Air volume control method, system and readable storage medium applied to 3D printing

A 3D printing and air volume control technology, applied in the direction of additive processing, etc., can solve the problems of affecting printing quality, unsuitable air volume, workpiece fault, etc., to achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

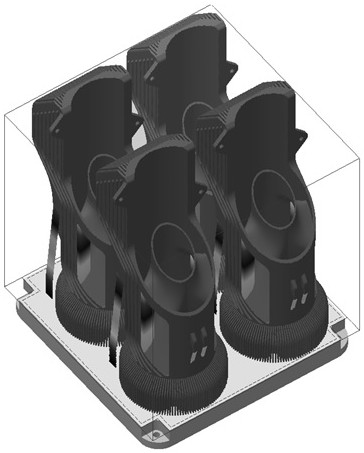

Image

Examples

Embodiment 1

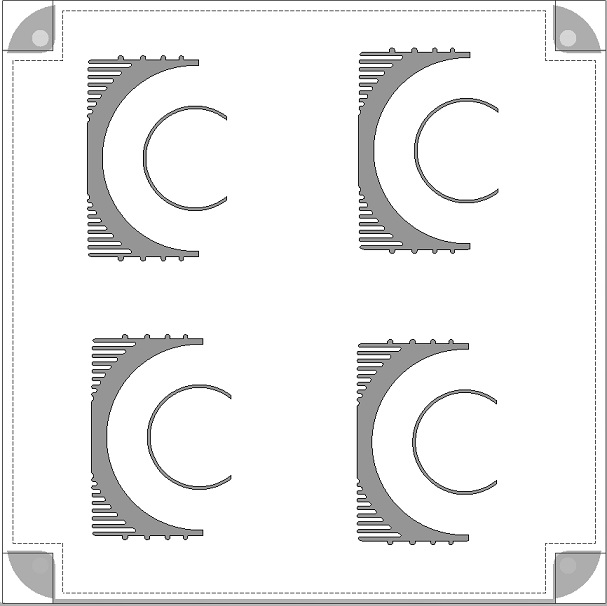

[0079] Such as Figure 6 As shown, the air volume control method applied to 3D printing includes the following steps:

[0080] Step 41, acquiring the current layer image of the working area every 100 milliseconds;

[0081] Step 42, arrange the pixels in the current layer image in an array, and perform trapezoidal correction to restore the distortion caused by the fisheye lens;

[0082] Step 43: Process the pixels from one side of the current layer image row by row or column by row according to the preset direction to obtain an intermediate image, the intermediate image includes all normal pixels and abnormal pixels, and all normal pixels and abnormal pixels pass through two Display after value processing, and remove noise from the intermediate image;

[0083] Step 44: Compare the intermediate image with the theoretical sintered section image, and judge whether there are abnormal pixels in the intermediate image that do not belong to the sintered section, and whether there ar...

Embodiment 2

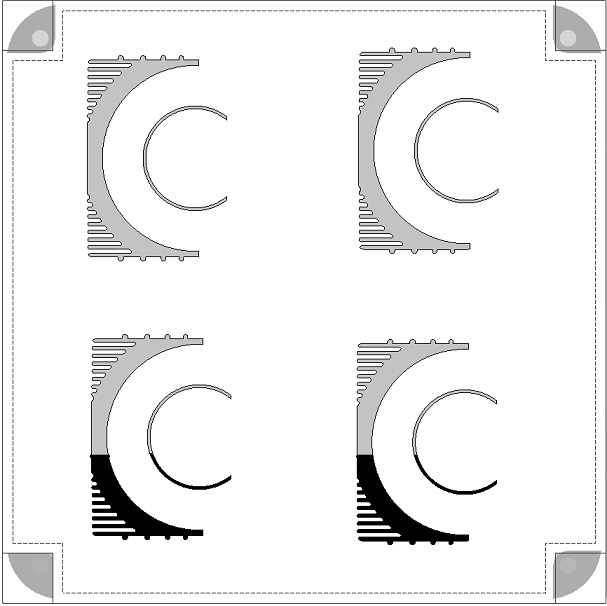

[0090] Such as Figure 7 As shown, the air volume control method applied to 3D printing includes the following steps:

[0091] Step 51, acquiring the current layer image of the working area every 100 milliseconds;

[0092] Step 52, arrange the pixels in the current layer image in an array, and perform trapezoidal correction to restore the distortion caused by the fisheye lens;

[0093] Step 53: Process the pixels from one side of the current layer image row by row or column by row according to the preset direction to obtain an intermediate image, the intermediate image includes all normal pixels and abnormal pixels, and all normal pixels and abnormal pixels pass through two Display after value processing, and remove noise from the intermediate image;

[0094] Step 54: Compare the intermediate image with the theoretical sintered section image, and judge whether there are abnormal pixels in the intermediate image that do not belong to the sintered section, and whether there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com