Patents

Literature

33results about How to "Improve beating degree" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of high-performance latex paper

InactiveCN102191725AImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensile strength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

Production technology of kraft vermicelli case board paper

InactiveCN105696395AHigh strengthIncrease the lengthPulp beating methodsPaper recyclingEnvironmental resistanceSurface layer

The invention discloses a production technology of kraft vermicelli case board paper. The production technology comprises the steps that recycled waste paper materials are screened, the recycled waste paper with low ash content is selected for pulping with softwood pulp, preliminary pulping is conducted through the processes of repulping, purifying, screening and the like, the fiber strength is emphatically improving in the grading and beating processes, longer fibers are screened to serve as surface layer pulp, the fiber beating degree is improved on the condition that the fiber strength is not damaged, and the fiber bonding strength is improved through the fiber arrangement mode on a net portion so as to improve the surface strength, toughness and folding strength of finished paper; by means of the measures of surface sizing, after-drying moisture precise control and finished paper coating, the product has the better explosion-proof line quality advantage and is more environmentally friendly, and the market share of the product is bound to be increased.

Owner:JIANGSU LEE & MAN PAPER MFG

Production method of recycled case board paper

PendingCN107460784AImprove beating degreeImprove bindingFlexible coversWrappersFiberFolding endurance

The invention relates to a production method of recycled case board paper. The recycled case board paper comprises a paper body, wherein the paper body sequentially comprises a face layer, a core layer and a bottom layer from top to bottom. The production method sequentially comprises the following steps of face layer raw material preparation in proportion, first time of pulping, first time of defibrination, core layer and bottom layer preparation in proportion, second time of pulping, second time of defibrination, bottom layer pulp preparation, core layer pulp preparation, mesh forming, squeezing, first time of drying, aspersive application on the surface, second time of drying, press-polishing and rolling and slitting. The production method has the advantages that a paper anti-burst agent is added in mesh forming and increases the contact area with fiber, more hydrogen bonds are formed for bonding, the bonding power of the fiber is improved, fiber cutinization is retarded, the folding endurance of the case board paper is improved, it is ensured that no shedding occurs on the surface after the paper is reused for multiple times, accordingly the damage rate of a smokebox is reduced, the one-time cyclic use rate of the smokebox is improved, it is ensured that the strength of paper cartons is not reduced and the cartons are not damaged after the paper is reused for multiple times, and secondary use is not affected.

Owner:ZHEJIANG JINGXING PAPER

Production process of decorative base paper

InactiveCN102330378AGood bonding strengthHigh surface finenessNon-fibrous pulp additionPulp beating methodsPulp treatmentChemical pulp

The invention relates to a production process of decorative base paper. The process comprises the following steps: carrying out pulping treatment on wood pulp, thus rough pulp is prepared; carrying out pulping treatment on the rough pulp, defibering fiber in paper pulp, cutting off moderately and brooming, thus mechanical pulp after knocking and needle leaf and broad leaf mixed chemical pulp after knocking are prepared; mixing the mechanical pulp and the chemical pulp, and adding starch and auxiliary chemicals in the pulp, thus pulp is prepared; and adding auxiliary chemicals such as glue, filler after dilution, and preparing the high-grade decorative base paper after the treatment of screening, processing of a wet end, processing of a pressing section, press polishing, paper winding and rewinding and packaging. According to the invention, through the improvement of production technology and devices in the production technology, the ratio of expansion and contraction, thickness, bubble points and other using performances are improved.

Owner:五洲特种纸业集团股份有限公司

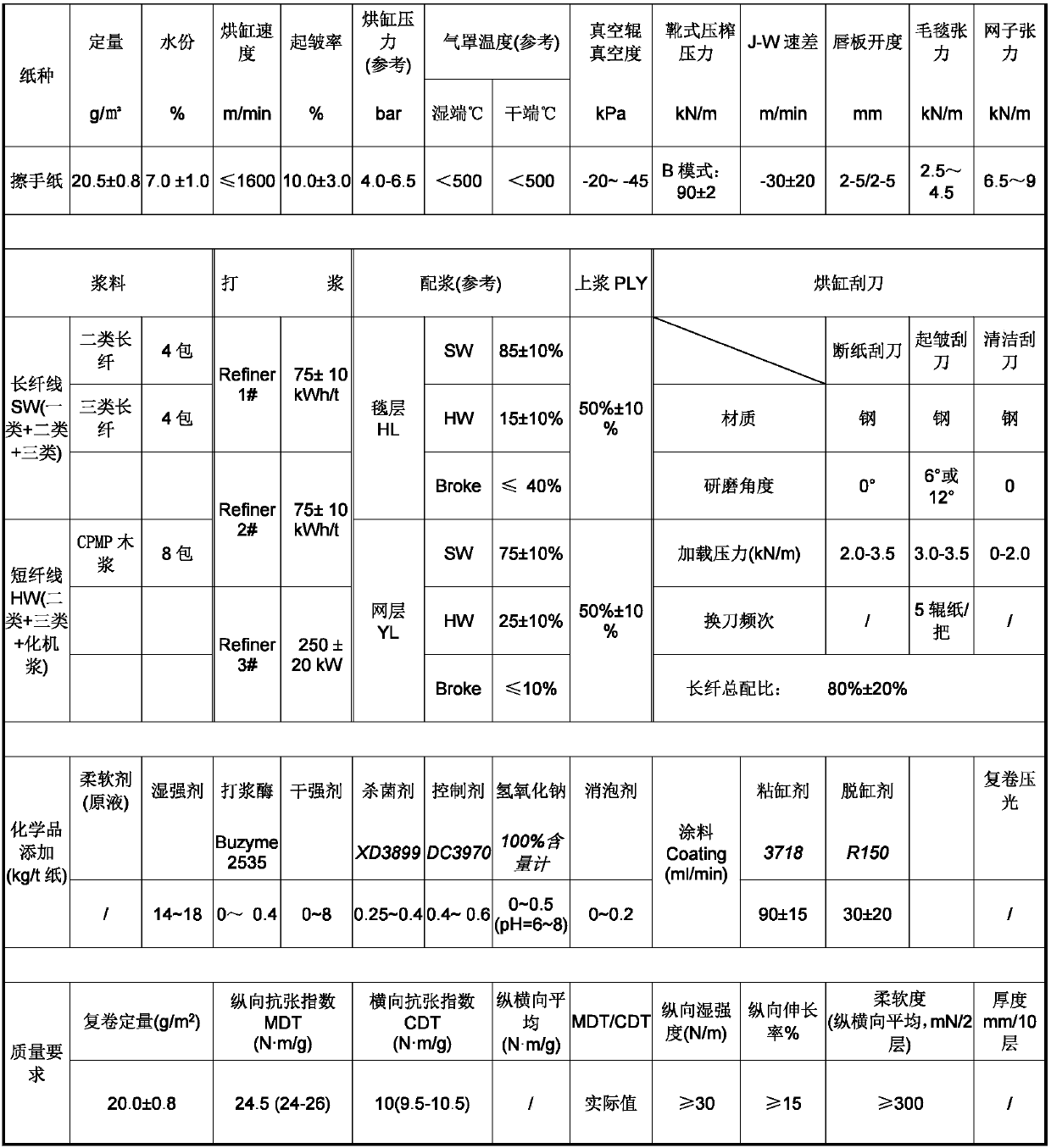

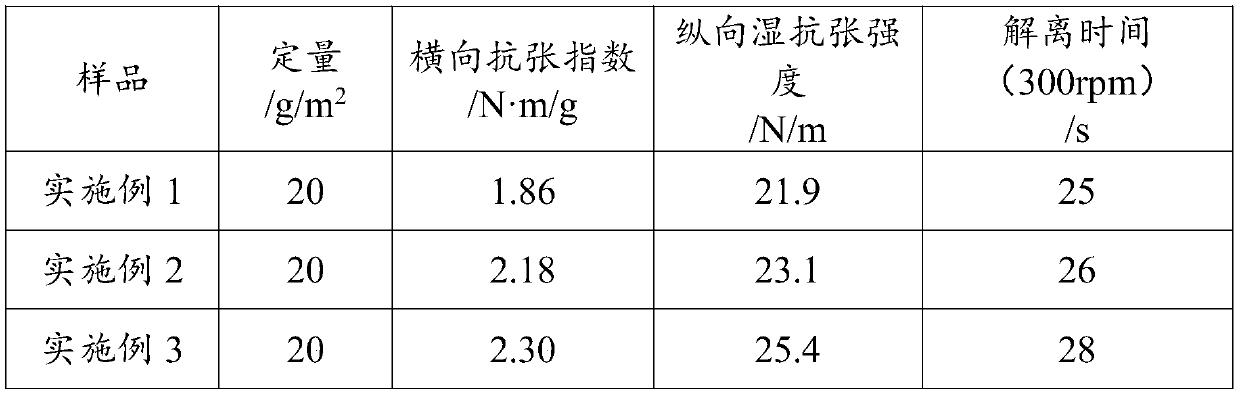

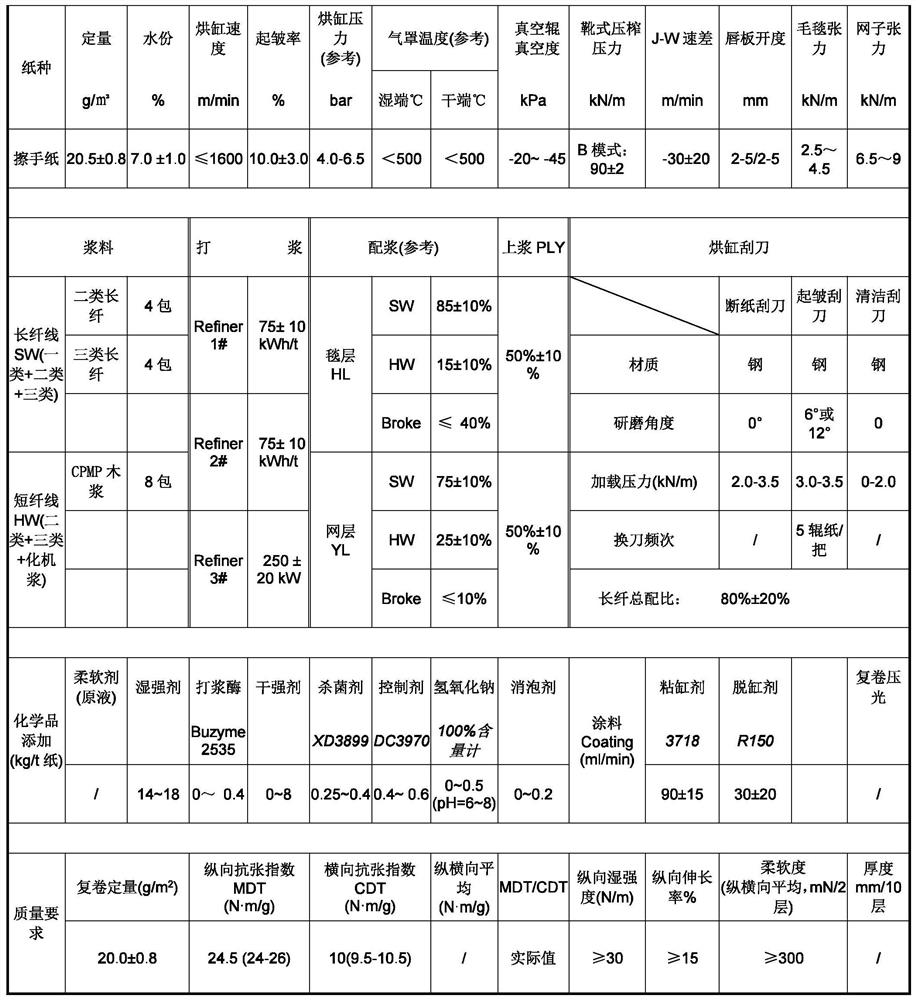

Sterile tissue and production process thereof

ActiveCN107663805AReduce porosityIncrease liquid absorptionSpecial paperPaper/cardboardFungicideSulfate

The invention discloses a sterile tissue and a production process thereof, and belongs to the technical field of tissue production. The tissue is prepared from, by weight, 20-60% of bleached sulfate softwood pulp, 30-70% of CPMP and 0-10% of broken paper pulp. According to the method, by adopting an appropriate principle and ratio, wet strength agents with low organic chlorine, biodegradable non-toxic fungicides and FDA-authenticated coatings, adopting forming equipment with a low vertical-horizontal tension ratio, a drying and sterilization process at the temperature higher than 40 DEG C andsafe non-toxic chemicals, and combining appropriate pressing printing processes, the produced tissue has the advantages of being low in quantification, low in vertical-horizontal tension ratio, sterile, environmentally friendly and high in water absorption performance.

Owner:SHANDONG HENGAN PAPER IND CO LTD

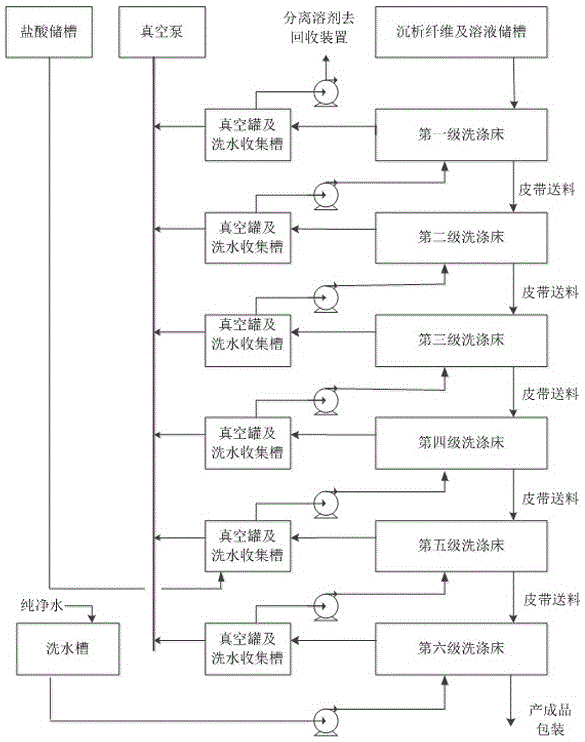

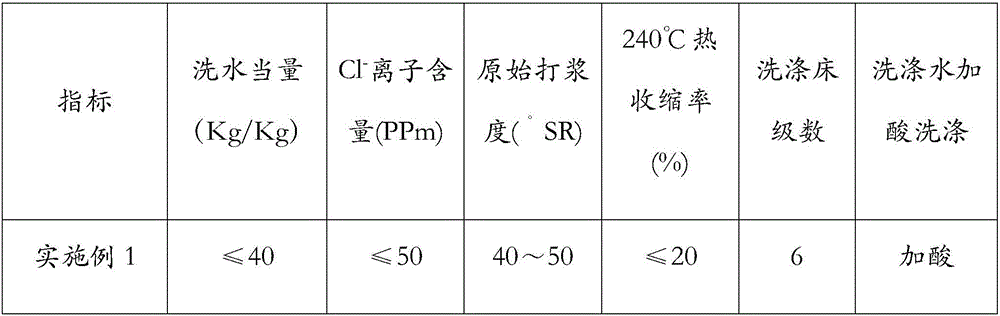

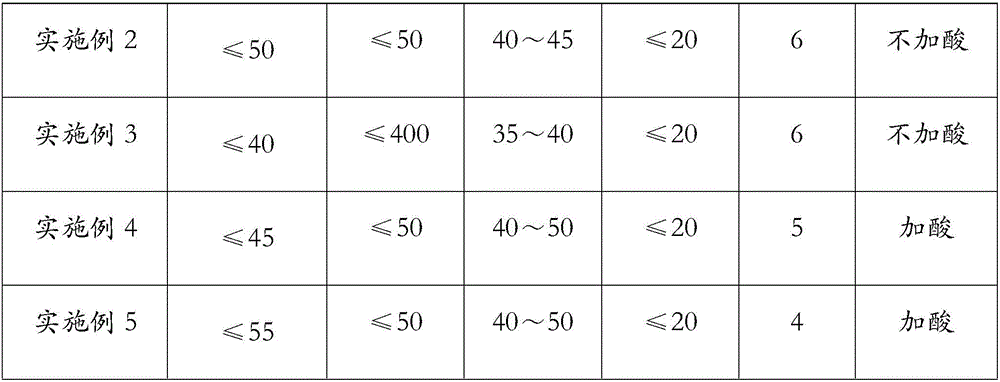

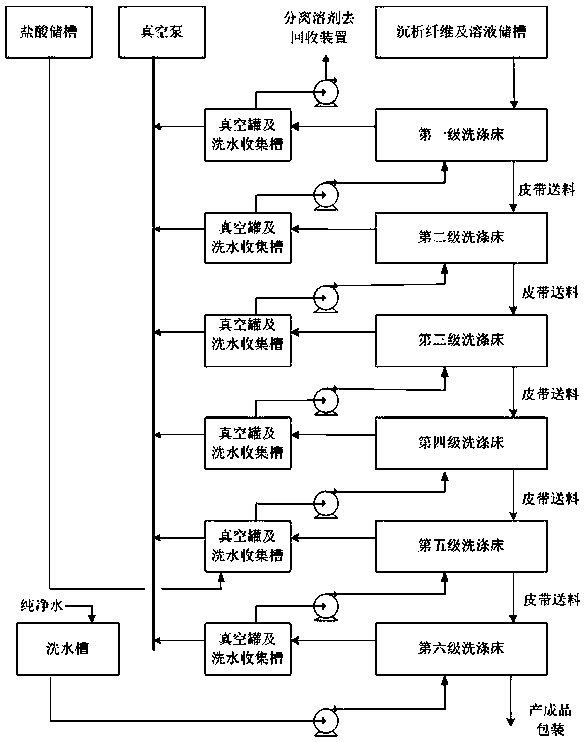

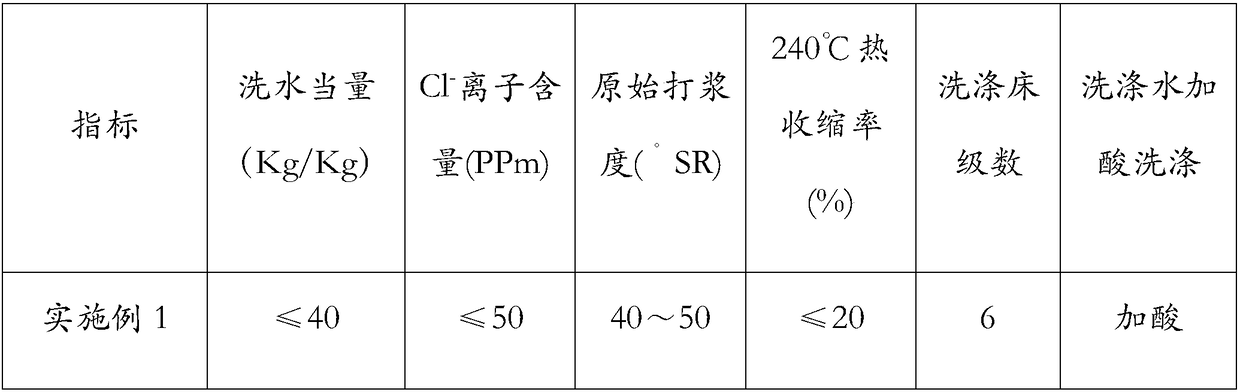

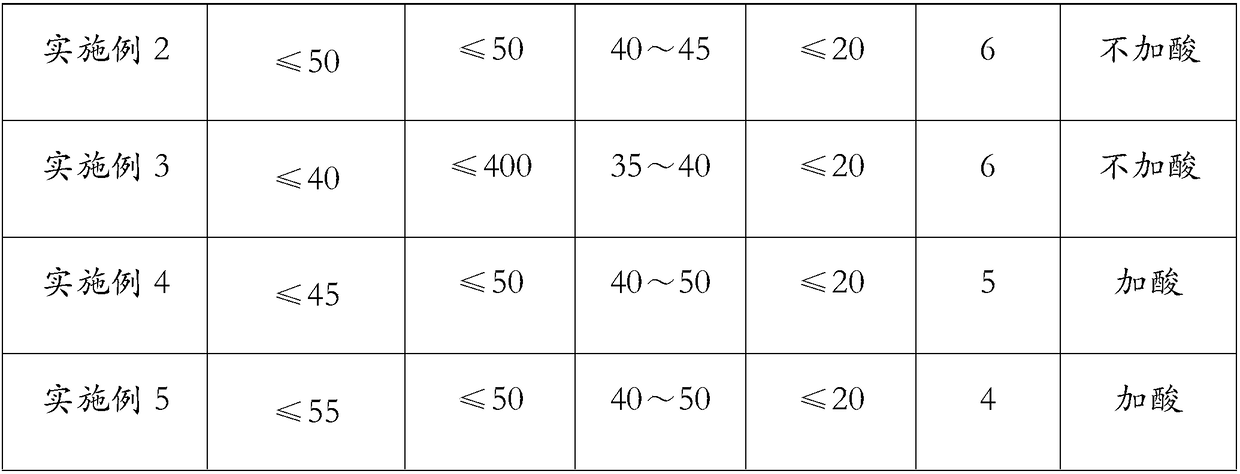

Method for washing meta-aramid fibrid

ActiveCN106367827AIncrease penetration rateAccelerated Diffusion DissolutionArtificial filament washing/dryingOligomerHydrolysate

The invention relates to the technical field of special synthesized fiber manufacturing, and in particular to a method for washing meta-aramid fibrid. The method comprises the following steps: performing continuous washing for six stages in sequence, from the sixth time of washing, performing countercurrent washing with pure water, recycling separated washing water for a former washing stage, and adding acid into washing water of the fourth stage to the first stage so as to acidify the fiber in an acid washing solution, so that the caked surface of the fiber is loosed, the infiltration rate of the washing water is increased, and diffusion dissolution of Cl- and chlorizated salts in the washing water in the fiber is accelerated; meanwhile, oligomers in the acid washing solution can be subjected to acidolysis and can be decomposed into acid hydrolysate which can be dissolved in the washing water, so that the product quality can be improved. By adopting the method, the content of Cl- ions of a fibrid product obtained by using the method can be less than or equal to 50PPm, the original beating degree of the fibrid product can be 35-50 DEG SR, the thermal shrinkage rate of the fibrid product at 240 DEG C is less than or equal to 20%, and the washing water equivalent of the fibrid product on a dry basis Kg is less than or equal to 40Kg.

Owner:四川辉腾科技股份有限公司

High-beating-degree cotton pulp product used for banknote paper and production method thereof

ActiveCN101967765AImprove beating degreeHigh folding resistancePulp beating methodsLiquid ratioFolding endurance

The invention provides a production method of a high-beating-degree cotton pulp product used for banknote paper, comprising the following steps: a) breaking and opening cotton linter; b) boiling and blanching, wherein, the alkali matching temperature is the normal temperature, the oven-dry amount of the matched alkali relative to the cotton linter is 0.5-4%; the oven-dry amount of hydrogen peroxide relative to the cotton linter is 0.5-5%; the matched alkali liquid ratio is 1:3-5; the relative oven-dry amount of oxygen bleaching stabilizer is 0.1-0.5%; and the relative oven-dry amount of penetrating agent is 0.5-0.9%; c) pulping and removing sands: 1) Holland pulping, wherein the current is 140A-160A, 2) fine fibering, wherein the pulping current is 150A-160A, 3) pulping again, and the pulping current is 300A-350A, 4) jordaning, and 5) removing the sands; and d) pulping. In the invention, low-temperature, low-alkali, boiling and leaching integrated pulping is adopted without chlorine, the boiling and leaching effects is improved by adding the oxygen leaching stabilizer and the penetrating agent assistant; and the produced cotton pulp has high beating degree, good strength, high folding endurance, and can be used for producing the banknote paper.

Owner:ANHUI SNOW DRAGON FIBER TECH

Preparation method of acrylic board surface lining protective body paper

ActiveCN109706780AReduce dosageReduce manufacturing costNon-fibrous pulp additionPaper/cardboardSpecific gravityXylanase

The invention discloses a preparation method of acrylic board surface lining protective body paper. The preparation method comprises following steps: by weight, 3 to 10 parts of cellulase, 1 to 8 parts of pectase, 3 to 10 parts of xylanase, 0.1 to 0.8 part of an alkylolamide, 0.1 to 0.6 part of Span-60, and 75.7 to 88.8 parts of water are combined to prepare a composite bio-enzyme preparation; byweight, 1 to 5 parts of a mixed pulpboard is introduced into a pulper, 95 to 99 parts of water is added, the composite bio-enzyme preparation is added, and defibering is carried out for 5 to 30min soas to obtain a mixed slurry, wherein the adding amount of the composite bio-enzyme preparation accounts for 100 to 300ppm of the weight amount of absolutely dry paper pulp; the mixed slurry is introduced into a pulping machine for pulp refining, pulping concentration ranges from 1 to 4%, and pulp refining is carried out until beating degree is 20 to 45 DEG SR; obtained paper pulp is subjected to dilution, screen moulding, squeezing, drying, and curling processing so as to obtain a finished product. According to the preparation method, the composite bio-enzyme preparation at an optimal ratio isadded in body paper pulp refining process, so that paper pulp beating degree is increased, pulp refining time is shortened, energy consumption is reduced, pollution is reduced, the ratio of fiber morphological substances in paper pulp is improved, and body paper object amount index is increased obviously.

Owner:浙江蓝宇新材料有限公司

Preparation method of color semi-transparent fruit bag paper

InactiveCN109056416ALow costImprove waterproof performanceDefoamers additionFlexible coversPapermakingProcess engineering

The invention relates to the technical field of papermaking, and provides a preparation method of color semi-transparent fruit bag paper, which overcomes the weaknesses of the prior art that the raw material and dye cost is high. The preparation method comprises the following steps: (1) pulping: pulping 25 to 30 parts by weight of broadleaf wood raw material, 35 to 50 parts by weight of needle wood raw material, 15 to 20 parts by weight of deinked pulp, 10 to 25 parts by weight of bagasse raw material by using a hydraulic disintegrator; (2) grinding the pulp; (3) mixing; (4) removing the slag;(5) performing the on-line papermaking; (6) wetting and dyeing: dyeing a semi-finished product by utilizing a wetting dyeing apparatus, wherein the wetting dyeing apparatus comprises an unwinding roller, a first guide roller, a second guide roller, a dyeing groove, a dye liquid storage drum, a rubber roller group, an air cylinder group, a third guide roller and a baking oven which are successively installed on a stander; and (7) finishing and slitting by virtue of a supercalender, packaging, and warehousing.

Owner:福建省晋江优兰发纸业有限公司

Production method of high-performance latex paper

InactiveCN102191725BImprove beating degreeHigh tensile strengthSpecial paperPaper/cardboardFiberTemperature resistance

The invention discloses a method for producing latex paper by using a circular-net multi-cylinder paper machine. 50 to 60 percent of bleached sulfate soft wood pulp, 35 to 45 percent of non-bleached sulfate soft wood pulp and 5 percent of manmade fiber are adopted, and the following technology is used at the same time so as to make the product better: defibrinating by using a previous-low-concentration fiberizer and a rear-middle-concentration fiberizer so that the beating degree is higher and the length of the fiber can be retained to the maximum extent, and the body paper has higher tensilestrength and flexibility and is hard to break during use; besides the two different soft wood pulps, a certain amount of manmade fiber is added into the fiber raw material, so that the strength and the anti-abrasion performance of latex paper are enhanced; the body paper subjected to dipping treatment according to an optimized latex formula has higher strength and water, oil and high temperature resistance performance; a specific surface coating and back coating mode is performed on the dipped body paper, so the tensile strength, the bending resistance and the liquid resistance of the finished paper are enhanced; meanwhile, the latex paper is softer and durable, and higher in the surface strength.

Owner:郭友实

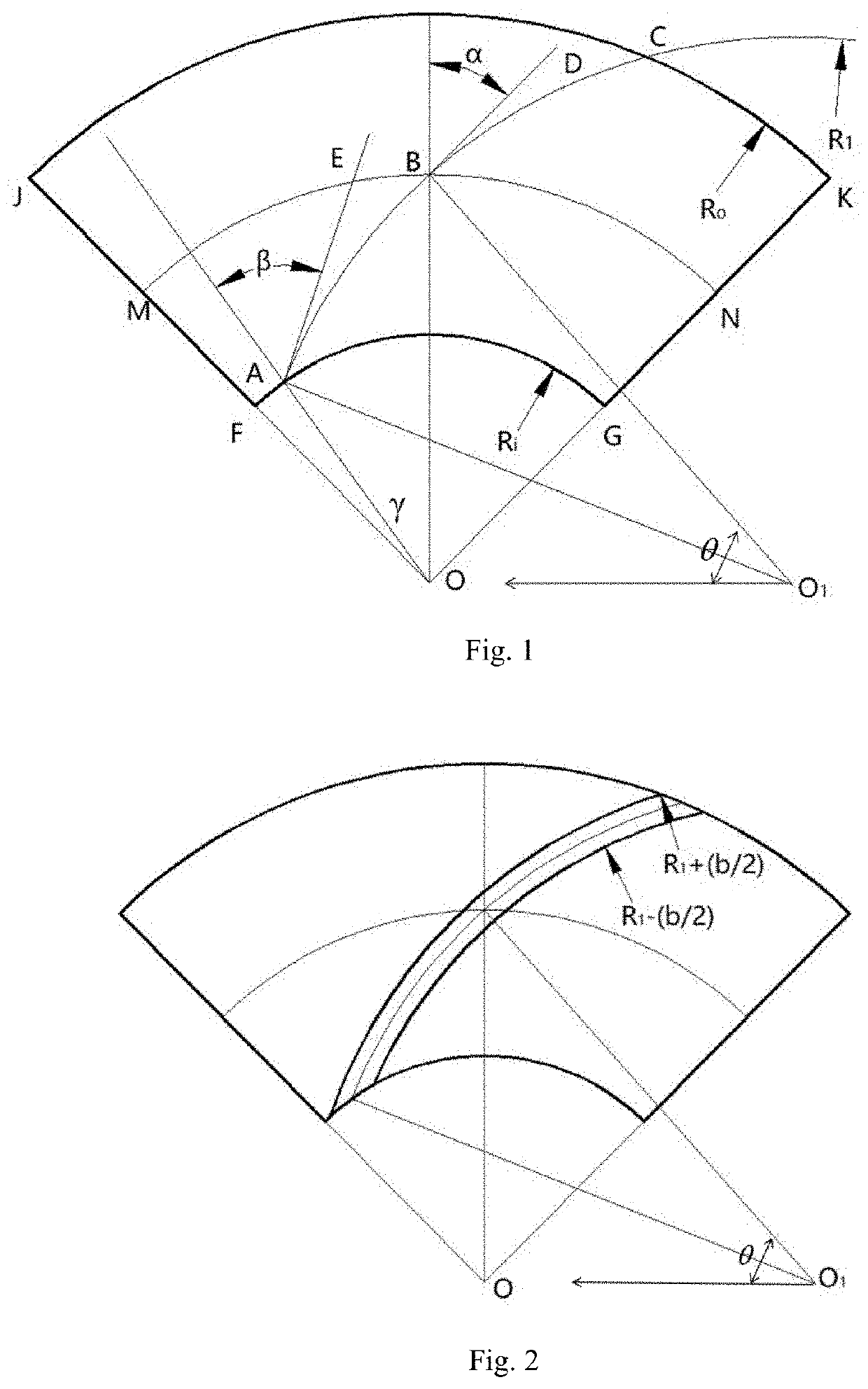

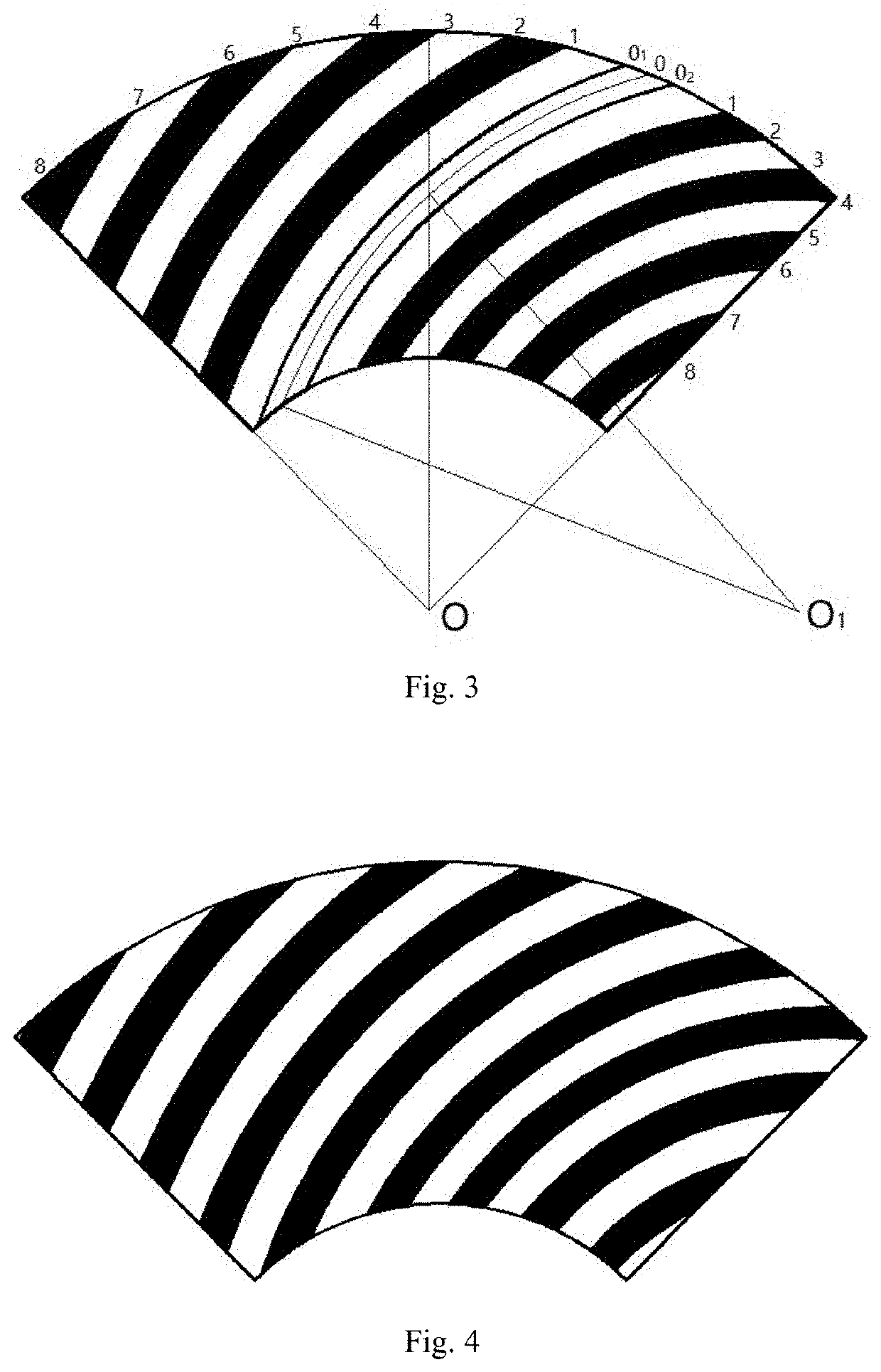

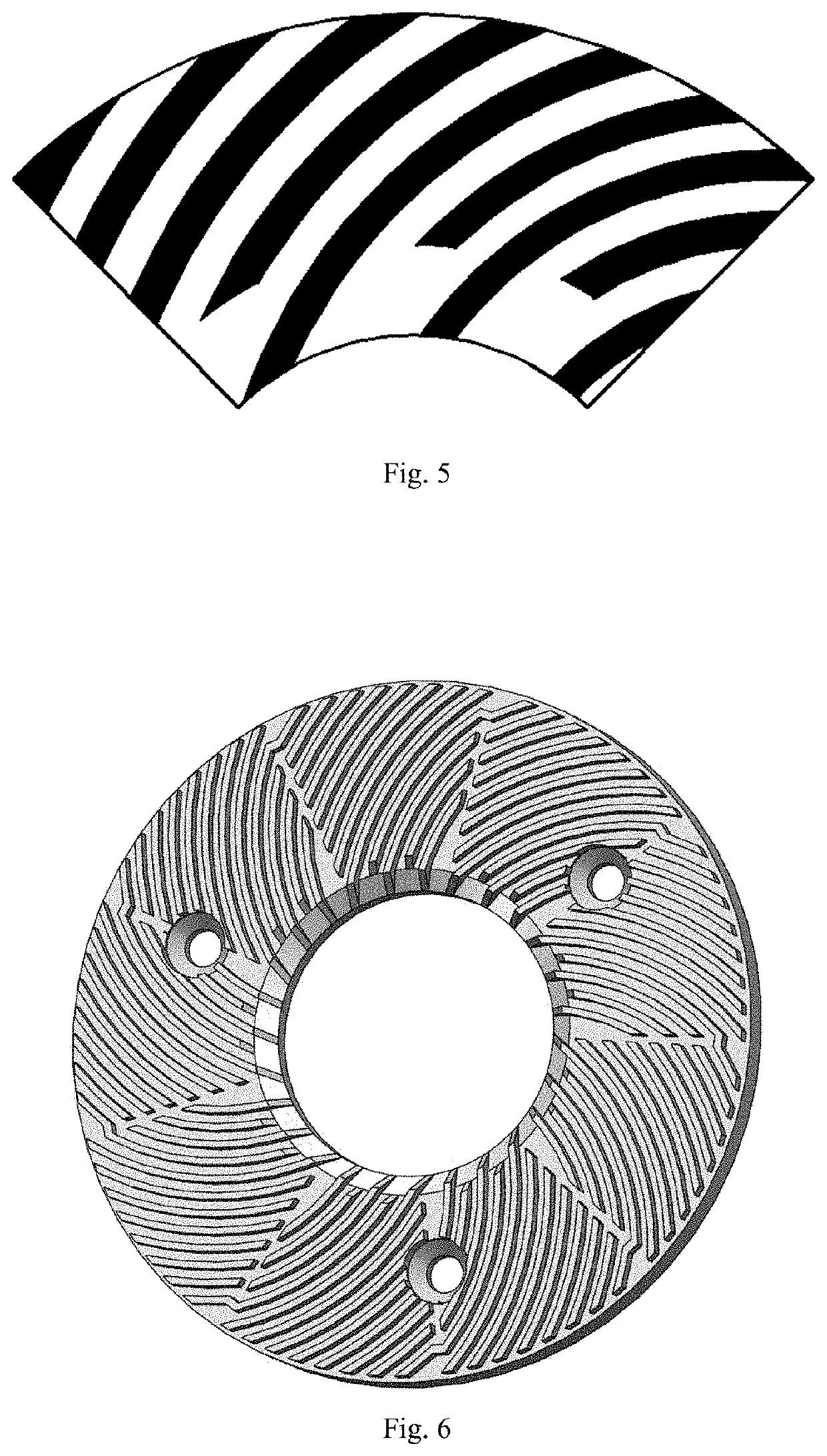

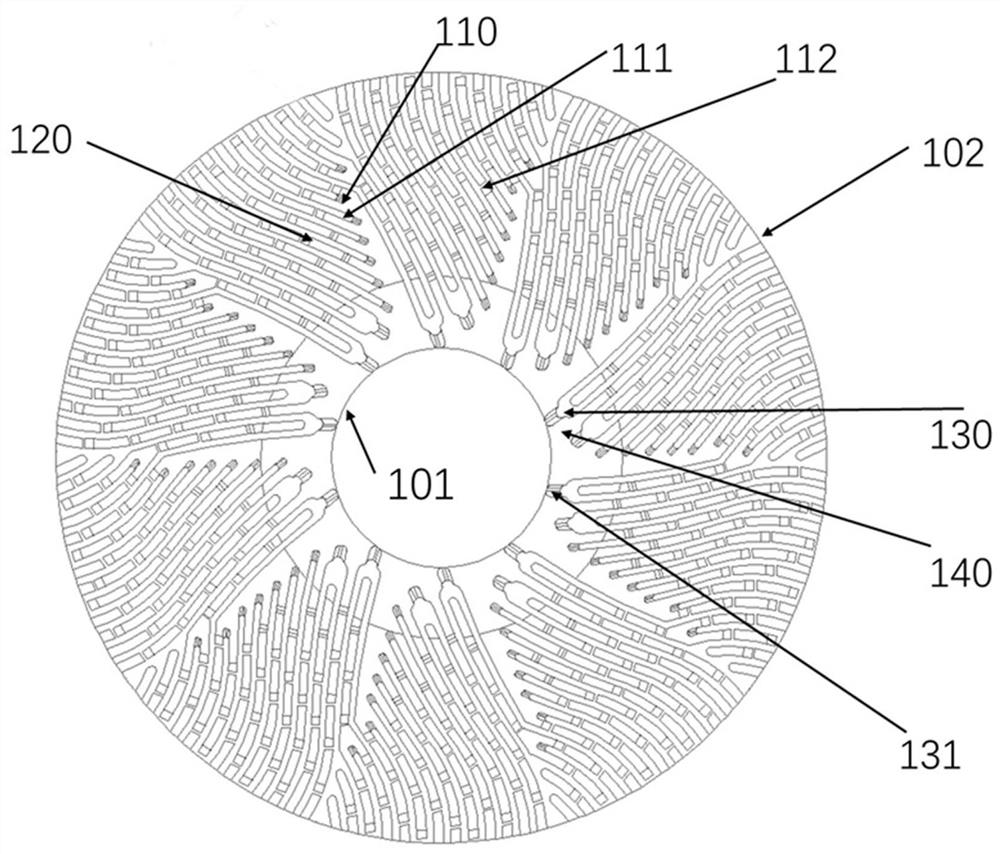

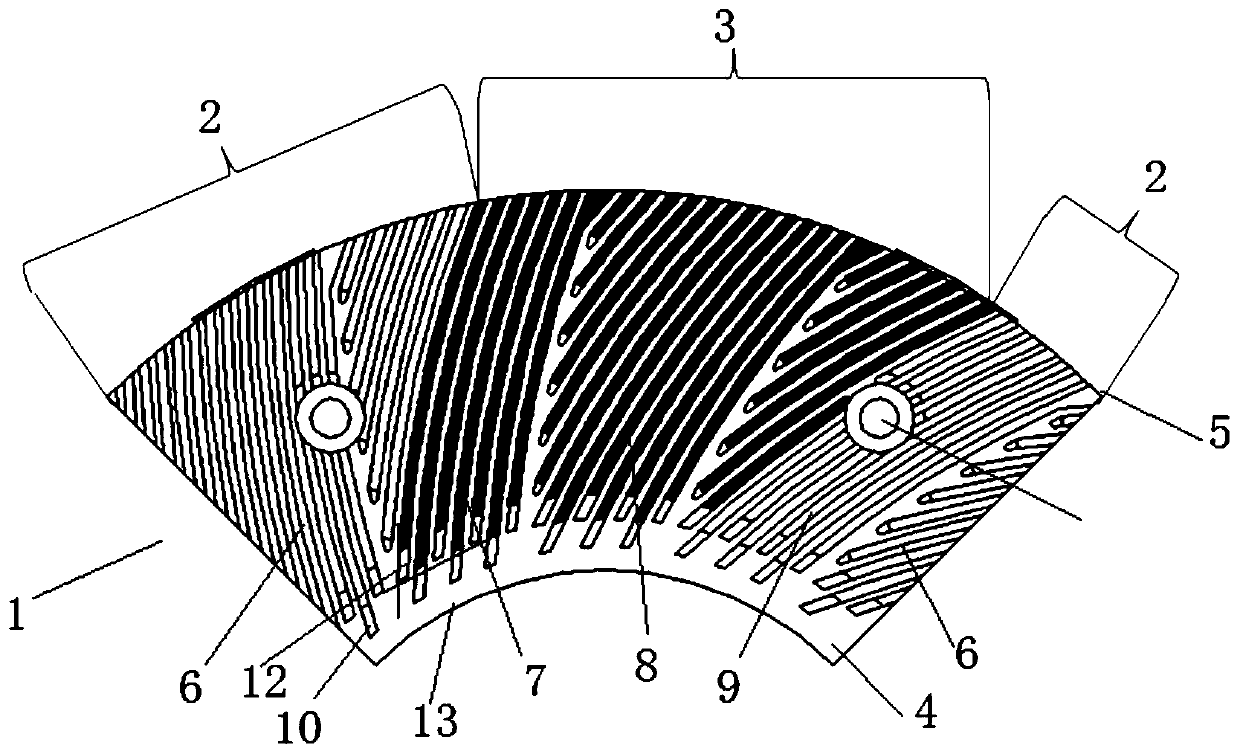

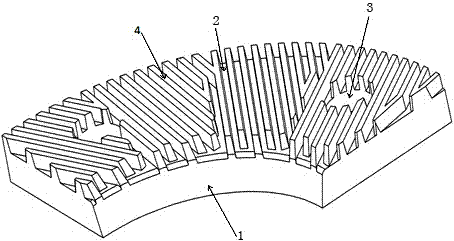

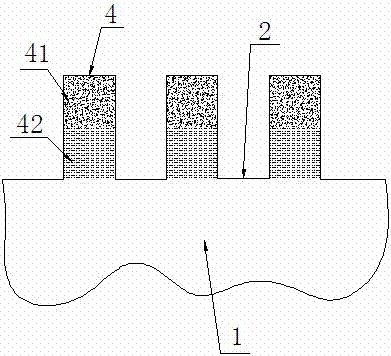

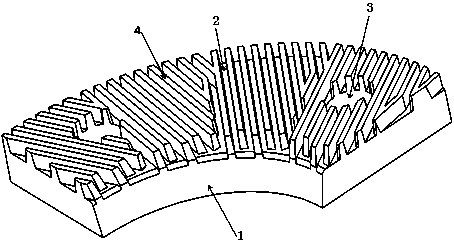

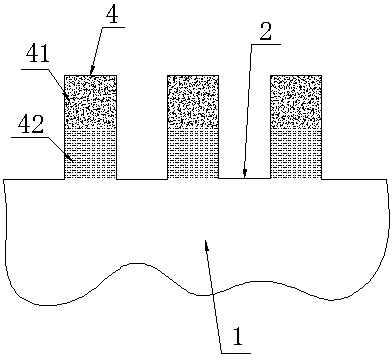

Method for designing refiner plates with equidistant curved bars

ActiveUS20200130055A1Simplify the design processLow refining intensityCasting safety devicesBonded abrasive wheelsStructural engineeringMechanical engineering

The present invention discloses a method for designing a refiner plate with equidistant curved bars, comprising following steps of: designing a central bar are of center curved bar and defining the bar angle for the equidistant curved bar; designing circle arcs for curved bars on two sides of center curved bar of equidistant curved bar segment; when the whole refining segment is full of circle arcs, trimming lines of outer circle arcs of the refining segment to complete the design of equidistant circle arcs on the two sides; and if required, dividing the bars into zones. In the present invention, by the definition of the bar angle for the curved bars and the parametric design of the equidistant curved bars by using circle are equations, it is ensured that the flexibility in designing an equidistant curved bar refiner plate is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Water-soluble toilet paper and preparation process thereof

PendingCN111335073AImprove bindingAvoid cutsNatural cellulose pulp/paperPaper/cardboardCarboxymethyl celluloseCellulose

The invention discloses water-soluble toilet paper and a preparation process thereof, and belongs to the technical field of toilet paper preparation. The method comprises the following steps: washingmixed bleached wood pulp with water, mixing the washed mixed bleached wood pulp and defibered and dispersed sodium carboxymethyl cellulose, and defibering and pulping in a pulping machine to obtain mixed pulp; screening and purifying the mixed pulp, slowly manufacturing paper with pulp by a papermaking machine, and squeezing to obtain paper sheets; and carrying out alkali treatment on the paper sheets by adopting a weakly alkaline sodium salt, drying, and rolling to obtain the water-soluble toilet paper. According to the invention, the preparation of the quick dissociation toilet paper is realized, the process is simple, the cost is low, and the preparation method is suitable for market popularization and application.

Owner:保定顺通卫生纸制造有限公司

Method for adding feather fiber for making air filtering paper applied in automobile industry

InactiveCN109137624AIncrease ventilationImprove beating degreeNon-fibrous pulp additionOrganic non-cellulose fibresHardwoodFilter paper

The invention discloses a method for adding feather fiber for making air filtering paper applied in the automobile industry. According to the method, hardwood pulp, softwood pulp and feather fiber pulp are mixed uniformly, a fast paper forming device is used for papermaking, then a paper blank is dried in a dryer, and an air filtering paper blank is prepared; styrene-acrylic emulsion and hydroxylsilicone oil emulsion are diluted by deionized water separately and then placed in soaking tanks respectively, the air filtering paper blank is soaked in the diluted styrene-acrylic emulsion at first,redundant emulsion on the paper blank is filtered off by a glue applying machine, and then the paper blank is dried on the dryer; then, the air filtering paper blank is placed into the diluted hydroxyl silicone oil emulsion for soaking, redundant emulsion on the paper is filtered off by the glue applying machine, then the paper blank is dried on a rotating drum type drier and put into a drying box for drying and solidification, and correspondingly the air filtering paper is prepared. The hydroxyl silicone oil emulsion can obviously improve the waterproof performance and dust holding capacityof the filtering paper. Since hydroxyl silicone oil has natural waterproof performance, the filtering paper has excellent waterproof performance, and especially through application of an adhesive structure, the dust holding capacity of the filtering paper is substantially increased.

Owner:BENGBU CITY MINGWEI FILTER CO LTD

Agricultural big seed bag paper and preparation method thereof

Belonging to the technical field of specialty paper manufacturing, the invention discloses an agricultural big seed bag paper and a preparation method thereof. The agricultural big seed bag paper comprises a plant fiber raw material and an auxiliary material. The plant fiber raw material and a reinforcing agent are in a weight part ratio of 100:1-4 (absolute dry weight). The beating degree of theplant fiber subjected to beating treatment is 25degree SR-50degree SR, and the wet weight range of the fiber is 6.0g-14.0g. The pulp subjected to beating treatment is added with water to be prepared into a 0.25%-0.35% slurry, a reinforcing agent is employed for reinforcement, and an inclined net papermaking machine wet papermaking process is adopted for preparation. The seed bag paper has the characteristics of low quantity, high dry strength and high bursting strength, etc., can meet the processing performance requirements of processing radish, green pepper and other large-particle size seedsinto seed ropes, seeding test shows that the obtained seed ropes have high seed emergence rate, fast paper decomposition speed and no pollution to soil, and meets the green and environmental protection requirements.

Owner:浙江鹏辰造纸研究所有限公司

Rotor untwisting toothed plate with low feeding resistance

PendingCN111979824AImprove breakdown crushIncrease the degree of fibrillationPulp beating/refining methodsRack unitStructural engineering

The invention discloses a rotor untwisting toothed plate with low feeding resistance. The rotor untwisting toothed plate is mounted on an untwisting machine rotating seat; the rotor untwisting toothedplate is used for being matched with a stator untwisting toothed plate of an untwisting machine static seat; the rotor untwisting toothed plate faces the stator untwisting toothed plate and is matched with the stator untwisting toothed plate in a plane contact manner; a plurality of rack units are distributed in the circumferential direction of the rotor untwisting toothed plate; the racks extendfrom the inner edge to the outer edge in the radial direction and are in an S shape in the longitudinal depth direction; a tooth groove is formed between every two adjacent racks in each rack unit; aplurality of blocking dams are transversely arranged in each tooth groove; every two adjacent racks are combined into an integrated wide tooth when each rack unit is located at the position 20-200 mmaway from the inner edge; and a bionic duckbilled flow guide end is arranged at the end, directly facing the inner edge, of each integrated wide tooth. The rotor untwisting toothed plate has the advantages of being high in abrasion resistance, good in impact resistance, not prone to tooth breakage, long in service life, capable of reducing power consumption and the like.

Owner:南通华严磨片有限公司

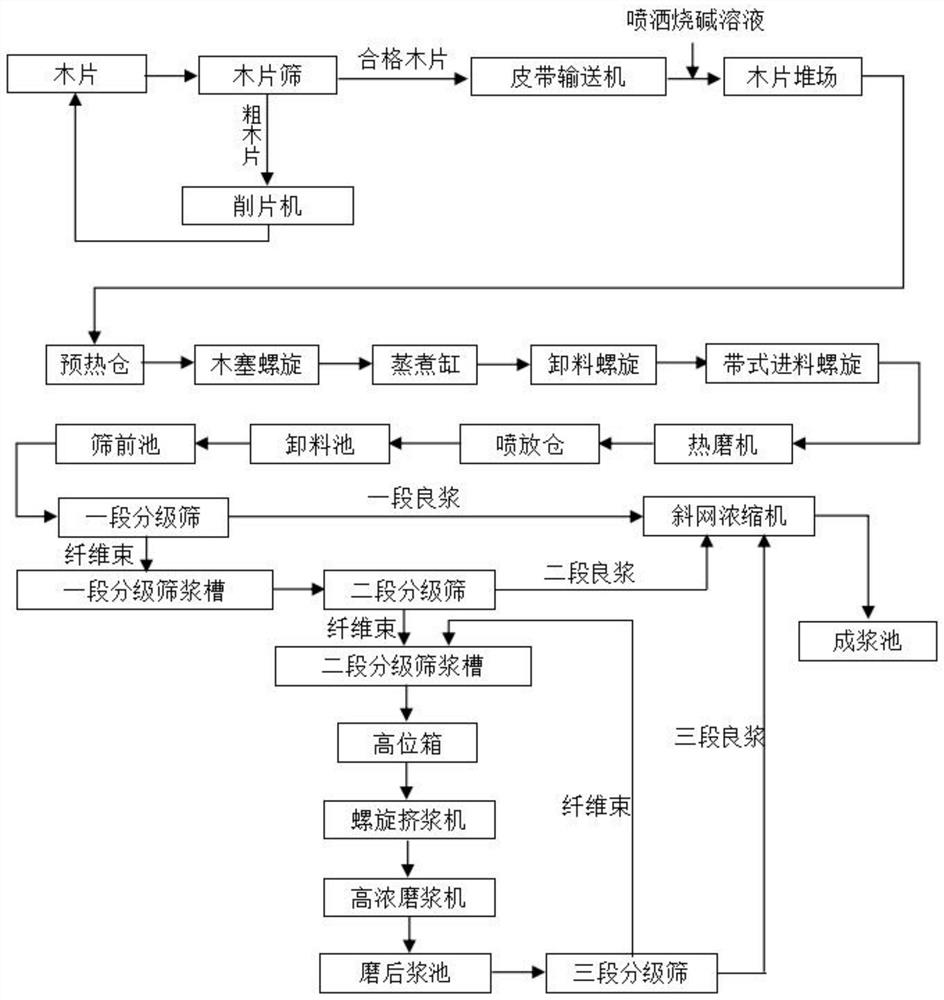

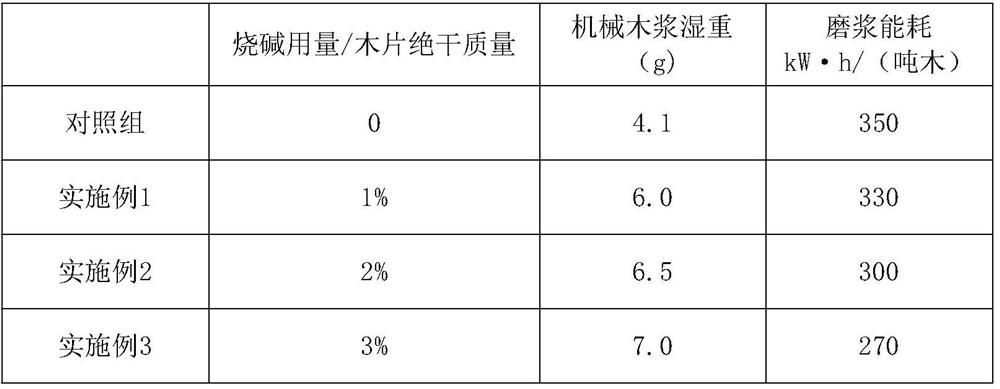

Wood chip pretreatment method and pulping method for grey paperboard production

ActiveCN112981998AImprove softening effectFully moistenedPretreatment with alkaline reacting compoundsDigestersPaperboardWoodchips

The invention relates to a wood chip pretreatment method for grey paperboard production, which comprises the following steps of: cutting wood chips by a chipping machine; screening the wood chips by a wood chip sieve to obtain qualified wood chips; uniformly spraying a caustic soda solution on the wood chips in the process of conveying the qualified wood chips by a belt conveyor; fully wetting the wood chips; and falling down the wood chips to a wood chip storage yard for storage. According to the wood chip pretreatment method for grey paperboard production, the surface of the wood chip is fully wetted through the caustic soda solution; the softening effect of the wood chip is promoted; the pulping energy consumption is reduced in the follow-up pulping production; the pulping degree of paper pulp and the fibrillation degree of fiber are improved; and therefore the quality of the paper pulp is improved.

Owner:DONGGUAN JINTIAN PAPER CO LTD

Grinding plate unit of grinding plate of pulping machine

PendingCN110952366AIncrease the effective contact lengthFacilitate gradual entryPulp beating/refining methodsGrinding teethMaterials science

The invention relates to a grinding plate unit of an grinding plate of a pulping machine, the grinding plate unit is a fan-shaped sheet and is provided with an inlet end and an outlet end, grinding teeth are arranged on a bottom plate of the grinding plate unit, tooth grooves are formed between every two adjacent grinding teeth, and in the circumferential direction of the grinding plate unit, thegroove width of a first tooth groove located in the middle of the grinding plate unit is larger than the groove width of second tooth grooves located in the two ends of the grinding plate unit. The tooth height of the first grinding teeth located in the middle of the grinding plate unit is larger than the tooth height widths of second grinding teeth located at the two ends of the grinding plate unit. The tooth widths of the grinding teeth on the whole grinding sheet unit are the same; and the grinding teeth are arc-shaped in the depth direction. Compared with the prior art, the grinding plateunit has the advantages of high beating degree and the like.

Owner:上海东冠纸业有限公司

Preparation method of double-sided high-gloss tissue paper

InactiveCN109056415AHigh glossImprove surface smoothnessPulp beating methodsDryer sectionState of artPapermaking

The invention relates to the technical field of papermaking, and provides a preparation method of double-sided high-gloss tissue paper, which solves the problem in the prior art that only one side isof high gloss. The preparation method comprises the following steps: 1) pulping, wherein the beating degree of pulp is 70-75 degrees SR; 2) degritting; and 3) papermaking, namely diluting the mixed pulp subjected to degritting with water, passing through a pressure screen, a head box, a net part, a press part and a drying part, and reeling and slitting to obtain the finished product, wherein the drying part comprises a first drying cylinder, a second drying cylinder, a third drying cylinder, and atomizing nozzles arranged at inlets of the drying cylinders, each drying cylinder is provided witha cylinder surface with high hardness and high smoothness, the atomizing nozzles spray a luster-enhancing remover to each of the drying cylinder surfaces, and carrier rollers are arranged at both sides of the second drying cylinder.

Owner:福建省晋江优兰发纸业有限公司

A kind of sterile paper towel and its production process

ActiveCN107663805BReduce porosityIncrease liquid absorptionSpecial paperPaper/cardboardTextile printerFungicide

Owner:SHANDONG HENGAN PAPER IND CO LTD

A kind of preparation method of acrylic plate veneer protection base paper

ActiveCN109706780BImprove beating degreeReduce the degree of beatingNon-fibrous pulp additionPaper/cardboardPectinaseFiber

Owner:浙江蓝宇新材料有限公司

Pulping method for reconstituted tobacco, pulp, reconstituted tobacco and application

The invention belongs to the field of tobacco products, and relates to a pulping method for reconstituted tobacco, which comprises the following steps of: (1) performing extraction and solid-liquid separation on a tobacco raw material to obtain a solid-phase substance, and grinding the solid-phase substance into pulp by using a high-concentration disc mill, wherein the content of absolutely dry substances in the solid-phase substance is 15-21%, and the gap of a grinding disc is 0.5-1 mm; (2) at the pH value of 3-7 and at the temperature of 20-43 DEG C, using an activated pectinase preparation to perform enzymolysis on the pulp for 0.5-5 hours to obtain an enzymolysis product, wherein 500-6000 u of enzyme activity is adopted for each kilogram of absolutely dry pulp; (3) grinding the enzymolysis product into thick liquid by a high-concentration disc mill, wherein the gap of a grinding disc is 0.3-0.45 mm; and (4) diluting the obtained pulp until the concentration is 0.8%-3.5%, and grinding the pulp by using a low-concentration refiner, wherein the gap of a grinding disc is 0.1-0.25 mm. The invention further relates to the prepared pulp, reconstituted tobacco and application. According to the method, the fiber yield, the beating degree and the fiber crimp rate of the tobacco pulp are improved, and the pectin content of the tobacco pulp is reduced.

Owner:CHINA TOBACCO FUJIAN IND

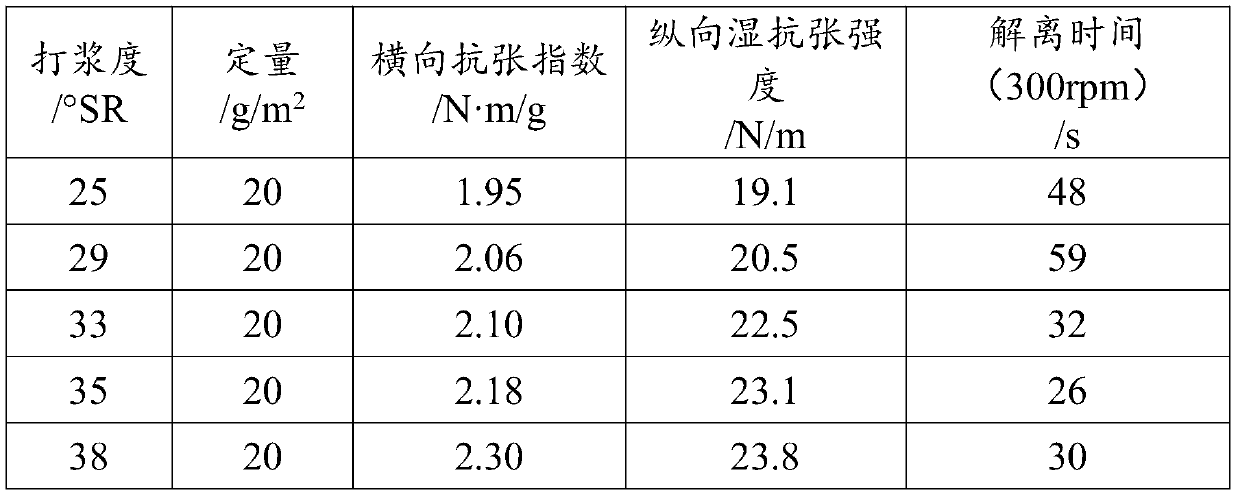

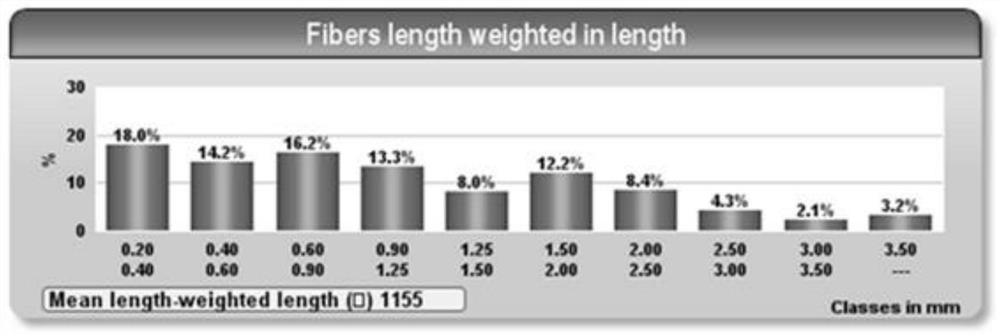

Pulping method for improving pulping degree of softwood pulp

InactiveCN108086027AImprove beating degreeEasy to cutPulp beating methodsNon-macromolecular organic additionEngineeringFiber structure

The invention belongs to the technical field of household paper, and particularly relates to a pulping method for improving the pulping degree of softwood pulp. The method comprises the following steps: defibering a softwood pulp board by using a hydraulic pulping machine, carrying out heat preservation treatment by using a treatment liquid, and then carrying out pulping with the cooperation of agrinding material. Compared with the prior art, the method provided by the invention has the following advantages that high-temperature soaking treatment is carried out on the softwood pulp board defibering material by using the treatment liquid, the fibers can be swelled, fine fibers are generated or fibers are refined, the fiber structure is destroyed, the effective components of the treatment liquid can enter the inner part of the fibers for forming an amorphous area in the fibers, the combination among the fibers is weakened, then with the cooperation of the use of the grinding material, the fiber surfaces can be further activated and relaxed, and under the mechanical force, the fibers can be easily cut off and fibrillated, so that the improvement of the pulping degree of the softwoodis facilitated.

Owner:ANHUI BILUN DOMESTIC PAPER CO LTD

A kind of washing method of meta-aramid precipitated fiber

ActiveCN106367827BIncrease penetration rateAccelerated Diffusion DissolutionArtificial filament washing/dryingOligomerHydrolysate

The invention relates to the technical field of special synthesized fiber manufacturing, and in particular to a method for washing meta-aramid fibrid. The method comprises the following steps: performing continuous washing for six stages in sequence, from the sixth time of washing, performing countercurrent washing with pure water, recycling separated washing water for a former washing stage, and adding acid into washing water of the fourth stage to the first stage so as to acidify the fiber in an acid washing solution, so that the caked surface of the fiber is loosed, the infiltration rate of the washing water is increased, and diffusion dissolution of Cl- and chlorizated salts in the washing water in the fiber is accelerated; meanwhile, oligomers in the acid washing solution can be subjected to acidolysis and can be decomposed into acid hydrolysate which can be dissolved in the washing water, so that the product quality can be improved. By adopting the method, the content of Cl- ions of a fibrid product obtained by using the method can be less than or equal to 50PPm, the original beating degree of the fibrid product can be 35-50 DEG SR, the thermal shrinkage rate of the fibrid product at 240 DEG C is less than or equal to 20%, and the washing water equivalent of the fibrid product on a dry basis Kg is less than or equal to 40Kg.

Owner:四川辉腾科技股份有限公司

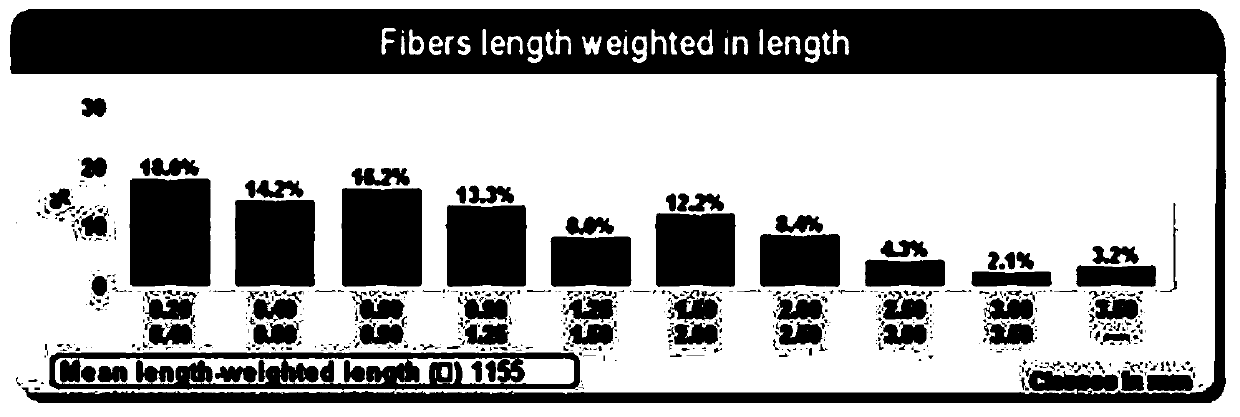

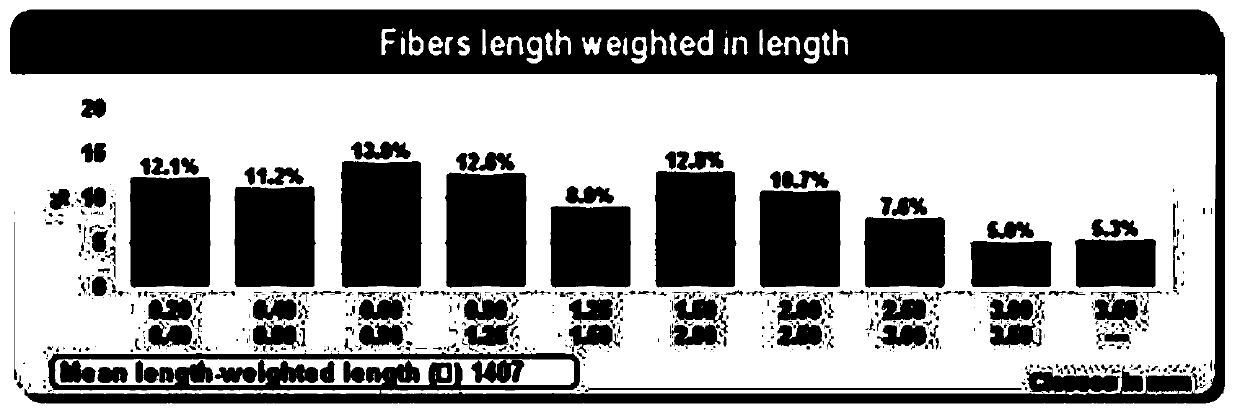

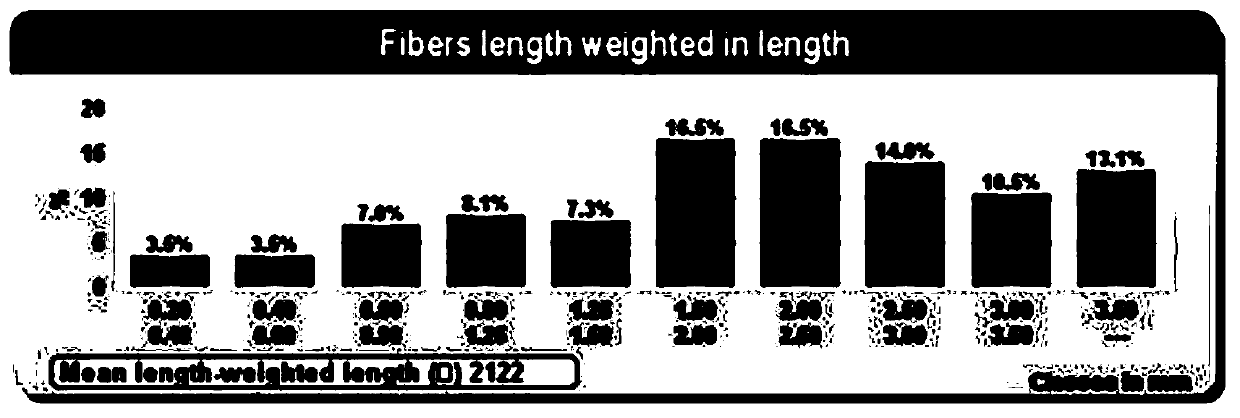

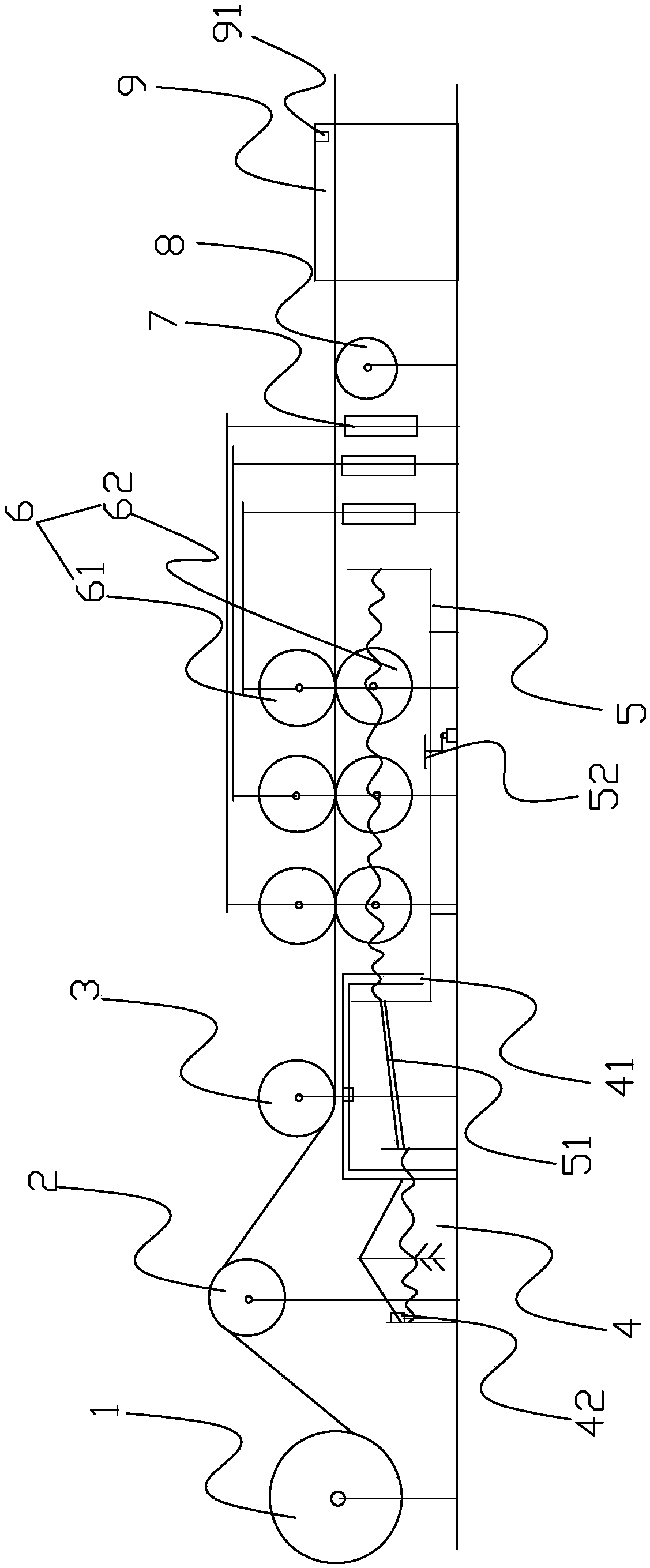

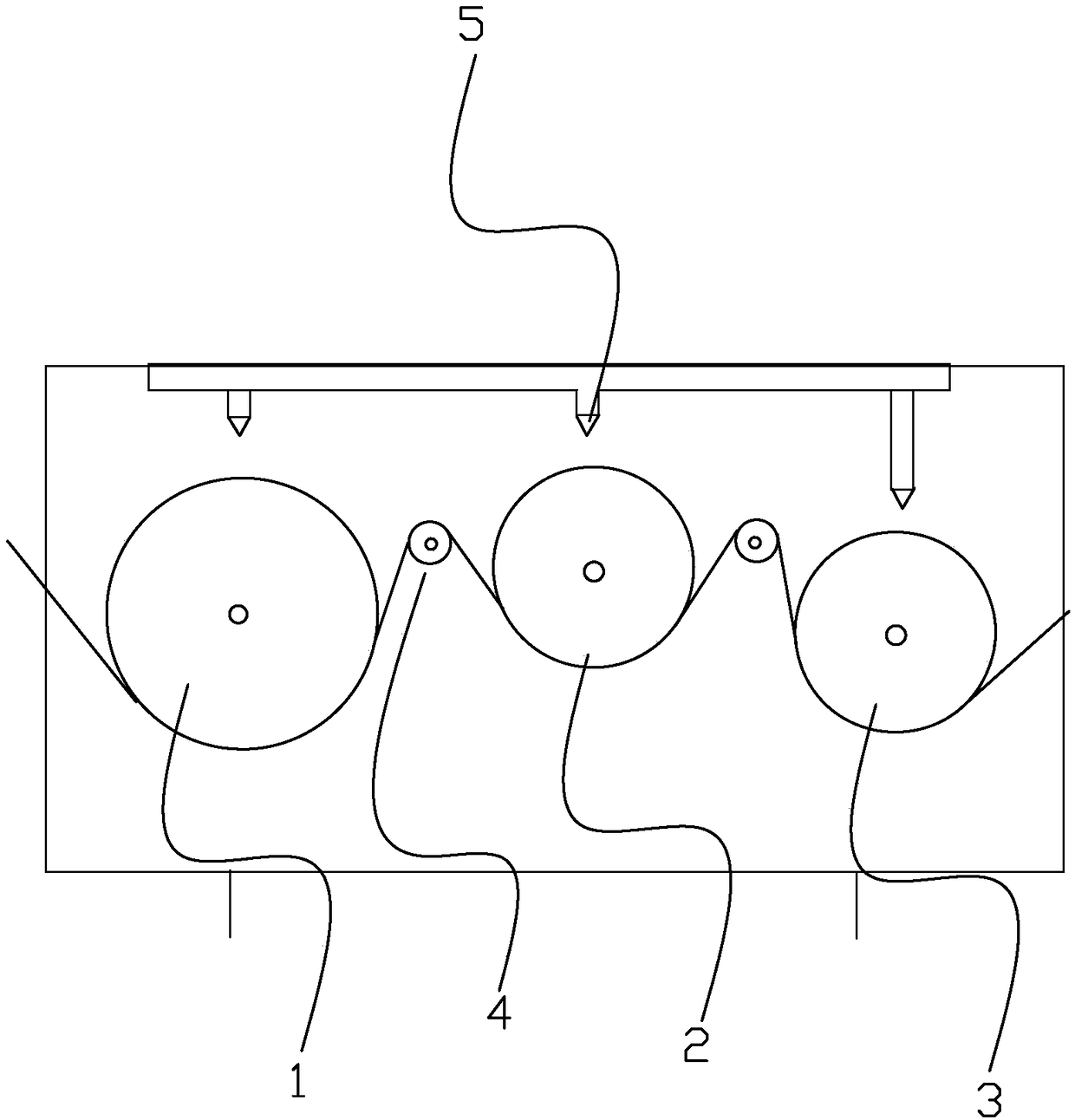

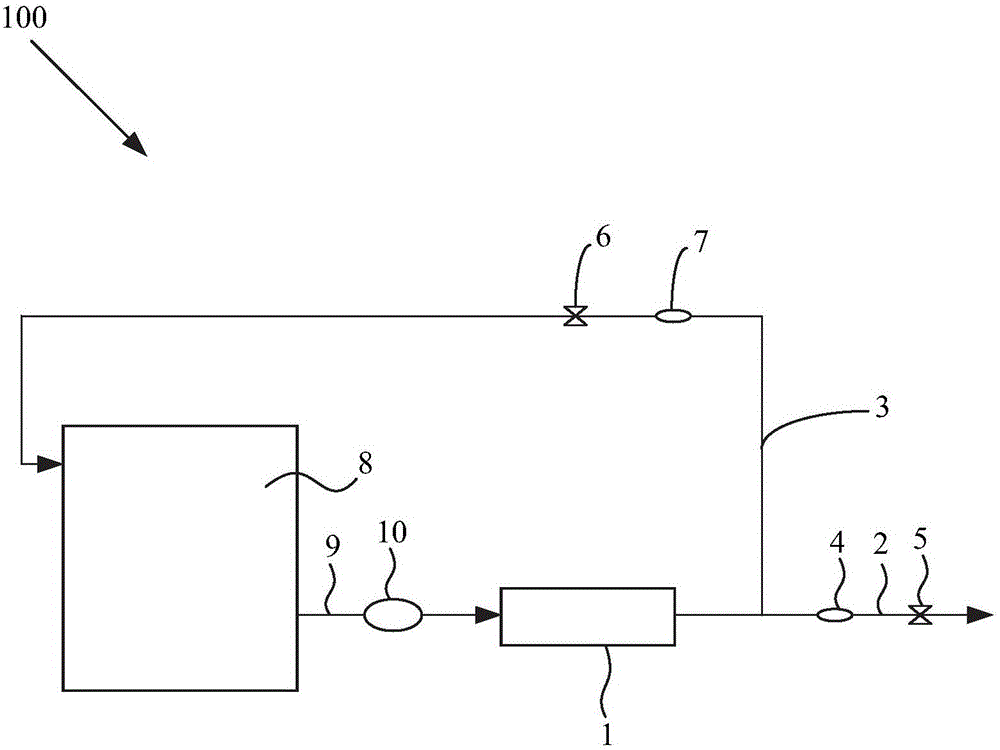

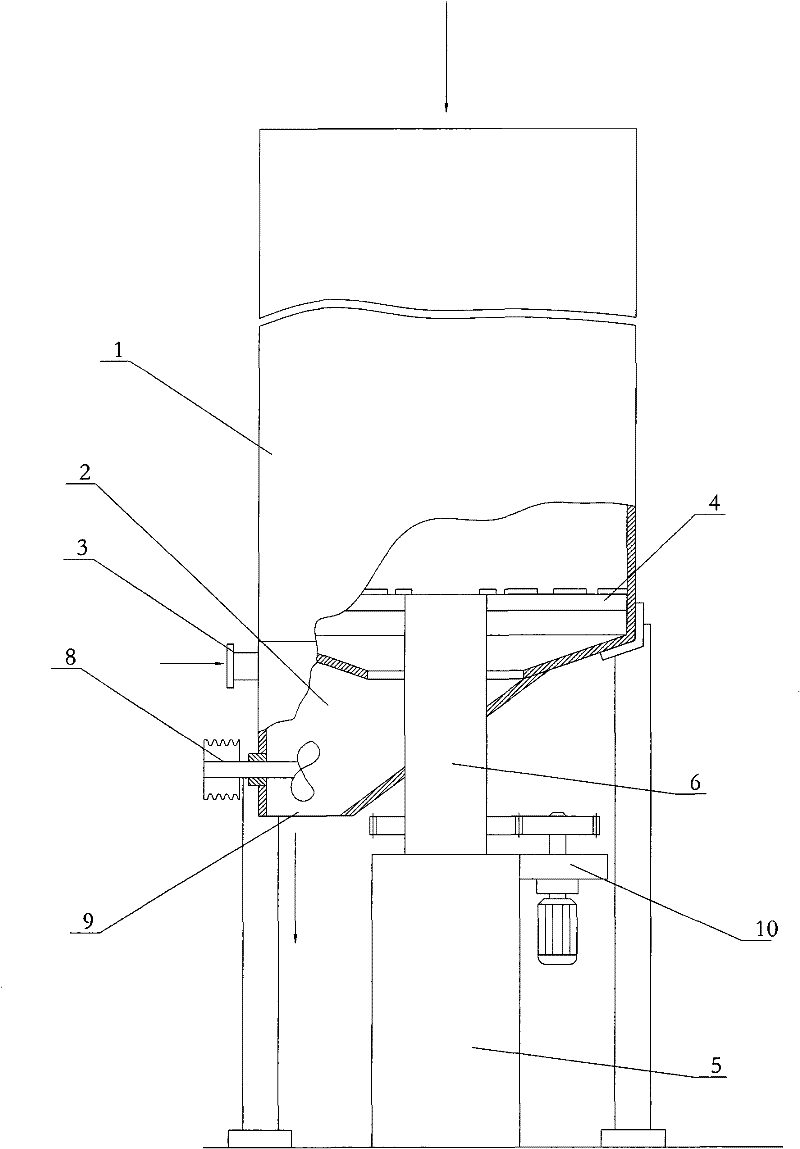

Pulping machine and long fiber beating degree control method and system thereof

InactiveCN106368037AReduce vibrationImprove beating degreePulp beating/refining methodsFiberPulp and paper industry

The invention discloses a pulping machine and a long fiber beating degree control method and system thereof. The pulping machine is provided with a pulping chamber, a return pipe and an output pipe, wherein an outlet of the pulping chamber is connected with the output pipe, and the return pipe is connected with the output pipe. The pulping machine further comprises an on-line pulp consumption detector, an on-line pulp return capacity detector, a return pipe control valve and an output pipe control valve; the on-line pulp consumption detector and the on-line pulp return capacity detector are used for detecting the pulp consumption and the pulp return capacity on line respectively; the return pipe control valve and the output pipe control valve are installed on the return pipe and the output pipe and used for controlling the pulp return capacity and the pulp consumption respectively; the return pipe control valve is controlled according to the detected pulp return capacity, and the output pipe control valve is controlled according to the detected pulp consumption. The pulping machine is low in vibration and high in beating degree.

Owner:UPM CHINA

A kind of high-strength water-resistant environment-friendly kraft cardboard and its preparation method

ActiveCN105484106BQuality assuranceGuaranteed weightSpecial paperWater-repelling agents additionFiberPulp and paper industry

High-strength, water-resistant and environment-friendly kraft paper is characterized by comprising a printing layer, a waterproof layer, a sandwich layer, a lining layer and a bottom layer, wherein paper pulp for the printing layer is 100% wood paper pulp, the waterproof layer adopts domestic waste paper pulp added with 2%-5% of a waterproof agent, paper pulp for the sandwich layer is 100% domestic waste paper pulp, the liner layer adopts mixed paper pulp of non-plant fibers and domestic waste paper pulp, and paper pulp for the bottom layer is 100% imported waste paper pulp. The preparation method comprises steps as follows: (1) preparation of ingredients; (2) pulping; (3), grit removal; (4) fiber sieving; (5) pulp refining; (6), layered water filtering and papermaking; (7), pre-drying; (8) coating; (9) pressing; (10) drying; (11) paper formation. The high-strength, water-resistant and environment-friendly kraft paper has the benefits as follows: the kraft paper has advantages of high strength, water resistance and easiness in printing, meanwhile, the cost of kraft paper is reduced by about 20%, and greater benefits are brought to enterprises.

Owner:河北昌泰纸业有限公司

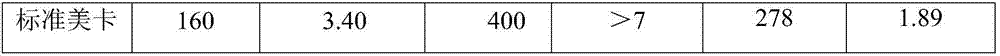

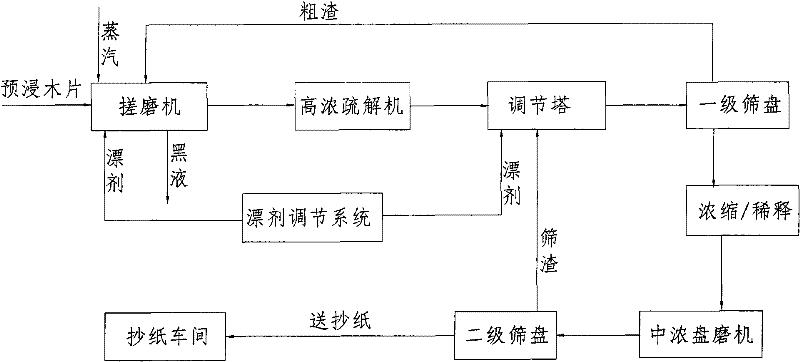

Production method of chemi-mechanical pulp

InactiveCN101666053BReduce power consumptionReduce wearPulp bleachingCellulose material pulpingPulpwoodSingle fiber

The invention provides a production method of chemi-mechanical pulp, which comprises the following steps: first pulping pulpwood and defibering and bleaching, thus obtaining defibered pulp; and then screening and thickening the defibered pulp, and conducting secondary thick grinding, thus obtaining single-fiberized chemi-mechanical pulp and directly delivering the single-fiber chemi-mechanical pulp to a papermaking shop. The production method of chemi-mechanical pulp reduces lumps in the pulp, effectively reduces power consumption during secondary thick grinding, reduces abrasion of a mill stone and improves the service life thereof, also obviously improves the pulping effect of the pulp, and leads to high single-fiberization rate and higher pulping degree of the pulp; and an adjusting tower is adopted in the production method for storing and thickening the pulp, and simultaneously the pulp can be further leached, therefore, the concentration of the pulp can be better controlled and can be even in the process, thus facilitating the follow-up working procedures.

Owner:GUANGDONG YINYAN HIGH NEW MATERIAL CO LTD

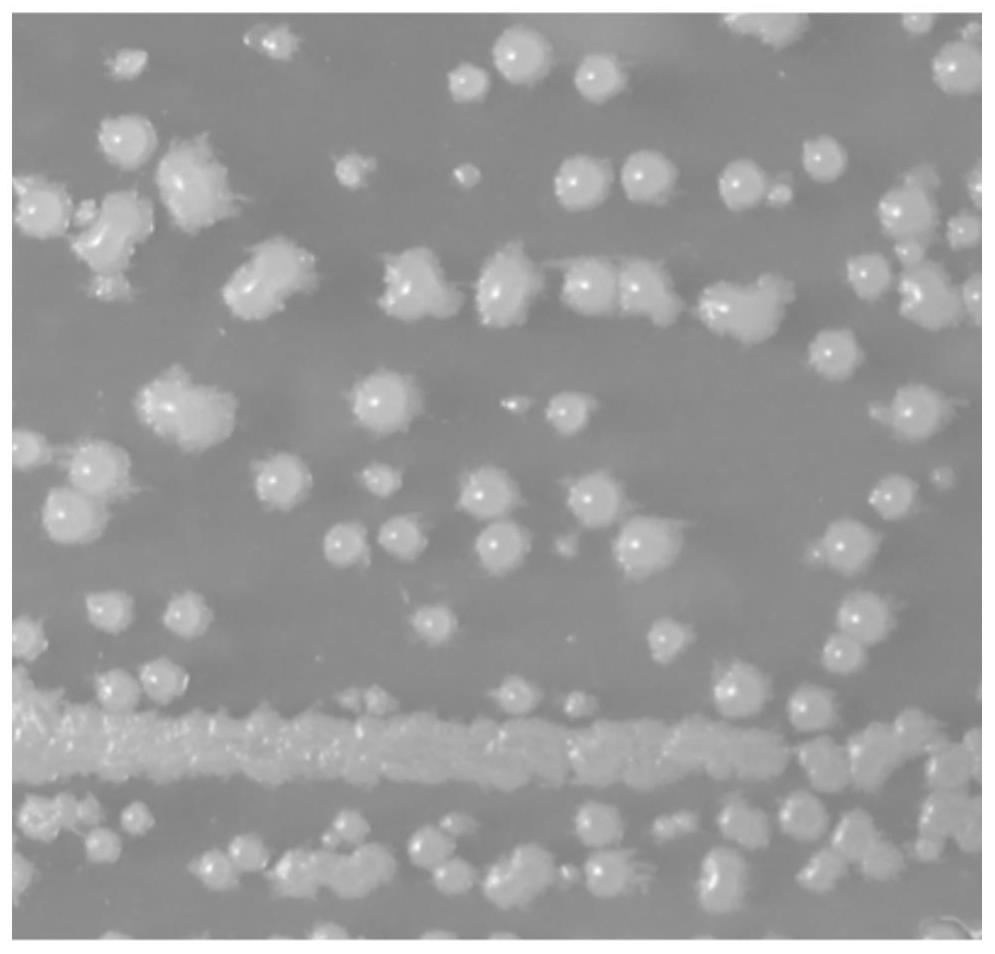

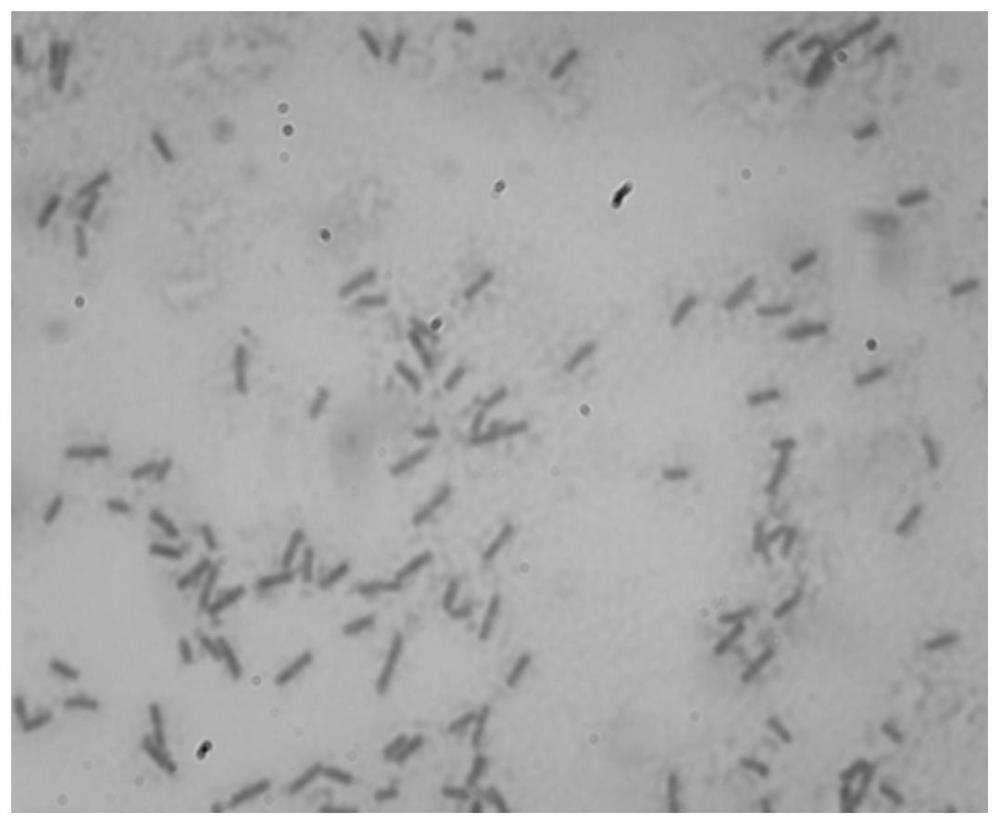

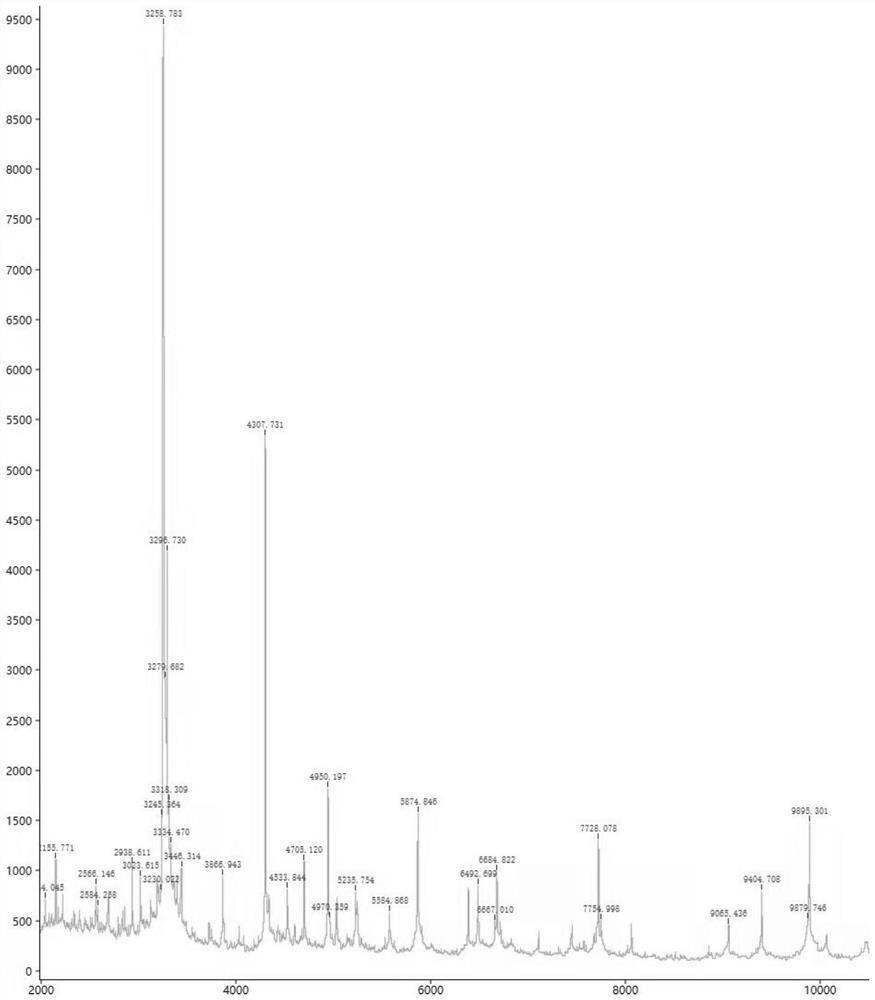

Bacillus licheniformis for straw degradation and application thereof

ActiveCN114480180AStrong toleranceIncrease enzyme activityBio-organic fraction processingFungiBiotechnologyBacillus licheniformis

The invention relates to the technical field of functional microorganism screening and application, and particularly provides bacillus licheniformis for straw degradation and application of the bacillus licheniformis. The preservation number of the bacillus licheniformis is CCTCC NO: M2019438, and the bacillus licheniformis can efficiently degrade straw fibers, is widely applied to straw returning and composting of organic materials, and remarkably improves the decomposition degree and fertilizer efficiency of compost. In addition, the strain can effectively promote softening of straw and is widely applied to the field of papermaking.

Owner:山东蔚蓝生物科技有限公司 +3

Forming method for multi-element alloy abrasive disc with coarse particles on surface

The invention discloses a forming method for a multi-element alloy abrasive disc with coarse particles on the surface. The forming method comprises the steps that metal particles and non-metal particles of different granularity are added into an appropriate adhesive according to different proportions to prepare a rack to be adhered to the surface of a casting mold cavity; and then metal liquids are poured at a high temperature, multi-element alloy particles and substrate metal are fused and permeated under the high-temperature action of the metal liquids, so that a hard multi-element alloy layer with relatively high impact resistance and high wear resistance is prepared on the surfaces of grinding teeth. According to the forming method, the multi-element alloy particles are fused and permeated with the substrate metal so that the hard multi-element alloy layer with the relatively high impact resistance and the high wear resistance can be prepared on the surfaces of the grinding teeth,and the surface of the abrasive disc rack is provided with certain coarse grains and micro-pores; and due to the fact that the surface of the abrasive disc rack is provided with the certain coarse grains and the micro-pores, in the pulping process, the friction force of the coarse grains and the micro-pores of the rack on fibers can be increased, and the fibrillation of the fibers and binding force between the fiber can be promoted.

Owner:HENAN CIGARETTE IND TOBACCO SLICE +2

A method for forming multi-component alloy grinding discs with coarse grains on the surface

The invention discloses a forming method for a multi-element alloy abrasive disc with coarse particles on the surface. The forming method comprises the steps that metal particles and non-metal particles of different granularity are added into an appropriate adhesive according to different proportions to prepare a rack to be adhered to the surface of a casting mold cavity; and then metal liquids are poured at a high temperature, multi-element alloy particles and substrate metal are fused and permeated under the high-temperature action of the metal liquids, so that a hard multi-element alloy layer with relatively high impact resistance and high wear resistance is prepared on the surfaces of grinding teeth. According to the forming method, the multi-element alloy particles are fused and permeated with the substrate metal so that the hard multi-element alloy layer with the relatively high impact resistance and the high wear resistance can be prepared on the surfaces of the grinding teeth,and the surface of the abrasive disc rack is provided with certain coarse grains and micro-pores; and due to the fact that the surface of the abrasive disc rack is provided with the certain coarse grains and the micro-pores, in the pulping process, the friction force of the coarse grains and the micro-pores of the rack on fibers can be increased, and the fibrillation of the fibers and binding force between the fiber can be promoted.

Owner:HENAN CIGARETTE IND TOBACCO SLICE +2

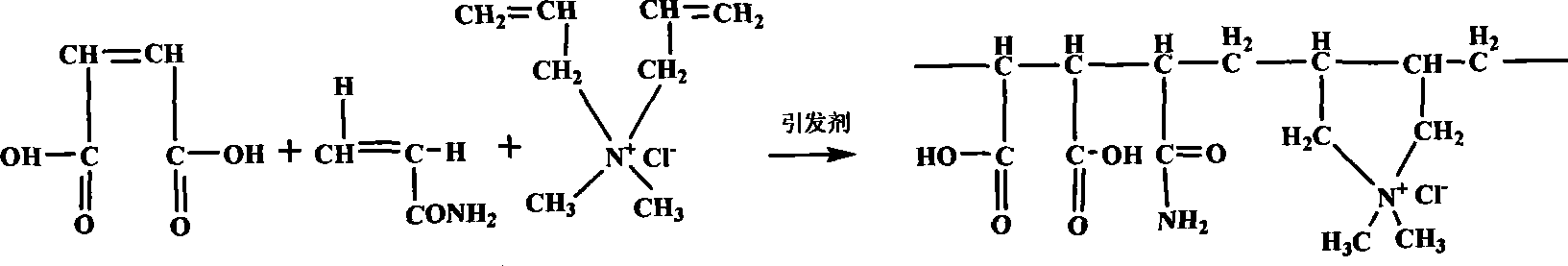

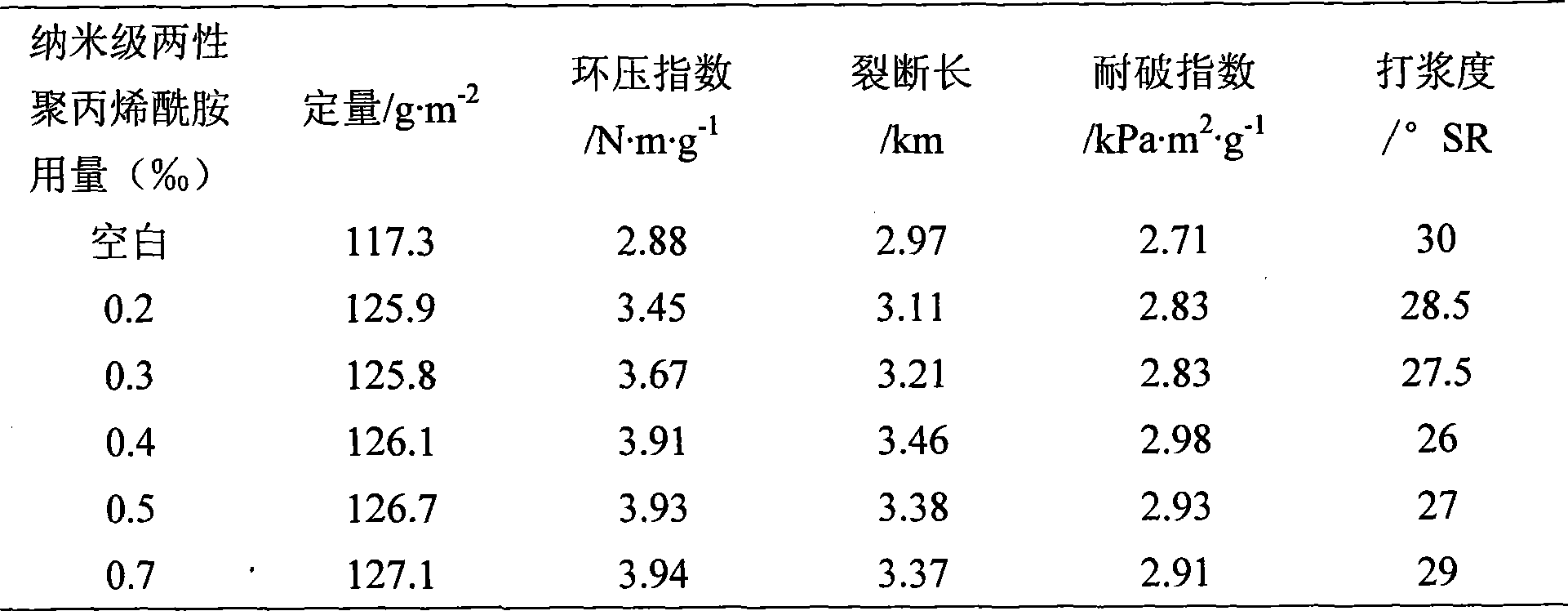

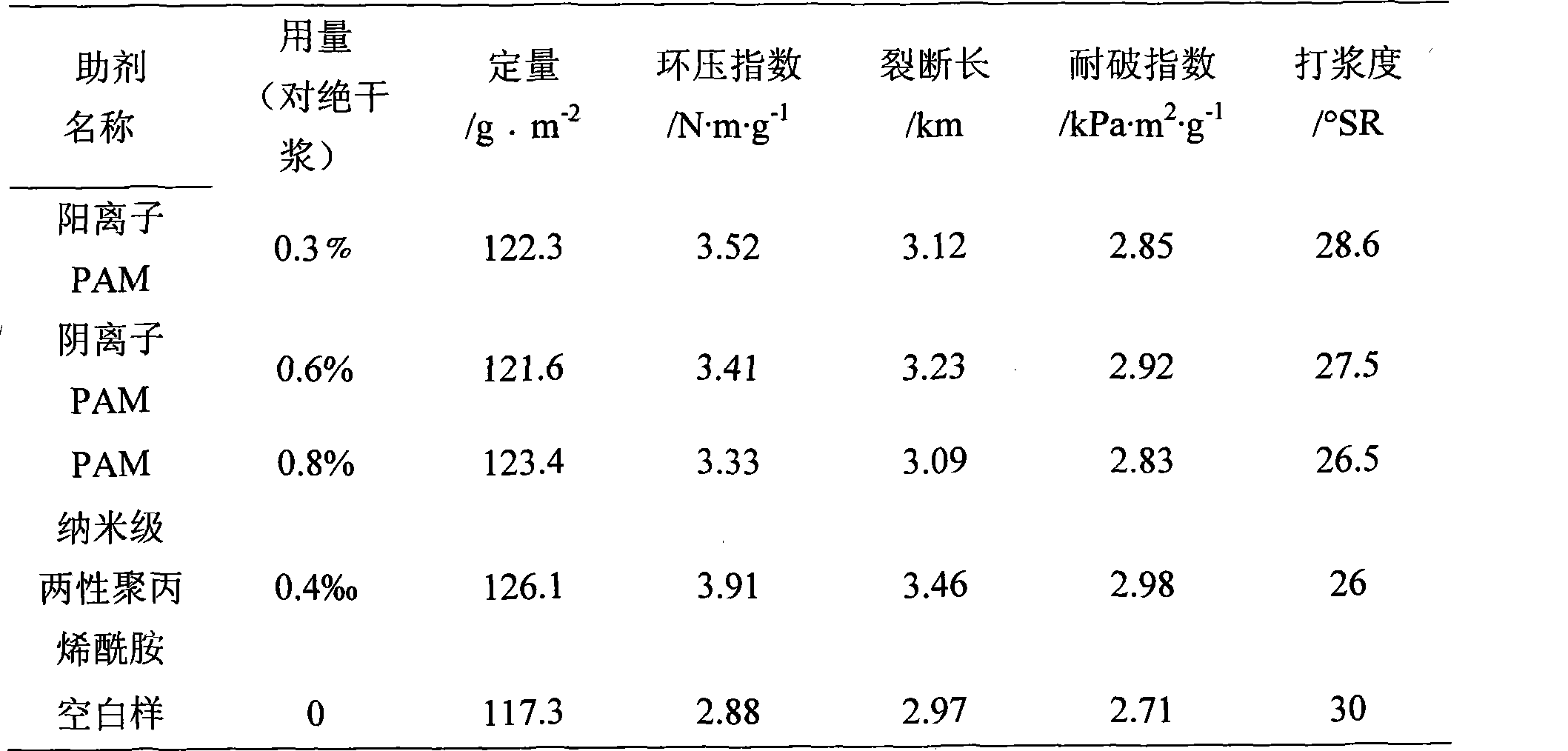

Method for preparing nano amphoteric polyacrylamide additives

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com