Outlet fitting for a toilet cistern

A technology for flushing water tanks and fittings, applied in the field of drainage fittings, which can solve the problems of expensive manufacturing of drainage fittings, achieve the effects of saving materials, preventing throat noise, and improving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

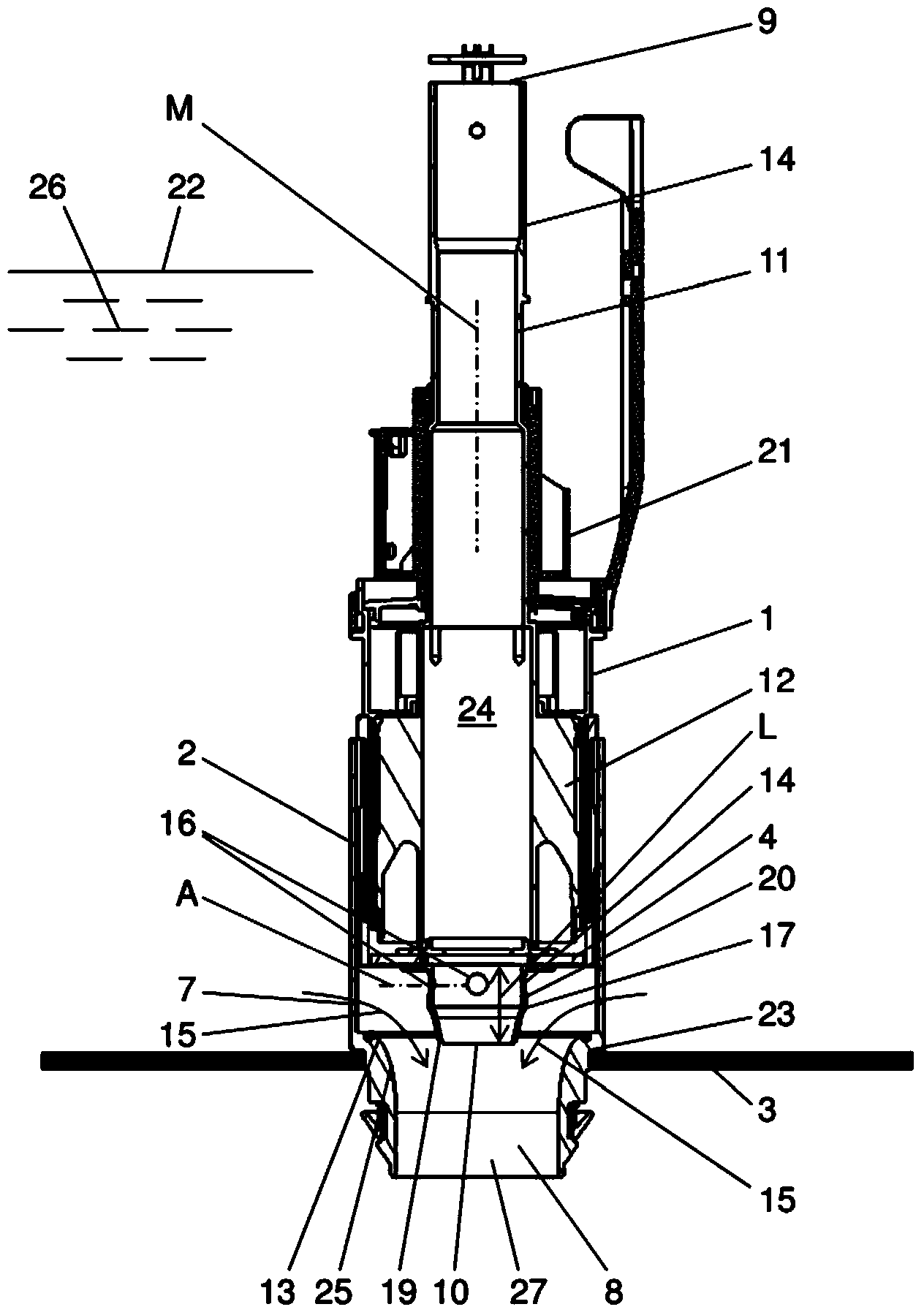

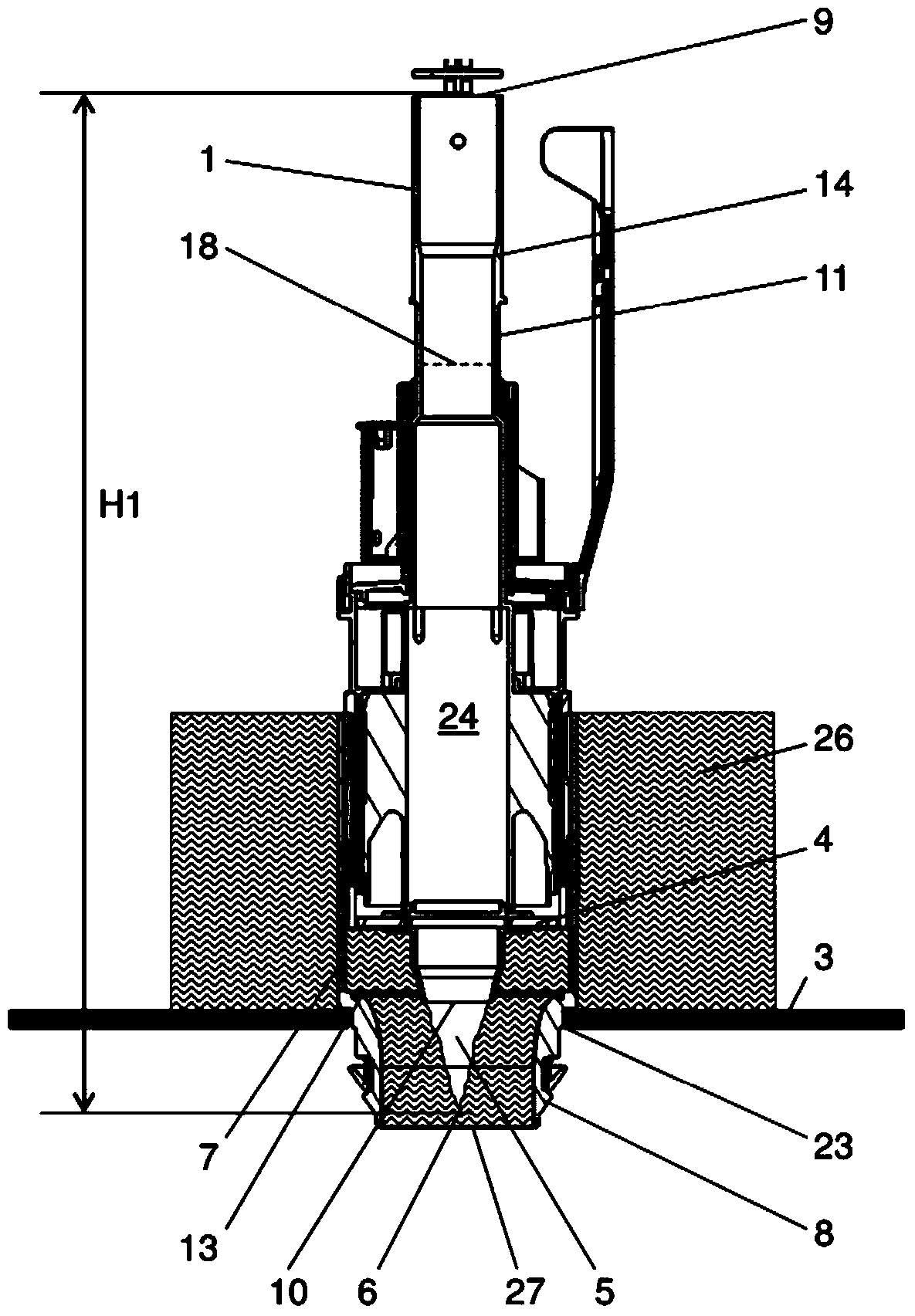

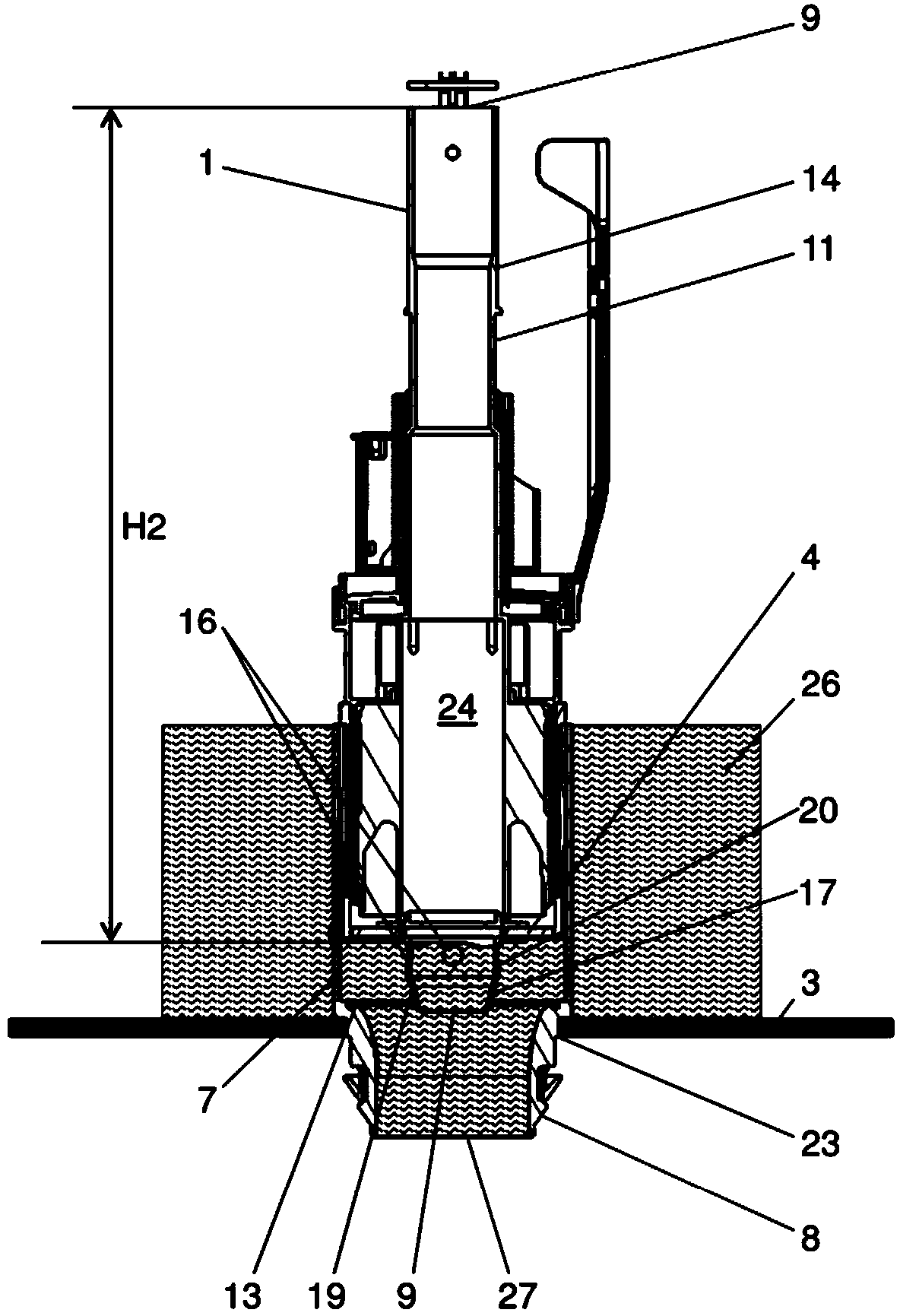

[0028] figure 1 A drain fitting 1 according to the invention is shown, which is fastened in an opening 23 of a flush tank 3 in a manner known per se. Here, only the region of the bottom of the flush tank 3 , known per se, is shown. This area is designed in a known manner such that it can hold water 26 up to water level 22 . The overflow pipe 11 has an inlet 9 at the top, which is above the water level 22 of the water 26 . The overflow pipe 11 has an outlet 10 at the bottom end. The overflow pipe 11 is arranged liftable in the housing 2 and has a buoy 12 and a closing weight 21 known per se. To bring about the flushing, the overflow pipe 11 is raised by means of an actuating device not shown here. exist figure 1 The overflow pipe 11 is shown in the raised state. In this case, the sealing element 4 is lifted from the valve seat 13 so that water 26 can pass through according to figure 2 The open valve flows out. The sealing element 4 is connected to the overflow line 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com