Pulping method for reconstituted tobacco, pulp, reconstituted tobacco and application

A technology for reconstituting tobacco leaves and pulp, applied in the field of tobacco products, can solve the problems of reducing fiber dispersion, disadvantage, disadvantageous fiber yield, etc., and achieves the effects of increasing fiber crimp rate, increasing fiber yield, and reducing pectin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

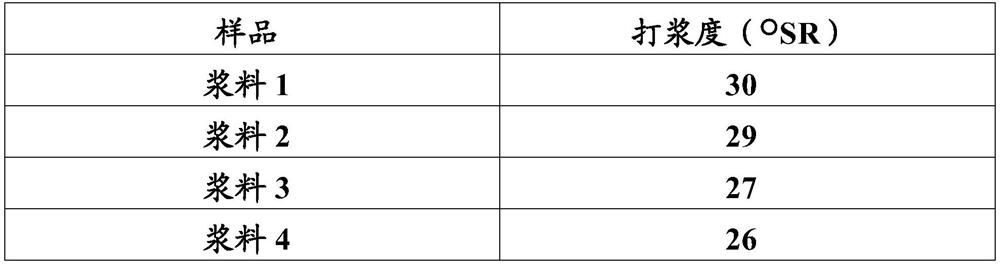

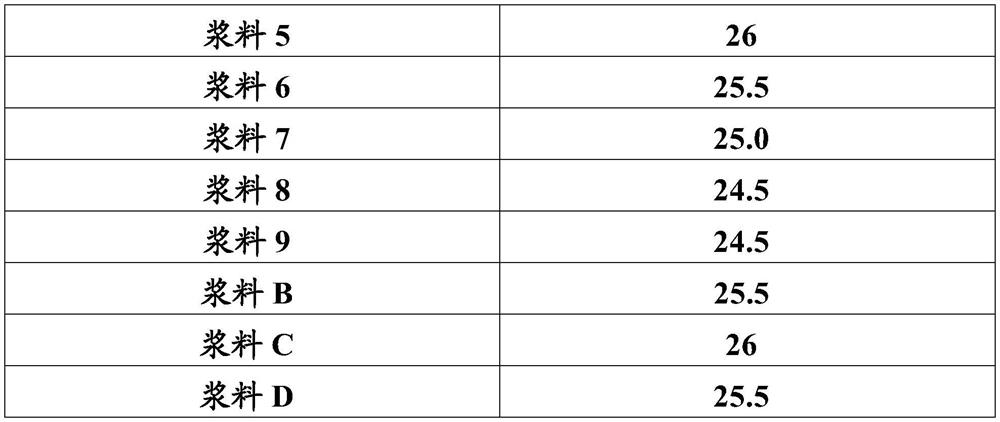

Embodiment 1

[0053] The pulping method for the reconstituted tobacco leaf of papermaking method comprises the following steps:

[0054] (1) Take tobacco stems as tobacco raw material, and the tobacco raw material is extracted with water to obtain a solid phase after separation, the absolute dry matter weight content of the solid phase is 18%, and the solid phase is refined by a high-concentration disc refiner, and processed The flow rate is 20kg / h, and the gap between the grinding discs is 0.6mm to obtain a coarse slurry with a weight concentration of 18%;

[0055] (2) Dissolve the pectinase produced by Aspergillus niger fermentation (purchased from Shanghai Yuanye Biotechnology Co., Ltd., model S10007) with an acetic acid-sodium acetate buffer solution with a pH value of 4 to obtain a pectinase solution with a concentration of 500u / ml; The pectinase solution was activated at 27°C for 30 minutes to obtain an activated pectin solution;

[0056] (3) According to the enzyme activity of 5000u...

Embodiment 2

[0060] In step (3), the activated pectinase solution was added to the coarse slurry according to the enzyme activity of 3000u / kg absolute dry slurry, and the rest were the same as in Example 1 to obtain the final slurry 2.

Embodiment 3

[0062] In step (3), the activated pectinase solution was added to the coarse slurry according to the enzyme activity of 1000u / kg absolute dry slurry, and the rest was the same as in Example 1 to obtain the final slurry 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com