Normal flow filler tower

A technology of regular flow packed tower and fluidized ball, applied in the direction of using liquid separating agent, chemical/physical/physical-chemical process, dispersed particle separation, etc., can solve the problems of increased power consumption, incomplete solution, complex structure, etc. Achieve the effect of avoiding scaling, less wearing parts, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

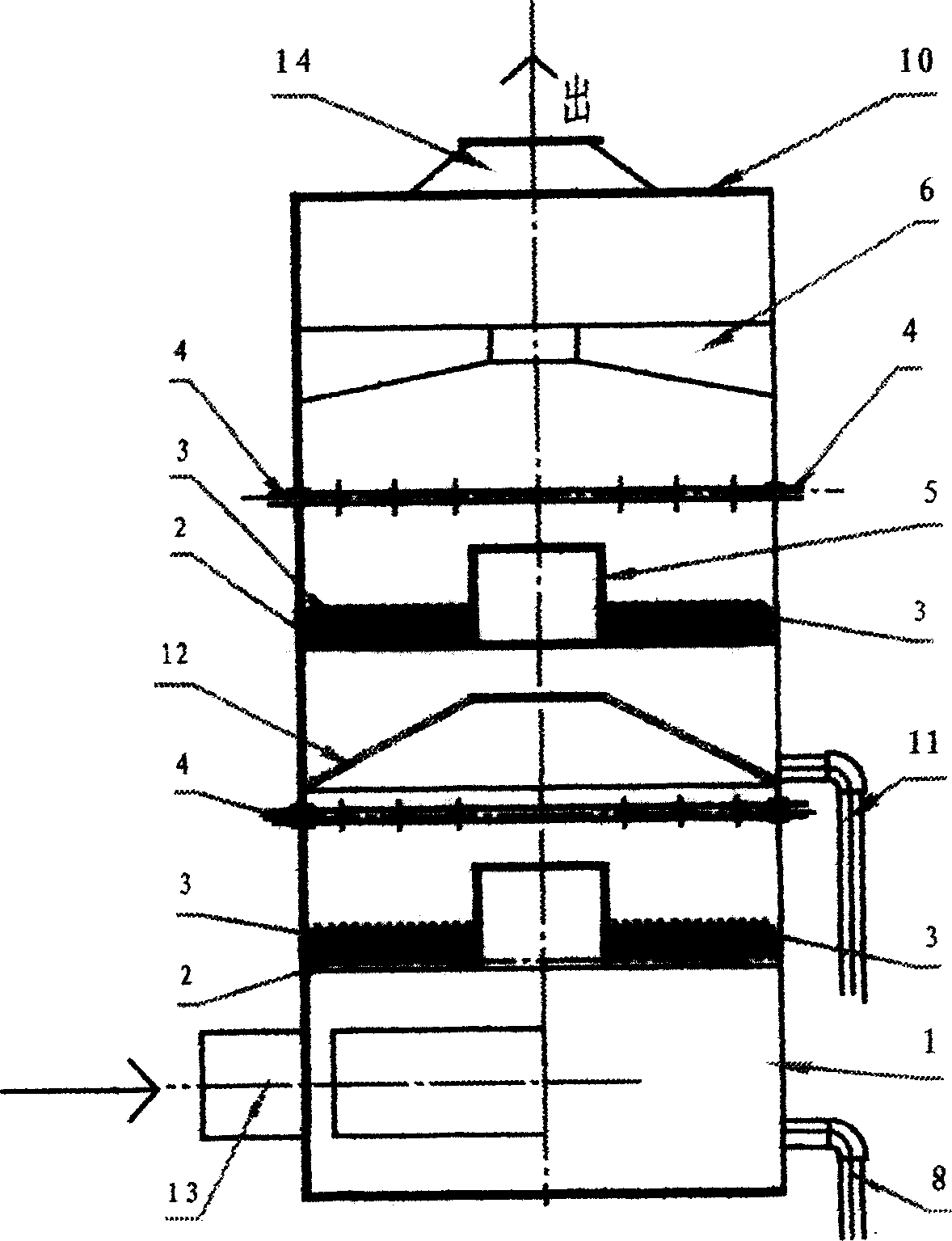

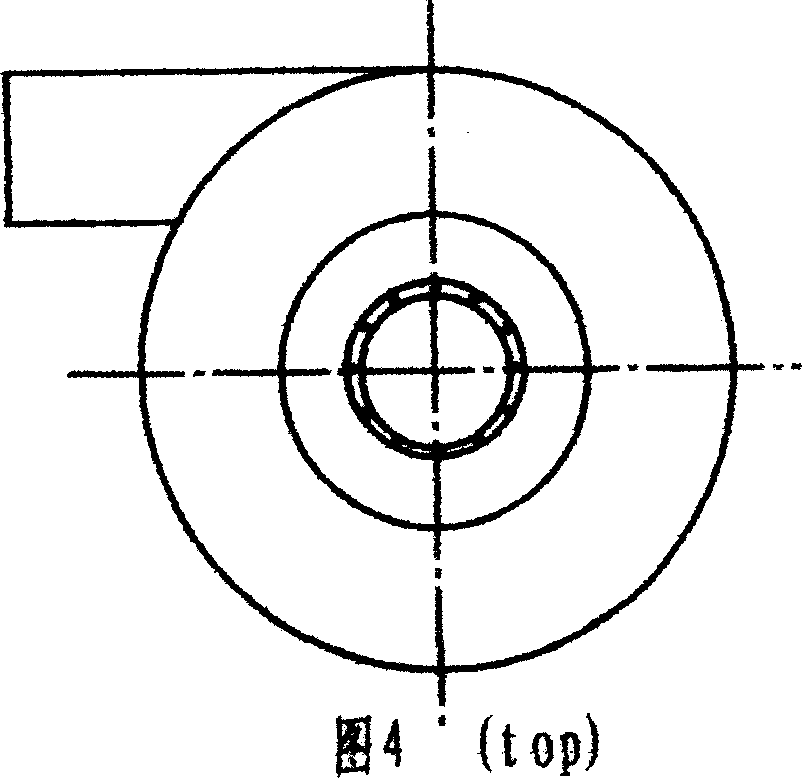

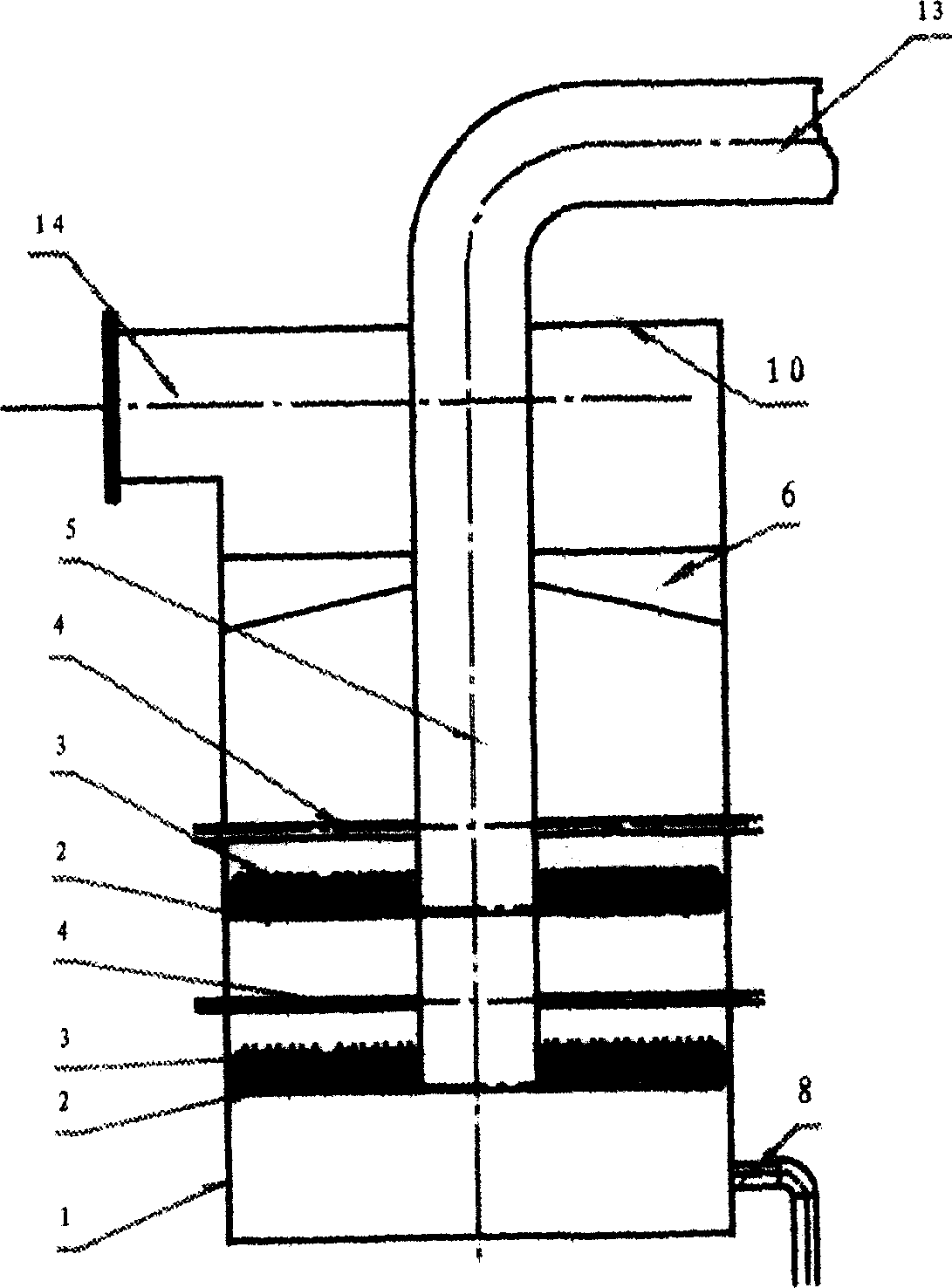

[0041] It can be seen from the accompanying drawings that a gauge-flow packed tower of the present invention includes an outer cylinder 1, a supporting plate 2 arranged in the outer cylinder, a fluidizing ball 3 located on the supporting plate and an absorption liquid spray pipe 4, the supporting plate The center of 2 is connected with an inner cylinder 5 and the circumference is provided with an opening 16 and a baffle 15 connected to the opening. Wherein supporting plate 2 is provided with the central through hole that can install inner cylinder 4, when outer cylinder 1 outer airflow inlet 13 is located at the bottom, this inner cylinder 4 is a non-through hole, see Fig. 1. An opening 16 and a guide vane 15 connected to the opening are provided along the circumference of the central through hole. The guide vane 15 forms an oblique angle with the surface of the supporting plate 2. The optimum inclination angle range of the guide vane 15 is in the acute angle range. In this imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com