Patents

Literature

65results about How to "Calcined evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of highly pure quartz sands

The invention discloses a preparation method of highly pure quartz sands. The method comprises the following steps: 1, roughing: cleaning a raw material, and crushing the cleaned raw material; 2, carrying out calcining and water quenching: calcining the crushed raw material, taking out particles, and quenching the particles in an ice-water mixture; 3, carrying out electric separation and magnetic separation: milling the quenched particles, carrying out electric separation and magnetic separation twice, and carrying out pulse magnetic field treatment; 4, pickling: immersing a material obtained in step 3 in a hydrochloric acid solution, filtering the immersed material, dialyzing the obtained first filtrate to recover hydrochloric acid, preparing a first mixed acid by using the recovered hydrochloric acid and a sulfuric acid solution, immersing quartz sands in the first mixed acid, filtering the immersed quartz sands, dialyzing the obtained second filtrate to obtain recovered mixed acid, preparing a second mixed acid by using the recovered mixed acid and a nitric acid solution, immersing the quartz sands in the second mixed acid, adding the immersed quartz sands to a sodium carbonate solution, and flushing the quartz ands; 5, floating the flushed quartz sands; and 6, drying the floated quartz sands. The preparation method allows highly pure quartz sands with the SiO2 content to be not lower than 99.995% to be produced, and takes a greatly lower acid amount than traditional methods.

Owner:江苏凯达石英股份有限公司

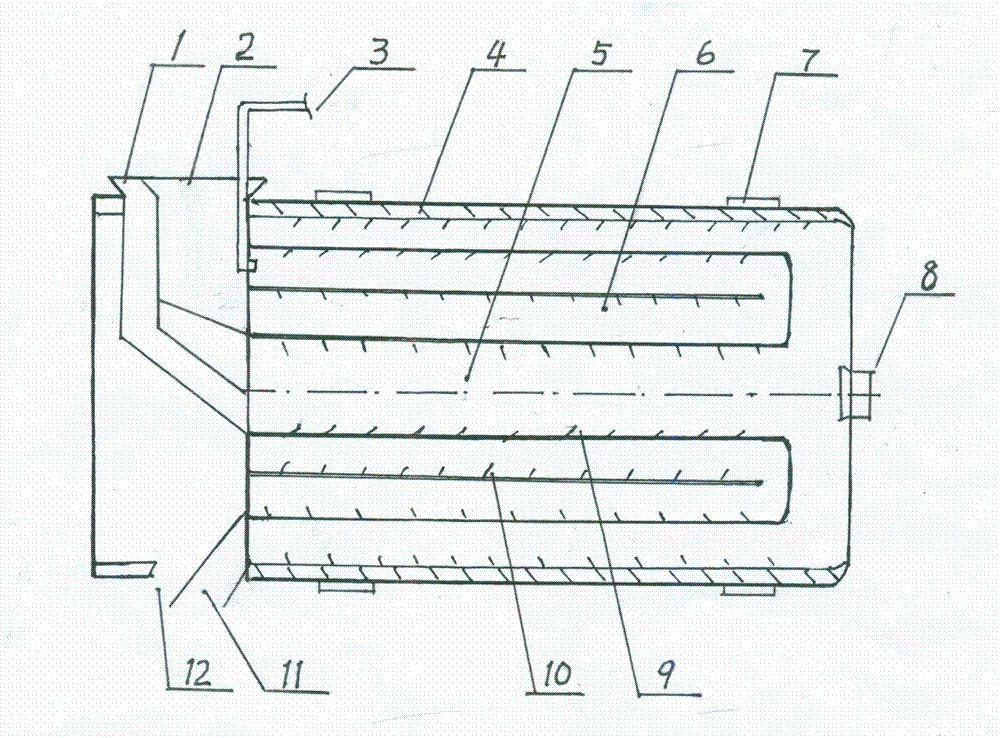

U-shaped internal-combustion rotating limekiln capable of recovering CO2

The invention belongs to the field of kiln, and provides a u-shaped internal-combustion rotating limekiln capable of recovering CO2. The limekiln is characterized in that the rotary kiln is horizontal, a u-shaped muffle heating furnace and a u-shaped calcining chamber are adjacently arranged inside the rotary kiln, blades are arranged on the inner wall of the muffle heating furnace and the inner wall of the calcining chamber, and a carbon dioxide collector is arranged through a limestone feeding inlet to communicate with the calcining chamber. Compared with present muffle rotary limekilns, the u-shaped internal-combustion rotating limekiln capable of recovering CO2 has significant advantages of reasonable structure, energy conservation, and emission reduction, and can recover and utilize materials and improve product quality.

Owner:赵光辉

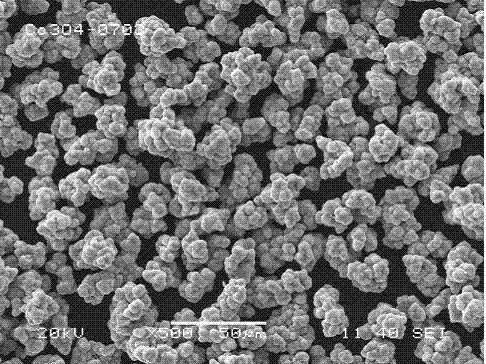

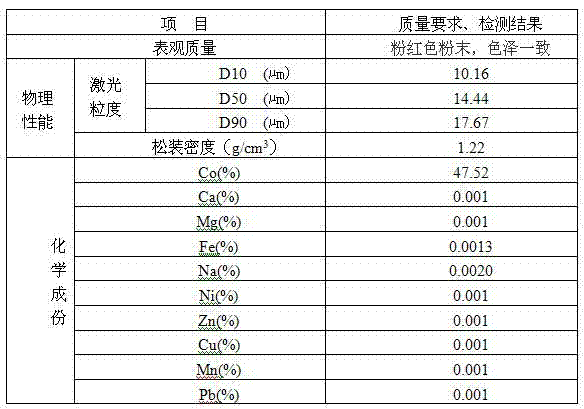

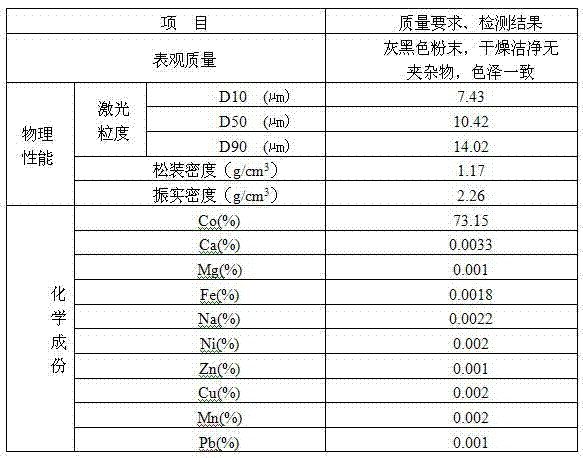

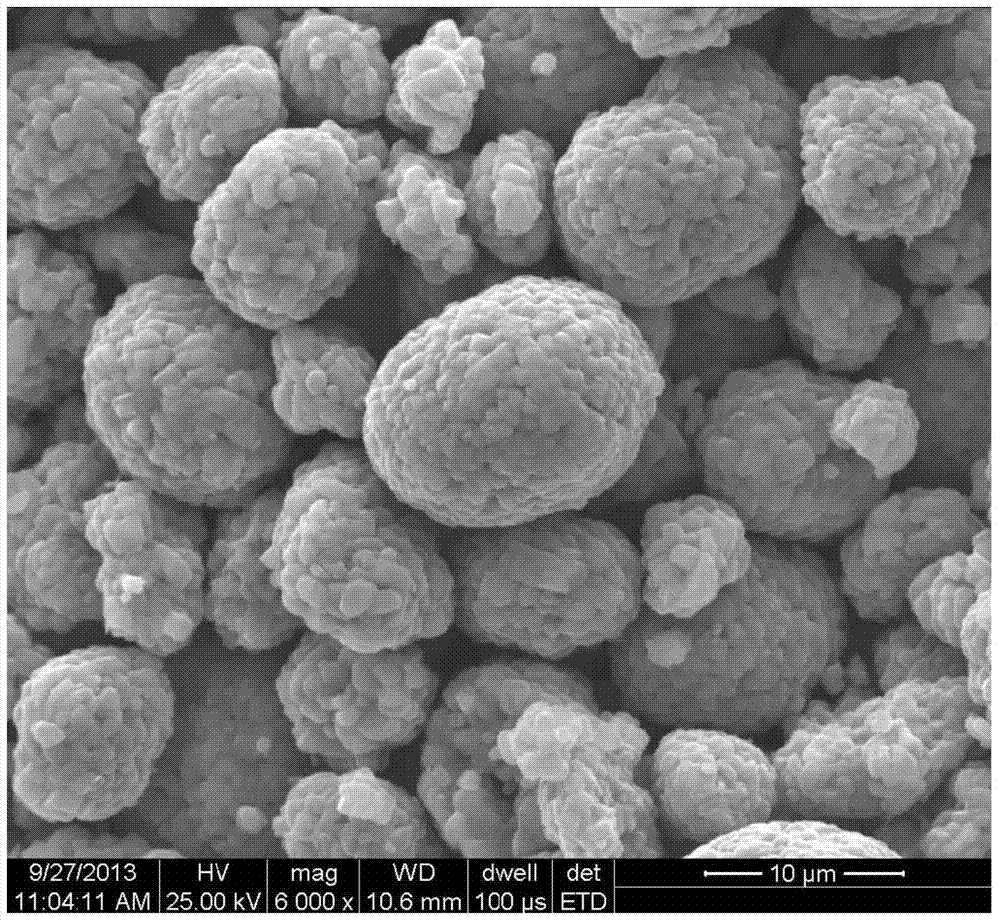

Preparation process of cobaltosic oxide for continuous production of batteries

ActiveCN102820468AGood lookingFine granularityCell electrodesCobalt compoundsAfter treatmentLithium carbonate

A preparation process of cobaltosic oxide for continuous production of batteries is a process for preparing the cobaltosic oxide by using a cobalt contained material to continuously synthesize cobalt carbonate and continuously roasting and resolving in an oxidizing atmosphere. Continuous production of the cobaltosic oxide can be completed through several steps of preparation of cobalt solution, preparation of precipitator, lithium carbonate synthesizing, ageing, filtering and washing, burning and after treatment. The preparation process continuously synthesizes the cobalt carbonate, and continuously roasts and resolves the cobaltosic oxide, is apt to control technical indexes in a production procedure, can achieve automatic production, is favorable for reduction of labor intensity, improves efficiency of labor and lowers cost. Produced products are high in purity, excellent in physical performance indexes and good in stability and consistency.

Owner:GANZHOU TENGYUAN COBALT INDAL

Method for preparing building gypsum by desulfurized gypsum and device of building gypsum

Owner:枣庄盛世机械科技有限公司

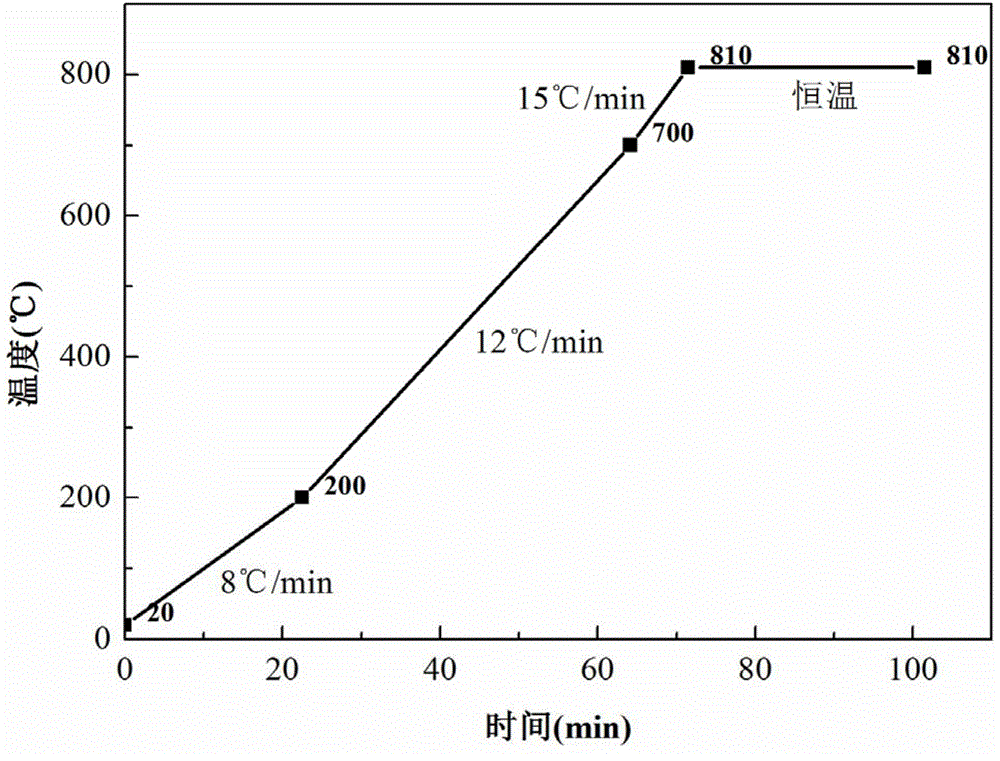

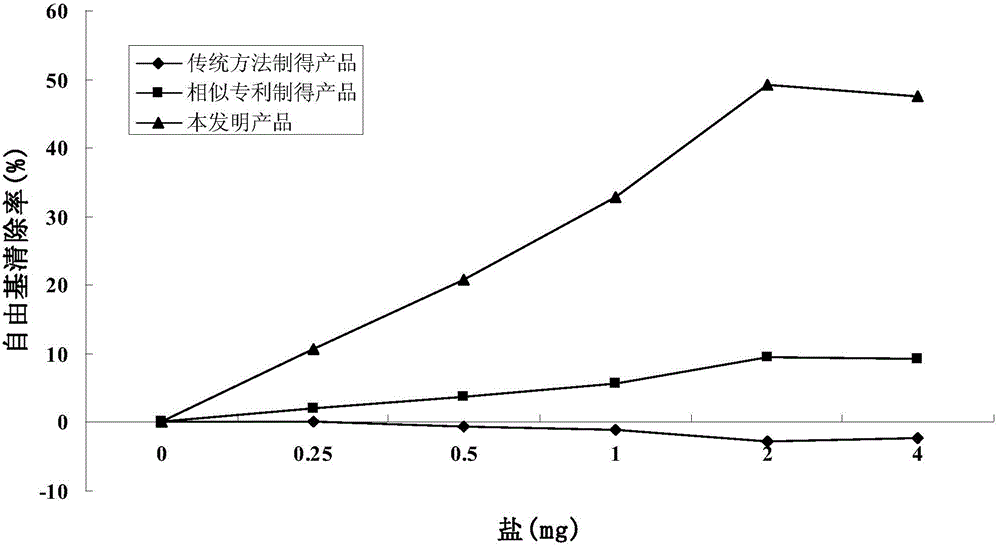

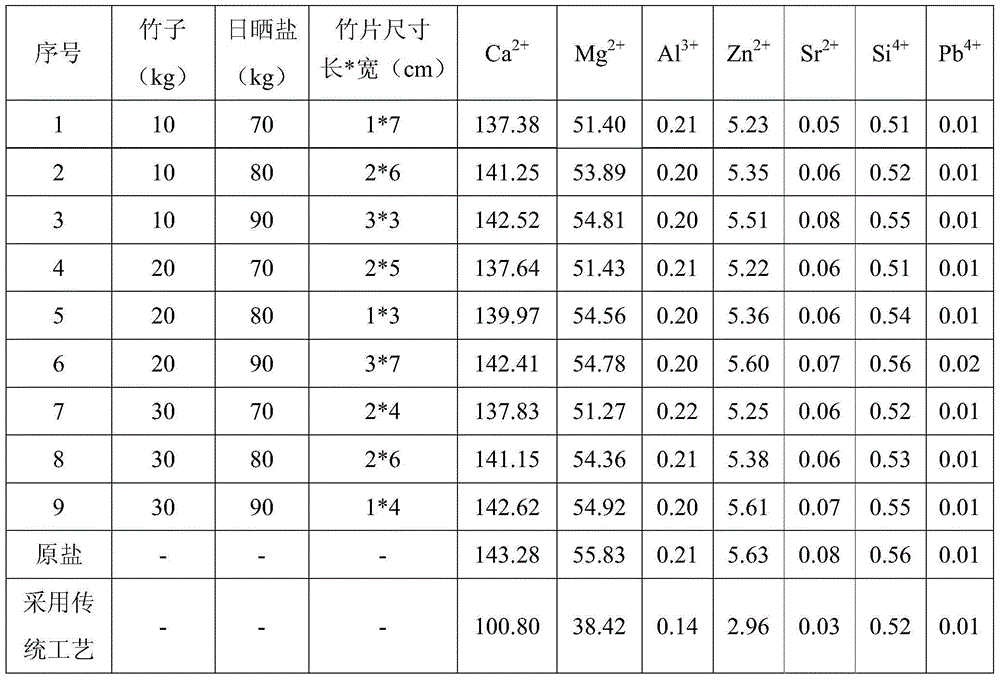

Method for preparing bamboo salt through temperature program

ActiveCN104621526AAchieve the purpose of enrichmentFully contactedFood preparationThree stageUniform - quality

The invention provides a method for preparing bamboo salt through temperature program, and relates to a preparation method of bamboo salt. The invention aims at providing a method for preparing bamboo salt by adopting a stage temperature program. The preparation method comprises the following steps: mixing raw materials; performing three-stage temperature rise calcining; cooling and crystalizing; and grinding. The method for preparing bamboo salt through temperature program, the loss of mineral substances is few, energy resources and raw materials can be saved, and the product bamboo salt has uniform quality and is high in quality. The method is used in the field of preparation of bamboo salt.

Owner:中盐国本盐业有限公司 +1

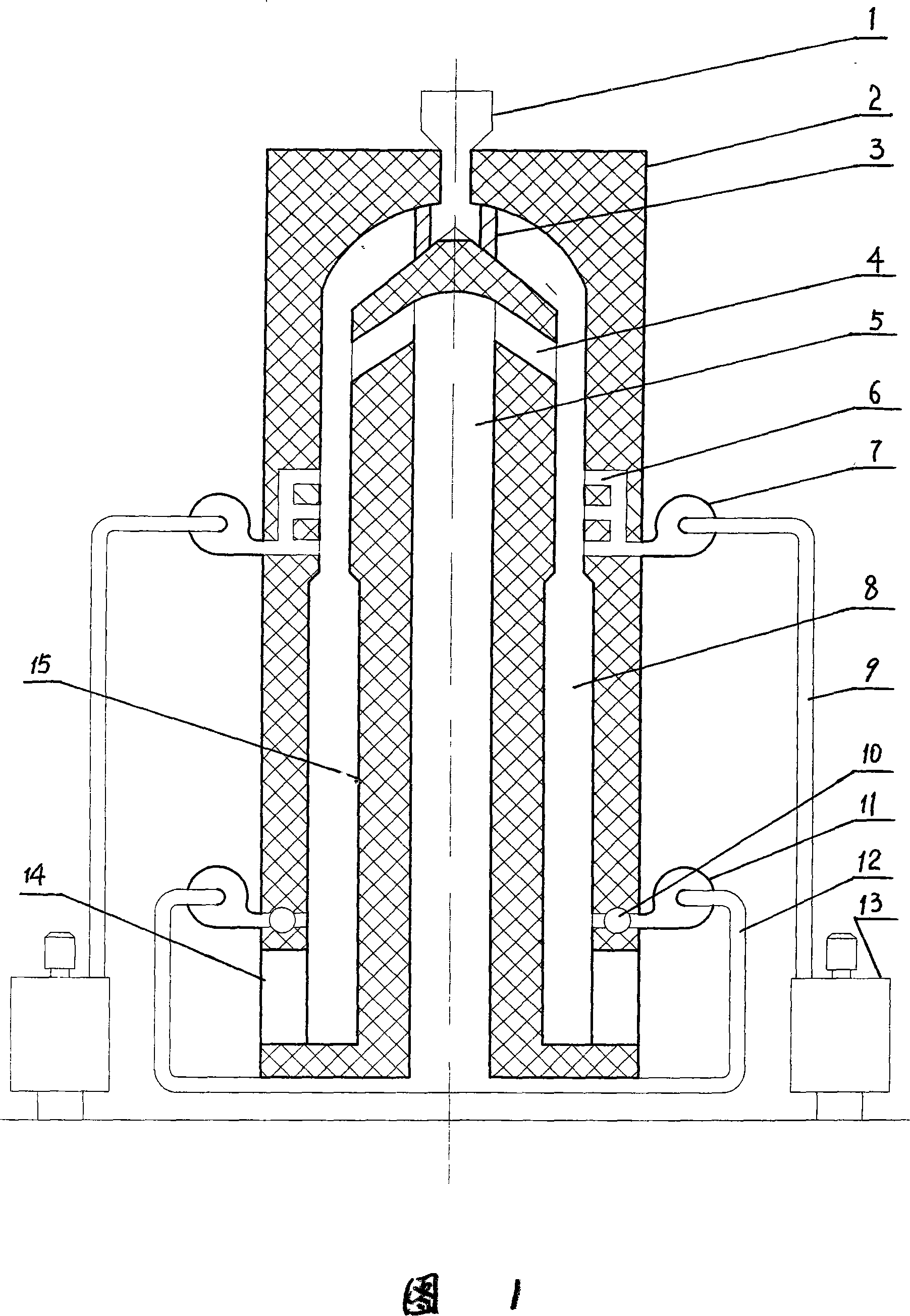

Built-in chimney flue type energy-saving environment protective smelting lime calcining kiln

InactiveCN101062844AIncrease profitImprove pressure resistanceLime productionCombustion chamberFlue gas

The invention discloses a energy-saving environmental protection metallurgy lime calcining kiln with built-in flue, which comprises the following steps: arranging a build-in chimney (15) in cave of kiln body (2); equipping a ring-shaped flue (10) with several flue gas reclaiming mouths at the lower of entering fire hole (6); communicating the flue gas reclaiming mouth with burning room (8); setting the built-in chimney (15) as hollow structure; opening circulating flue (4) at the upper; connecting the lower end to the ring-shaped flue (10) through flue gas pipe (12) and lower exhauster (11). This invention can be cycling utilized, which can decrease environmental pollution degree.

Owner:刘永智

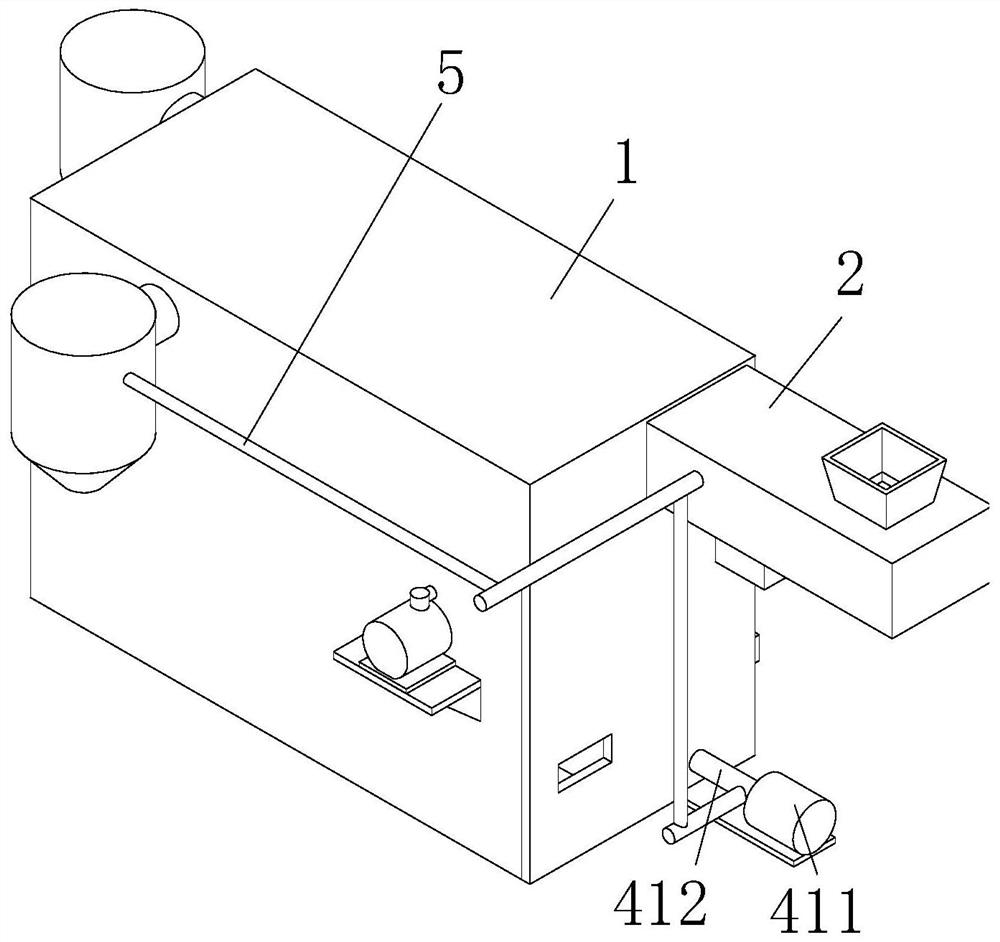

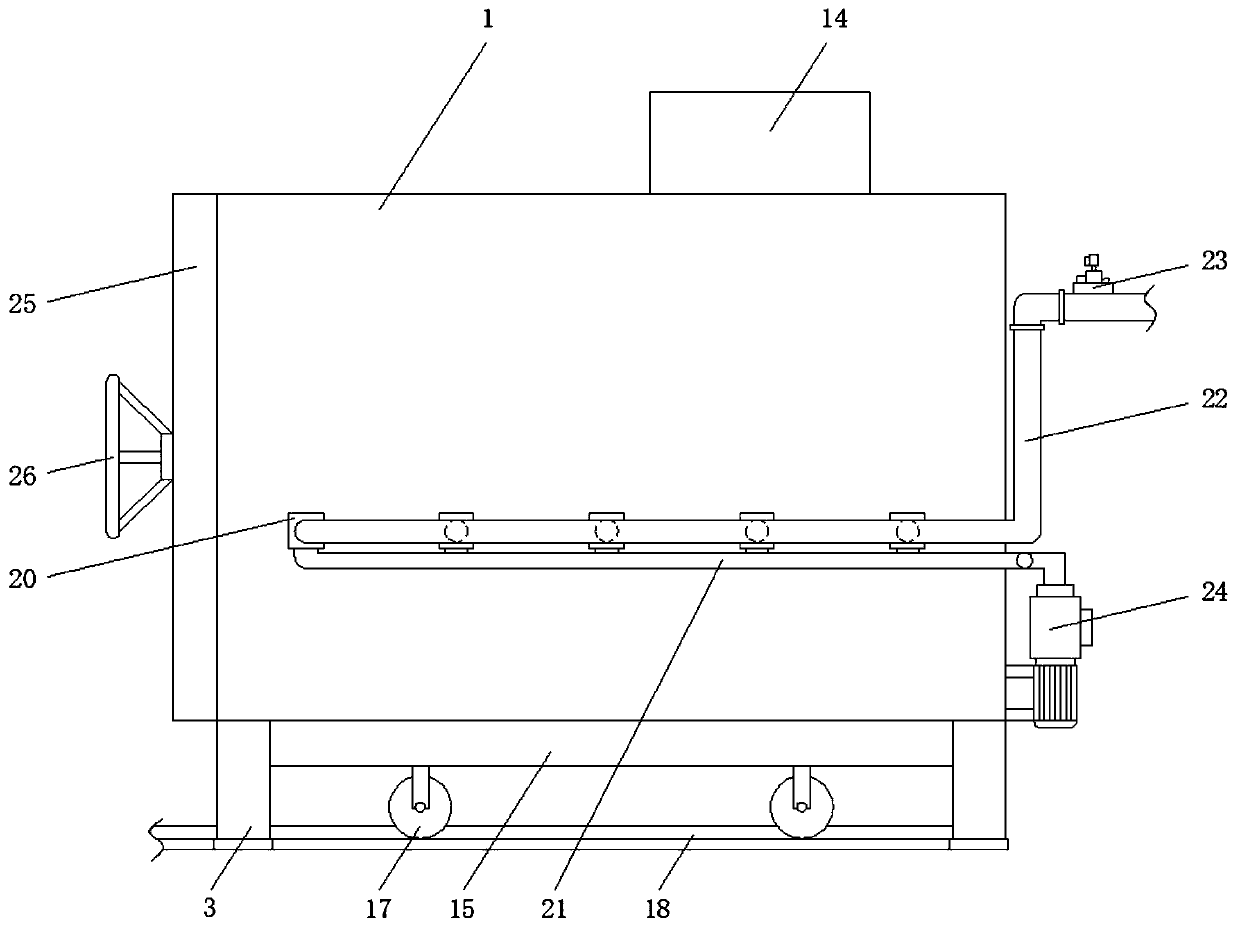

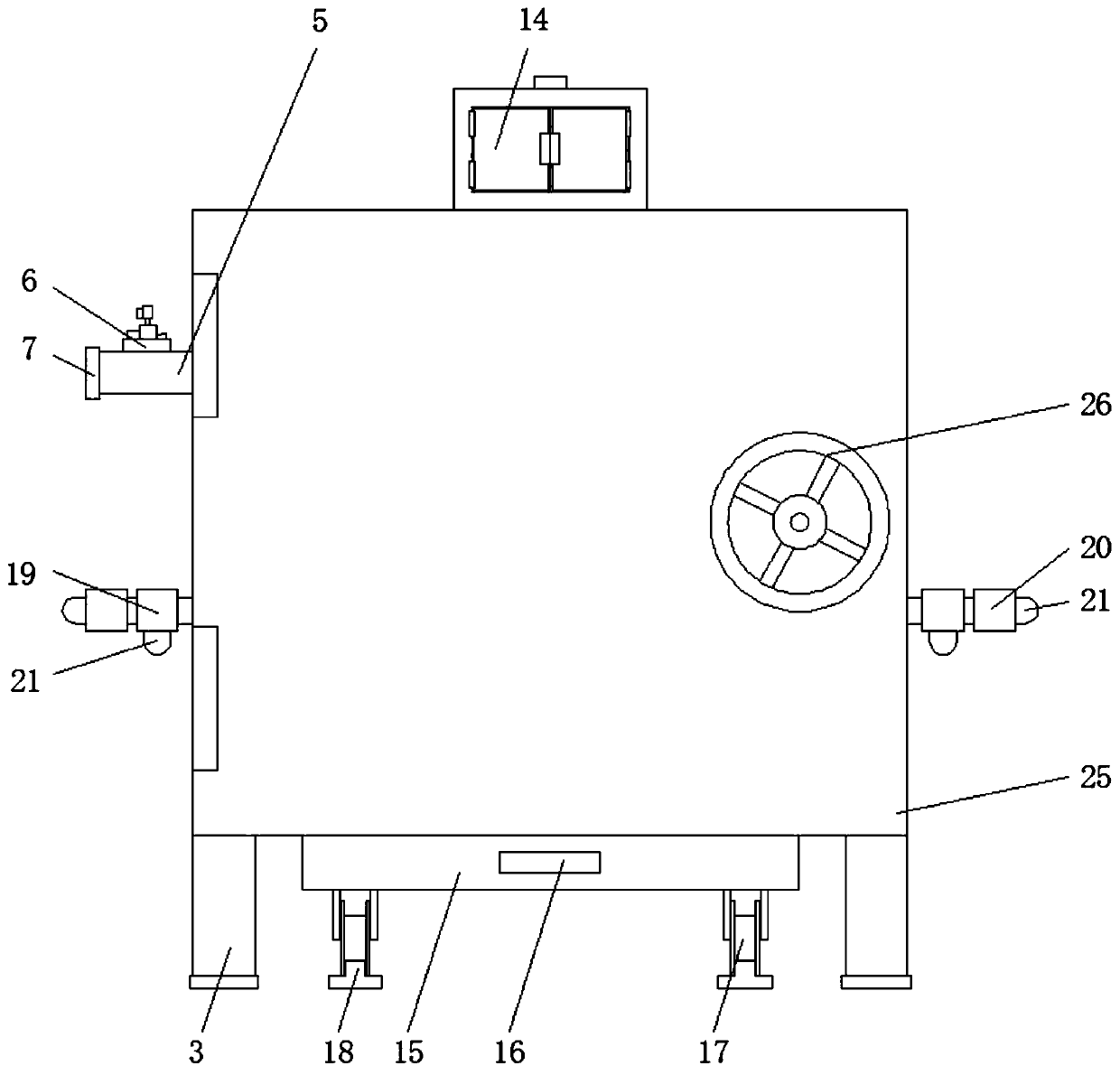

Calcining equipment for gypsum powder

The invention discloses calcining equipment for a gypsum powder. The equipment comprises a calcining box, a pre-drying feeding device is arranged at the top of one side of the calcining box, and the interior of the calcining box is divided into a heating cavity and a calcining cavity through a heat conduction partition plate; a hot baking calcining device is arranged in the calcining cavity, the hot baking calcining device comprises a plurality of heat dissipation plates, and an adjusting part is arranged at the bottom of each heat dissipation plate; and a wind power calcination device is arranged at the bottom of the hot baking calcination device and comprises a wind power transmission component and a heating power component, the heating power component is arranged on one side of the heat conduction partition plate, the wind power transmission component is arranged at the bottom of the hot baking calcination device, the side wall of the heating cavity is provided with a transmission pipe, and the transmission pipeline is used for conveying hot air exhausted by the heating cavity into the pre-drying feeding device and the wind power transmission component. According to the calcining equipment, exhaust heat can be recycled, raw materials and clinker are convenient to separate, pollution of gypsum powder is avoided, and the processing quality is high.

Owner:江西中科高博科技服务有限公司

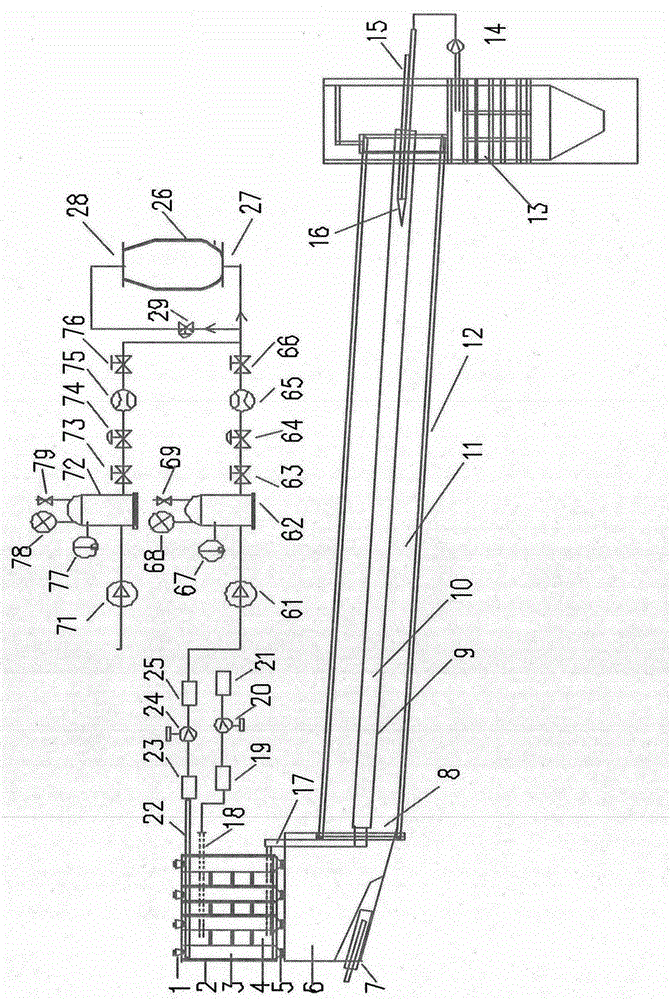

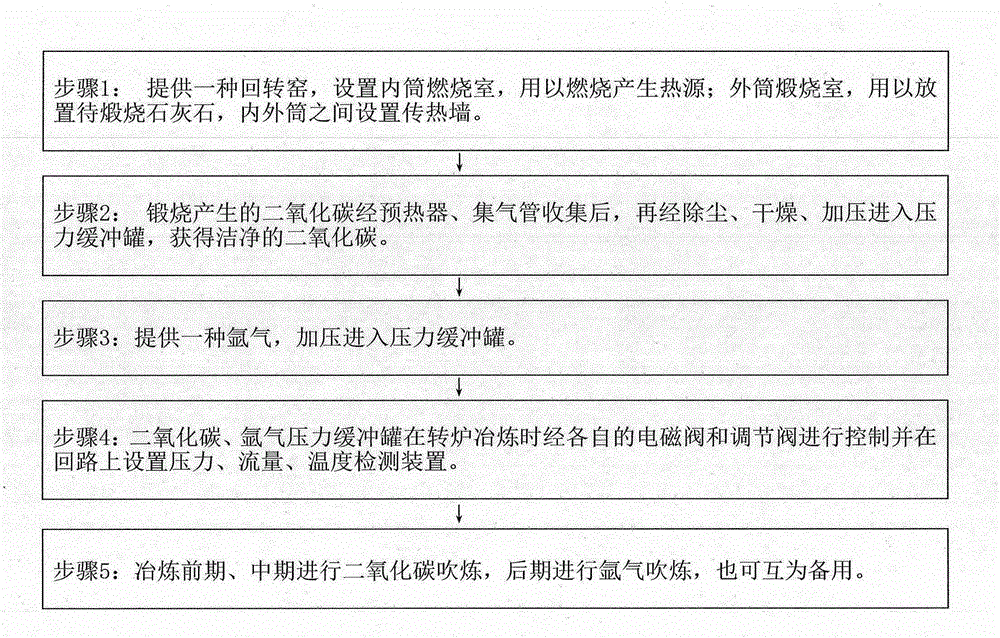

Control device and method for converter smelting through CO2 and argon of rotary kiln

InactiveCN105274278AImprove purification effectSolve pollutionCarbon compoundsManufacturing convertersSteelmakingCombustion chamber

The invention provides a control device and method for converter smelting through CO2 and argon of a rotary kiln. The control device comprises a rotary kiln part and a converter smelting part. An inner cylinder combustion chamber used for performing combustion to generate a heat source and an outer cylinder calcining compartment used for containing to-be-calcined limestone are arranged in the rotary kiln. A heat transmission wall is arranged between an inner cylinder and an outer cylinder. After carbon dioxide generated through calcination is collected through a preheater and a gas collecting pipe, dust removing, drying and pressurizing are carried out on the carbon dioxide, then the carbon dioxide enters pressure buffering tanks, and the clean carbon dioxide is obtained. The converter smelting part comprises a composite carbon dioxide and argon blowing control system mainly composed of the carbon dioxide and argon pressure buffering tanks, pressure detecting devices, flow detecting devices, temperature detecting devices, electromagnetic valves, adjusting valves and the like. During smelting, the respective electromagnetic valves and the respective adjusting valves are used for performing controlling, carbon dioxide blowing is carried out in the earlier stage and the medium stage, argon blowing is carried out in the later stage, and the electromagnetic valves and the adjusting valves can complement one another. According to the control device and method, the steelmaking production cost is reduced, the carbon emission and greenhouse effect can be reduced, and the control device and method conform to circular economy.

Owner:李正福

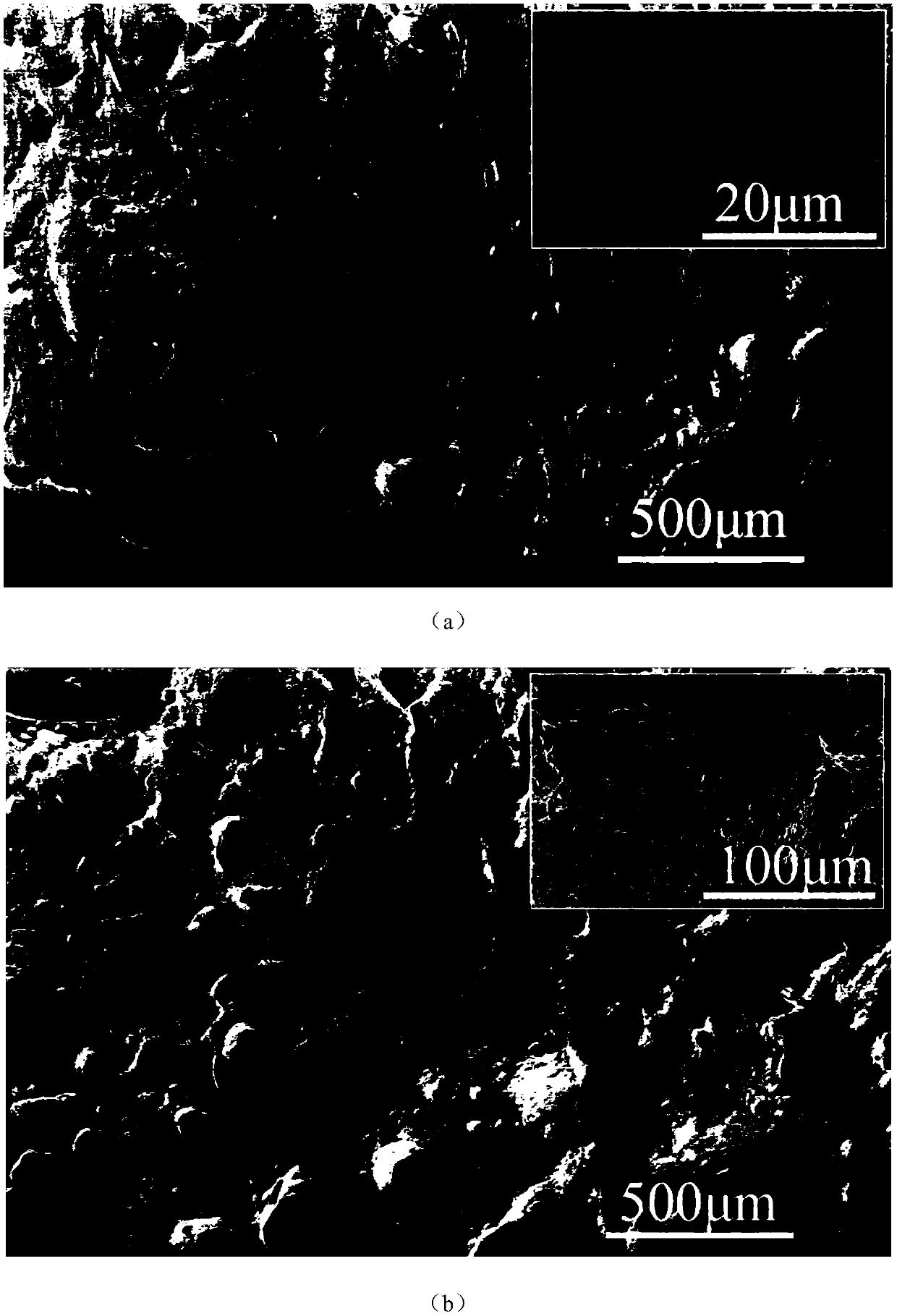

Adsorption type bone apatite and preparation method and application thereof

ActiveCN110841588AWide variety of sourcesHigh specific surface areaOther chemical processesWater contaminantsO-Phosphoric AcidEngineering

The invention belongs to the field of environment-friendly materials, and particularly relates to adsorption type bone apatite and a preparation method and application thereof. The preparation methodcomprises the following steps: removing organic matters in animal bones; calcining the animal bones without the organic matters to obtain bone apatite; and carrying out surface chemical modification on the bone apatite by adopting a phosphoric acid solution to obtain the adsorption type bone apatite. The adsorption type bone apatite can be used for adsorbing heavy metal ions in industrial sewage,and the specific surface area of the adsorption type bone apatite is increased from 47.832 (m<2> / g) to 131.566 (m<2> / g) compared with the specific surface area of the adsorption type bone apatite before modification; when the initial concentration of Pb<2> is 200 mg / L, a removal rate can reach 98.3%; for Zn<2> and Cu<2> ions with an initial concentration of 200 mg / L, the removal rate of the ions can reach 70% or above; so the adsorption type bone apatite has good heavy metal ion removal capacity. The technical problem that bone apatite in the prior art is not high enough in adsorption capacityis solved.

Owner:XI AN JIAOTONG UNIV

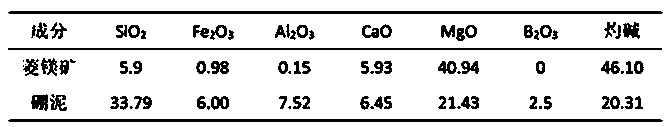

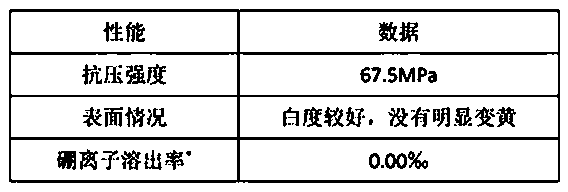

Comprehensive utilization method for high-iron high-calcium high-silicon waste magnesite and boron mud

ActiveCN111153610AImprove reaction efficiencySimple processOrganic compound preparationSolid waste managementOXALIC ACID DIHYDRATEGlycerol

The invention discloses a comprehensive utilization method of high-iron high-calcium high-silicon waste magnesite and boron mud, which comprises the following steps: calcining waste magnesite in a rotary kiln, pulverizing light calcined magnesia powder, and leaching iron and calcium with an oxalic acid and glycerol alcohol solution to obtain calcium oxalate and complex iron oxalate; and adding magnesium sulfate and boric sludge, and carrying out stirring to prepare a magnesium building material product. According to the invention, high-iron high-calcium high-silicon waste magnesite and boron mud are used as raw materials, iron and calcium impurities are leached out through oxalic acid, glycerol alcohol and oxalic acid are subjected to graft polymerization under the hydration heat release condition of magnesium oxysulfate cement, hydroxyl in a formed polymer reacts with boron to solidify boron, then the boron is further solidified through a magnesian cementing material, secondary utilization of solid waste is achieved, and the method is environmentally friendly. The preparation method is simple, the light calcined magnesia powder prepared by using the rotary kiln is small in grain size, high in activity, relatively low in cost, safe, non-toxic, low in leaching harmful impurities and large in dosage, and is used for building material products, and the prepared building material product is relatively high in whiteness and good in performance.

Owner:辽宁科大中驰镁建材科技有限公司 +1

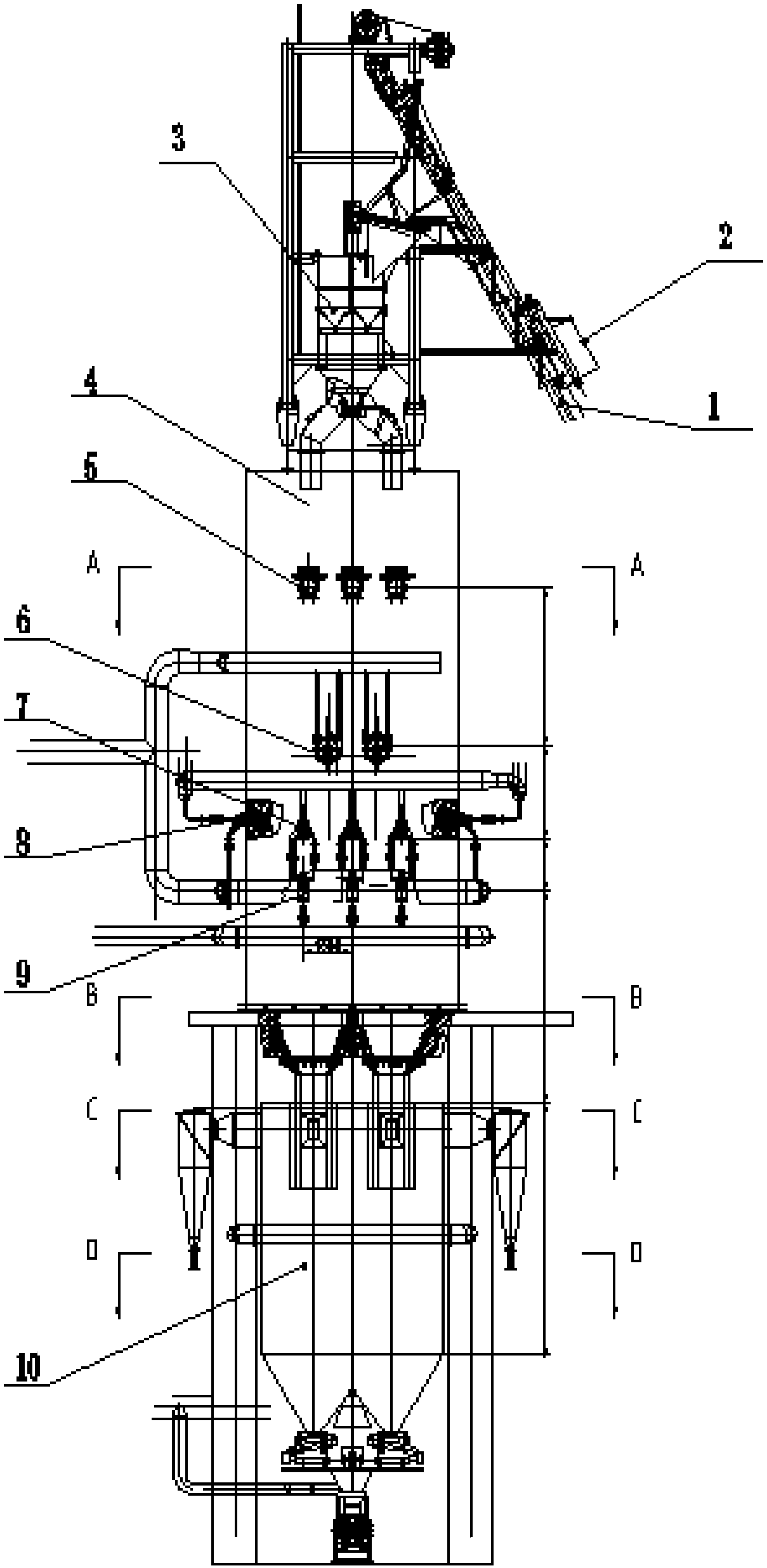

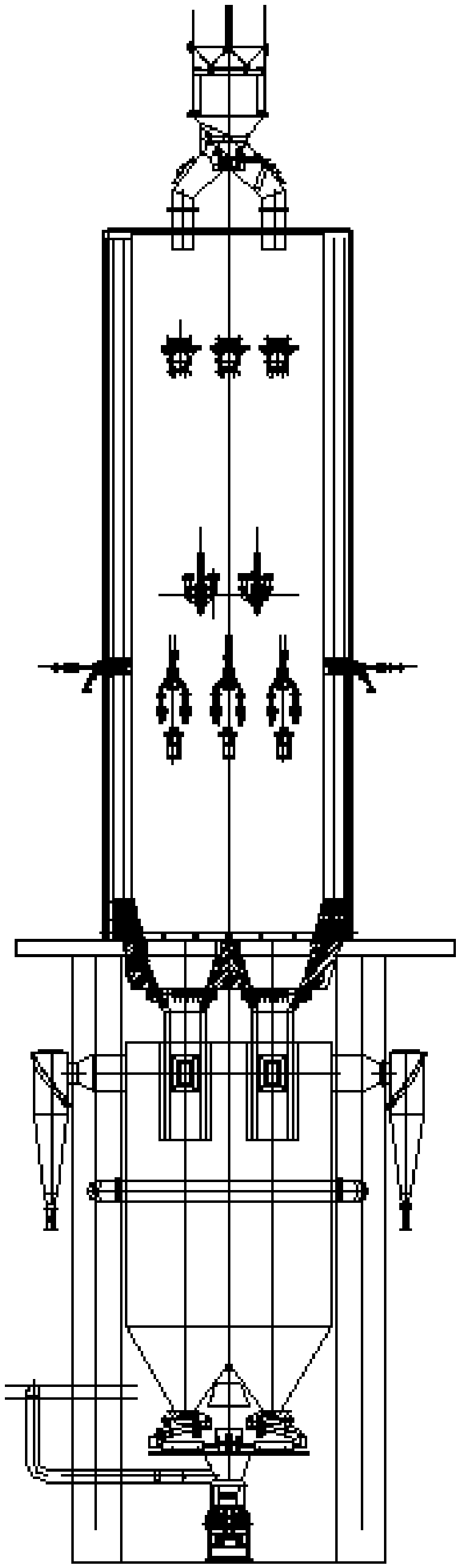

Five-section-type caustic calcined magnesite energy saving and environmental protection shaft kiln

InactiveCN109520284ADoes not affect air volume balanceAir volume increase or decreaseVertical furnacesCombustionDecomposition

The invention discloses a five-section-type caustic calcined magnesite energy saving and environmental protection shaft kiln. The five-section-type caustic calcined magnesite energy saving and environmental protection shaft kiln is characterized in that the kiln is divided into five hot work area sections from top to bottom, and the five hot work area sections are a preheating decomposition zone,a calcination zone, a rear calcination zone, a heat insulation zone and a cooling separation zone sequentially; a balance air-exhaust demodulator 5 is arranged on the upper part in the kiln; a secondary combustion-supporting air distributor and a cooling separator are included; the preheating decomposition zone is located between the balance air-exhaust demodulator and a burner; and the rear calcination zone is located between the burner 7 at the lower part in the kiln and the secondary combustion-supporting air distributor 9, the heat insulation zone is located at the lower part of the rear calcination zone, and the cooling separation zone is located at the lower part of a kiln body. The five-section-type caustic calcined magnesite energy saving and environmental protection shaft kiln hasthe advantages that when passing through the calcination zone, preheated magnesite can be evenly calcinated, and the phenomena of deviant fire and deviant combustion are avoided. One of the outstanding characteristics of the five-section-type caustic calcined magnesite energy saving and environmental protection shaft kiln is the heat insulation zone, the heat insulation zone is arranged accordingto the sintering characteristic of the caustic calcined magnesite, undecomposed magnesium carbonate can be decomposed at the heat insulation zone, and the yield is further increased.

Owner:LIAONING JINDA HUAJIE ENG TECH CO LTD

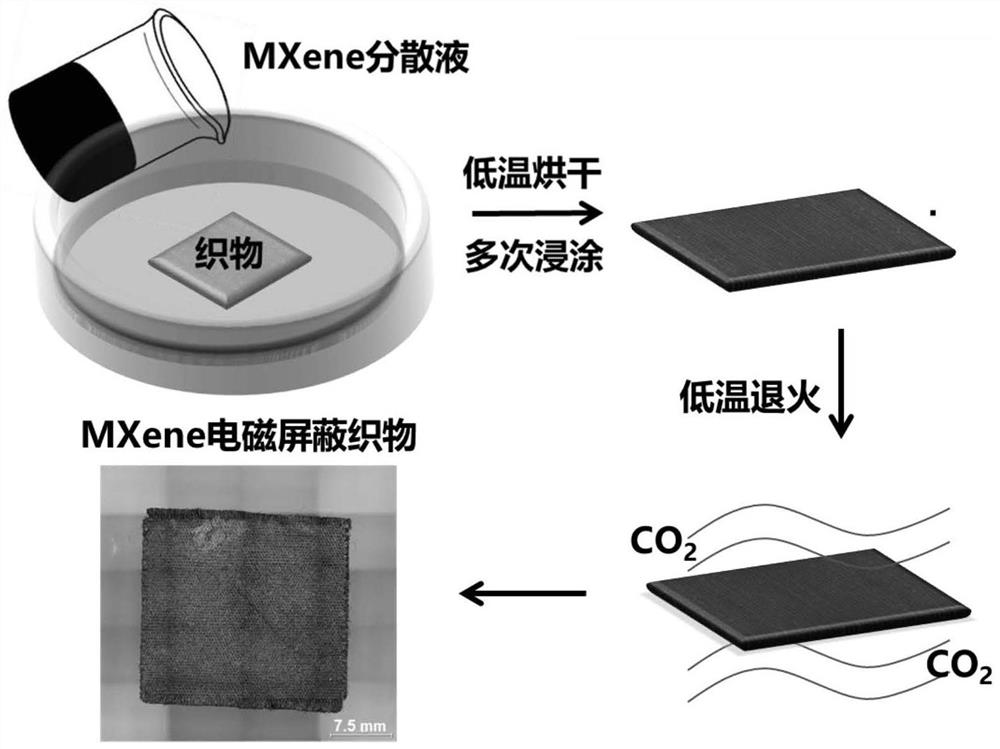

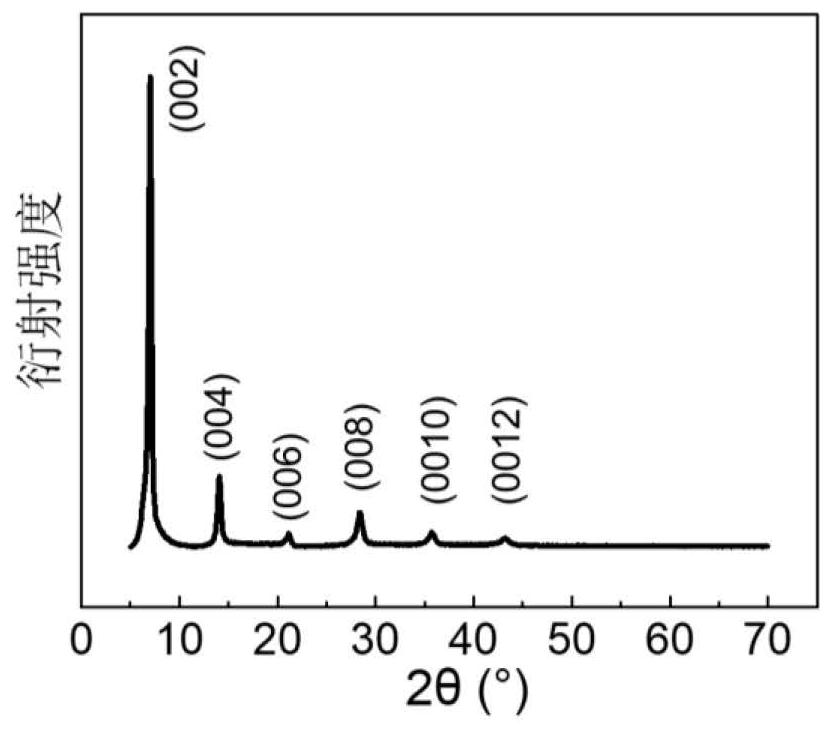

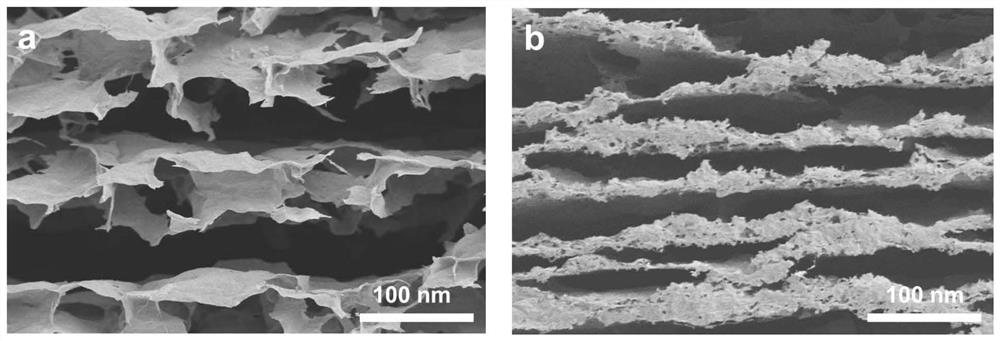

MXene electromagnetic shielding fabric as well as preparation method and application thereof

ActiveCN112663323AHigh strengthStrong adhesionUltrasonic/sonic fibre treatmentElectromagnetic shieldingMechanical engineering

The invention relates to an MXene electromagnetic shielding fabric as well as a preparation method and application thereof. The method comprises the following steps of carrying out plasma pretreatment on a flexible fabric substrate, dipping in an MXene dispersion liquid, taking out, drying, and carrying out low-temperature annealing treatment under a CO2 condition. The electromagnetic shielding fabric has good flexibility, washing resistance and electromagnetic shielding characteristics.

Owner:DONGHUA UNIV

High-calcium active lime

ActiveCN110981228ALess impuritiesIncrease contentProcess efficiency improvementPhysical chemistryCalcium content

The invention belongs to the field of materials, and particularly relates to high-calcium active lime. A preparation method comprises the steps of pretreatment, activation, impurity removal and the like. According to the method, low-grade limestone with the total content of SiO2 and Fe2O3 being greater than 3% is utilized; the calcium content of the active lime produced by the process disclosed bythe invention reaches 97.3%, the carbon content is lower than 0.5%, the sulfur content is lower than 0.02%, the SiO2 content is lower than 1.0%, and the Fe2O3 content is lower than 1.0%, the producedactive lime has few impurities and can reach the standards of various fields, and the application range is expanded.

Owner:GUIZHOU ANKAIDA IND

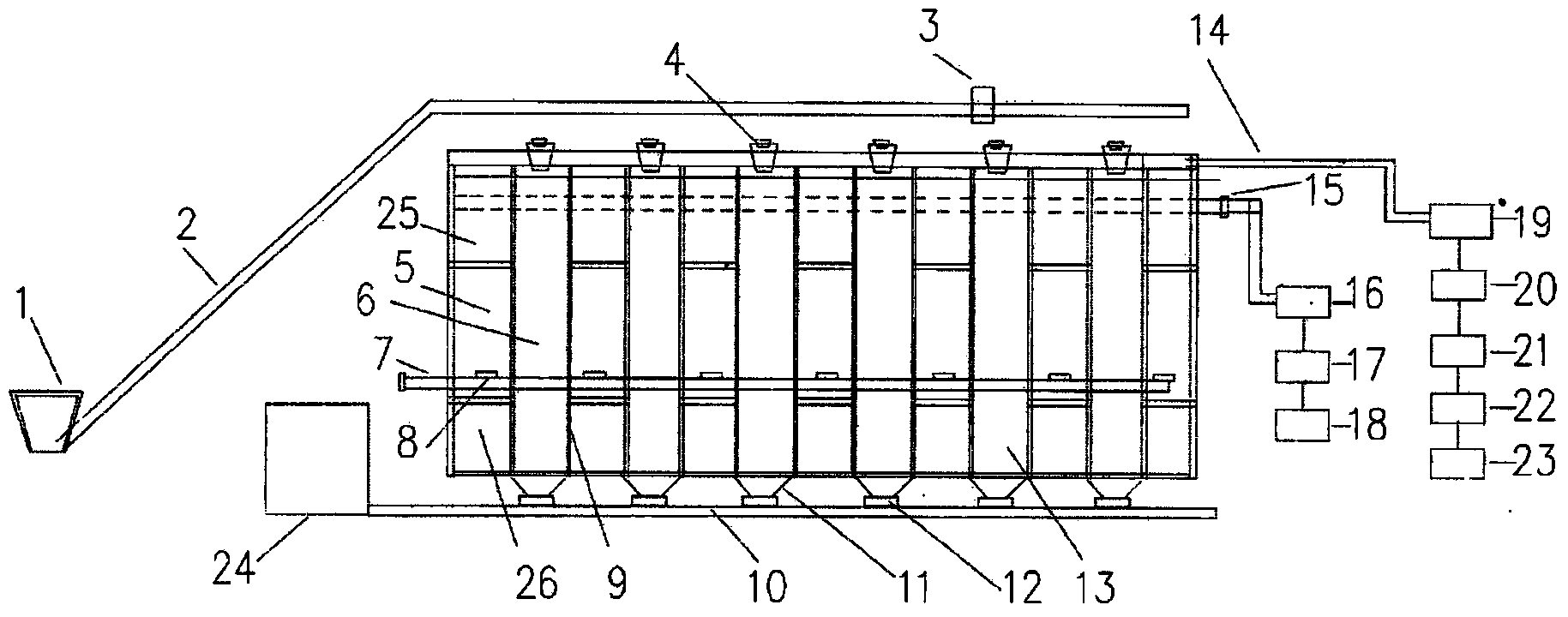

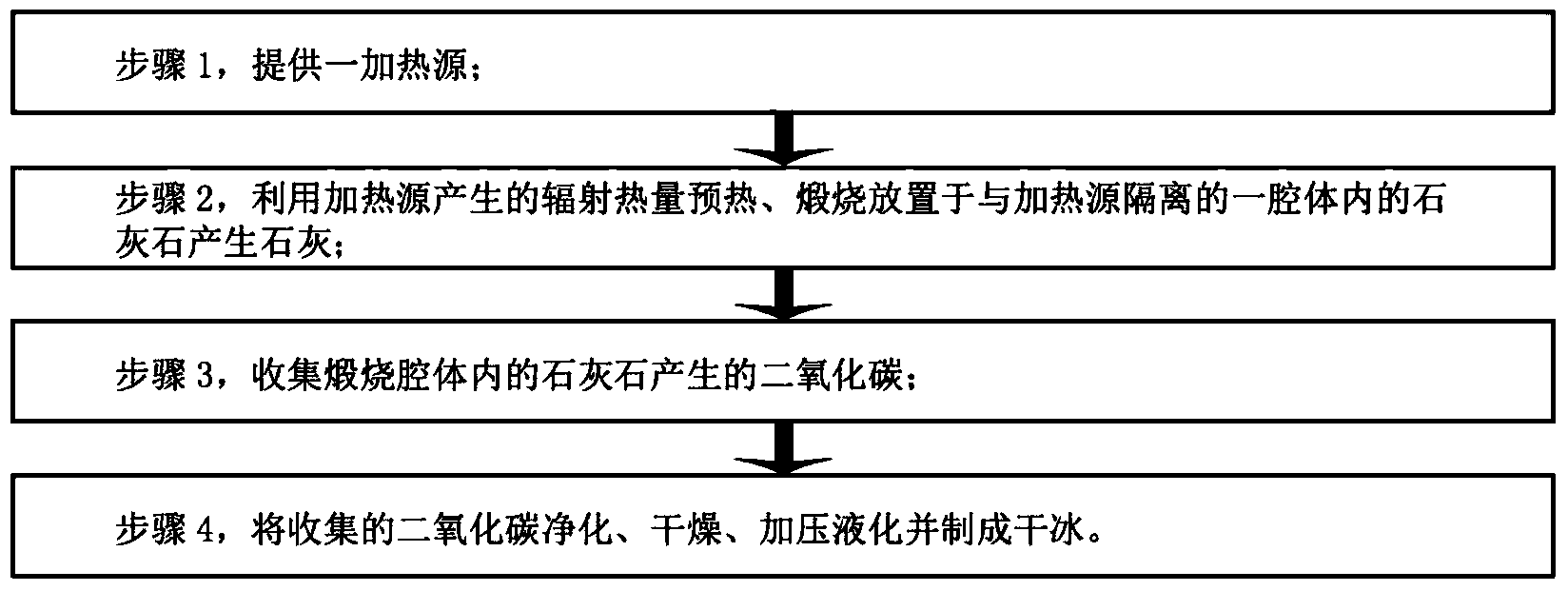

Device and method for manufacturing dry ice by utilizing radiant heat to produce active lime

InactiveCN104261700AImprove product qualityHigh purityCarbon compoundsEnergy inputCombustion chamberRadiant heat

The invention provides a device and a method for manufacturing dry ice by utilizing radiant heat to produce dry ice. The device and the method are applied to lime stones with small particle size of 20-40 mm in mine production. Roasting is carried out through heat transferred through radiation by a combustion chamber in a roasting chamber, the roasted lime stones are decomposed into calcium oxide and carbon dioxide, the calcium oxide is cooled, discharged out through an ash discharging device and fed into an ash bin for storage, the carbon dioxide passes through a drying device, a pressure device, a carbon dioxide liquefying plant and a dry ice device through connected waste gas pipelines to generate dry ice, after coal gas or powdered coal in the combustion chamber is combusted, the coal gas or powdered coal is discharged out through a fan for waste heat recovery and are discharged through a chimney. Active lime with higher quality can be obtained, pure carbon dioxide can be effectively recycled and is processed and manufactured into food grade dry ice, and meanwhile waste heat can be recycled for secondary use, so that a new way with larger market prospect is developed for the production of active lime and comprehensive application of resources in our country.

Owner:李正福

High-efficiency energy-saving lime kiln

The invention provides a high-efficiency energy-saving lime kiln which comprises a furnace body, a hearth, a main grate, side grates, an unloading system and an air supply system, wherein the periphery of the hearth is sequentially provided with a refractory brick layer and a molten iron slag-cement mixture layer, and coated with an iron sheet; the top of the furnace body is provided with a flue; the flue port is communicated with a deduster via a blower through a pipeline; the lower part of the hearth is provided with a discharge hopper; an unloading bin is arranged below the discharge hopper; and the upper part of the main grate is a conical structure. The grates can implement balanced and smooth unloading; the added wall-mounted fire bar increases the mounting height of the main grate bar, thereby increasing the effective calcination area of the hearth; the formed circular discharge channel can implement smoother lime discharge and uniform lime calcination, thereby achieving the goals of energy saving and consumption reduction; and the lime kiln is convenient for maintenance and friendly to the environment.

Owner:刘建轻

Four-hearth shaft kiln for dolomite calcination and dolomite calcining method thereof

PendingCN111620573ATake advantage ofHigh activityProcess efficiency improvementShaft furnaceRefractoryEngineering

The invention provides a four-hearth shaft kiln for dolomite calcination and a dolomite calcination method thereof. A shaft kiln body comprises a kiln body shell and a refractory material. The shaft kiln body is provided with four kiln cylinders, the four kiln cylinders are encircled into a circle, and the four kiln cylinders are communicated with one another through connecting channels at the lower parts of respective calcination zones; a feeding bin is arranged in the center of the top of the shaft kiln body, a rotary distributing device and four feeding pipes are arranged at the bottom of the feeding bin, and the outlet ends of the four feeding pipes are located in the four kiln cylinders respectively. An exhaust cylinder, a compressed air nozzle and a fuel nozzle are further arranged at the top of each kiln cylinder; the bottom of each kiln cylinder is connected with a cooling fan, and a discharging mechanism is arranged at the bottommost portion of each kiln cylinder. According tothe four-hearth shaft kiln, kiln cylinder feeding and airflow reversing are controlled, heat is transferred to cold materials, the space utilization rate is high, the heat utilization rate is high, losses are small, calcination is uniform, the phenomena of overburning and underburning are avoided, the product quality is high, the investment cost is low, and the four-hearth shaft kiln is suitablefor large-scale industrial production and application.

Owner:BEIJING OUFEI JINTAI TECH CO LTD

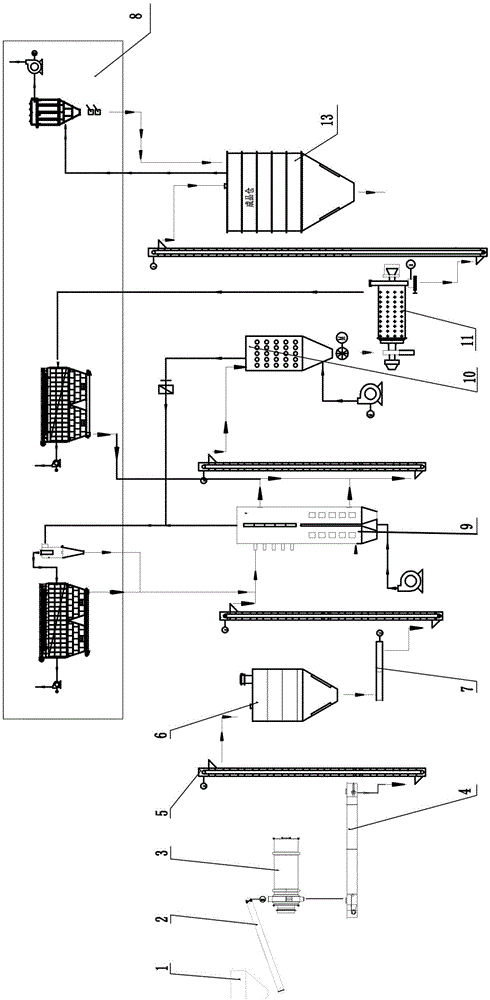

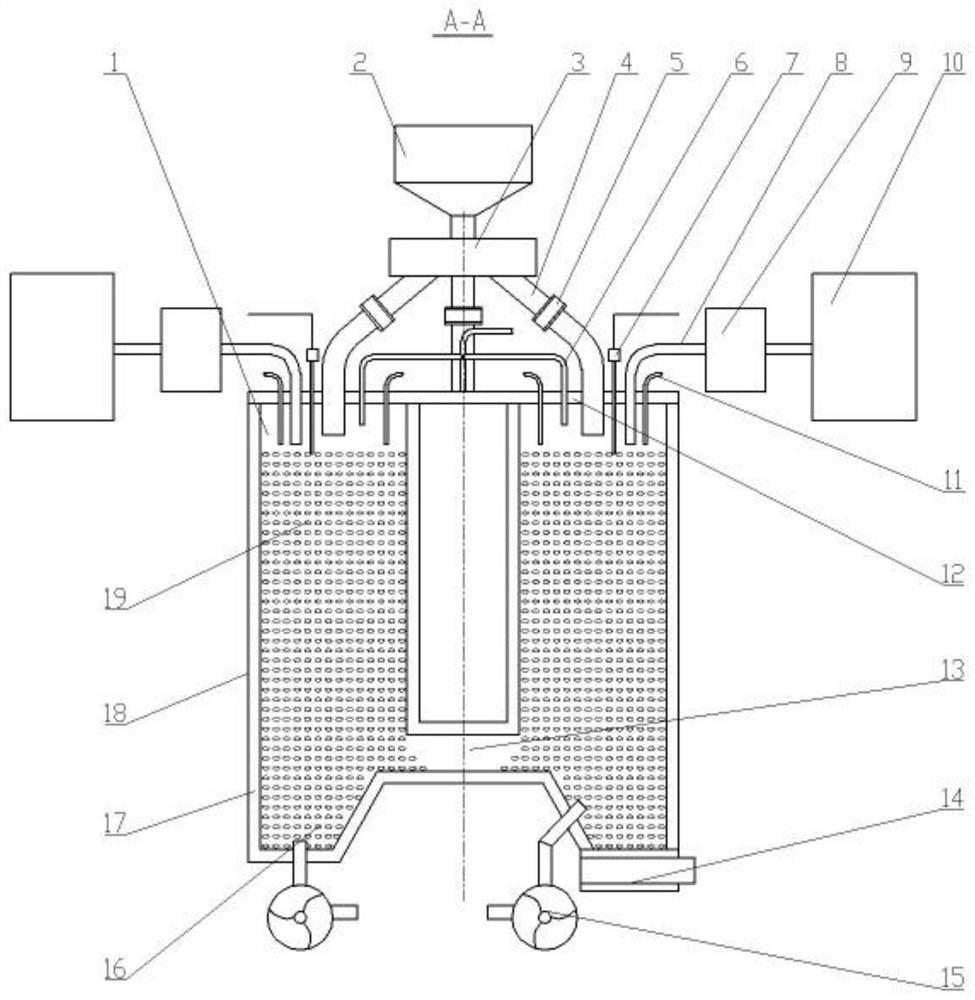

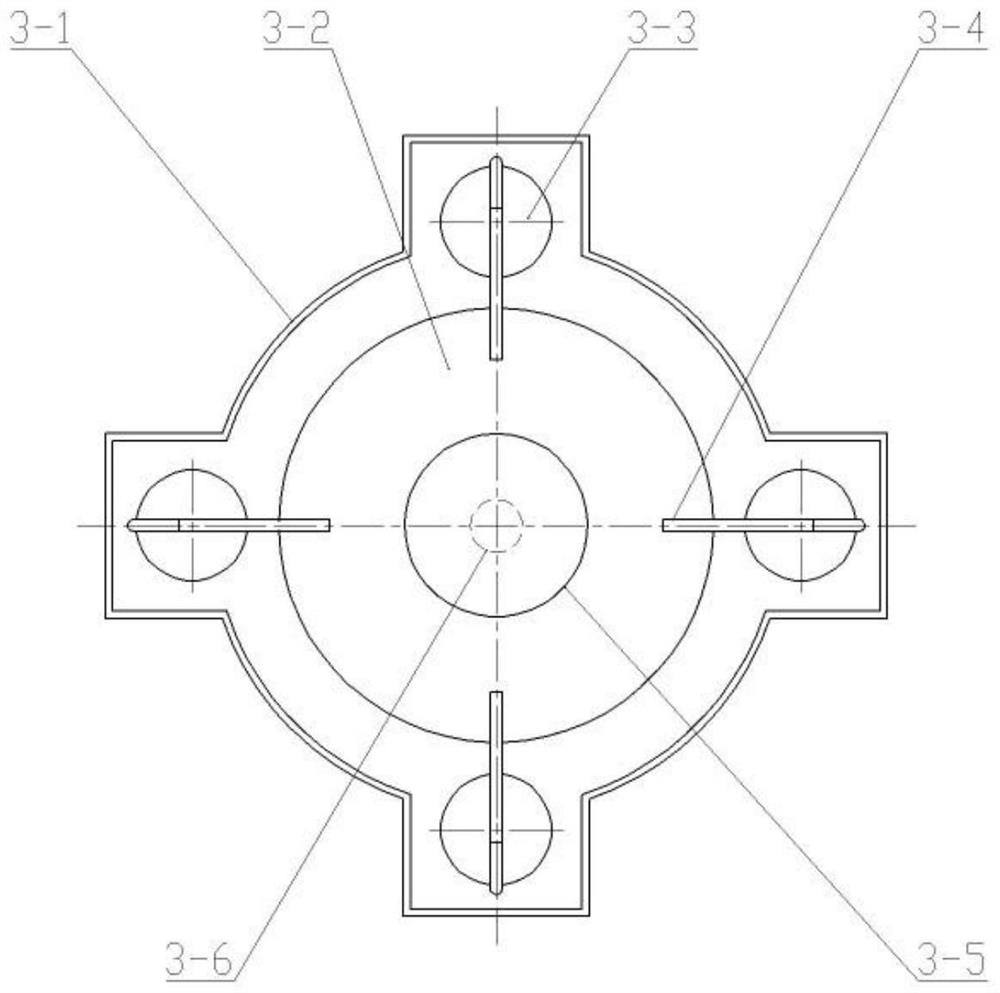

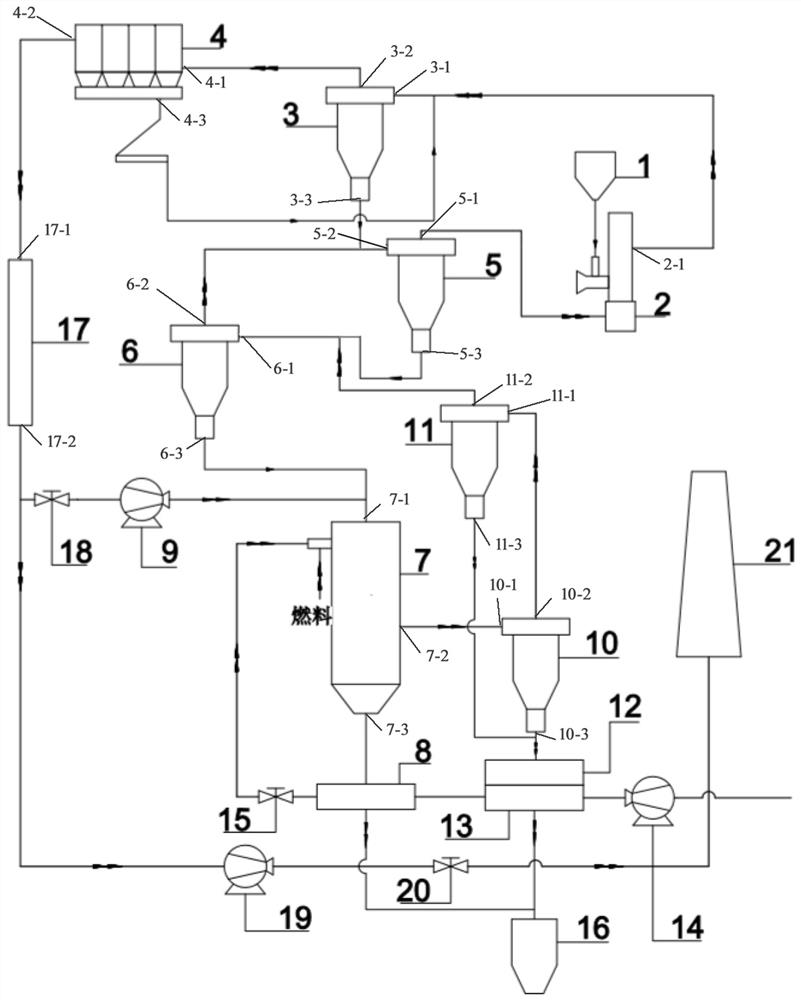

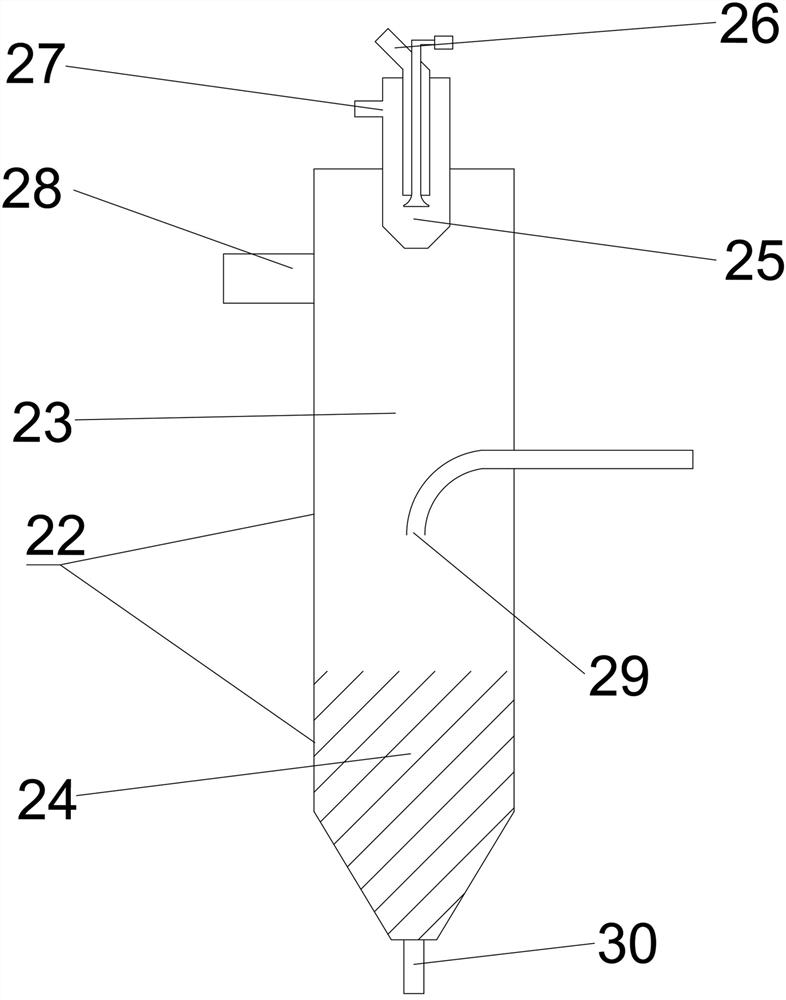

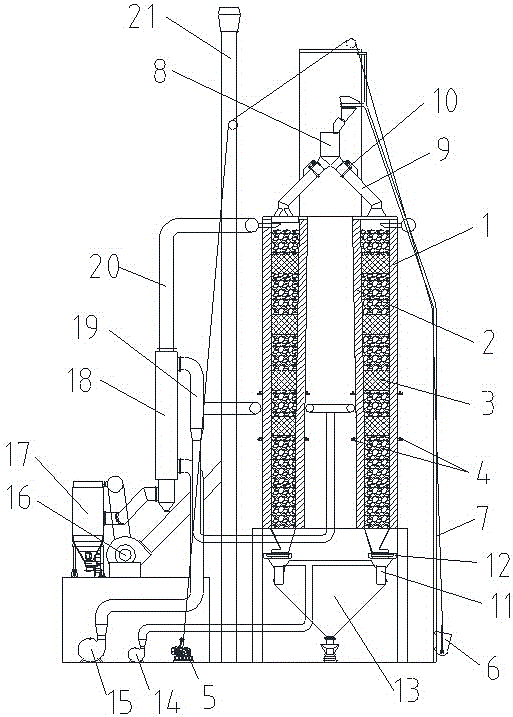

Device and process method for preparing light calcined magnesia by suspension calcination

The invention relates to a device and a process method for preparing light calcined magnesia through suspension calcination. The device comprises a raw material bin, a flash dryer, a raw material multistage preheating device, a suspension calcinator, a waste gas treatment device, a gas-material separation device, a product heat recovery device and a smoke exhaust device. The process method for preparing light calcined magnesia through suspension calcination comprises the steps that magnesite powder is dried; multi-stage preheating is conducted after the magnesite powder is dried; the preheatedmagnesite powder is calcined and subjected to heat preservation; and the material subjected to heat preservation enters a product heat recovery device to be cooled. The problems that existing light calcined magnesia calcining equipment is poor in waste heat recycling rate and uneven in product quality are solved, and energy consumption of the suspension calcining furnace can be remarkably reduced.

Owner:SHENYANG POLYTECHNIC UNIV

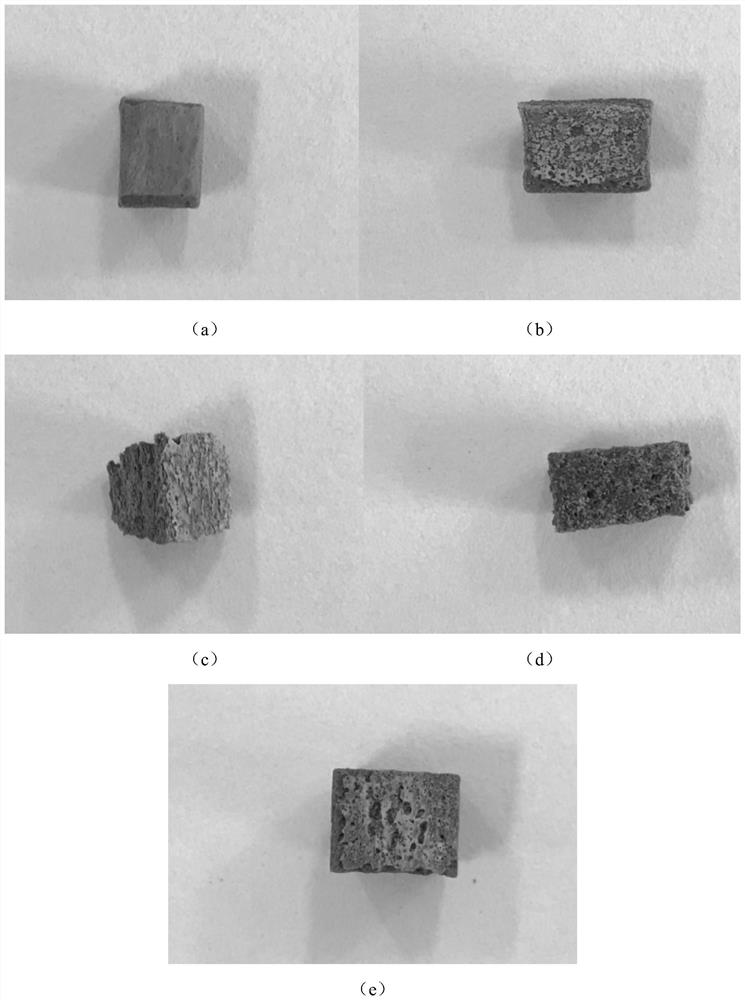

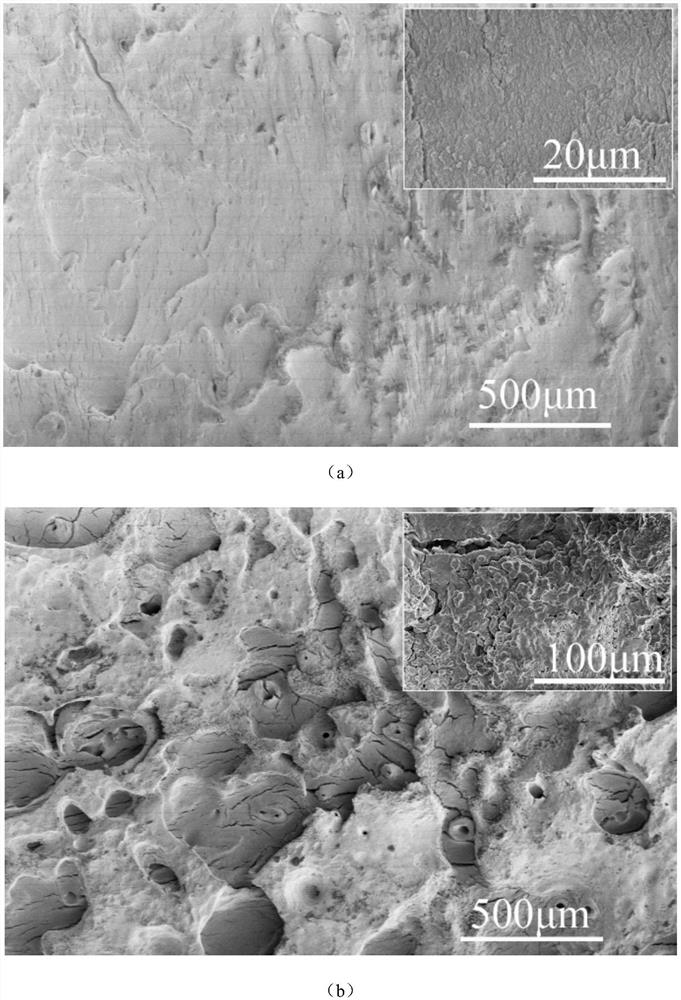

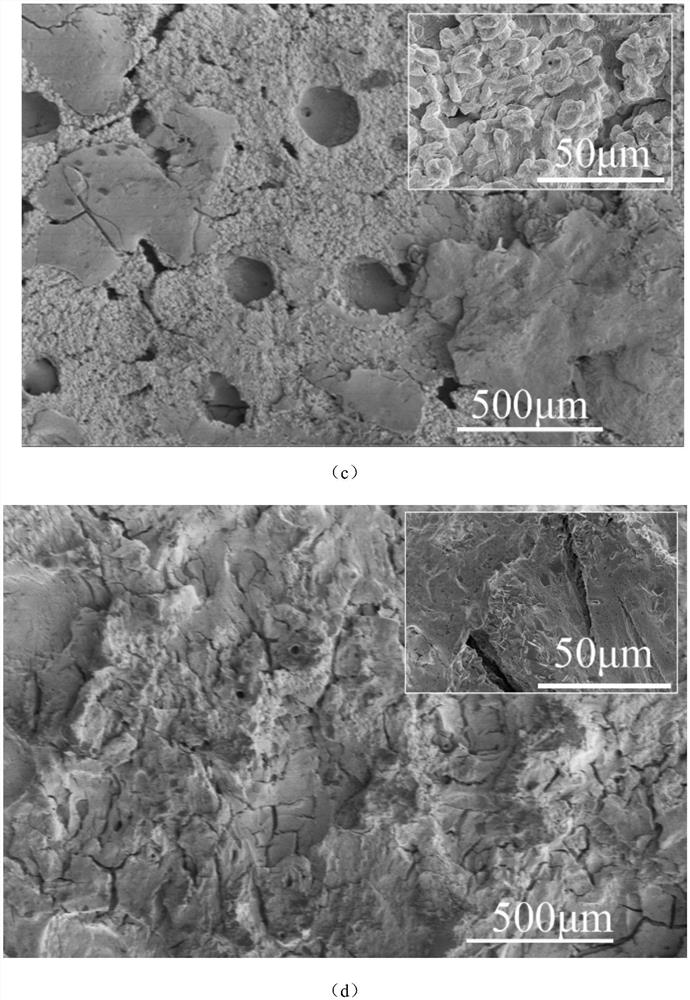

A kind of adsorption type bone apatite and its preparation method and application

ActiveCN110841588BWide variety of sourcesLarge specific surface areaOther chemical processesWater contaminantsO-Phosphoric AcidEngineering

The invention belongs to the field of environmental protection materials, and specifically relates to an adsorption-type bone apatite and its preparation method and application. During the preparation, the organic matter in the animal bone is removed; the animal bone from which the organic matter has been removed is calcined to obtain the bone apatite; The phosphoric acid solution is used to chemically modify the surface of the bone apatite to obtain the adsorbed bone apatite. The adsorption-type bone apatite of the present invention can be used to adsorb heavy metal ions in industrial sewage, compared with the specific surface area before modification from 47.832 (m 2 / g) increased to 131.566(m 2 / g); in Pb 2+ When the initial concentration is 200mg / L, the removal rate can reach 98.3%. For the initial concentration of 200mg / LZn 2+ 、Cu 2+ Ions, the removal rate can reach more than 70%, and it has good ability to remove heavy metal ions. The invention solves the technical problem of insufficient bone apatite adsorption capacity in the prior art.

Owner:XI AN JIAOTONG UNIV

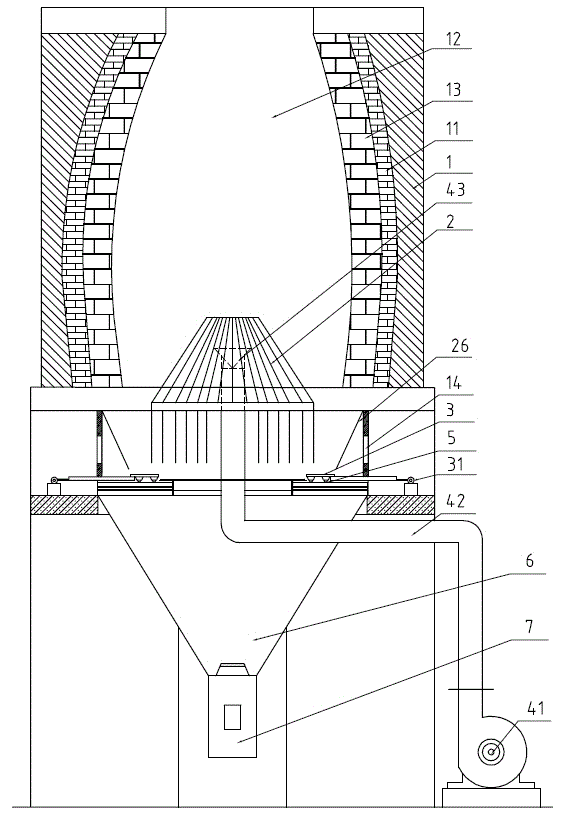

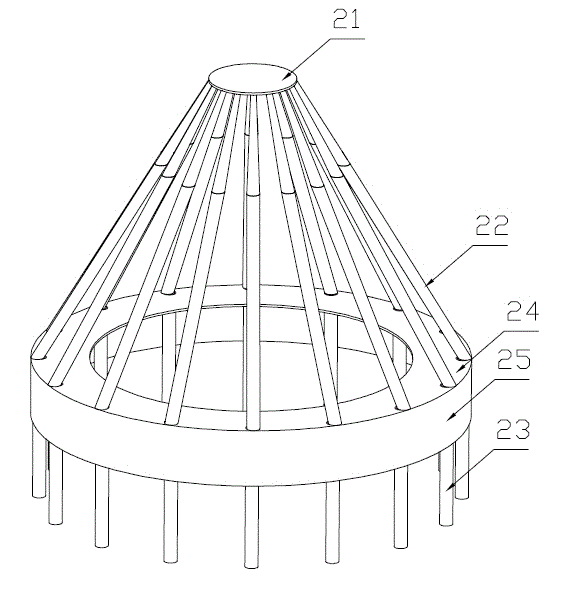

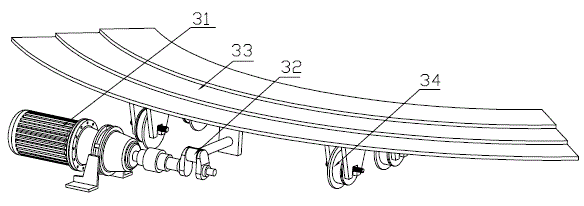

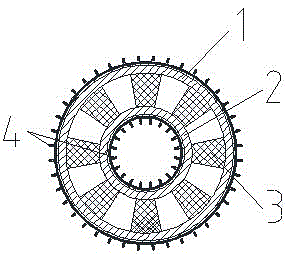

Ring Lime Shaft Kiln

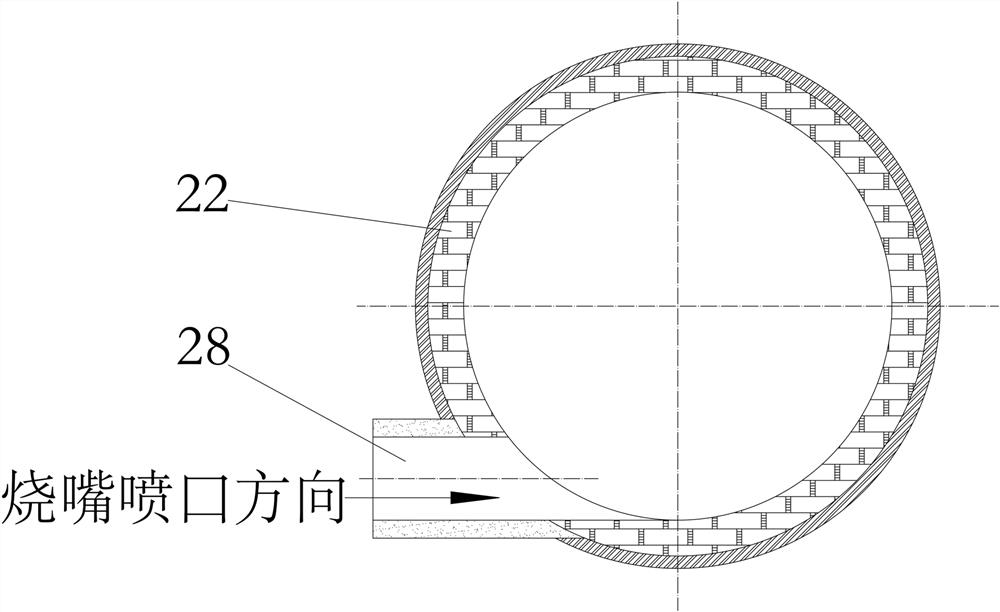

ActiveCN104803618BFacilitate multi-faceted calcinationEvenly distributedLime productionCombustionEngineering

The invention discloses an annular lime shaft kiln. The annular lime shaft kiln comprises kiln bodies, wherein each kiln body consists of an outer ring wall and an inner ring wall, an annular cavity is formed between the inner ring wall and the outer ring wall, lintels through which the outer ring wall and the inner ring wall are connected are arranged in the annular cavity, the annular cavity is divided into a preheating zone, a calcining zone and a cooling zone from up to down, and burner nozzles are respectively arranged at the parts at the calcining zone of the outer ring wall and the inner ring wall; a distribution mechanism is arranged at the upper ends of the annular cavities, a discharging mechanism is arranged at the bottoms of the annular cavities, a feeding mechanism, a combustion supporting mechanism, a cooling mechanism and a waste-gas dust-removal system are arranged on the outer sides of the inner ring walls and the outer ring walls. The annular lime shaft kiln adopts annular structures of the inner ring walls and the outer ring walls, so that the air in the kiln bodies can be uniformly distributed, limestone can be uniformly calcined in a plurality of directions, and the phenomenon that limestone is stuck is avoided; the annular lime shaft kiln has the characteristics of being high in production efficiency, low in energy consumption, environment-friendly, safe in running, simple to operate, small in occupied area, low in investment, and the like.

Owner:山东万方窑炉工程科技有限责任公司

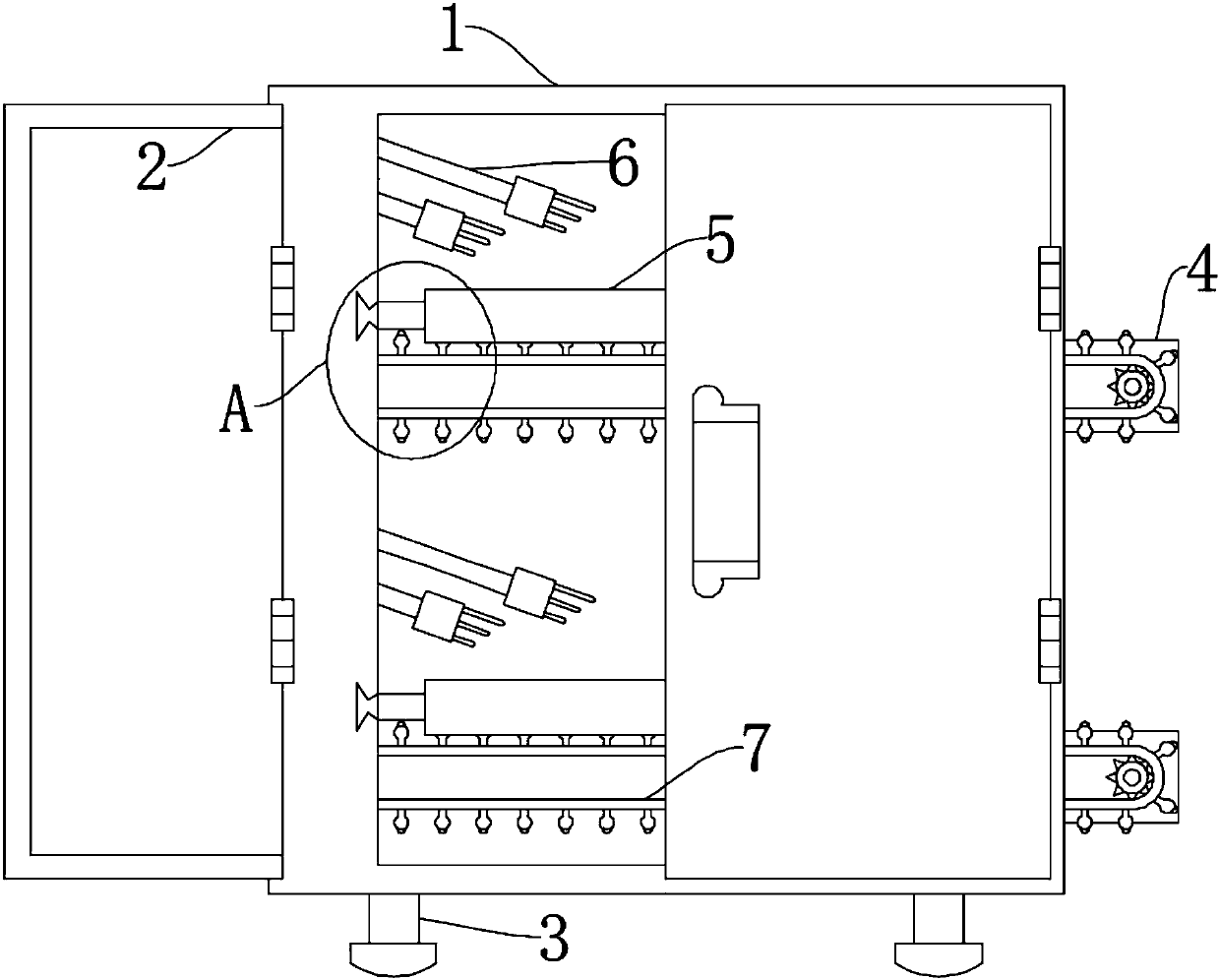

Kiln equipment used for high borosilicate glass pipe and capable of being subjected to convenient cleaning and convenient maintenance

PendingCN110723889AEasy to cleanEasy maintenanceGlass furnace apparatusGlass productionSpray nozzleExhaust fumes

The invention provides kiln equipment used for a high borosilicate glass pipe and capable of being subjected to convenient cleaning and convenient maintenance. The kiln equipment comprises a furnace body, wherein a heat insulation layer is arranged in the furnace body, bases are respectively and fixedly connected to the two sides of the bottom of the furnace body, and a heat insulation plate is slidably connected between the two sides of the bottom of the inner wall of the heat insulation layer. According to the invention, through the heat insulation plate capable of being pulled out of the furnace body, the maintenance worker can enter the furnace body to perform detection and maintenance so as to conveniently clean the interior; through the placing frame, different heights can be adjusted according to different production requirements so as to adapt to different types of glass pipes; incompletely-combusted waste gas and black ash in a combustion process can be treated through the waste gas treatment device; and the material can uniformly calcined through the multiple spraying nozzles arranged in the furnace body so as to improve the production efficiency.

Owner:YANGZHOU FENGZE SPECIAL CABLE MATERIAL

Preparation method of high-purity calcium oxide

PendingCN111573705AHigh purityHigh yieldMaterial nanotechnologyCalcium/strontium/barium oxides/hydroxidesCalcium hydroxidePolyvinyl alcohol

The invention provides a preparation method of high-purity calcium oxide. Calcium hydroxide is produced by using raw materials with extremely high calcium oxide content, the dispersity of calcium ionsis improved by using stearic acid and polyvinyl alcohol 124, and the crystal form and the particle size of the calcium ions are controlled so that calcium hydroxide solids are high in fineness and good in dispersity, and finally, calcium oxide with high purity and good dispersity is prepared through high-temperature calcination. Calcium hydroxide with good dispersity can be better and more uniformly calcined at high temperature so that the production efficiency is improved, the yield of waste gas CO2 is reduced, and the cost of subsequent treatment is reduced. The method is simple in process,safe, environmentally friendly and high in production efficiency, and the prepared calcium oxide product is high in purity and good in dispersity.

Owner:NANNING XIAYANG CHEM TECH CO LTD

Intensifier for adjusting congelation of cement prepared from ardealite

This invention relates to a method for producing cement thickening control enhancer for cement from phosphogypsum. The method comprises: mixing phosphogypsum with lime and limestone, pressing, calcining at 800-1000 deg.C to obtain a semi-product, and mixing with grinding aid to obtain the product. The method has such advantages as simple process, reasonable formula, and low cost. The cement thickening control enhancer can control the thickening time of cement, increase the strength of cement, increase the doping amounts of mixed materials in cement, decrease the consumption of cement clinker, save energy and resources, and increase profit.

Owner:UNIV OF JINAN

Antibacterial wear-resistant transparent glaze

The invention mainly relates to the technical field of ceramic glaze processing,and discloses an antibacterial wear-resistant transparent glaze. The glaze is prepared from 35-37 parts of feldspar,24-26 parts of dolomite,21-23 parts of talcum,20-22 parts of limestone,17-19 parts of phlogopite,4-6 parts of niobium pentoxide and 3-5 parts of anatase titanium dioxide. The antibacterial wear-resistanttransparent glaze is bright,transparent and light yellow in luster,has relatively good antibacterial property and wear resistance,can effectively avoid color changing and scratches of ceramic productsin the use process,keeps the ceramic products attractive,and prolongs the service life of the ceramic products. The phlogopite is crushed and added into a sodium carbonate solution,and the mixture isfrozen and then subjected to high-temperature calcination,so that combination of sodium carbonate and phlogopite particles is promoted,the alkali resistance and wear resistance of phlogopite are improved,the elasticity and the sliding property are reduced,then the transparent glaze can be tightly attached to ceramic,the sintering temperature after glazing is reduced,and a large amount of energy is saved.

Owner:合肥汉甲陶瓷科技有限公司

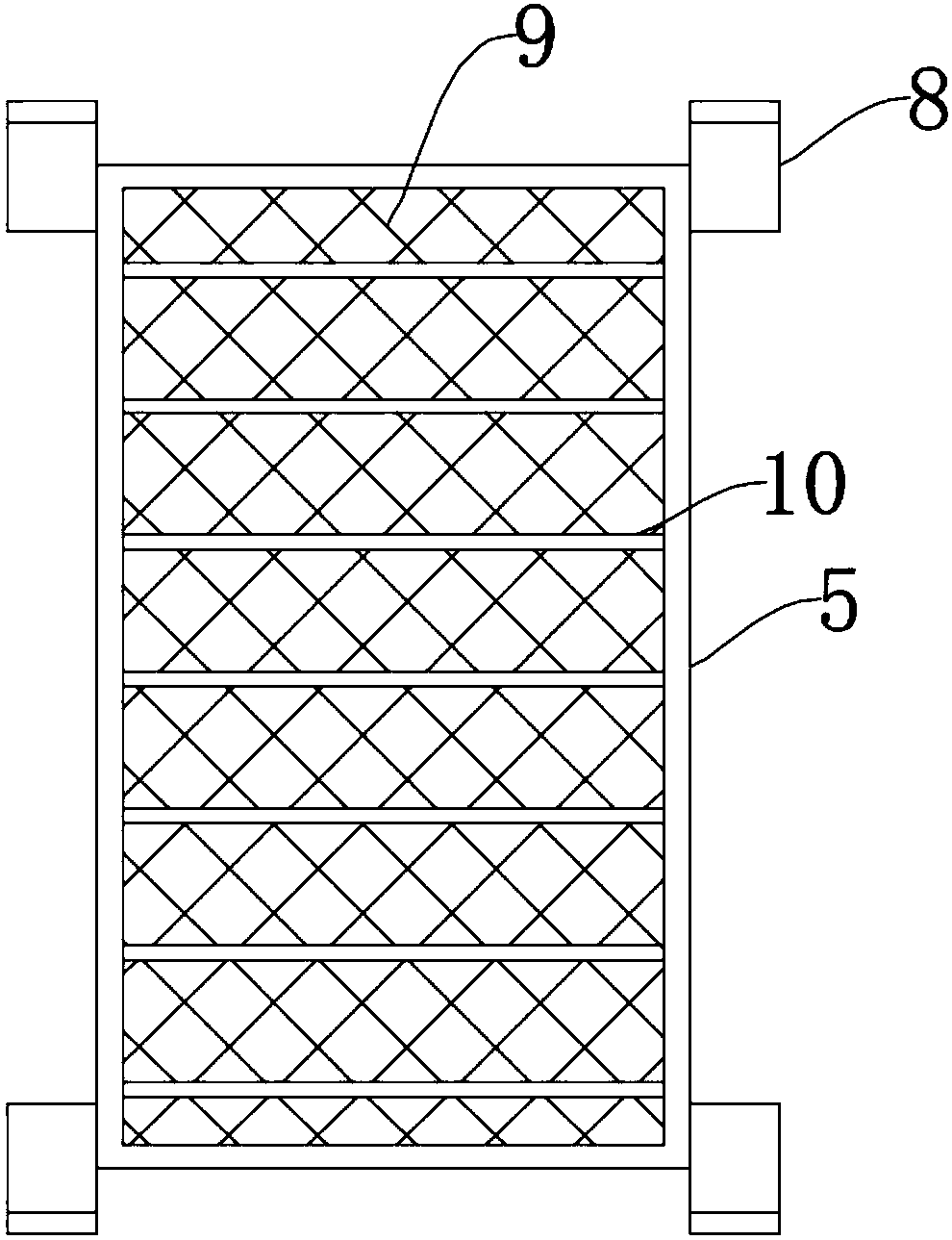

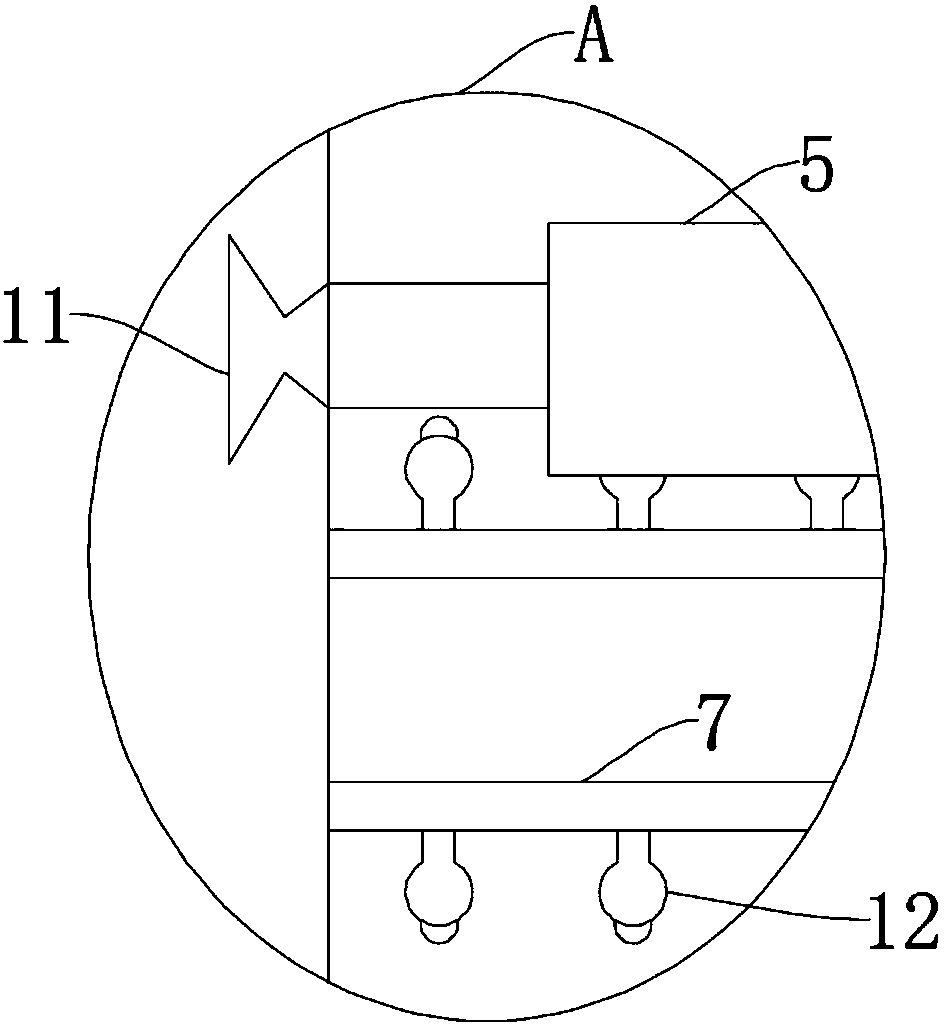

High-temperature calcining apparatus for preparing food-grade tricalcium phosphate

InactiveCN110540181ACalcined evenlySimple structurePhosphorus compoundsAlpha-tricalcium phosphateEngineering

The invention discloses a high-temperature calcining apparatus for preparing food-grade tricalcium phosphate. The high-temperature calcining apparatus comprises a calcining work chamber, calcining pipes and a shelving device. According to the invention, one ends of the calcining pipes are fixed to the inner wall of the calcining work chamber, the other ends of the calcining pipes are inclined towards movable plates, and altogether four calcining pipes are symmetrically arranged relative to the movable plates, so the calcining pipes in the structure of the apparatus can realize more uniform calcining of the movable plates; two shelving frames are arranged along the longitudinal direction of the calcining work chamber, the calcining work chamber is provided with sliding chutes correspondingto fixed sliding blocks, and the fixed sliding blocks are slidably connected with the sliding chutes, so the structure is simple and clear, and has high practicability; and the movable plates and movable rods are movably connected with the shelving frames, the movable rods are fixed to the lower end faces of the movable plates, and fixed protruding blocks are elastically connected with conveying belts through torsional springs and are movably connected with the movable rods, so the movable plates in the novel structure can be jacked up rhythmically, and better calcining effect is obtained.

Owner:SUQIAN MODERN CHEM

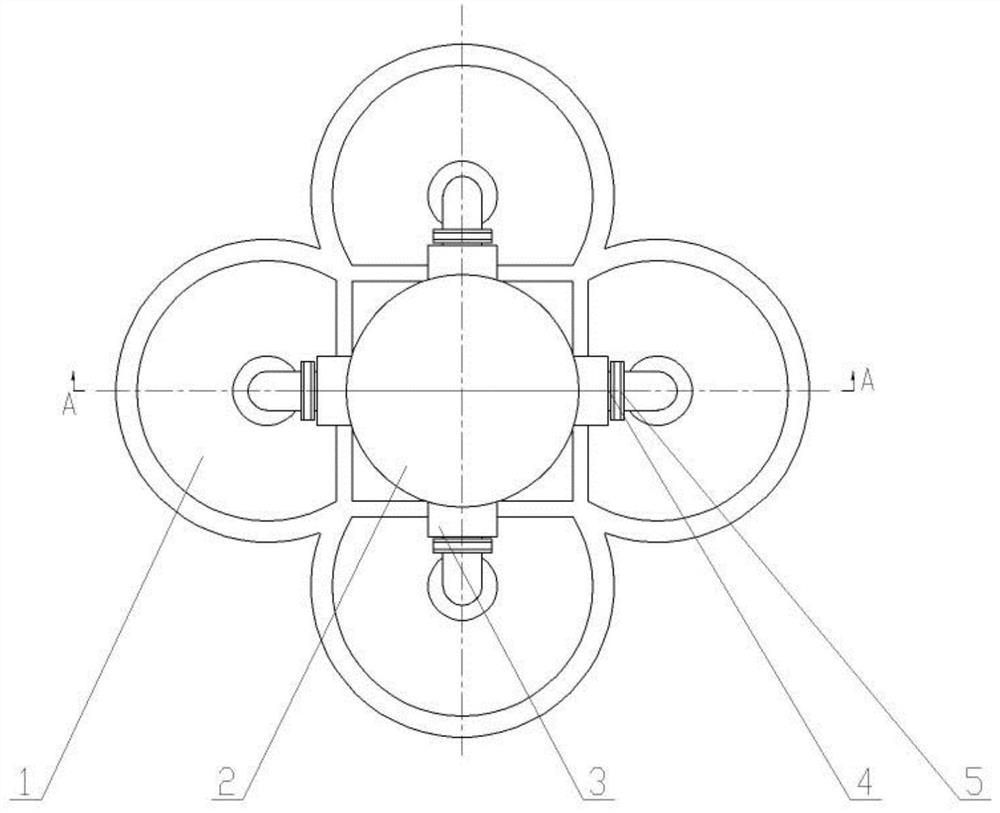

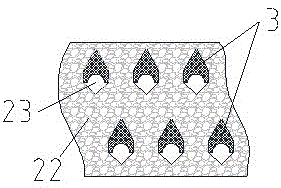

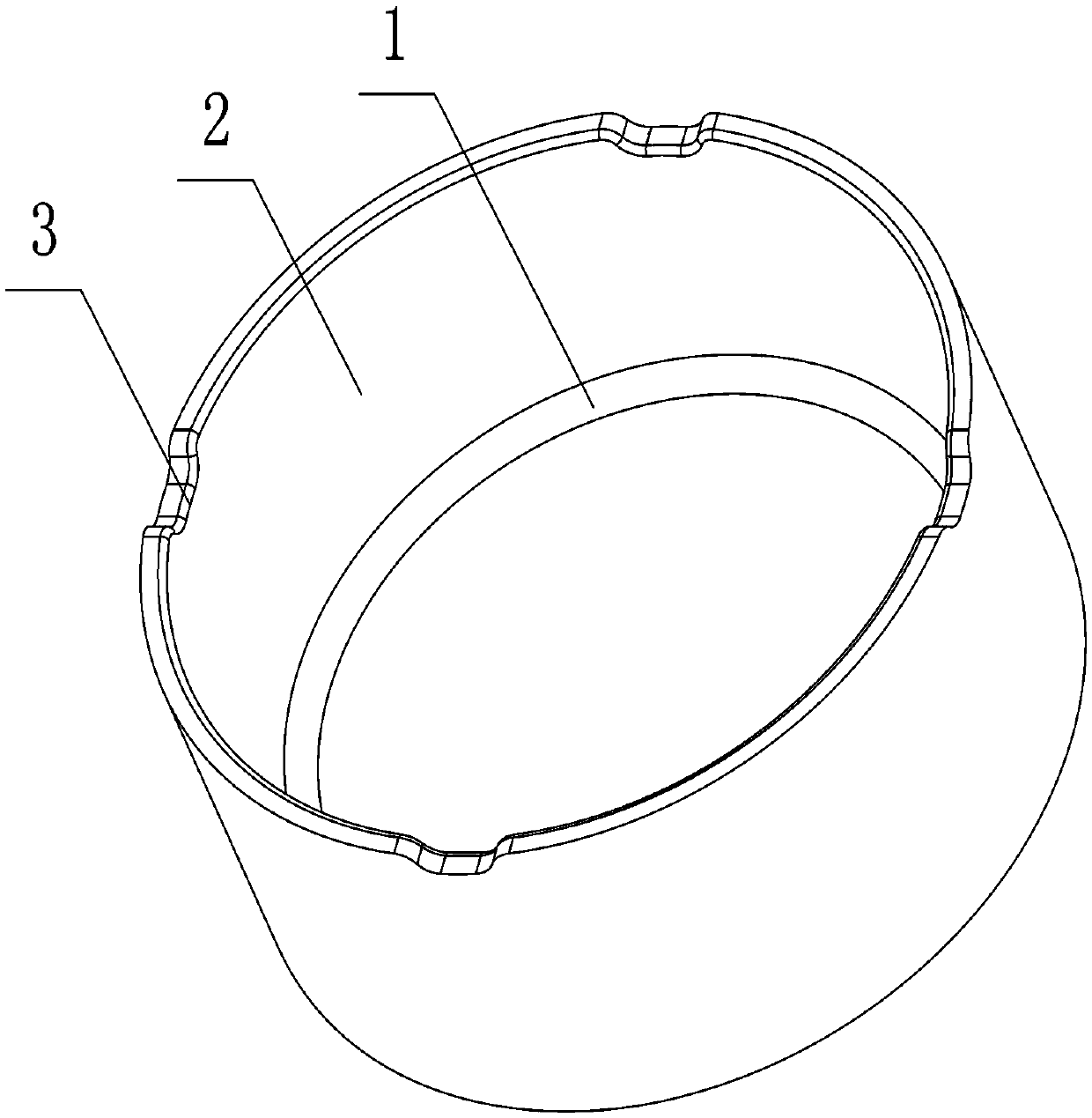

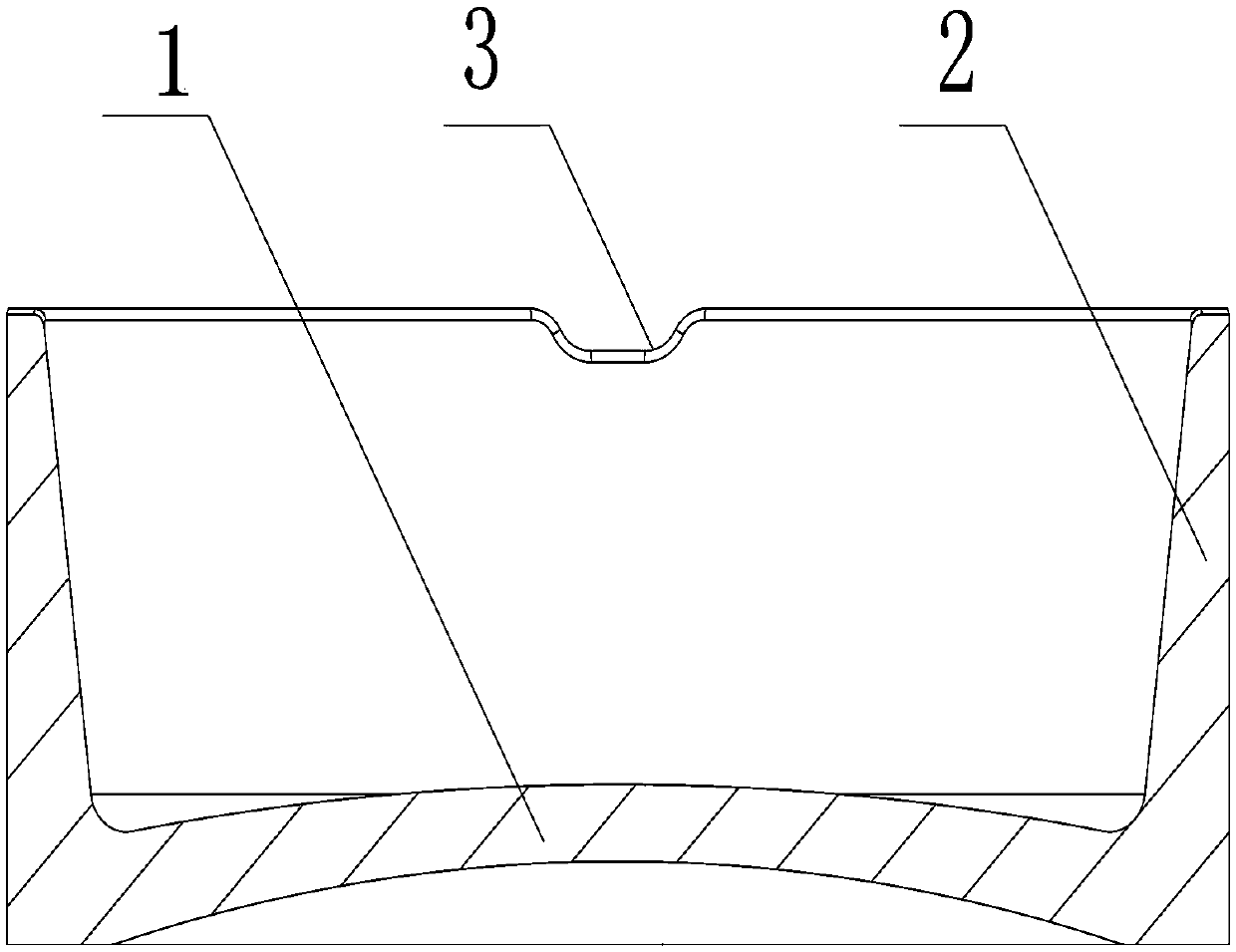

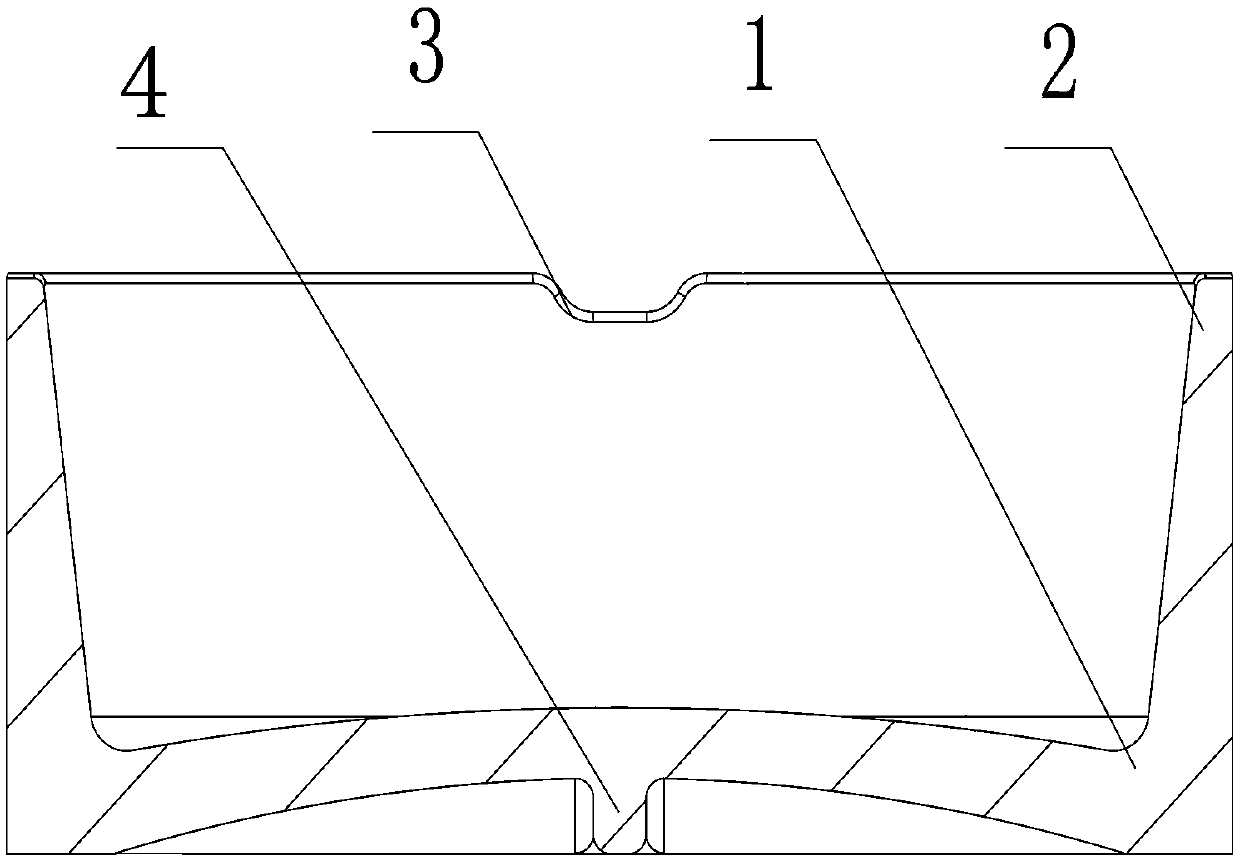

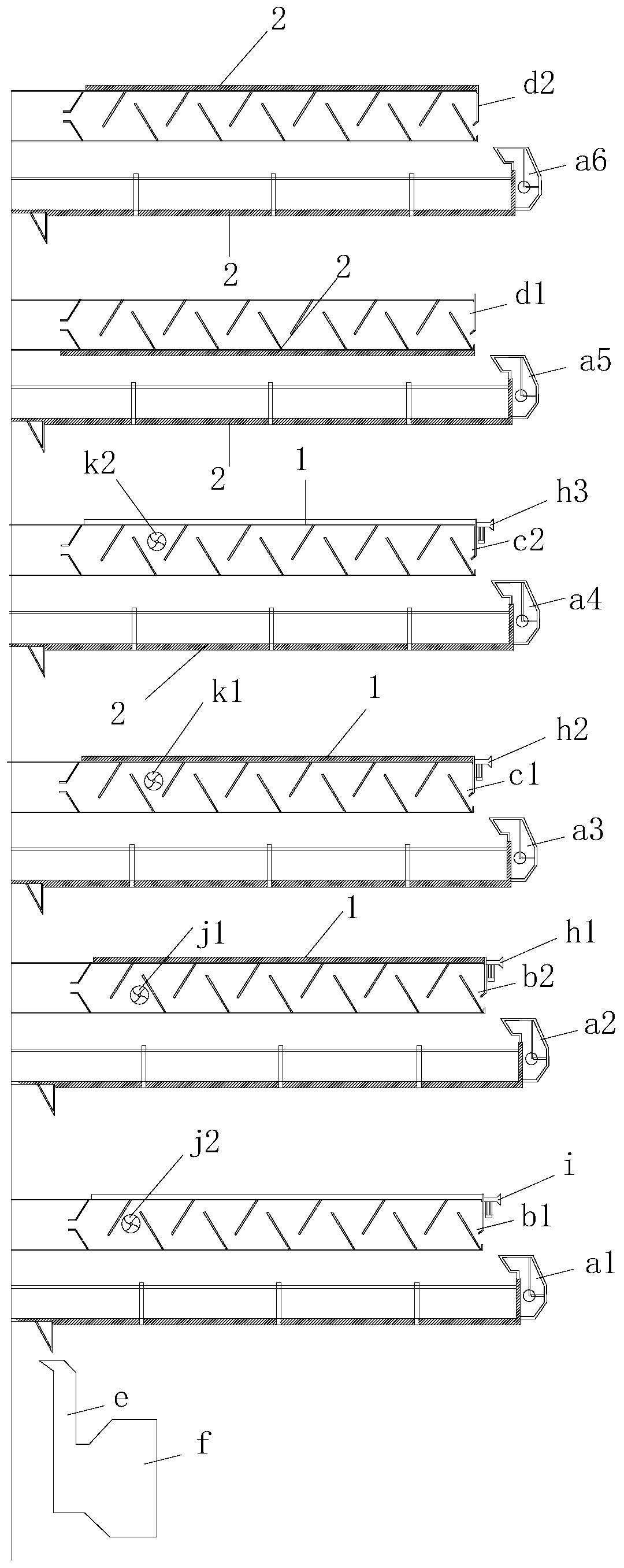

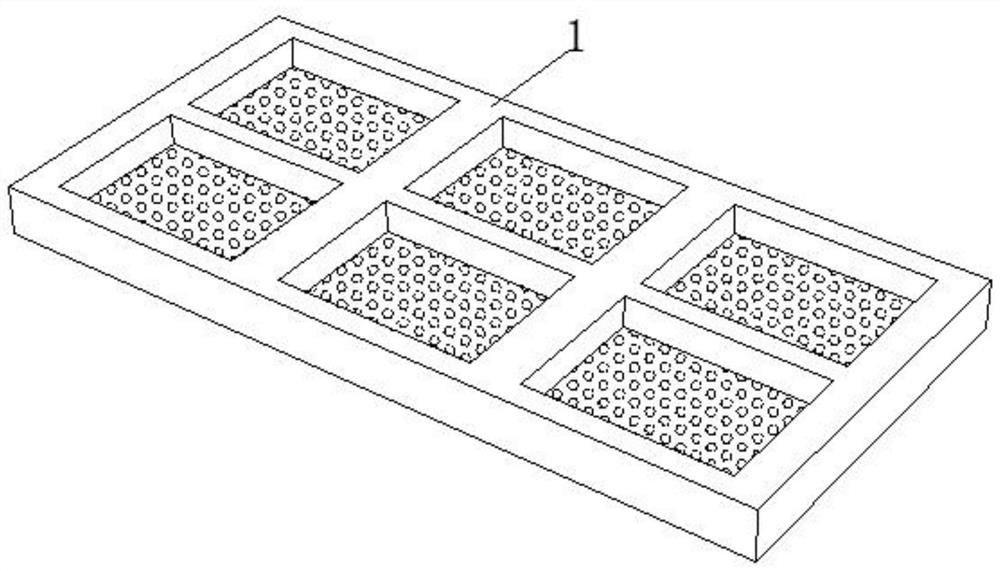

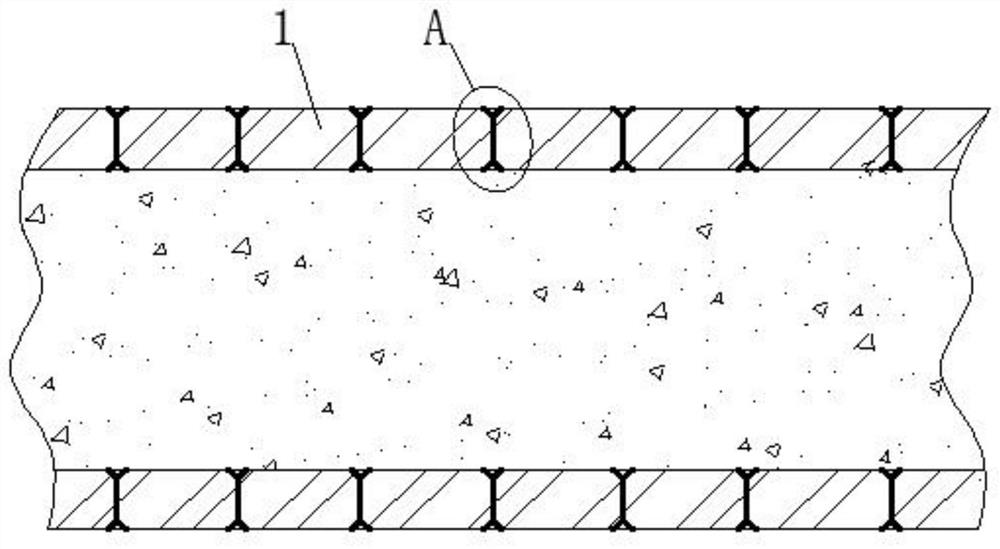

Saggar and method for producing abrasive material through saggar

The invention provides a saggar. The saggar is provided with a saggar base (1) and a saggar wall (2), wherein the saggar base (1) is provided with an upward groove, two or more air holes (3) are uniformly formed in the top of the saggar wall (2), and therefore the ability of the saggar to resist deformation at high temperature is improved, and the heat conduction and air permeation performance of material in the saggar is improved through the structure. The invention further provides a method for producing abrasive material through the saggar. The method comprises the steps of loading the abrasive material into the saggar, stacking the saggar on a kiln car for high-temperature calcination, cooling the abrasive material to the indoor temperature and then obtaining finished products of the abrasive material. The method has the advantages that the process is simple, the energy consumption is small, and the strength and the machinability of the abrasive material are improved.

Owner:ZHENGZHOU HONGJI ABRASIVE TECH CO LTD

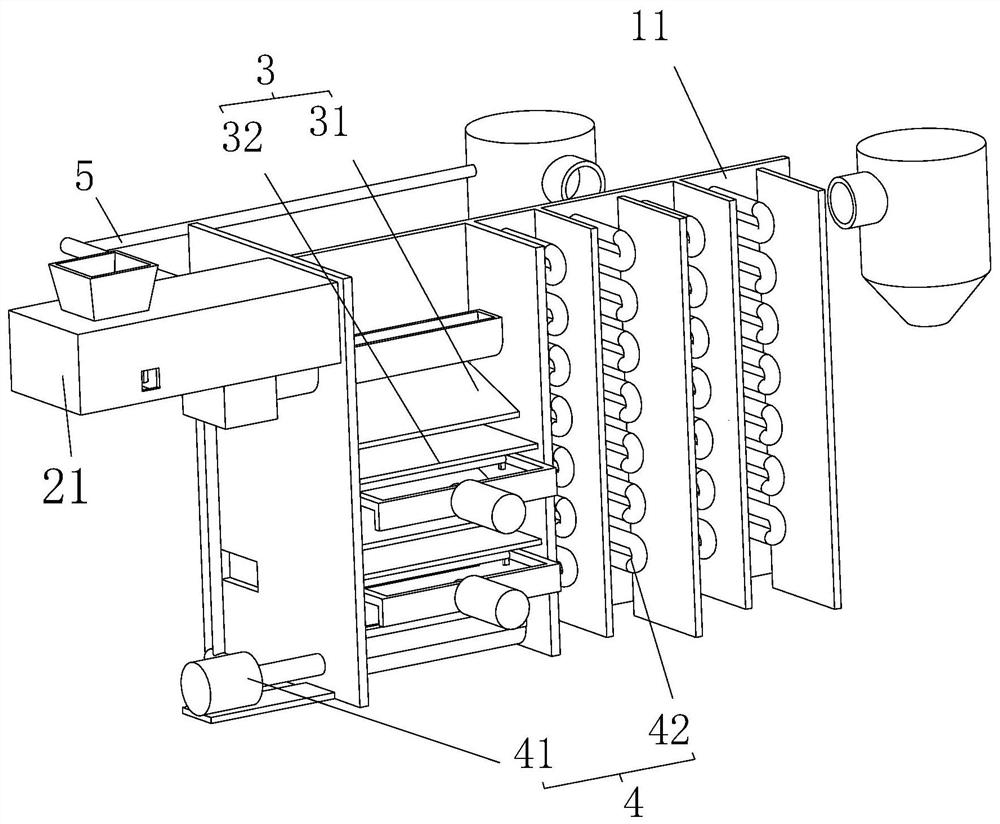

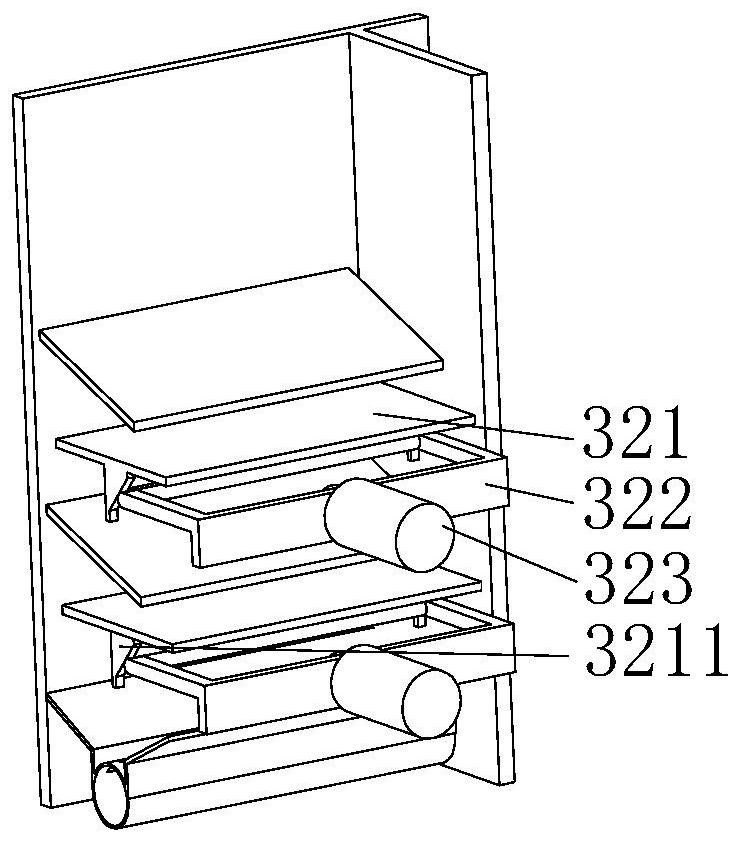

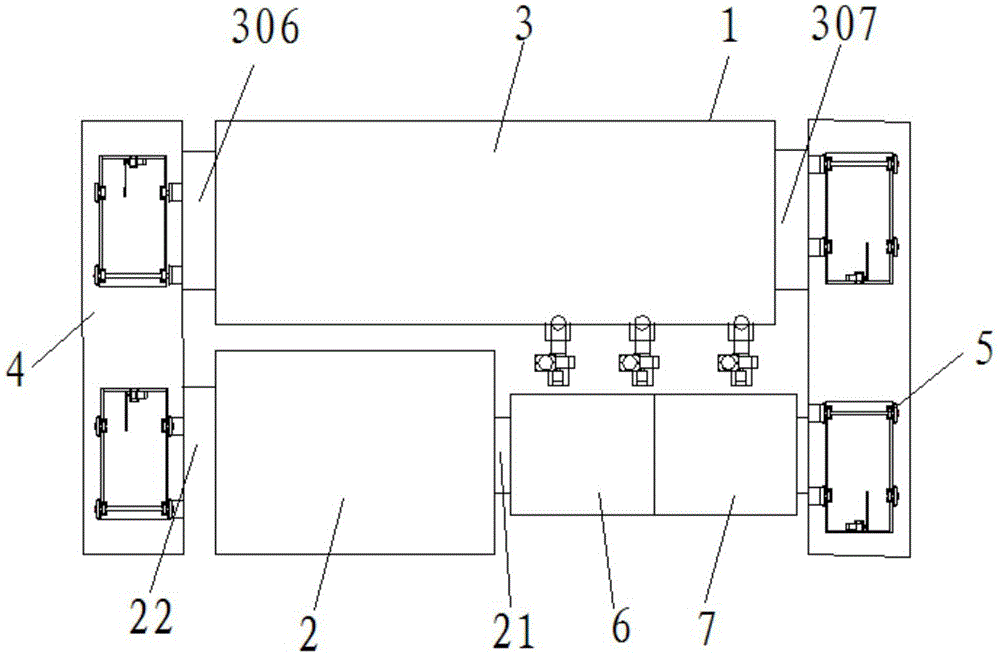

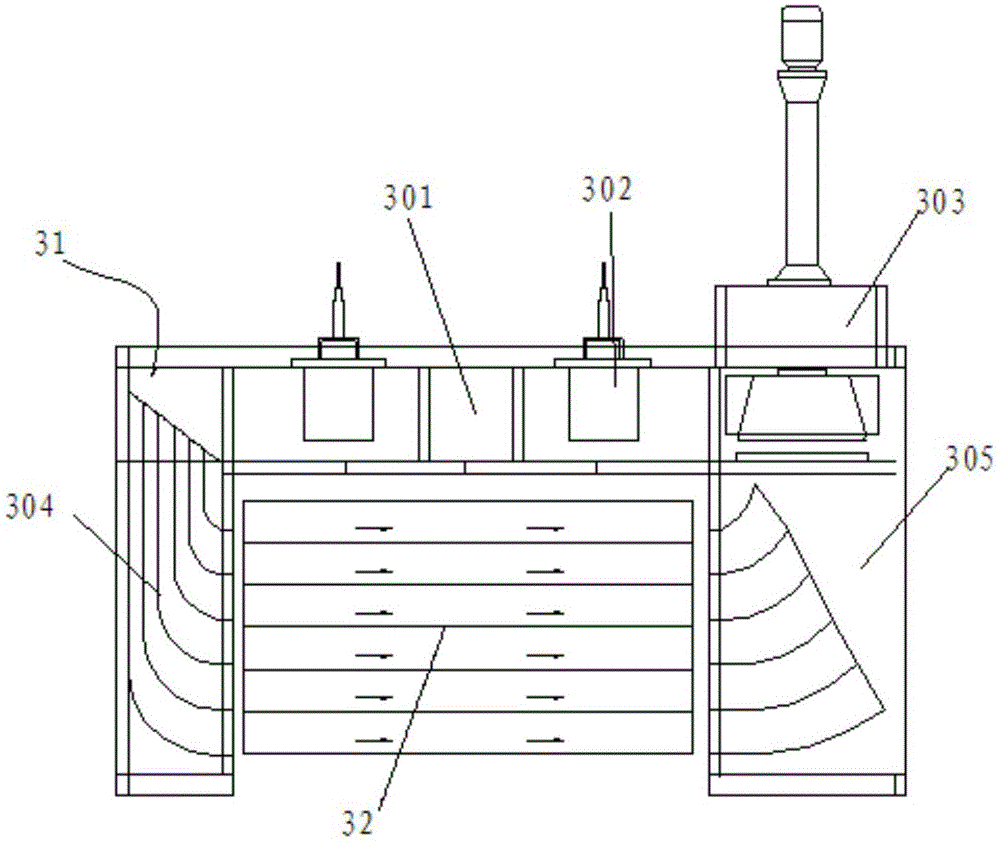

Three-dimensional dynamic turn-back flow preheating, drying and calcining system

PendingCN110879008ACalcined evenlyReduce manufacturing costFurnace typesHandling discharged materialHot blastExhaust gas

The invention discloses a three-dimensional dynamic turn-back flow preheating, drying and calcining system. A first preheater is arranged on the side edge of a first elevator, a second preheater is arranged on the side edge of a second elevator, a first calcinator is arranged on the side edge of a third elevator, a second calcinator is arranged on the side edge of a fourth elevator, a first cooleris arranged on the side edge of a fifth elevator, a second cooler is arranged on the side edge of a sixth elevator, a feeding port of the first elevator is connected to a stock bin through an auger,a first high-temperature heating source is arranged on a middle machine body of the first calcinator, a second tail gas hot air outlet is formed in the rear end of the first calcinator, a second high-temperature heating source is arranged on a middle machine body of the second calcinator, and a third tail gas hot air outlet is formed in the rear end of the second calcinator. A three-dimensional inclined plate turn-back flowing process is adopted, so that the preheating, drying and calcining time of the materials can be ensured. Meanwhile, no power exists in the turn-back flow process, the natural flow process can guarantee uniform material calcination, the production cost is saved, and automatic production can be achieved.

Owner:营口仁和昌顺耐火材料有限公司

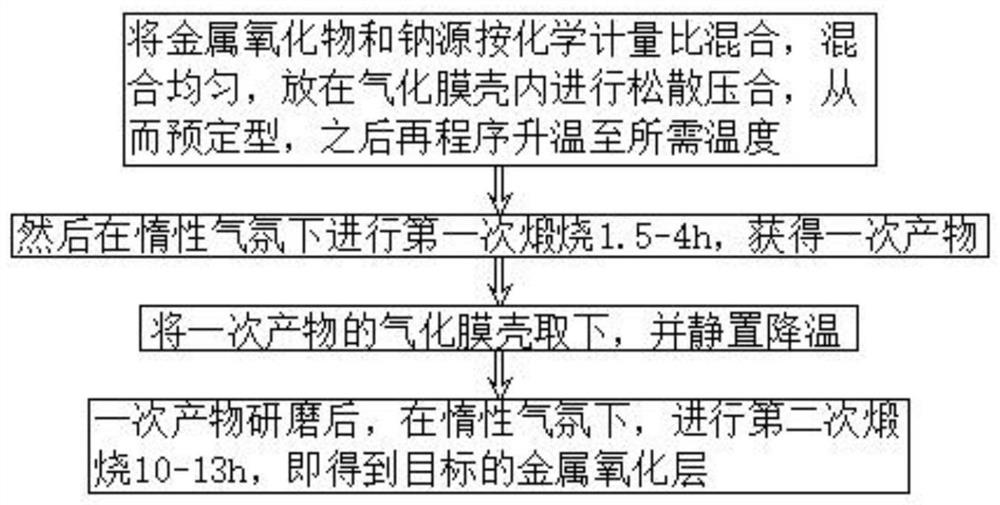

A kind of preparation method of metal oxide layer on the electrolyte surface of sodium battery

ActiveCN110416601BGuaranteed clearanceCalcined evenlySecondary cellsElectrical batteryPhysical chemistry

Owner:钠悦新能源(上海)有限公司

A lithium-ion battery nickel-cobalt lithium manganate positive electrode material and preparation method thereof

ActiveCN104810520BImprove performanceUniform shapeElectrode thermal treatmentSecondary cellsElectrical batteryManganate

The invention discloses a lithium-ion battery nickel-cobalt-lithium-manganese-oxide positive electrode material and a preparation method thereof, belonging to the technical field of preparation of lithium-ion battery positive electrode materials. The preparation method comprises the following steps: 1, lithium salt, nickel salt, cobalt salt And dissolving the manganese salt in a solvent to obtain a first solution, wherein 0<x<1, 0<y<1; 2, adding a chelating agent and a carbon source to the first solution, and mixing them uniformly to obtain a second solution; 3 , to obtain the precursor powder after removing the solvent in the second solution; 4. In an inert gas atmosphere, first heat the precursor powder at a temperature of 300-400° C. for 0.5-2 hours, and then use infrared light to As a heat source, the temperature of the precursor powder is raised to 800-900° C., and the temperature is kept for 3-4 hours; after cooling, the lithium-ion battery nickel-cobalt-lithium-manganese-oxide cathode material is obtained. The obtained nickel-cobalt lithium manganese oxide cathode material has regular shape and uniform size; meanwhile, heating time is shortened, energy is saved, and cost is reduced.

Owner:CHERY AUTOMOBILE CO LTD

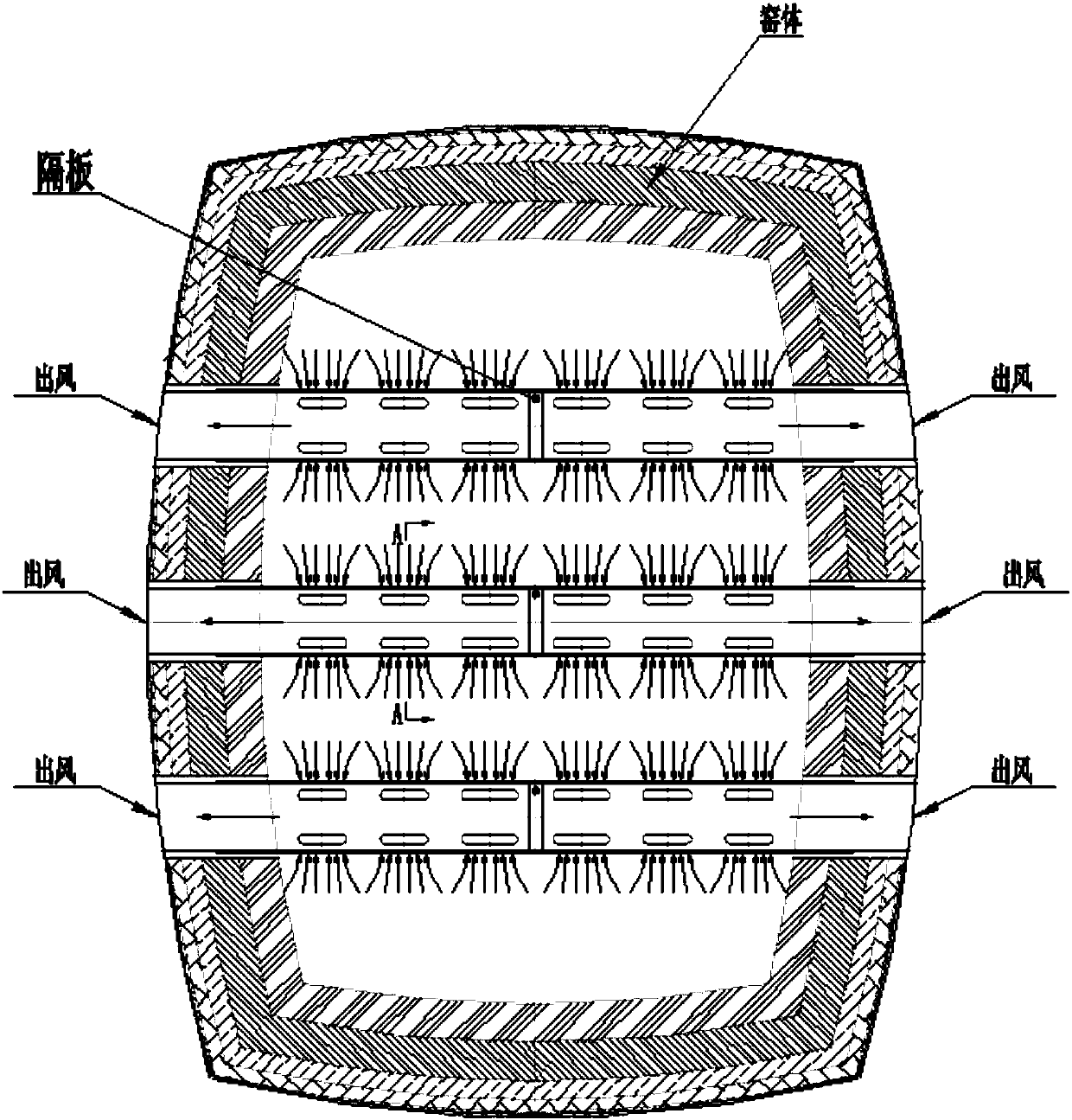

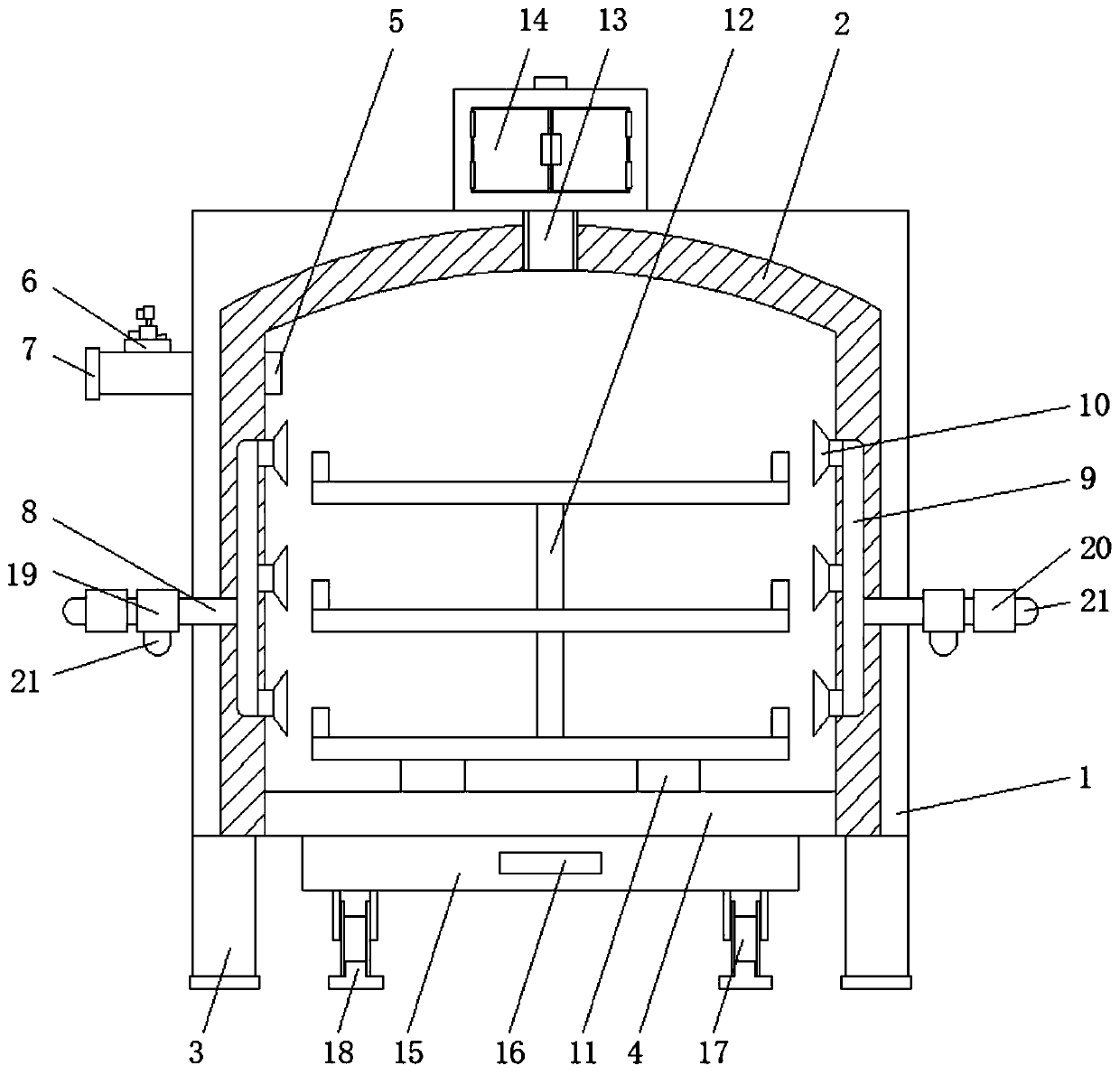

Catalyst regeneration furnace

InactiveCN105126932ACalcined evenlyHigh regeneration rateCatalyst regeneration/reactivationProcess engineeringAutomation

A provided catalyst regeneration furnace comprises a furnace body, a material transportation vehicle return system, and a drying area and a calcining area arranged in the furnace body; the drying area and the calcining area are two mutually independent areas through a transition area; and the calcining area comprises a circulation wind inner container and a hearth, and the circulation wind inner container comprises a circulation wind channel, a heater arranged in the circulation wind channel and a circulation fan. By arranging the circulation wind inner container in the calcining area, heat generated by the circulation wind inner container can be fully contacted with a catalyst, so that the catalyst can be uniformly heated and calcined, and the catalyst is high in regeneration rate and high in catalytic activity. The disclosed catalyst regeneration furnace solves the problems that a conventional catalyst regeneration furnace is complex in regeneration process and generates corrosive gases, also realizes whole-course automation control and simplifies operator work.

Owner:SHIJIAZHUANG DAFENG FURNACE

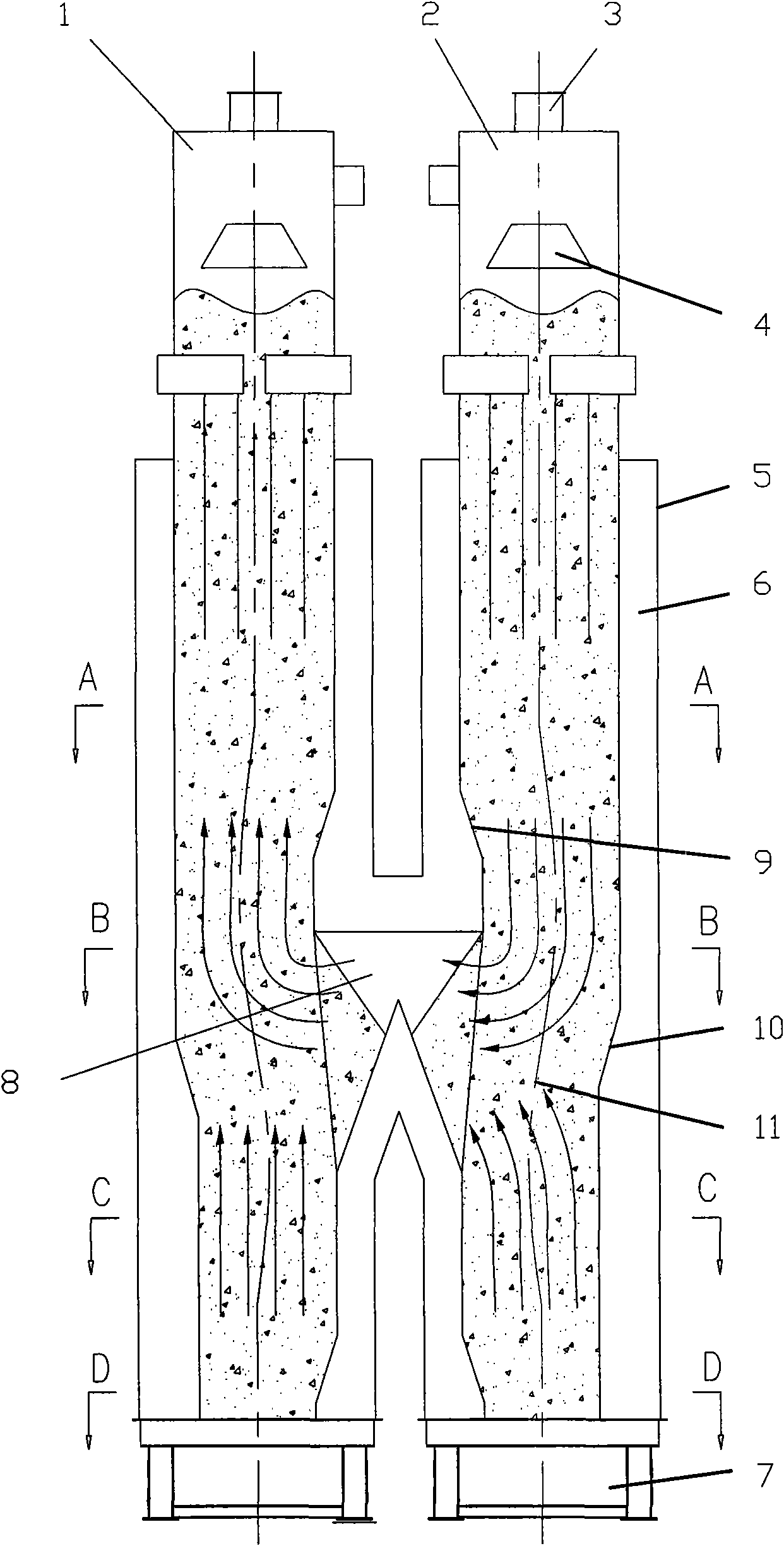

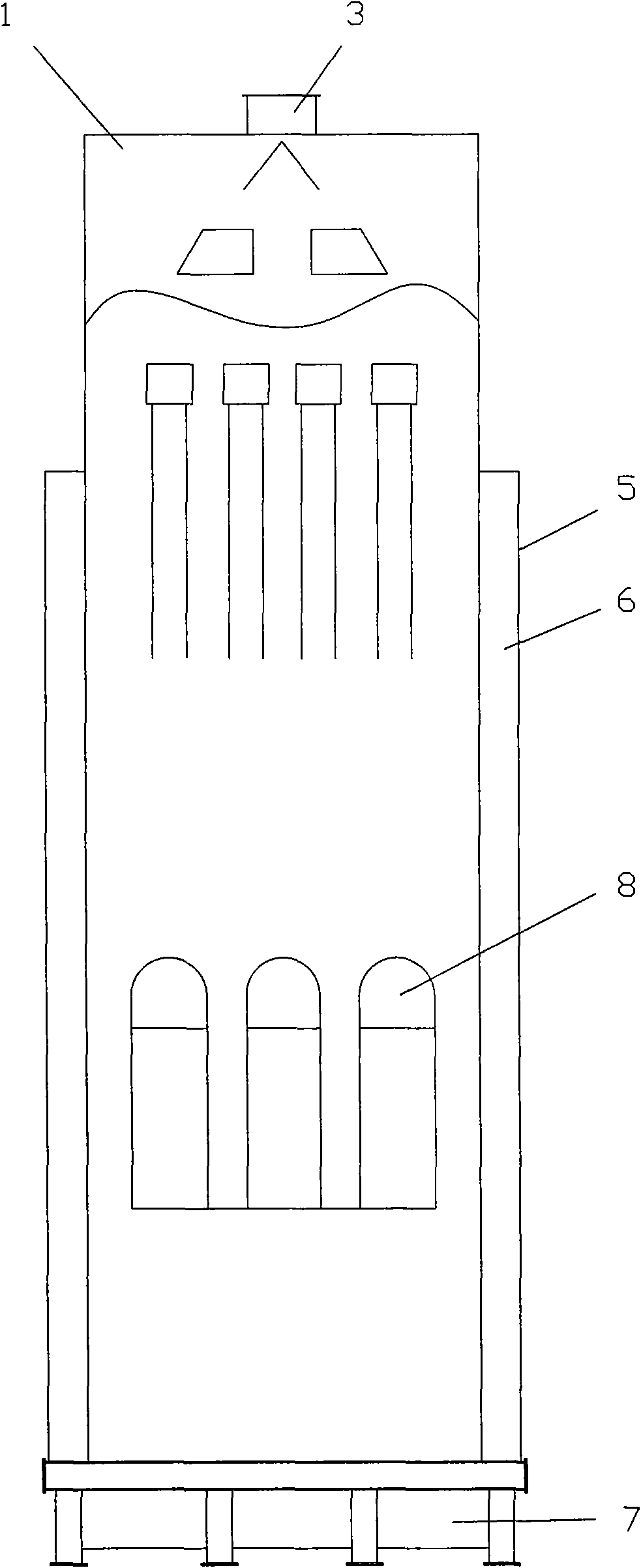

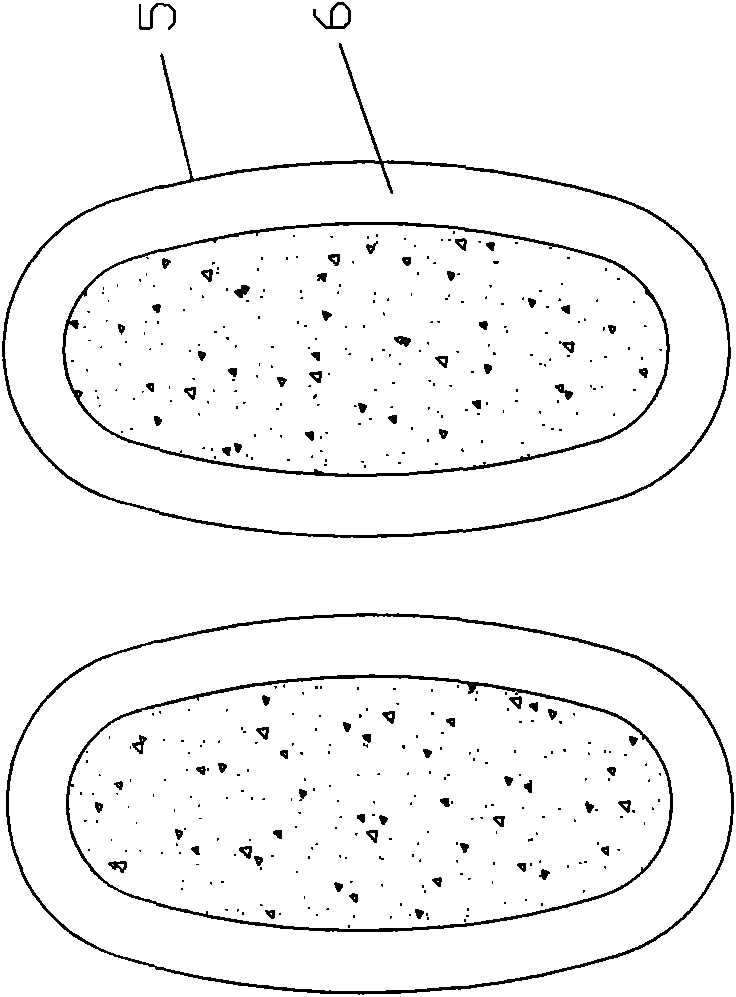

Curved-chamber kiln

The invention relates to a curved-chamber kiln, in particular to the curved-chamber kiln for calcining massive ore such as limestone, dolomite and the like. The curved-chamber kiln comprises two kilncylinders, each kiln cylinder comprises a feeding device, a fuel spraying gun, a kiln shell, a bricklaying layer and a discharging device from top to bottom, the two kiln cylinders are connected by asmoke channel, and the curved-chamber kiln is characterized in that the cross section of each bricklaying layer of each kiln cylinder is oblate; the upper insides of the smoke channel in the middle part of the kiln cylinders are respectively provided with an outward guiding wind slope, and the lower outsides of the smoke channel in the middle part of the kiln cylinders are respectively provided with an inward dragging wind slope; and the kiln cylinders between the guiding wind slopes and the dragging wind slopes become narrow in the left-right direction. The curved-chamber kiln has the advantages of small cavity width, good calcining quality and easy operation.

Owner:XINXING HEBEI ENG & RES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com