A kind of processing technology of persimmon liquor

A persimmon processing technology, applied in the field of persimmon liquor processing technology, can solve the problems of dark color, short storage time and strong oxidative flavor of persimmon wine, and achieve the effect of strong fruit flavor, low alcohol content and low pectin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

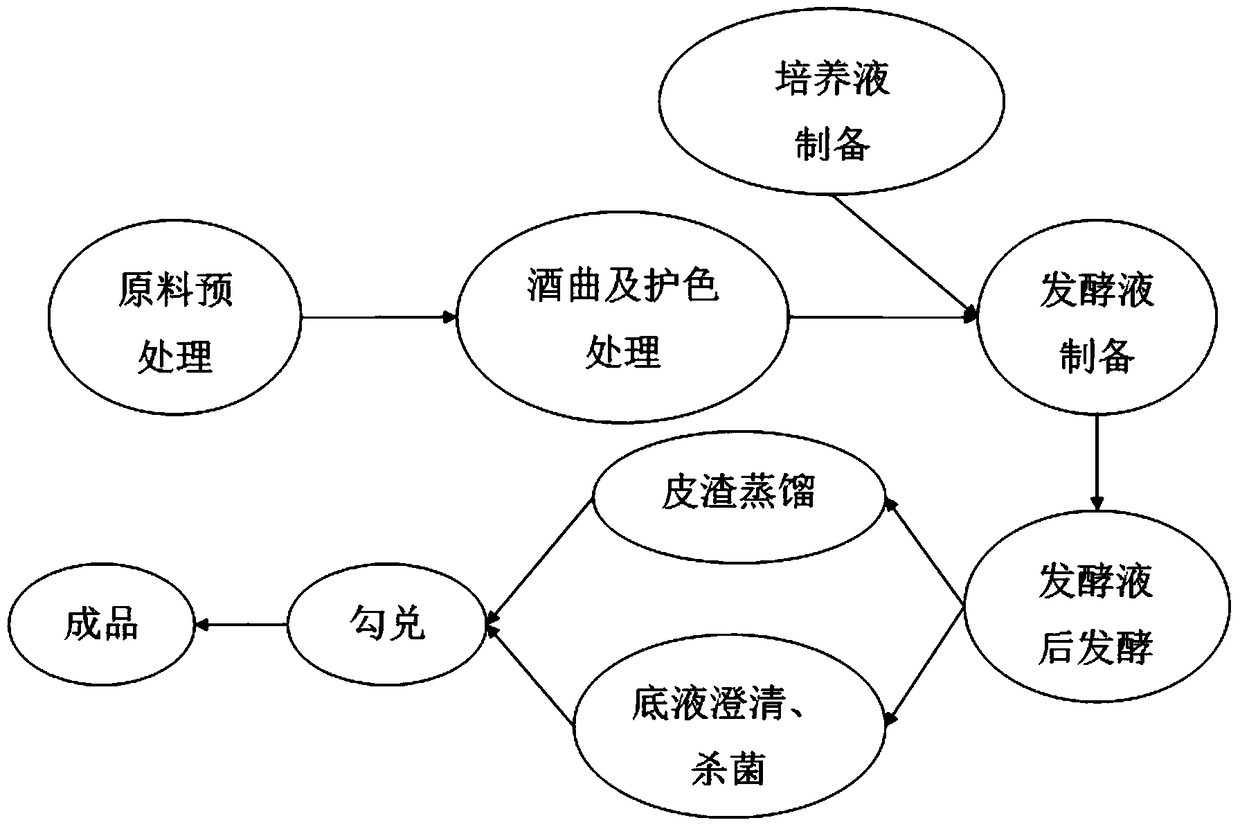

[0024] Example 1 as figure 1 Shown, the processing technology of the persimmon liquor of the present embodiment comprises:

[0025] 1) Preparation of culture medium: Weigh wheat bran, corn flour, and sorghum flour with a total weight of 1Kg at a ratio of 2:1:1, steam sterilize at 121°C and 0.1mpa for 30 minutes, and then add 2.5KG or 2.5 1 L of warm boiled water at 40°C, stirred into a paste and used as a medium; take 100g of dry yeast and dissolve it in warm water at 30°C, then add it to the medium, stir evenly, activate and propagate at 30°C for 24 hours, and obtain a culture medium ;

[0026] The production method of dry yeast is as follows: in summer, knead the flour and water to form a dough and expose it to the sun. After the dough is fully fermented, divide it into 5cm×3cm×2cm (length, width and height) cuboids, dry in the shade, and store in a cool place;

[0027] 2) select the tangerine persimmon varieties that were plucked within one week before and after the frost...

Embodiment 2

[0036] Example 2 as figure 1 Shown, the processing technology of the persimmon liquor of the present embodiment comprises:

[0037] 1) Preparation of culture medium: Weigh wheat bran and corn flour with a total weight of 1.5Kg at a ratio of 2:1, steam sterilize at 121°C and 0.1mpa for 30min, and then add 3.75KG or 3.75L of 40°C 150g of dry yeast was dissolved in warm water at 30°C, then added to the medium, stirred evenly, and activated and propagated at 30°C for 24 hours to obtain a culture medium;

[0038] The production method of dry yeast is as follows: in summer, knead the flour and water to form a dough and expose it to the sun. After the dough is fully fermented, divide it into 5cm×3cm×2cm (length, width and height) cuboids, dry in the shade, and store in a cool place;

[0039]2) select the tangerine persimmon varieties that were plucked within one week before and after the frost solar term, and prepare them for use after cleaning and destemming pretreatment;

[0040]...

Embodiment 3

[0048] Example 3 as figure 1 Shown, the processing technology of the persimmon liquor of the present embodiment comprises:

[0049] 1) Preparation of culture medium: Weigh wheat bran and sorghum flour with a total weight of 1.5Kg at a ratio of 2:1, steam sterilize at 121°C and 0.1mpa for 30min, and then add 3.75KG or 3.75L of 40°C 150g of dry yeast was dissolved in warm water at 30°C, then added to the medium, stirred evenly, activated and propagated at 30°C for 24 hours, to obtain a culture medium;

[0050] The production method of dry yeast is as follows: in summer, knead the flour and water to form a dough and expose it to the sun. After the dough is fully fermented, divide it into 5cm×3cm×2cm (length, width and height) cuboids, dry in the shade, and store in a cool place;

[0051] 2) select the tangerine persimmon varieties that were plucked within one week before and after the frost solar term, and prepare them for use after cleaning and destemming pretreatment;

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com