Apparatus and method for producing acetic acid by reducing carbon dioxide through microbial-electrochemical system

A microbial electrochemistry, carbon dioxide technology, applied in biochemical equipment and methods, methods of stress stimulating microbial growth, biochemical instruments, etc. The rate of acetic acid, the rate of reduction to acetic acid, and the effect of improving the mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

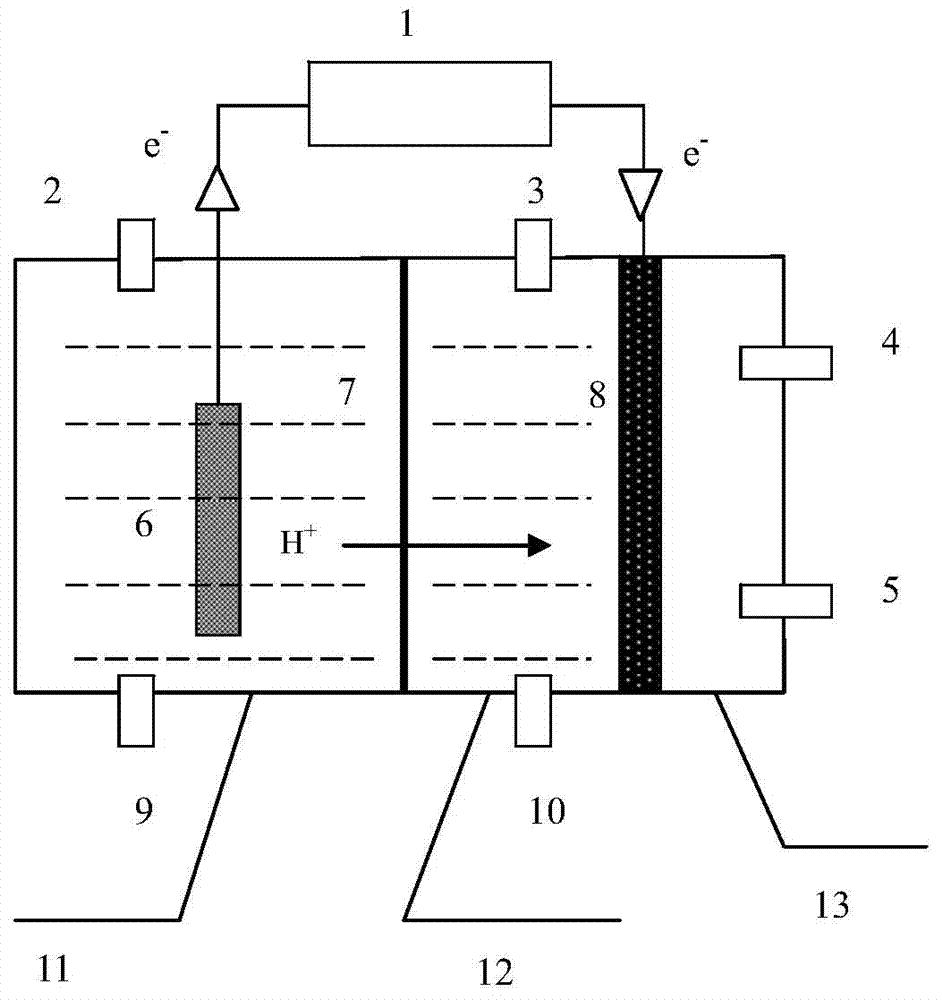

[0035]This example illustrates the specific structure, application method and working principle of a microbial electrochemical system reducing carbon dioxide to produce acetate according to the present invention.

[0036] 1. Construction of microbial electrochemical reaction device.

[0037] Such as figure 1 As shown, a bioelectrochemical system for reducing carbon dioxide to produce acetic acid is mainly composed of 1-power supply; 2-anolyte outlet; 3-catholyte outlet; 4-gas outlet; 5-gas inlet; 6-anode; 7- Diaphragm, 8-gas diffusion cathode, 9-anolyte inlet, 10-catholyte inlet, 11-anode chamber, 12-catholyte chamber, 13cathode gas chamber. The anode 6 is connected to the anode chamber 11, the diaphragm 7 is located between the cathode 8 and the anode 6, the power source 1 connects the anode 6 and the cathode 8 to form a loop, and the cathode 8 separates the cathode chamber into a catholyte chamber 12 and a cathode gas chamber 13. The cathode 8 has one side rich in catalyst...

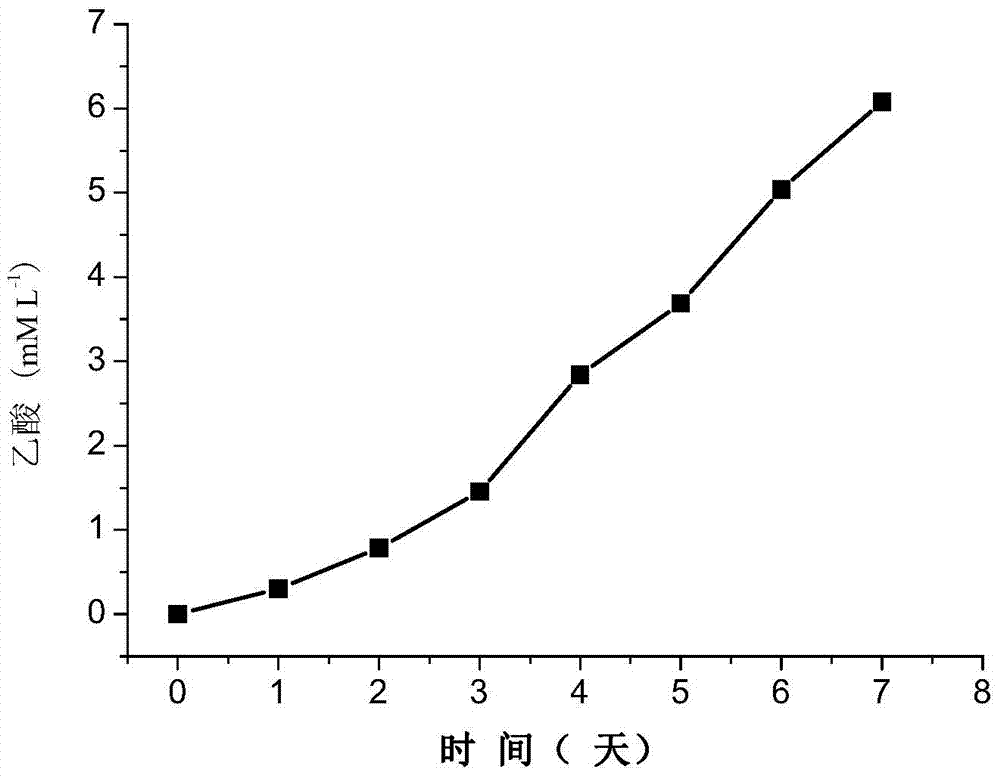

Embodiment 2

[0053] A method for producing acetate by reducing carbon dioxide in a microbial electrochemical system

[0054] The construction of the microbial electrochemical reaction device and the biofilm hanging on the cathode are the same as in Example 1, wherein the preparation of the gas diffusion cathode is as follows:

[0055] (1) Soak the carbon cloth in an aqueous solution of 5wt% polytetrafluoroethylene, and treat it at 380°C for 3 hours to make the carbon cloth hydrophobic;

[0056] (2) Ultrasonic mixing of carbon black, water, ethanol, and polytetrafluoroethylene emulsion at a mass ratio of 1:3:10:5, and the obtained mixture is applied to the side of the electrode surface close to the cathode gas chamber, and heated at 380°C Treat for 0.5h under the same conditions to prepare the electrode diffusion layer;

[0057] (3) On the electrode diffusion layer obtained in step (2), apply an aqueous solution of 30wt% polytetrafluoroethylene as a waterproof layer, and treat it at 380°C ...

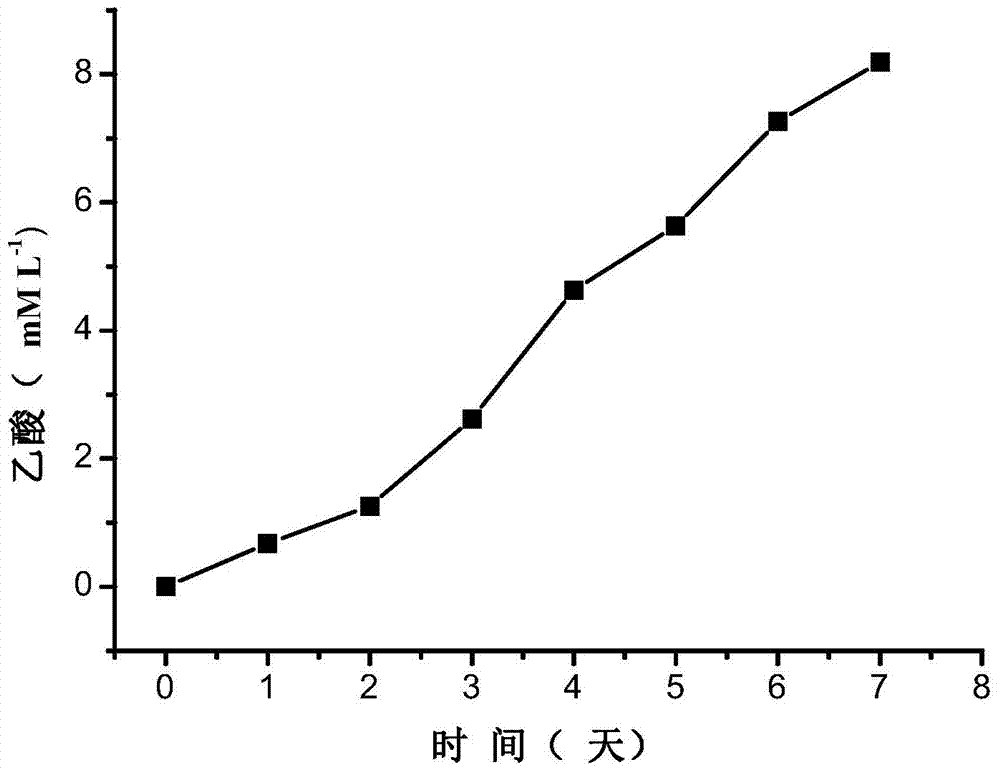

Embodiment 3

[0062] A method for producing acetate by reducing carbon dioxide in a microbial electrochemical system

[0063] The construction of the microbial electrochemical reaction device and the method of hanging biofilm on the cathode are the same as in Example 1, the selection of acetic acid bacteria (Sporomusa sphaeroides Moeller ATCC 35900), wherein the preparation of the gas diffusion cathode is as follows:

[0064] (1) Soak the carbon cloth in an aqueous solution of 5wt% polytetrafluoroethylene, and treat it at 380°C for 4 hours to make the carbon cloth hydrophobic;

[0065] (2) Ultrasonic mixing of carbon black, water, ethanol, and polytetrafluoroethylene emulsion at a mass ratio of 0.2:5:15:10, and the obtained mixture is applied to the side of the electrode surface close to the cathode gas chamber, and heated at 380°C Under the condition of treatment for 1h, the electrode diffusion layer was prepared;

[0066] (3) On the electrode diffusion layer obtained in step (2), apply a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com