Five-section-type caustic calcined magnesite energy saving and environmental protection shaft kiln

An energy-saving, environmentally friendly, light-burning magnesium technology, applied in vertical furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as lowering the average grade, uneven heating of materials, waste, etc., to promote continuous decomposition, uniform calcination, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

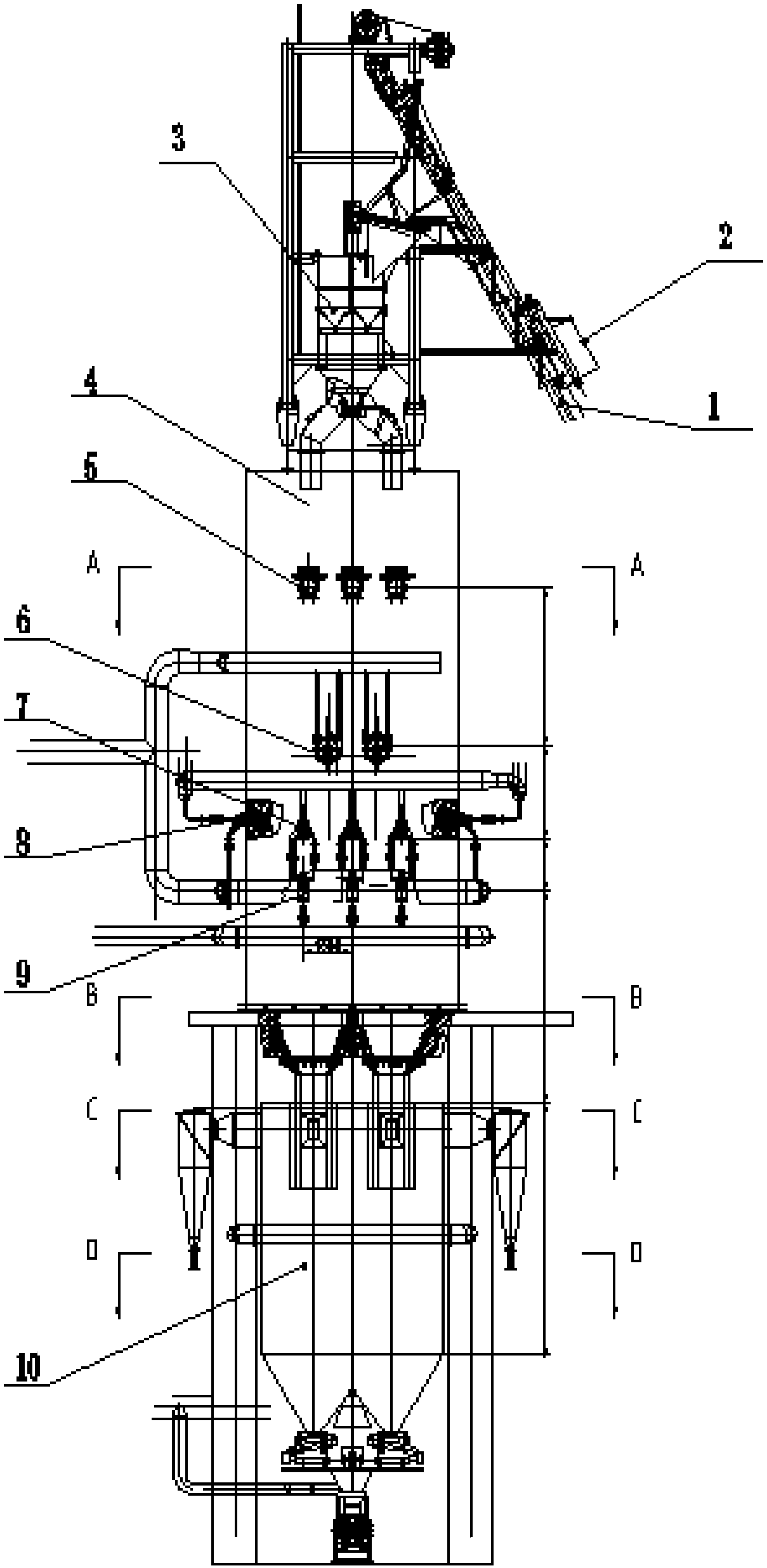

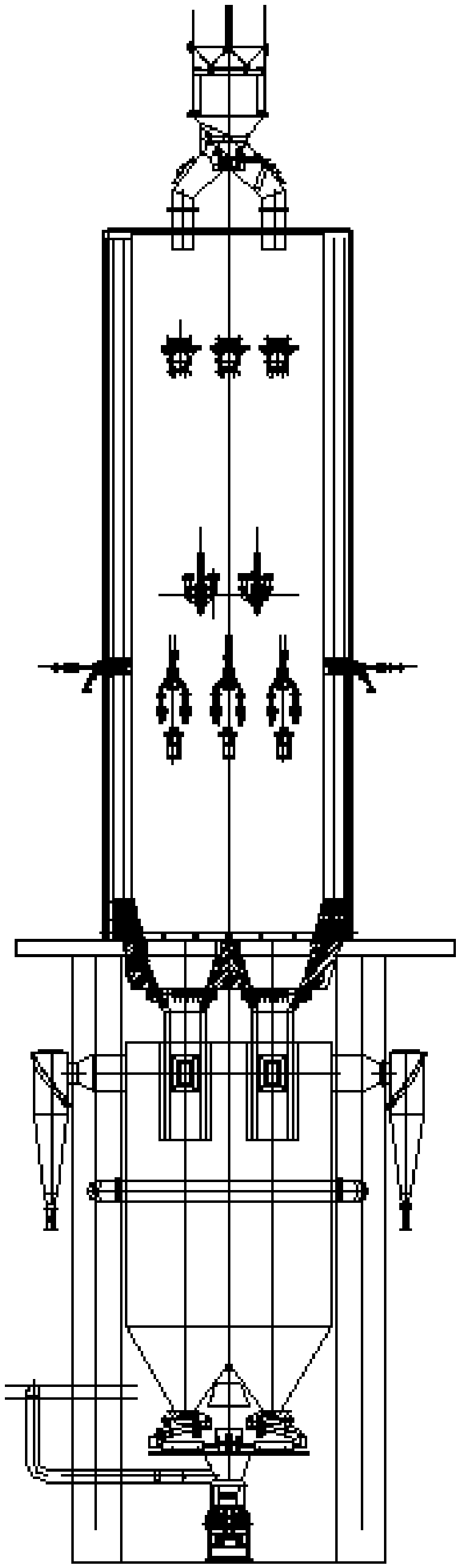

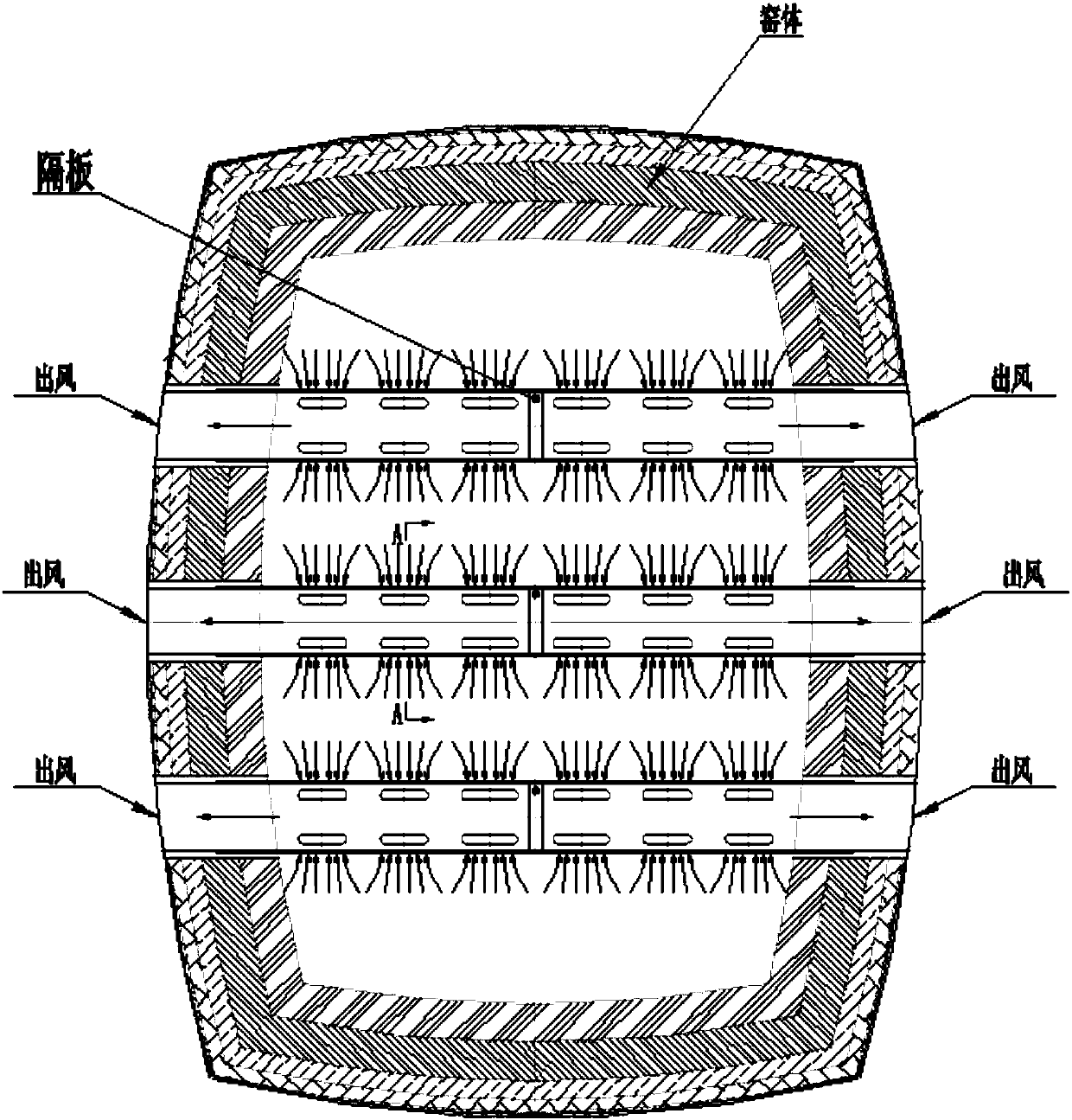

[0037] The invention provides a five-stage light-burned magnesium energy-saving and environment-friendly vertical kiln, which is characterized in that: the five-stage light-burned magnesium energy-saving and environment-friendly vertical kiln includes five thermal sections from top to bottom, The sequence is preheating decomposition zone, calcining zone, post calcining zone, heat preservation zone, cooling separation zone;

[0038] Kiln upper balanced exhaust regulator 5; secondary combustion air distributor 9; cooling separator 10. The preheating decomposition zone is between the balanced exhaust air conditioner 5 and the burner 6; the calcination zone is between the burners 6 and 7; the post-calcination zone is between the burner 7 and the secondary combustion air distributor 9 in the lower part of the kiln. room; the post-calcination zone is a heat preservation zone; the lower part of the kiln body is a cooling separation zone.

[0039] The upper part of the kiln is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com