Four-hearth shaft kiln for dolomite calcination and dolomite calcining method thereof

A dolomite and shaft kiln technology, applied in the direction of shaft furnaces, furnaces, furnace types, etc., can solve the problems of frequent maintenance, low heat utilization rate, greenhouse gas effect, etc., and achieve high space utilization rate, low investment cost, and uniform calcination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

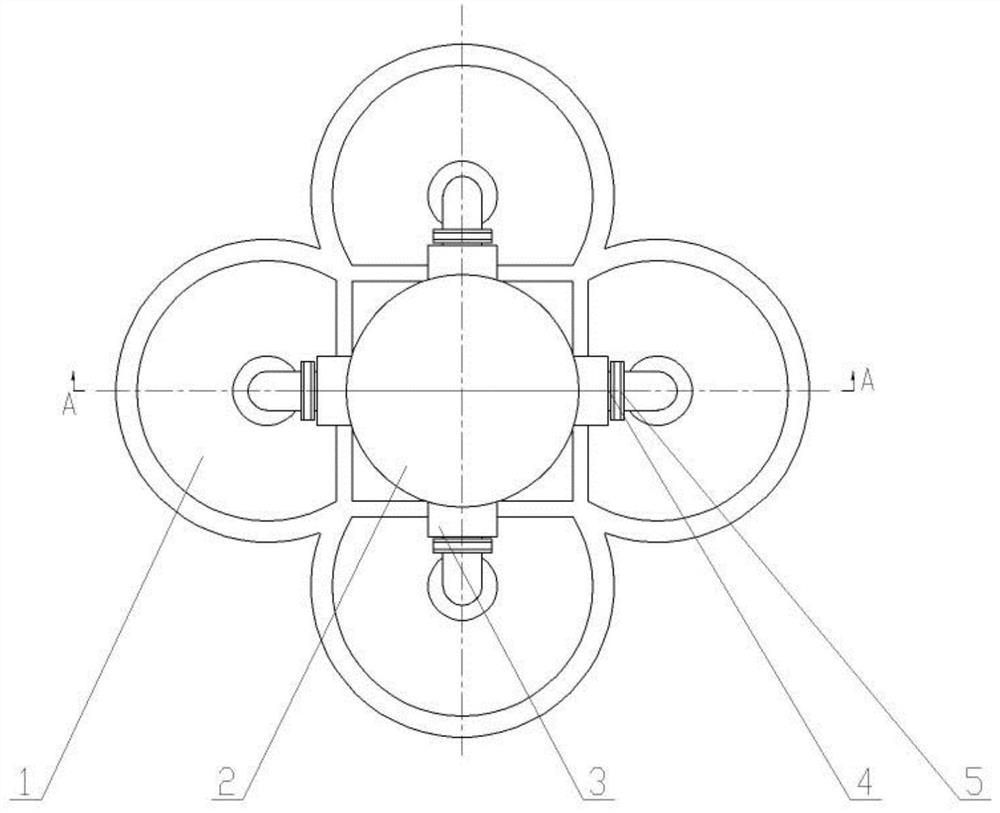

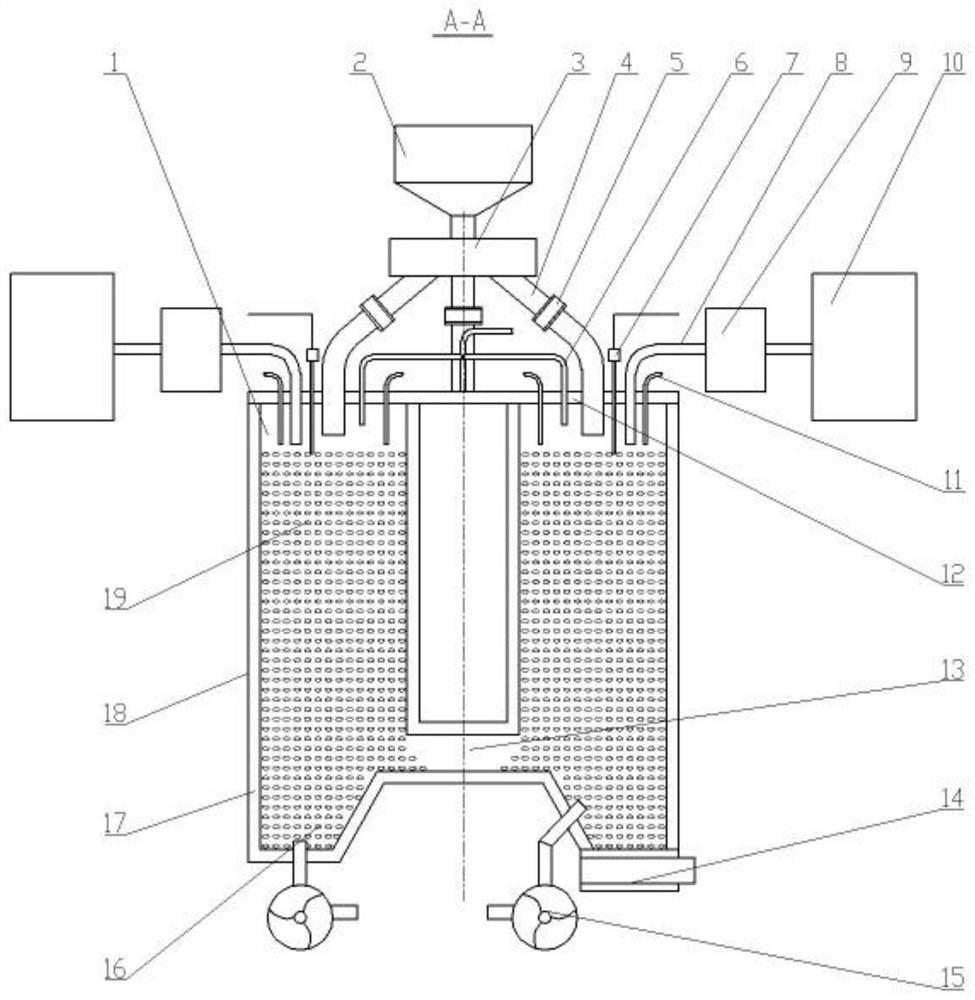

[0041] Each of the four-chamber shaft kilns has a diameter of 6 meters and a height of 15 meters. The output is 1200 tons / d per day.

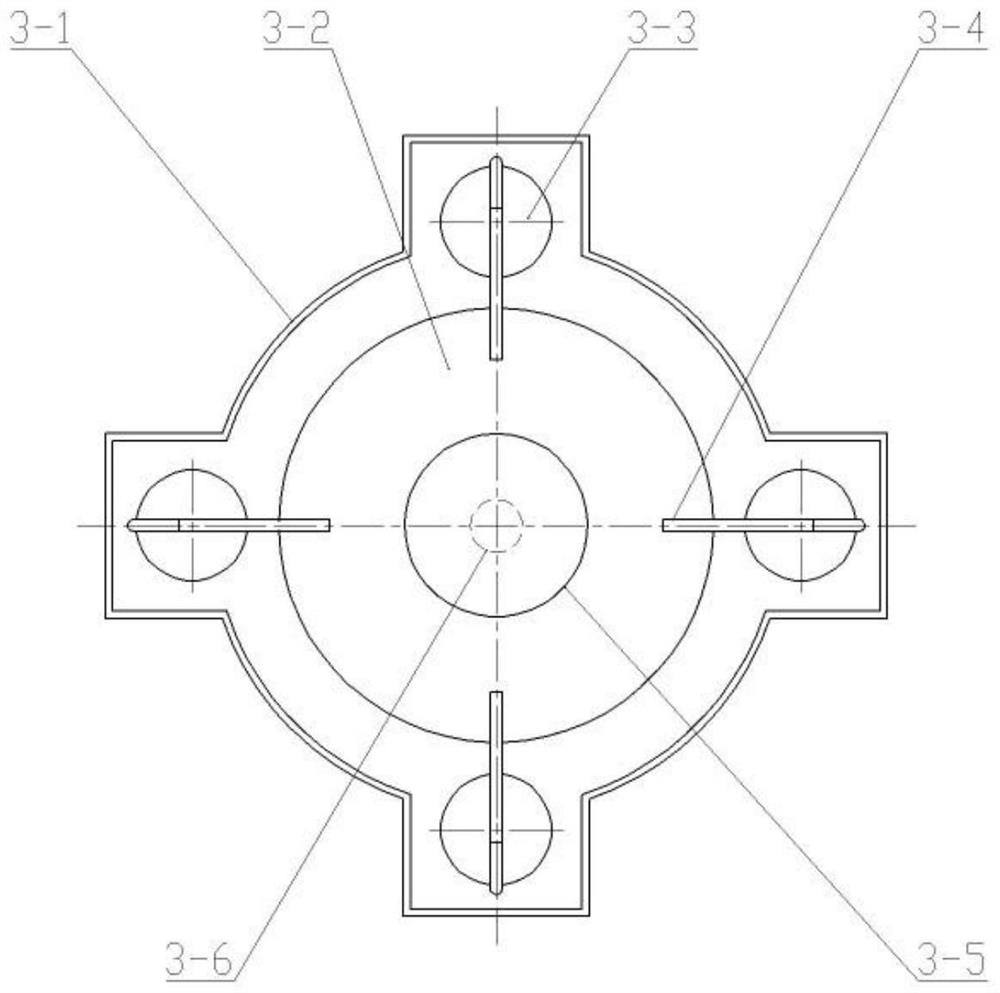

[0042] The dolomite raw material is screened by the underground feeder, belt conveyor, and raw material vibrating screen, and then enters the feeding bin 2, and then is fed into the kiln barrel as a heat storage chamber through the rotary feeder 3 through the feeding pipe 4 for heat storage. The four-chamber vertical kiln has four kiln barrels, and while the three kiln barrels are used as heat storage chambers, the other kiln barrel is used for calcination. Change direction once every 30-100 minutes, release the kiln pressure through the action of the hydraulic valve of the exhaust cylinder, change the position of the gate at the same time, control the shutdown of the combustion-supporting air and gas fuel at the top of the kiln, and realize the calcination kiln and exhaust kiln conversion. In the calcination chamber, coal gas (or natural gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com