Axial Fan

A technology of axial flow fan and wind wheel, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of short contact length between wind and blade, low efficiency, and small flow, so as to increase the effective contact length, Improve efficiency and prevent side air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

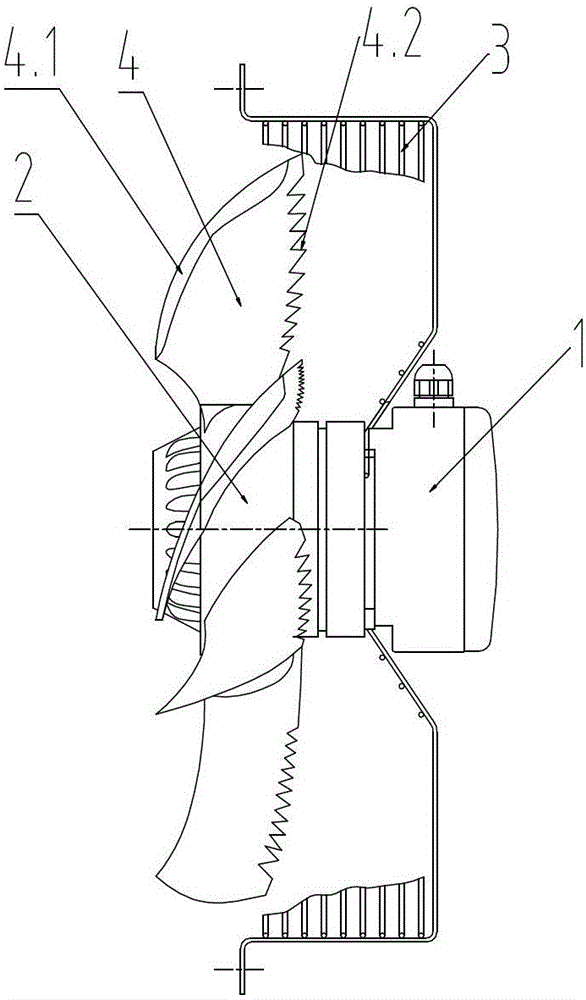

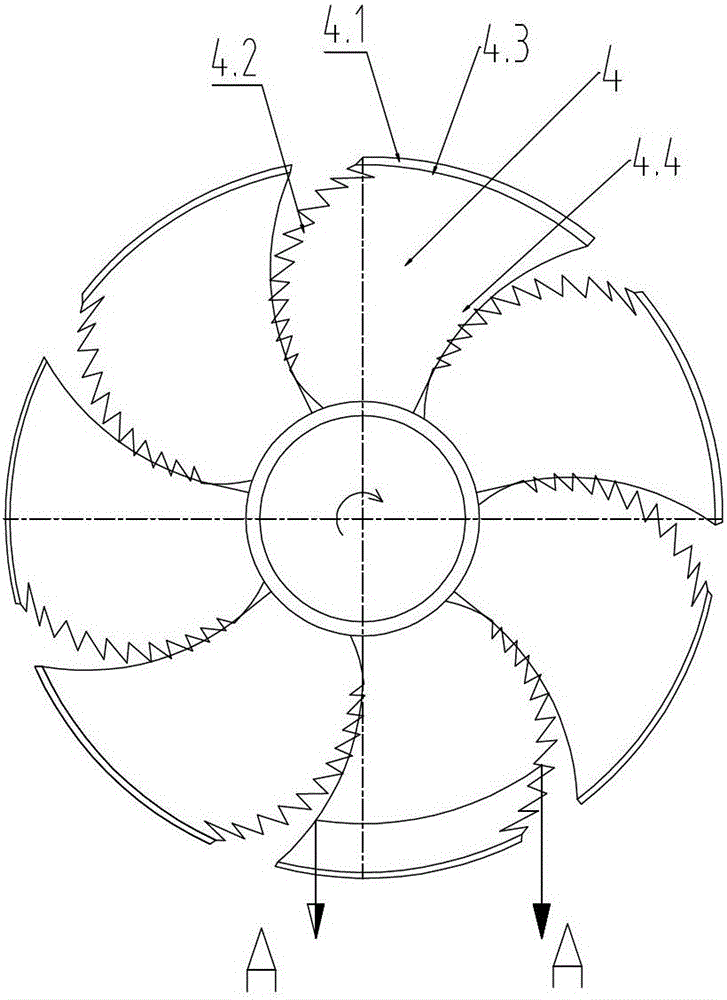

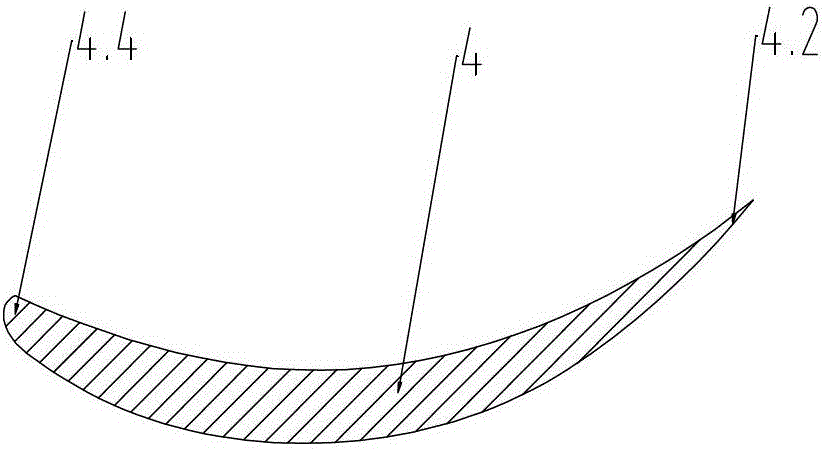

[0016] like figure 1 , figure 2 , image 3 As shown: the present invention provides an axial flow fan, which includes a motor 1, a wind wheel 2 and a net cover 3, the wind wheel 2 is installed on the outer rotor of the motor 1, and the middle of the wind wheel 2 in this embodiment passes through an interference Press fit on the outer rotor of the motor 1, the wind wheel 2 rotates with the rotation of the outer rotor, the net cover 3 is installed on the end cover of the motor 1, the wind wheel 2 is provided with blades 4, the A baffle plate 4.1 is provided at the front outer edge 4.3 of each blade 4, and the rear edge 4.2 of each blade 4 is sawtooth-shaped.

[0017] Said that the rear edge 4.2 of each blade 4 is zigzag means that the rear edge 4.2 of each blade 4 is provided with several continuous triangular protrusions.

[0018] The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com