3D intelligent modeling method and system and a flexible manufacturing system of 3D model

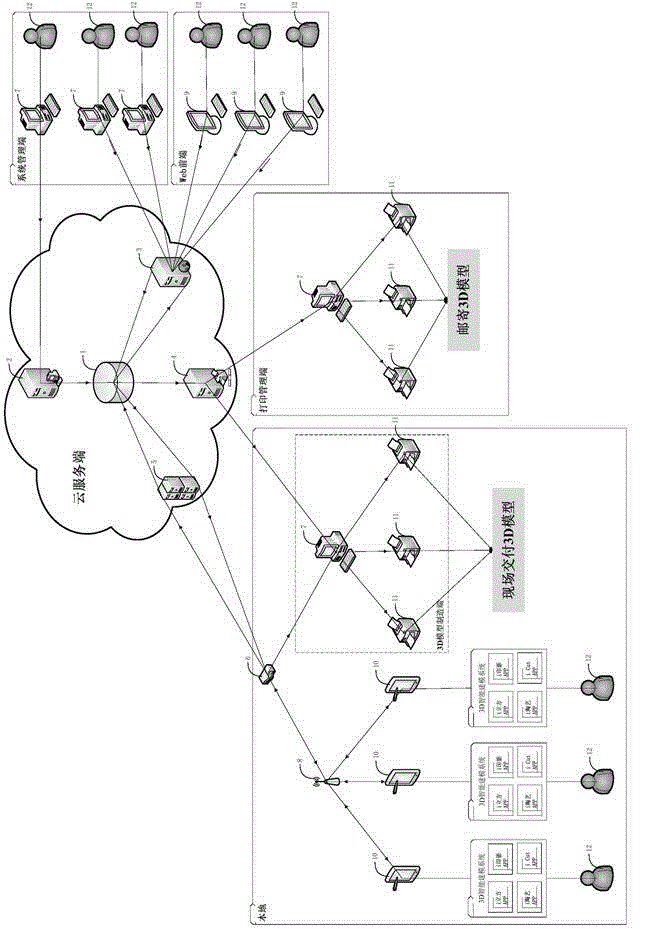

An intelligent, 3D technology, applied in the field of 3D model flexible manufacturing system, can solve the problems of incomplete experience service process, incompatible 3D model data, and 3D printing cloud service cannot be widely used for mass users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described below in conjunction with the accompanying drawings.

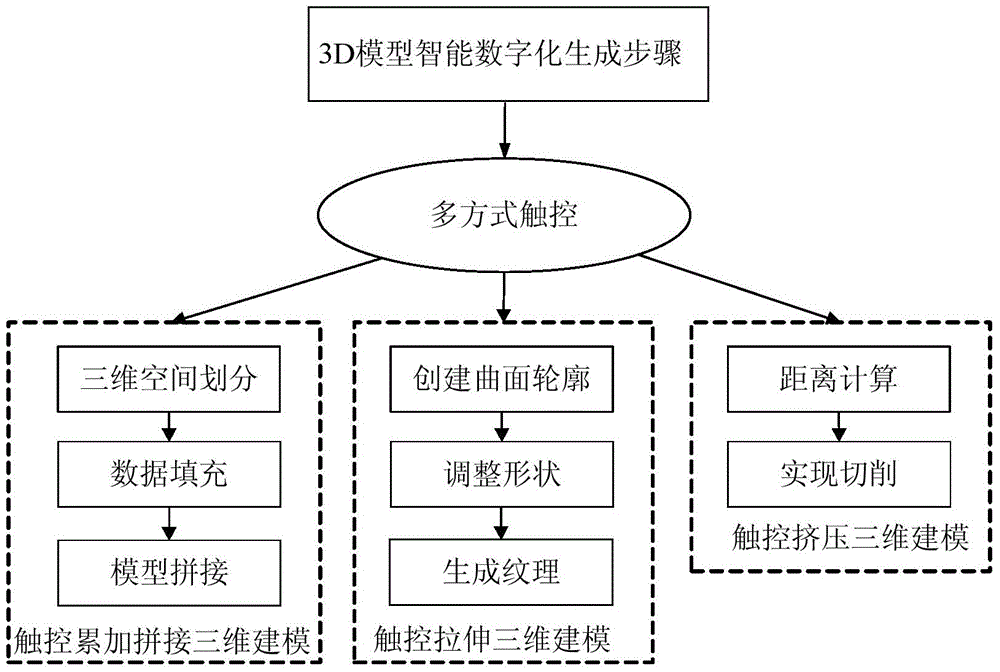

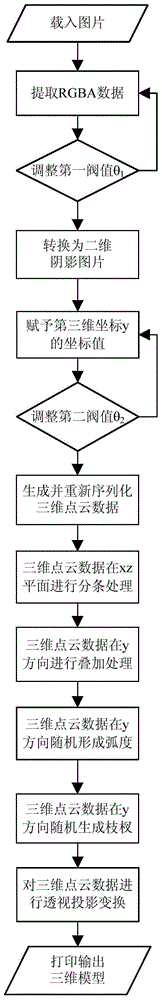

[0039] The invention relates to a 3D intelligent modeling method, which includes the steps of intelligently digitizing a 3D model, three-dimensional modeling of touch accumulative stitching, three-dimensional modeling of touch stretching, and three-dimensional modeling of touch extrusion. Wherein, in the intelligent digital generation step of the 3D model, the picture or photo is converted into a two-dimensional shadow picture using graphics processing technology, and the two-dimensional shadow picture includes black and white picture information; and then each pixel in the two-dimensional shadow picture is generated into a two-dimensional point cloud data, and endow the third-dimensional coordinate data, re-serialize the 3D point cloud data to form a 3D model; Grid unit division; then convert the screen coordinates of the touch points into three-dimensional world coordinates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com