Grinding plate unit of grinding plate of pulping machine

A refiner and refiner technology, used in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problem of low beating degree, etc., to enhance the kneading characteristics, improve efficiency, and increase effective contact effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

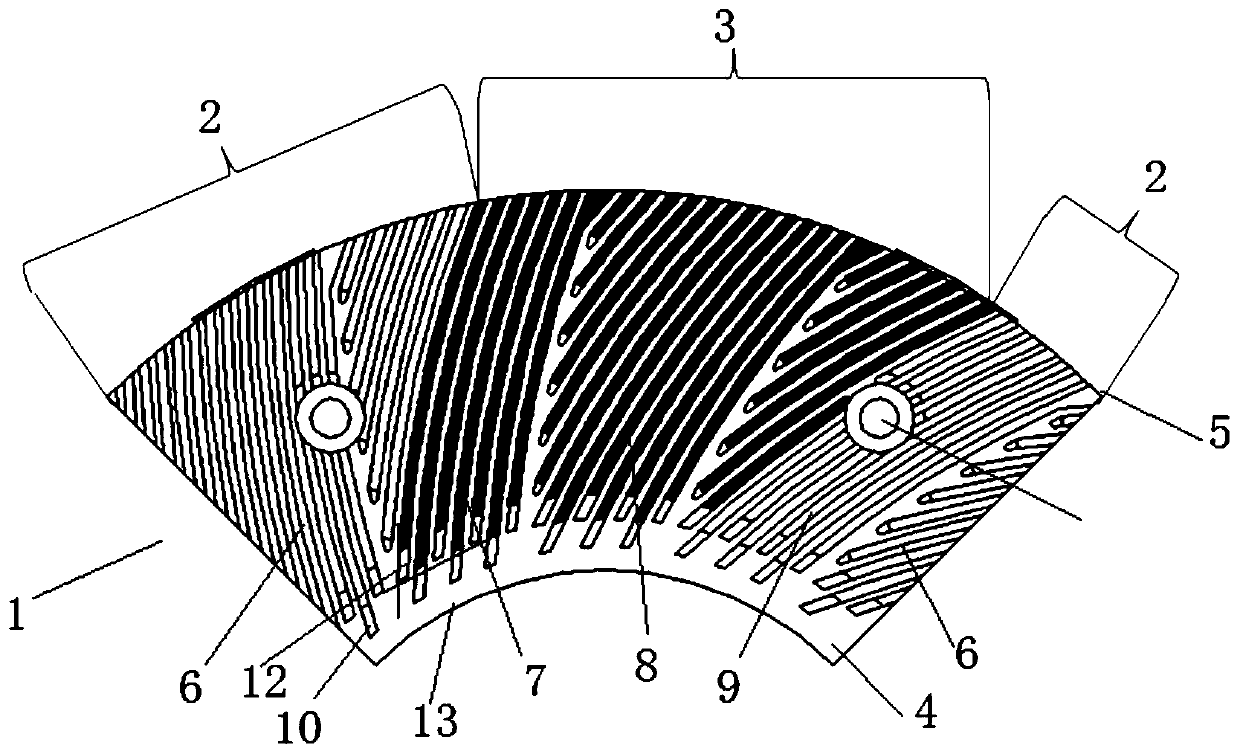

[0023] A kind of refining unit of the refining machine, the refining machine refining unit is sequentially spliced by four refining units 1; as figure 1 As shown, the grinding unit 1 is a fan-shaped piece, and is provided with an inlet port 4 and an inlet port 5; grinding teeth are provided on the bottom plate 13 of the grinding unit 1, and tooth grooves are arranged between adjacent grinding teeth, and the grinding teeth are The depth direction is arc-shaped, the arc corresponds to a radius of 1680mm, and the radius corresponding to the outer side of the fan-shaped piece of grinding unit 1 is 508mm, and the ratio of the two is 3.3. The specific range is designed according to actual needs. Generally, the arc corresponds to The radius range of the grinding unit 1 is 900-1200mm; the radius range corresponding to the outer arc of the grinding unit 1 is 400-600mm; The bottom plate 13 of the grinding unit 1 forms an included angle; the position of the end of the starting end 10 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com