Patents

Literature

528 results about "Mass transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

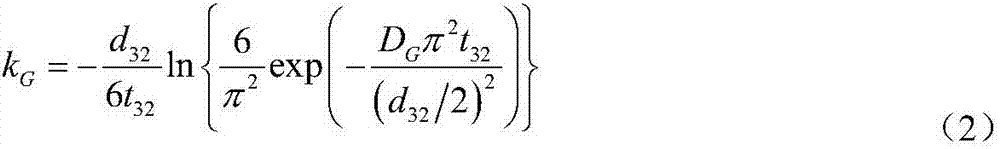

In engineering, the mass transfer coefficient is a diffusion rate constant that relates the mass transfer rate, mass transfer area, and concentration change as driving force:

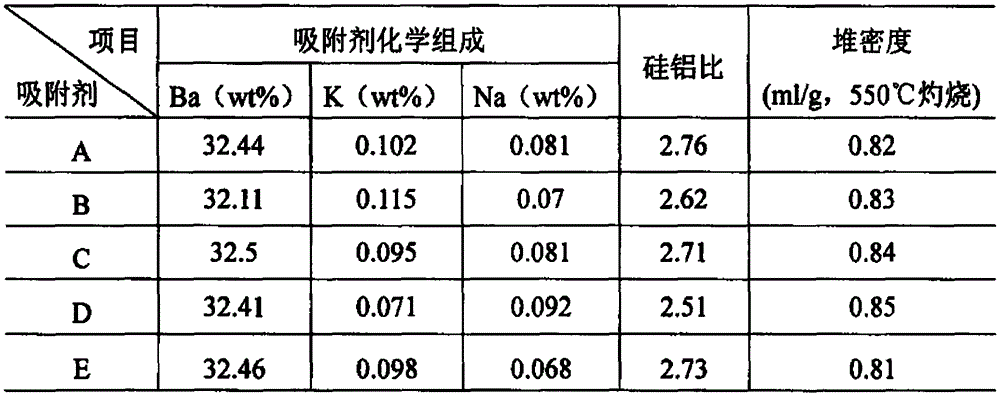

Agglomerated zeolite adsorbents and process for producing the same

ActiveUS20110105301A1Large hole volumeImprove mass transfer effectMolecular sieve catalystsOther chemical processesSorbentIon exchange

An agglomerated zeolite adsorbent which comprises 95-99.5 mass % of X zeolite and 0.5-5.0 mass % of binder, wherein the exchangeable cationic sites of said X zeolite are occupied by Group IIA metal and / or K, the total pore volume of said adsorbent is no less than 0.26 mL / g as measured by mercury porosimetry, the volume of pores with pore diameters from 100 to 500 nm is at least 60% based on the total pore volume. During shaping, a pore-forming agent is added to this adsorbent, and then the adsorbent is alkali treated for in-situ crystallization, followed by ion exchange. Said adsorbent has high adsorption capacity, fast mass transfer rate and good mechanical strength. Said adsorbent is suitable for liquid phase adsorptive separation of para-xylene from C8 aromatic hydrocarbons and is also suitable for adsorptive separation of other alkyl aromatic hydrocarbons isomers.

Owner:CHINA PETROCHEMICAL CORP +1

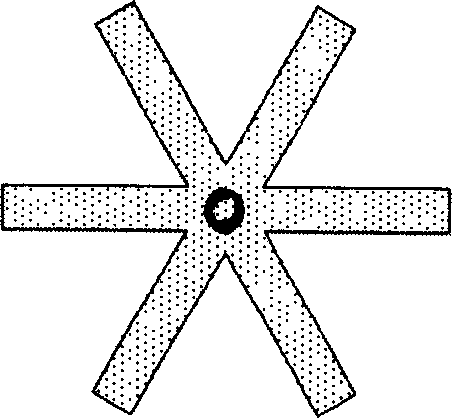

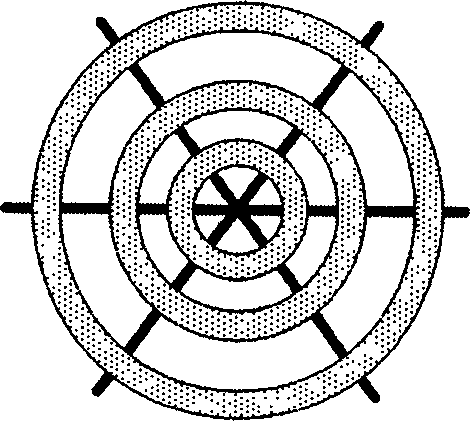

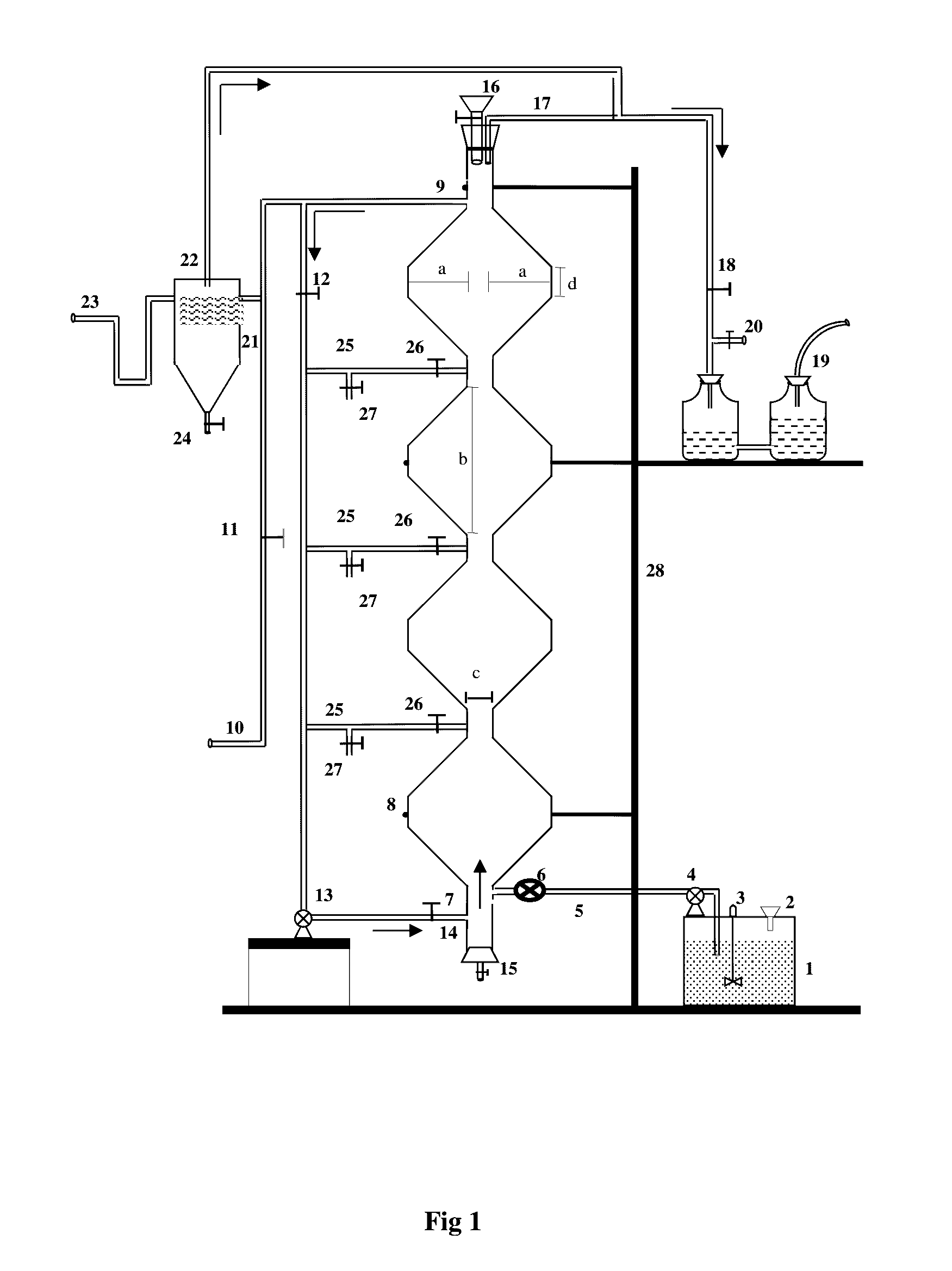

Bubbling tower reactor having damping internal construction member

InactiveCN1785495AIncrease mass transfer rateInhibit flow rateLiquid-gas reaction processesEngineeringTower

A bubbling column reactor with internal damping member features that said internal damping member is coaxially installed in the reaction region above gas distributor for suppressing the flow speed in central region to make the radial speed distribution more uniform and interferring the flow field to promote local turbulence and increase gas-liquid mass transfer speed.

Owner:ZHEJIANG UNIV

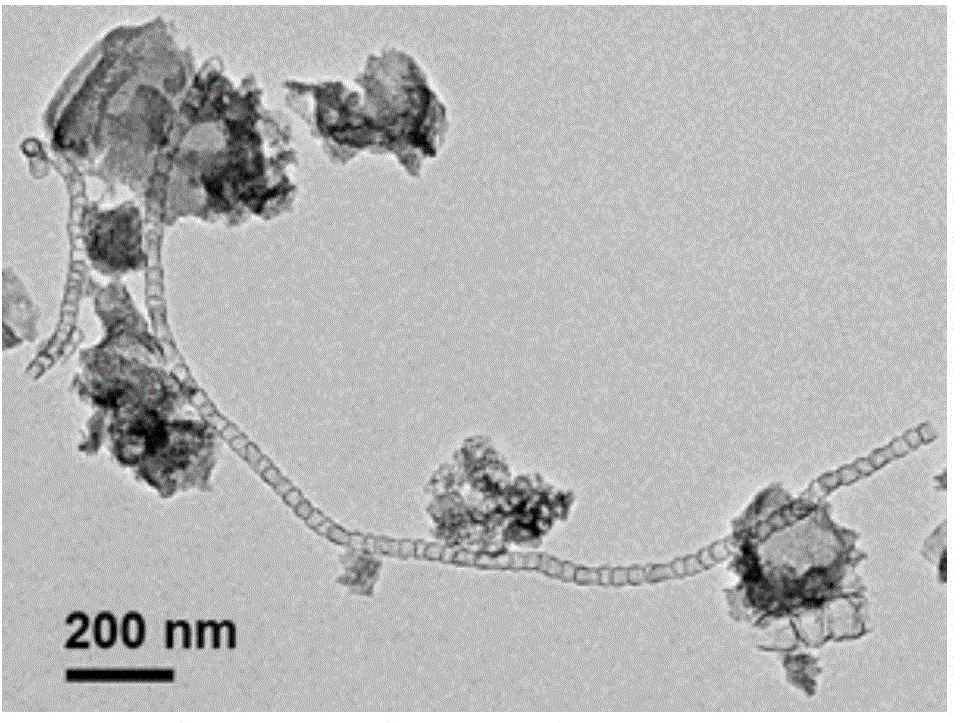

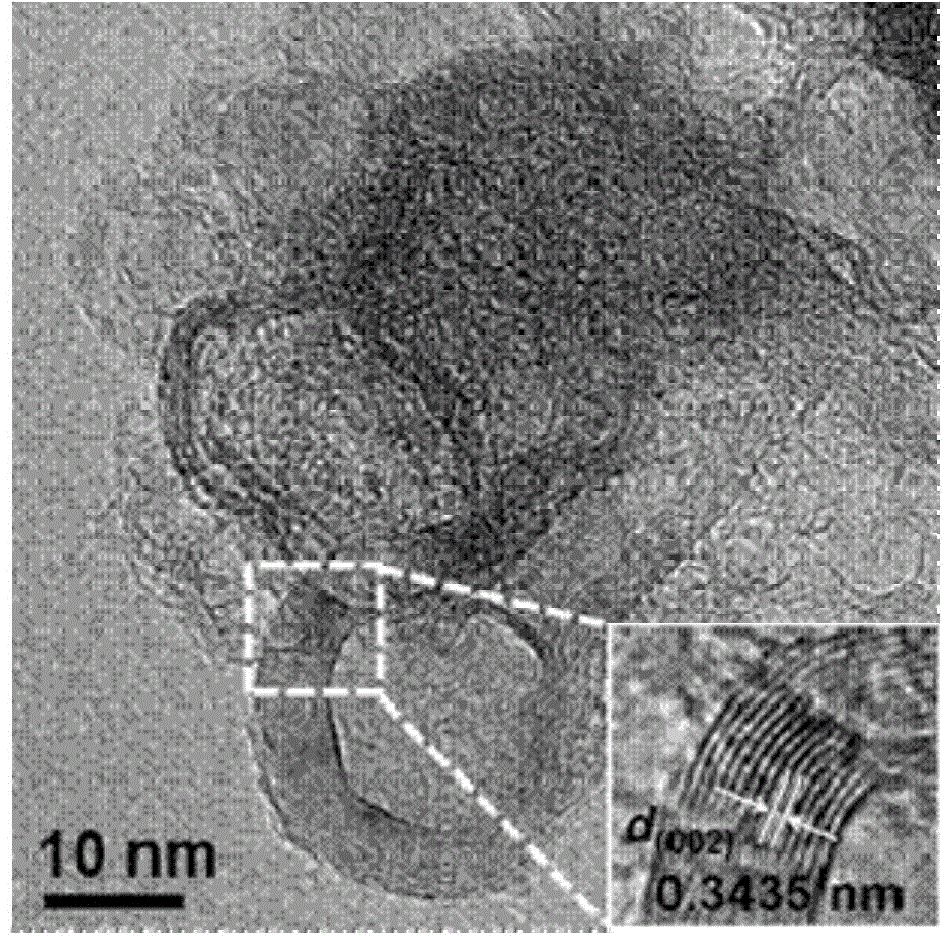

Compound type fuel cell cathode catalyst NGPC/NCNTs and preparation method thereof

ActiveCN106159287AThe preparation method is simple and controllableLower synthesis costCell electrodesMetal-organic frameworkCarbon nanotube

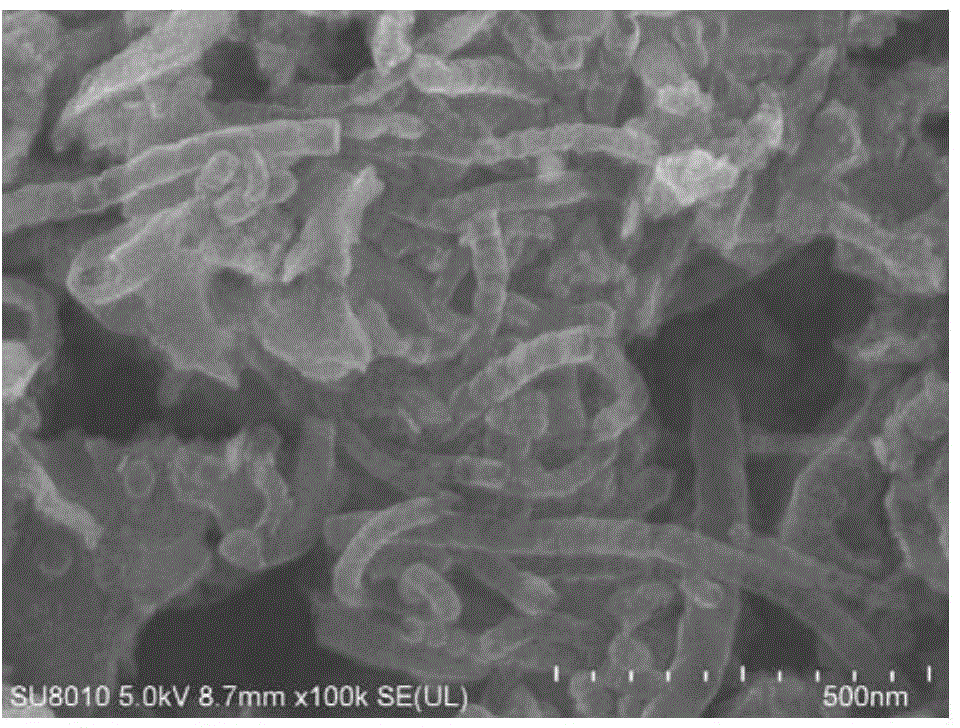

The invention discloses a compound type fuel cell cathode catalyst NGPC / NCNTs and a preparation method thereof, belongs to the technical field of catalyst preparation and aims to develop a cheap and efficient non-precious metal catalyst to solve the problem of high cost of a fuel cell cathode catalyst made of a Pt-based material. An MOF (metal-organic framework) material as a C source of the NGPC / NCNTs is pre-carbonized at a low temperature firstly, a graphitization catalyst and a N source are introduced step by step, two times of corresponding high-temperature heat treatment are performed, and the NGPC / NCNTs are prepared. The active component of the NGPC / NCNTs is N-doped graphitized porous C or CNTs, a pore structure is in a micropore-mesopore compound type, and a continuous conduction framework in three-dimensional space is formed through structural connection of dispersed porous C particles by the CNTs, so that the NGPC / NCNTs have good conductivity and higher mass transfer rate and can show efficient catalytic activity, methyl alcohol tolerance and cycle stability, which are better than those of a commercial Pt / C electrocatalyst, in an alkaline medium.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

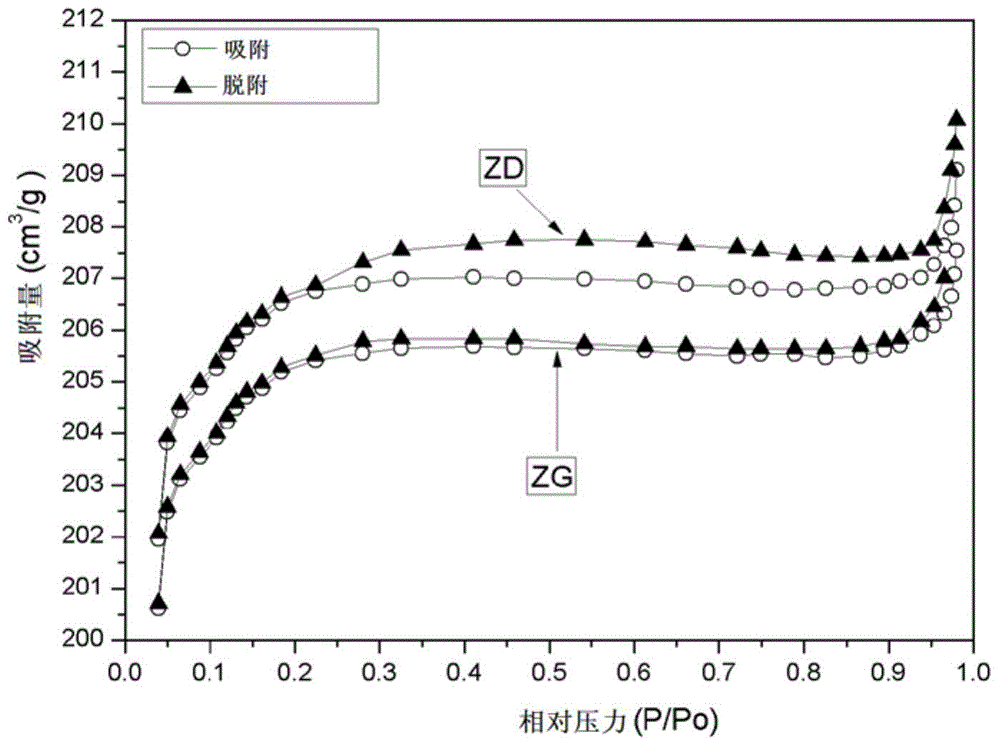

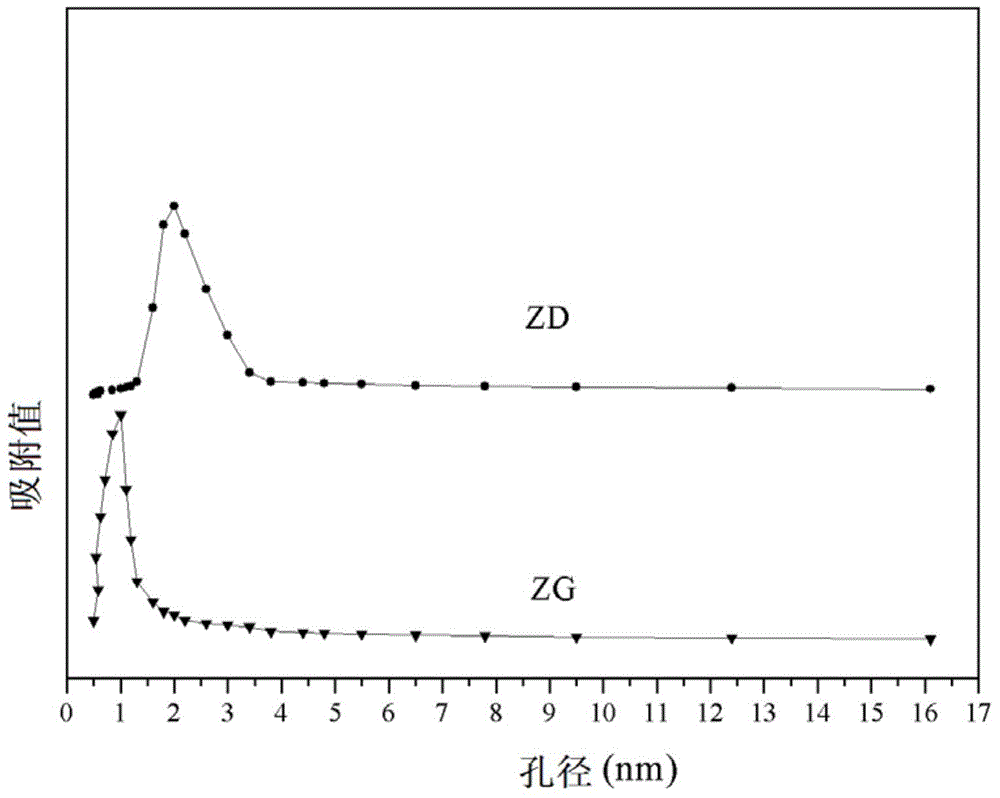

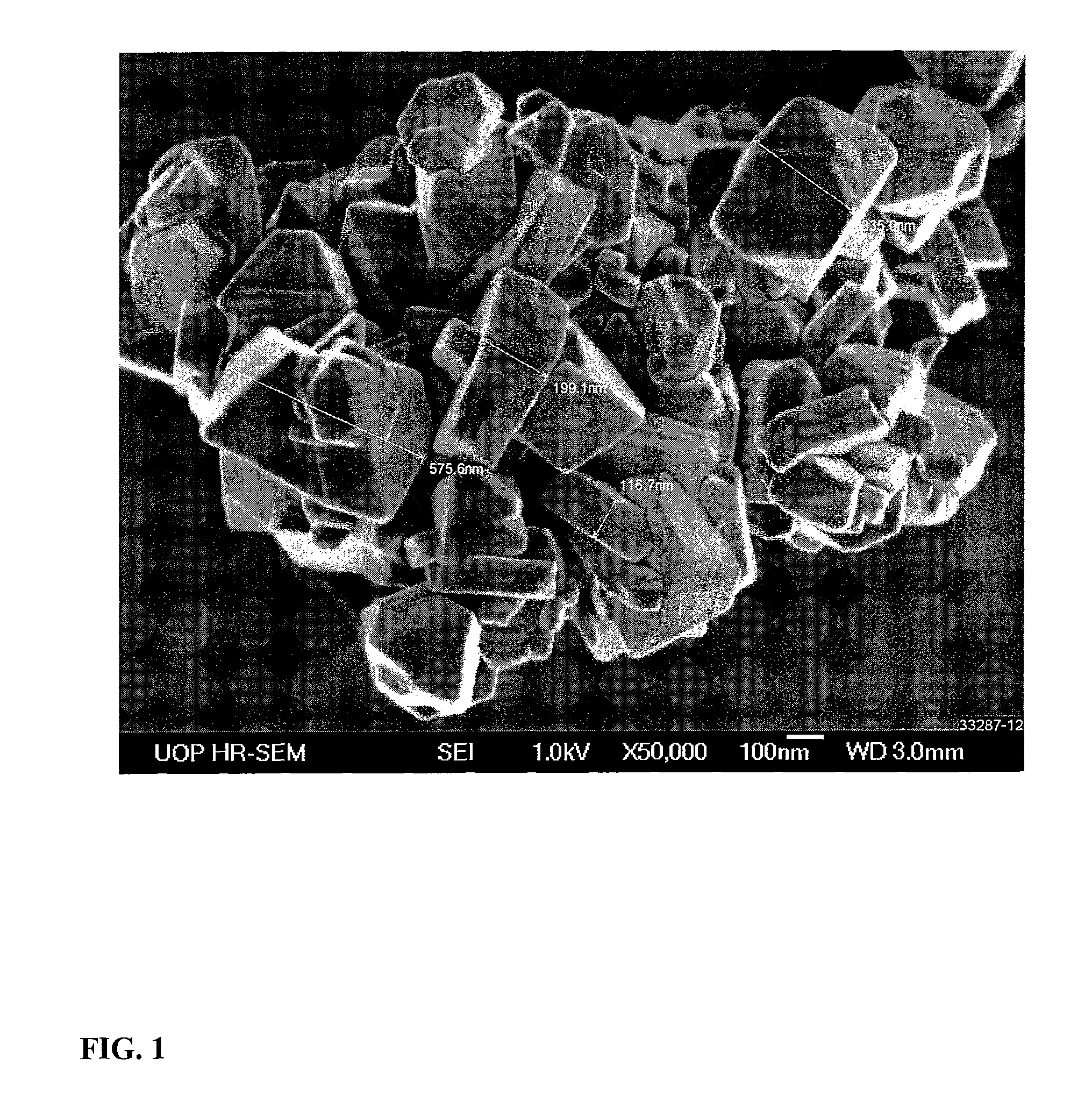

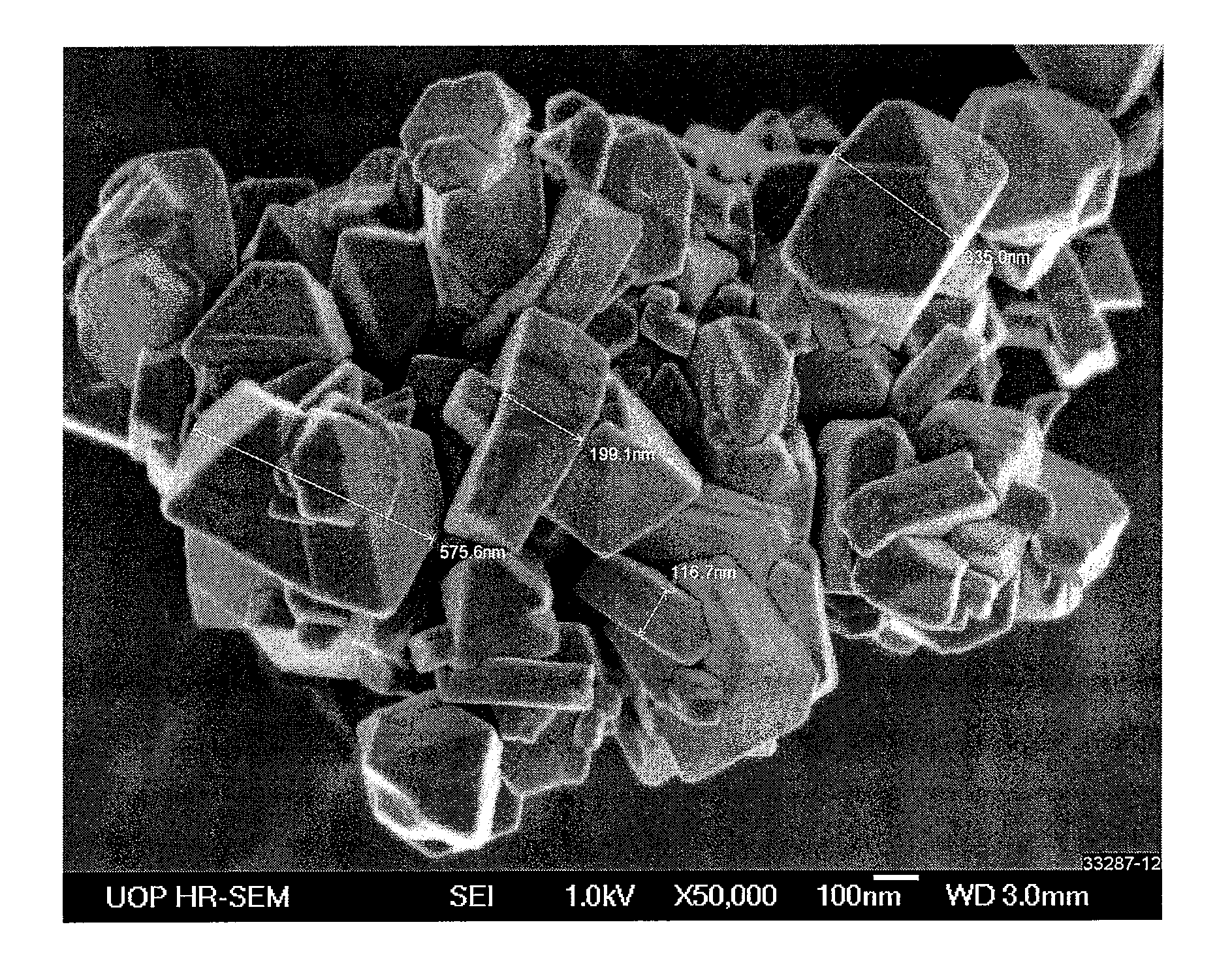

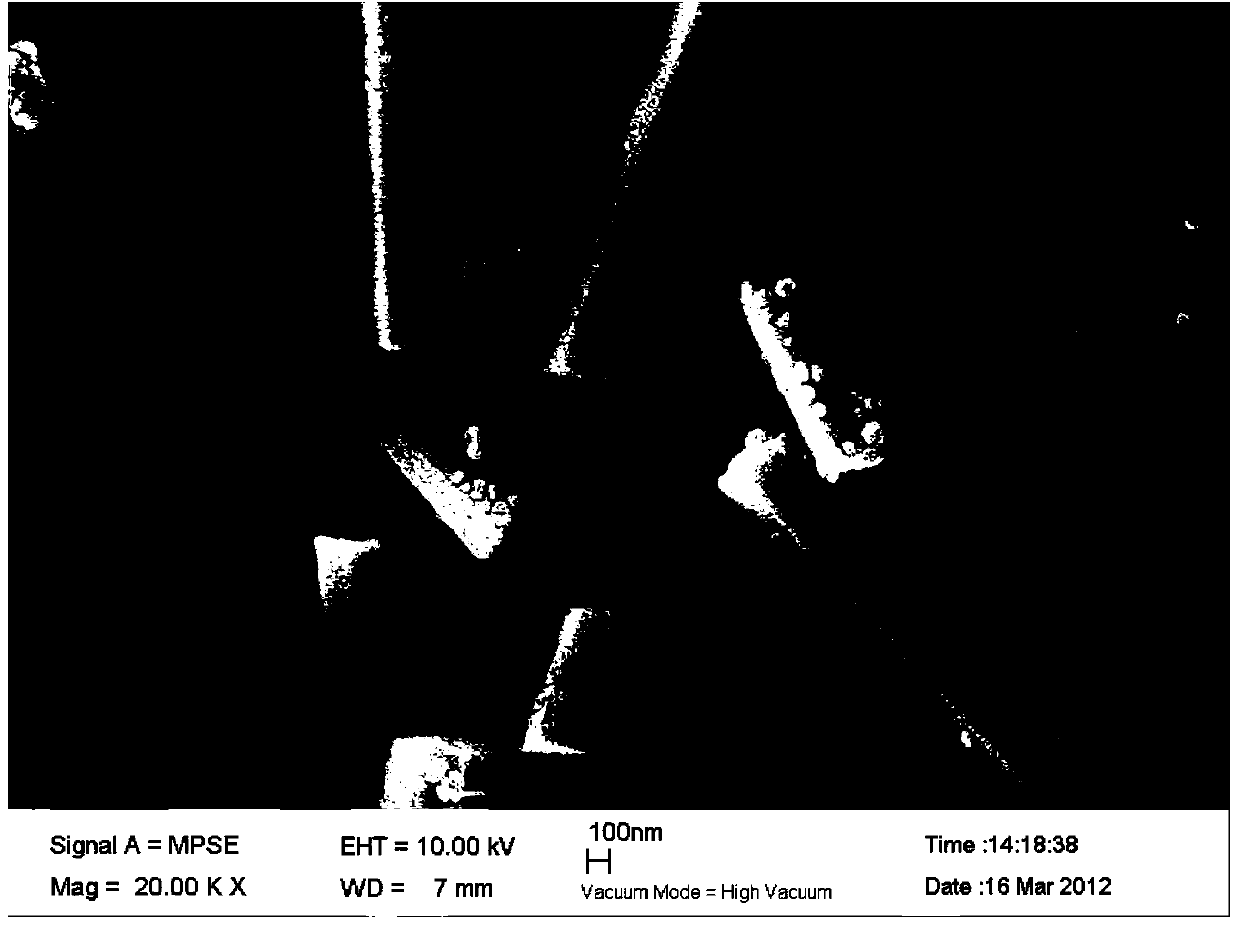

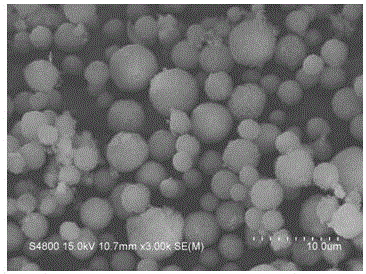

Mesoporous X-type molecular sieve, adsorbent based on molecular sieve, and preparation and application thereof

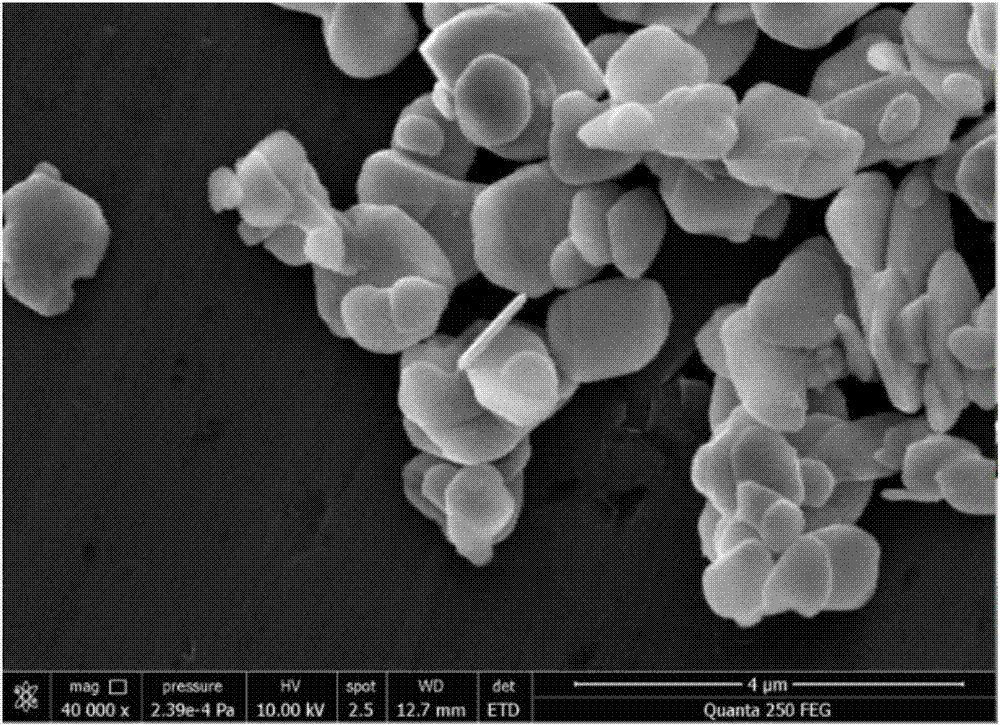

InactiveCN104477937AHigh adsorption selectivityImprove adsorption capacityOther chemical processesFaujasite aluminosilicate zeolitePore distributionSorbent

The invention relates to a preparation method of a mesoporous X-type molecular sieve and a method for preparing an adsorbent by using the molecular sieve as an active component. The prepared adsorbent based on the mesoporous X-type molecular sieve is used as a paraxylene adsorptive separation adsorbent. The method for preparing the mesoporous X-type molecular sieve comprises the following steps: by using water glass as a silicon source and aluminum hydroxide as an aluminum source, adding a template, and carrying out hydrothermal synthesis to obtain the mesoporous X-type molecular sieve. The mesoporous molecular sieve and kaolin are proportionally molded to obtain 0.3-0.8mm granules, and the granules are subjected to barium ion or (and) potassium ion exchange until the exchange degree is greater than 99%, thereby obtaining the adsorbent which has excellent adsorptive separation capacity for paraxylene in C8 aromatic hydrocarbons. Compared with the prior art, the active component mesoporous X-type molecular sieve of the adsorbent, which is prepared by using the template, has the crystal form structure of the X-type molecular sieve and the pore distribution of the mesoporous and microporous dual models; the mesoporous pore size distribution is 2nm or so; and thus, the problem of overlow mass transfer rate in the adsorbent can be solved.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

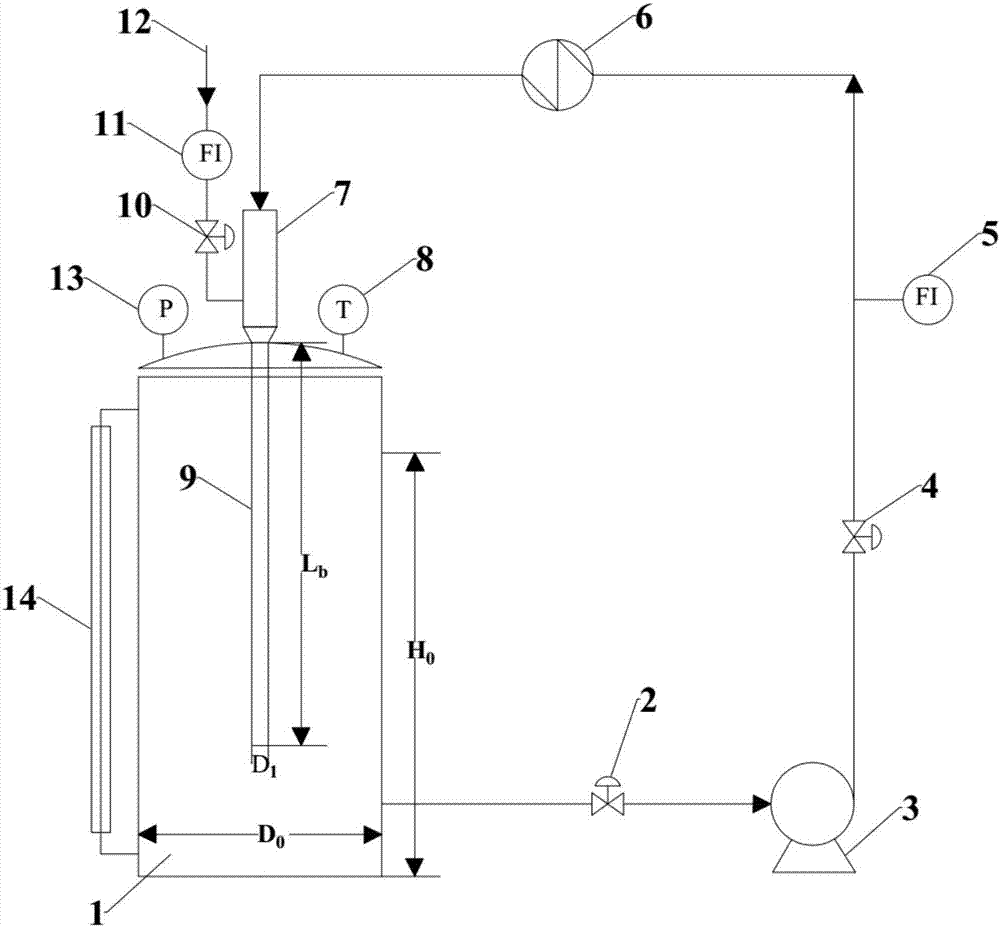

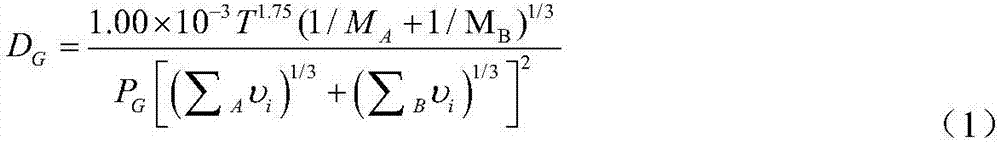

Modeling method for mass transfer rate structure-effect regulating model of micro-interface enhanced reactor

ActiveCN107346378AReduce mistakesImprove versatilityChemical processes analysis/designSpecial data processing applicationsModel methodMaterial consumption

The invention discloses a modeling method for a mass transfer rate structure-effect regulating model of a micro-interface enhanced reactor. Rigorous theoretical derivation is adopted for respectively establishing a gas-side mass transfer coefficient calculation model and a liquid-side mass transfer coefficient calculation model. The mass transfer rate structure-effect regulating model established according to the modeling method disclosed by the invention can be adopted for directly viewing the relationship between the mass transfer rate and the bubble size and a theoretical basis is established for researching a micro-interface system, so that the target of acquiring the maximum energy efficiency and physical effect in the reaction process can be achieved in the manner of regulating structure parameter and operation parameter or an efficient reactor structure is designed under the conditions of given reaction target (task), energy consumption and material consumption.

Owner:NANJING UNIV

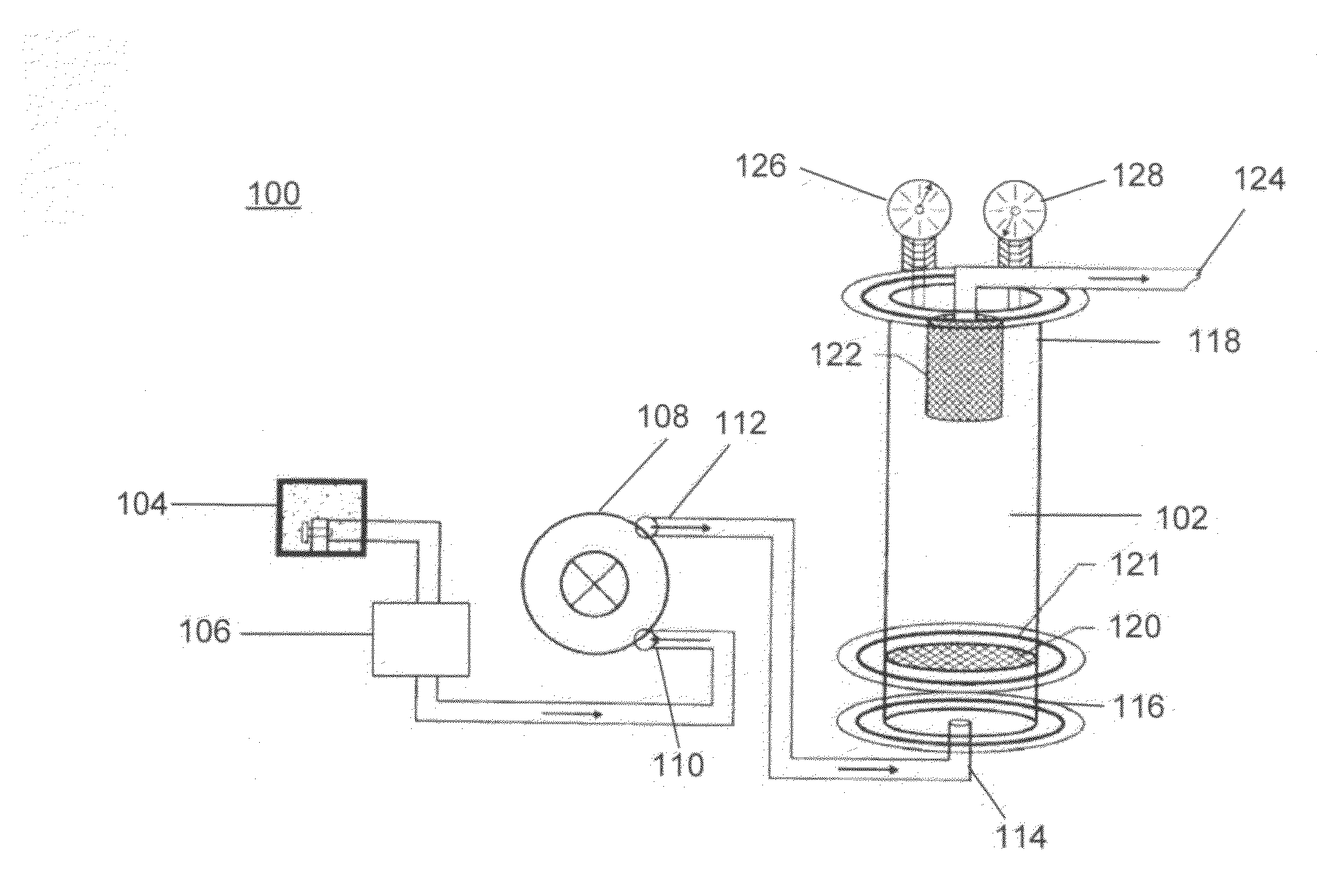

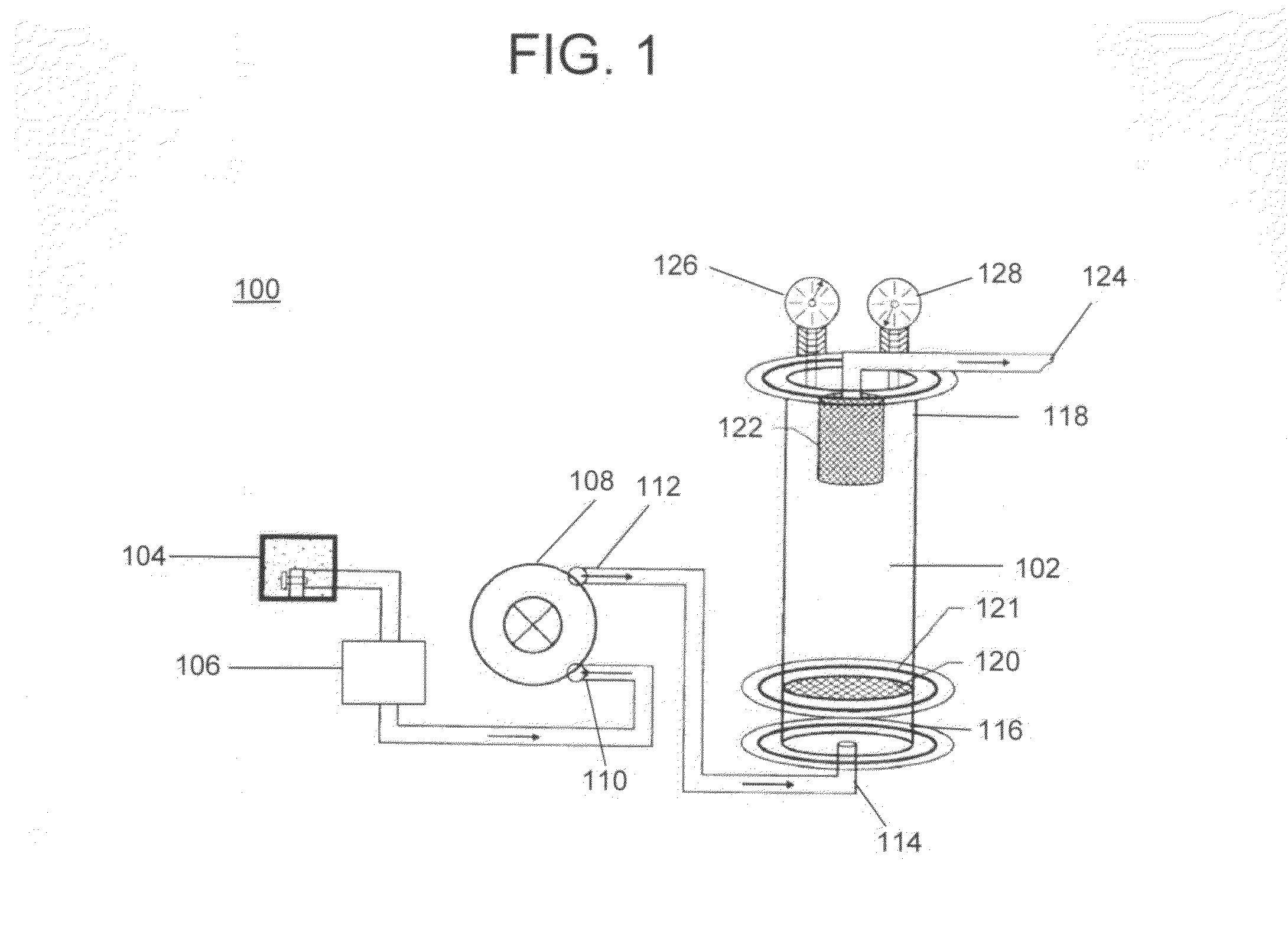

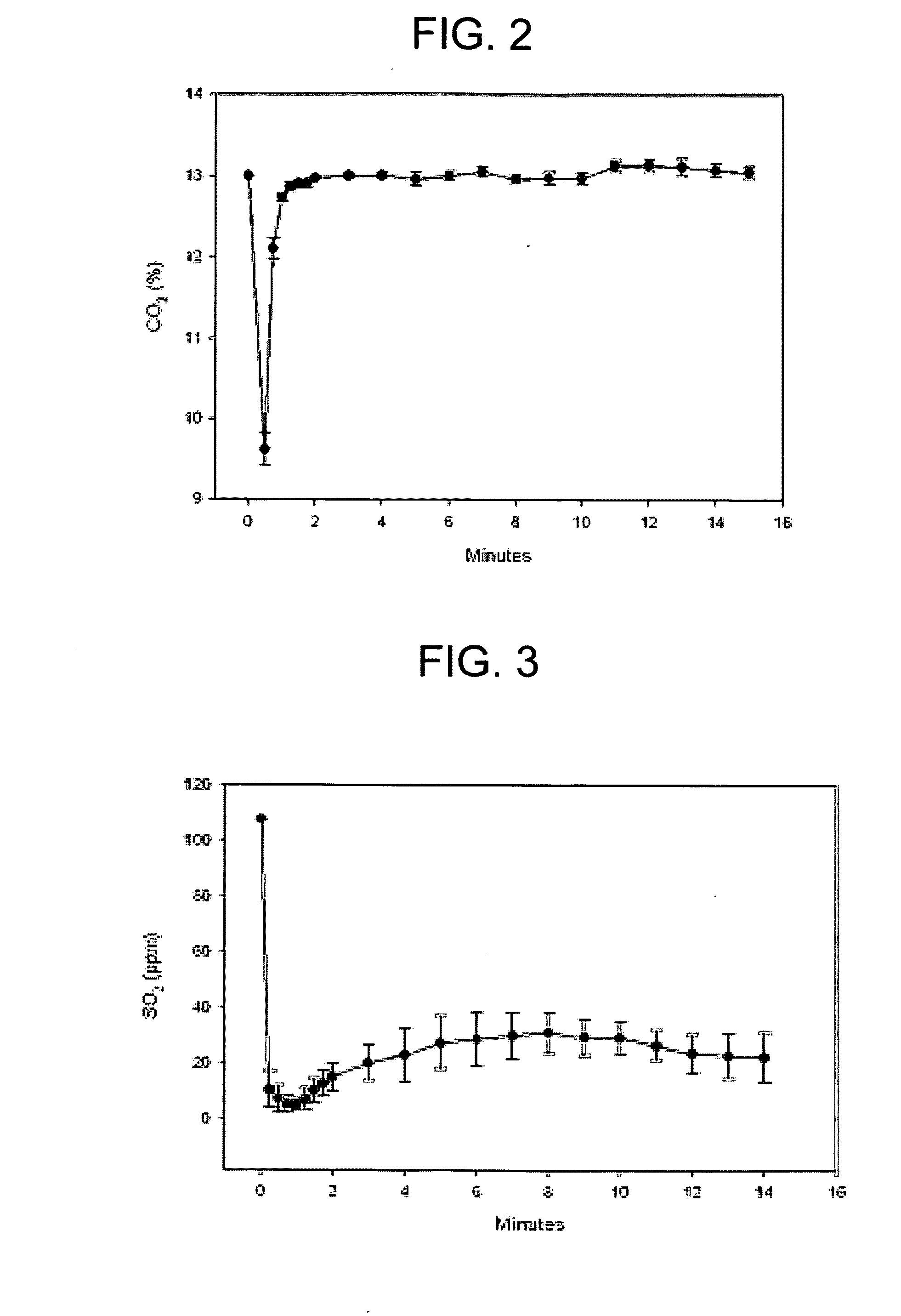

Apparatus and method to sequester contaminants

ActiveUS20090263301A1Mass transfer speedReduce carbon footprintGas treatmentNitrogen compoundsFlue gasMass transfer rate

The invention relates to an apparatus and method for reducing contaminants from industrial processes. More particularly, the invention is directed to a method of sequestering pollutants from flue gases in operational plants. The method includes sequestering contaminants from a point source by reacting an alkaline material with a flue gas containing contaminants to be sequestered, wherein the reaction has a rapid mass transfer rate to sequester at least a portion of the contaminants.

Owner:UNIVERSITY OF WYOMING

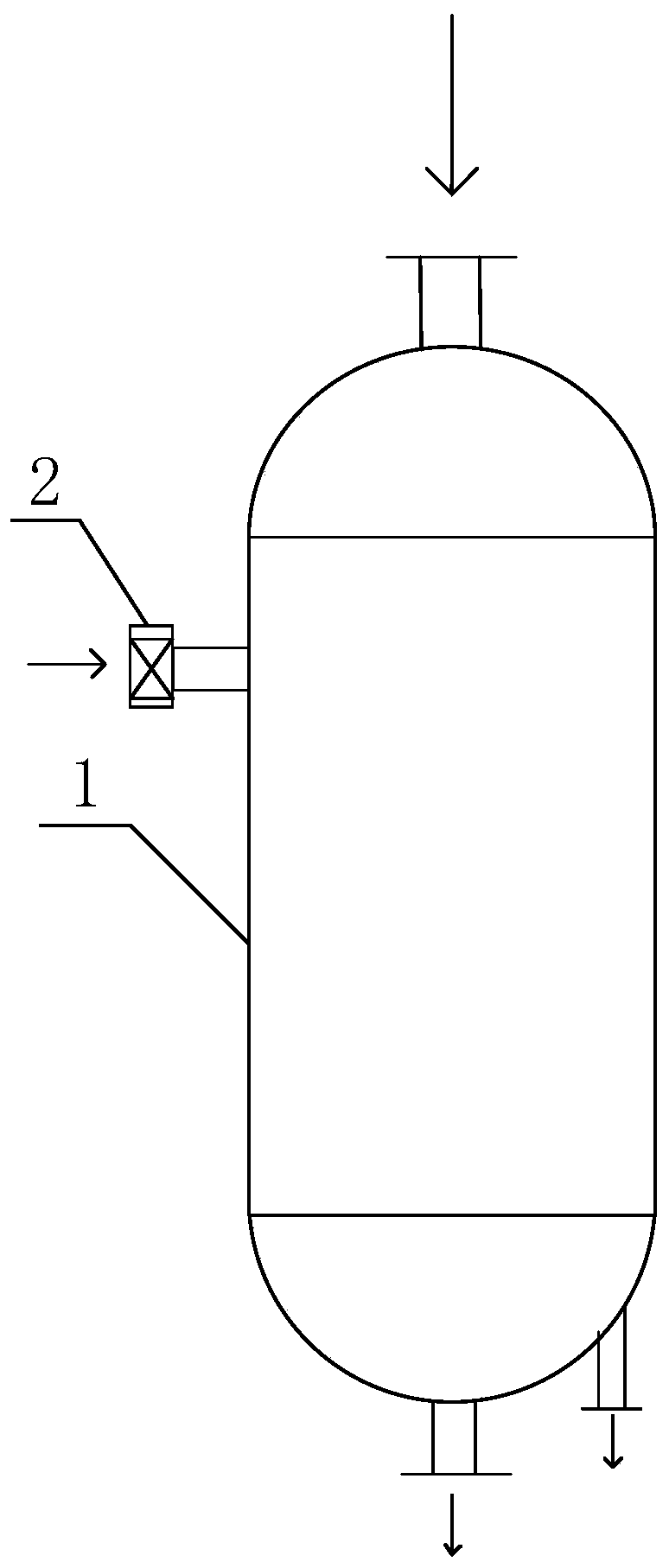

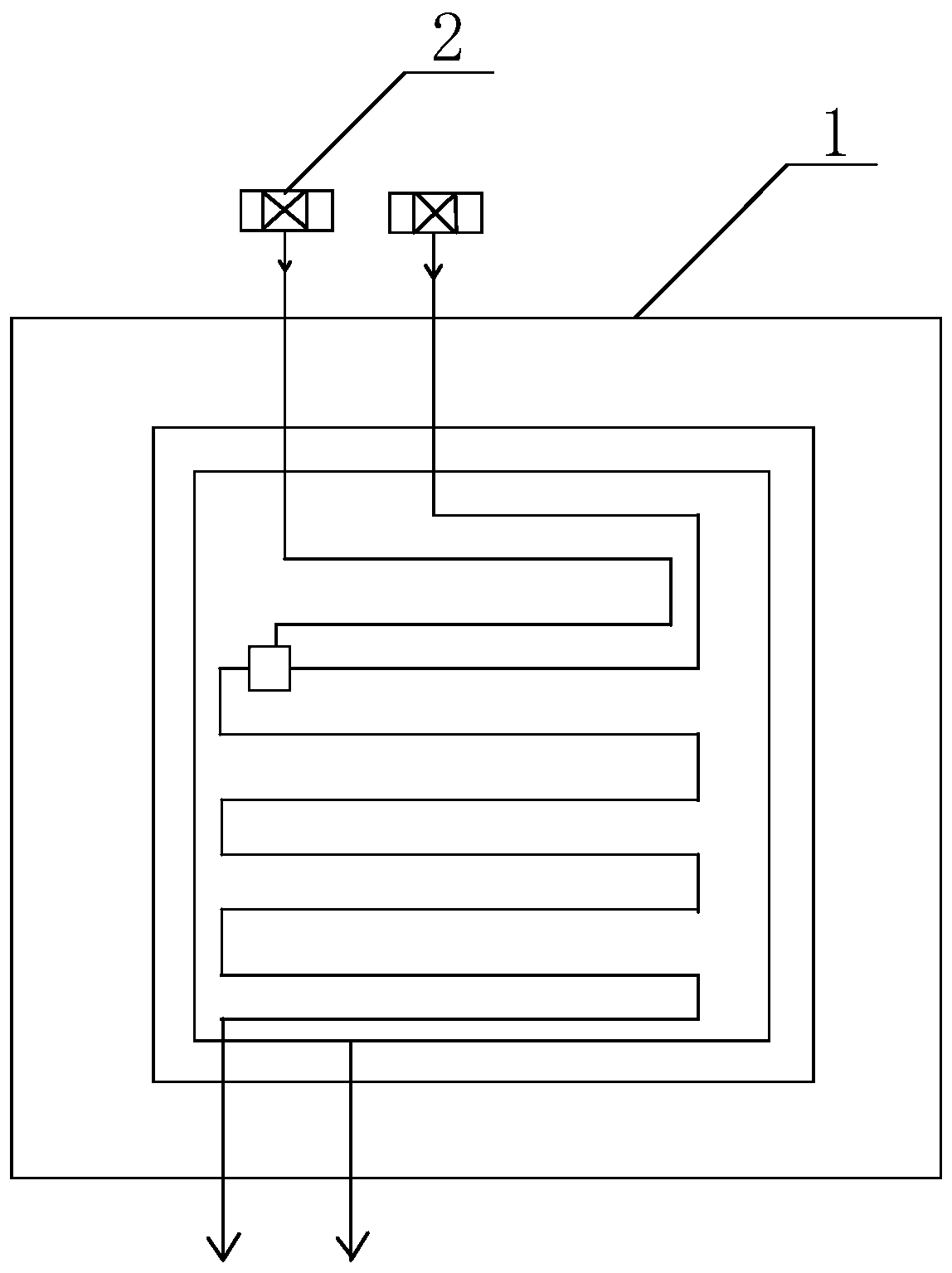

Micro-interface enhanced hydrogenation reaction system

InactiveCN111359556AIncrease the mass transfer area of the phase boundaryImprove mass transfer efficiencyChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesFluid phaseHydrogenation reaction

The invention provides a micro-interface enhanced hydrogenation reaction system. The system comprises: a reactor main body used as a reaction chamber in a hydrogenation reaction process so as to ensure that the hydrogenation reaction can be fully carried out; and a micro-interface generator, wherein the micro-interface generator is connected with the reactor main body, the micro-interface generator is used for crushing hydrogen and / or liquid-phase reactants into micro-bubbles and / or a solid-liquid mixed material with micron-sized diameters in the micro-interface generator through a mechanicalmicrostructure and / or a turbulence microstructure in a preset action manner before the hydrogen and the liquid and / or solid-liquid mixed material enter the reactor main body in the hydrogenation reaction process, so the mass transfer efficiency between reaction phases is improved, and the reaction hydrogenation reaction is enhanced under the conditions of preset temperature and pressure. The system effectively solves the problem that the mass transfer rate is affected due to the fact that the phase boundary contact area of a reaction phase is small in the using process of an existing reactionstrengthening system.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

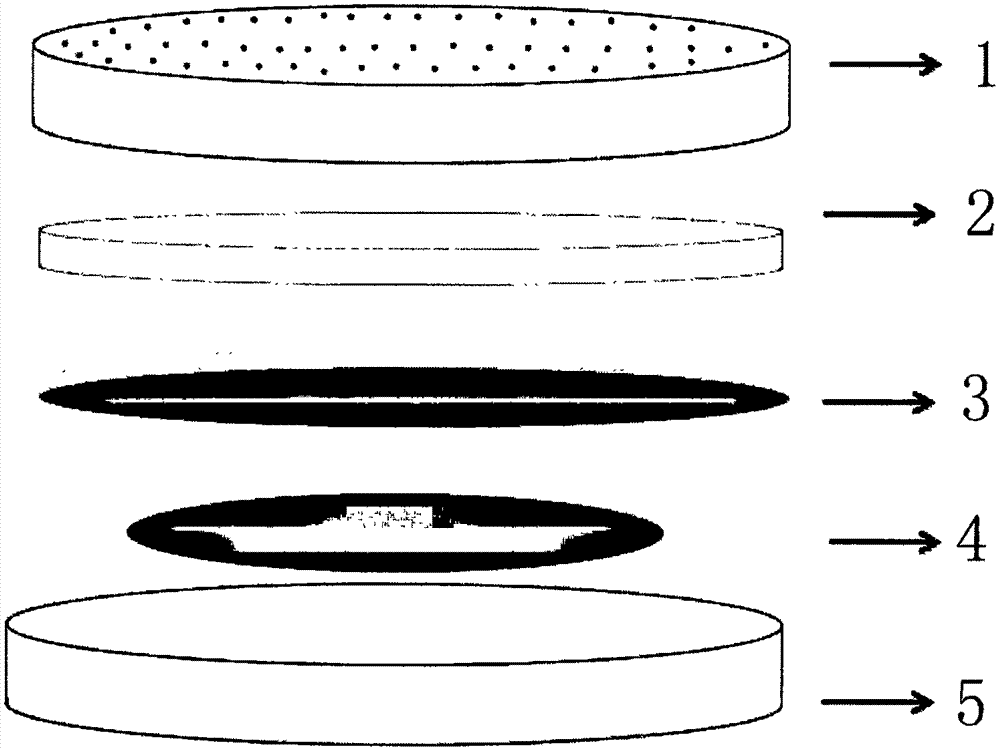

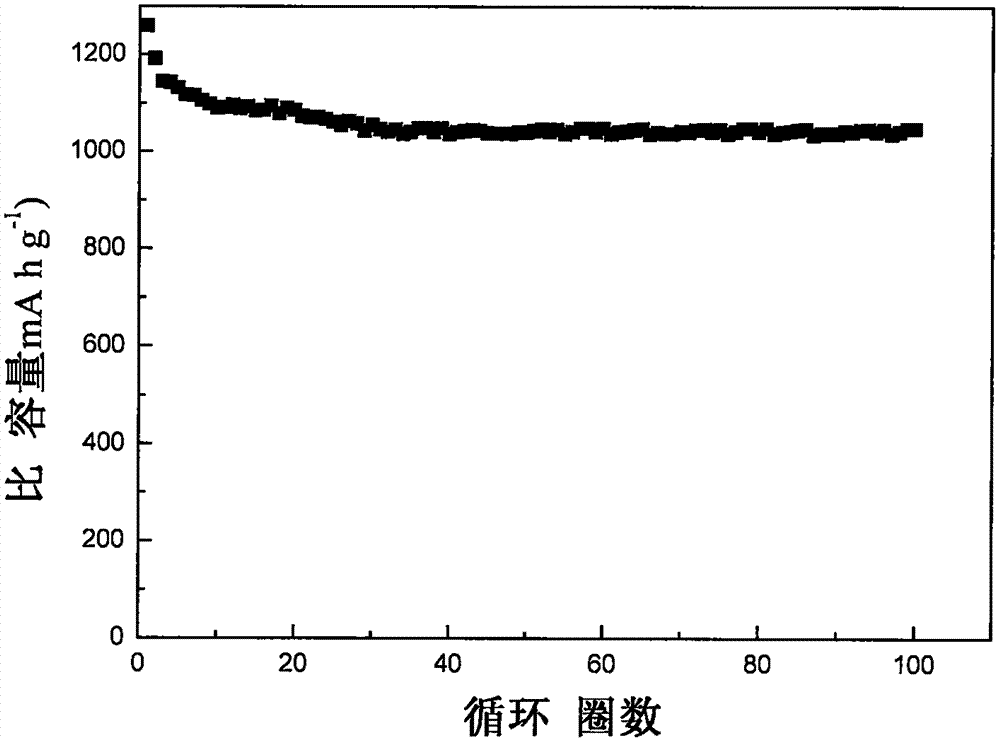

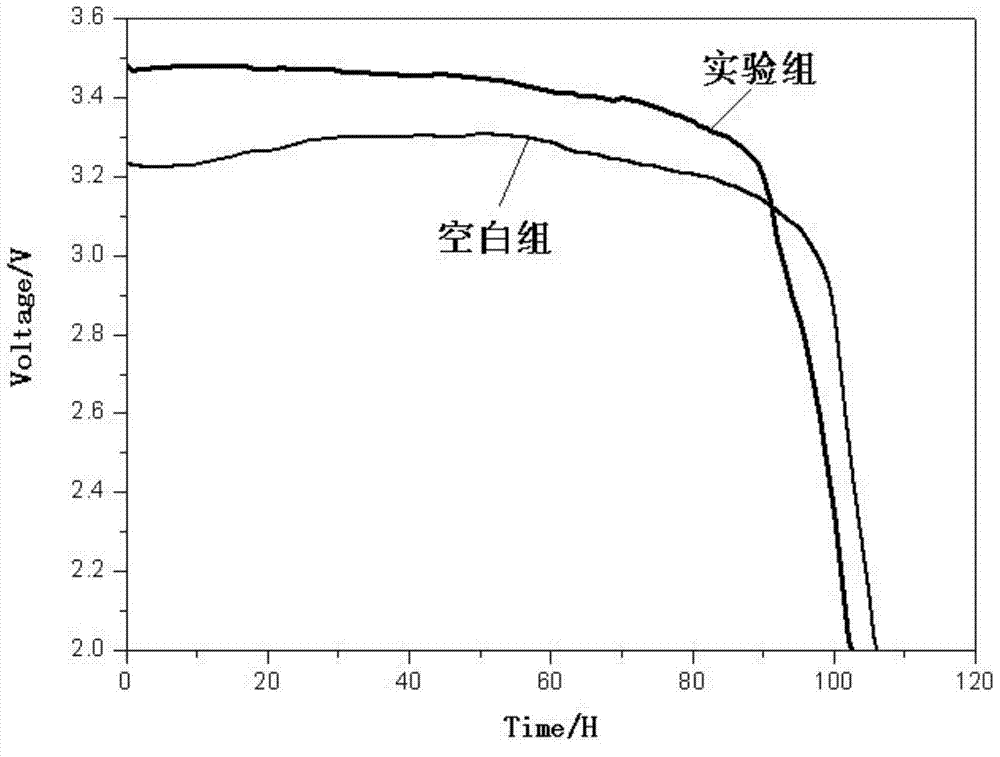

Isolating layer used for lithium-sulfur battery

InactiveCN106935773ALower internal resistanceIncrease loopCell seperators/membranes/diaphragms/spacersSulfonateInternal resistance

The invention relates to an isolating layer used for a lithium-sulfur battery. The surfaces of a positive electrode, a negative electrode or a diaphragm are coated with the isolating layer, or the isolating layer can be attached to the space between the positive electrode and diaphragm or between the negative electrode and diaphragm in an independent sheet-shaped solid way so as to protect the battery; and the functional isolating layer comprises three components, including a functional agent, a binder and a conductive agent, wherein the functional agent is a lithium sulfonate group-containing carbon material, a polymer, or a mixture of the carbon material and the polymer, and a material formed by the carbon material and the polymer and corresponding metal oxides thereof based on different proportions in a mixing manner. By virtue of lithium sulfonate included in the components of the isolating layer, lithium ion concentration in an electrolyte and ion mass transfer rate are improved; by virtue of the existence of sulfonate, the ionic conductivity can be reinforced, and by matching with the use of the binder, an obvious chemical blocking and adsorption effect on lithium polysulfide is achieved, so that dissolving and diffusion are effectively suppressed, and surface passivation, formed by deposition of insoluble lithium polysulfide, on the lithium negative electrode surface can be relieved; and meanwhile, by virtue of the addition of the conductive agent, the internal resistance of the battery is lowered.

Owner:NO 63971 TROOPS PLA

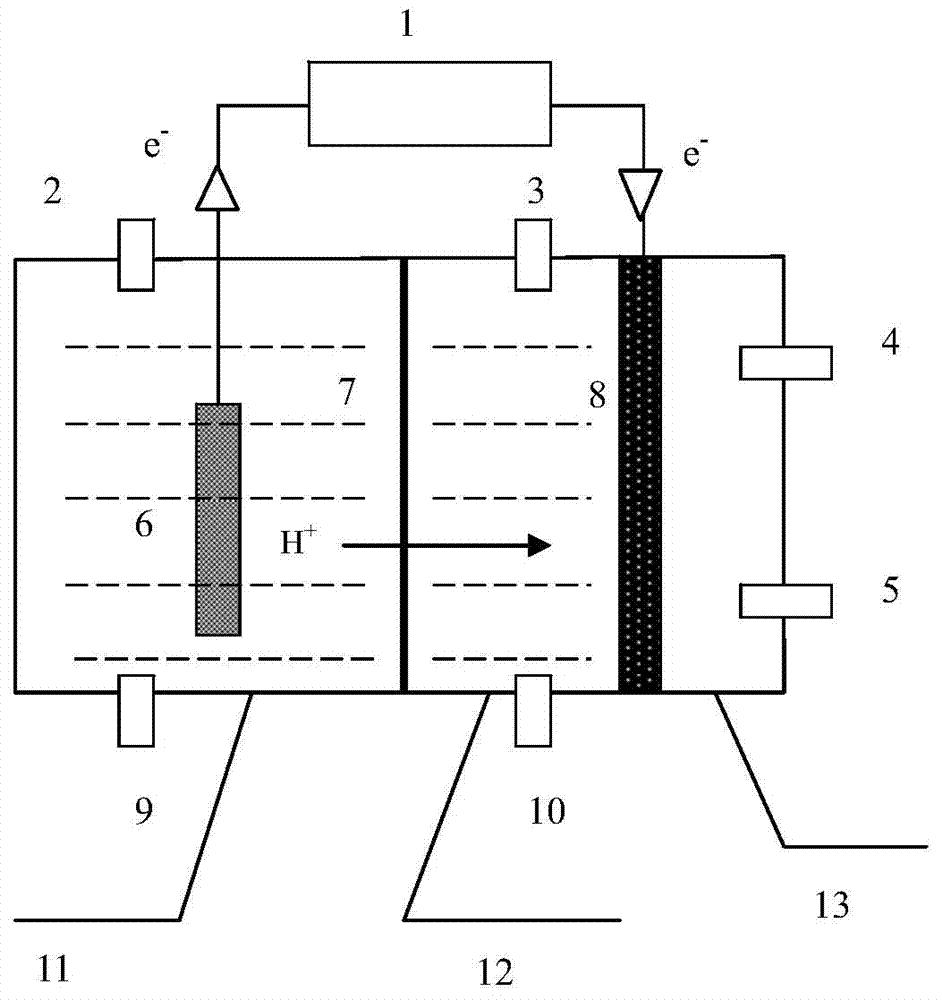

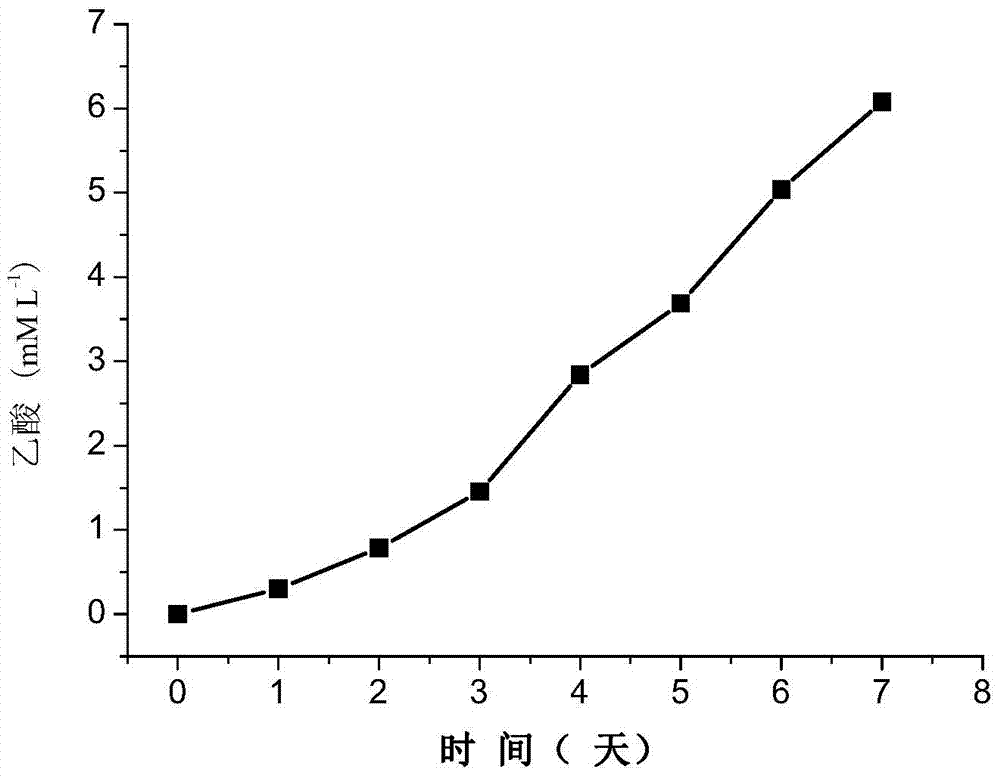

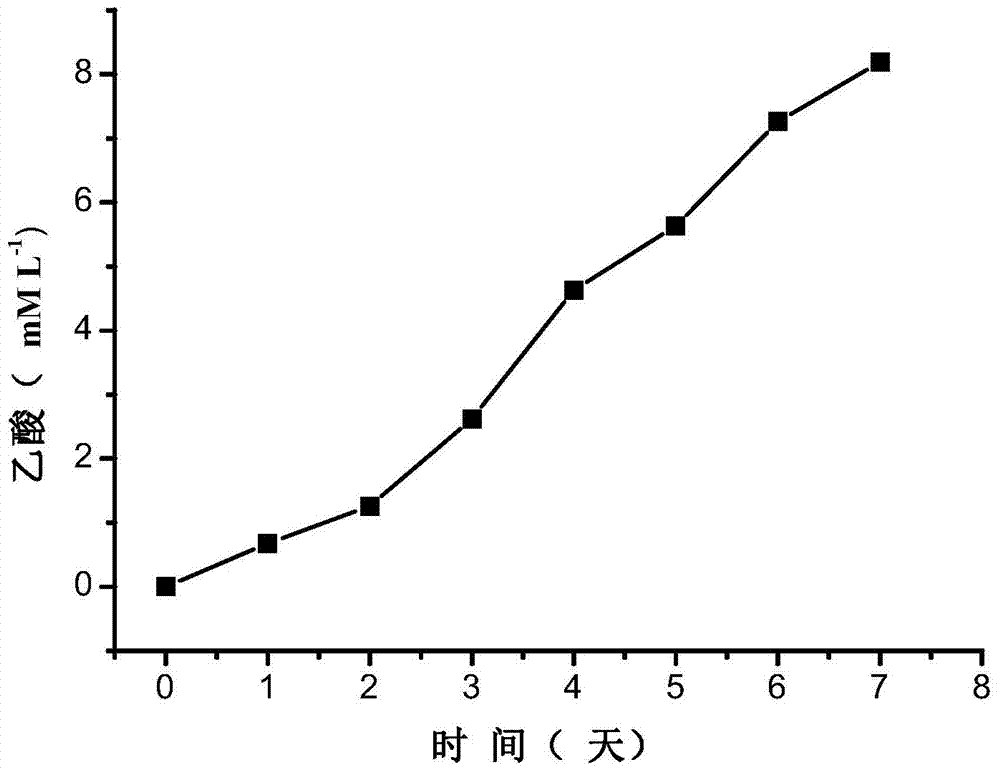

Apparatus and method for producing acetic acid by reducing carbon dioxide through microbial-electrochemical system

ActiveCN104328046ALow costIncrease mass transfer rateProductsElectrolysis componentsElectrochemical responseAcetic acid

The invention provides an apparatus and a method for producing acetic acid by reducing carbon dioxide through a microbial-electrochemical system. The apparatus includes an anode chamber and a cathode chamber, wherein the anode chamber and the cathode chamber separated by a separator. An anode is arranged inside the anode chamber and a cathode is arranged inside the cathode chamber. The anode and the cathode are connected in series outside the anode chamber and the cathode chamber through a power supply to form a loop. The cathode divides the cathode chamber into a cathode liquid chamber and a cathode gas chamber and is a gas diffusion electrode. The invention also discloses a method for producing acetic acid by reducing carbon dioxide through the apparatus. In the invention, the cathode is in the structure of a gas diffusion electrode so that a mass transfer rate and a catalytic rate of carbon dioxide in an electrochemical reaction. An acetic acid generating rate is higher. The apparatus and the method have an important application prospect in fixation and conversion of carbon dioxide.

Owner:NANJING UNIV OF TECH

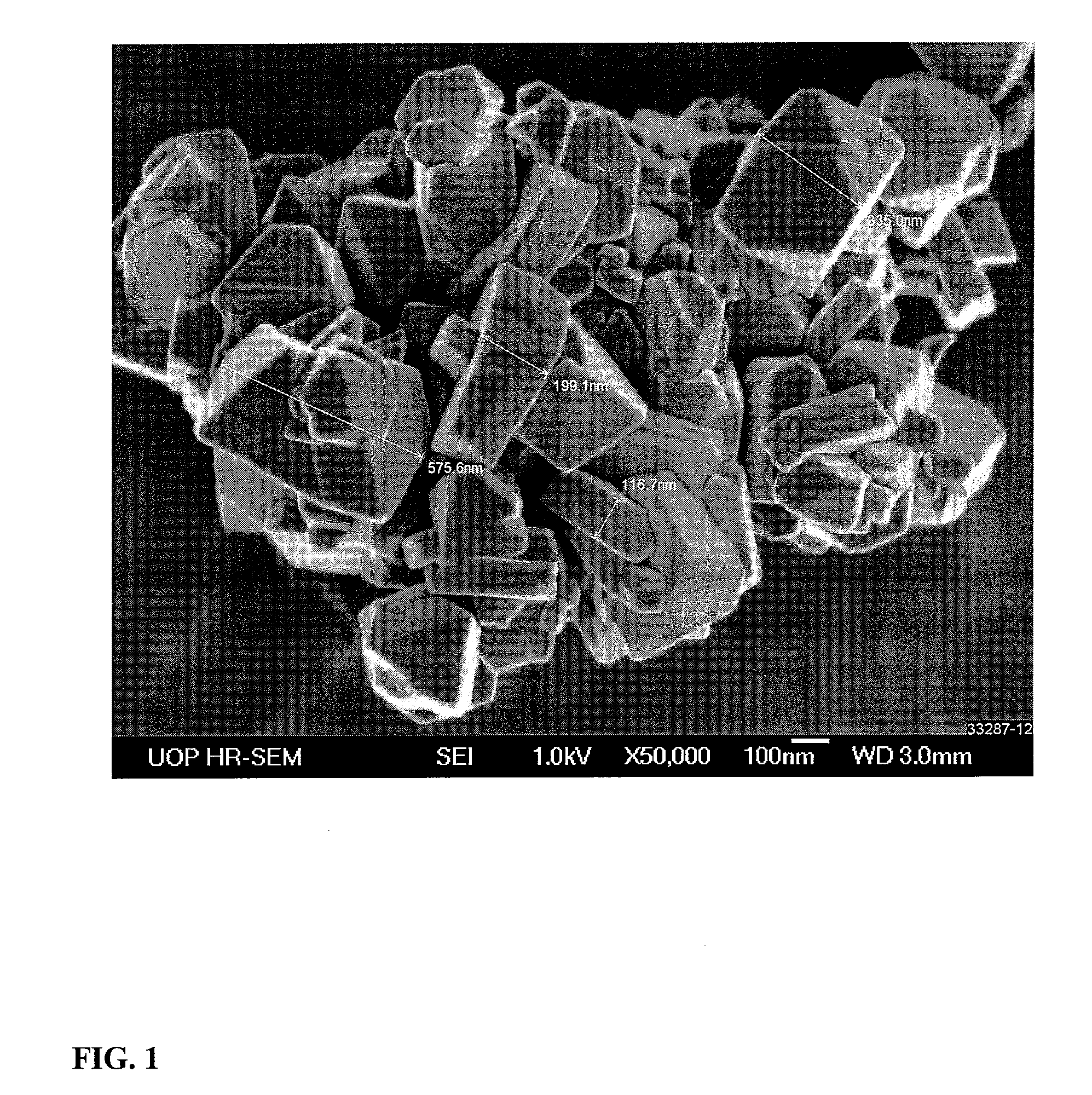

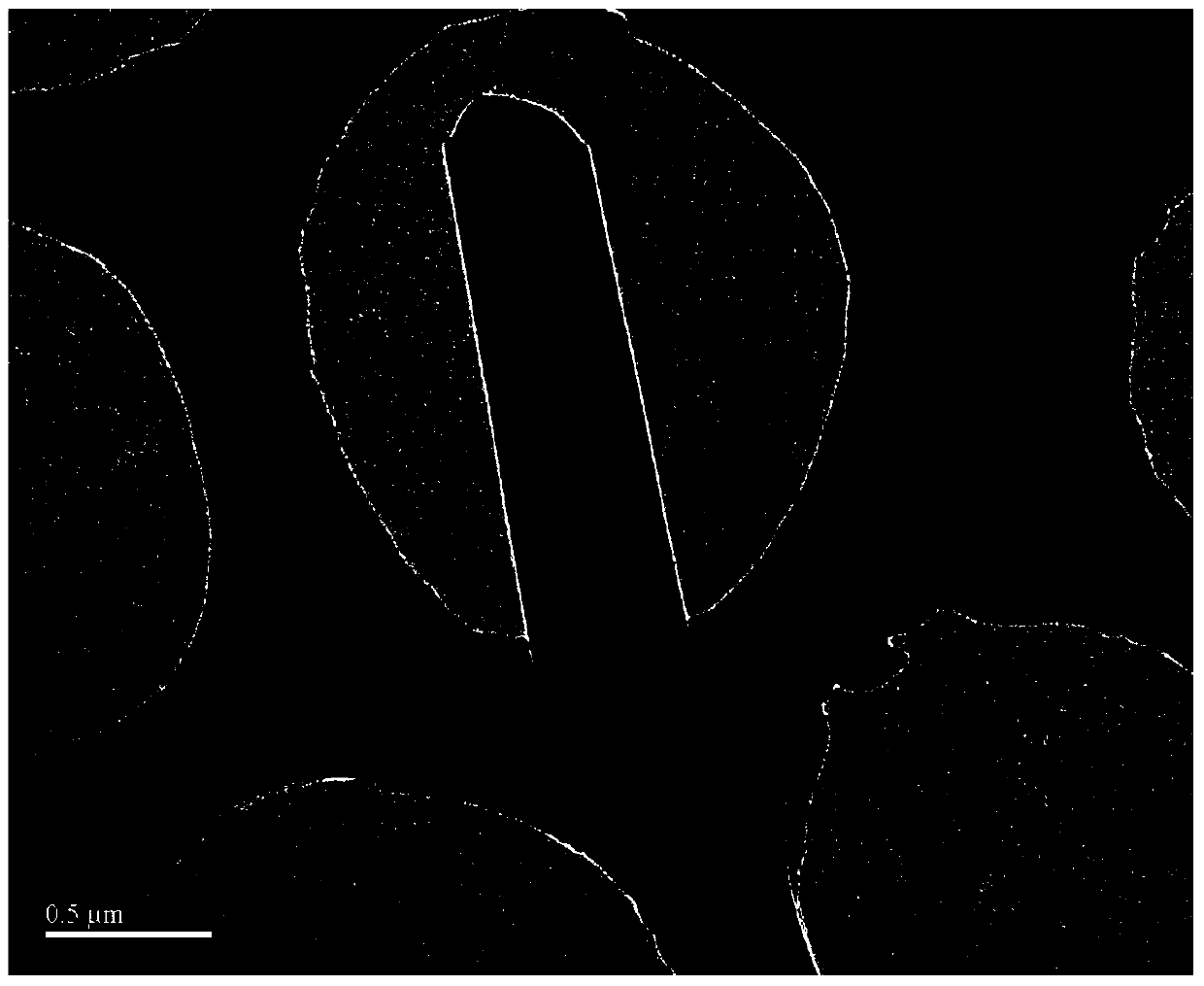

Adsorbent and process for the separation of meta-xylene from aromatic hydrocarbons

ActiveUS7728187B2Improve performanceGreat massMaterial nanotechnologyHydrocarbonsMeta-xyleneOrtho-xylene

Owner:UOP LLC

Method for preparing high-purity bulleyaconitine A

The invention discloses a method for preparing high-purity bulleyaconitine A. The method comprises the following steps of: soaking a fresh radix aconiti agrestis root in acid aqueous solution, performing homogenate extraction and cavitation mixing solid-liquid extraction, collecting and concentrating the filtrate, and respectively performing gradient elution to obtain a crude bulleyaconitine A product through ion exchange resin column chromatography and macroporous adsorption resin column chromatography; and uniformly mixing crude bulleyaconitine A product and ethanol aqueous solution, dissolving in a water bath, cooling the filtrate to room temperature, standing and crystallizing at the temperature of 4 DEG C, repeatedly washing the crystal by using the ethanol aqueous solution, and obtaining a final product. According to the method, crushing and extracting are finished in one step through a homogenization method, and the method has the advantages of zero dust and simple flow. By adoption of a negative-pressure cavitation extraction technology, the mass transfer rate is improved, heating is not required, and the production period is shortened; and moreover, the reagents used in the whole process are ethanol and water, the organic solvent amount is greatly reduced, the production cost can be reduced, the environmental pollution is reduced, and the method has good application prospect.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

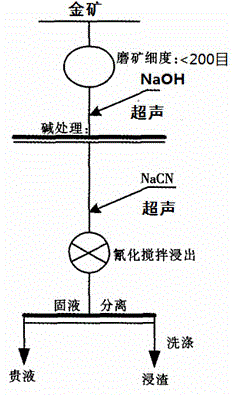

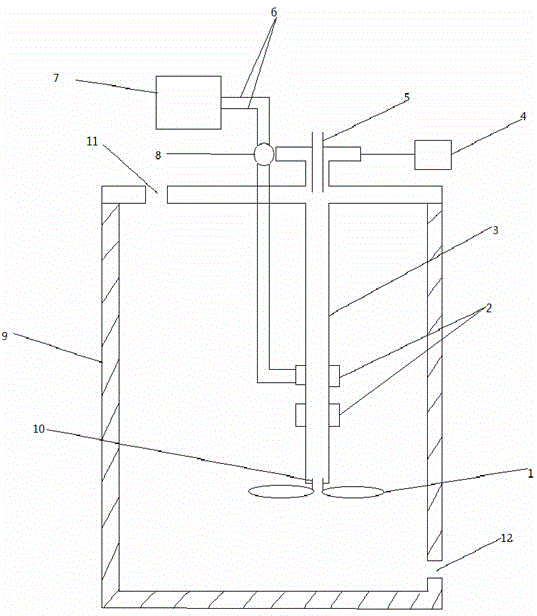

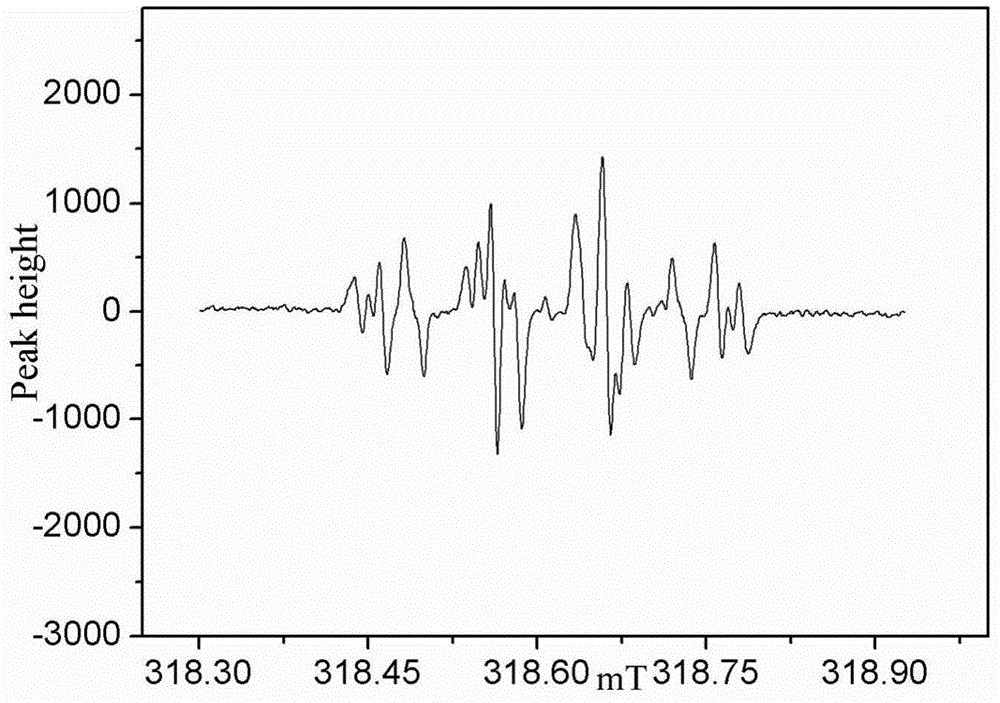

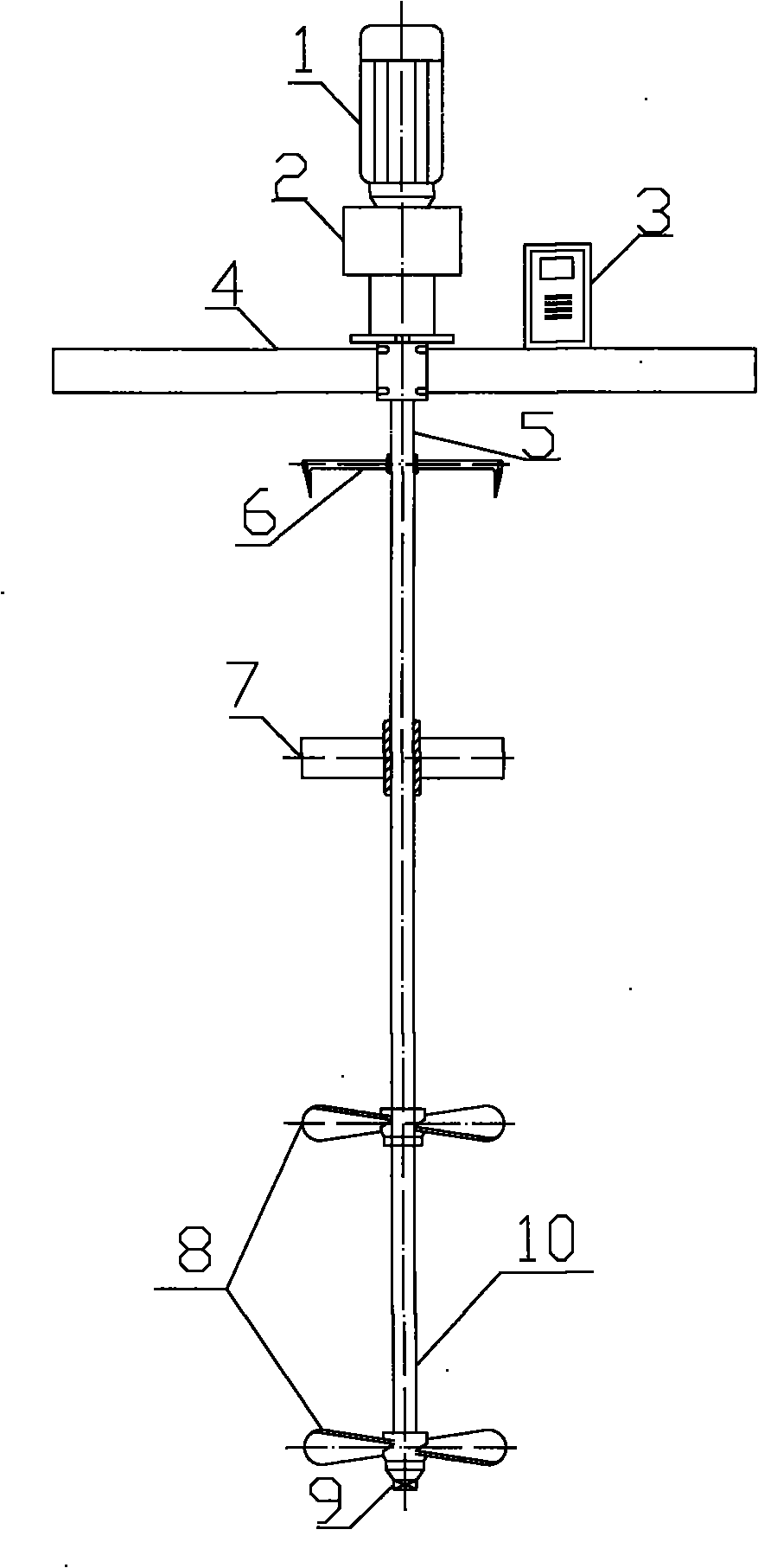

Ultrasonic intensified leaching method for refractory gold ores and ultrasonic intensified gold leaching stirrer

InactiveCN104131160AAccelerated gas stirringReduce disassemblyProcess efficiency improvementImpellerGas phase

Belonging to the technical field of wet metallurgy, the invention relates to an ultrasonic intensified leaching method for refractory gold ores and an ultrasonic intensified gold leaching stirrer. The method includes: firstly crushing gold ores to prepare an ore pulp, and then subjecting the ore pulp to pretreatment and leaching processes, in which ultrasonic intensified treatment is adopted. The ultrasonic intensified gold leaching stirrer includes a trough body, a feed inlet, a discharge port, a stirring structure, an ultrasonic structure and a ventilation structure. In the pretreatment and leaching processes, the method employs the ultrasonic method to perform intensified treatment on refractory gold ores, especially by adopting the ultrasonic method in the pretreatment process, the reaction time is shortened, and the leaching effect is intensified. The transmission shaft and stirring impellers of the ultrasonic intensified gold leaching stirrer deviate from the trough body center, thus effectively preventing the swirling phenomena, being beneficial to uniform mixing of solid-liquid-gas phase, and increasing the mass transfer rate.

Owner:KUNMING UNIV OF SCI & TECH

Hydrogen sulfide removal method based on photocatalytic spraying

Owner:JIANGSU UNIV

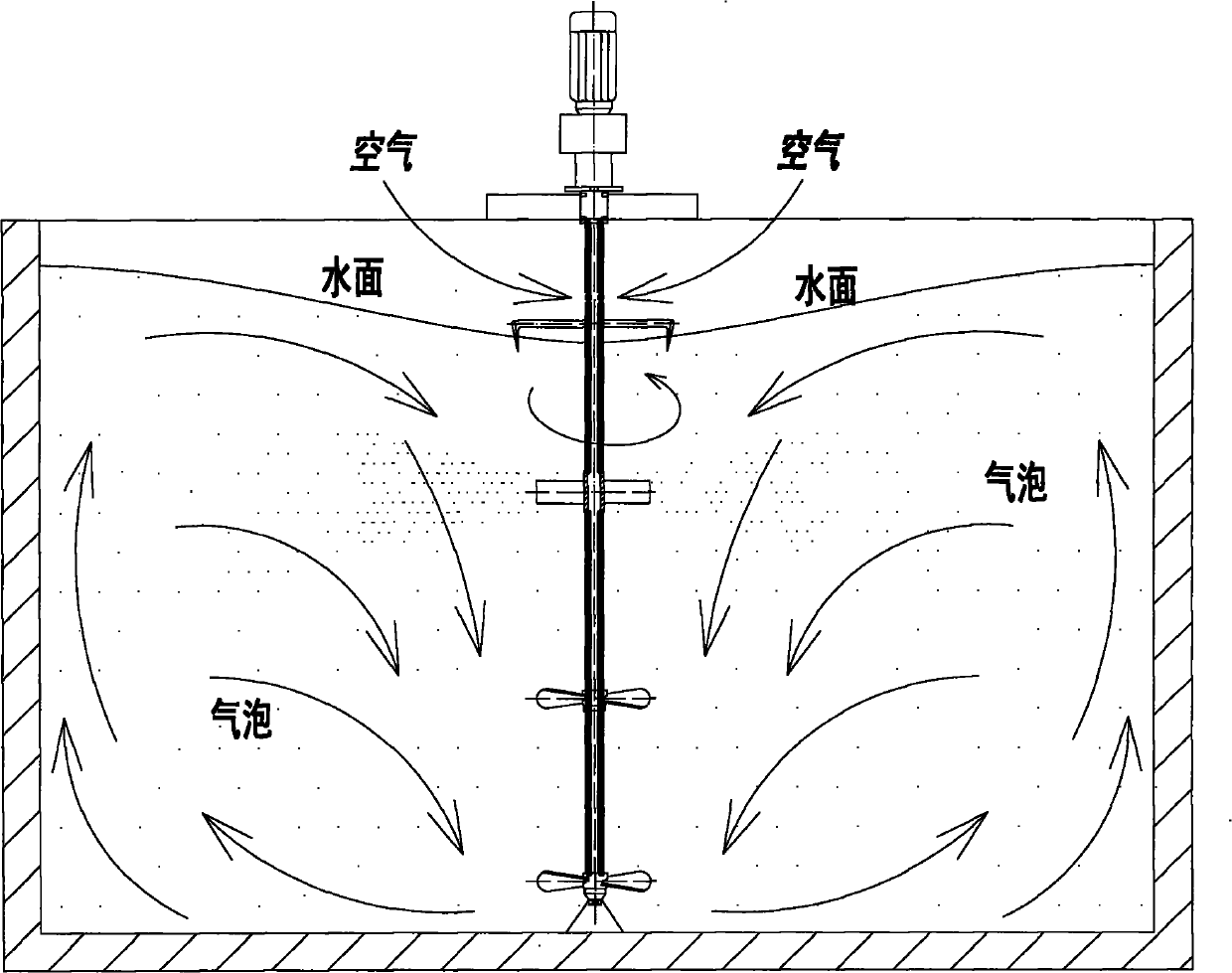

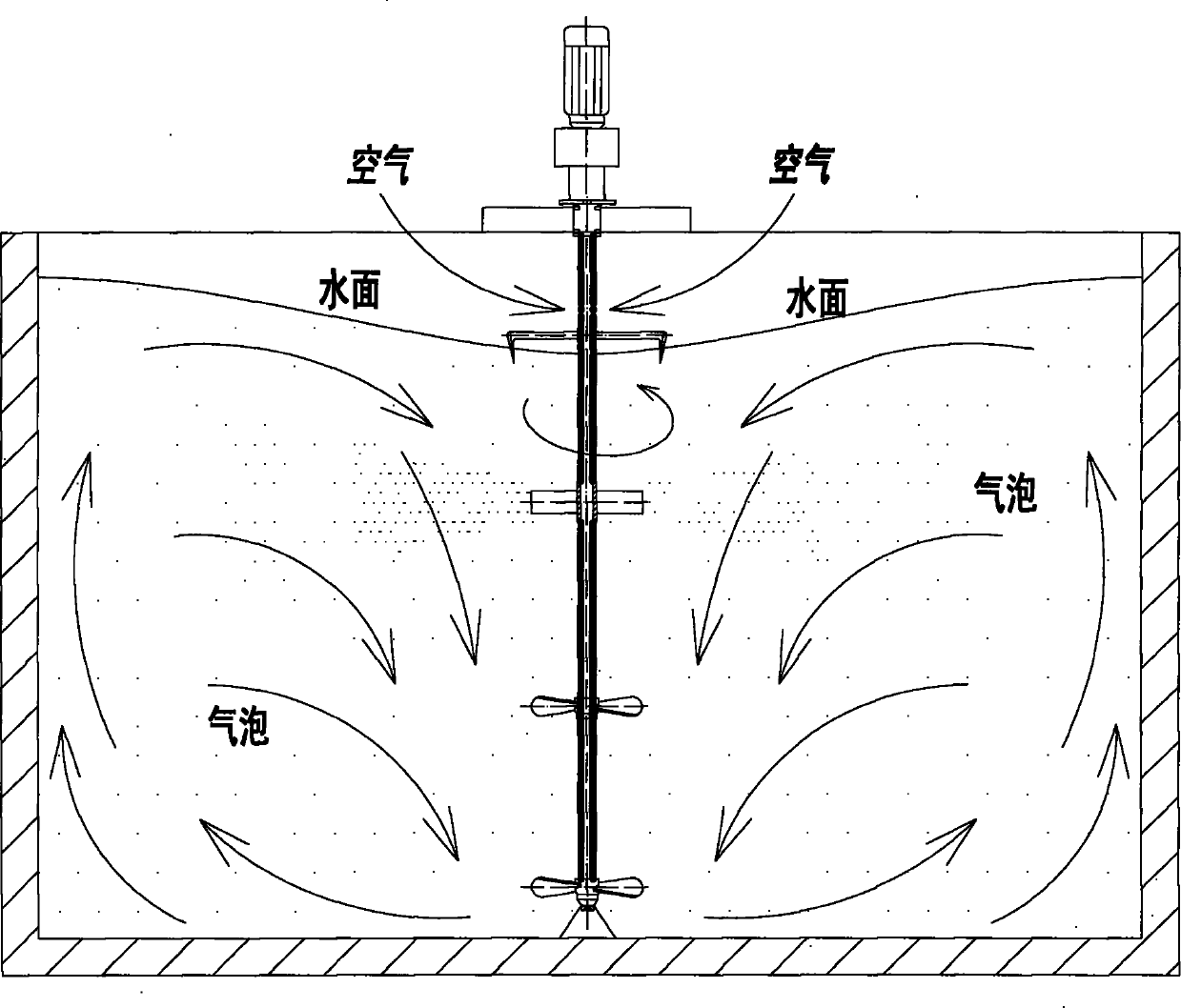

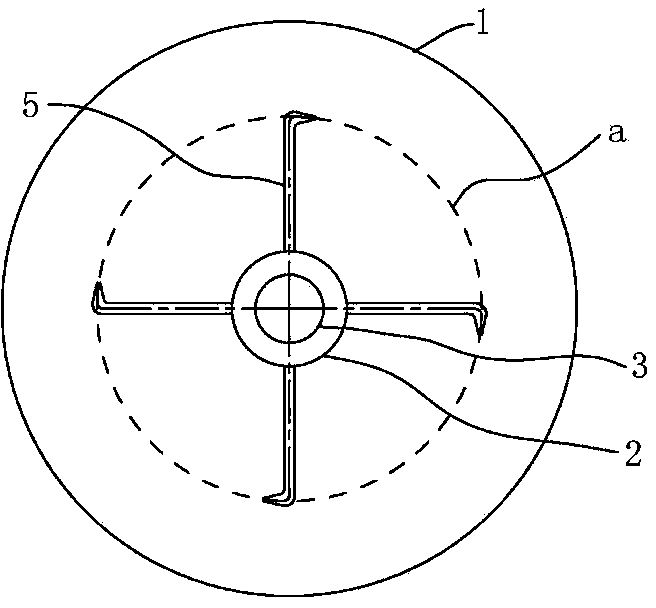

Multifunctional high-efficiency aerator and using method thereof

InactiveCN101767887AIncrease mass transfer rateOptimal treatment processWater aerationTreatment with aerobic and anaerobic processesMicro bubbleSludge

The present invention provides a multifunctional high-efficiency aerator and using method thereof, comprising the following steps: when aeration, starting an electric motor to drive a hollow shaft, a de-foaming paddle, an air inhaling turbine and stirring impellers to rotate; inhaling air by an air hole at the upper end of the hollow shaft and spraying out from a pore in the turbine when rotation speed of the air inhaling turbine reaches to the critical rotation speed; simultaneously, dispersing big bubbles to fine micro-bubble by shearing force nearby the turbine and fluctuant force of dynamic pressure; cutting and crushing big bubbles by the de-foaming paddle; simultaneously, forming axial flow under the actions of the stirring impellers and continuously updating liquid level; bringing foam on surface to the bottom of the pool; uniformly dispersing bubbles in a reactor under the mixing and stirring of the stirring impellers; forming a suspending state for mud; achieving complete contact of three-phase of air-solid-liquid. The aeration method provided in the present invention has high mass transfer rate of oxygen, good oxygenation effect and strong property for suiting environment.

Owner:宜兴阳源环境工程有限公司

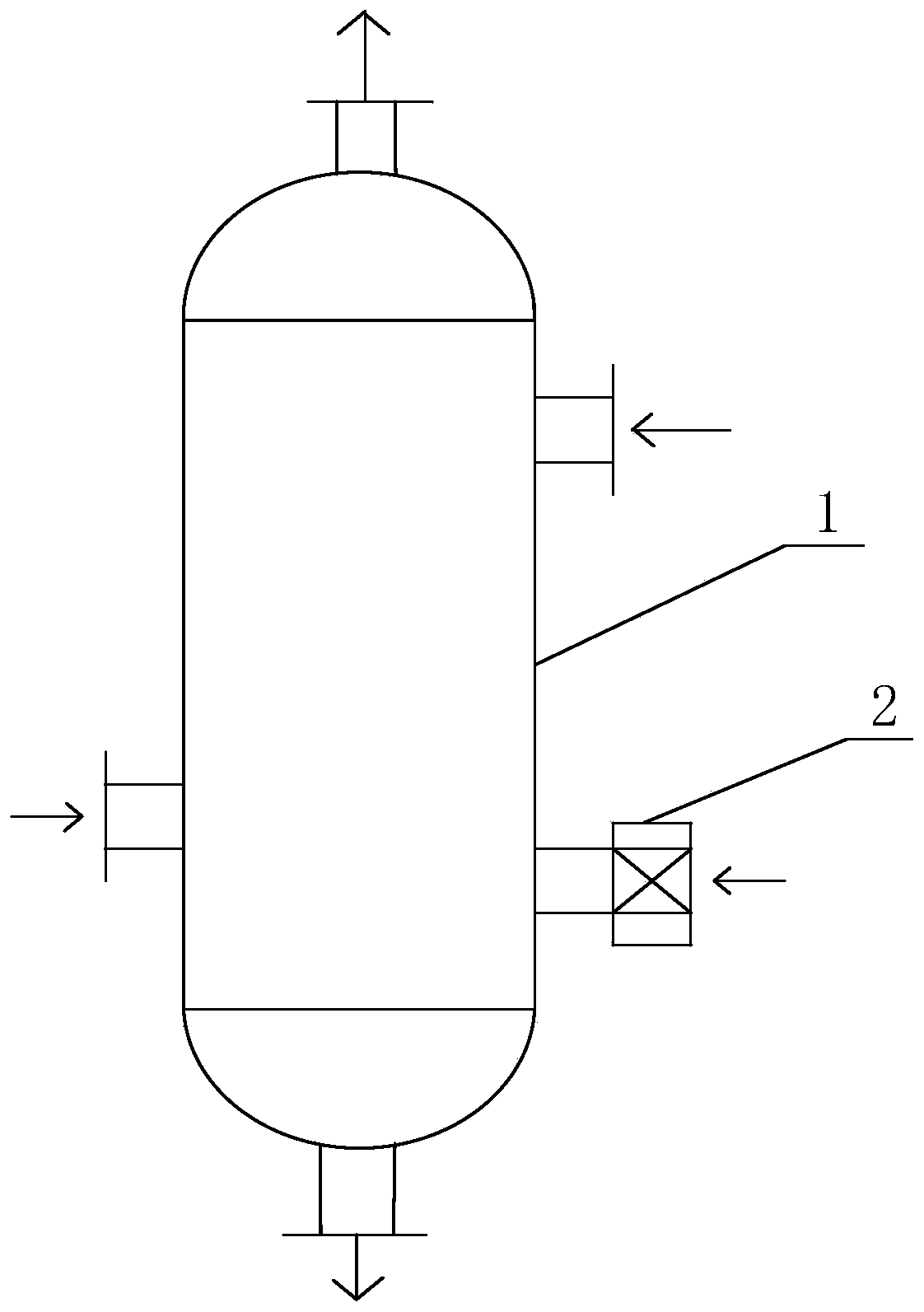

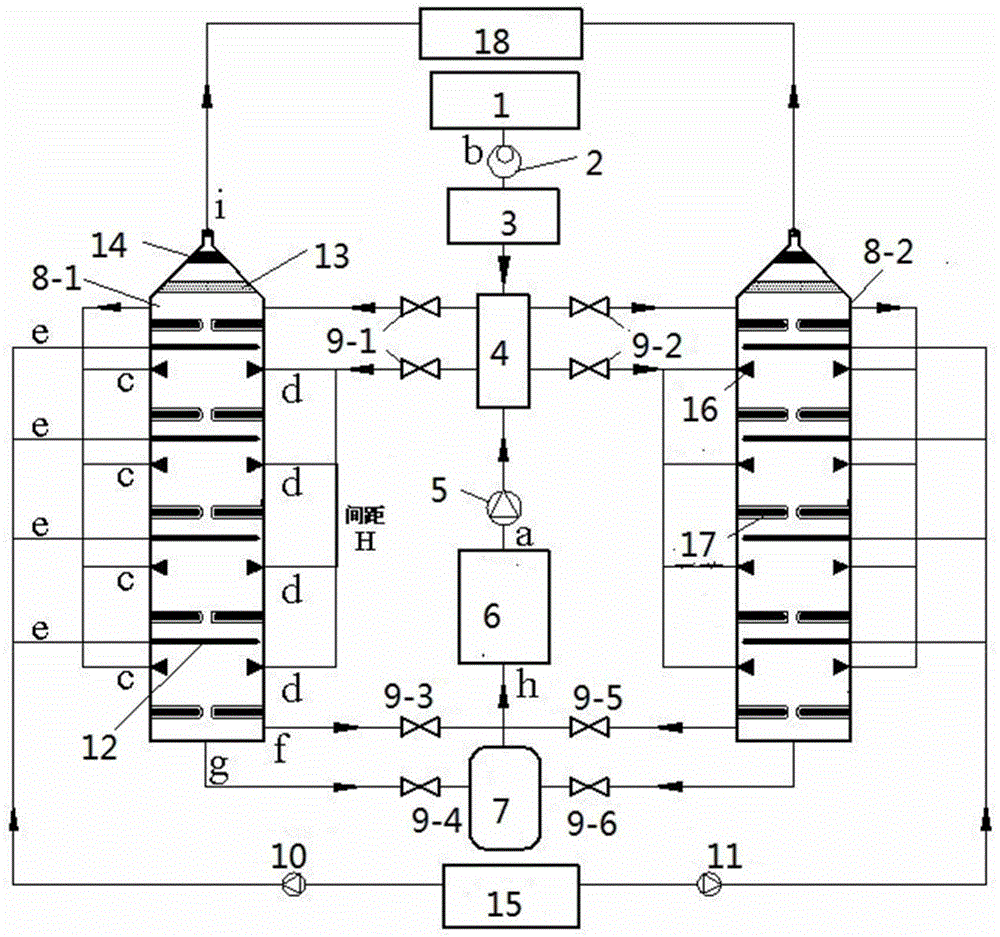

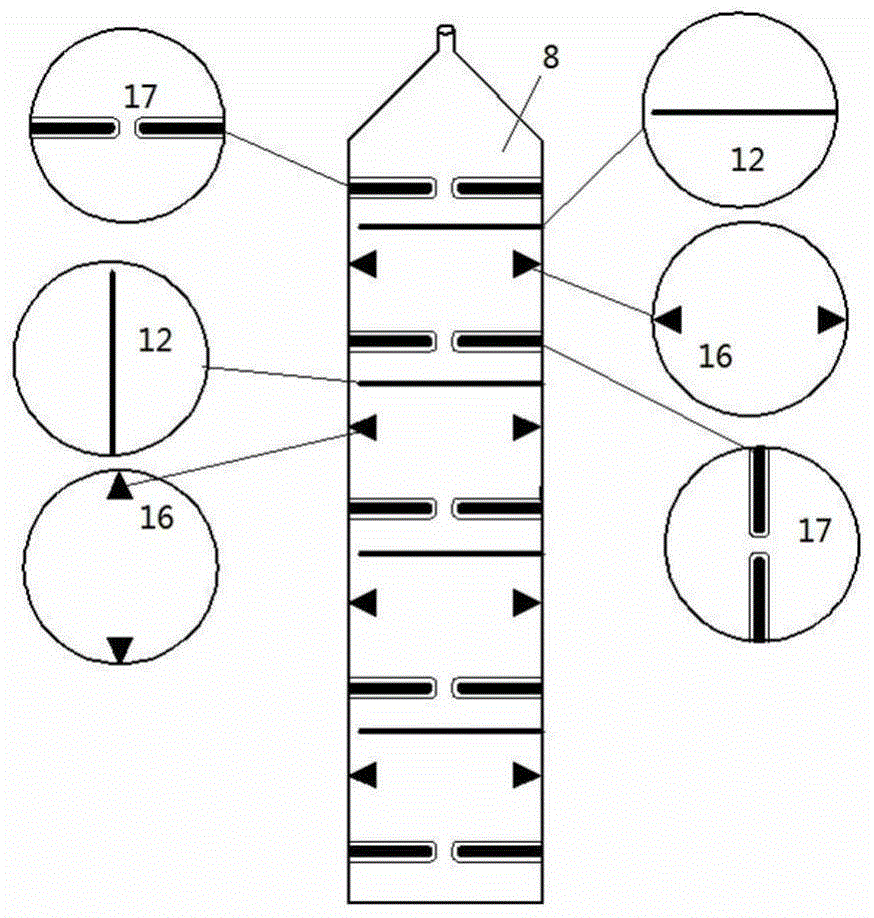

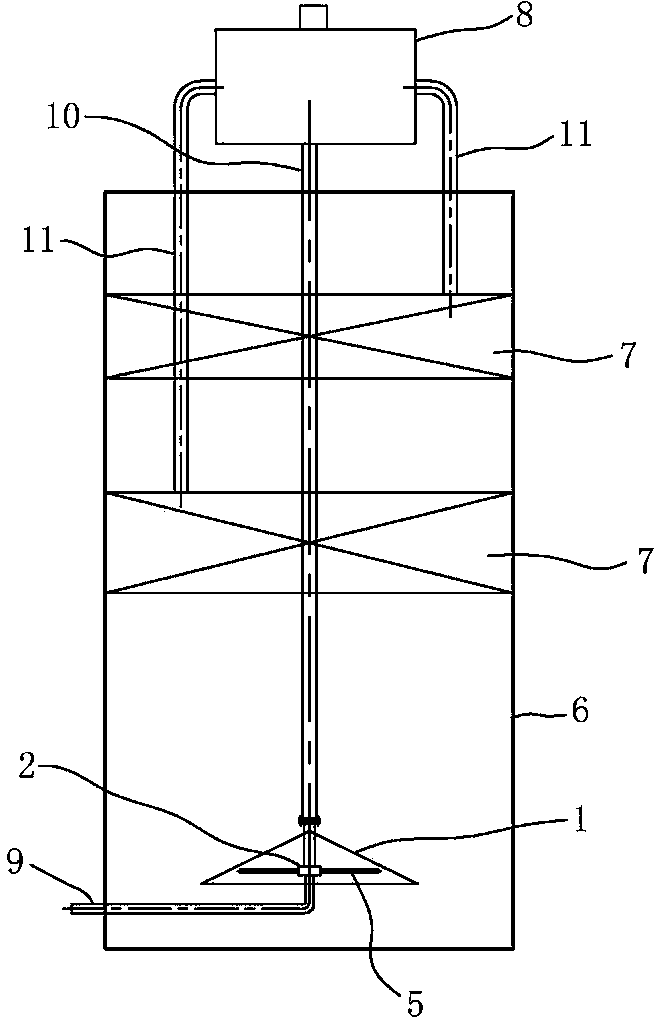

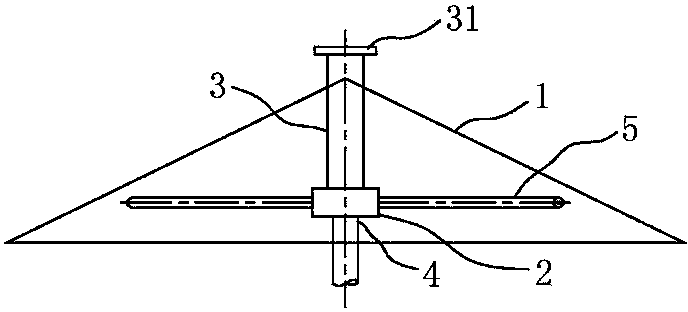

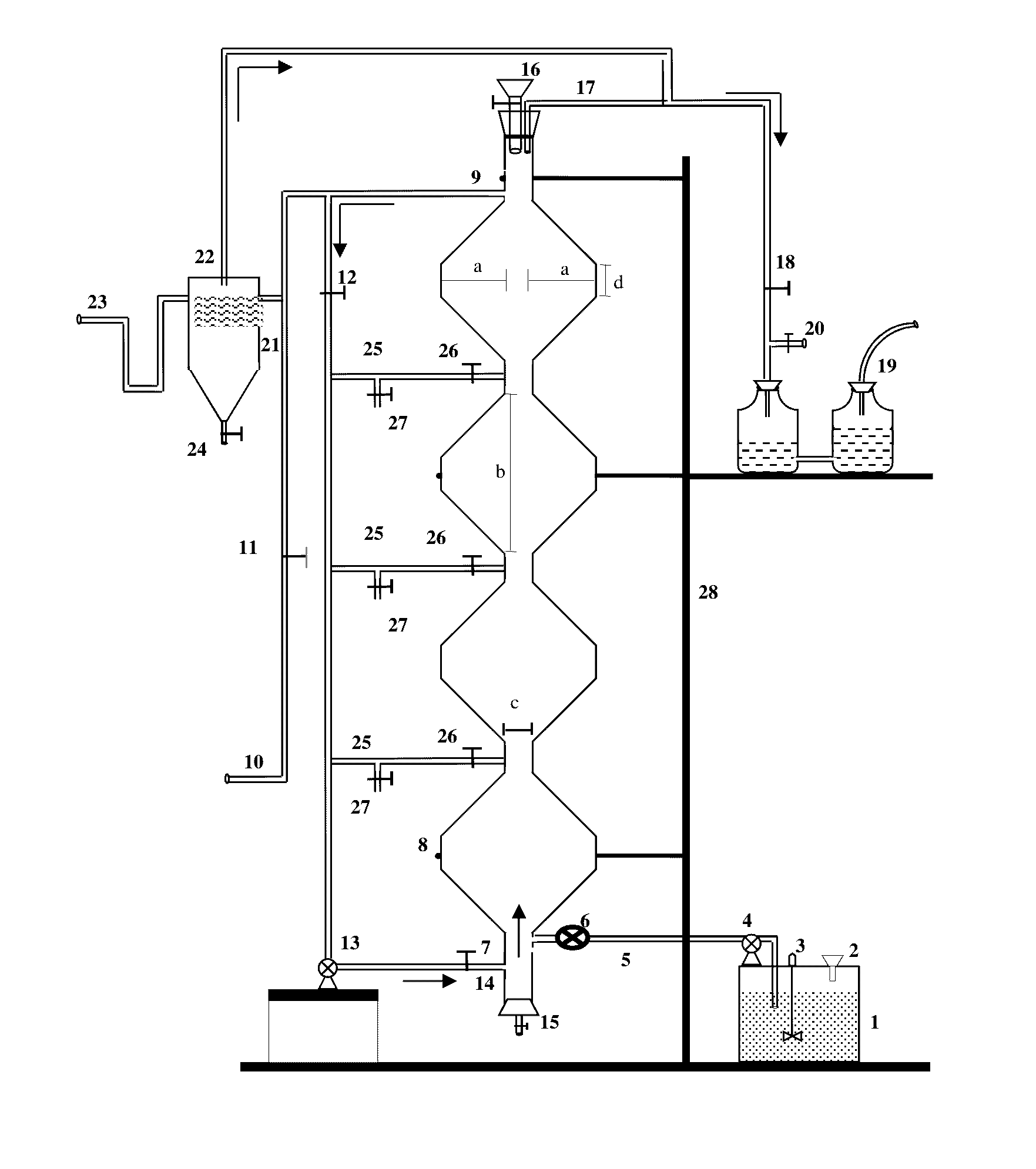

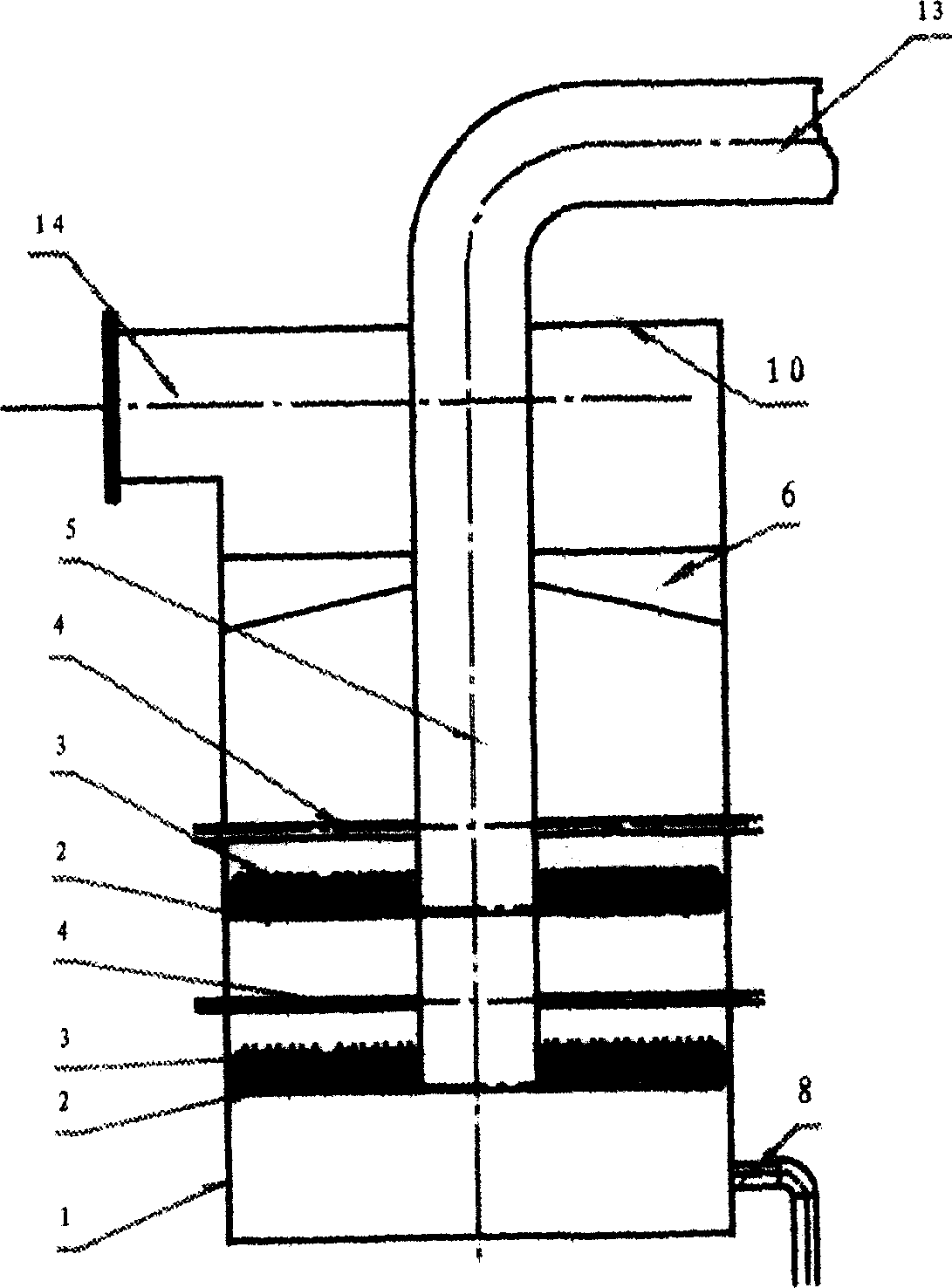

Anaerobic reactor and swirl water distributor with integrated water feeding and internal circulation of anaerobic reactor

InactiveCN103723826ASimple structureReduce head pressure lossTreatment with anaerobic digestion processesAnaerobic reactorDistributor

The invention discloses a swirl water distributor with integrated water feeding and internal circulation. The swirl water distributor comprises a water distribution umbrella and an inlet water distributor which is positioned in the water distribution umbrella and on the central axis of the water distribution umbrella, wherein the inlet water distributor is provided with a water inlet and a back flow receiving pipe with an upward opening, a plurality of water distribution branch pipes with water distribution nozzles at tail ends and positioned in the water distribution umbrella are extended at the periphery of the inlet water distributor at the same time, and the water distribution nozzles are positioned on the water outlet circumference. The invention also discloses an anaerobic reactor provided with the swirl water distributor. The anaerobic reactor provided with the swirl water distributor can fully and uniformly distribute water and enable wastewater to fully contact with sludge, so that the mass transfer rate and volume load are improved, and water is uniformly distributed; moreover, the water distributor is simple in structure and simple and convenient in mounting, backflow liquid can reduce the water head pressure loss of the inlet water distributor, and the working efficiency is greatly improved compared with that of the swirl water distributor in the past. The swirl water distributor and the anaerobic reactor disclosed by the invention are widely used in wastewater treatment environmental protection engineering.

Owner:GUANGDONG JINLI ENVIRONMENTAL PROTECTION TECH +1

Adsorbent and process for the separation of meta-xylene from aromatic hydrocarbons

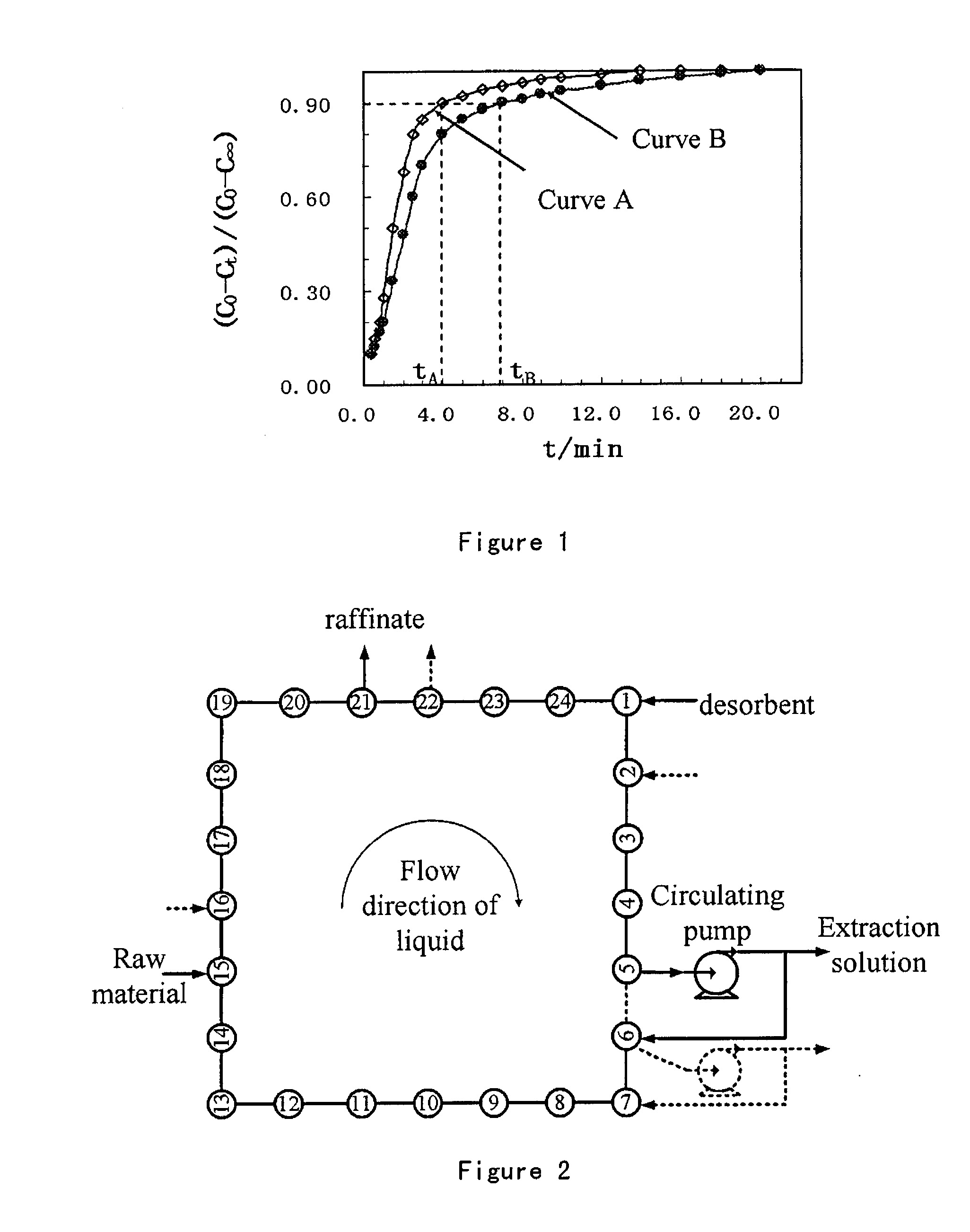

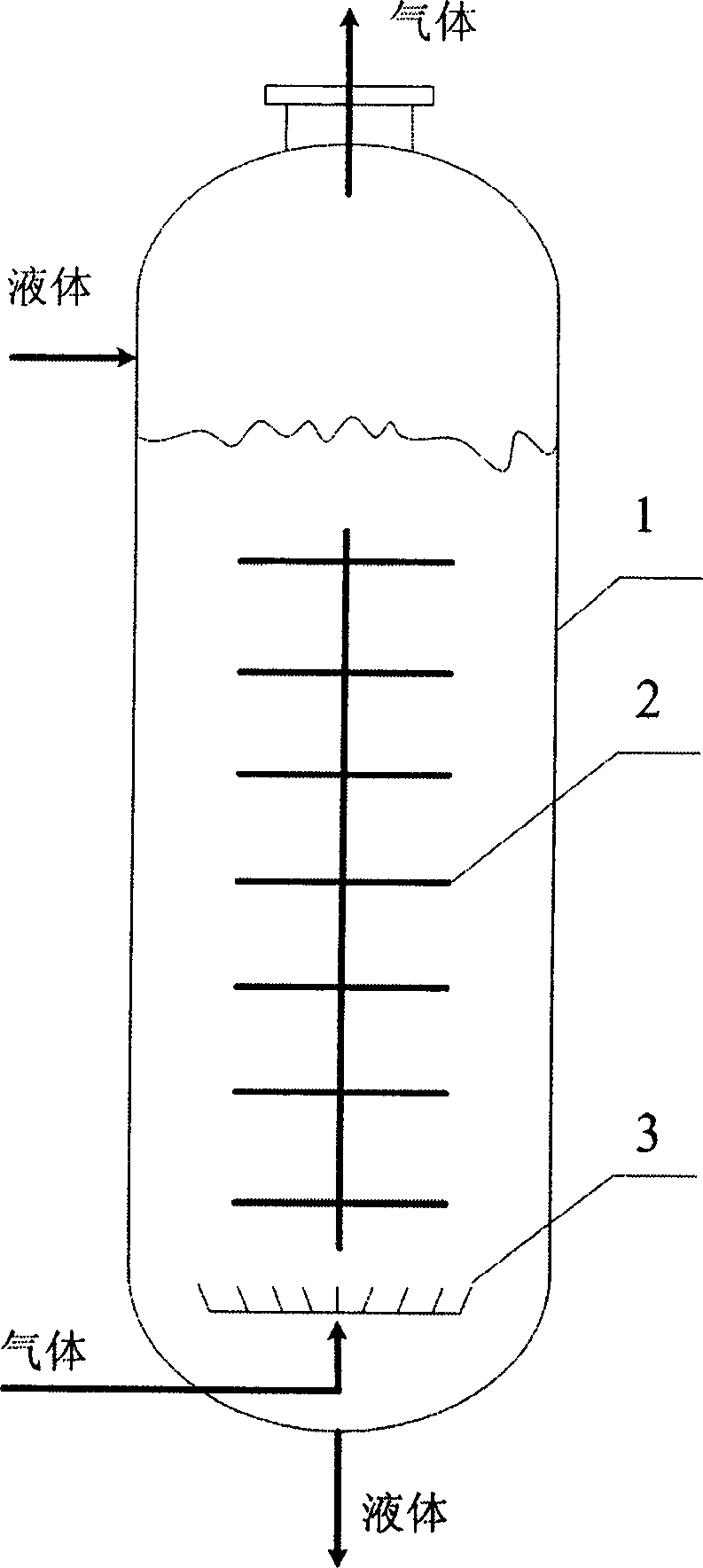

ActiveUS20090326310A1Improve performanceGreat massMaterial nanotechnologyHydrocarbonsCrystalliteMass transfer rate

Adsorbents and methods for the adsorptive separation of meta-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable adsorbents comprise sodium zeolite Y having an average crystallite size from about 50 to about 700 nanometers. The adsorbents provide improved separation efficiency, which may be associated with a higher meta-xylene mass transfer rate and / or other beneficial effects. Exemplary desorbents for use in the process may comprise toluene, benzene, or indan.

Owner:UOP LLC

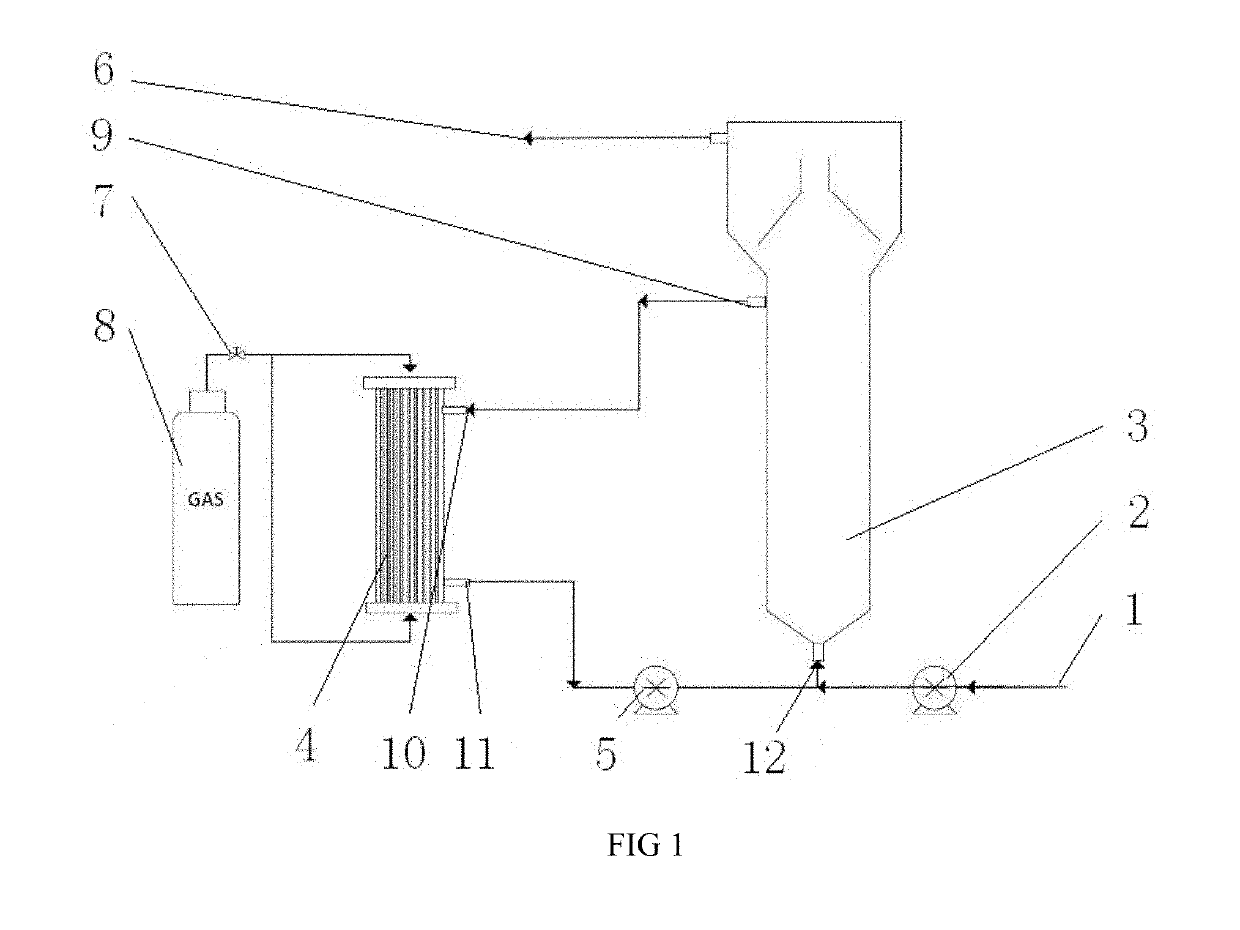

Novel Membrane Aeration Anaerobic Granular Sludge Reactor and Efficient Nitrogen Removal and Greenhouse Gas Emission Reduction Method Thereof

ActiveUS20190202722A1Reduce solubilityLarge gas-liquid mass transfer resistanceWater treatment parameter controlDispersed particle filtrationSolubilityGas cylinder

The present invention discloses a novel membrane aerated anaerobic granular sludge reactor, belonging to the technical field of wastewater treatment. The reactor solves the problems of low solubility of gas substances in an aqueous solution, large gas-liquid mass transfer resistance and low mass transfer rate. The top of a reactor body is provided with a water outlet, and the middle side wall of the reactor body is provided with a middle water outlet; the middle water outlet of the reactor body is connected with a water inlet of a membrane module; a water outlet of the membrane module is connected with a bottom water inlet of the reactor body through a circulating pump, a water inlet is connected with the bottom water inlet of the reactor body through a feed pump, a high pressure gas cylinder outputs high pressure gas to the membrane module, and a gas pressure regulating valve is arranged between the high pressure gas cylinder and the membrane module. The novel membrane aerated anaerobic granular sludge reactor improves the content of a gas substrate therein, and shortens the formation time of granular sludge. The method for efficient nitrogen removal and greenhouse gas mitigation has higher nitrate and ammonia removal rates and a higher dissolved methane removal rate within a shorter time.

Owner:HARBIN INST OF TECH

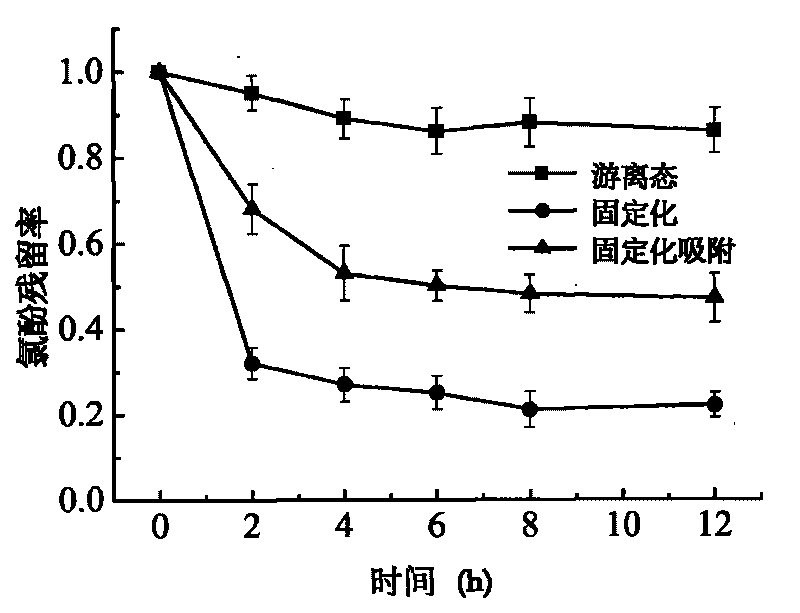

Method for removing 2, 4-dichlorophenol in water by using polyurethane sponge fixed white rot fungi

InactiveCN101734801AAvoid inactivationHigh removal rateWater contaminantsNature of treatment waterPorosityBiological reaction

The invention discloses a method for removing 2,4-dichlorophenol in water by using polyurethane sponge fixed white rot fungi, belonging to the field of environmental microbiology. The method comprises the following steps: preprocessing a carrier, preparing fixed white rot fungi and removing 2, 4-dichlorophenol in water. The carrier has the characteristics of porosity, hydrophily and good adsorbability, enjoys stable chemical property and hydrolytic resistance, high organism bearing capacity and mass transfer rate and is not soluble in acid / alkaline water solution; while the fixed carrier can effectively absorb and fix white rot fungi, improve capacity of fixed white rot fungi in removing 2,4-dichlorophenol in water and leads the fixed white rot fungi to be easily separated from the product, thus being applicable to execute biological reaction processing on multiple sewages.

Owner:BEIJING NORMAL UNIVERSITY

Composite material of nitrogen doped three-dimensional graphene supported nano silver and preparation method thereof

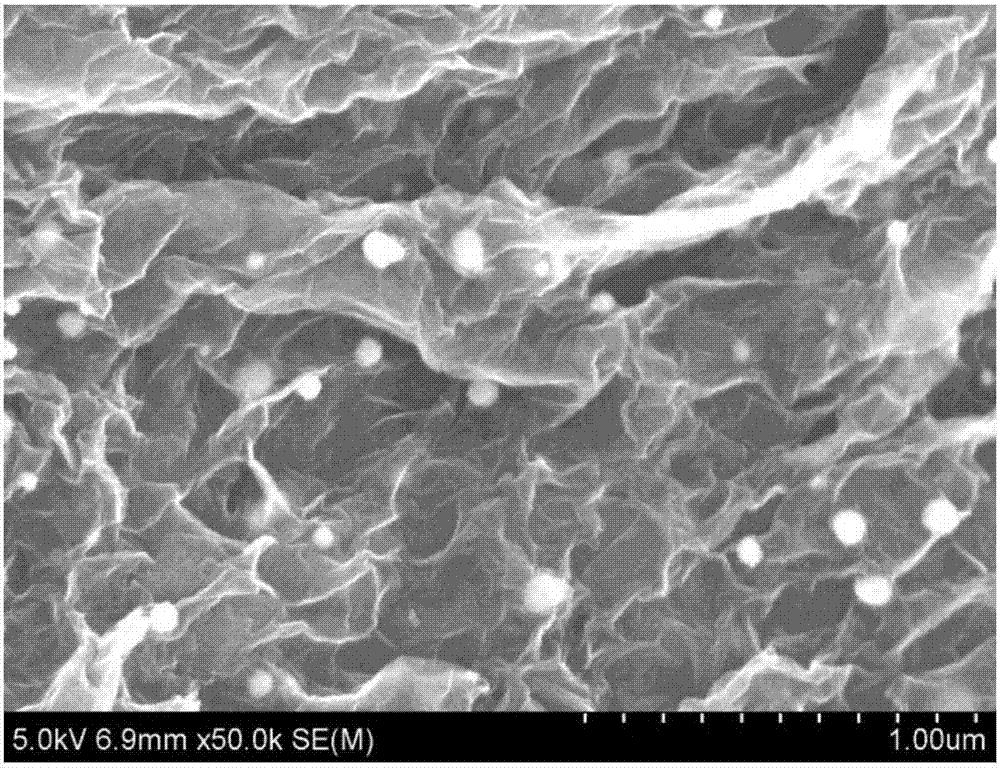

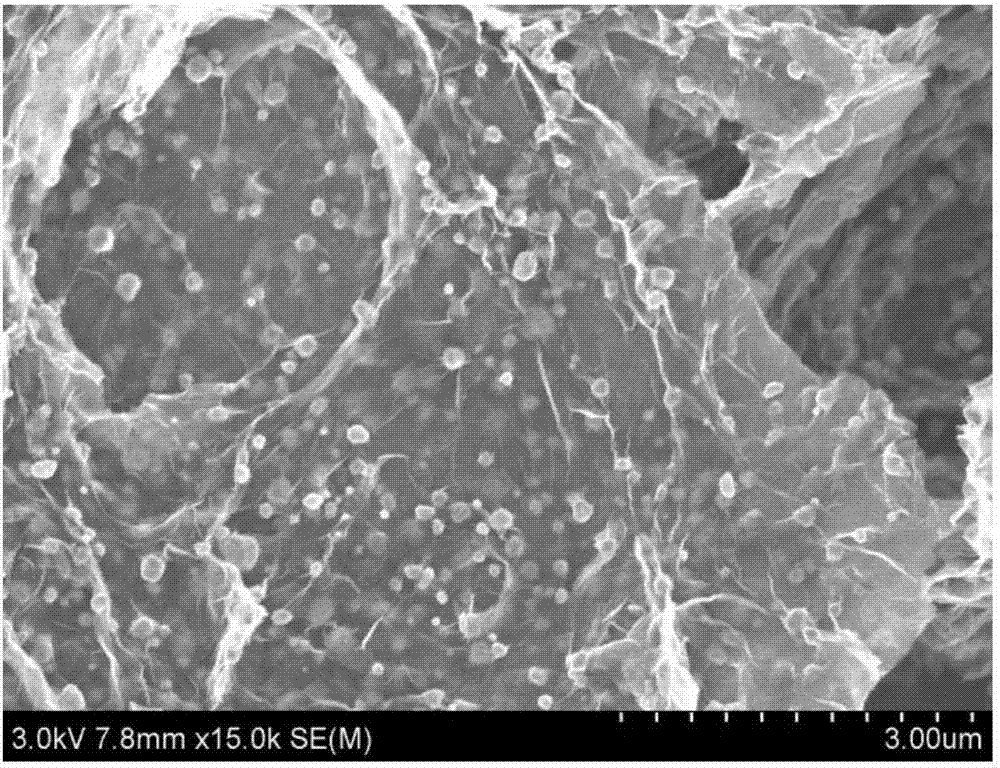

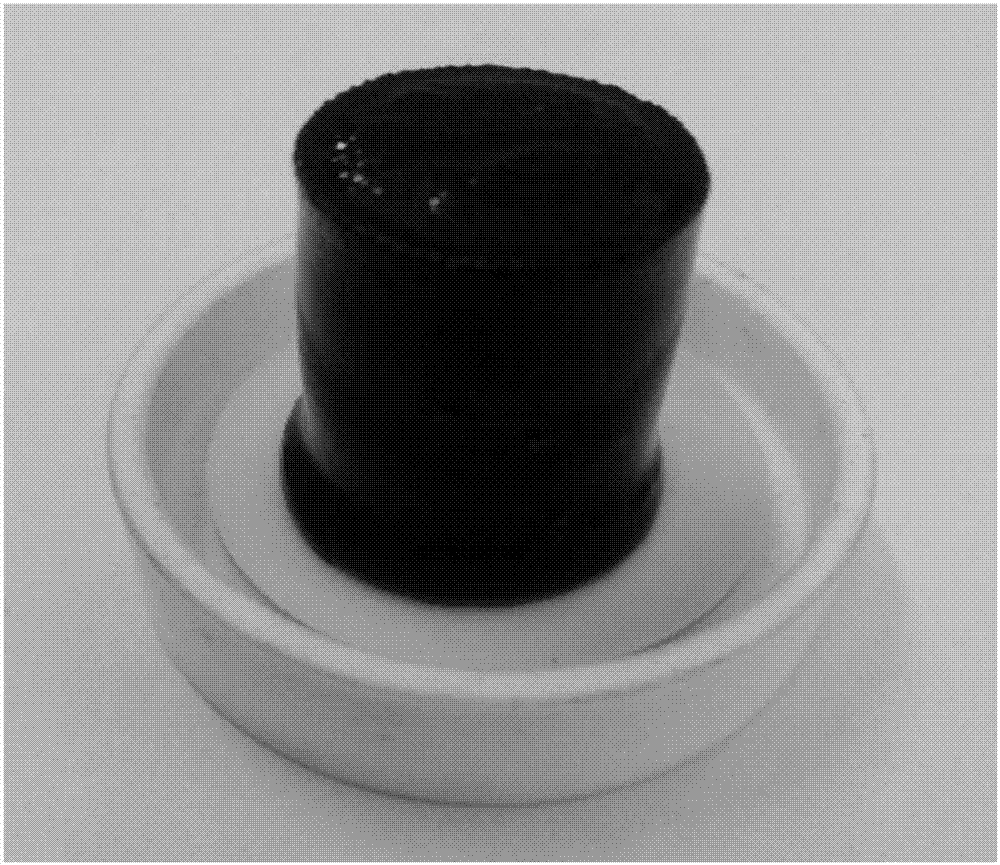

ActiveCN107248581AAvoid reunionLarge specific surface areaMaterial nanotechnologyCell electrodesOxygenNitrogen doped

The invention provides a composite material of nitrogen doped three-dimensional graphene supported nano silver, wherein the composite material is a porous three-dimensional network structure which is formed by the self assembly of a graphene sheet with a nitrogen doping amount of 2.3 to 8.8% under the action of temperature and pressure; silver particles with a particle size of 80 to 120nm are evenly dispersed on the three-dimensional grapheme surface and the loading capacity of the composite material is 12 to 51%. The preparation method of the composite material comprises the following steps: taking graphite paper as an anode, a carbon rod as a cathode, concentrated sulfuric acid as electrolyte, performing oxidization and exfoliation, and preparing a thin layer graphene oxide material; and orderly adding ethanediamine and silver nitrate into graphene oxide suspension, performing an one step hydrothermal reaction, and then drying, thus the composite material is obtained. The preparation method of the composite material of the nitrogen doped three-dimensional graphene supported nano silver provided by the invention is simple in operation and low in cost; in an electrocatalysis process, a porous structure of the composite material greatly increases a three-phase reaction interface, thereby improving the mass transfer rate of oxygen; and meanwhile, the composite material has higher electrical conductivity.

Owner:YANSHAN UNIV

Anaerobic column reactor for biodegradation of wastes and the process thereof

ActiveUS20170050892A1Prevent escapeEnhances biomass substrate contactBioreactor/fermenter combinationsBio-organic fraction processingProcess engineeringAnaerobic reactor

The present invention relates to an anaerobic column reactor for biodegradation of wastes. Particularly the present invention relates to a process for conversion of biodegradable wastes to biogas and compost. More particularly, the present invention relates to an anaerobic reactor with unique arrangement of expanded and constricted portions alternatively placed vertically over each other which enhances the mixing pattern and thereby the mass transfer rates while controlling the biomass washout by regulating the upflow liquid velocity.

Owner:COUNCIL OF SCI & IND RES

Up-conversion fluorescent molecular imprinted polymer and preparation method thereof

InactiveCN104211857AEasy to collectPromote enrichmentOther chemical processesLuminescent compositionsFluorescenceUp conversion

The invention provides an up-conversion fluorescent molecular imprinted polymer and a preparation method thereof, and relates to the field of novel high polymer enrichment materials. Up-conversion fluorescent nano particles NaYF4:Yb<3+> and Er<3+> are used as novel carriers, the novel carriers are combined with a molecular imprinting technology. The invention particularly relates to an up-conversion fluorescent molecular imprinted polymer with good adsorbing and separating functions on carbamate pesticide metolcarb molecules and a preparation method of the up-conversion fluorescent molecular imprinted polymer. The synthesized up-conversion fluorescent molecular imprinted polymer is great in specific surface area, so that the mass transfer rate and the adsorbing capacity are improved greatly in comparison with those of the conventional materials. And moreover, the preparation method is low in cost, simple in synthesis process, and easy in reaction condition control. The prepared up-conversion fluorescent molecular imprinted polymer has the characteristics of high sensitivity and high selectivity on a target product, good reproducibility and good application prospect.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

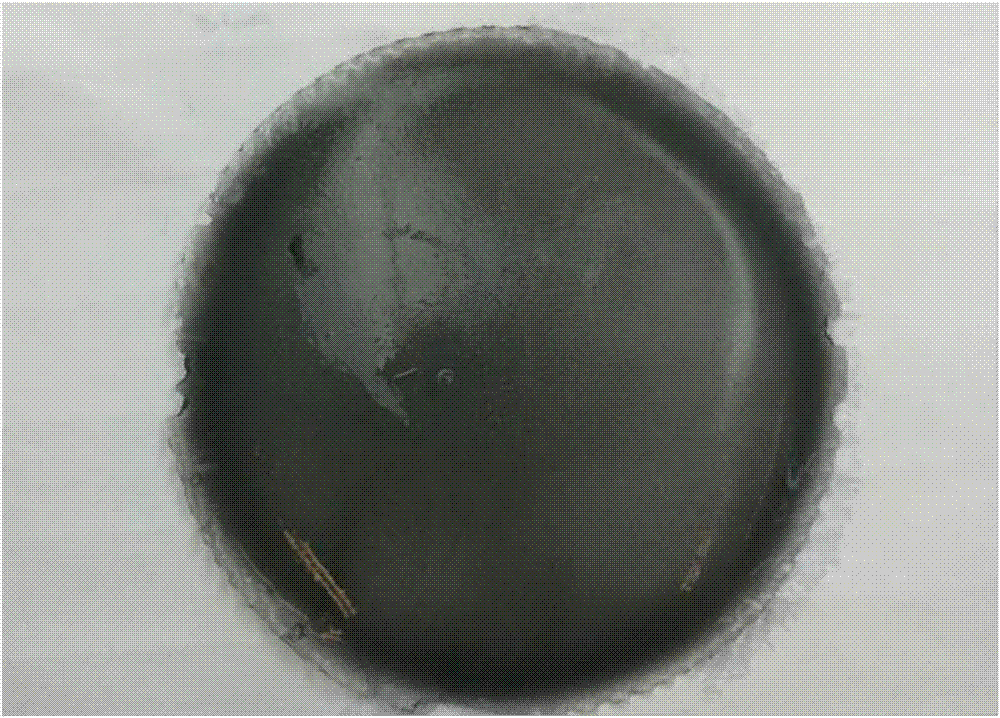

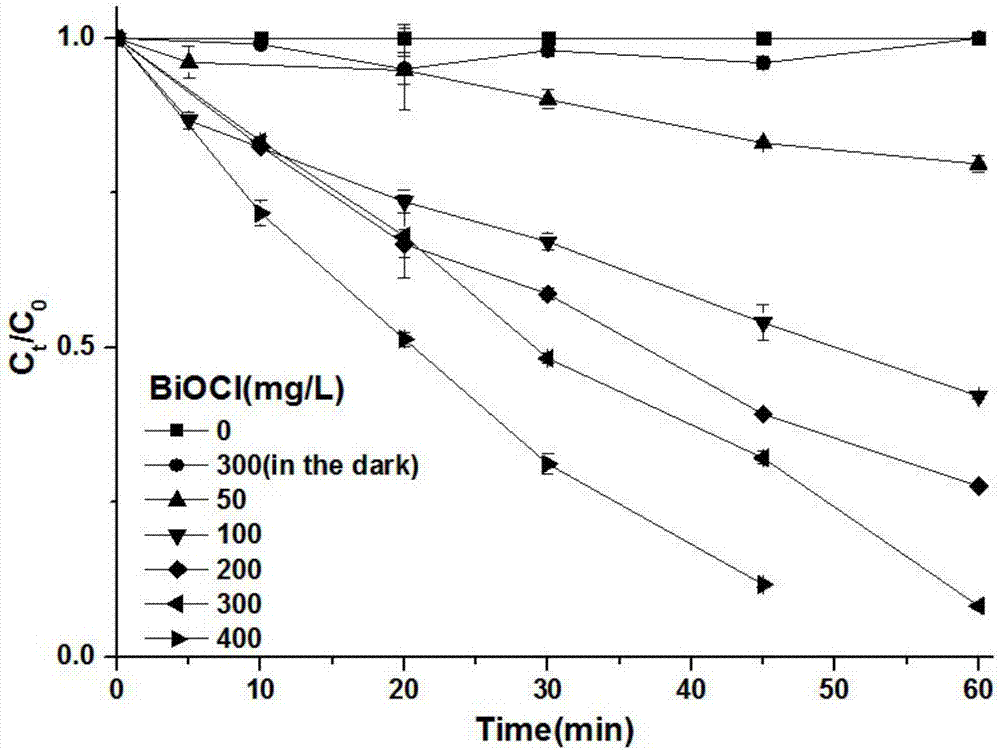

Photocatalyst-supported hydrogel as well as preparation method and application thereof

ActiveCN107051586APromote degradationEasy to prepareWater/sewage treatment by irradiationWater treatment compoundsSynthesis methodsConductive materials

The invention discloses photocatalyst-supported hydrogel as well as a preparation method and an application thereof and belongs to the field of environment function materials and catalysis. The photocatalyst-supported hydrogel comprises a conventional hydrogel composite conductive material and a photocatalysis material, wherein conventional hydrogel comprises acyclic acid / acrylamide hydrogel and can also be hydrogel formed through polymerization of other monomers. The conductive material comprises graphite, graphene and the like, and a photocatalyst can comprise bismuth oxychloride, titanium dioxide and the like. Bismuth oxychloride is immobilized, and the photocatalysis properties of bismuth oxychloride and electrical stimulation responsiveness of the hydrogel are combined. The conductive material in the compound hydrogel can transfer photo-induced electrons produced by bismuth oxychloride under illumination, the mass transfer rate between a catalyst and a pollutant cannot be affected, and the photocatalysis performance of bismuth oxychloride is improved. The synthesis method is simple and efficient, can realize industrial production and can be used for degrading atenolol, other medicines, personal care products and other organic pollutants in water.

Owner:NANJING UNIV

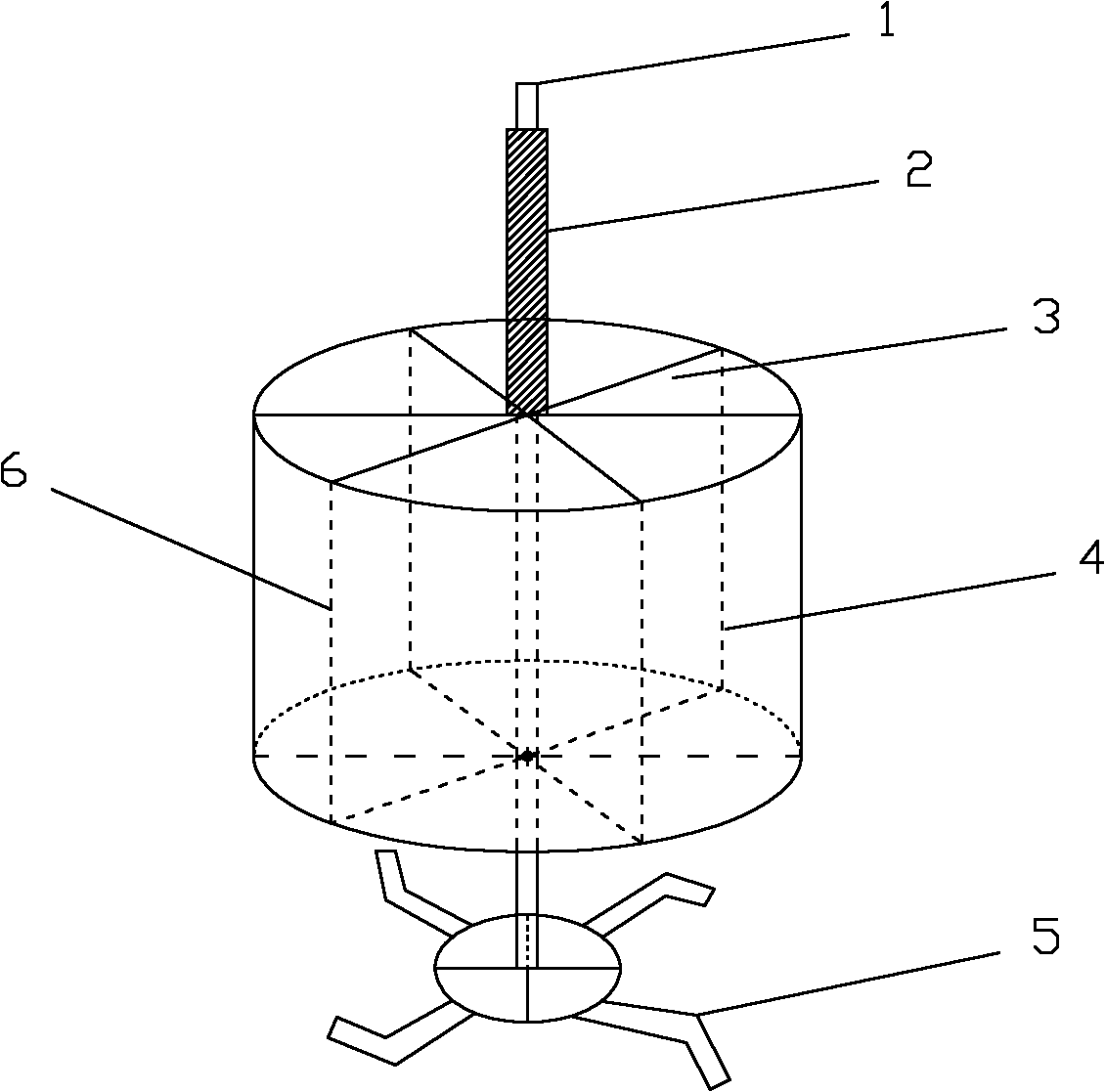

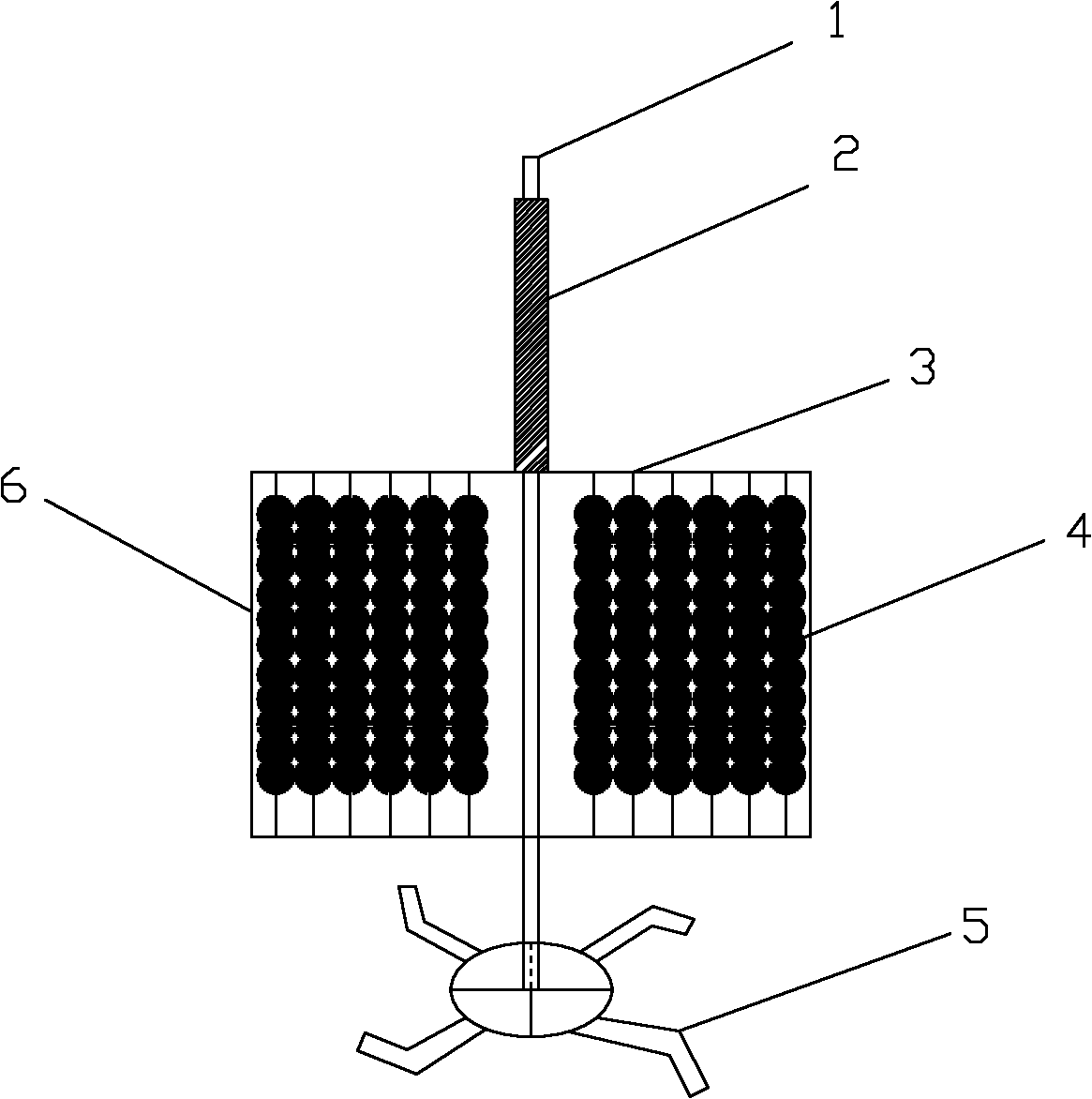

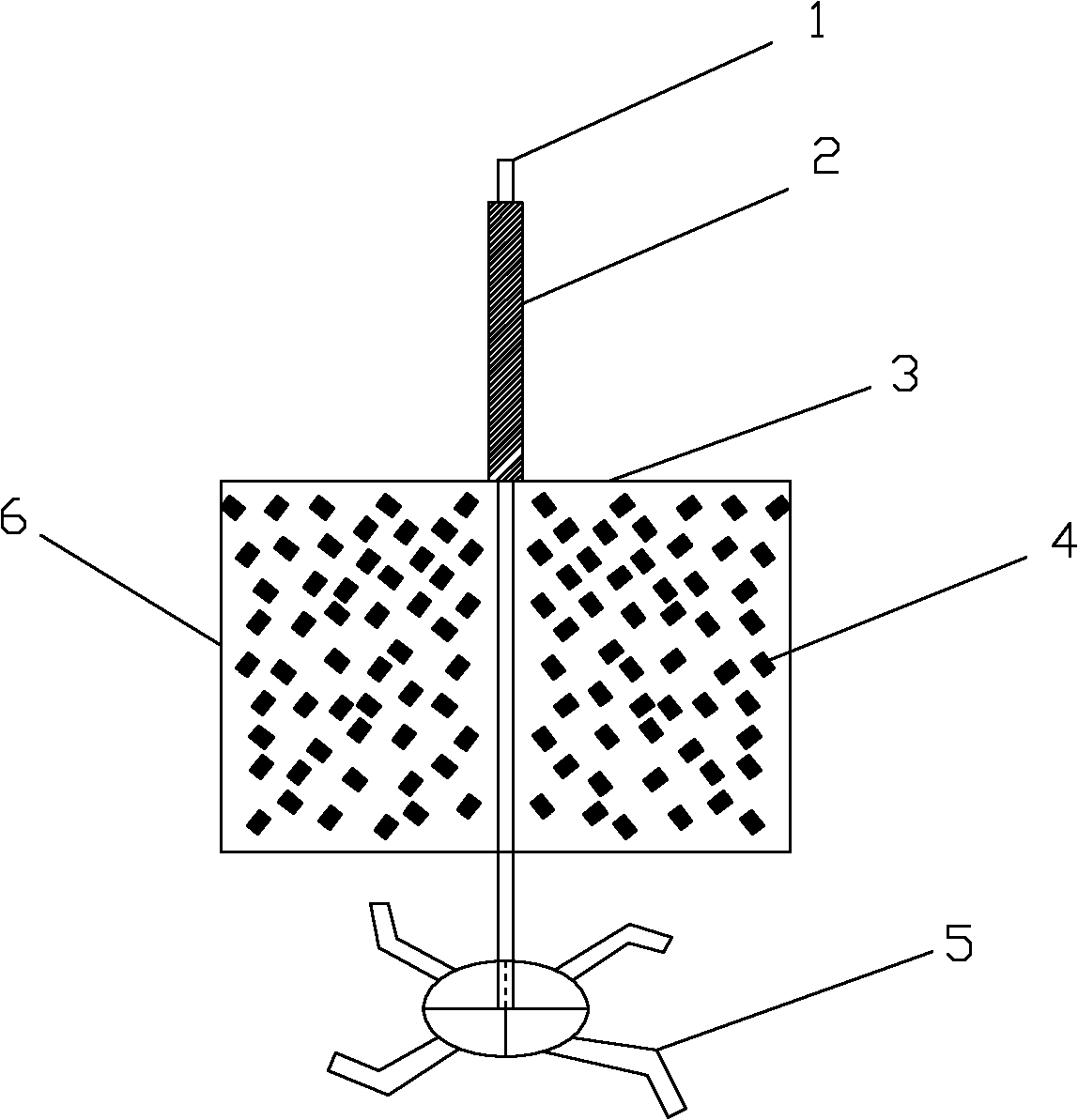

Riverway channel water quality biologically-intensifying device and application thereof

ActiveCN101913696ARemove the maximum efficiencyRealize simultaneous denitrificationBiological water/sewage treatmentChemical oxygen demandGrating

The invention provides a riverway channel water quality biologically-intensifying device and application thereof, belonging to the field of water treatment. The riverway channel water quality biologically-intensifying device comprises a transferring shaft and a filler area, wherein with the transferring shaft is positioned in the center of the riverway channel water quality biologically-intensifying device; the filler area encloses the transferring shaft. The riverway channel water quality biologically-intensifying device is characterized in that an upper fixed plate (3), a lower fixed plate and the transferring shaft (1) are integrated into a whole by taking the transferring shaft (1) as a center; an impeller (5) is fixed on the lower fixed plate; the filler area (4) is divided into fourregions through a grating sieve mesh (6), and biological fillers are filled in the regions. The integral riverway channel water quality biologically-intensifying device is driven to move by taking water flows as a driving force when being applied to the treatment of riverway channel water bodies, prevents the fillers from washing away by combining the fixed biological fillers with suspension fillers, can achieve the effective elimination and the synchrous denitrification of COD (Chemical Oxygen Demand), achieves the moving bed effect and also greatly enhances the mass transfer rate of nutrient substances and dissolved oxygen; and in addition, the riverway channel water quality biologically-intensifying device can carry out the treatment aiming at the pollution conditions of different water layers of riverway channels and also has the advantages of energy saving, environmental protection, low acquisition cost and operation cost, and the like.

Owner:江苏三强环境工程有限公司

Method for preparing super-hole fibrin microsphere protein absorbing medium

InactiveCN101036876AEvenly distributedImprove stabilityOther chemical processesPeptide preparation methodsCelluloseMicrosphere

The present invention discloses a preparation method for superporous cellulose microglobulin adsorption medium, which belongs to the preparation technology of cellulose gel medium of bioseparation engineering field. The method comprises the steps of: dispersing calcium carbonate particles to the cellulose viscose to form composite water phase; putting the viscose into the transformer oil and adding composite emulsifier potassium oleate and Span 60 and then executing agitating and emulsification; heating and curing to form particles; adding ethylene glycol diglycidyl ether and epichlorohydrin to execute double crosslinking reaction under alkaline condition; removing the calcium carbonate particles by using muriate acid and then using sodium borohydride to reducing so as to prepare superporous cellulose microglobulin adsorption medium. The medium not only maintains the advantages of the quondam cellulose gel medium but also increases a plurality of superporous, so that the resistance to pressure, the mass transfer rate and the dynamic adsorption capacity of the medium are all obviously improved, thereby, the novel superporous cellulose microglobulin adsorption medium has wide application prospect.

Owner:TIANJIN UNIV

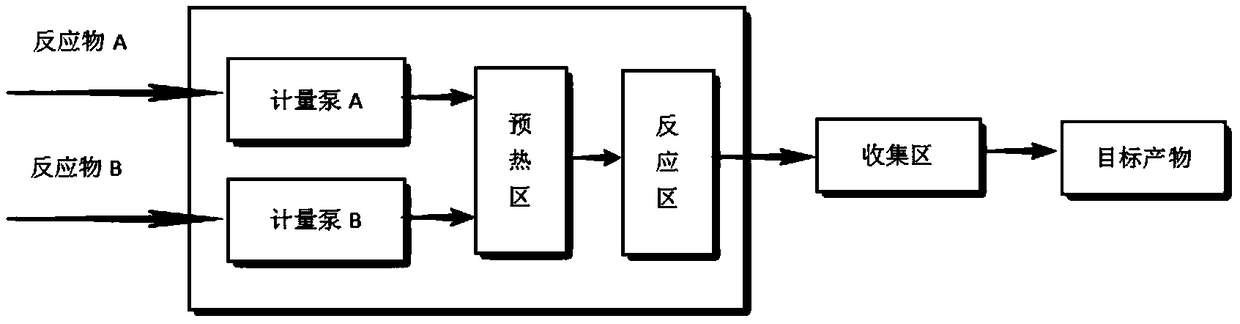

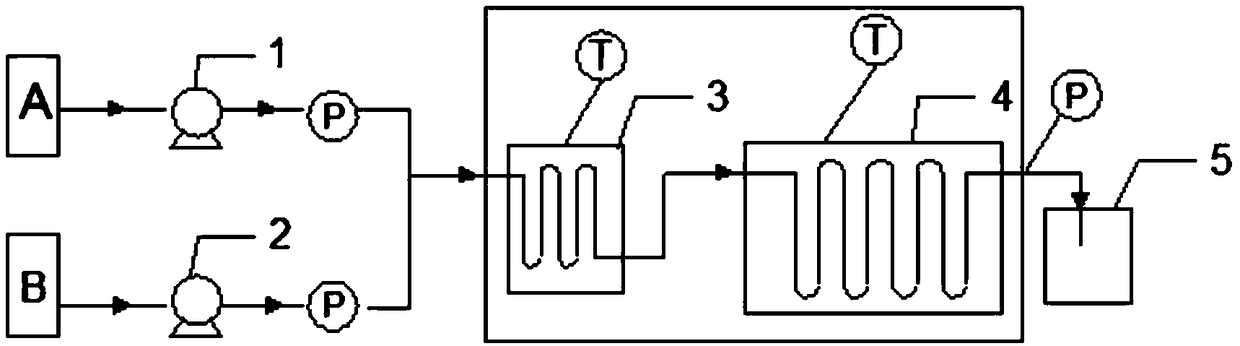

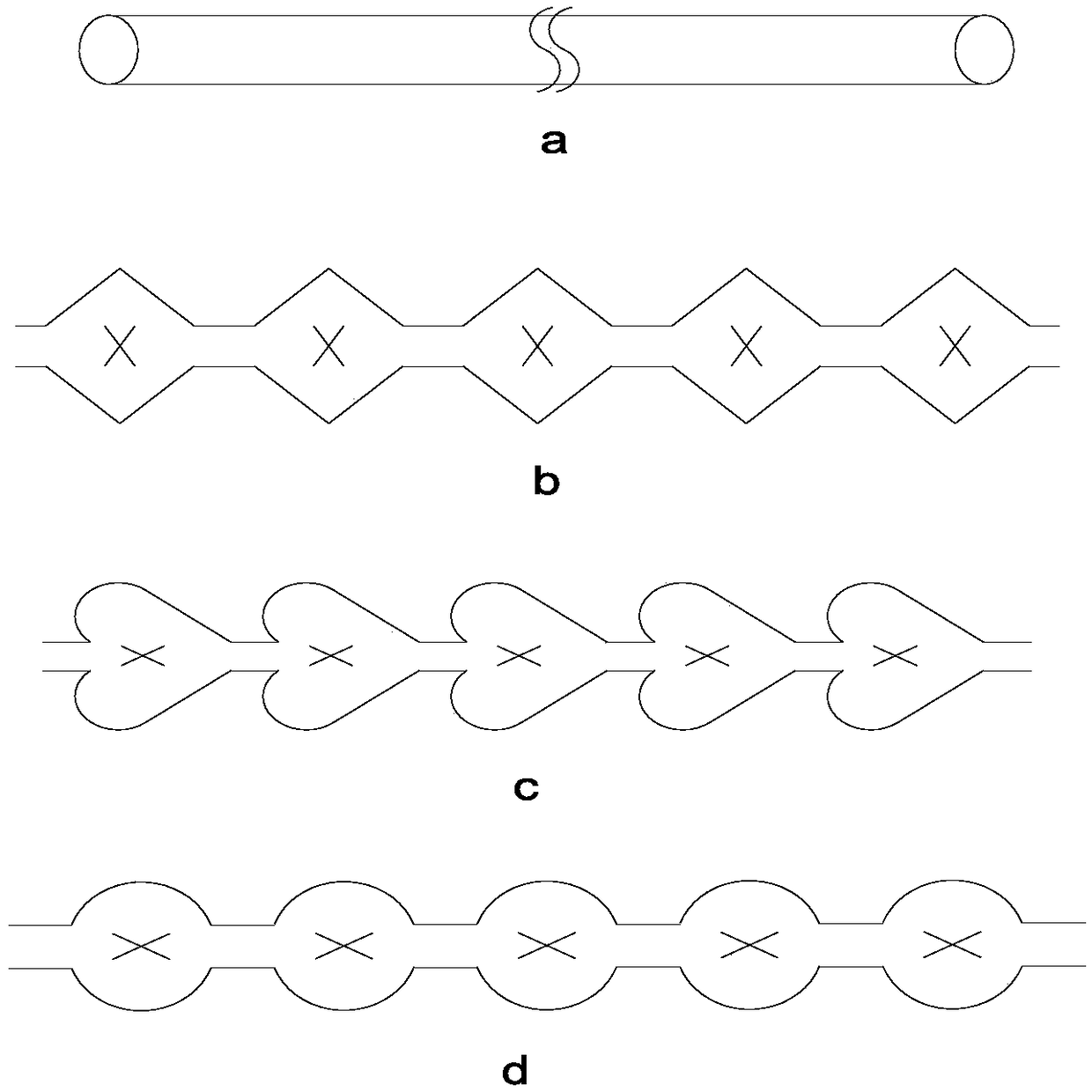

Method for continuous synthesis of dialkyl phosphite in micro-channel reactor

InactiveCN108840884AShort reaction timeIncrease temperatureGroup 5/15 element organic compoundsChemical industryAlcoholDolichyl phosphate

The invention discloses a method for continuous synthesis of dialkyl phosphite in a micro-channel reactor and belongs to the technical field of organic synthesis technologies. The method is used for generating the dialkyl phosphite through continuous reaction in the micro-channel continuous-flow reactor by using alcohol and phosphorus trichloride as substrates. Phosphorus trichloride is used as the material A, an alcohol solution is used as the material B, and the material A and the material B enter a micro-channel simultaneously through a metering pump for the continuous esterification reaction. According to the technological method, the high mass and heat transfer efficiency of the micro-channel reactor is utilized, the mass transfer rate between the two phase materials is effectively increased, and the safety and the operability of a test are greatly improved.

Owner:CHANGZHOU UNIV

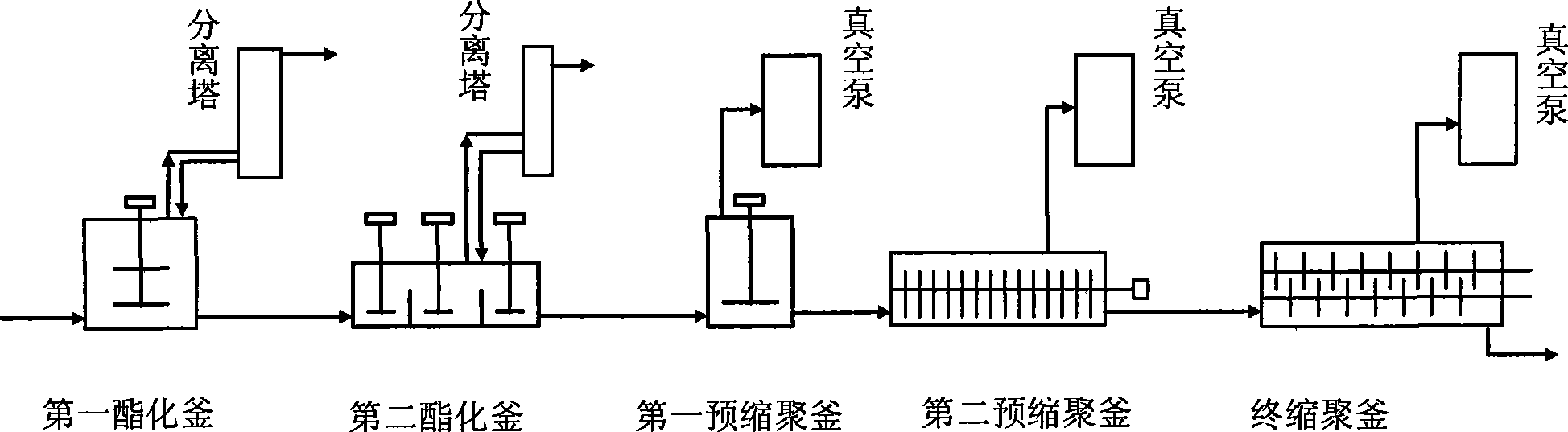

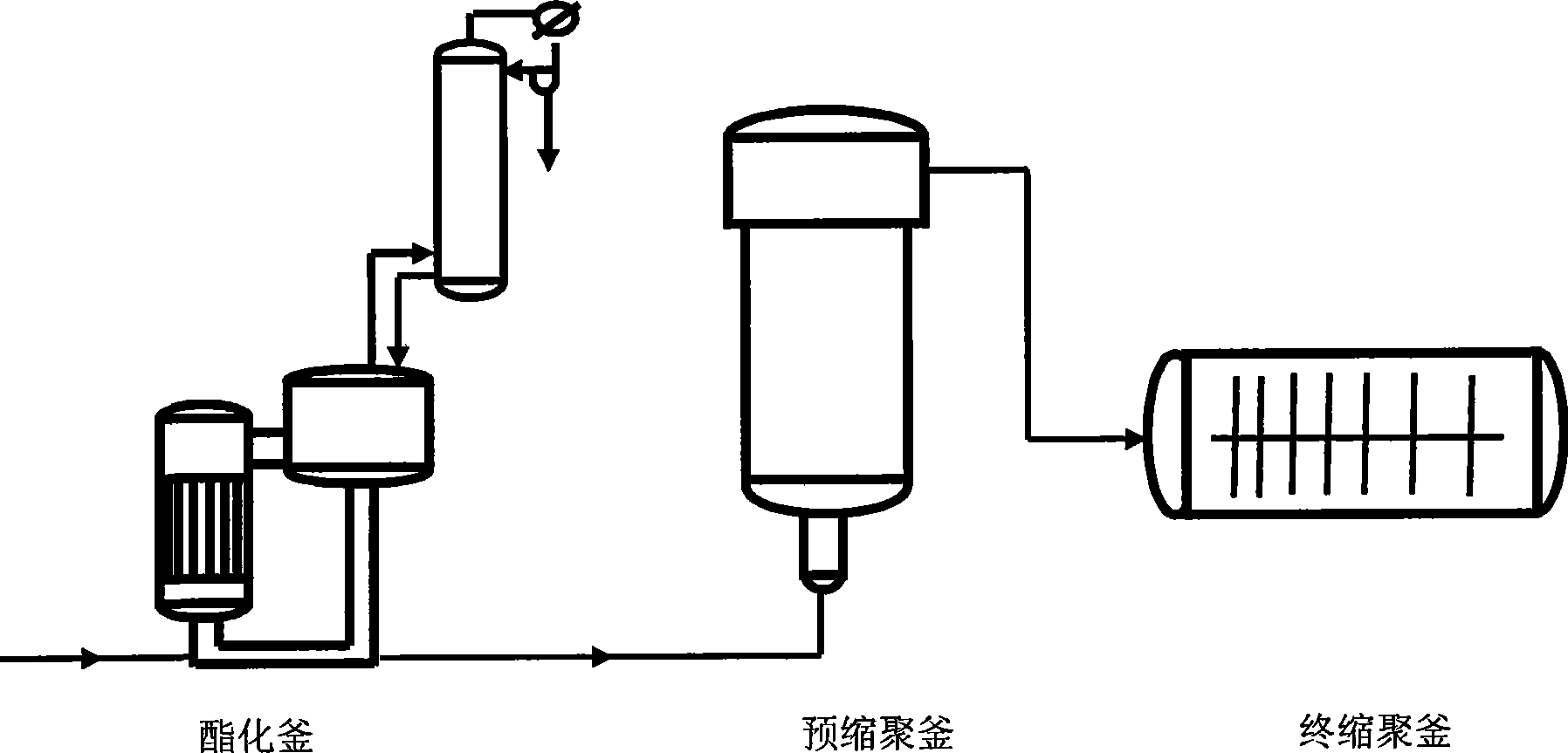

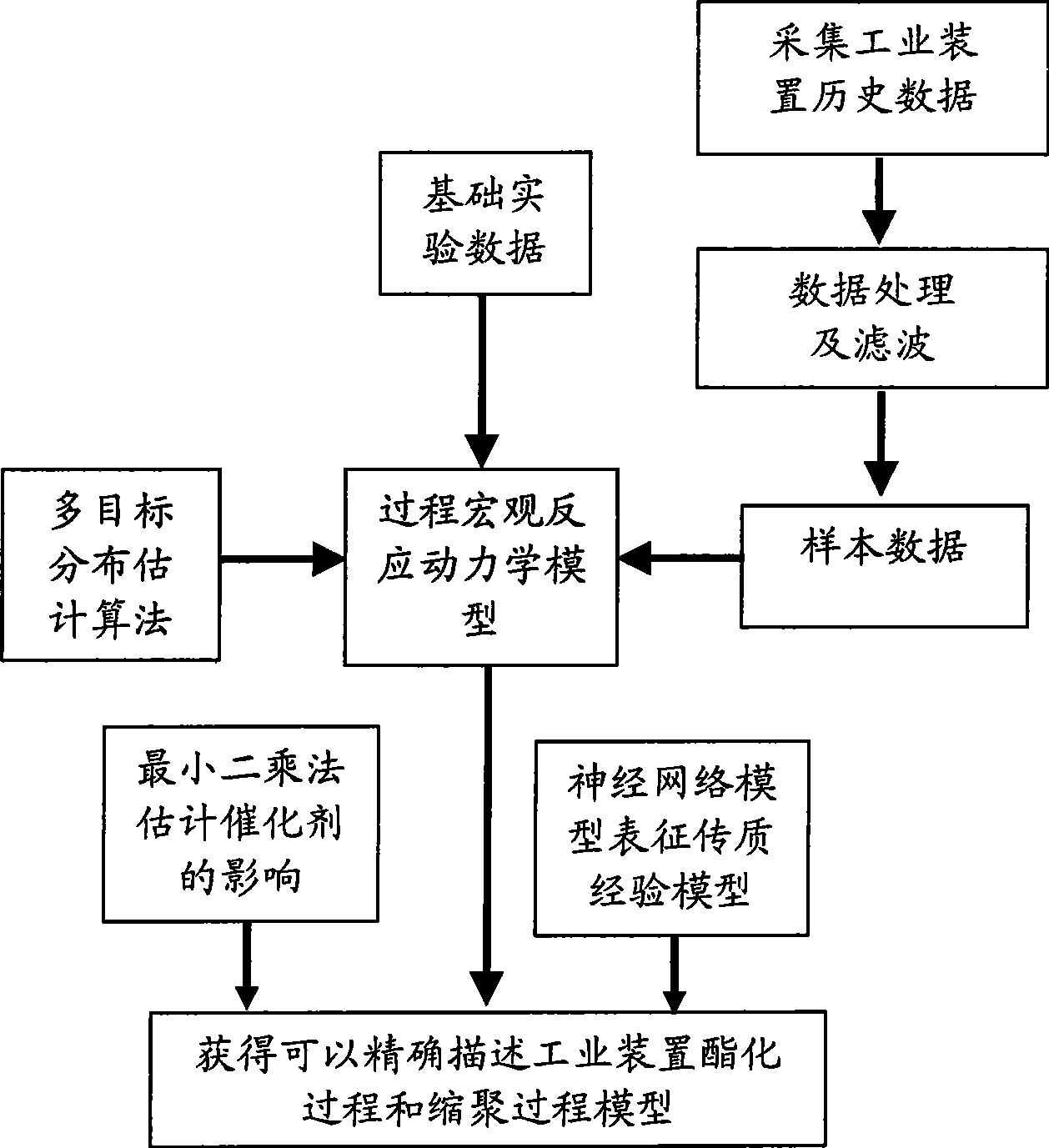

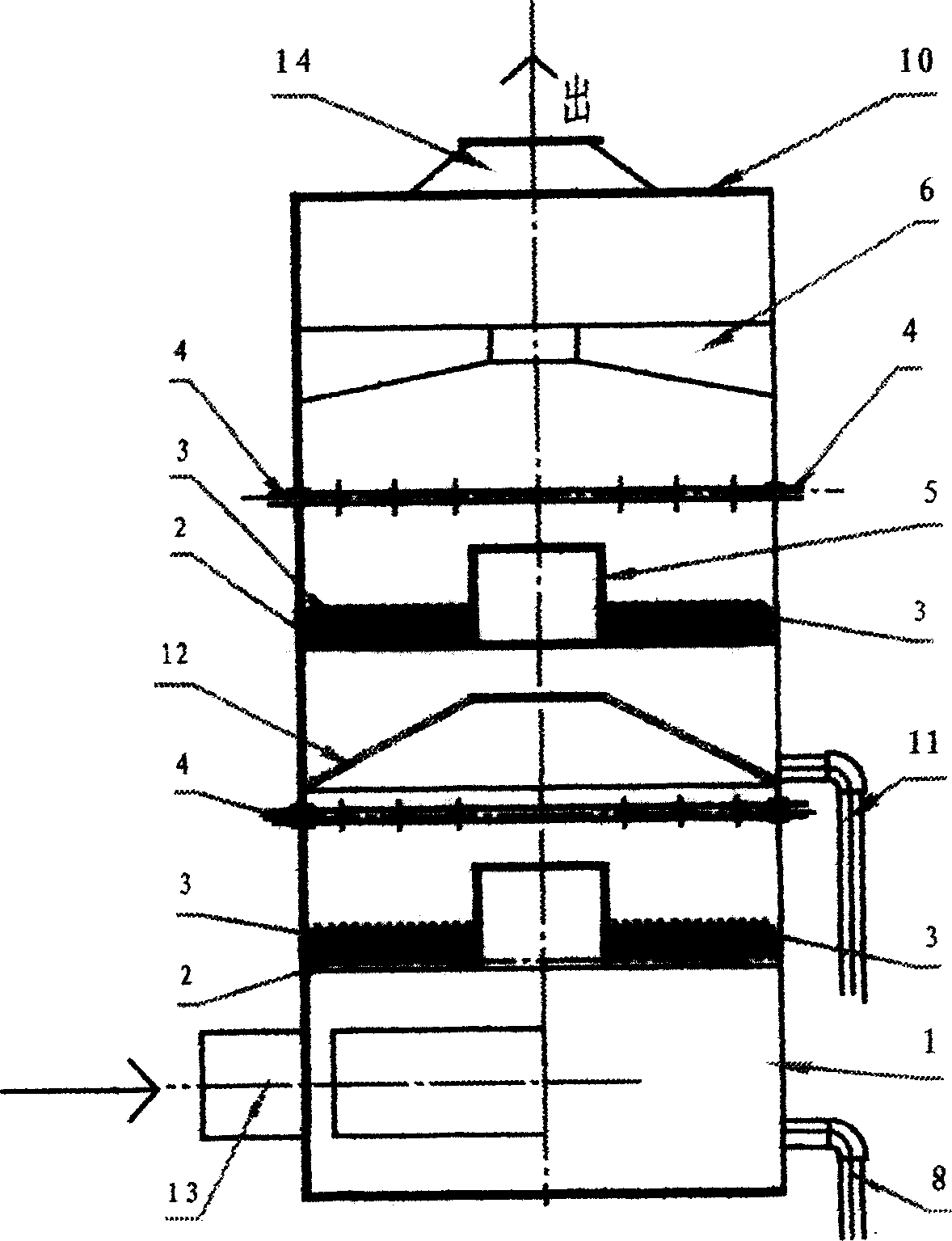

Intelligent modeling method in industrial polyester production process

The invention relates to an intelligent modeling method during the industrial polyester production process. Firstly, a mechanism model of the polyester production process based on reaction kinetics is established according to the mechanism of polyester reaction process; and then, parameters in the technical mechanism model are optimized by a multiple-target distribution estimation algorithm, so as to describe the actual operation characteristic of the industrial polyester production process exactly. At the same time, considering the influence on the reaction during the pre-polycondensation stage caused by catalyst, influence factor of the catalyst is added in reaction speed constant of the mechanism model, and a model between the catalyst and the reaction speed constant is established by a least square method; in a final polycondensation reactor, the mass transfer rate is reduced, and the influence on the process speed is increased, so that an artificial neural network is used for establishing an empirical model while the influence of mass transfer is considered, and the process speed is expressed in a form of resistance equation while combining with the reaction speed to ensure that the model is exacter. The modeling method can be applied to the modeling during three-reaction and five-reaction technical process during the industrial polyester production process at present.

Owner:EAST CHINA UNIV OF SCI & TECH

Normal flow filler tower

InactiveCN1748841ASolve a series of difficult problems that seriously affect the mass transfer rateLarge specific surface areaUsing liquid separation agentChemical/physical/physico-chemical processesChemical reactionEngineering

The regular packing tower includes outer cylinder, bearing plate and fluidizing balls, and the bearing plate matching the inner wall of the outer cylinder and has one inner cylinder in the center and baffles. The present invention adopts the technological scheme with fluidizing balls possessing ring rotating orbit to raise the mass transfer rate. The present invention has the advantages of stable running, full utilization of absorbing liquid, high mass transfer effect, capacity of multiple stage shutting and liquid phase treatment, low cost, simple structure, etc. and is suitable for various kinds of mass transfer reaction.

Owner:方达辉

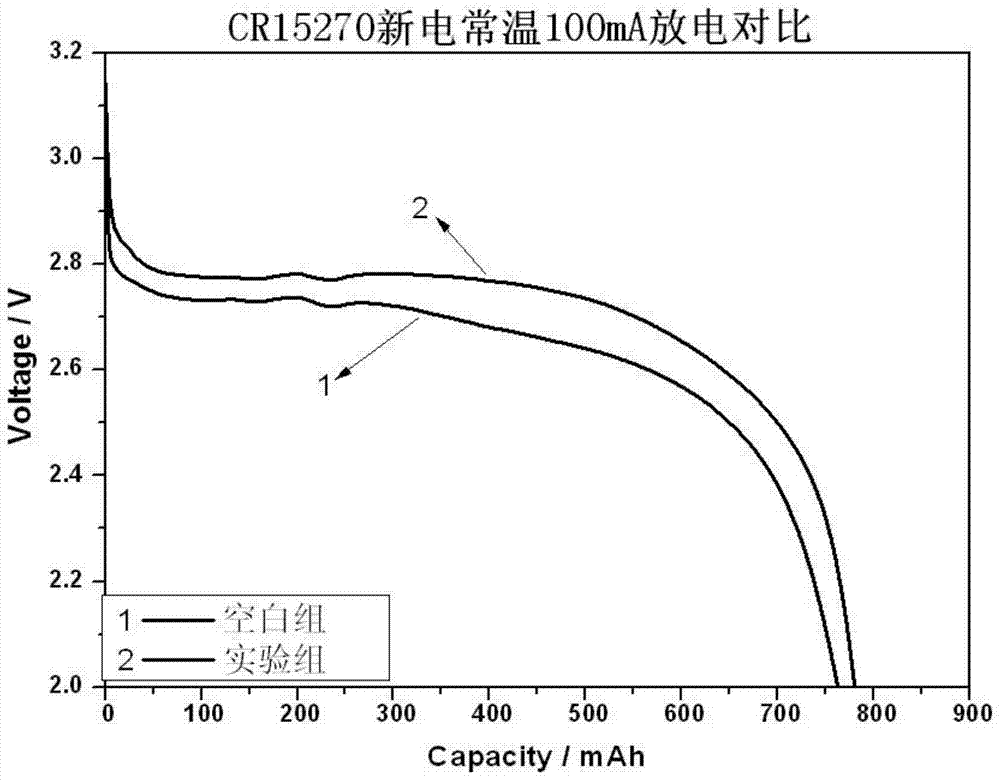

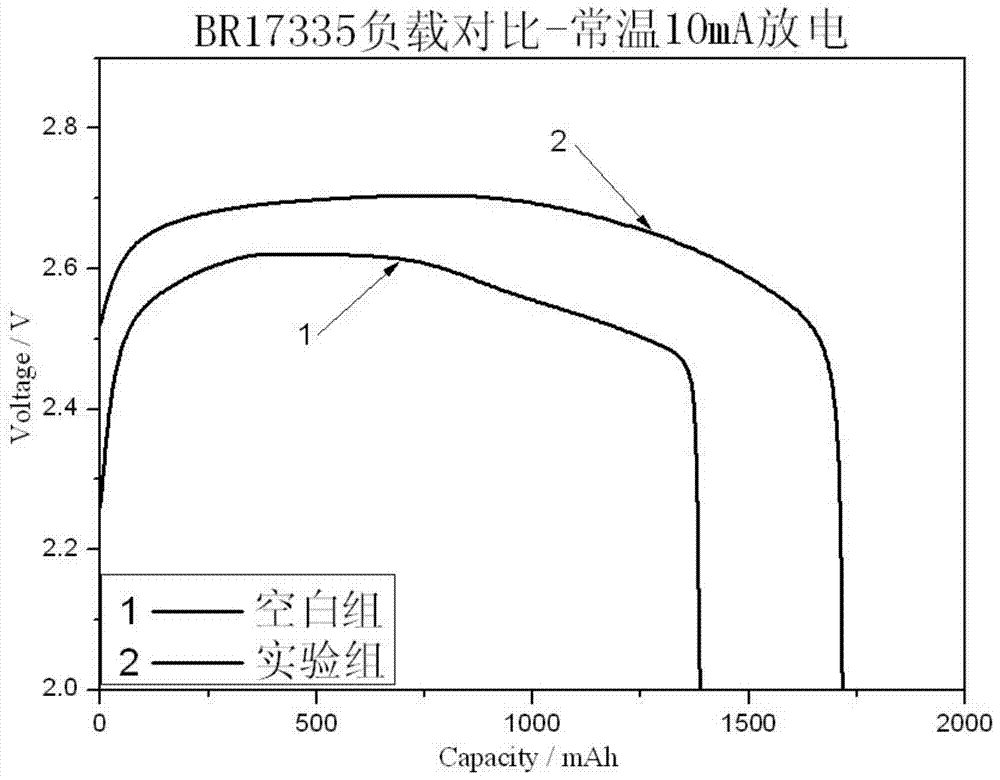

Electrolyte for lithium battery and lithium battery using the electrolyte

InactiveCN103814473AIncrease discharge voltageImprove conductivityFinal product manufacturePrimary cellsEster sulfonateSuccinic acid

The invention discloses an electrolyte for a lithium battery. The electrolyte contains a pyridine ionic liquid, and the pyridine ionic liquid contains cations and anions; the cations are N-alkylpyridine; and the anions are one kind of the anions of a group consisting of halite ions, tetrafluoroboric acid anions, hexafluorophosphoric acid anions, bis(trifluoromethanesulphonyl)imine anions, lactic acid anions, p-methyl benzene sulfonate acid radical anions, acetyl sulfonyl imide anions, saccharin anions, amino acids anions, sulfuric acid ester anions, succinic acid diisooctyl ester sulfonate radical anions, 4,5-dimetridazloe anions, and 5-nitrotetrazolato anions. The electrolyte can change the reaction mechanism of the battery, improve the reduction rate of a cathode active material and the mass transfer rate of the electrolyte, and increase the electrical conductivity of the electrolyte, so the discharge voltage of the lithium battery is improved. Furthermore, the invention further discloses a preparation method for the electrolyte and the lithium battery containing the electrolyte.

Owner:EVE ENERGY CO LTD

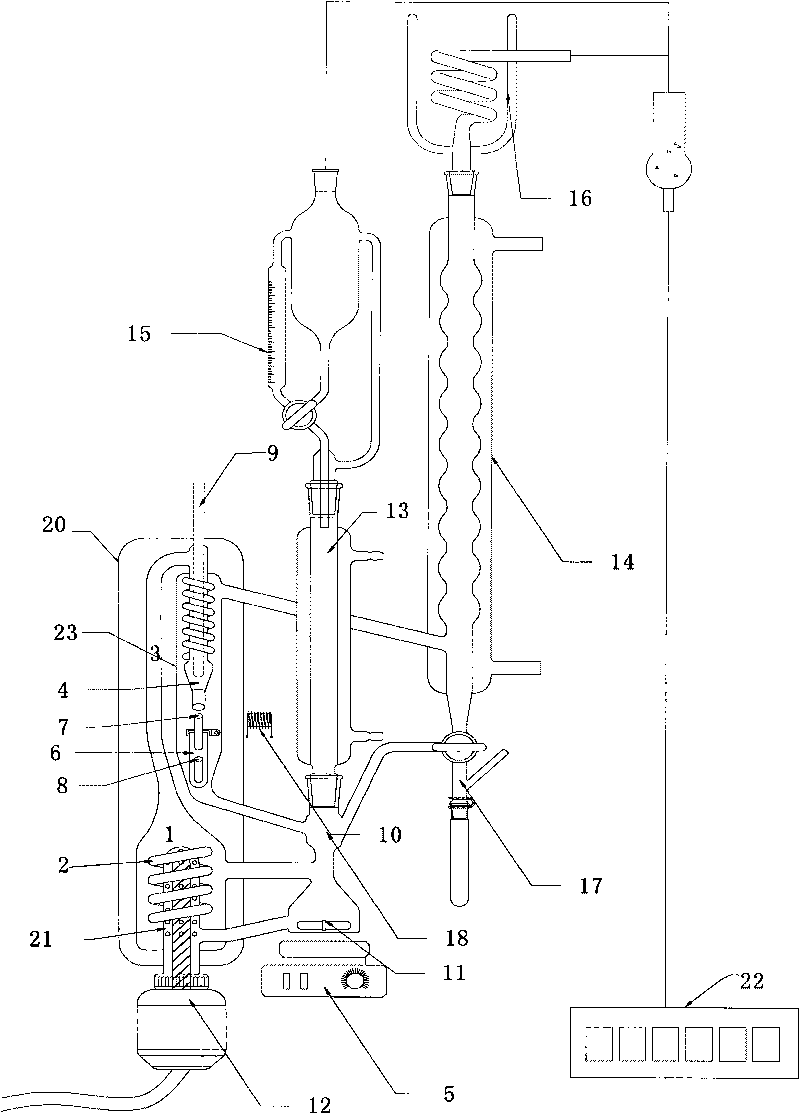

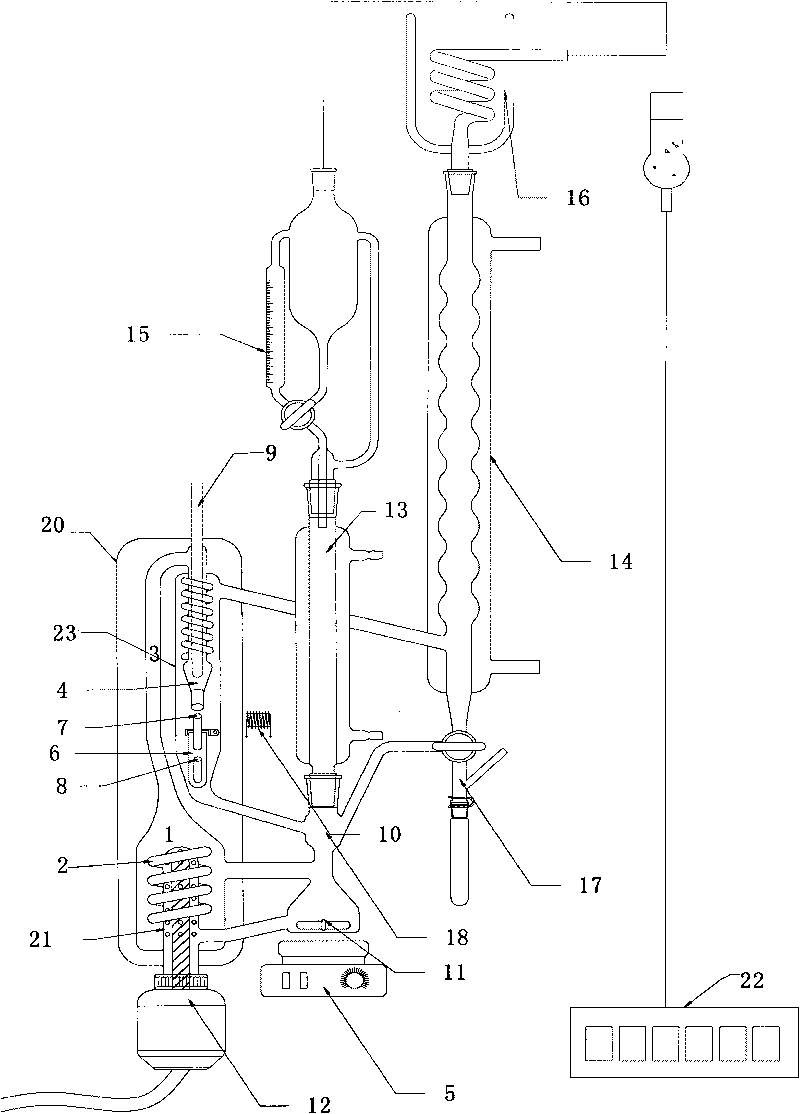

Gas-liquid-liquid equilibrium data measurement device

InactiveCN101726507AFully contactedAccurate measurementLaboratory glasswaresInvestigating phase/state changeMeasurement deviceThree-phase

The invention discloses a gas-liquid-liquid equilibrium data measurement device. An equilibrium still comprises three circulation loop structures for accelerating the circular mixing of fluid. The liquid phase in a hating still is homogenized by an ultrasonic homogenizer for improving the mass transfer rate and rapidly achieving the equilibrium. The separation is performed through stirring and heating. A liquid-liquid split phase tube is arranged in a gas-liquid separation chamber, so the liquid-liquid split phase experiment condition is the same as the gas-liquid equilibrium condition. The still is used for performing gas-liquid-liquid equilibrium measurement; gas-liquid-liquid three phase samples accurately representing gas-liquid-liquid equilibrium components can be obtained, time consumption is low, the equilibrium components and equilibrium temperature are accurately measured, and the experimental operation is simple and convenient.

Owner:SUN YAT SEN UNIV

Preparation method for light calcium carbonate

ActiveCN106587125AEasy to synthesizeGood gas-liquid mass transfer effectCalcium/strontium/barium carbonatesMicron scaleSmall droplet

The invention discloses a preparation method for light calcium carbonate. In the method, a Ca(OH)2 turbid liquid and CO2 compressed gas respectively pass through two fluid atomizing spray nozzles, wherein the Ca(OH)2 turbid liquid is dispersed into micron-scale droplets by high-pressure CO2, and meanwhile, a carbonization reaction is carried out to generate the light calcium carbonate, which is rapidly dried by hot air flow to directly prepare light calcium carbonate powder. Compared with a conventional carbonization method, in the method, the Ca(OH)2 droplets, being a dispersion phase, and the CO2 gas, being a continuous phase, are contacted in forward direction, so that because the atomized Ca(OH)2 turbid liquid has small droplets, contact area of gas-liquid two-phase mass transfer is effectively increased. Meanwhile, gas-liquid mass transfer rate is increased since the Ca(OH)2 droplets have large speed difference from the CO2 gas, thereby completing the carbonization reaction in a short time. The sprayed droplets are rapidly dried by hot air flow after the carbonization reaction, thereby producing the light calcium carbonate powder.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com