A kind of super amphiphobic coating material for catalyst and its preparation method and application

A coating material, super-amphiphobic technology, applied in the direction of coating, device for coating liquid on the surface, special surface, etc., can solve the problem of short service life, and achieve the effect of avoiding surface pollution, stable structure, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The super-amphiphobic coating material provided in this embodiment is prepared through the following steps:

[0029] S1. Apply 20g of polytetrafluoroethylene and 3g of fluorosilane coupling agent to form a base coating with a thickness of 60 μm by spraying;

[0030] S2. Heat 1g of nano-silica to 330°C, and then spray it on the surface of the polytetrafluoroethylene base layer; after the polytetrafluoroethylene is cooled, raise the overall temperature of the obtained composite coating to 328°C, keep it warm, and turn on the ultrasonic treatment at the same time 10min, turn off the ultrasound, cool to room temperature;

[0031] S3. Continue to repeat step S2 for the coating obtained in S2 for 50 times to obtain a super-amphiphobic coating material.

Embodiment 2

[0033] The super-amphiphobic coating material provided in this embodiment is prepared through the following steps:

[0034] S1. Apply 20g of fluorine-modified polystyrene and 2.5g of silane coupling agent to form a base coating with a thickness of 100 μm by spraying;

[0035] S2. Heat 1g of nano-titanium dioxide to 170°C, and then spray it on the surface of the fluorine-modified polystyrene base layer; after the obtained coating is cooled, raise the overall temperature of the obtained composite coating to 170°C, keep it warm, and turn on the ultrasonic treatment for 10 minutes at the same time , turn off the ultrasound, and cool to room temperature;

[0036] S3. Continue to repeat step S2 for the coating obtained in S2 for 50 times to obtain a super-amphiphobic coating material.

Embodiment 3

[0038] The super-amphiphobic coating material provided in this embodiment is prepared through the following steps:

[0039] S1. Coating 10g of polytetrafluoroethylene, 10g of polyvinylidene fluoride and 2.8g of silane coupling agent into a base coating with a thickness of 30 μm by spraying;

[0040] S2. Heat 1g of nano-alumina to 330°C, and then spray it on the surface of the polytetrafluoroethylene and polyvinylidene fluoride-based layers; after the obtained coating is cooled, the overall temperature of the obtained composite coating is raised to 330°C, heat preservation, and at the same time Turn on the ultrasonic treatment for 10 minutes, turn off the ultrasonic, and cool to room temperature;

[0041] S3. Continue to repeat step S2 for the coating obtained in S2 for 50 times to obtain a super-amphiphobic coating material.

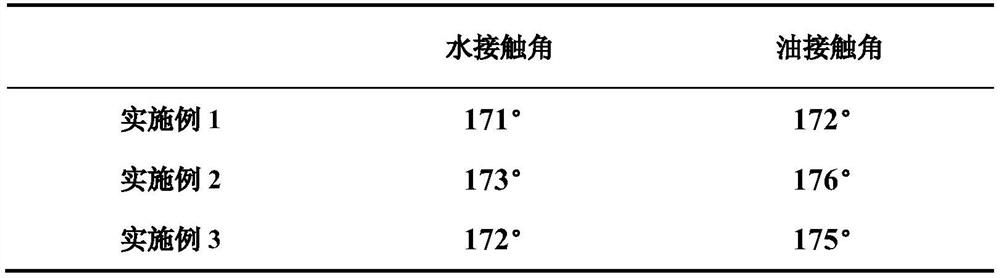

[0042] Pure water and glycerin were used to measure the static contact angle of the superamphiphobic coatings obtained in Examples 1-3, and the results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com