Method for producing okra seed oil, compound feed and fungal matrix by processing of okra seeds

A compound feed and okra seed technology, applied in botany equipment and methods, animal feed, animal feed, etc., can solve the problem of high, generally around 0.4%, supercritical extraction equipment requires a large investment, and the oil yield is only 10% or so, to achieve low production costs, improve animal production performance, and shorten the feeding period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Prepare okra oil

[0033] 1) Harvesting okra seeds

[0034] Take the brown, cracked and fully mature fruit pods of the husk, and after drying or drying, they can be mechanically threshed by an improved nail-toothed corn thresher.

[0035] 2) drying

[0036] Okra seeds pass through the dryer (L=15m, The inlet temperature is 100°C, the outlet temperature is 40°C), and the moisture is lower than 13%.

[0037] 3) Featured

[0038] Impurities and moldy seeds are removed by wind screening, gravity separation and color separation.

[0039] 4) Shelling

[0040] Use a camellia seed sheller to peel the shells.

[0041] 5) Separation of shell and kernel

[0042] The separation of shell and kernel is realized by blower separator.

[0043] 6) cold pressing

[0044] The peeled oilseeds are cold-pressed once with a double-screw cold press to obtain crude oil I and seed meal. Seed meal.

[0045] The double-screw cold press adopts the double-screw oil press from Wuhan Foo...

Embodiment 2

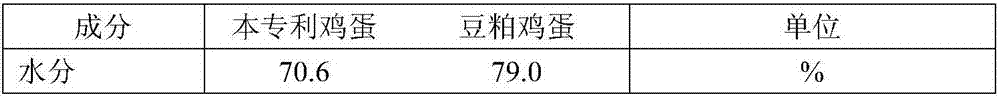

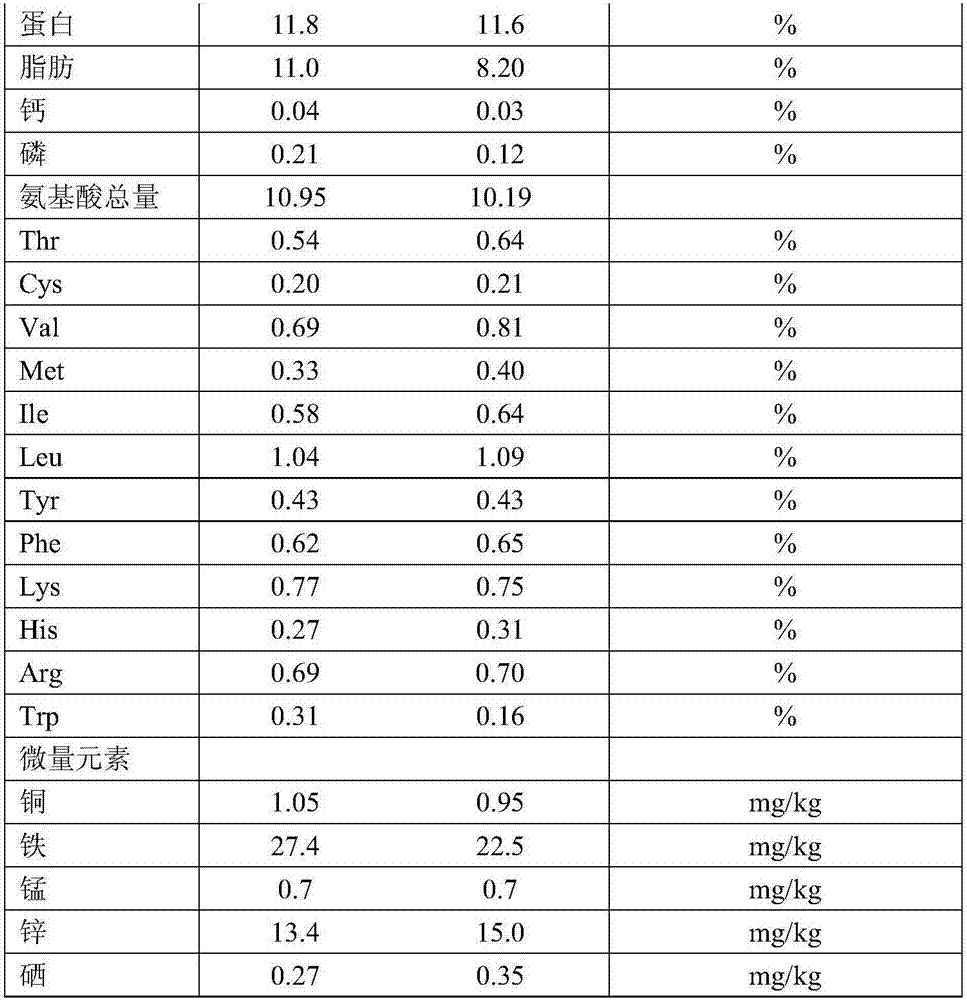

[0070] Embodiment 2: feed feeding experiment

[0071] This experiment was carried out at the laying hen farm in Huaiyang County. 300 180-day-old Hai-Line brown layer hens were randomly selected as feeding objects, and they were divided into two groups, namely the test group and the control group, with 150 chickens in each group, 3 replicates in each group, and 50 chickens in each replicate. The feed formulations of the control group and the test group are shown below, and other management measures are the same. The test was carried out for 35 days, and 15 days after the start of the test, the egg production was counted for each repetition in each group, and the statistics were continued for 20 days to calculate the egg production rate. In the last 10 days of the experiment, 20 eggs were collected for each repetition in each group, and the egg quality was determined.

[0072] Conventional laying hen feed for the control group: corn 58.4%, wheat bran 3%, soybean meal 28%, calc...

Embodiment 3

[0079] Step 11) Add sesamin and vitamin E to the refined edible oil according to the mass ratio of 100:0.5:1.5, and stir evenly to obtain a finished oil, and the remaining steps are the same as in Example 1. The shelf life reaches 6 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com