Patents

Literature

50results about How to "Reserve length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of high-performance latex paper

InactiveCN102191725AImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensile strength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

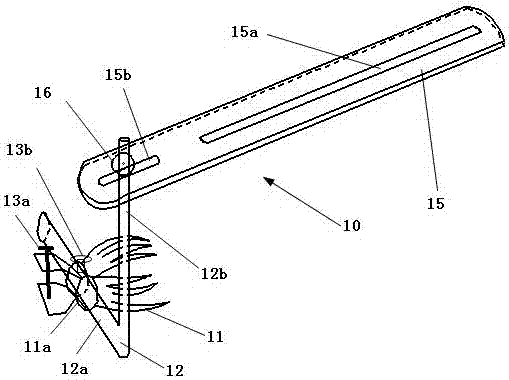

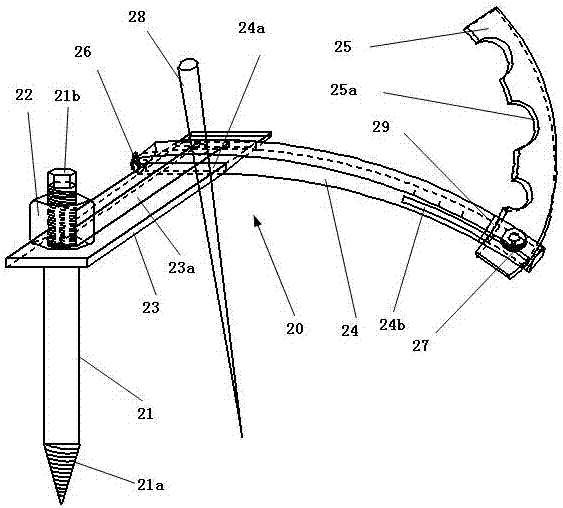

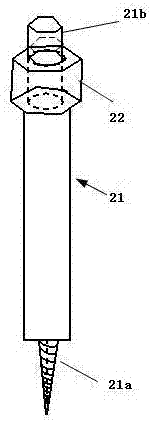

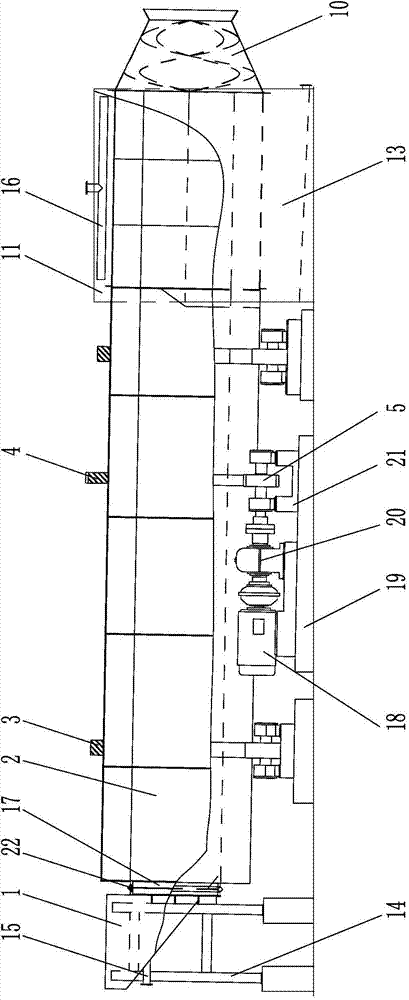

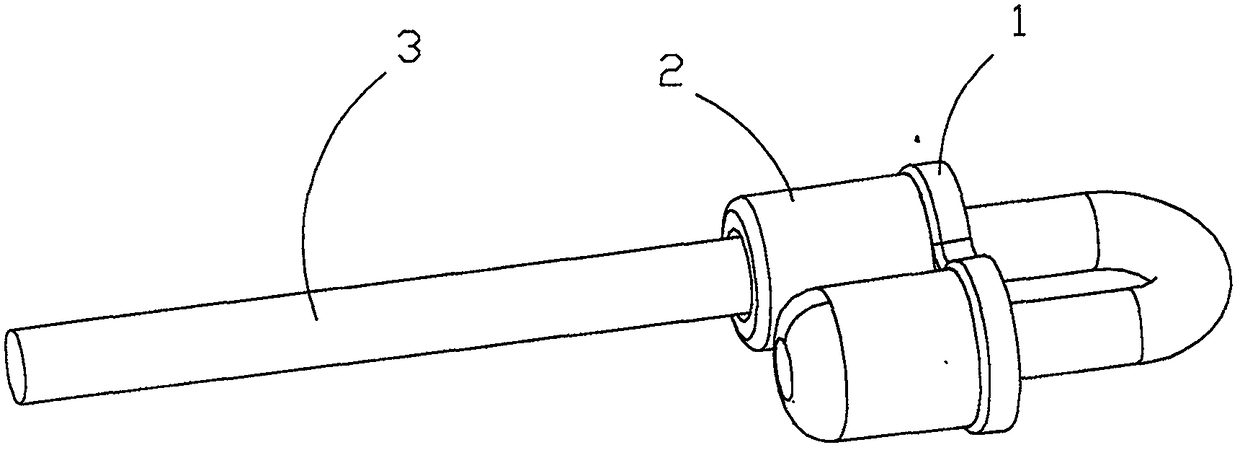

Complete locating device for total hip arthroplsty

PendingCN107149490AReduce the chance and degree of loosening or saggingGuaranteed stabilitySurgical sawsBone drill guidesMedullary cavityCalcar

The invention discloses a complete set of positioning device for artificial total hip joint replacement, which belongs to the field of medical equipment. The positioning device is conducive to the accurate osteotomy of the femoral neck with the oscillating saw, the accurate positioning of the use direction of the acetabular file, the square head bone knife, and the medullary cavity file, and the insertion of the femoral prosthesis into the femoral marrow at the original position and original angle. The cavity is beneficial to preserve the femoral calcar and the length of the femoral neck, which is conducive to the correct placement of the acetabular cup, shortens the operation time, reduces intraoperative bleeding, improves the success rate of the operation, relieves joint pain, corrects deformity, restores and improves joint movement Function.

Owner:汤向阳

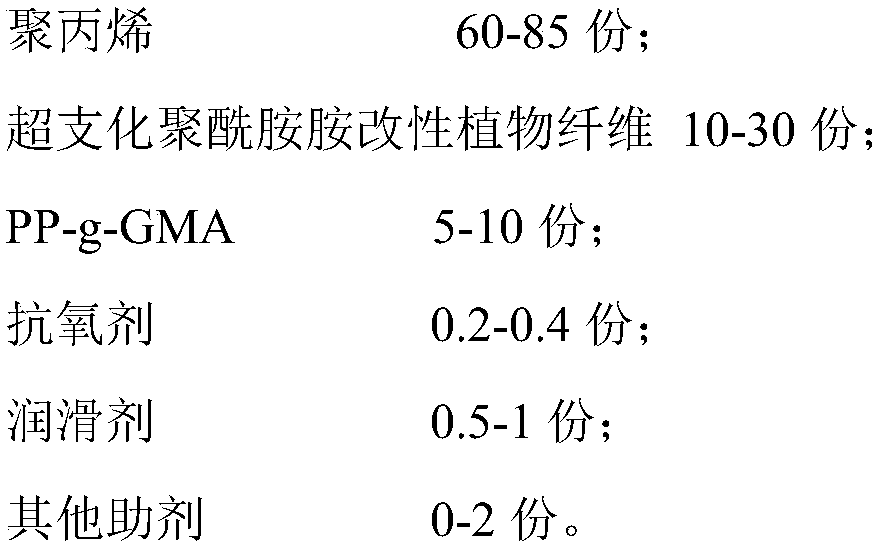

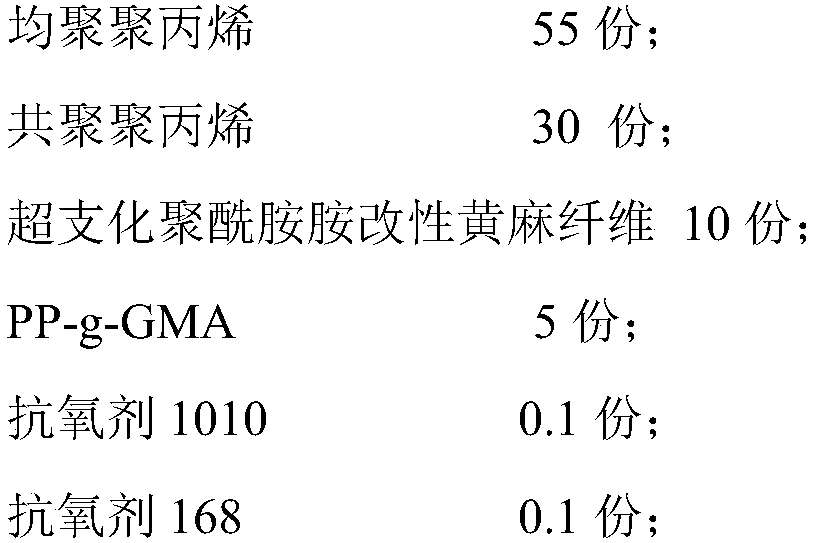

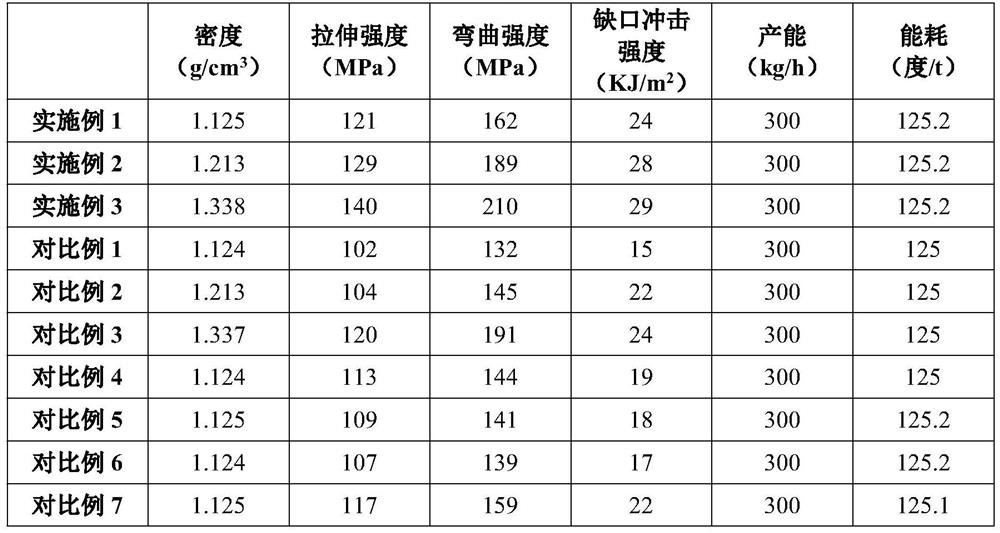

Hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro foaming material and preparation method thereof

InactiveCN108192200AImprove surface activityImprove compatibilityPolypropylene compositesMaterials science

The invention discloses a hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro foaming composite material and a preparation method thereof. The hyperbranched polyamidoaminemodified plant fiber reinforced polypropylene micro foaming composite material consists of 97-98 wt% of polypropylene composite material and 2-3 wt% of chemical foaming agent, wherein the polypropylene composite material consists of polypropylene, hyperbranched polyamidoamine plant fiber, PP-g-GMA, antioxidant, lubricant and other additives. The hyperbranched polyamidoamine modified plant fiber reinforced polypropylene micro foaming composite material has the characteristics of low density, high strength, high rigidity, fine cell pores, uniform distribution, etc., can meet application requirements of automobile parts, adapts to development concepts of energy saving and environmental friendliness, and is in line with the development trend of automotive lightweight, therefore, the materialhas a broad development prospect in the field of automobiles.

Owner:ORINKO NEW MATERIAL CO LTD

Production method of non heat seal teabag paper

InactiveCN102877378ARetain fiber lengthGuaranteed bondingReinforcing agents additionPaper/cardboardProcess engineeringSizing

The invention discloses a production method of non heat seal teabag paper. Final products can be obtained through a surface sizing process or a coating process in the existing production method of the non heat seal teabag paper, and a plurality of adhesives and additives are needed to add. The production method includes subjecting plant fibers to special processing, and reserving the length of fibers as far as possible during fully fibrillation; and adding appropriate thermosetting type reinforcing agent into the fiber after the special processing to obtain a body paper product through papermaking. The body paper product can be used directly without the surface sizing and the follow-up coating processing and can adapt to processing requirements for modern high-speed packing machines. According to the production method, the defect that final products can be obtained through the surface sizing or coating in the existing production method of the non heat seal teabag paper is overcome, the paper is formed once, the surface sizing or coating process is reduced, usage of chemical additives in the non heat seal teabag paper is reduced, obtained products are environment-friendly and good in processability, simultaneously, the production process is simplified, and the energy consumption and cost are reduced.

Owner:ZHEJIANG WINBON SPECIALTY PAPER

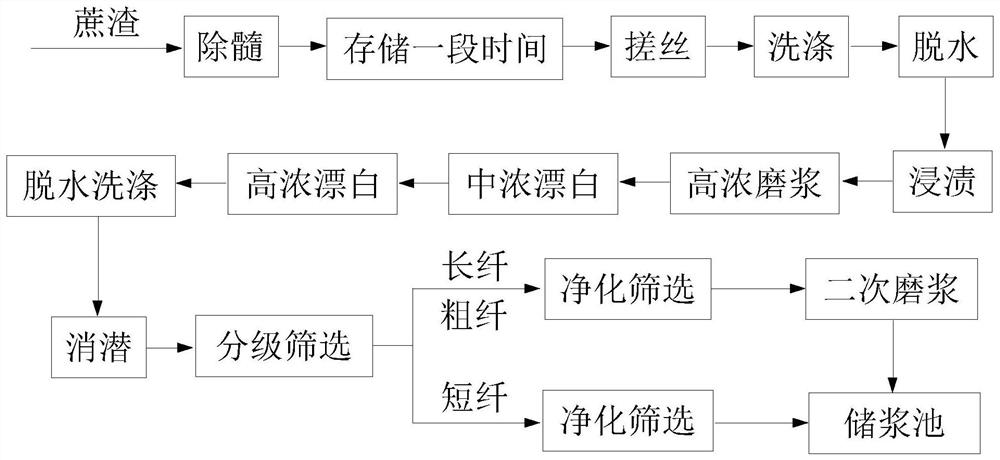

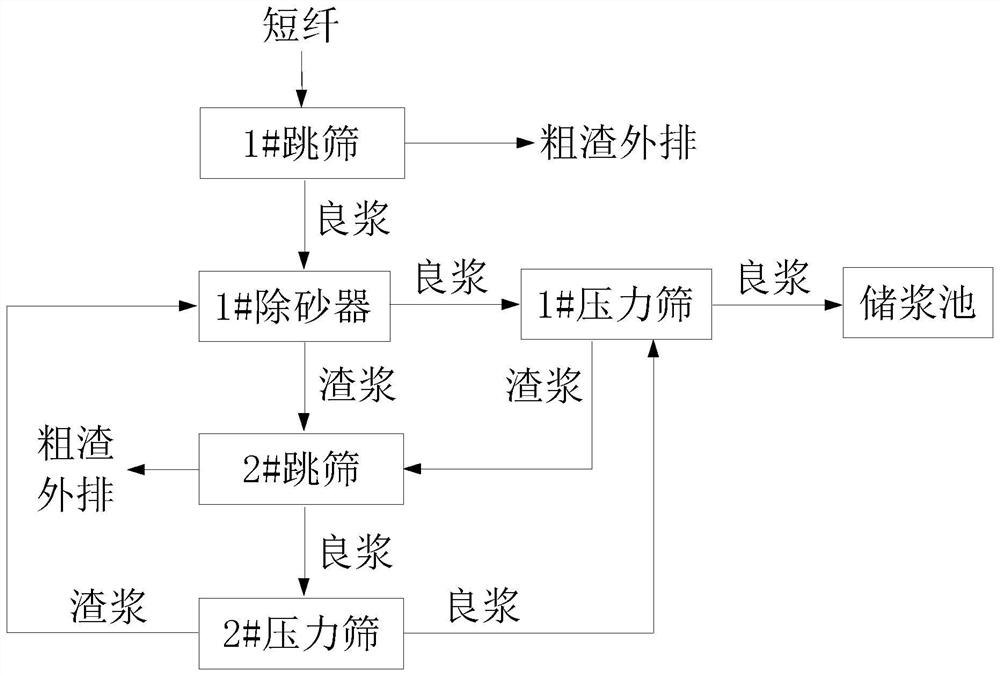

Straw and/ or ryegrass raw material semi-chemical pulp preparation method

InactiveCN101260630AImprove plasticityReduce cut-offPulp de-wateringPulp beating/refining methodsFiberEnergy consumption

The invention discloses a semi-chemical pulp preparation method of a straw and / or wheat straw hood raw material, comprising the following steps that: (1) after the straw and / or wheat straw hood raw material is processed by the chemical pre-dipping treatment or is boiled, the straw and / or wheat straw hood raw material is sent to a hydrabrusher to dilute and disperse, the concentration is added with water to adjusted within the range of 2.5 to 4.5 percent, and the straw and / or wheat straw hood raw material is dispersed into even materials; (2) the diluted and dispersed material is sent to a fluffer by a pump to process, the straw and / or wheat straw hood raw material is dispersed and disintegrated to become a fasciculus; (3) the dewatering and concentrating are performed: the paste after dispersed and disintegrated by the fluffer is transported to a dewatering device to dewater and is concentrated to a solution with a concentration ranging from 6 to 10 percent; (4) the pulping is performed: the dewaterd and concentrated pulp is pumped up to a disk grinder to perform the pulping in order to obtain the pulp for papermaking. The preparation method effectively keeps the fiber length, improves the intensity performance of the paper and has low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing tobacco sheets through tobacco waste materials by papermaking method

InactiveCN102318895AReduce cut-offGood physical propertiesTobacco preparationPapermakingPulp treatment

The invention provides a method for preparing tobacco sheets through tobacco waste materials by a papermaking method, which comprises the following steps of: respectively soaking tobacco powder and mixtures of washed tobacco stems and crumbled tobacco leaves into water, carrying out extraction, respectively obtaining solid tobacco stems, tobacco leaf mixtures, solid smoke powder and two kinds of extraction liquid through solid and liquid separation, and combining two kinds of extraction liquid; regulating the tobacco stem and tobacco leaf mixtures obtained through extraction into the materialconcentration being 15 to 30 percent, and then carrying out defibering; regulating the defibered materials into the concentration being 6 to 12 percent and carrying out pulping treatment; diluting the solid smoke powder and the pulped pulp materials to the required concentration after mixing, and making the materials into substrates by a papermaking method after sieving; and concentrating the combined extraction liquid, using the concentrated extraction liquid as coating liquid to be coated on the substrates, and drying and cutting the substrates into tobacco sheet products. The preparation method provided by the invention has the advantages that the damage to material tissue structures in the preparation process is effectively reduced, the physical performance of the tobacco sheets is improved, the yield is high, and the energy consumption is low.

Owner:SOUTH CHINA UNIV OF TECH +2

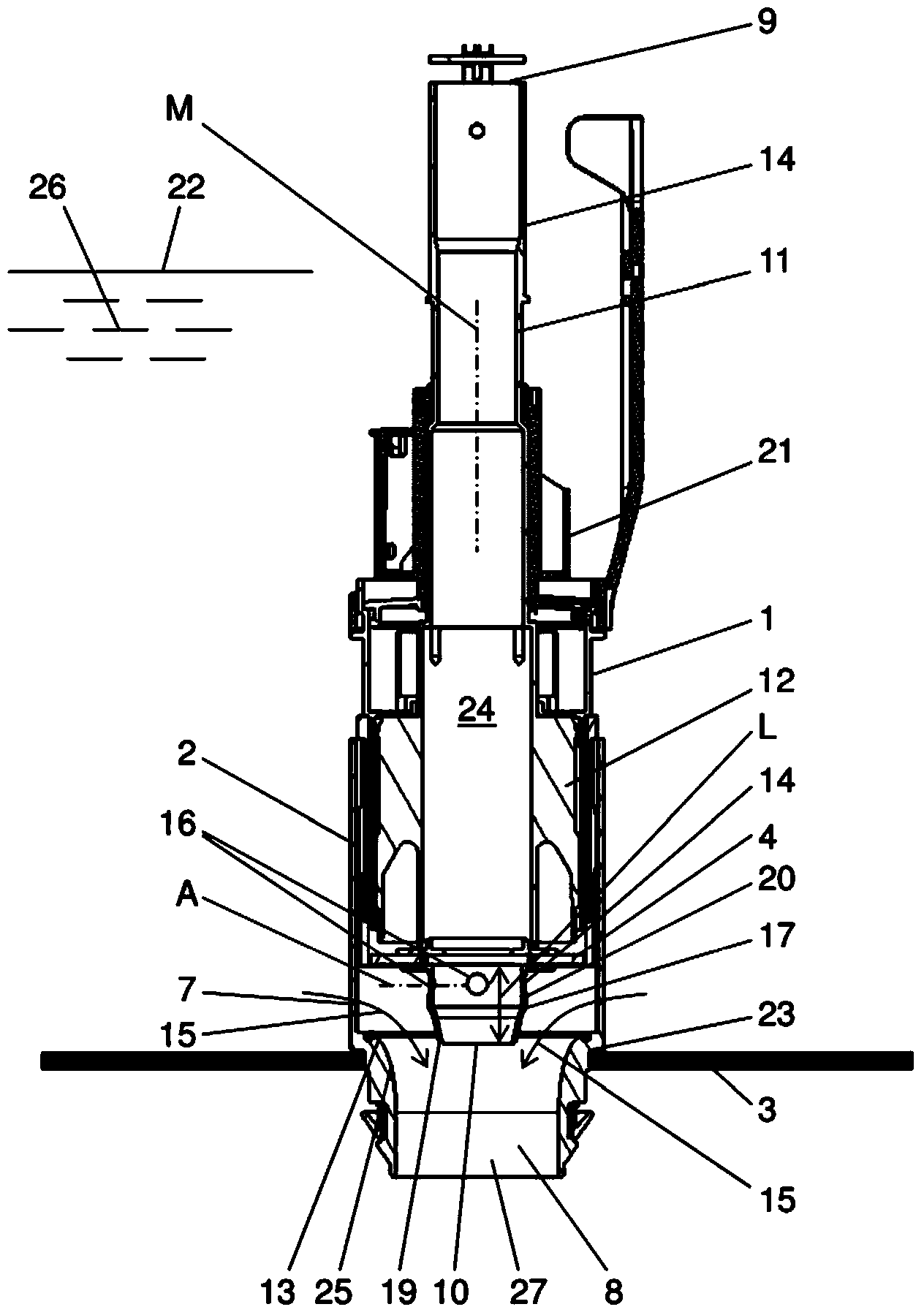

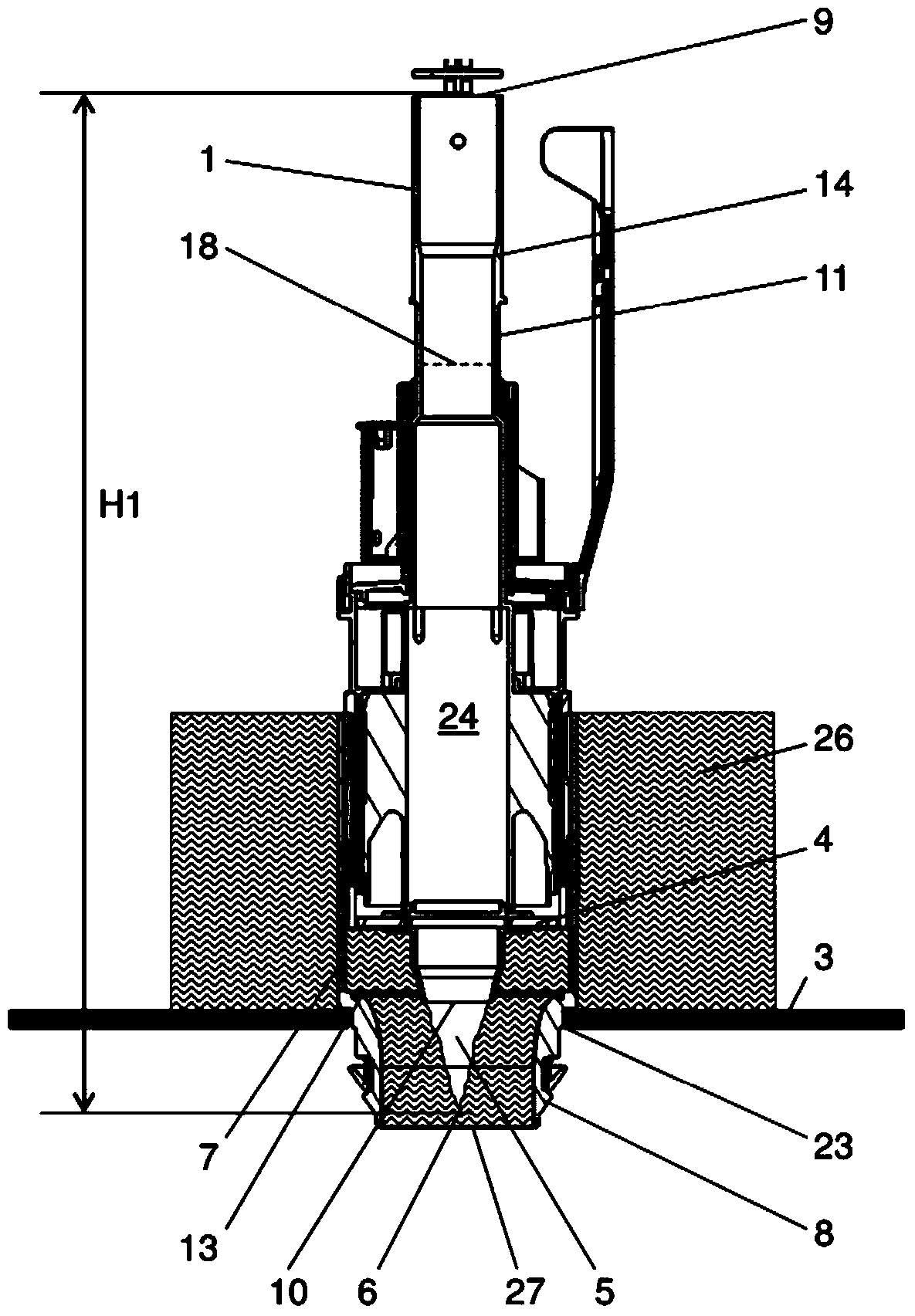

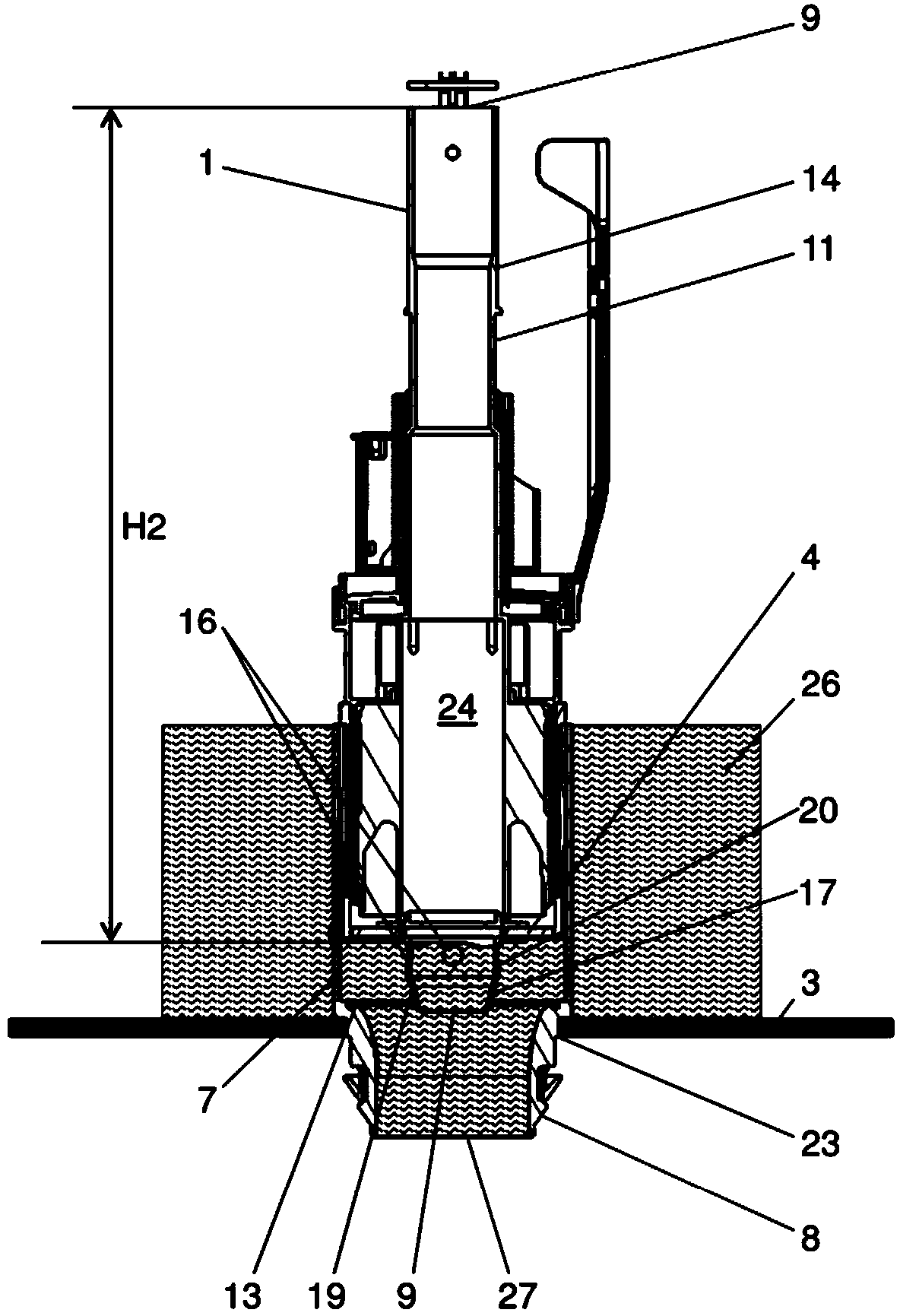

Outlet fitting for a toilet cistern

InactiveCN103981934AImprove noisePrevent throat noiseFlushing devicesLavatory sanitoryCisternMechanical engineering

The invention provides an outlet fitting for a toilet cistern. The fitting (1) has a valve seat (13) arranged before an outlet opening (27) when viewed in a flow direction. A sealing element (4) of an overflow pipe (11) operates together with the valve seat (13). The pipe is upwardly moved for triggering flushing. The pipe (11) includes an inlet opening (9), an outlet opening (10), and a pipe wall (14), which circulates around a middle axis (M). At least one recess (16) is arranged in the wall (14) in a lower region (17) of the overflow pipe (11).

Owner:GEBRERIT INT

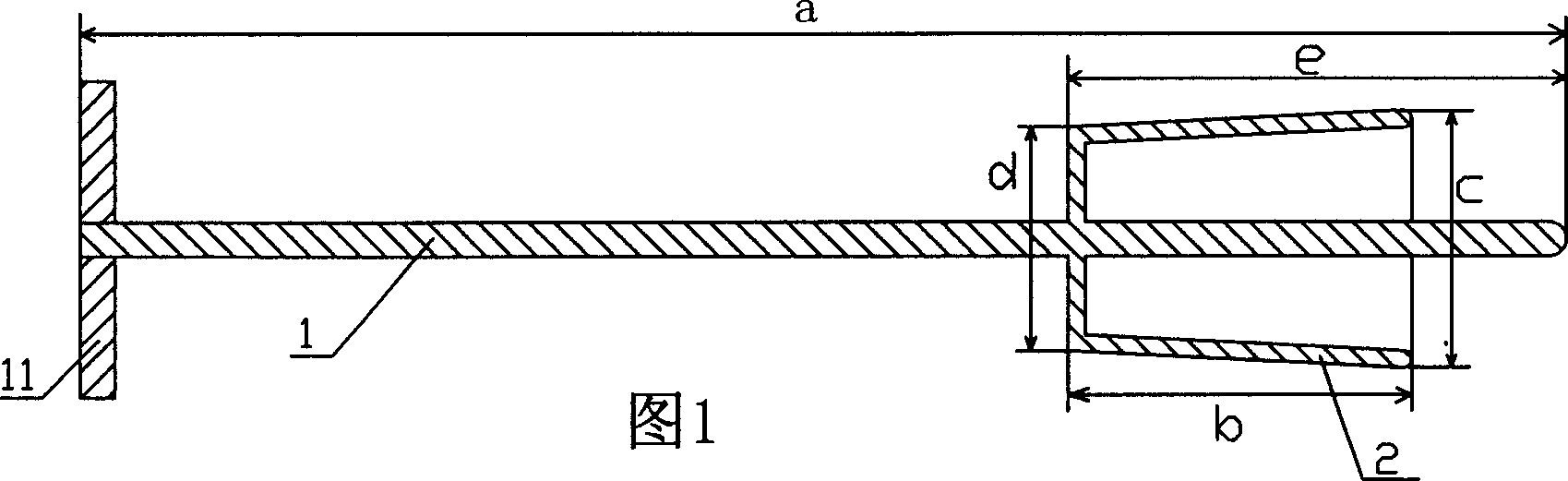

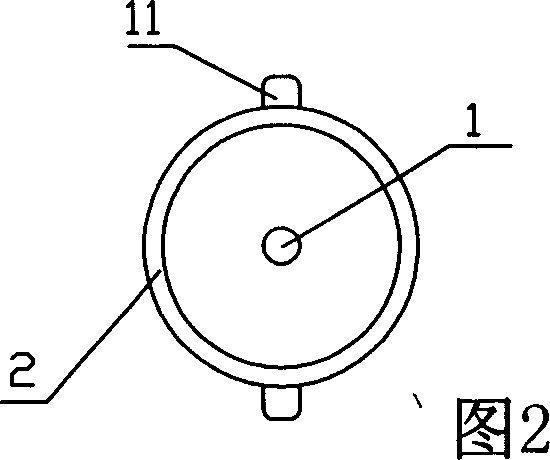

Special vaginal foraix location retractor for hysterectomy under peritoneoscope

A fornix vaginae locating retractor for the hysterectomy by use of peritoneoscope is composed of a cup shaped sleeve tube and a rod unit passing through the cup bottom of said cup-shaped sleeve tube and with a front end extended out of the cup mouth and a tail end as handle.

Owner:JINAN UNIVERSITY

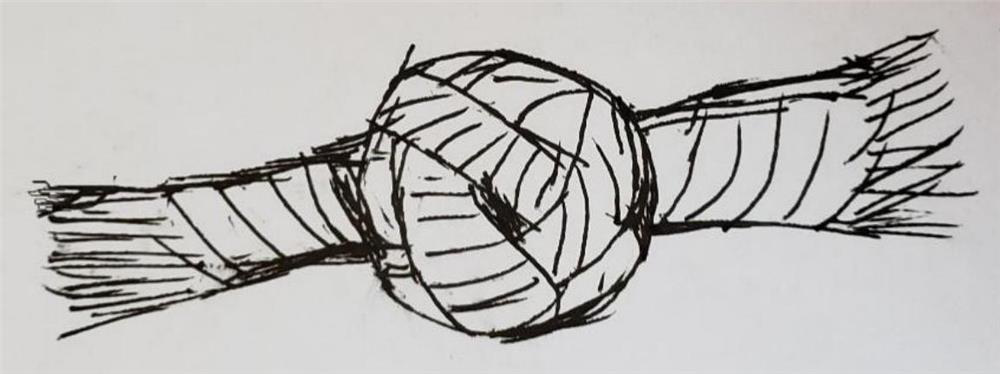

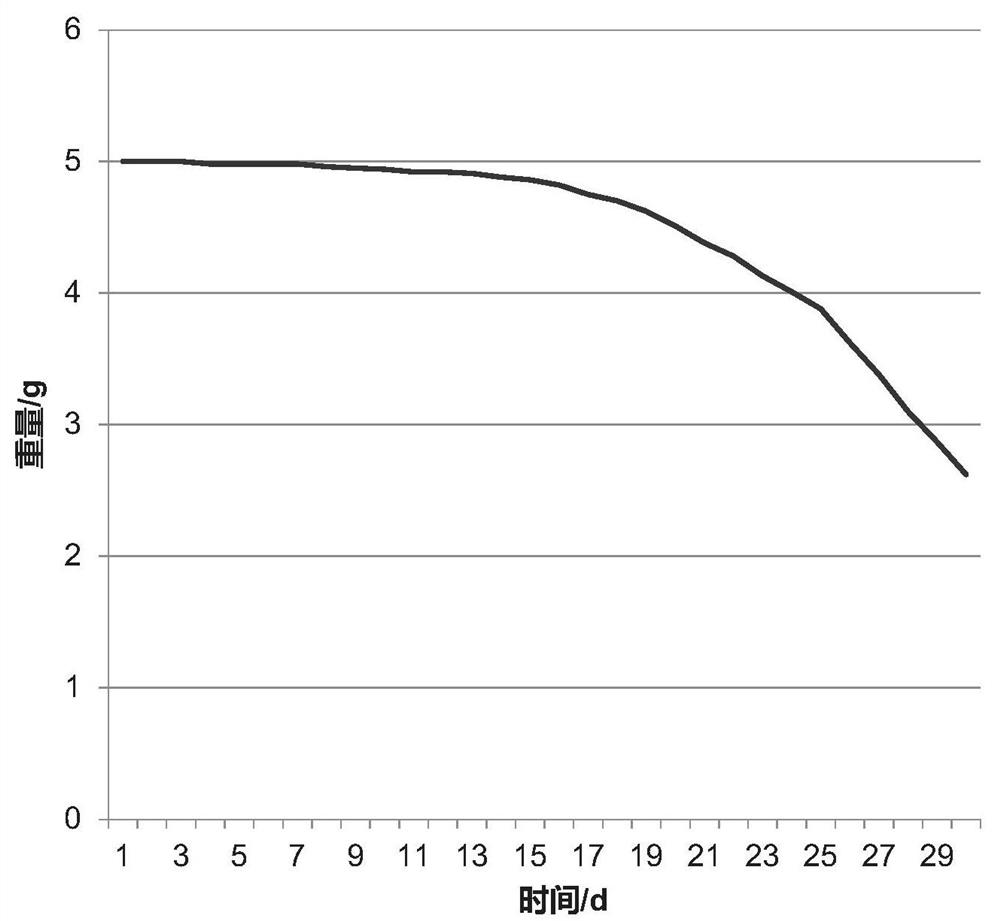

Novel environment-friendly biological knot and use method thereof

ActiveCN113027379AAvoid enteringWon't leaveFluid removalSealing/packingFiberArchitectural engineering

The invention discloses an environment-friendly biological knot which adopts a rope knot type design, is used for staged fracturing and can replace a bridge plug and a use method of the environment-friendly biological knot. Degradable fiber materials with the tensile strength greater than 120 MPa are woven into a rope, then, the rope is made into a rope knot, and woven lines with certain lengths are respectively reserved at two ends of the rope knot. The diameter of the environment-friendly biological knot used for staged fracturing and capable of replacing the bridge plug is prepared according to the size of a hole needing to be plugged. The construction risk of the bridge plug is reduced, the reservoir is uniformly fractured, and staged fracturing can be performed on the casing deformation section; section loss of a casing deformation well is avoided; staged fracturing can be performed on the casing deformation section according to design; and the influence of casing deformation on the yield of the well is reduced. Meanwhile, the construction defects of the existing temporary plugging ball and temporary plugging agent are overcome.

Owner:SICHUAN WELDON CHEM

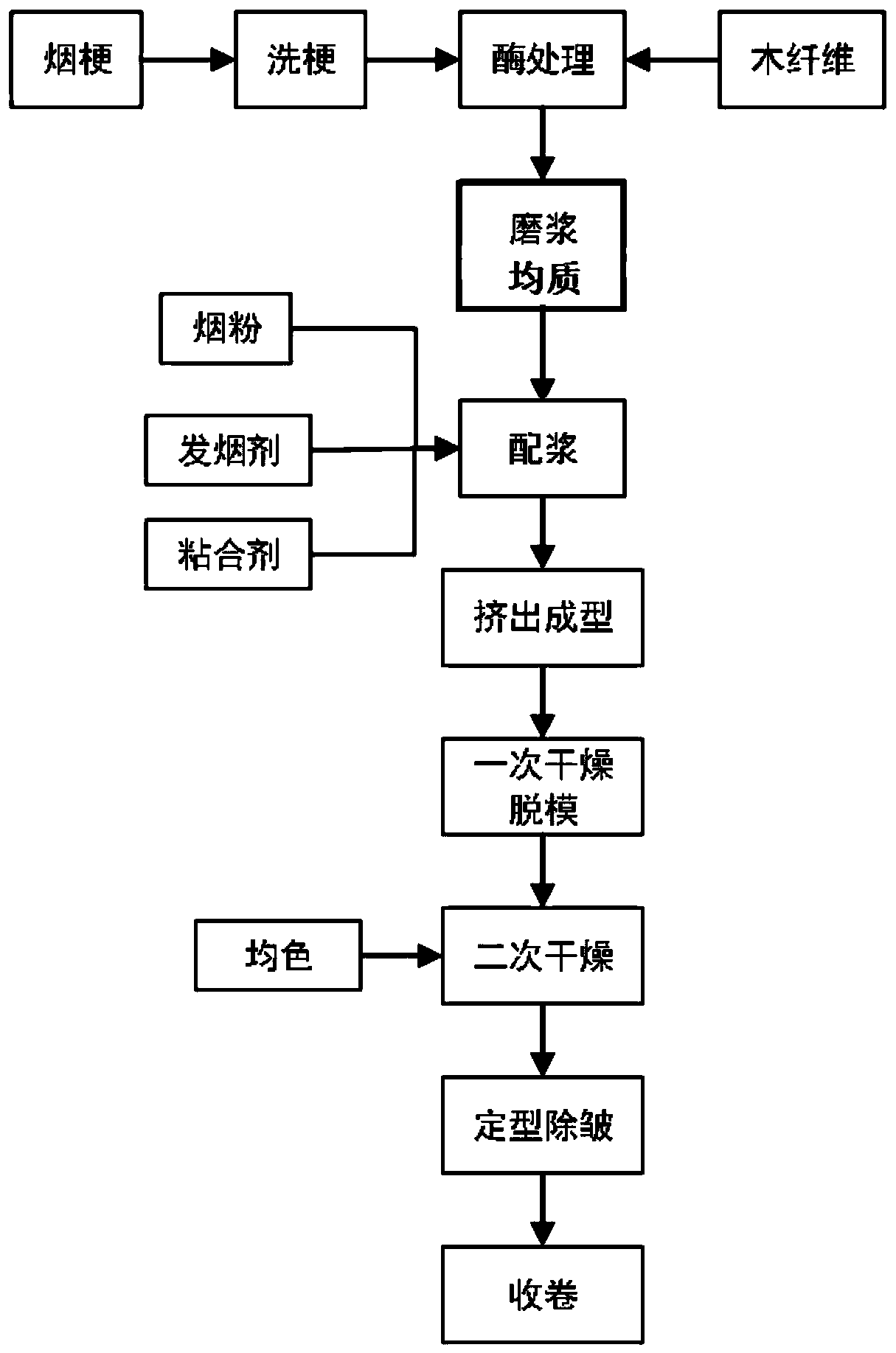

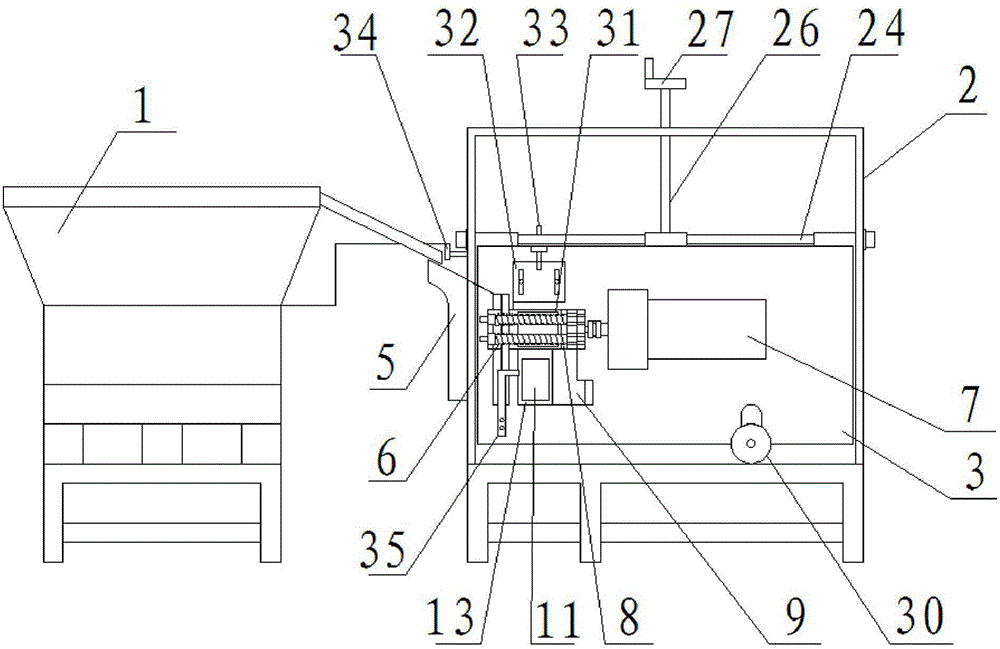

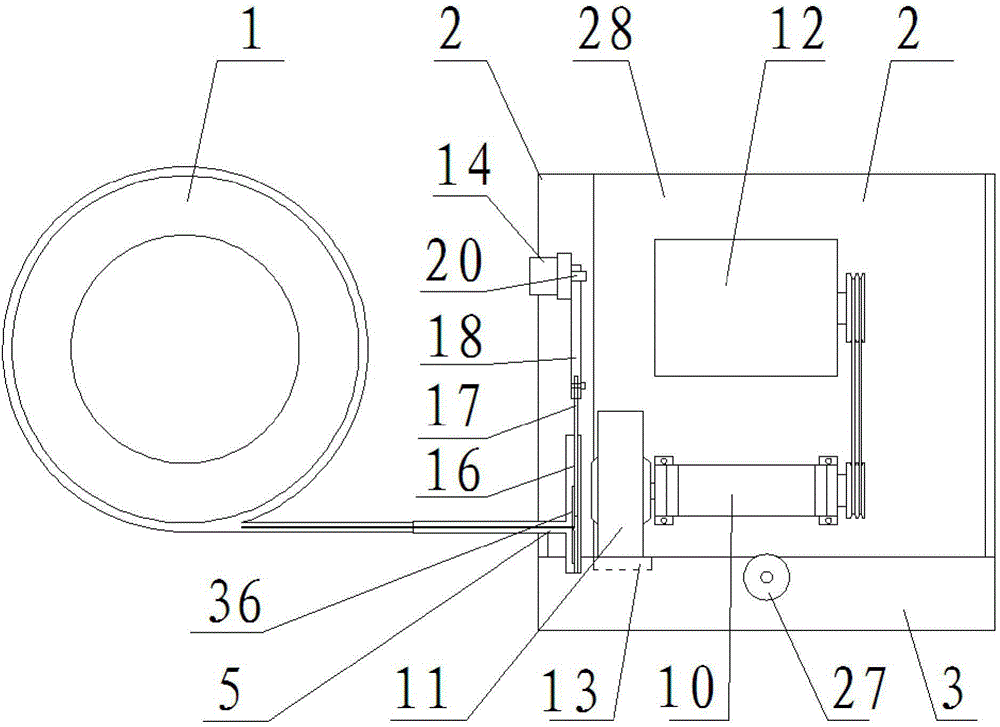

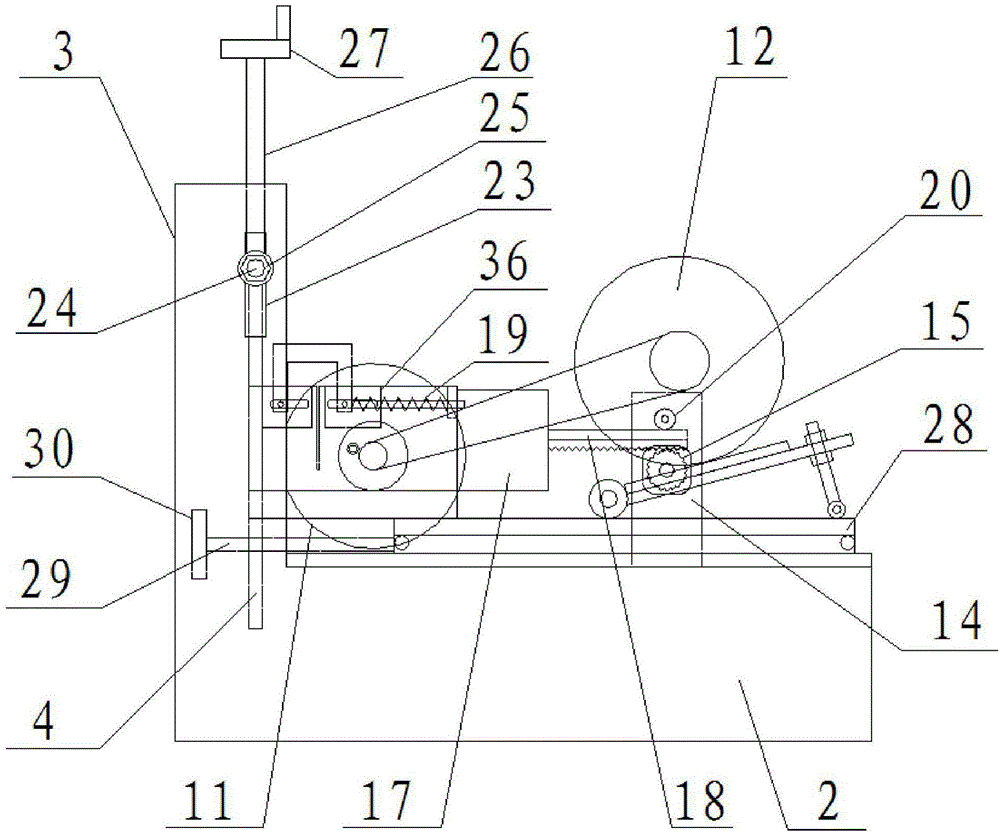

Method for producing high-strength homogenized tobacco material by thick pulp papermaking method

The invention relates to a method for producing a high-strength homogenized tobacco material by a thick pulp papermaking method. The method comprises the following steps: washing tobacco stems with water, mixing with wood fibers, and carrying out enzyme treatment; mixing and pulping the tobacco stems and the wood fibers to obtain homogeneous mixed pulp; adding tobacco powder, a smoke agent and anadhesive into the mixed pulp, and preparing the pulp to form a tobacco base material; continuously extruding and molding the tobacco base material on a stainless steel strip, carrying out primary drying by using hot steam, and then demolding by using a scraper; vertically spraying atomized liquid on one surface, which is not the steel strip, of the molded tobacco base material after demolding, andcarrying out color homogenizing treatment; and drying for the second time by using drying equipment, removing wrinkles, and carrying out shaping and rolling. According to the invention, the tobacco raw material is subjected to refined processing, and integrated processes such as extrusion molding, graded drying, color homogenizing treatment and the like are adopted, so that the prepared tobacco material has the advantages of large atomizing agent loading capacity, high tobacco component proportion, large product smoke release amount, high release stability, good processing resistance and thelike.

Owner:POWERTHINK (BEIJING) TECH CO LTD

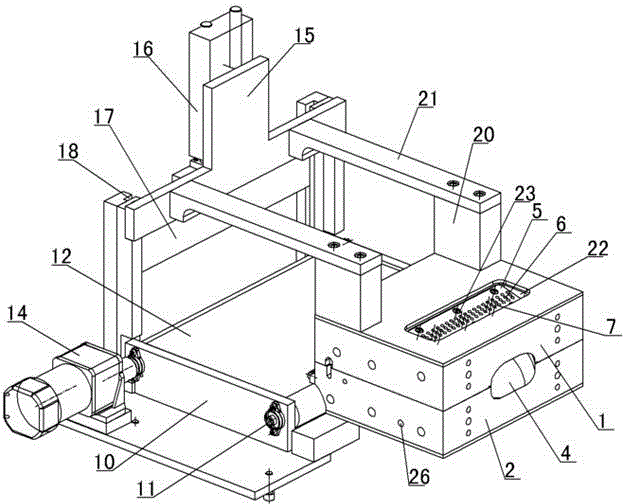

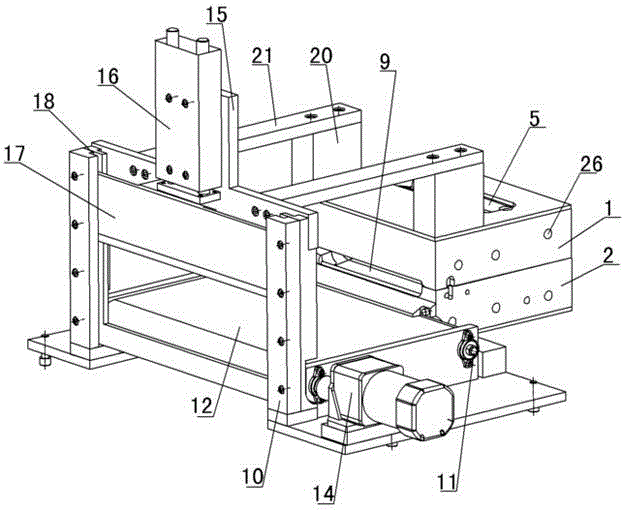

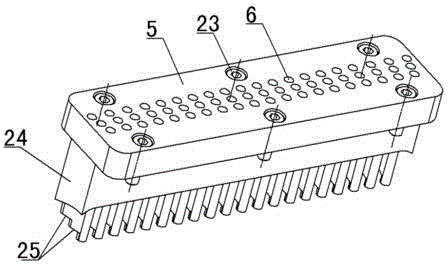

Full-automatic nail polishing machine

ActiveCN104440466AAvoid harmEasy to operateEdge grinding machinesGrinding feedersEngineeringDistributor

The invention relates to a full-automatic nail polishing machine which comprises a vibration disc feeder, a horizontal nail polishing machine tool body and a vertical nail polishing machine tool body, wherein a front panel is arranged on the vertical nail polishing machine tool body; an automatic nail arranging distributor, a transmission screw rod and a transmission motor are fixed on the front panel; the automatic nail arranging distributor is connected with a discharging port of the vibration disc feeder; a discharging port of the automatic nail arranging distributor is propped against the outer thread at one end of the transmission screw rod; a discharging port is formed in the other end of the transmission screw rod; a grinding wheel and a grinding wheel transmission motor are fixed on the horizontal nail polishing machine tool body; a polishing port is formed in the vertical nail polishing machine tool body and below the transmission screw rod; the polishing surface of the grinding wheel extends into the polishing port. The full-automatic nail polishing machine is convenient to operate, and during the operation, the nails to be polished are put in the vibration disc feeder and then starting is carried out on the polishing machine, so that the labor intensity of manual emptying and polishing is decreased, the polishing efficiency is improved, the harm from the dust to the operators is avoided, the approximately same length and shape of the polished nails are realized, and the polishing quality is improved.

Owner:山东佰盛能源科技有限公司

A kind of preparation method of paper-making tobacco sheet and tobacco sheet thereof

InactiveCN104382218BReserve lengthCut offTobacco preparationTobacco treatmentFiberIndustrial engineering

Owner:SOUTH CHINA UNIV OF TECH

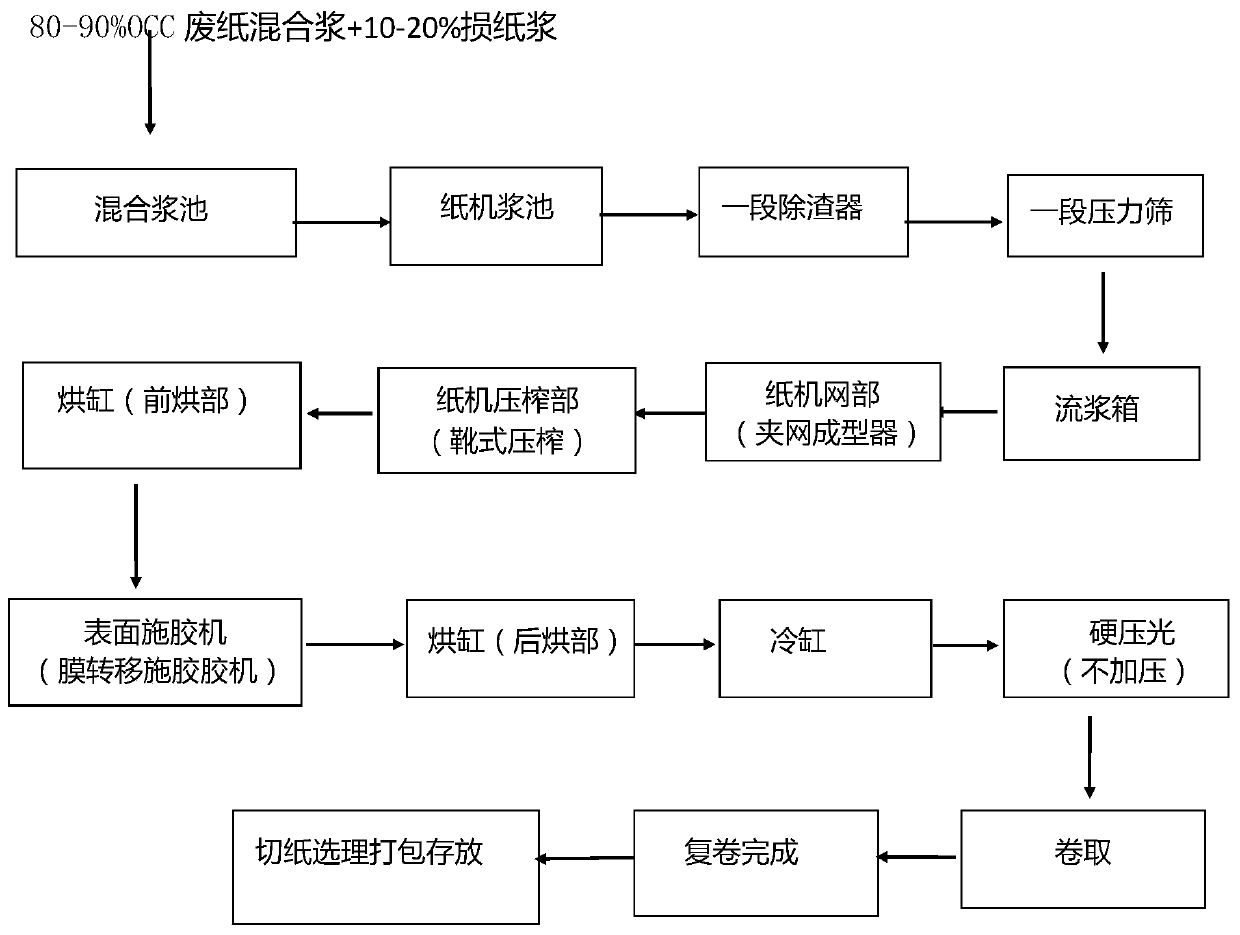

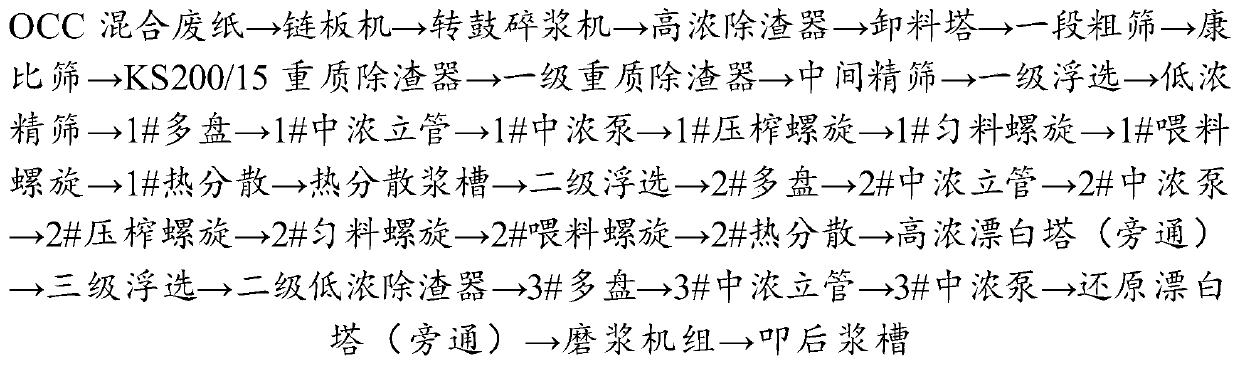

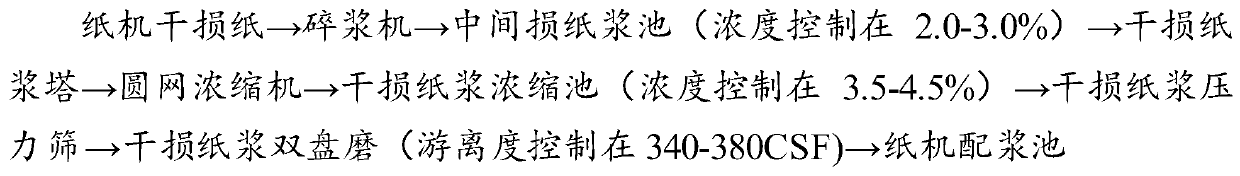

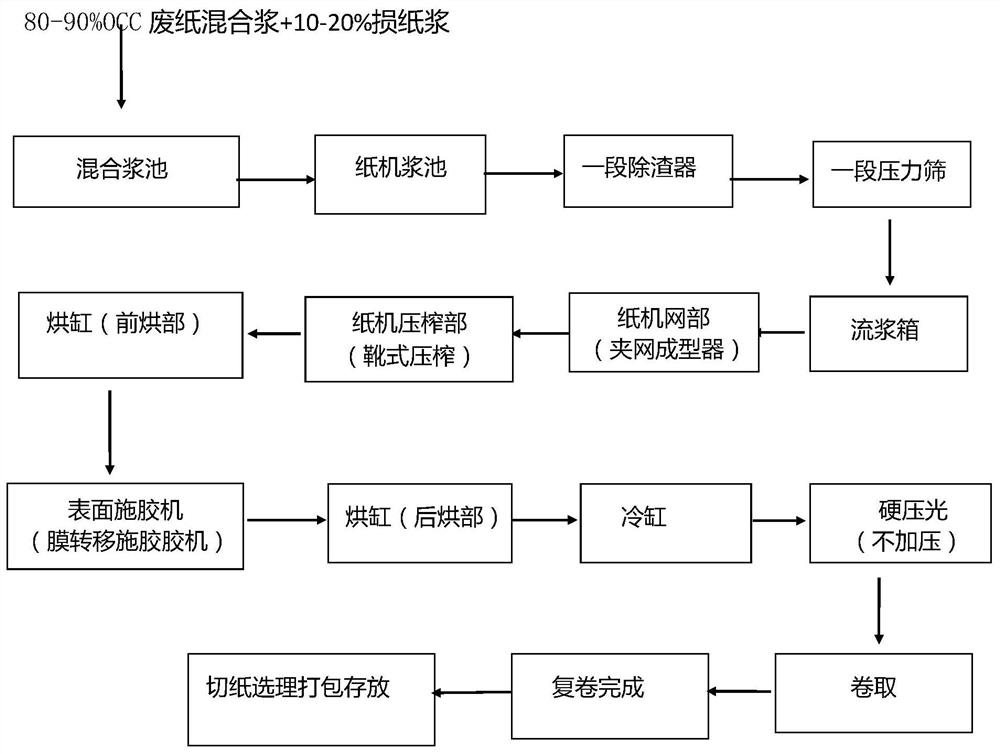

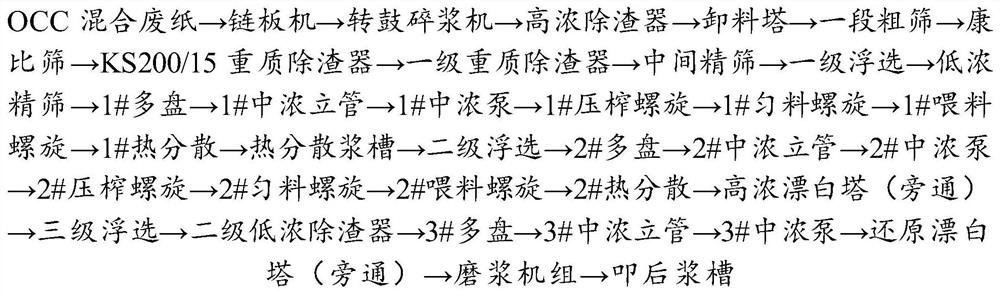

Preparation method of high-strength corrugated raw paper

ActiveCN110700005AHigh bonding strengthPrevent shrinkagePulp de-wateringPaper recyclingFiberProcess engineering

The invention provides a preparation method of high-strength corrugated raw paper. The method comprises the following steps of mixing 30-50 parts by weight of domestic waste general cargo paper, 10-30parts by weight of Japanese OCC waste paper and 40-60 parts by weight of European waste OCC and / or British OCC waste paper for pulping to obtain OCC waste paper mixed pulp, wherein the domestic wastegeneral cargo paper is domestic waste general cargo A level and / or B level; mixing the OCC waste paper mixed pulp with the waste paper pulp, removing slag, and then performing papermaking and sizingto obtain high-strength corrugated raw paper, wherein the mass ratio of the OCC waste paper mixed pulp to the damaged paper pulp is (80-90): (10-20). Compared with the prior art, the Japanese OCC waste paper, the European OCC waste paper and the British OCC waste paper are used as raw materials, the waste paper is paper produced by raw wood pulp, the fiber length and the strength are reserved, thefiber impurity cells and the impurity content in the waste paper pulp are less, the contraction of the fiber paper is favorably avoided, and the bonding strength of the paper is improved.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Method for processing materials for manufacturing tobacco sheets and tobacco sheets manufactured with method

InactiveCN104382217AImprove performanceReserve lengthTobacco preparationTobacco treatmentCross-linkPorosity

The invention belongs to the technical field of tobacco sheet manufacturing, and discloses a method for processing materials for manufacturing tobacco sheets with tobacco waste and the tobacco sheets manufactured with the method. The method includes the steps that after a mixture of tobacco stems and tobacco powder is extracted, the concentration is gradually lowered under the medium concentration condition; multistage soft defibrination processing is carried out; smashing and defibrination are carried out on materials obtained through defibrination processing and outer-fiber long-fiber stuff; and obtained slurry is evenly mixed to obtain materials used for manufacturing tobacco sheet base sheets. According to the method, gradual, sufficient and even mixing and defibering are carried out on the solid-phase mixture of the tobacco stems and the tobacco powder in the multistage soft defibrination processing process; moderate thin fibrillation is generated; the cutting effect and the damage effect on the materials in the defibrination process are reduced; the high thin fibrillation degree of the outer-fiber long-fiber stuff is obtained under the high pulping strength; the adsorption effect and the cross linking effect on thin components in the materials are facilitated; the retention rate of the tobacco powder and packing on a net is improved; the yield is improved; and the porosity and the physical performance of the tobacco sheet are improved.

Owner:SOUTH CHINA UNIV OF TECH

Graphene and continuous carbon fiber synergistically-reinforced polyamide composite material and preparation method thereof

The invention discloses a graphene and continuous carbon fiber synergistically-reinforced polyamide composite material and a preparation method thereof, wherein PA66, PA6, continuous carbon fiber, modified graphene, an antioxidant, a composite anti-hydrolysis agent, a composite light stabilizer, a lubricant, black masterbatch and a metal oxide are mixed, extruded, impregnated and granulated to prepare the graphene and continuous carbon fiber synergistically-reinforced polyamide composite material, wherein the surface of graphene is pre-treated with sodium dodecyl benzene sulfonate and a silane coupling agent to form the modified graphene. According to the present invention, the modified graphene is added, the anti-hydrolysis agent and the composite light stabilizer are compounded, and the polyamide material is modified through the melting impregnation pultrusion process, such that the prepared material has advantages of excellent rigidity, excellent impact toughness, excellent weathering resistance and good hydrolysis resistance, no fiber is exposed to the surface of the injection molding product, and the applications of carbon fiber reinforced polyamide in different fields can be met.

Owner:HEFEI GENIUS NEW MATERIALS

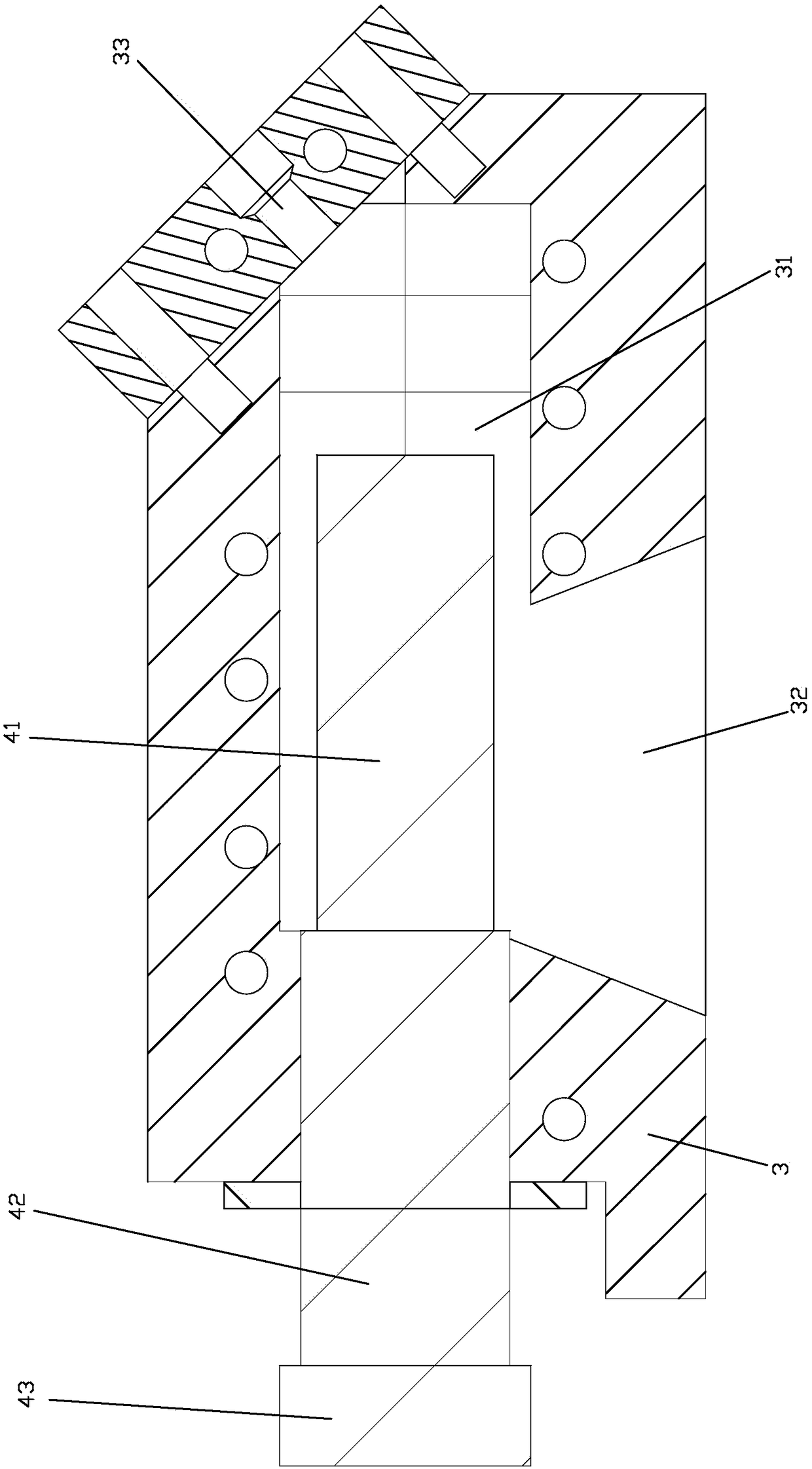

Mould with long glass fiber composite material co-extrusion machine opening

ActiveCN104309094AImprove mechanical propertiesReduce heatingMetal working apparatusGlass fiberButt joint

The invention provides a mould with a long glass fiber composite material co-extrusion machine opening. The mould comprises an upper mould and a lower mould, wherein a mould cavity is arranged between the upper mould and the lower mould, a feed opening in butt joint with an extruding machine is processed at one of the sides of the upper mould and the lower mould, a discharge opening is processed in each of the other sides of the upper mould and the lower mould, a long glass fiber introduction plate is arranged in the upper mould, a long glass fiber introduction hole is processed in the long glass fiber introduction plate, a long glass fiber is inserted into the long glass fiber introduction hole, a conveying mechanism is arranged besides the discharge opening, and a cutting device is installed on the conveying mechanism. Compared with the prior art, the long glass fiber is directly introduced into the mould cavity through the introduction hole to reduce the existing heating, plasticizing fusion and cooling process of the long glass fiber, and the length of the long glass fiber can be kept in the extrusion process to a larger extent to reinforce the mechanical property of the material, thereby increasing the building board intensity, saving the energy consumption, shortening the production cycle and reducing the production cost.

Owner:ZHEJIANG HENGDA PLASTIC MOLD

Production method of high-performance latex paper

InactiveCN102191725BImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensilestrength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

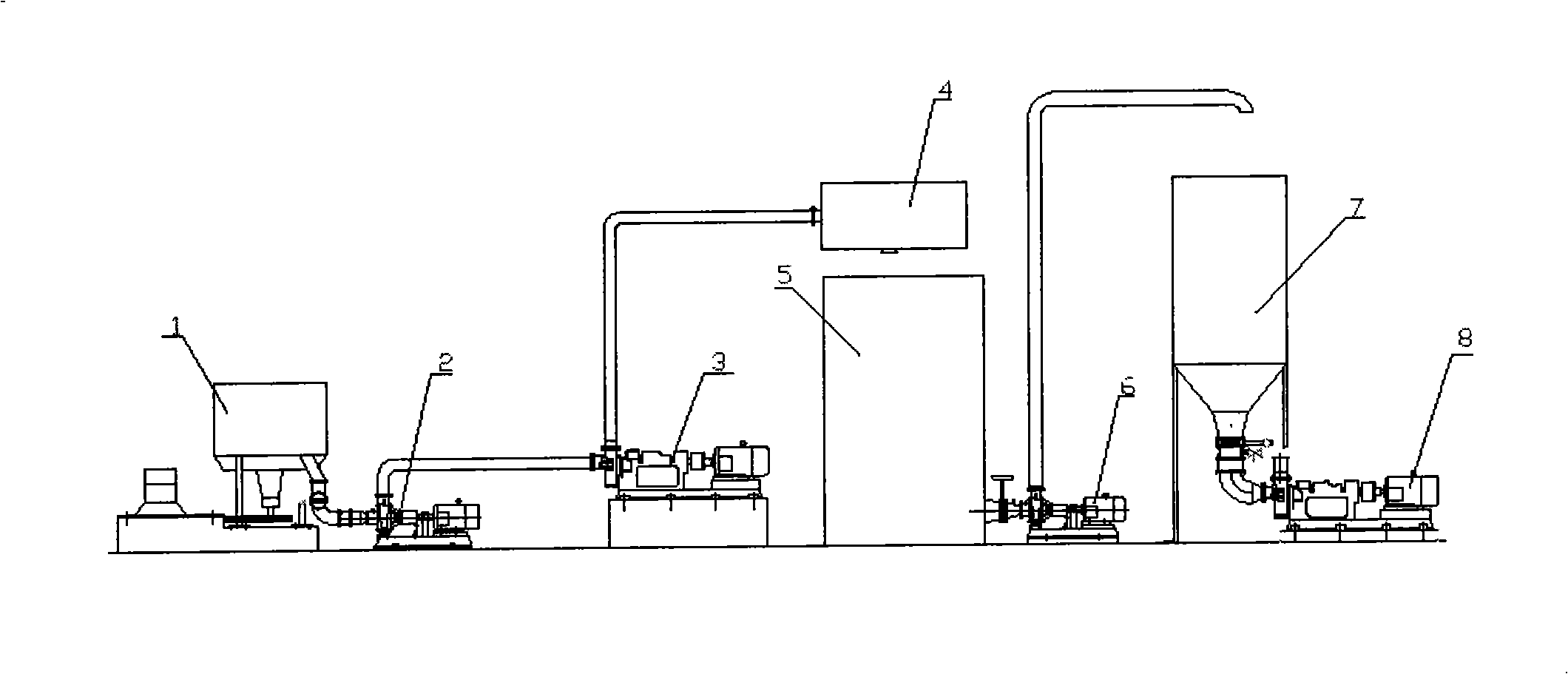

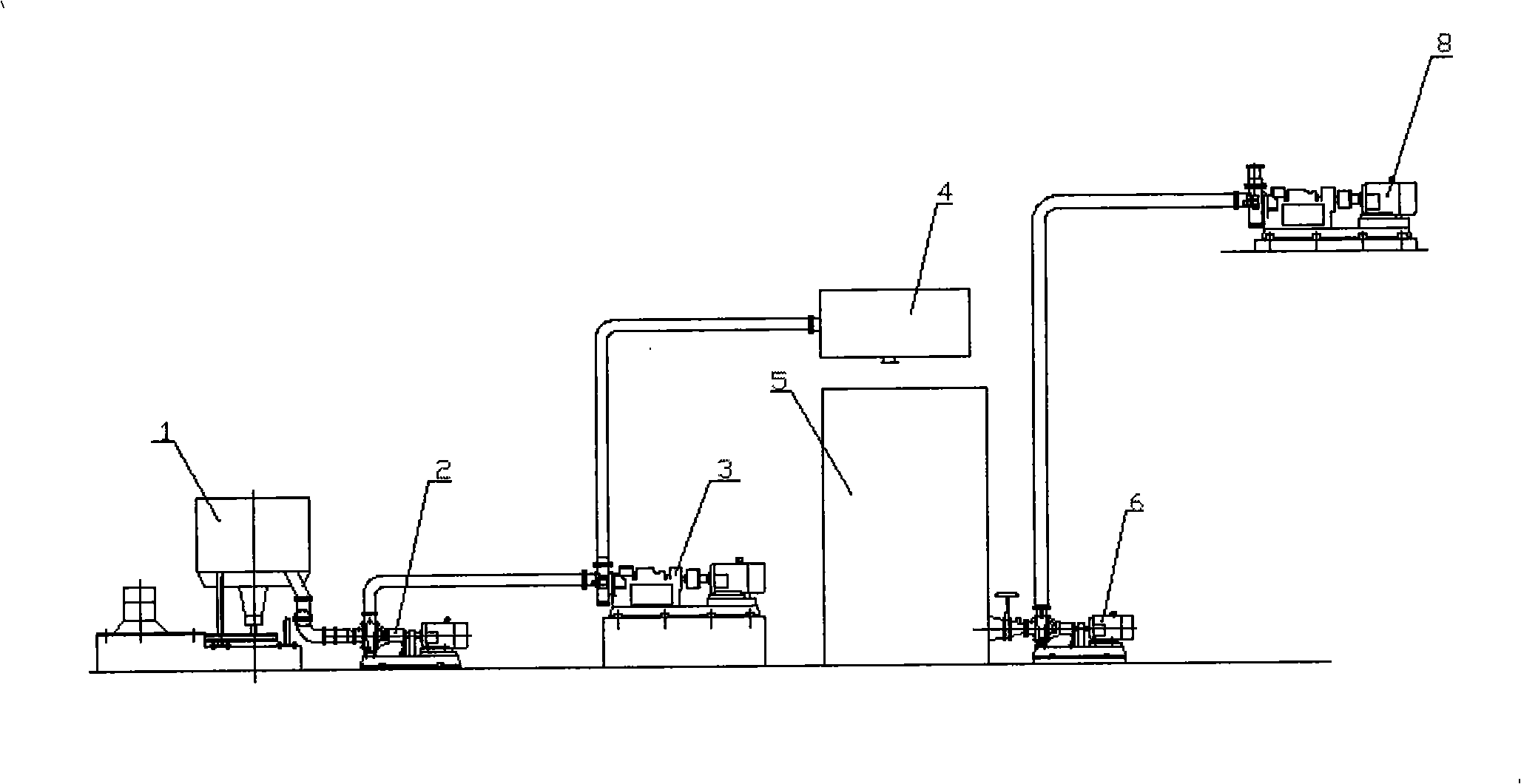

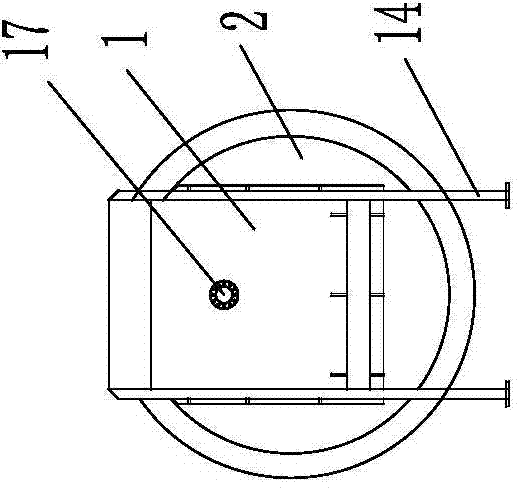

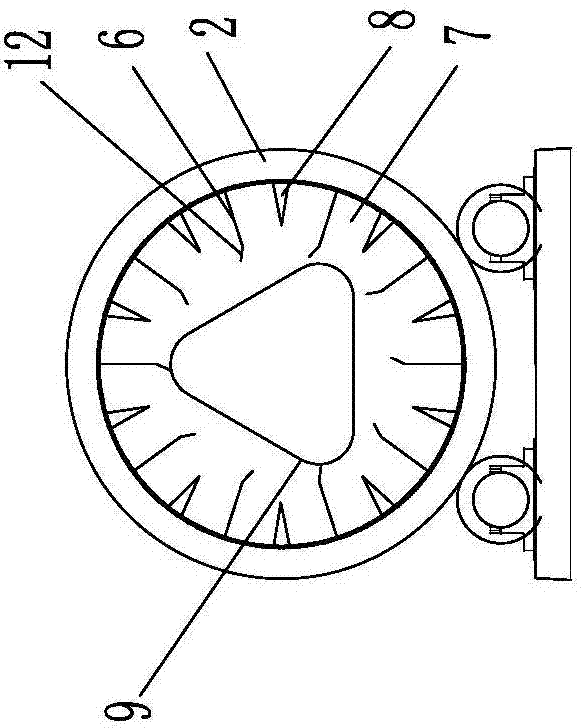

Rotary drum type hydraulic power disintegrator

InactiveCN104514167ANo damageQuality improvementPaper recyclingRaw material divisionImpellerEngineering

The invention discloses a rotary drum type hydraulic power disintegrator which comprises a charging hopper, a rotating drum, a rotating drum transmission device, a riding wheel device and a sealing device, wherein two large riding wheels are arranged on the outer side wall of the rotating drum, the two large riding wheels are both positioned on the riding wheel device at the bottom of the rotating drum, a plurality of strips parallel to the inner side wall of the rotating drum in axial direction are arranged on the inner side wall of the rotating drum, a plurality of baffle plates perpendicular to the strips are arranged inside the rotating drum, a plurality of uniformly arranged scraping plates are arranged on the side wall, between adjacent strips, of the rotating drum, and a pulp chest with an opening upward is arranged below the rotating drum inside a guard shield. The rotary drum type hydraulic power disintegrator provided by the invention changes a form that the traditional hydrapulper adopts a high speed revolution impeller and a blade for repulping, is a moderate and defibering, and ensures that impurities are discharged completely, the follow-up pulp processing load is alleviated, wastepaper can enter the rotating drum for decomposing without need of selecting, and the rotary drum type hydraulic power disintegrator is convenient for decomposing waste soft drink packages, household wastepaper, office wastepaper and the like, which are difficult to treat.

Owner:诸城市天工造纸机械有限公司

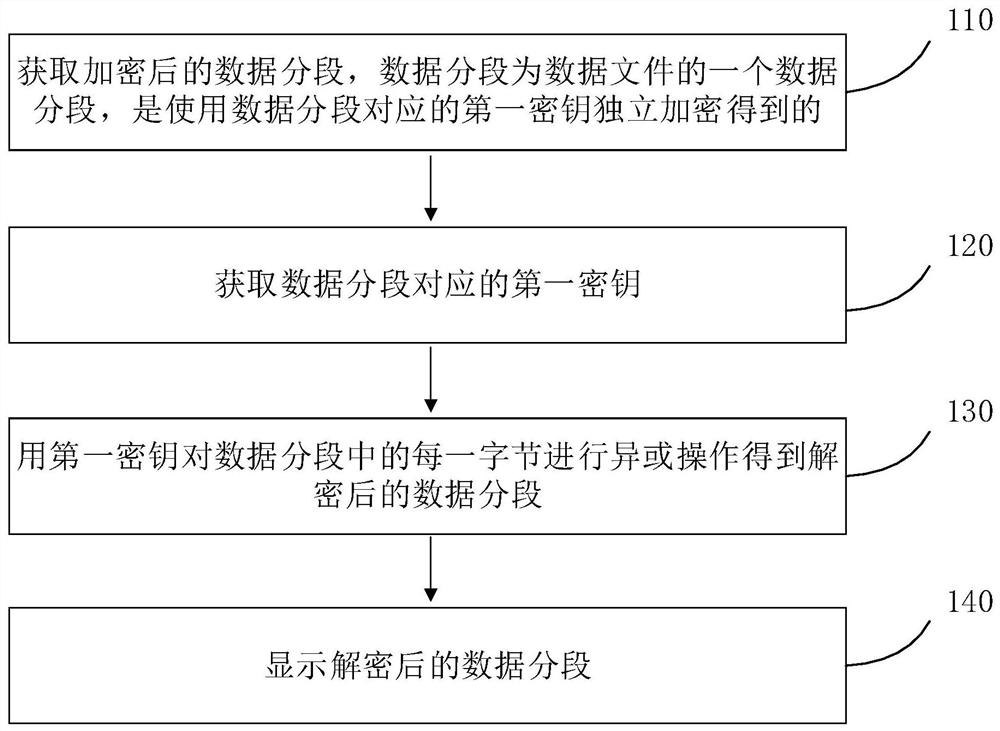

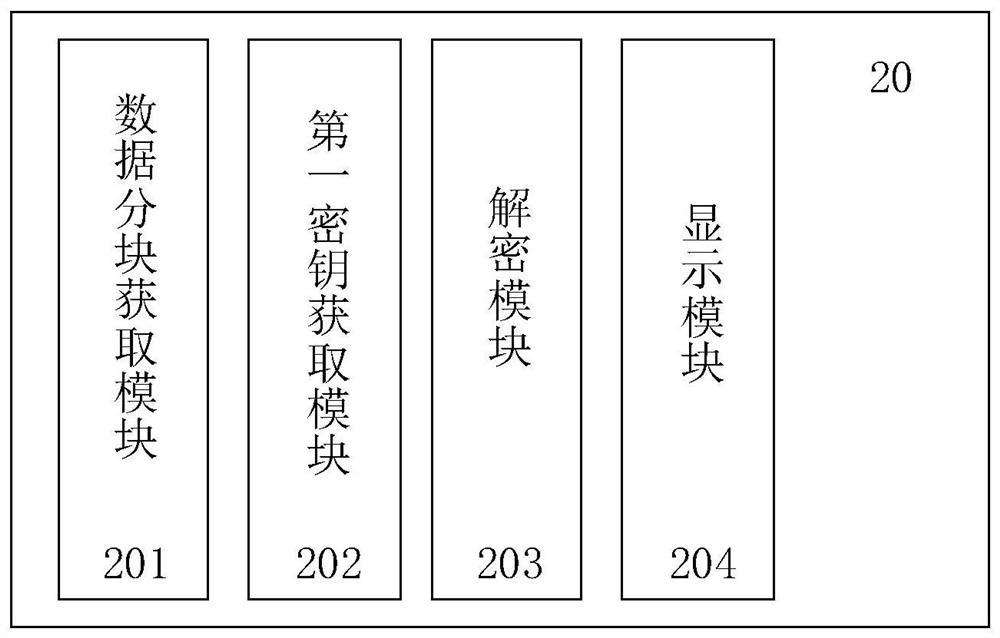

Information processing method and device and storage medium

InactiveCN112182512ADoes not change lengthReserve lengthDigital data protectionProgram/content distribution protectionData fileData striping

The invention discloses an information processing method and device and a storage medium. The method comprises the following steps: firstly, acquiring a data segment encrypted by using a first key, the data segment being a data segment of a data file; obtaining a first secret key corresponding to the data segment; then, carrying out exclusive-OR operation on each byte in the data segment by usinga first secret key to obtain a decrypted data segment; and then, displaying the decrypted data segments. The data file is encrypted in a segmented manner, so that the data file can be decrypted in a segmented manner, all data does not need to be loaded during online reading, and only the currently read content needs to be loaded and decrypted at the same time according to needs, so that the firstloading time is greatly shortened, and the reading efficiency is improved. Moreover, the length of the file is not changed by encrypting and decrypting each byte in an XOR manner, so that the purposesof the length of the file in various scenes can be reserved to the maximum extent.

Owner:北京幻想纵横网络技术有限公司

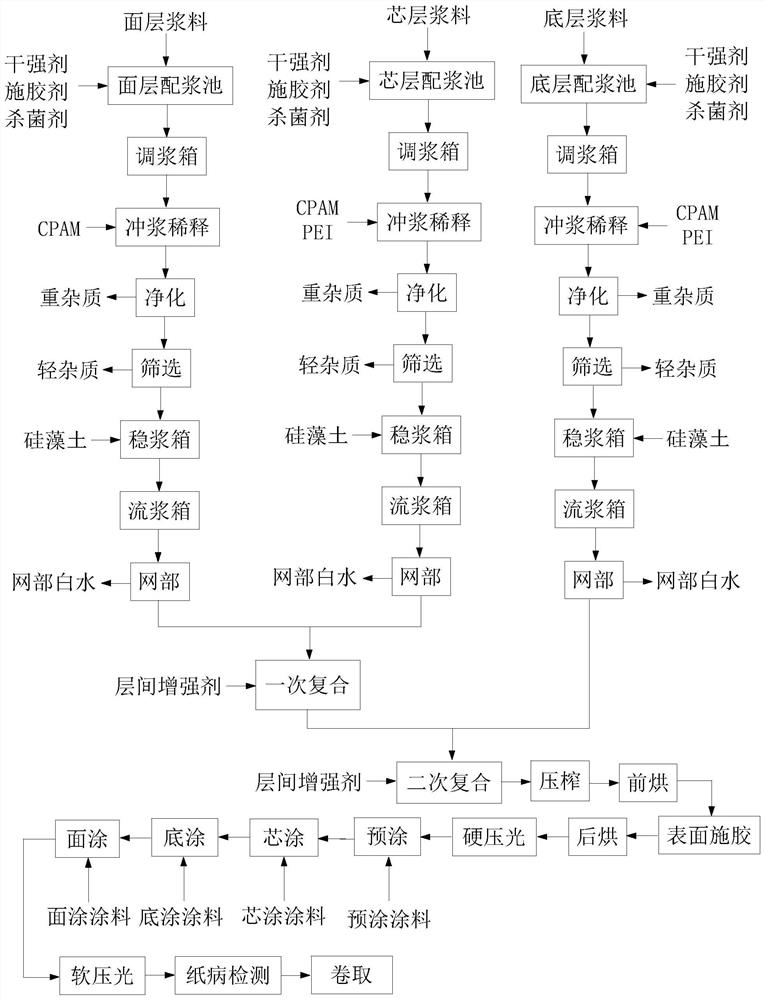

Coated white cardboard made of various fiber raw materials and production process of coated white cardboard

PendingCN114507999AAlleviate shortagesIncrease bulkSpecial paperWater-repelling agents additionBagasse pulpCardboard

The invention relates to a coating white cardboard made of various fiber raw materials and a production process thereof, the fiber raw materials of a core layer comprise bleached sulfate softwood pulp, bleached hardwood chemical thermo-mechanical pulp, white cardboard waste pulp and bagasse pulp, and the fiber raw materials of a bottom layer comprise bleached sulfate softwood pulp, bleached sulfate hardwood pulp and high-grade deinked pulp. An interlayer reinforcing agent is sprayed between the layers; the bagasse pulp can be chemically bleached mechanical pulp, and the interlayer enhancer comprises 40-75 parts of spraying starch, 10-20 parts of water-based novolac epoxy resin emulsion and 8-15 parts of styrene-acrylic emulsion; the retention and drainage aid in the slurry of the core layer and the bottom layer comprises PEI, CPAM and bentonite. According to the method, the problem of shortage of wood raw materials can be relieved, the cost is reduced, the defects of the strength, water resistance and the like of fiber pulp are overcome by spraying the interlayer reinforcing agent between layers, the finished pulp can have better water filtering performance and papermaking performance by chemically bleaching the mechanical bagasse pulp, and meanwhile, the strength performance of the finished paper is improved.

Owner:湛江晨鸣浆纸有限公司

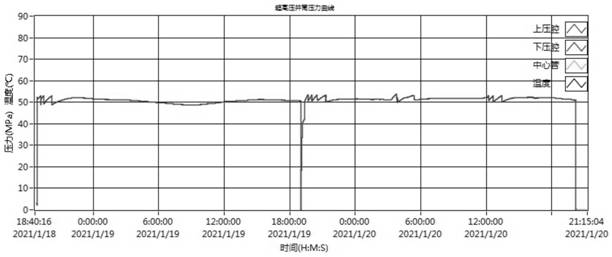

Oil and gas well fracturing construction method

ActiveCN112696184AReduce construction riskUniform fracturingFluid removalSealing/packingPetroleum engineeringGeotechnical engineering

Owner:SICHUAN WELDON CHEM

Online mixing injection molding process suitable for carbon fiber automobile part

The invention discloses an online mixing injection molding process suitable for a carbon fiber automobile part. Equipment for achieving the process comprises a double-screw extruder, an injection molding machine, an automatic feeding machine, a forced side feeding system, a mold temperature machine and a water cooler. The online mixing injection molding process is characterized by comprising the steps that plastic particles, additives and fillers are added into the double-screw extruder to be mixed and plasticized through the automatic feeding machine and the forced side feeding system according to a formula resin system; recycled carbon fibers are added into the back section of a screw through the forced side feeding system, and mixing and plasticizing are further conducted; the uniformly mixed plastic and carbon fibers enter an injection cylinder of the injection molding machine through a feeding valve of the forced side feeding system; an injection mold is closed through a mold locking unit; an injection valve of the injection molding machine is opened, the uniformly mixed plastic and carbon fibers in the injection cylinder of the injection molding machine are injected into a forming mold through the injection valve of the injection molding machine, meanwhile the temperature is controlled through the mold temperature machine, then cooling solidification through the water cooler and demolding are conducted, and a semi-finished product can be obtained; and after the semi-finished product is subjected to demolding, the required product can be obtained through trimming and other working procedures.

Owner:宁波华翔汽车技术有限公司

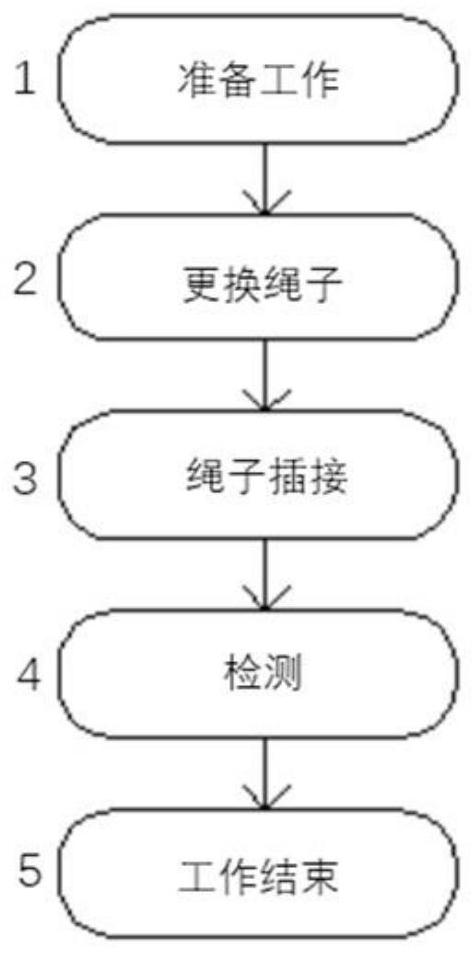

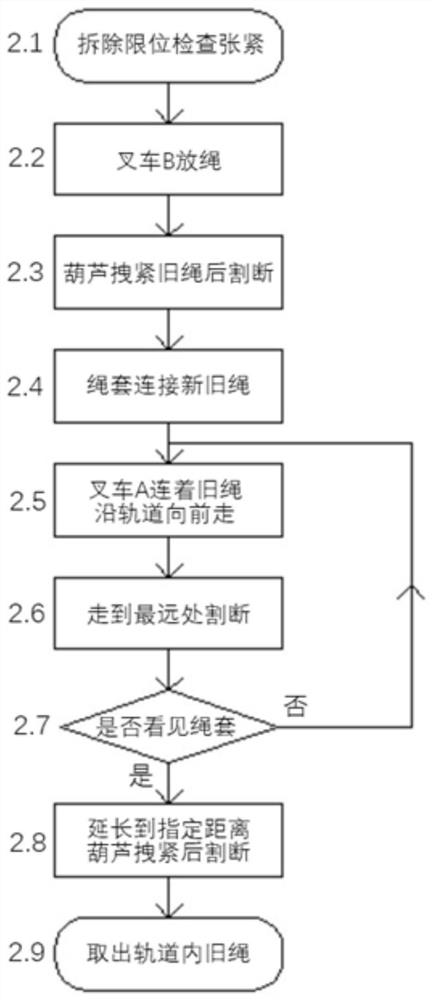

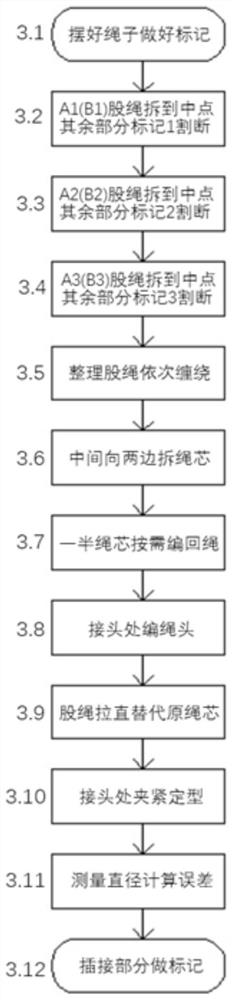

Switching method and switching system for steel wire rope in automobile crash test traction equipment

ActiveCN112629871AEnter perfectlyAccurate replacementRope making machinesVehicle shock testingCrash testWire rope

The invention relates to a switching method and a switching system for steel wire rope in automobile crash test traction equipment; the switching method comprises the steps: cutting off an old steel wire rope at an initial position, enabling the rear end of the cut-off old steel wire rope to be connected with a moving device, and enabling the front end to be connected with the free end of a new steel wire rope; driving, by the moving device, the rear end to move towards the end point of the underground rail, meanwhile, driving, by the front end, the new steel wire rope to enter the underground rail, when the moving device moves to the end point of the underground rail, cutting off the old steel wire rope again at the initial position to obtain a cut-off part and the rear end, and returning the moving device to the initial position and connects the rear end to the moving device; repeating the steps until the front end is taken out of the underground rail, completely cutting off the old steel wire rope, cutting off the new steel wire rope, and then inserting the two ends of the new steel wire rope together. The method adopts the mode that the old steel wire rope drives the new steel wire rope to enter the rail, finally completes change-over, can ensure that the new steel wire rope completely enters the rail without errors, and is convenient and accurate to change and low in cost.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +2

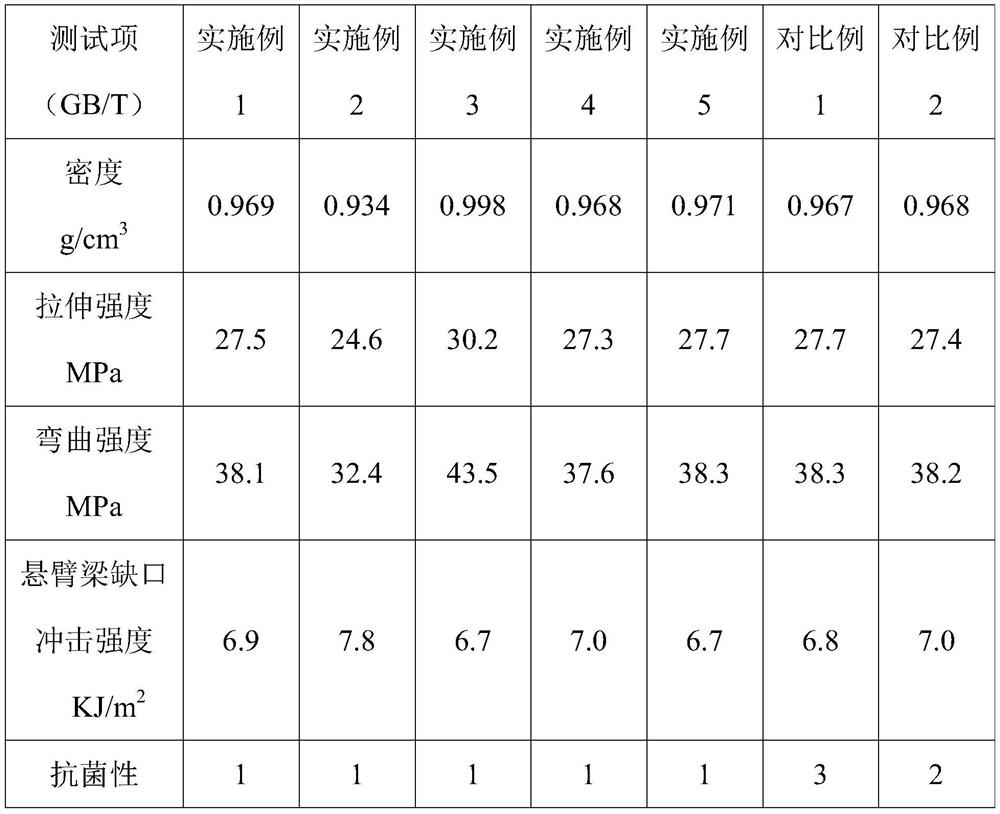

Antibacterial ramie fiber reinforced polypropylene composite material and preparation method thereof

PendingCN114149638AReduce hydrophilicityEfficient and durable antibacterialPolypropylene compositesAntibacterial agent

The invention discloses an antibacterial ramie fiber reinforced polypropylene composite material and a preparation method thereof, and relates to the technical field of polypropylene composite materials, the antibacterial ramie fiber reinforced polypropylene composite material is prepared from the following raw materials by weight: 65-85 parts of polypropylene, 10-30 parts of modified ramie fiber, 3-6 parts of a compatilizer, and 1-3 parts of an auxiliary agent; wherein the modified ramie fibers are obtained by performing alkali treatment and oxidation treatment on ramie fibers and grafting a PHMG antibacterial agent; the preparation method of the polypropylene composite material comprises the following steps: mixing the raw materials, carrying out melt extrusion, and drying. Ramie fiber reinforced polypropylene is adopted, alkali treatment and oxidation treatment are firstly carried out on the ramie fiber, on one hand, the surface roughness of the fiber is increased, the hydrophilicity of the ramie fiber is reduced, and the interface bonding between the ramie fiber and a polypropylene matrix is improved; on the other hand, PHMG can be grafted to the surface of the fiber through Schiff base reaction, and the grafted ramie fiber has a long-acting antibacterial effect; the composite material prepared by the invention is excellent in mechanical property and efficient in antibiosis.

Owner:重庆会通科技有限公司

A kind of preparation method of high-strength corrugated base paper

The invention provides a method for preparing high-strength corrugated base paper, comprising: mixing 30-50 parts by weight of national waste paper, 10-30 parts by weight of Japanese OCC waste paper, and 40-60 parts by weight of European waste OCC and / or British OCC waste paper mixed pulping to obtain OCC waste paper mixed pulp; the national waste paper is grade A and / or B grade; the OCC waste paper mixed pulp is mixed with broke pulp, after slag removal, Papermaking and sizing are carried out to obtain high-strength corrugated base paper; the mass ratio of the mixed OCC waste paper to broke pulp is (80-90): (10-20). Compared with the prior art, the present invention uses Japanese OCC waste paper, European OCC waste paper and British OCC waste paper as raw materials. These waste papers are paper produced from primary wood pulp, and the fiber length and strength are retained. The fibers in the waste paper pulp are miscellaneous. The content of cells and impurities is low, which is beneficial to avoid shrinkage of fiber paper and improve the bonding strength of paper.

Owner:DONGGUAN NINE DRAGONS PAPER IND

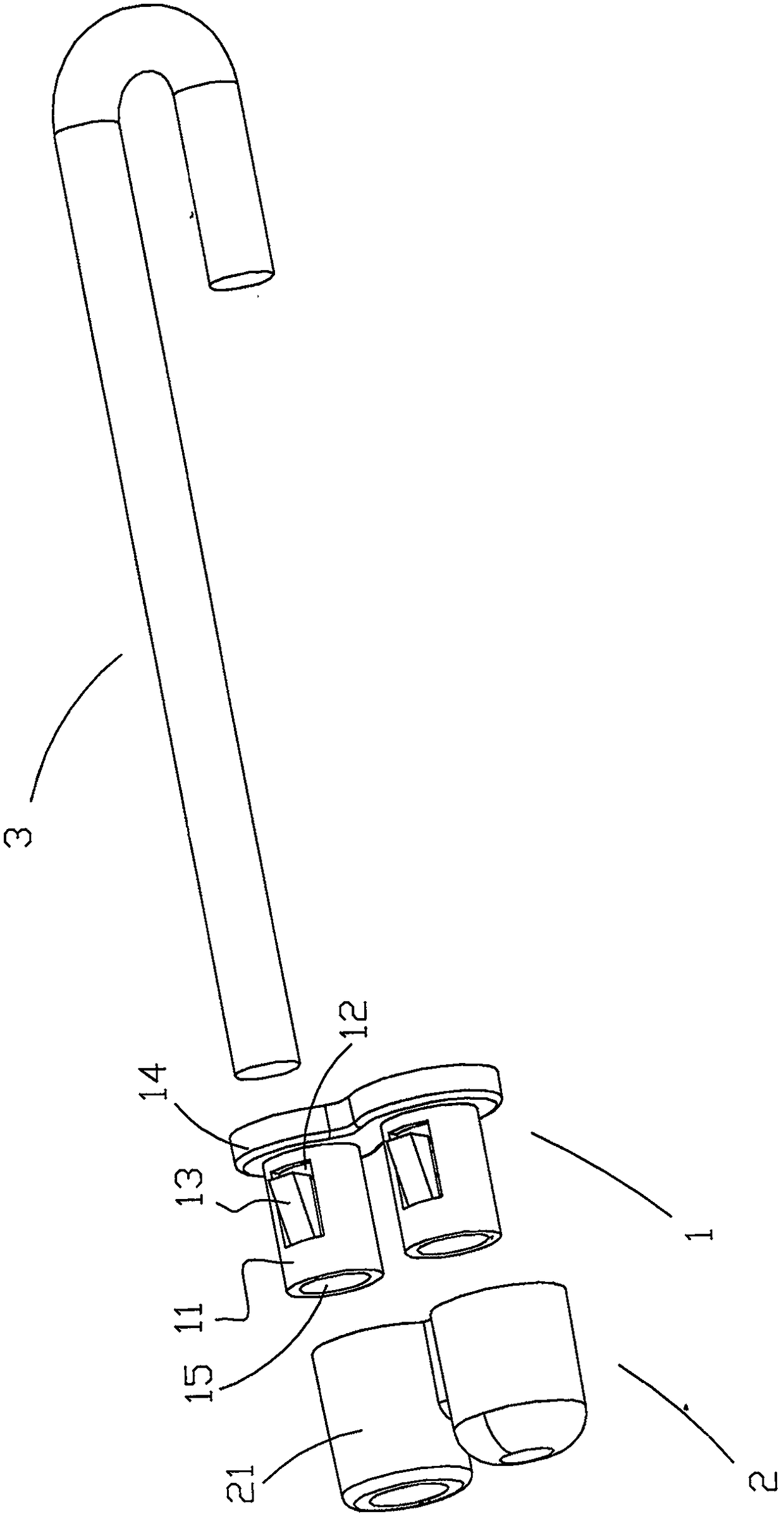

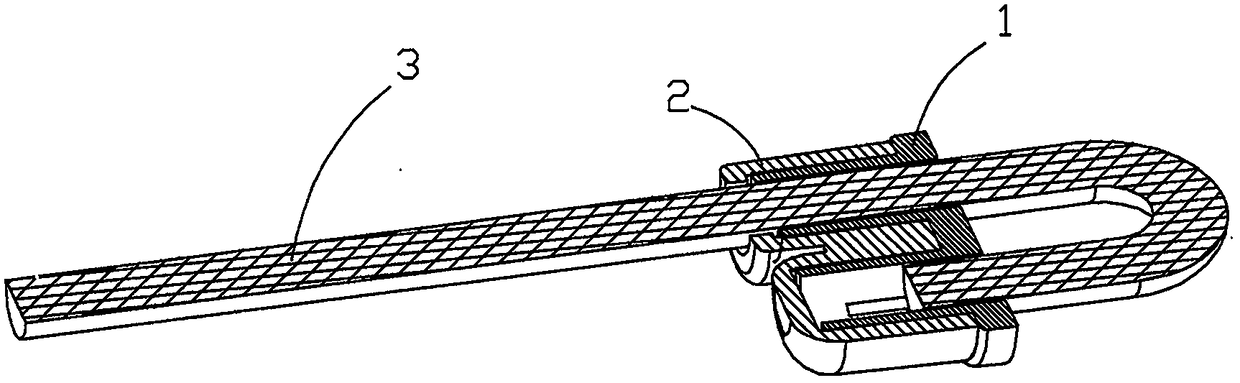

Fast adjusting buckle for skipping rope

Disclosed is a fast adjusting buckle for a skipping rope. The buckle comprises a sleeve tube and a lock sleeve, the sleeve tube is provided with two tubular bodies arranged side by side, the two tubular bodies are integrally connected and provided with axial through holes for a rope to penetrate through respectively, the outer walls of the front portions of the two tubular bodies are circumferentially provided with at least two longitudinal opening grooves communicated with the respective axial through holes and elastically-deformable clamping jaws which are located in the grooves and extend out of axial suspension arms respectively; the lock sleeve is provided with two sleeve bodies matched with the two tubular bodies on the sleeve tube, and the two sleeve bodies can extrude the clampingjaws on the two tubular bodies and tightly sleeve the sleeve tube respectively. Through the combination of the sleeve tube with a pair of parallel holes and the lock sleeve, one end of the rope can penetrate through one hole and then reversely penetrate through the other hole, and then the rope can be ingeniously clamped by the clamping jaws. The fast adjusting buckle is simple in structure and convenient to operate, the lock sleeve can be adjust to clamp or loosen the rope without any tool, and the length of the rope is quite convenient to adjust or the rope is quite convenient to replace.

Owner:石永潮

A processing method for materials used in preparing tobacco sheets and tobacco sheets thereof

The invention belongs to the technical field of tobacco sheet manufacturing, and discloses a method for processing materials for manufacturing tobacco sheets with tobacco waste and the tobacco sheets manufactured with the method. The method includes the steps that after a mixture of tobacco stems and tobacco powder is extracted, the concentration is gradually lowered under the medium concentration condition; multistage soft defibrination processing is carried out; smashing and defibrination are carried out on materials obtained through defibrination processing and outer-fiber long-fiber stuff; and obtained slurry is evenly mixed to obtain materials used for manufacturing tobacco sheet base sheets. According to the method, gradual, sufficient and even mixing and defibering are carried out on the solid-phase mixture of the tobacco stems and the tobacco powder in the multistage soft defibrination processing process; moderate thin fibrillation is generated; the cutting effect and the damage effect on the materials in the defibrination process are reduced; the high thin fibrillation degree of the outer-fiber long-fiber stuff is obtained under the high pulping strength; the adsorption effect and the cross linking effect on thin components in the materials are facilitated; the retention rate of the tobacco powder and packing on a net is improved; the yield is improved; and the porosity and the physical performance of the tobacco sheet are improved.

Owner:SOUTH CHINA UNIV OF TECH

High-impregnation-degree long glass fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a high-impregnation-degree long glass fiber reinforced polypropylene composite material and a preparation method thereof. The high-impregnation-degree long glass fiber reinforced polypropylene composite material is prepared from the following raw materials in parts by weight: 43.2 to 63.2 parts of polypropylene resin, 30 to 50 parts of glass fibers, 1 to 10 parts of a compatilizer, 1 to 10 parts of a flexibilizer, 0.1 to 1 part of an antioxidant and 0.2 to 2 parts of a lubricant. The glass fibers pass through a glass fiber heating pre-dispersing device and a cooling device on line, then are electrified through friction of silk, and finally pass through a static electricity generating device to directly enter a dipping tank for production. The high-impregnation-degree long glass fiber reinforced polypropylene composite material disclosed by the invention has the following technical effects that each glass fiber is wrapped by the polypropylene resin, so that the glass fibers are prevented from being damaged in a pellet plasticizing process, the length of the glass fibers in a product is reserved, and the tensile strength, flexural modulus, impact strength and other properties are greatly improved.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

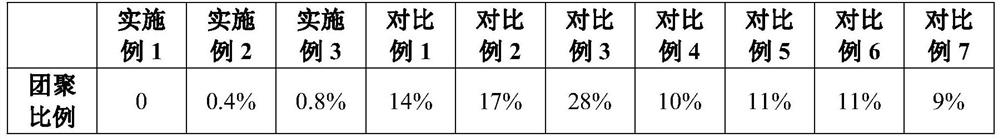

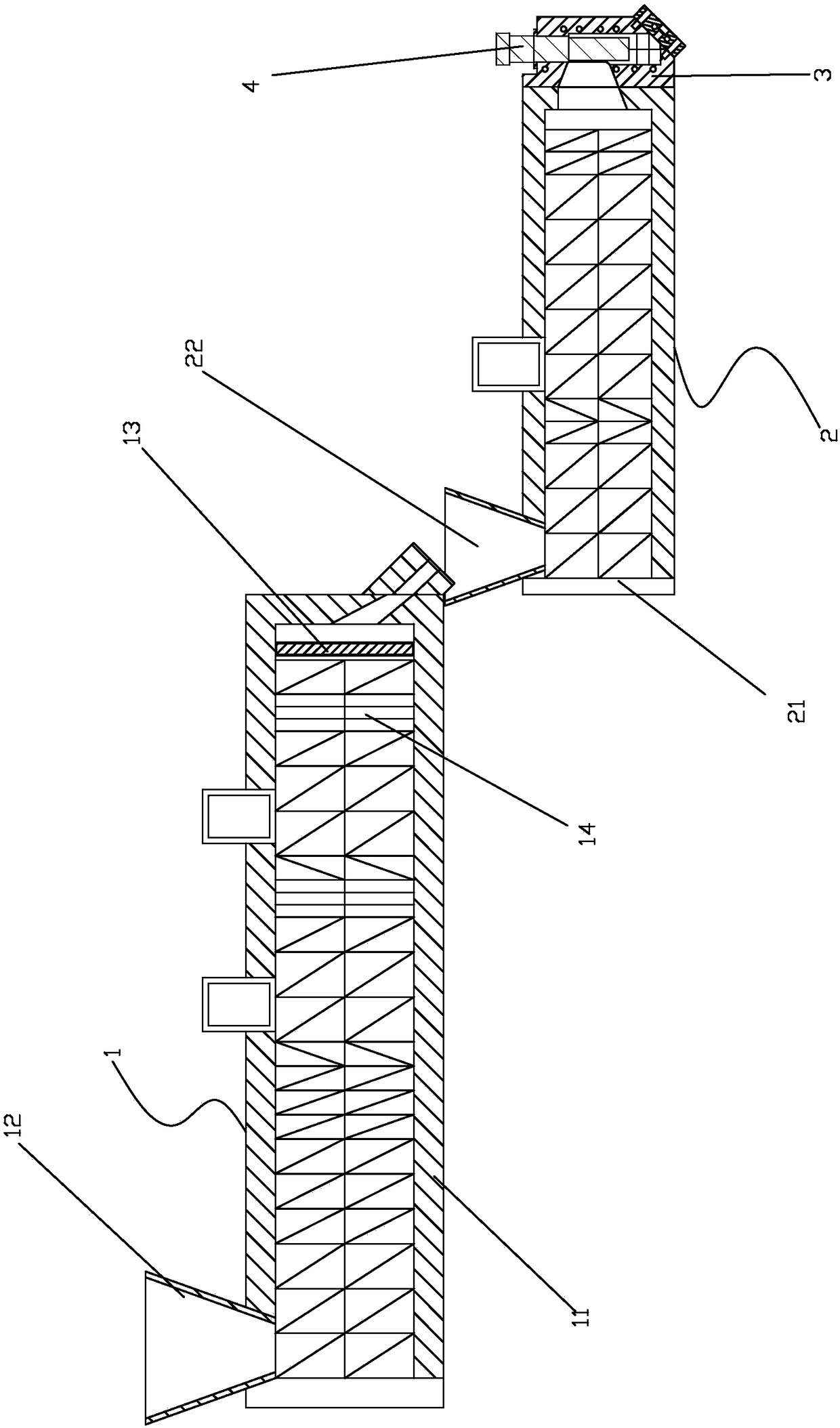

A kind of recycling glass fiber reinforced plastic melt granulation extrusion equipment and its extrusion method

The invention discloses extrusion equipment for fusion and granulation of recovered glass fiber-reinforced plastic. According to the technical scheme, the extrusion equipment for fusion and granulation of recovered glass fiber-reinforced plastic comprises a double-screw extruder and a single-screw extruder which are connected in sequence; the double-screw extruder comprises a first-order cylinder with a heating function, a first-order feeding port used for feeding is formed in the front portion of the first-order cylinder, a filter screen is arranged on the rear portion of the first-order cylinder and used for filtering fused polymers, and a mixing unit is further arranged in the position, close to the filter screen, of the interior of the first-order cylinder; and the single-screw extruder comprises a second-order cylinder with a heating function, a second-order feeding port is formed in the front portion of the second-order cylinder and used for collecting short glass fibers and the polymers filtered by the filter screen, an extruder head is arranged on the rear portion of the second-order cylinder, and an ultrasonic vibration mechanism used for promoting the glass fibers and the polymers to be mixed is arranged on the extruder head. According to the extrusion equipment for fusion and granulation of recovered glass fiber-reinforced plastic, the cut short glass fibers are effectively protected, and the physical index of products is effectively increased.

Owner:中山市联科泰贸易有限公司

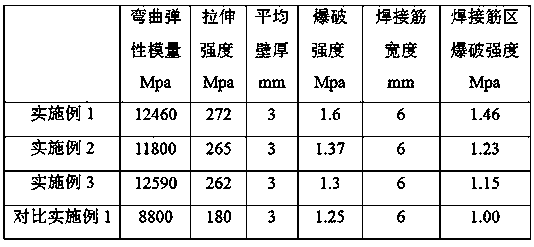

PA6 composite material special for engine air intake manifolds

The invention discloses a PA6 composite material special for engine air intake manifolds. The PA6 composite material comprises the following raw materials by weight: 60-70 parts of PA6 resin, 25-35 parts of glass fiber, 0.5-1 part of a dispersant, 4-5 parts of a compatibilizer, 0.5-1 part of a coupling agent, 1-2 parts of carbon black, and 1-2 parts of an antioxidant, and is prepared by: mixing the raw materials by a high-speed mixer, then conducting mixing milling by a millstone type mixing device, and carrying out parallel twin-screw extrusion granulation. The glass fiber is high strength glass fiber with a monofilament diameter of 8micrometer, the compatibilizer is formed by compounding of a maleic anhydride grafted butane-octene copolymer and N, N'-ethylene bis stearamide in a weight ratio of 3:1. The PA6 composite material special for engine air intake manifolds has good secondary fusion welding bondability and high strength after welding. The engine air intake manifolds preparedfrom the PA6 composite material special for engine air intake manifolds have the advantages of high integral strength, good toughness, little glass fiber exposure, strong blast resistance ability in awelded rib area and the like.

Owner:LIAONING FENGDI ENGINE AIR INTAKE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com