Soft measuring system and method for quality indexes of multielement molten iron of blast furnace

A quality index, soft measurement technology, applied in blast furnaces, blast furnace details, manufacturing calculation systems, etc., can solve the problems of long calculation time of soft measurement model, unable to fully reflect the complex state inside the blast furnace, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

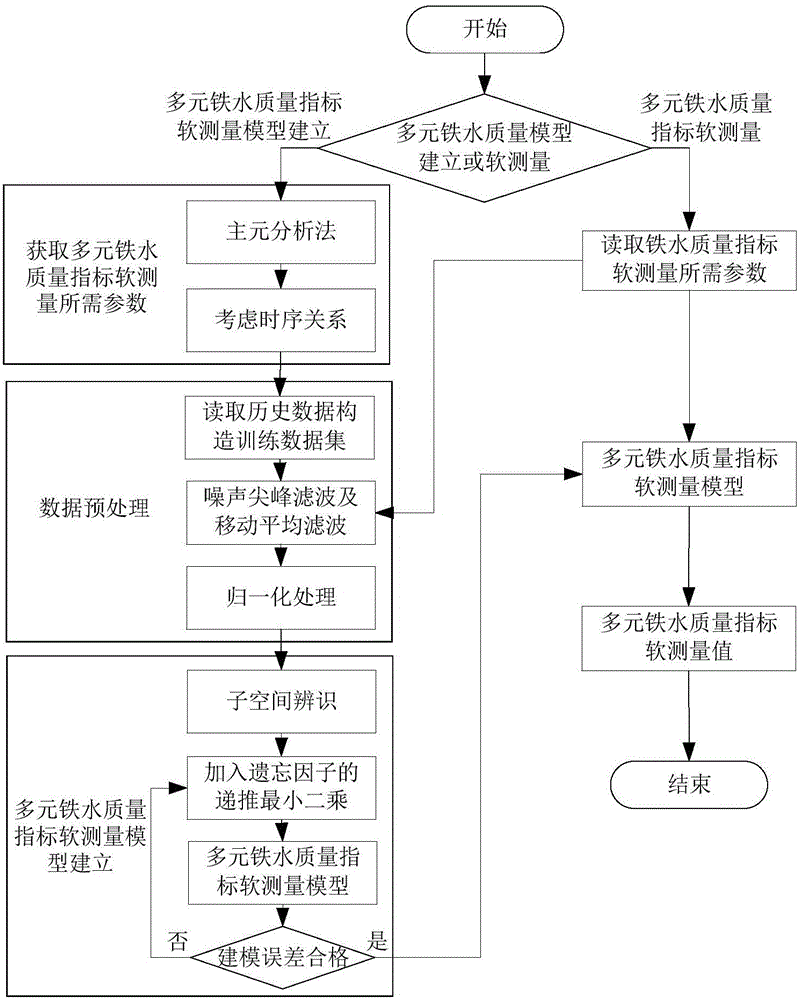

[0057] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

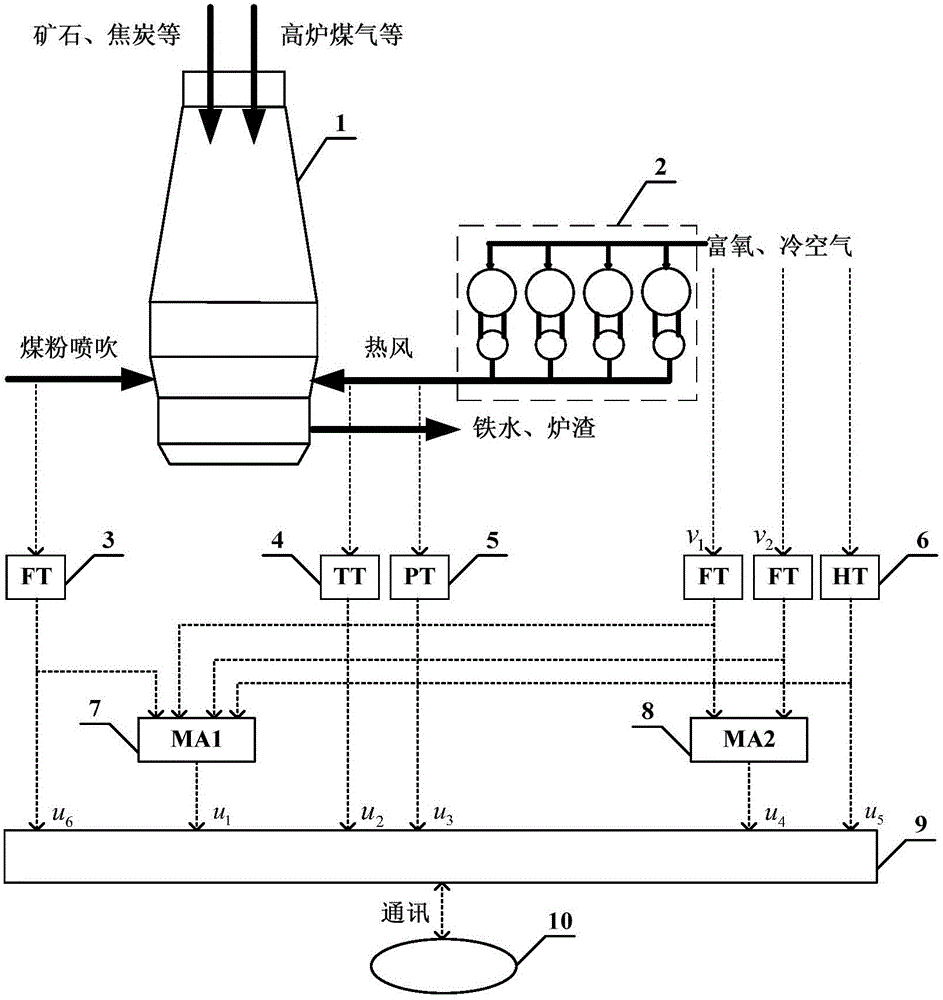

[0058] This embodiment adopts detection equipment, data collector 9, and computer system 10 to realize the soft measurement method of blast furnace multi-element molten iron quality index, such as figure 1 As shown, the detection equipment includes a flowmeter 3, a thermometer 4, a pressure gauge 5, a hygrometer 6, a bosh gas volume measurement analyzer 7, and an oxygen enrichment rate measurement analyzer 8. These conventional measurement instruments are installed in each corresponding part of the blast furnace smelting system. Location. The data collector 9 is connected to various detection devices, and connected to the computer system 10 through a communication bus. The conventional measuring system mainly includes the following conventional measuring instruments including:

[0059] Three flowmeters 3 are used to measure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com