Preparation method for light calcium carbonate

A light calcium carbonate, mass fraction technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve problems such as complex production process, achieve short carbonization reaction time, easy Commercial production, good gas-liquid mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

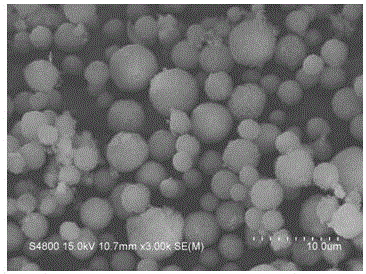

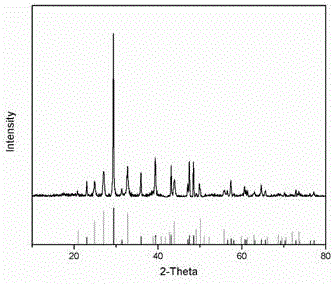

[0013] 1 g Ca(OH) 2 The solid powder was dissolved in 999 g of deionized water and configured as Ca(OH) with a mass fraction of 0.1wt%. 2 solution. CO control 2 Gas flow at 3 L / min, Ca(OH) 2 The solution is pumped to the two-fluid atomizing nozzle through a peristaltic pump, and is absorbed by CO 2 Dispersed into micron-sized droplets, followed by drying by a 400°C hot air stream. Obtain light calcium carbonate powder. Depend on figure 1 It can be seen from the scanning electron microscope photos that the calcium carbonate prepared by the present invention has a spherical structure with a particle size of about several microns, and is composed of two crystal forms of calcium carbonate, calcite and vaterite.

Embodiment 2

[0015] 3 g Ca(OH) 2 The solid powder was dissolved in 997 g of deionized water and configured as Ca(OH) with a mass fraction of 0.3wt%. 2 solution. CO control 2 Gas flow rate of 12 L / min, Ca(OH) 2 The solution is pumped to the two-fluid atomizing nozzle through a peristaltic pump, and is absorbed by CO 2 Disperse into micron-sized droplets, followed by drying by a hot air stream at 300°C. Obtain spherical light calcium carbonate powder.

Embodiment 3

[0017] 6 g Ca(OH) 2 The solid powder was dissolved in 994 g of deionized water and configured as Ca(OH) with a mass fraction of 0.6wt%. 2 solution. CO control 2 Gas flow rate is 6 L / min, Ca(OH) 2 The solution is pumped to the two-fluid atomizing nozzle through a peristaltic pump, and is absorbed by CO 2 Dispersed into micron-sized droplets, followed by drying by a hot air stream at 200 °C. Obtain spherical light calcium carbonate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com