High-impregnation-degree long glass fiber reinforced polypropylene composite material and preparation method thereof

A technology of composite material and impregnation degree, which is applied in the field of long glass fiber reinforced polypropylene composite material with high impregnation degree and its preparation, can solve the problems of reducing the interaction force and not improving the impregnation degree of glass fiber, so as to increase energy consumption and impact The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

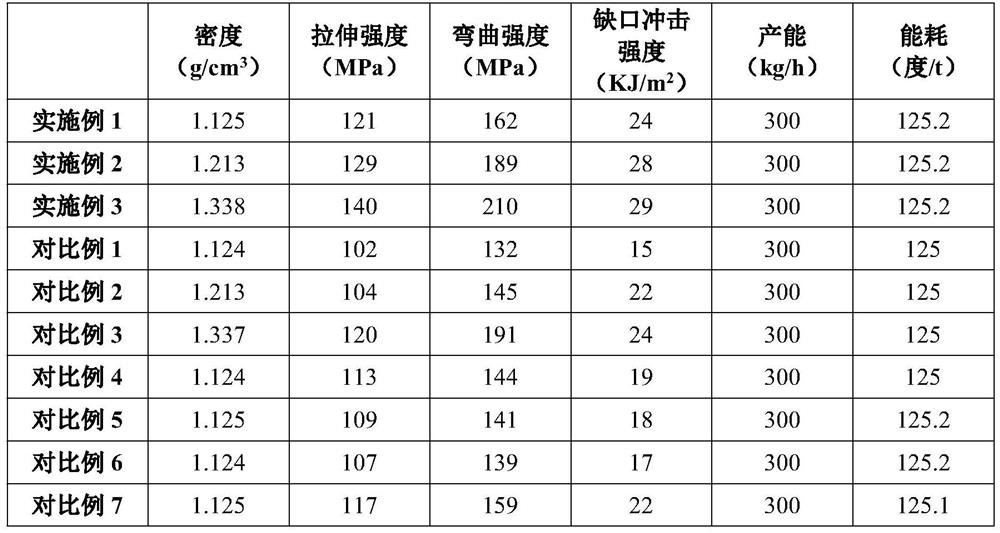

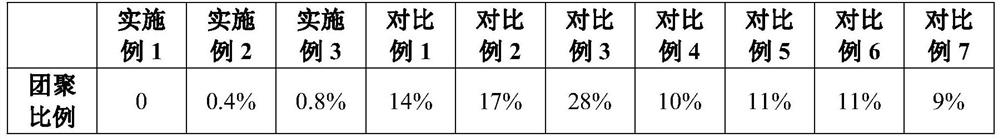

Examples

Embodiment 1

[0023] 1) The continuous glass fiber passes through the glass fiber heating and pre-dispersing device and the cooling device on the drawing line, then passes through the silk friction and electrification, and finally passes through the static electricity generating device, and then enters the impregnation tank with polypropylene melt. The electrostatic generating device is composed of two parts, the first part is composed of electrostatic electret electrostatic generator, high voltage wire, bracket, insulating support, molybdenum wire parts; the second part is composed of heating device;

[0024] 2) Weigh 63.2 parts of raw material polypropylene resin (Yangzi Petrochemical XPJ-3100H, melting value 100g / 10min, 2.16kg, 230°C) according to the weight ratio, and dry in an oven; add 5 parts of maleic anhydride grafted poly Propylene, 3 parts of maleic anhydride grafted EPDM, 0.2 part of hindered phenol antioxidant 1010, 0.1 part of phosphite antioxidant 168, and 0.5 part of pentaery...

Embodiment 2

[0027] 1) The continuous glass fiber passes through the glass fiber heating and pre-dispersing device and the cooling device on the drawing line, then passes through the silk friction and electrification, and finally passes through the static electricity generating device, and then enters the impregnation tank with polypropylene melt. The electrostatic generating device is composed of two parts, the first part is composed of electrostatic electret electrostatic generator, high voltage wire, bracket, insulating support, molybdenum wire parts; the second part is composed of heating device;

[0028] 2) Weigh 53.2 parts of raw material polypropylene resin (Yangzi Petrochemical XPJ-3100H, melting value 100g / 10min, 2.16kg, 230°C) according to the weight ratio, and dry in an oven; add 4 parts of maleic anhydride grafted poly Propylene, 3 parts of maleic anhydride grafted POE, 0.2 part of hindered phenol antioxidant 1010, 0.1 part of phosphite antioxidant 168, and 0.5 part of glyceryl ...

Embodiment 3

[0031] 1) The continuous glass fiber passes through the glass fiber heating and pre-dispersing device and the cooling device on the drawing line, then passes through the silk friction and electrification, and finally passes through the static electricity generating device, and then enters the impregnation tank with polypropylene melt. The electrostatic generating device is composed of two parts, the first part is composed of electrostatic electret electrostatic generator, high voltage wire, bracket, insulating support, molybdenum wire parts; the second part is composed of heating device;

[0032] 2) Weigh 43.2 parts of raw material polypropylene resin (Yangzi Petrochemical XPJ-3100H, melting value 100g / 10min, 2.16kg, 230°C) according to the weight ratio, and dry in an oven; add 3 parts of maleic anhydride grafted poly Propylene, 3 parts of maleic anhydride grafted SEBS, 0.3 part of antioxidant GA80, and 0.3 part of erucamide are stirred and mixed evenly in a high-speed machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com