sprag type one-way clutch

A one-way clutch and wedge-type technology, applied in the field of mechanical transmission components, can solve the problems of one-way clutch failure, difficult to meet the service life requirements of starting and stopping motors, and roller failure, so as to reduce the design volume and ensure the use of The effect of increasing the life and the ability to transmit torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

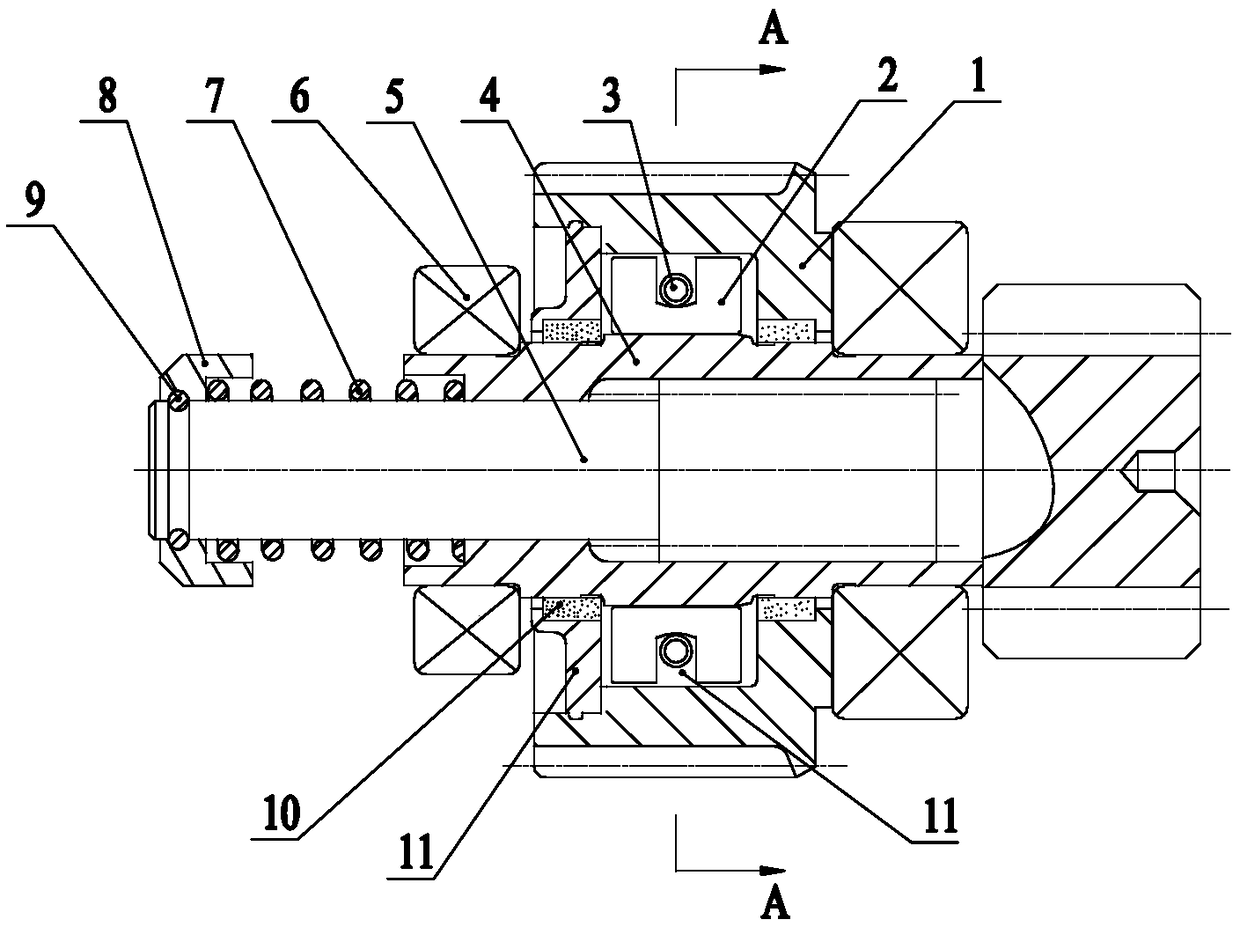

[0027] Such as figure 1 , figure 2 As shown, the wedge type one-way clutch in embodiment 1 is mainly composed of a star wheel 1, a wedge 2, an elastic ring 3, a driving gear 4, a gear shaft 5, a bearing 6, a spring 7, a cover 8, a snap ring 9, Shaft sleeve 10 and dust cover 11 etc. are formed.

[0028] Such as figure 1 , figure 2 As shown, the star wheel 1 is used to connect with the starter motor shaft to input torque. In this embodiment 1, the star wheel 1 is connected to the starter motor shaft in the form of gear reduction transmission, the outer peripheral surface of the star wheel 1 is provided with outer gear teeth, and the drive gear is installed on the starter motor shaft. The gear meshes with the outer gear teeth on the outer peripheral surface of the star wheel 1, so that the star wheel 1 realizes the connection transmission with the starter motor shaft.

[0029] Such as figure 1 , figure 2 As shown, the surface of the inner hole of the star wheel 1 is a s...

Embodiment 2

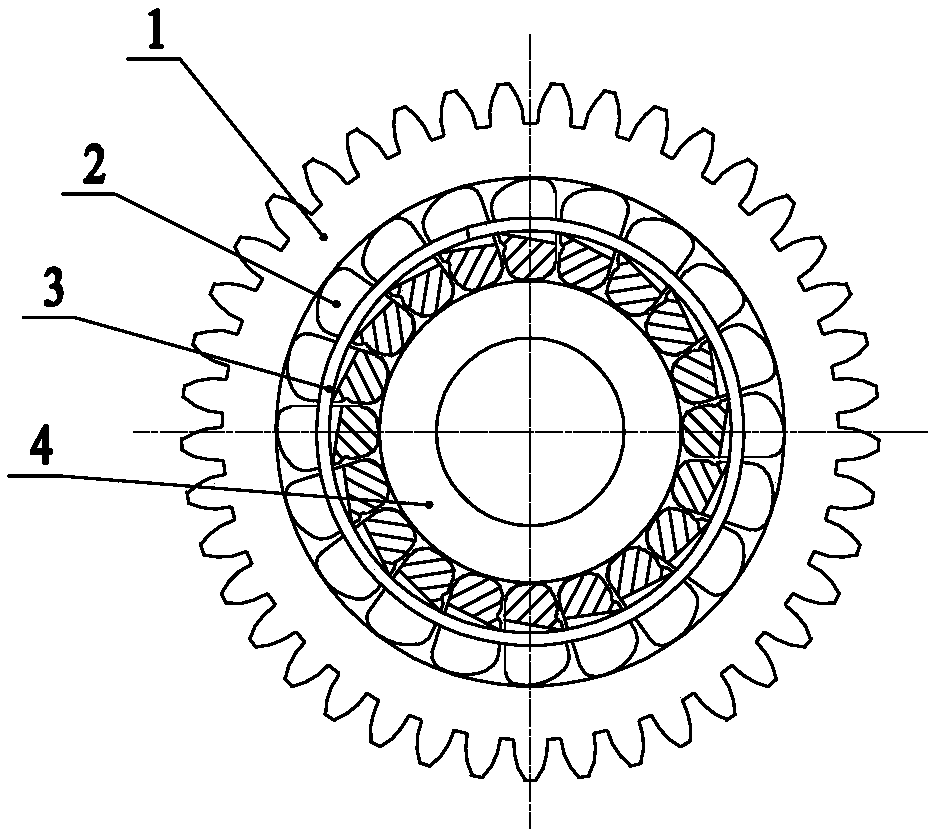

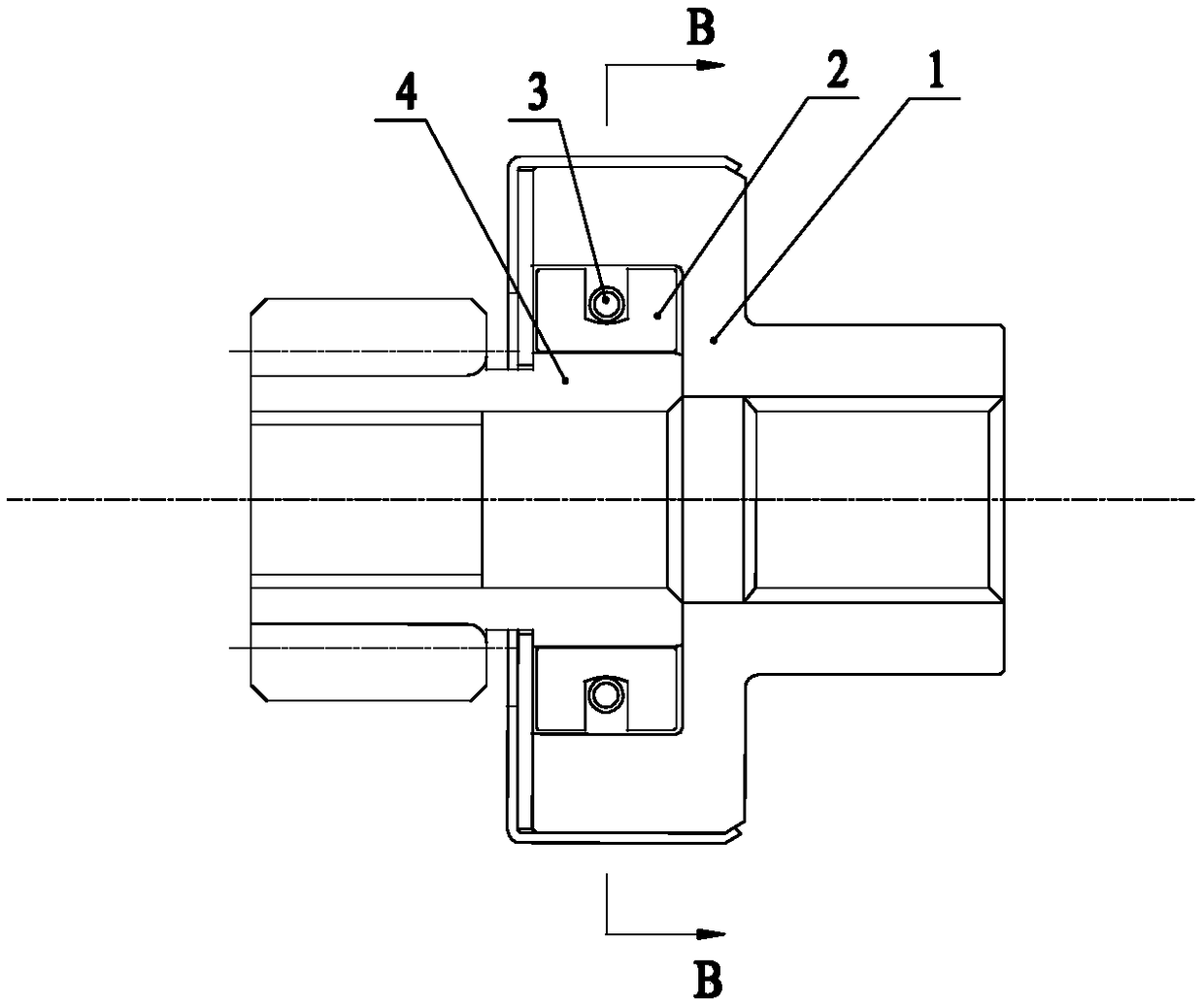

[0036] Such as image 3, Figure 4 As shown, the sprag type one-way clutch in Embodiment 1 is mainly composed of star wheel 1 , sprag 2 , elastic ring 3 and drive gear 4 .

[0037] Such as image 3 , Figure 4 As shown, the star wheel 1 is used to connect with the starter motor shaft to input torque. In the second embodiment, the star wheel 1 and the starter motor shaft are connected in the form of planetary reduction transmission, the outer peripheral surface of the star wheel 1 is provided with splines, the starter motor shaft is connected with an inner ring gear, and the star wheel The wheel 1 is set coaxially at the center of the ring gear. Between the ring gear and the star wheel 1, there are several planetary gears uniformly distributed around the star wheel 1. The outer side of the planetary gear meshes with the inner ring gear, and the inner side of the planetary gear Engage with the splines on the outer peripheral surface of star wheel 1. The splines on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com