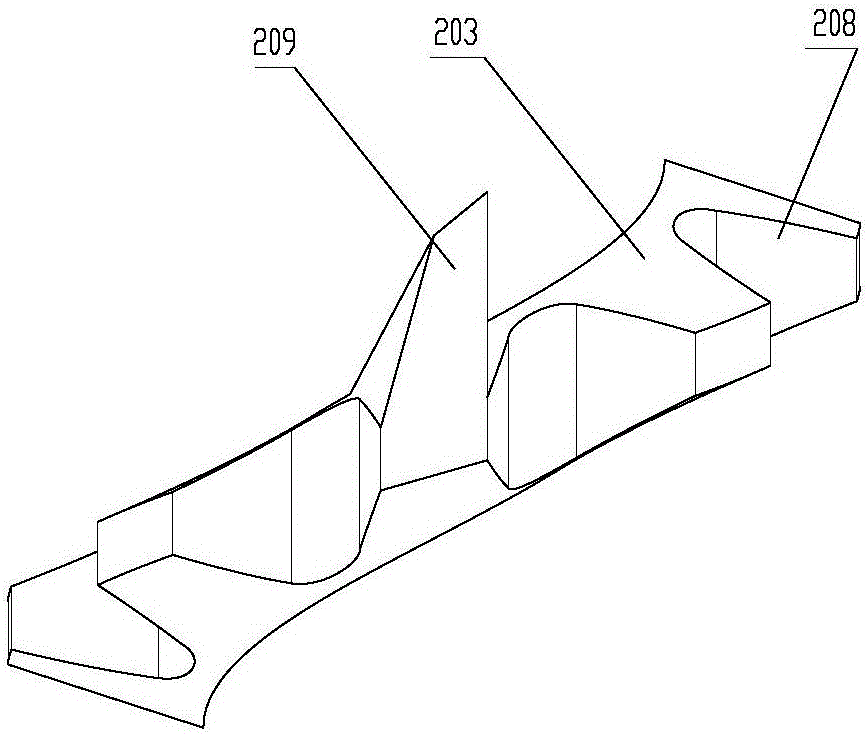

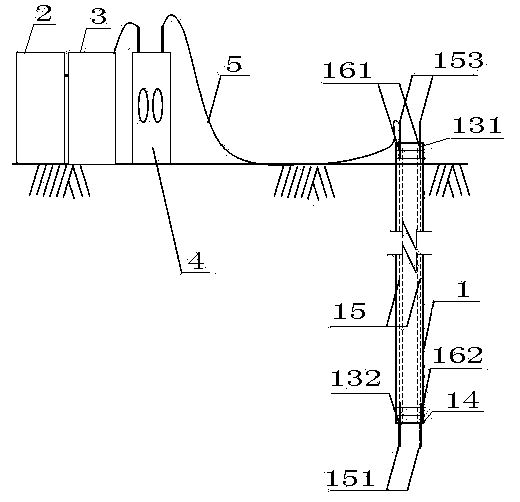

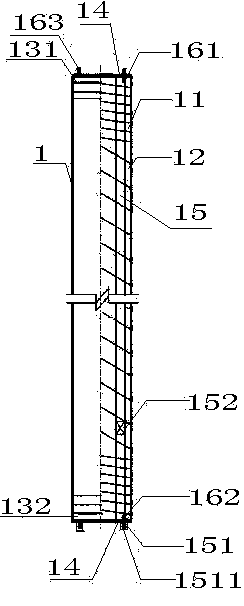

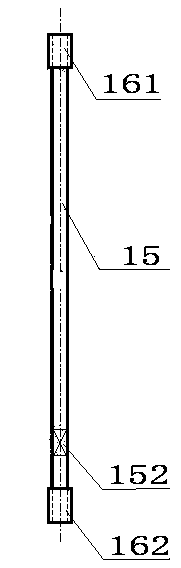

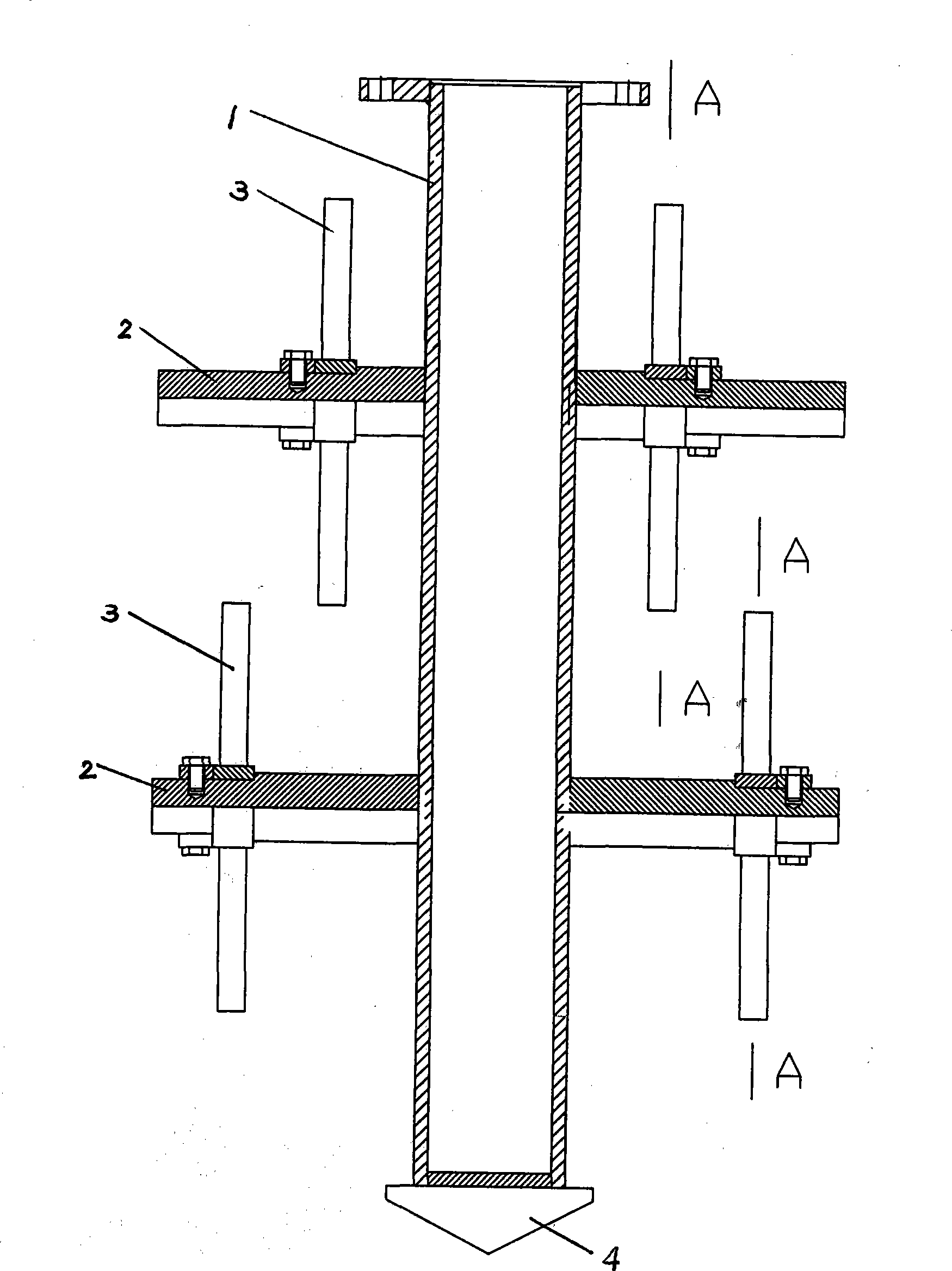

Prestress high intensity concrete square pile and its production method and moulding die

InactiveCN101054800AHigh pile rateIncrease profitCeramic shaping apparatusBulkheads/pilesHigh strength concretePre stress

The invention belongs to the architecture field, which relates to an improvement with the foundation pile shape and the structure and the manufacturing method of the foundation pile and the foundation pile shaper in the architecture field, in particular the invention is a prestressing force high strength concrete square pile and the manufacturing method thereof and the shaping device. In the invention a square terminal plate is disposed on the two ends of the square pile, and the four sides of the terminal plate is provided with a groove, while the center is equipped with a circular hole, and between the circular hole and the four sides, a strain hole and a threading hole are arranged symmetrically; a stirrp of a reinforcement cage in a twist is welded on the principal reinforcement continuously, wherein the principal reinforcement is the steel strand or the steel bar; the concrete square pile and the four-side corners of the terminal plate are in a stress elimination arc, and the pile core is a columnar mid level outlet having the same diameter with the terminal plate central circular hole. The manufacturing method is characterized in that, the principal reinforcement has the fix ed length and blanking, and the stirrp of the reinforcement cage is welded in the seam welder with the high degree of mechanisation; the principal reinforcement is stretched in a group of a whole pile fixed value, wherein the stretching performance is good and the balance is consistent; the disposable high pressure has short shaping time, low energy consumption, high product grade; the die design meets with the shaping requirement of the shape, which is convenient to use.

Owner:SHANGHAI ZHONGJI PILE IND

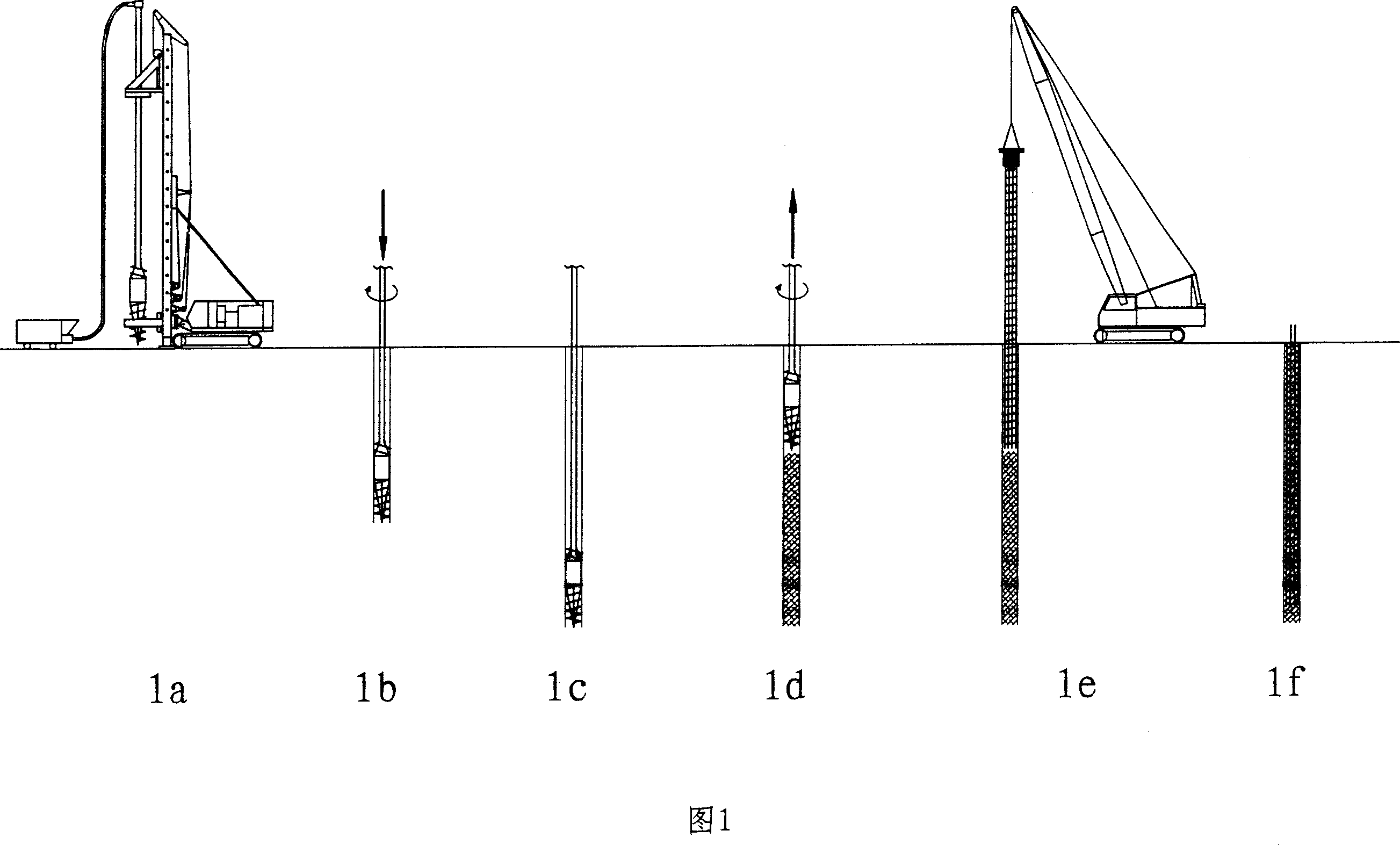

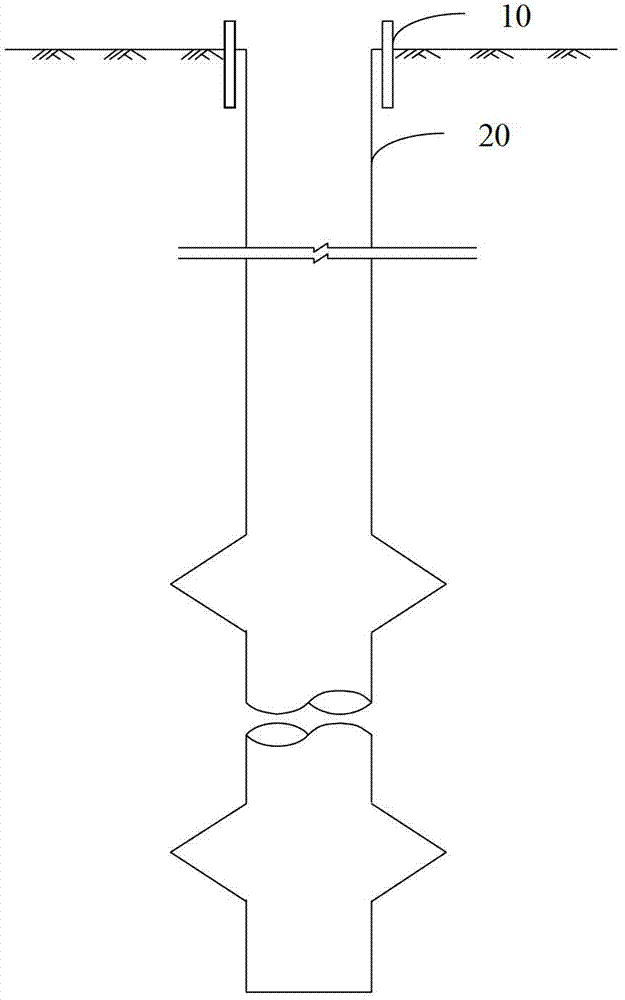

Bidirectional helix extruding-enlarging pile construction method and bidirectional helix closed extruding-enlarging aiguille

ActiveCN101012649AIncrease resistanceImprove bearing capacityDrill bitsBulkheads/pilesConcrete pumpEnergy consumption

The invention relates to a construction method for bidirectional spiral expand pile and the bidirectional spiral closed expand bit. The construction method comprises drilling and expanding bore by the bidirectional spiral closed expand bit; pushing soil, which is obtained in drilling and expanding bore downwards, into the side wall of pile bore; the bidirectional spiral closed expand bit rotating upwards to drill and expand the bore again; pushing soil, which is obtained in drilling, expanding and lifting upwards, into the side wall of pile bore; starting the concrete pump to press the pile material into the pile bore while the bit is lifted. The bidirectional spiral closed expand bit comprises a connecting bar. At the lower of the connecting bar spiral expand body, closed expand body and dynamic sealing expand body are assembled on the connecting bar in the same axial line in turn from the bottom to the top or they are machined on the connecting bar together. The invention is provided with high loading capacity, small sedimentation quantity, better quality, low cost and smaller energy consumption so on.

Owner:CHINA JINGYE ENG

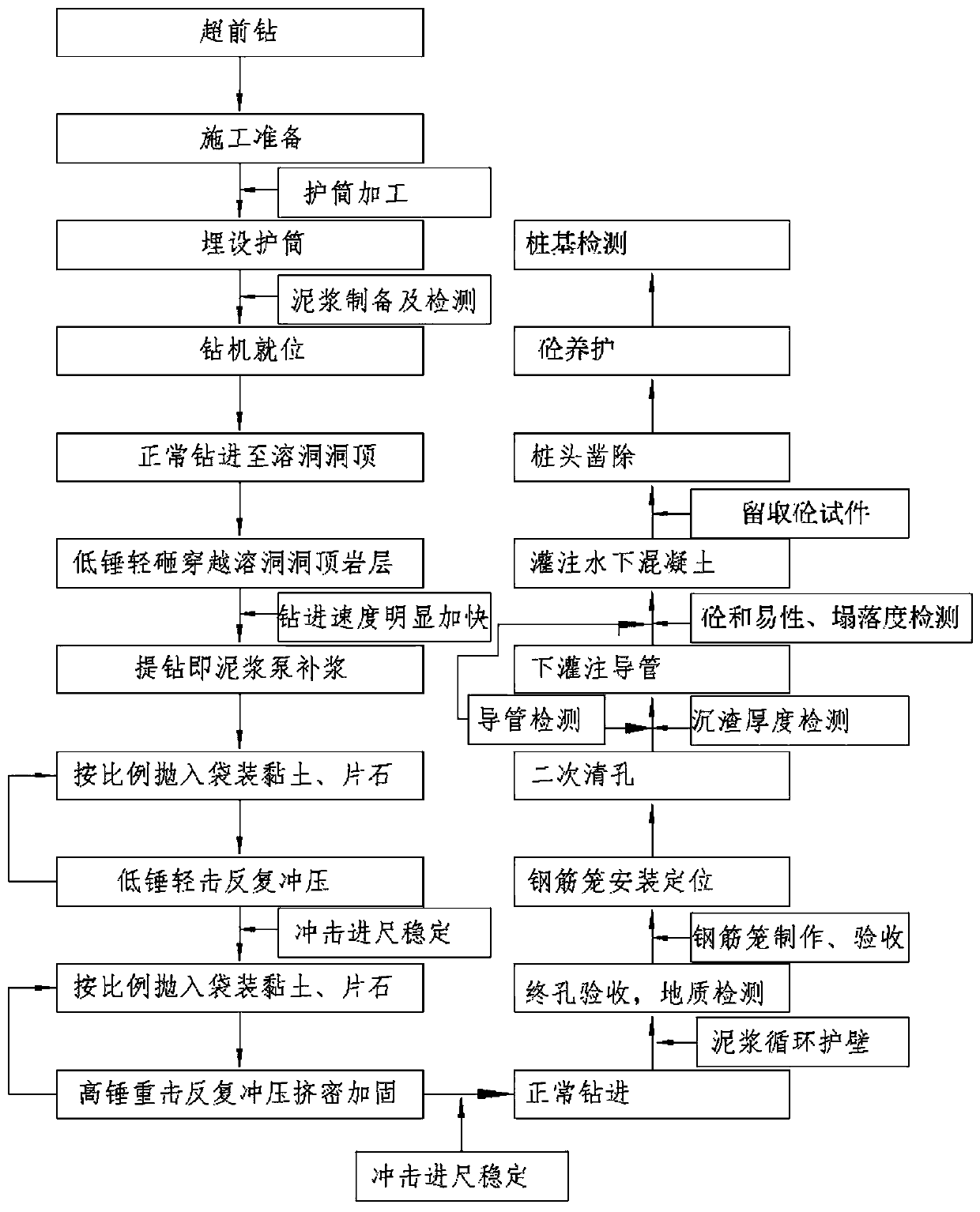

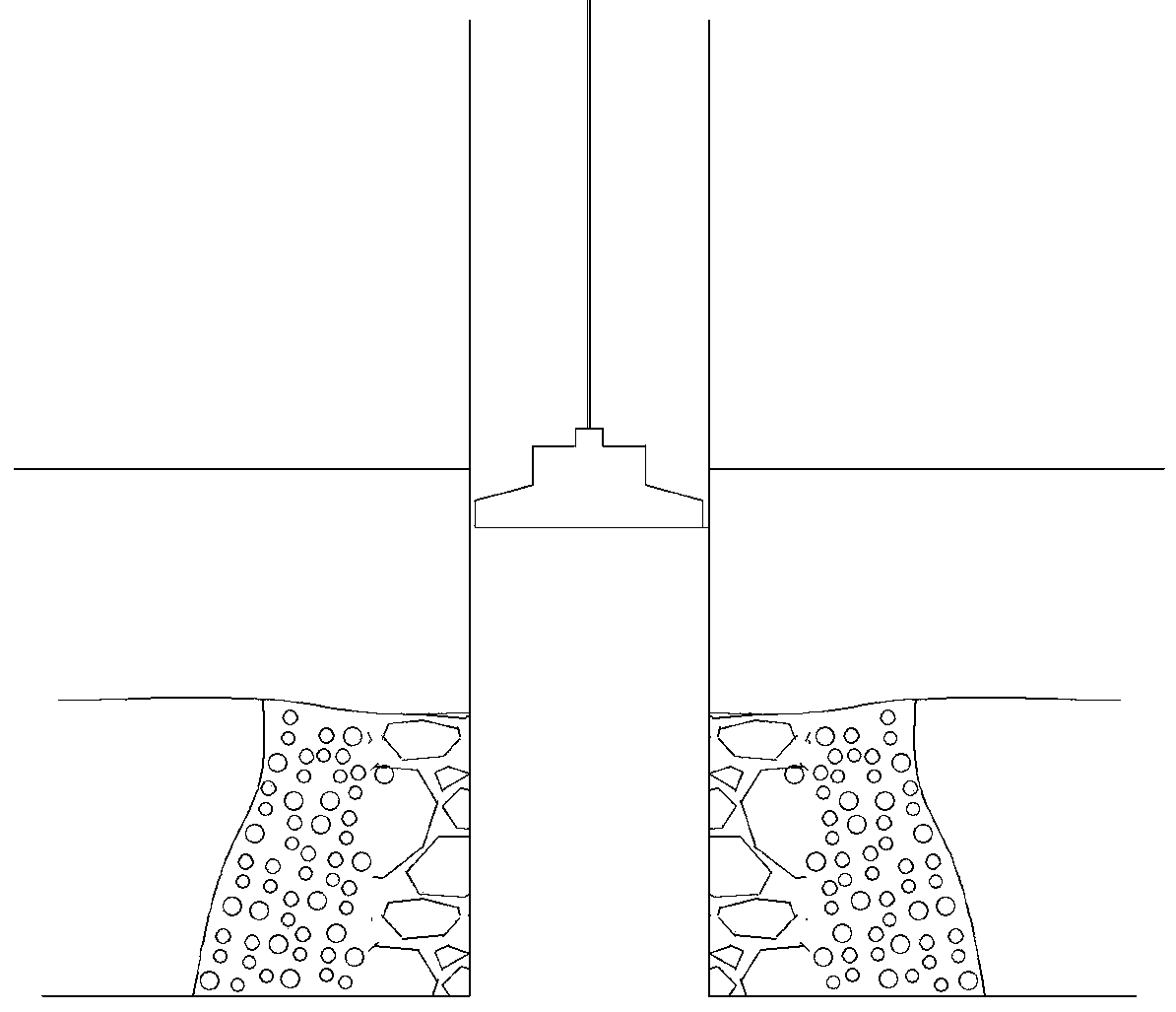

Pile foundation construction method penetrating all-filled type cave

The invention relates to the pile foundation construction technology, in particular to a pile foundation construction method penetrating an all-filled type cave. The method includes the following steps of advanced drilling exploitation, construction preparation, protecting barrel burying, mud pond and sedimentation pond setting, in-place installing of a drilling machine, drilling operation, drilling filling, hole clearing, making and installing of a steel reinforcement cage, underwater concrete pouring, chiseling away of a pile head and pile foundation detection; a percussion drill is used fordrilling a punching hammer, the impacting force of the punching hammer is used for penetrating various soil layers or breaking various rock layers, and the work efficiency is effectively improved; inthe process of penetrating the all-filled type cave by means of impacting hole forming, firstly, bagged clay is adopted for backfilling and is slightly beaten in a lower hammer manner to be extrudedinto the cave, the hole wall surrounding rock stability is improved, and the hole collapse risk is reduced; slabstone and bagged cement are adopted for backfilling, and are heavily beaten in a high hammer manner to be extruded into the cave, and the hole wall stability is further improved. By means of the construction method, the hole forming quality, the hole wall stability and the construction operation efficiency of a pile foundation are improved, and the risks of hole collapse, drill jamming, drill burying, slurry leaking and the like are effectively lowered.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

Rotary-digging combined pile-forming construction method in complicated geological conditions

InactiveCN102644275AEnsure safetySolve the technical problems of easy reamingBulkheads/pilesSlagRebar

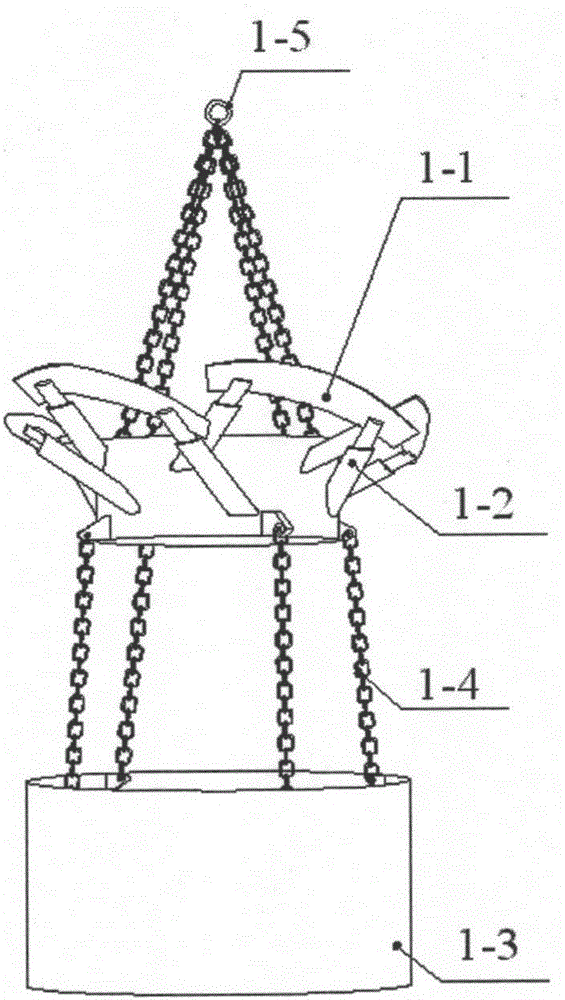

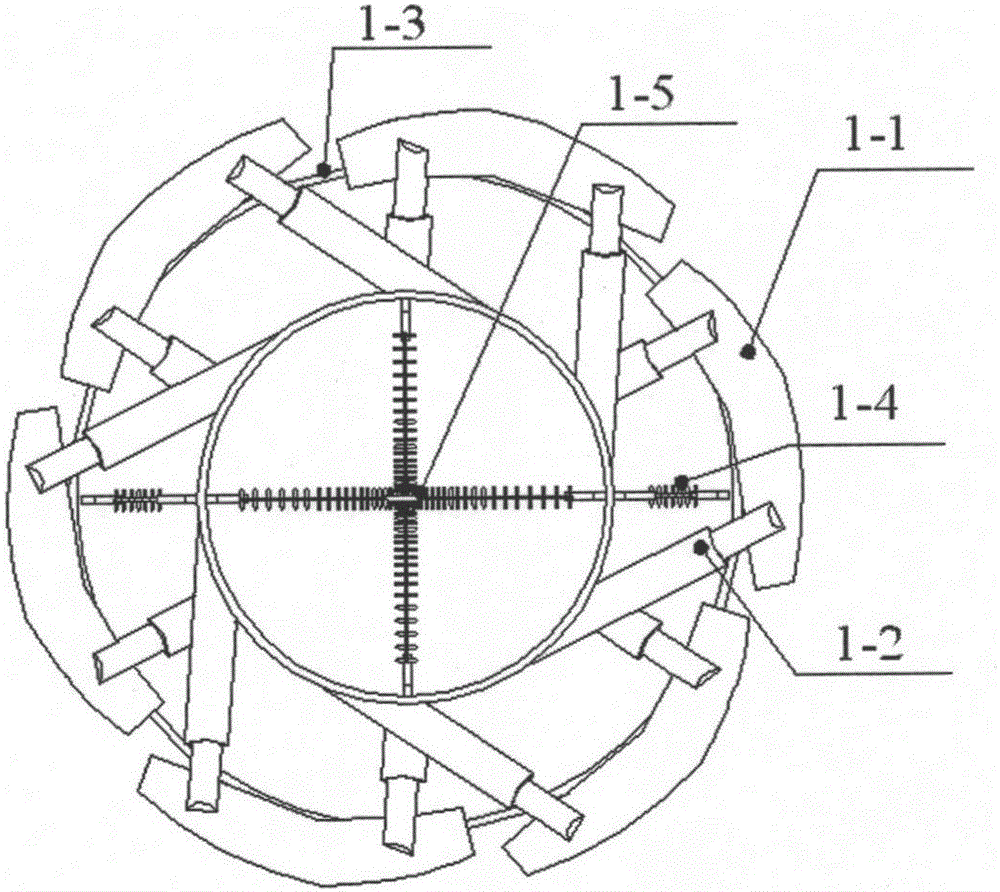

The invention provides a rotary-digging combined pile-forming construction method in complicated geological conditions. The method comprising the following steps of: firstly, positioning a pile foundation; secondly, positioning a steel protecting barrel; thirdly, sinking the steel protecting barrel; fourthly, when the steel protecting barrel penetrates through a boulder layer without encountering the boulder, sinking the steel protecting barrel to the design elevation by using a vibration hammer; fifthly, starting a rotary digging and drilling machine to perform rotary digging and drilling at the inner side of the steel protecting barrel; sixthly, hoisting an impacting and catching hammer by a hoist, and downwards hammering and impacting the boulder by the impacting and catching hammer; seventhly, starting the rotary digging and drilling machine to continuously perform rotary digging and drilling to the design elevation; eighthly, fishing slag from the bottom of a hole; ninthly, checking and accepting a final hole; tenthly, aligning the skeleton of a steel reinforcement cage to the opening of the hole and slowly hoisting into the hole by the hoist; eleventhly, secondly cleaning the bottom; twelfthly, concreting; and thirteenthly, after primarily setting the concrete, lifting up the steel protecting barrel by the hoist. The method has the advantages of high safety and reliability, strong stratum adaptability and high construction progress and is suitable for the pile foundation engineering in cities with complicated geological conditions.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Rock engaged combined pile and its construction method

The rock engaged combined pile includes pile section inside soil layer and pile section inside rock formation combined together and includes also stuffing. The pile section inside soil layer may be prefabricated reinforced concrete pipe or steel pipe with grouted stuffing or steel pipe pile with outer coating stuffing. The pile section inside rock formation may be steel cage, steel member or prefabricated reinforced concrete member or their combination filled with stuffing. The pile section inside rock formation has its load diffused to deep rock formation via the combination of the stuffing to rock hole wall. Owing to the large contact area of the stuffing, the pile of the present invention can provide large anchoring force.

Owner:LIJI ENG

Cast-in-place pile construction method using steel pipe column splicing piles

The invention provides a cast-in-place pile construction method using steel pipe column splicing piles. The method includes: a) forming pile holes and forming slurry protecting walls automatically during formation of the pile holes; b) making the steel pipe column splicing piles which comprise steel tubes and reinforcing cages, and fixing the bottom ends of the steel pipes to the top ends of the reinforcing cages; c) lifting and positioning the steel pipe column splicing piles in the pile holes; d) pouring concrete into the pile holes through injection pipes on the steel pipe column splicing piles; and e) filling soil between the steel pipe column splicing piles and pipe hole walls. With the filling pile construction method, unity of cast-in-place piles is improved during the construction process of underground engineering, so that pipe formation quality of the cast-in-place piles is improved, and construction processes of cast-in-place piles are decreased.

Owner:MCC COMM CONSTR GRP CO LTD

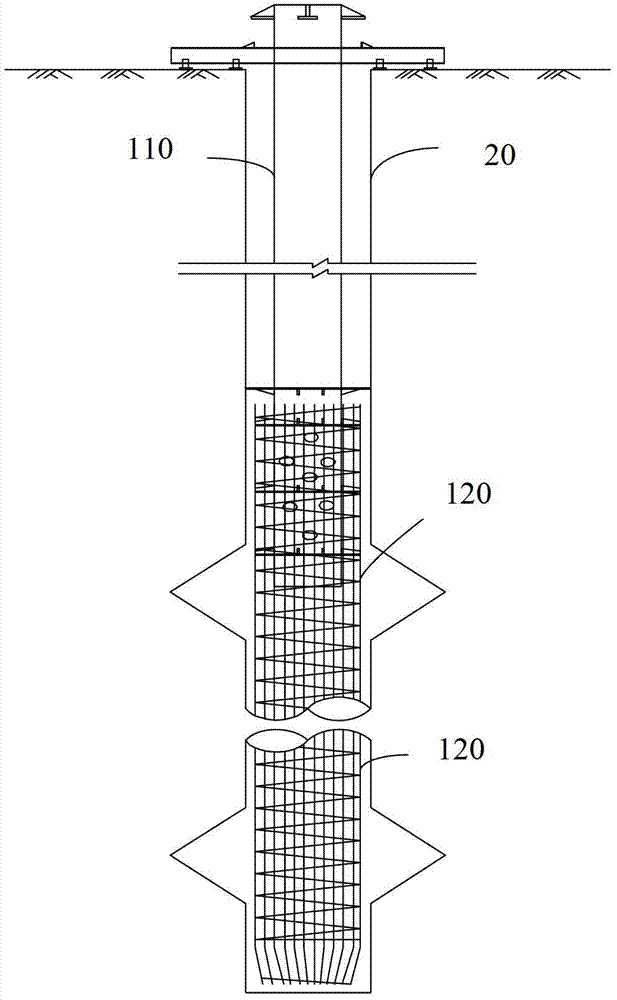

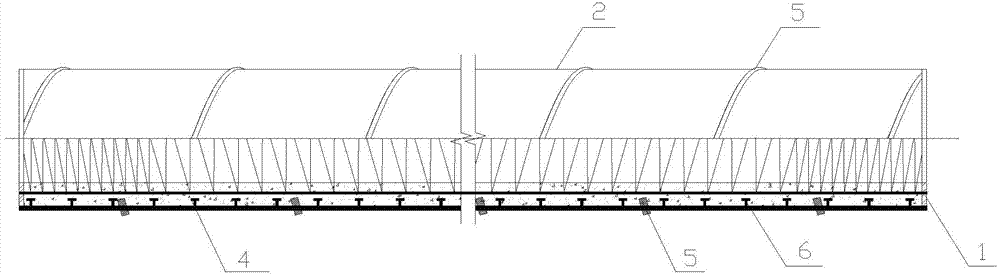

Ribbed prestressed pipe pile, and manufacturing method and drilling-planting construction process thereof

ActiveCN103603349AImprove ultimate carrying capacityReduce construction hazardsShaping reinforcementsBulkheads/pilesPre stressGrout

The invention discloses a ribbed prestressed pipe pile, and a manufacturing method and a drilling-planting construction process thereof. The ribbed prestressed pipe pile comprises an upper ribbed prestressed pipe pile and a plurality of lower ribbed prestressed pipe piles. The upper and lower ends of each lower ribbed prestressed pipe pile are provided with an external thread end plate and a closed end plate. Two ends of the upper ribbed prestressed pipe pile are provided with an external thread end plate and an internal thread end plate. According to the drilling-planting construction process, gravels are placed at the bottom of the pile and around the pile, grout is injected to the bottom of the pile and around the pile, and accordingly, limit bearing capacity of the single pile can be improved significantly and piles are saved. In addition, an injection pipe can be recycled after grout injection, so that fewer injection pipes are needed.

Owner:SHANDONG UNIV

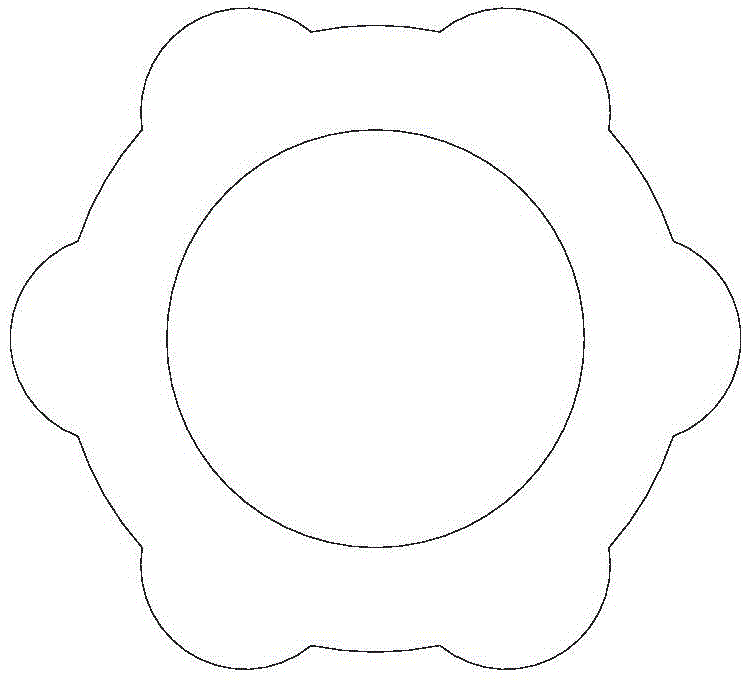

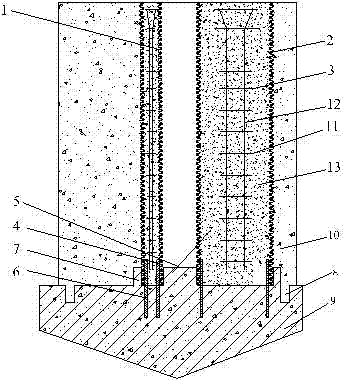

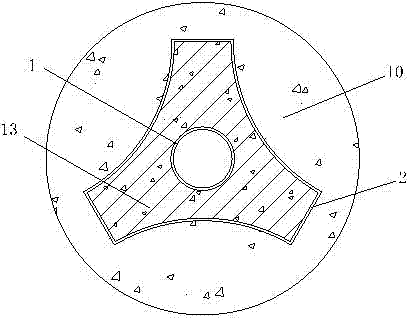

Bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and construction method

ActiveCN103485334BIncrease girthImprove mechanical performanceBulkheads/pilesReinforced concreteEngineering

The invention relates to a bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and a construction method. The pile is characterized by structurally comprising the inverted-arch cambered hollow special-shaped pile, a pile toe arranged at the bottom end of the special-shaped pile and fixed through fixing parts, and a precast reinforced concrete pile tip; a cemented soil layer is arranged on the outer side of a pile body; a cross section of the special-shaped pile is Y-shaped or X-shaped, and bushings with threads are arranged in a round hole in the center of the pile body and on the outer side of the pile body; a reinforcement cage, which is in the same shape as the pile body but slightly smaller than the pile body, is arranged in the pile body; horizontal and longitudinal tensile reinforcements are arranged in the reinforcement cage; and the fixing parts corresponding to the bushings and an immersed tube are arranged on the top face of the precast reinforced concrete pile tip. During construction, the pile toe and the inner bushing are fixed firstly, then the reinforcement cage and the outer bushing are sleeved, and concrete is poured between the inner bushing and the outer bushing as well as between the outer bushing and the immersed tube to respectively form a concrete pile core and a pile-side cemented soil layer. Area of the cross section of the pile body is small, consumption of building materials is reduced, bearing capacity is high, and the pile body is high in capability of resisting to environmental erosion.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

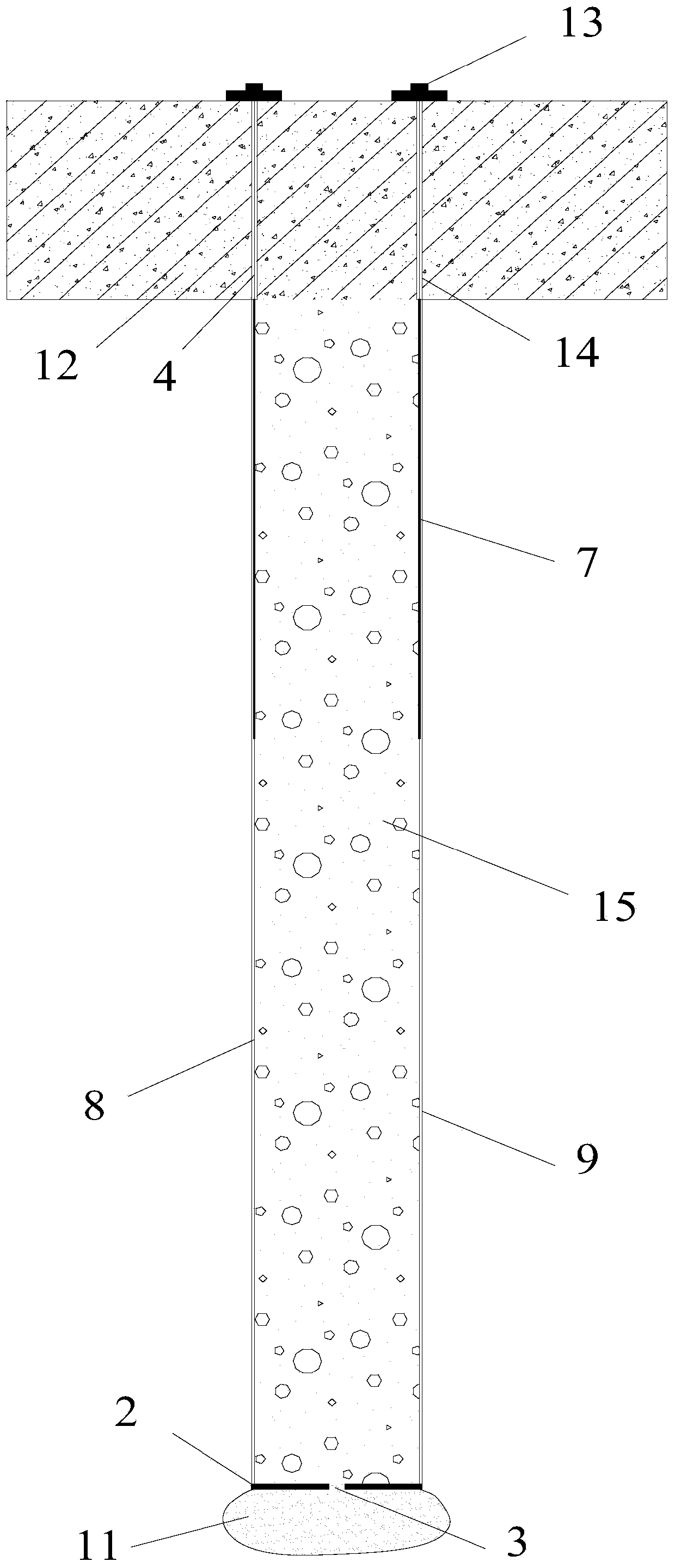

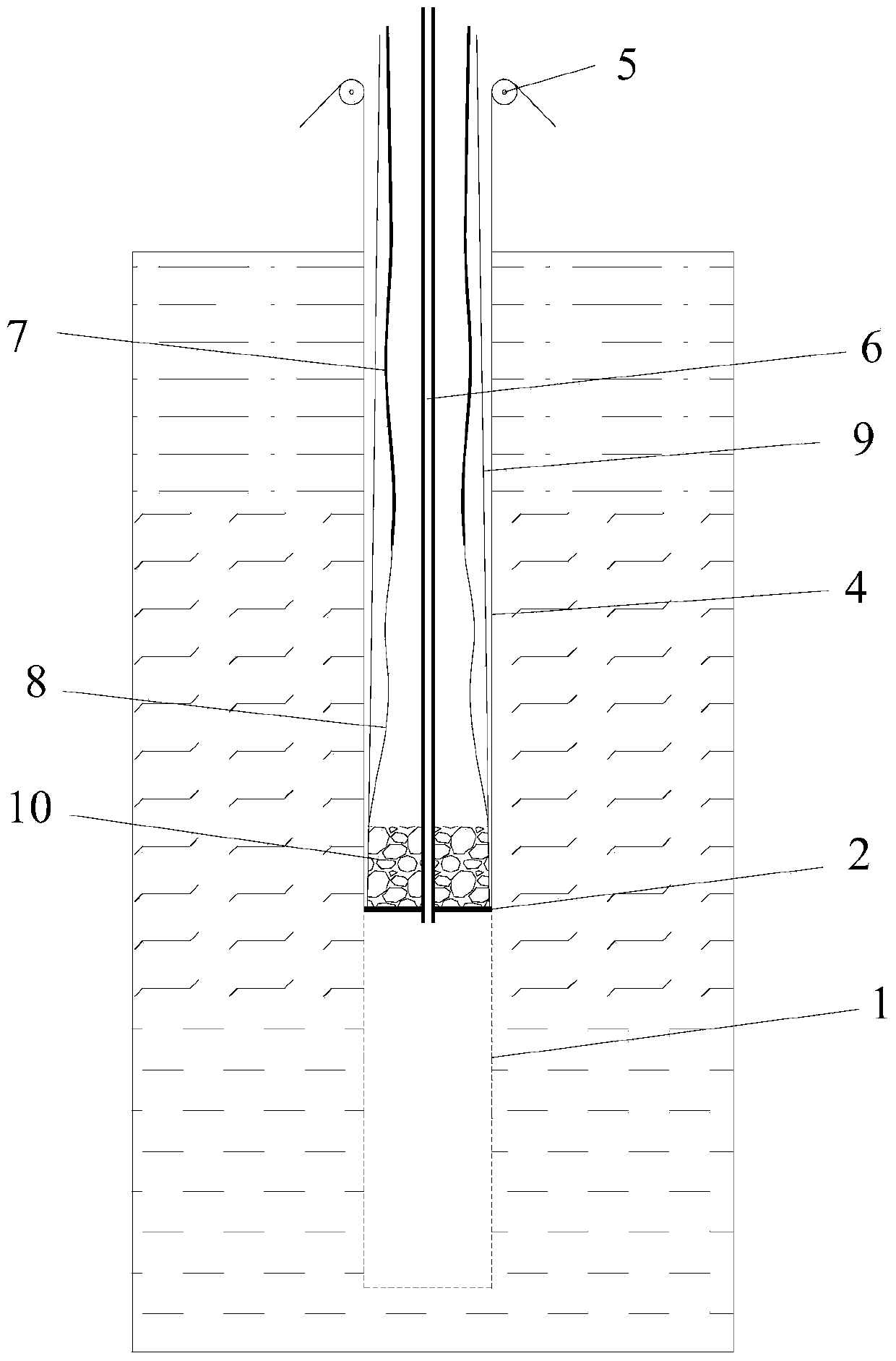

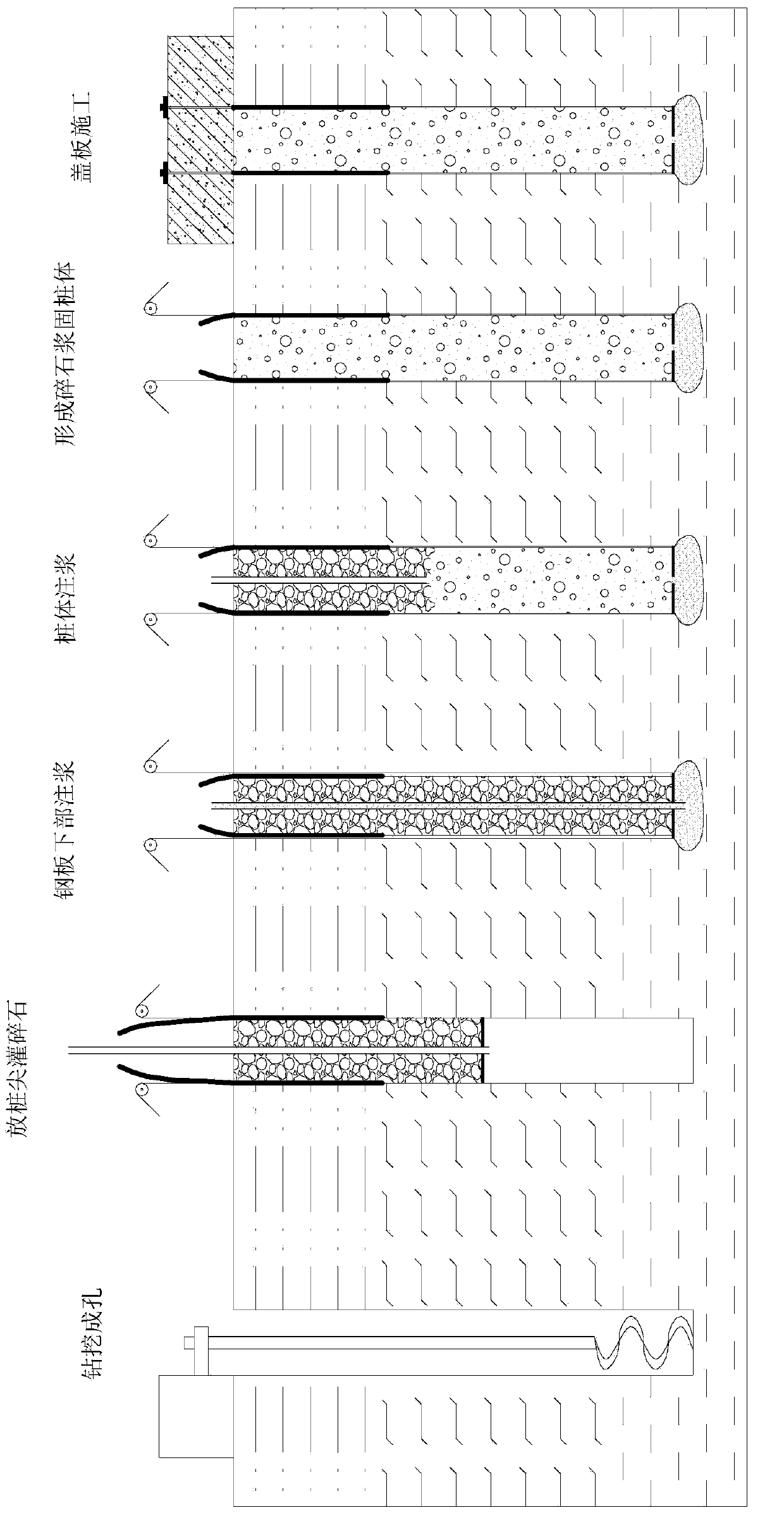

Crashed stone grouting pile with lead holes implanted in cloth bag and construction method

The invention discloses a crashed stone grouting pile with lead holes implanted in a cloth bag and a construction method. The crashed stone grouting pile is mainly composed of a prefabricated pile tip, steel strands, the geotechnical cloth bag, a pile end pulp solidification body, a crashed stone pulp solidification pile body and a cover plate. The fabricated pile tip is arranged at the bottom of the pile body. A reserved hole allowing a grouping pipe to penetrate through is formed in the center of the prefabricated pile tip, and holes allowing the steel strands to penetrate through are formed in the edge of the prefabricated pile tip. The pile tip pulp solidification body is formed at the bottom of the prefabricated pile tip through grouting. The crushed stone pulp solidification pile body is arranged on the upper portion of the prefabricated pile tip, and the geotechnical cloth bag is arranged outside the crushed stone pulp solidification pile body. The cover plate is arranged above the crushed stone pulp solidification pile body. The crashed stone grouting pile has the advantages that performance of bulk solid material is given into full play, the problems of necking, expansion, hole collapse, mud contamination and the like are solved for the pile body, the integrity and the bearing performance of the structure are improved, sedimentation of the pile body is reduced, the improvement of the bearing capacity of the foundation is accelerated, and quality of the pile is improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

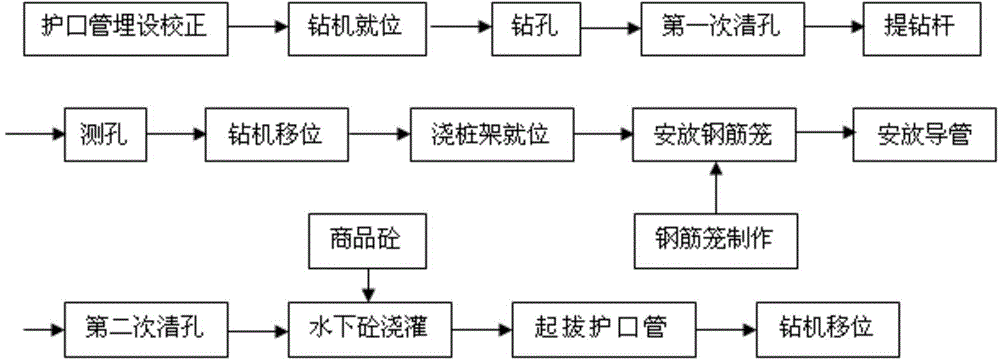

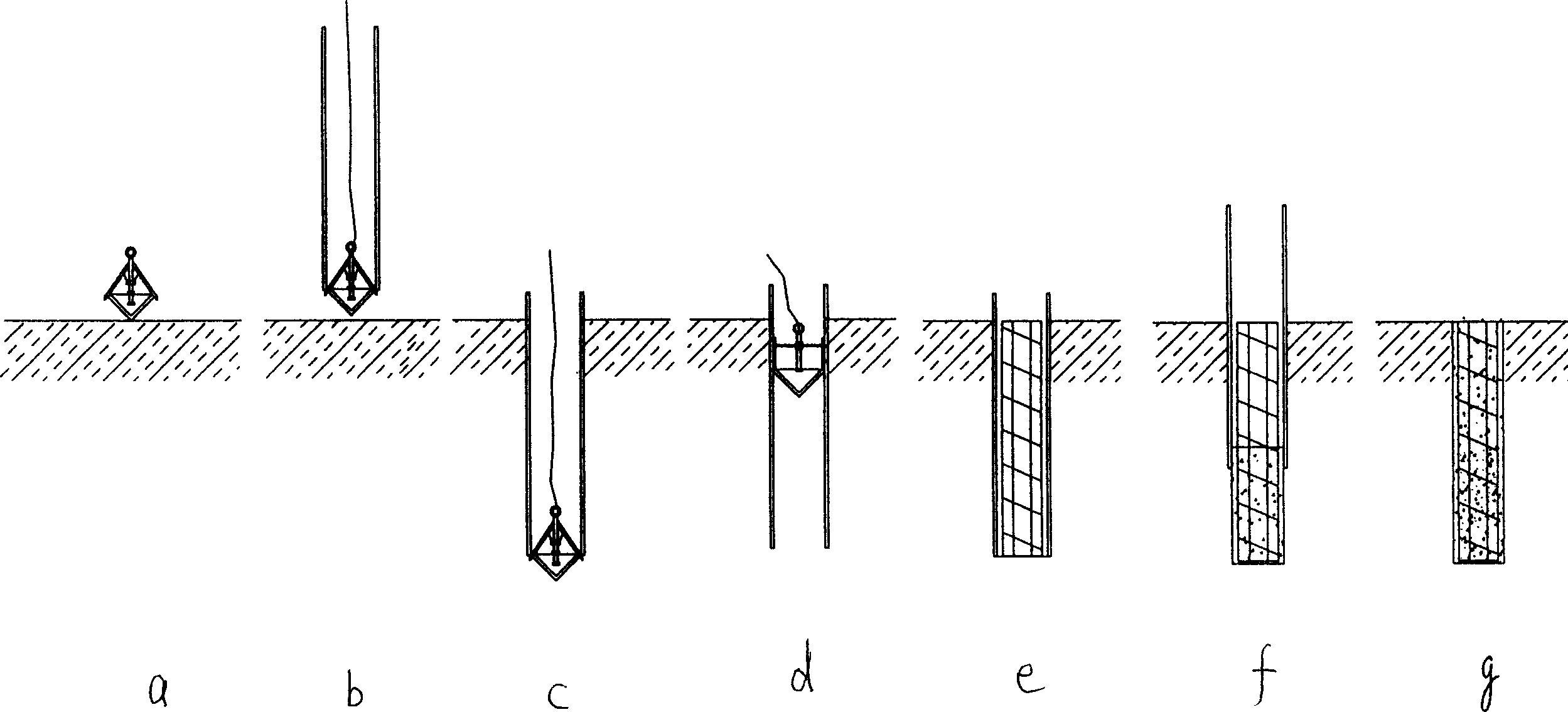

Construction method of long spiral cast-in-situ bored pile

InactiveCN102628266AReduce the impactImprove pile qualityBulkheads/pilesEnvironment effectEngineering

The invention discloses a construction method of a long spiral cast-in-situ bored pile. When used for constructing the cast-in-situ bored pile in an underground station, the method has the advantages of good pile forming quality, short construction period, high effect, no need of mud preparing, circulating and disposal sites and other places, small influence on the surrounding environment, good pile forming quality and the like, and can satisfy the characteristics and requirements, such as high construction environment protection requirement, of the underground station. In addition, the construction method disclosed by the invention is also applicable to various soils, such as clays, silts and miscellaneous fills, and can be used for constructing cast-in-situ bored piles under complicated geological conditions which are liable to generate collapse, hole shrinkage and the like, such as soft soil, drift sand formation, sand-pebble layers, and high underground water levels.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +2

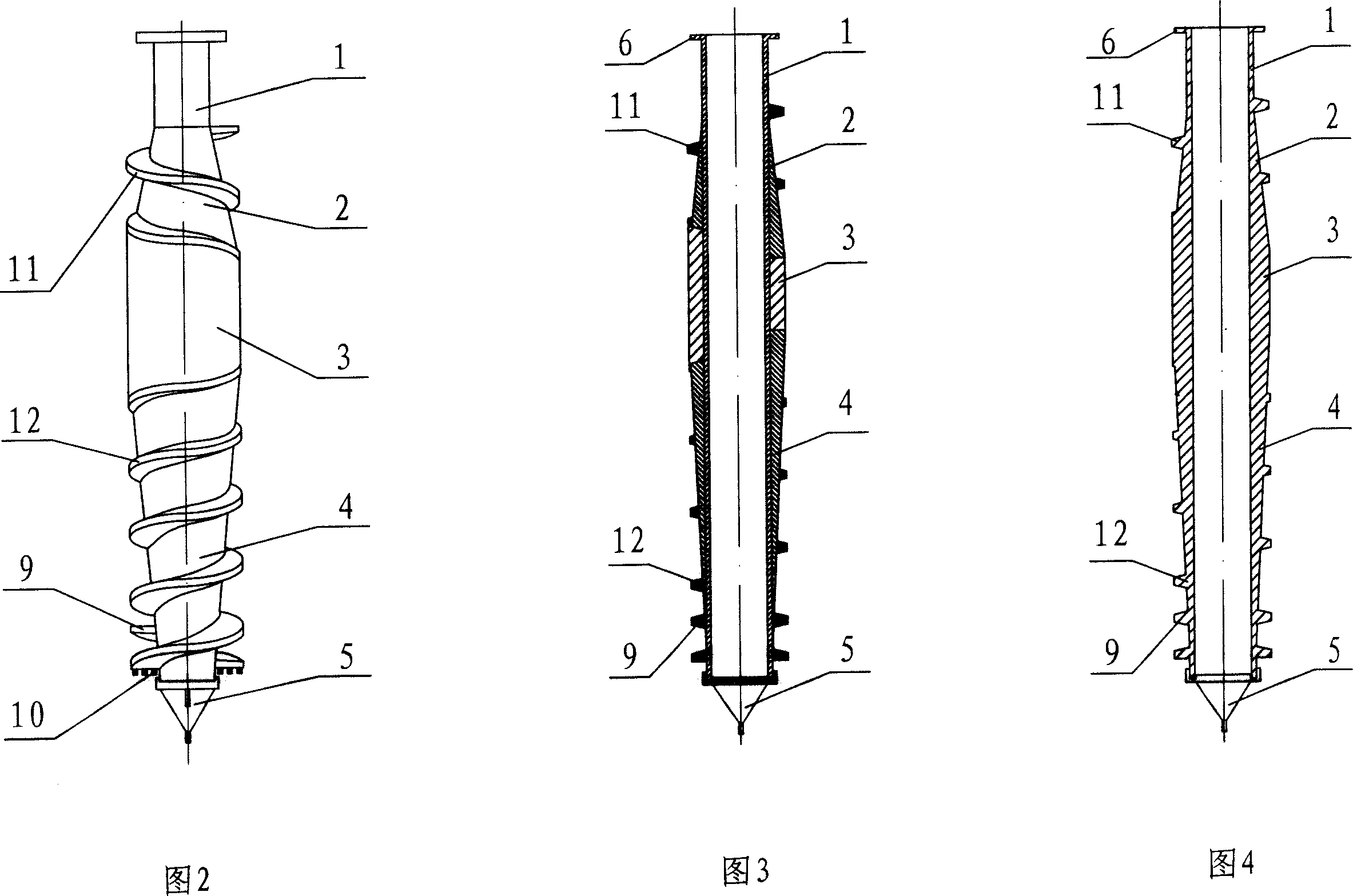

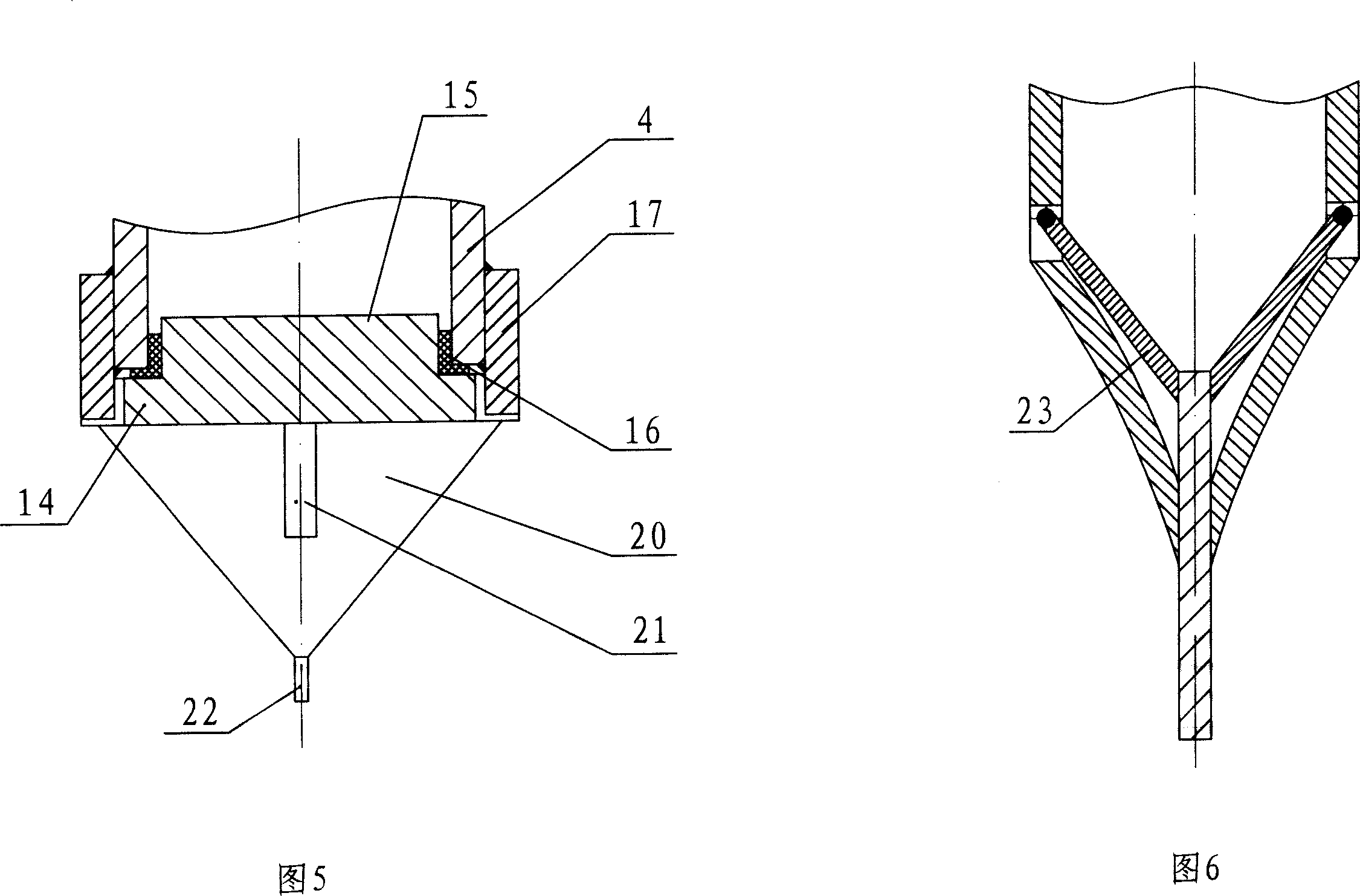

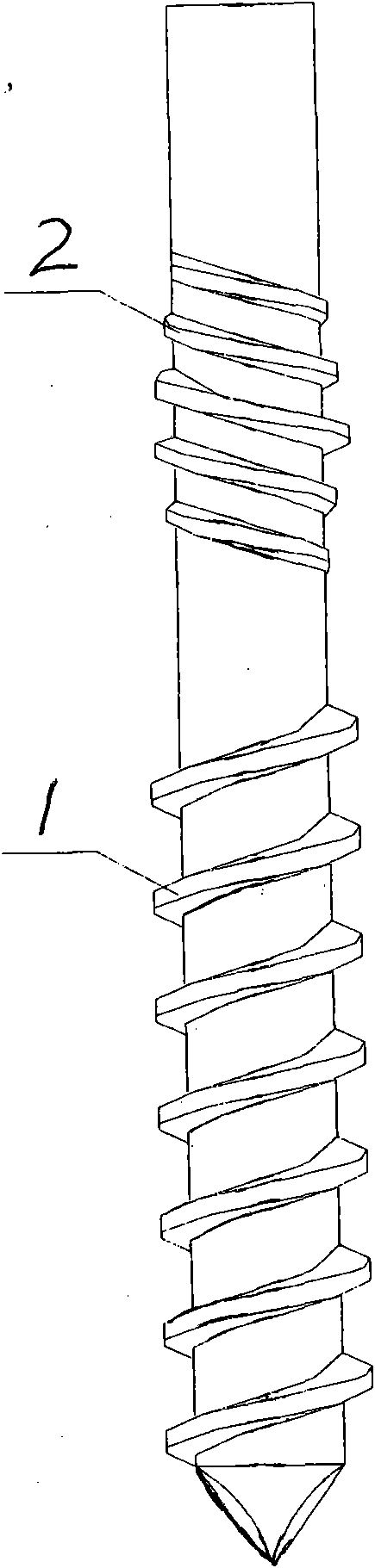

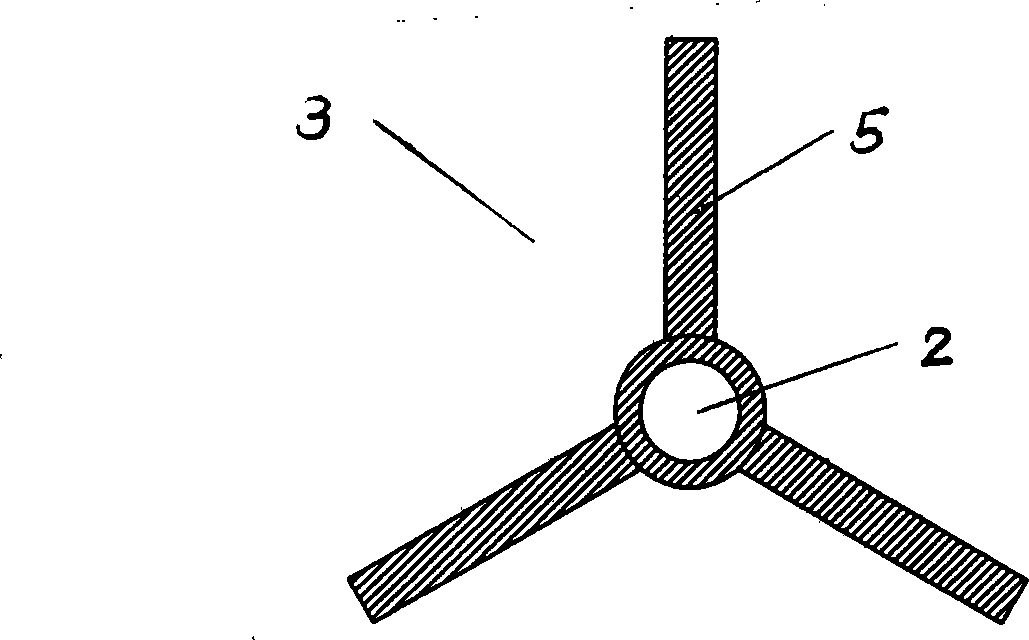

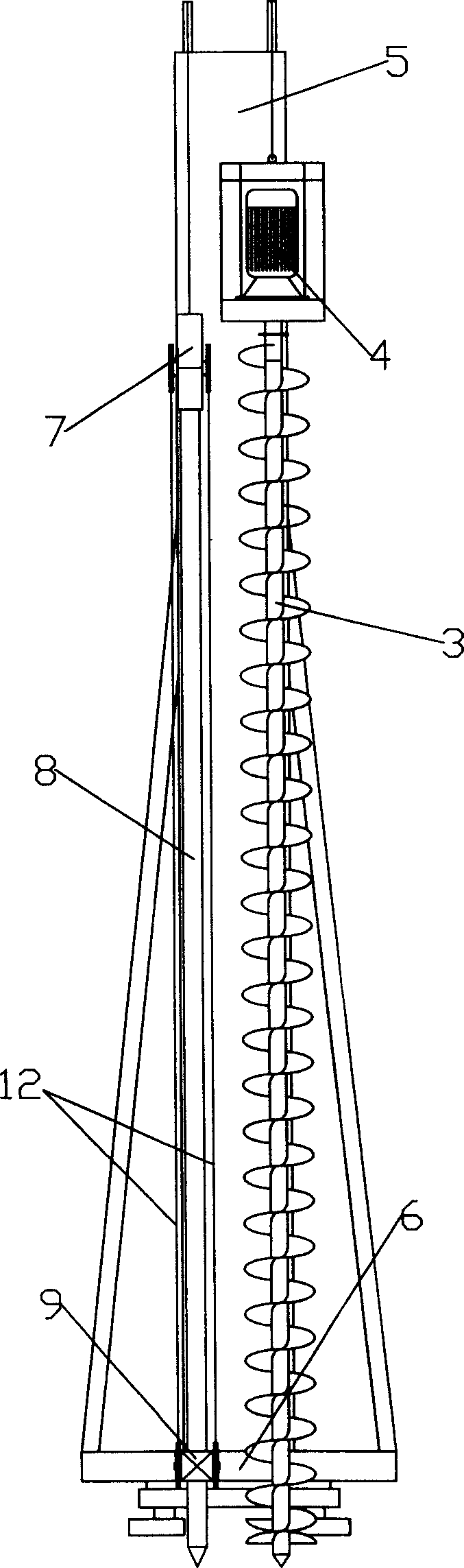

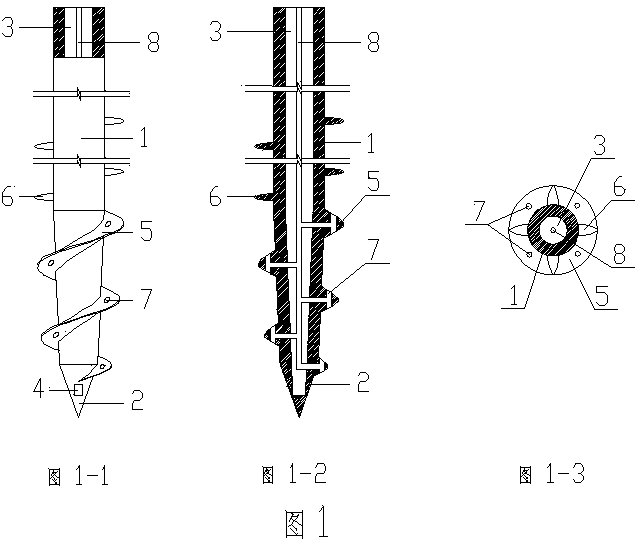

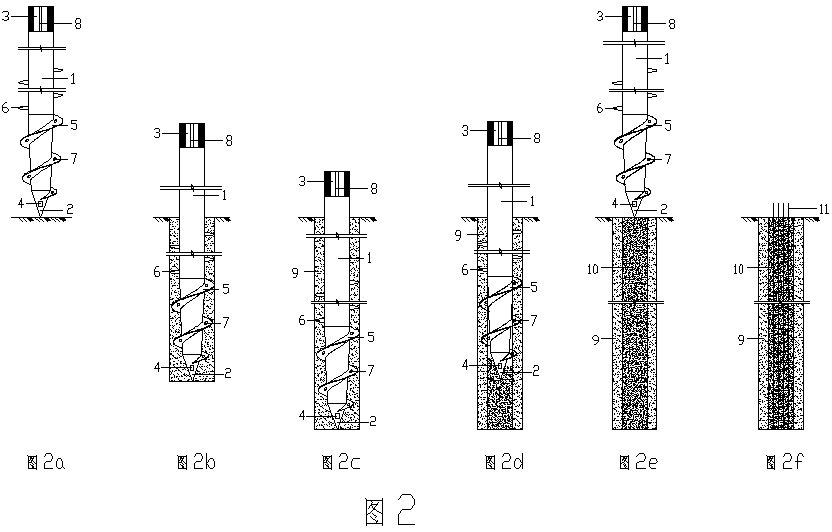

Pile-forming drilling tool for screw pile and pile-forming construction method thereof

InactiveCN101864768ASimplify the construction processSimple and fast operationDrill bitsDrilling rodsReinforced concreteRebar

The invention relates to a pile-forming drilling tool for a screw pile and a pile-forming construction method thereof, wherein forward drilling threads are arranged at the lower part of the pile-forming drilling tool, and backward sweeping threads are detachably arranged on the upper part thereof. The pile-forming construction method comprises the following steps: adopting special screw pile equipment to be assorted with the drilling tool to align with a pile position; utilizing the drilling tool to drill downwards so as to form threaded soil holes to reach the design depth of the pile, and meanwhile utilizing the sweeping threads at the upper part of the drilling tool to extrude and sweep the soil threads to form straight holes which reach the design depth of a straight lever section; lifting up the drilling tool in a rotating mode, and simultaneously concreting to form the thread section and the straight lever section of the pile; and after concreting is completed, placing a reinforcing cage to form the reinforced concrete screw pile. The drilling tool provided by the invention can effectively eliminate part of a threaded soil mass to form the straight holes by adopting forward threads and backward threads, thus achieving the effect of forming screw pile holes by boring at a time and realizing hole-forming and pile-forming of the screw pile at a time; and the pile-forming construction method has simple working procedures, faster speed, reduced construction resistance and no need of taking soil.

Owner:彭桂皎

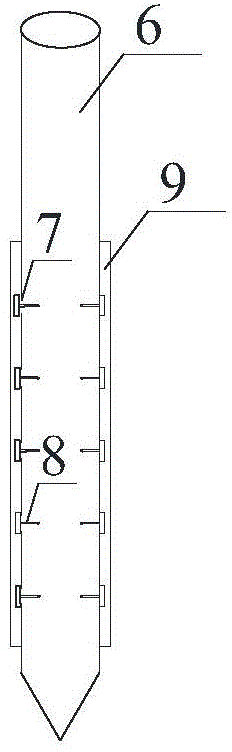

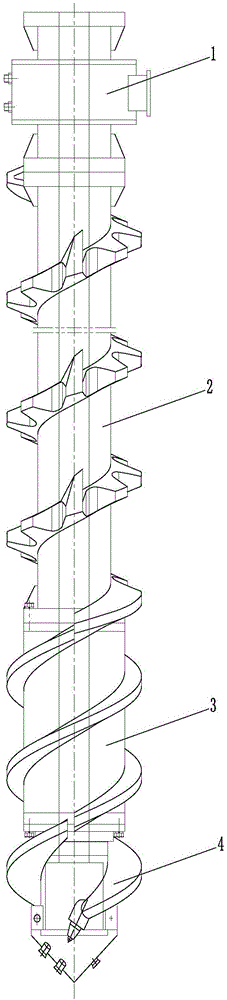

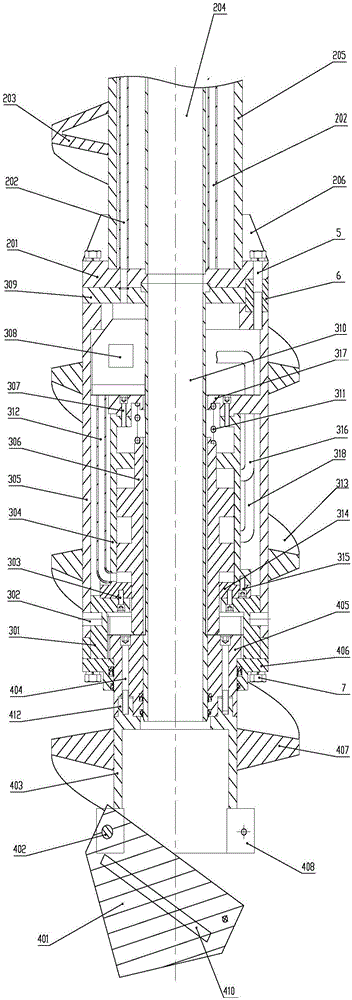

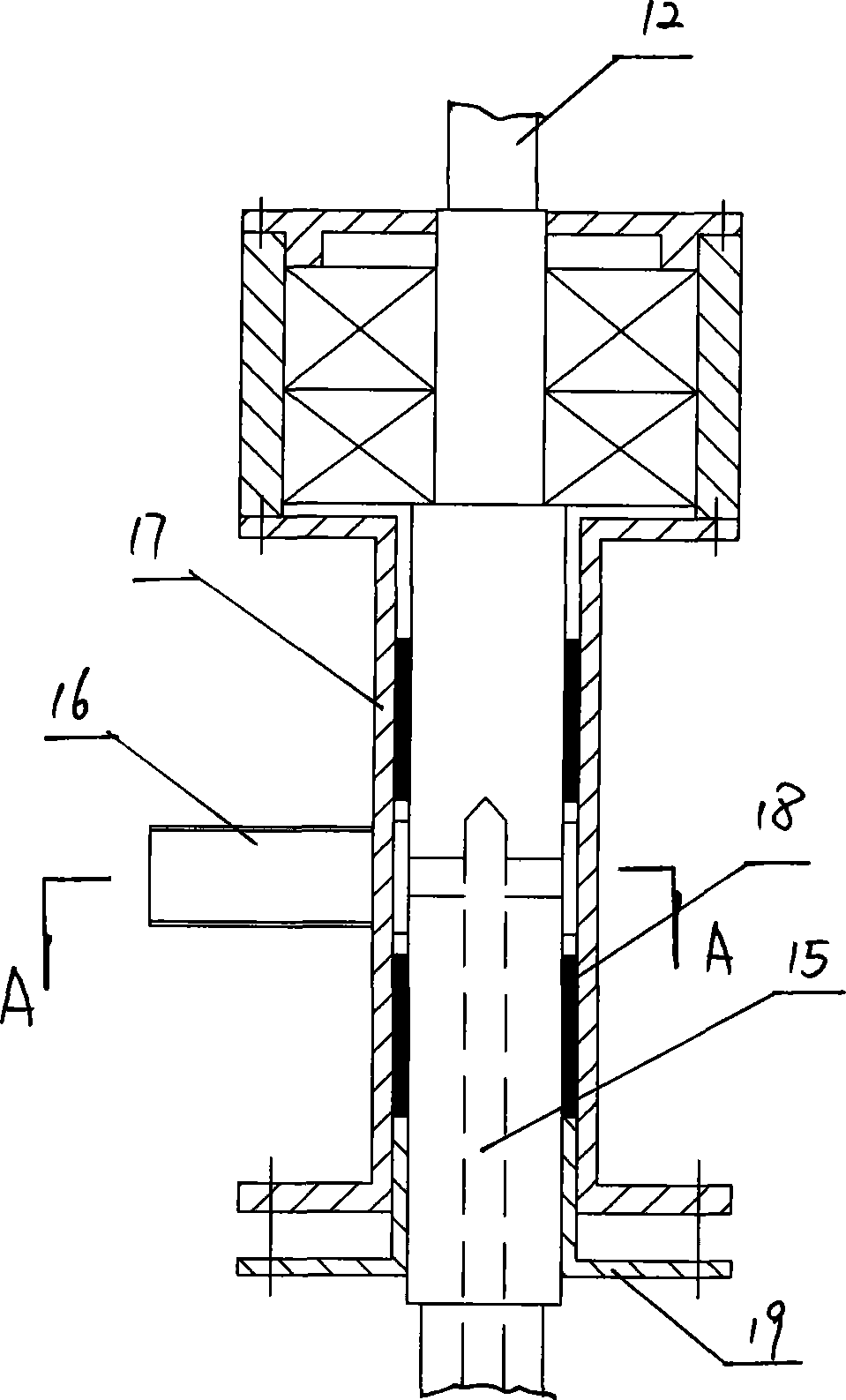

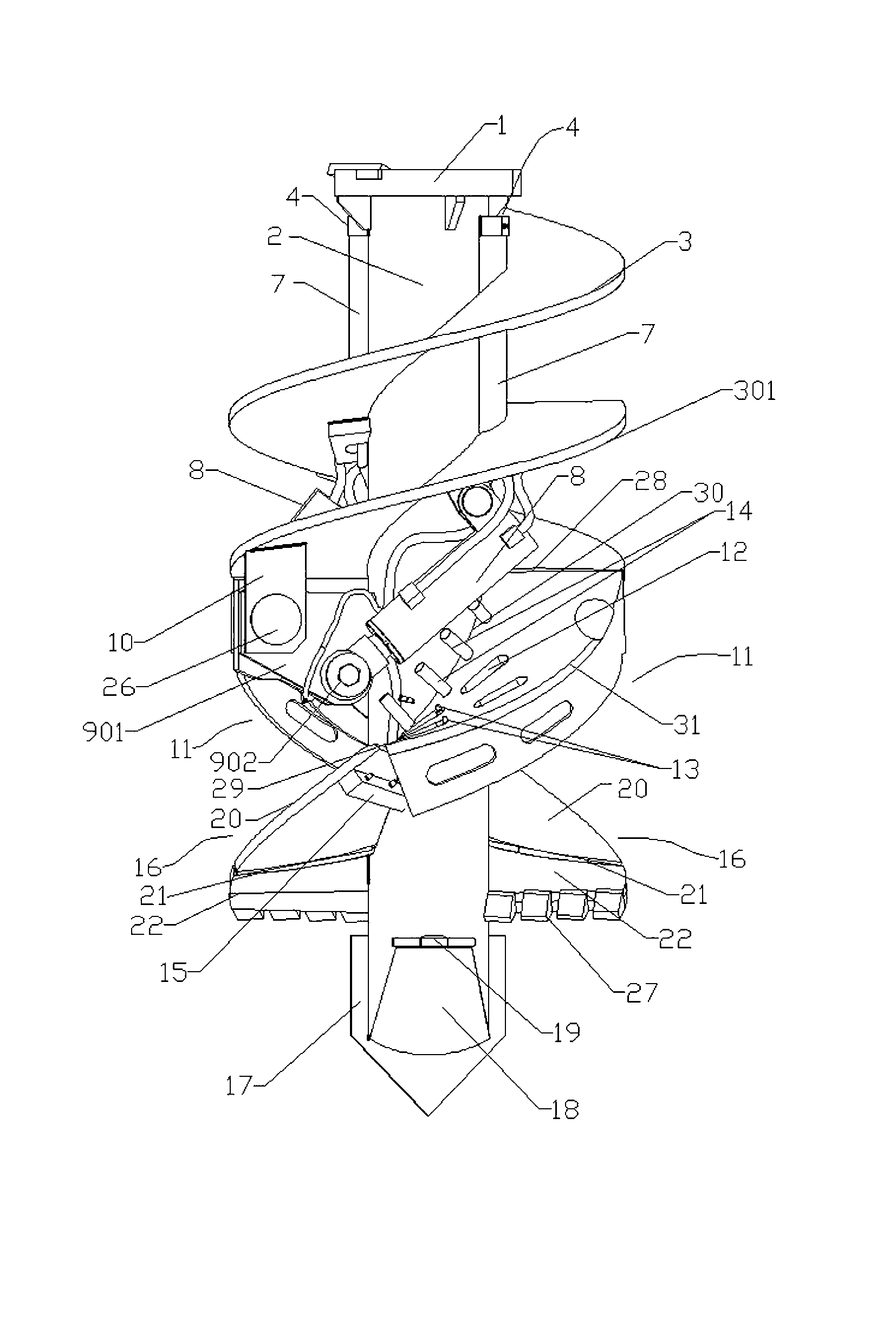

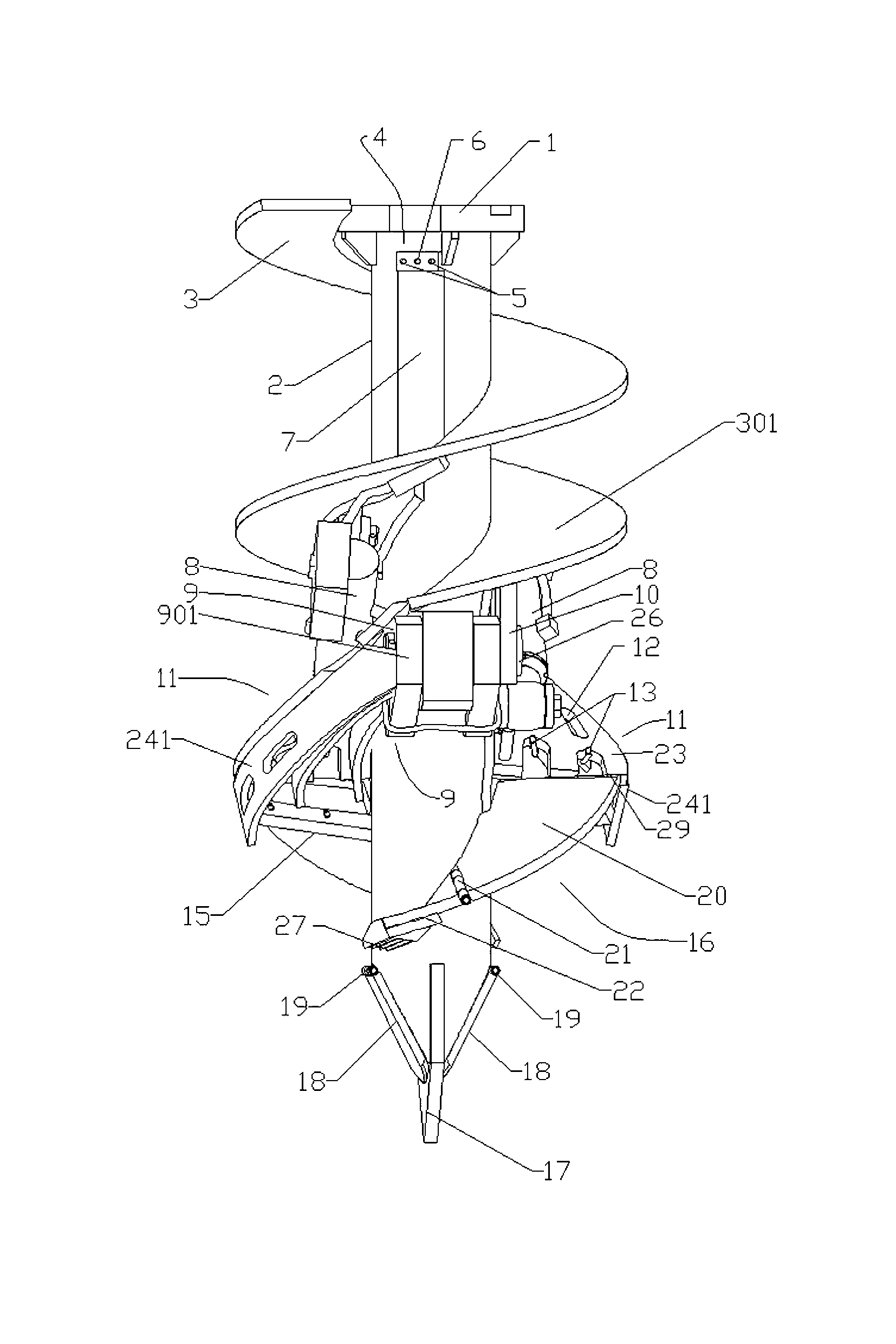

Spiral soil-squeezing downhole rock embedding device and pile forming method

ActiveCN106246099AImprove construction efficiencyReduce construction costsDrill bitsDrilling rodsFlangeDrill bit

The invention relates to a spiral soil-squeezing downhole rock embedding device and a pile forming method. The spiral soil-squeezing downhole rock embedding device is composed of a rotating unit, a standard soil squeezing drill rig, an impactor and a drill bit. The rotating unit is mounted at the upper end of the standard soil squeezing drill rig. The standard soil squeezing drill rig and the impactor are connected with an upper connecting plate through a standard flange. The impactor and the drill bit are positioned through a guiding spline between a lower body and an upper body, and the lower body, a pile casing and the upper body are connected into a whole through bolts and flanges. An impacting unit mounted in the impactor is movably connected with the upper body, and an inner tube II penetrates through the impactor and the drill bit. By means of the pile forming method, a rock-embedded pile with the rock bearing capacity larger than 500 Kpa is constructed, the construction quality is guaranteed, construction efficiency is improved, and the requirements for energy saving and environmental protection are met.

Owner:东营正诺技术服务有限公司

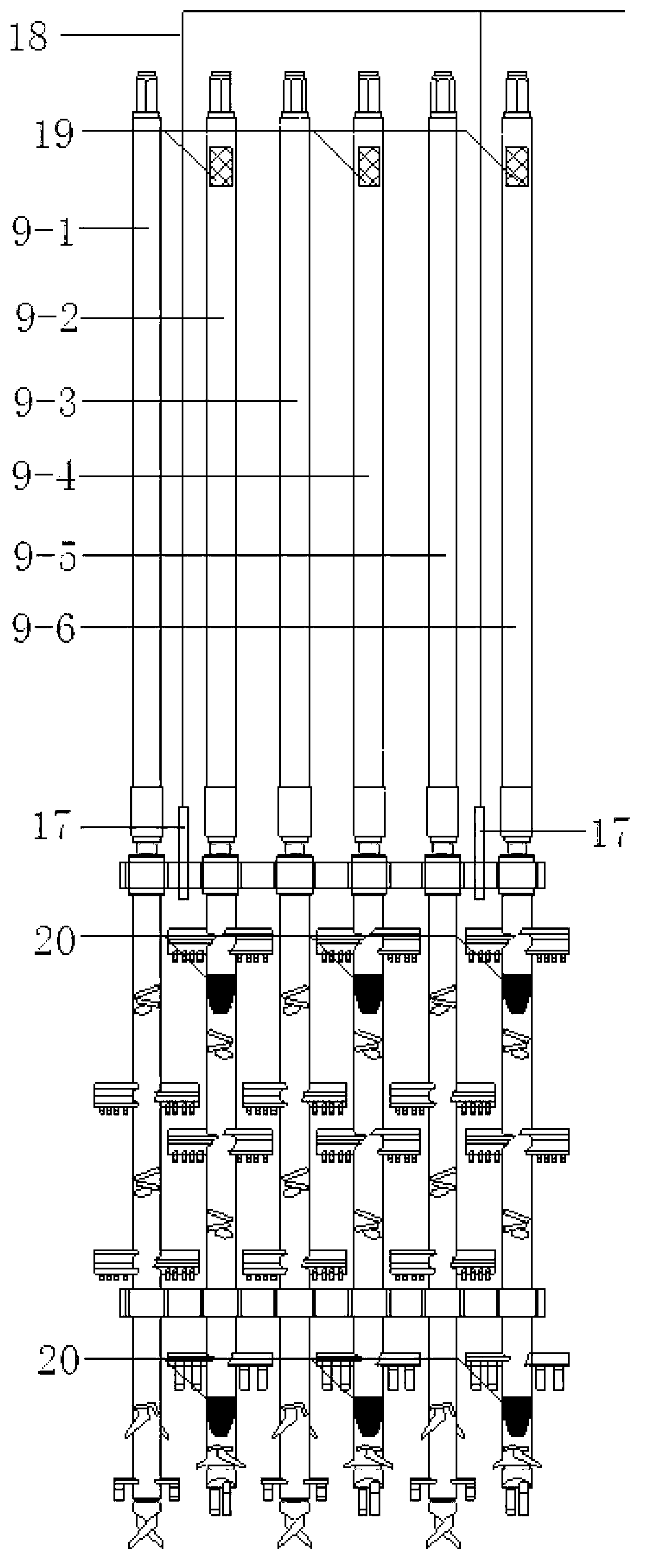

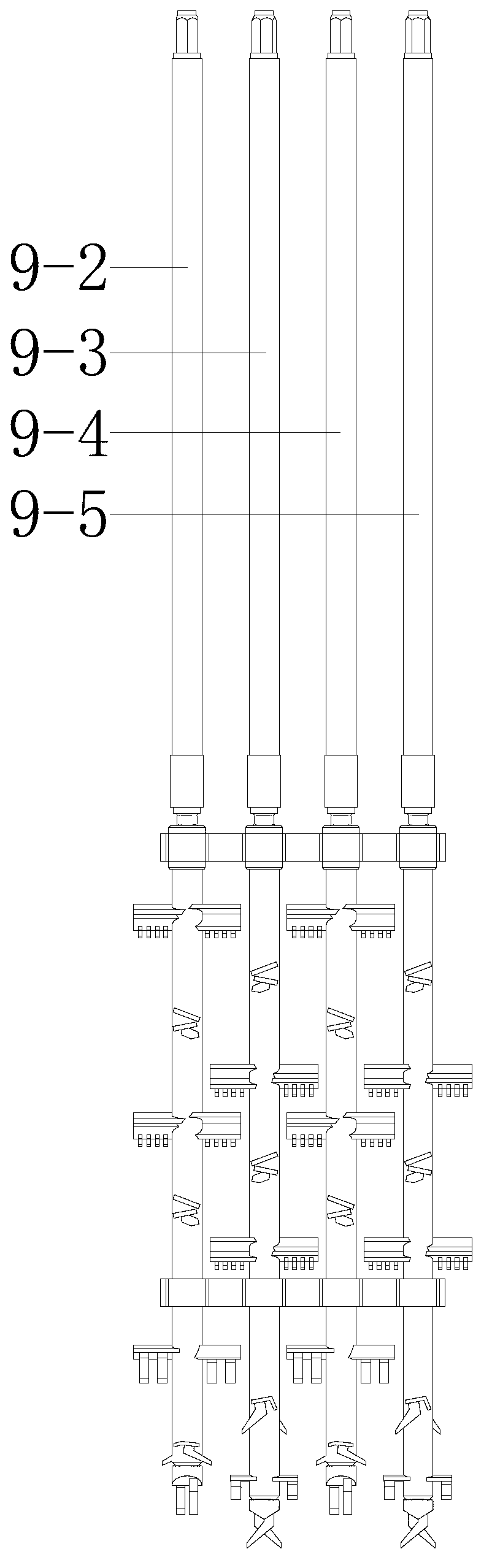

Two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and construction method thereof

ActiveCN103074892AReduce the number of lapsImprove the water-stop effectSurveyDirectional drillingCement slurrySoil cement

The invention relates to a two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and a construction method thereof. The device comprises a host, a guide rod, a power assembly, a plurality of drill pipes, drill pipes with wings, multifunction drill bits, a background cement slurry stirring system, flow meters, a soil penetrating depth sensor and verticality real-time monitors, wherein the power assembly is connected with the drill pipes, the lower end of each drill pipe with the wing is connected with each multifunction drill bit, the top part of each drill pipe is provided with a slurry inlet, the middle part of each drill pipe is provided with a middle bearing bracket, each flow meter is arranged on a slurry spraying port, the penetrating depth sensor is arranged on a slide rail of the guide rod, each verticality real-time monitor is arranged on each middle bearing bracket, the flow meters, the soil penetrating depth sensor and the verticality real-time monitors are respectively connected with the host, and detachable drill pipes are adopted as the drill pipes. Compared with the prior art, the device has the advantages that the pile forming function is versatile, the cost is saved, the verticality is controllable, the pile forming effect is good, and the like.

Owner:SHANGHAI CHENGDI CONSTR

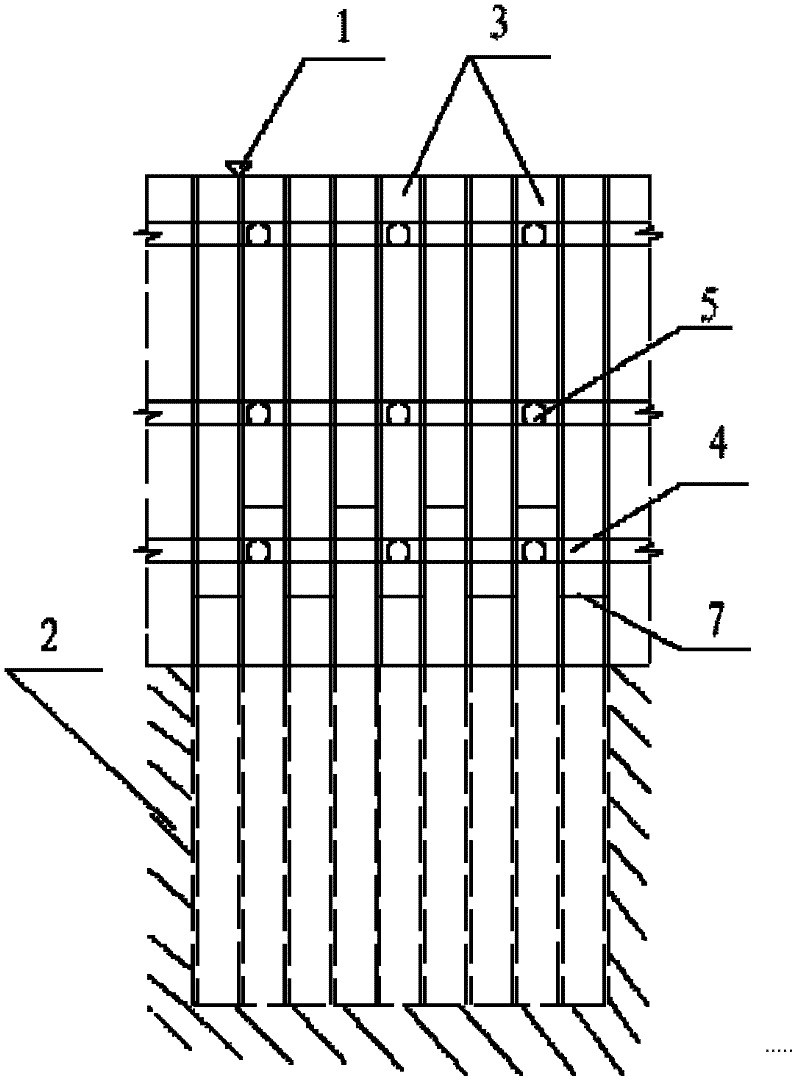

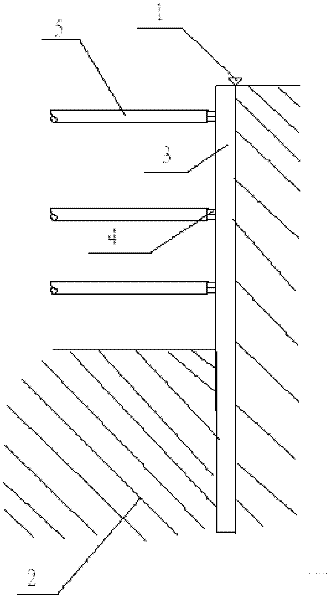

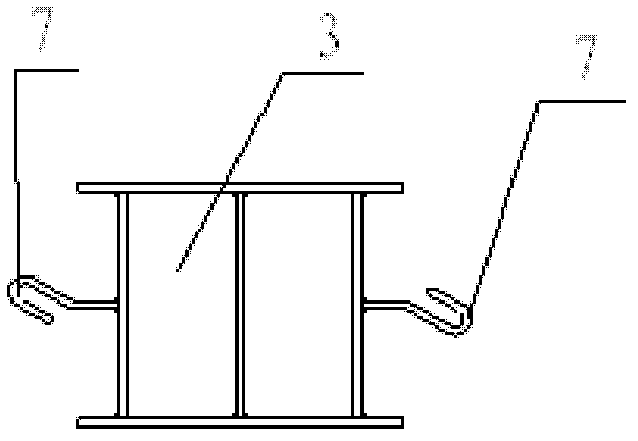

Method for bracing foundation pit by using steel box piles

InactiveCN102359112AImprove construction efficiencyShort construction periodExcavationsBulkheads/pilesSteel platesPurlin

The invention discloses a method for bracing a foundation pit by using steel box piles. The method comprises the following steps of: (1) making the steel box piles: welding profile steels or steel plates into a steel box pile box, and arranging transverse connecting members among the piles at two sides of the steel box pile box; (2) arranging a ground guiding structure: pouring reinforced concrete to form a foundation pit bracing guiding wall or arranging steel members to form the ground guiding structure; (3) positioning: sequentially positioning a plurality of steel box piles along the guiding structure respectively; (4) sinking the piles: driving the steel box piles into soil; (5) lengthening the piles: when the foundation pit is relatively deep and the prefabricated steel box piles are not long enough, lengthening the steel box piles through pile body lengthening members; and (6) digging and supporting: digging layer by layer, arranging enclosing purlins and erecting supports in the foundation pit of the steel box piles, and completing the construction. The method has the advantages of high construction efficiency, short construction period, reliable pile forming quality, low engineering cost, resource economization and the like, and is particularly suitable for weak strata in which holes and grooves are not easily formed such as silt soil, peat soil, saturated water-containing sand layers, powdery clay, soil sand and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

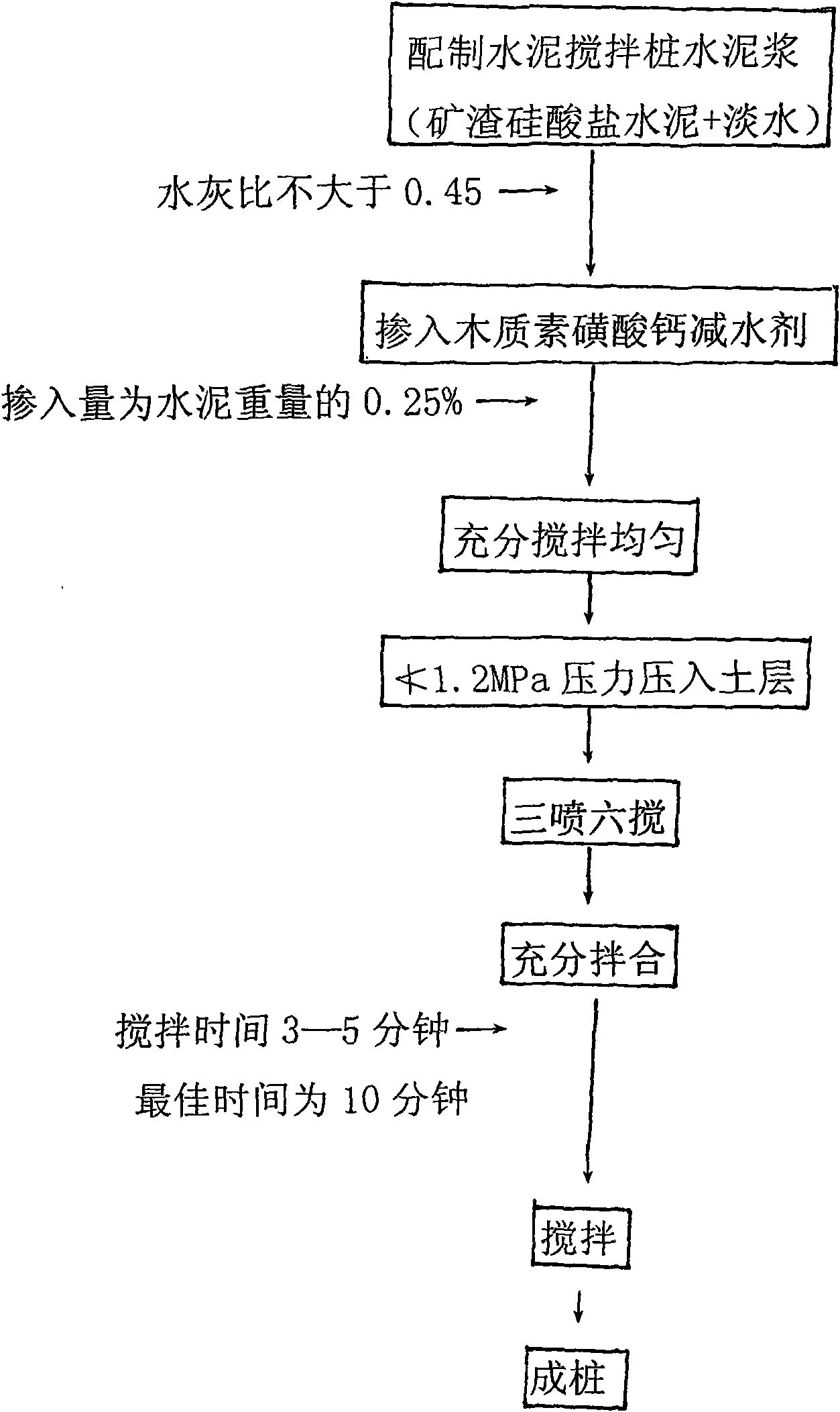

Treatment method of coastal sludge soft soil foundation cement mixing pile

The invention relates to a treatment method of a coastal sludge soft soil foundation cement mixing pile, which selects the adaptive portland slag cement as a modifier, adds a calcium lignosulphonate water-reducing agent and adopts the construction process of three times of spraying and six times of stirring for carrying out foundation reinforcement for the cement mixing pile. The doping amount ofthe portland slag cement is 20%, the water-cement ratio is not more than 0.45, the adding amount of the calcium lignosulphonate water-reducing agent is 0.25%, and the even stirring is carried out in ashort period of time. Slurry and the construction process can improve the characters of a clay foundation, in particular to sludge clay and the sludge foundation, and improve the piling quality of the cement mixing pile. The treatment method has the advantages of good piling quality and high strength, the strength of the cement mixing pile after piling can be improved by about 30%, and mineral products and wastes are comprehensively utilized, thereby protecting the environment, reducing the cost and having good economic benefits and social benefits.

Owner:天津津滨铁道设计咨询有限公司 +3

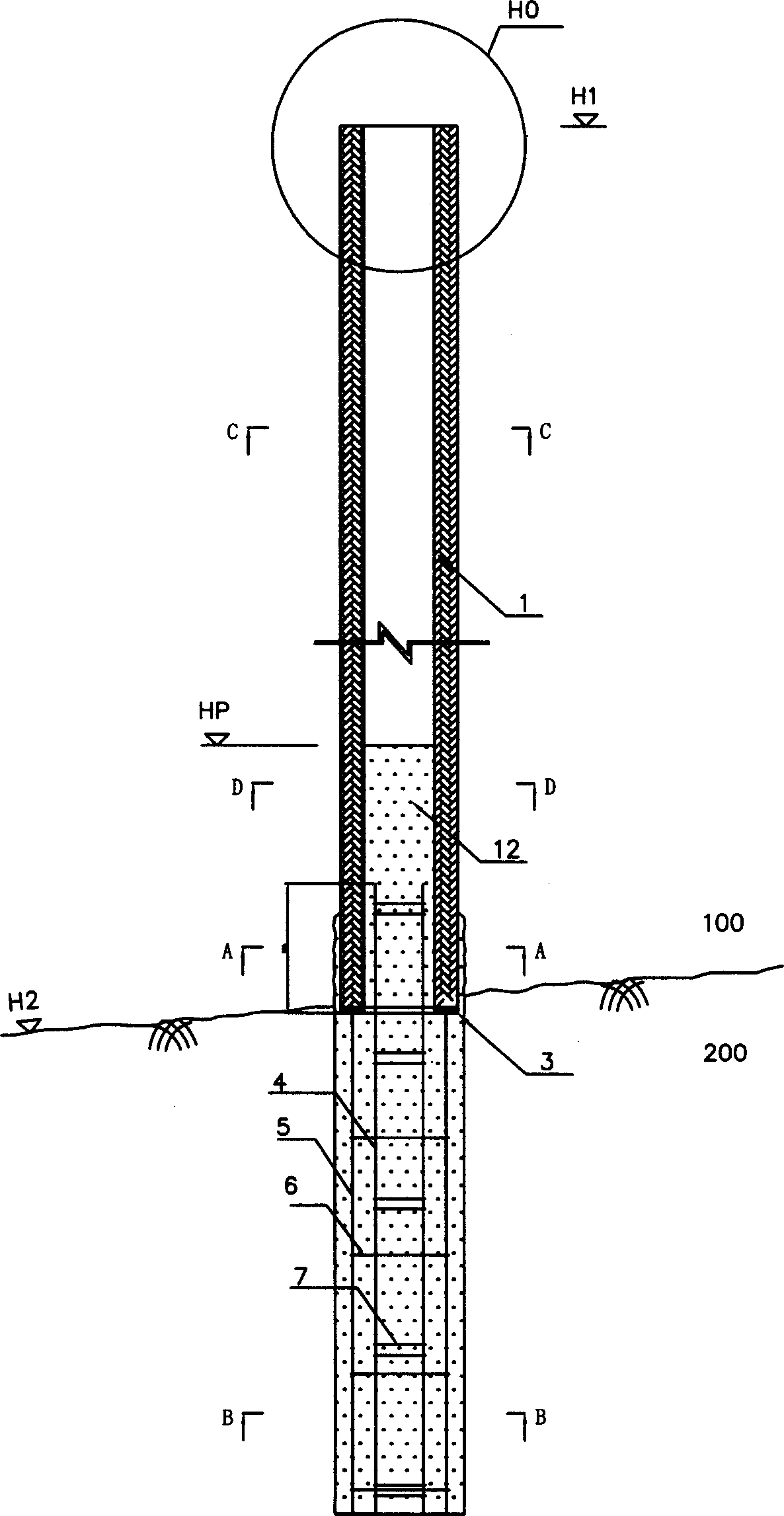

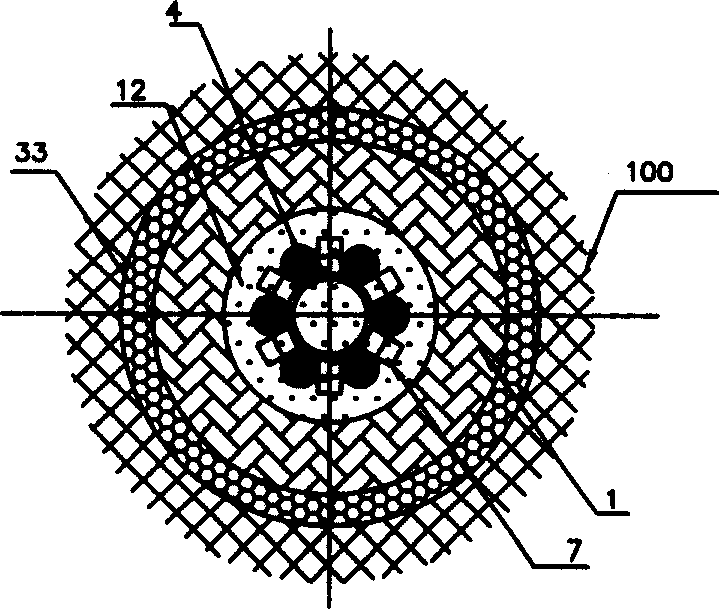

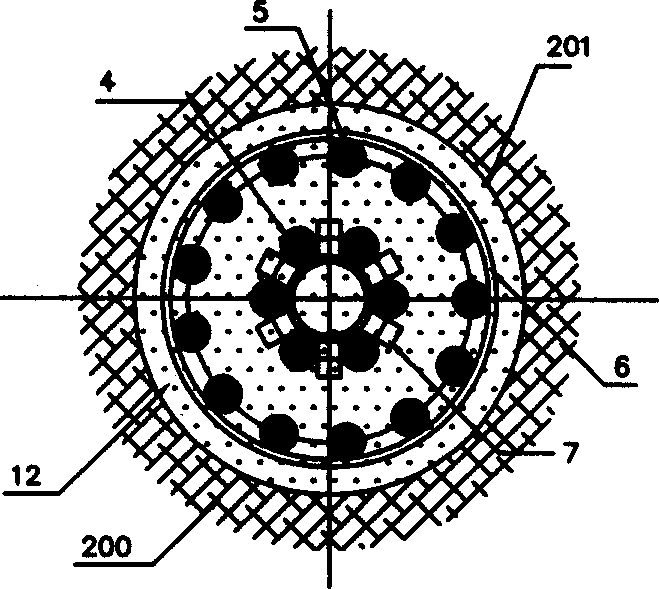

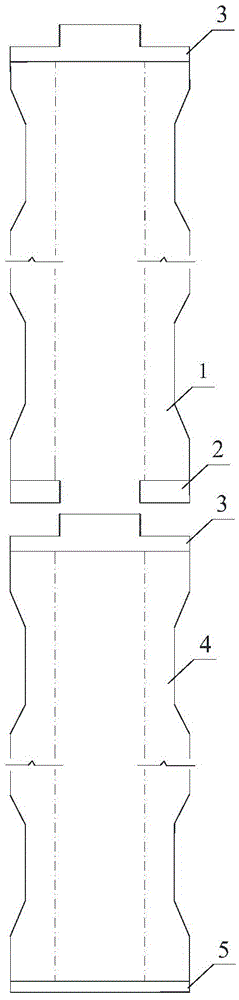

Precast pile post-grouting device and precast pile post-grouting process

InactiveCN104234055AGrouting construction method after solutionImprove pile sinking efficiencyBulkheads/pilesPre stressSlurry

The invention relates to the technical field of foundation stabilization, in particular to a precast pile post-grouting device and a precast pile post-grouting process. The technical scheme adopted by the invention is that the precast pile post-grouting device comprises a precast pile, a stirrer, a slurry tank, a grouting pump and a grouting hose; a pile body of the precast pile is provided with a prestressed reinforcement, a spiral bar, an upper end plate and a lower end plate. The precast pile post-grouting device is characterized in that grouting holes are also formed in the precast pile, and the precast pile is also provided with grouting pipes, an upper transition pipe and a lower transition plate. Compared with the prior art, the precast pile post-grouting device and the precast pile post-grouting process have the beneficial effects that a construction process of pile tip and pile tip peripheral grouting and the arrangement form of the grouting pipes can be realized on piles with various pile diameters (large diameters and small diameters), various pile types (square piles, round piles, hollow piles and solid piles) and various pile lengths (short piles and long piles), and the problems of a post-grouting construction method of all precast pile types are solved.

Owner:顾孙平

Multi-azimuth tridimensional stirring drill for mollisol or spongy soil reinforcing stirring pile

The invention discloses a multiple position tridimensional stirring drill bit used for leading soft soil or mollisol to reinforce a stirring pile, comprising a drill rod, a front drill point which is positioned at the front end of the drill rod and a multilayer main blade fixed on the drill rod; wherein, the main blade is provided with at least one group of stirring wheels which rotate by taking the main blade as a rotating shaft and does not have power in the process that the drill rod rotates. The multiple position tridimensional stirring drill bit makes use of the energy which is supplied by the rotation of the drill rod and by means of the reaction force of stratum so as to realize the rotation of the stirring wheels, thereby completing the multiple position tridimensional stirring to the stratum by combining the main blade and the stirring wheels and achieving the aim of forming the pile by stirring. The multiple position tridimensional stirring drill bit can remarkably improve the quality of pile forming and effectively reinforce the depth, which has the advantages of uniform stirring, simple structure, strong stratum adaptability, high pile forming efficiency and effectively controlling slurry return.

Owner:徐玉杰

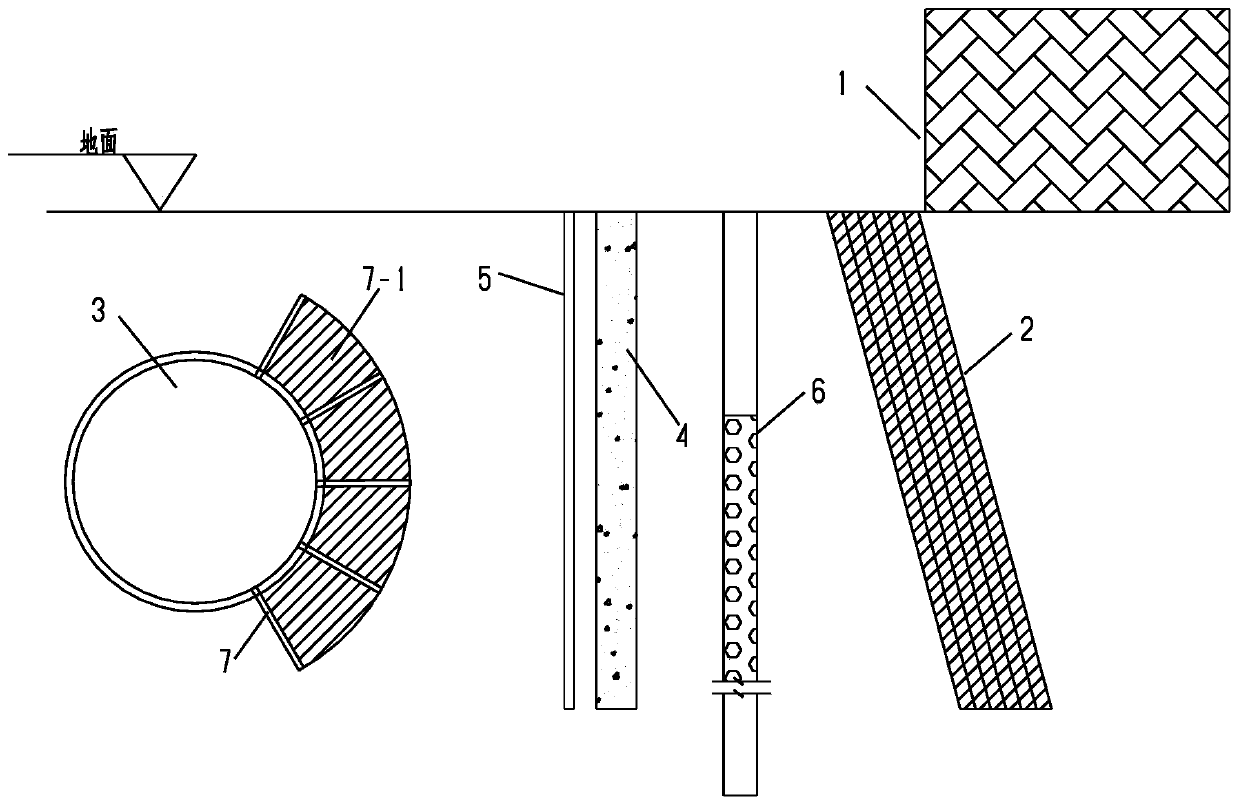

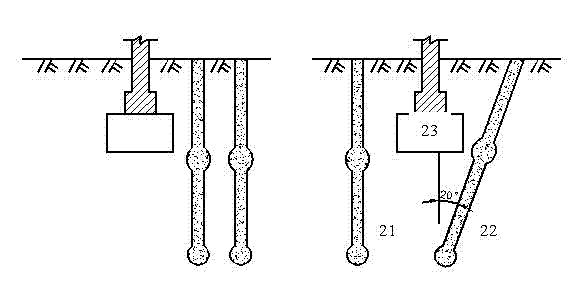

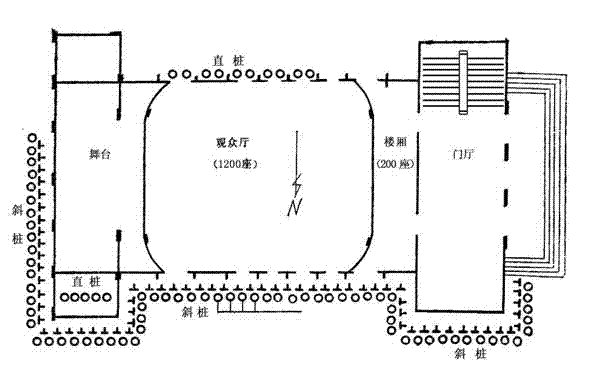

Construction method for lateral penetration of building by shield

PendingCN110359921AImprove pile qualityLarge pile diameterMining devicesUnderground chambersPrecipitationShield tunneling

The invention provides a construction method for lateral penetration of a building by a shield. The construction method specifically comprises the following steps: before the shield passes through, MJS construction method piles with angles of 15-30 degrees are constructed, a lower stratum of the building is reinforced, and plain concrete piles are adopted for isolation protection of a front area between the building and a tunnel; the middle of the plain concrete piles is drilled near the tunnel is drilled to embed sleeve valve pipes for isolation protection of un-engaged weak places of the plain piles; recharge wells are arranged around the building; water level, precipitation and inclination monitoring points are arranged around the building; in the shield tunneling process, shield parameters are controlled, and the monitoring points are used for monitoring; and after the tunnel is driven, small guide pipes are arranged in the tunnel near the building in a range of 120 degrees for grouting to prevent long-time accumulated influence on the building in later operation process. The construction method prevents the influence on the building by near-distance construction of the shielded tunnel, guarantees the structure stability of the building, and can effectively control the precipitation penetrating through the area.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

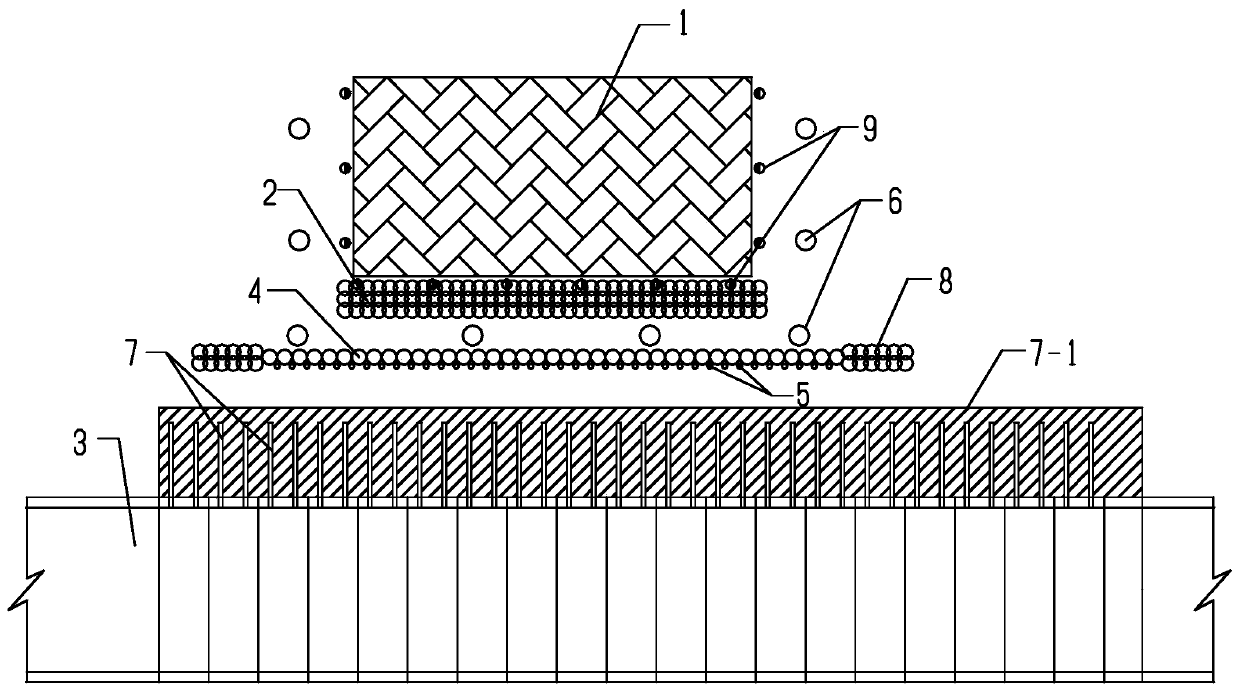

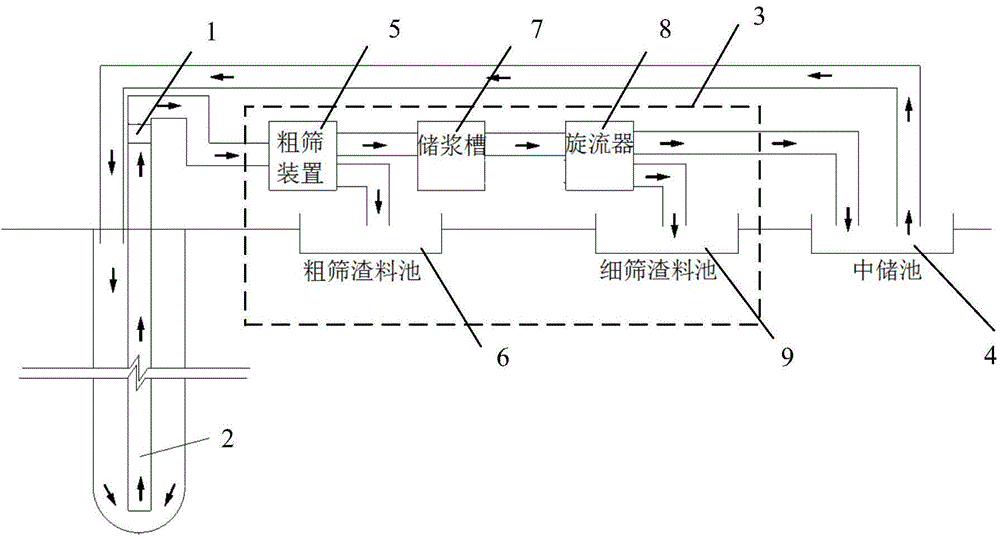

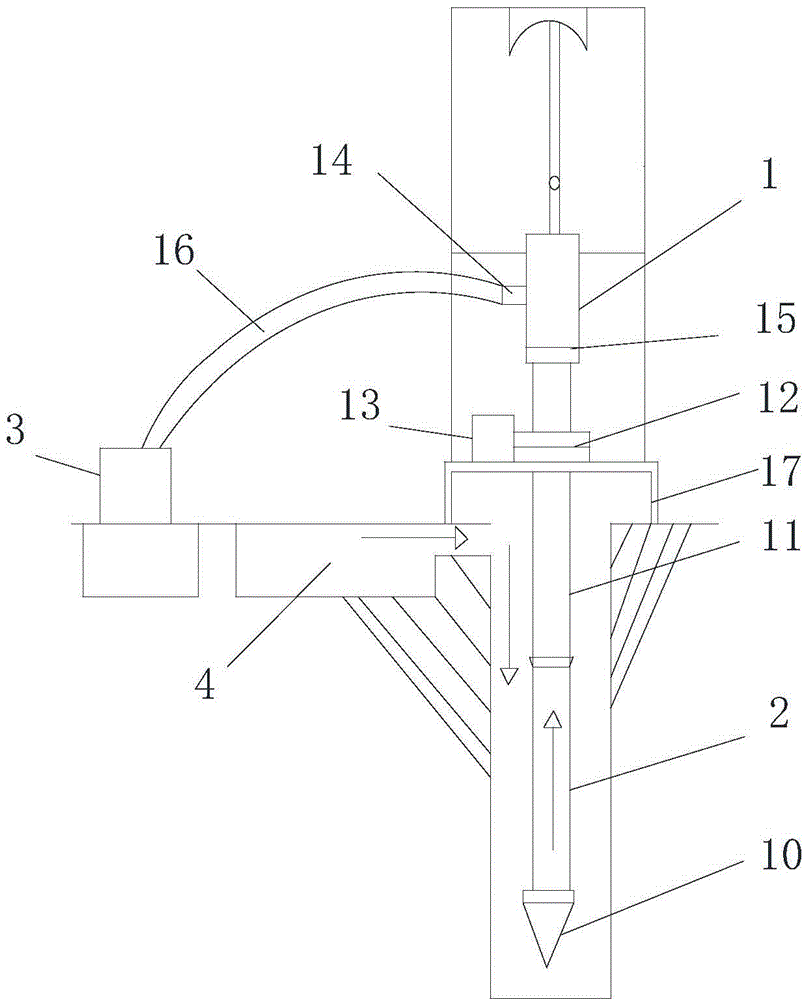

Cast-in-situ bored pile hole-forming device and method

ActiveCN105804059ASmall amount of shrinkageEmission reductionFlushingBulkheads/pilesSlagStorage tank

The invention discloses a cast-in-situ bored pile hole-forming device and method. Dirt slurry at the hole bottom is conveyed to a coarse screening device through a drilling rod by means of a gravel pump, a coarse slag material flows into a coarse screening slag material pool after the dirt slurry is subject to coarse screening through the coarse screening device, and the rest of the dirt slurry flows into a slurry storage tank; the slurry in the slurry storage tank is conveyed to a hydrocyclone through a slag slurry pump and is subject to fine screening through the hydrocyclone, then a fine slag material flows into a fine screening slag material pool, and the rest of the slurry flows into a middle storage tank; and the slurry inside the middle storage tank is conveyed to space between the drilling rod and the hole wall by an overflowing opening formed in the pool wall or through a slurry pump, and therefore a reverse circulation loop is formed. By adopting a pumping suction reverse circulation hole cleaning manner, the hole-forming rate and the hole cleaning efficiency can be improved, the waste slurry discharge amount is less, the single-pile construction time is shortened, the inward contraction amount of the hole wall is reduced, and the construction quality is improved. By means of two-stage screening through the coarse screening device and the hydrocyclone, the quality of slurry circulated back to holes can be improved, slag sinking to the hole bottom is further reduced effectively, and the hole wall is more stable.

Owner:SHANGHAI MECHANIZED CONSTR GRP

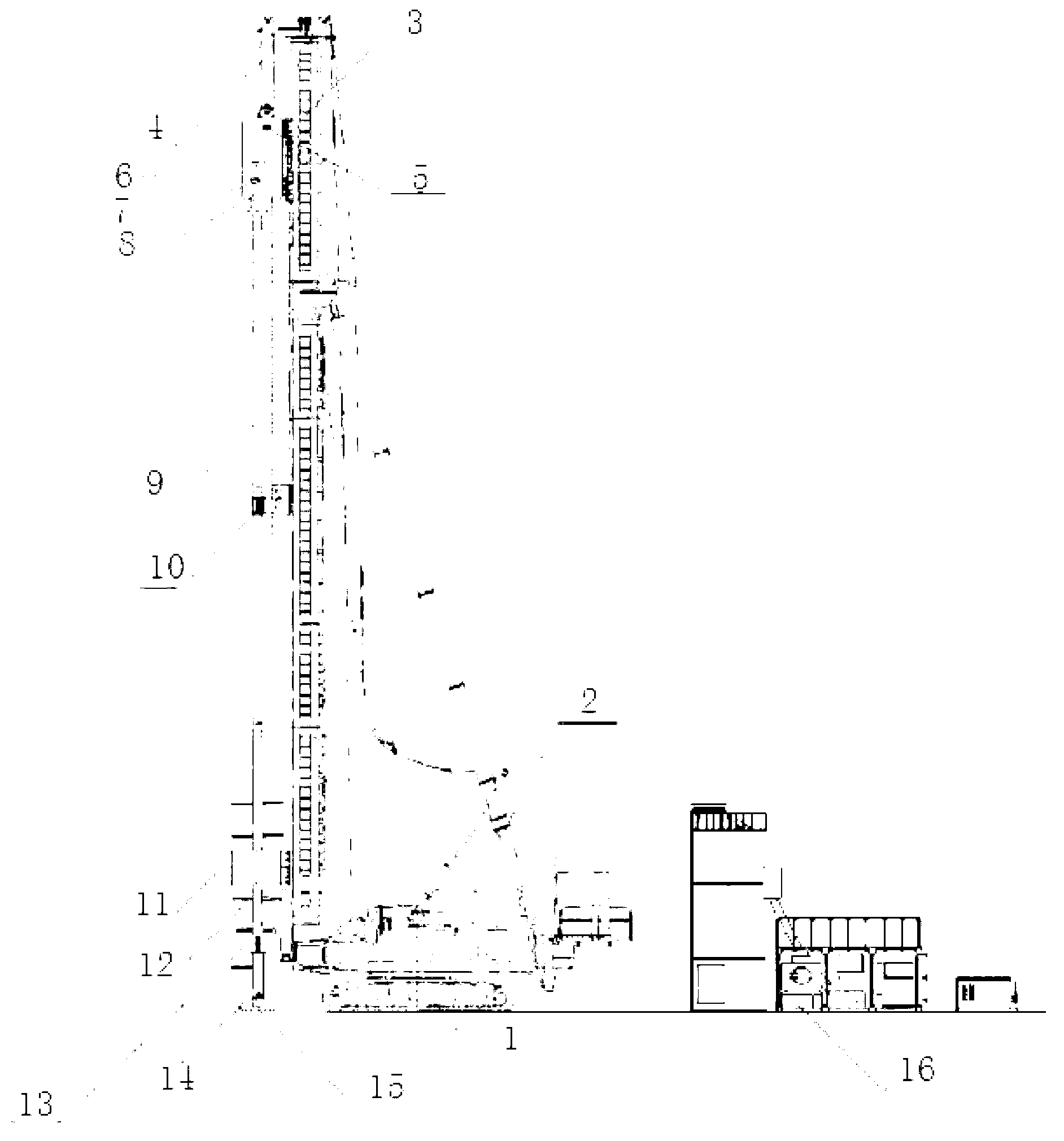

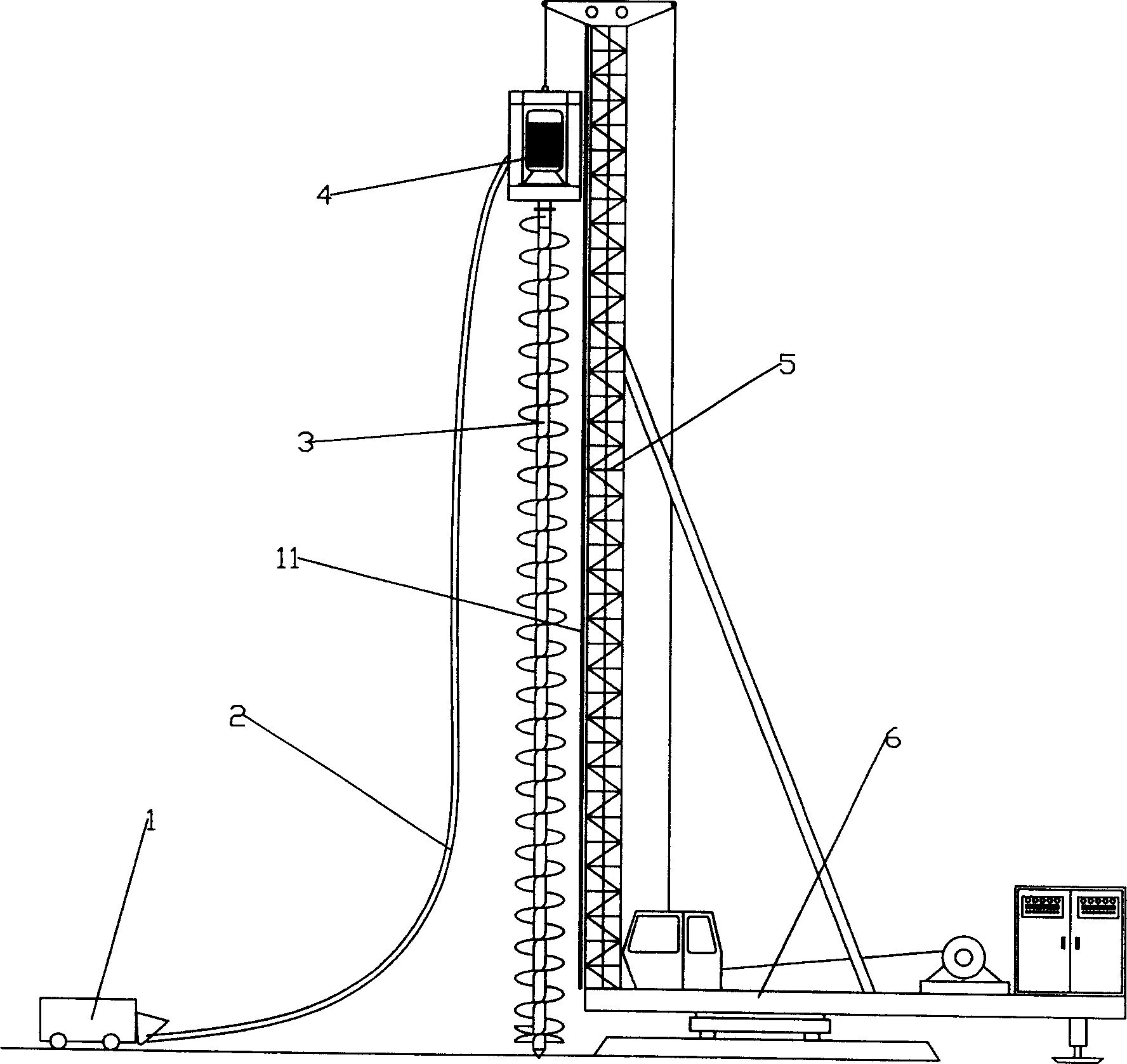

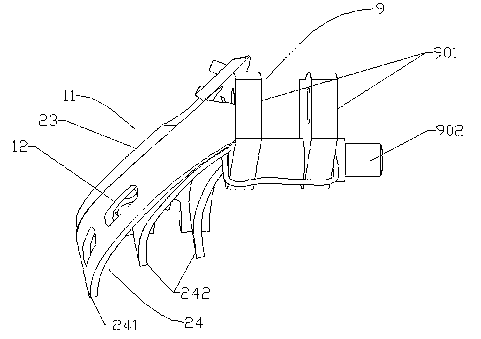

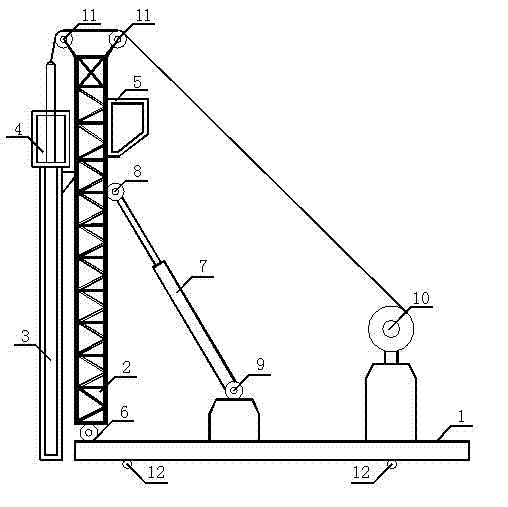

Construction machinery for long spiral press pouring concrete lock pin combination piles

The invention discloses a construction machine for long helical grouting concrete core-inserted composite piles. A long helical drilling and grouting pile mechanism and a static pressure pile mechanism are installed side by side on the walking chassis of a walking pile machine. The long helical auger The center points of the hole-pressing pile filling mechanism and the pile-pressing mechanism are all located on the same circle centered on the center point of the turntable of the traveling chassis of the pile machine. After the long spiral construction is completed, the static pile-pressing mechanism can be quickly aligned only by turning the turntable. The pile driver can independently complete the construction of the long spiral pressure grouting concrete core-inserted composite pile, and has the advantages of convenient construction, reliable quality and low construction cost.

Owner:雷玉华

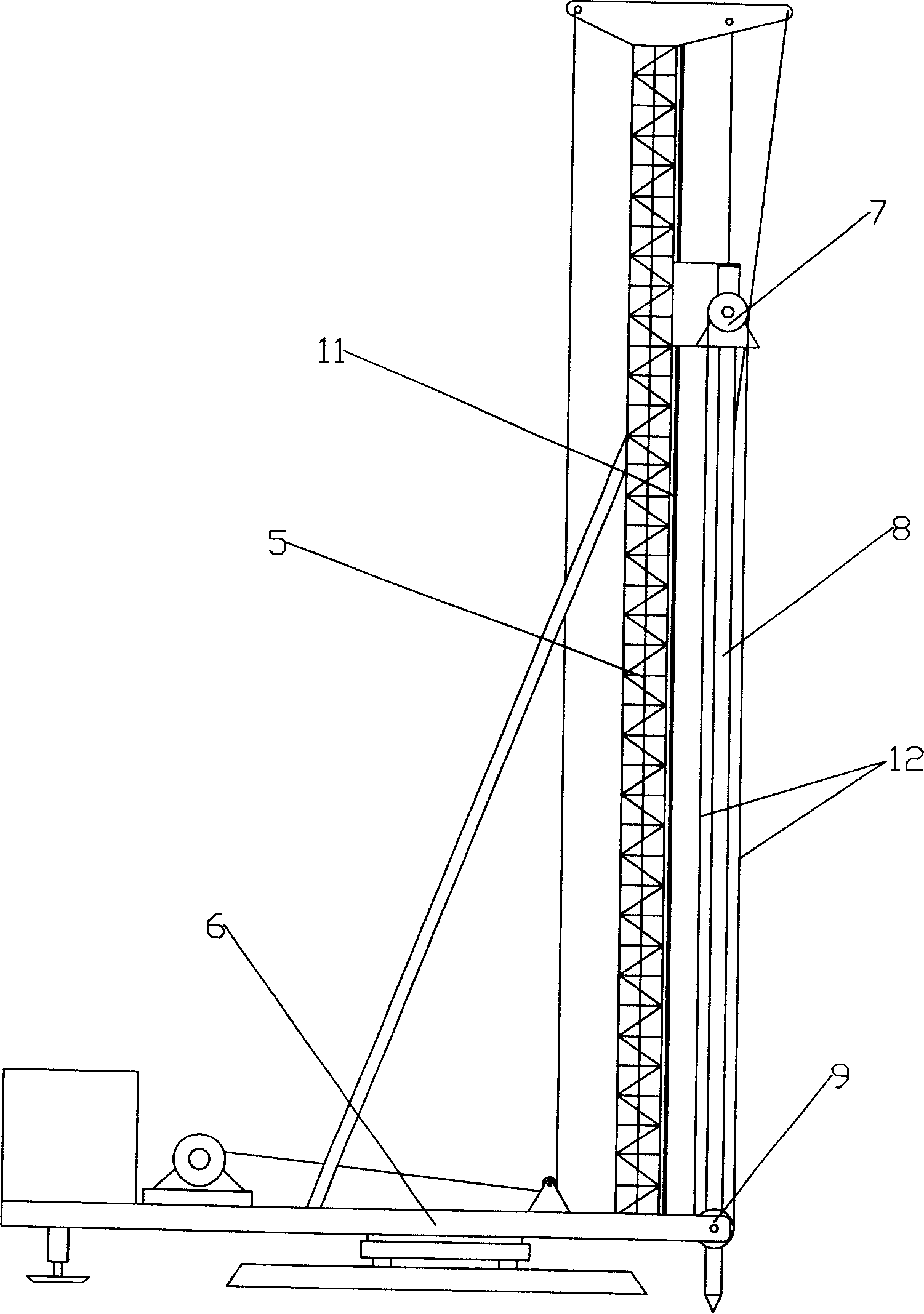

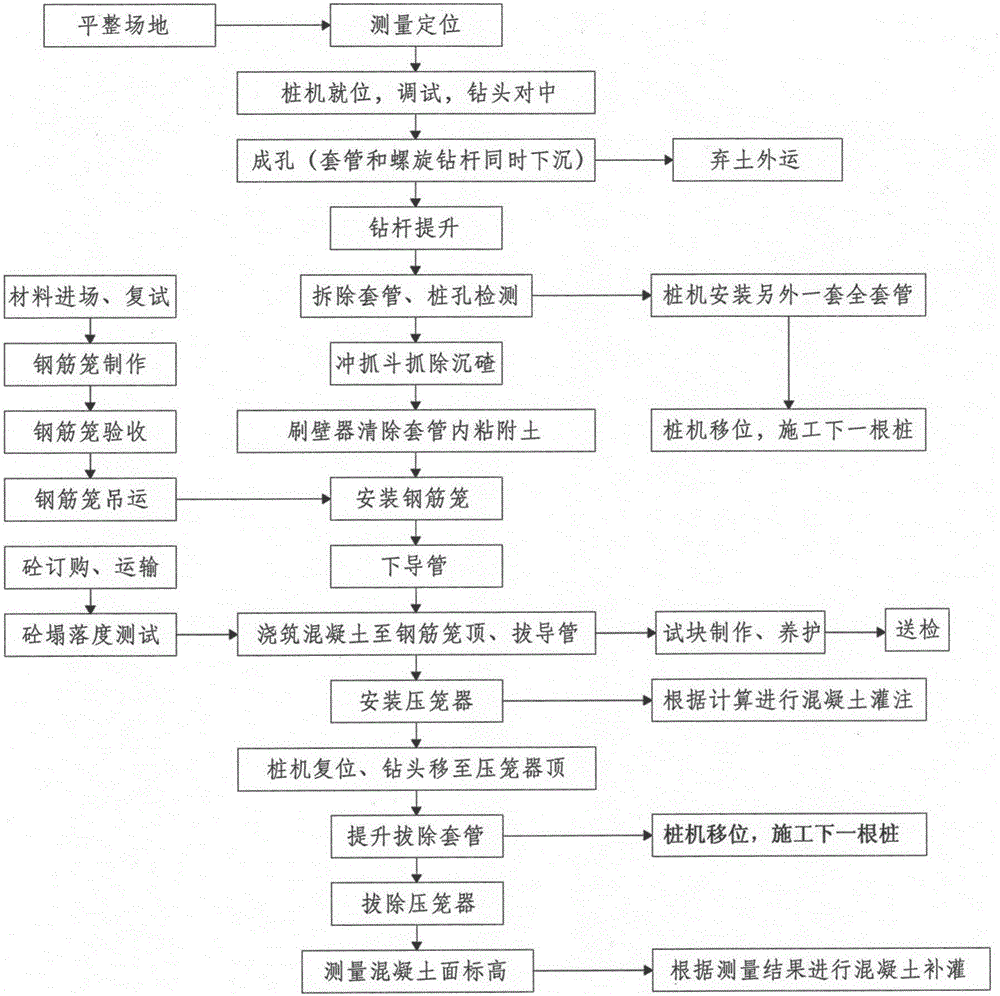

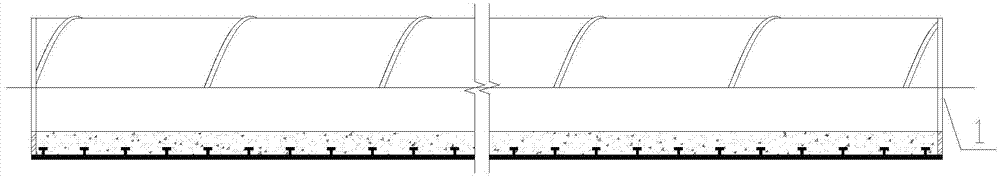

Construction method for full-casing long spiral bored piles

The invention provides a construction method for full-casing long spiral bored piles. The method includes the steps that firstly, a casing pipe and a spiral drill pipe of a full-casing long spiral drilling machine simultaneously rotate and sink so as to form a hole after being aligned with a pile position; secondly, the drilling machine is moved to the next pile for hole formation operation, and meanwhile, adhering soil on the inner wall of the casing pipes in the formed hole is removed in a brushing mode through a wall brushing device; thirdly, a reinforcement cage is hoisted into the hole, concrete is poured into the reinforcement cage, and concrete pouring is stopped after the concrete is poured to the top elevation of the reinforcement cage; fourthly, a cage pressing device is hoisted into the casing pipe, and concrete pouring continues; fifthly, a pile machine is located in place, and a drill bit is elevated to the cage pressing device to press the reinforcement cage; and finally, the casing pipe is lifted and pulled out, the cage pressing device is removed, and pile forming is completed. The construction method provided by the invention is high in construction efficiency, the wall of a formed pile hole is regular in shape, a pile body is high in perpendicularity, and the pile forming quality is good; soil squeezing, hole collapse and vibration are avoided, and construction noise is low; and slurry pollution in the construction process is avoided, the outward slurry transport cost is reduced, the cost is reduced, and the construction method is environmentally friendly.

Owner:上海腾尚基础工程有限公司

Ground strengthening cement mortar rotary-spraying pile and construction method

The present invention discloses a foundation reinforced cement mortar rotary-spraying pile and the construction method thereof. The conventional rotary-spraying pile uses the slurry as the neat cement grout and the cement is added with fine powder sand. The slurry has obvious effect for improving the character of the clay foundation and increasing the pile forming quality of the rotary-spraying pile. The phenomenon of low pile-forming strength of conventional rotary-spraying pile in the clay formation is overcome. The same formation adopts a cement mortar rotary-spraying pile. The strength of the cement-treated soil after pile forming is increased for about 30% compared with the conventional neat cement group rotary-spraying pile and the cement is saved for more than 20%.

Owner:徐玉杰

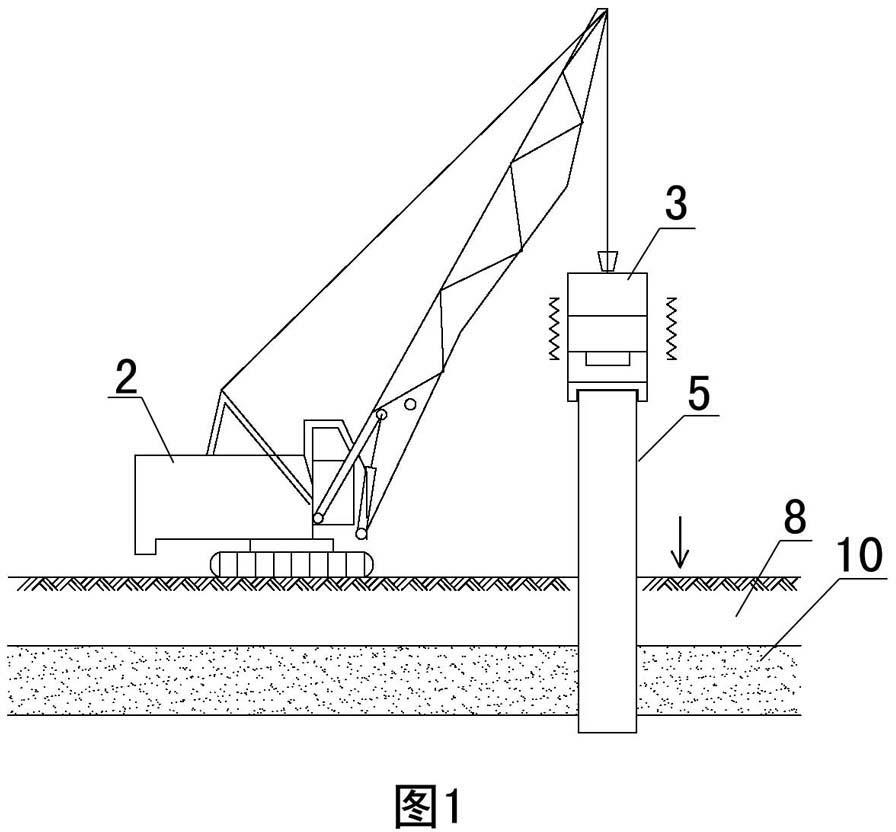

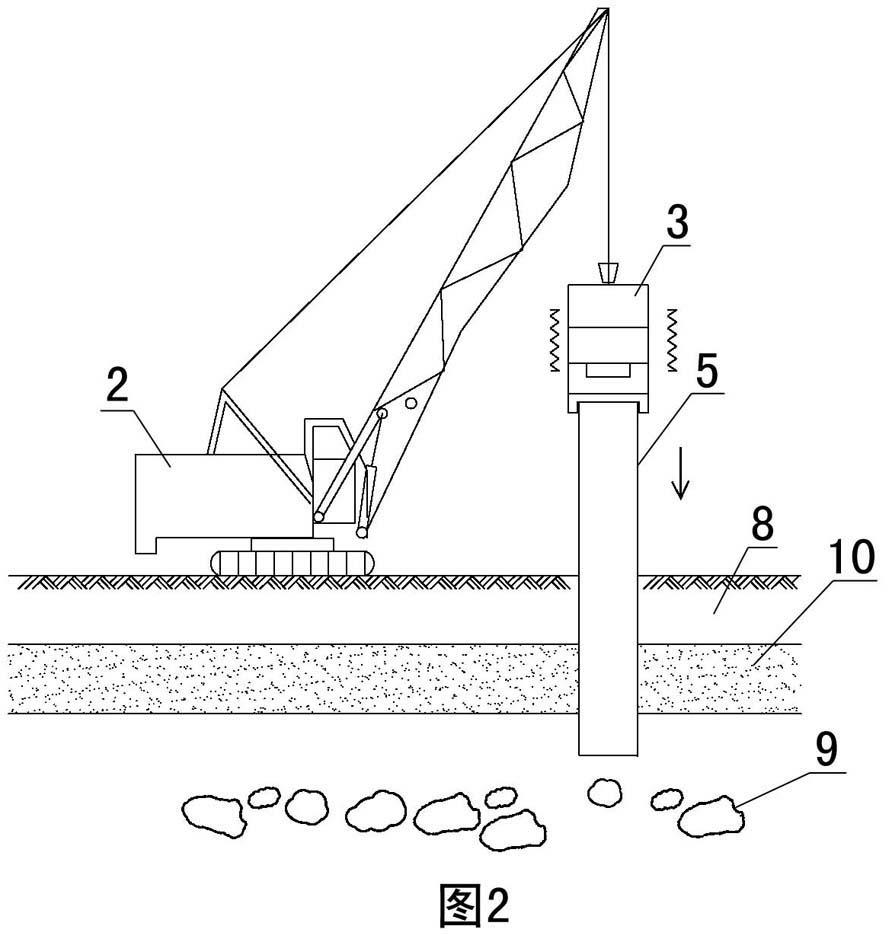

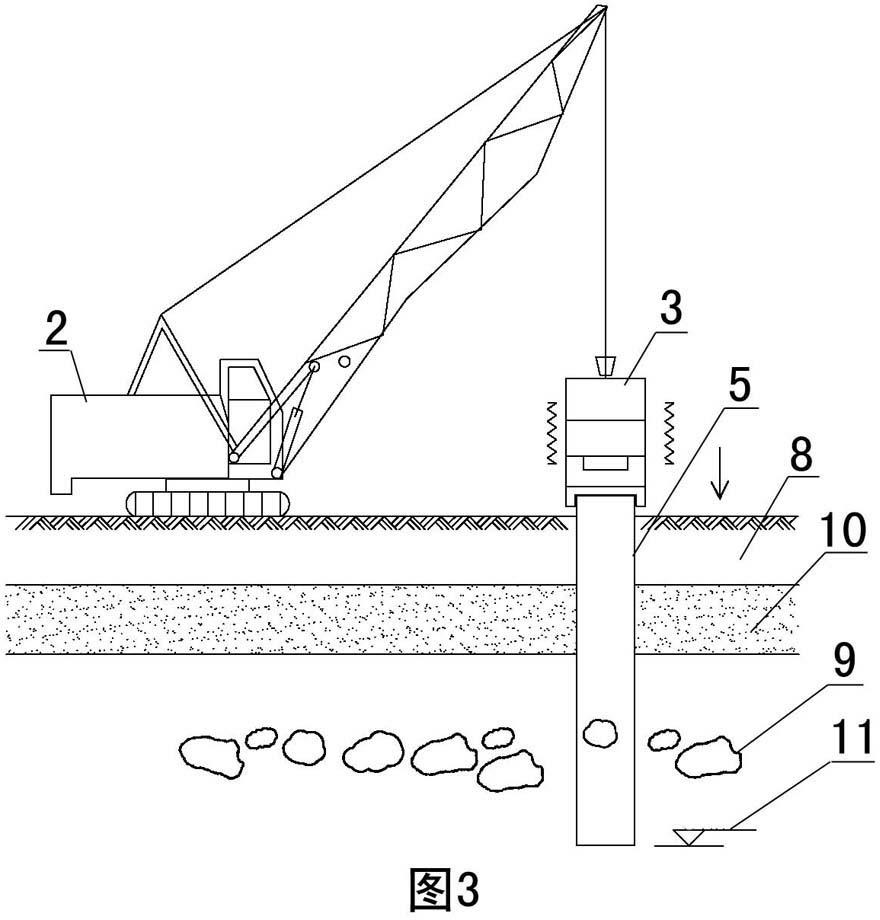

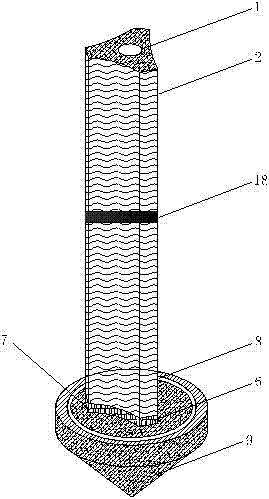

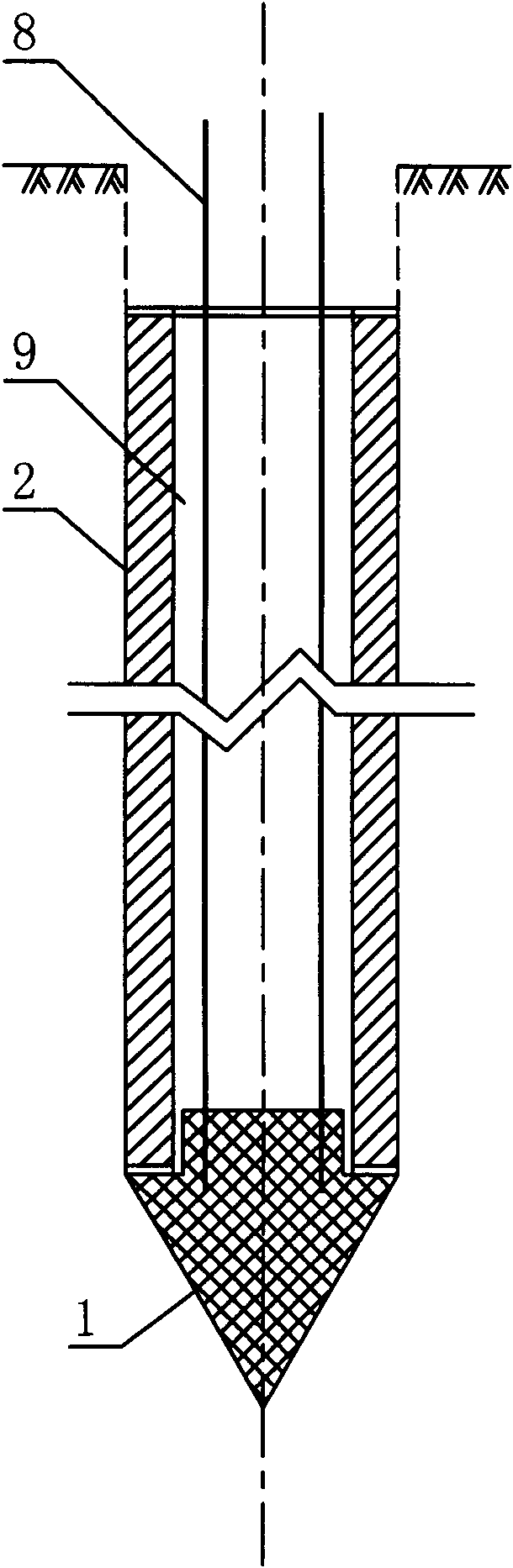

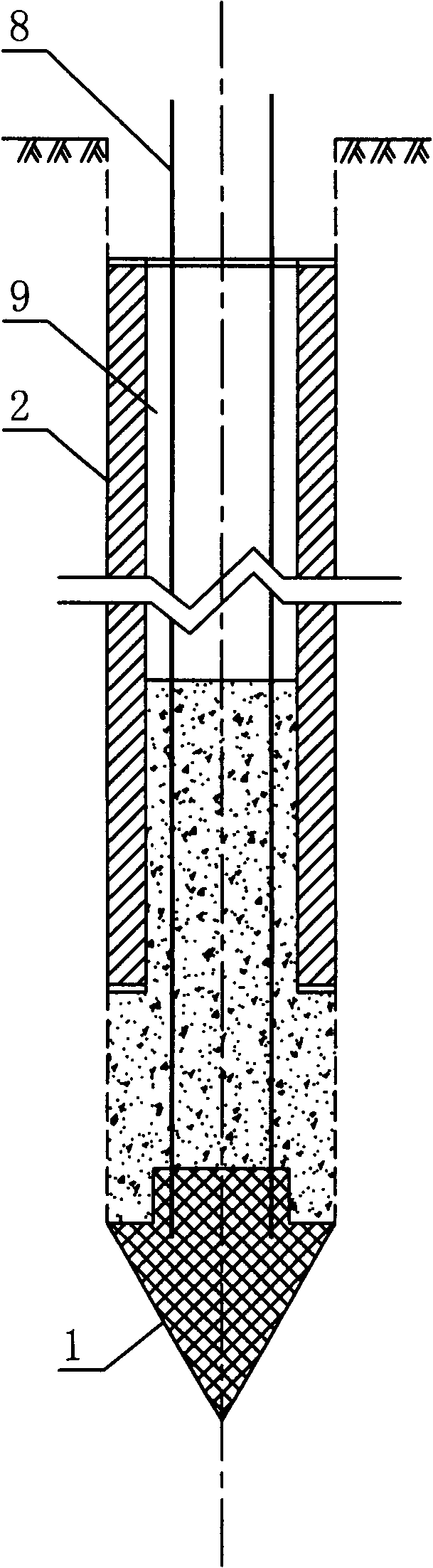

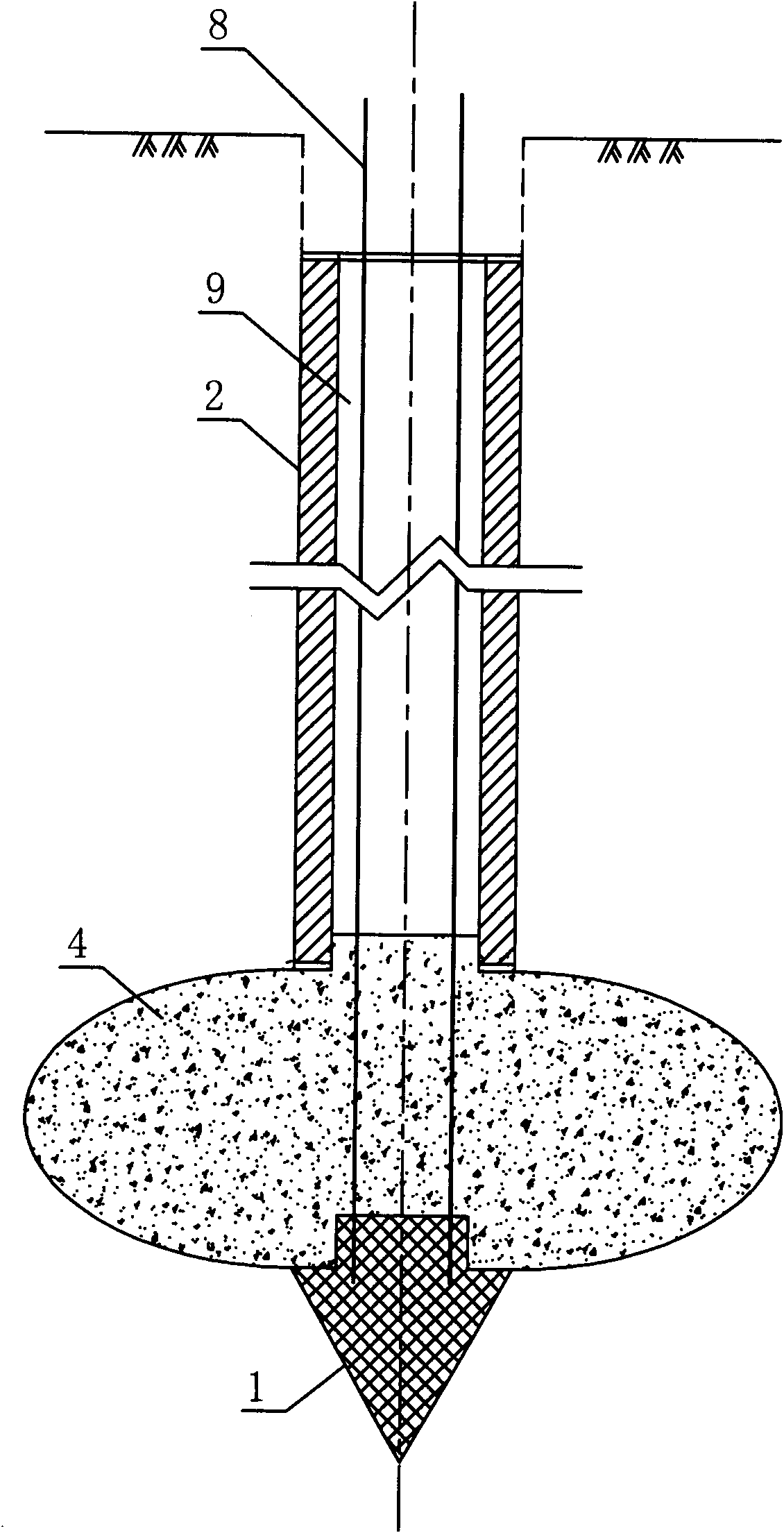

Precast expanding pile as well as construction method and construction mechanical equipment thereof

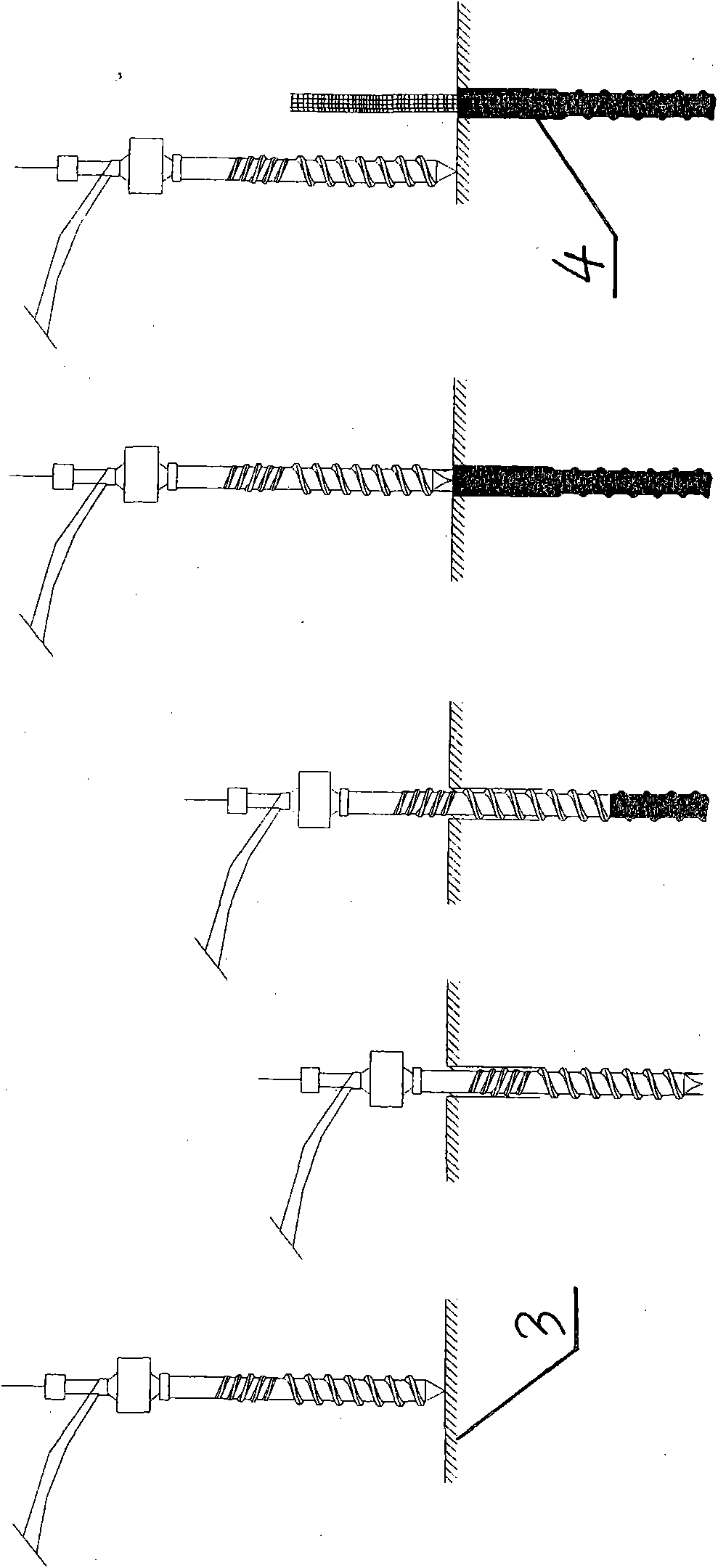

InactiveCN101936004AImprove bearing capacityLow costBulkheads/pilesMechanical equipmentFoundation engineering

The invention relates to a precast expanding pile as well as a construction method and construction mechanical equipment thereof in the field of pile foundation engineering. The construction method of the precast expanding pile of the invention comprises the following steps of: sedimentating a hollow precast pile (2) into a preset depth, wherein the bottom of the hollow precast pile (2) is connected with a pile plug (1); moving away the pile plug (1) and pouring an immature pile body material into the hollow precast pile (2); squeezing the immature pile body material into a soil body at the lower part of the hollow precast pile (2) to form a pile bottom expanding segment (4); and repeating the steps until the pile bottom expanding segment (4) satisfies the requirement. The precast expanding pile obtained through the construction comprises the hollow precast pile (2) at the upper part, the pile bottom expanding segment (4) at the lower part and the pile plug (1) at the bottom, and high-efficiency construction equipment is developed, the pile in the form is convenient to construct, has reliable quality, greatly improves the bearing capacity of the end parts of the precast piles, such as PHC (Prestress High Cement ) tubular pile, hollow square piles, and the like which are widely applied at present and can be used as an pulling and compression resistant bearing pile with high bearing capacity and low manufacture cost.

Owner:张继红

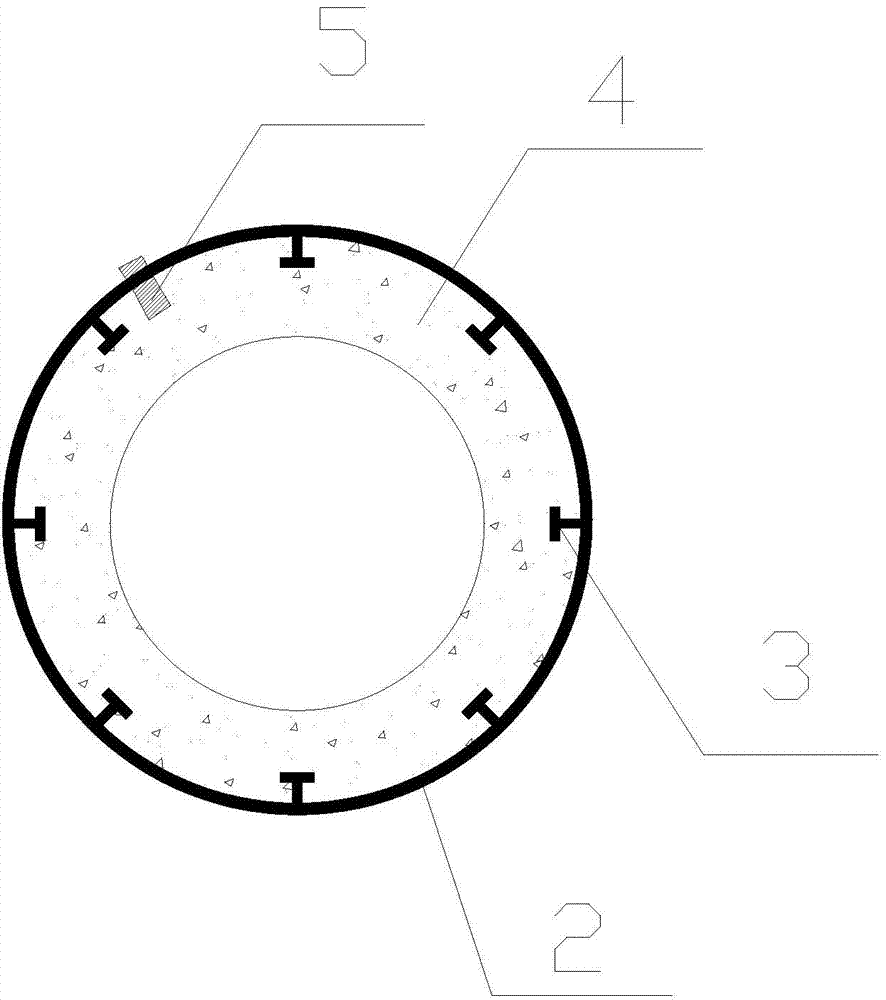

Steel pipe concrete pile

InactiveCN104762954AImprove bending resistanceImprove adhesionSurface layering apparatusCeramic shaping mandrelsBiting forceBinding force

The invention provides a steel pipe concrete pile. The steel pipe concrete pile comprises an outer-layer steel pipe; a spiral rib is fixed on the inner wall of the outer-layer steel pipe; a plurality of circles of rivets are fixed at the circumference of the inner wall of the outer-layer steel pipe; the outer-layer steel pipe is lined with a concrete inner layer, and an end plate is arranged at the end portion of the outer-layer steel pipe; according to the structural design, the biting force of the steel pipe and the concrete comprises three parts, namely the biting force of the spiral rib and the concrete, the anchoring force of the rivet and the concrete and the binding force of the inner wall of the steel pipe and the concrete; the added spiral rib rivet is capable of improving the binding of the concrete and the steel pipe to a large extent, so that the concrete and the steel pipe can be bound firmly and the impact resistance can be enhanced, and in the striking process, the concrete and the steel pipe are not separated from each other. According to experimental verification, after the spiral rib is added and the rivet is arranged, the bending resistance and the shear-bearing capacity of the novel pipe pile are improved by 50%.

Owner:建华建材(蚌埠)有限公司

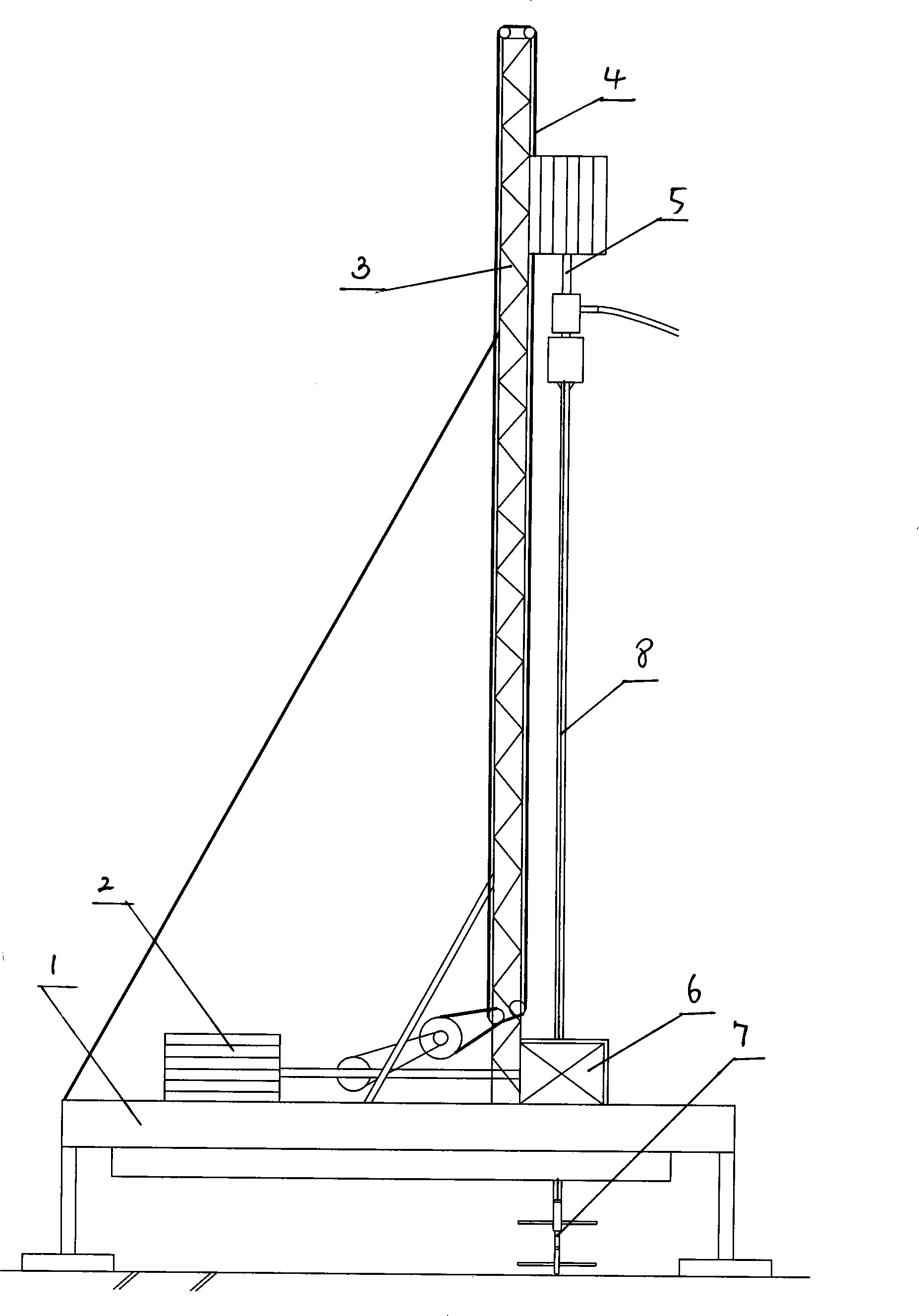

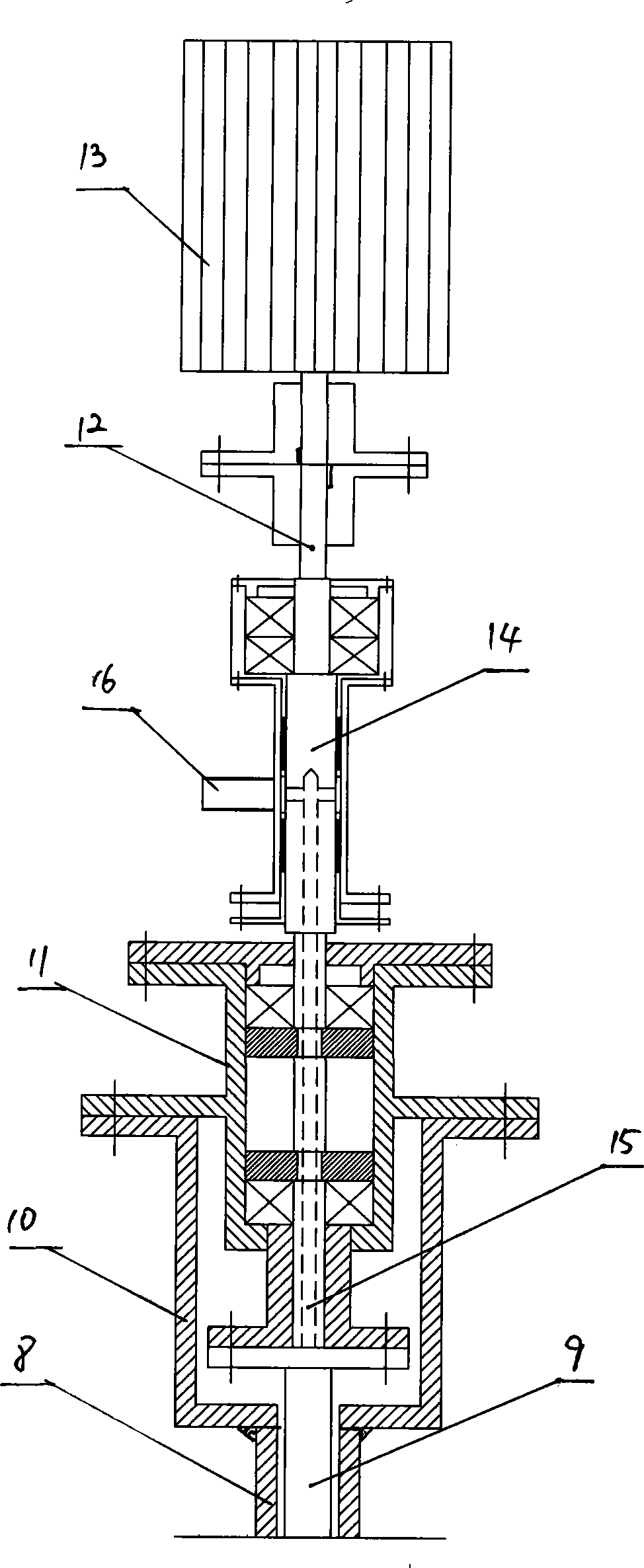

Bidirectional stirring pile machine

ActiveCN101245594AImprove construction efficiencyStir wellBulkheads/pilesDrilling machines and methodsElectric machinerySquare Shape

The invention relates to a two-way stirring pile machine used in pile-forming through stirring at two opposite directions, which comprises a chassis, a tower, an inner drill pipe and an outer drill pipe coaxially sheathed together, and a drill bit. The outer drill pipe has a square-shaped or hexagon-shaped cross section; the rotation of the outer drill pipe is driven by a turntable on the chassis; the inner drill pipe is provided with a circular cross section; the rotation of the inner drill pipe is driven by an upper driving motor at the upper end of the drill pipe; the upper driving motor is connected with the inner drill pipe through a transmission shaft; a feeding device is arranged at the upper part of the transmission shaft, and a rotating sleeve for the outer drill pipe is arranged at the lower part of the transmission shaft; the rotating sleeve for the outer drill pipe is connected with the outer drill pipe through flanges. The two-way stirring pile machine can be used for both powder-spraying pile machine and slurry-spraying pile machine; the drilling speed is controlled by driving chains to realize pressuring and decompressing drilling; the piles are formed at one time, and a second repetitive stirring is not needed, thus doubling the construction efficiency with even stirring, steady construction, and high-quality of the formed pile; no ash back-feeding phenomenon occurs, and the cement consumption can be reduced by 10 to 20 percent, thus saving construction cost.

Owner:江苏盛泰建设工程有限公司

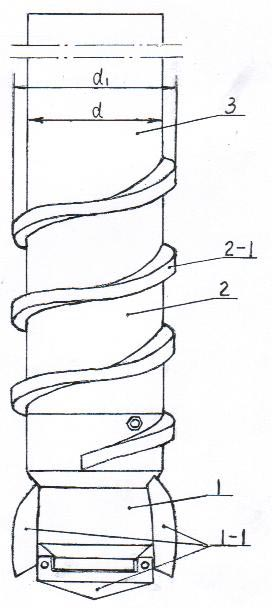

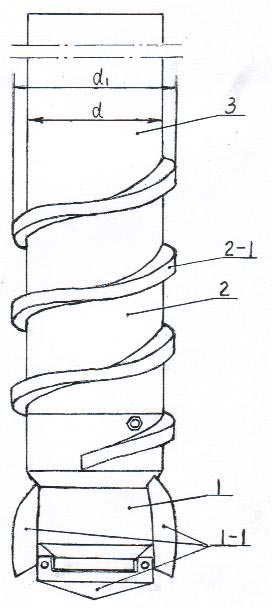

Half soil squeezing screw expansion pile forming method

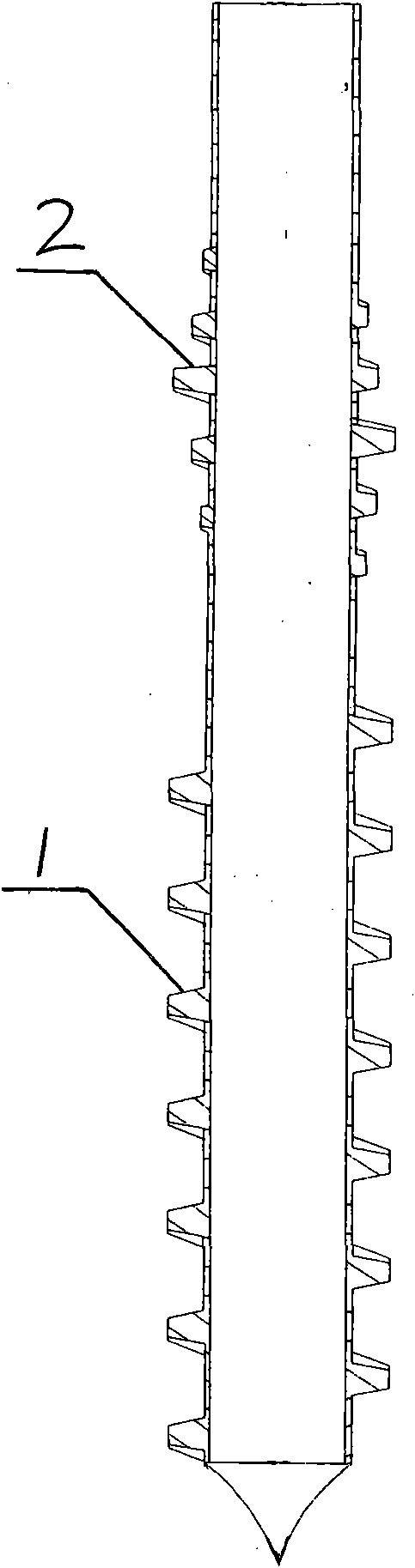

InactiveCN102312427AStrong roughnessReduce torqueDrill bitsDrilling rodsScrew threadUltimate tensile strength

The invention belongs to a building construction method, and in particular relates to a half soil squeezing screw expansion pile forming method. The adopted combined drilling tool consists of a soil taking spiral drill bit (1) with at least two drill tips (1-1) and a soil squeezing threaded drill rod (2) connected with the spiral drill bit (1) or a polished rod (3) connected to the upper part of the spiral drill bit (1); the threaded drill rod has the characteristics that the diameter of the core rod is greater than that of a long spiral drilling tool, the blade is thick and the strength is higher; and according to the half soil squeezing screw expansion pile forming method, soil is taken by the drill bit part and squeezed by the threaded drill rod part, so that the torque is greatly reduced, the downward penetrating capacity is stronger, drilling is easy, pore forming or pile forming speed is increased, the soil squeezing effect is reduced, the penetrating capacity is enhanced, the torque is reduced, equipment faults are reduced, and the service life of the equipment is prolonged.

Owner:王庆伟

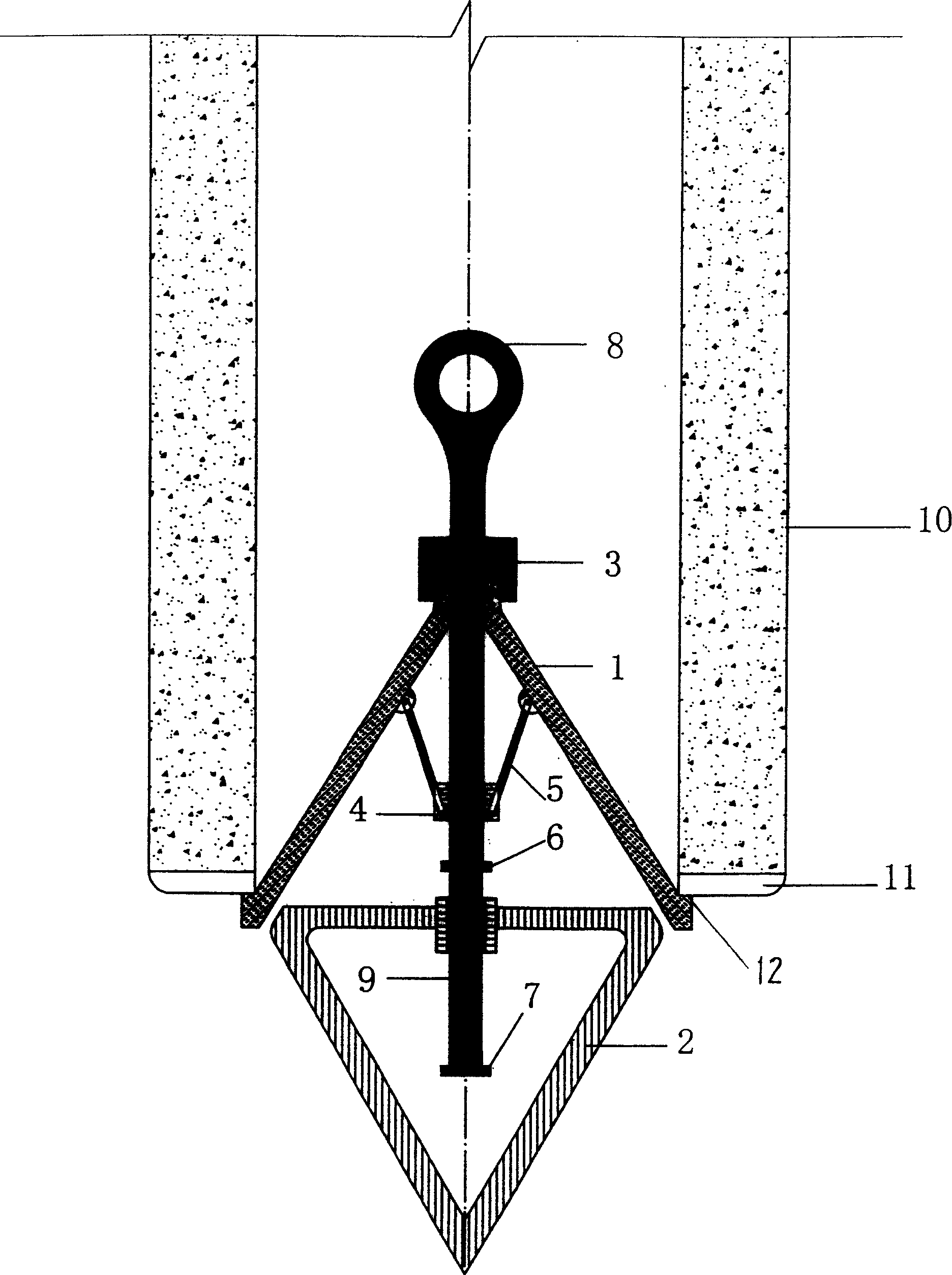

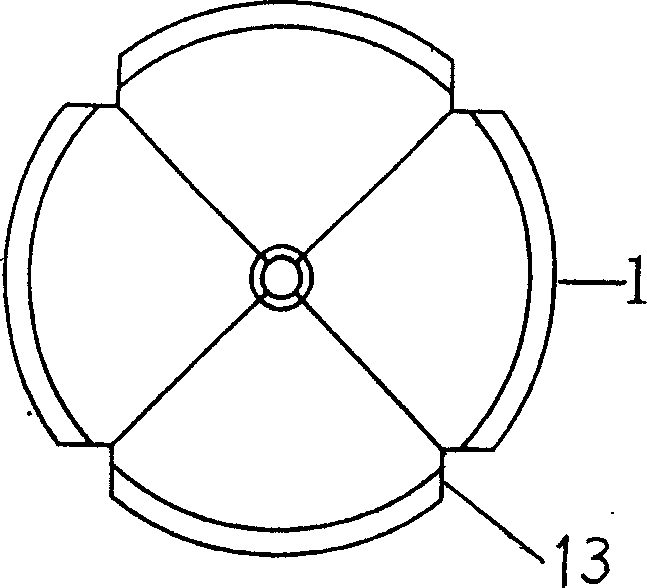

Immersed tube grout pile construction process and pile tip bearing capacity reinforcement equipment

The invention is a sinking tube pouring picket constructing technique and picket-end bearing capacity enhancer, placing the enhancer at positioning point of the picket base; the picket machine takes its place to align the end of the steel sleeve with the enhancer; starting sinking the tube to the calculated position; pulling the rope linked with the enhancer to drive axial umbrella rod, so that the top cap relieves the inclined support from restriction, the fixed stop block drives the annular slide block to make the supporting link rod push and spread the inclined support around so as to shrink into the steel sleeve, and the active stop block drives the picket boot to take out the enhancer. Placing bar reinforcement cage in the steel sleeve; vibrantly pulling the tube while pouring the concrete, and forming a picket. It can enhance the penetrating property of the steel sleeve, extrude picket end soil body closely, heighten picket-end bearing capacity, reduce deposition quantity, heighten picket forming quality and constructing efficiency, etc.

Owner:北京中技天昊工程技术有限公司

Reamer bit for building long-screw pile machine

The invention discloses a reamer bit for a building long-screw pile machine. The reamer bit comprises a drill pipe, the lower end of the drill pipe is fixedly connected with a drill tip, screw blades are fixedly connected on the outer wall of the drill pipe, the lower end portions of the screw blades are linked with reaming devices, and power driving devices capable of driving the reaming devices to be opened or closed are arranged on the screw blades. By adopting the technical scheme, the reamer bit for the building long-screw pile machine integrates functions of hole drilling, hole cleaning, hole reaming and slip casting, pile hole working can be completed through one-time drilling, and the reamer bit is high in pile-forming quality, reasonable in structure and convenient to use.

Owner:SHANDONG HONGTAI CONSTR GROUP

Concrete pile forming device and construction method thereof

The invention aims at providing a concrete pile forming device. The concrete pile forming device is characterized in that the internal part of a drill rod is a hollow pipe, a grout supply pipe is arranged in the hollow pipe, the upper section of the outer wall of the drill rod is a straight rod, the middle section is provided with an agitating blade, the lower section is provided with a helical blade and the helical blade is provided with mortar outlets. The invention further provides a concrete pile construction method of the above-mentioned pile forming device. The concrete pile construction method comprises the following steps: 1) aligning the pile forming device to a pile position; 2) supplying cement grout into the grout supply pipe to inject into a soil body while drilling a soil layer through a drill bit and the helical blade, conducting forcible agitation through the helical blade and the agitating blade; 3) continuing until preset design depth is reached; 4) supplying concrete into the hollow pipe to fill the central part of a cement-soil pile body; 5) reversely rotating and upwards lifting the drill rod while supplying the concrete, and forming a concrete reinforcing body with certain diameter in the center of the cement-soil pile body; 6) conducting subsequent construction according to the structural form of a foundation.

Owner:王继忠

Given force variable stiffness discrete material pile ramming and expanding machine and application thereof

InactiveCN102392447AMeet the trait requirementsFast reinforcement effectBulkheads/pilesSoil preservationVariable stiffnessElectricity

The invention relates to a given force variable stiffness discrete material ramming and expanding machine which comprises a chassis, a traveling part, a control system, a hoist system, a portal steel frame and a pile pipe ramming and expanding system. The pile pipe ramming and expanding system comprises a straight-through ramming hammer head, a hammer cushion and inner and outer sleeve pile pipes. The portal steel frame for supporting and stabilizing the inner and outer sleeve pile pipes is arranged on the chassis. A telescopic pull rod for controlling a piling angle is also connected onto the portal steel frame. The hoist system comprising lifting inner and outer pile pipes, a lifting straight-through ramming hammer head and a lifting vibrator part and the control system comprising an electric motor and an electrohydraulic linking and illuminating device are also arranged on the chassis. The straight-through ramming hammer head is positioned at the upper part of double layers of pile pipes in the sleeve structure. The given force variable stiffness discrete material ramming and expanding machine not only can be used for piling a multi-section enlarged head discrete material flexible pile, but also can be used for piling a concrete rammed and expanded rigid pile. The machine can be suitable to be applied to piling of a new construction, an extension project, a reconstruction project and the engineering for treating pathological accidents on weak or poor foundations such as interlayer soft clay, loose fine sandy soil, plain fill, miscellaneous fill, collapsed loess and the like.

Owner:苏州予力再生建材有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com