Method for preparing bamboo salt through temperature program

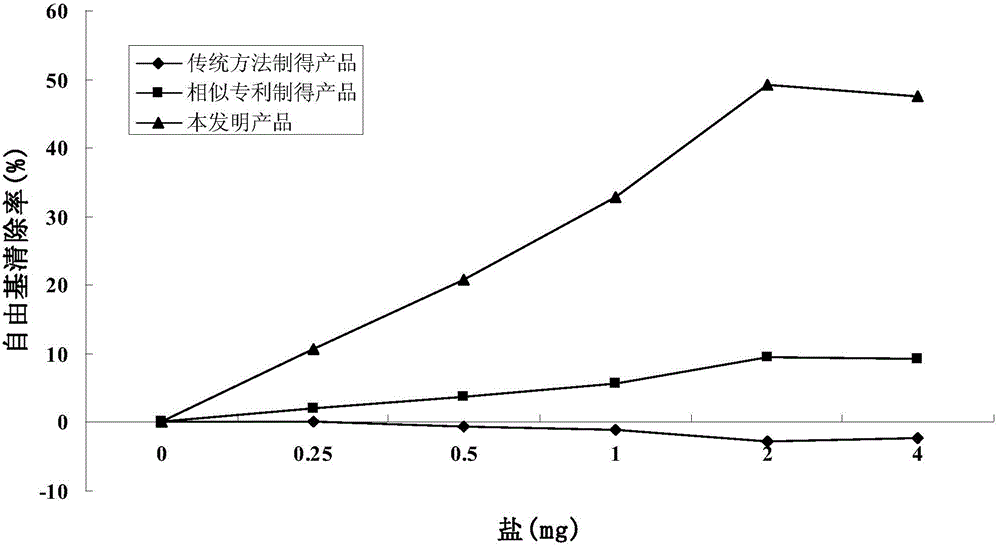

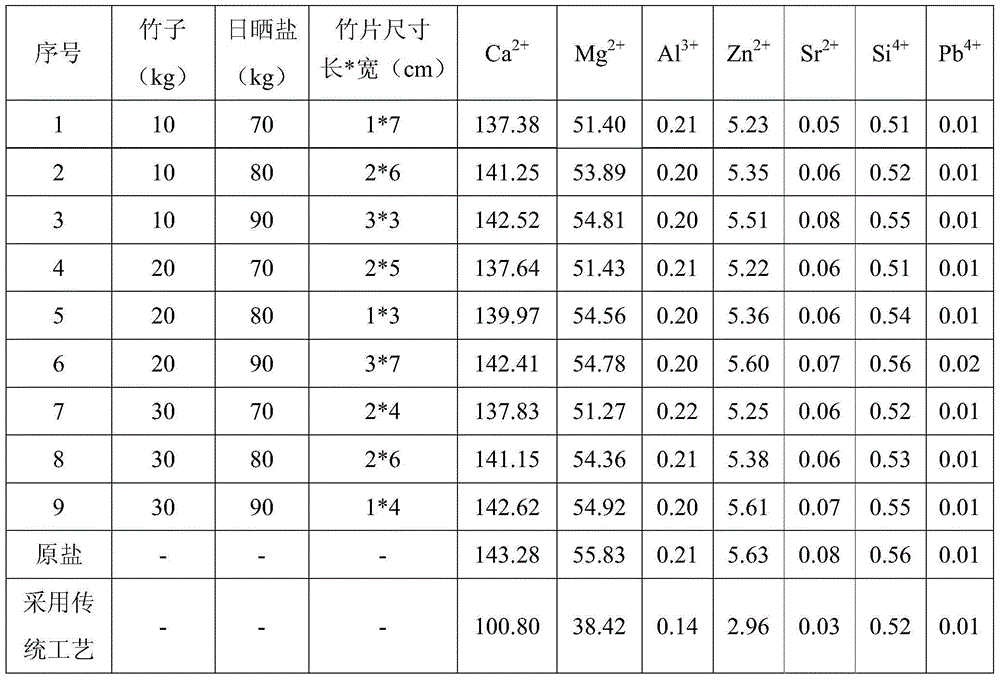

A temperature-programmed, bamboo salt technology, applied in food preparation, application, food science and other directions, can solve the problems of effective ingredients and minerals destruction and loss, uneven color, high content of sulfur compounds, and achieve good airtightness, high temperature Fast, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of method of temperature programming of present embodiment prepares bamboo salt, carries out according to the following steps:

[0024] 1. After mixing the bamboo slices and solar salt, place them in the calciner;

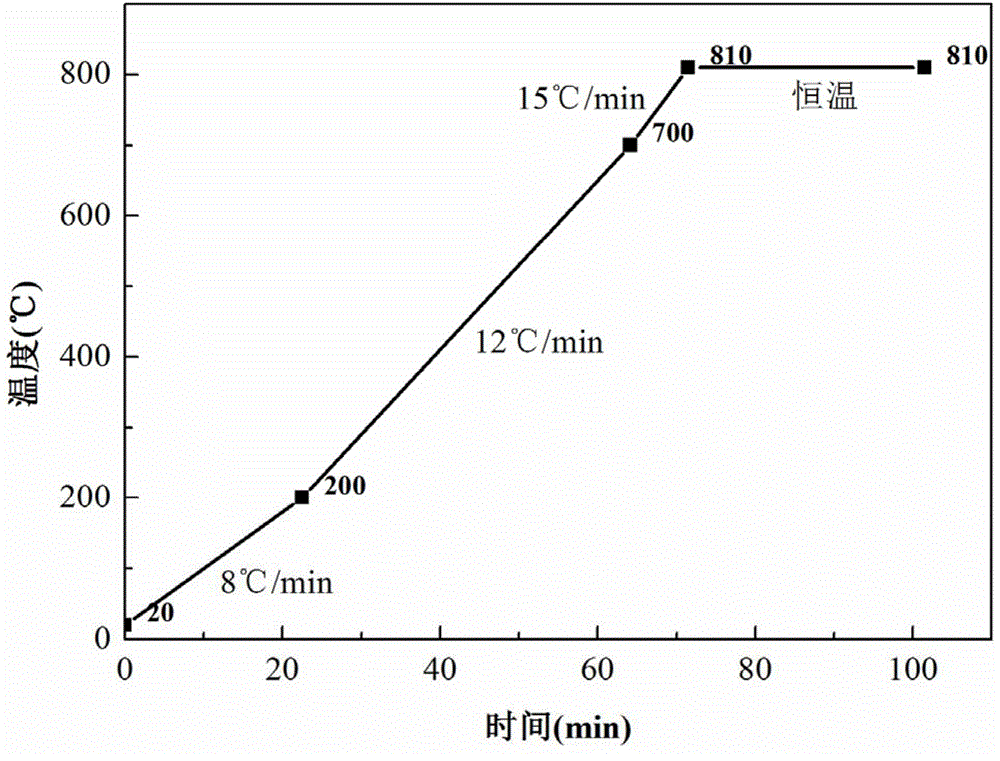

[0025] Two, three-stage heating: the first stage: the temperature is raised from 20°C to 200°C, and the heating rate is 8°C / min; the second stage: the temperature is raised from 200°C to 700°C, and the heating rate is 12°C / min; The third stage: raise the temperature from 700°C to 810°C, the heating rate is 15°C / min, when the temperature rises to 810°C, keep it warm for 30 minutes;

[0026] 3. Cooling and crystallization: After the calcined mixture is cooled and crystallized, it is taken out and pulverized to obtain bamboo salt.

[0027] In step 2 of this embodiment, the three-stage heating is as follows: figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com