Forced flow type quasi liquid membrane extraction separation and enrichment device and use method thereof

A separation, enrichment, flow-type technology, applied in the direction of liquid solution solvent extraction, etc., to achieve the effect of high selectivity, considerable application prospects, and high enrichment ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0049] Examples 1 and 2 - Embodiments of the device according to the invention

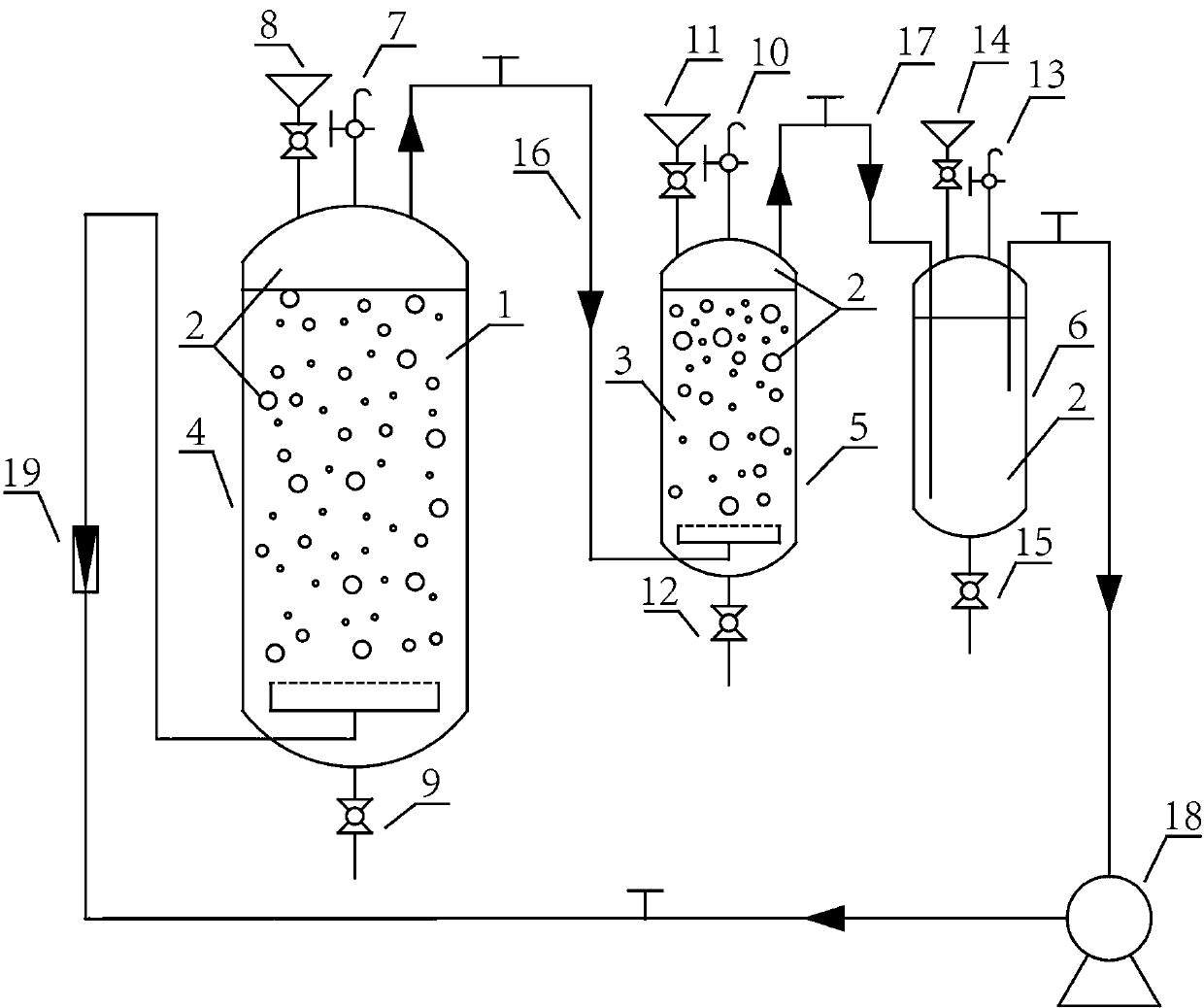

[0050] Example 1 see figure 1 : Among them, the raw material phase (1) and the stripping phase (3) are miscible or partially miscible, and the density of the extraction phase (2) is smaller than that of the raw material phase (1) and the stripping phase (3). The extractor (4) is a cylindrical or cuboid reactor; wherein, the top of the reactor has an exhaust port (7) with a valve, a feed port (8) with a valve and a hopper, and an output pipe of the extraction phase (2) There is a discharge port (9) with a valve at the bottom of the reactor; the extraction phase (2) enters from the bottom of the container through the input pipeline, and the extraction phase (2) is blown into the container by a dispersing device, and dispersed in the raw material phase ( 1) Medium contact mass transfer; the extraction phase (2) and the raw material phase (1) are separated due to the density difference, and then the...

Embodiment 2

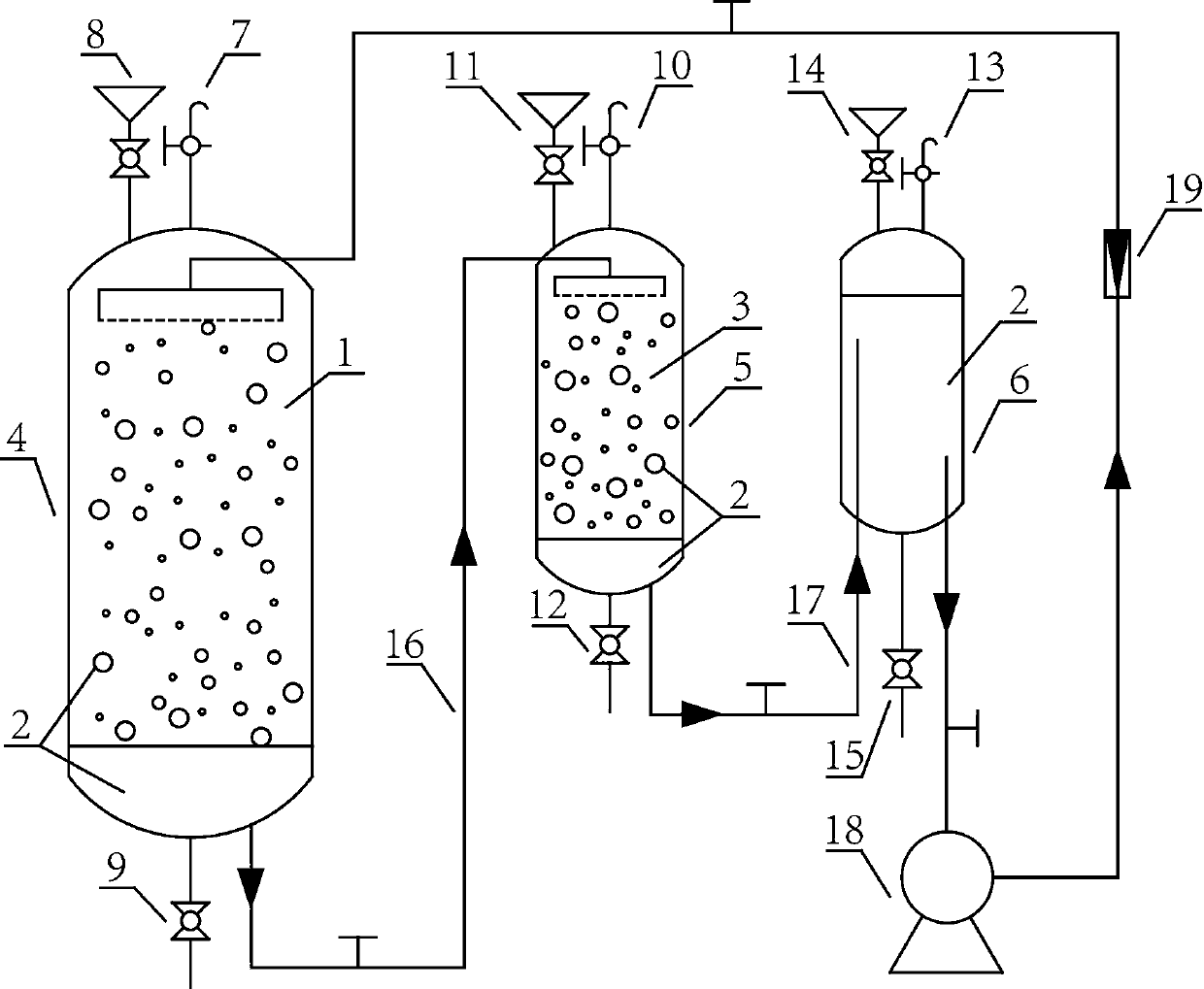

[0051] Example 2 see figure 2 : Wherein, the difference from Example 1 is that the density of the extraction phase (2) is larger than that of the raw material phase (1) and the stripping phase (3). This makes embodiment 2 produce corresponding structural difference with embodiment 1, see for details figure 2 . Similarly, if the density of the extraction phase (2) is larger than that of the raw material phase (1) and smaller than that of the stripping phase (3), other corresponding transformations need to be carried out: the extractor (4) adopts the structure as in Example 2, and The back extractor (5) adopts the structure as in Example 1, and the extract phase storage tank (6) adopts the structure as in Example 1.

Embodiment 3 and 4

[0052] Embodiment 3 and 4 - utilize the device of the present invention and its using method to carry out the embodiment of separation and enrichment operation

[0053] Use the device described in Example 1 to carry out the separation and enrichment operation, including the following steps: First, the start-up and enrichment process of the device is carried out in sequence according to the steps S1-S4 described in the summary of the invention, and the extraction phase (2) is used in the extractor (4), the circulation flow mode between the stripper (5) and the extract phase storage tank (6). After the set extraction time is reached, the process of static phase separation and liquid drainage is carried out according to steps S5-S7.

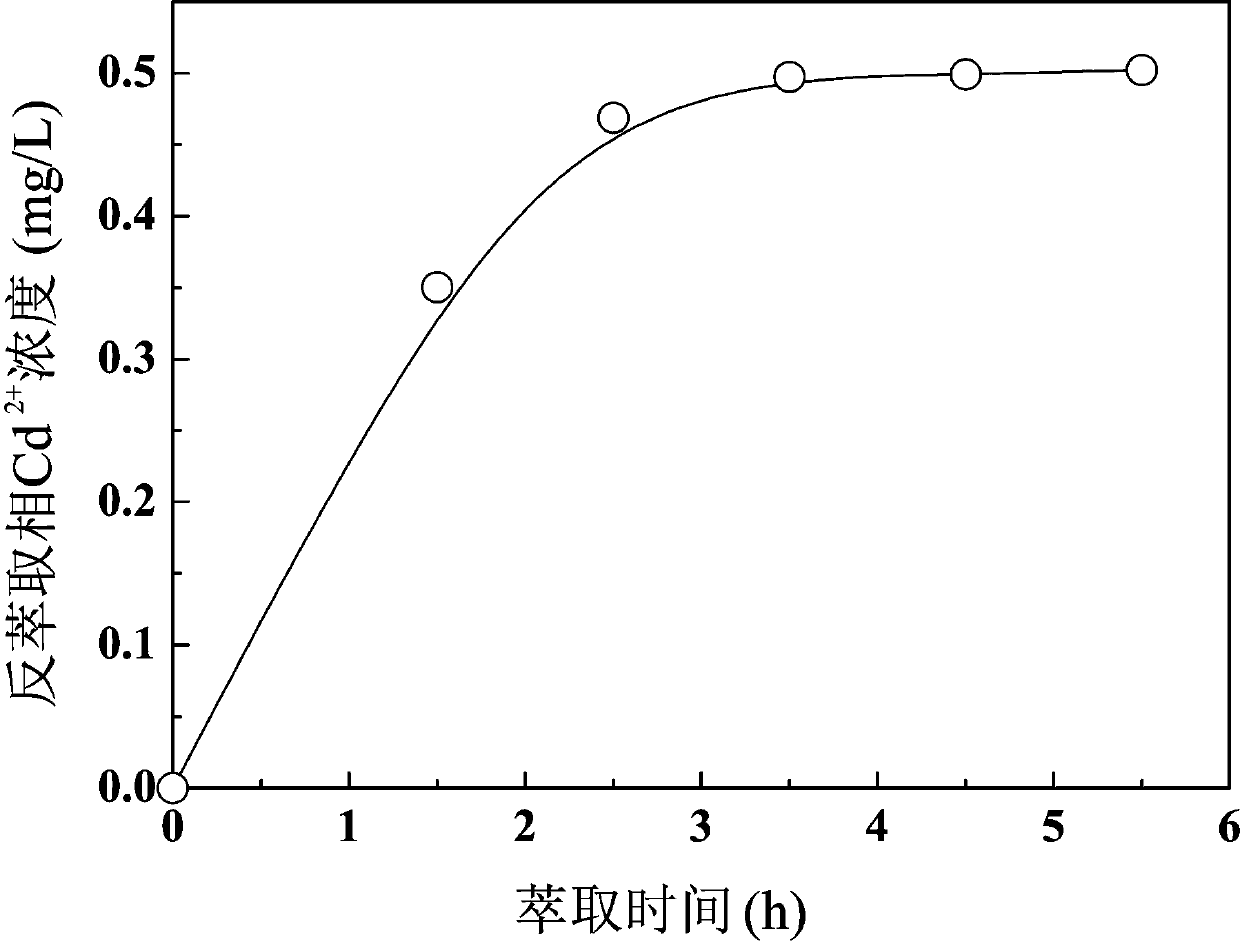

[0054] Among them, the purpose of Example 3 is to use the present invention to efficiently enrich low-concentration solute components: the 0.005 mg / L low-concentration Cd in the raw material phase (1) 2+ (The concentration limit of cadmium in II-IV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com