Patents

Literature

37 results about "Wood gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood gas is a syngas fuel which can be used as a fuel for furnaces, stoves and vehicles in place of gasoline, diesel or other fuels. During the production process biomass or other carbon-containing materials are gasified within the oxygen-limited environment of a wood gas generator to produce hydrogen and carbon monoxide. These gases can then be burnt as a fuel within an oxygen rich environment to produce carbon dioxide, water and heat. In some gasifiers this process is preceded by pyrolysis, where the biomass or coal is first converted to char, releasing methane and tar rich in polycyclic aromatic hydrocarbons.

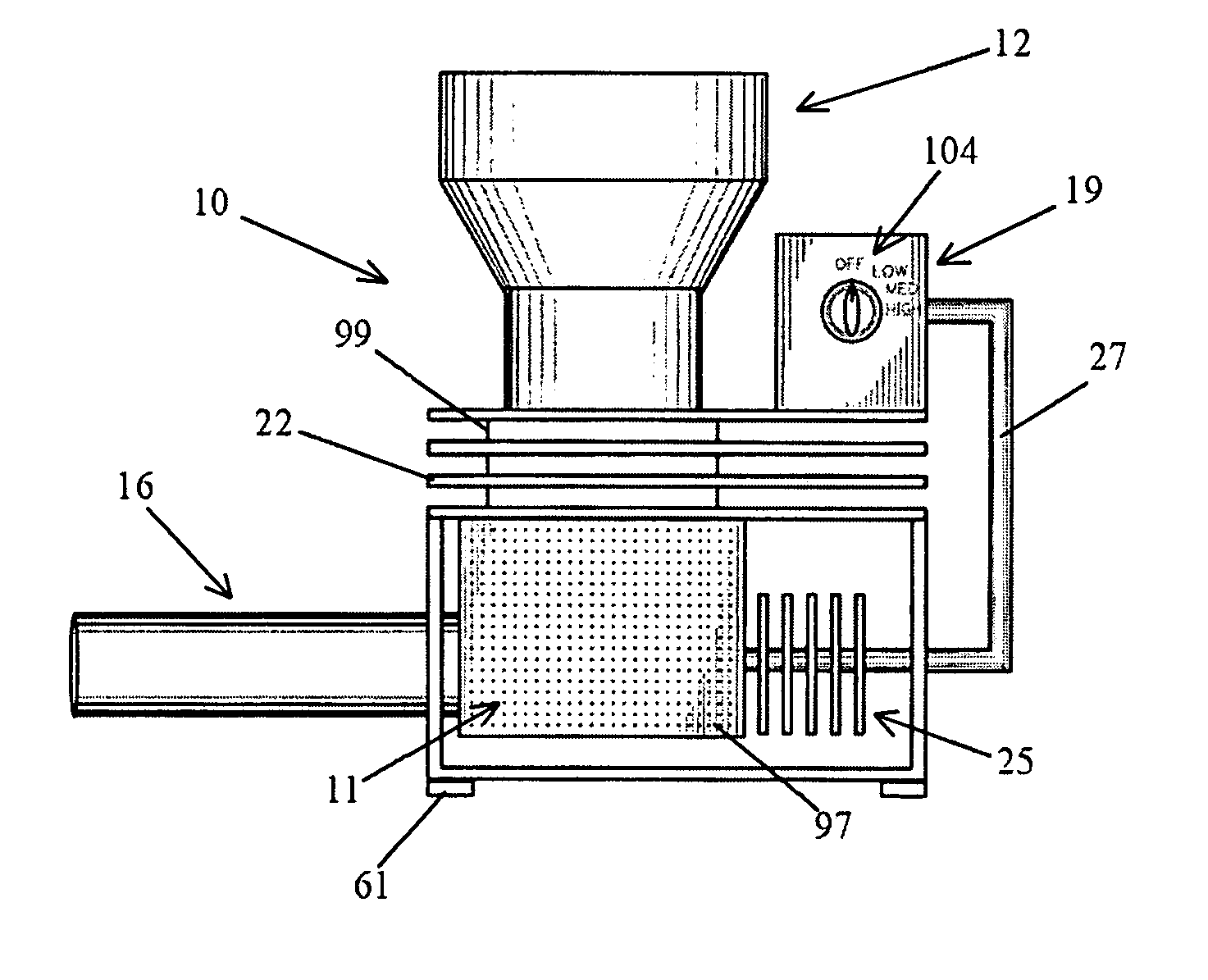

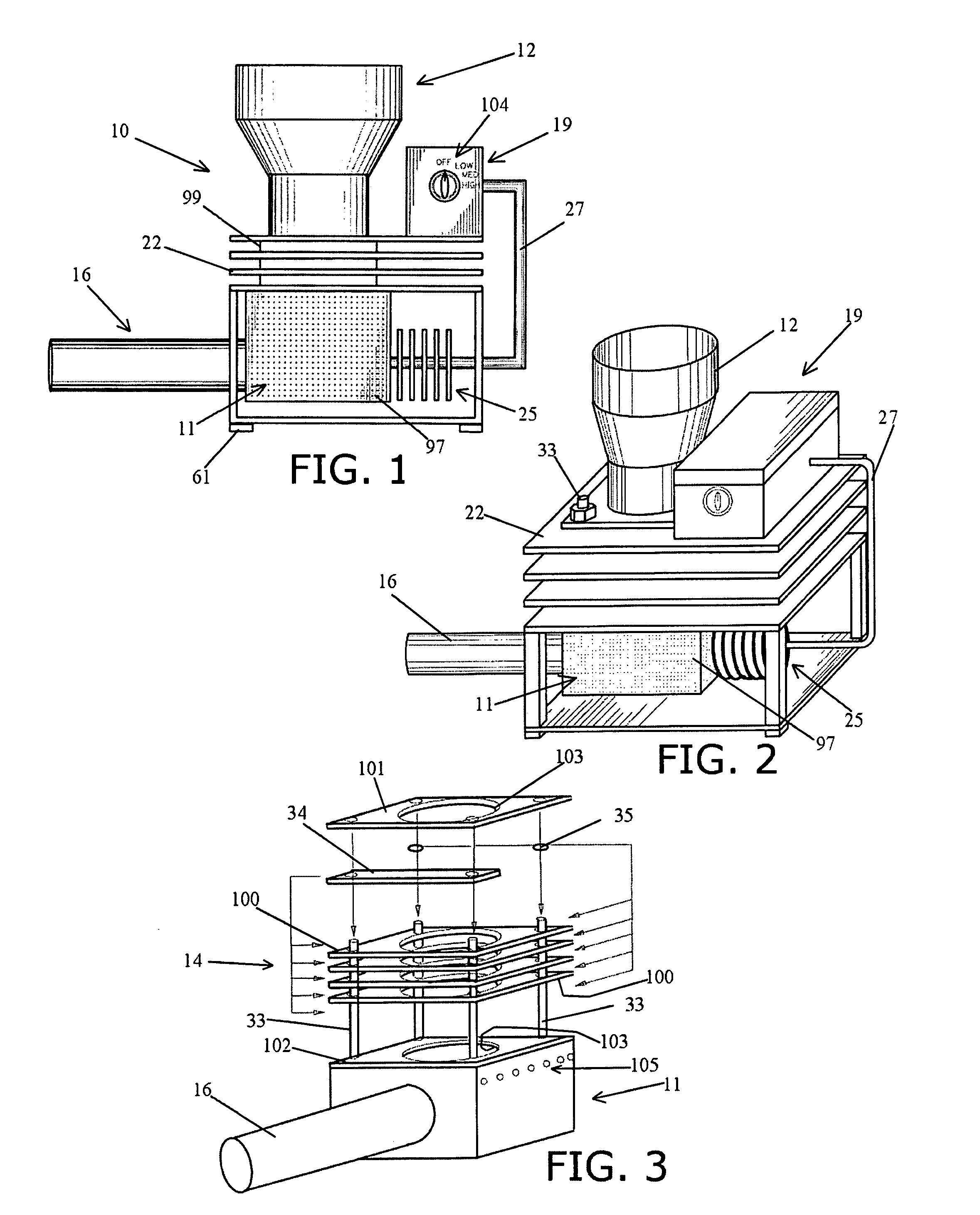

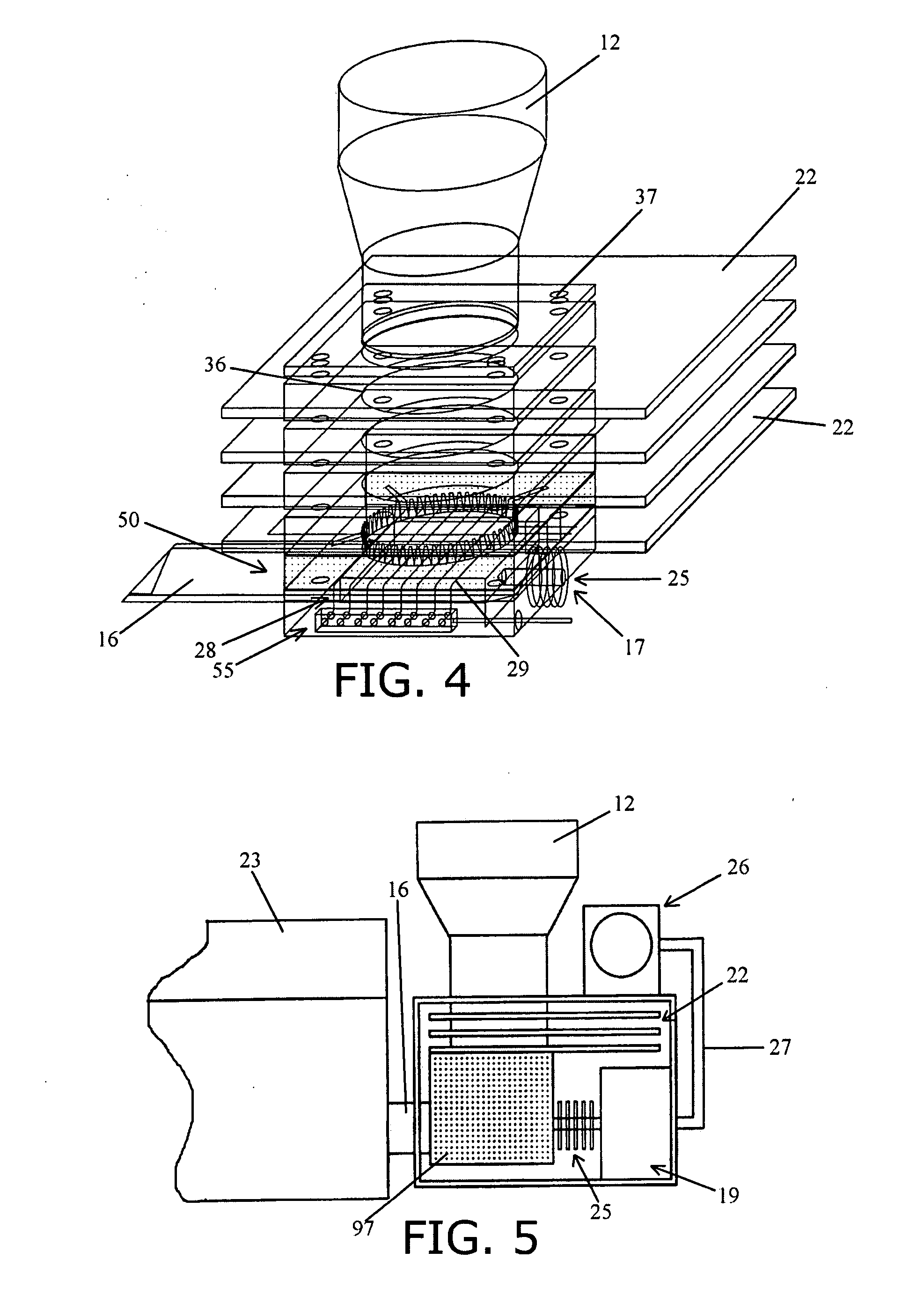

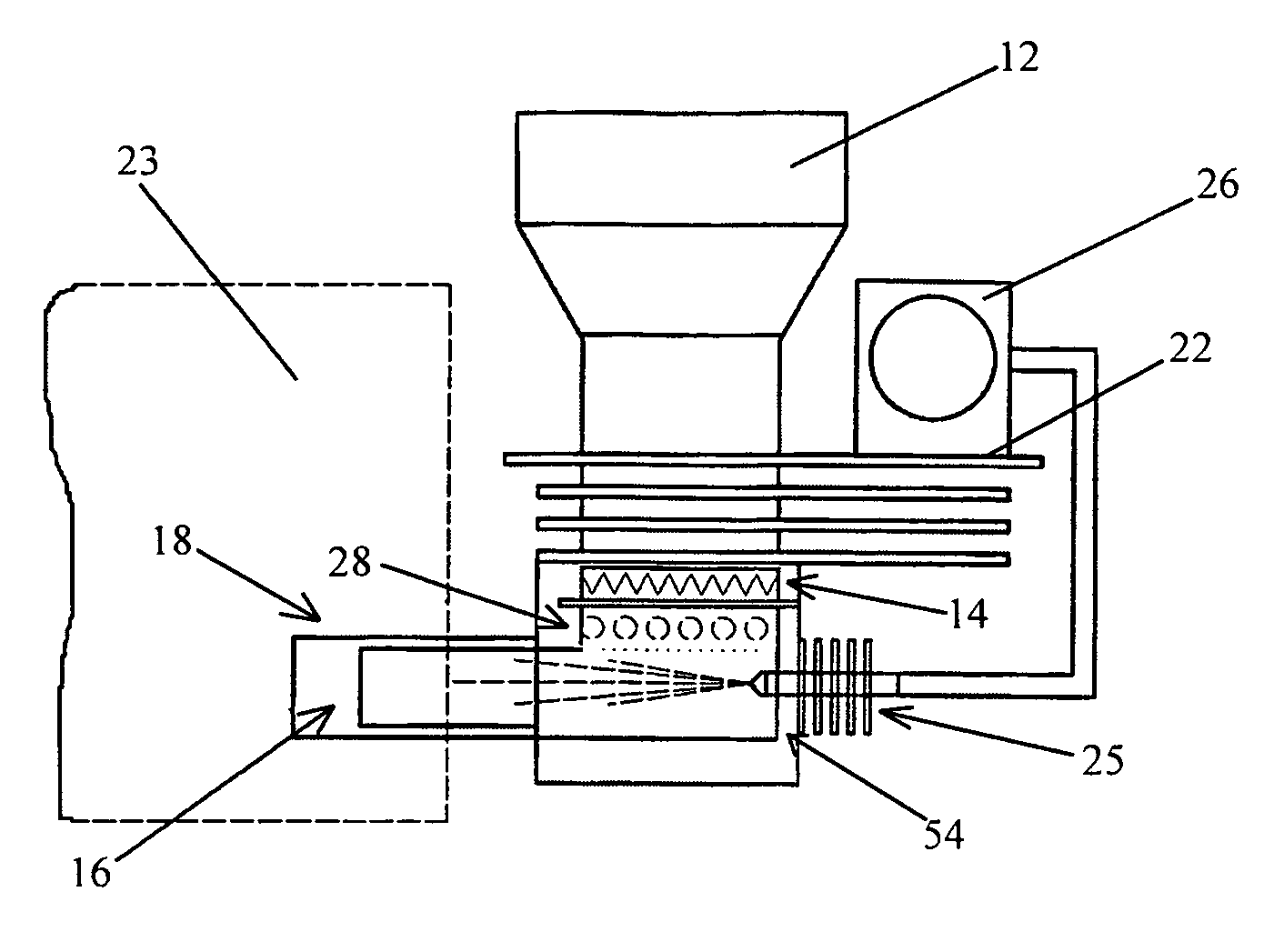

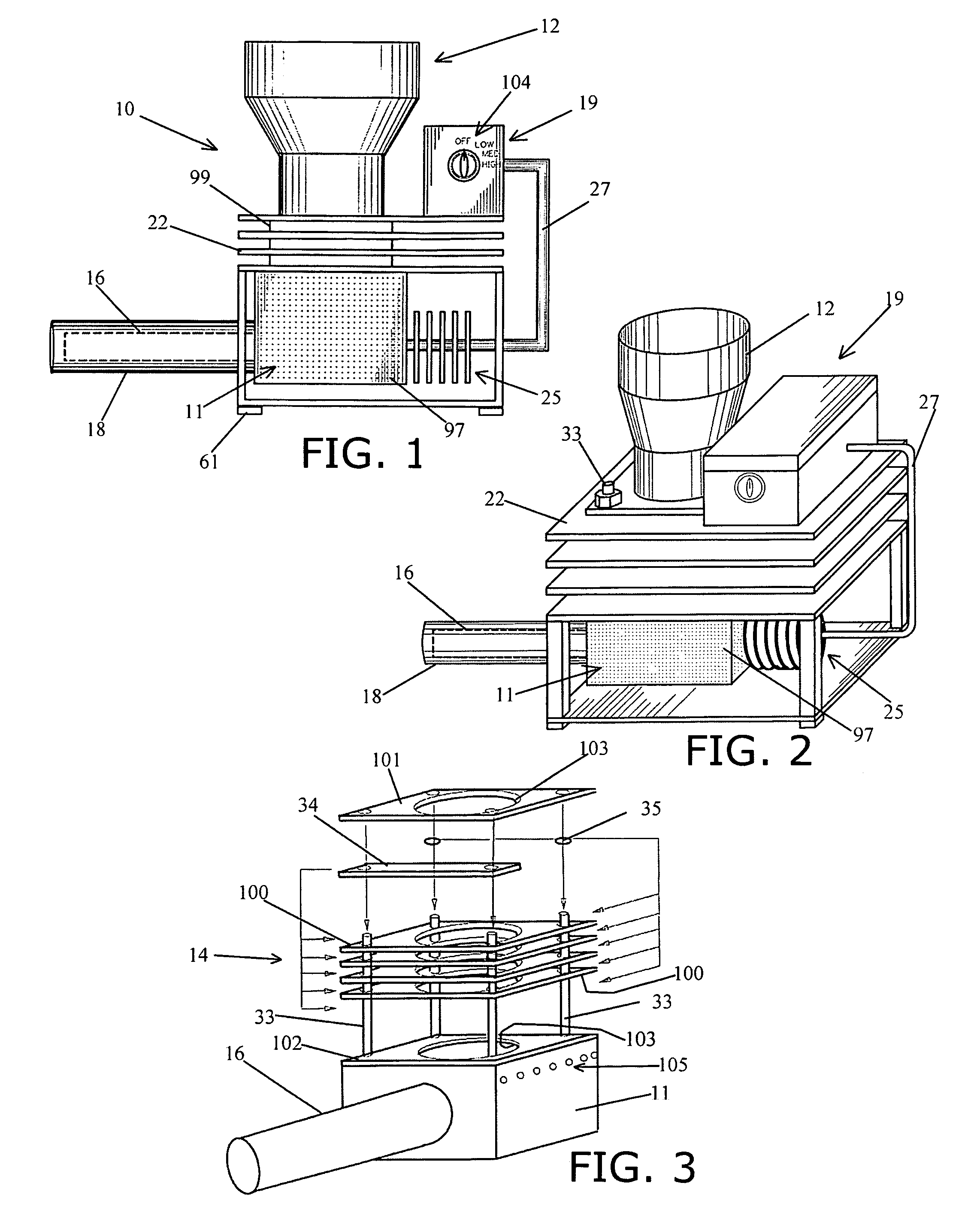

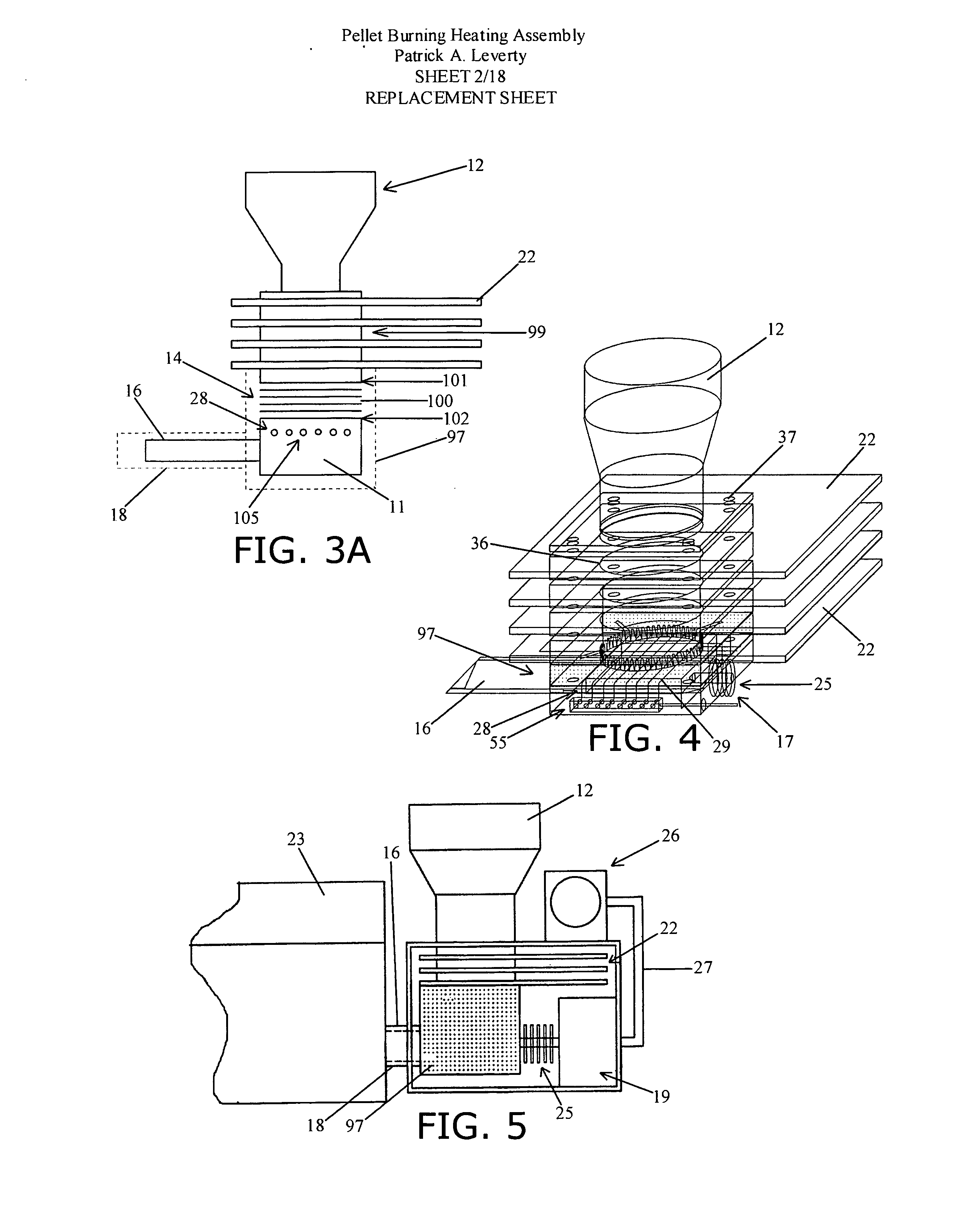

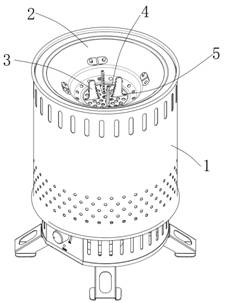

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

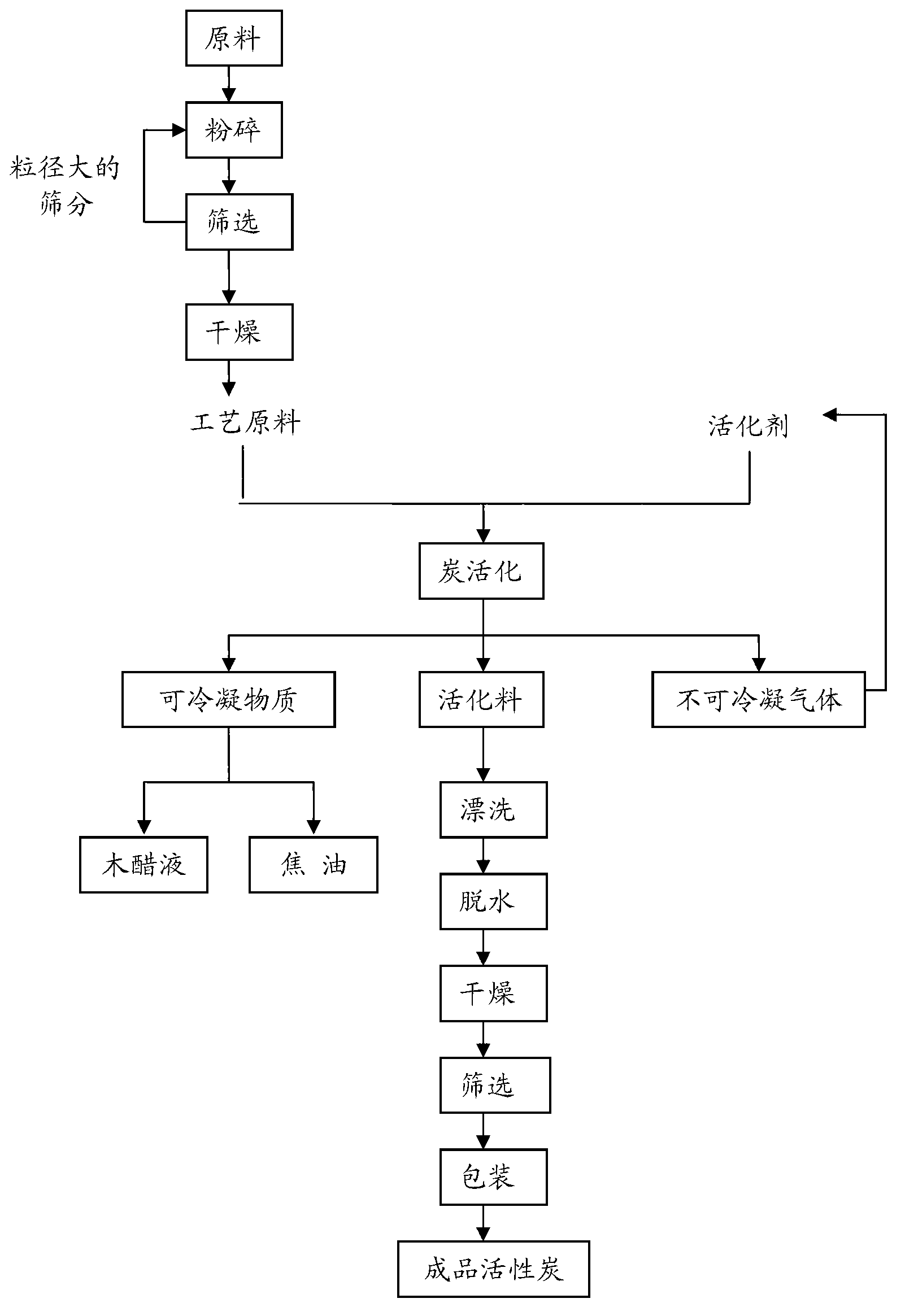

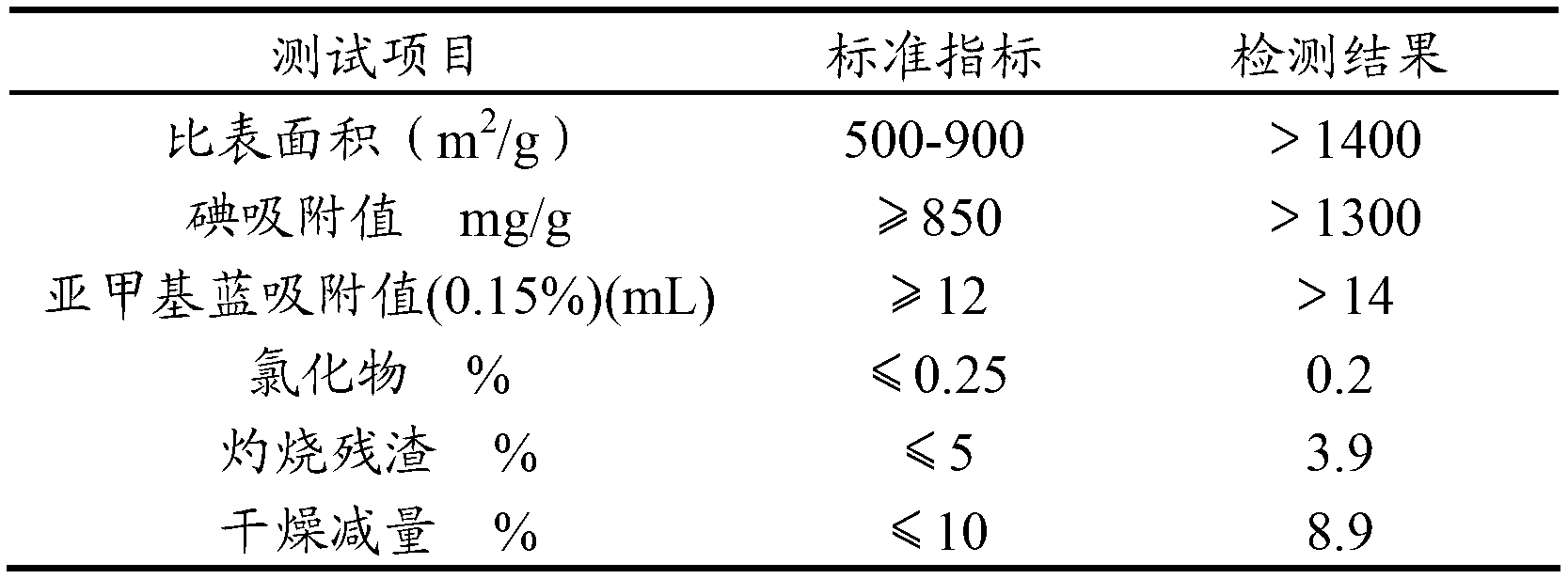

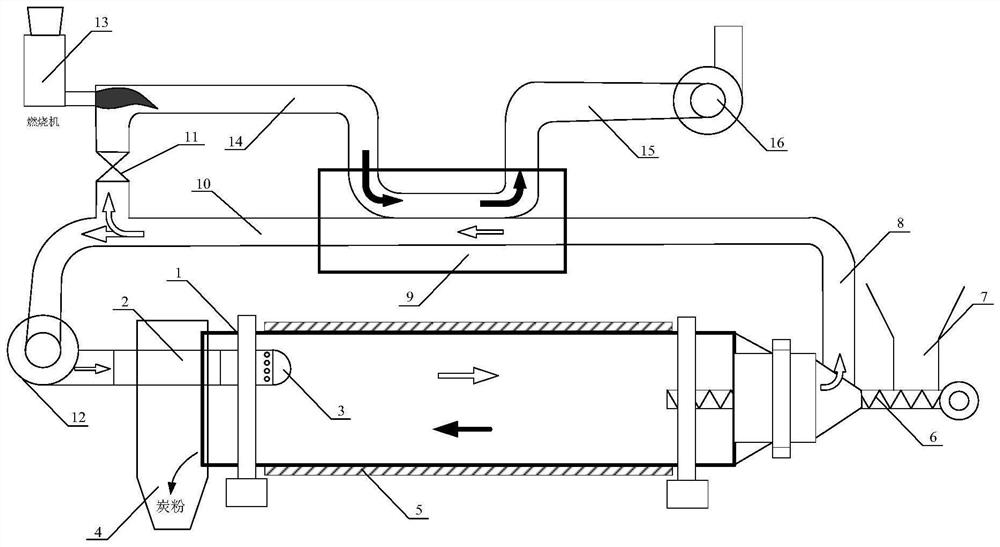

Method for producing active carbon

The invention discloses a method for producing active carbon, comprising the following steps: grinding corn cobs and cornstalks into flocculent corn cob materials and flocculent cornstalk materials bya grinder respectively, evenly mixing and then sending the materials into a particle forming machine to be extruded into particle materials; placing the particle materials into a carbonization kiln to be carbonized to obtain carbonized materials; directly sending the carbonized materials into an activation kiln to be activated without cooling to obtain activated materials; grinding and grading the activated materials to obtain the finished product of active carbon. Wood gas discharged from the flue of the carbonization kiln is introduced into a heating chamber on the lower part of an activation chamber to be ignited for heating the activation kiln; high temperature flue gases generated by combustion of the wood gas are introduced into the flue on the upper part of the activation chamber for carrying out secondary heating on the activation kiln; the flue gases discharged from the flue on the upper part of the activation chamber are introduced out to serve as the heat sources of a steamboiler, and the high temperature steam generated by the steam boiler enters the activation chamber to activate the carbonized materials. The active carbon produced by the method is good in quality and low in cost.

Owner:XIFENG DENGYUN JIEGAN COMPREHENSIVE UTILIZATION DEV

Pellet burning heating assembly

Owner:GRILLSON

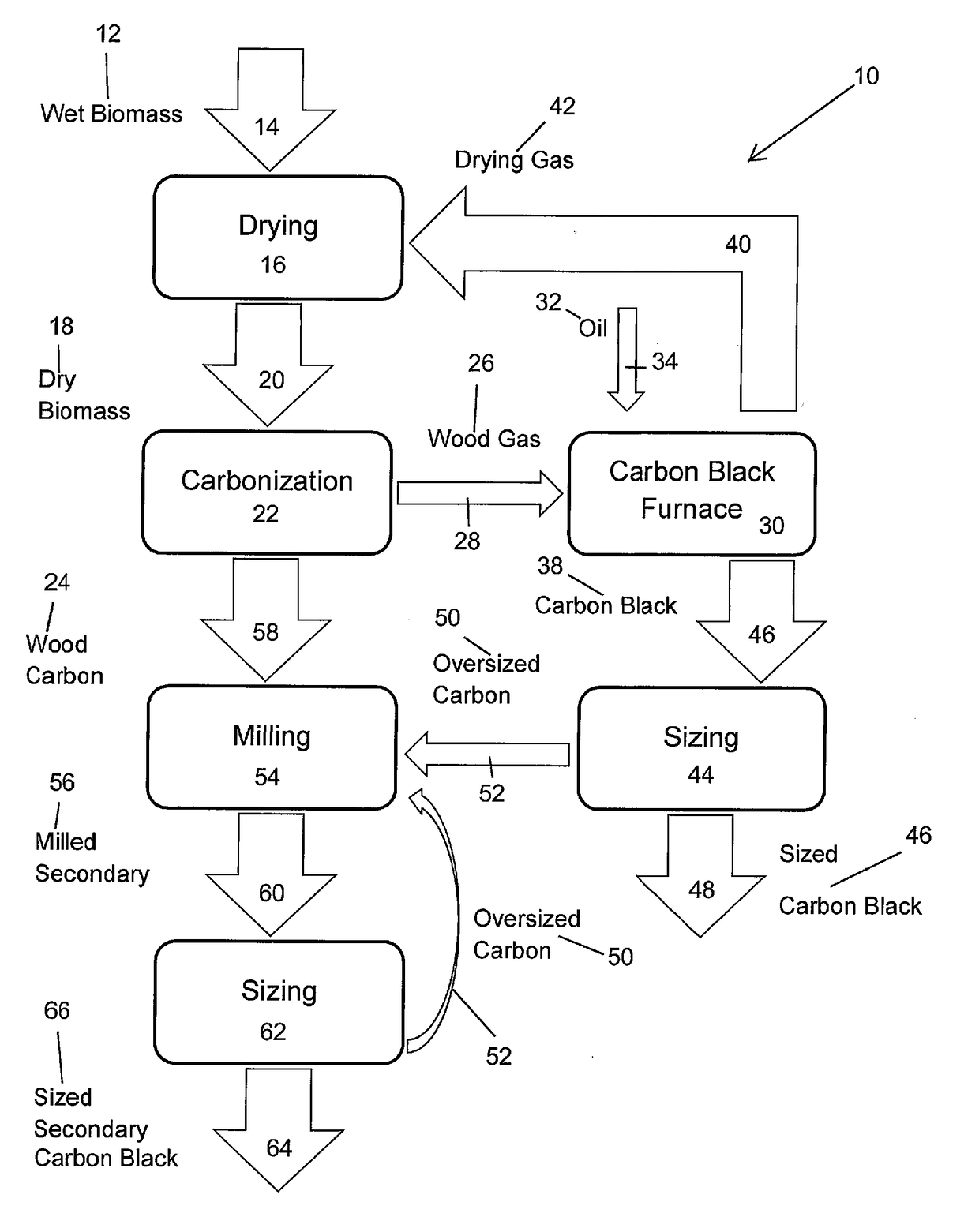

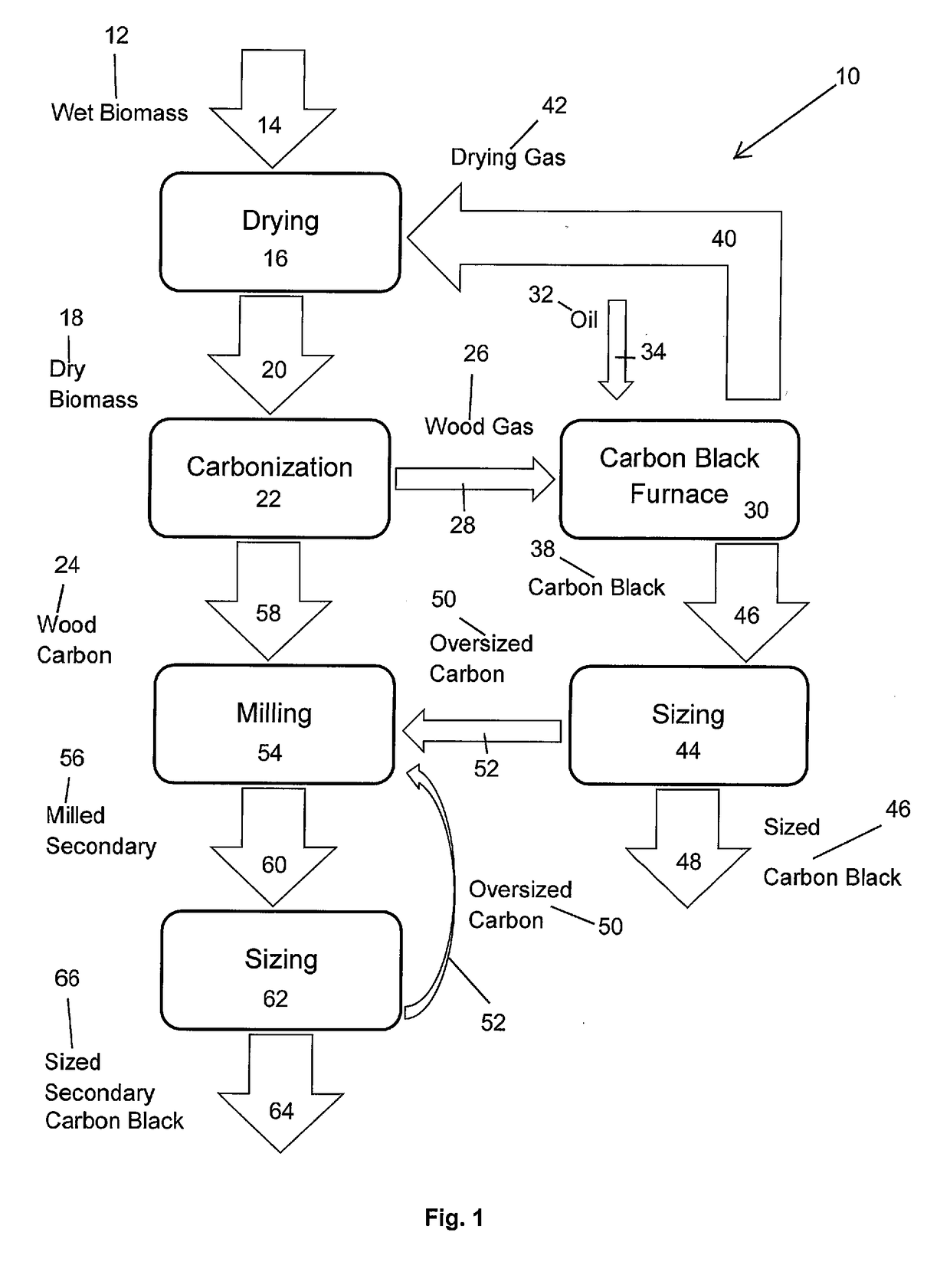

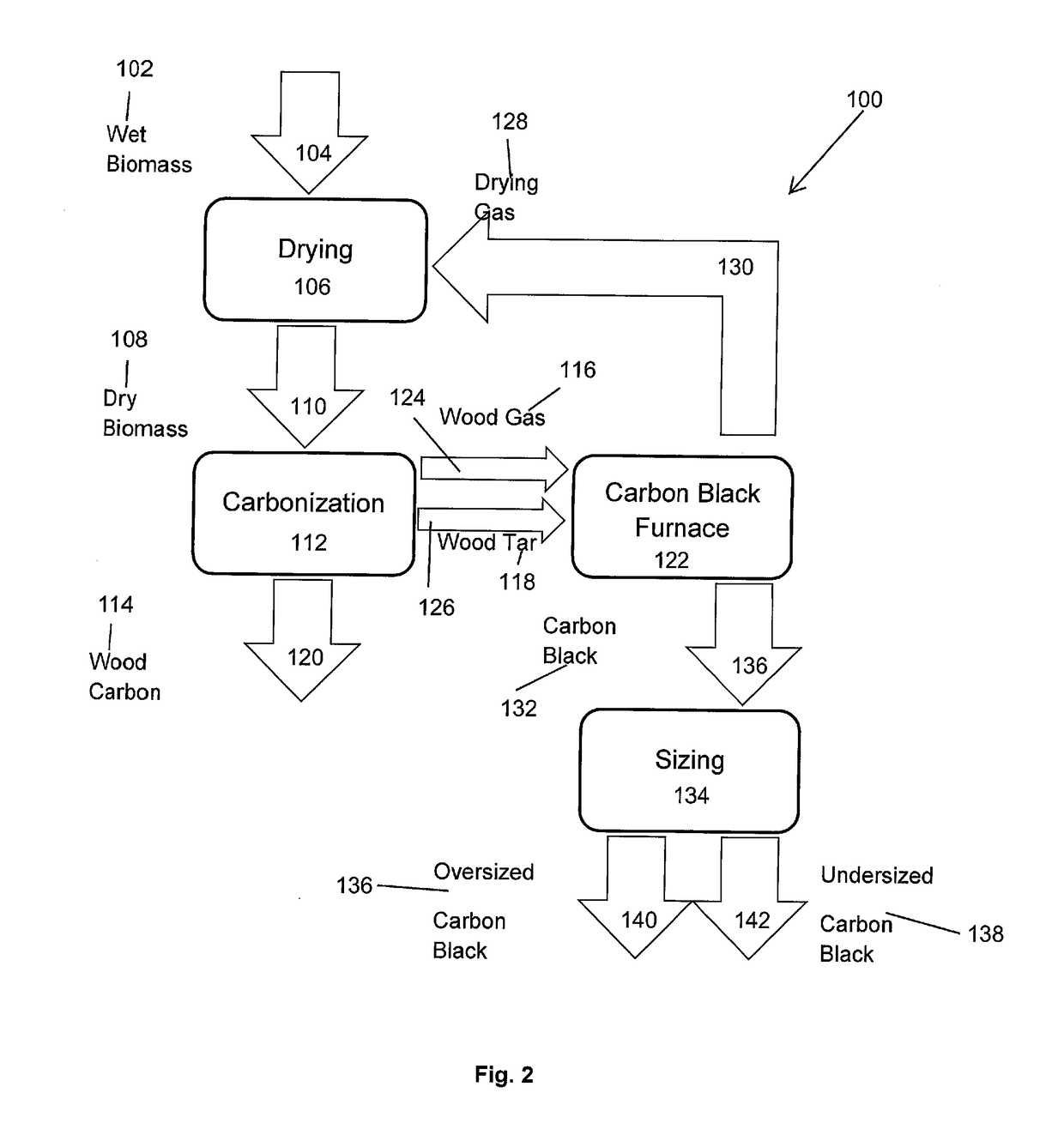

Renewable Pyrolysis-Gas Derived Carbon Black Material and Method of Making the Same

A method for the production of a carbon black entirely from raw biomass feedstock by pyrolytically decomposing the biomass feedstock in a controlled processing atmosphere at a preselected temperature for a preselected period of time to produce solid carbon material and wood gas, and using the wood gas as a fuel to pyrolyze added oils in a carbon black furnace to produce carbon black and gaseous by-products for processing the biomass feedstock. The carbon material has a carbon content of greater than 90% by volume of non-volatile, high purity fixed elemental carbon, is free of environmentally hazardous chemical compounds and components surface area, and includes specific properties, such as density, hardness, or chemical composition to provide superior properties in diverse applications.

Owner:CARBON RES & DEV CO

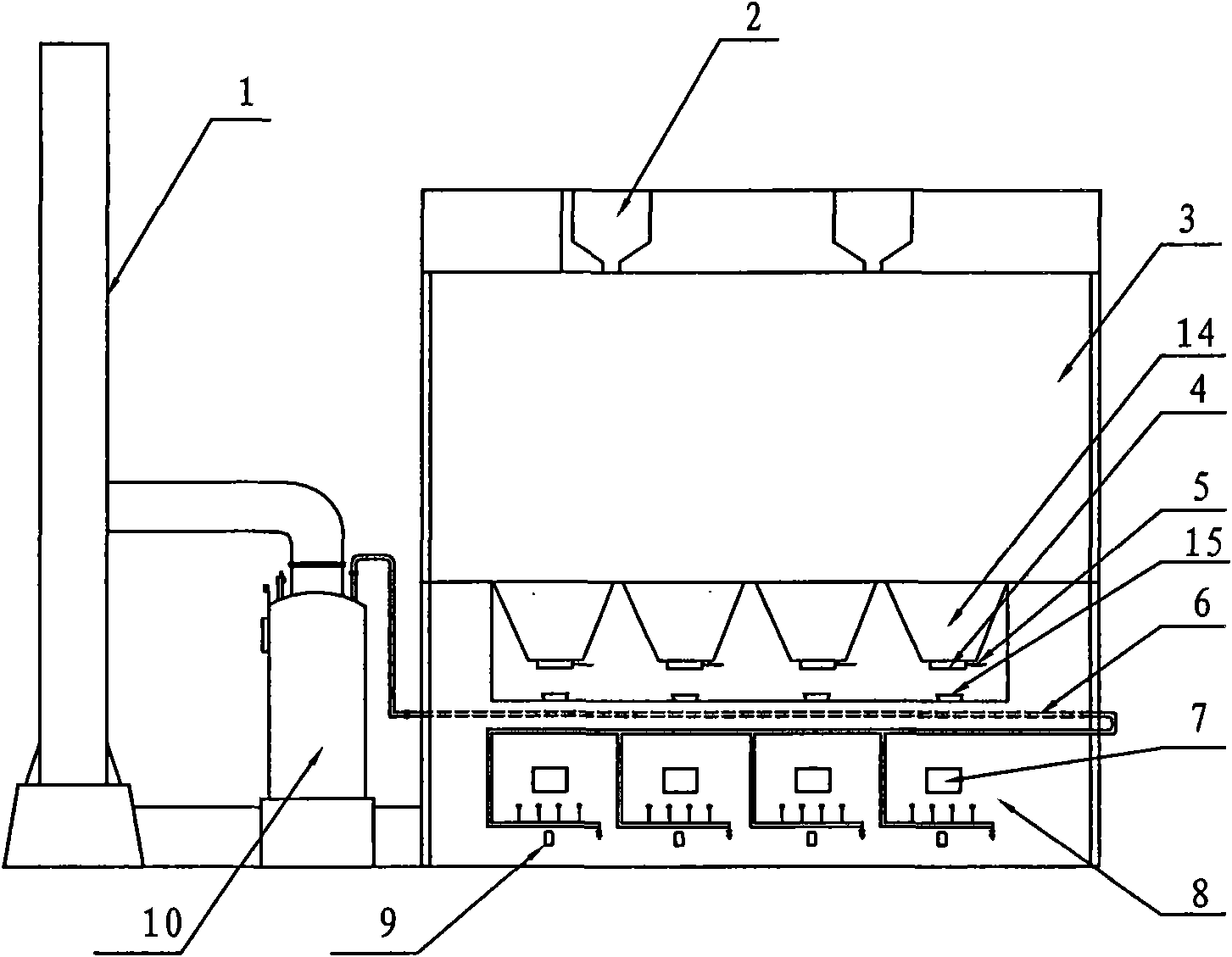

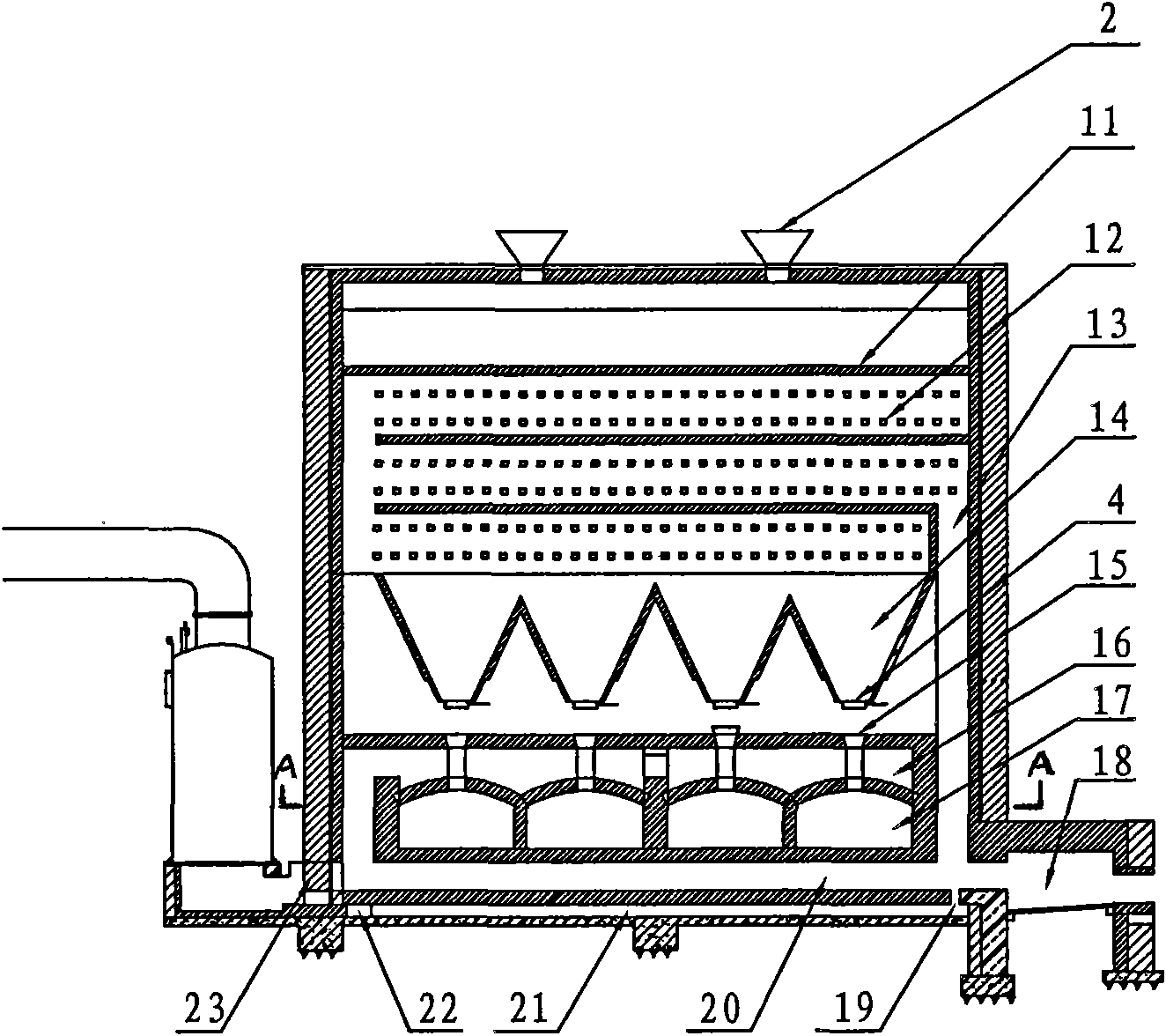

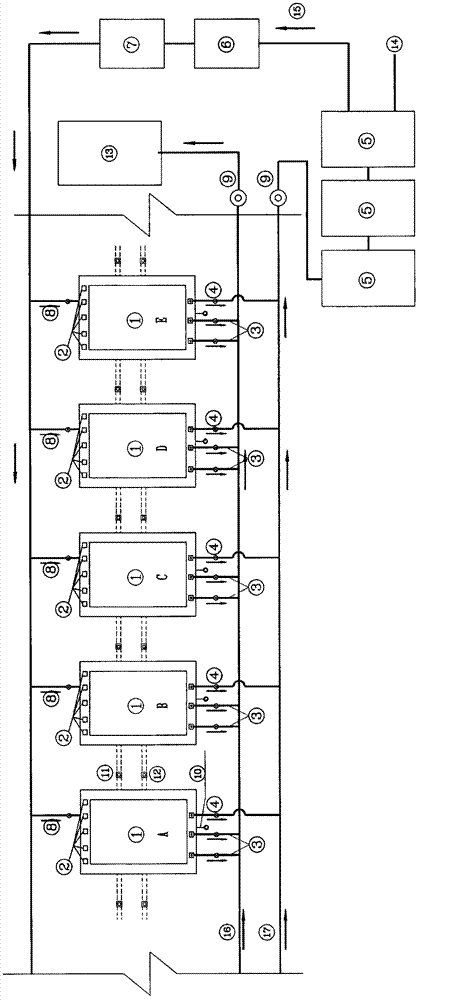

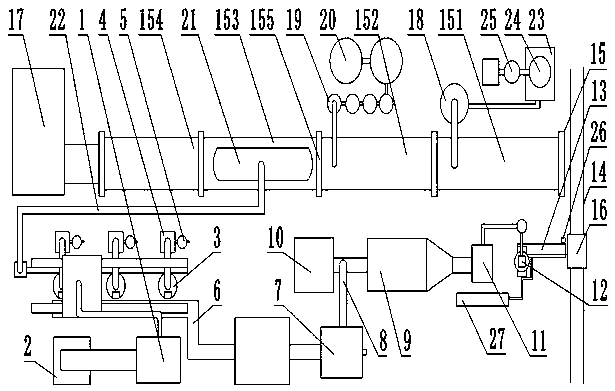

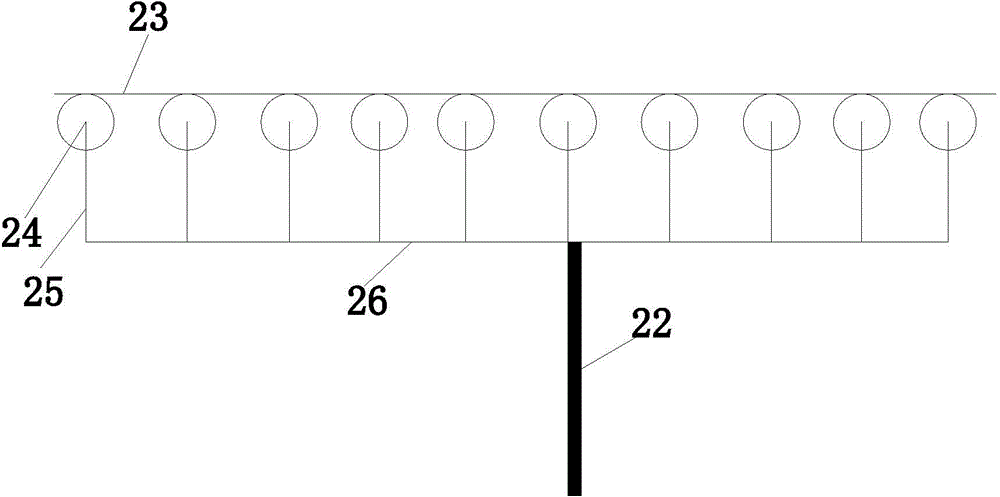

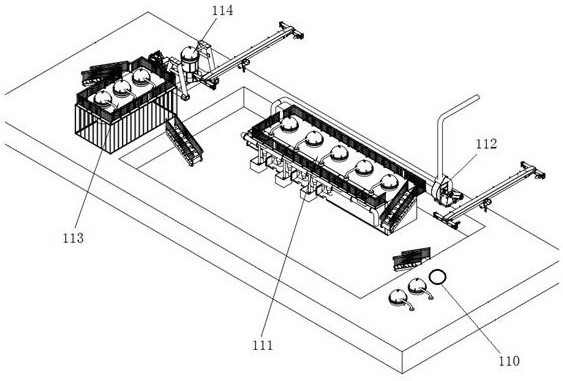

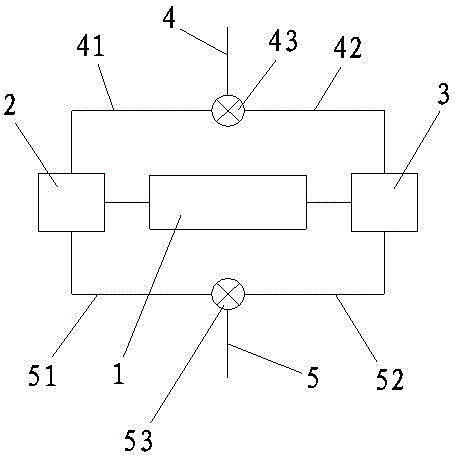

Cleaner production system of carbonization furnace group

InactiveCN103361085ARealize cleaner productionEfficient productionBiofuelsRetortsSpontaneous combustionCarbonization

The invention discloses a cleaner production system (figure 1) for intermittent carbonization furnaces, which realizes mass transfer and heat transfer between the carbonization furnaces and colony using of the carbonization furnaces. The system adopts the technical scheme that hot air and oil-gas can be transferred to a plurality of following carbonization furnaces (B, C and D) which are not ignited from a current heating (spontaneous combustion or furnace chamber heating) carbonization furnace A through inter-furnace mass transfer and heat transfer passages, so as to progressively realize preheating, drying or preliminary thermal cracking of the carbonization furnaces (B, C and D), which in turn shortens the preparation time of ignition and thermal cracking and facilitates quick temperature reduction after the completion of thermal cracking. The cleaner production system adopting the working mode is conducive to improving the production efficiency, speed and benefits. Moreover, the whole production process is very clean and energy is saved, as the flue gas generated during combustion heating and the oil-gas generated during thermal cracking are processed respectively, the flue gas is directly used for drying biomass materials, the oil-gas enters into a special oil-gas separating tower for processing after being subjected to tunnel cooling (the exchanged heat can be used for geothermal energy of raw materials yards), collected noncondensable gas, namely wood gas, serves as a thermal cracking fuel, and condensed fluid serves as an important by-product of the production.

Owner:申买君 +1

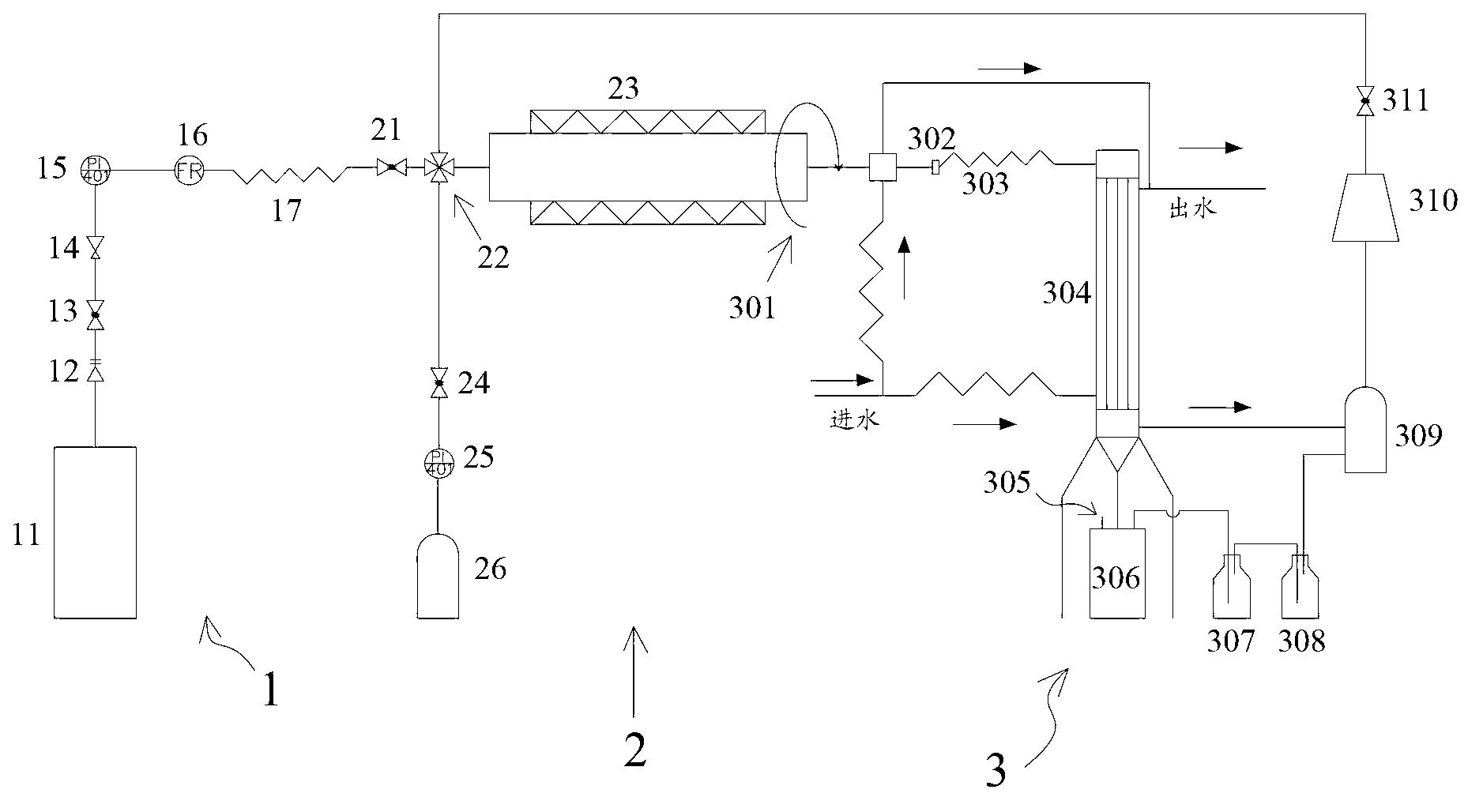

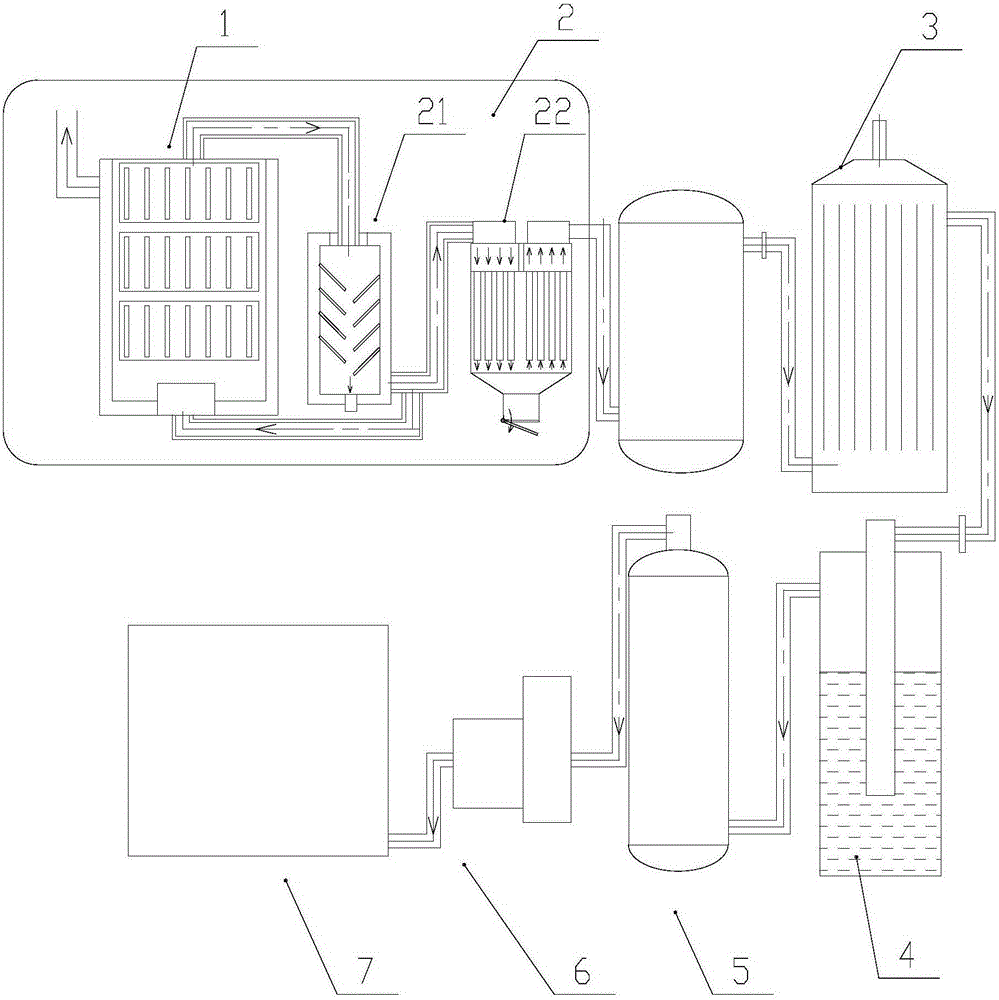

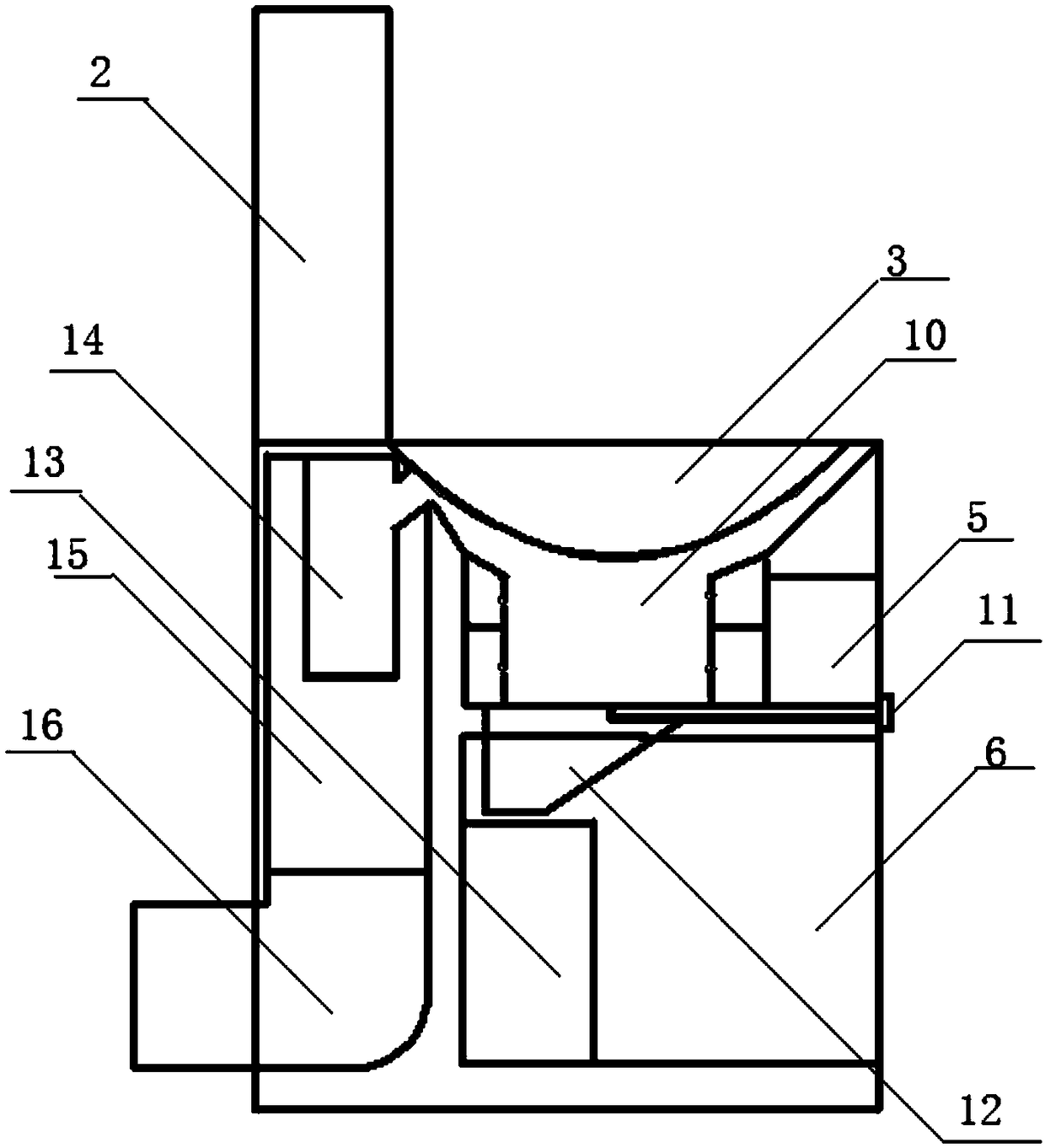

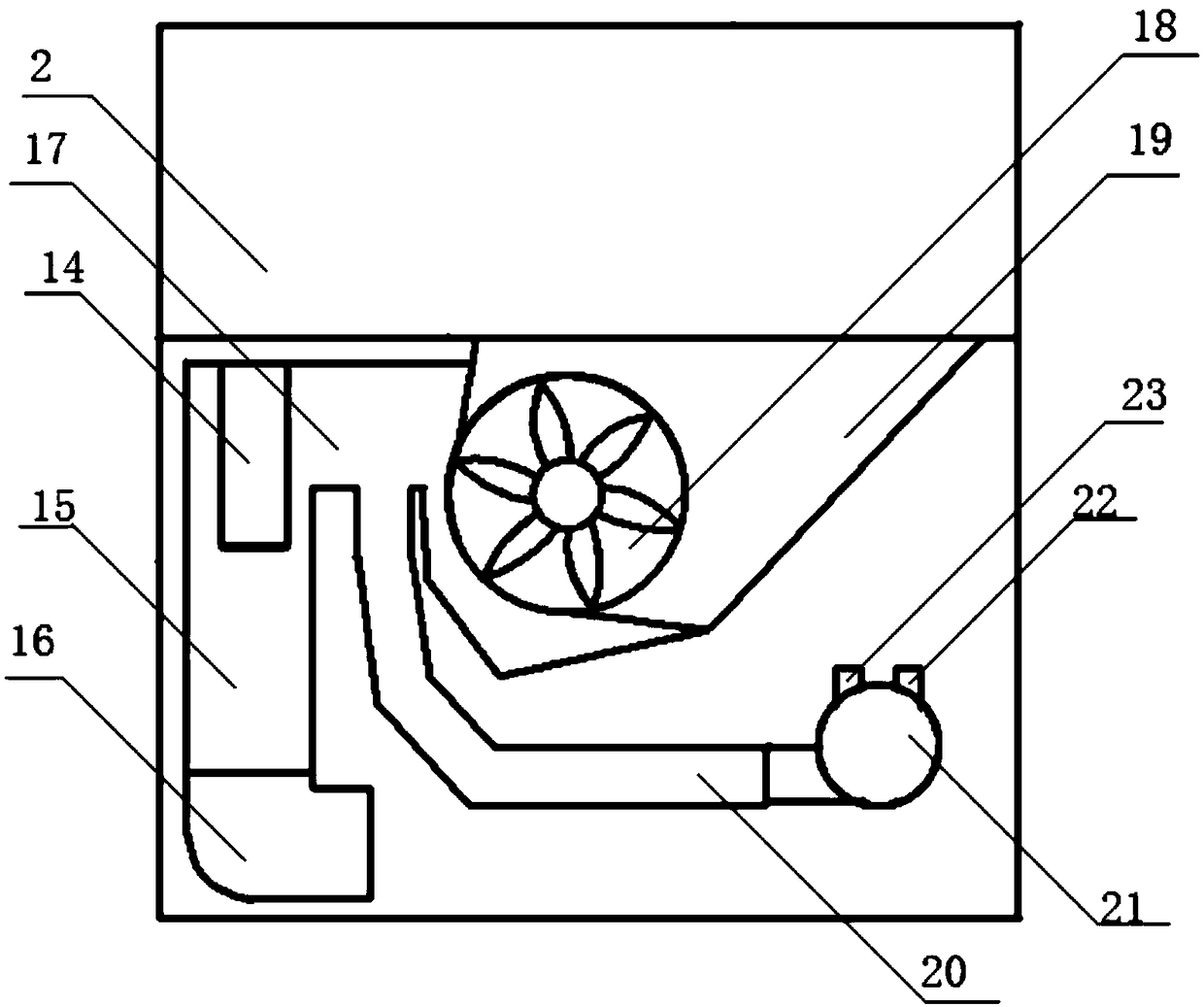

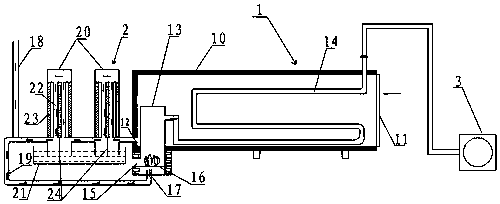

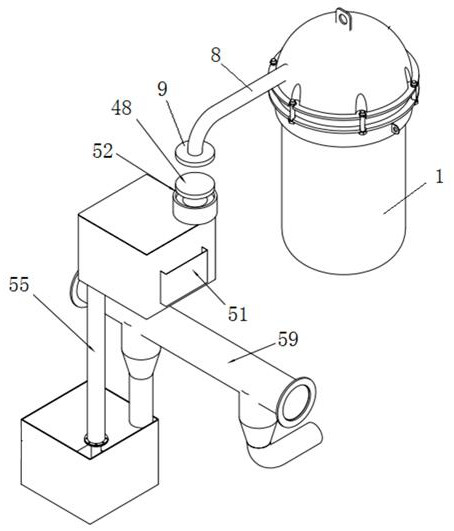

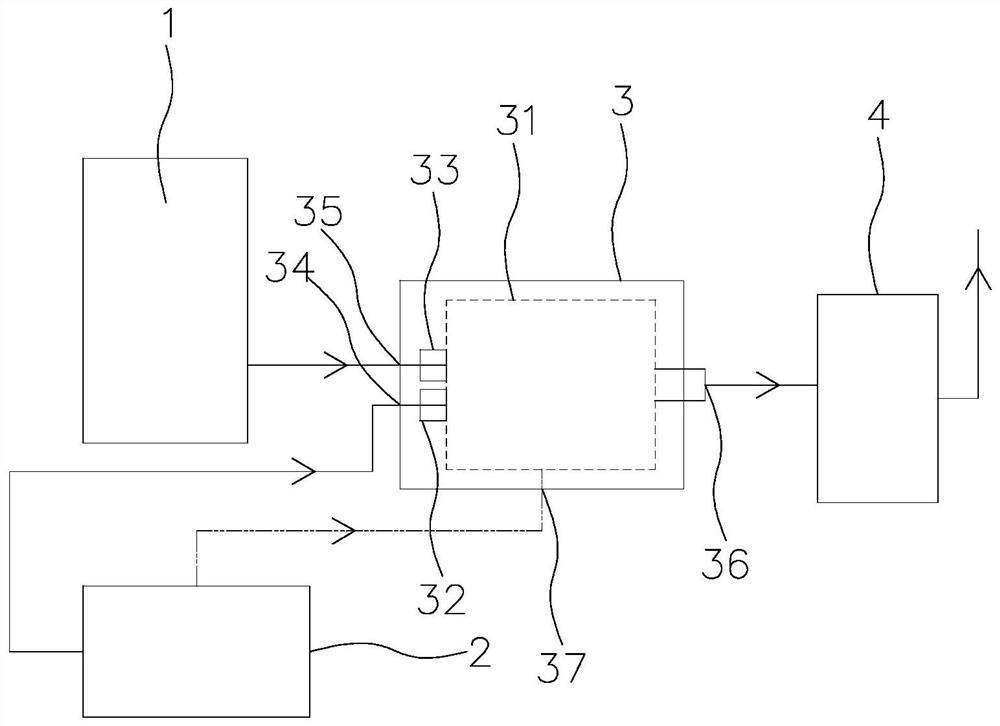

Activated carbon production equipment and method for applying the equipment to production of activate carbon, pyroligneous liquor, tar and wood gas

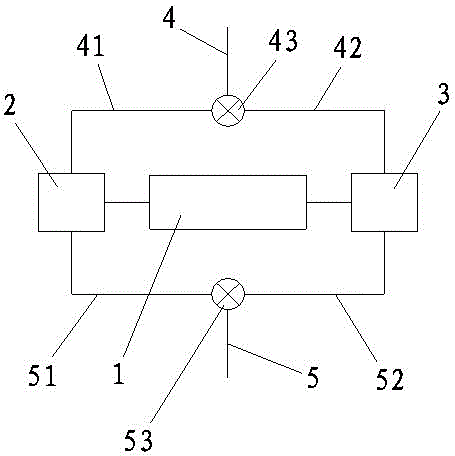

The present invention relates to an activated carbon production equipment and a method for applying the equipment to production of activate carbon, pyroligneous liquor, tar and wood gas, including a steam generation device (1), a high-temperature pyrolysis reaction device (2), and an integrated condensing device (3), with the above equipments intercommunicated in turn. The integrated condensing device (3) is equipped with a condensate collector (306) and a non-condensable gas collector (309), and the non-condensable gas collector is communicated with the high-temperature pyrolysis reaction device (2). The equipment provided by the present invention recycles and develops the waste gas produced in the process of activate carbon production while producing activate carbon, which improves the value added of activate carbon production with energy conservation and reduction of raw material consumption, resolving the problem of environment pollution in the process of activated carbon production.

Owner:NORTHWEST A & F UNIV

Method for producing environment-friendly mechanism charcoal and coproducing wood tar oil and biogas by using anredera cordifolia

InactiveCN103497774ATake advantage ofHigh mechanical strengthGaseous fuelsBiofuelsHigh carbonWood gas

The invention discloses a method for producing environment-friendly mechanism charcoal and coproducing wood tar oil and biogas by using anredera cordifolia. The method comprises the following steps: (1) crushing rattans, rhizomes and roots so as to obtain crushed materials; (2) drying the crushed materials; (3) carrying out two-times separation so as to remove ash content and moisture; (4) preparing a mechanism charcoal semi-finished product; (5) feeding the mechanism charcoal semi-finished product into a carbonization furnace and carrying out dry distillation; (6) coproducing the wood tar oil and wood gas; and (7) coproducing biogas. The method has the advantages that the wood crushed materials can be obtained at high efficiency by using a hammer mill for crushing the rattans, the rhizomes and the roots and then drying; the dry distillation time is appropriate, and the charcoal finished product has good mechanical strength, high carbon content and high heat value and relatively long burning time; the wood gas is reused as fuel, so that the environment-friendly production is realized, and the production cost is also reduced; exceedingly-rich raw materials are supplied for the production of the mechanism charcoal, the wood tar oil and the biogas, and the disaster problem caused by alien invasive plants is also solved; and each ton of mechanism charcoal semi-finished products can be used for generating 200-250kg of wood tar oil during dry distillation.

Owner:贵州省黎平县侗乡米业有限公司

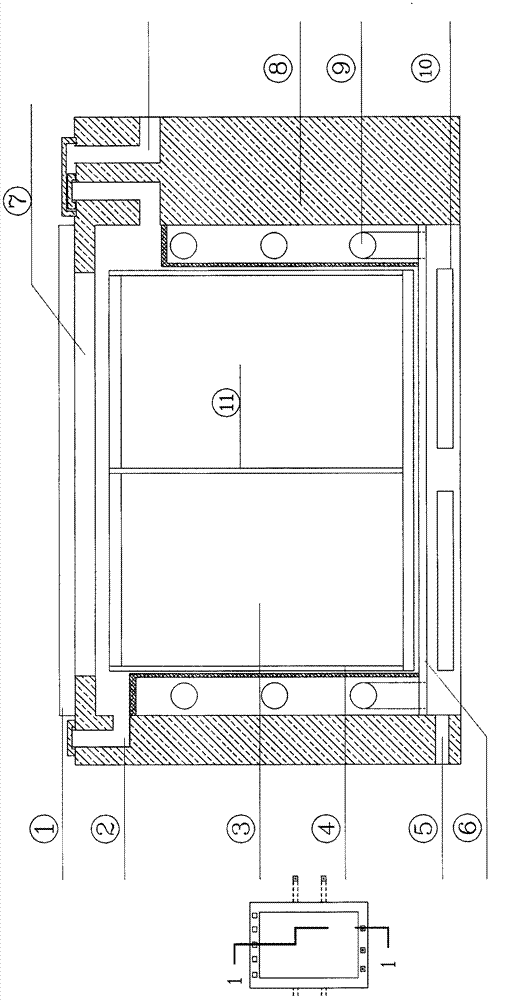

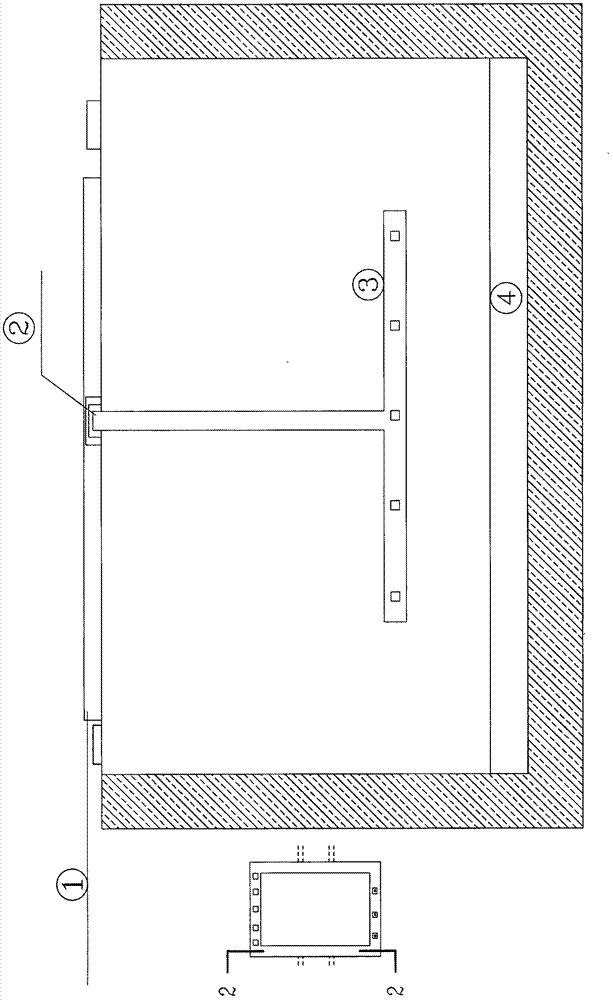

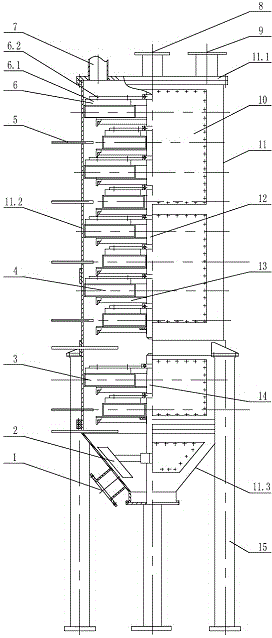

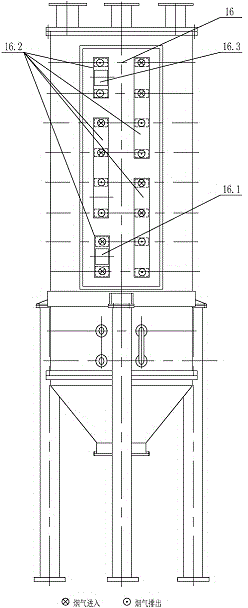

Continuous carbonization furnace for waste wood chips

InactiveCN104312602AShorten the production cycleIncrease profitMechanical conveying coke ovensBiofuelsCarbonizationWood gas

The invention discloses a continuous carbonization furnace for waste wood chips. The continuous carbonization furnace comprises a sealed tower body, wherein a reaction gas outlet pipe, a nitrogen inlet pipe and a waste wood chip inlet pipe are arranged on an upper end cover of the tower body; large heating plates and small heating plates are respectively alternately fixed on a plurality of angle iron brackets which are arranged along the axial direction at intervals on the upper part of a barrel of the tower body; large cooling plates and small cooling plates are respectively alternately fixed on a plurality of angle iron brackets which are arranged along the axial direction at intervals on the lower part of the barrel of the tower body; runners of the plurality of heating plates are connected with a flue gas distribution system; scraping and stirring devices on the plurality of heating plates and the plurality of cooling plates are respectively driven to rotate by upper and lower transmission shafts; a powdered carbon outlet pipe is arranged on the side of a stirrer of a lower conical shell of the tower body; the upper and lower transmission shafts are respectively connected with motors; and a plurality of thermocouples are arranged on the barrel along the axial direction. The powdered carbon is continuously and quickly prepared by using the waste wood chips, and meanwhile, by-products such as wood gas, wood tar, wood vinegar and the like can be recycled. The continuous carbonization furnace has the characteristics of being short in production period, low in energy consumption, uniform in carbonization, large in operation elasticity, large in adaptability and the like, and continuous operation can be achieved.

Owner:ZHEJIANG UNIV

Wood gas permeability analysis and testing method

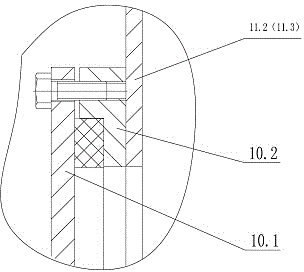

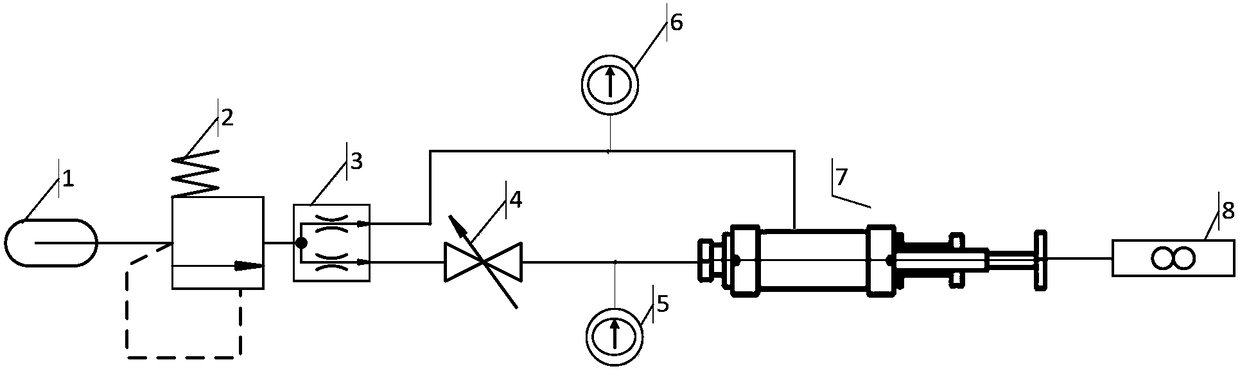

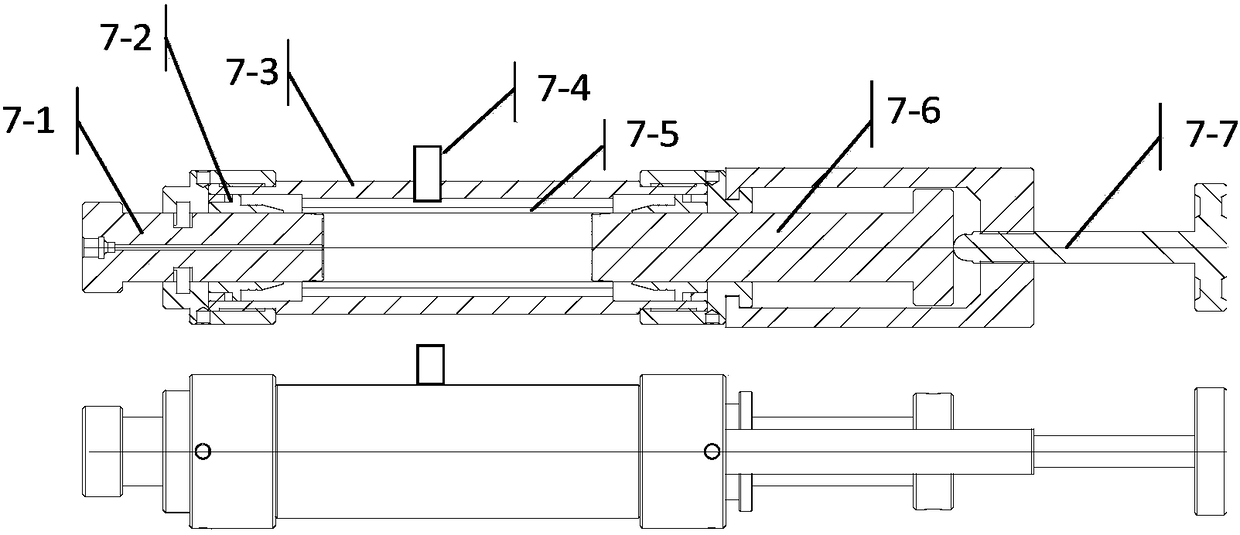

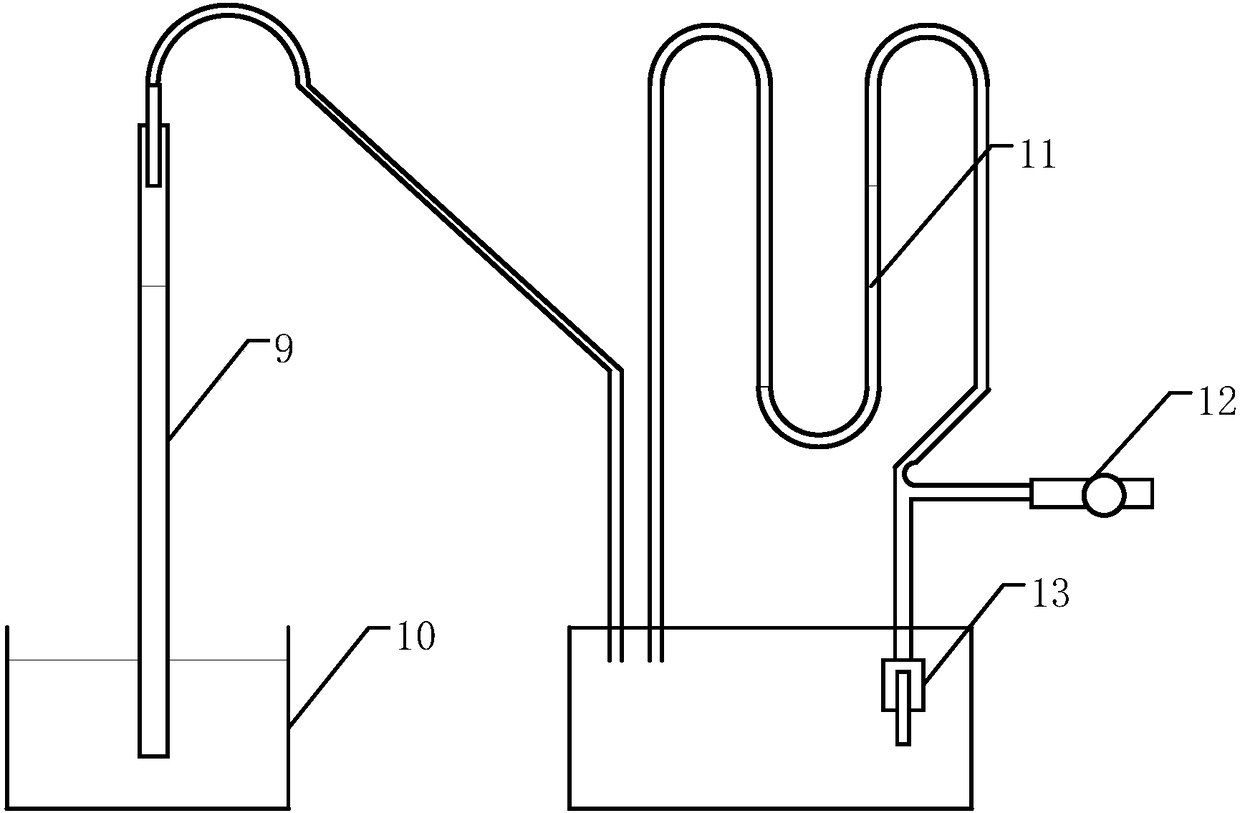

PendingCN108181222AGuaranteed air tightnessPermeability/surface area analysisPhysical performance testingPositive pressure

The invention provides a wood gas permeability analysis and testing method and relates to the field of wood physical property testing. Positive-pressure gas is used as a driving source, and a decompression valve and a pressure regulation valve are arranged between a pressurizing air source and a wood test sample to be detected; driving pressure on a test sample up-flow high-pressure end is controlled. A wood test sample clamping device ensures the air tightness of a penetration testing process, and testing air flow completely passes through a section of the wood test sample; an air flow inlethigh-pressure end of the clamping device is fixed and a slidable member is arranged at an air flow outlet of a low-pressure end. A high-pressure end pressure meter is arranged at the high-pressure endof the wood test sample clamping device; when the permeability is determined, upstream pressure of the wood is displayed; the low-pressure end is communicated with atmosphere; two ends of the wood test sample to be detected have stable positive pressure difference so that the air flow flowing through the wood test sample flows stably. The flow of flowing-out gas is determined at the low-pressureend and a wood gas permeability measurement result is obtained according to a gas permeability calculation equation; the testing method is a stable-state positive-pressure-difference gas permeabilitytesting method and a testing process is simple and convenient.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Device for producing wood charcoal and recovering wood vinegar and wood tar

InactiveCN105542815AQuality improvementReduce consumptionDirect heating destructive distillationBiofuelsCombustion chamberHusk

The invention discloses a device for producing wood charcoal and recovering wood vinegar and wood tar, which is composed of a carbonization furnace, an induced fan, a condenser, a low-temperature condenser and a flue gas filter. A retort technique is adopted and comprises the following steps: putting wood, husks and other wood raw materials in the closed carbonization furnace body, adding fuel into the combustion chamber, and igniting to heat the furnace body by using the added fuel so as to heat the raw materials in the carbonization furnace body and perform carbonization; leading out the flue gas byproduct by the induced fan, condensing the flue gas byproduct by the condenser to recover the wood tar, and passing through the low-temperature condenser to recover the wood vinegar, wherein the treated flue gas mainly comprises wood gas; introducing the treated flue gas into the combustion chamber, and combusting, thereby implementing good recovery; and after the carbonization finishes, treating the flue gas through the filter, and discharging the treated flue gas into air.

Owner:XINJI YUAN XIANG GREEN ENERGY TECHOLOGY CO LTD

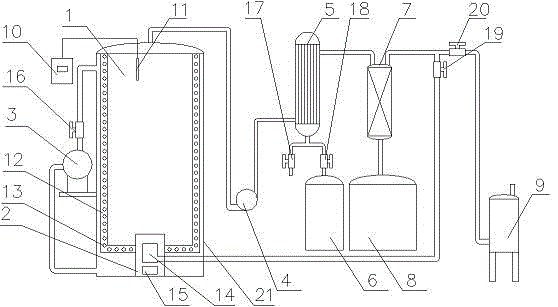

Machine-made charcoal charring and decoking technology and apparatus thereof

ActiveCN105199761ASatisfy the use of power generationBiofuelsGas purification with selectively adsorptive solidsWood gasHigh voltage

The invention discloses a machine-made charcoal charring and decoking technology. The technology comprises the following steps: 1, charring: charring a biomass raw material in a charring furnace; 2, carrying out decoking purification on a gas generated in the charring process; 3, carrying out high-voltage electrostatic decoking; 4, carrying out liquid phase separation; 5, carrying out active carbon purification; and 6, supercharging, and collecting. The invention also discloses an apparatus for realizing the technology. The apparatus comprises the charring furnace, a coarse decoking device, a high-voltage electrostatic decoking tower, a liquid phase separator, an active carbon purifying tower, a compressor and a gas storage tank which are sequentially connected through a pipeline. The technology and the apparatus allow the charred wood gas to be fully purified and especially allow tar to be removed in order to make the charred and decoked charcoal be used in power generation.

Owner:CHONGQING ZHUHAI NEW ENERGY DEV CO LTD

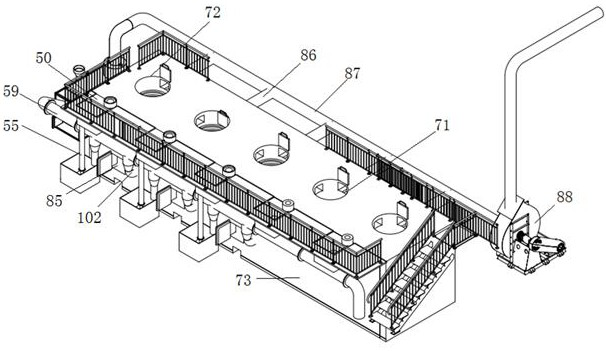

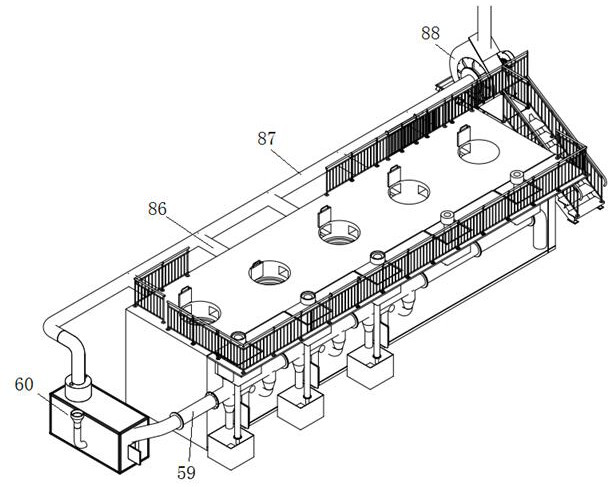

Biomass type intelligently-integrated essence charcoal gasoline extraction technology and system thereof

PendingCN105505586AImprove drying effectIncrease added valueUsing liquid separation agentBiofuelsTunnel kilnNaphtha

The invention discloses a biomass type intelligently-integrated essence charcoal gasoline extraction technology and a system thereof. The technology includes obtaining incense naphtha after high-temperature decomposition, cooling and oil-water separation; after fine wood bits are subjected to rolling drying, producing bars by a bar machine; performing low-temperature calcining, high-temperature pyrolysis, charring and cooling in a tunnel kiln to obtain wood vinegar, wood tar oil, wood gas and charcoal bars; packing the charcoal bars by a separation packing machine quantitatively. The system comprises a conveying fan, a hopper and a distillation retort, the distillation retort is connected with an oil-water separation box through a cooling water tank, a conveying belt is arranged on one side of the distillation retort, a roller screen, a stirring cage and a roller dryer are connected to one end of the conveying belt sequentially, a drying oven is connected at one end of the roller dryer, a buffer, a separator, the bar machine, guide rails and the tunnel kiln are connected at the other end sequentially, bar loading trolleys are arranged on the guide rails, and the separation packing machine is arranged at an outlet of the tunnel kiln. The biomass type intelligently-integrated essence charcoal gasoline extraction technology and the system thereof have the advantages that product diversification, high production profit and good environmental protection are achieved.

Owner:李观德

Method and device for pyrolysis of wood tar through microwave

InactiveCN104152186AFully lysedReduce cracking power consumptionGas purification by catalytic conversionThermal energyWood gas

The invention relates to a method and a device for pyrolysis of wood tar through microwave. According the method, oxygen-free wood gas is fed into honeycomb activated carbon for being heated, wherein the honeycomb activated carbon is heated to 800-1200 DEG C through the microwave, so that macromolecules in the wood tar is heated and pyrolyzed into micromolecules and further wood gas containing non-caked wood tar. The device includes a microwave heating body in which the honeycomb activated carbon is disposed. A regenerator A is arranged on a gas inlet of the microwave heating body and a regenerator B is arranged on a gas outlet of the microwave heating body. By means of the device and the method, pyrolysis of the wood tar is more complete with catalysis of the honeycomb activated carbon and energy consumption of the pyrolysis is reduced due to recycle of thermal energy in a loop, wherein the pyrolysis itself is free of energy consumption. The wood gas is pyrolyzed in a microwave oven at high temperature under an oxygen-free condition and is high in quality. The pyrolysis techonology is simple and reliable in structure.

Owner:卢元强

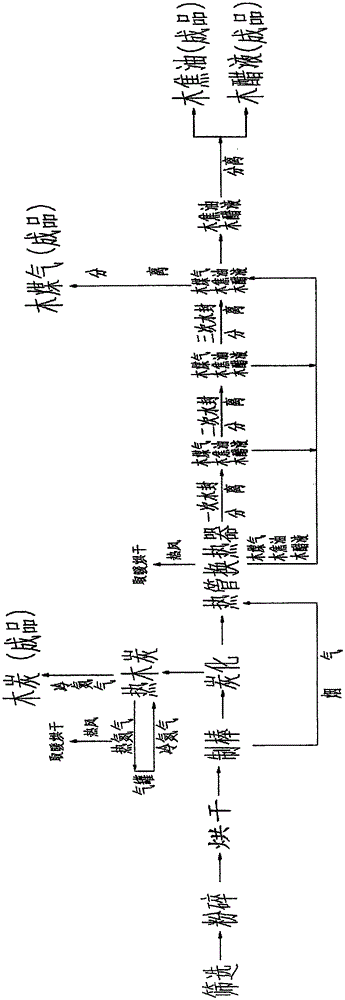

A sheet-like solid perfume for cigarette and preparation method and application thereof

ActiveCN109156881ACompatibility is reasonableStimulus releaseTobacco preparationTobacco treatmentFlavorSlurry

The invention discloses a sheet-like solid flavor for cigarette and a preparation method and application thereof. The solid flavor is a sheet solid flavor for cigarette with a thickness of 0.05-1mm, which is prepared by adding a natural flavor material into slurry or a coating liquid for preparing recycled tobacco leaves. The solid flavor of the invention adopts pure natural plant flavor, the compatibility among the raw materials is reasonable, the aroma can be dragged remarkably in the cigarette, and the release of tobacco smoke can be stimulated, at the same time, the wood gas can be removed, the impurity gas can be cleared, the tobacco aroma can be further supplemented, the tobacco aroma can be fostered, the smell of cigarette can be improved, and the aroma of cigarette can be mellow and mild.

Owner:YUNNAN FENGLIAN TECH

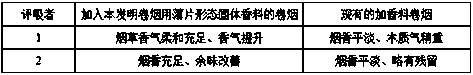

Method for carrying out equipment extraction on charcoal, wood gas, wood tar and wood vinegar

InactiveCN105419831AImprove utilizationEmission reductionBiofuelsSolid fuelsAgricultural residueWood gas

The invention discloses a method for carrying out equipment extraction on charcoal, wood gas, wood tar and wood vinegar. The method comprises the following steps that 1, screening is carried out; 2, smashing is carried out; 3, drying is carried out; 4, bar making is carried out; 5, carbonizing is carried out; 6, water seal separating is carried out on the wood vinegar, the wood tar and the wood gas three times to obtain a wood vinegar, wood tar and wood gas mixture; 7, primary separating is carried out on the wood vinegar, wood tar and wood gas mixture to obtain a finished wood gas product; 8, secondary separating is carried out on the wood vinegar and wood tar mixture after being separated in the step 7 to obtain a finished wood vinegar product and a finished wood tar product. The technical support is provided for developing comprehensive utilization of biomass energy, a series of problems of pollution and fire safety caused by air storage and incineration of trees, cut processing residues, straw and agricultural residues can be effectively solved, a great deal of cost of environmental protection management can be reduced each year, emission of carbon dioxide is reduced easily, and the greenhouse effect of the earth is reduced.

Owner:朴显泽

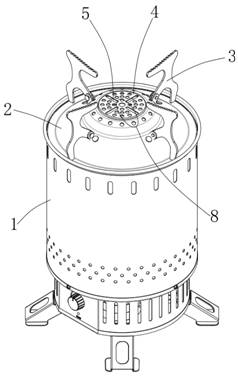

Multifunctional fire gathering cover and infrared energy gathering and flame dividing net cover for clean type firewood-gas stove

PendingCN112524644ANo condensation blackening phenomenonImprove heat utilizationDomestic stoves or rangesLighting and heating apparatusFirewoodMetal forming

The invention discloses a multifunctional fire gathering cover and infrared energy gathering and flame dividing net cover for a clean type firewood-gas stove. A hearth fire outlet of a firewood-gas stove body is provided with a fire gathering cover; the upper surface of the fire gathering cover is hinged to a plurality of turnover pot stands which are evenly distributed in the circumferential direction; the fire gathering cover is provided with an infrared energy gathering and flame dividing net cover; the infrared energy gathering and flame dividing net cover is provided with strip holes usedfor containing the turnover pot stands; the fire gathering cover and the infrared energy gathering and flame dividing net cover are both metal thin-wall conical circular truncated cones; the caliberof the large end of the infrared energy gathering and flame dividing net cover is larger than that of the large end of the fire gathering cover; and the caliber of the large end of the fire gatheringcover is larger than that of the hearth fire outlet of the firewood-gas stove. The conical angle of the fire gathering cover ranges from 60 degrees to 160 degrees, the diameter of a fire gathering opening in the fire gathering cover ranges from 60 mm to 120 mm, and the infrared energy gathering and flame dividing net cover is a single-layer metal forming punched net cover or a refractory materialnet and metal forming punched combined net cover. The wood gas generated in a hearth is fully mixed and combusted, the firepower is sufficient, the temperature is high, combustion is sufficient, smokeand harm are avoided, and cleanness and environmental protection are achieved.

Owner:成都火食科技有限公司

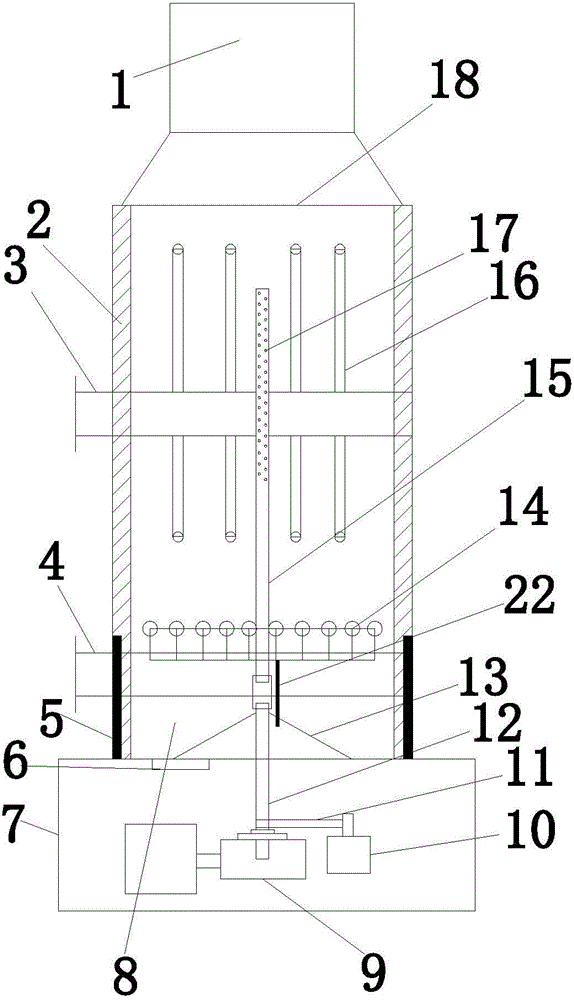

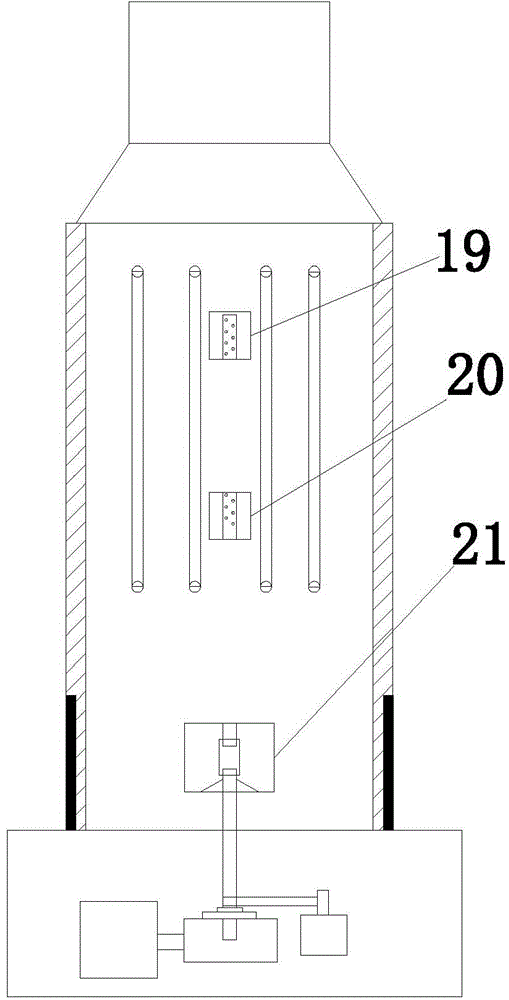

Biomass high-level cold wood burner and use method thereof

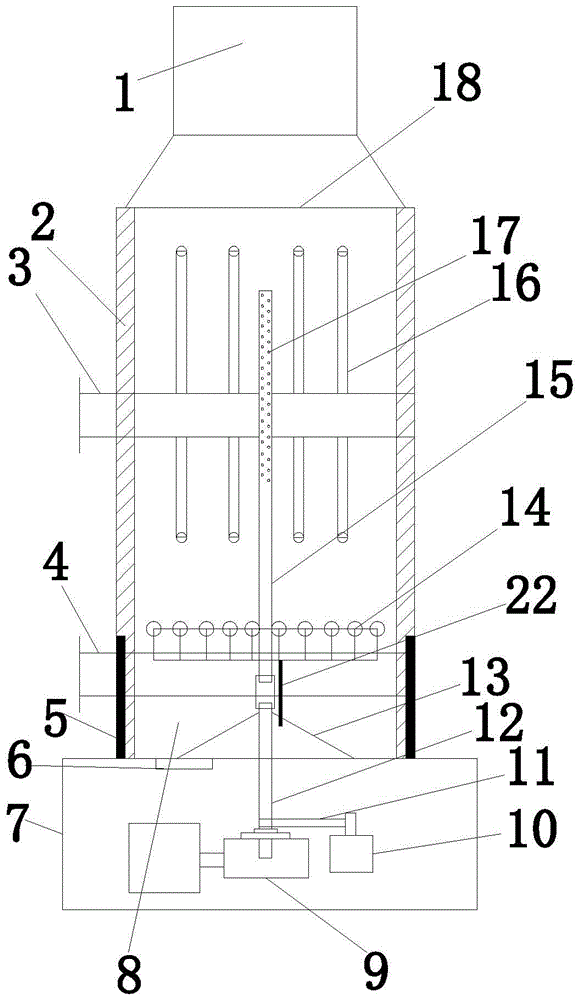

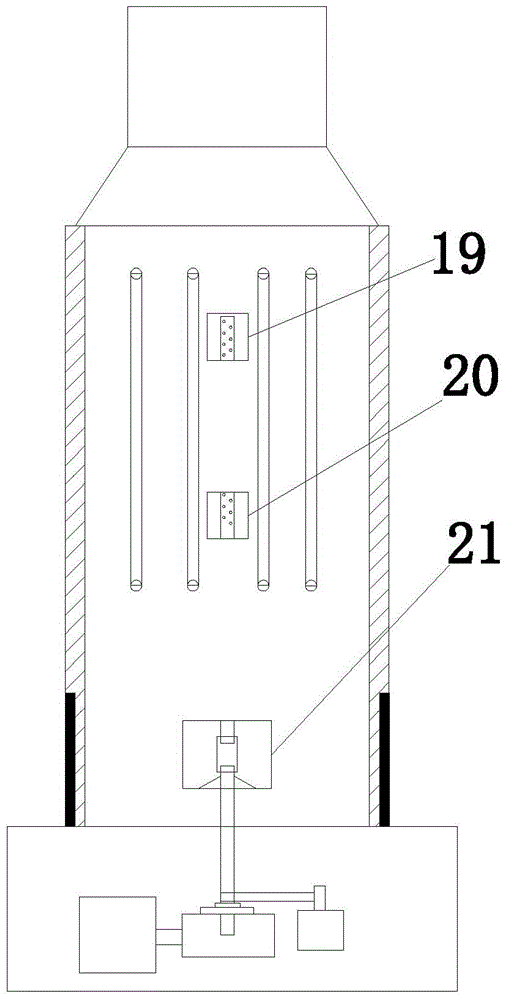

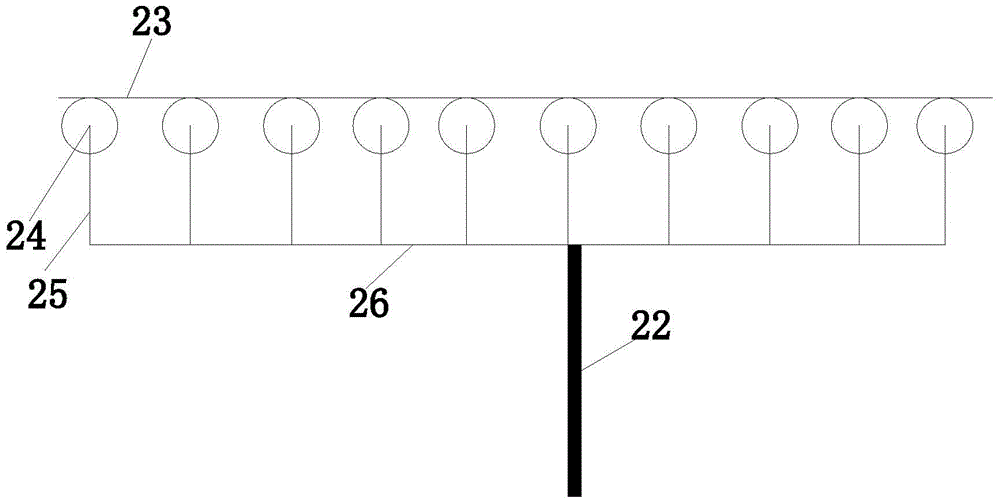

ActiveCN104479741AImprove sealingImprove fire resistanceGasifier mechanical detailsCombustible gas productionWood gasEngineering

The invention discloses a biomass high-level cold wood burner and a use method thereof; the structure includes a furnace body and a feed inlet on the furnace body; the side wall of the furnace body is equipped with a wood gas upper outlet and a wood gas lower outlet, and the bottom of the furnace body is equipped with an ash-settling chamber; the ash-settling chamber is equipped with a plate-overturning ash discharge furnace disc, and the bottom of the ash-settling chamber is equipped with a carbon discharge port; the lower part of the furnace body is equipped with an ash discharge power mechanism; the ash discharge power mechanism is connected with a hollow rotation pipe; the lower end of the rotation pipe is arranged in a wind inlet box, and the upper end of the rotation pipe is equipped with a plurality of scraping blades and is arranged in the ash-settling chamber; the plate-overturning ash discharge furnace disc is arranged at the side face of the scraping blades by connecting rods; the upper end of the rotation pipe is connected with a center oxygen inlet pipe arranged in the furnace body; the center oxygen inlet pipe is equipped with a plurality of through holes; the outside of the furnace body is vertically equipped with a plurality of outer wall oxygen inlet pipes. The use method comprises that a material is fed through the feed inlet and then is burnt in the furnace body, at the same time, oxygen is supplemented through the outer wall oxygen inlet pipes and / or the center oxygen inlet pipe, and thus wood gas is obtained from the wood gas upper outlet and the wood gas lower outlet, and ash is discharged through the plate-overturning ash discharge furnace disc.

Owner:湖州环清环保科技有限公司

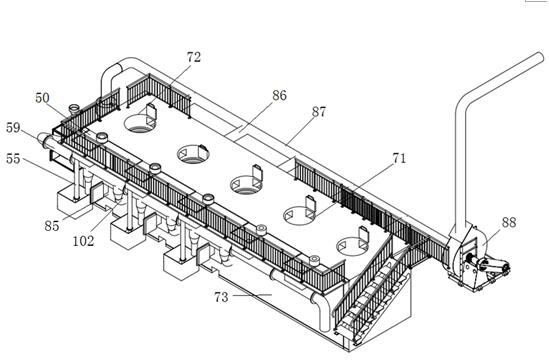

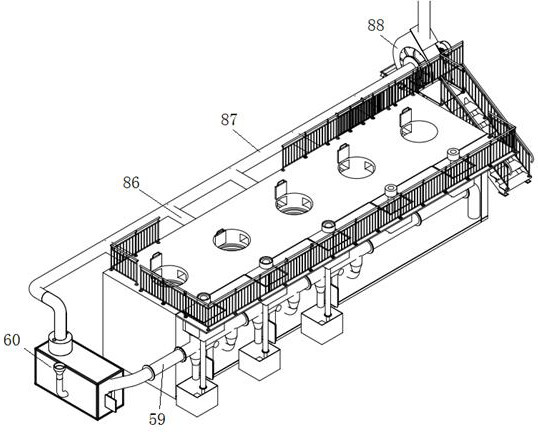

Biochar production equipment

InactiveCN113355115AReduce labor intensityEasy to addGaseous fuel feeder/distributionBiofuelsCombustion chamberProcess engineering

The invention relates to biochar production equipment, and belongs to the technical field of biochar processing equipment. The biochar production equipment comprises a combustion base provided with a plurality of preheating chambers and a plurality of combustion chambers, the preheating chambers and the combustion chambers are communicated with one another, a wood gas conveying pipe is arranged outside the combustion base and communicated with a plurality of branch pipes extending into the combustion chambers, one end of the wood gas conveying pipe is connected with a wood gas combustion hearth, a discharge chimney, a preheating chamber and a combustion chamber of the wood gas combustion hearth are all communicated with a smoke induced draft fan, a discharge pipeline of the reaction kettle is communicated with a cooling box body, the cooling box body is mounted on a combustion foundation, the bottom of the cooling box body is communicated with a wood vinegar output pipe and a wood gas output pipe, and the wood gas output pipe is communicated with a wood gas conveying pipe. The biochar production equipment is novel in structural design, capable of separating wood gas in smoke and recycling the wood gas, high in production efficiency, energy-saving and environment-friendly.

Owner:栖霞市泰宇生物工程有限公司

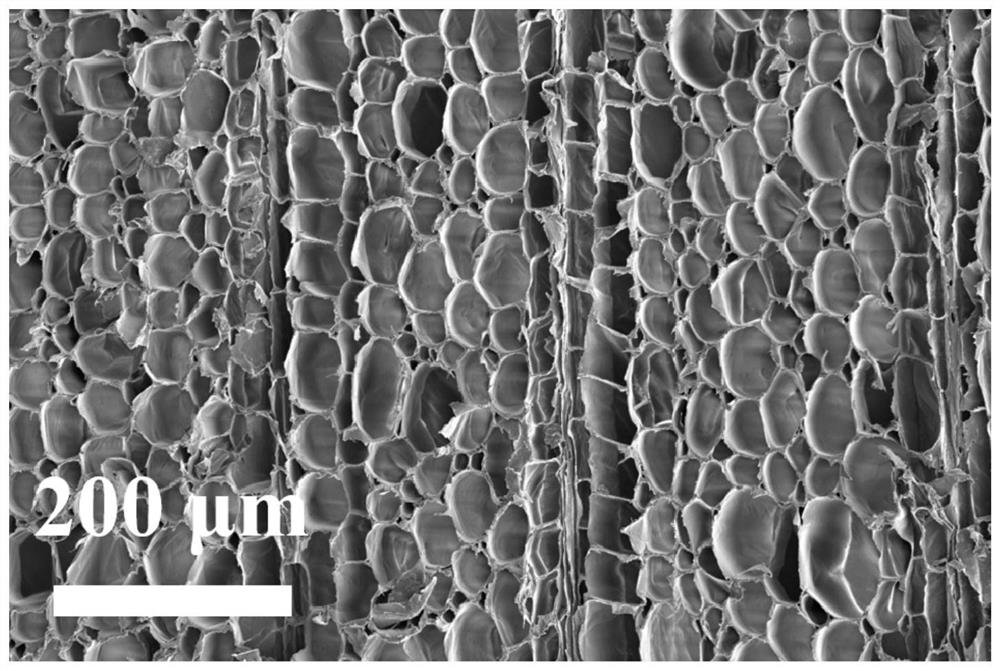

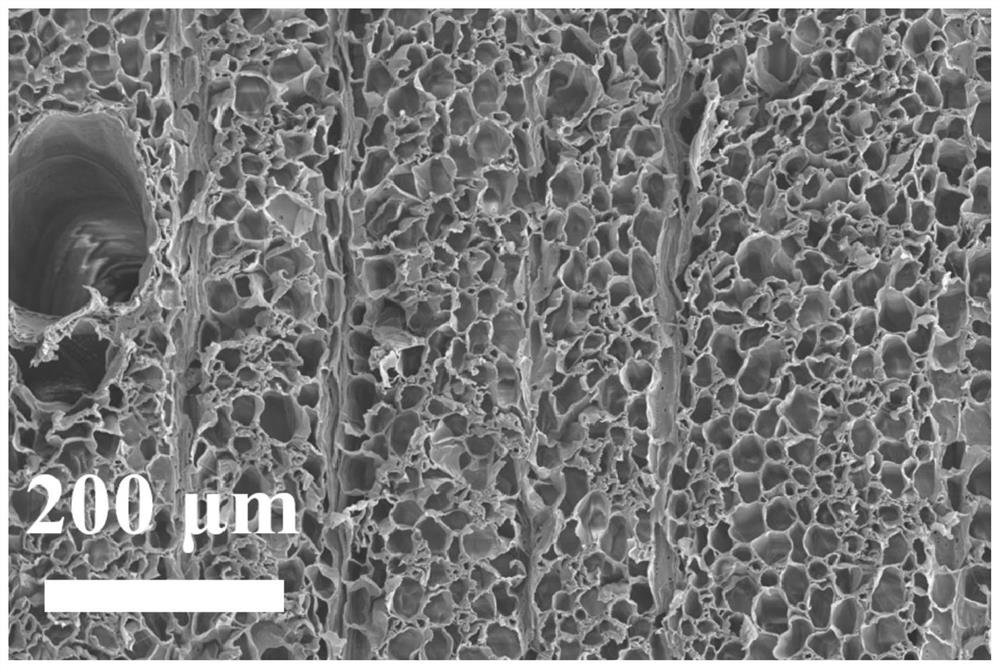

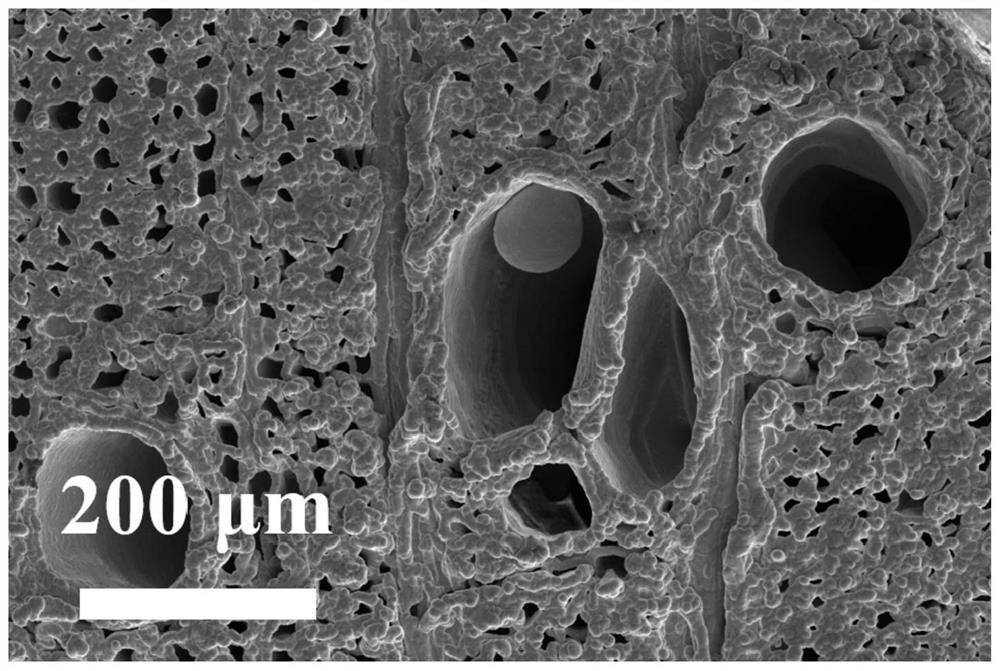

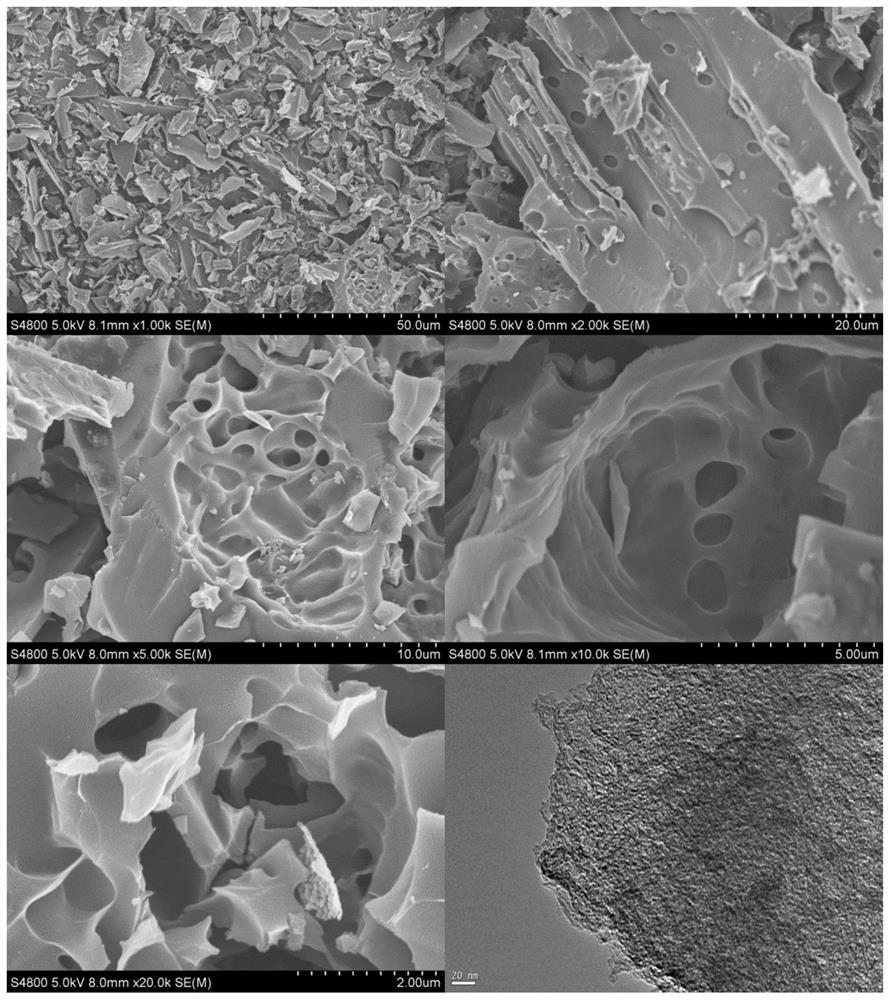

A preparation method and application of wood airgel for oxygen and hydrogen production by alkaline seawater electrolysis

ActiveCN113046776BImprove hydrophilicityFacilitated DiffusionElectrodesCalcium hydroxidePtru catalyst

The invention discloses a preparation method and application of wood aerogel for alkaline seawater electrolysis to produce oxygen and hydrogen, and relates to a preparation method and application of wood aerogel. The purpose of the present invention is to solve the problem of insufficient activity of the all-electrolytic bifunctional catalyst in alkaline seawater, insoluble magnesium hydroxide / calcium hydroxide and some interfering ions precipitate from seawater to the electrode surface, thereby poisoning the OER / HER catalyst. Methods: 1. removing lignin and hemicellulose of natural porous wood; 2. activating; 3. immersing the activated wood airgel in a plating solution for plating; 4. etching and activating; 5. drying in vacuum. Wood airgel for oxygen and hydrogen production by electrolysis of alkaline seawater is used for full electrolysis of oxygen and hydrogen in alkaline seawater. The invention can obtain a wood aerogel used for alkaline seawater electrolysis to produce oxygen and hydrogen.

Owner:QINGDAO UNIV

Method for reducing irritation of papermaking-process tobacco sheets

The invention relates to a method for reducing irritation of paper-making tobacco sheets, and belongs to the field of paper-making tobacco sheet preparation. The method comprises the following steps:carrying out alcohol extraction and concentration on tobacco powder to obtain an alcohol-soluble concentrate; uniformly mixing the alcohol-soluble concentrate with an alcohol-soluble extract of a plant, glycerol, an Amadori compound, monoglyceride and a sweetening agent to obtain an alcohol-soluble coating solution; uniformly mixing the alcohol-soluble coating solution with a carrier solution, adding alcohol-soluble protein, and uniformly mixing to obtain a carrier alcohol-soluble coating liquid; adding the carrier alcohol-soluble coating liquid into a conventional tobacco sheet coating liquidto prepare a coating liquid; and adding the coating liquid into a tobacco sheet paper base, and drying to obtain the tobacco sheet. Although the content of harmful components such as tar is low, thecontent of carbon monoxide is high, the drying feeling is serious, irritation is large, smoke is not coordinated, and wood gas is serious in an existing tobacco sheet, so irritation of the papermakingmethod tobacco sheet is reduced.

Owner:山东瑞博斯烟草有限公司

Biomass high-rise cold wood burner and its application method

ActiveCN104479741BImprove sealingImprove fire resistanceGasifier mechanical detailsCombustible gas productionWood gasEngineering

The invention discloses a biomass high-level cold wood burner and a use method thereof; the structure includes a furnace body and a feed inlet on the furnace body; the side wall of the furnace body is equipped with a wood gas upper outlet and a wood gas lower outlet, and the bottom of the furnace body is equipped with an ash-settling chamber; the ash-settling chamber is equipped with a plate-overturning ash discharge furnace disc, and the bottom of the ash-settling chamber is equipped with a carbon discharge port; the lower part of the furnace body is equipped with an ash discharge power mechanism; the ash discharge power mechanism is connected with a hollow rotation pipe; the lower end of the rotation pipe is arranged in a wind inlet box, and the upper end of the rotation pipe is equipped with a plurality of scraping blades and is arranged in the ash-settling chamber; the plate-overturning ash discharge furnace disc is arranged at the side face of the scraping blades by connecting rods; the upper end of the rotation pipe is connected with a center oxygen inlet pipe arranged in the furnace body; the center oxygen inlet pipe is equipped with a plurality of through holes; the outside of the furnace body is vertically equipped with a plurality of outer wall oxygen inlet pipes. The use method comprises that a material is fed through the feed inlet and then is burnt in the furnace body, at the same time, oxygen is supplemented through the outer wall oxygen inlet pipes and / or the center oxygen inlet pipe, and thus wood gas is obtained from the wood gas upper outlet and the wood gas lower outlet, and ash is discharged through the plate-overturning ash discharge furnace disc.

Owner:湖州环清环保科技有限公司

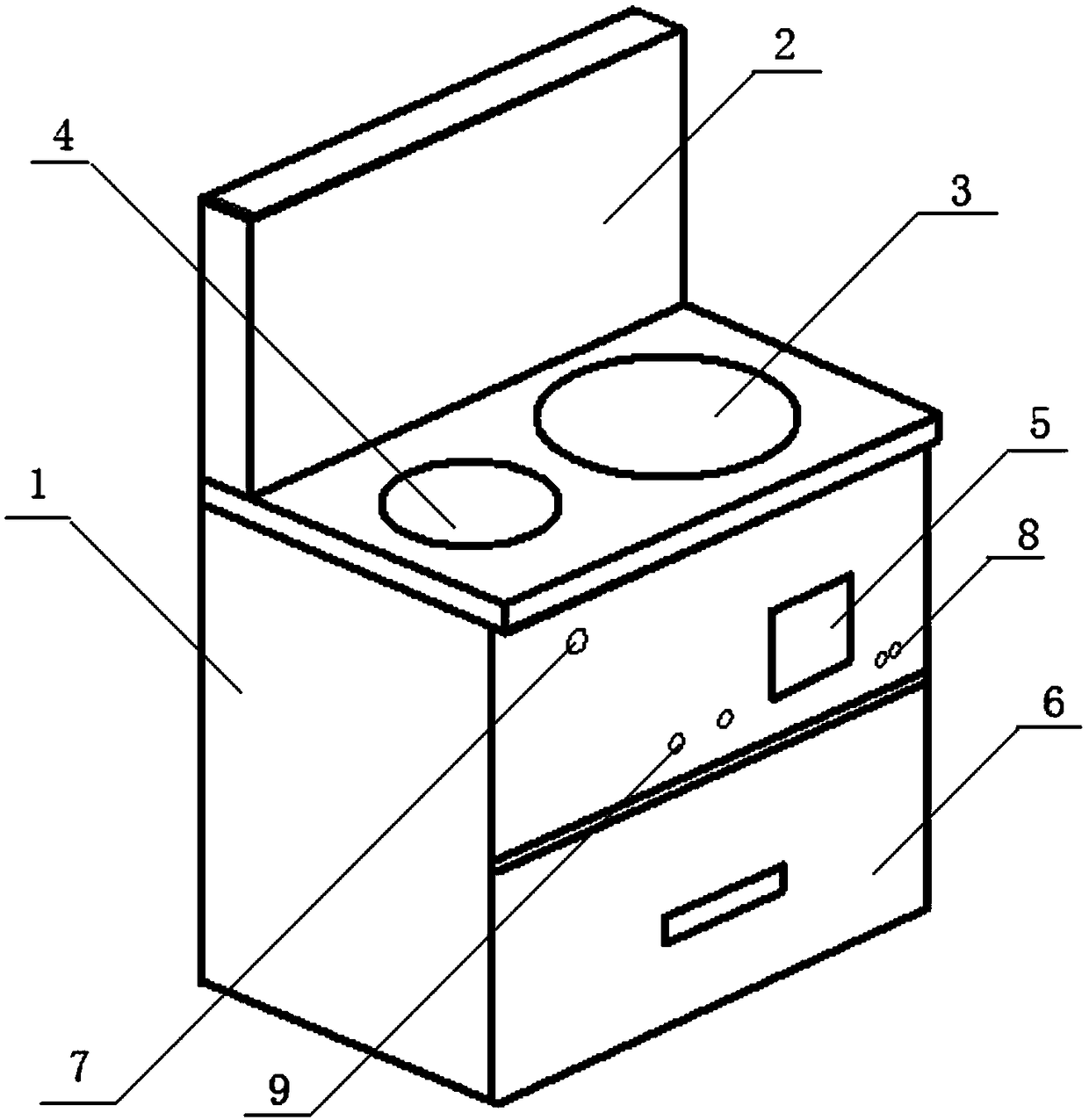

Wood-gas combinative integrated stove

InactiveCN109253483AEasy to useDomestic stoves or rangesLighting and heating apparatusWood gasExhaust fumes

The invention relates to a wood-gas dual-purpose integrated stove, which is characterized in that a mesa of a stove body (1) is provided with two stoves of a firewood stove (3) and a gas stove (4), wherein a combustion chamber (10) is arranged below the firewood stove (3); and a raw material needed for using the firewood stove (3) is put into from a feed inlet (5) in the side of the combustion chamber (10). The wood-gas dual-purpose integrated stove provided by the invention is novel in design and reasonable in structure, can be used for sufficiently guaranteeing the sufficient combustion of afuel, moreover, the wood-gas dual-purpose integrated stove is provided, on a hearth, with the two stoves, for which the different fuels are used, of the gas stove and the firewood stove, and can be still normally used in the condition of the lack of some fuel. In addition, a waste gas elbow pipe at the bottom of the stove body is a rotatable elbow pipe; a chimney pipeline connected to the exterior of the stove body can be randomly erected on the side surface or the back surface of the stove body; and the wood-gas dual-purpose integrated stove can be used at any position in a kitchen.

Owner:HUBEI XIN NONGJIA TECH CO LTD

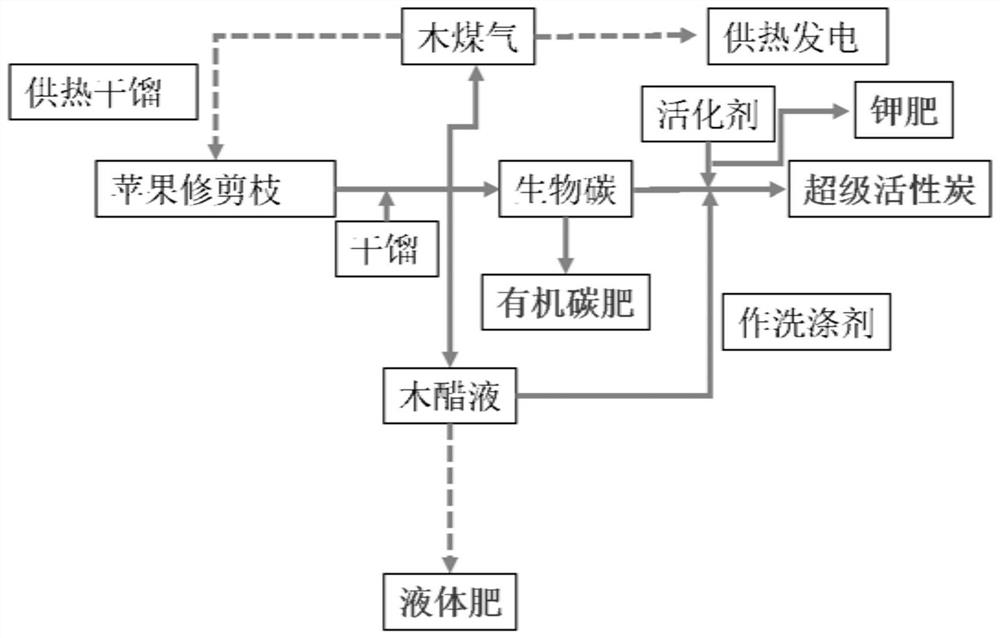

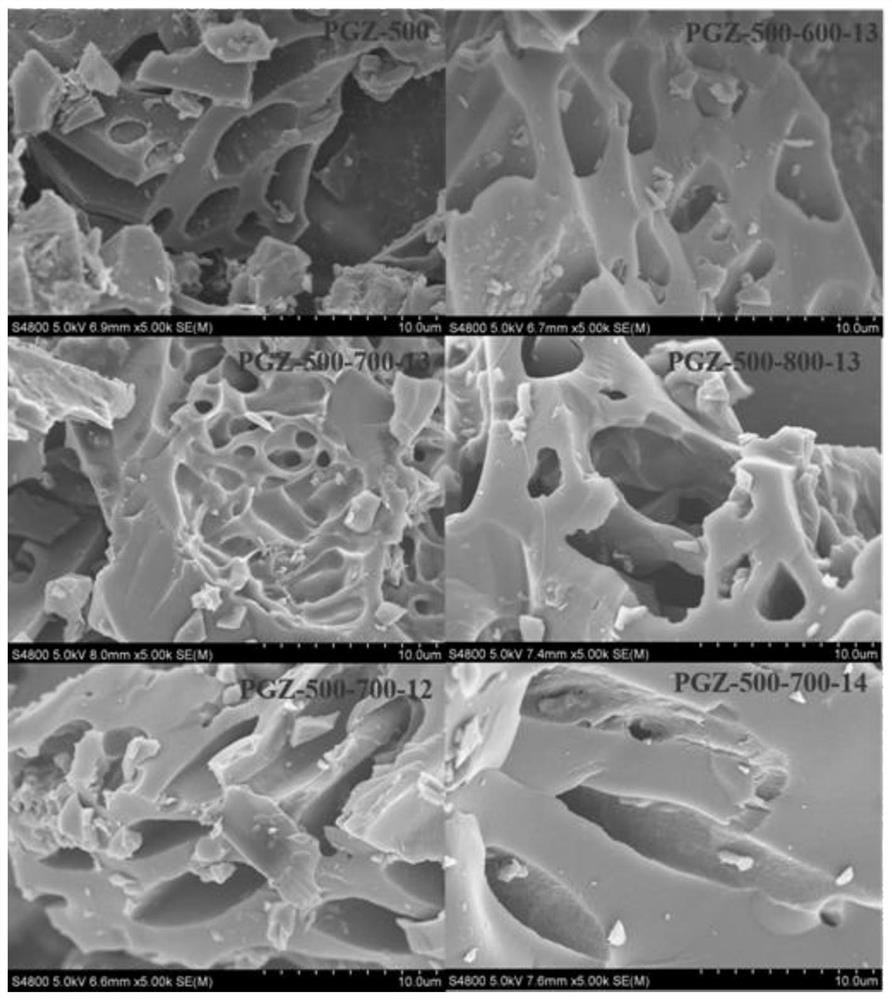

Super-capacitance carbon prepared by utilizing apple trimmed scrap branches, as well as preparation method and application thereof

ActiveCN111977650AReduce collectionReduce transportationCarbon compoundsHybrid capacitor electrodesActivated carbonOrganic liquids

The invention belongs to the technical field of wooden activated carbon and relates to super-capacitance carbon prepared by utilizing apple trimmed scrap branches and a method thereof. The method comprises the following steps: (1) breaking apple trimmed scrap branches into small pieces of scrap branches; (2) performing dry distillation and pre-carbonation on the small pieces of scrap branches to obtain a pre-carbonated product, a dry distilled solution and wood gas; (3) mixing the pre-carbonated product with an activator to obtain an activated product; (4) stirring, washing and filtering the activated product with an acidic solution to obtain a primary solid and a primary liquid, washing and filtering the primary solid with hot water to obtain a secondary solid and a secondary liquid, anddrying and grinding the secondary solid to obtain the super-capacitance carbon; and (5) mixing the primary liquid and the secondary liquid, and adjusting the pH value of the mixture with the dry-distilled solution to obtain organic liquid fertilizer. The super-capacitance carbon provides a novel and low-price raw material to development of high-performance super-capacitance carbon and provides a high-value novel approach to comprehensive development and utilization of apple trimmed scrap branches, so that the production cost can be reduced, and environmental pollution can be reduced.

Owner:山西群发生物质能源有限公司

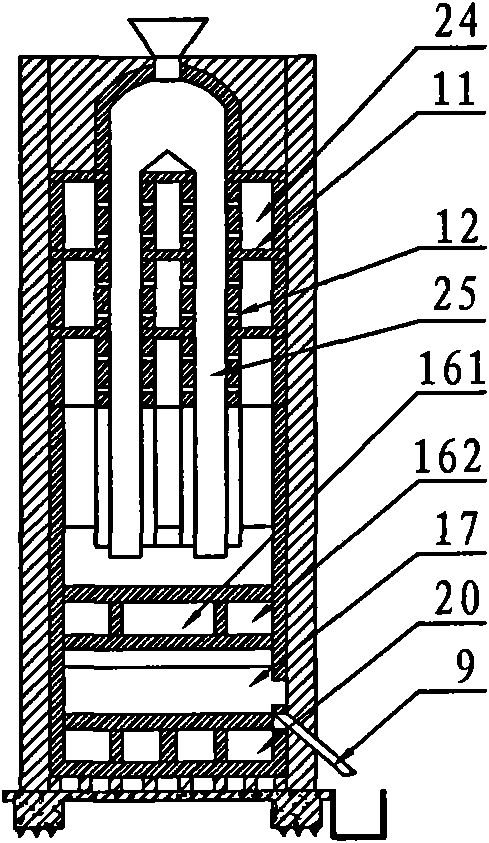

Internal heating carbonization furnace

InactiveCN108048115ASolve the problem of serious waste and high pollution dischargeSimple structureStationary retortsCooling towerThermal insulation

The invention provides an internal heating carbonization furnace, which comprises a carbonization furnace main body and a wood gas cooling tower, wherein the carbonization furnace main body is a hollow carbon steel tank body, a thermal insulation layer is arranged outside the carbon steel tank body, the carbonization furnace main body is provided with a material inlet door plate, a wood gas outletand a combustion cylinder, the upper portion of the combustion cylinder is provided with a heat dissipating pipe extending into the carbonization furnace main body, the lower portion of the combustion cylinder is provided with a combustion inlet and a furnace grate, the bottom end of the combustion cylinder is provided with a fuel gas inlet, the wood gas outlet is communicated to the wood gas cooling tower through a wood gas pipeline, the other end of the wood gas pipeline is communicated to the fuel gas inlet on the bottom end of the combustion cylinder, and the middle portion of the wood gas pipeline is provided with a wood gas branch pipeline. According to the present invention, the rotary heat dissipating pipe is used, such that the structure is simple, the calcination is uniform, thewood gas generated during the charcoal calcining is fully utilized, the polluted air is not directly discharged, and the wood tar and the pyroligneous liquor in the wood gas are collected and used toturn the waste wood gas into treasure so as to substantially improve the profits of carbon-making enterprises.

Owner:王志斌

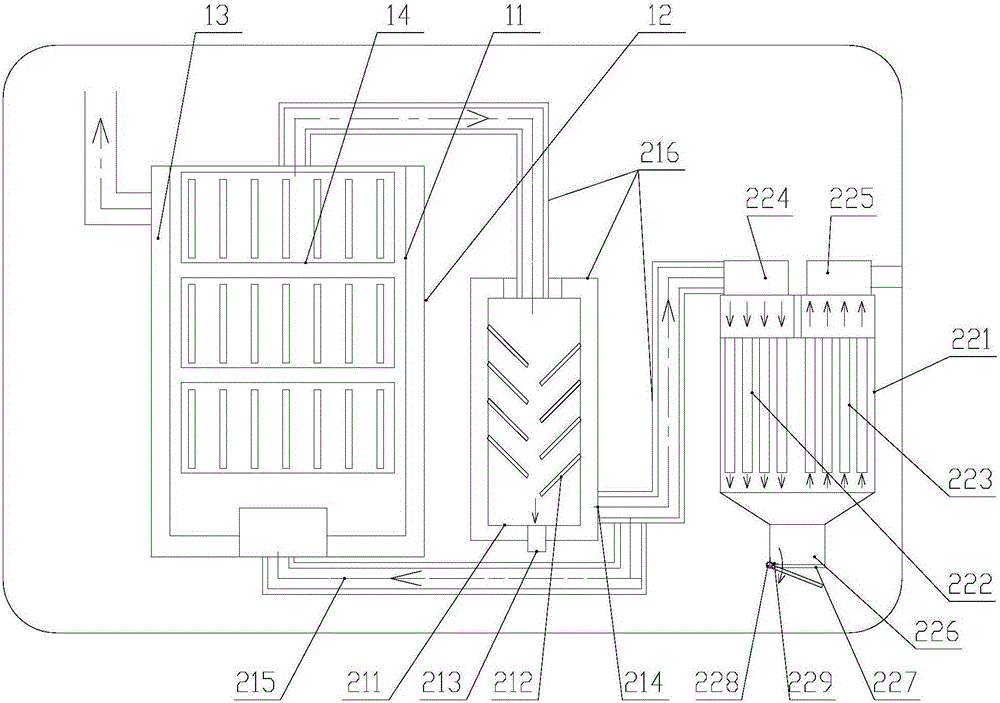

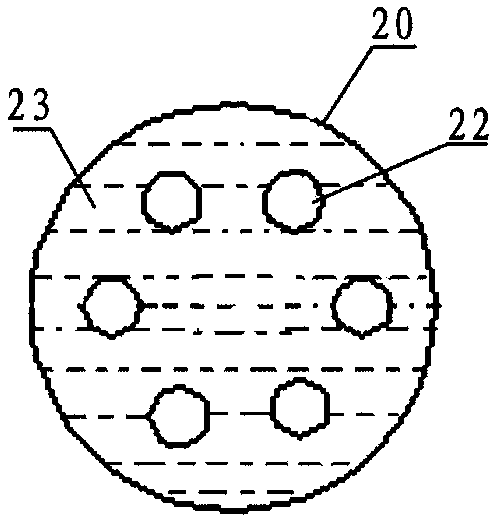

Internal circulation biomass carbonization device

PendingCN114231304AReduce volumeReduce investmentDirect heating destructive distillationBiofuelsThermal insulationCarbonization

The invention discloses an internal circulation biomass carbonization device, and relates to the field of biomass thermochemical energy conversion. Comprising a rotary kiln, a rotary kiln gas inlet pipeline, a hood, a blanking port, a thermal insulation material, a feeder, a feeding hopper, a low-temperature wood gas pipeline, a gas heat exchanger, a high-temperature wood gas pipeline, a gas valve, a high-temperature fan, a burner, a high-temperature flue, a low-temperature flue and a tail gas fan. Internal self-circulating wood gas is used as an energy carrier, and the high-temperature wood gas releases heat in the rotary kiln to supply heat to cracking reaction of biomass raw materials; the high-temperature wood gas after heat release is converted into low-temperature wood gas, and the low-temperature wood gas enters a gas heat exchanger through a low-temperature wood gas pipeline; in the gas heat exchanger, the low-temperature wood gas and the high-temperature flue gas are subjected to non-contact heat exchange to be heated into high-temperature wood gas; and finally, the high-temperature wood gas is circulated back into the rotary kiln through power provided by the high-temperature fan.

Owner:XIAMEN UNIV

A kind of microwave wood tar cracking method and its device

InactiveCN104152186BFully lysedReduce cracking power consumptionGas purification by catalytic conversionThermal energyWood gas

Owner:卢元强

Preparation method and application of tobacco liquid additive capable of improving burning and smoking quality of cut stems

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for directly separating pyroligneous liquor from wood tar on line

Owner:NORTHWEST A & F UNIV

Biochar processing system

PendingCN113355114ASave energyGood energy saving effectBiofuelsSpecial form destructive distillationCombustion chamberProcess engineering

The invention relates to a biochar processing system, and belongs to the technical field of biochar processing equipment. The biochar processing system comprises a combustion base provided with a plurality of preheating chambers and a plurality of combustion chambers, the preheating chambers and the combustion chambers are communicated with one another, a wood gas conveying pipe is arranged outside the combustion base and communicated with a plurality of branch pipes extending into the combustion chambers, one end of the wood gas conveying pipe is connected with a wood gas combustion hearth, a discharge chimney, a preheating chamber and a combustion chamber of the wood gas combustion hearth are all communicated with a smoke induced draft fan, a discharge pipeline of the reaction kettle is communicated with a cooling box body, the cooling box body is mounted on a combustion foundation, the bottom of the cooling box body is communicated with a wood vinegar output pipe and a wood gas output pipe, and the wood gas output pipe is communicated with a wood gas conveying pipe. The system is novel in structural design, capable of separating wood gas in smoke and recycling the wood gas, high in production efficiency, energy-saving and environment-friendly.

Owner:栖霞市泰宇生物工程有限公司

A kind of carbonization furnace heat exchange method

ActiveCN109280557BImprove recycling ratesCombined useCoke ovensBiofuelsCombustion chamberThermodynamics

Owner:FUJIAN MINAN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com