Half soil squeezing screw expansion pile forming method

A semi-squeeze soil and pile-forming technology, which is applied in the direction of drill pipe, sheet pile wall, and earth cube drilling, can solve the problems of increasing equipment investment, reducing the speed of the power head, and affecting penetration, etc., so as to prolong the service life of the equipment, The effect of reducing equipment failure and enhancing penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

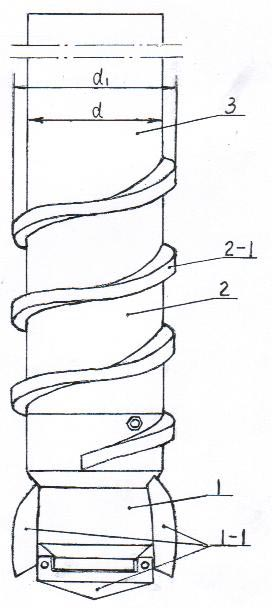

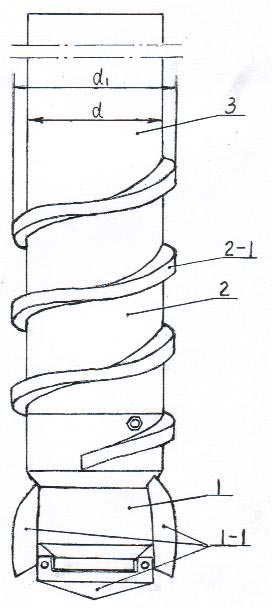

[0011] Examples, see attached figure 1 , the hole-forming combination drilling tool used in the semi-extruded soil screw extruded and expanded pile method is a three-point drill bit 1 with drill points 1-1 in the middle and symmetrical sides. The three-point drill bit 1 is connected to the threaded drill rod 2 , the upper part can also be connected to the polished rod 3, the screw diameter d of the threaded drill rod 2 is smaller than the designed pile diameter, and the thread 2-1 outer diameter of the threaded drill rod 2 is d 1 It is greater than the diameter of the drill pipe d and equal to the designed pile diameter. Its piling method is: 1. Connect and fix the drill bit 1 with three drill points and the threaded drill rod 2 together. The drill bit of the combined drilling tool is the soil-taking type, and the threaded drill rod 2 connected with it is squeezed in the process of rotation. Soil-based, the drill tool is drilled to the designed pile depth once to form a pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com