A kind of highly conductive lithium iron phosphate powder and preparation method thereof

A lithium iron phosphate, high-conductivity technology, applied in the direction of electrode manufacturing, circuits, electrical components, etc., can solve problems such as insufficient purity, increased production energy consumption costs, operational complexity, and long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

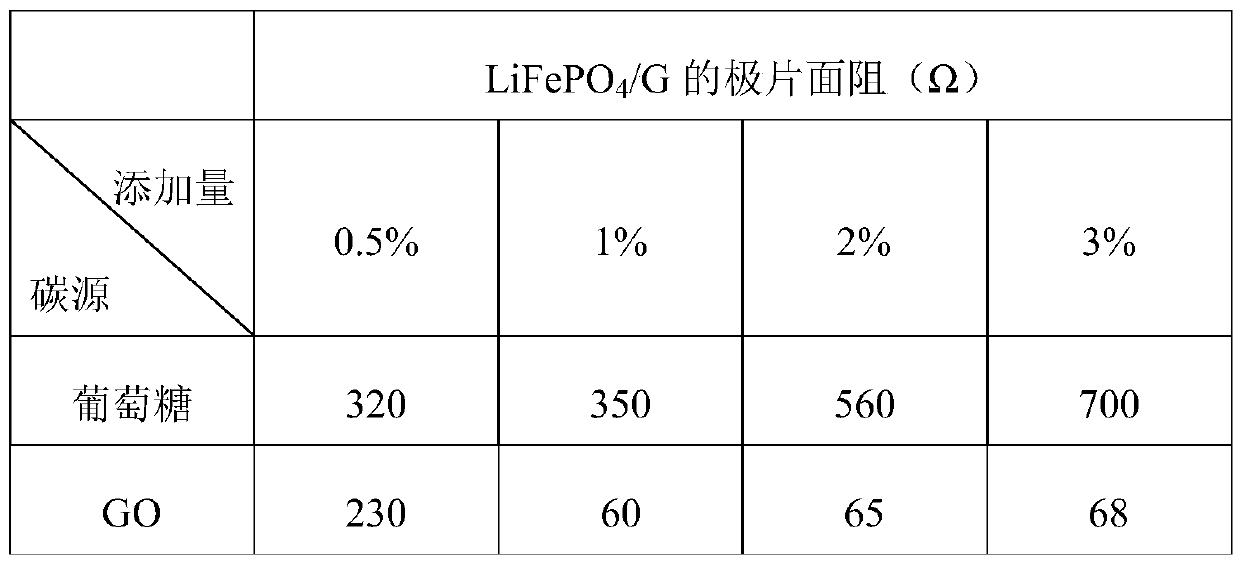

[0039] An embodiment of the present invention provides a method for preparing a highly conductive lithium iron phosphate powder, comprising the following steps:

[0040] 1) Formation of highly conductive lithium iron phosphate precursor

[0041] Lithium hydroxide solution is stirred and mixed with phosphoric acid;

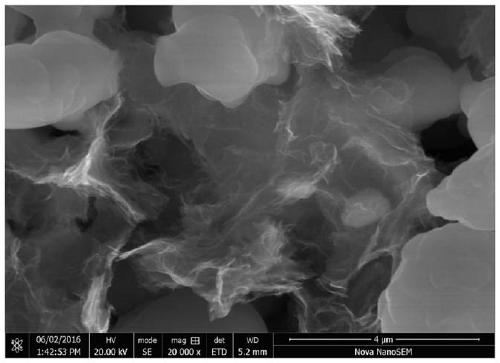

[0042] Then add the graphene oxide dispersion and stir;

[0043] Then add ferrous sulfate heptahydrate, stir to obtain a uniform mixture;

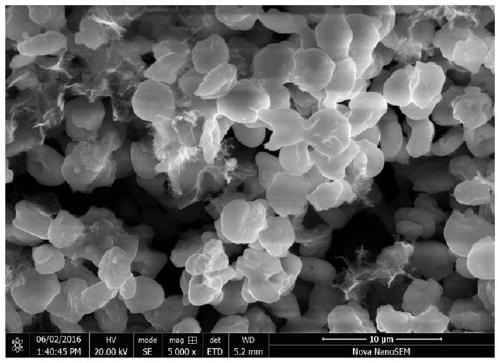

[0044] The mixture is filtered, washed, and dried to obtain a black powder, which is the precursor of highly conductive lithium iron phosphate;

[0045] 2) Formation of highly conductive lithium iron phosphate powder

[0046] The precursor of the highly conductive lithium iron phosphate obtained in step 1) is uniformly blended with lithium carbonate ball mill, and then calcined under an atmosphere of an inert gas to obtain a highly conductive lithium iron phosphate powder.

[0047]In one aspect of this embodiment, in the st...

Embodiment 1

[0057] 1) Lithium hydroxide is dissolved in water, then phosphoric acid is added in the lithium hydroxide solution according to the amount ratio of 1.0:2.0 with lithium hydroxide substance, magnetic stirring forms uniform solution;

[0058] 2) Add the graphene oxide dispersion with a concentration of 1 mg / mL into the above homogeneous solution according to 0.1 wt% of the added amount of ferrous sulfate heptahydrate, and magnetically stir until the mixed solution is uniform;

[0059] 3) Add ferrous sulfate heptahydrate to the above-mentioned homogeneous mixture according to the ratio of 1.0:1.0 to the amount of phosphoric acid, keep magnetic stirring, keep warm in a water bath at 40°C for a certain period of 20 minutes, and obtain a uniform mixing system;

[0060] 4) The mixed system is filtered, washed, and dried to obtain a black highly conductive lithium iron phosphate precursor;

[0061] 5) After uniformly blending the black highly conductive lithium iron phosphate precurso...

Embodiment 2

[0063] 1) Lithium hydroxide is dissolved in water, then phosphoric acid is added in the lithium hydroxide solution according to the amount ratio 2.0:0.5 with lithium hydroxide substance, magnetic stirring forms uniform solution;

[0064] 2) Add the graphene oxide dispersion with a concentration of 5 mg / mL into the above homogeneous solution according to 0.2 wt% of the added amount of ferrous sulfate heptahydrate, and magnetically stir until the mixed solution is uniform;

[0065] 3) Add ferrous sulfate heptahydrate to the above-mentioned uniform mixture according to the ratio of 1.0:1.5 to the amount of phosphoric acid substance, keep magnetic stirring, keep warm in a water bath at 45°C for a certain period of time for 30min, and obtain a uniform mixing system;

[0066] 4) The mixed system is filtered, washed and dried to obtain a black highly conductive lithium iron phosphate precursor;

[0067] 5) After uniformly blending the black highly conductive lithium iron phosphate pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com