Treatment method of coastal sludge soft soil foundation cement mixing pile

A technology for cement mixing piles and silty soft soils, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low cost performance, low pile body strength, and large amount of slurry return, and achieve good economic benefits and social benefits. Benefits, good pile quality, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

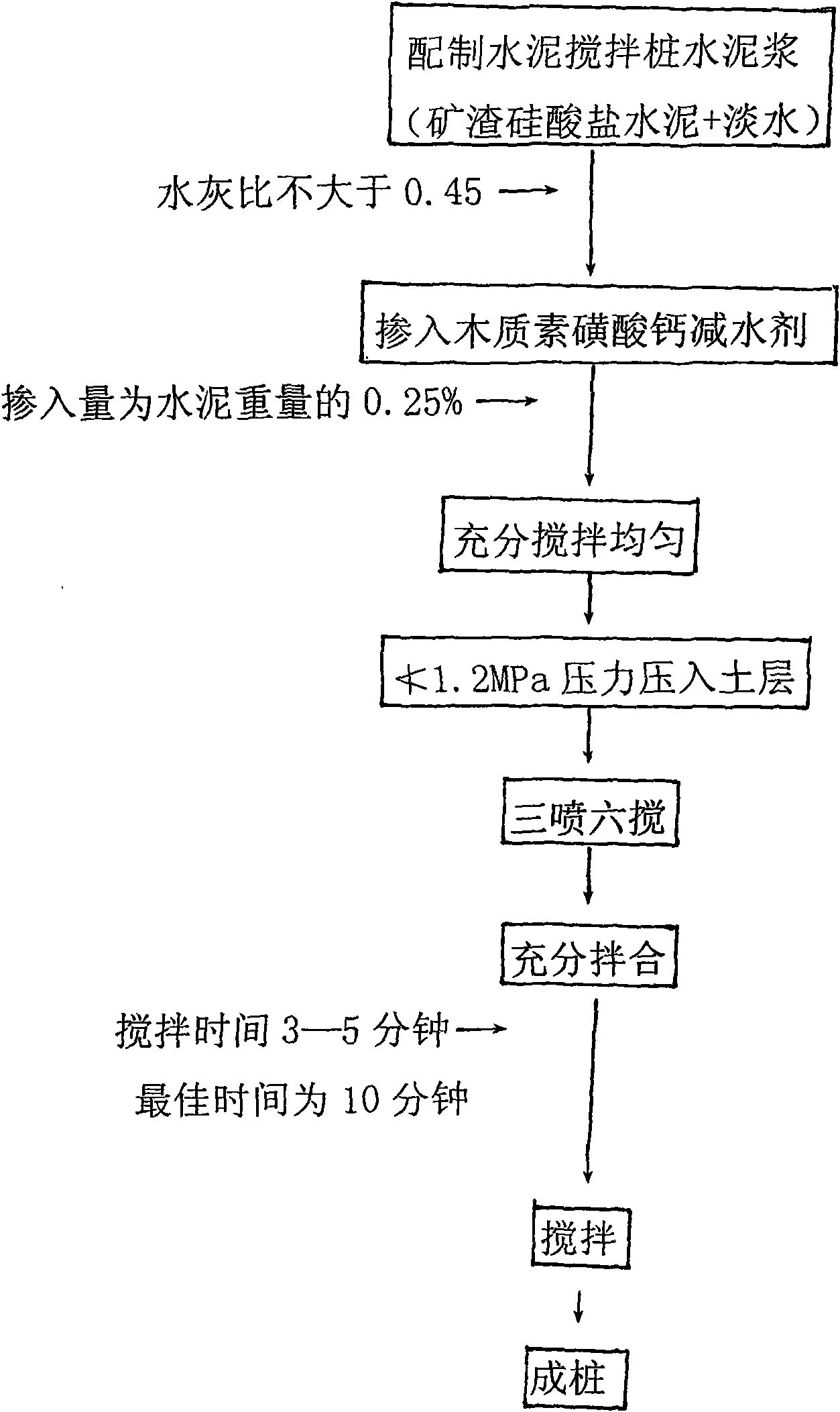

[0017] In order to further understand the characteristics and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to figure 1 .

[0018] Such as figure 1 Shown: the production process of the present invention is as follows:

[0019] ①. First, use 32.5# slag Portland cement and fresh water to prepare cement slurry for cement mixing piles. The water-cement ratio is not greater than 0.45. 32.5# slag Portland cement has a good effect on improving muddy soft soil, and it can be mixed with fresh water. Effectively control the concentration of chloride ions and sulfate ions in foundation soil. The cement grade of the 32.5# slag Portland cement used is P.S32.5;

[0020] ②. Adding calcium lignosulfonate superplasticizer, the mixing amount is 0.25% of the weight of the cement, and the strength of the pile body is increased by 30.6%. After the cement is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com