Patents

Literature

135 results about "Intelligent modeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent modeling, transformation and manipulation system

InactiveUS6879946B2Computation using non-denominational number representationImage generationData compression3d shapes

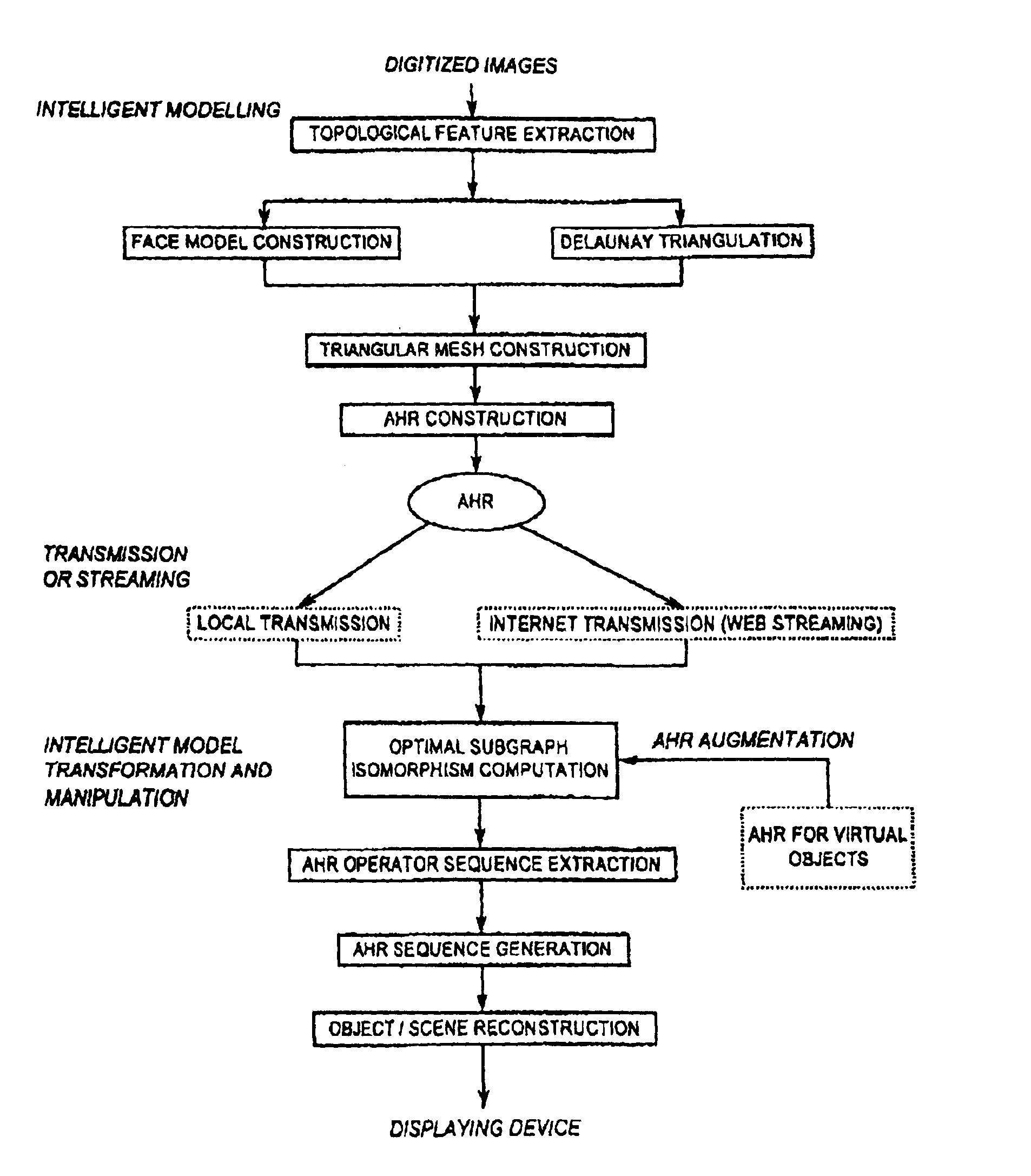

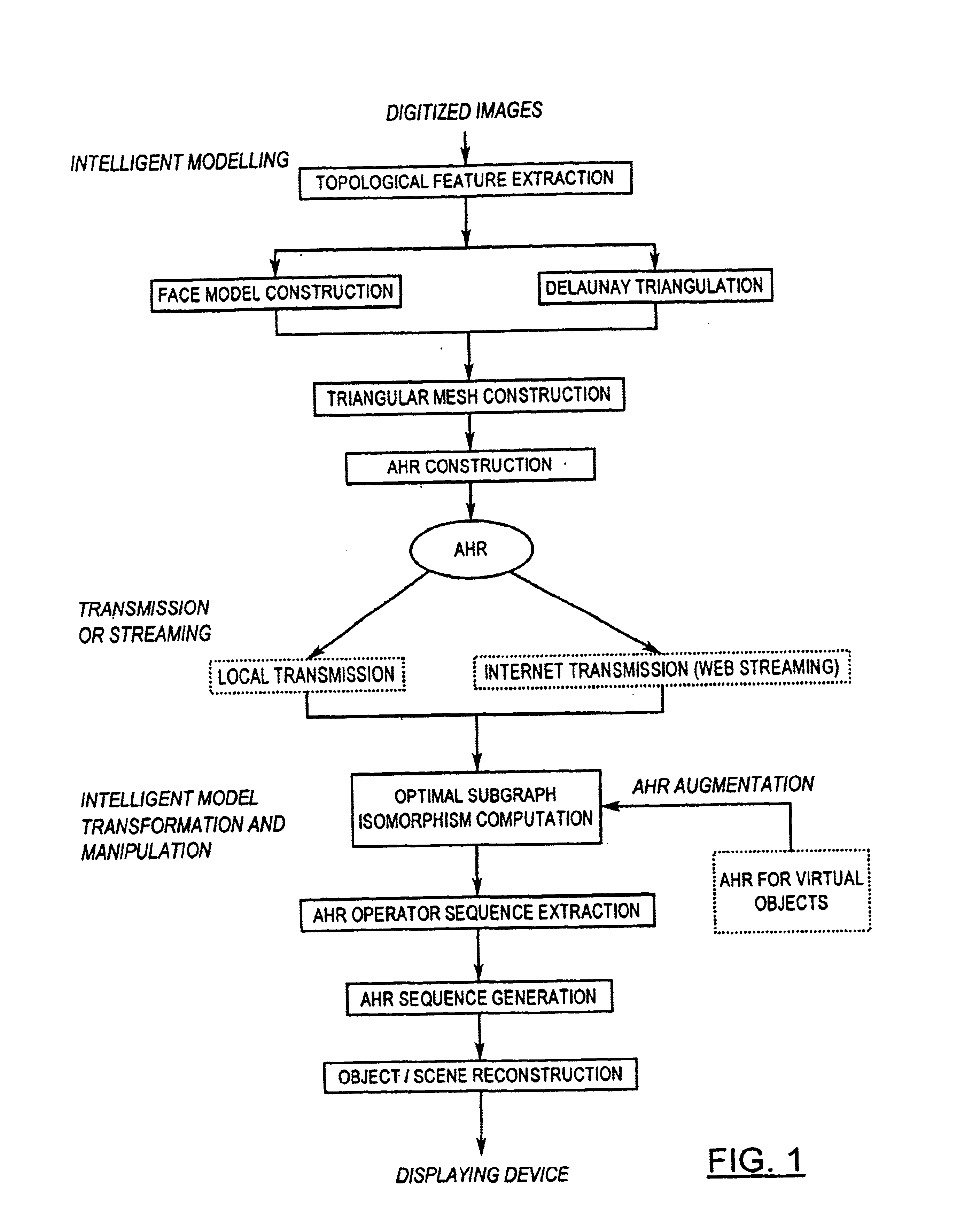

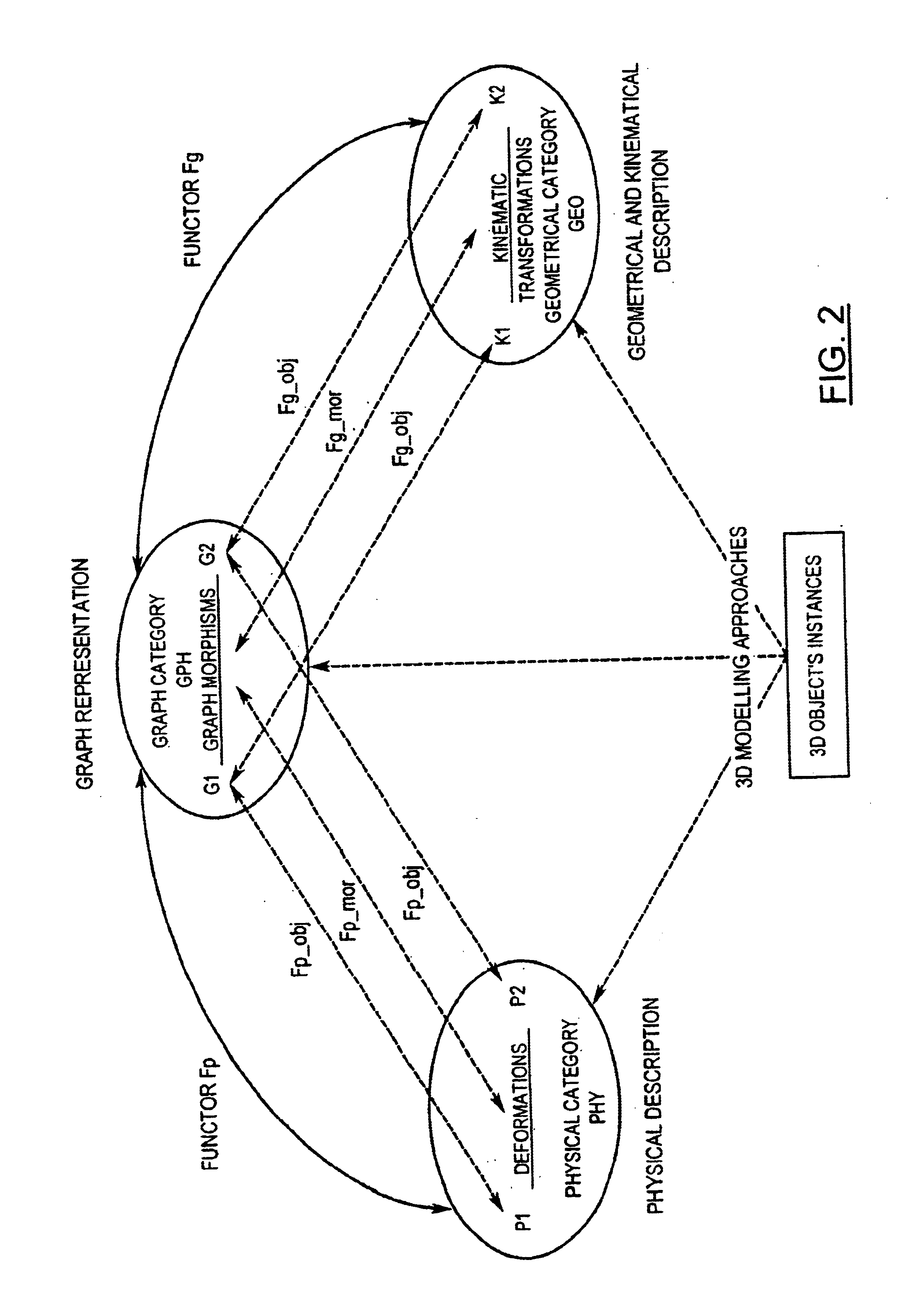

The present invention relates to a method of intelligent 2D and 3D object and scene modeling, transformation and manipulation and more particularly this invention relates to the field of computer modeling, virtual reality, animation and 3D Web streaming. The method uses attributed hypergraph representations (AHR) for modeling, transforming and manipulating objects. From one or more 2D views of a 3D object or scene, range information is first computed and then a triangular mesh model is constructed. The data structure is designed to handle the transformations on the representation corresponding to movements and deformations of the object. In an attributed hypergraph, the attributes associated with the hyperedges and the vertices facilitates modeling of various shapes with geometrical, physical or behavior features. As a hierarchical and generic representation, AHR enables pattern matching, recognition, synthesis and manipulation to be carried out at different resolution levels on different subsets depending on the context. Symbolic computation on knowledge represented in the format of attributed hypergraphs becomes straightforward. Given the features of a 3D object or scene, the procedure of constructing the AHR corresponds to the concept of functor in category theory, which maps one category to another one. The transformations of AHR are in the form of a set of operations defined on attributed hypergraphs, which stand for the motions and deformations of the object. This representation is applied to various modeling and manipulation tasks on 3D objects. The process of motion analysis of a 3D object is the task of extracting a sequence of AH operators from the AHR of the object. A 3D scene can be modeled by AHR and then altered / augmented with other 3D models, by which an augmented reality can be built. Given the AHR's of two different 3D shapes, 3D morphing may be accomplished by matching the two AHR's and then mapping the difference to a sequence of AH operators. Model based animation of an object can be accomplished by applying a set of AH operators to its AHR. The AHR method forms a data compression system for efficient web streaming over the Internet.

Owner:PATTERN DISCOVERY SOFTWARE SYST

Computer assisted hidden tooth abnormal correction system

InactiveCN1686058ANo oral wearNo discomfortOthrodonticsSpecial data processing applicationsData acquisitionIntelligent modeling

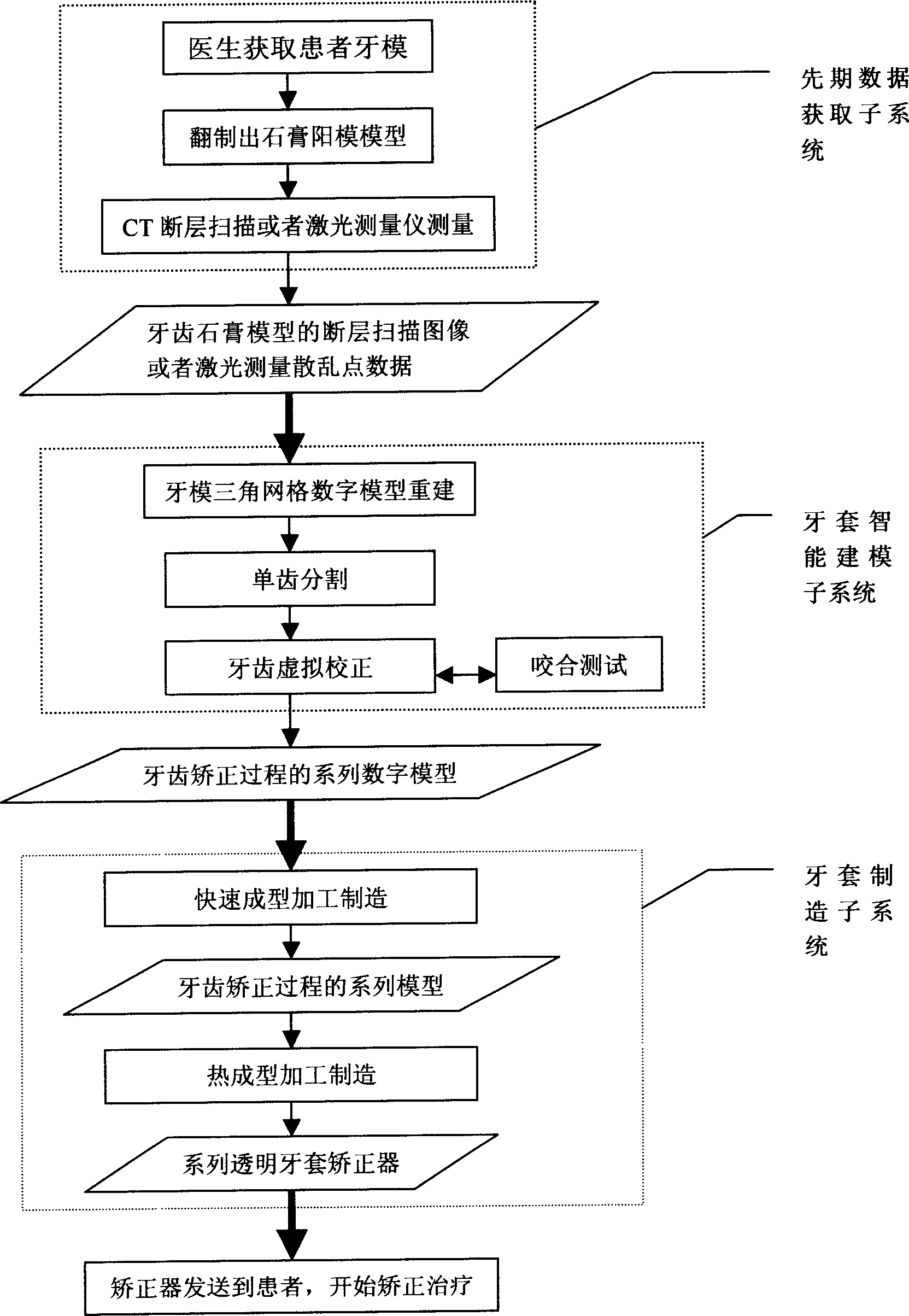

A computer aided hidden tooth deformity correcting system is composed of a data acquisition subsystem, an intelligent tooth sleeve modelling subsystem, transparent tooth sleeve manufacture subsystem and data bus.

Owner:YINCHILI MEDICAL TECH SHANGHAI

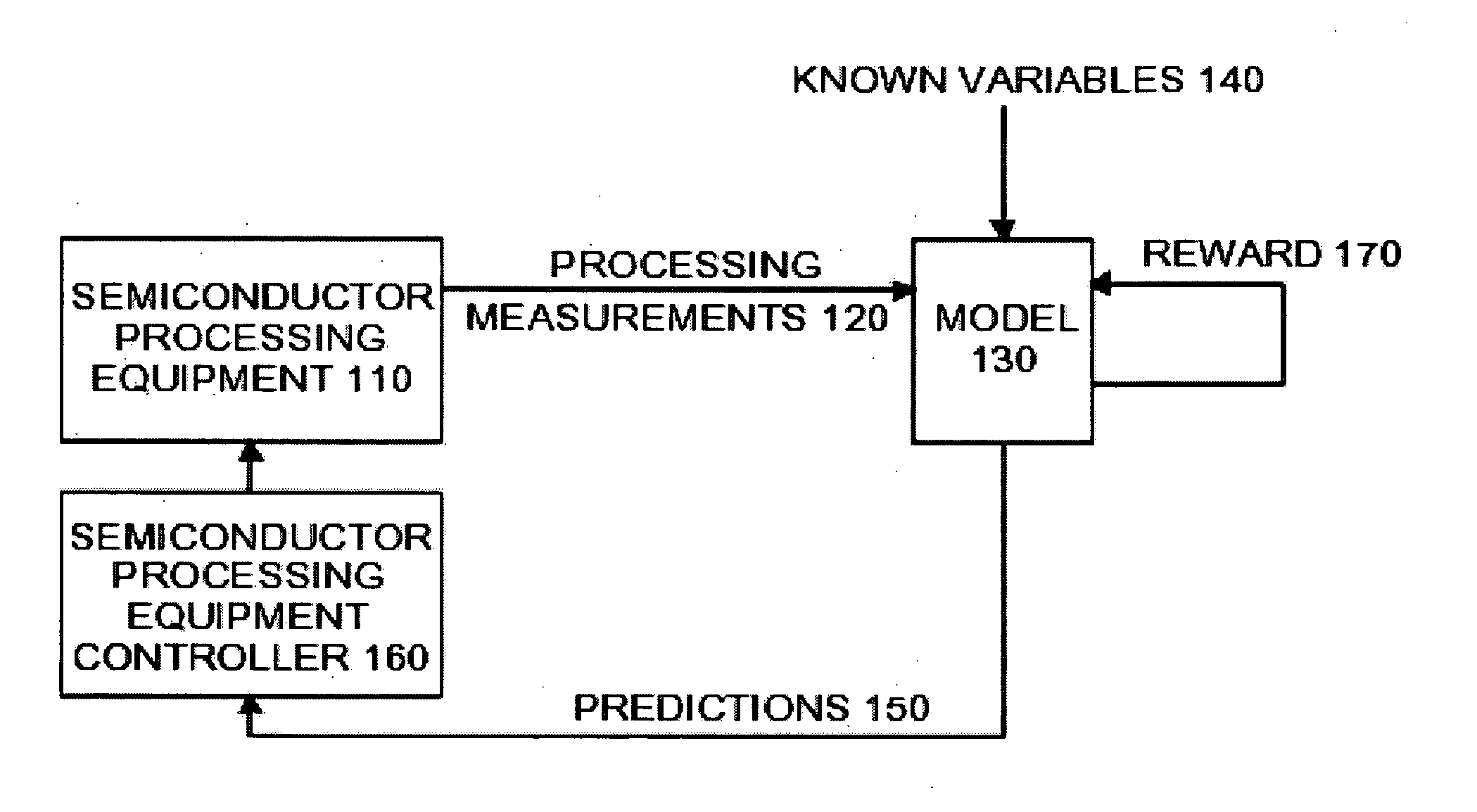

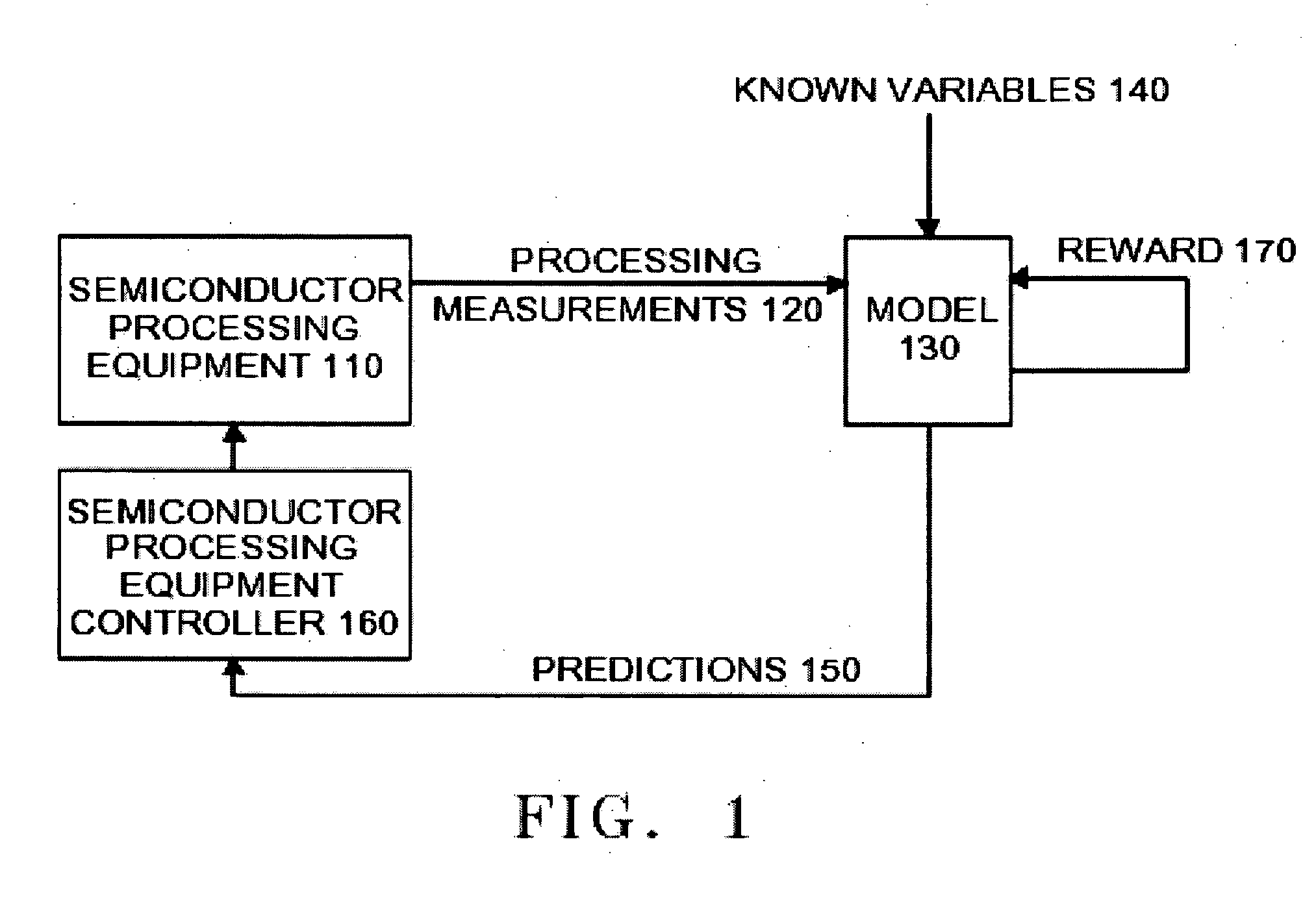

Intelligent system for detection of process status, process fault and preventive maintenance

Embodiments of an intelligent modeling method and system monitor and perform analysis of semiconductor processing equipment as well as predict future states of that equipment based on the analysis, predict failures of the semiconductor processing equipment and / or determine equipment maintenance schedules.

Owner:TOKYO ELECTRON LTD

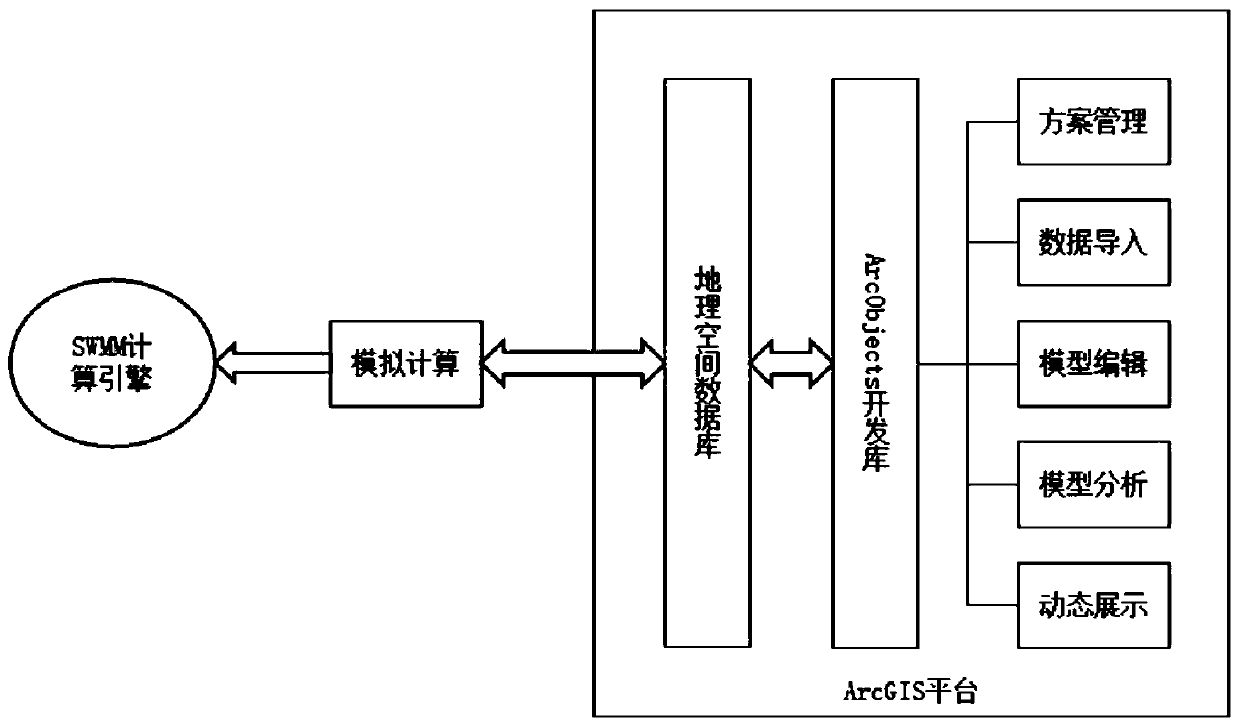

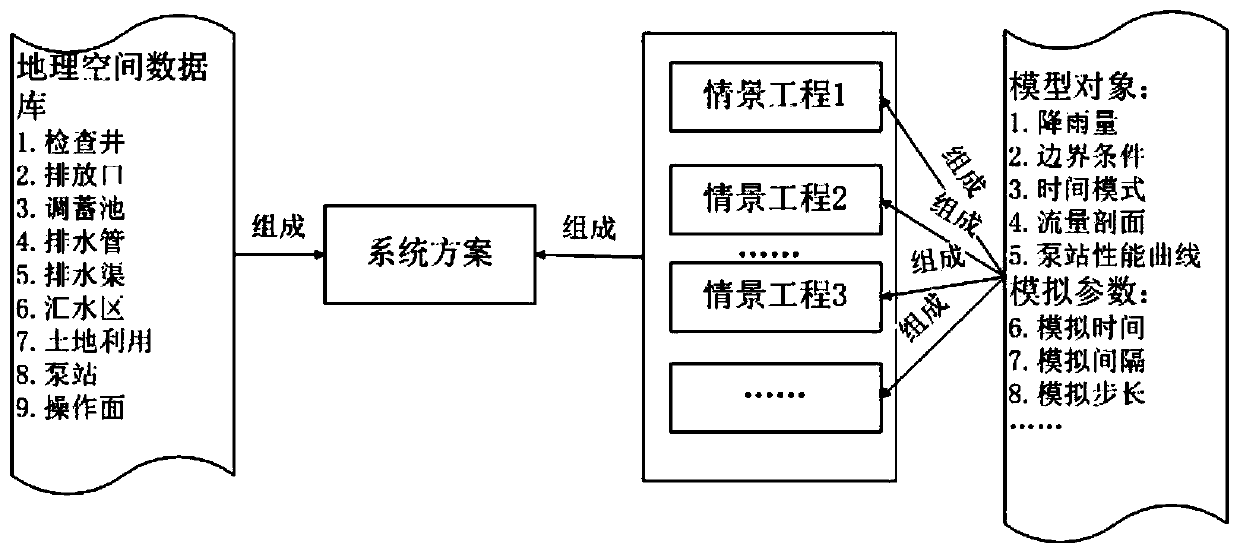

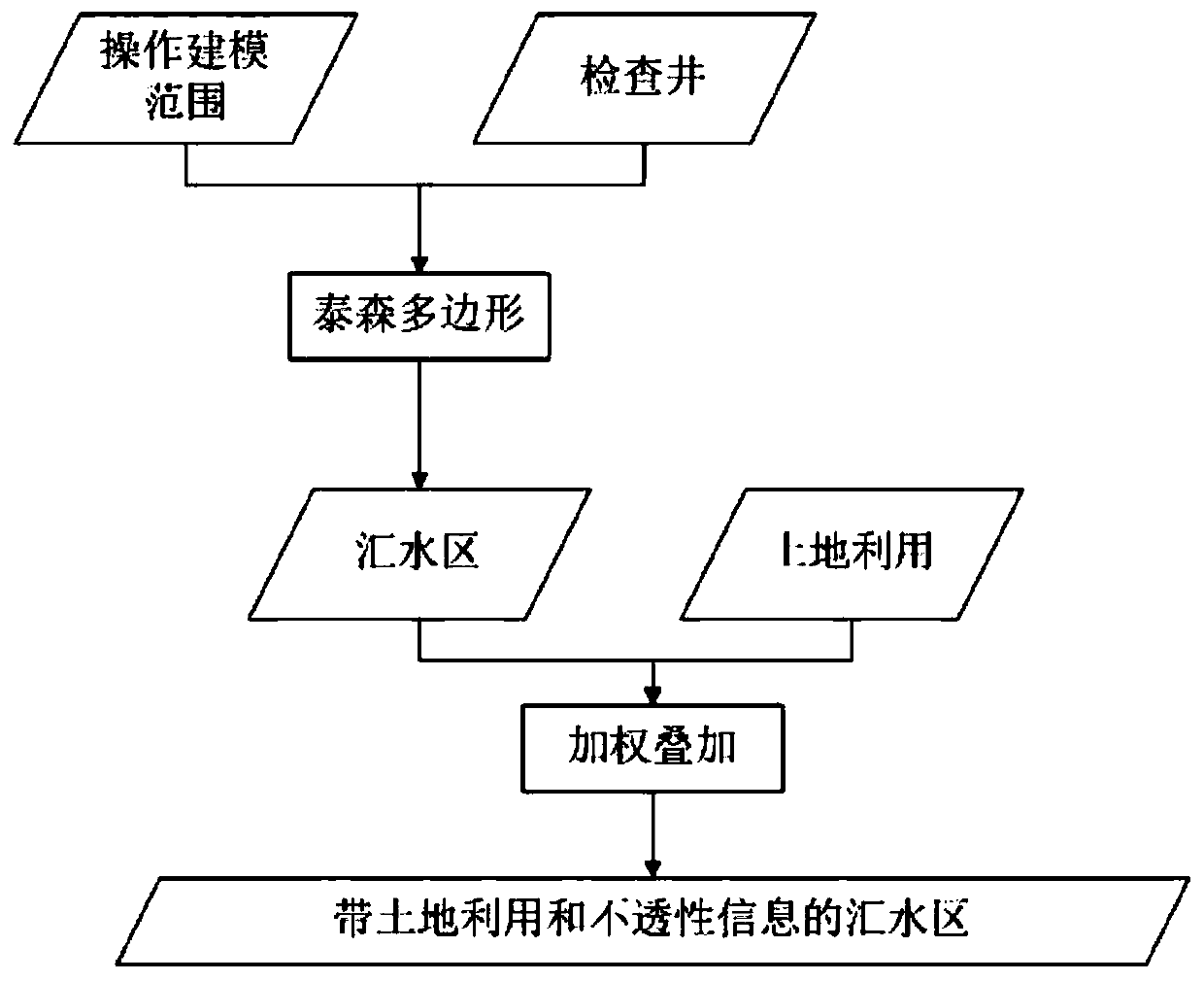

Urban inland inundation intelligent modeling and analysis method based on GIS and SWMM

ActiveCN110298076AHigh degree of construction automationThe analysis results are accurate and highClimate change adaptationDesign optimisation/simulationRisk levelCoupling

The invention relates to an urban inland inundation intelligent modeling and analysis method based on a GIS and an SWMM. The method comprises the following steps: constructing a simulation system based on the GIS and the SWMM; carrying out automatic preprocessing on the model data and automatically identifying topology errors; calculating a hydrological-hydrodynamic coupling model based on the SWMM by combining rainfall, calculating the amount of rainwater converged into a drainage pipe network system, simulating to obtain actual condition information in the drainage pipe network, and obtaining pipe point overflow data; performing surface water inundation analysis according to the pipe point overflow data, simulating the surface water to obtain the depth of the surface water, and distributing the surface water flow based on a window method; performing early warning analysis on waterlogging of surface water, comprehensively considering prediction of the surface water, automatically dividing waterlogging risk levels of different areas according to a calculation result of a hydrological-hydrodynamic coupling model and a result of surface water inundation analysis, and providing an early warning scheme for drainage waterlogging prevention emergency. The method has the advantages of being low in construction cost, high in model construction automation degree and accurate in analysisresult.

Owner:GUANGZHOU AOGE INTELLIGENT TECH CO LTD

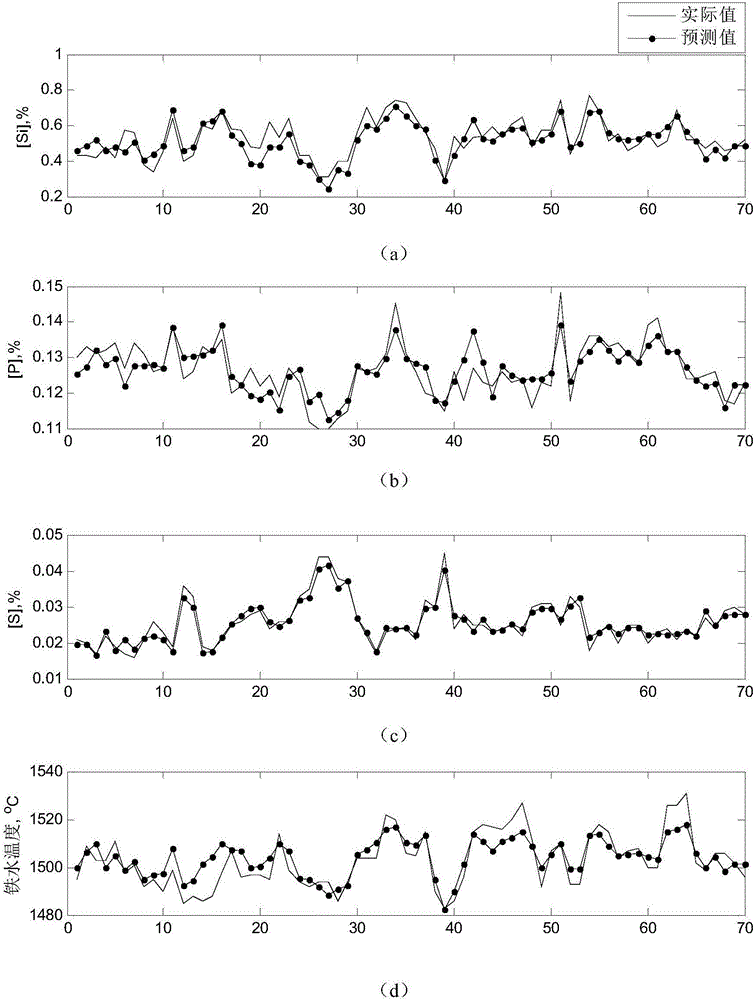

Blast furnace liquid iron quality online forecasting system and method based on multivariable online sequential extreme learning machine

ActiveCN104651559ARealize multivariate dynamic online forecastingEasy to controlBlast furnace componentsBlast furnace detailsTime lagData acquisition

The invention provides a blast furnace liquid iron quality online forecasting system and method based on a multivariable online sequential extreme learning machine. The forecasting system is composed of a conventional measurement system, a data acquisition unit, M-OS-ELM online forecasting software and a computer system for running the software. The forecasting method comprises the following steps of (1) auxiliary variable selection and model input variable determination; and (2) M-SVR soft measurement model training and utilization. According to the forecasting system and the forecasting method, a multivariable liquid iron quality forecasting model having output self-feedback and considering the timing sequence and time lag relation of input and output is established by use of the online process data provided by the conventional detection system and based on the M-OS-ELM intelligent modeling technology, and the multivariable online dynamic determination of four major liquid iron quality indexes, namely Si content, P content, S content and liquid iron temperature, is realized simultaneously; in short, the model has the characteristics of good practicability, more accurate measurement effects and stronger generalization ability.

Owner:NORTHEASTERN UNIV

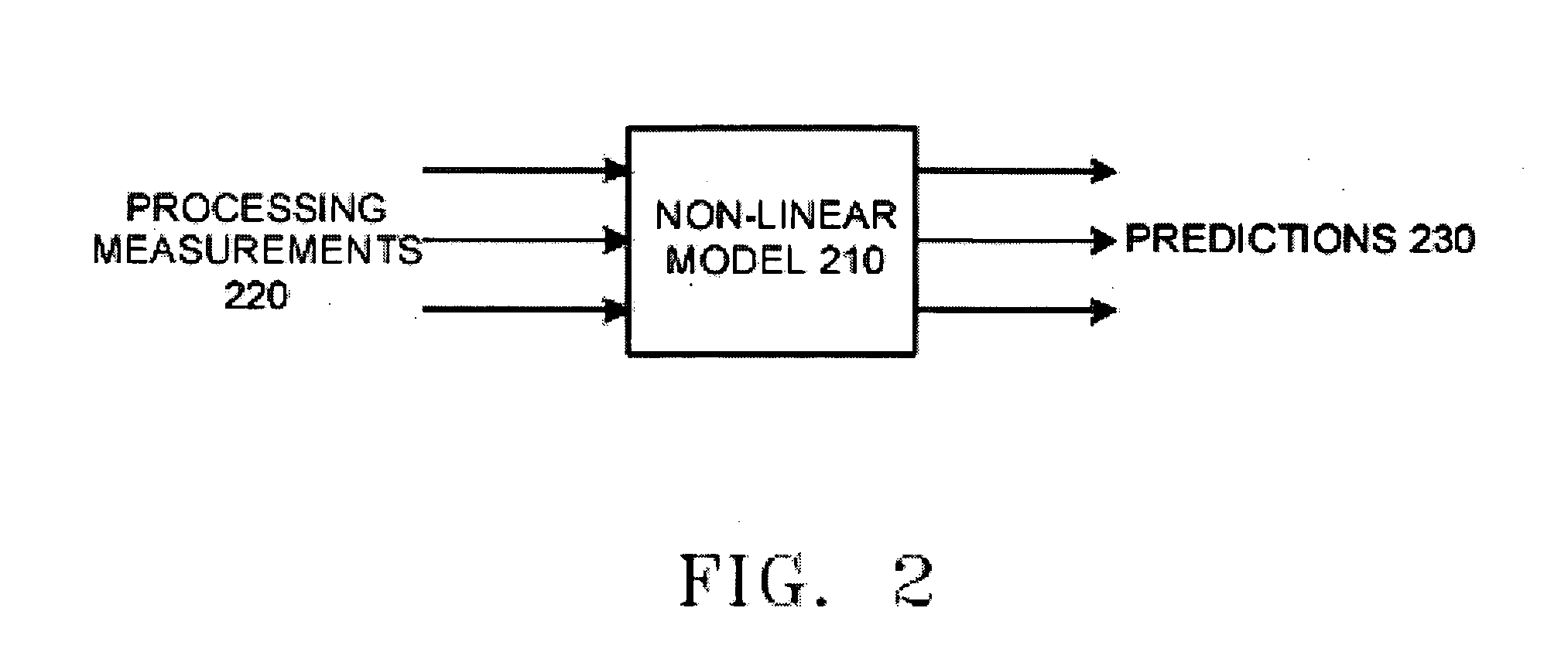

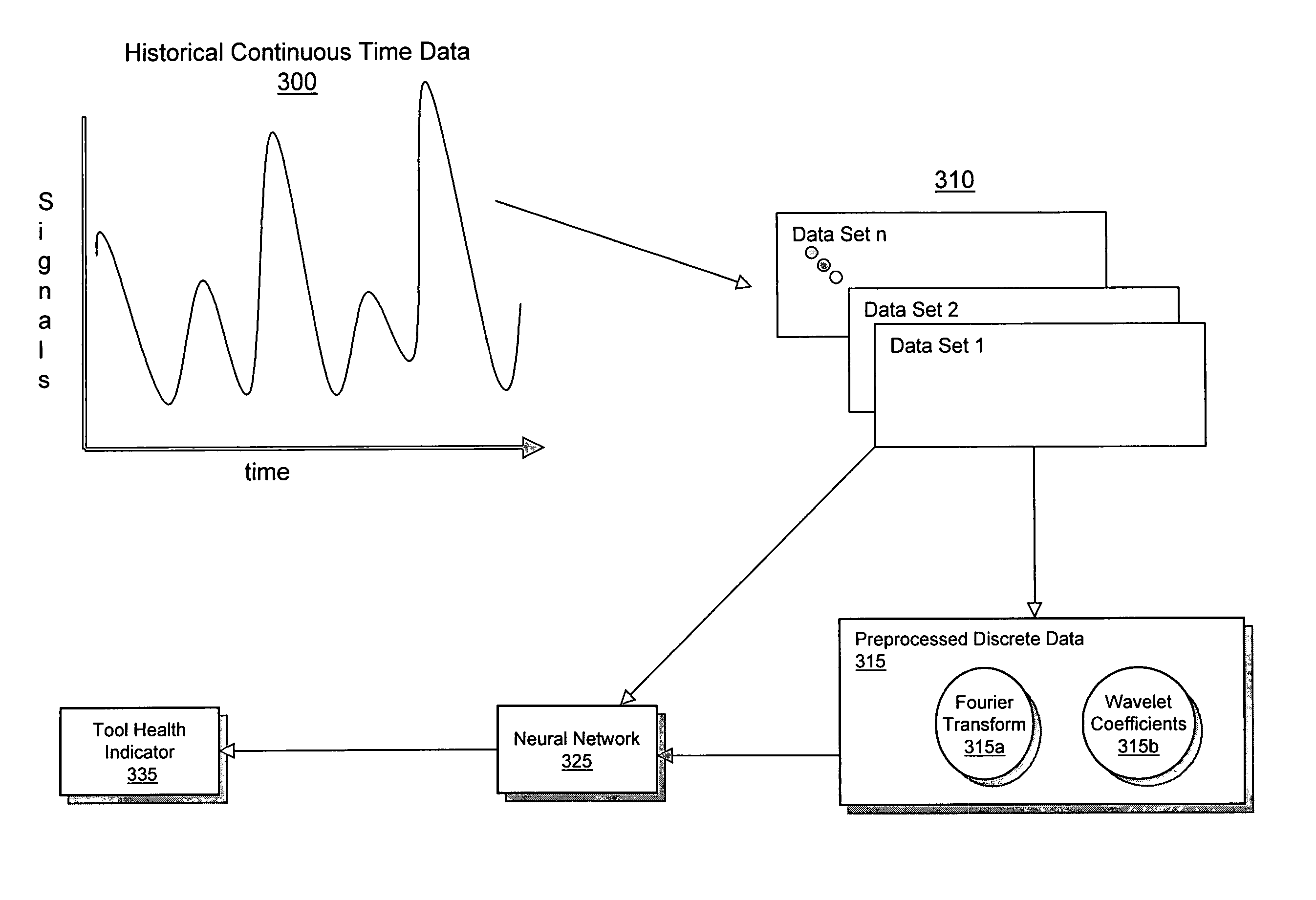

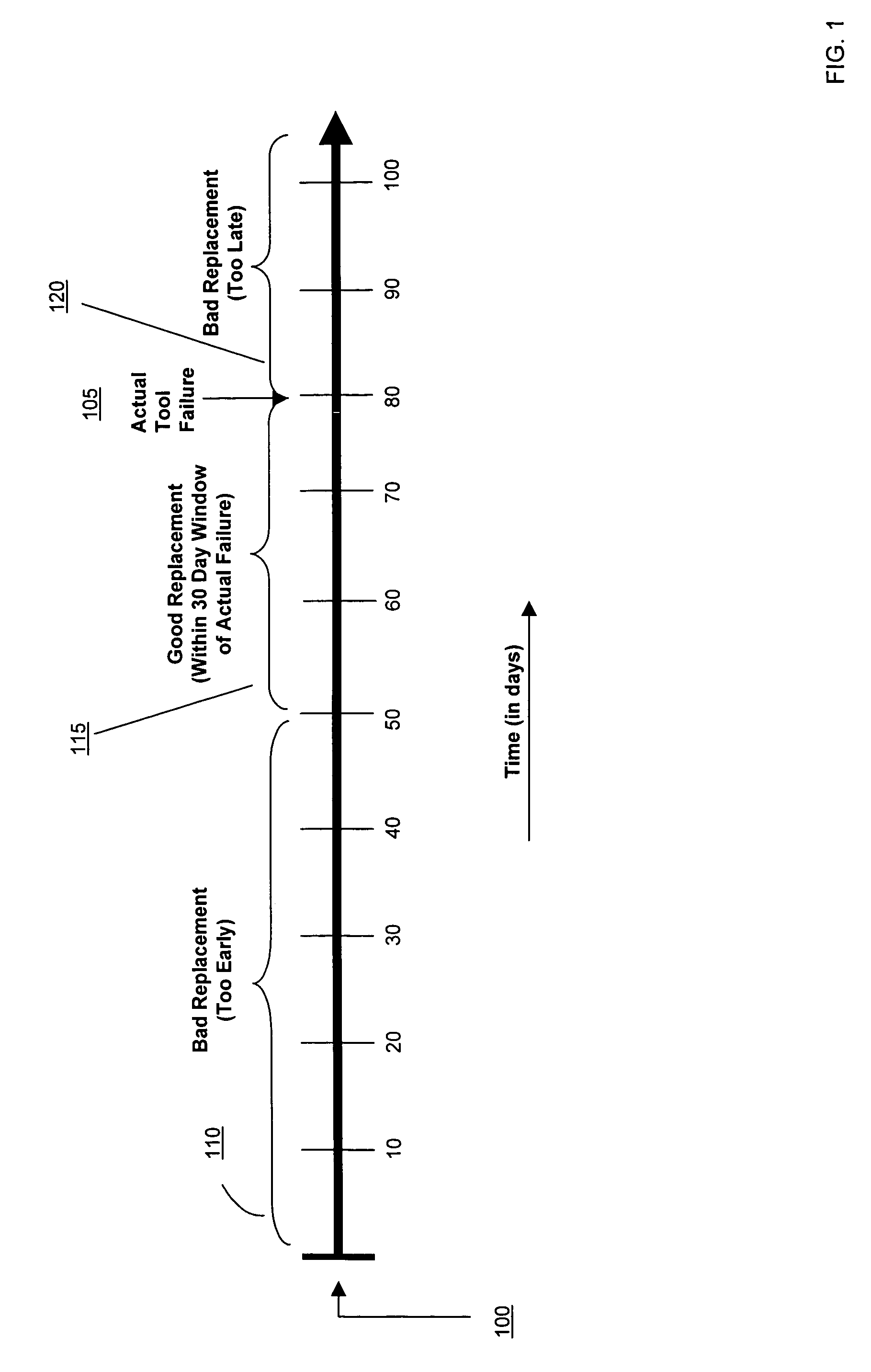

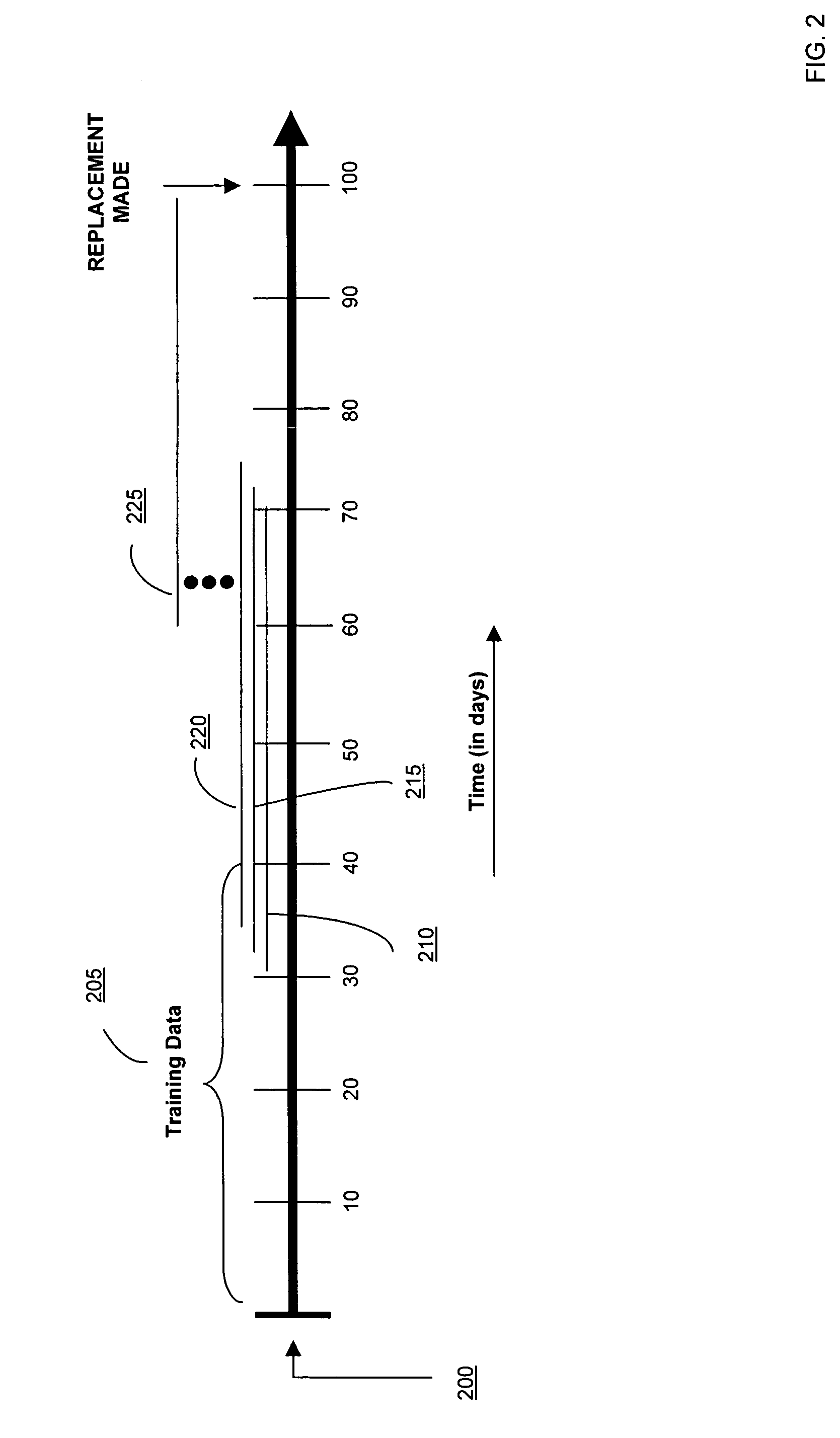

Intelligent modelling of process and tool health

InactiveUS7020569B2Accurate identificationAvoid failureProgramme controlElectric testing/monitoringSliding time windowData set

The health of a tool is predicted based on temporally ordered input data representing parameters indicative of tool health. A sliding time window is used to partition input data into temporally displaced data sets. Non-linear regression models determine, based on the data sets, a set of predictive values relating to tool health at a future time. A tool-health metric is then determined based on one or more of the predictive values.

Owner:IBEX PROCESS TECH

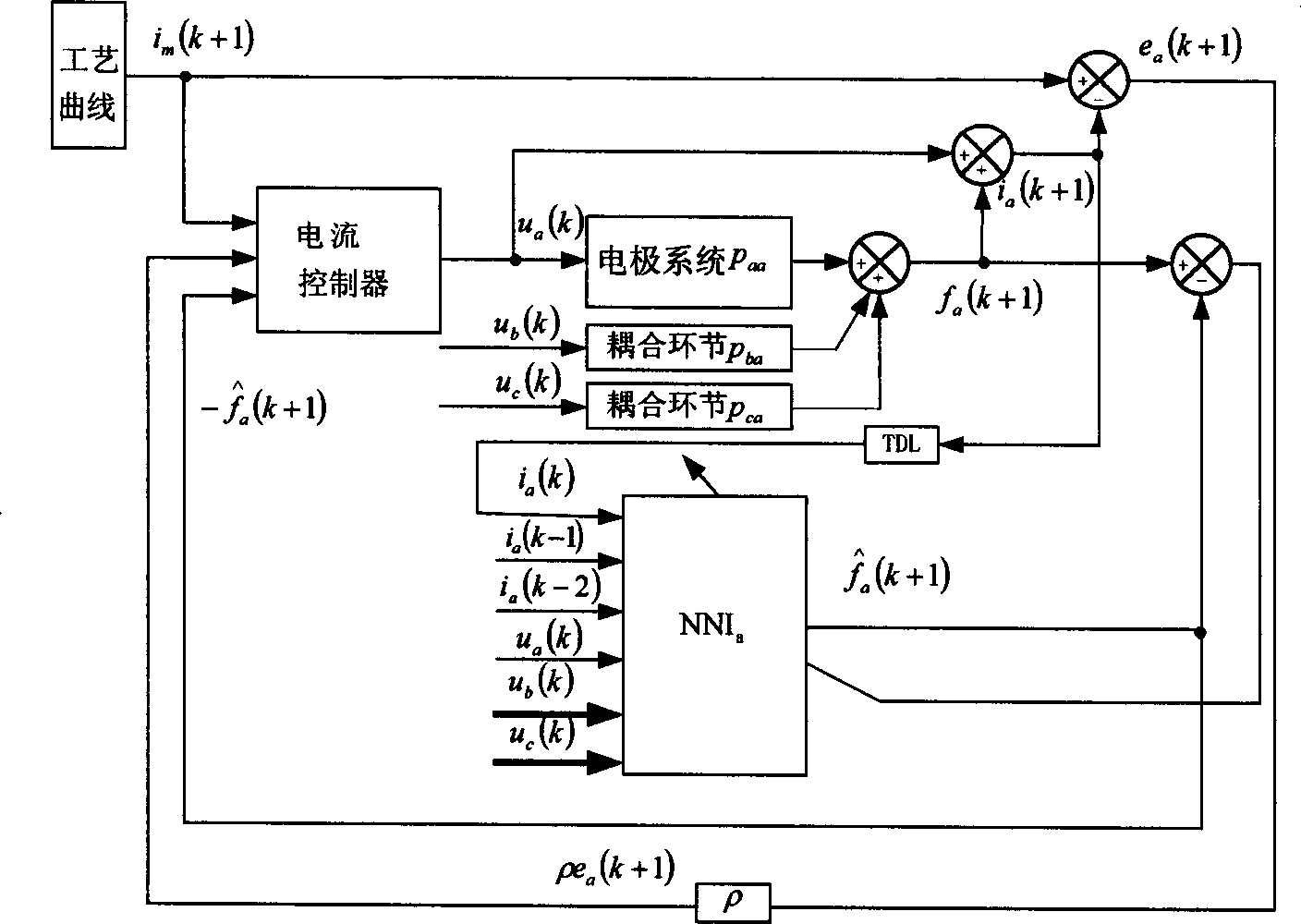

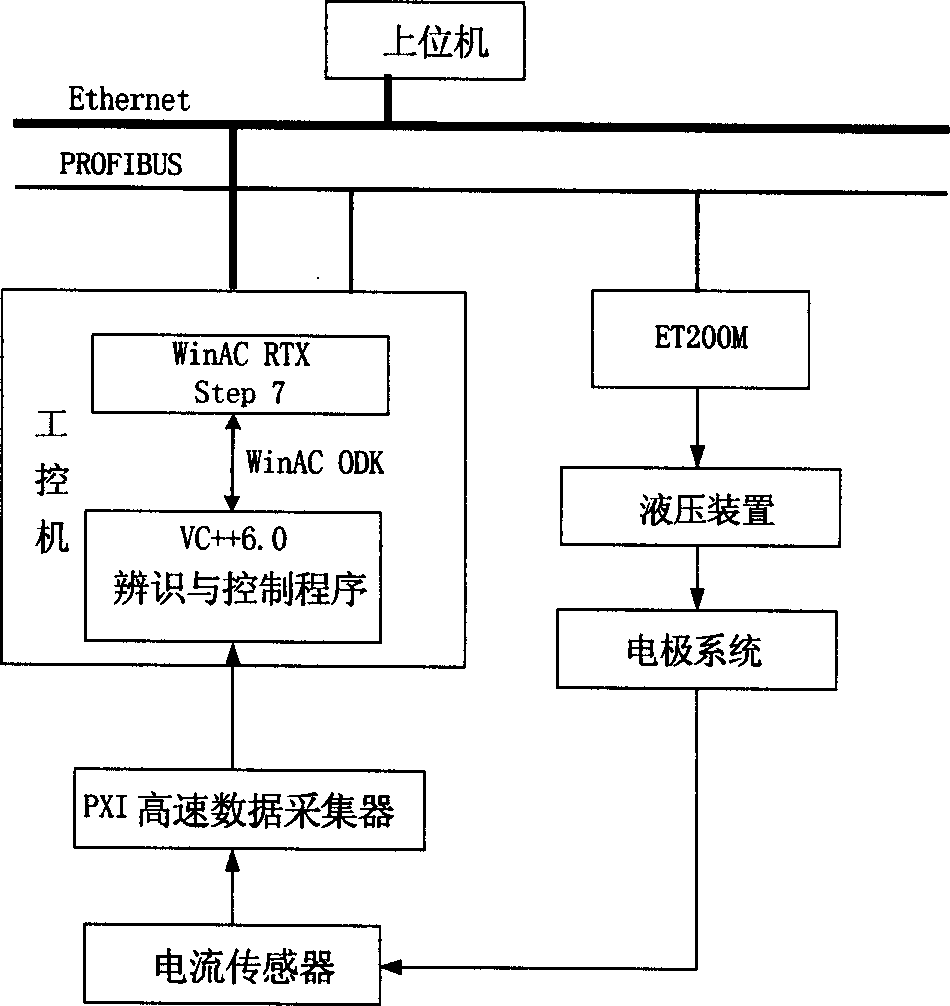

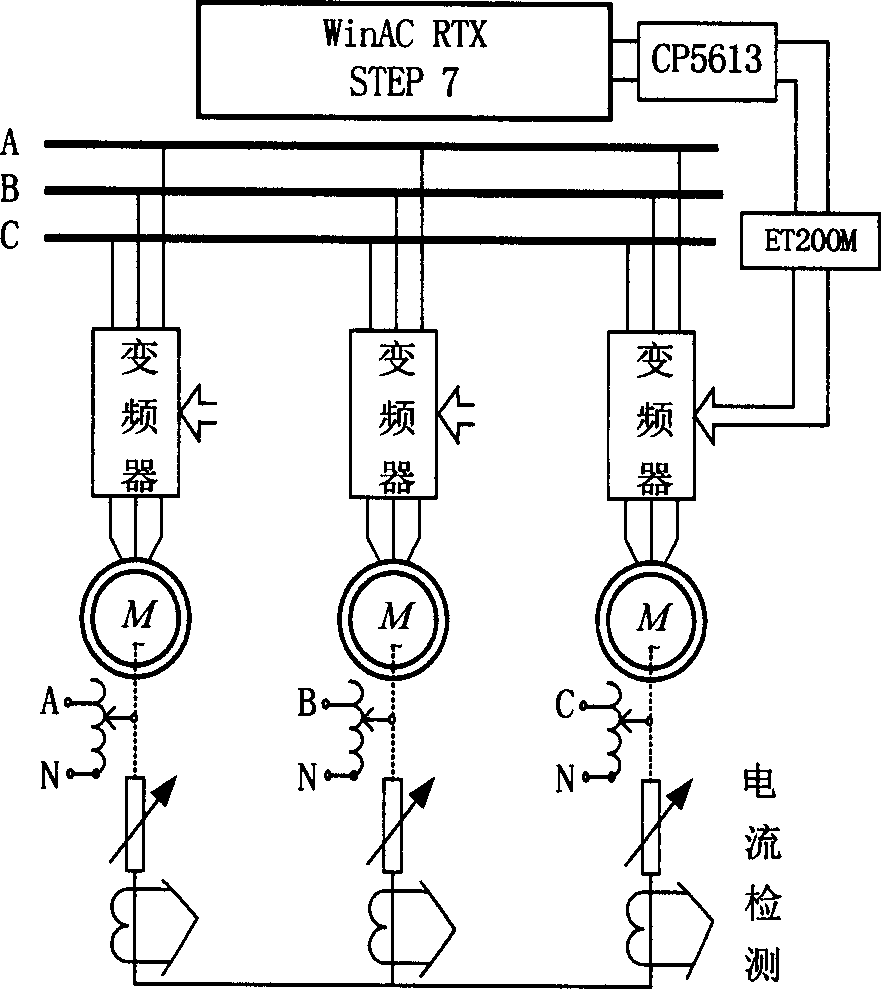

Simple method for neural network decoupling of multi-variable system based on model reference adaptive control

InactiveCN1790197APrecise and stable controlElectric discharge heatingIncreasing energy efficiencyNerve networkControl signal

The invention discloses a shortcut method of nerve network decoupling based on the adaptive control multiple-variable system in the complex system intelligent modeling and decoupling control technique domain, which is characterized by the following: adapting on-line identification and decoupling of nerve network; guiding the other two-phase control signal into the input end of nerve network identifier as two signal reference and identification when certain one phase of the three-phase electrode system is on-line identifying; decoupling and controlling the three-phase electrode.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

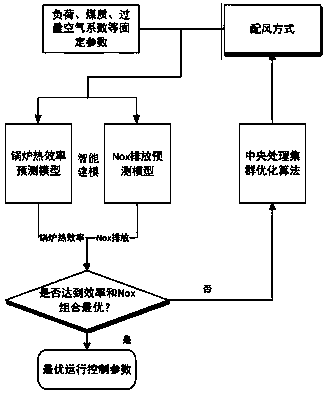

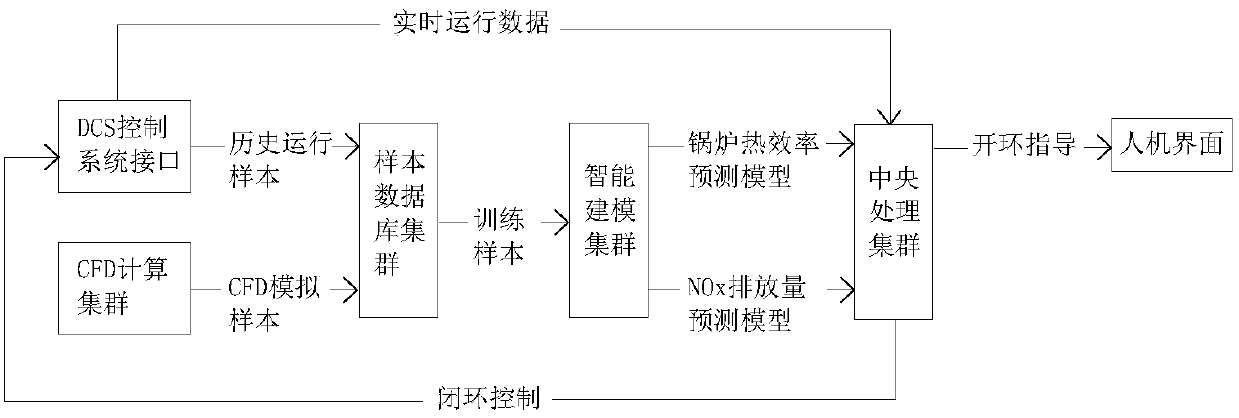

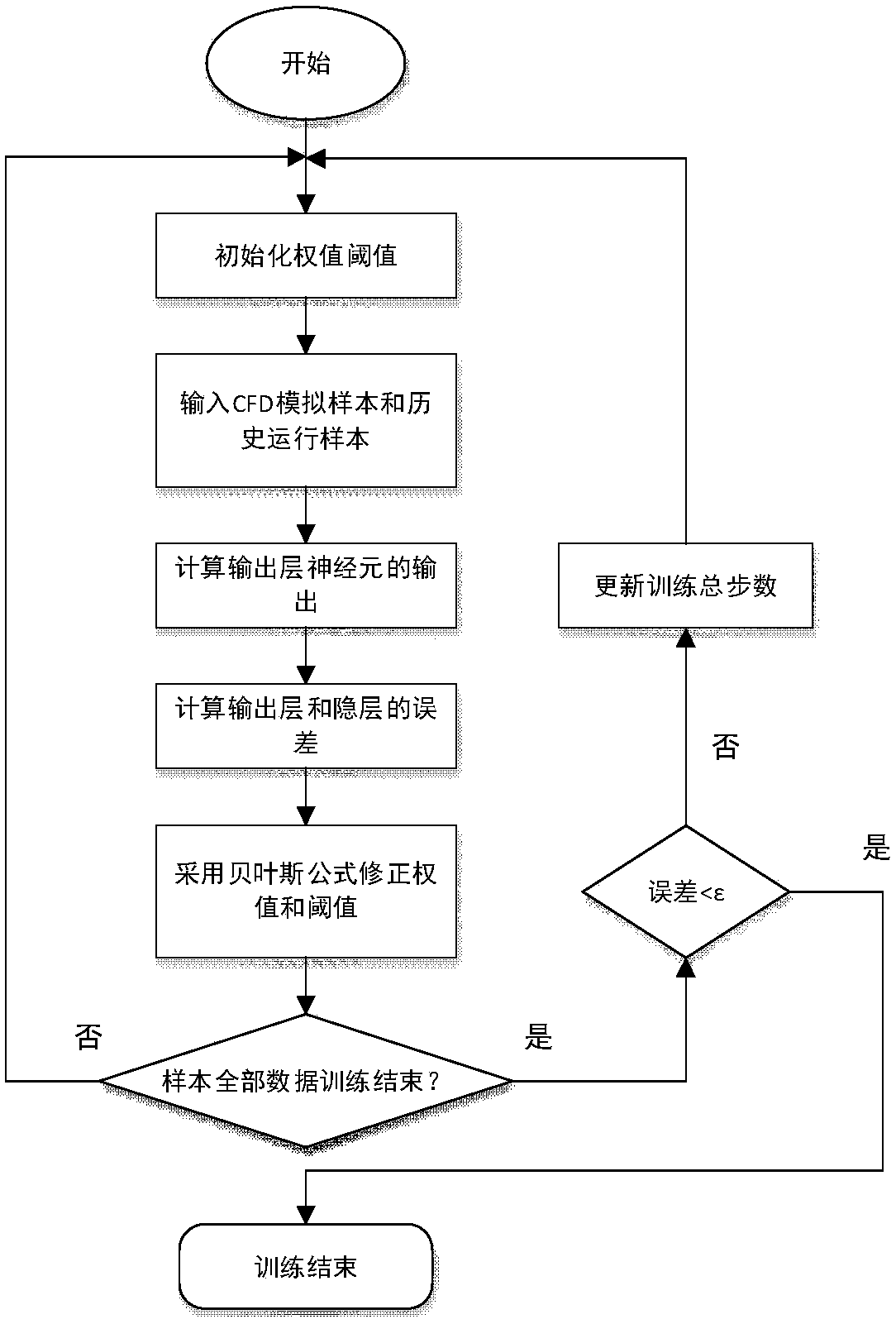

Boiler combustion optimization system and method based on CFD numerical simulation and intelligent modeling

ActiveCN107726358AImprove accuracyOptimize combustion thermal efficiencyCombustion regulationHuman–machine interfaceSimulation

The invention discloses a boiler combustion optimization system and method based on CFD numerical simulation and intelligent modeling. The boiler combustion optimization system comprises a DCS controlsystem interface, a CFD computing cluster, a sample database cluster, an intelligent modeling cluster, a central processing cluster and a human-computer interface. Real-time matching of the optimal air distribution types of the unit along with variation of network load instructions, coal as fired quality characters and excess air coefficients by storing, modeling and optimizing a CFD simulation sample and a history running sample. The modeling accuracy is improved by using a CFD numerical simulation technology, a DCS control system can be directly called to realize closed-loop control in optimization, the air distribution way is enabled to quickly respond to the load change, and the unit combustion heat efficiency and the NOx emission are optimized in a real-time manner.

Owner:SOUTHEAST UNIV

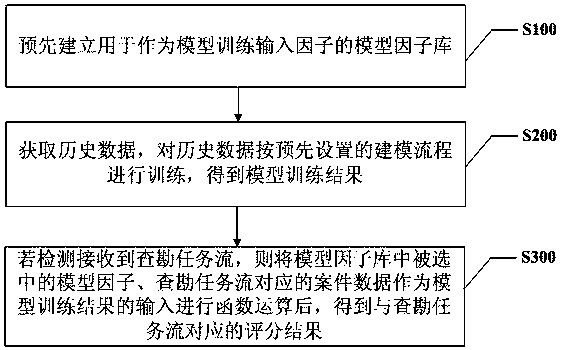

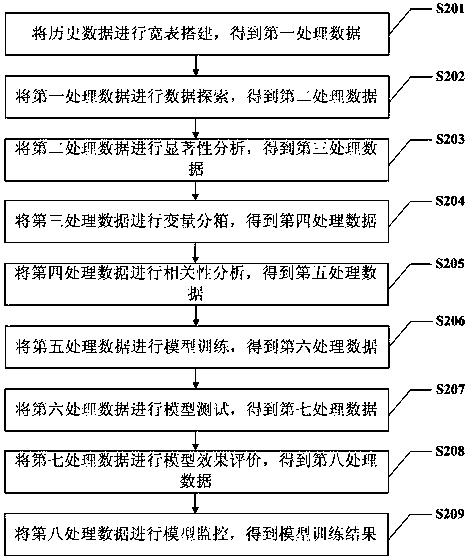

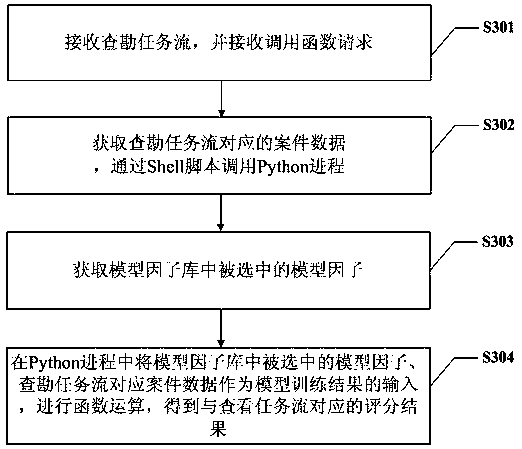

Model output method and device for intelligent modeling, and storage medium

The invention provides a model output method and device for intelligent modeling, and a storage medium. The method comprises the steps of pre-establishing a model factor library used as model traininginput factors; obtaining historical data, and training the historical data according to a preset modeling process, thereby obtaining a model training result; and if it is detected that survey task flow is received, performing function operation by taking the selected model factors in the model factor library and case data corresponding to the survey task flow as inputs of the model training result to obtain a score result corresponding to the survey task flow. According to the method, the model training result obtained by training according to an SMP is deployed; when the factors of the modelfactor library and the survey task flow are received by a model deployment platform, case risk scoring is performed directly by the model training result; and functions deployed in a model deploymentplatform can be subjected to optimization iteration at any time.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

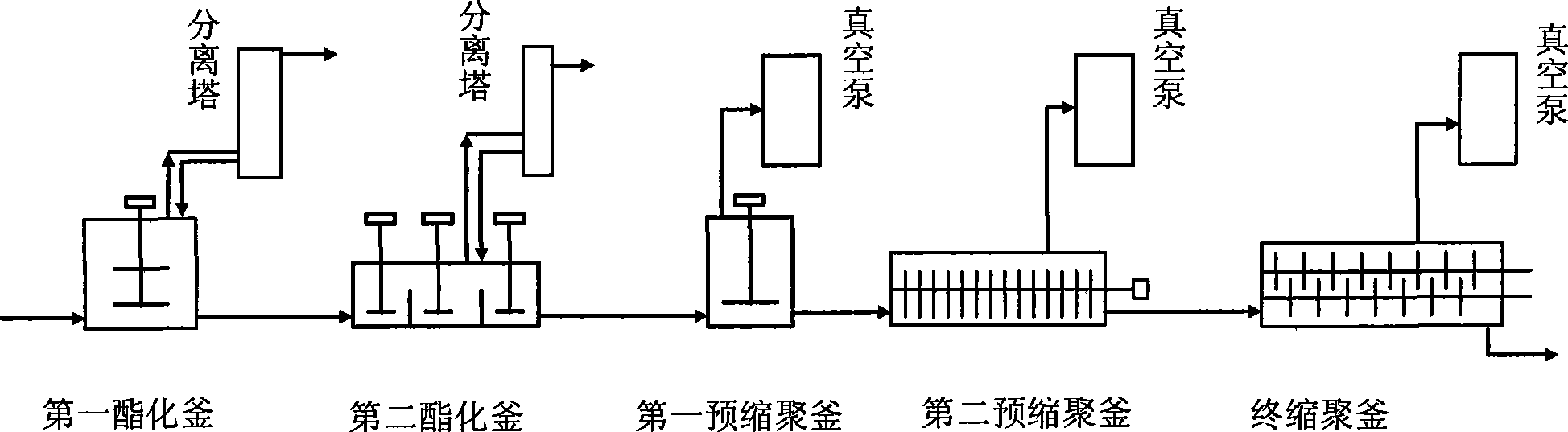

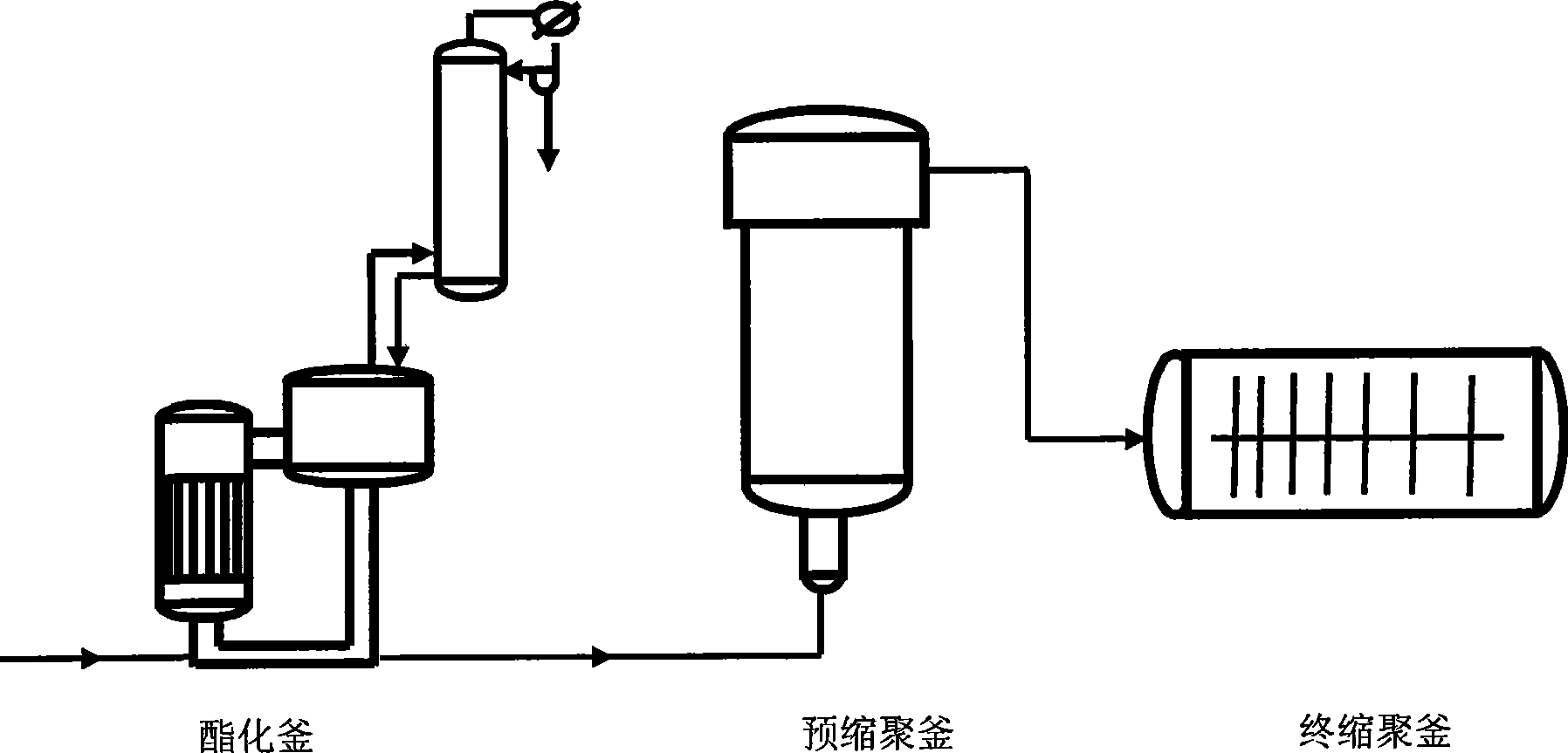

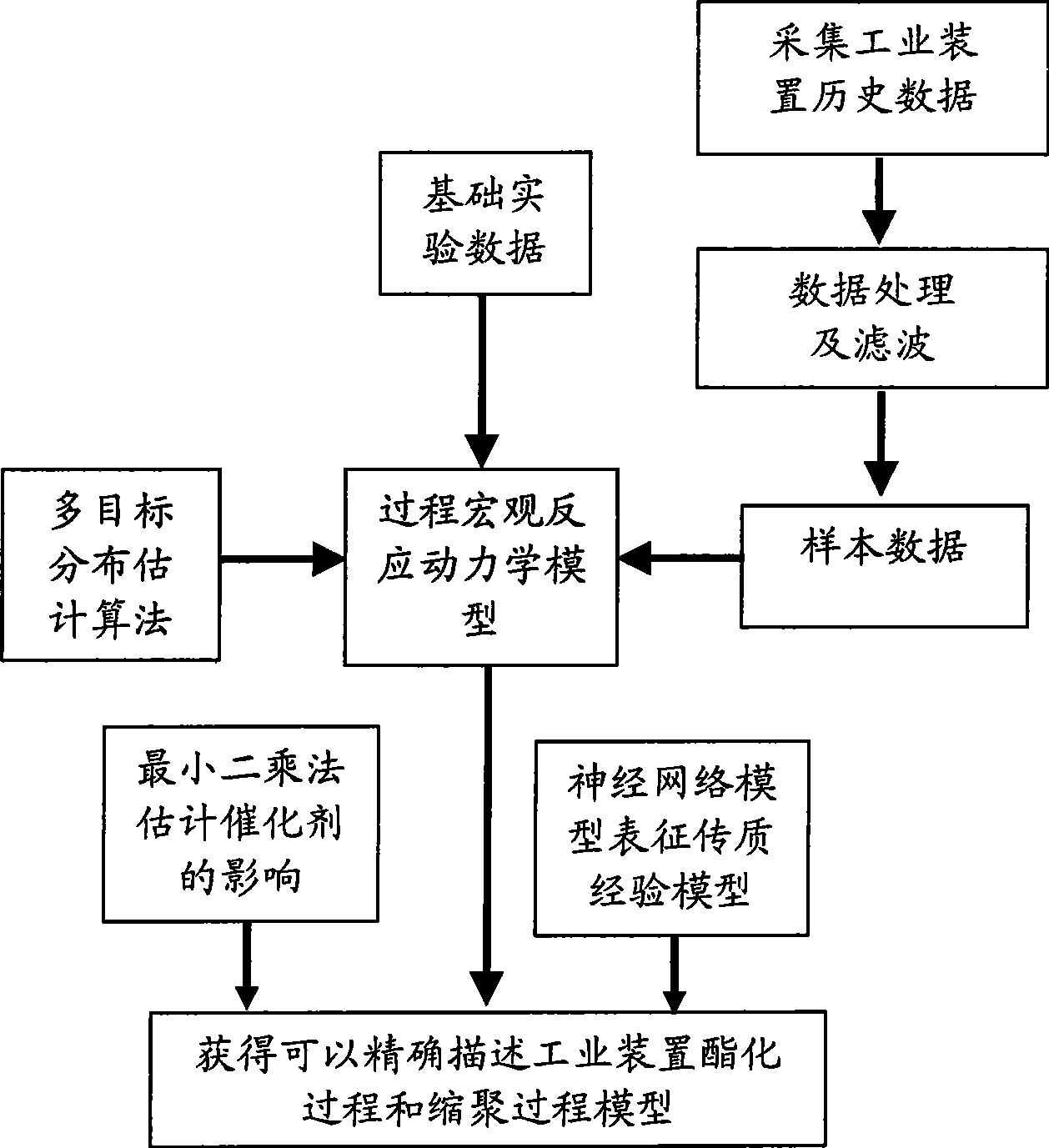

Intelligent modeling method in industrial polyester production process

The invention relates to an intelligent modeling method during the industrial polyester production process. Firstly, a mechanism model of the polyester production process based on reaction kinetics is established according to the mechanism of polyester reaction process; and then, parameters in the technical mechanism model are optimized by a multiple-target distribution estimation algorithm, so as to describe the actual operation characteristic of the industrial polyester production process exactly. At the same time, considering the influence on the reaction during the pre-polycondensation stage caused by catalyst, influence factor of the catalyst is added in reaction speed constant of the mechanism model, and a model between the catalyst and the reaction speed constant is established by a least square method; in a final polycondensation reactor, the mass transfer rate is reduced, and the influence on the process speed is increased, so that an artificial neural network is used for establishing an empirical model while the influence of mass transfer is considered, and the process speed is expressed in a form of resistance equation while combining with the reaction speed to ensure that the model is exacter. The modeling method can be applied to the modeling during three-reaction and five-reaction technical process during the industrial polyester production process at present.

Owner:EAST CHINA UNIV OF SCI & TECH

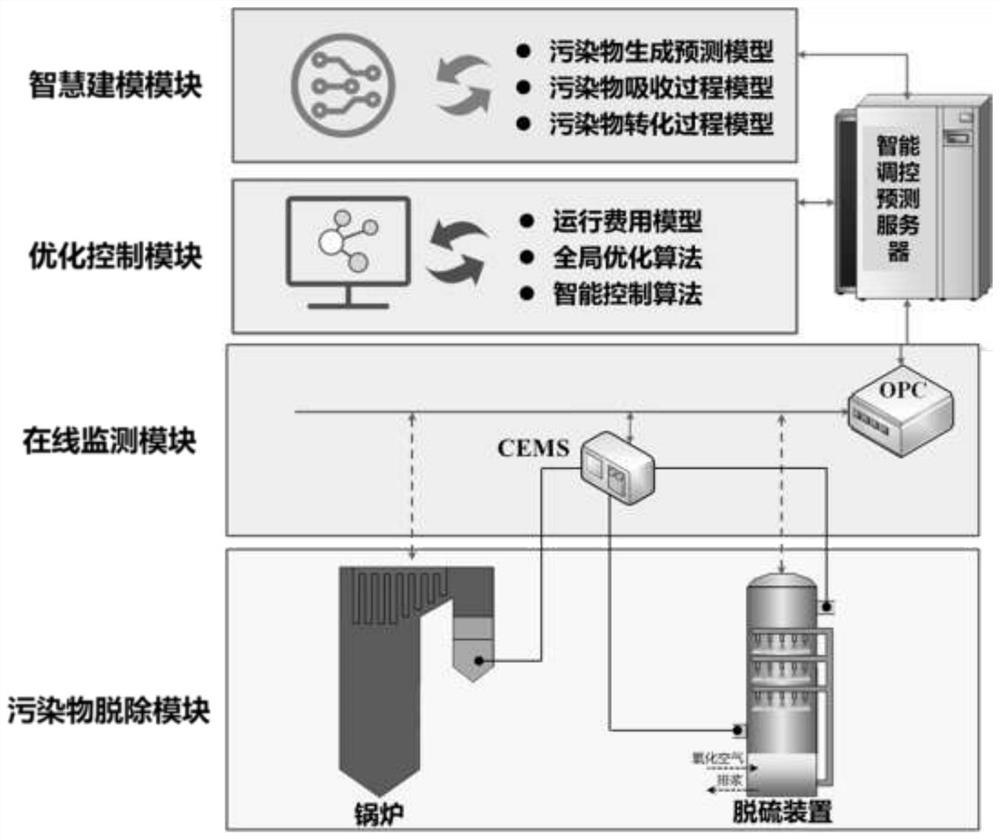

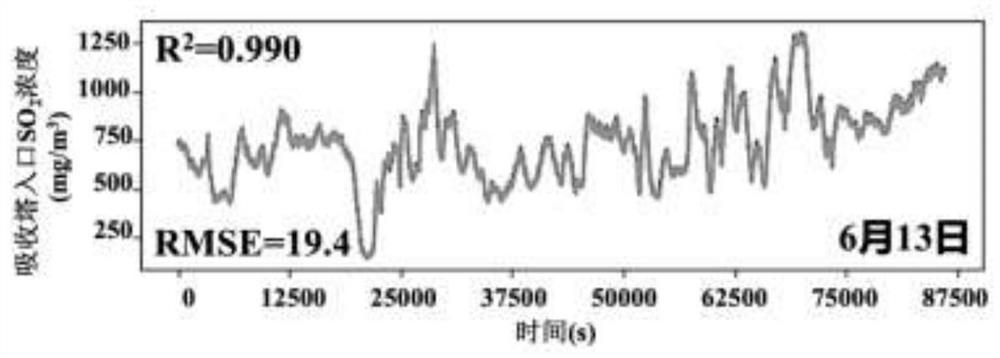

Whole-process intelligent operation regulation and control system of wet desulphurization device

ActiveCN113082954AImprove reliabilityConcentrated concentration distributionGas treatmentDispersed particle separationCirculator pumpIntelligent modeling

The invention relates to a whole-process intelligent operation regulation and control system of a wet desulphurization device. The whole-process intelligent operation regulation and control system comprises a pollutant removal module, an online monitoring module, an optimization control module and an intelligent modeling module. The system can accurately predict the influence of each control variable on the desulfurization efficiency, the operation cost and the product quality of the wet desulfurization system, accurately regulate and control the operation parameters such as the pH value, the frequency and the liquid level, and ensure that the outlet concentration stably reaches the standard under the working conditions of variable load and variable coal quality; energy consumption and material consumption distribution among devices such as a circulating pump, an oxidation fan and a gypsum dehydrator is coordinated, so that the cost of the wet desulphurization system is optimal; by-product components are controlled to ensure that the purity of the target substance reaches the standard; and safe, stable, economical and efficient operation of the wet desulphurization device is realized.

Owner:ZHEJIANG UNIV

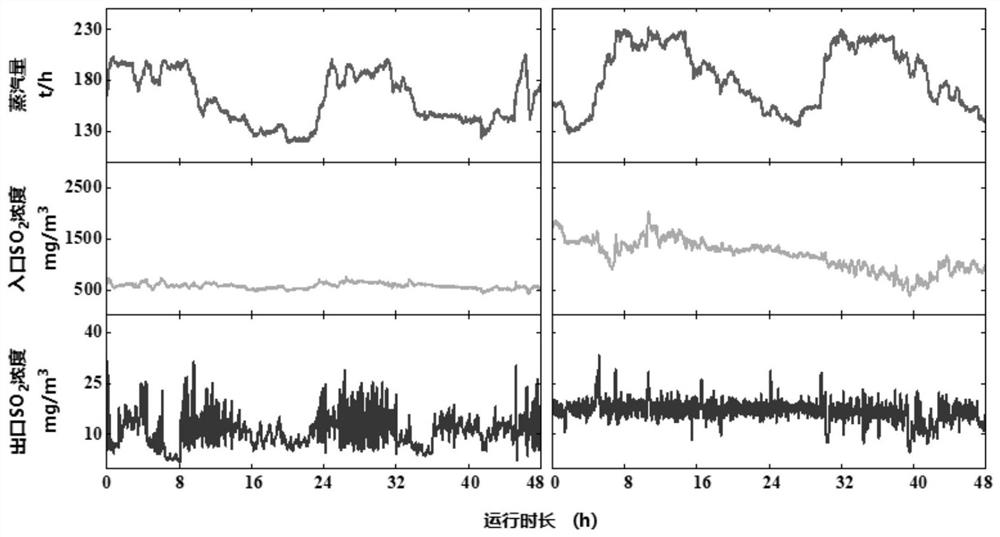

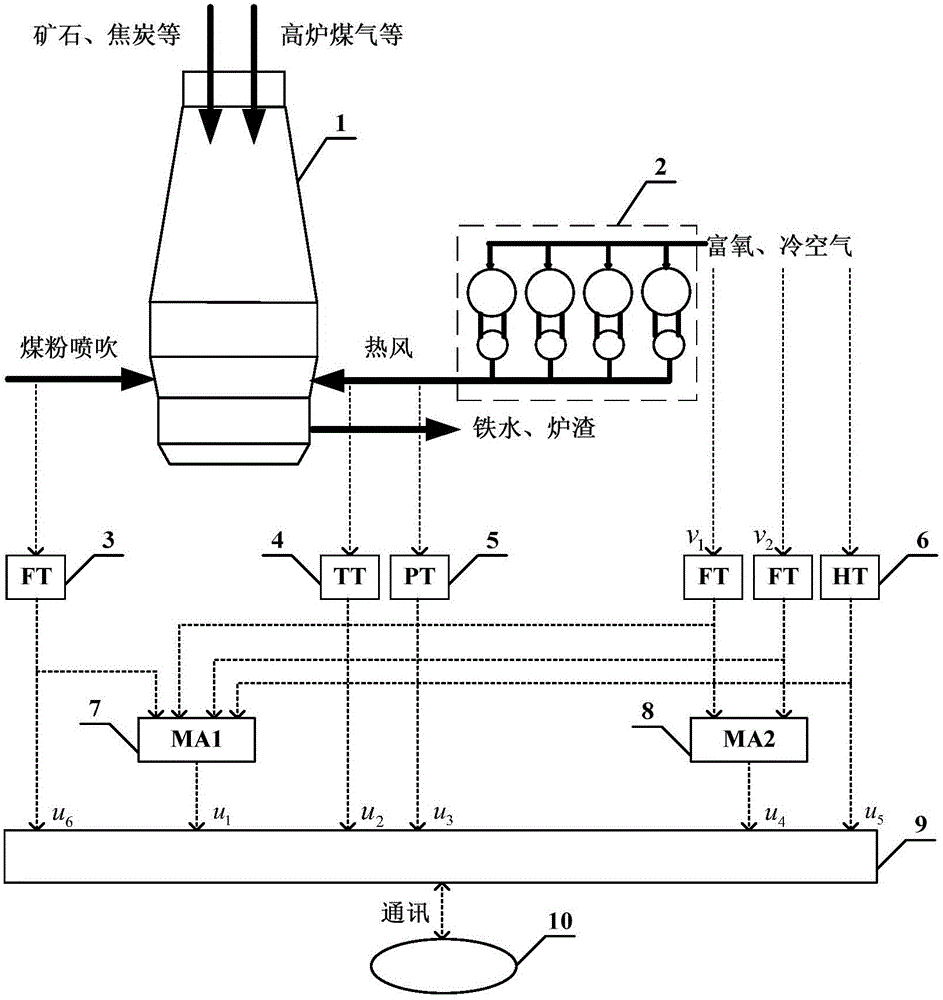

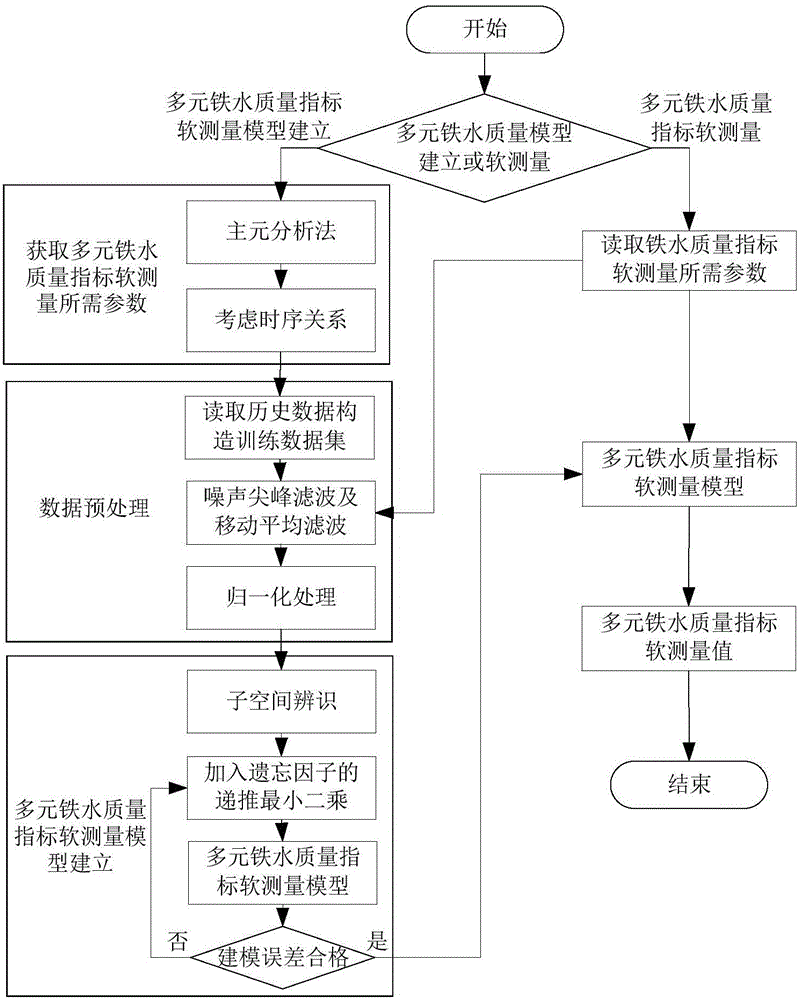

Soft measuring system and method for quality indexes of multielement molten iron of blast furnace

InactiveCN105821170ARealization of dynamic soft sensorSimple structureSteel manufacturing process aspectsForecastingHysteresisNoise removal

Provided are a soft measuring system and method for the quality indexes of multielement molten iron of a blast furnace. The system comprises a data collecting unit, a data preprocessing unit and a soft measuring unit. The method comprises the steps that parameters needed for soft measurement of the quality indexes of multielement molten iron of the blast furnace are acquired; the parameters needed for dynamic soft measurement of the quality indexes of multielement molten iron of the blast furnace are subjected to filtering, noise removal and normalization processing; dynamic soft measurement of multielement molten iron of the blast furnace is carried out through a blast furnace multielement molten iron quality index dynamic soft measurement model; and the parameters needed for soft measurement of the quality indexes of multielement molten iron of the blast furnace obtained after filtering and normalization processing are adopted as input, the current quality indexes of multielement molten iron of the blast furnace are adopted as output, output self-feedback is adopted, and the quality indexes of multielement molten iron of the blast furnace are dynamically predicted through online recurrence. The sequential relationship between the hysteresis characteristic of the blast furnace melting process and input and output variables is considered, the recurrence subspace intelligent modeling technology is adopted, and dynamic online soft measurement of the quality indexes of multielement molten iron of the blast furnace in the smelting process is achieved.

Owner:NORTHEASTERN UNIV

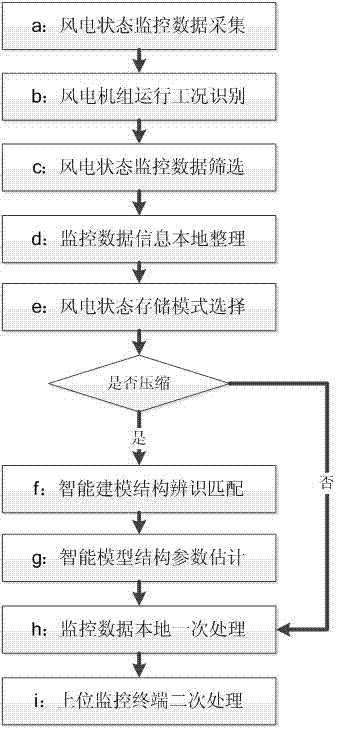

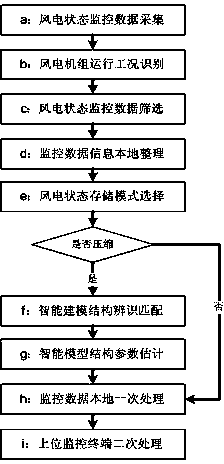

Wind turbine generator system state monitoring system data compressing method

The invention provides a data modeling based wind turbine generator system state monitoring system data compressing method. Monitoring data are subjected to mathematical modeling in a local wind turbine generator system so as to extract strong features and compress and restore data in a high compression ratio mode. The method includes the following steps of wind power state monitoring data collection, wind turbine generator system operation condition identification, wind power state monitoring data screen, monitoring data information local settlement, wind power state storage mode selection, intelligent modeling structure identification matching, intelligent modeling structure parameter estimation, monitoring data local primary processing, and upper monitoring terminal secondary processing. By means of the wind turbine generator system state monitoring system data compressing method, problems existing in on-line transmission and long-term continuous monitoring and storage of mass data are solved.

Owner:北京能高普康测控技术有限公司

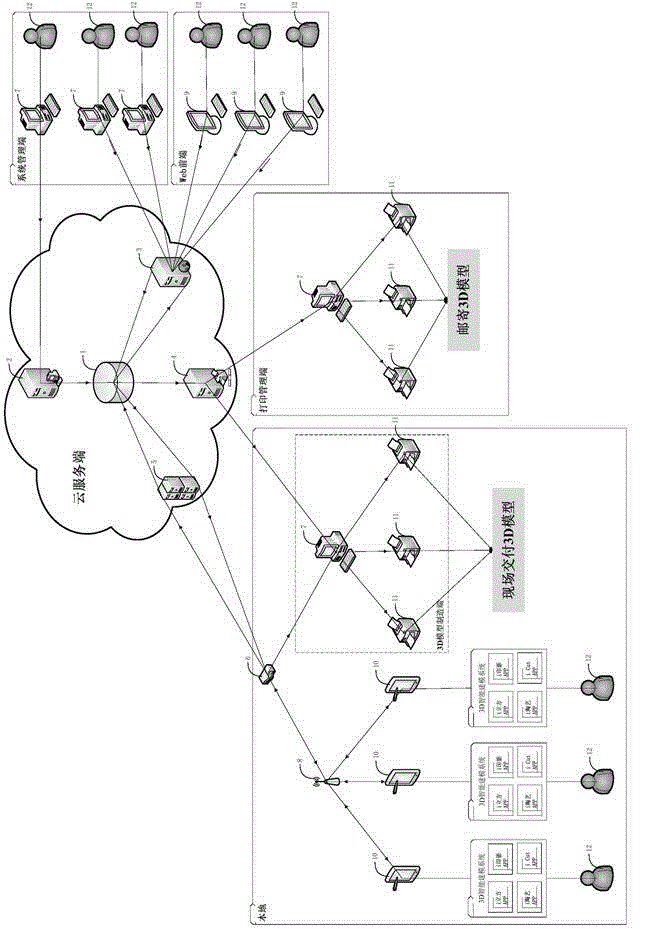

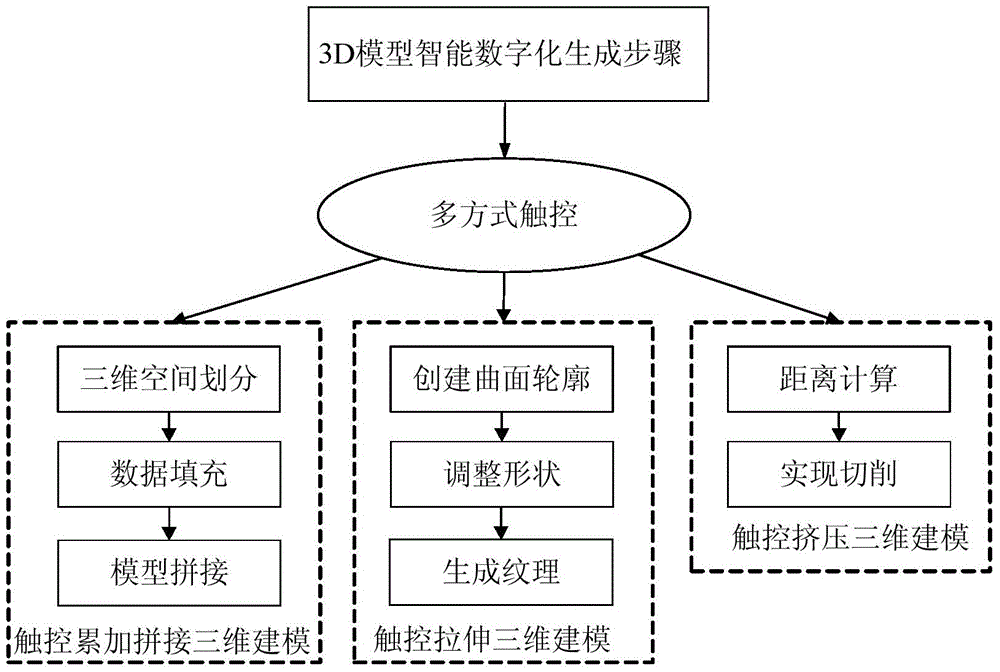

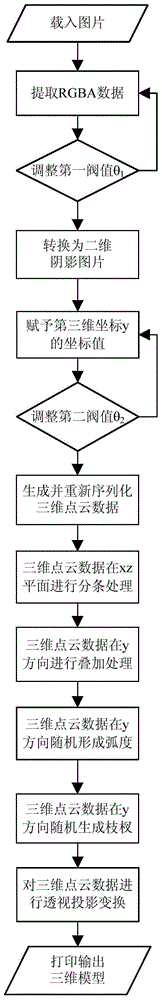

3D intelligent modeling method and system and a flexible manufacturing system of 3D model

ActiveCN104103091AReduce demandGuaranteed a high degree of freedom3D-image rendering3D modellingFlexible manufacturing systemIntelligent modeling

The invention relates to a 3D intelligent modeling method and system and a flexible manufacturing system of a 3D model. A single photograph or picture is converted into a 2D shadow picture; after a 3D model is constructed, the information of the 2D shadow picture is hidden in the 3D model, a shadow presented by the 3D model with the hidden information of the 2D shadow picture through illumination angle projection is in an original picture or photograph shape, and 3D intelligent modeling can be realized by methods, such as accumulation, splicing, stretching, extrusion and the like. The flexible manufacturing system of the 3D model enables a user to integrally experience the processes of 3D modeling and 3D printing, 3D modeling compatible data is created, stored, transmitted and managed for a user, and the user is guaranteed to carry out 3D printing at any time and place so as to realize the flexible manufacture of the 3D model.

Owner:北京毛豆科技有限公司

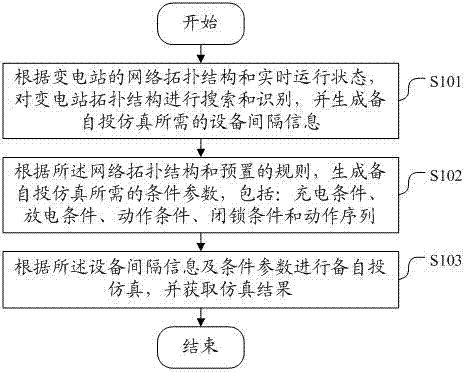

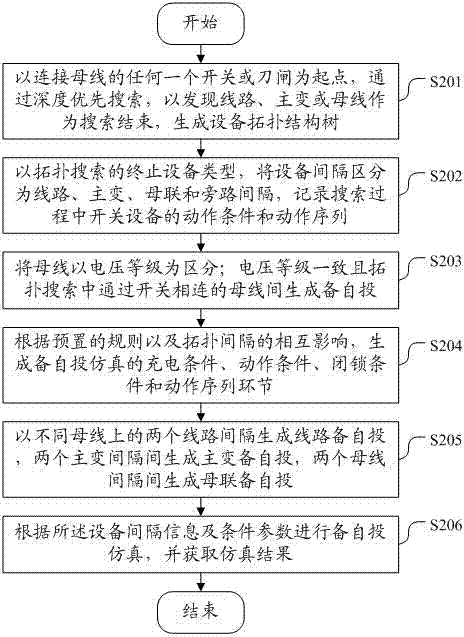

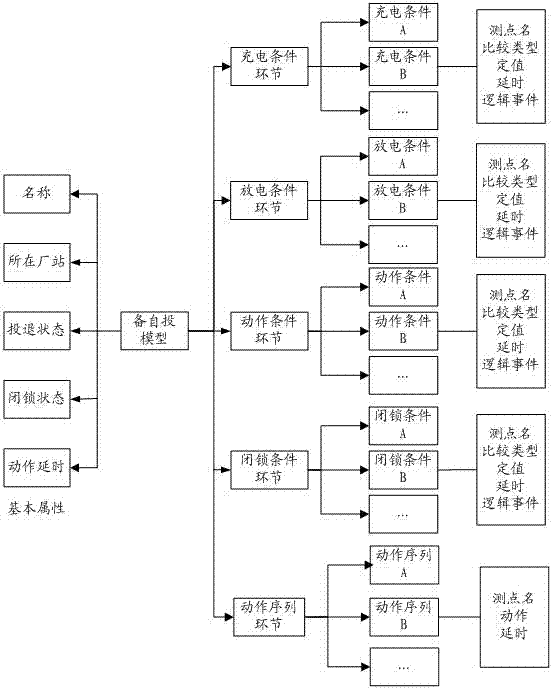

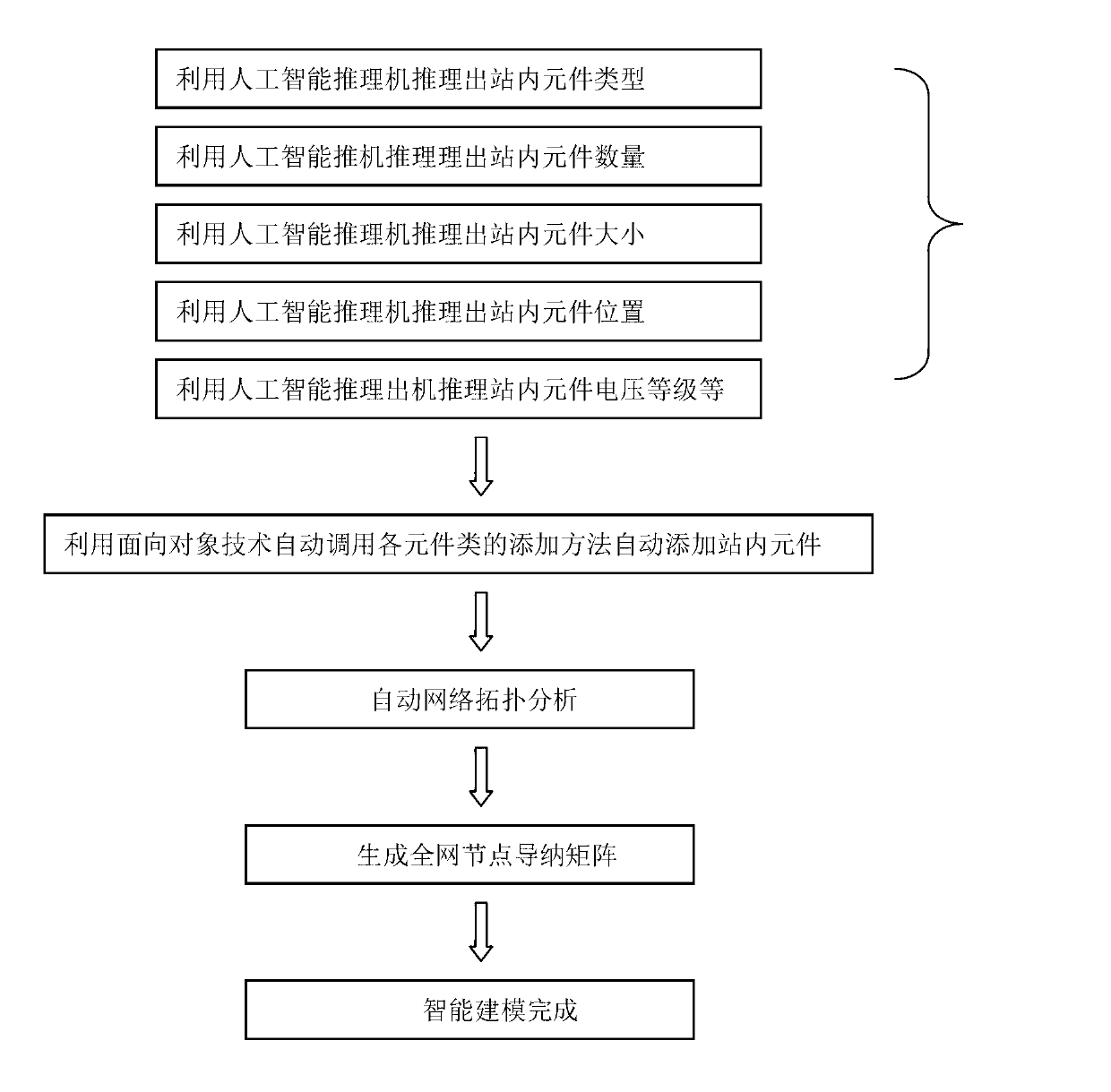

Spare power automatic switching simulation method of power grid

ActiveCN102904333ARealize intelligent modelingRealize automatic generationPower network operation systems integrationInformation technology support systemIntelligent modelingPower grid

The invention provides a spare power automatic switching simulation method of a power grid. The method comprises the following steps of: searching and identifying a substation topology structure according to a network topology structure and a real-time operation state of a substation, and generating equipment interval information required by a spare power automatic switching simulation; generating condition parameters required by the spare power automatic switching simulation according to the network topology structure and preset rules, wherein the parameters comprises a charge condition, a discharge condition, an action condition, a locking condition and an action sequence; and carrying out the spare power automatic switching simulation according to the equipment interval information and the condition parameters, so as to obtain the simulation result. With the adoption of the spare power automatic switching simulation method, the intelligent modeling and the automatic generation of a spare power automatic switching model are realized according to a real-time state of a power grid and different topology structures of grid frames in the substation, the maintenance working quantity of a simulation system is reduced, the construction and the use of a power grid simulation training system are facilitated, and the practical application level is further improved.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

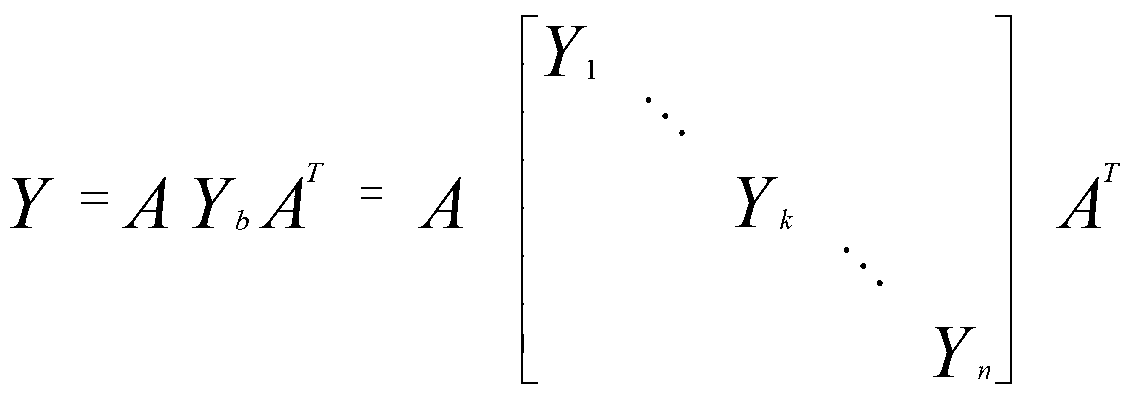

Modeling method for relay protection setting calculation system

InactiveCN103279824AReduce time spentImprove modeling efficiencyResourcesElectric power systemSystem maintenance

The invention relates to the field of relay protection systems, in particular to a modeling method for a relay protection setting calculation system. The modeling method comprises the steps of formation of an original model by using artificial intelligence, conventional graphic modeling, automatic network topology analysis and the like. The modeling method has the effects that the modeling efficiency is greatly improved and the time occupied for system maintenance is greatly reduced; the system safety is greatly improved, the accuracy of the established model is fully guaranteed and a feasible and powerful technical supporting means is provided for effectively avoiding incorrect setting; and according to the actual needs, the effect of unifying power systems of a whole province and even the whole nation into one grid can be very easily realized through modeling, the intelligent modeling advantage is more remarkable when the grid is larger, and the large grid can be easily managed.

Owner:STATE GRID CORP OF CHINA +1

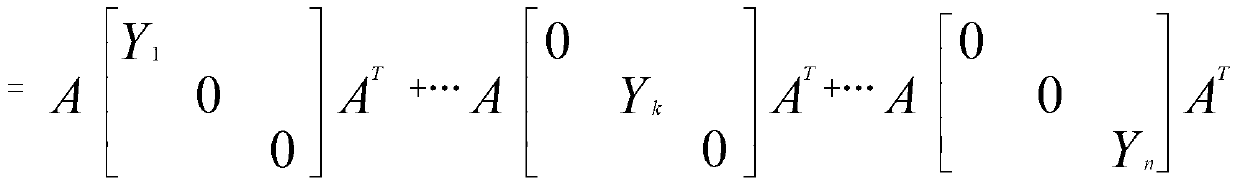

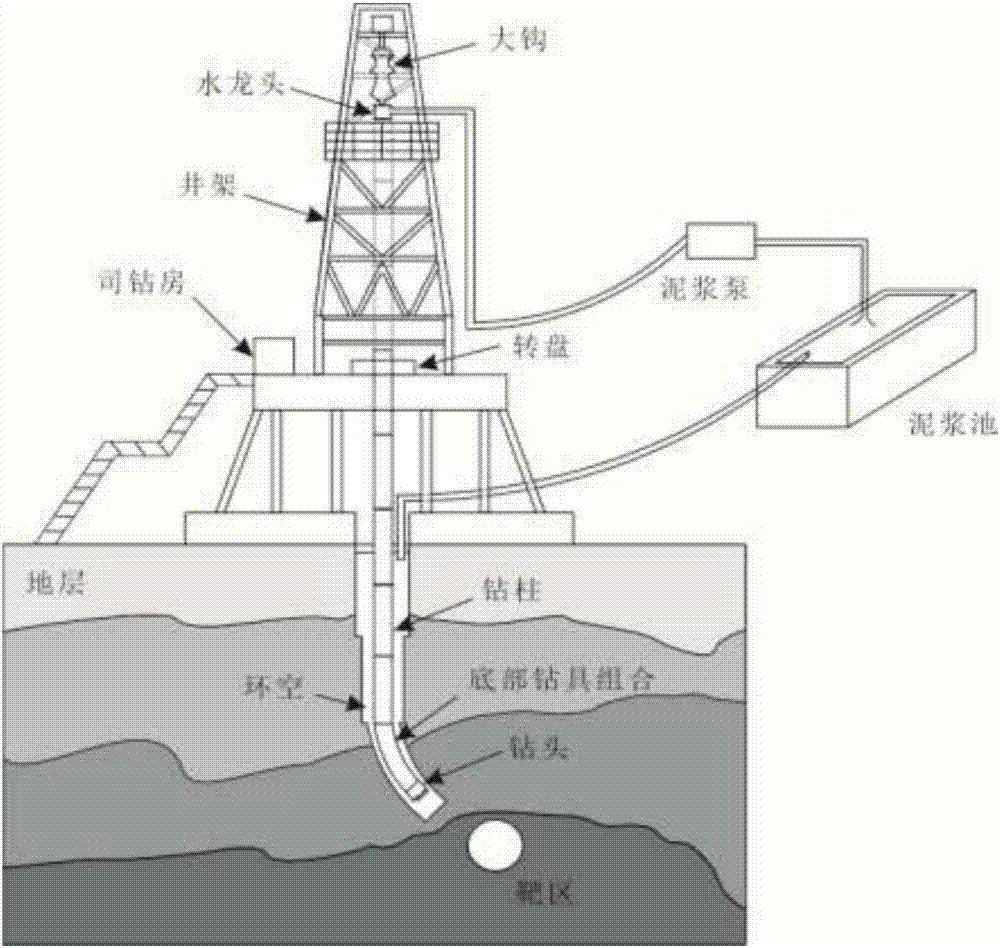

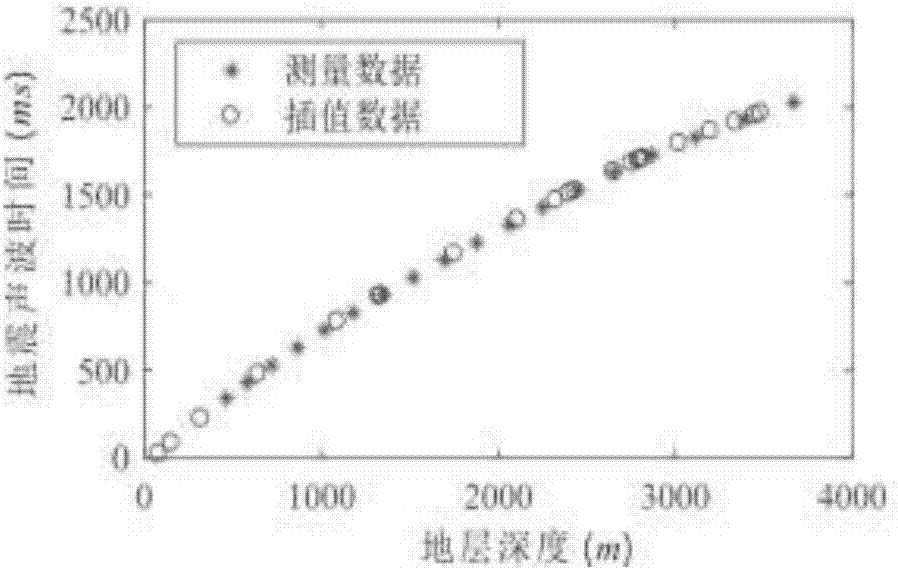

Double-layer intelligent drilling speed modeling method for geological exploration drilling process

ActiveCN107100611AModeling works wellGood forecastAutomatic control for drillingData setIntelligent modeling

The invention discloses a double-layer intelligent drilling speed modeling method for the geological exploration drilling process. Modeling work is divided into four steps, specifically, partially-lacked earthquake acoustic wave and time data are made up through the sectional three-time Hermite interpolation method firstly so as to obtain a sample datum set; then a stratum drillability sub model is established through the Nadaboost-ELM algorithm; then the parameters which are high in correlation with the drilling speed are determined through the Pearson correlation analysis method; and finally a drilling speed sub model is established through the modified PSO-RBF algorithm. According to the method, the defects that in a previous drilling speed modeling method, the key parameter, namely the stratum drillability, and the drilling speed are not subjected to hierarchy division and do not form a unified framework, and a confirmatory or single intelligent modeling method is used are overcome, accuracy of drilling speed modeling and the generalization ability are improved, and the good foundation is laid for intelligent control of the geological exploration drilling process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

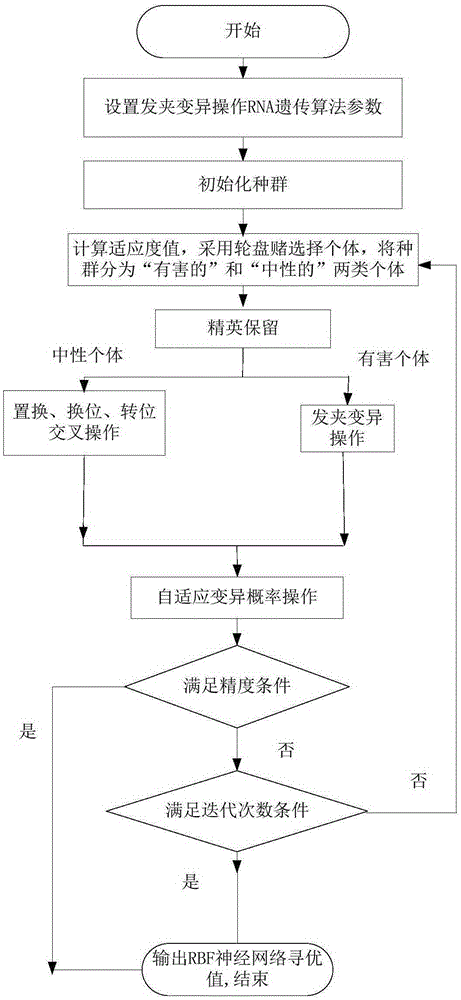

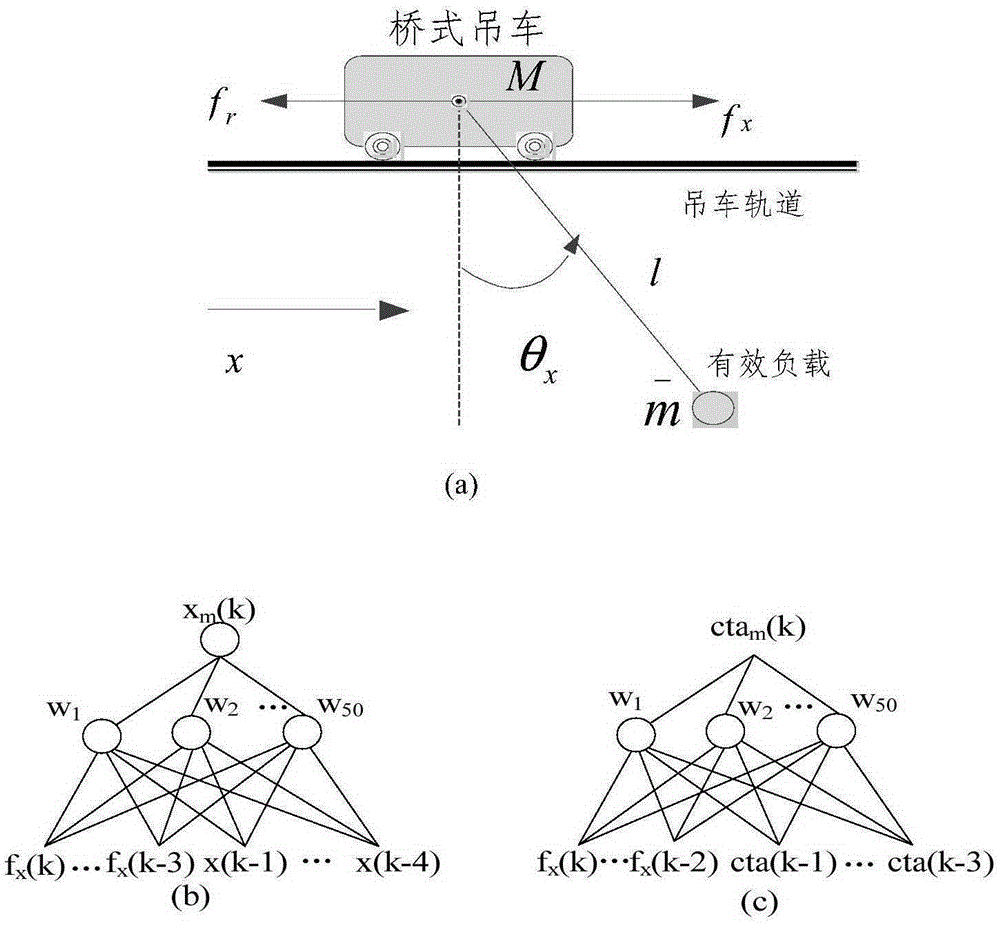

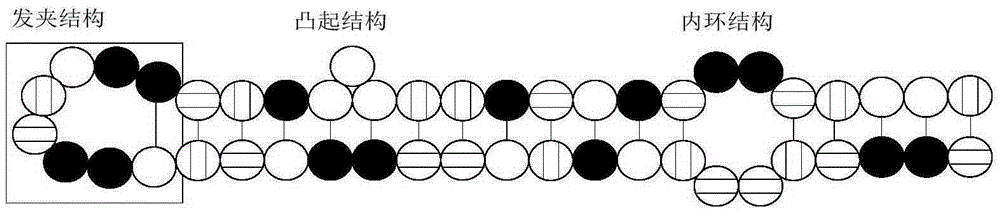

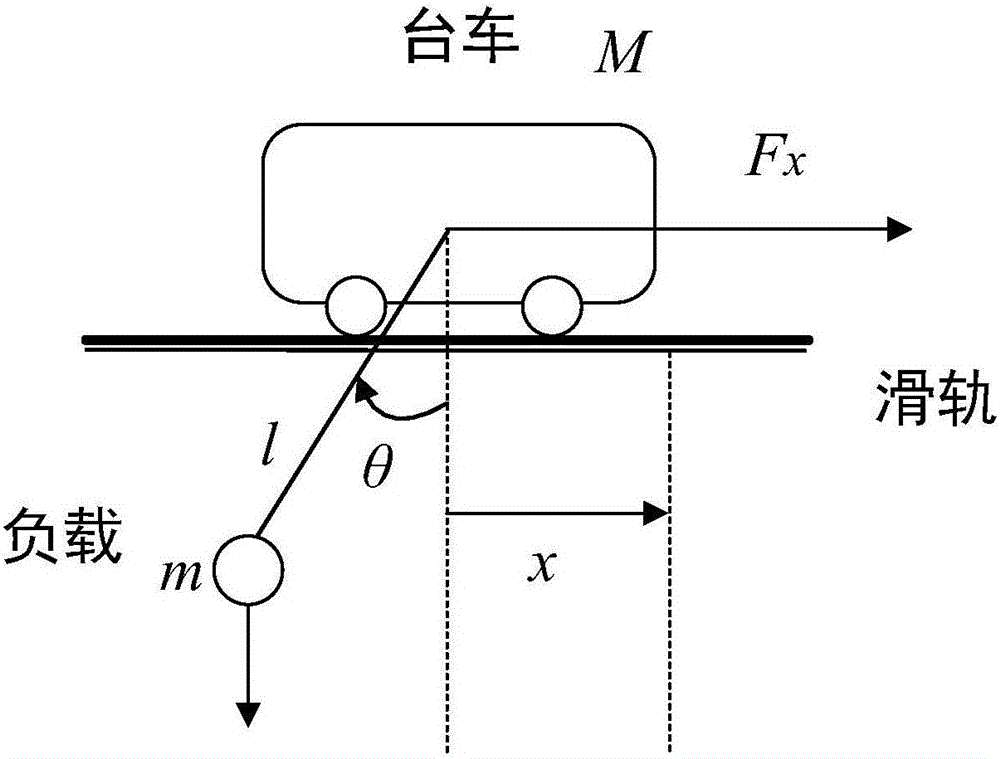

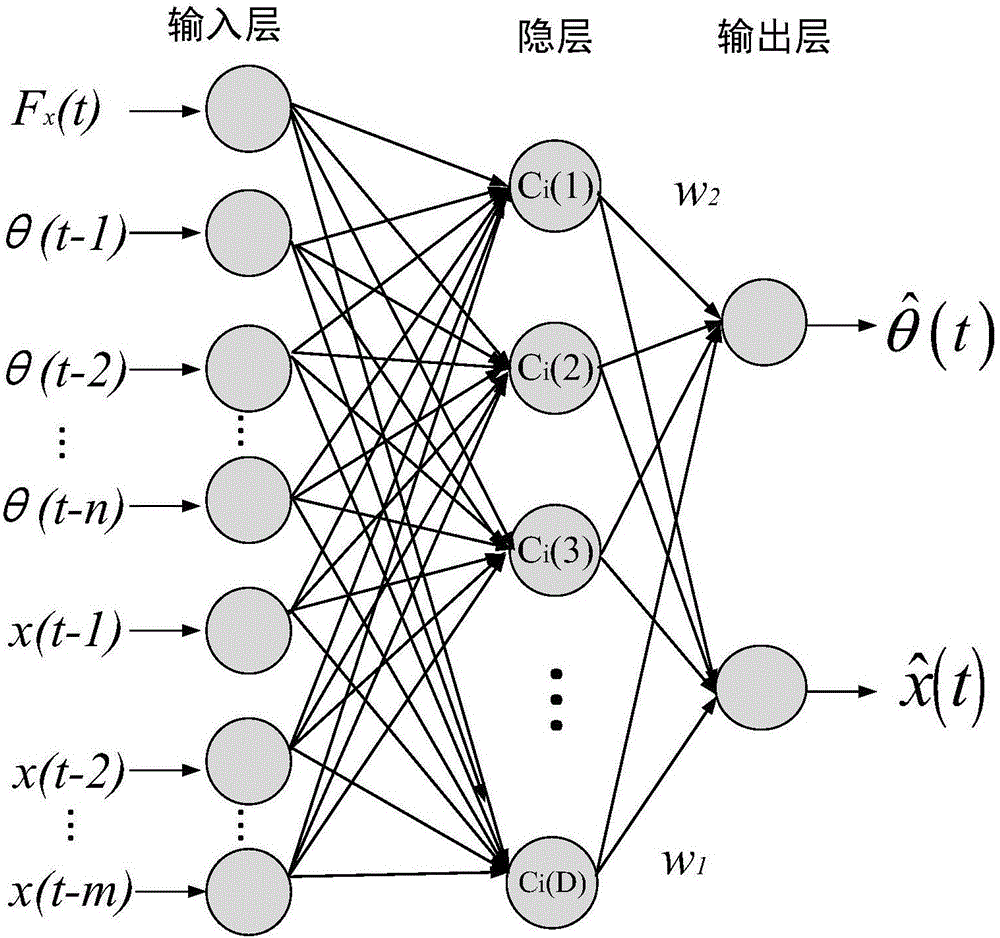

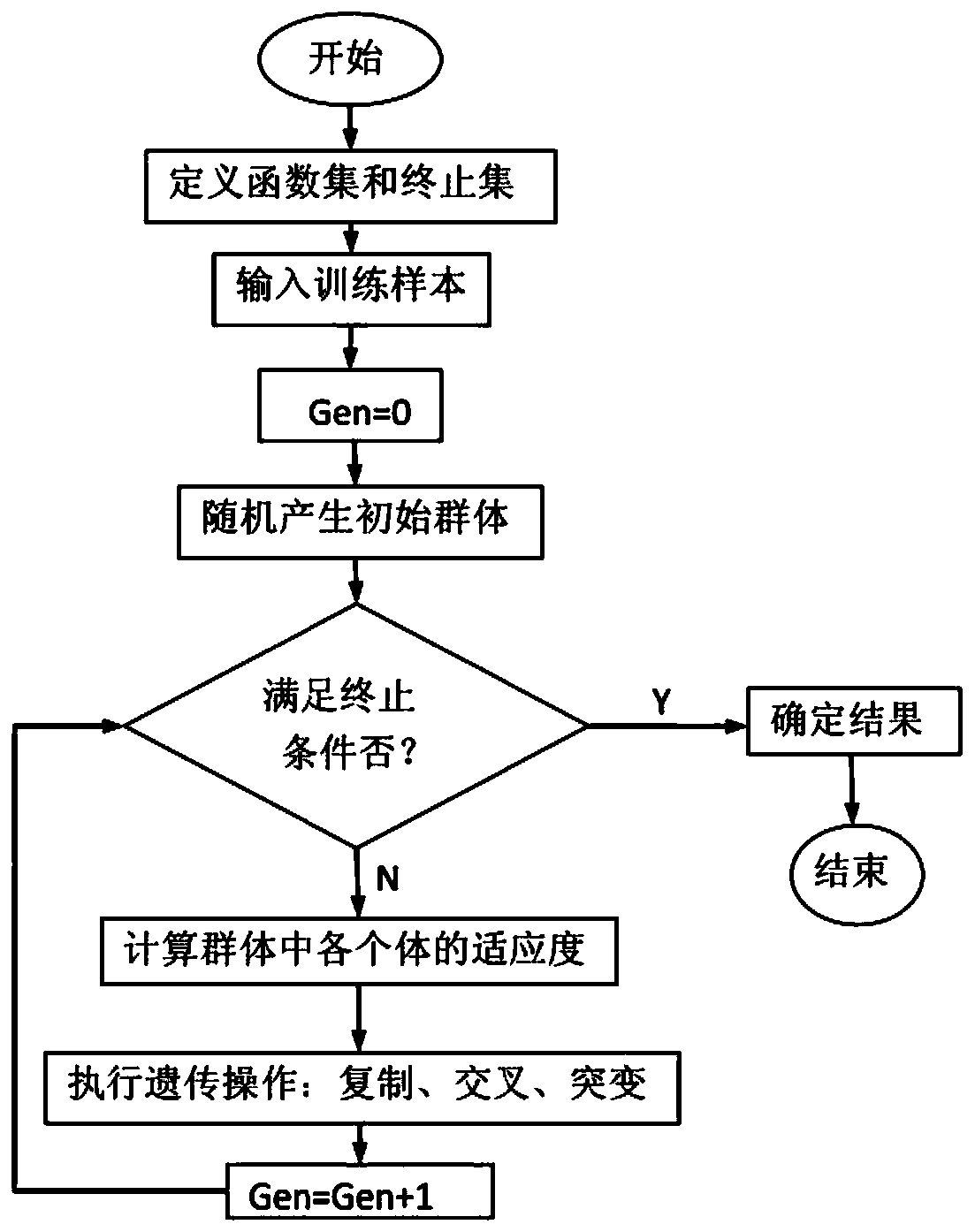

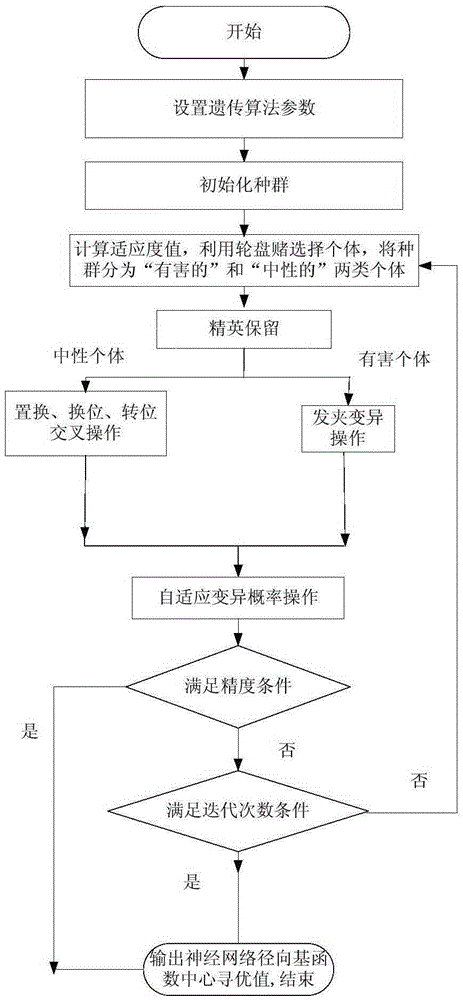

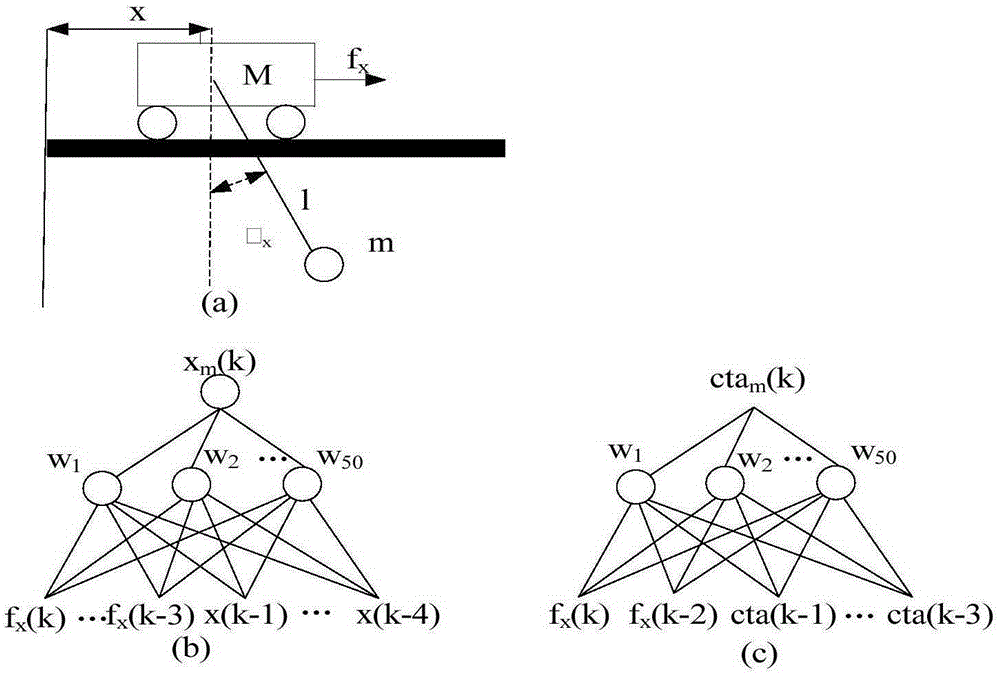

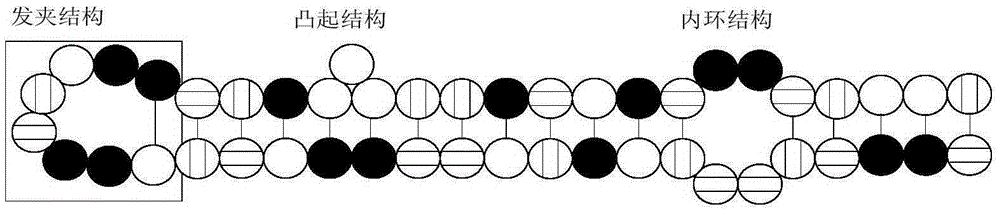

Overhead crane neural network modeling method based on RNA genetic algorithm of hairpin mutation operation

InactiveCN105302966AIncrease diversityOvercome deficienciesBiological neural network modelsSpecial data processing applicationsNerve networkAlgorithm

The invention discloses an overhead crane neural network modeling method based on an RNA genetic algorithm of a hairpin mutation operation, and belongs to the field of intelligent modeling. An overhead crane is a highly non-linear under-actuated complicated system, and the establishment of a high-precision overhead crane system model is a crucial foundation for achieving the purpose of effective control. The invention, for the problem in overhead crane modeling precision, provides overhead crane nonlinear regression models based on a position and an angle of an RBF (Radial Basis Function) neural network. Under the inspiration of a hairpin structure, the RNA genetic algorithm of the hairpin mutation operation is abstracted, and the RBF center of the RBF neural network for the position and the swing angle of the overhead crane is optimized by running the RNA genetic algorithm of the hairpin mutation operation, so that a neural network model of the overhead crane is obtained. The modeling method has the characteristic of high modeling precision, and is also suitable for modeling other complicated nonlinear systems.

Owner:ZHEJIANG UNIV

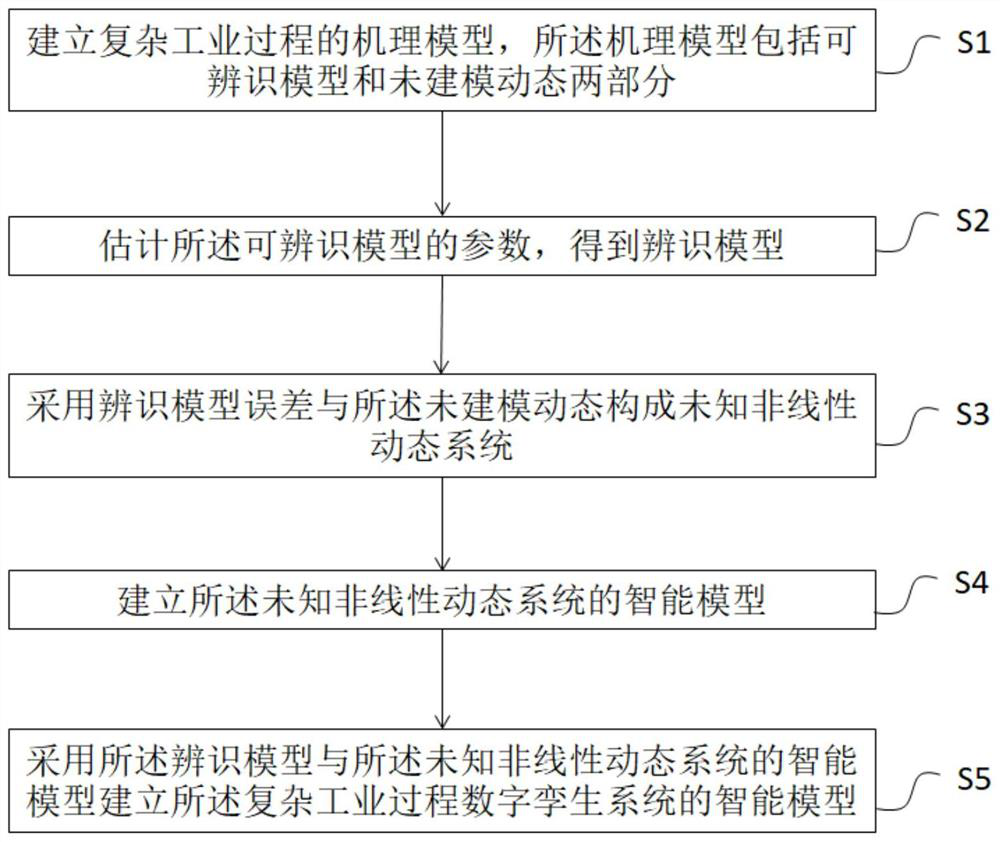

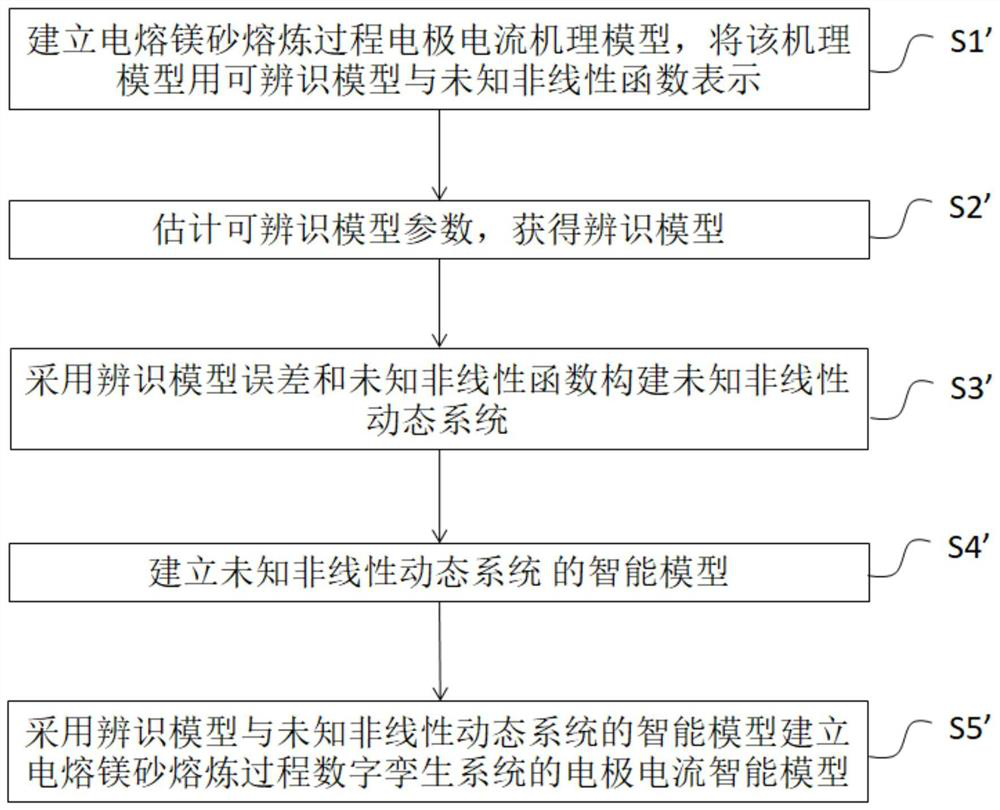

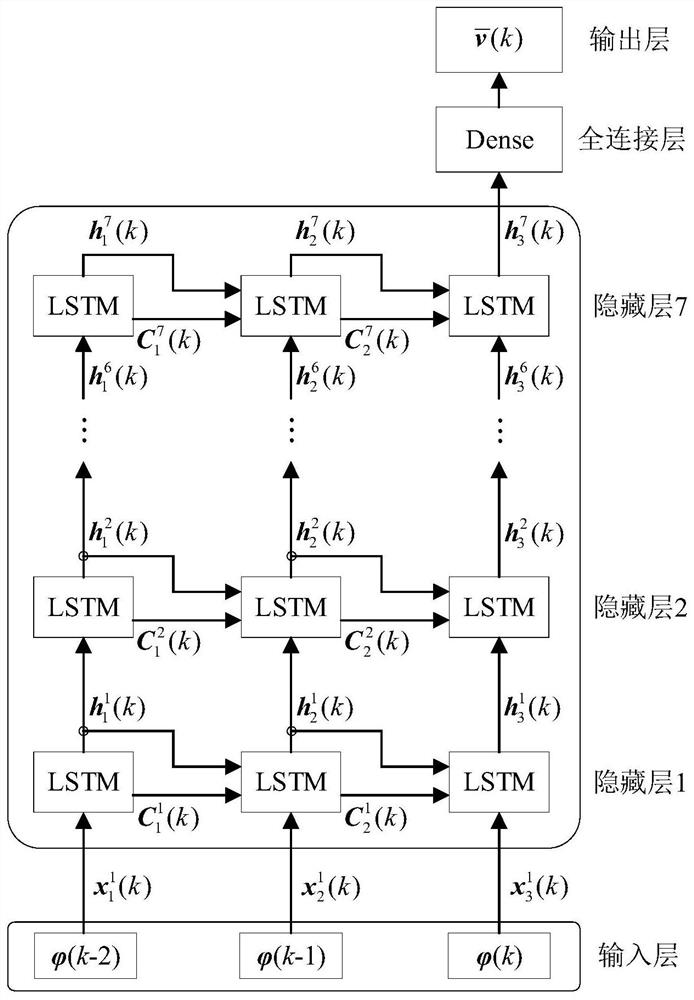

Intelligent modeling method and device for digital twin system in complex industrial process, equipment and storage medium

PendingCN112560337ASolving Modeling ChallengesImprove modeling accuracyDesign optimisation/simulationNeural architecturesDynamic modelsIntelligent modeling

The invention provides an intelligent modeling method and device for a digital twinning system in a complex industrial process, equipment and a storage medium. The intelligent modeling method for thedigital twin system in the complex industrial process comprises the following steps: establishing a mechanism model of the complex industrial process, wherein the mechanism model comprises an identifiable model and an unmodeled dynamic model; estimating parameters of the identifiable model to obtain an identification model; adopting an identification model error and the unmodeled dynamics to forman unknown nonlinear dynamic system; establishing an intelligent model of the unknown nonlinear dynamic system; establishing an intelligent model of the complex industrial process digital twin systemby adopting the identification model and the intelligent model of the unknown nonlinear dynamic system, wherein the identification model error is a model output error caused when parameters in the identifiable model are replaced by identification values of the parameters. Aiming at the problem that the precision of a digital twinning system in a complex industrial process is difficult to guarantee, a system identification method based on a mechanism model is combined with a deep learning method based on big data, and an intelligent model of the digital twinning system in the complex industrialprocess is established by adopting an end-to-side cloud cooperation mode. The modeling problem of a digital twin system in a complex industrial process is solved, and the modeling precision is improved.

Owner:NORTHEASTERN UNIV

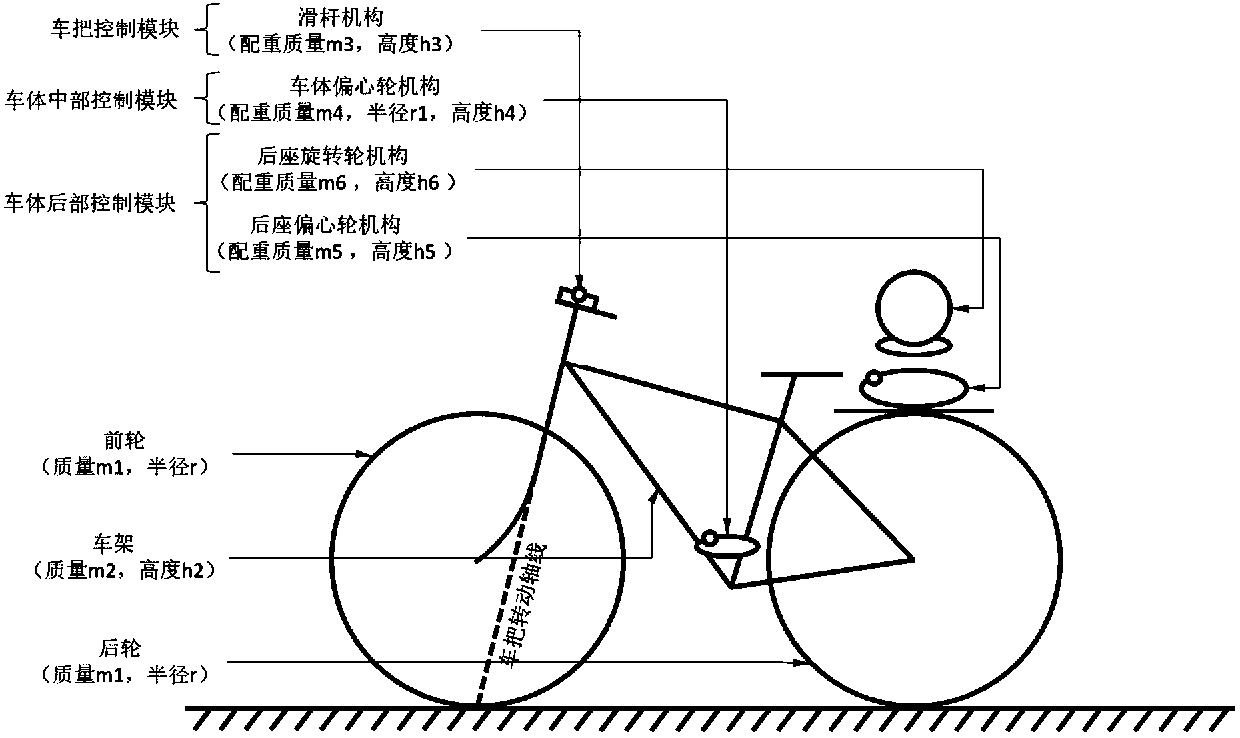

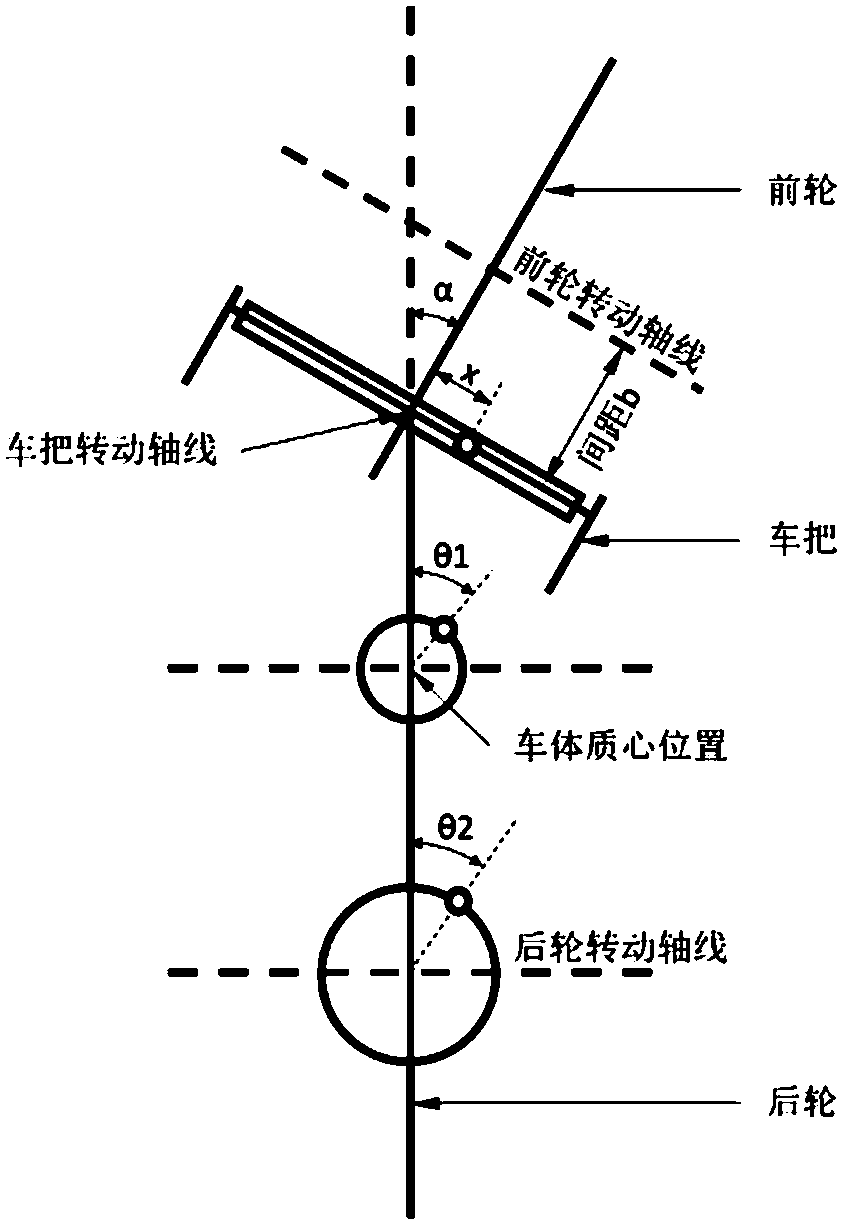

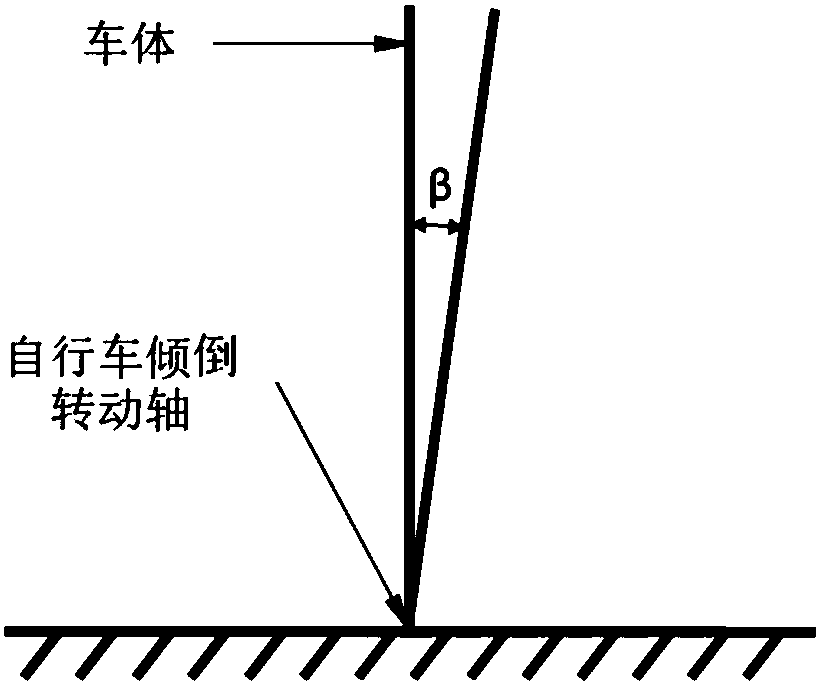

Self-balancing unmanned bicycle and control method thereof

ActiveCN108327841AWith self-balancing functionRealize unmanned drivingGeometric CADSpecial data processing applicationsIntelligent modelingComputer module

The invention discloses a self-balancing unmanned bicycle and a control method thereof. The self-balancing unmanned bicycle comprises a bicycle, a sensor module, a handlebar control module, a vehiclebody middle control module and a vehicle body rear control module. The control method comprises self-balancing control and unmanned control. Realization of self-balancing comprises simulation modeling, automatic modeling and intelligent modeling; the step of unmanned control comprises the content of selecting a desired bicycle variable according to the target motion state, and unmanned driving ofthe bicycle is achieved. According to the unmanned bicycle, a self-balancing function can be achieved in various motion states with a coupled control method, an indirect driving method is adopted, further refitting of the ordinary bicycle is not needed, and self-balancing and unmanned driving of the bicycle can be achieved by only mounting three controller modules on the ordinary bicycle.

Owner:ZHEJIANG UNIV

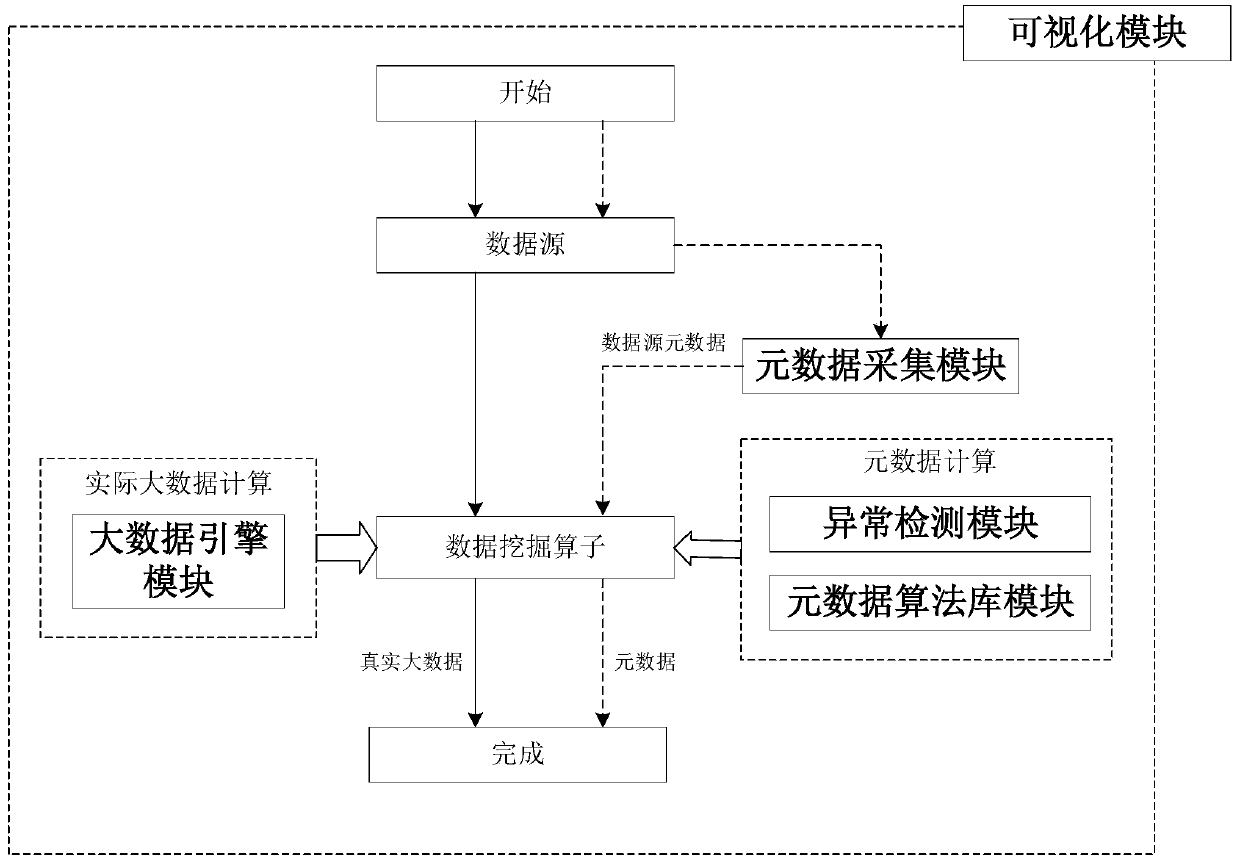

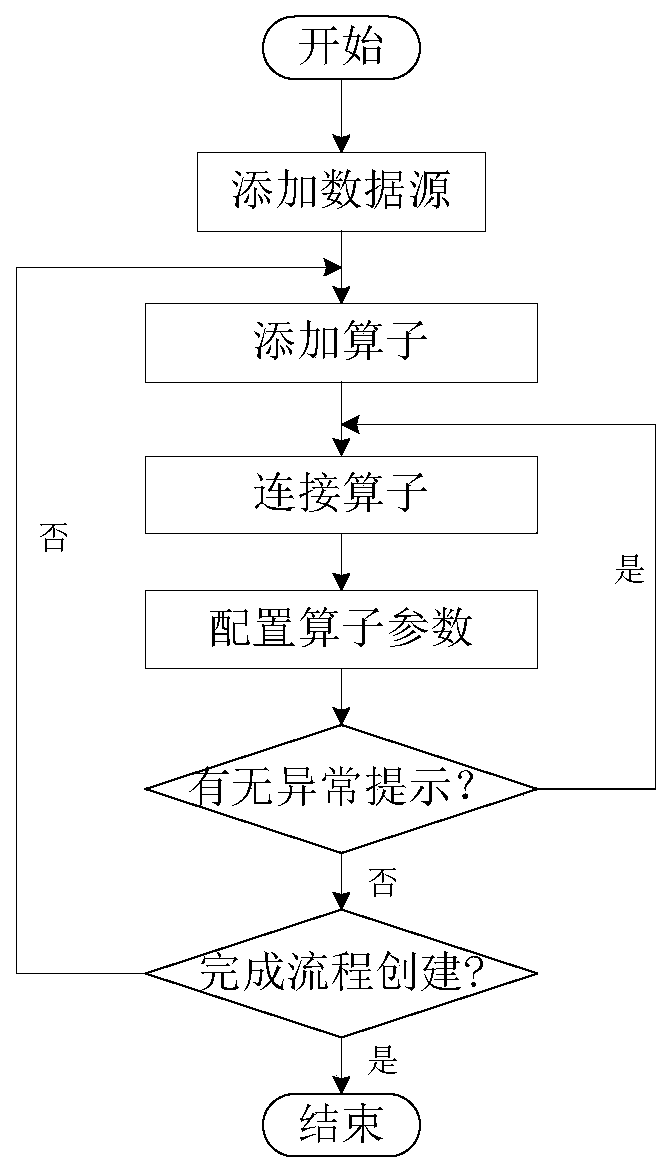

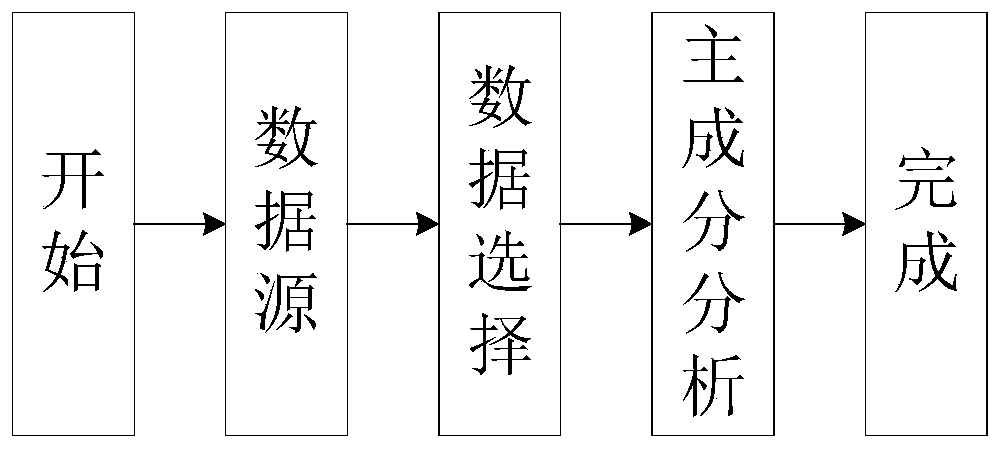

Big data intelligent modeling system and method based on dynamic metadata

ActiveCN111125052AImprove real-time performanceImprove reliabilitySpecial data processing applicationsDatabase design/maintainanceModelSimIntelligent modeling

The invention discloses a big data intelligent modeling system and a method based on dynamic metadata. The system comprises a metadata acquisition module, a metadata algorithm library module, an abnormity detection module, a visualization module and a big data engine module. The method has the beneficial effects that (1) an intelligent modeling strategy based on metadata is provided, the whole data mining conversion process is simulated on the premise that actual data does not need to be loaded and even a big data mining engine does not need to be started, an output result of a current computing node is estimated in real time, modeling operation of an operator is assisted, and the technical threshold of big data modeling is reduced; and (2) an abnormity detection mechanism is further developed based on metadata, real data is replaced by the metadata, and matching detection is performed on data transmission forms and contents between upper and lower nodes, so that the method has the advantages of good real-time performance and high reliability compared with inspection of a big data set, thereby realizing real-time early warning of wrong process connection and improving the modelingefficiency.

Owner:BEIJING HUARU TECH

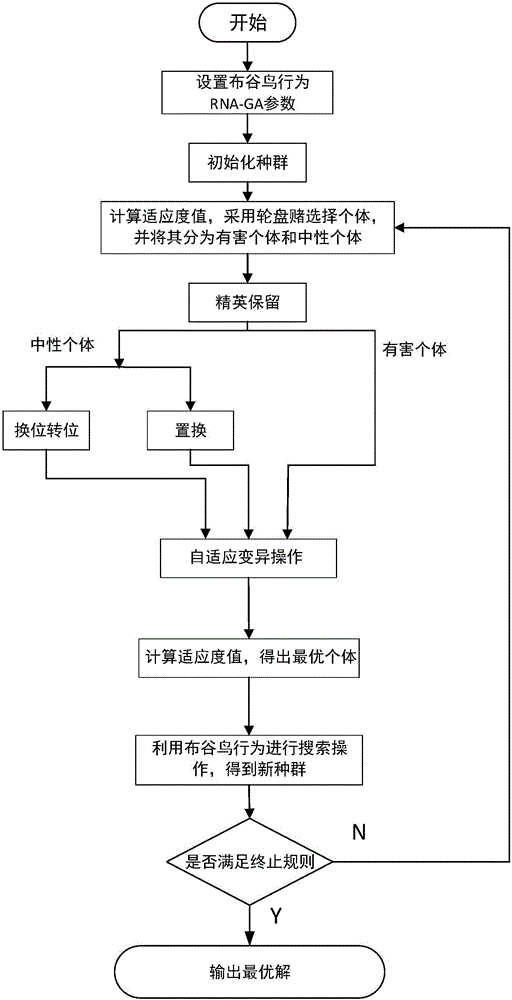

Cuckoo-behavior-RNA-GA-based bridge crane neural network modeling method

The invention, which belongs to the intelligent modeling field, discloses a cuckoo-behavior-RNA-GA-based bridge crane neural network modeling method. The bridge crane is a complicated under-actuated non-linear system; and effective control realization is based on establishment of a high-precision bridge crane model. With the Cuckoo-behavior RNA genetic algorithm, optimizing is carried out on a radial basis function center of a bridge crane neural network model, thereby obtaining a corresponding RBF neural network model. According to the method, an ideal effect is realized during testing. And the method is suitable for modeling of other complicated non-linear systems.

Owner:ZHEJIANG UNIV

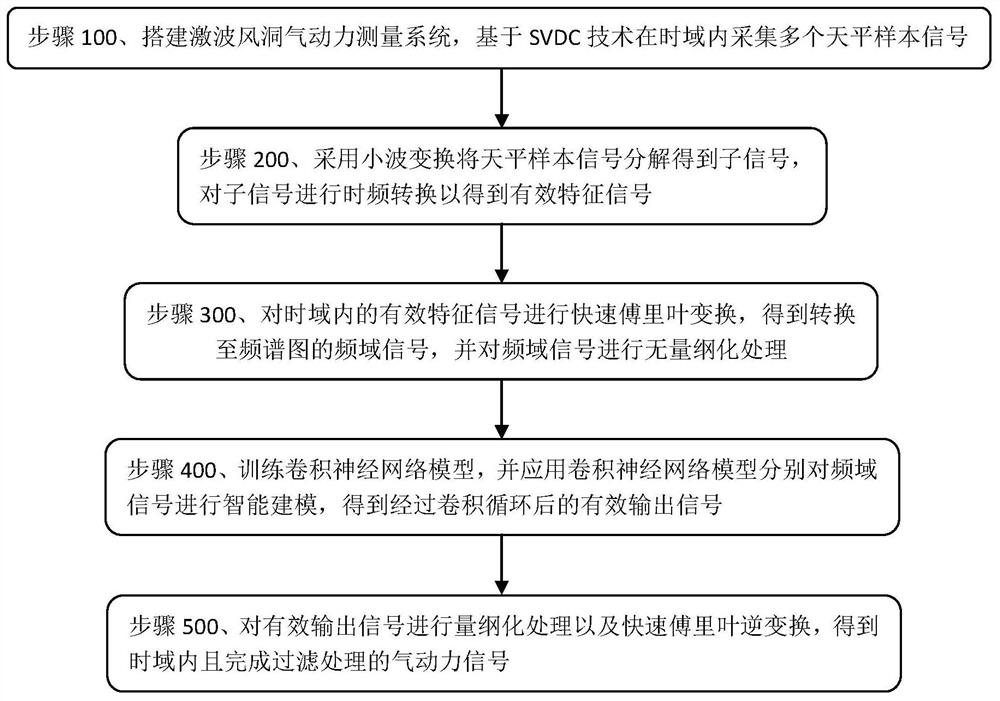

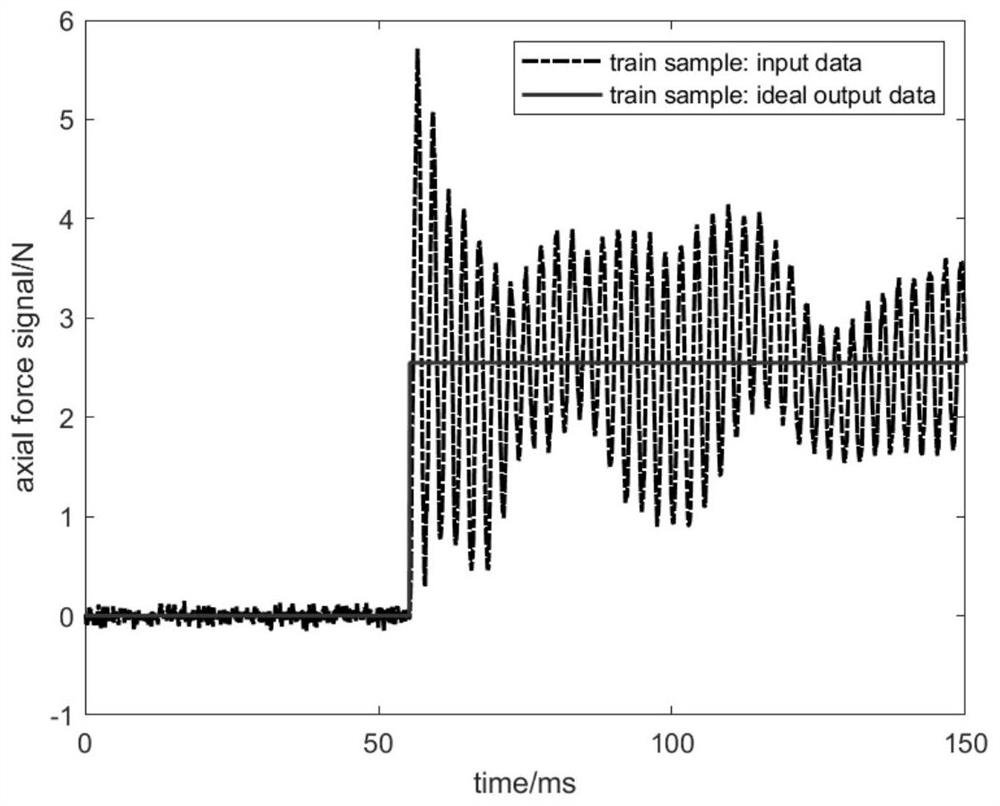

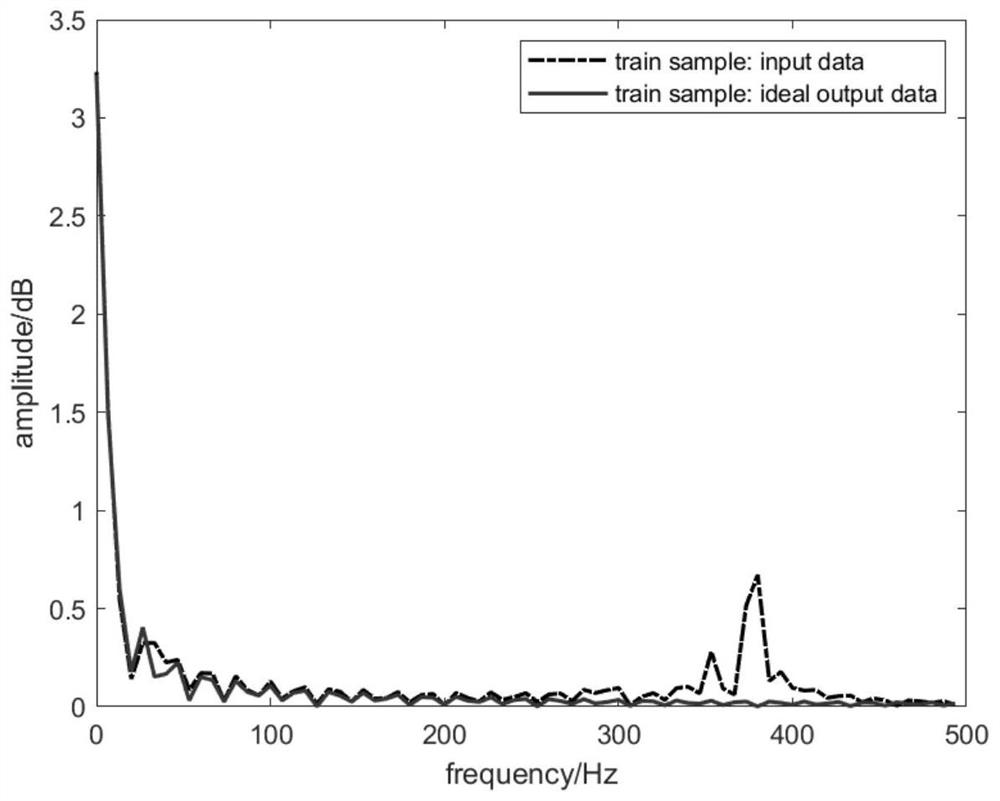

Shock tunnel force measurement signal frequency domain analysis method based on deep learning

ActiveCN113970420AAccurate identificationImprove reliabilityAerodynamic testingFrequency spectrumIntelligent modeling

The invention discloses a shock tunnel force measurement signal frequency domain analysis method based on deep learning. The method comprises the steps of: building a shock tunnel aerodynamic force measurement system, and collecting a plurality of balance sample signals in a time domain based on an SVDC technology; decomposing the balance sample signal by adopting wavelet transform to obtain sub-signals, and performing time-frequency conversion on the sub-signals to obtain effective characteristic signals; performing fast Fourier transform on the effective feature signals in the time domain to obtain frequency domain signals converted to a spectrogram, and performing dimensionless processing on the frequency domain signals; training a convolutional neural network model, and performing intelligent modeling on the frequency domain signals by using the convolutional neural network model to obtain effective output signals after convolution circulation; and performing dimensionalization processing and inverse fast Fourier transform on the effective output signals to obtain filtered aerodynamic force signals in a time domain. Inertial vibration signals are filtered, real aerodynamic force signals are obtained, and reliability and precision indexes of pulse wind tunnel force measurement results are improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Method for compressing data of status monitoring system of wind turbine generator system

The invention provides a method for compressing data of a status monitoring system of a wind turbine generator system. Strong features are extracted in the mode that mathematical modeling is conducted on the monitoring data locally in the wind turbine generator system, and data compression and recovery are conducted according to a high compression ratio. The method comprises the following steps of collection of the wind electricity status monitoring data, identification of operating conditions of the wind turbine generator system, filtration of the wind electricity status monitoring data, local collating of monitoring data information, wind electricity status storage mode selection, identification and matching of intelligent modeling structures, estimation of parameters of the intelligent modeling structures, local primary processing of the monitoring data and upper monitoring terminal secondary processing. By means of the method, mass data on-line transmission and long-term continuous monitoring storage are achieved.

Owner:姜炳芳

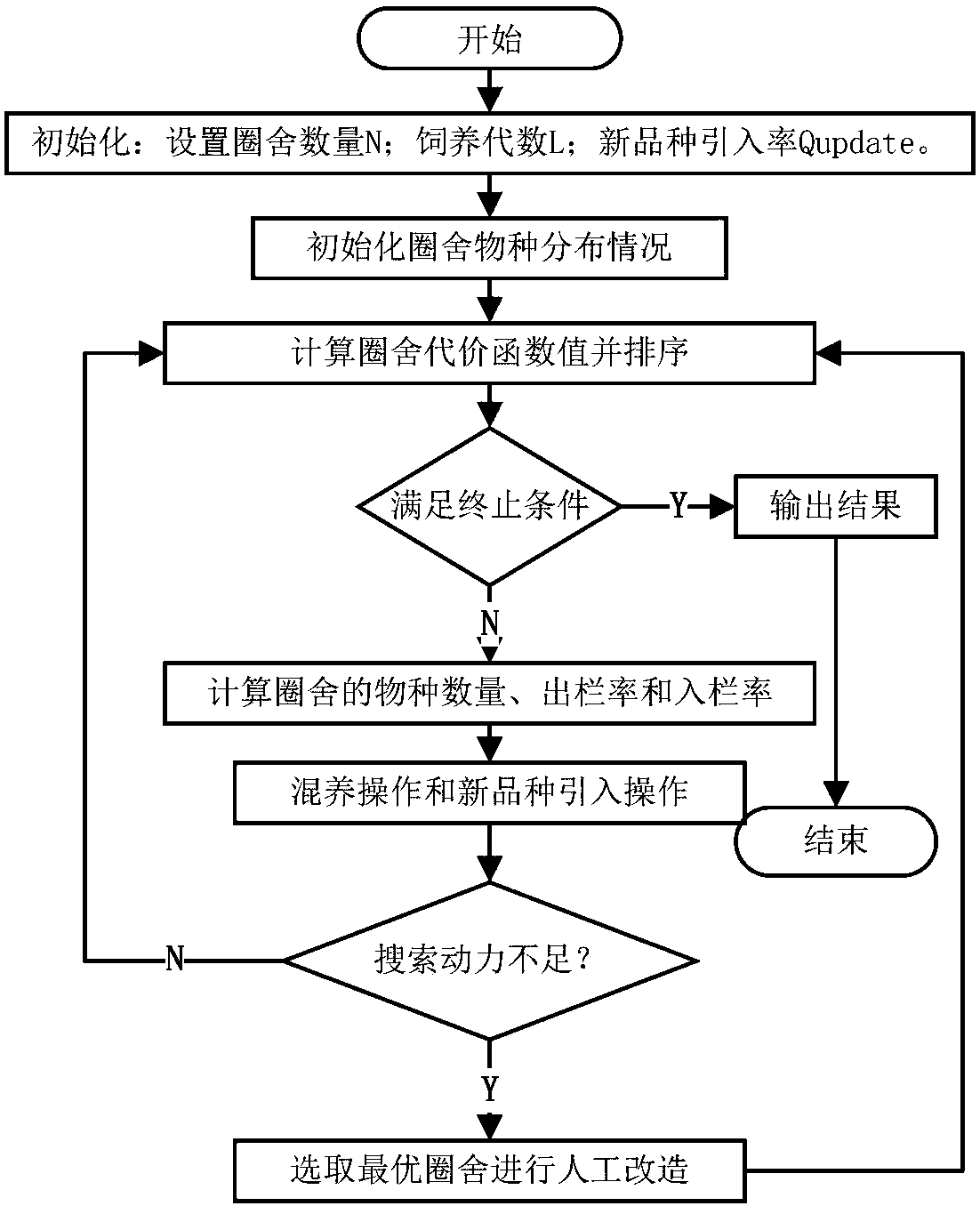

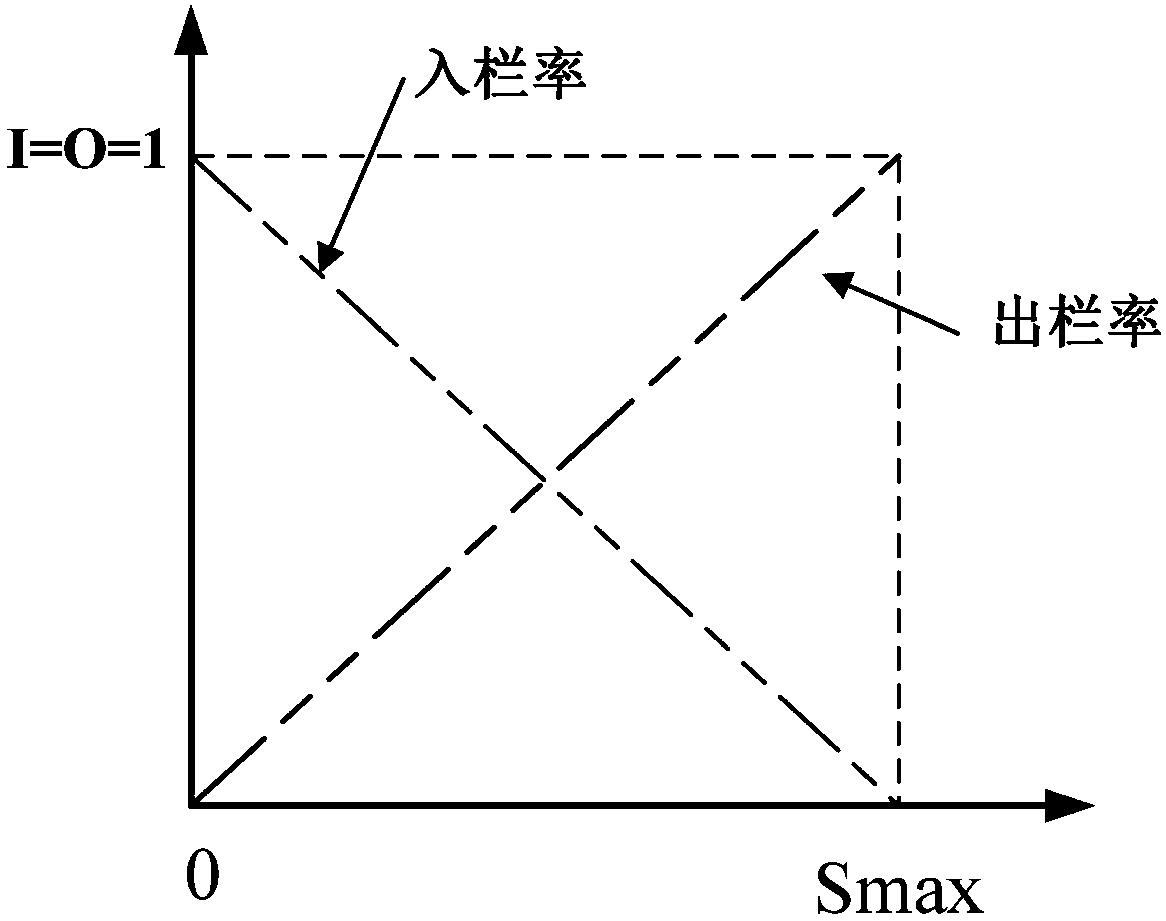

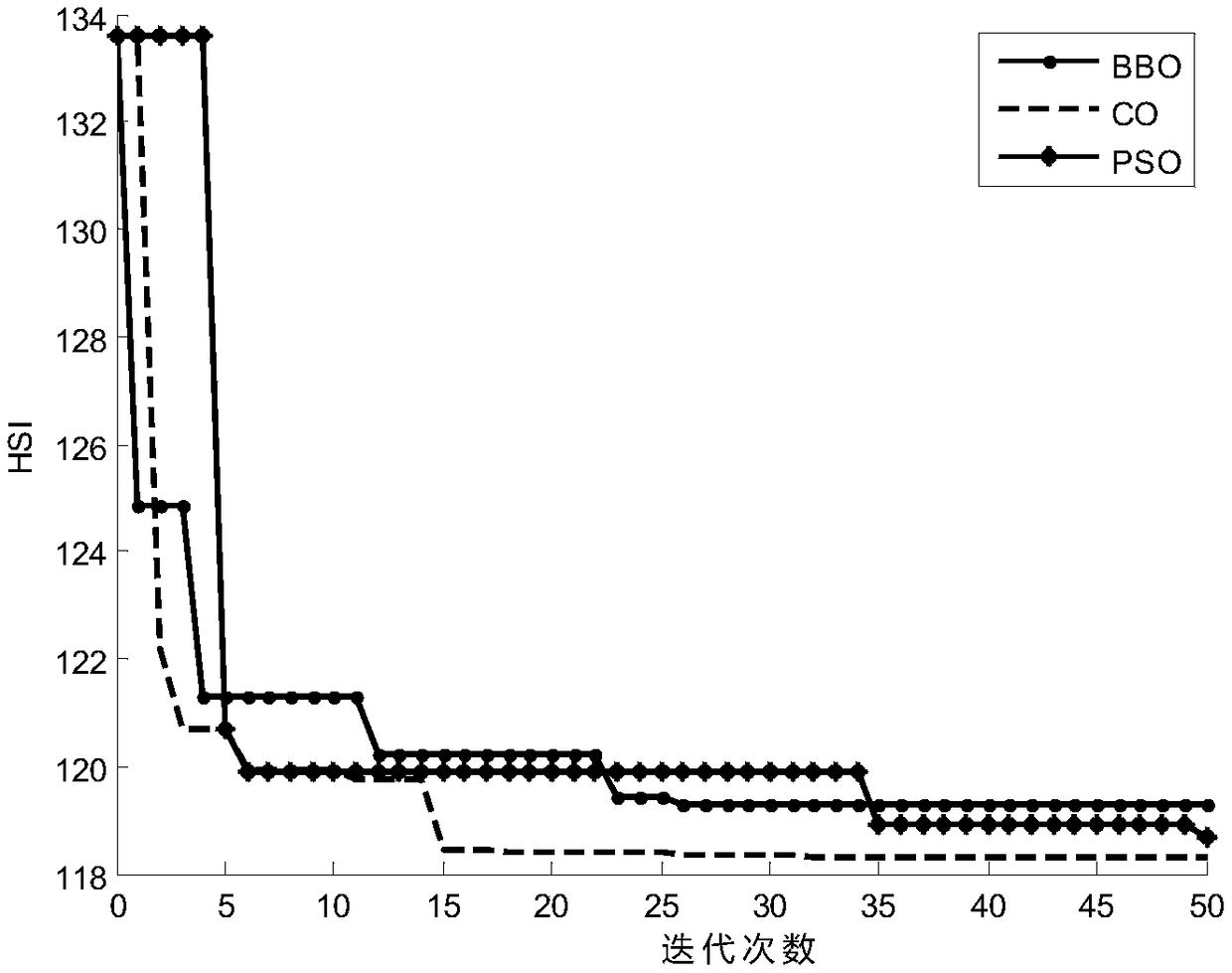

Intelligent sensitive plate temperature modeling method based on mixed elite captivity optimization

The invention, which relates to the technical fields of model establishment and controlling of the chemical engineering process industrial system model, discloses an intelligent sensitive plate temperature modeling method based on mixed elite captivity optimization. Being different from the natual-calculation-based optimization algorithm, an optimization algorithm based on mixed elite captivity introduces the artificial captivity concept to cultivate expected key species with great effort. The temperature of a sensitive plate in a rectifying tower is adjusted by adjusting the opening of a valve of a reboiler heat source; and the control loop is one first-order plus dead-time link. When the algorithm is applied to the model identification of the first-order plus dead-time system, the precision of model identification of the sensitive plate temperature control loop of the rectifying tower can be improved well; and the solid foundation is laid for using the advance control plan on the type of device. The method is operated simply; the searching power is high and the convergence is accelerated; the trapping in local optimum is prevented; the time is saved for the optimization problem and the system identification requirement is met completely.

Owner:BEIJING CENTURY ROBUST TECH

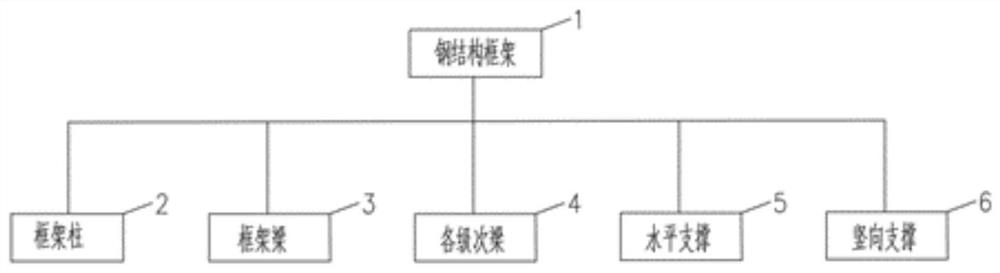

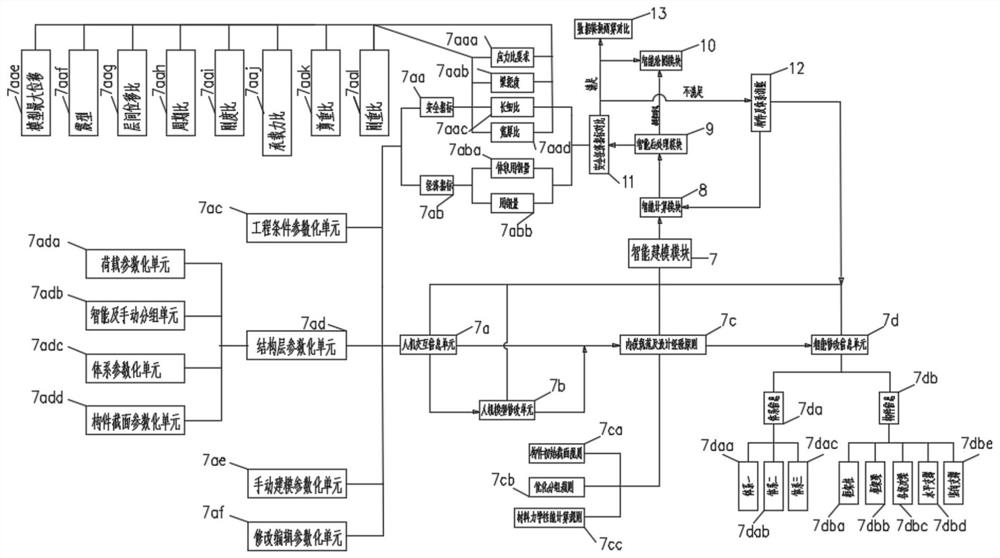

Intelligent modeling module of steel frame structure intelligent optimization design system

The invention provides an intelligent modeling module and method for an intelligent design system of a steel frame structure. The module comprises a man-machine interaction information unit, a man-machine model modification unit, an embedded rule and design experience unit and an intelligent information modification unit. The technical scheme provided by the invention is suitable for various developed steel frame structure forms. By adopting the intelligent modeling module, subsequent work can be submitted to software for automatic operation through dozens of parameter input and selection of the man-machine interaction information unit, an initial structure model is intelligently constructed, and a final structure model can be automatically iterated and optimized according to interconnection and intercommunication of subsequent intelligent modules. By adopting the intelligent modeling module, a plurality of workloads such as manual model building, component section selection and arrangement, load arrangement, material mechanical property adjustment and parameter setting of a designer in the steel frame structure design process are omitted, and the design efficiency and the design quality are greatly improved.

Owner:DATANG ENVIRONMENT IND GRP

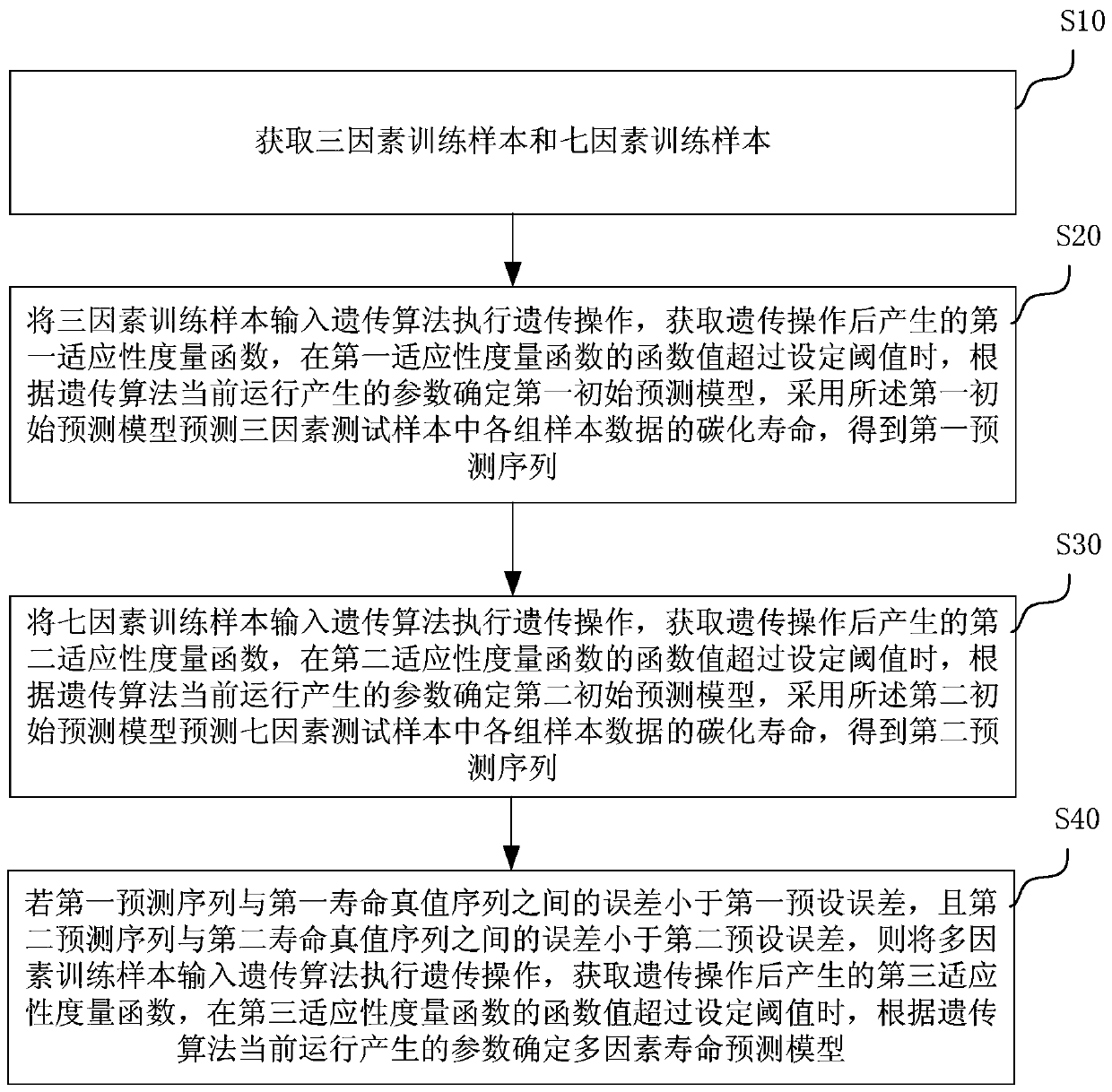

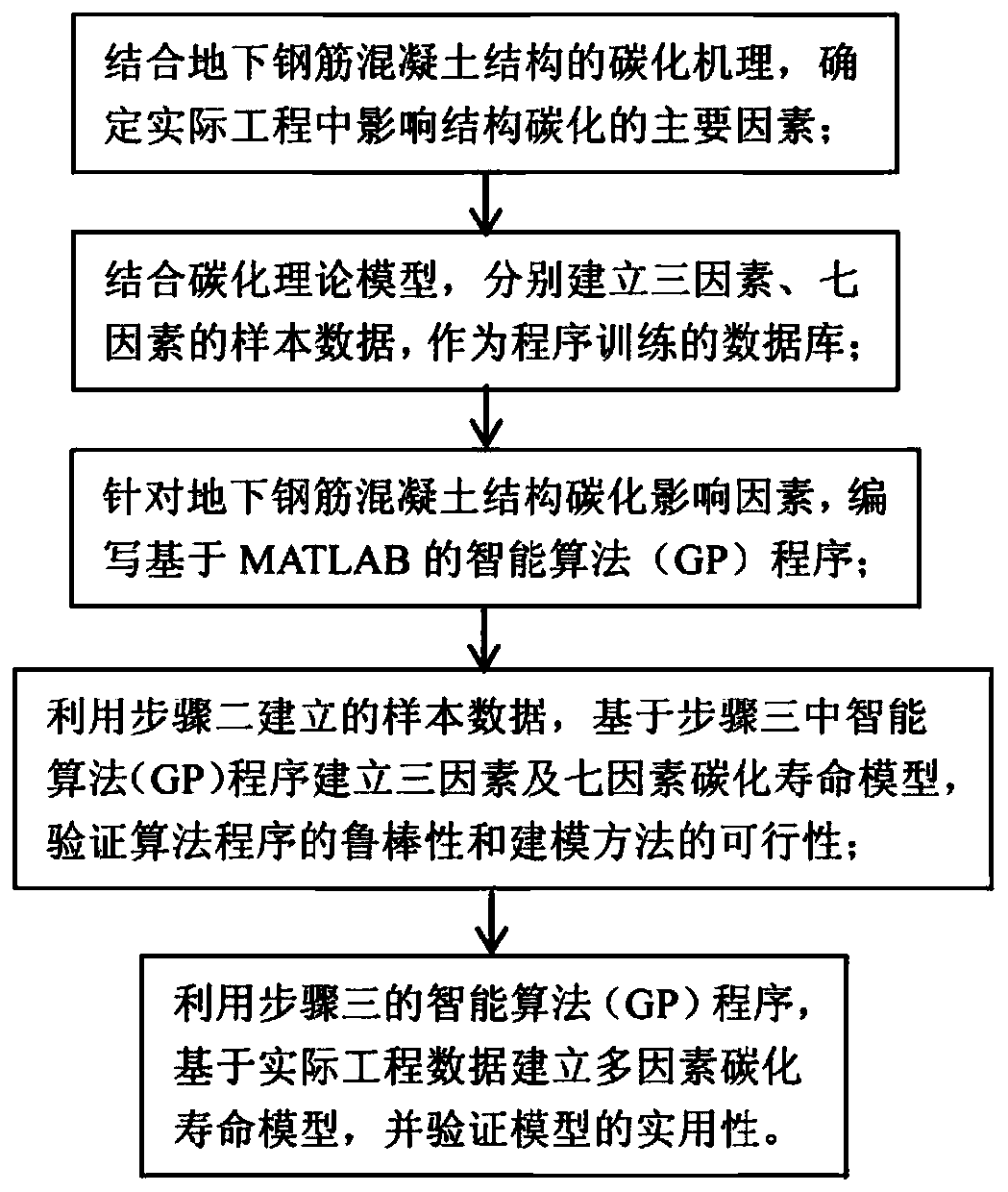

Underground reinforced concrete structure carbonization life intelligent modeling method based on big data

ActiveCN110991067AIncrease flexibilityDesign optimisation/simulationReinforced concreteIntelligent modeling

The invention discloses an underground reinforced concrete structure carbonization life intelligent modeling method based on big data. The method comprises the steps: selecting main factors influencing the carbonization life of an underground reinforced concrete structure according to the carbonization mechanism of the reinforced concrete structure and the consideration of an actual engineering situation; according to different factors influencing the carbonization life of the underground reinforced concrete structure and a theoretical model, establishing three-factor and seven-factor sample data; compiling an intelligent genetic algorithm program based on MATLAB, obtaining a corresponding carbonization life model through training according to different sample data, comparing and verifyingcalculation values of a three-factor carbonization life model and a seven-factor carbonization life model with an actual value of the data, and proving the robustness of the intelligent genetic algorithm program for establishing the models and the reasonability of the modeling method ; and finally, collecting actual engineering data in a carbonization environment, establishing a structural carbonization life model considering multiple factors of engineering by utilizing an intelligent algorithm (GP) program, and verifying the engineering practicability of the model by utilizing the actual engineering data.

Owner:HOHAI UNIV

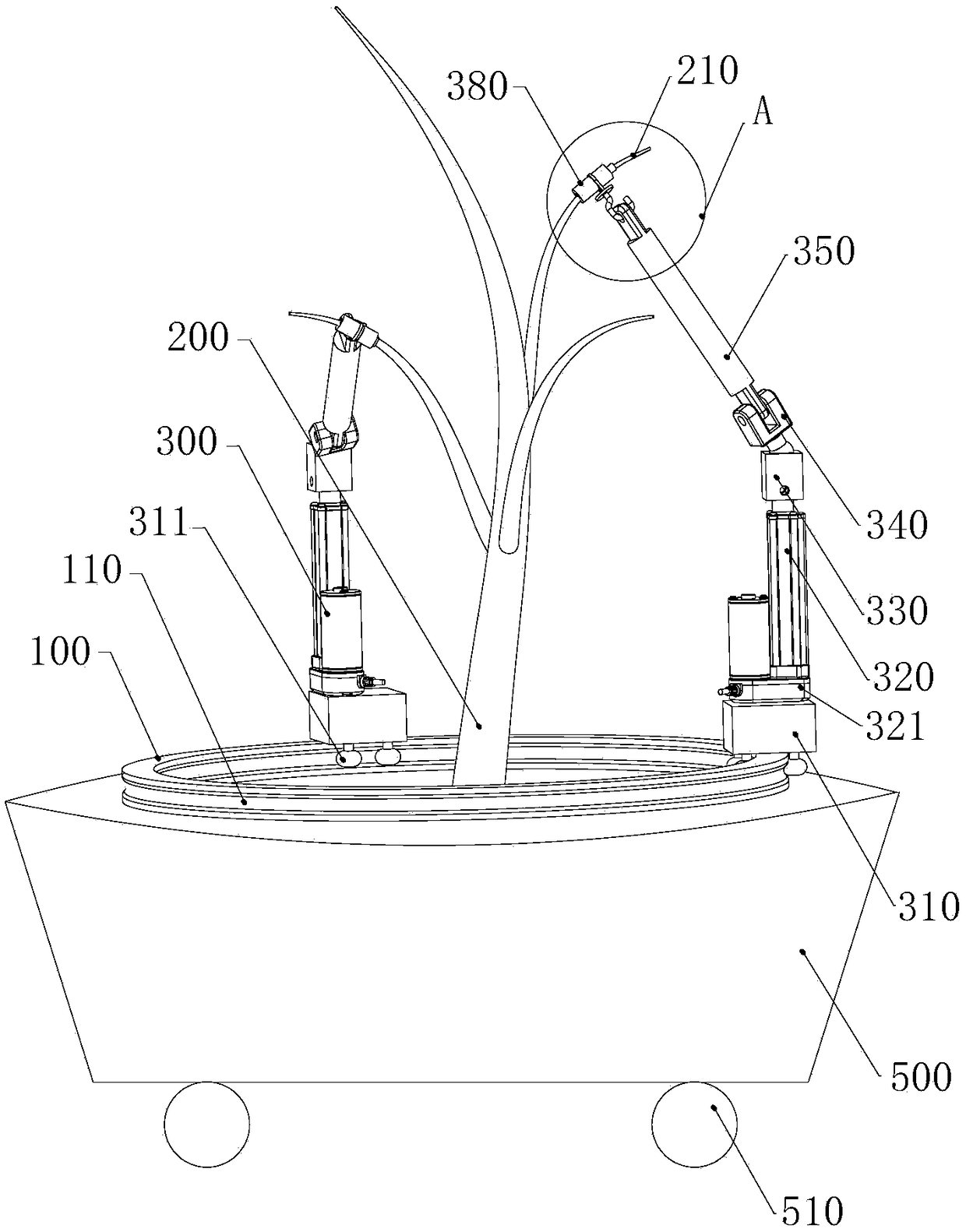

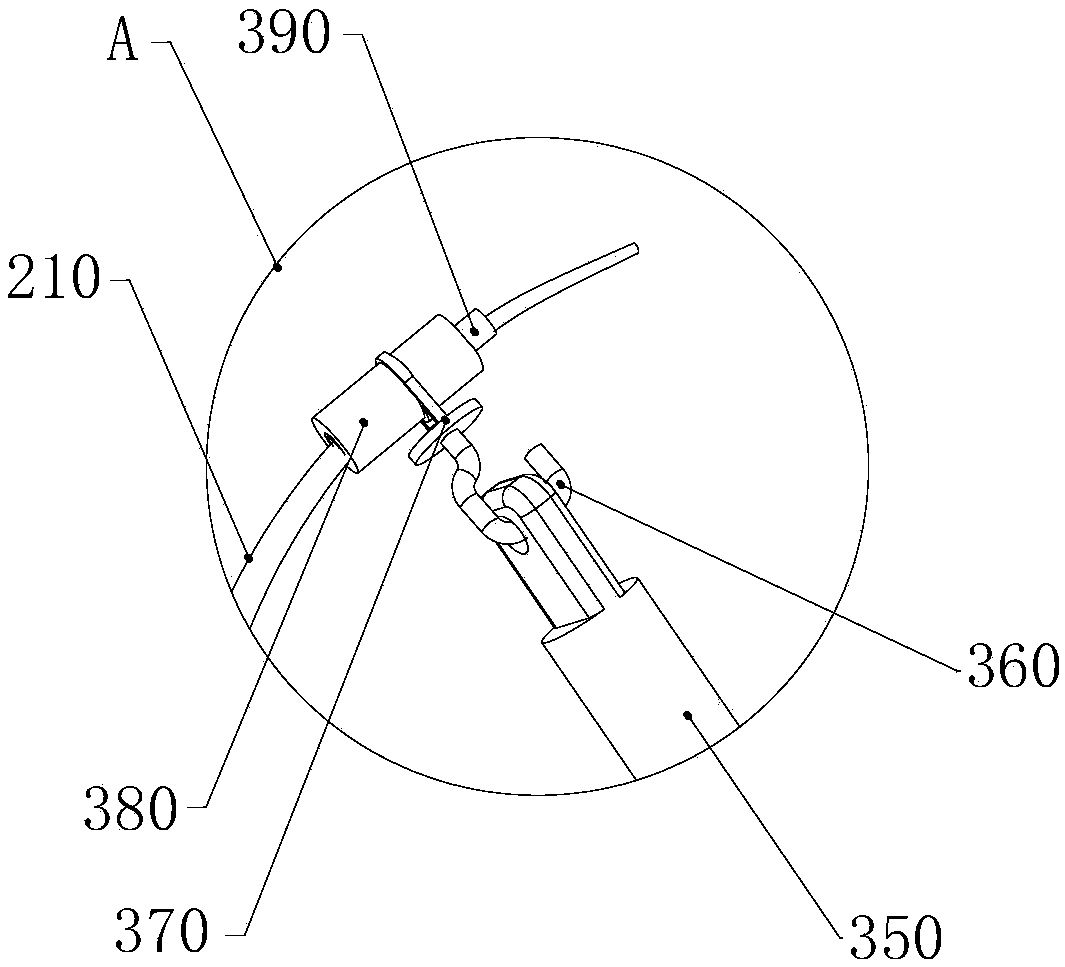

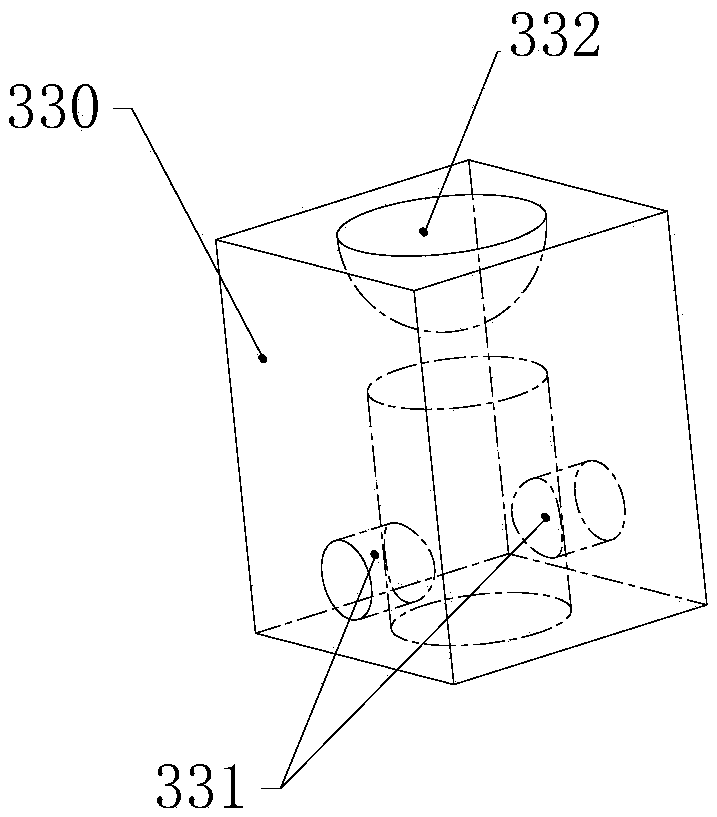

Convenient-to-move bonsai modeling device

The invention relates to a convenient-to-move bonsai modeling device which comprises an intelligent control system, a sliding rail, a plurality of sets of main branch supports and a plurality of setsof fine branch supports, wherein each set of main branch supports are in sliding fit with the sliding rail and are electrically connected with the intelligent control system; and the fine branch supports are used for modeling the fine branches on a main branch, and each set of fine branch supports corresponds to a fine branch on one main branch. Each set of fine branch supports comprises a slidingblock, a first telescopic rod and a second telescopic rod, wherein the sliding block is arranged on the sliding rail in a sliding mode, the first telescopic rod is fixedly arranged at the top of thesliding block, the top of the second telescopic rod is connected with the bottom of the first telescopic rod through a ball, and the top of the second telescopic rod is connected with the main branchthrough a small hook. The method has the advantages that the position and the shape of the main branches are controlled through the intelligent control system, so that the intelligent modeling of themain branches of a bonsai can be realized; and the shapes of the fine branches on the main branches can be modeled by the aid of the fine branch supports.

Owner:WUHAN BAIQI TECH CO LTD

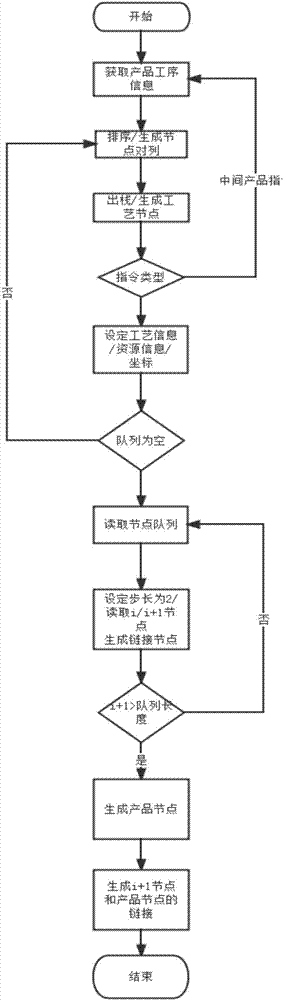

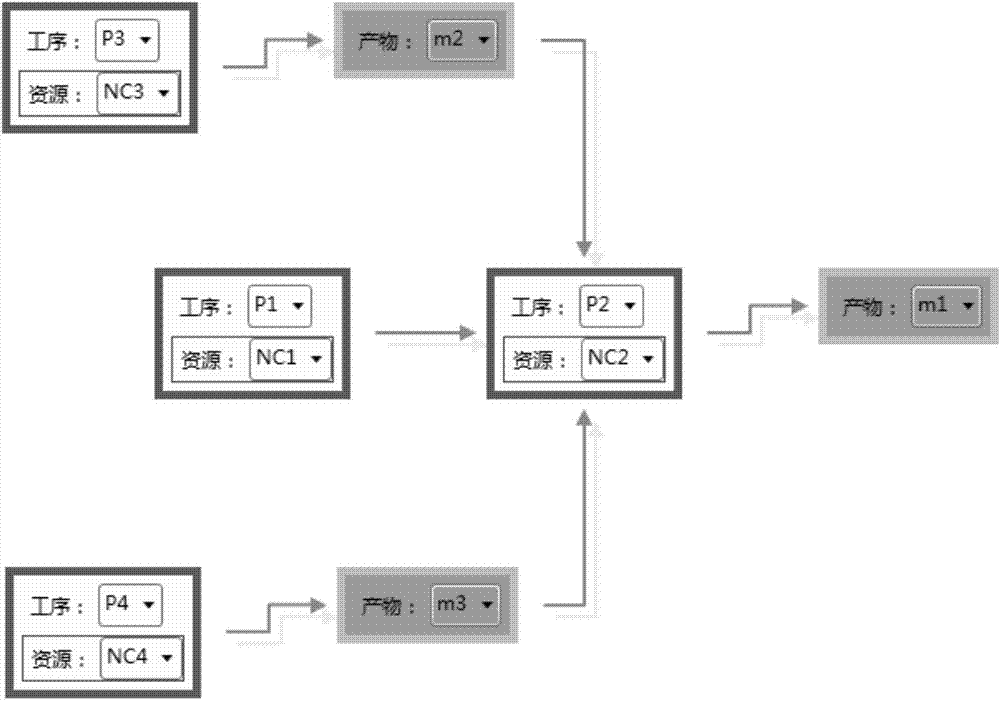

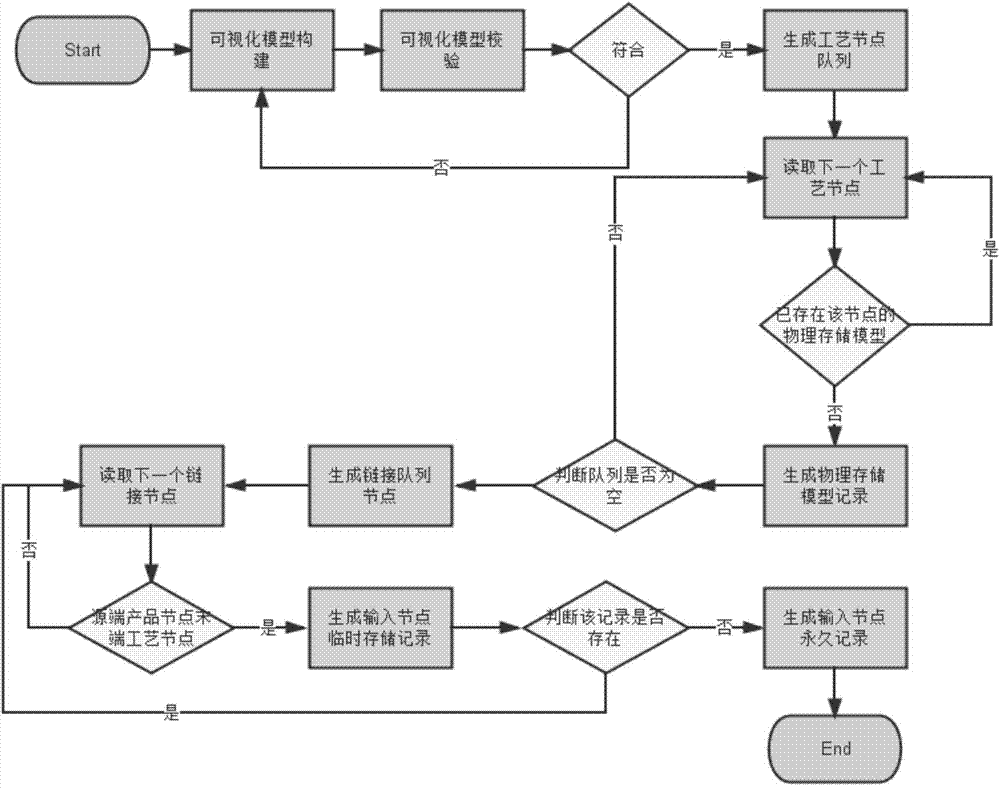

Complex production process intelligent modeling method

ActiveCN104850068ASupport visual operationTotal factory controlProgramme total factory controlBuilding productRelationship - Father

The invention relates to a complex production process intelligent modeling method in the manufacturing industry; the intelligent modeling technology comprises two parts: product manufacturing process model visualization and visualization form intelligent building product manufacturing process modeling technology; the product manufacturing process model visualization comprises the following steps: reading a product physical storage model; building a product processing craft assembly; building a product assembly; building hinges between all assemblies; traversing all technical nodes, if certain craft needs other processing product, then building a visualization tree, a father node assembly and a craft assembly of the processing product, and the building process repeats the said steps. The visualization form intelligent building product manufacturing process modeling technology comprises the following steps: building a product visualization tree; verifying the visualization tree; traversing the visualization tree and forming the physical storage model. The complex production process intelligent modeling method is the main base for production scheduling, production monitoring, production tracking, and production early warning, thus improving product quality, reducing material consumption, optimizing production composition, and improving company market competitiveness.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Bridge crane modeling method adopting hairpin mutation operation RNA genetic algorithm

ActiveCN105260556AIncrease diversityOvercome deficienciesSpecial data processing applicationsNerve networkIntelligent modeling

The invention discloses a bridge crane modeling method adopting a hairpin mutation operation RNA genetic algorithm and belongs to the field of intelligent modeling. A bridge crane is a highly nonlinear complicated system, and building a high-precision bridge crane system model is a fatal basis for the purpose of effectively control. For high bridge crane modeling precision, a bridge crane nonlinear regression model based on the position and the angle of an RBF nerve network. Under inspiration of a hairpin structure, the hairpin mutation operation RNA genetic algorithm is abstracted and applied to optimize the radial basis function center of the bridge crane RBF nerve network so as to obtain a nerve network model of the bridge crane. The bridge crane modeling method has the characteristic of high modeling precision and is also suitable for modeling other complicated nonlinear systems.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com