Patents

Literature

31results about How to "Avoid reunion situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber and preparation method thereof

ActiveCN102061047AImprove aging resistanceImprove flame retardant performanceInsulating bodiesEthylenediamineElastomer

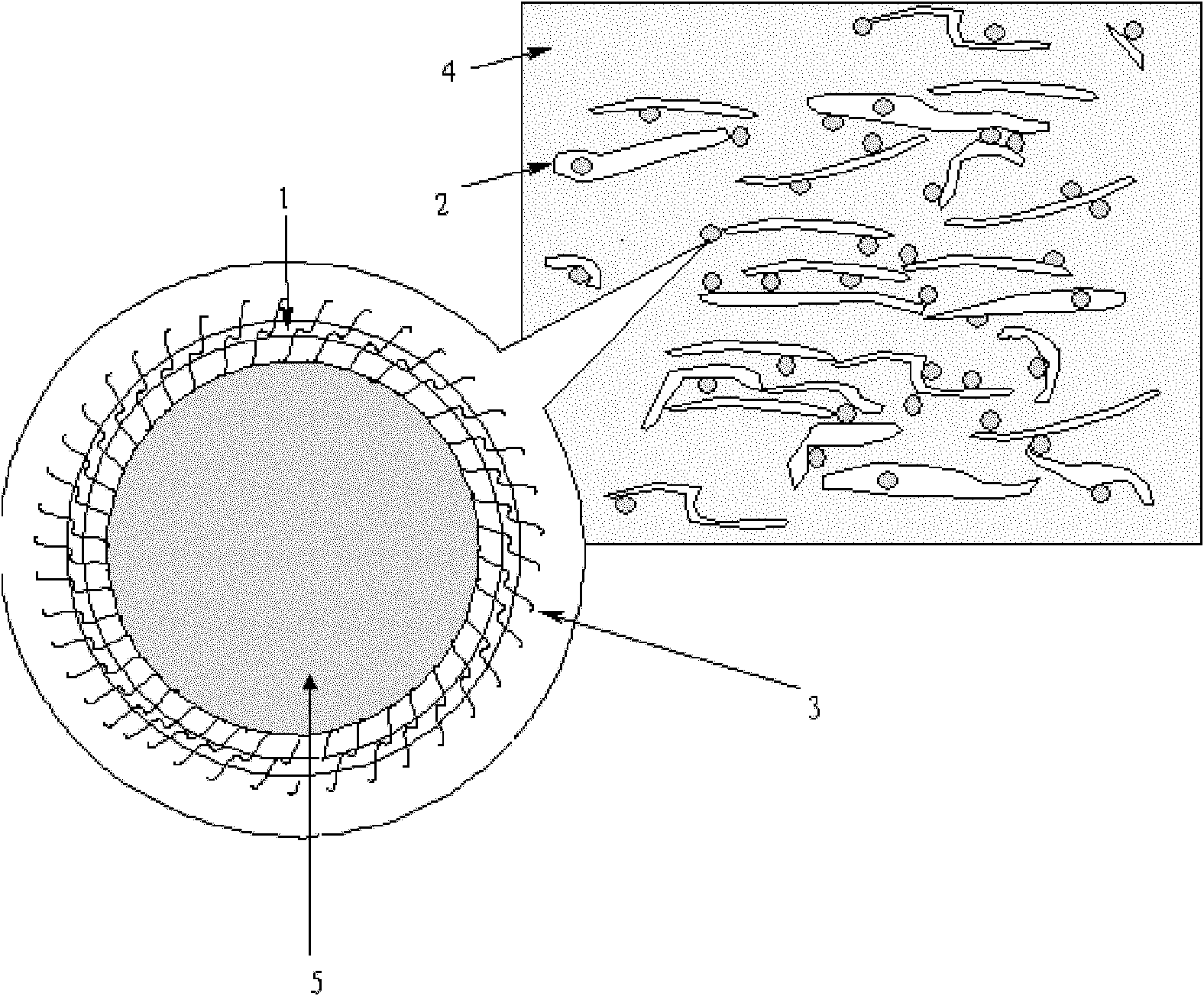

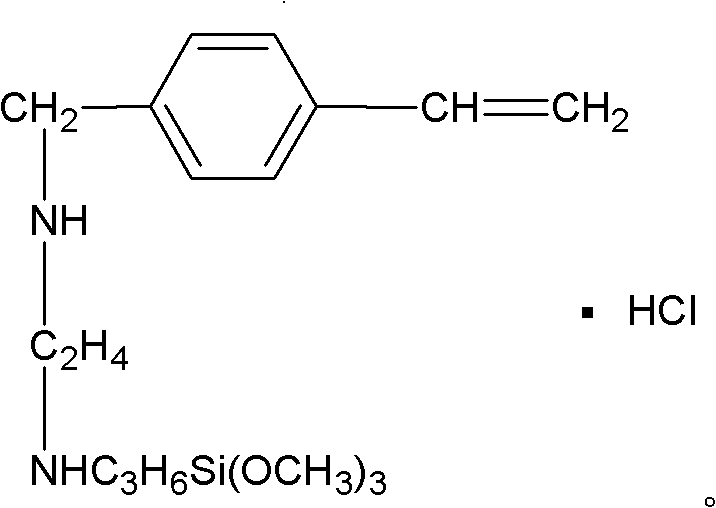

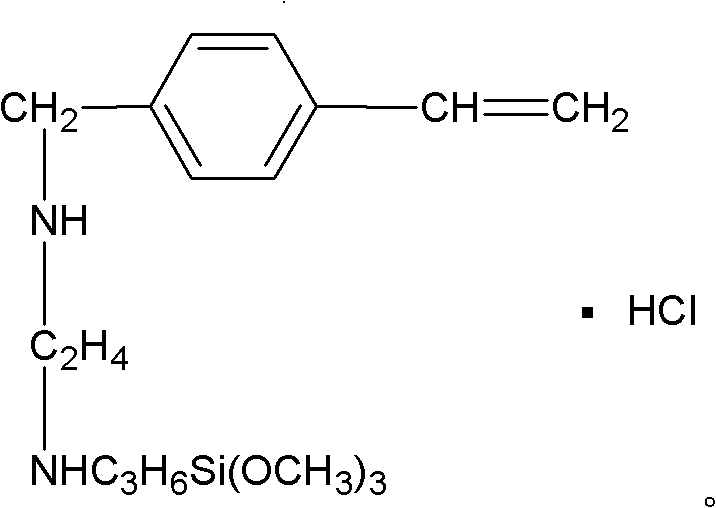

The invention discloses a composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber. The composite material is prepared from the following raw materials in parts by weight: 50-90 parts of fluorubber, 9-30 parts of PVC elastomer with super high molecular weight and 1-20 parts of nanometer carbon black with surface modified by a silane coupling agent, wherein the silane coupling agent is N'-vinyl benzyl-N-trimethoxysilane propyl ethylenediamine salt. The invention modifies the surface of the nanometer carbon black by adopting the silane coupling agent VTSD and realizes a nanometer carbon black / PVC / fluorubber multi-phase composite structure with uniform dispersion in mixing rubber so that the modified nanometer carbon black effectively reinforces PVC / fluorubber. The invention also discloses a preparation method of the composite material, and the method is simple, easy to control and suitable for industrial production.

Owner:杭州顺和轨道交通新材料有限公司

Alloy powder homogenizing treatment method for flux-cored wire

InactiveCN109317867AEvenly dispersedEasy to useTransportation and packagingWelding/cutting media/materialsAdhesiveAlloy

The invention discloses an alloy powder homogenizing treatment method for a flux-cored wire. The alloy powder homogenizing treatment method comprises the following steps of: S1, keeping the basic requirements for the grain size of used primary raw material powder, and keeping the grain size of a to-be-added little secondary powder raw material to be smaller than 100 meshes, thereby forming a powdered raw material; S2, adopting a pelletizing adhesive which is a sodium silicate solution diluted by adding water, wherein the pelletizing adhesive needs to add with 20-70% of water to dilute for use;S3, adding the adhesive and the powdered raw material into a stirrer to stir, wherein adding amount of the adhesive and weight percentage of the powdered raw material are smaller than 30%; S4, uniformly mixing the adhesive with the powdered raw material to obtain a mixture, then, taking out the mixture to spread on a heat-resistant steel disc to sinter and dry; and S5, crushing and sieving to a required mesh number, using a 40-50-mesh screen to screen, thereby completing a pelletizing process for the screened powder. The alloy powder homogenizing treatment method realizes modifying flux-coredwire powder, and further improves uniformity of the added alloy, so that the expected grain refinement or other metallurgical effects are achieved.

Owner:SUZHOU U P WEAR RESISTANCE COMPOUND MATERIALS

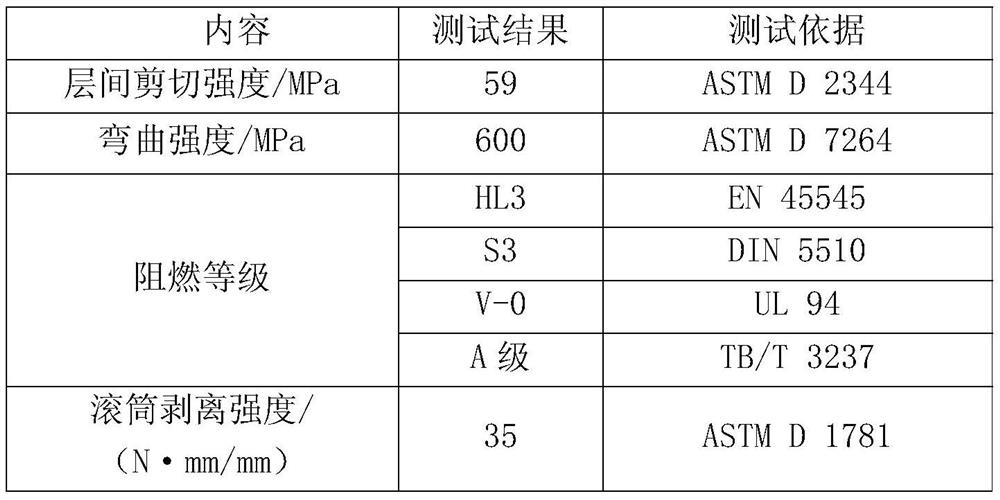

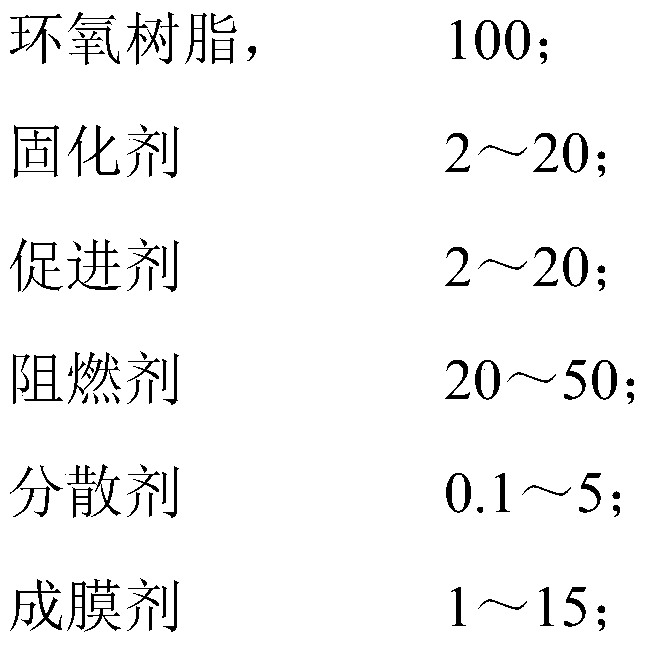

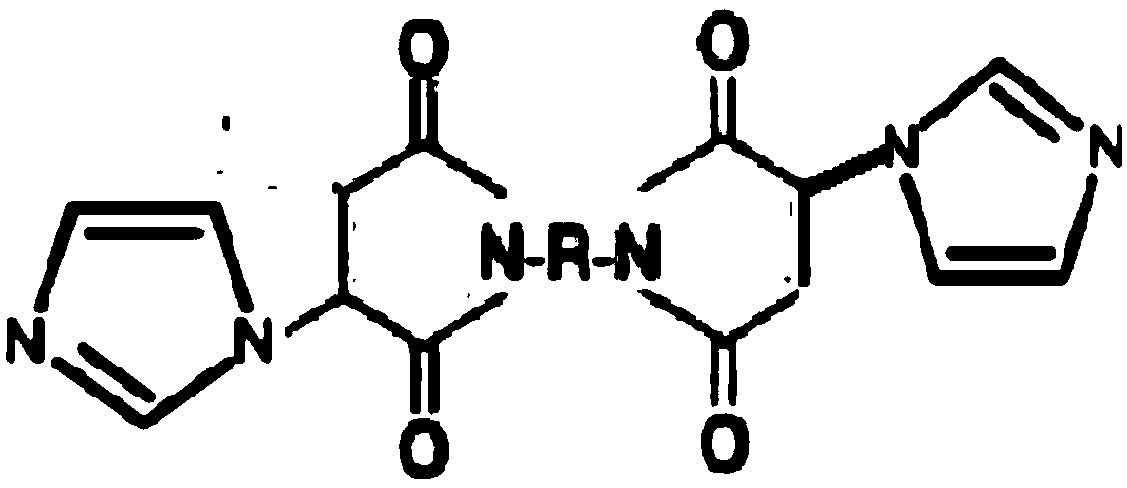

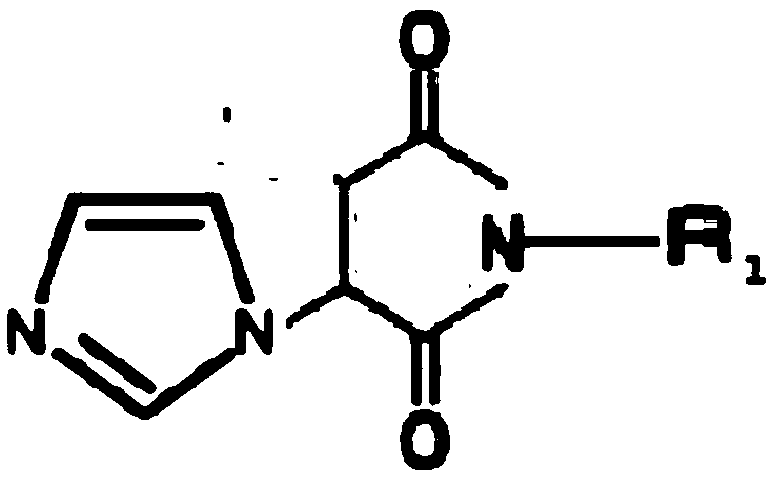

Self-adhesive flame-retardant epoxy resin and preparation method thereof

InactiveCN112226042AImprove flame retardant performanceEnables self-adhesive applicationsCarbon layerPolymer science

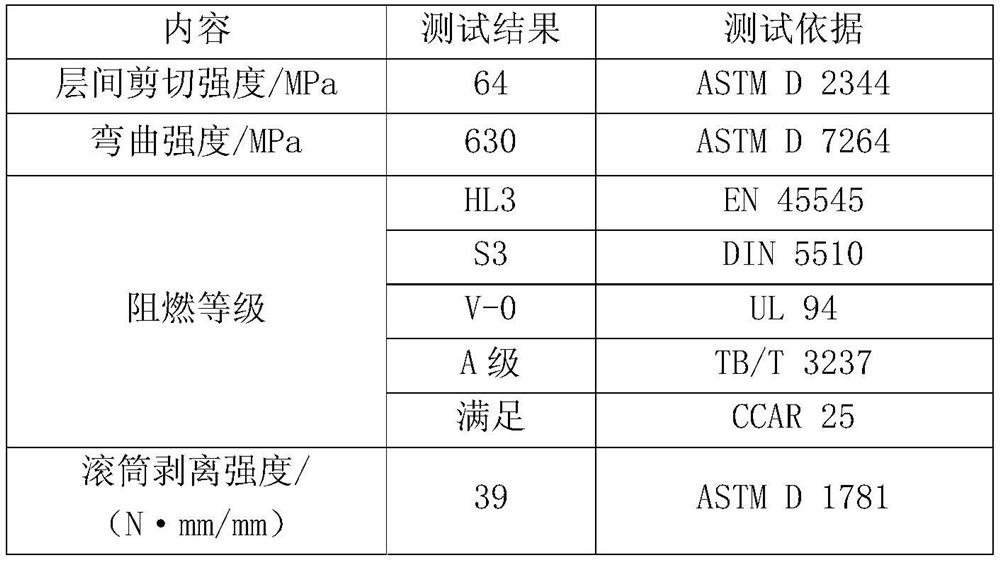

The invention discloses self-adhesive flame-retardant epoxy resin, which is prepared from the following components: epoxy resin, a curing agent, an accelerant, a flame retardant, a dispersing agent and a toughening agent. The epoxy resin does not contain halogen, and a phosphorus element, a nitrogen element and a metal oxide contained in the epoxy resin generate a synergistic flame-retardant effect with novolac epoxy resin at a set ratio, so that condensed phase flame retardance and gas phase flame retardance are simultaneously carried out during combustion of the material, formation of a carbon layer on the surface of resin is promoted, inert gas is released to dilute combustible gas, free radicals are released at the same time to capture active groups in a combustion reaction, and the flame retardance of the resin is greatly improved. The prepreg / composite material prepared from the resin has excellent flame retardancy, and meets the requirements of DIN5510(S3), UL-94 (V-0), EN45545(HL3), TB / T 3237(A), CCAR25 and the like.

Owner:AVIC COMPOSITES +1

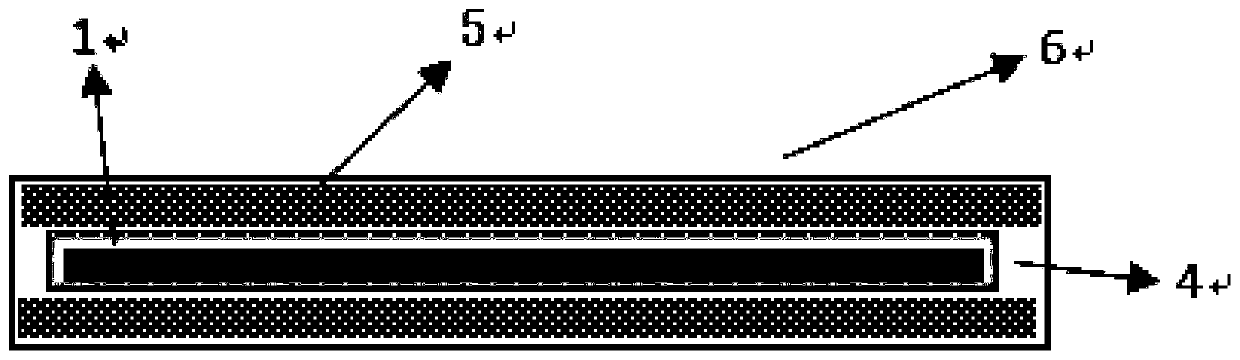

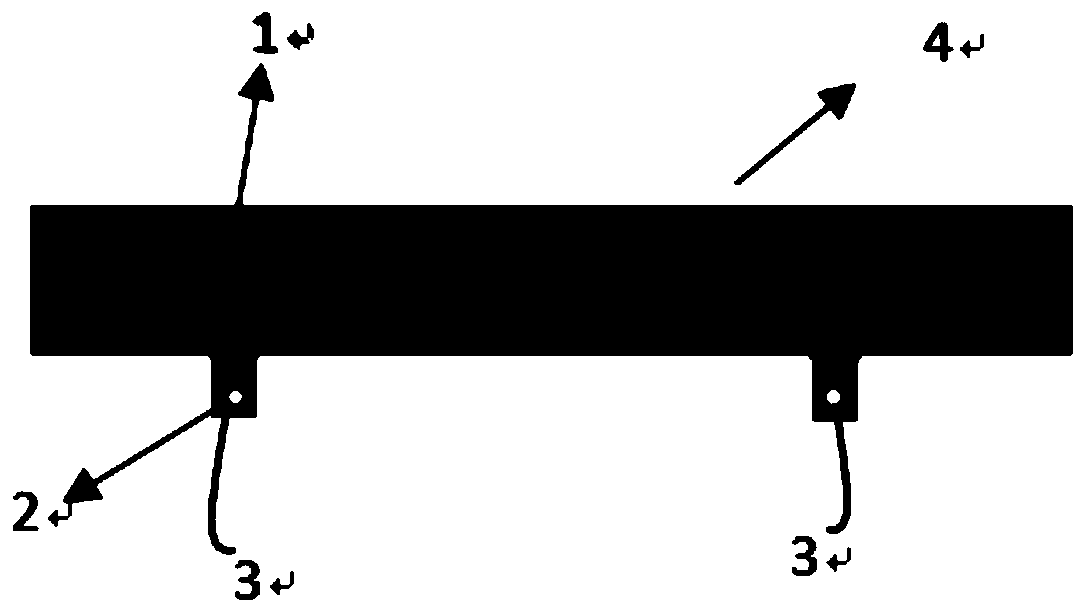

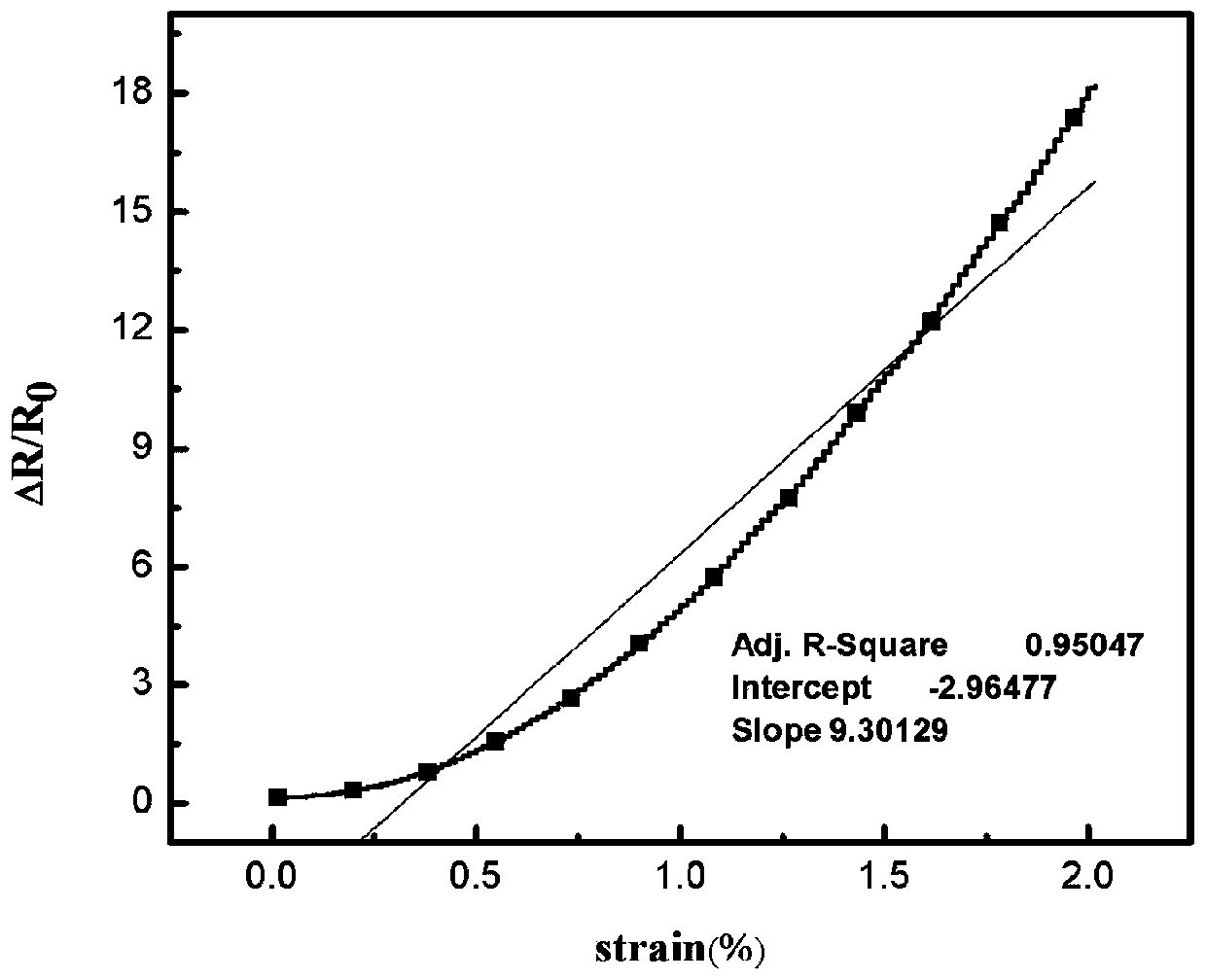

Preparation method of flexible sensor based on carbon nanometer paper

The invention discloses a preparation method of a flexible sensor based on carbon nanometer paper, and belongs to the technical field of sensors. The preparation method comprises the steps that the carbon nanometer paper is taken, the carbon nanometer paper is cut according to the mold size, the cut carbon nanometer paper is put on a glass slide and is fixed, the cut carbon nanometer paper and a wire are bonded and fixed through an adhesive to be cured, and a carbon nanometer paper sensor is prepared; the curing temperature ranges from 50 DEG C to 150 DEG C, and the curing time ranges from 15min to 30 min; silicone rubber and a curing agent are mixed uniformly according to the proportion, and a silicone rubber solution is prepared; and the carbon nanometer paper sensor is soaked in the silicone rubber solution and is subjected to curing forming, and the flexible sensor based on the carbon nanometer paper is prepared. In the preparation process, the silicone rubber is soaked in the carbon nanometer paper, vacuum forming is combined, and agglomeration can be effectively avoided; and the prepared flexible sensor has good electric conductivity, and compared with metal sensors, the thickness can be greatly reduced.

Owner:SHENYANG AEROSPACE UNIVERSITY

Continuous preparation method for antibody (or antigen)-coated microspheres

InactiveCN109030810AWell mixedHigh speedMicroballoon preparationMaterial analysisAntigenHigh volume manufacturing

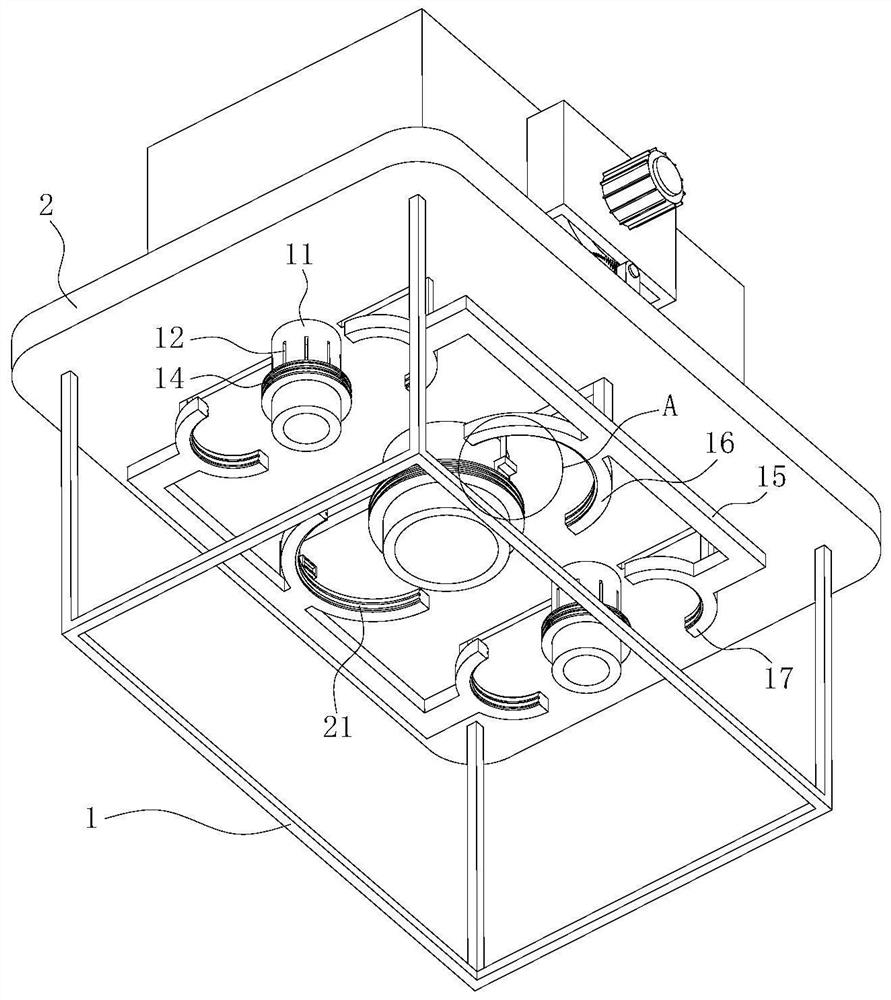

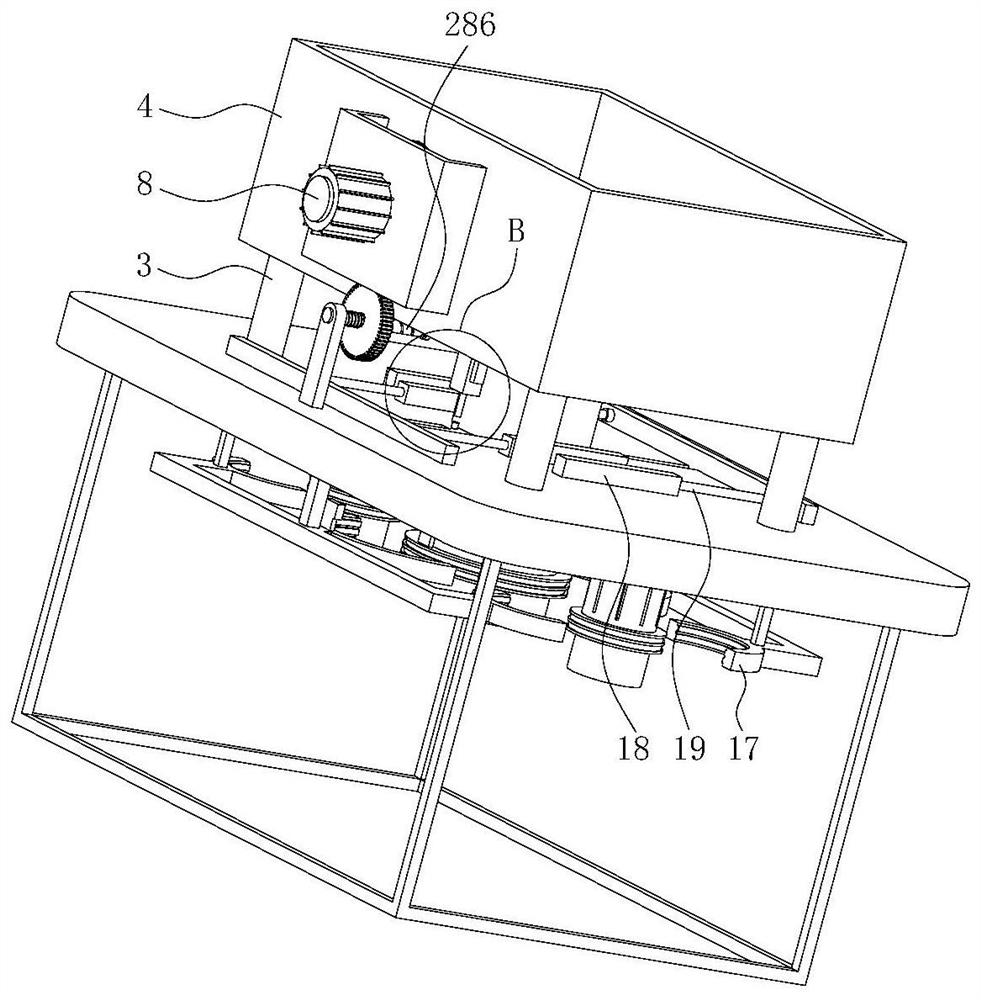

The invention discloses a continuous preparation method for antibody (or antigen)-coated microspheres. The method comprises the specific preparation steps that first, microspheres, an antibody or antigen solution, a condensing agent and a buffer solution are prepared; and second, the microspheres in a microsphere tank and the condensing agent in a condensing agent tank are injected into a first tank body through a first pressure pump and a pipeline for mixing, and the antibody or antigen solution in an antibody or antigen solution tank and the buffer solution in a buffer solution tank are injected into a second tank body through the first pressure pump and the pipeline for mixing. According to the method, by introducing hot air through air inlet pipes in the liquid mixing process, liquid mixing is more uniform, and mixed liquid can be heated to improve the speed and efficiency of microsphere coating by antibodies or antigens, so that the microspheres are better coated; and moreover, the processing steps are simple, continuous preparation can be realized, and the method can be suitable for large-batch production.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

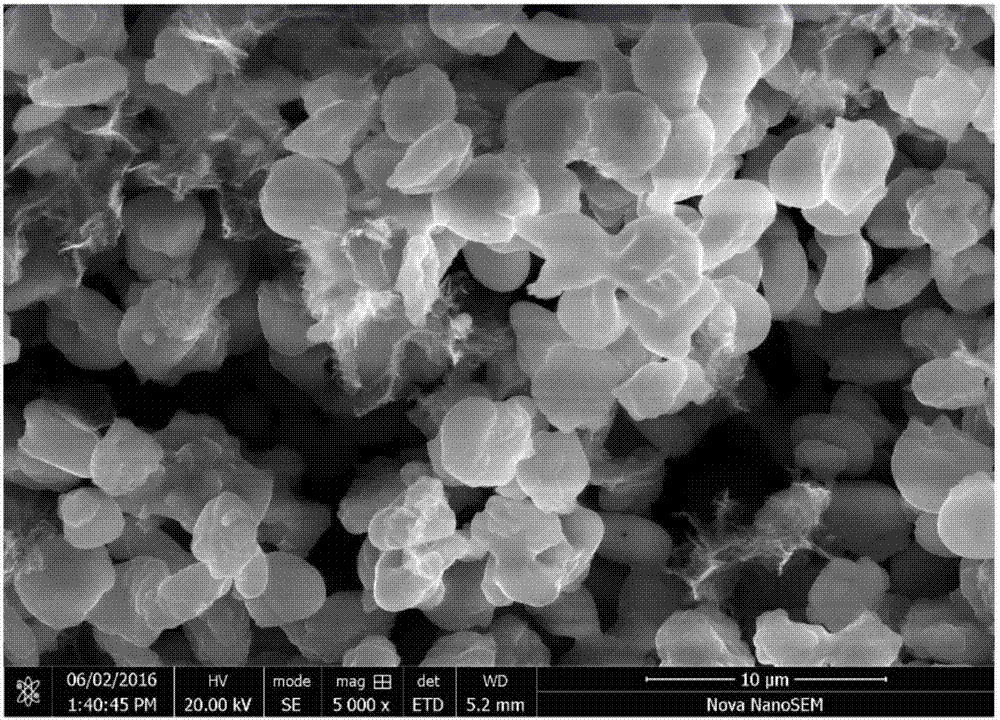

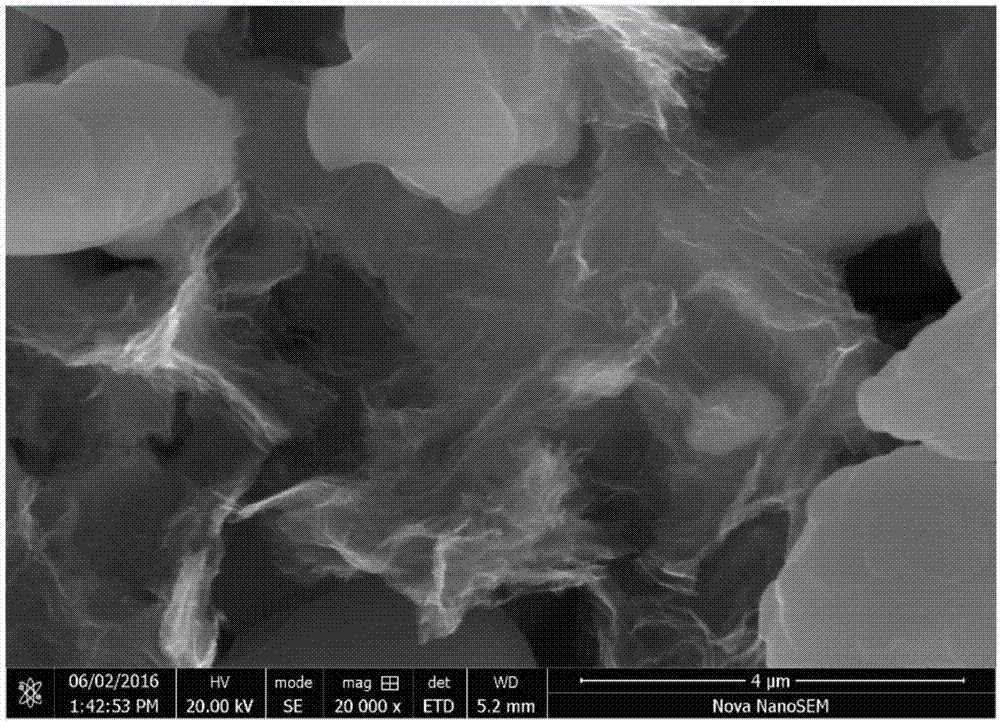

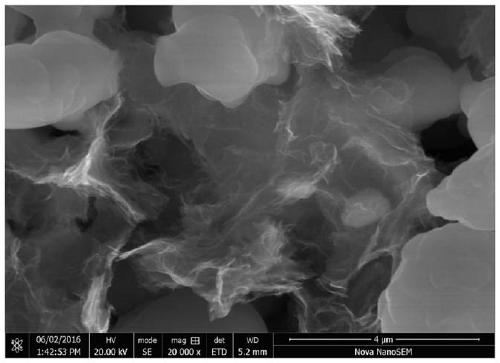

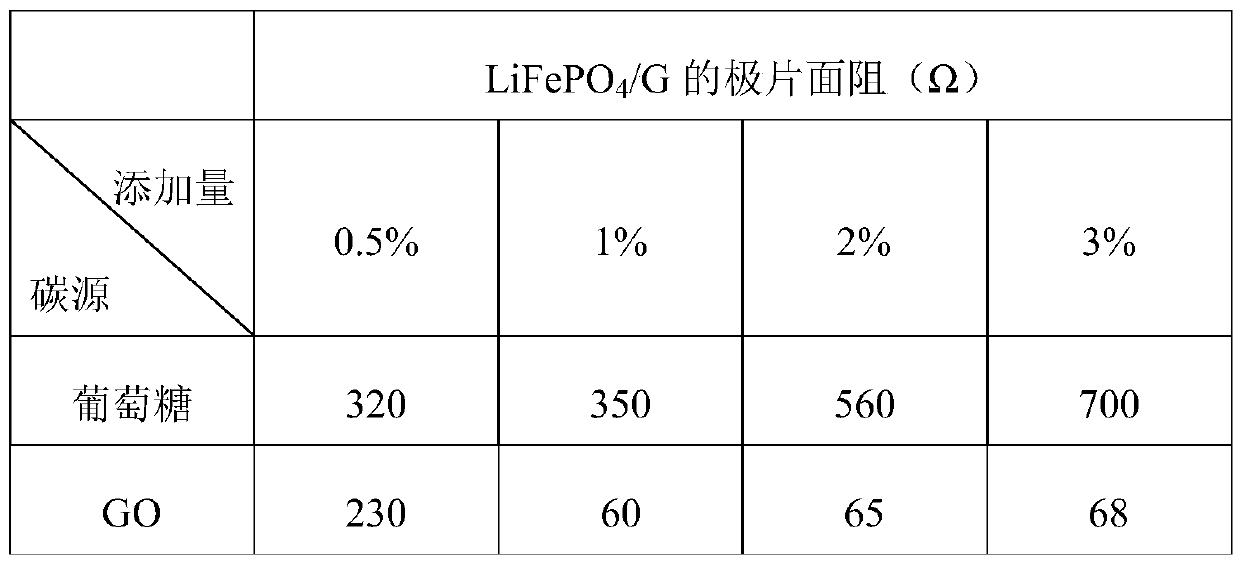

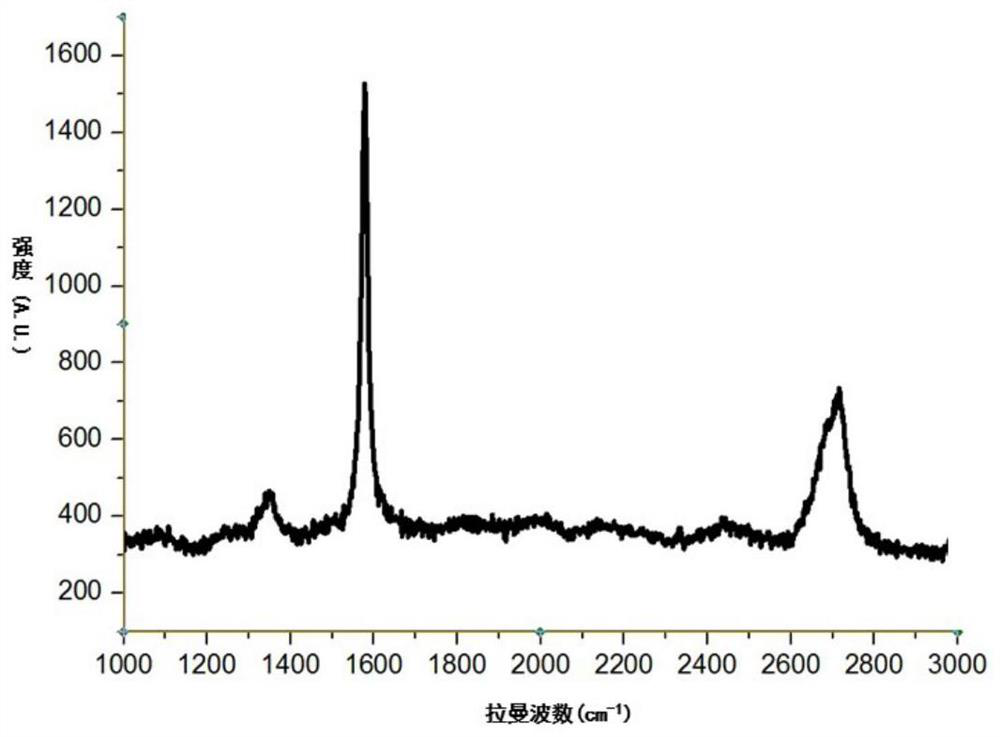

High-conductivity lithium iron phosphate powder and preparation method thereof

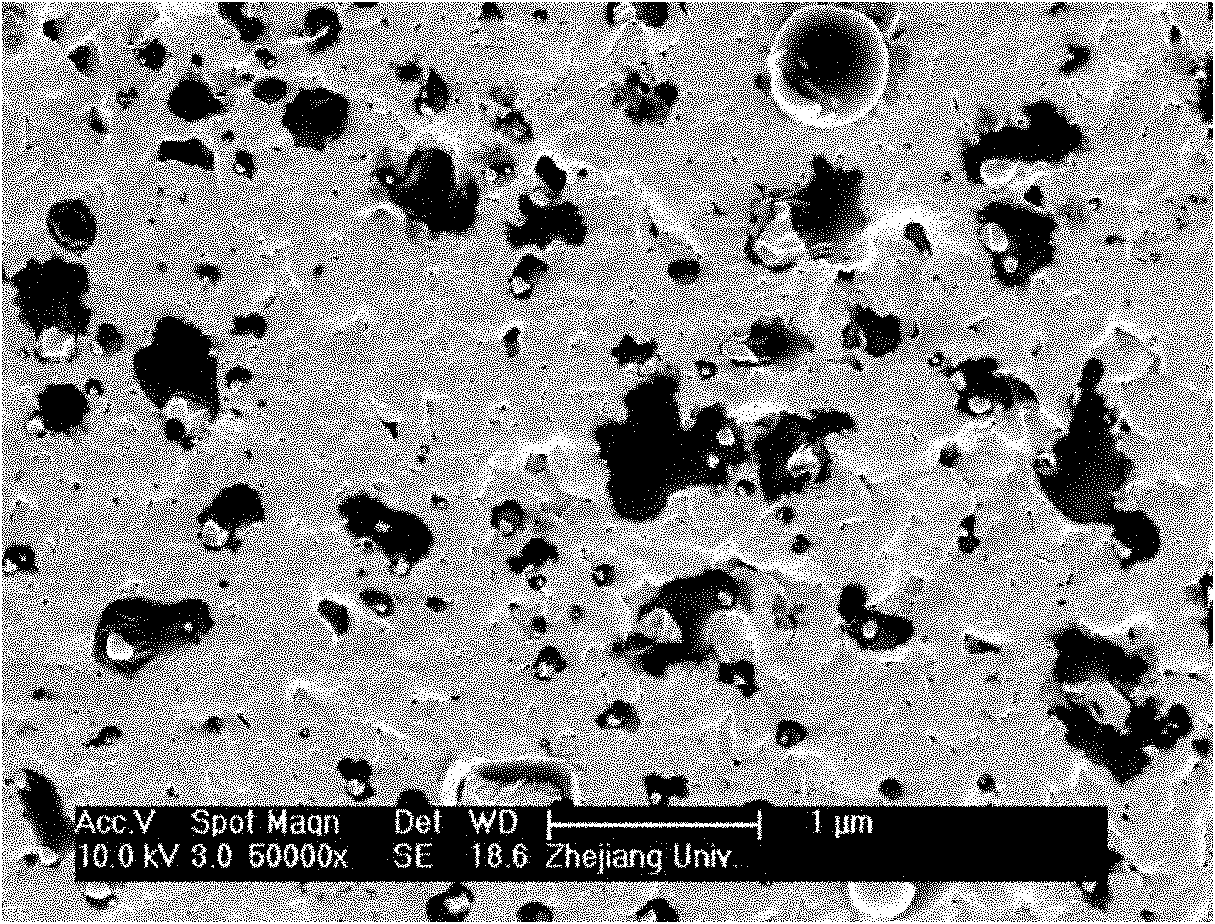

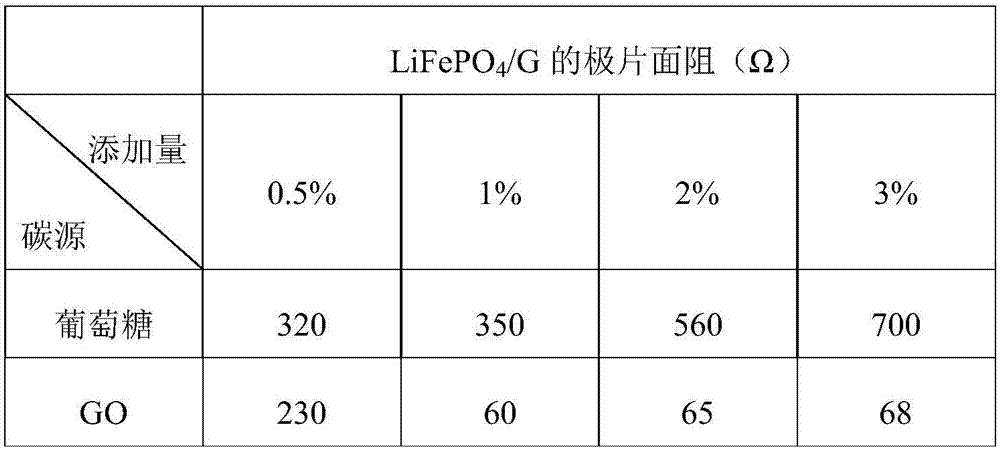

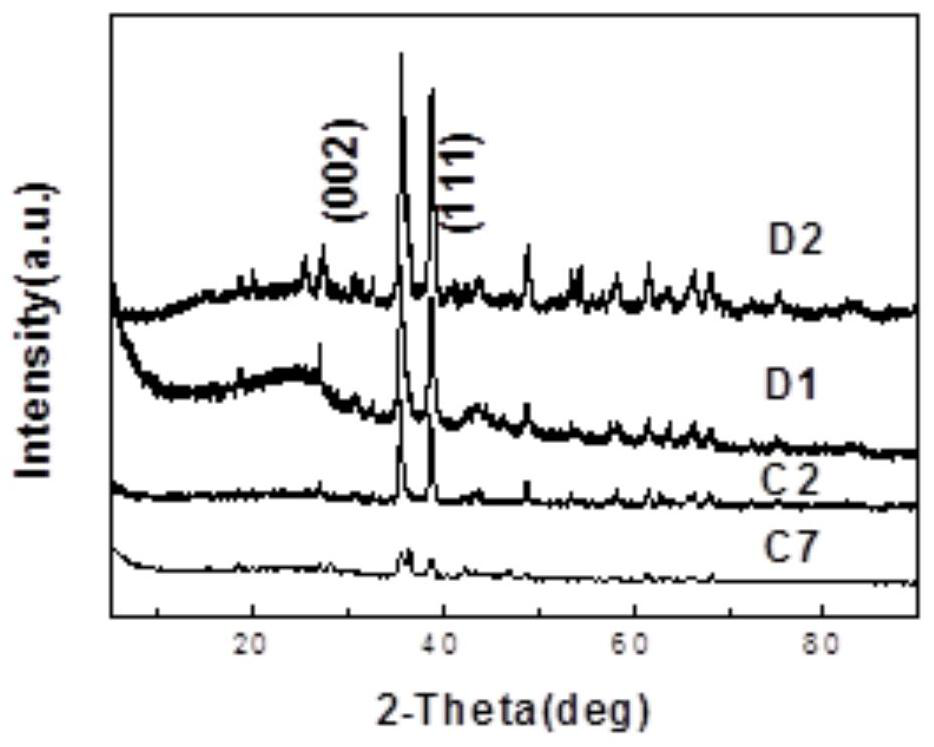

ActiveCN107403902AImprove conductivityAvoid reunionElectrode thermal treatmentLithium electrodePole piece

The invention discloses high-conductivity lithium iron phosphate powder and a preparation method thereof. The preparation method comprises the steps as follows: 1) formation of precursor of high-conductivity lithium iron phosphate: a lithium hydroxide solution is stirred and mixed with phosphoric acid; a graphene oxide dispersion liquid is added and stirred; iron sulfate heptahydrate is added and stirred, and a uniform mixture is obtained; the mixture is filtered, washed and dried, and black powder, namely, the precursor of the high-conductivity lithium iron phosphate, is obtained; 2) formation of high-conductivity lithium iron phosphate powder: the precursor, obtained in the step 1), of high-conductivity lithium iron phosphate and lithium carbonate are subjected to ball milling and uniformly mixed, the mixture is calcined in the atmosphere of inert gas, and the high-conductivity lithium iron phosphate powder is obtained. The lithium iron phosphate powder prepared with the method has high conductivity, large specific surface area and higher compaction density, has the particle size of 0.5-1 mu m, has 1-5 layers of graphene and has the iron-phosphorous ratio of 0.95-1.05, and a produced pole piece has the surface resistance of 60 omega and has wide application prospects in the lithium ion battery field.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Preparation method of high-dispersion titanium dioxide doped polyamide reverse osmosis film

ActiveCN110801737AImprove pollutionAvoid mutual influenceMembranesGeneral water supply conservationReverse osmosisPolyamide

According to the preparation method, tetrabutyl titanate is hydrolyzed into titanium dioxide in an organic phase, and then interfacial polymerization is performed to obtain a titanium dioxide doped polyamide reverse osmosis film, so that the dispersion uniformity of titanium dioxide particles in an organic phase is ensured, the hydrolysis process and the interfacial polymerization process are separated, and the mutual influence between the hydrolysis process and the interfacial polymerization process is avoided; an alcohol-water mixture is used as a hydrolysis solution, the pH is adjusted to be acidic, and the low hydrolysis temperature is controlled to control the slow hydrolysis process of the tetrabutyl titanate in the organic phase, so that the dispersion uniformity and dispersion concentration of the tetrabutyl titanate in the organic phase are ensured, and finally, the anti-pollution capacity and water flux of the polyamide reverse osmosis film are effectively improved.

Owner:南京驰探科技有限公司

Adsorption arsenic removal catalyst and preparation method thereof

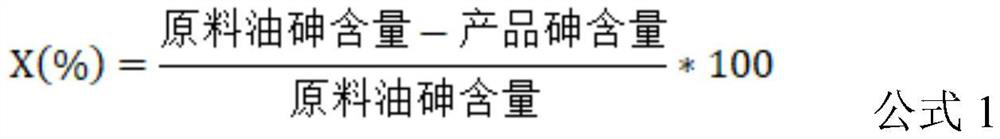

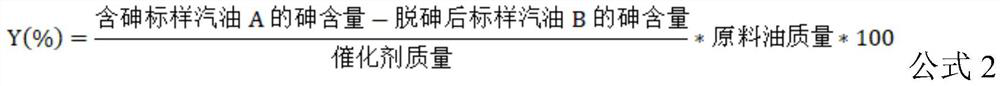

PendingCN114377668AIncrease profitFacilitated DiffusionCatalyst carriersCatalyst activation/preparationActivated carbonPtru catalyst

The invention discloses a catalytic cracking gasoline adsorption dearsenification catalyst with large specific surface area, hierarchical pore distribution and high dearsenification performance and a preparation method thereof, and the method comprises the following steps: 1) mixing active carbon and pseudo-boehmite in proportion, grinding, stirring, adding a pore-enlarging agent and an acid solution, extruding into strips, drying, and roasting under an anaerobic condition to prepare a carbon-alumina composite carrier; (2) adjusting the pH value of the metal precursor solution, and impregnating the solution containing the active metal precursor into the carrier by adopting an isovolumetric saturated impregnation method; and 3) drying the catalyst, and roasting in an oxygen-free environment to obtain the finished product catalyst. The carrier with a composite pore channel structure can improve diffusion, reaction and escape of reactant molecules in pore channels, and the reaction efficiency is improved; metal with partially filled d tracks is selected as active metal, so that the acting force between the arsenide and the metal can be improved, and the arsenide is deeply removed; the pH value of the metal precursor solution is adjusted to be higher than the isoelectric point of the metal oxide or hydroxide, the acting force between the metal and the carrier can be weakened, the dispersity of the metal is improved, and finally the arsenic removal efficiency of the catalyst is improved.

Owner:PETROCHINA CO LTD

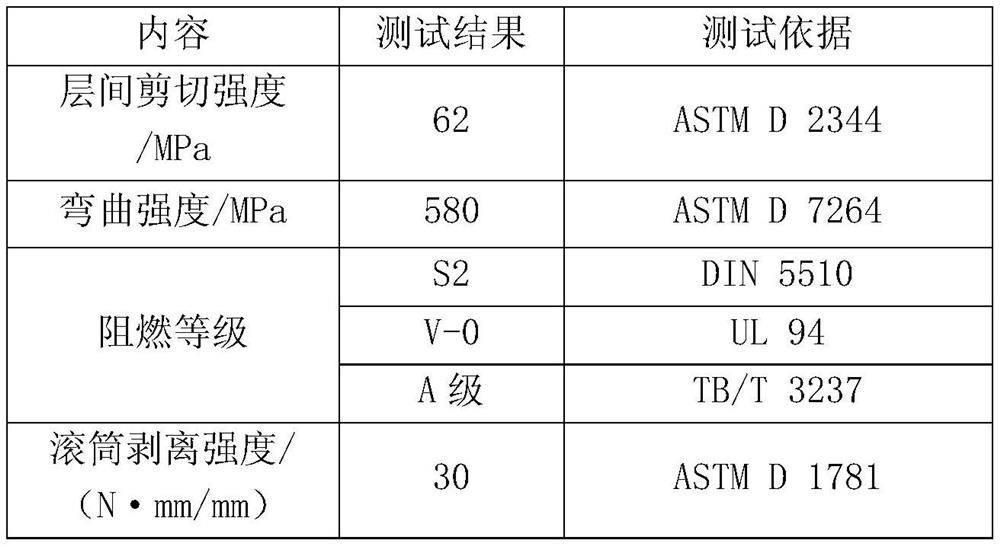

Medium-temperature fast-curing flame-retardant epoxy resin and preparation method thereof

InactiveCN110922718AImprove flame retardant performanceLong storage periodPolymer sciencePolymer chemistry

The invention relates to medium-temperature fast-curing flame-retardant epoxy resin and a preparation method thereof. The epoxy resin does not contain halogen. A phosphorus element, a nitrogen elementand a metal oxide contained in the resin generate a synergistic flame-retardant effect with the phenolic aldehyde-based epoxy resin under a set ratio so that condensed phase flame retardance and gasphase flame retardance are performed when the material is combusted. The prepreg / composite material prepared from the epoxy resin has excellent flame retardancy and meets the requirements of DIN5510 (S4 / ST2 / SR2), UL-94 (V-0), EN45545 (HL3), TB / T 3237 (A), FAR25, CCAR and the like.

Owner:AVIC COMPOSITES +1

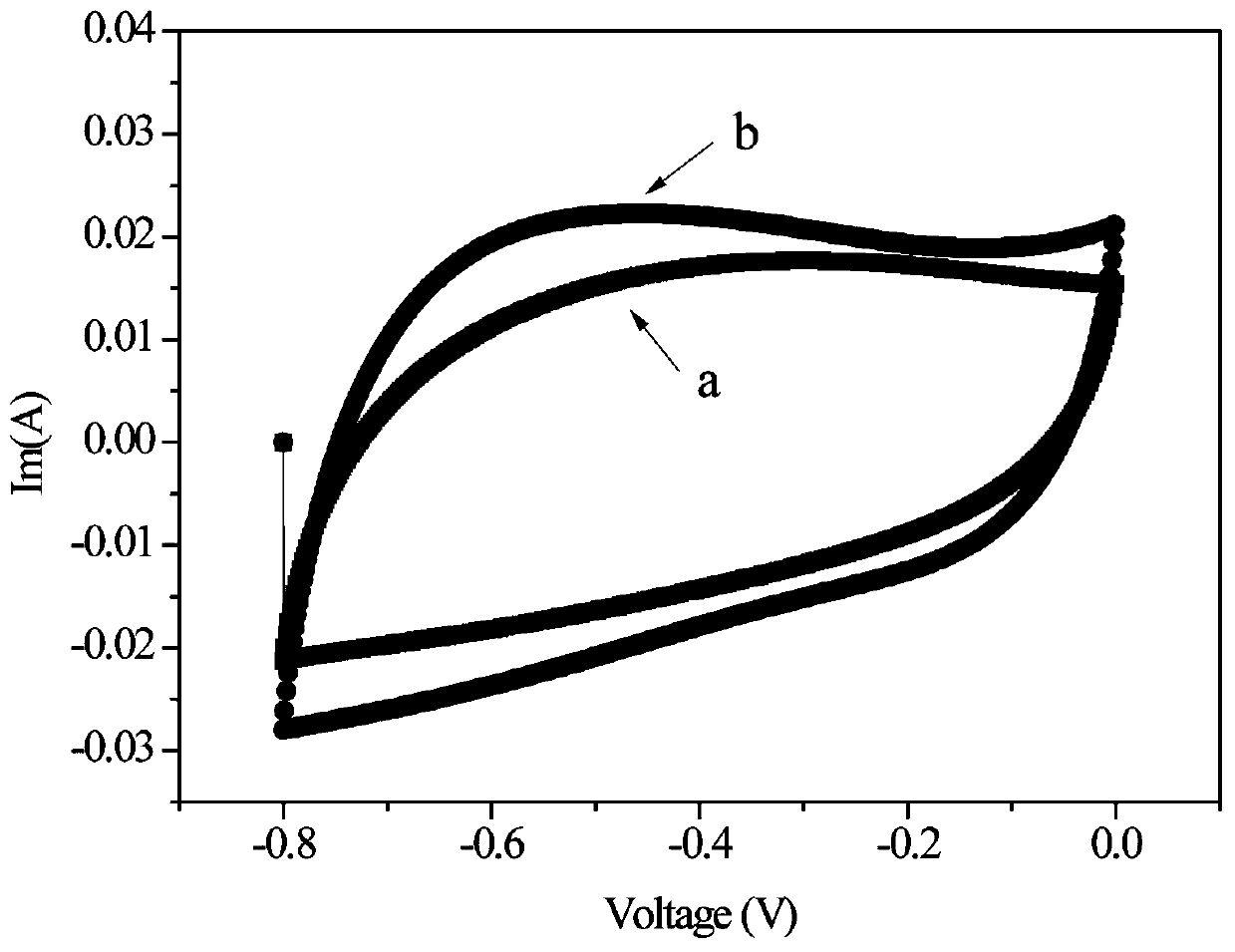

Electrically conductive organic polymer coated phenolic resin-based porous carbon composite material

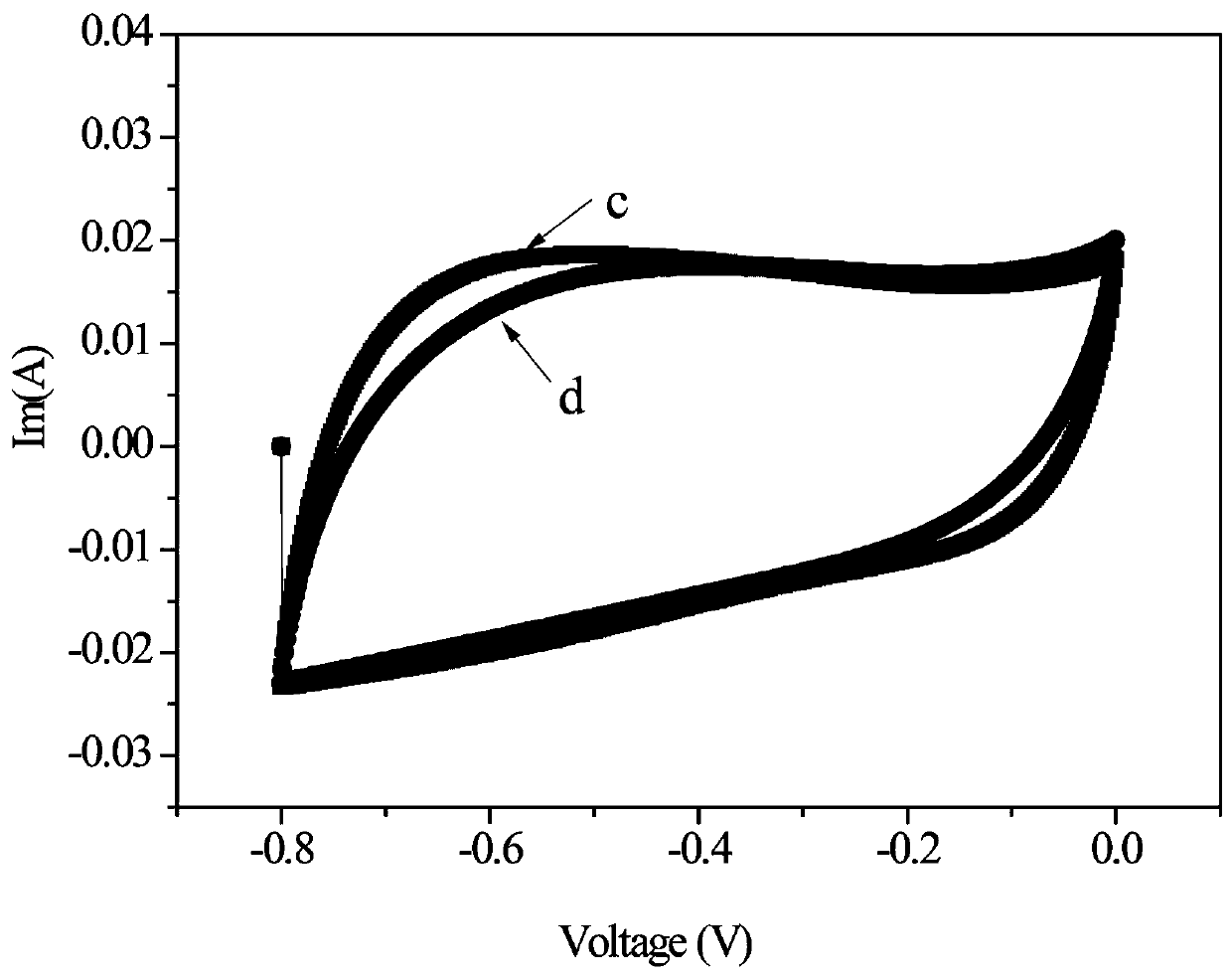

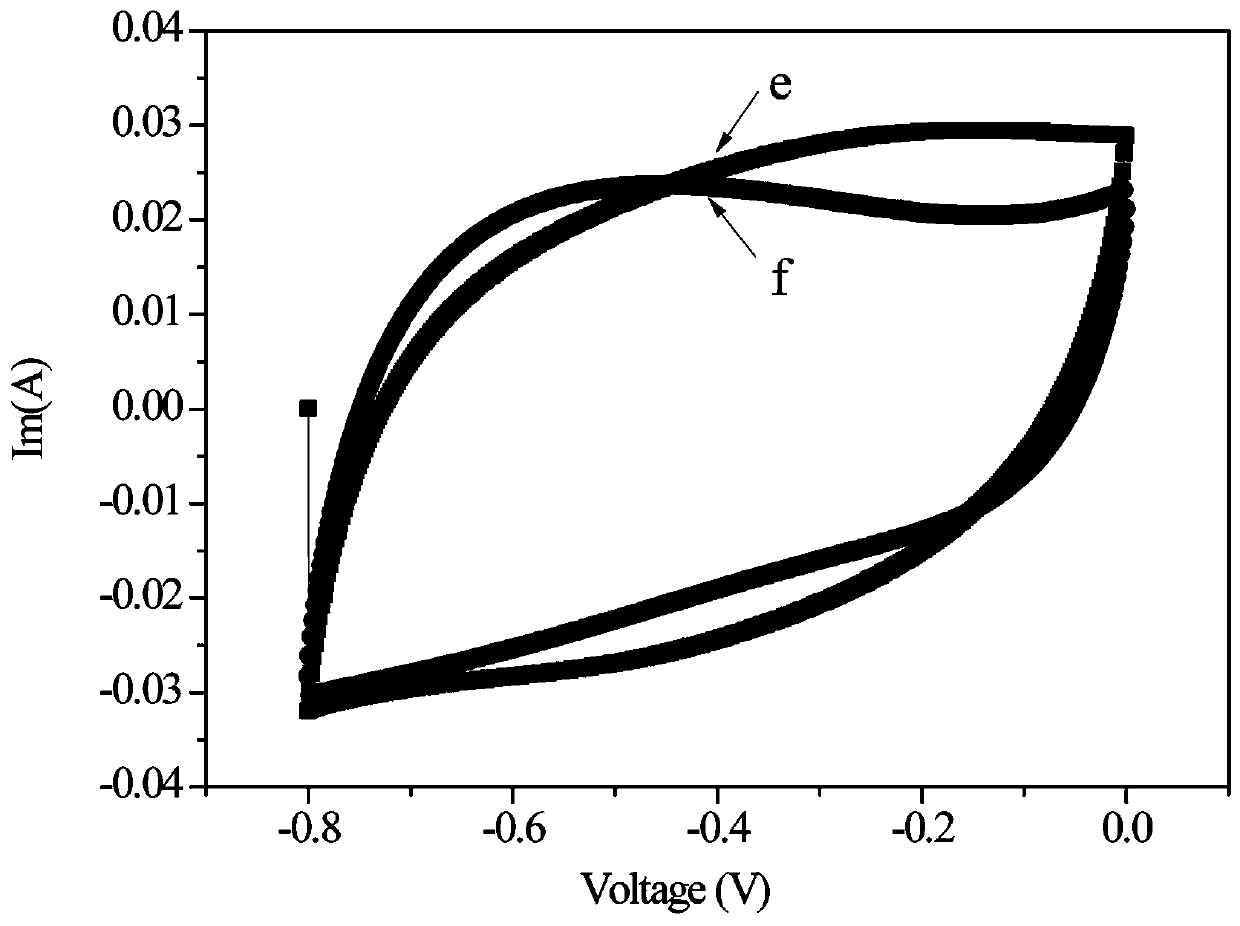

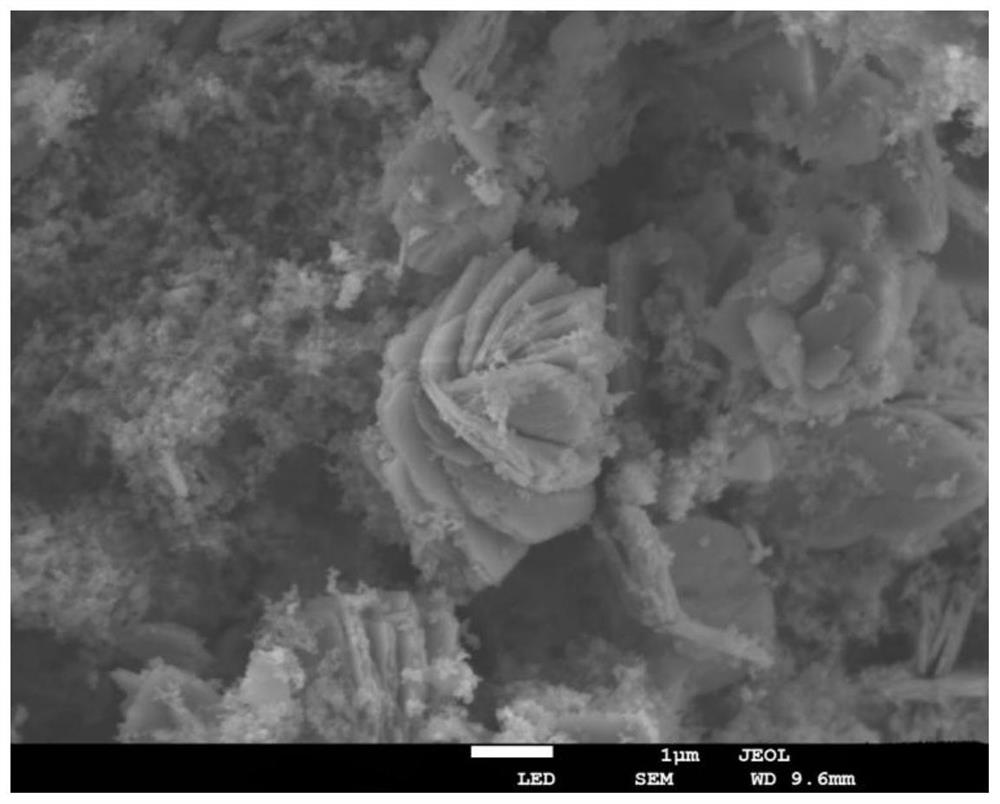

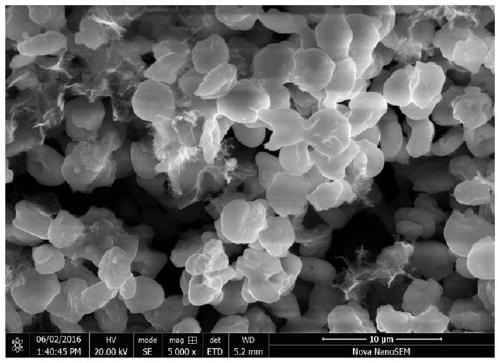

ActiveCN110444411ACheap and easy to getEasy to makeHybrid capacitor electrodesResin microspherePorous carbon

The invention relates to an electrically conductive organic polymer coated phenolic resin-based porous carbon composite material. A preparation method for the material comprises the following steps: (1) water-soluble phenolic resin and curing agent are orderly added in an anhydrous alcohol solution to obtain a mixture; after stirring and curing operation, a cured phenolic resin is obtained; (2) phenolic resin microspheres obtained in step (1) are carbonized and calcined in an inert gas atmosphere at a temperature of 850 to 950 DEG C to obtain phenolic resin-based porous carbon; (3) the phenolic resin-based porous carbon obtained in step (2) is added to a 30-60 ml acetone solution, and then a surfactant is added to obtain a mixed solution after ultrasonic dispersion. Electrically conductivepolymer monomers are ultrasonically dispersed in an acetone solution to obtain an electrically conductive polymer monomer acetone solution. The electrically conductive polymer monomer acetone solution is added dropwise to the mixed solution, microwave hydrothermal reaction was performed, and the electrically conductive organic polymer coated phenolic resin-based porous carbon composite material with high specific capacity, specific energy density, and good cycle stability is obtained.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Catalyst and preparation method for preparing 1,6-hexanediol by reduction of adipic acid

ActiveCN110354877BReduce manufacturing costImprove catalytic performanceOrganic compound preparationHydroxy compound preparationActivated carbonPtru catalyst

The invention discloses a catalyst for preparing 1,6-hexanediol by reduction of adipic acid, which comprises an active component, a transition metal, phosphorus and a carrier, the active component is Ru, and the transition metal is Co, Cu , at least one of Ni, Fe, Mo and Zn, and the carrier is a porous structure material, such as diatomaceous earth, activated carbon, etc. First configure a mixed solution containing soluble salts and phosphorus salts of any of the above transition metals, and pass inert gas into the solution to form a gas-liquid interface with inert gas bubbles as a template; then slowly add a certain concentration of NaBH 4 solution, and then quickly add catalyst active components; add the reacted mixed solution to the carrier, react for a period of time, wash with water until neutral, filter, and dry to obtain an amorphous catalyst. The catalyst has low cost, the conversion rate of adipic acid is as high as 90%, and the yield of 1,6-hexanediol can reach 65%, which has achieved good technical effects and has good industrialization prospects.

Owner:QINGDAO UNIV OF SCI & TECH

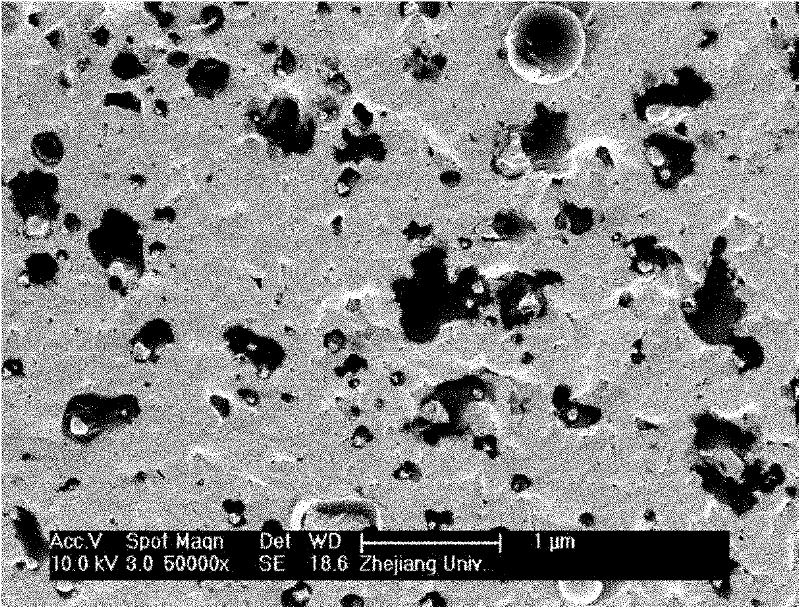

A kind of highly conductive lithium iron phosphate powder and preparation method thereof

ActiveCN107403902BReduce agglomeration defectsReduce reunionElectrode thermal treatmentIron sulfateLithium oxide

The invention discloses high-conductivity lithium iron phosphate powder and a preparation method thereof. The preparation method comprises the steps as follows: 1) formation of precursor of high-conductivity lithium iron phosphate: a lithium hydroxide solution is stirred and mixed with phosphoric acid; a graphene oxide dispersion liquid is added and stirred; iron sulfate heptahydrate is added and stirred, and a uniform mixture is obtained; the mixture is filtered, washed and dried, and black powder, namely, the precursor of the high-conductivity lithium iron phosphate, is obtained; 2) formation of high-conductivity lithium iron phosphate powder: the precursor, obtained in the step 1), of high-conductivity lithium iron phosphate and lithium carbonate are subjected to ball milling and uniformly mixed, the mixture is calcined in the atmosphere of inert gas, and the high-conductivity lithium iron phosphate powder is obtained. The lithium iron phosphate powder prepared with the method has high conductivity, large specific surface area and higher compaction density, has the particle size of 0.5-1 mu m, has 1-5 layers of graphene and has the iron-phosphorous ratio of 0.95-1.05, and a produced pole piece has the surface resistance of 60 omega and has wide application prospects in the lithium ion battery field.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

A kind of preparation method of highly dispersed titanium dioxide doped polyamide reverse osmosis membrane

ActiveCN110801737BImprove pollutionAvoid mutual influenceMembranesGeneral water supply conservationAlcoholReverse osmosis

Owner:南京驰探科技有限公司

A Structurally Optimized Antifouling Polyamide Composite Membrane

ActiveCN111282439BGuaranteed retention rateIncrease water fluxReverse osmosisPolymer sciencePolyamide

The invention provides a structurally optimized anti-fouling polyamide composite membrane, the polyamide composite membrane sequentially includes a porous support layer, a polyamide separation layer and a polyamide functional layer, the polyamide functional layer contains titanium dioxide particles and It has a looser pore structure than the polyamide separation layer; the polyamide functional layer is contacted by the aqueous phase monomer II and the organic phase monomer II containing tetrabutyl titanate to simultaneously occur the interfacial polymerization process and tetrabutyl titanate It is obtained through hydrolysis of butyl ester, and the contact process is completed by standing still at a constant temperature of 40-60°C for 10-20s. Compared with the prior art, the present invention provides a new type of polyamide composite membrane, which utilizes a loose polyamide functional layer to fix titanium dioxide on the surface of the polyamide separation layer, thereby ensuring the stability of titanium dioxide while increasing the membrane flux .

Owner:南京宏遥系统科技有限公司

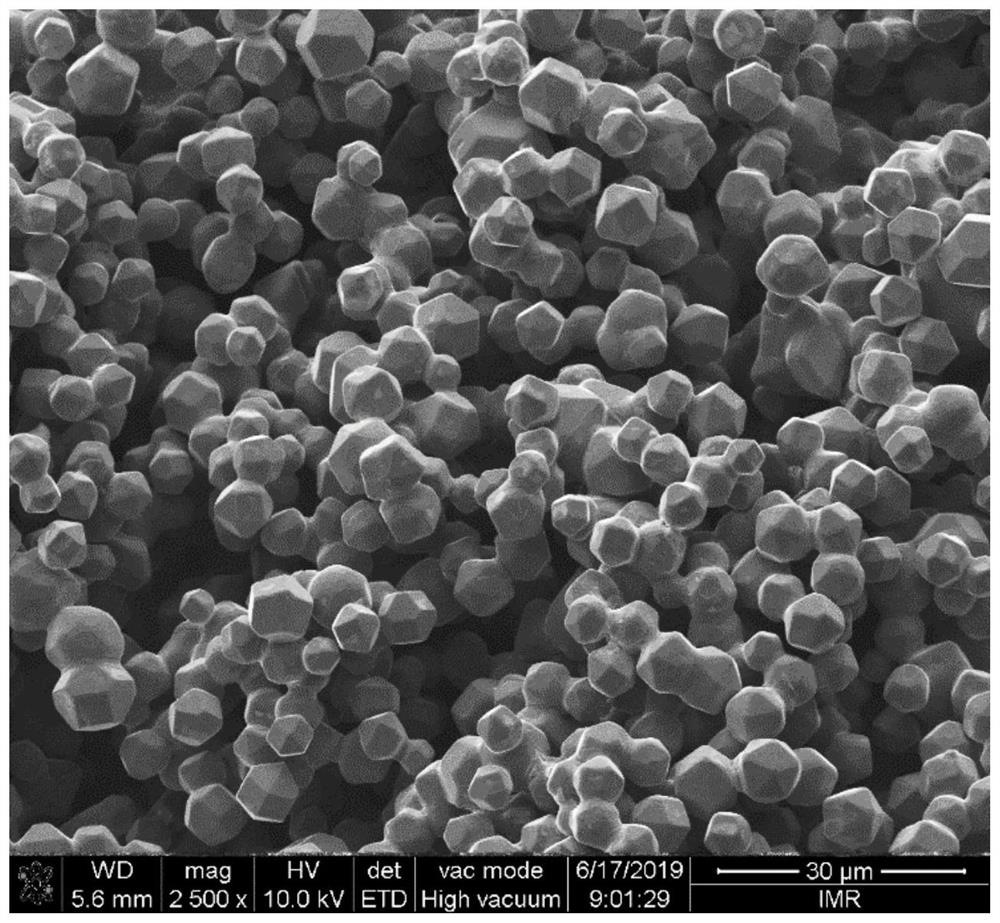

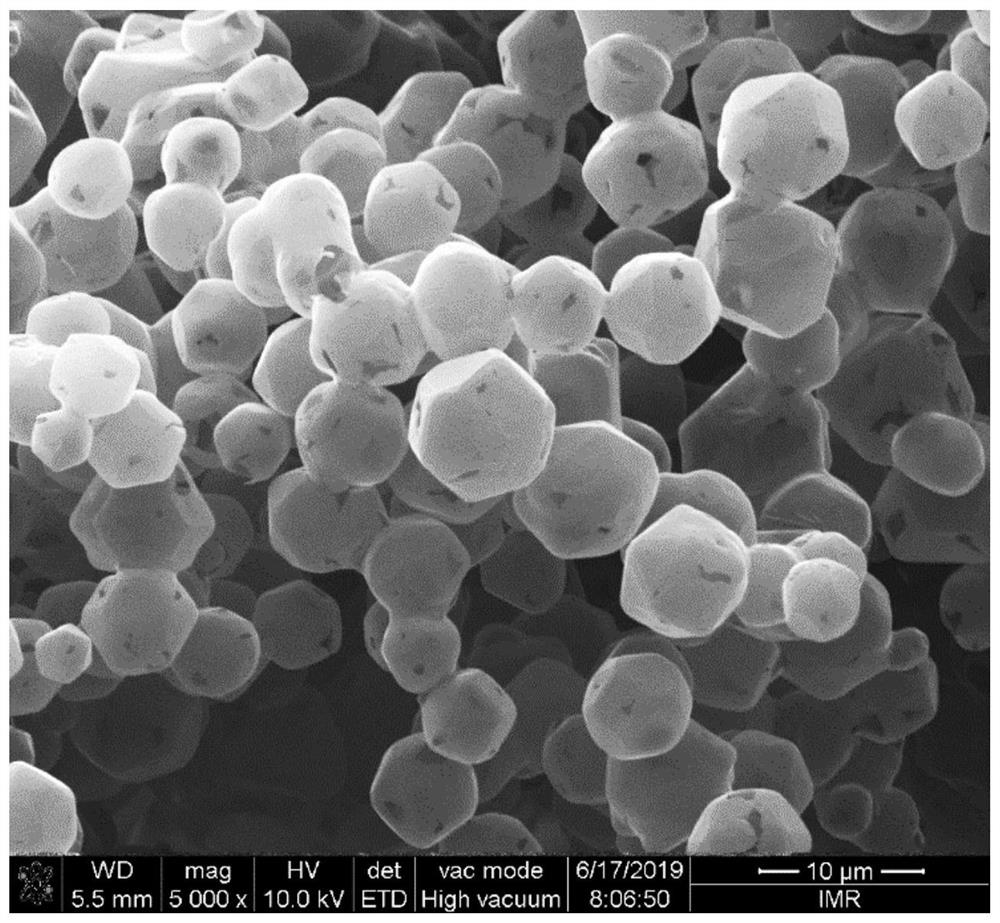

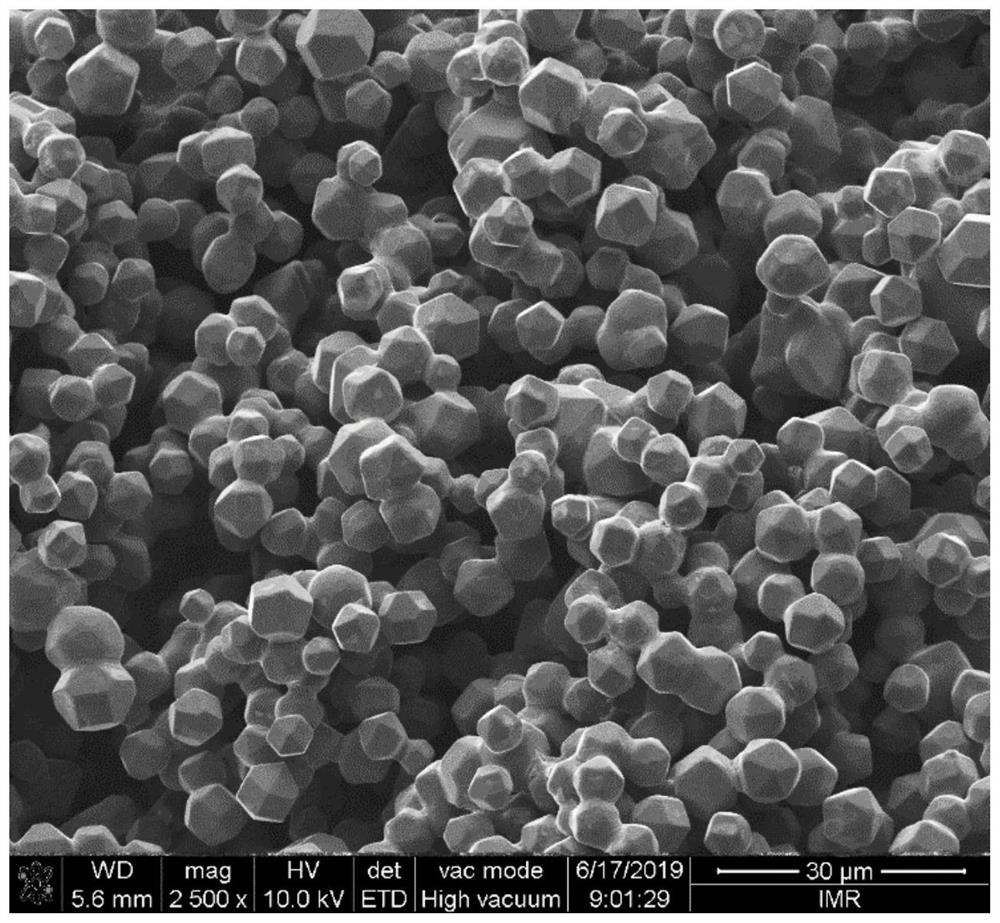

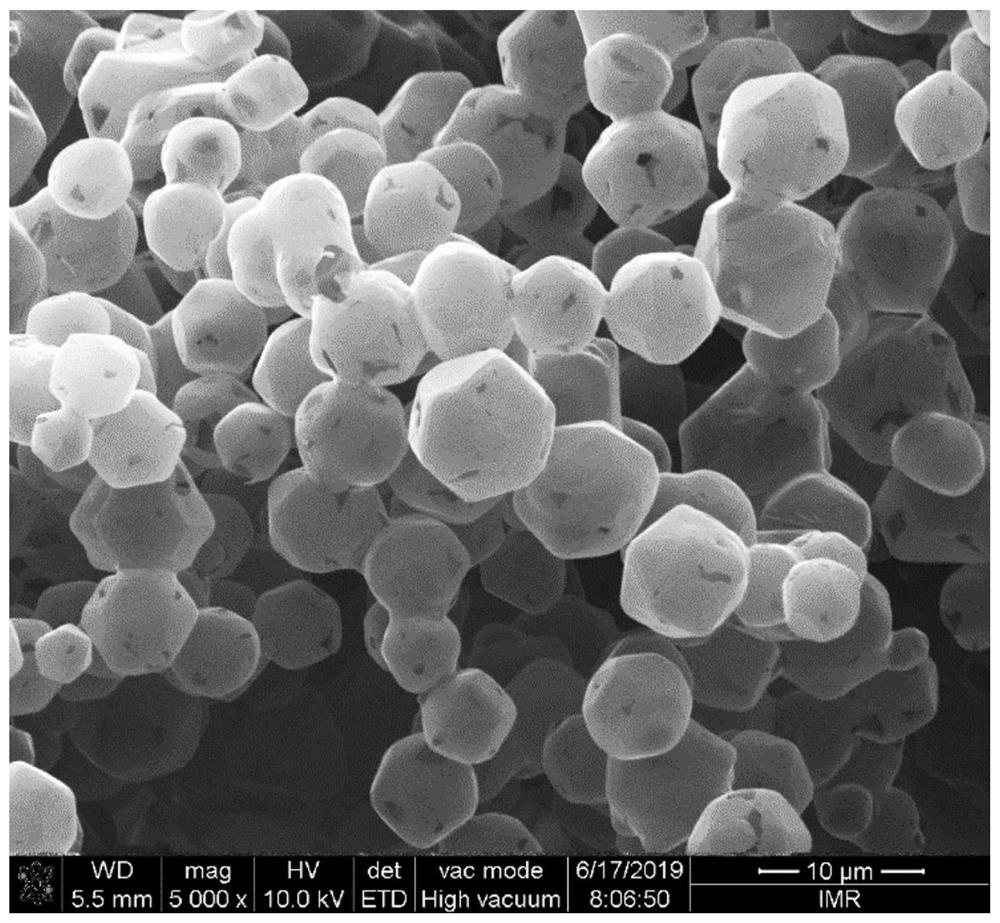

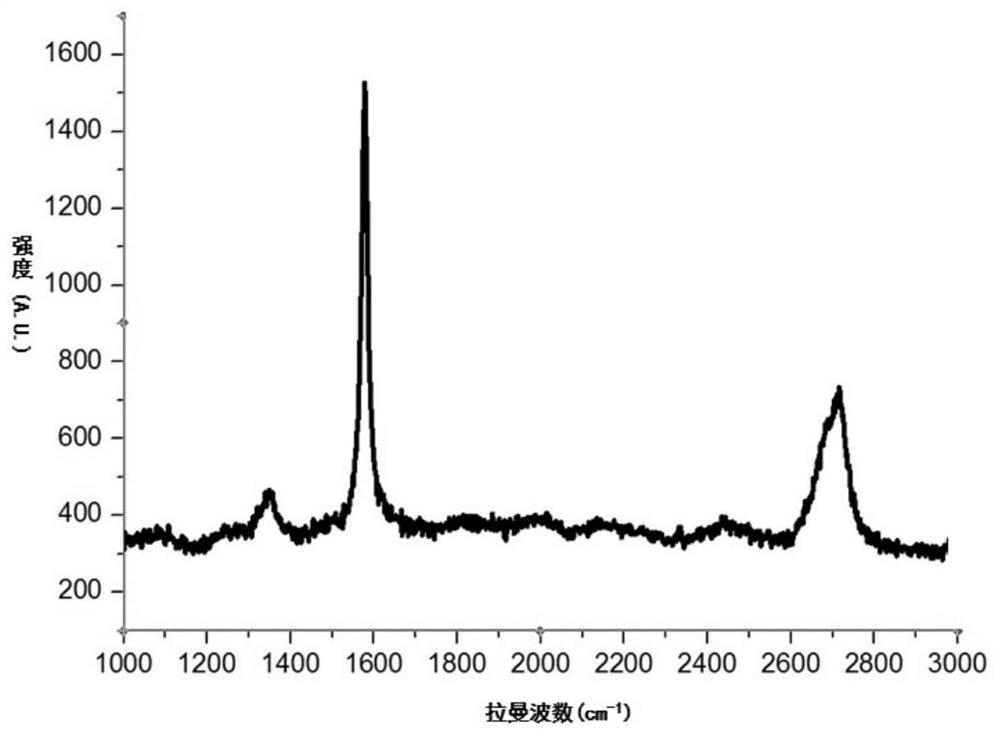

A kind of graphene powder with controllable shape and preparation method thereof

The invention discloses a form-controllable high-quality graphene powder and a preparation method thereof, belonging to the field of new materials. The invention uses the metal salt of the transition group as a template, utilizes a chemical vapor deposition process, and catalyzes the growth of graphene on the surface of the metal salt (reduced to metal) under suitable temperature and atmosphere conditions. The obtained graphene powder can retain or remove the substrate according to the needs of the application to form a graphene / metal-shell-core composite structure or a graphene hollow cavity structure. By adjusting the reaction parameters, the particle size and shape of the graphene powder can be adjusted. The metal salt and the corresponding etching acid solution can be recovered and recycled, and the whole production process only consumes a certain amount of electric energy and reaction gas. The invention has the advantages of simple process, low production cost and easy mass production. The prepared graphene has high crystalline quality, excellent thermal conductivity and electrical conductivity, and can be used as a filler in many fields.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

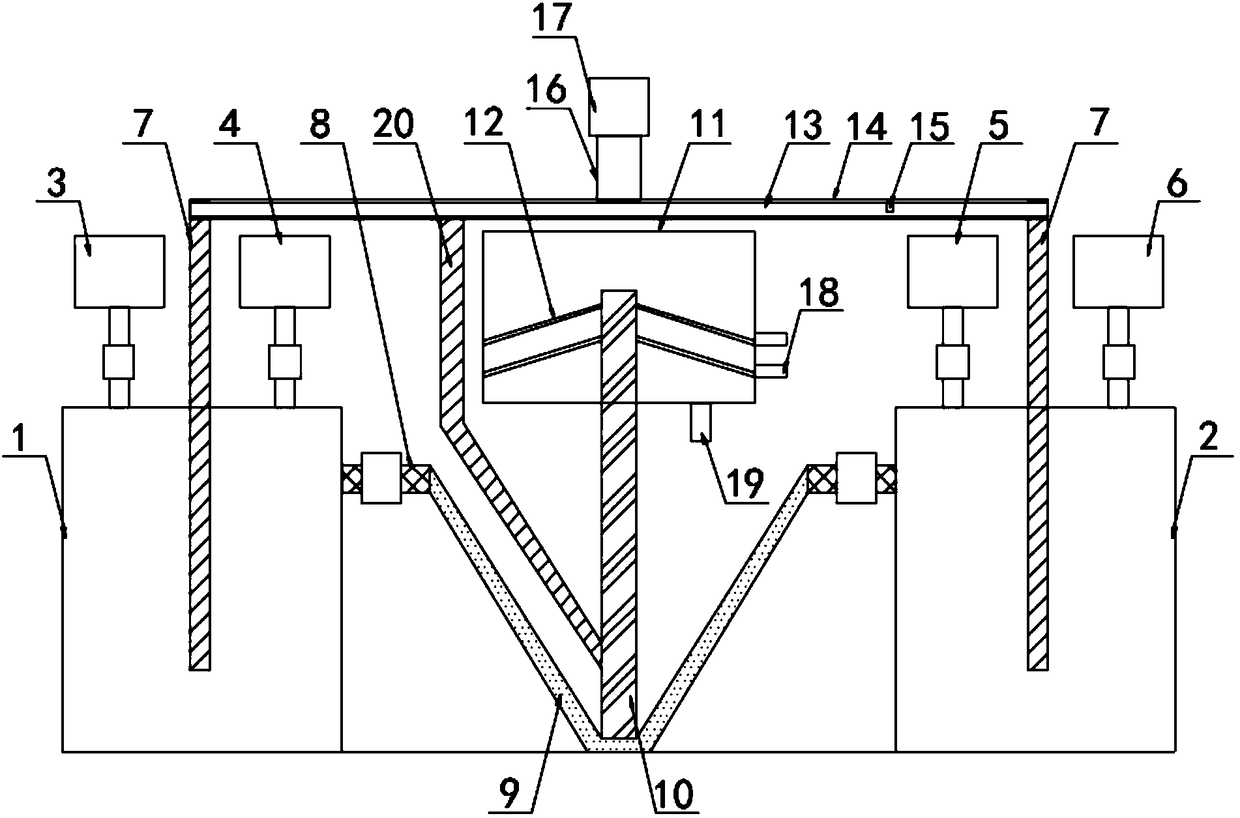

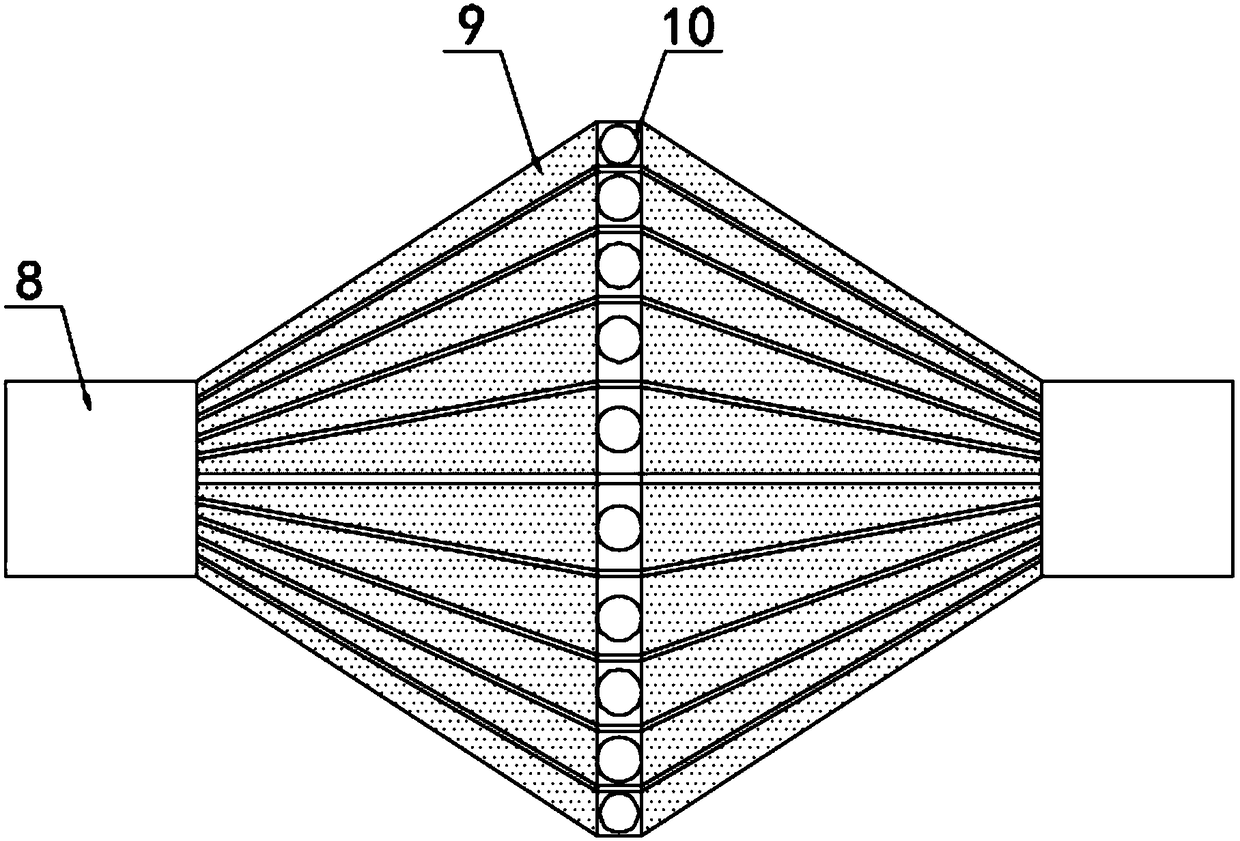

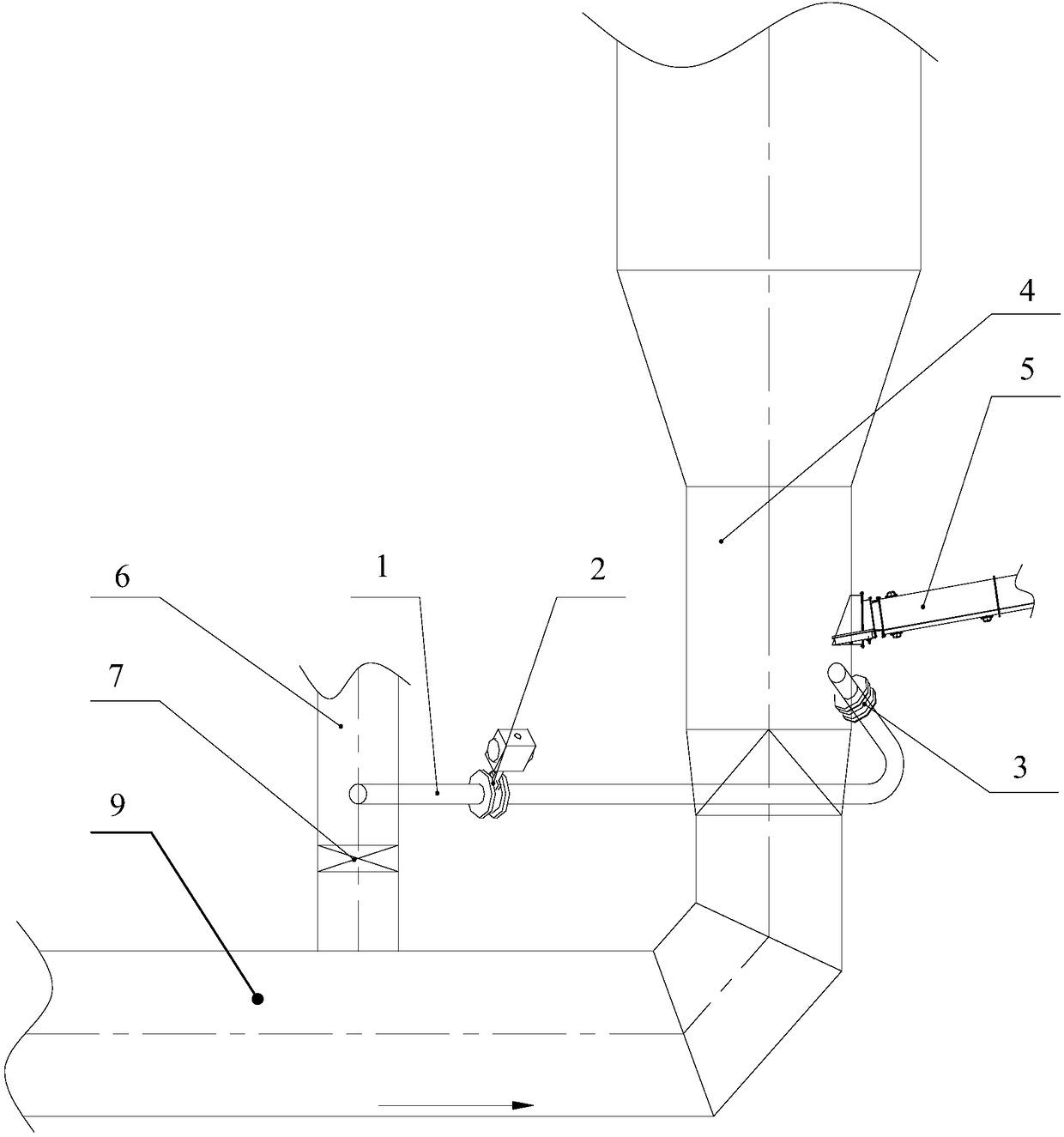

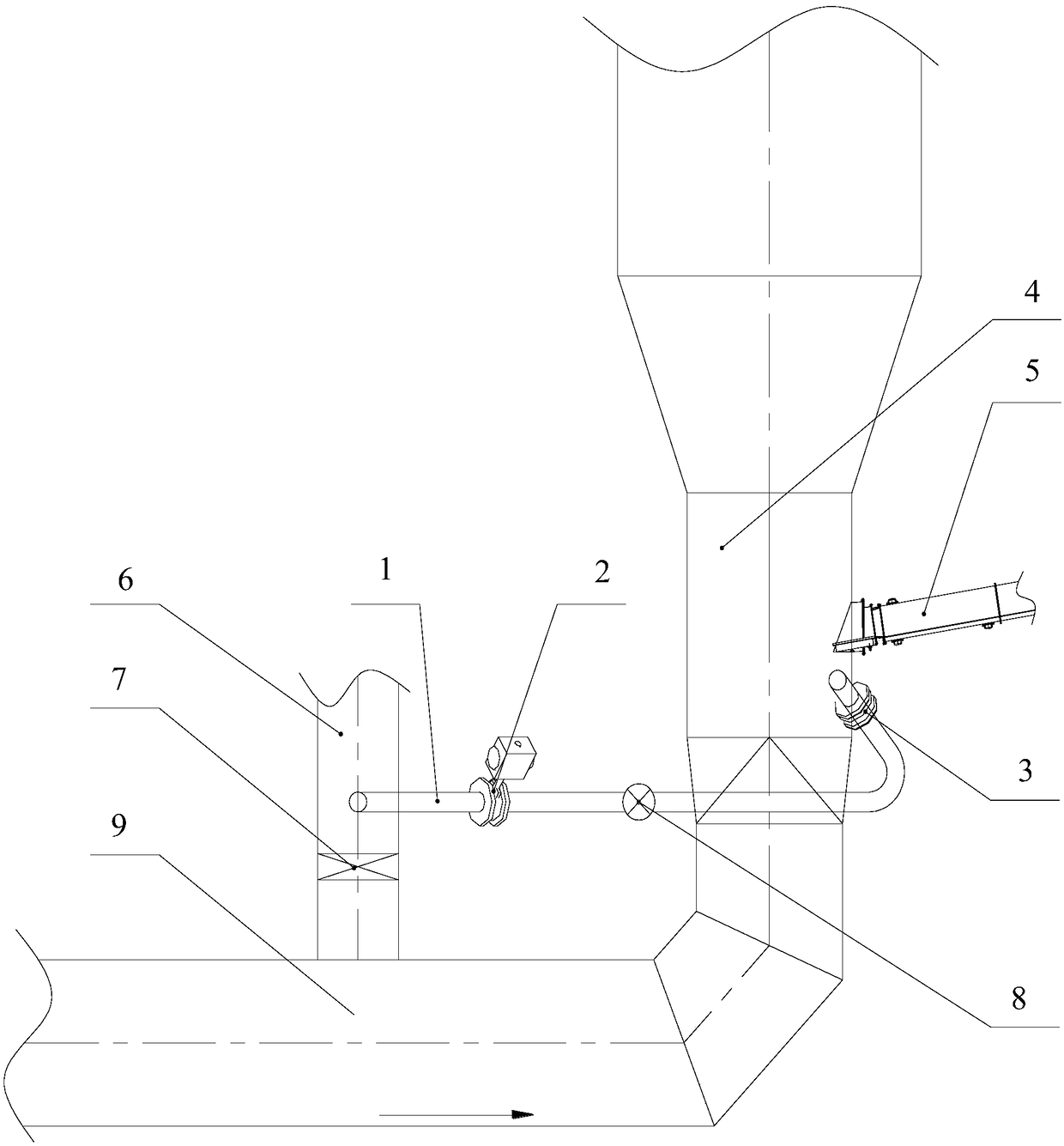

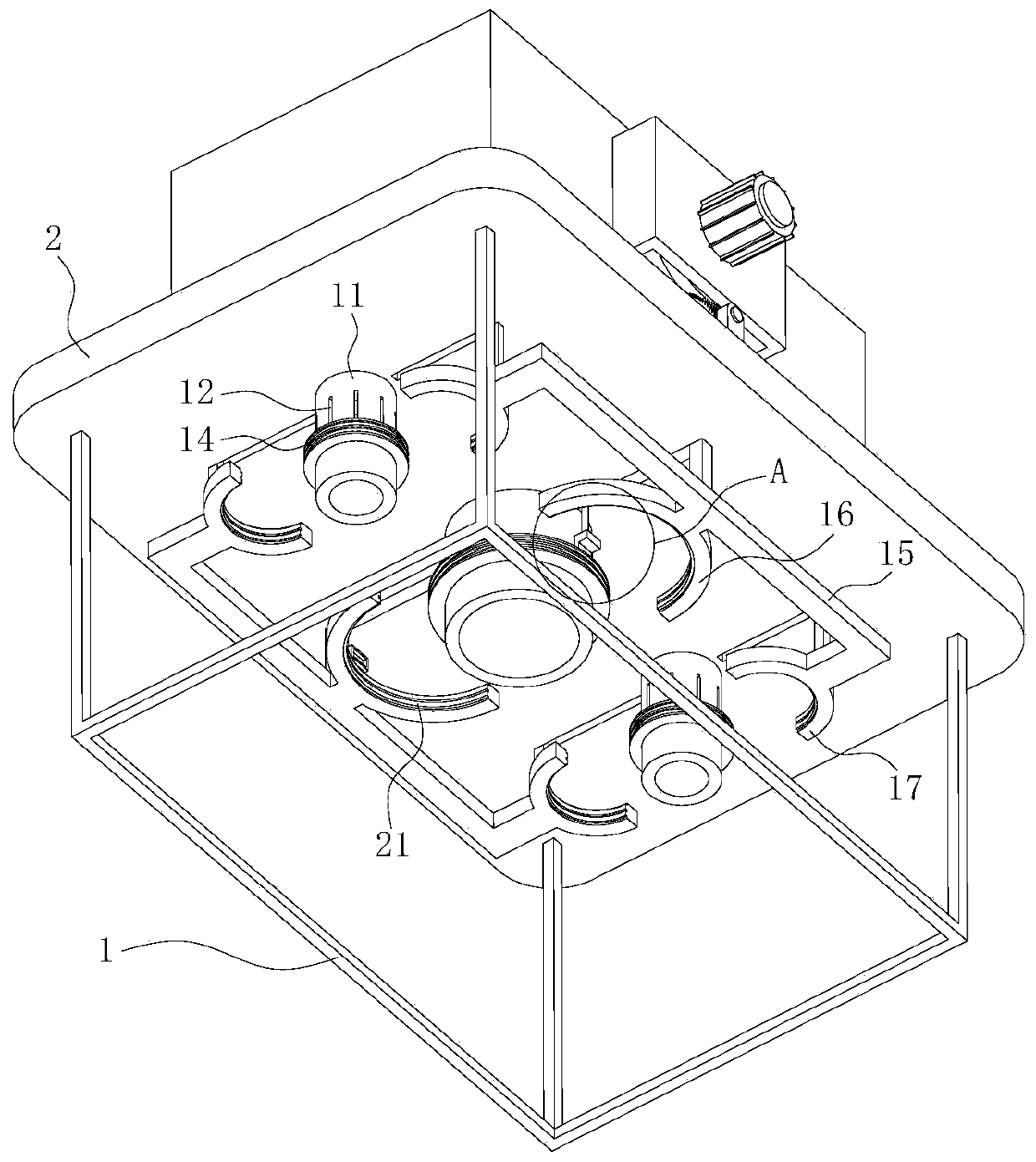

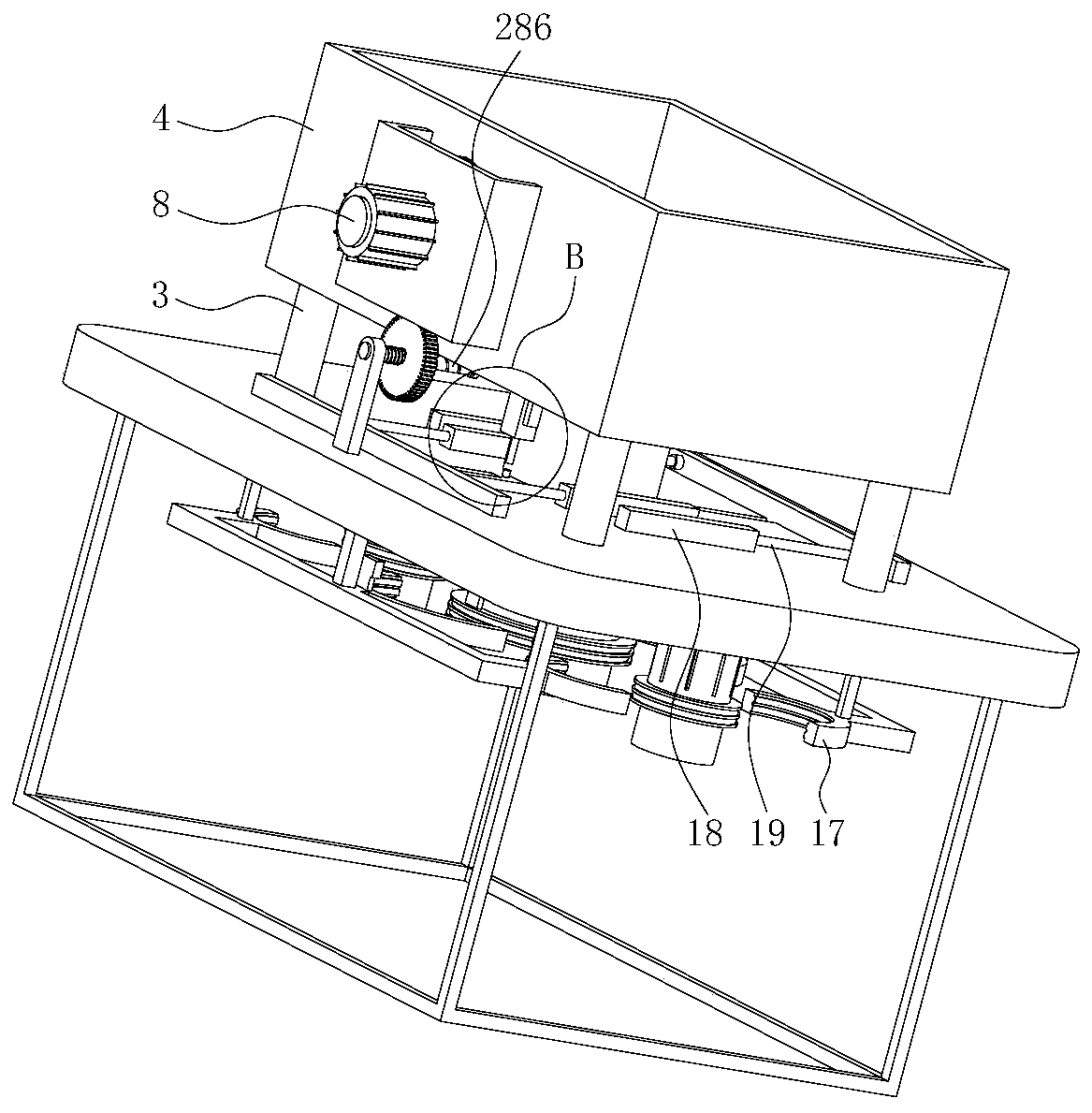

Smoke gas recycling system and its material homogenizing device

PendingCN108144433AAvoid reunion situationsIncrease profitGas treatmentDispersed particle separationEngineeringTower

The invention provides a smoke gas recycling system and its material homogenizing device. The material homogenizing device comprises a feeding section (4) of a reaction tower, a circular chute (5) connected with the feeding section (4), a reaction tower inlet smoke flue (9) connected to the lower part of the feeding section (4) and a recycling smoke flue (6) connected to the reaction tower inlet smoke flue (9). The material homogenizing device further comprises an ash blowing pipeline (1), one end of the ash blowing pipeline (1) is an air inlet connected with the recycling smoke flue (6), andthe other end thereof is connected with the feeding section (4) and faced to the blowing opening at the lower part of the circular chute (5). The material homogenizing device effectively avoids the material agglomeration in the vicinity of the feeding opening of the circular chute, and further avoids the partial flow caused by different smoke gas rates, and also avoids the ash falling caused by material agglomeration; moreover, the device effectively improves the utilization rate of the materials.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

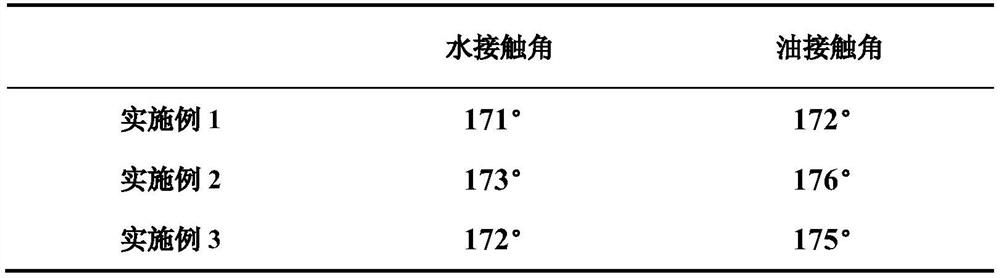

A kind of super amphiphobic coating material for catalyst and its preparation method and application

ActiveCN108296137BGood superamphiphobic propertiesStable structurePretreated surfacesSpecial surfacesCoated surfacePtru catalyst

The invention relates to the technical field of preparation of super-amphiphobic materials, and specifically provides a super-amphiphobic coating for catalysts and its preparation method and application. The super-amphiphobic coating contains uniformly distributed inorganic Nanoparticles, the high content of inorganic nanoparticles makes the surface of the coating have a strong degree of roughness, so that the prepared coating exhibits excellent super-amphiphobic properties. The invention also provides a preparation method of the super-amphiphobic coating. By spraying low-concentration particles for many times, all the nanoparticles are in a good dispersion state when sprayed onto the coating body. By heating the nanoparticles to the viscous fluidization temperature of the coating body, they are "embedded" and fixed on the coating body when they come into contact with the coating body, and then the whole coating is heated by cooling first. And ultrasonic treatment, so that the nanoparticles enter the coating body at the relative position of maintaining the dispersed state, thereby avoiding the agglomeration of the nanoparticles.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A conductive organic polymer-wrapped phenolic resin-based porous carbon composite

ActiveCN110444411BSpeed up aggregationAvoid reunion situationsHybrid capacitor electrodesResin microsphereConductive polymer

The invention relates to a conductive organic polymer-wrapped phenolic resin-based porous carbon composite material, comprising the following steps: (1) adding water-soluble phenolic resin and a curing agent to an absolute ethanol solution to obtain a mixture, stirring and curing, Obtaining a cured phenolic resin; (2) carbonizing and calcining the phenolic resin microspheres obtained in step (1) at a temperature of 850-950°C in an inert gas atmosphere to obtain a phenolic resin-based porous carbon; (3) converting the step ( 2) The obtained phenolic resin-based porous carbon was added to 30~60mL acetone solution, and then a surfactant was added for ultrasonic dispersion to obtain a mixed solution, and the conductive polymer monomer was ultrasonically dispersed in the acetone solution to obtain a conductive polymer monomer acetone solution , the conductive polymer monomer acetone solution was added dropwise to the mixed solution, and microwave hydrothermal reaction was carried out to obtain a conductive organic polymer-wrapped phenolic resin-based porous carbon composite material with high specific capacity, specific energy density and good cycle stability.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

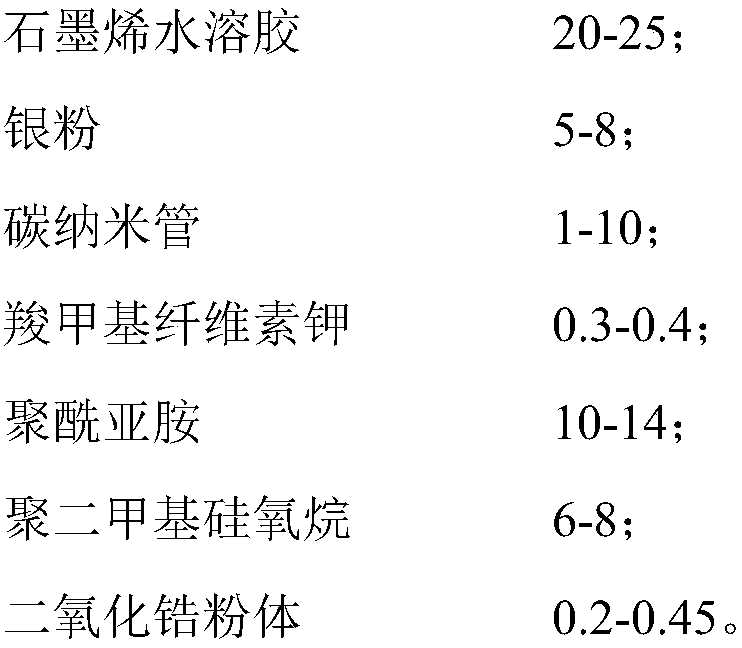

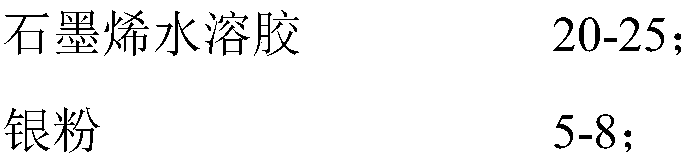

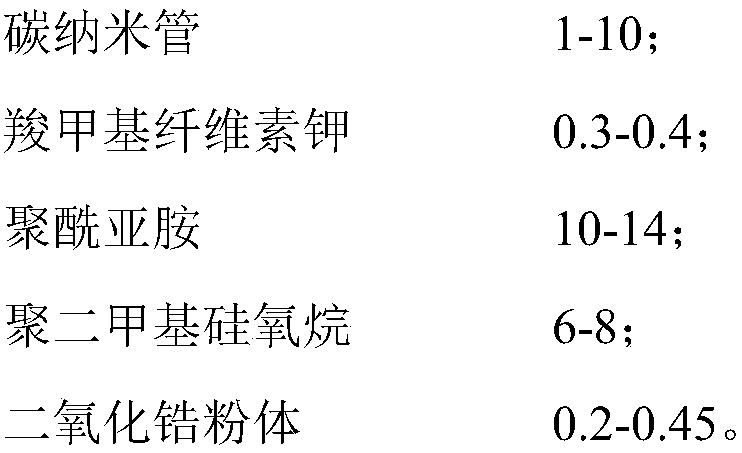

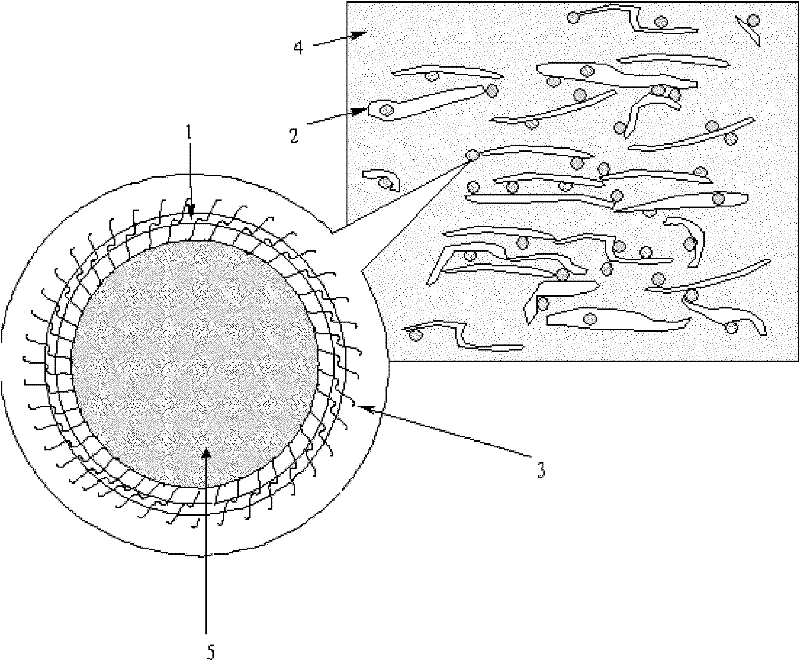

High-conductivity flexible touch graphene composite material and preparation method thereof

InactiveCN108795042AAvoid reunion situationsOptimize the conductive network structureCarbon nanotubePotassium

The invention relates to a high-conductivity flexible touch graphene composite material and a preparation method thereof. The high-conductivity flexible touch graphene composite material comprises thefollowing components: 20 to 25 parts of graphene hydrosol, 5 to 8 parts of aluminum powder, 1 to 10 parts of carbon nanotube, 0.3 to 0.4 part of potassium carboxymethylcellulose, 10 to 14 parts of polyimide, 6 to 8 parts of polydimethylsiloxane, and 0.2 to 0.45 part of zirconium dioxide powder. The preparation method comprises the following step: mixing all the components, so as to form the high-conductivity flexible touch graphene composite material. The method is simple in technology, effectively avoids the situation of agglomeration caused by large specific surface area of graphene powderthrough the added the graphene hydrosol, optimizes a conductive network structure in the composite material through the added zirconium dioxide powder and a potassium carboxymethylcellulose dispersingagent, further improves the electrical conductivity of the composite material while enhancing the ductility of the composite material through the added aluminum powder, and meets the application requirements on flexible touch materials by current electronic devices.

Owner:TIANJIN BAOXINGWEI TECH

Structure-optimized anti-pollution polyamide composite membrane

ActiveCN111282439AGuaranteed retention rateIncrease water fluxReverse osmosisPolymer sciencePolyamide

The present invention provides a structure-optimized anti-pollution polyamide composite membrane comprising a porous support layer, a polyamide separation layer, and a polyamide functional layer in order. The polyamide functional layer contains titanium dioxide particles and has a more loose pore structure than the polyamide separation layer. The polyamide functional layer is obtained by contacting a water-phase monomer II with an organic-phase monomer II containing tetrabutyl titanate so as to simultaneously generate an interfacial polymerization process and a tetrabutyl titanate hydrolysis process, and the contact process is completed by standing for 10-20 seconds at the constant temperature of 40-60 DEG C. Compared with the prior art, the novel polyamide composite membrane provided by the invention has the advantages that the titanium dioxide is fixed on the surface of the polyamide separation layer by utilizing the loose polyamide functional layer, so that the stability of the titanium dioxide is ensured while the membrane flux is improved.

Owner:南京宏遥系统科技有限公司

A kind of composite filler based on graphene and preparation method thereof

ActiveCN110835423BImprove crystal qualityImprove thermal conductivityChemical vapor deposition coatingElectric propertiesCatalytic growth

The invention discloses a graphene-based composite filler and a preparation method thereof, belonging to the technical field of new materials and their applications. The composite filler includes graphene powder with a hollow cavity and functional materials filled in the cavity; the filled functional material is a phase change material, a magnetic material, a catalytic material or an active material and the like. The invention uses the metal salt of the transition group as a template, utilizes a chemical vapor deposition process, and catalyzes the growth of graphene on the surface of the metal salt (reduced to metal) under suitable temperature and atmosphere conditions. After removing the base of the obtained graphene powder with an acid, the graphene powder with a hollow cavity is formed, and the composite filler is obtained after being filled with functional materials. The graphene prepared by the invention has high crystallization quality, excellent thermal conductivity and electrical conductivity, and can be used as a filler in many fields after being filled with functional materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of aluminum alkali cleaning corrosion inhibitor and its preparation method and application

ActiveCN104372362BHigh corrosion inhibition efficiencyGood corrosion inhibitionAcridineDiacrylate ester

The invention discloses an aluminum alkali-washing corrosion inhibitor, and a preparation method and application thereof, belonging to the field of aluminum alloy corrosion inhibition. The corrosion inhibitor is composed of water, sodium silicate, sodium gluconate, benzotriazole, calcium tartrate, acridine and phthalate diethylene glycol diacrylate (PDDA). The preparation method comprises the following steps: (1) uniformly mixing the PDDA, calcium tartrate and water to obtain a solution A; (2) uniformly mixing the sodium silicate, benzotriazole and water to obtain a solution B; (3) uniformly mixing the sodium gluconate, acridine and water to obtain a solution C; and (4) adding the solution B and solution C into the solution A, and stirring uniformly to obtain the corrosion inhibitor. The corrosion inhibitor has the advantages of favorable effect, environment friendliness, simple preparation technique and mild conditions, is suitable for corrosion inhibition protection of the aluminum alloy material in the alkali washing process, and is easy to manufacture.

Owner:马鞍山市鸿伟环化有限公司

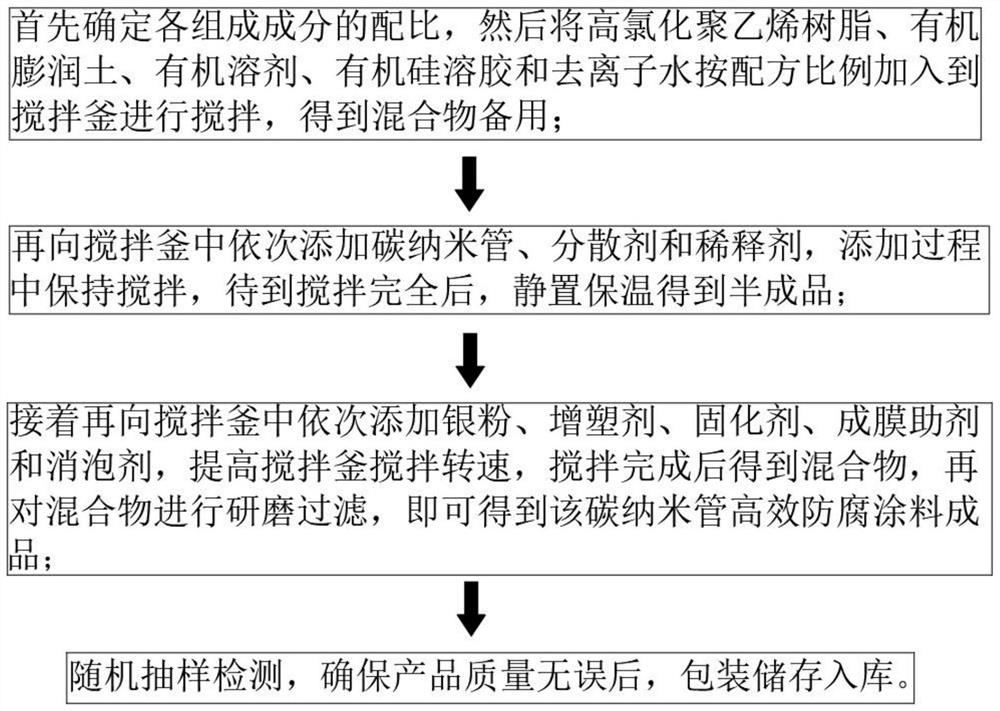

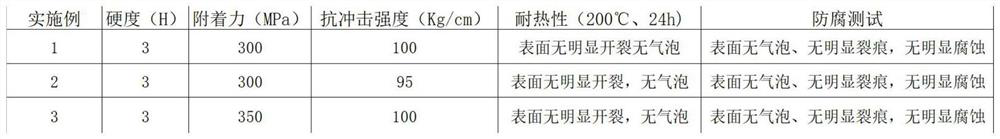

Formula and preparation method of carbon nanotube high-efficiency anticorrosive paint

InactiveCN114213911AAvoid reunion situationsImprove heat resistanceFireproof paintsAnti-corrosive paintsPolymer scienceOrganic solvent

The invention relates to the technical field of anti-corrosion coatings, in particular to a formula and a preparation method of a carbon nanotube efficient anti-corrosion coating. The formula of the carbon nanotube high-efficiency anticorrosive coating consists of high chlorinated polyethylene resin, organic bentonite, carbon nanotubes, an organic solvent, organic silica sol, a defoaming agent, a dispersing agent, a curing agent, a coalescing agent, a diluent, silver powder, a plasticizer and deionized water. In the preparation process of the carbon nanotube anticorrosive paint, the diluent, the silver powder and the plasticizer are added, so that the viscosity and the rheological property of the paint can be adjusted, the Van der Waals force among anticorrosive paint molecules can be properly weakened, and the condition of agglomeration among the paint in the storage process can be avoided; meanwhile, the heat resistance of the whole carbon nanotube anticorrosive paint in the using process can be improved, the overall using performance of the paint is further improved, and the using effect of the whole paint is further improved through the coalescing agent.

Owner:深圳市中科纳米科技有限公司

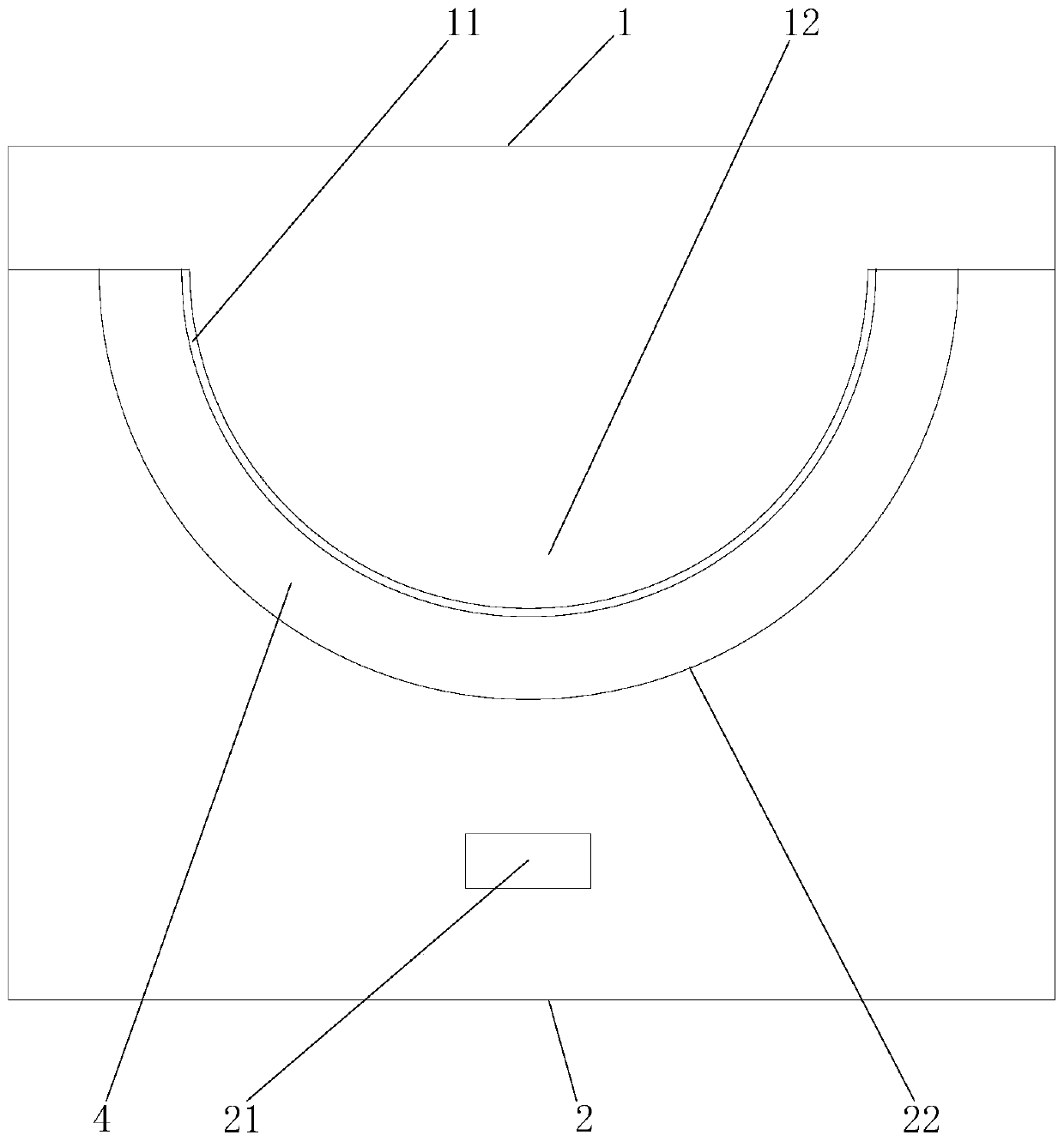

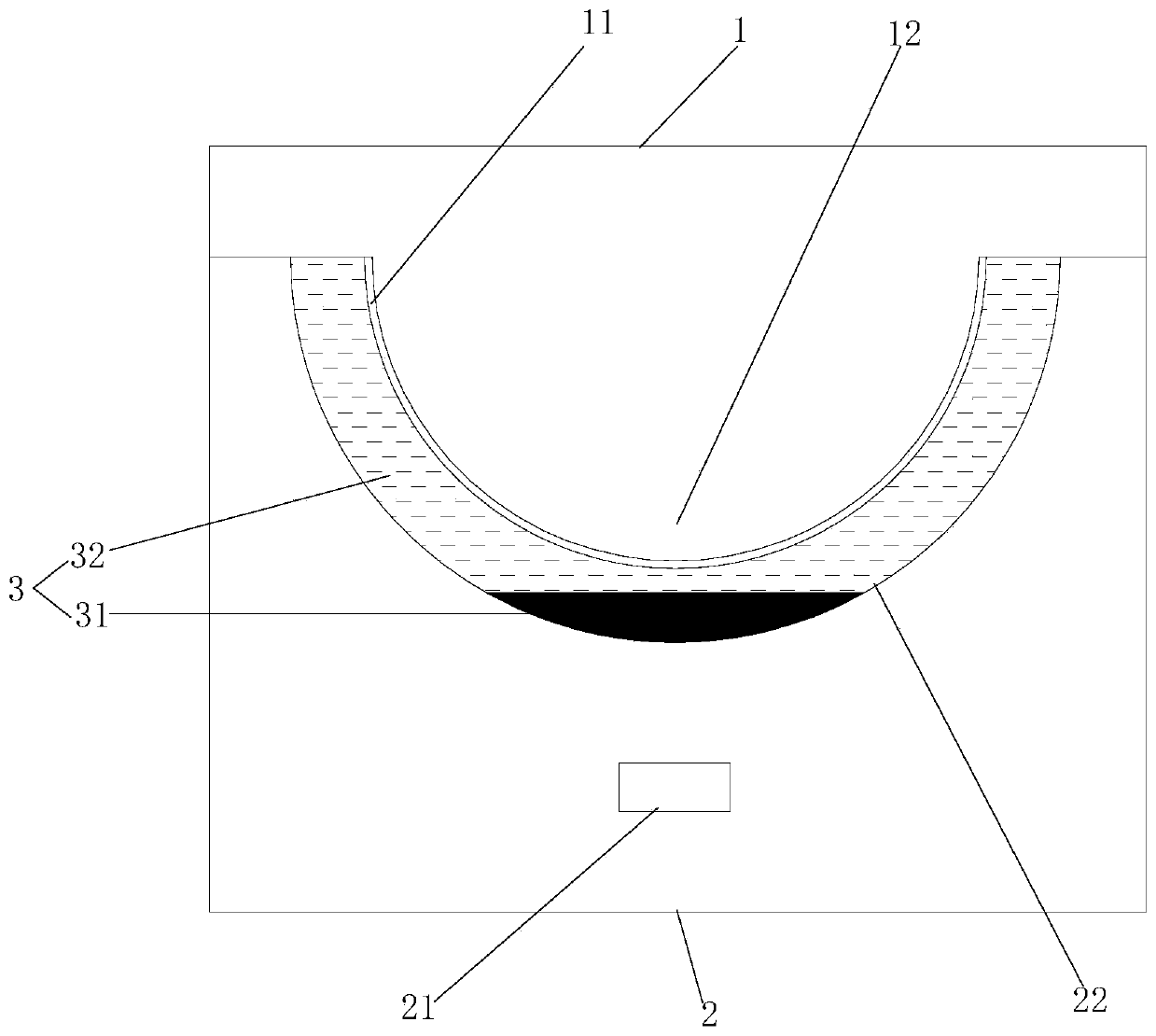

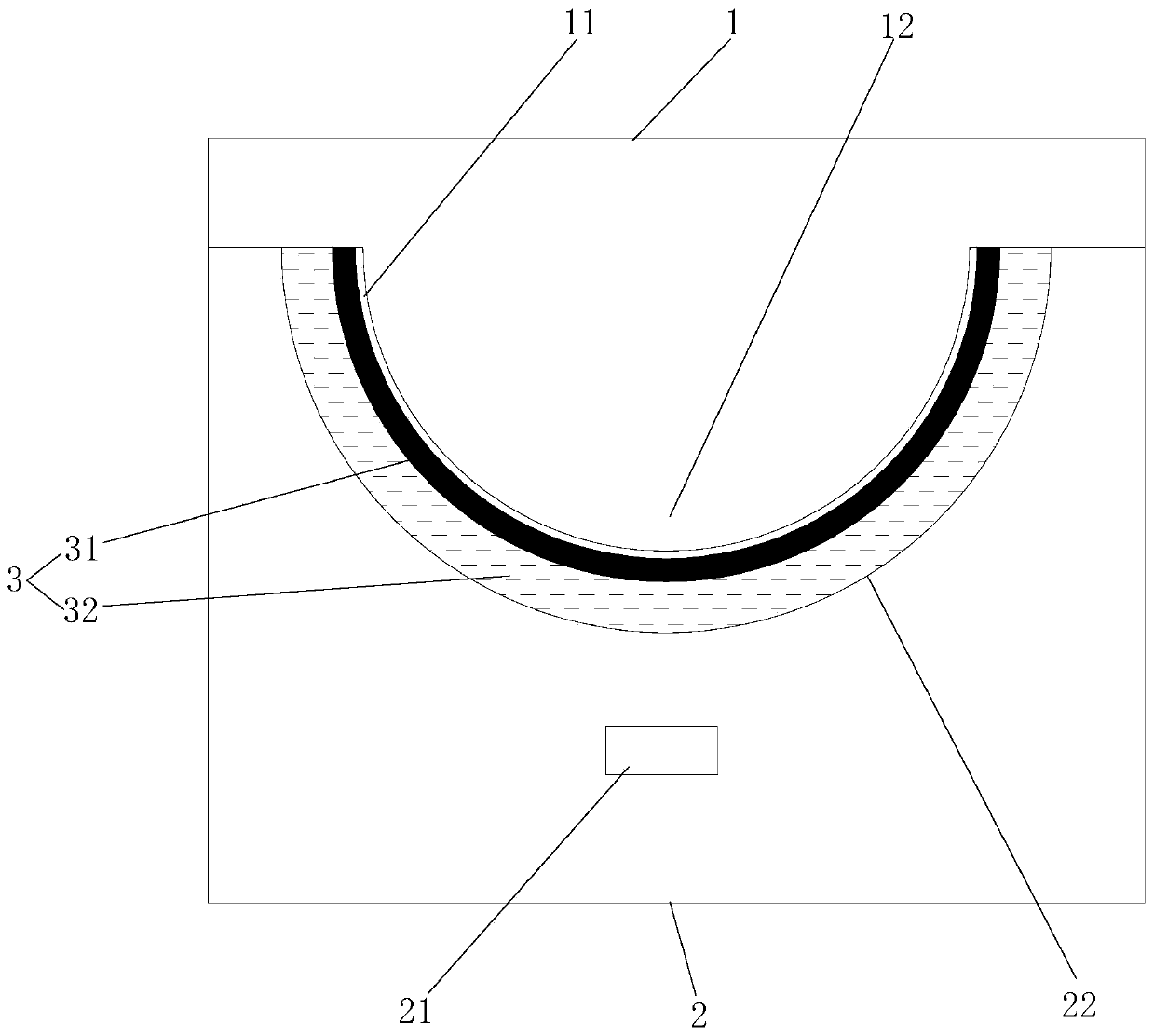

Display module and electronic equipment

ActiveCN108445690BGuaranteed display effectAvoid accumulationNon-linear opticsEngineeringMaterials science

The invention relates to a display module and electronic equipment, and relates to the field of display technology. The technical problem to be solved is to solve the problem of agglomeration of charged particles on an electronic ink screen and to speed up the display response speed. The technical solution mainly adopted is: a display module, which includes: an upper substrate, the upper substrate is provided with a first electrode, the first surface of the upper substrate is provided with a plurality of arc-shaped protrusions arranged in a matrix; the lower substrate , the lower substrate is provided with a second electrode, the first surface of the lower substrate is provided with a plurality of arc-shaped grooves arranged in a matrix; an inverse emulsion; wherein, the first surface of the upper substrate and the first surface of the lower substrate A surface fit, each of the arc-shaped protrusions cooperates with one of the arc-shaped grooves to form a groove-shaped accommodation space, and the reverse emulsion is filled in the groove-shaped accommodation space. The display module provided by the invention can avoid the agglomeration of charged particles and accelerate the display response speed.

Owner:BOE TECH GRP CO LTD +1

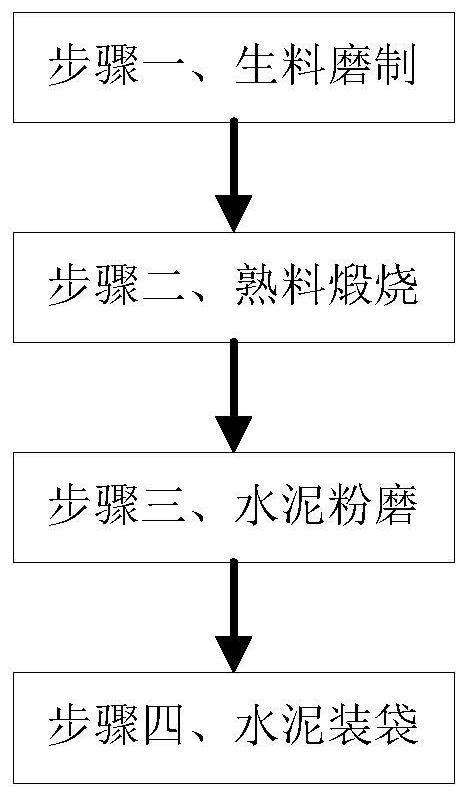

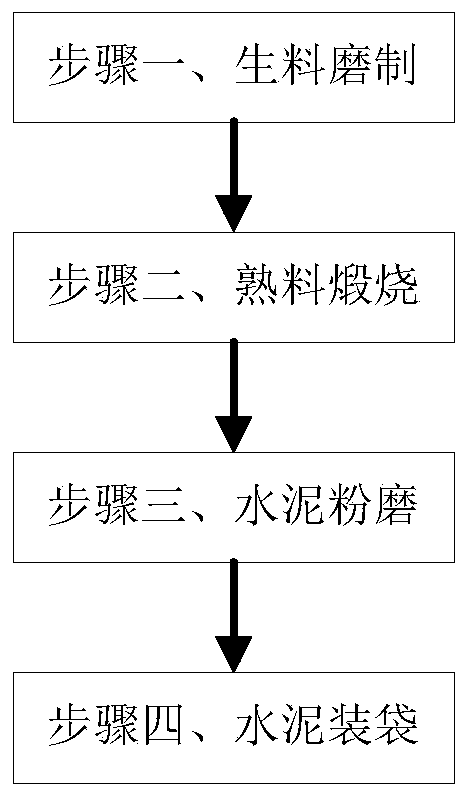

A kind of cement production method

The invention belongs to the technical field of cement manufacture, and in particular relates to a cement production method, comprising the following steps: Step 1, raw material grinding: limestone and clay are crushed and ground and then homogenized. Step 2, clinker calcination: send the homogenized raw meal particles into the preheater and rotary kiln for calcination and slaking; step 3, cement grinding: grind the calcined clinker to a suitable particle size to form a certain Grain gradation; step 4, cement bagging: bagging and sealing the powdered cement after grinding. Wherein, the cement bagging process described in step 4 adopts a kind of cement bagging machine cooperation. When the cement is bagged by the present invention, the sealing effect at the mouth of the bag is improved, and the powdery cement is avoided from overflowing; at the same time, the occurrence of cement powder agglomeration is avoided, the bagging efficiency is improved, and it is possible to ensure The bagging volume is the same.

Owner:内蒙古伊东冀东水泥有限公司

Composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber and preparation method thereof

ActiveCN102061047BAchieving Multiphase Composite StructuresEvenly dispersedInsulating bodiesEthylenediamineElastomer

The invention discloses a composite material combining PVC (Polyvinyl Chloride) elastomer with super high molecular weight and fluorubber. The composite material is prepared from the following raw materials in parts by weight: 50-90 parts of fluorubber, 9-30 parts of PVC elastomer with super high molecular weight and 1-20 parts of nanometer carbon black with surface modified by a silane coupling agent, wherein the silane coupling agent is N'-vinyl benzyl-N-trimethoxysilane propyl ethylenediamine salt. The invention modifies the surface of the nanometer carbon black by adopting the silane coupling agent VTSD and realizes a nanometer carbon black / PVC / fluorubber multi-phase composite structure with uniform dispersion in mixing rubber so that the modified nanometer carbon black effectively reinforces PVC / fluorubber. The invention also discloses a preparation method of the composite material, and the method is simple, easy to control and suitable for industrial production.

Owner:杭州顺和轨道交通新材料有限公司

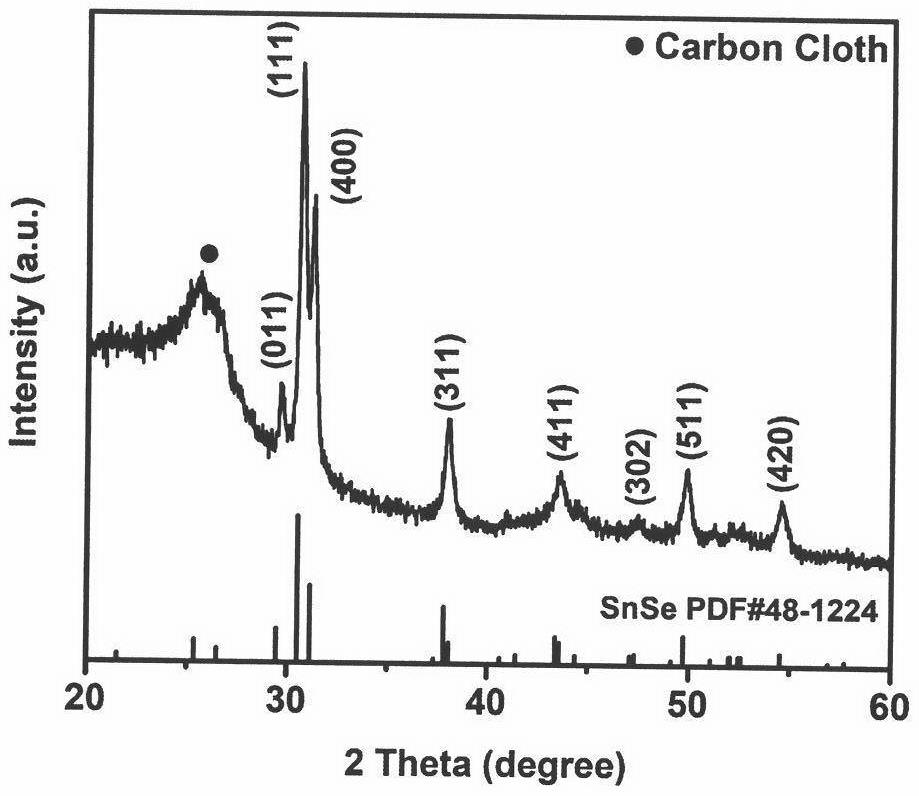

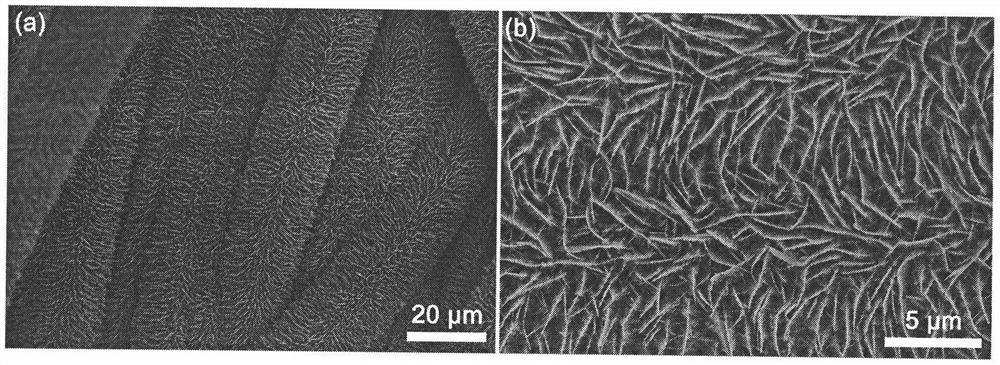

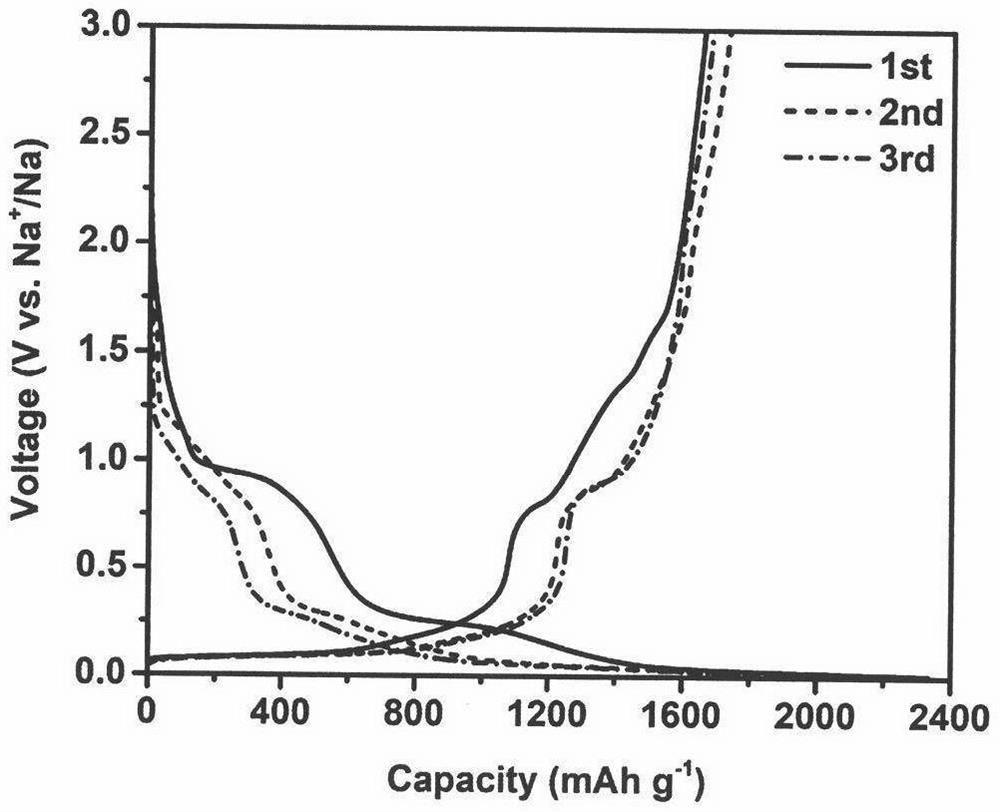

Tin selenide nanosheet array/carbon cloth composite negative electrode material structure for sodium ion battery

PendingCN114583160AAvoid joiningAvoid reunion situationsCell electrodesElectrical batterySodium-ion battery

The invention provides a tin selenide nanosheet array / carbon cloth composite negative electrode material structure for a sodium ion battery, and belongs to the technical field of nano materials and batteries. The negative electrode material structure is prepared by adopting a simple vacuum thermal evaporation technology, and tin selenide powder is heated to a certain temperature in a vacuum environment to sublimate and deposit on carbon cloth to form a tin selenide nanosheet array, so that the composite negative electrode material structure is formed. The tin selenide nanosheet array uniformly covers the surface of the carbon cloth, so that each nanosheet can contribute effective capacity, the agglomeration phenomenon of a powder material can be effectively avoided, and the specific capacity and the cycling stability of the material are improved. And the composite negative electrode structure has the flexibility of the carbon cloth, and the conductivity of the composite negative electrode structure is improved by the carbon cloth. Compared with a traditional battery negative electrode material, the structure does not need to use a binder and a conductive agent, can be directly used as a sodium ion battery negative electrode, has high specific capacity and has a good application prospect.

Owner:GUANGDONG UNIV OF TECH

Graphite electrode negative electrode powder and preparation method thereof

ActiveCN111668486AAvoid reunion situationsExtended service lifeCell electrodesGraphite electrodeLead oxide

The invention relates to the technical field of electrodes, and particularly relates to graphite electrode negative electrode powder. The graphite electrode negative electrode powder comprises the following components: 10-15 parts of lead oxide, 5-8 parts of magnesium oxide, 20-30 parts of graphite, 1-2 parts of a smoothing agent, 2-4 parts of a dispersing agent and 0.5-1 part of a drying agent. The invention also provides a preparation method of the graphite electrode negative electrode powder. The graphite electrode negative electrode powder has the characteristics that agglomeration of thenegative electrode powder is avoided, so that contact points between particles are facilitated to increase the specific surface area, the capacity of the battery is improved, and meanwhile, the service life of the battery is prolonged.

Owner:宁夏众城新能源科技有限公司

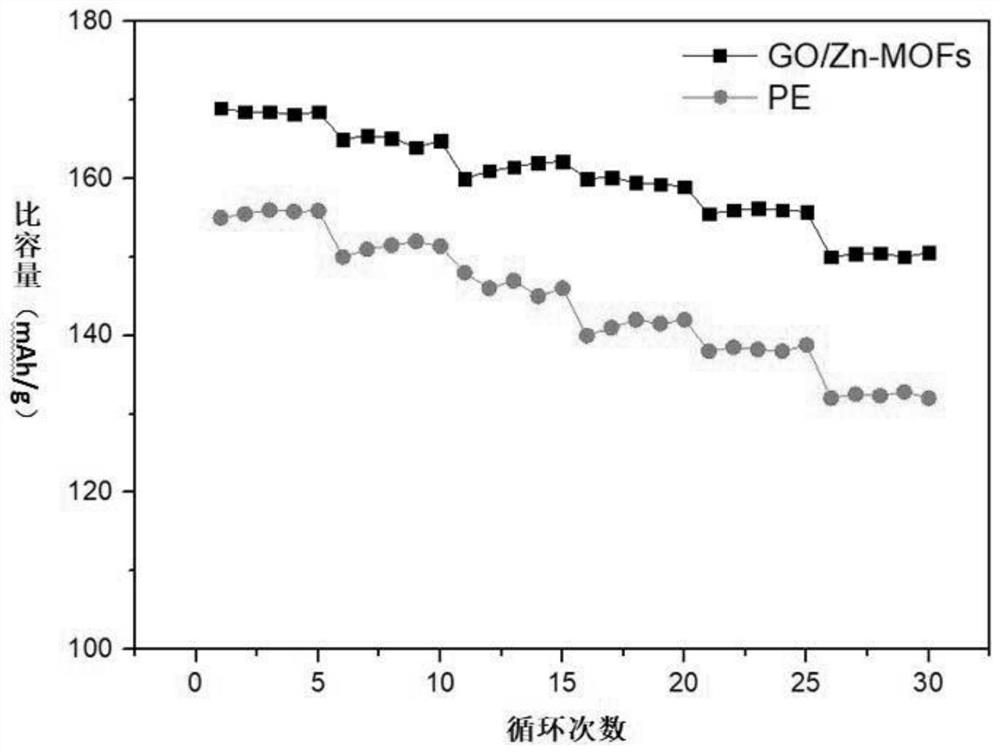

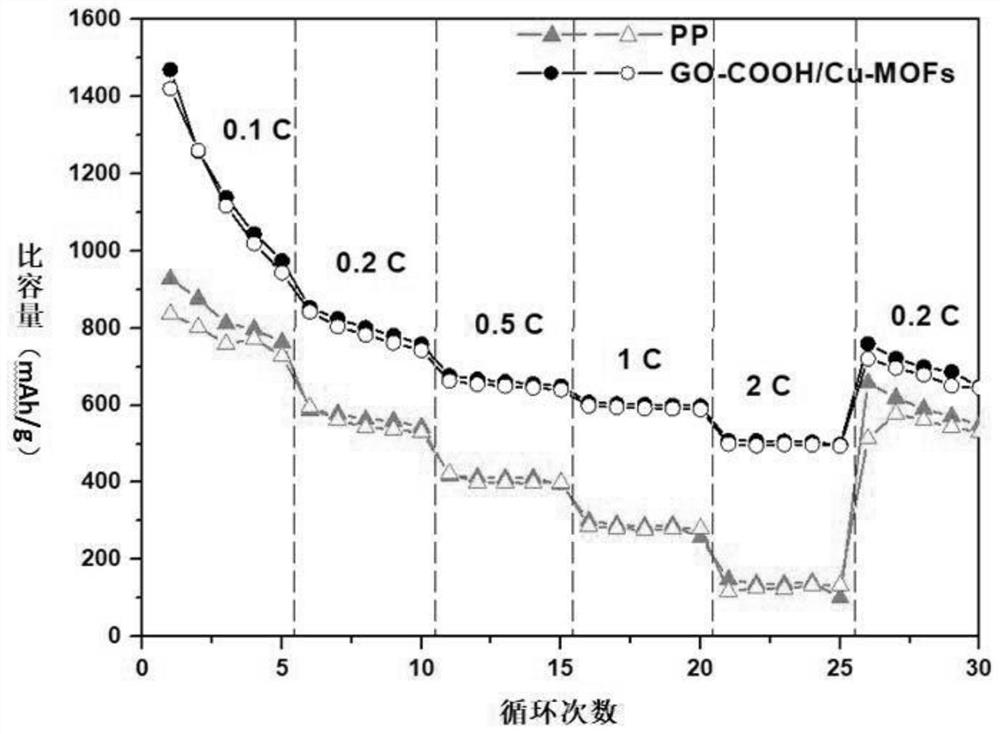

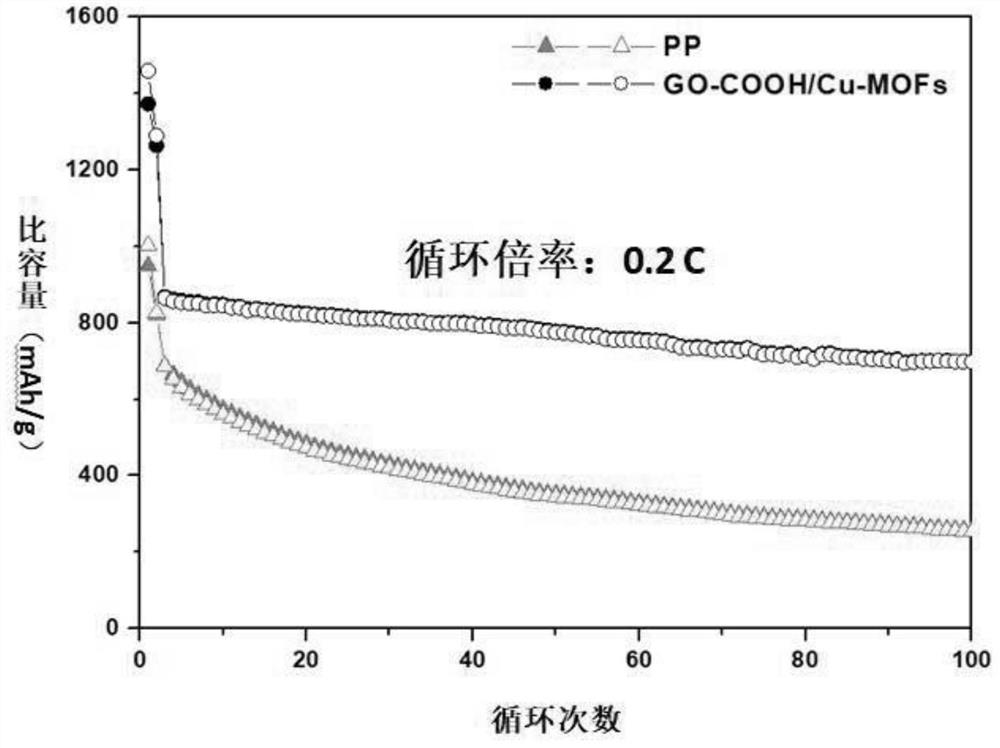

Multifunctional thin film for energy storage device and preparation method thereof

PendingCN113991241AImprove wettabilityInhibition of the shuttle effectGrapheneCell component detailsElectrolytic agentNew energy

The invention relates to a multifunctional thin film for an energy storage device and a preparation method. The preparation method comprises the following steps: firstly, dispersing a graphene-based material, a metal-organic framework material or a precursor of the metal-organic framework material into a solvent respectively; obtaining a graphene-based material dispersion liquid, a metal-organic framework material dispersion liquid or a precursor dispersion liquid of the metal-organic framework material respectively; mixing the graphene-based material dispersion liquid with the metal-organic framework material dispersion liquid or the precursor dispersion liquid of the metal-organic framework material to obtain a mixed system; transferring the mixed system to a planar substrate; and removing the solvent to obtain the multifunctional film for the energy storage device. On the premise of ensuring good wettability, the prepared thin film also has good multiplying power and cycle performance, has good tensile strength and puncture resistance, is suitable for new energy storage devices, and overcomes the defects that a traditional thin film is poor in mechanical performance, poor in electrolyte wettability, complex in preparation process and the like.

Owner:LUOYANG NORMAL UNIV

Cement production method

The invention belongs to the technical field of cement manufacturing and particularly relates to a cement production method. The method comprises the steps of first, raw material grinding, wherein limestone and clay are homogenized after being broken and ground; second, clinker calcination, wherein homogenized raw material particles are sent into a preheater and a rotary kiln for calcination and curing; third, cement grinding, wherein calcined clinkers are ground to appropriate granularity, and a certain particle grading is formed; and fourth, cement bagging, wherein ground powdery cement is bagged and sealed. In the fourth step, a cement bagging machine is adopted for cooperation in the cement bagging process. When the cement is bagged through the method, the sealing effect at a bag opening is improved, and overflow of the powdery cement is avoided; and meanwhile, the situation of cement powder aggregation is avoided, bagging efficiency is improved, and it can be guaranteed that the bagging amount is identical every time.

Owner:内蒙古伊东冀东水泥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com