Internal heating carbonization furnace

A carbonization furnace and internal heating technology, which can be applied to stationary carbonization furnaces and other directions, can solve the problems of energy waste, insufficient utilization of wood gas, and high pollution emissions, and achieve the effect of improving profit space, simple structure and uniform calcination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

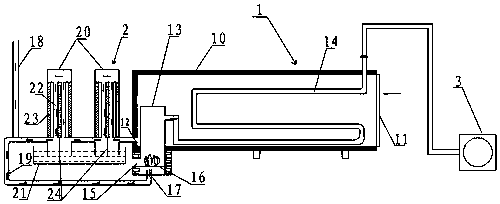

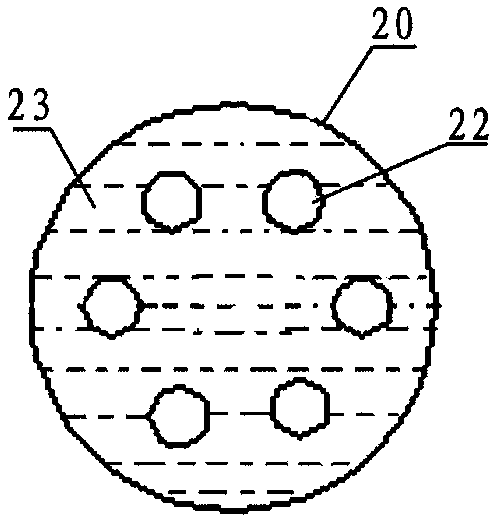

[0011] see figure 1 , figure 2 As shown, the present invention provides an internal heating carbonization furnace, comprising a carbonization furnace main body 1 and a wood gas cooling tower 2 connected to the carbonization furnace main body through pipelines, the carbonization furnace main body is a hollow carbon steel tank body, and the carbon steel tank body is An insulation layer 10 is provided, and one end of the main body of the carbonization furnace is provided with a feed door 11 that can be opened, and the other end is provided with a wood gas outlet 12 and a combustion tube 13, the upper part of the combustion tube is located in the main body of the carbonization furnace, and the lower part is located in the main body of the carbonization furnace In addition, the upper part of the combustion tube is provided with a cooling pipe 14 extending into the main body of the carbonization furnace, the lower part of the combustion tube is provided with a fuel inlet 15 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com