Patents

Literature

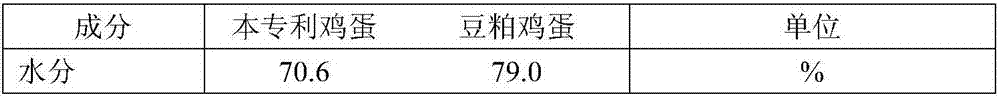

53results about How to "Reduce pectin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for producing concentrated clear peach juice

InactiveCN101411530AThe production process parameters are reasonableReasonable designFood preparationFleshUltrafiltration

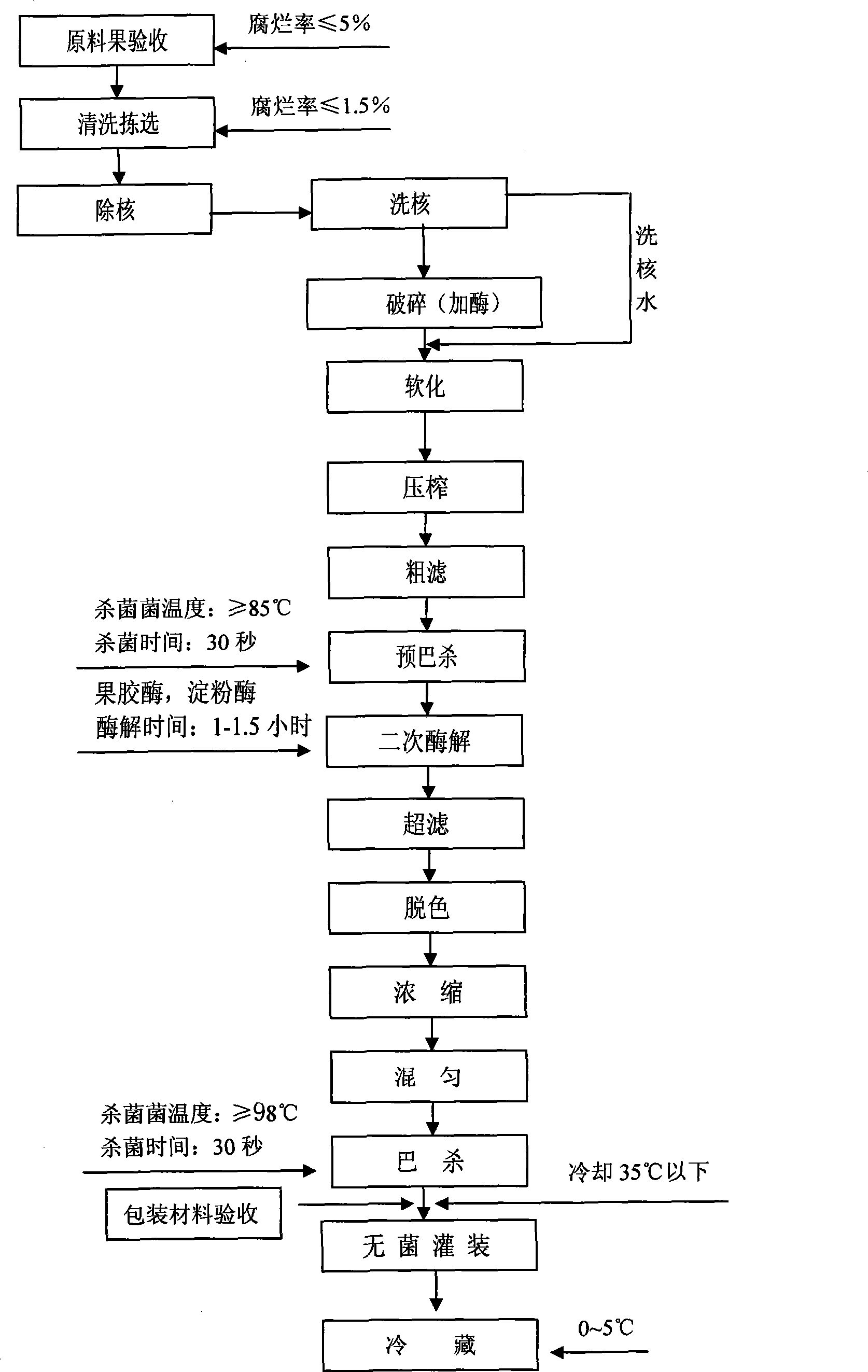

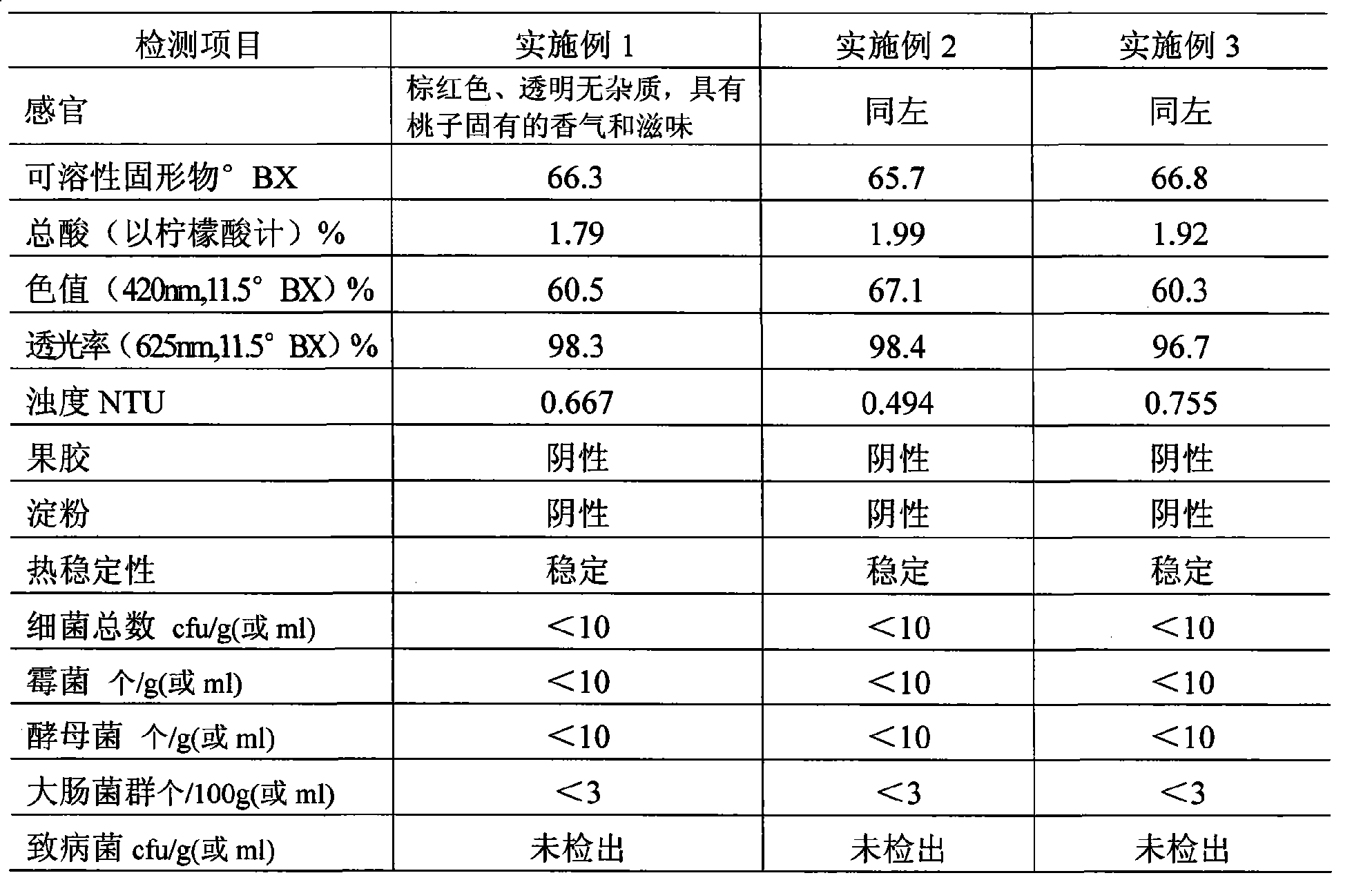

The invention relates to a process for producing concentrated peach clear juice. The process aims to solve or relieve the technical problems that the process of fruit juice processing has fruit juice brown stain, post turbidness, nutriment loss, aromatic substances dissipation and the like. The main process comprises the following steps: cleaning and selecting peaches, removing and washing peach cores, and crushing the peaches; adding fruit pulp enzyme and pectinase into the peaches to soften the peach fleshes, and storing the peach fleshes for a short time after softness; squeezing the peach fleshes, and filtering the fruit juice roughly; and performing the steps of pre-pasteurization, ultrafiltration, concentration, secondary pasteurization, filling, storing and the like. The process is designed reasonably, improves fruit juice yield and the polyphenols content in the fruit juice, and basically eliminates or relieves the problems of the fruit juice brown stain, the post turbidness, the nutriment loss, the aromatic substances dissipation and the like; the produced peach juice is transparent without impurities and has connatural fragrance and taste of the peach; at the same time, peach concentrated pulp is processed and produced, thus the fleshes on the peach cores are fully used so as to save peach resources and reduce the production cost.

Owner:河南省湖滨果品加工新技术研究院

Extraction method of roselle red color

ActiveCN103665924AAvoid conversionAvoid degradationNatural dyesEcological environmentProcess engineering

The invention discloses an extraction method of roselle red color. The method comprises the steps of selecting materials, drying, smashing, digesting, enzyme treatment, clarifying, concentrating, blending, sterilizing and drying. Compared with the prior art, the method has the advantages that low pigment loss rate is ensured in a raw material drying process, the unit raw material utilization efficiency and pigment extraction rate are increased, the problem of thickness of an extracting solution is solved in a mild way, the stability of pigments in a processing process is ensured, the processing cost is reduced remarkably, and the product quality is enhanced. The method contributes to saving energy and protecting the environment, is friendly to the ecological environment, does not cause any adverse effect, and is a novel processing process which is worthy of popularization for natural plant pigments.

Owner:婺源县聚芳永茶业有限公司

Producing method of fruit cake

The invention discloses a method for producing fruit cake in food field. The method provides an improved technology and compounding, can solve the problems of non-diversified products, high cost, tedious procedures, and usage of alum in traditional fruit cake production. The invention changes the current situation in the dependence of using abundant refined sugar, fruit juice, and alum and hard production of other fruit cakes beside hawthorn cake because of the low content of pectin by using hexanedioic acid, malic acid, potassium citrate, ethanedioic acid, tea polyphenols, flavor potentiator beside agar, pectin, xanthan gum, konjak gum, guar gum, modified starch, maltose syrup, edulcorator, and citric acid, facilitate the application of mechanization, improve product quality and quantity, and reduce cost.

Owner:曲清波

Frozen-irradiated auxiliary degumming process for china-hemp fibers

InactiveCN101275289AConvenient lengthImprove finenessFibre treatment to obtain bast fibreQuenchingHemp fiber

The invention discloses a hemp fiber freezing radiation auxiliary de-gumming technique, comprising the following steps of undergoing UV radiation, quenching, and heating treatment after hot bath, acid pre-etching, and pre-chlorination, and then undergoing base oxygen-mechanical associative de-gumming treatment, finally adding a softener for secondary scouring. The hemp fiber surface de-gumming effect treated by the technique is prior to ordinary base oxygen method and mechanical de-gumming, and the former meets the requirement of product of national first grade; the lignin content meets requirement of finishing technique after spinning, which obtains good whiteness and flexibility, and controls breaking strength and tensile stretch of fiber in requirement of spinnability, with improved length and fineness of fiber is improved, greatly improved serviceability, and less pollutant effluents discharged, so that the invention is environment-friendly.

Owner:TAIYUAN UNIV OF TECH

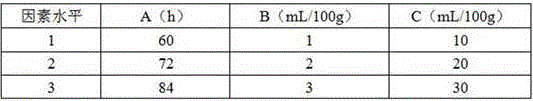

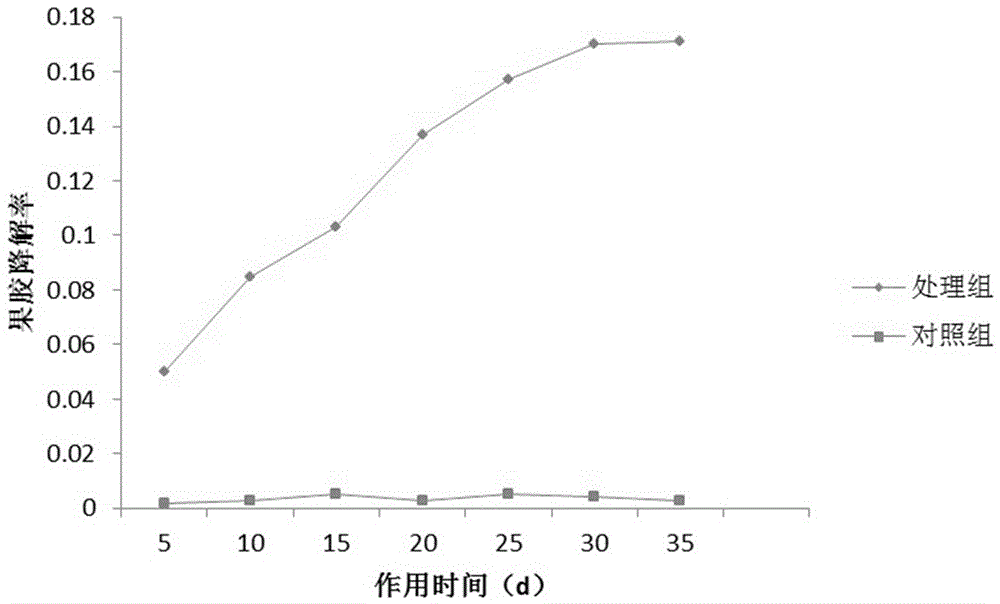

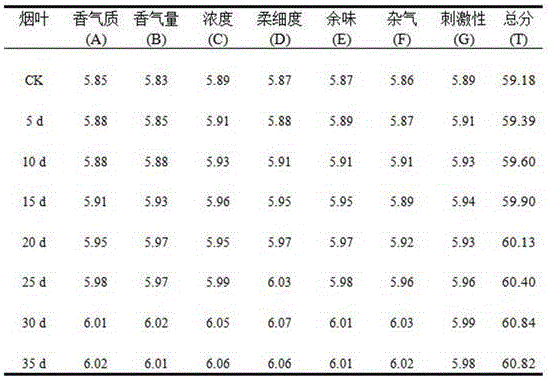

Pectinase produced through mixed bacterium fermentation, and application thereof in tobacco sheet processing

InactiveCN104745558AGood application potentialDelicate aroma of cigarettesTobacco treatmentMicroorganism based processesPectinaseSmoke tobacco

The invention relates to the technical field of tobacco preparation, and in particular relates to a pectinase produced through mixed bacterium fermentation, and an application thereof in tobacco sheet processing. The pectinase is obtained through the steps of strain activation, seed liquid preparation, fermentation culture, enzyme solution crude extraction, and the like. The crude enzyme solution is diluted by 0-20 times, and the diluted crude enzyme solution is used for treating tobacco sheets by enzymolysis for 2-6h at a temperature of 40-50 DEG C according to a ratio that tobacco sheet to pectinase is 1:(1-5). An overall technical route of the application comprises the following steps: specific strains are mixed and fermented, wherein an optimal fermentation condition is obtained by screening and optimization, such that the crude enzyme solution with highest pectinase enzyme activity is obtained; the crude enzyme solution is used for treating tobacco sheets, such that pectin content in the tobacco sheets can be reduced, and a best degradation effect can be obtained. The maximal enzyme activity of the crude enzyme solution provided by the invention can be higher than 3200U / mL. When the crude enzyme solution is used in tobacco sheet treatment, the pectin content in the tobacco sheets can be reduced by approximately 1 / 4, and tobacco smoking quality can be well improved.

Owner:CHINA TOBACCO HENAN IND +1

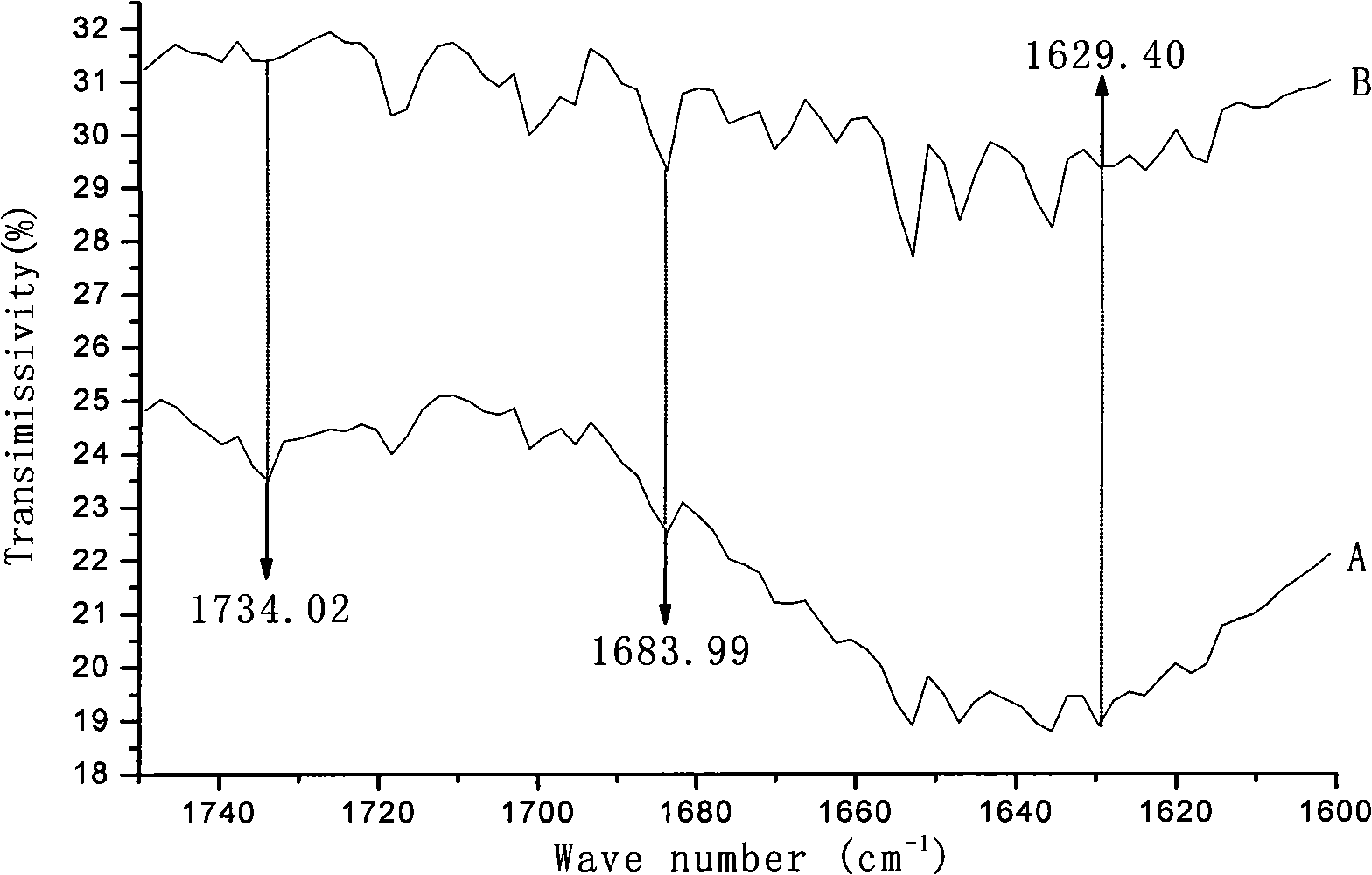

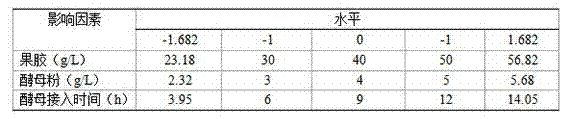

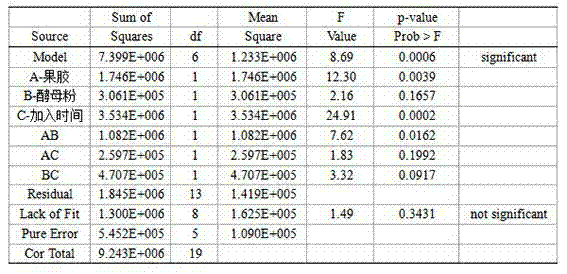

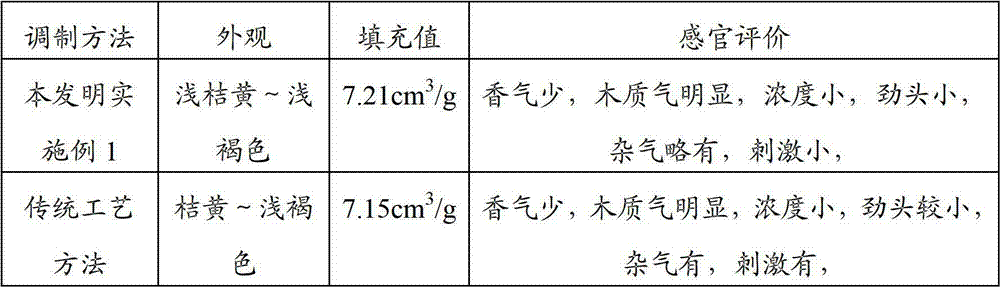

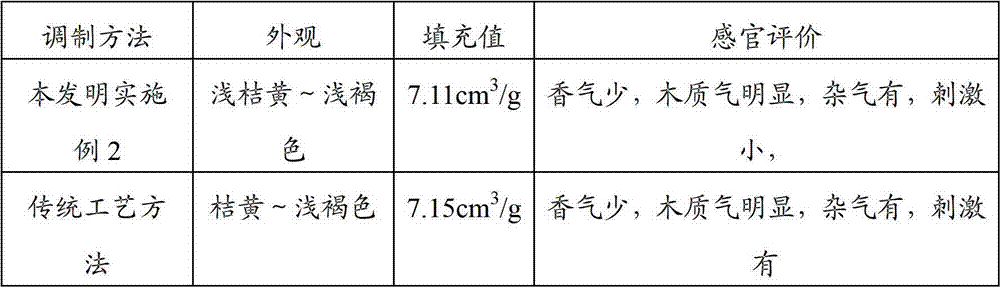

Processing technology for lowering pectin content in cut stem

ActiveCN102783704AReduce pectin contentReduce manufacturing costTobacco treatmentSODIUM METAPHOSPHATEHydrogen

The invention provides a processing technology for lowering pectin content in a cut stem, which comprises the following steps of: A) sieving and peeling: cutting a thick stem into even stem sections of 8-10mm, sieving according to the thickness, enabling the thick stem section of which a diameter is less than 2.38mm to directly enter the next working procedure, peeling and polishing the thick stem of which a diameter is more than or equal to 2.38mm, and removing the bast part of a tobacco stem by mechanical force; B) chemical stem cleaning and dipping: after the tobacco stem is cleaned with sodium metaphosphate contained citric acid solution of which the pH (potential of hydrogen) is 3.0+ / -0.5, keeping the temperature of 50-60DEG C, and dipping for half hour; C) washing the stem with clean water; D) after feeding, pressing and cutting off the stem; and E) drying and storing the stem. Compared with the cut stem prepared by the traditional technology, the cut stem prepared with the method disclosed by the invention has the advantages that the physical behavior does not have obvious difference, but the aesthetic quality is obviously improved, the irritation is reduced, and the miscellaneous qi is reduced. After the cut stem is added into rolled cigarettes, the cigarette sucking comfort can be improved, and the tar content is lowered.

Owner:HUBEI CHINA TOBACCO IND

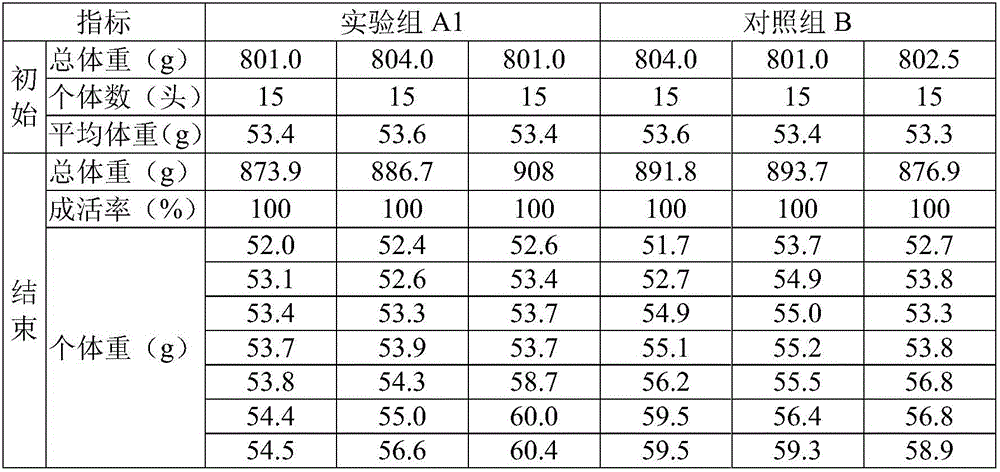

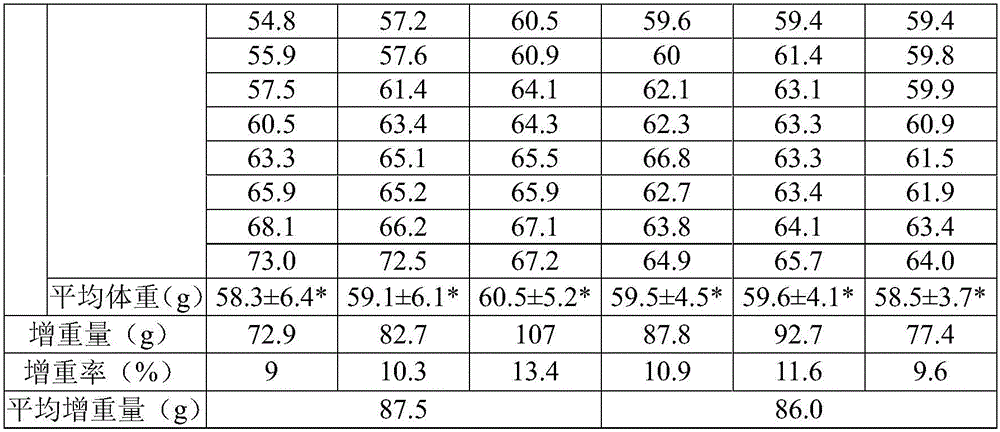

Foraging feed of special compound feed for breeding stichopus japonicus and preparation method of foraging feed

InactiveCN106666247AImprove disease resistanceImprove palatabilityClimate change adaptationAnimal feeding stuffBetaineYeast Proteins

The invention relates to a foraging feed of a special compound feed for breeding stichopus japonicus and a preparation method of the foraging feed. The technical problems of poor disease control, high cost and the like in conventional breeding of the stichopus japonicus are solved. The foraging feed is prepared through the following steps of adding mixed microbe fluid to the following raw materials in parts by weight of 7-13 parts of soybean meal, 6-9 parts of sweet potato residues, 5-8 parts of corn steep liquor, 5-10 parts of sea mud, 3-5 parts of bran, 8-10 parts of soybean protein concentrate, 5-8 parts of yeast protein, 6-10 parts of wheat flour, 3-6 parts of shrimp powder, 3-5 parts of spirulina powder, 5-10 parts of sea spinach powder, 0.5-1.6 parts of sodium alginate, 0.5-1 part of bentonite, 4-8 parts of betaine, 0.5-4 parts of immune polysaccharide, 0.3-0.5 part of taurine, 0.5-2 parts of honeysuckle flowers, 1-3 parts of radix astragali, 0.5-1 part of gypsum, 0.8-2 parts of haws, 1-3 parts of licorice roots, 1-3 parts of activated carbon, 0.5-1.0 part of calcium propionate, 3-5 parts of complex vitamins, 0.5 part of complex enzymes and the like, and performing fermentation. The foraging feed is prepared through the following steps of mixing the raw materials, performing crushing, performing screening, performing fermentation, performing drying and the like. The foraging feed of the special compound feed is widely applied to breeding of the stichopus japonicus.

Owner:WEIHAI GOLD FEED

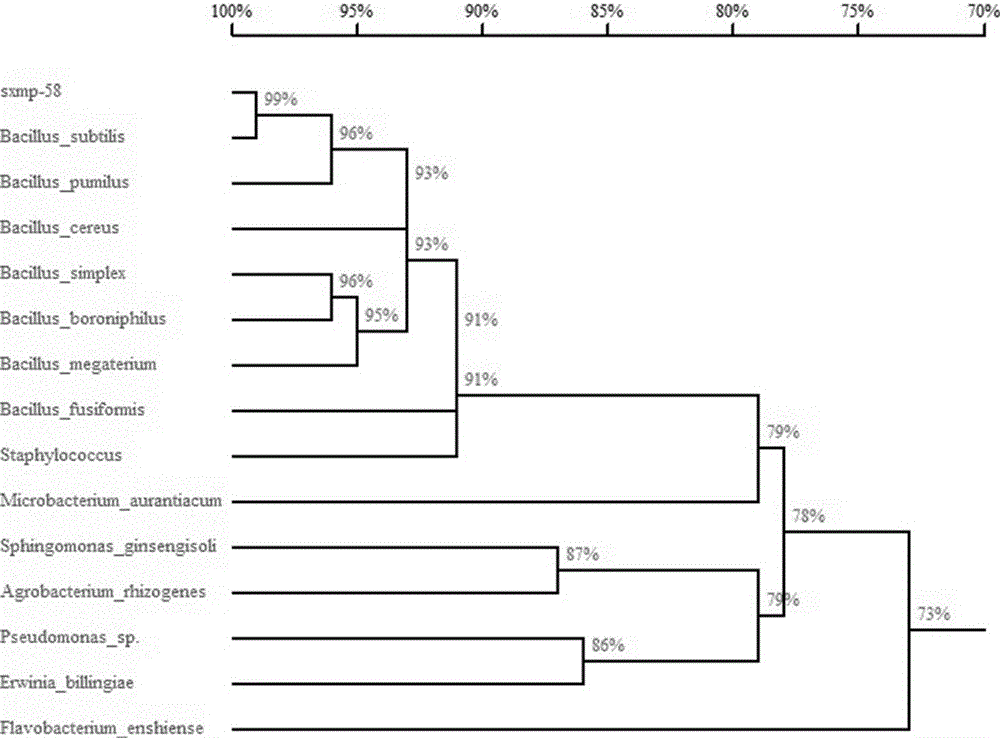

SMXP-58 strain for degrading pectin in tobacco leaves and application of SMXP-58 strain

ActiveCN106434450AReduce pectin contentSimple processTobacco treatmentBacteriaTreatment costsTobacco leaf

The invention belongs to the technical field of cigarette tobacco leaf mellowing, and particularly relates to a bacillus SMXP-58 strain for degrading pectin in tobacco leaves and application of the SMXP-58 strain in tobacco leaf mellowing. The strain is bacillus subtilis SMXP-58 and is preserved in the China Center for Type Culture Collection in Wuhan at present, and the preservation number is CCTCC NO:M 2016083. Due to the fact that the technical scheme for easily and conveniently treating the tobacco leaves through a bacterium agent is designed by screening the specific strain, the bacillus SMXP-58 strain has the technical advantages that the technological processes are simple and convenient to operate, the tobacco leaf treatment cost is low, the tobacco leaf treatment cycle is short, the pectin content in the tobacco leaves can be obviously decreased, and the tobacco leaf quality can be improved, and then the bacillus SMXP-58 strain has a good application and popularization value in the technical field of cigarette manufacturing.

Owner:CHINA TOBACCO HENAN IND +1

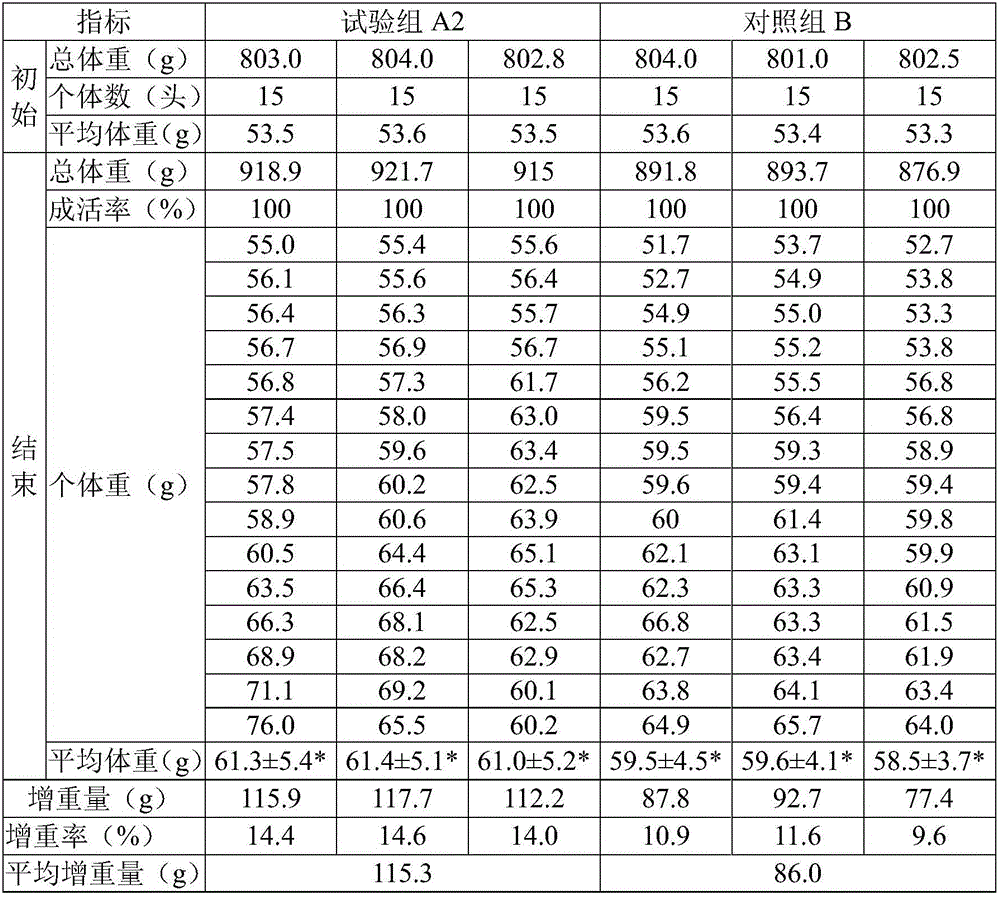

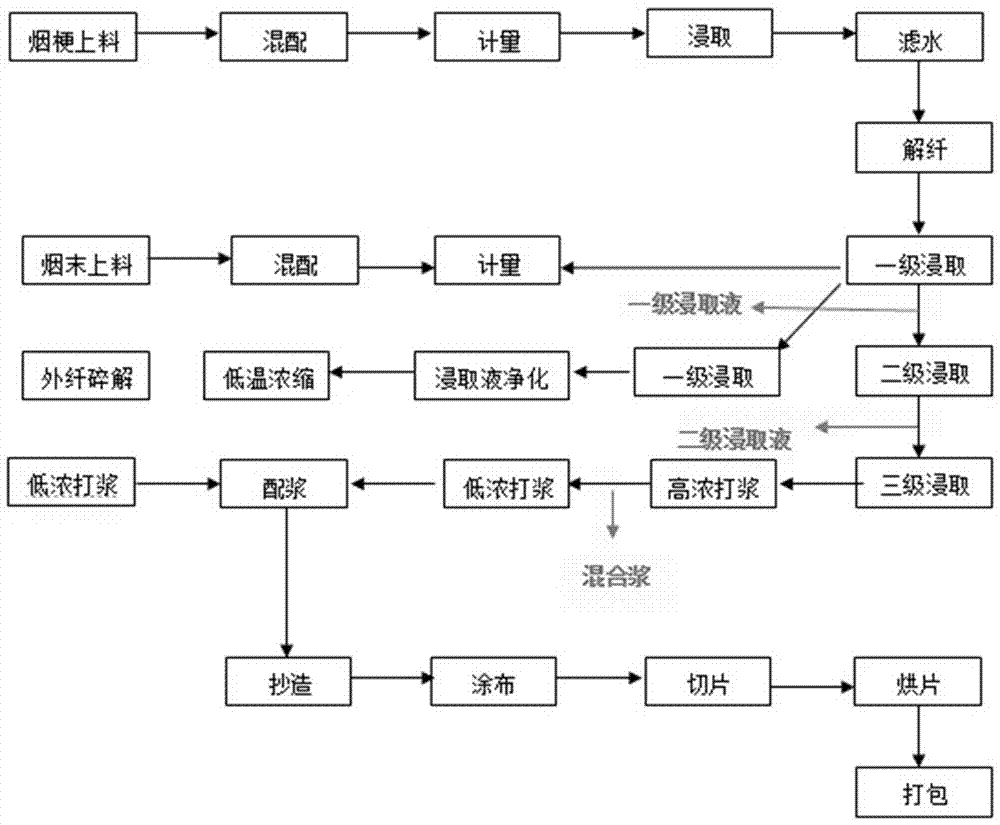

A kind of preparation method of agarwood aroma style dry-process flakes

An embodiment of the invention discloses an agilawood fragrance style dry-method slice preparation method which can effectively reduce the content of wood gas and harmful substances in a dry-method slice so as to enable the dry-method slice to have a strong agilawood fragrance style. The method comprises the following steps: soaking tobacco stems in water to obtain soaked tobacco stems; carrying out bio-enzyme processing on the soaked tobacco stems, and drying the processed tobacco stems to obtain the tobacco stems subjected to the bio-enzyme processing; laying the tobacco stems subjected to the bio-enzyme processing onto a forming net after mechanical fiber separating to form a fiber thin layer; spraying chitosan adhesive on the surface of the fiber thin layer and carrying out drying to obtain a dry-method slice substrate; spraying aloewood powders on the surface of the dry-method slice substrate; spraying cigarette powders on the surface of the dry-method slice substrate; spraying chitosan on the surface of the dry-method slice substrate; and then, carrying out drying to finally obtain the dry-method slice which has the strong agilawood fragrance style, and of which the content of the harmful substances is reduced.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

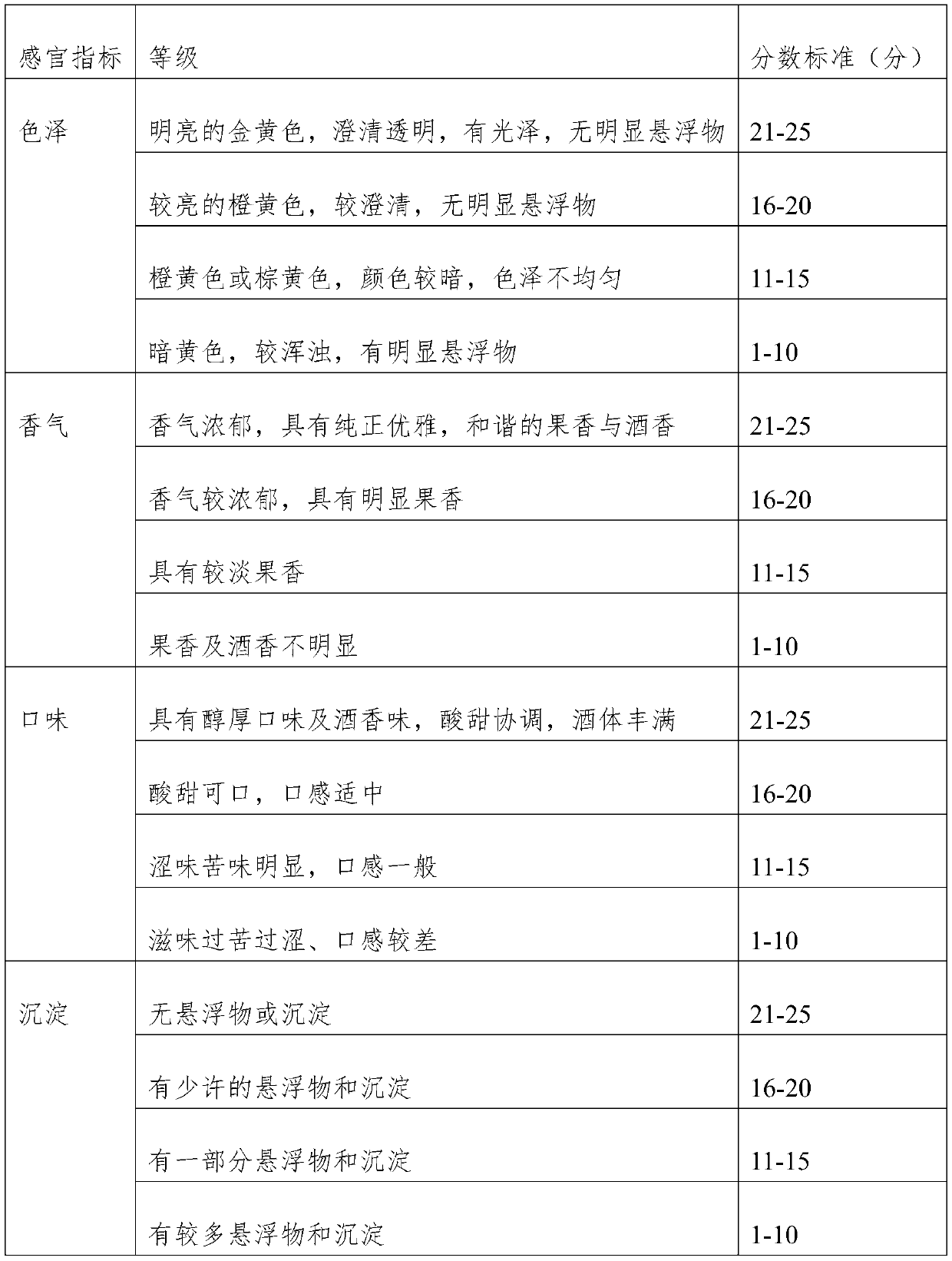

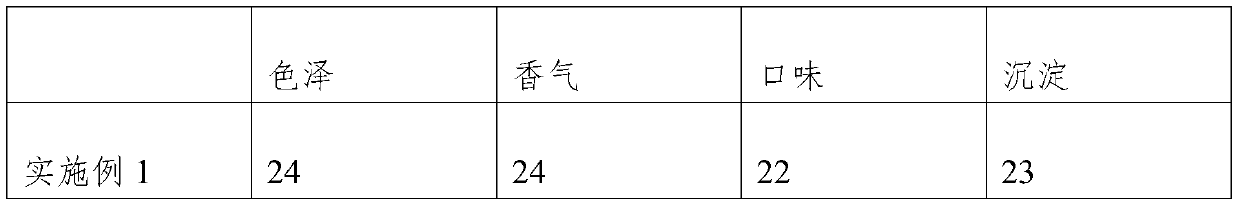

Preparation method of rosa sterilis honey fruit wine

PendingCN111004698AFull of nutritionFragrantAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

Belonging to the technical field of wine brewing, the invention particularly relates to a preparation method of rosa sterilis honey fruit wine. The method includes the steps of: (1) raw material treatment; (2) juice taking; (3) fermentation liquor adjustment; (4) yeast inoculation; (5) primary fermentation; (6) clarification; (7) ageing; (8) blending; and (9) filtering and bottling: filtering theblended fruit wine by a filtering instrument, and then performing bottling. The rosa sterilis honey fruit wine provided by the invention adopts rosa sterilis and honey as the raw materials, wherein the rosa sterilis is rich in nutrition, contains a lot of vitamin C and polyphenol, has strong fragrance, is coordinated with the mellow and sweet taste of honey, so that the wine body is clear and bright, has harmonious fragrance, delicate and refreshing taste and moderate acerbity, the fruit wine having harmonious fruit fragrance, honey fragrance and wine fragrance is unique in flavor, has low alcoholic strength, more conforms to the development trend of massive health, and is suitable for people of all ages to drink.

Owner:GUIZHOU INST OF TECH

Application of bacillus subtilis in degrading pectin in tobacco product

ActiveCN106676035AQuality improvementImprove suction effectBacteriaTobacco treatmentNicotiana tabacumMicrobiology

The invention belongs to the technical field of tobacco preparation, and particularly relates to an application of bacillus subtilis xp strain in degrading pectin in a tobacco product. The bacillus subtilis is bacillus subtilis xp strain, the strain is preserved at China Center for Type Culture Collection, and a preservation number is CCTCC No: M 2011452; the strain is used for reducing the content of pectin in the tobacco product; and when in use, the bacillus subtilis xp strain is prepared into a microbial inoculum, the microbial inoculum is uniformly sprayed onto the surface of the tobacco product according to a mass ratio of 1.0 percent of the tobacco product, and then the storage and alcoholization are performed for 30 to 40 days at the temperature of 30 to 37 DEG C and the humidity of 55 to 65 percent. By selecting the specific bacillus subtilis strain, the bacillus subtilis is proved to have an effect on effectively reducing the content of pectin in the tobacco product, increasing the tobacco grade, ensuring the alcoholization effect and further accelerating the tobacco leaves alcoholization process.

Owner:CHINA TOBACCO HENAN IND

Frozen-irradiated auxiliary degumming process for china-hemp fibers

InactiveCN101275289BHigh whitenessGood flexibilityFibre treatment to obtain bast fibreBreaking strengthOxygen

Owner:TAIYUAN UNIV OF TECH

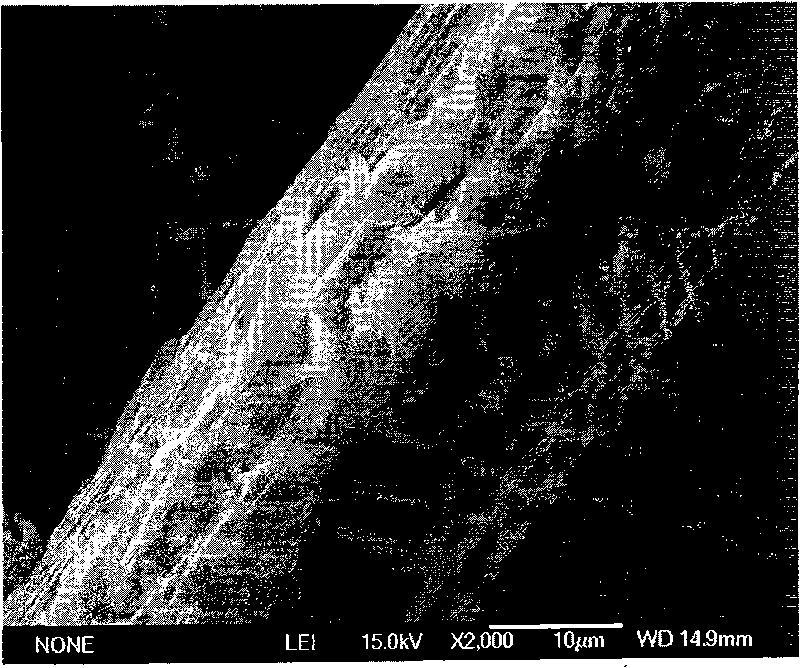

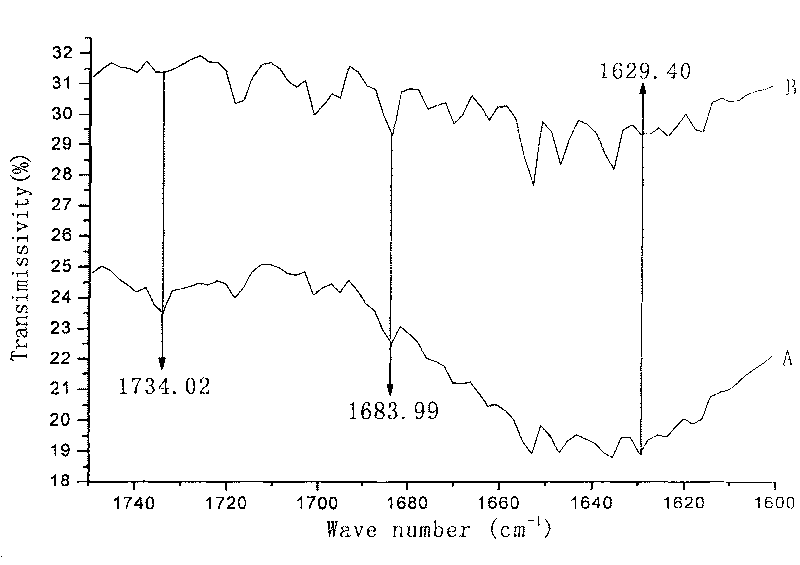

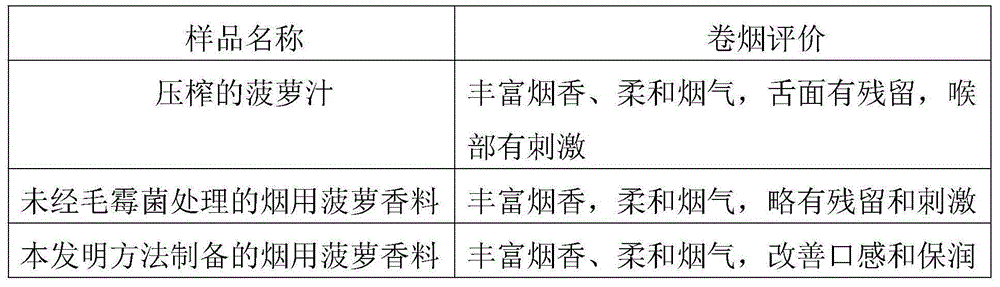

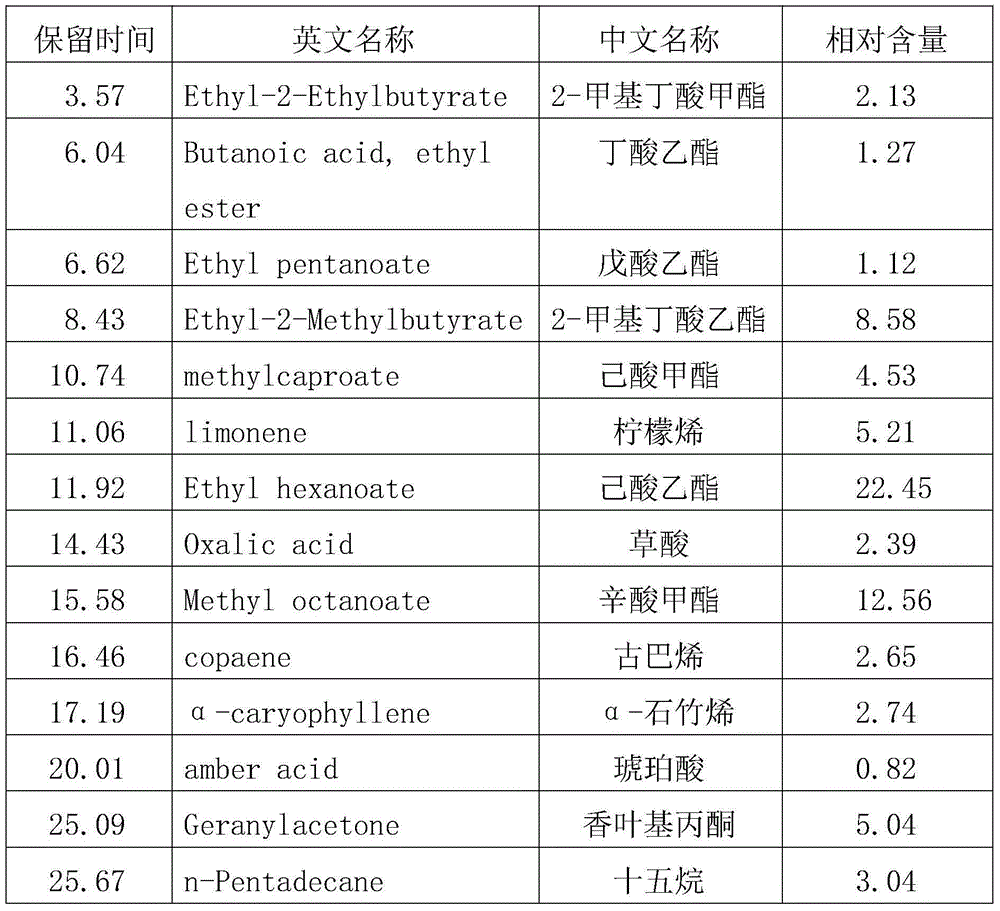

Method for preparing tobacco pineapple flavor by processing pineapple juice by using mucor

ActiveCN104962394AReduce contentImprove filtering effectTobacco treatmentEssential-oils/perfumesNicotiana tabacumPineapple Flavor

The invention provides a method for preparing a cigarette pineapple flavor by processing pineapple juice by using mucor, relates to a preparation method of a tobacco flavor, and belongs to the technical field of tobaccos. According to the method, pineapples serve as raw materials, the pineapple juice is processed by using the mucor, pectin of the pineapple juice is degraded to be converted into an acid substance with a function of fining and gentling smoke in a cigarette, and the novel cigarette pineapple flavor is obtained. In addition, through mucor processing, the pineapple flavor is convenient to filter, a filtrate is clear, and therefore a new economical and efficient way of directionally producing natural cigarette flavors is opened.

Owner:HUBEI CHINA TOBACCO IND +1

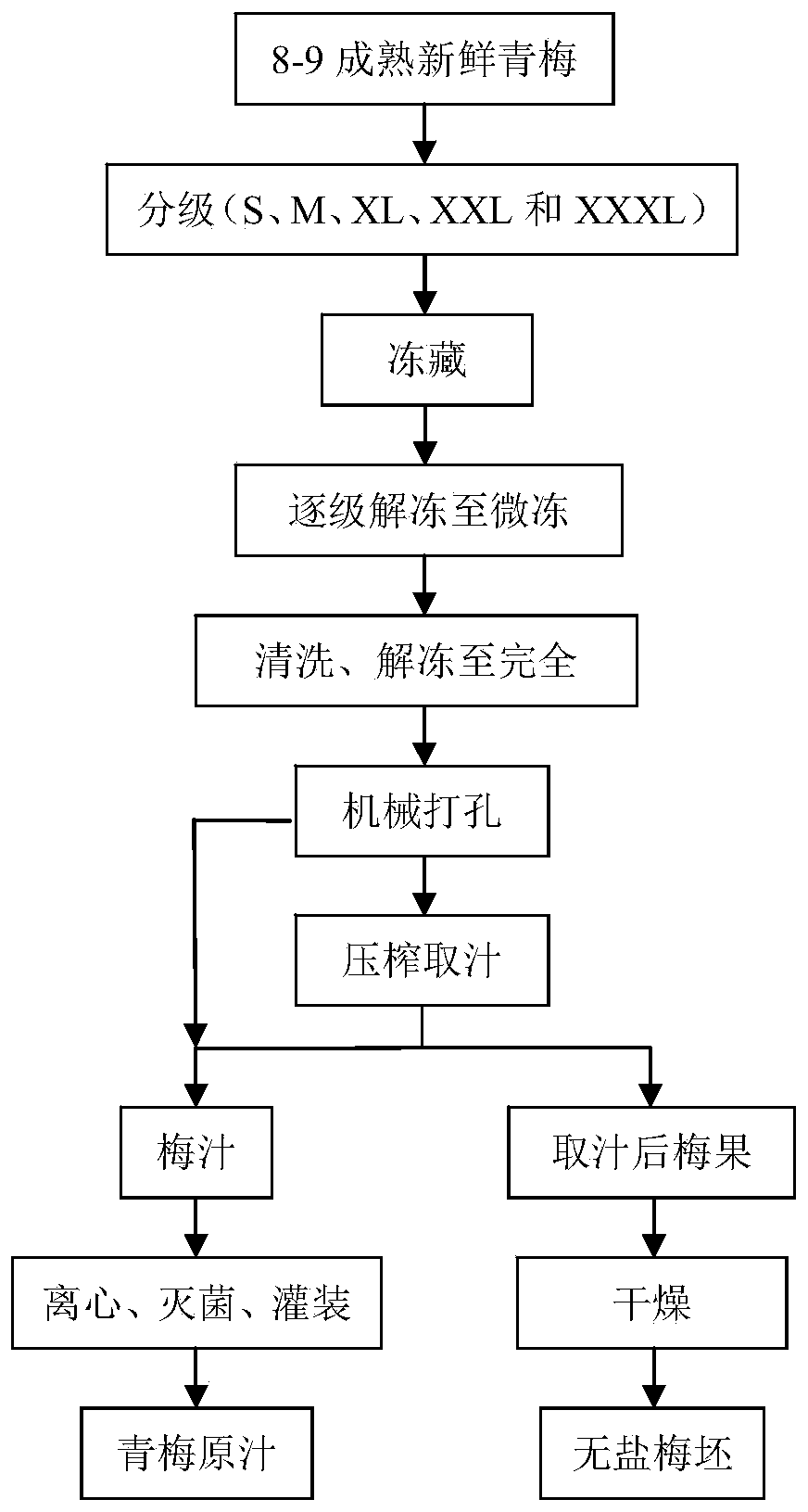

Green plum processing method for coproducing normal green plum juice and salt-free green plum blanks

PendingCN111053168ARealize joint production of greengage juiceRealize the purpose of plum blankFood freezingClimate change adaptationBiotechnologySucrose

The invention discloses a green plum processing method for coproducing a normal green plum juice and salt-free green plum blanks. The method comprises the following steps:(1) collecting green plums, grading the green plums, and carrying out freezing treatment until the water in the green plums is completely frozen; (2) unfreezing the completely frozen green plums step by step until the green plumsare in a partial freezing state, and then cleaning the green plums; (3) air-drying and completely unfreezing the cleaned green plums; (4) pricking holes in the surfaces of the completely-unfrozen green plums, and collecting the juice leaked in the pricking process; (5) juicing the pierced green plums, collecting the squeezed juice, then combining the juice in the step (4), and performing centrifugation, sterilization and filling to obtain the normal green plum juice; and (6) drying the juiced plum fruits to obtain the salt-free plum blanks. The method has the advantages of full utilization ofgreen plum resources, simultaneous obtaining of the normal green plum juice and the salt-free green plum blanks, preservation of the green plums without adding edible salt or sucrose, environmental friendliness, and remarkable shortening of the production period of the green plum blanks.

Owner:陆河国泰青梅产业发展有限公司

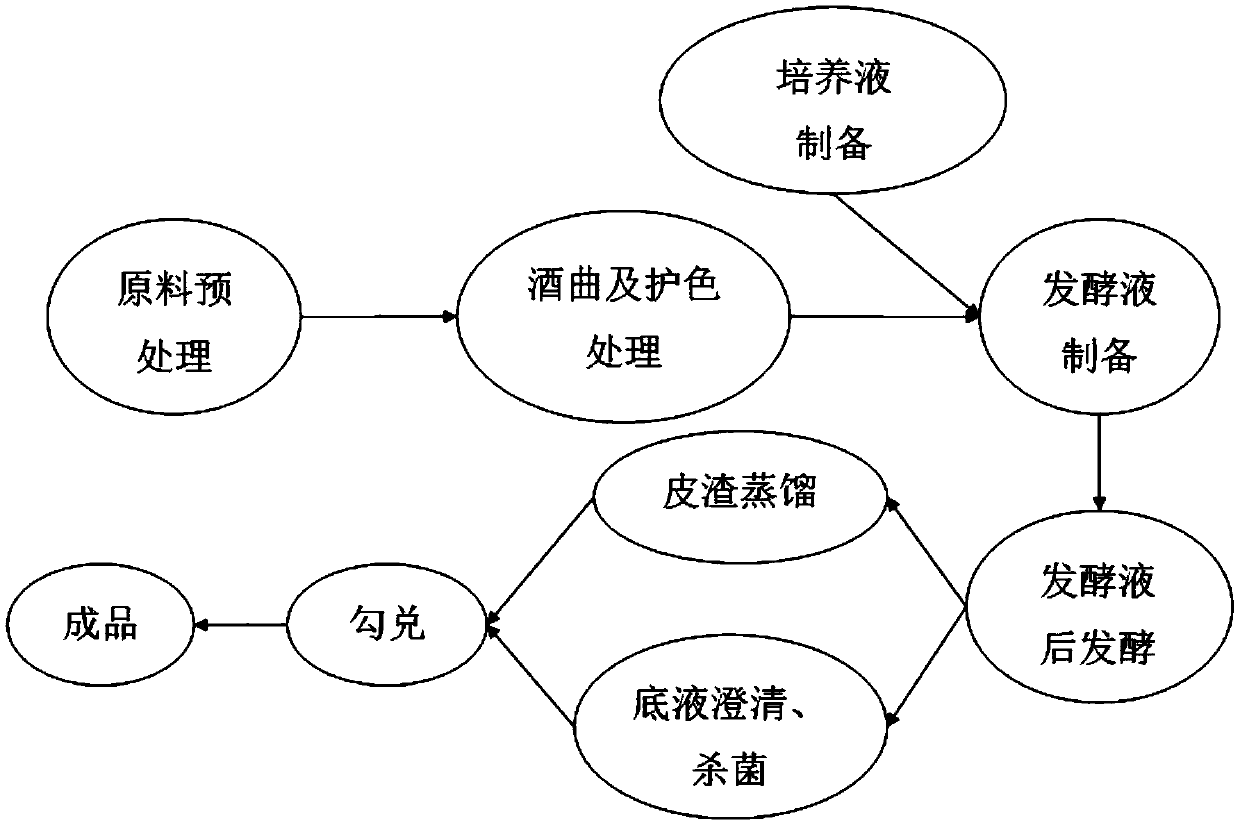

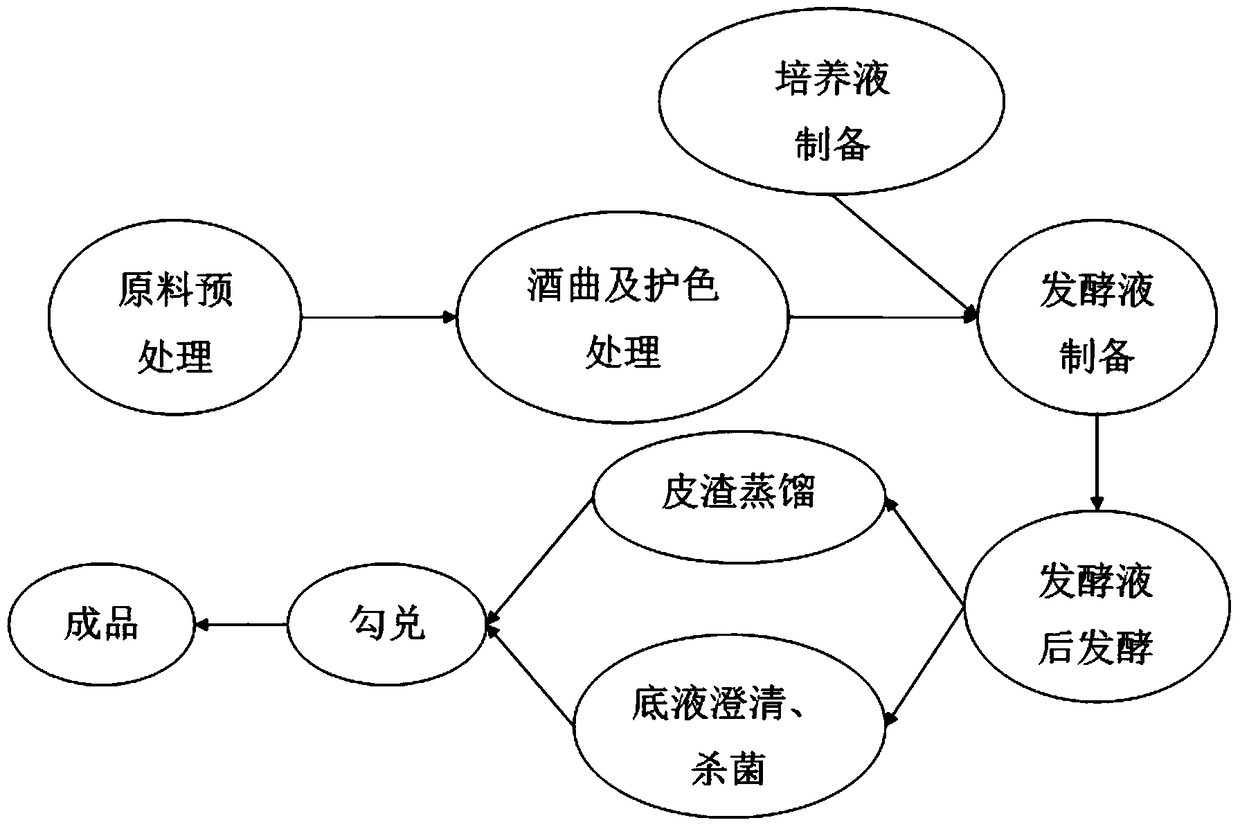

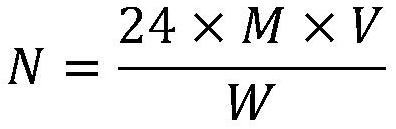

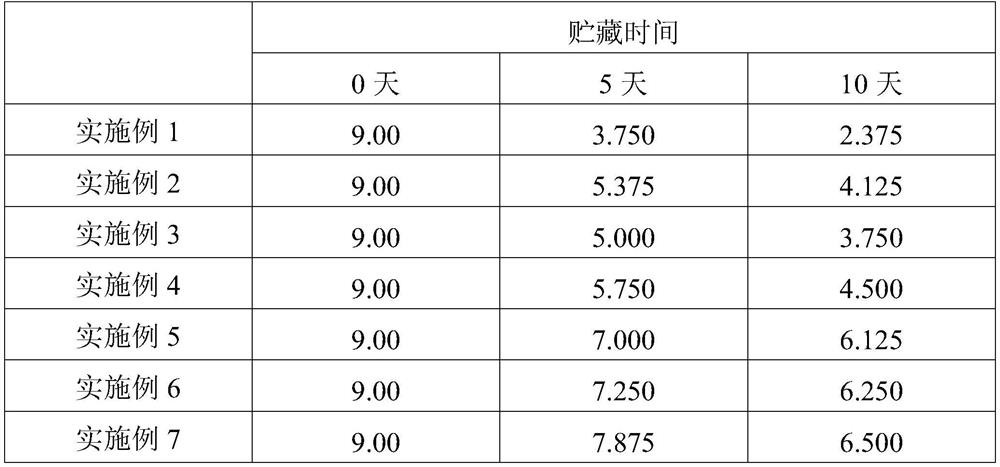

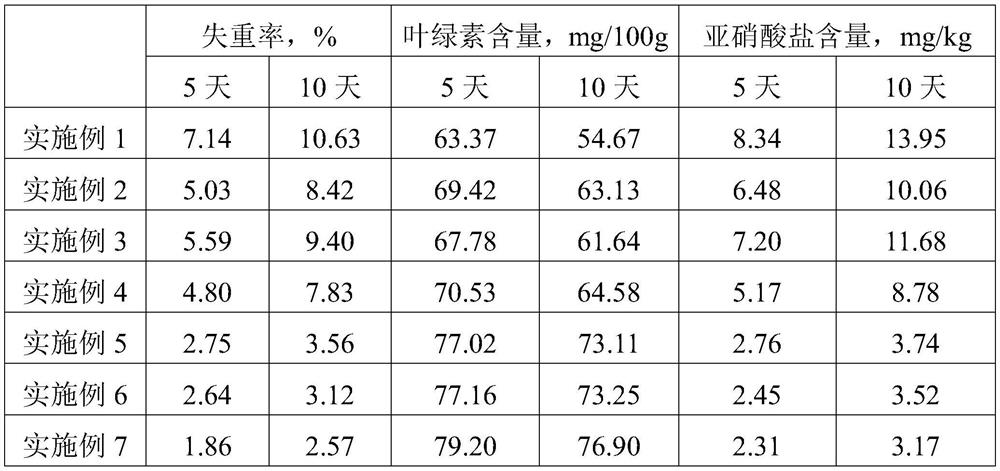

Processing technology of persimmon white spirit

The invention discloses a processing technology of persimmon white spirit. The processing technology comprises the following steps: 1) preparation of a culture solution; 2) pretreatment of raw materials; 3) distiller's yeast and color protection treatment; 4) preparation of fermentation liquor; 5) after fermentation of the fermentation liquor; 6) distillation; 7) clarification of a base solution; 8) pasteurization of the base solution; 9) blending; and 10) detection of the finished product. The processing technology disclosed by the invention is used for solving the problems of the persimmon wine produced by the existing conventional making methods such as excessively deep color, excessively thick astringency, thick oxidation smell, turbid wine liquid, low stability and short storage time.

Owner:YUNCHENG UNIVERISTY

Processing method of compound blueberry okra lactic-acid-bacterium beverage

InactiveCN107927491ARetain nutrientsLower water activityFood extractionFood ingredient as mouthfeel improving agentMicroorganismLactic acid bacterium

The invention discloses a processing method of a compound blueberry okra lactic-acid-bacterium beverage. According to the processing method of the compound blueberry okra lactic-acid-bacterium beverage, blueberry fruits and okra are taken as main raw materials; white granulated sugar and a compound stabilizer are added, stirring is performed so as to carry out dissolving, and microwave enzyme inactivation treatment is carried; and then, activated lactobacillus plantarum is inoculated so as to carry out fermentation. Compared with the prior art, prepared okra juice and blueberry juice are compounded in equal volumes, and enzymatic hydrolysis treatment is performed by utilizing compound enzyme preparations after color protection treatment so as to effectively reduce pectin and tannin contents in the mixed juice; and thus, taste and clarity of the beverage are improved. The microwave enzyme inactivation treatment is adopted so that enzyme inactivation is rapid in speed, and low in energyconsumption; moreover, instantaneous high-power-pulse microwave treatment is performed on the fermented beverage at normal temperature so that microorganisms in the materials can be killed at a lowertemperature compared with conventional heating methods, and thus, nutrients of the blueberry fruits and the okra are preserved while a new way for developing the blueberry fruits and the okra is provided.

Owner:安徽伟航饮品有限公司

A kind of hemp fiber cryogenic-mechanical combined degumming treatment method

ActiveCN106591961BReduce releaseReduce pectin contentMechanical treatmentEnvironmental resistanceUsability

The invention discloses a fibrilia cryogenic-machinery combined degumming processing method. The method comprises: after preprocessing, performing cryogenic treatment on hemp fibers, rapidly heating to normal temperature status, and degumming in a mechanical beating method, performing water processing, and drying for standby application. Processing of pectin and hemicellulose and other impurities makes the hemp fibers treated by the process satisfy to be used as a fiber reinforced base, and in use, VOC emission reaches national requirement, and the hemp fiber also reaches requirement of being used for weaving. Processing the fibrilia by the method improves usability of fibers, and sewage discharge is little, and the method is an efficient environmentally-friendly process. The fibrilia made by the method is good in fiber quality, and fiber surface is concave-convex and is beneficial for combining with an interface of a matrix. The fibrilia is good in degumming effect and wide in purposes, and can be widely used for fiber-reinforced-based fibers, and can be used for spinning industry. The method has good application prospect.

Owner:JILIN UNIV

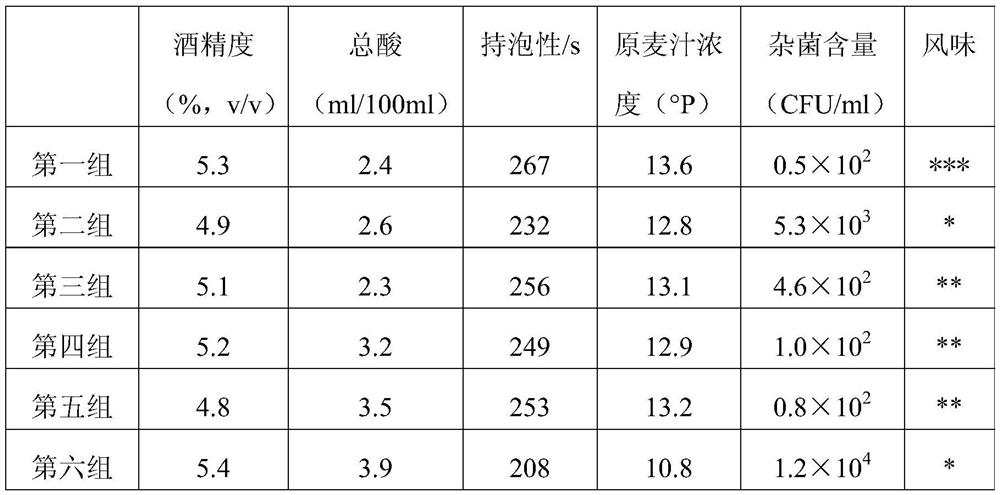

Brewing method for banana-flavored craft beer

PendingCN111718811ARetain nutritional valuePreserve the flavorBeer brewingNutritive valuesProcess engineering

The invention relates to the technical field of food processing, in particular to a brewing method for banana-flavored craft beer. The method of the invention comprises the following steps: (1) wort preparation; (2) wort sterilization; (3) banana pulping; (4) banana pulp preparation; (5) banana pulp sterilization; (6) wort canning and inoculation; and (7) banana pulp fed-batch fermentation. The banana-flavored craft beer prepared by the brewing method of the invention not only has the original aroma and nutrition of beer, but also retains the nutritional value and flavor of bananas. Compared with traditional beer, the banana-flavored craft beer has relatively rich and unique product functions and flavor, can meet different needs of consumers, further enriches and expands the types of beer,and has broad development prospects.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

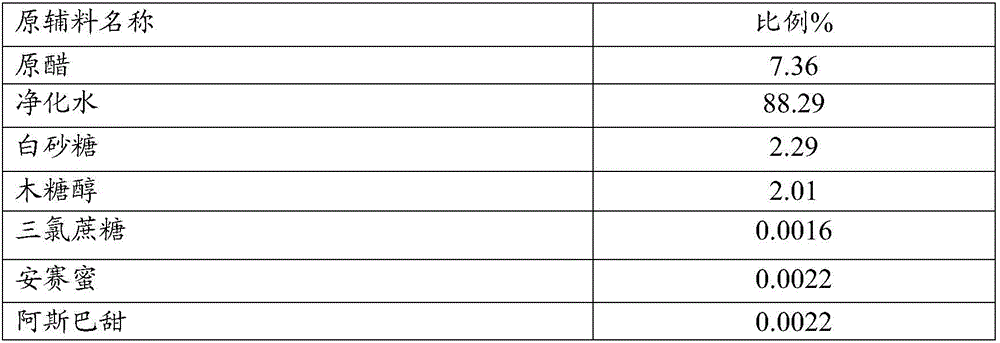

Production method of red dragon fruit vinegar

PendingCN106635732AAvoid odorImprove odorMicroorganism based processesVinegar preparationPectinaseFruit juice

The invention discloses a production method of red dragon fruit vinegar. The production method comprises the following steps: pulping red dragon fruits; controlling the viscosity value of dragon fruit juice at 100 to 140mpa.s; adding pectinase in an amount of 0.4 to 0.6 percent based on the volume of the juice; stirring uniformly; stirring at the temperature of 47 to 52 DEG C for enzymolysis for 2.5 to 3 hours; adjusting the sugar degree of the juice to 20 to 25 degrees BX; sterilizing; inoculating yeast: after the juice is cooled to 40+ / -2 DEG C, filtering the juice by a 80-mesh screen and adding 0.02 to 0.04 percent brewer's yeast; activating and stirring uniformly; fermenting at the room temperature till the alcohol by volume of the juice is more than or equal to 16+ / -1 percent; ageing the fruit wine; activating an acetic acid strain; performing fruit vinegar fermentation, ageing, blending, sterilizing and hot filling. The fruit vinegar product has the advantages of high quality, safety for eating, pure taste and short production period.

Owner:GUIZHOU UNIV +1

Composite microbial inoculum for improving tobacco quality

InactiveCN109480328AReduce contentReduce degradationTobacco preparationBacteriaNicotiana tabacumAureobasidium sp.

The invention belongs to the technical field of cigarette raw material production processing, and particularly relates to the patent application issue of a composite microbial inoculum for improving tobacco quality prepared by using specific microorganism strains. The effective ingredients of the composite microbial inoculum are the viable bacteria of a bacillus thuringiensis strain XC-3, a bacillus pumilus strain SMXP-3 and a bacillus subtilis strain SMXP-58. The microbial inoculum is the combination which is obtained after liquid culturing objects are mixed. According to microbial inoculum,a simpler technical scheme of using a composite microbial inoculum preparation for processing reconstituted tobaccos is designed through the screening of the specific strains and the combination developing of the composite microbial preparation, so that the microbial inoculum has the advantages that the technological process is simpler, the processing cost is lower, the processing period is shorter, the content of starch, protein and pectin in the tobaccos can be significantly reduced, the quality of the tobaccos is improved, and therefore the microbial inoculum has better application popularization value in the technical field of cigarette production.

Owner:CHINA TOBACCO HENAN IND

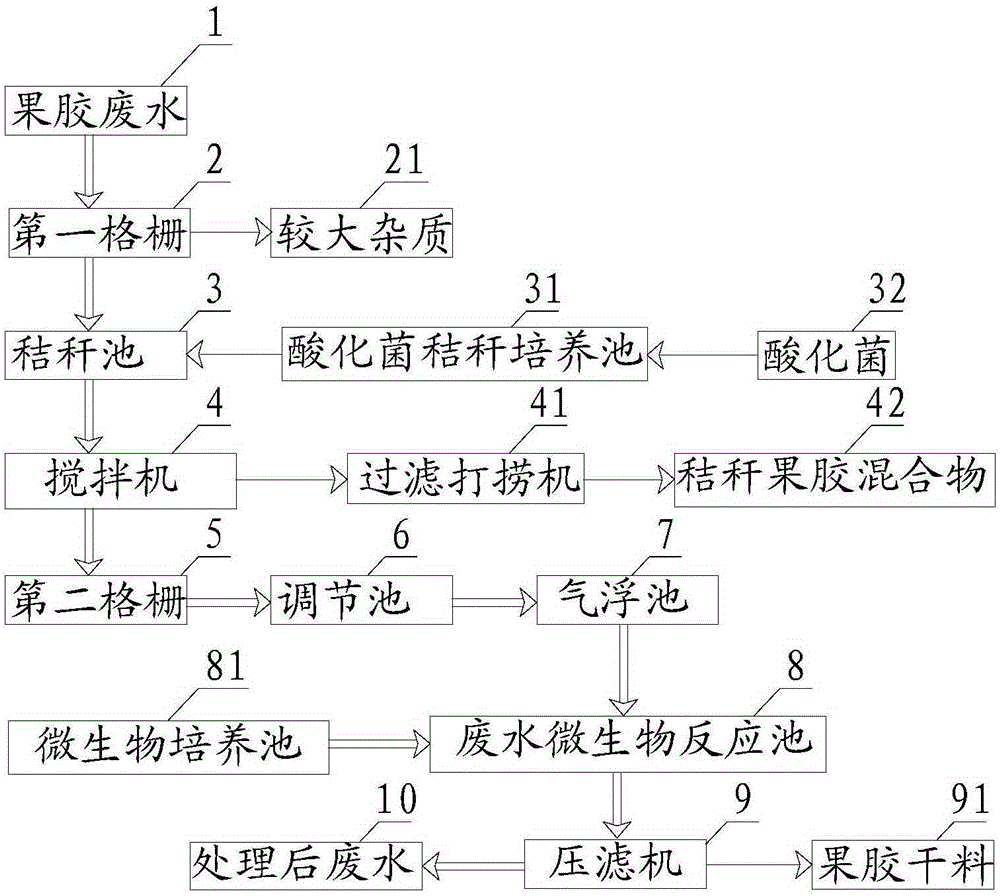

Pectin wastewater decomposition drying treatment technology

InactiveCN105174602AEfficient removalHigh efficiency in decomposing pectinMultistage water/sewage treatmentWaste water treatment from food industryDecompositionTherapeutic effect

The invention discloses a pectin wastewater decomposition drying treatment technology. The technology comprises the following steps: allowing pectin wastewater to go through a first grid in order to remove large impurities; arranging straws in an acidification bacterium straw culture pool, and culturing acidification bacteria in the straws; introducing wastewater to the straw pool, pouring the straws to the straw pool, mixing, and taking out the straws; allowing obtained wastewater to go through a second grid; introducing wastewater to an air floatation pool, and carrying out an aeration air floatation process to remove a certain amount of pectin in the wastewater; adjusting the pH value of the wastewater to 3-8; introducing obtained wastewater to a wastewater microbe reaction pool, and introducing moulds in a microbe culture pool to the wastewater microbe reaction pool; and filtering and compressing obtained wastewater by using a filter press to press pectin in the wastewater into a dry pectin material. The technology well meets treatment of wastewater generated in the orange production process, and has the advantages of good treatment effect and high efficiency.

Owner:颍上县阜淮米业有限责任公司

Composite microbial agent and application thereof in tobacco stems

InactiveCN109370938APromote degradationLower proteinBacteriaTobacco treatmentCelluloseMicrobial agent

The invention belongs to the technical field of production and processing of cigarette raw materials and in particular relates to a composite microbial agent prepared by utilizing a specific microbialstrain and patent application matters of application thereof in tobacco stems. The active ingredients of the agent comprise bacillus subtilis XC-19-1, bacillus pumilus strains SMXP-3 and living bacteria of bacillus pumilus SMXP-58, and the agent is a complex obtained by mixing liquid culture of various bacteria. By virtue of screening of specific strains and complex development of the composite microbial agent, a simple technical scheme of treating the tobacco stems by the composite microbial agent is designed. Therefore, the composite microbial agent has the technical advantages that the process flow is simple and convenient, the treatment cost is low, the treatment cycle is short, the content of cellulose, proteins and pectin in the tobacco stems can be obviously reduced, and the quality of the tobacco stems is improved. Therefore, the composite microbial agent has excellent popularization and application value in the technical field of cigarette manufacturing.

Owner:CHINA TOBACCO HENAN IND

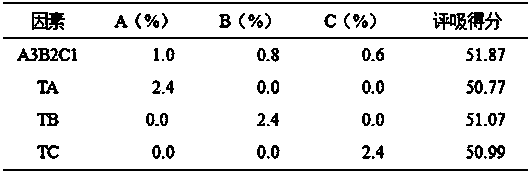

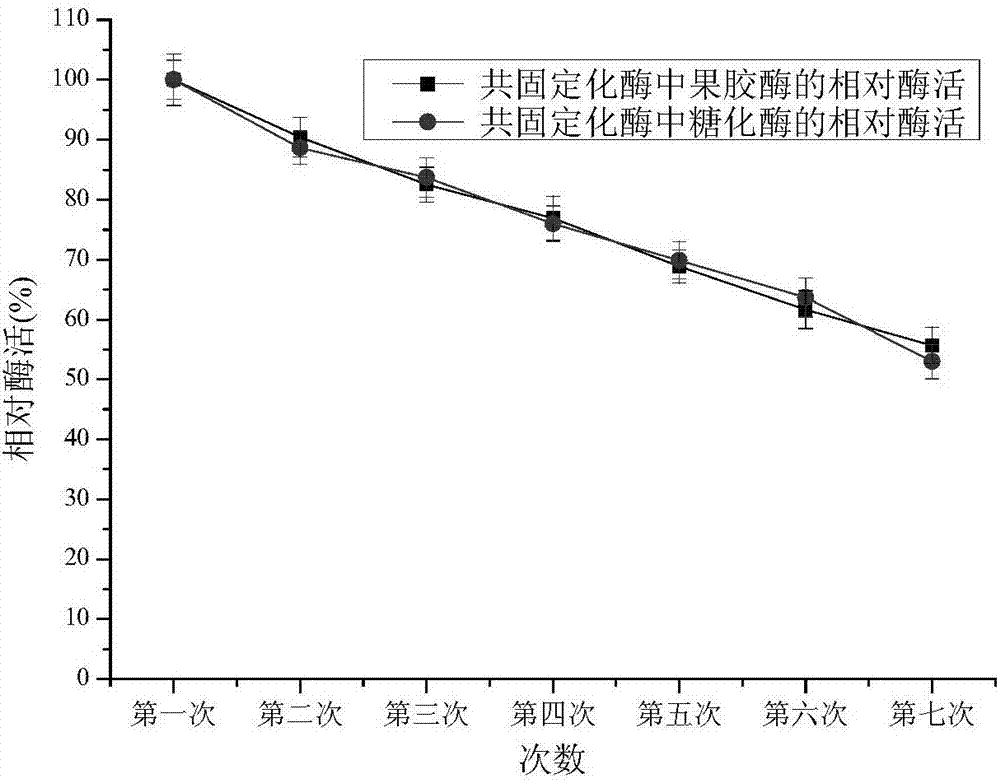

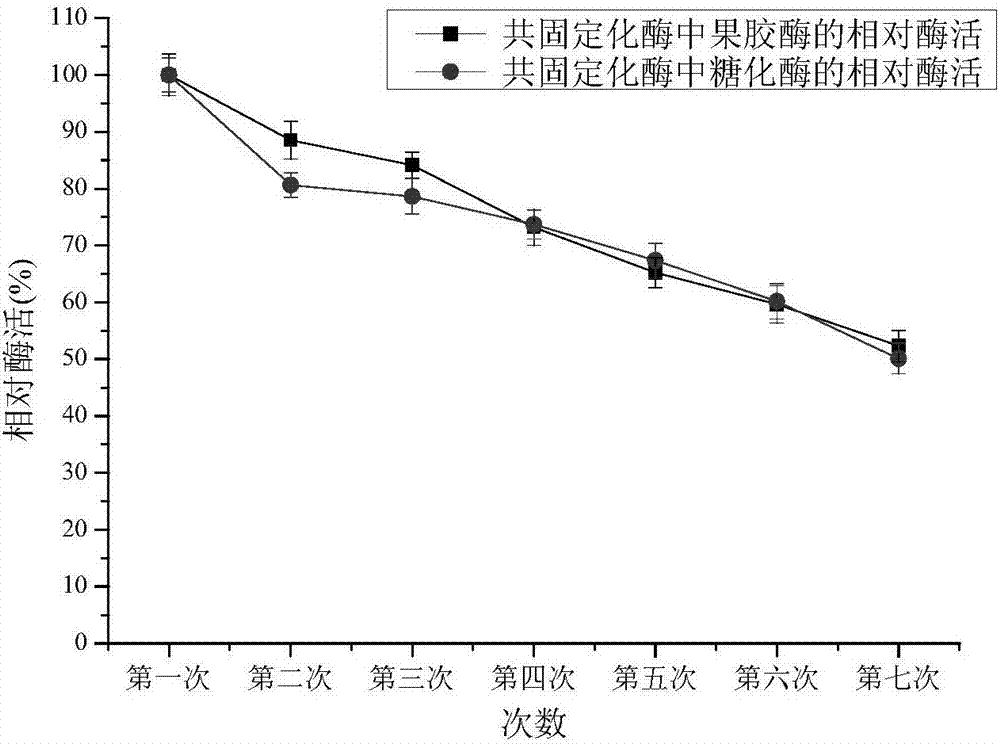

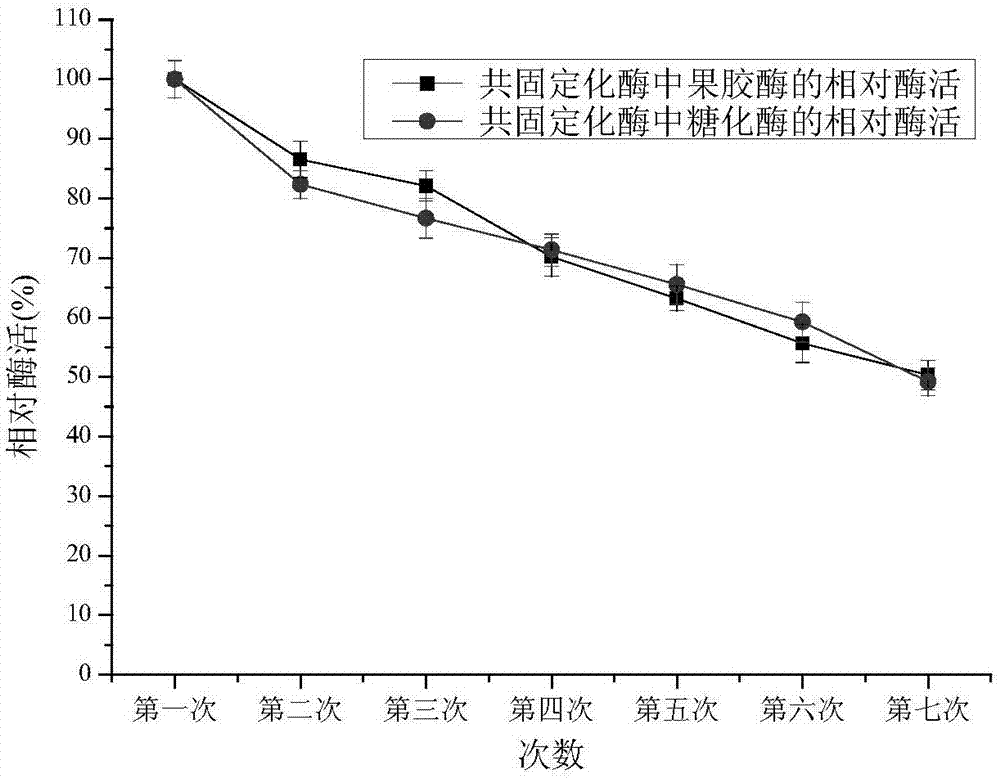

Method for processing clear fructus cucurbitae-fructus crataegi compound juice by adopting immobilized enzyme

ActiveCN106867991AImprove hydrophilic abilityGood biocompatibilityOn/in organic carrierOn/in inorganic carrierPectinaseN-Hydroxysuccinimide

The invention discloses a method for preparing immobilized pectinase-glucoamylase. The method comprises the following steps: activating sodium alginate / graphene oxide gel beads (prepared by adopting a gel method) by adopting N, N'-dicyclohexyl carbodiimide (DCC) / N-hydroxysuccinimide (NHS), thus obtaining activated beads with the activated carboxyl, and coupling pectinase and glucoamylase mixed enzyme to the beads by adopting amido bonds, thus obtaining the immobilized pectinase-glucoamylase with high vitality. The invention further discloses a method for processing clear fructus cucurbitae-fructus crataegi compound juice by adopting the immobilized pectinase-glucoamylase prepared by adopting the method provided by the invention. The method for processing the clear fructus cucurbitae-fructus crataegi compound juice comprises the following steps: selecting raw materials (fructus cucurbitae and fructus crataegi), washing, blanching, carrying out pulping, carrying out enzymolysis treatment by adopting the immobilized pectinase-glucoamylase, carrying out filtering, carrying out centrifugalizing, carrying out sterilizing, and carrying out aseptic packaging, thus obtaining the clear fructus cucurbitae-fructus crataegi compound juice.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Method for producing okra seed oil, compound feed and fungal matrix by processing of okra seeds

ActiveCN106962608AReduce manufacturing costSimple processSuperphosphatesCalcareous fertilisersBiotechnologyFermentation

The invention discloses a method for producing okra seed oil, compound feed and fungal matrix by processing of okra seeds. According to the method, the okra seed oil is produced by twice cold pressing, degumming, decoloring, deodorizing and dephenolizing; okra dregs are subjected to cooking detoxification and microbial fermentation and then compounded with eupolyphaga scraps to produce the compound feed; okra seed shells are compounded with calcium superphosphate, urea and gypsum powder to prepare the fungal matrix through fermentation, so that complete replacement of cotton seeds for production of high-performance products including the okra seed oil, the compound feed and the fungal matrix can be realized. By adoption of a twice double-helix cold pressing process, the oil yield is up to 18-20%, and the produced compound feed is larger than or equal to 45% in crude protein content, larger than or equal to 0.27% in calcium and larger than or equal to 26% in total content of amino acids. By the process, components such as pectin and gossypol in the okra seeds can be removed completely.

Owner:济南飞天农业科技有限公司

Preparation method and application of coffee aroma style coating thick paste sheet

ActiveCN111887464AImprove comfortThe amount of smoke is stableTobacco preparationClimate change adaptationCoffee bean dustWarm water

The invention relates to a preparation method of a coffee aroma style coating thick paste sheet. The method comprises the following steps of: soaking plant fibers in warm water, then carrying out enzyme treatment, dehydrating and drying, and carrying out mechanical defibering; crushing baked coffee beans into coffee powder; uniformly mixing the defibered plant fibers with the coffee powder, and then laying the mixture on a forming net to form a fiber thin layer; spraying an aqueous solution of an adhesive on the surface of the fiber thin layer, and drying to obtain a substrate; uniformly stirring edible spices, a smoke-producing agent and the coffee powder to form a base material; putting the substrate on a stainless steel belt, uniformly smearing the base material, then carrying out primary drying on the substrate by using hot steam, demolding and turning over the substrate subjected to primary drying, uniformly smearing the base material on one surface, which is not smeared with thebase material, of the substrate, and then carrying out secondary drying to obtain the coated thick paste sheet. Smoke generated after the sheet is heated does not generate nicotine and other addicts harmful to health, the smoke amount is large, the aerial fog amount is stable, and the smoking sensory comfort is good.

Owner:POWERTHINK (BEIJING) TECH CO LTD

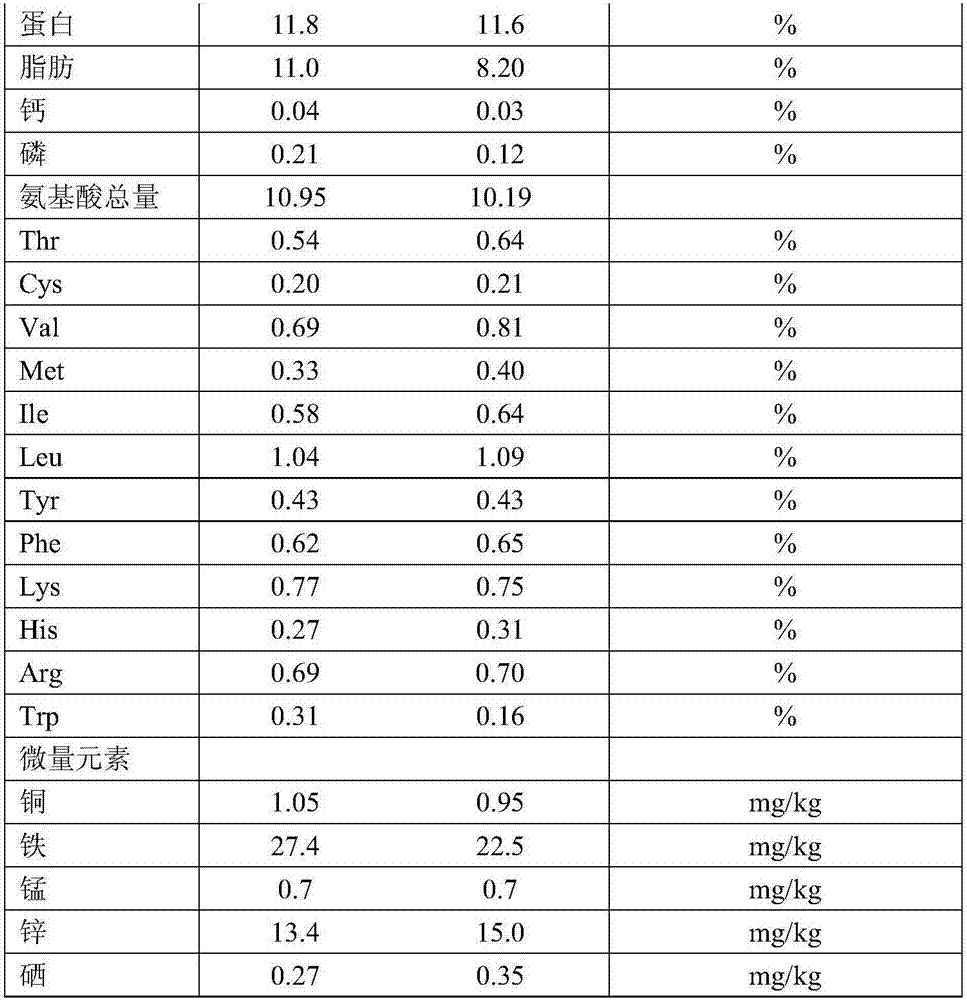

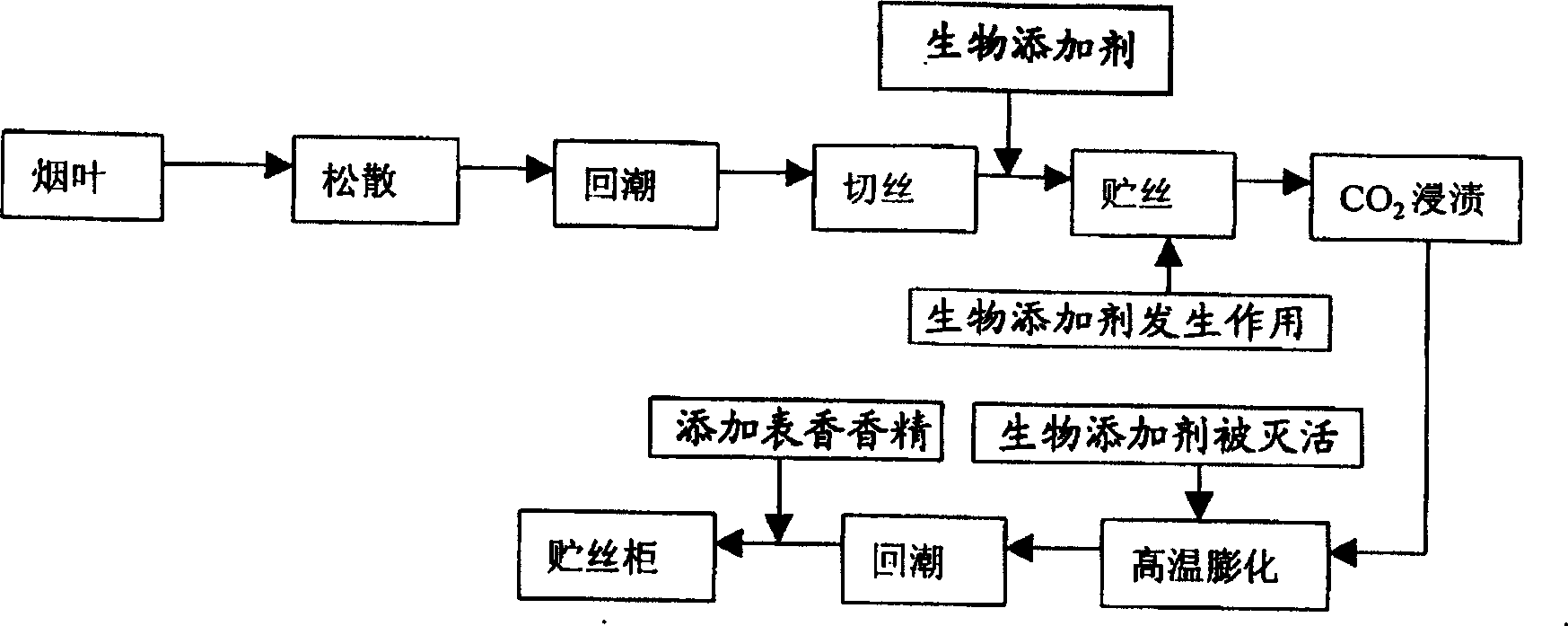

Tobacco-swelling biological additive and its prepn. and application

A biological additives to expand tobacco and its producing method and applications are disclosed whose compositions and contents are tobacco leaf protein degradation enzyme of 0.1-10%, starch degradation enzyme of 1.0-10%, pectin degradation enuzyme of 0.2-10%, polyose degradation enzyme of 0.5-20%, fiber modifier of 0.5-20%, polyphenol oxidation degradution enzyme of 0.1-5%, carbon chain enzyme of 0.1-10%, vitamin C of 0.1-5% and water of 100%. The invented additives can be added into tabocco after the tabocco is remoistened and cut into pieces but before the tabocco is expanded with adding quantity as 0.2-5% of tobacco pieces weight at the temperature of 30 degree c to 50 degree C. The present invention can not bring negative influence to tobacco but can decrease the composition contents which is harmuful in smoking.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Production method for making pineapple fruit wine

InactiveCN110846181AHigh clarityUnique flavorAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

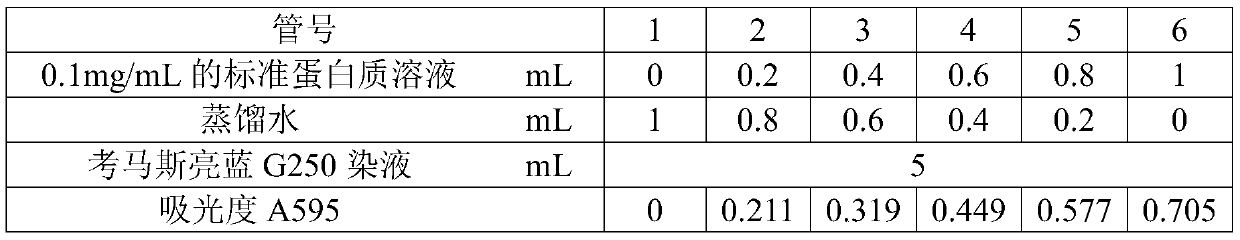

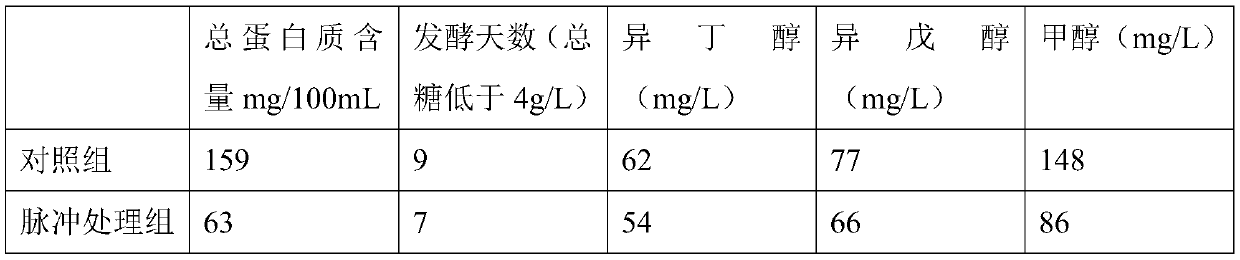

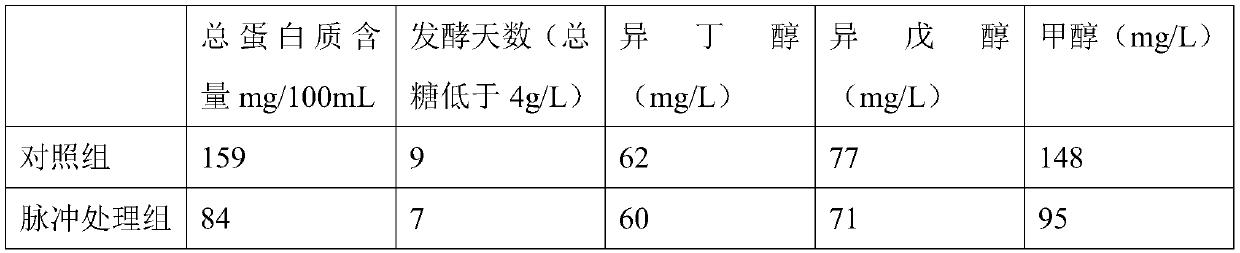

The invention discloses a production method for making pineapple fruit wine. The method includes the steps: squeezing fresh pineapple fruits into juice, adding sulfur dioxide, adjusting pH (potentialof hydrogen) to reach 3.4-3.5 by the aid of tartaric acid, adding food-grade NaCl to adjust intensity of conductivity of the juice, preheating the juice to reach the temperature of 30-38 DEG C, keeping the temperature for 3-5 minutes, and pumping the juice in a high-strength electric pulse electric field treating chamber; placing the treated pineapple juice at the temperature of 0-4 DEG C, and taking liquid supernatant; adjusting pineapple sugar degree in the liquid supernatant; taking adjusted clarified pineapple juice, adding yeast, and fermenting mixture for 5-7 hours by controlling the temperature of 20-25 DEG C; adding activated bentonite into the pineapple fruit wine, standing at low temperature, taking liquid supernatant, enabling the liquid supernatant to pass a deep filter film and a sterilization filter film, and filling cans with the liquid supernatant to obtain the pineapple fruit wine. According to the method, by a high-strength electric pulse electric field treating mode,the tartaric acid and the NaCl are added, components of the pineapple juice are adjusted, pretreatment before fermentation is implemented, and the prepared pineapple fruit wine is unique in flavor, high in clarity degree and quality and low in fusel oil and methyl alcohol.

Owner:SOUTH CHINA UNIV OF TECH +1

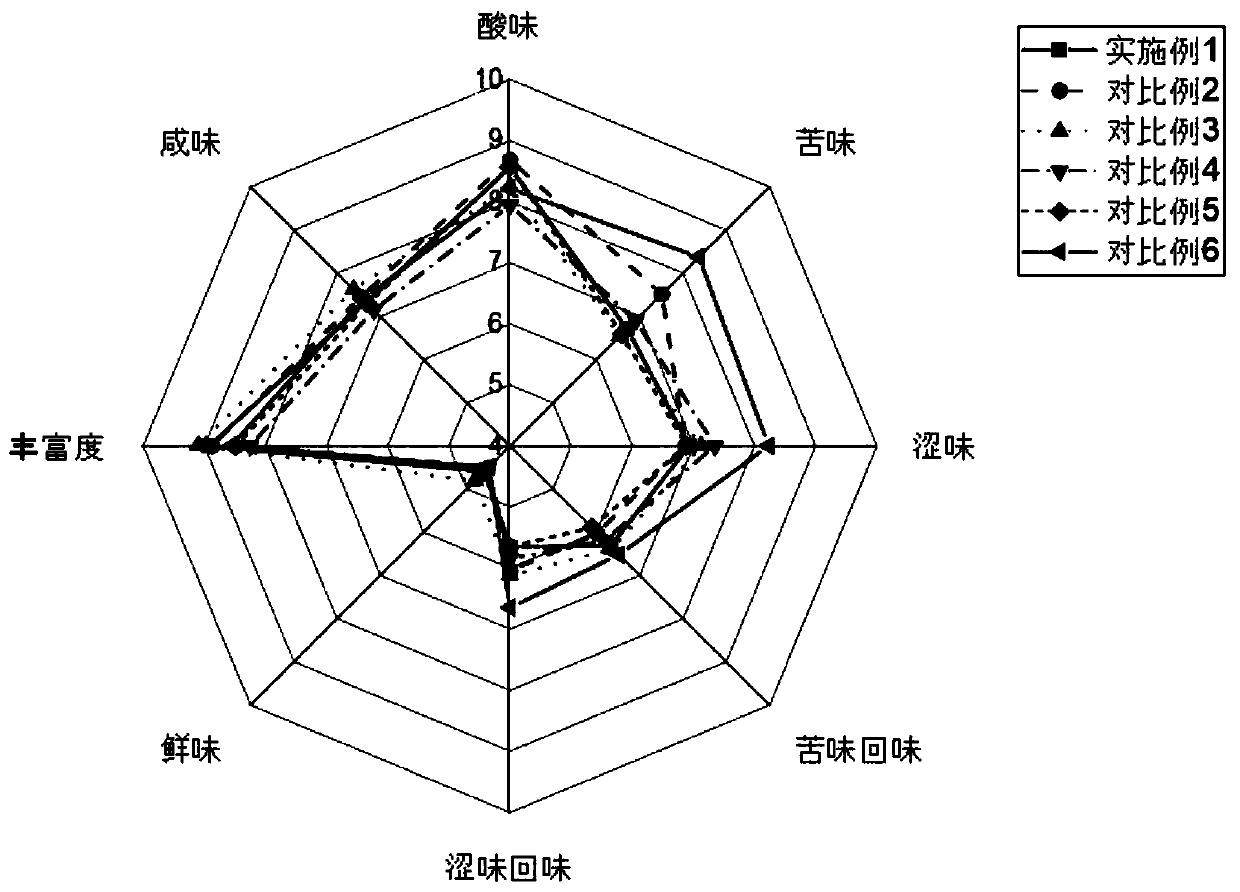

A method for reducing the tobacco sheet pectin content through a three-step manner

InactiveCN107338232AReduce pectin contentTightly boundTobacco preparationMicroorganism based processesEnzymatic hydrolysisFermentation

The invention belongs to the technical field of tobacco preparation, and particularly relates to a method for reducing the tobacco sheet pectin content through a three-step manner. A specific strain is subjected to fermentation firstly, a crude enzyme solution having maximum pectinase activity is prepared, and the crude enzyme solution is directly used in a tobacco sheet production process by adopting a three-step manner, thus reducing the pectin content of a sheet product. Through optimizing a processing process, an optimum degrading effect is obtained, thus improving tobacco quality. The enzyme activity of the crude enzyme solution prepared by fermentation of the specific strain can be as high as 2986.87 U / mL, and application potential is good. After the crude enzyme solution is further used for tobacco sheet raw material processing, the pectin content of a tobacco sheet is finally reduced. The three-step manner is a manner for performing enzymatic hydrolysis in different processing stages of a tobacco raw material leachate in a tobacco sheet processing process, and the pectinase prepared by fermentation is added separately in different process stages so that the pectin content of a tobacco sheet finished product is reduced.

Owner:CHINA TOBACCO HENAN IND +1

A kind of processing technology of persimmon liquor

The invention discloses a processing technology of persimmon liquor, comprising: 1) preparation of culture liquid; 2) pretreatment of raw materials; 3) treatment of distiller's yeast and color protection; 4) preparation of fermentation liquid; 5) post-fermentation of fermentation liquid; 6) distillation; 7) Clarification of bottom liquid; 8) Pasteurization of bottom liquid; 9) Blending; 10) Finished product testing. The invention solves the problems that the persimmon wine produced by the existing conventional brewing method is too dark in color, too astringent, strong in oxidation, turbid in liquor, poor in stability, short in storage time and the like.

Owner:YUNCHENG UNIVERISTY

Clean vegetable processing method

InactiveCN112602769APrevent browningReduce churnNatural extract food ingredientsFood dryingMicroorganismNutritive values

The invention provides a clean vegetable processing method, which mainly comprises the steps of harvesting, vacuum precooling, trimming, cleaning, cutting, fresh keeping, dehydration, packaging, cold storage and the like; the method is safe and efficient, can effectively remove microorganisms on the surface of the clean vegetable, better prolongs the shelf life of the clean vegetable, and ensures the quality and nutritional value of the clean vegetable to the maximum extent.

Owner:广西振合供应链管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com