Patents

Literature

1016results about How to "Safe handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

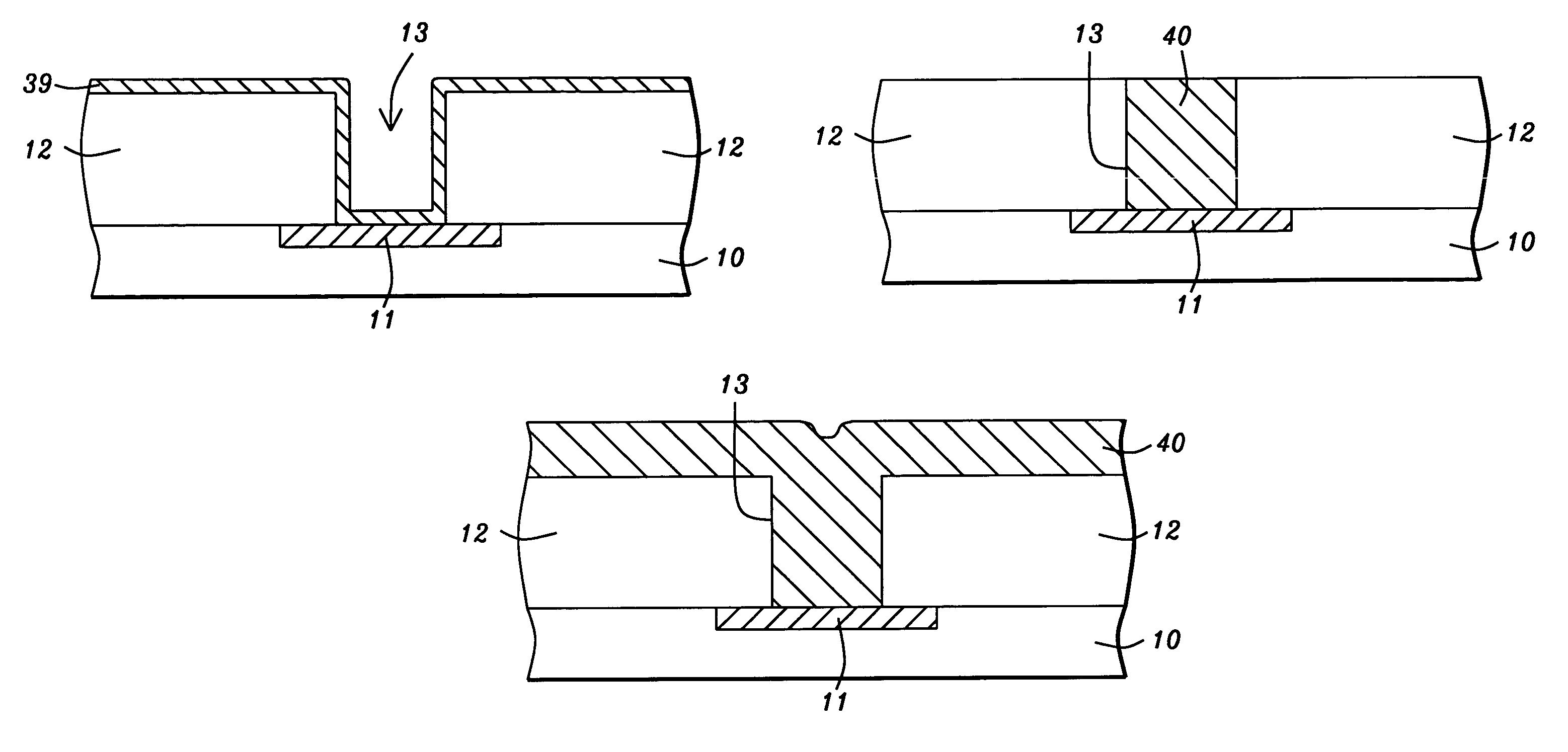

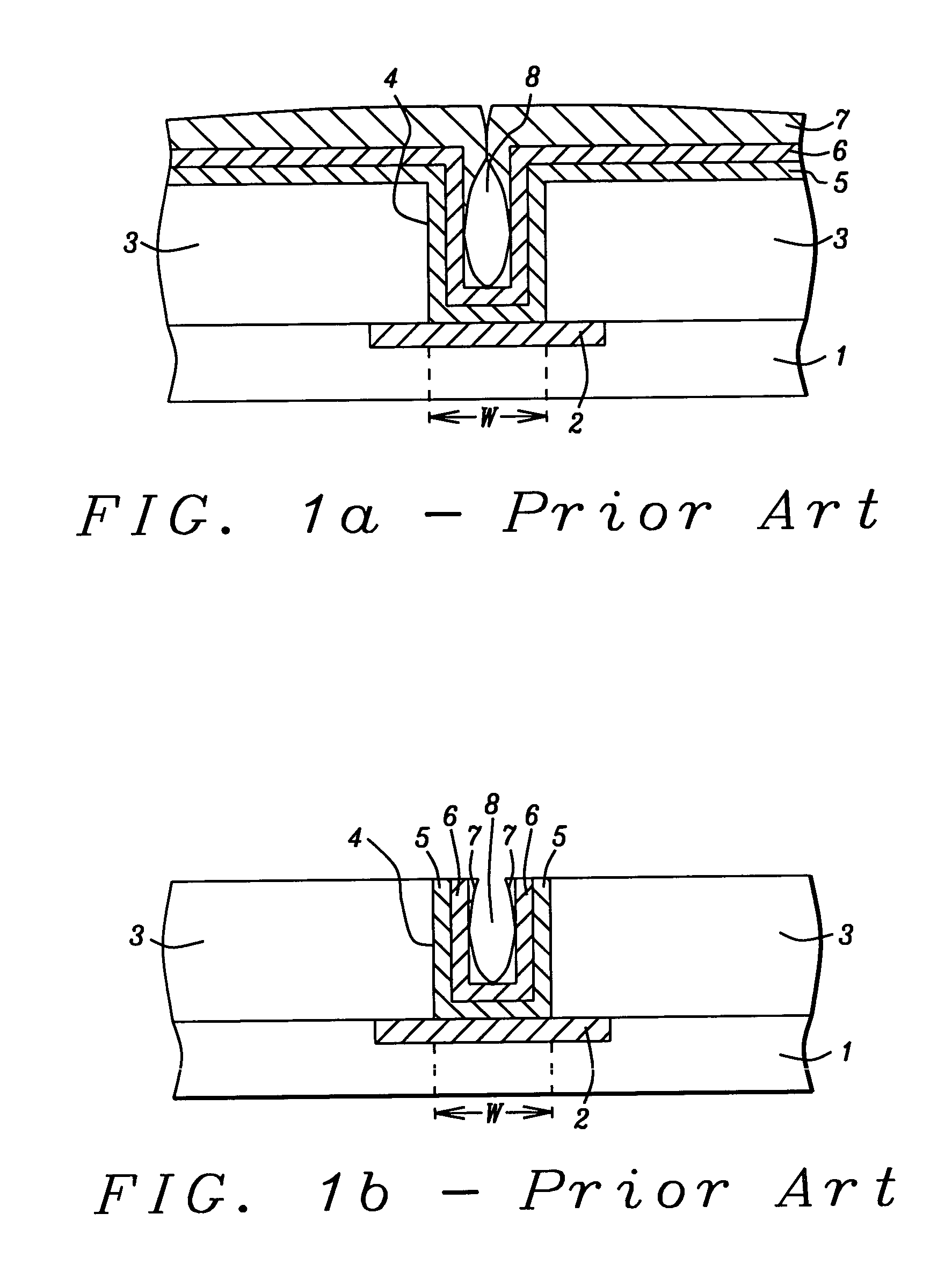

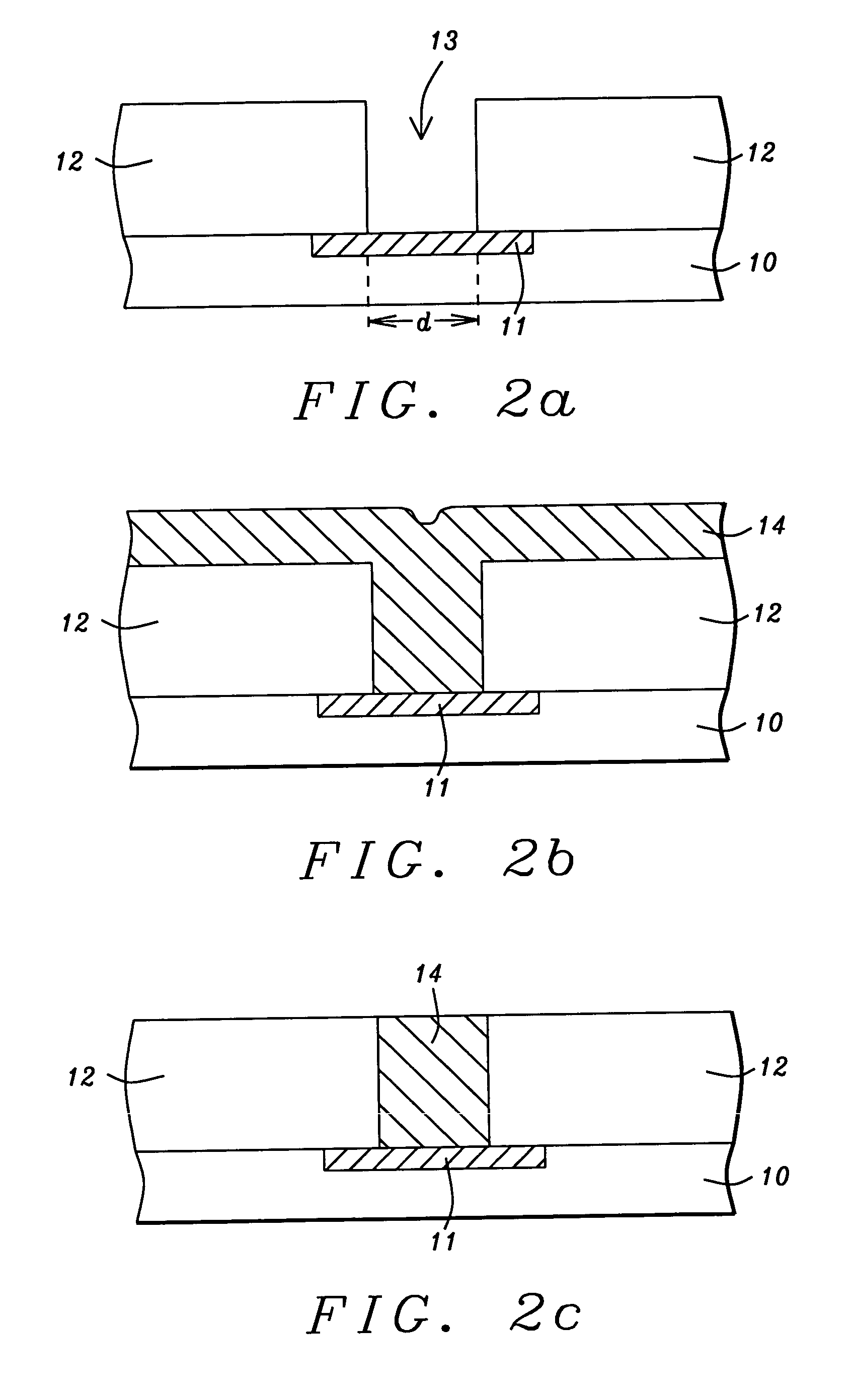

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS7235482B2Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionContamination

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrat. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

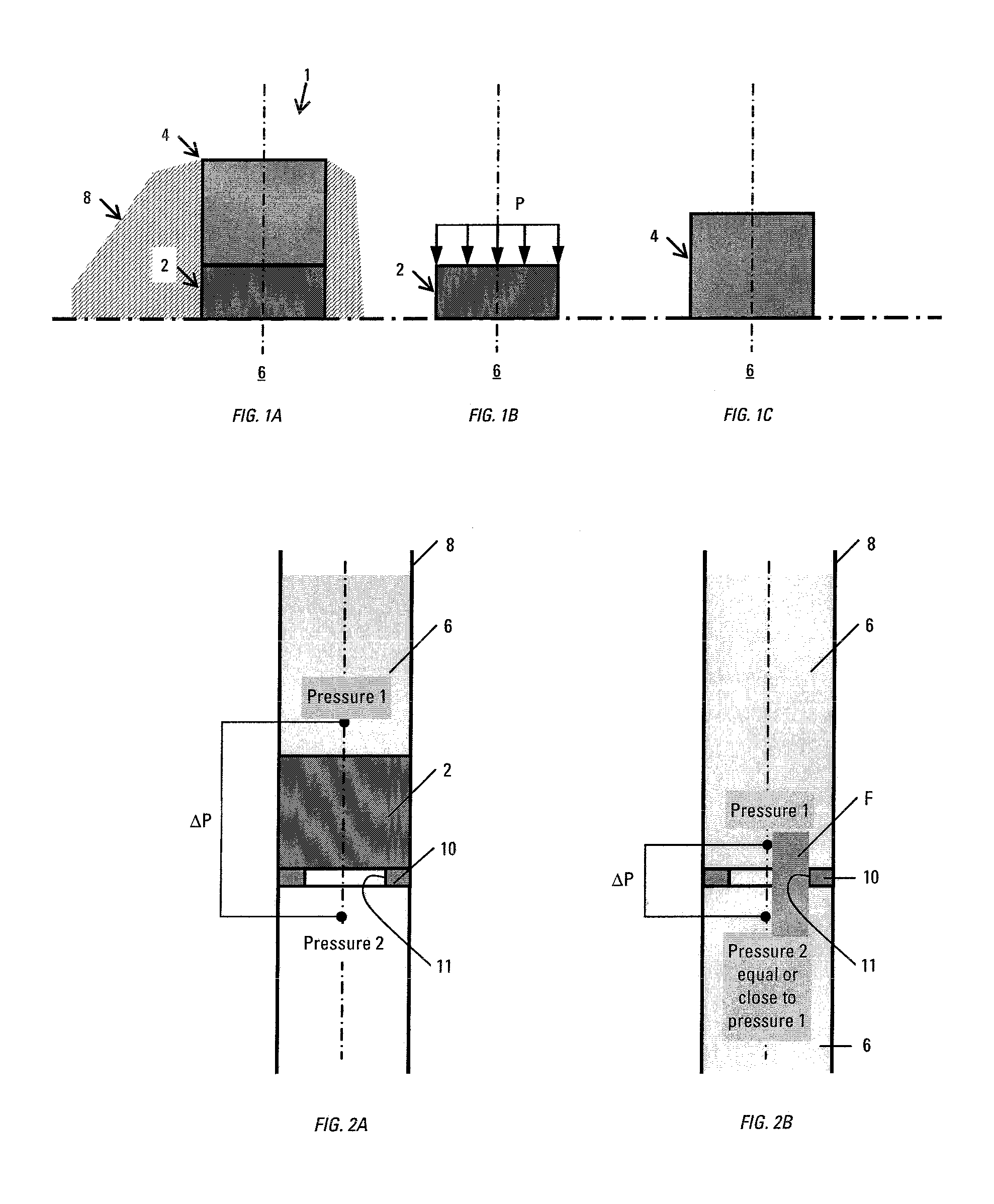

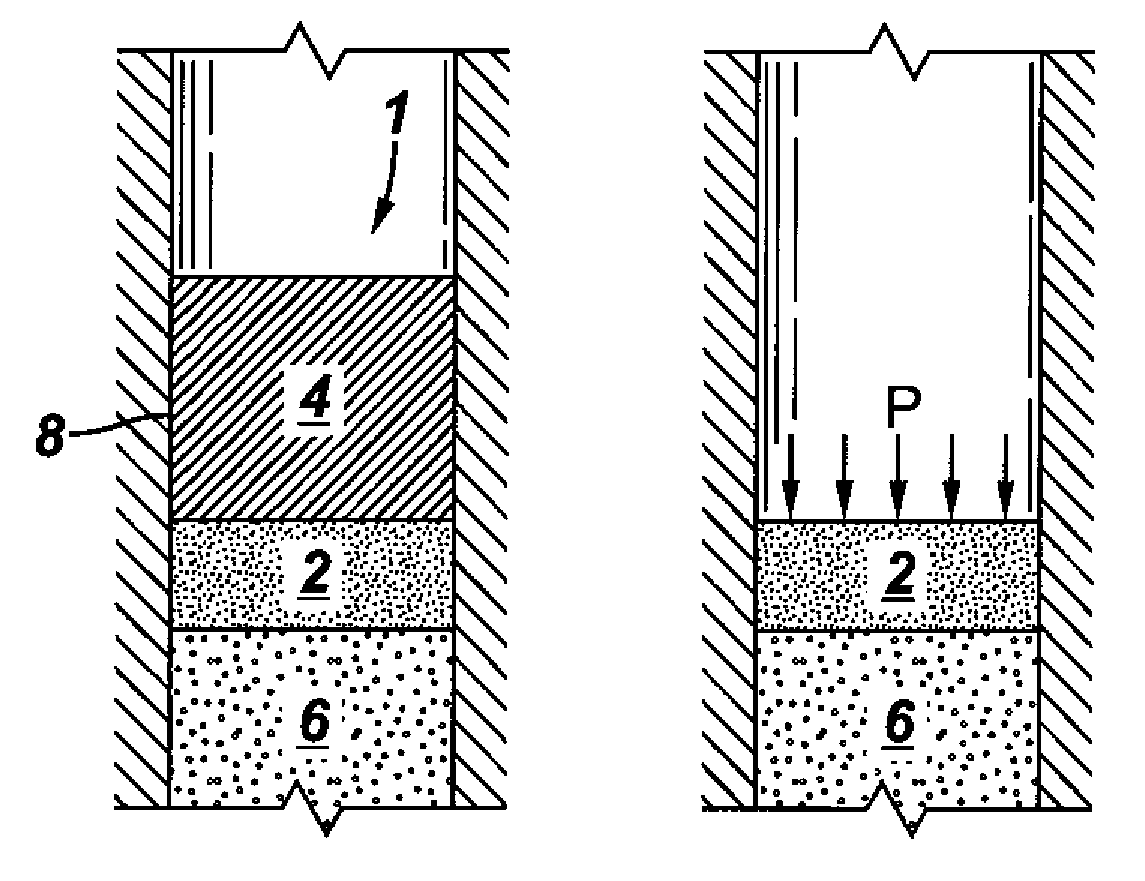

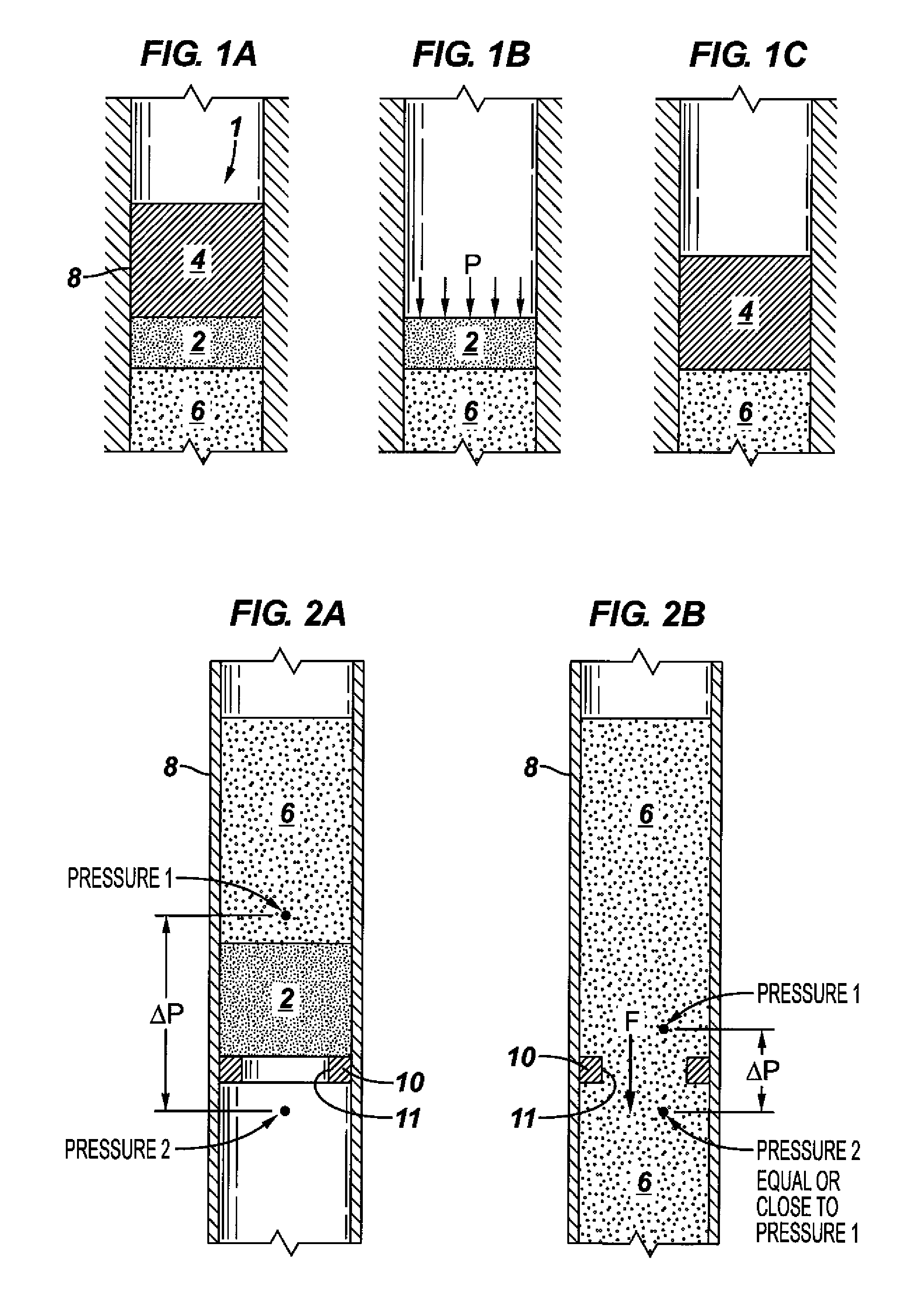

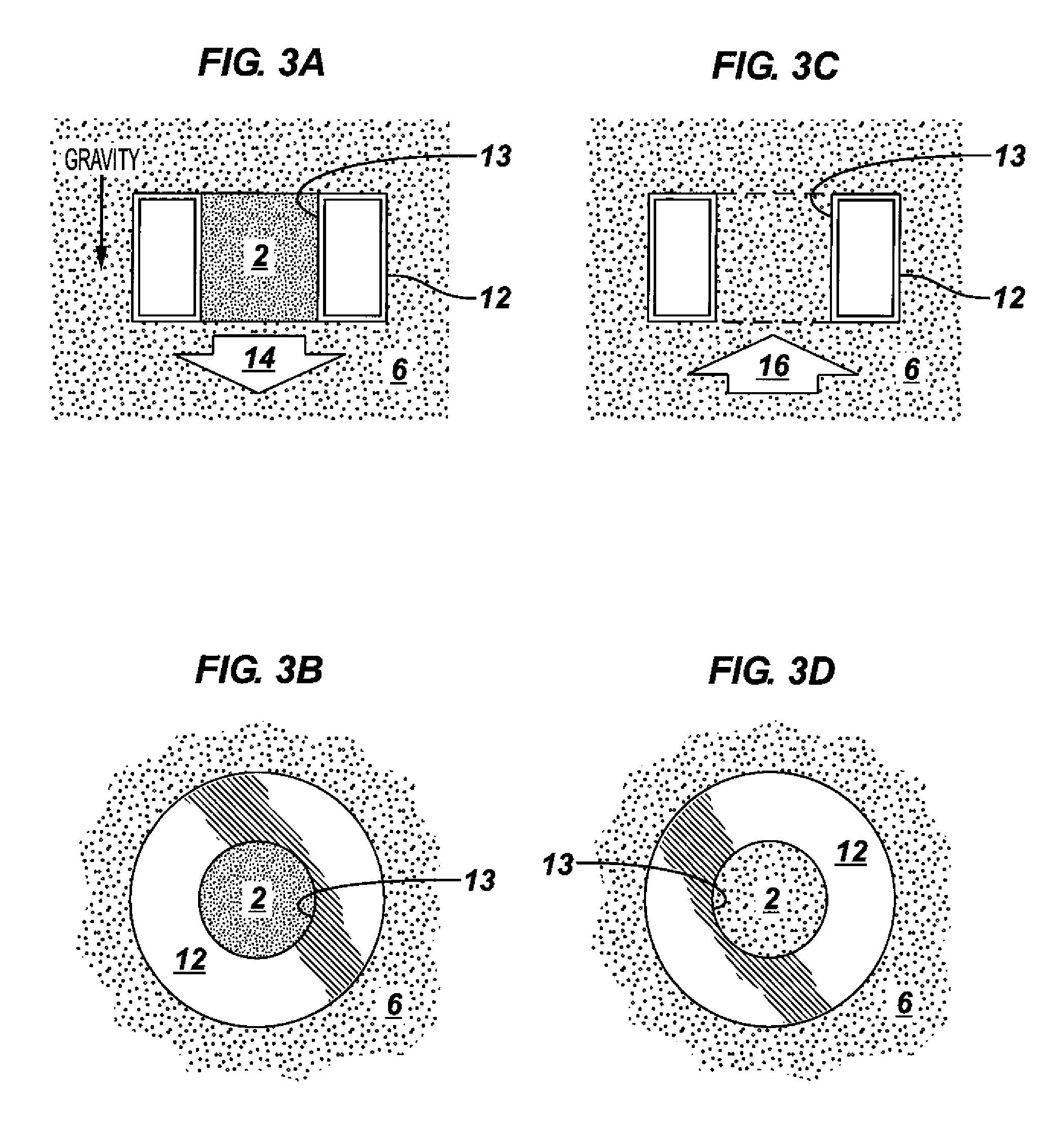

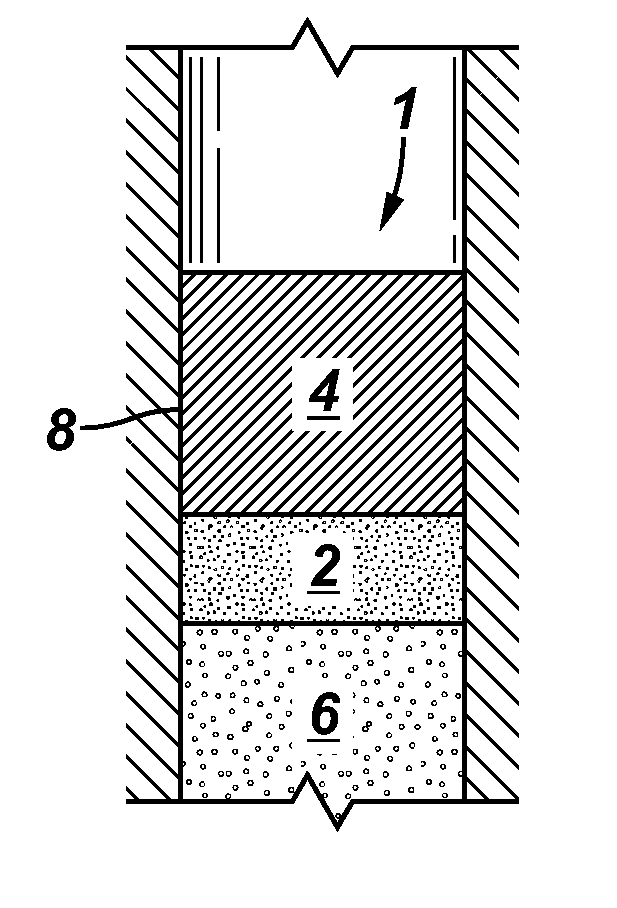

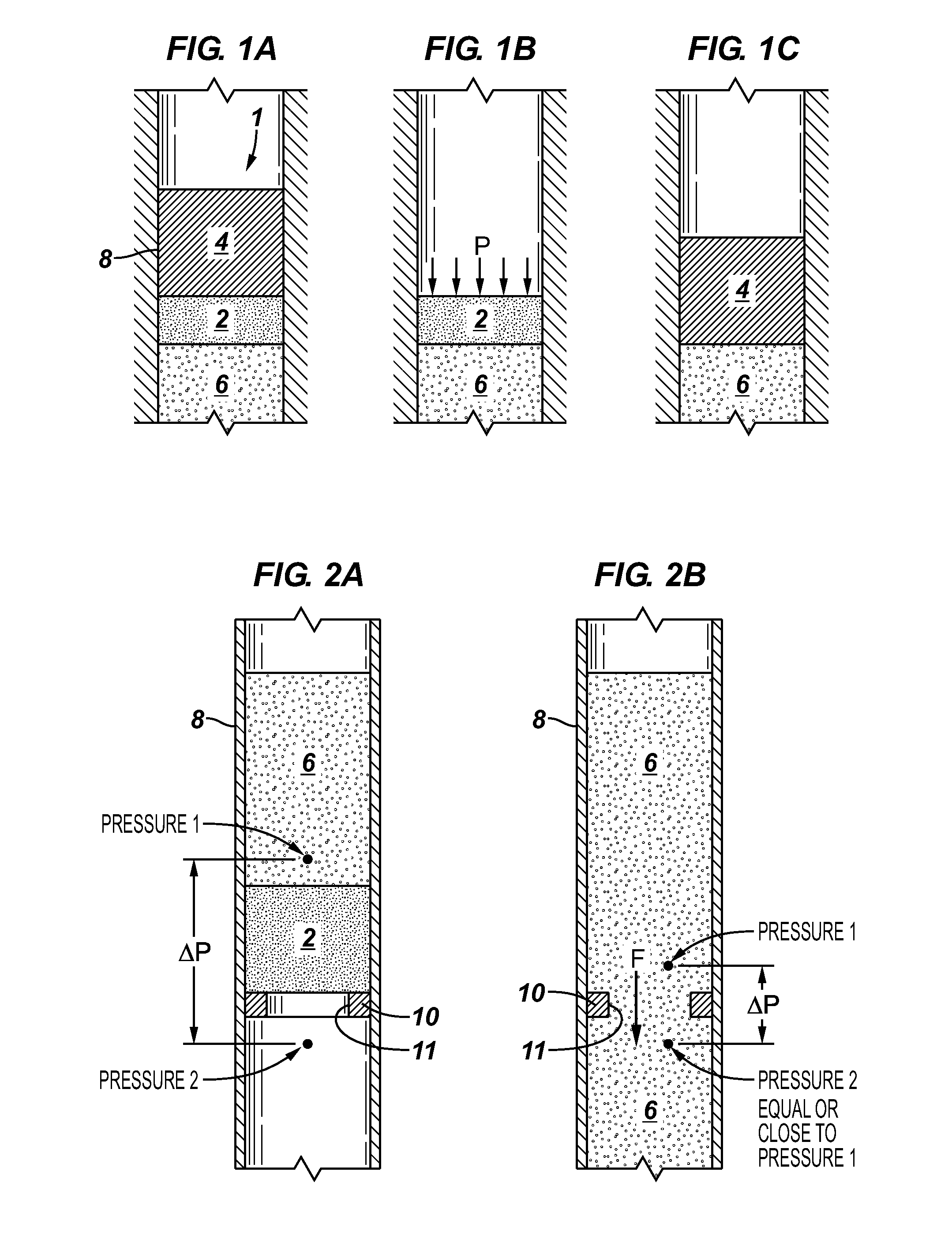

Degradable Compositions, Apparatus Comprising Same, and Method of Use

InactiveUS20070181224A1Improve responseSafe handlingDrilling compositionSealing/packingElemental compositionSubject matter

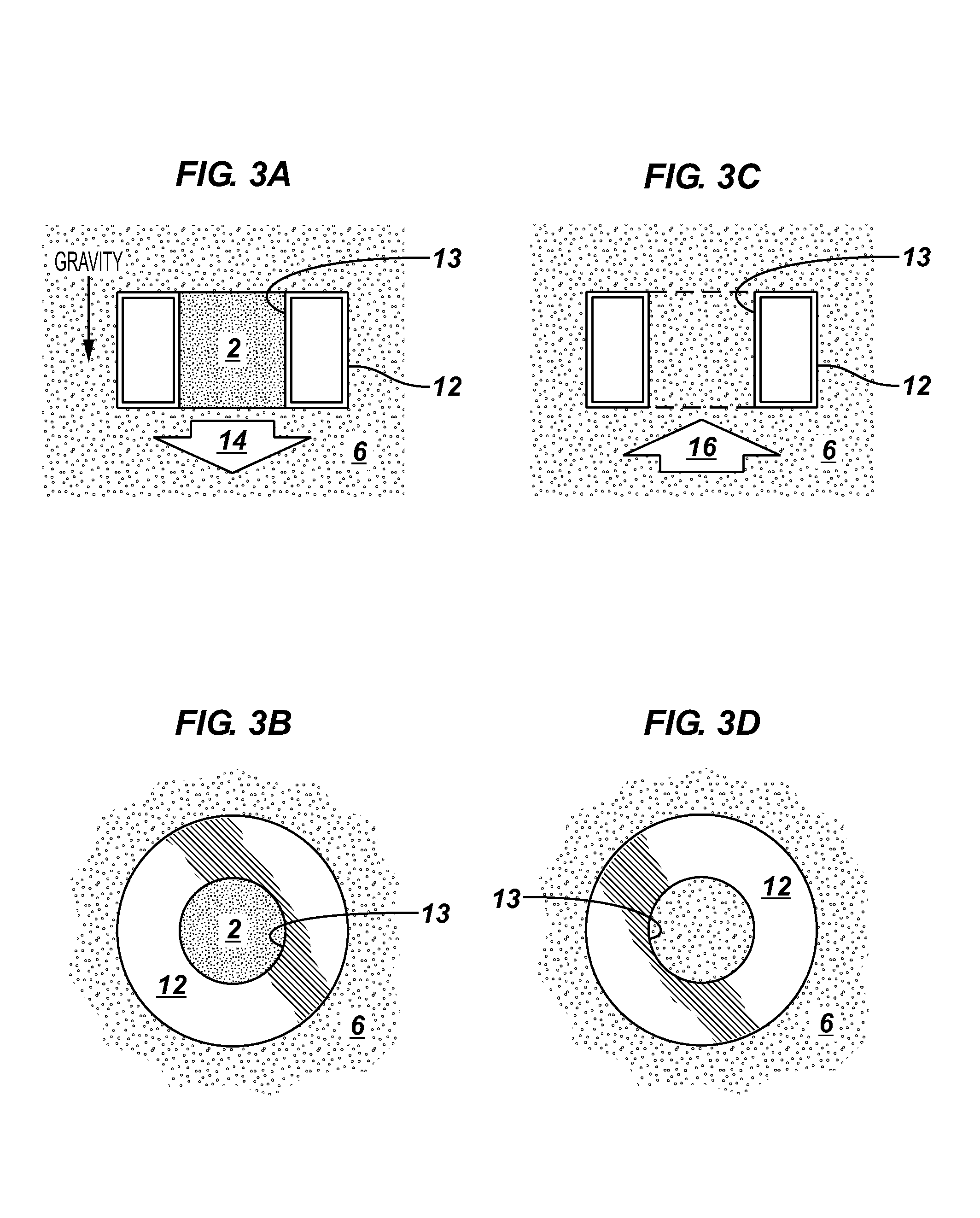

Compositions, apparatus incorporating a composition, and methods of use are described, one composition embodiment consisting essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Compositions of the invention may exist in a variety of morphologies, including a reactive metal or degradable alloy processed into an alloy of crystalline, amorphous or mixed structure that may constitute the matrix of other composition, for instance a composite. Methods of using apparatus comprising a composition, particularly in oilfield operations are also described (e.g. flow and displacement control, sensors, actuators). This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:SCHLUMBERGER TECH CORP

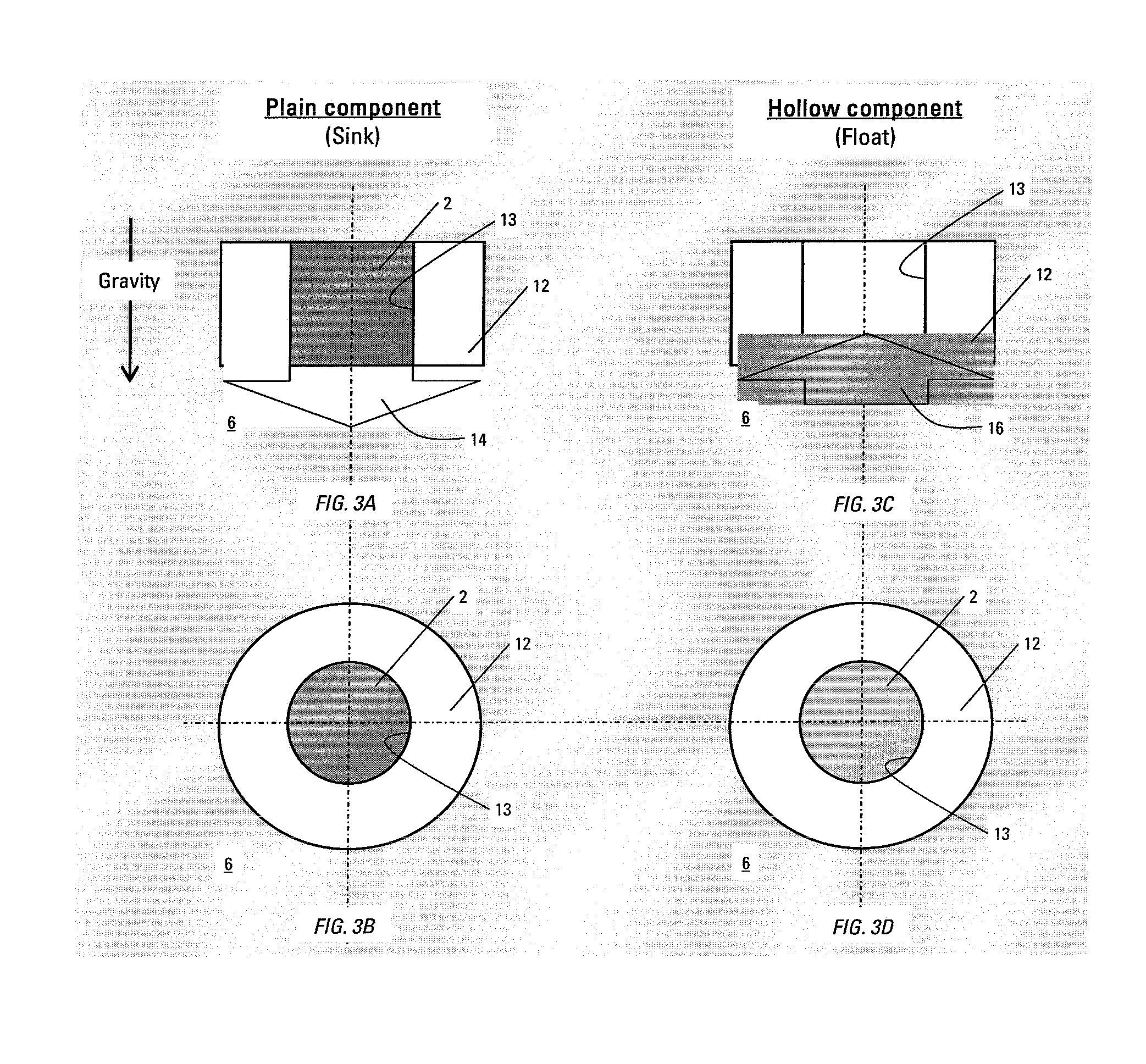

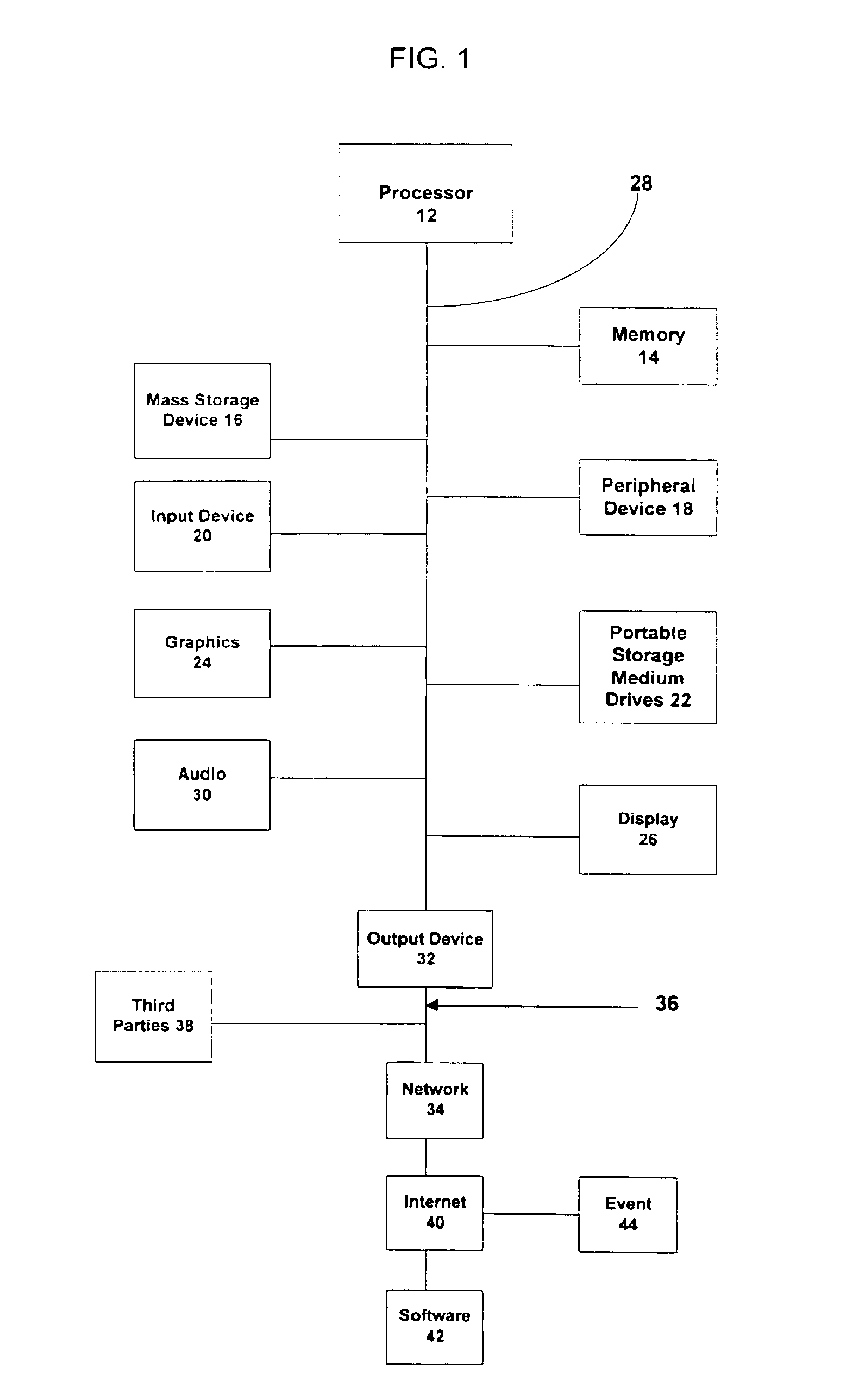

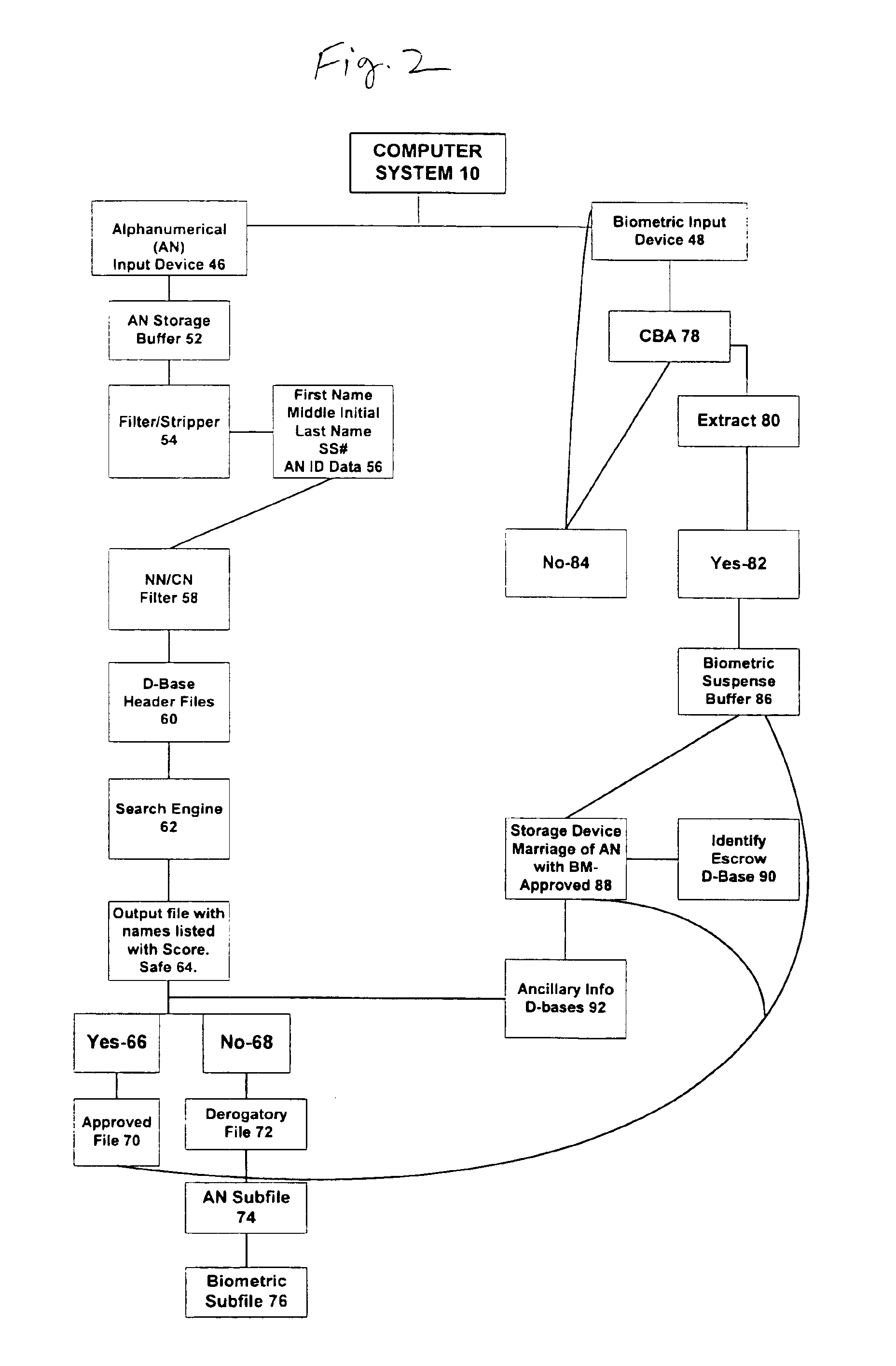

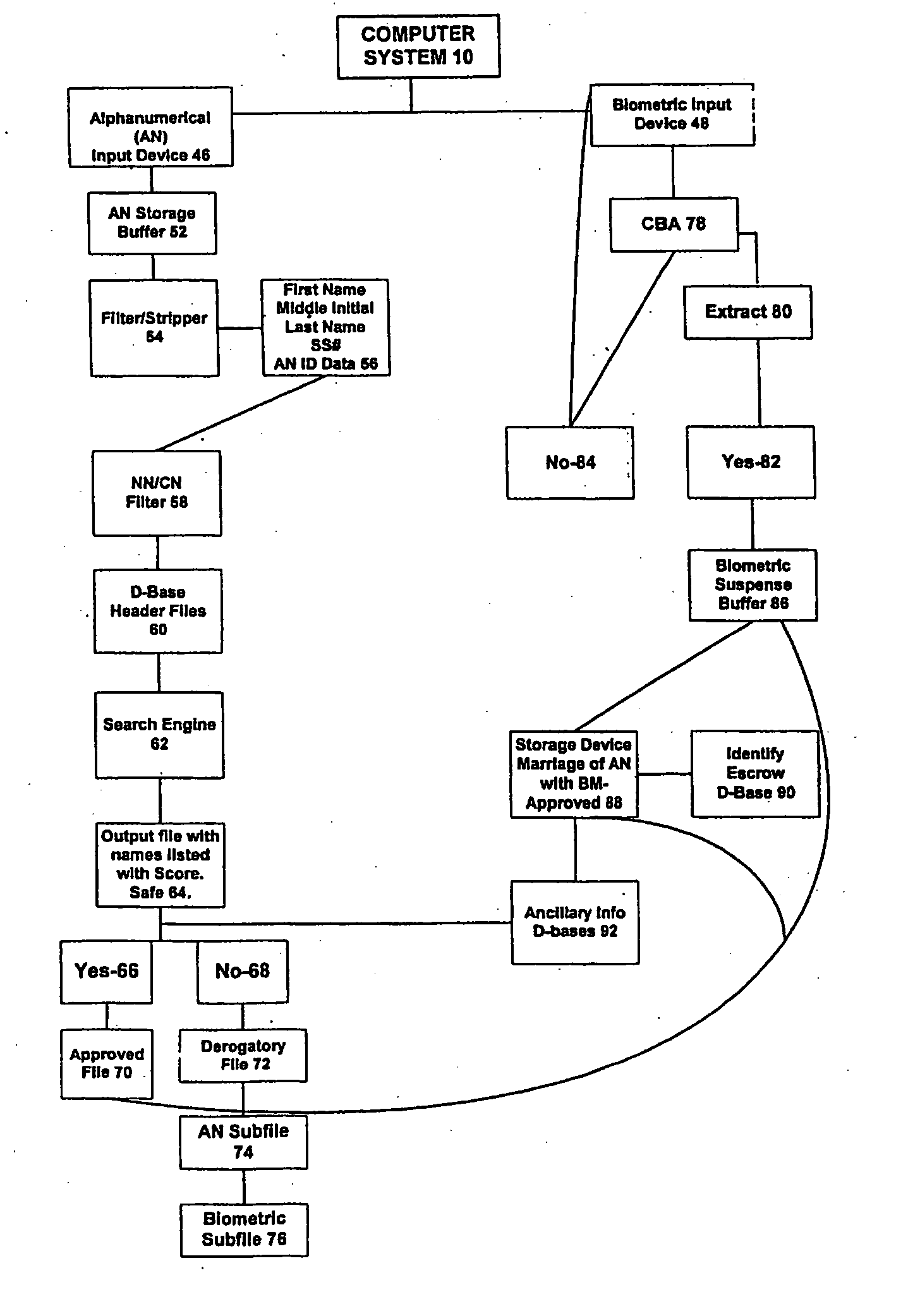

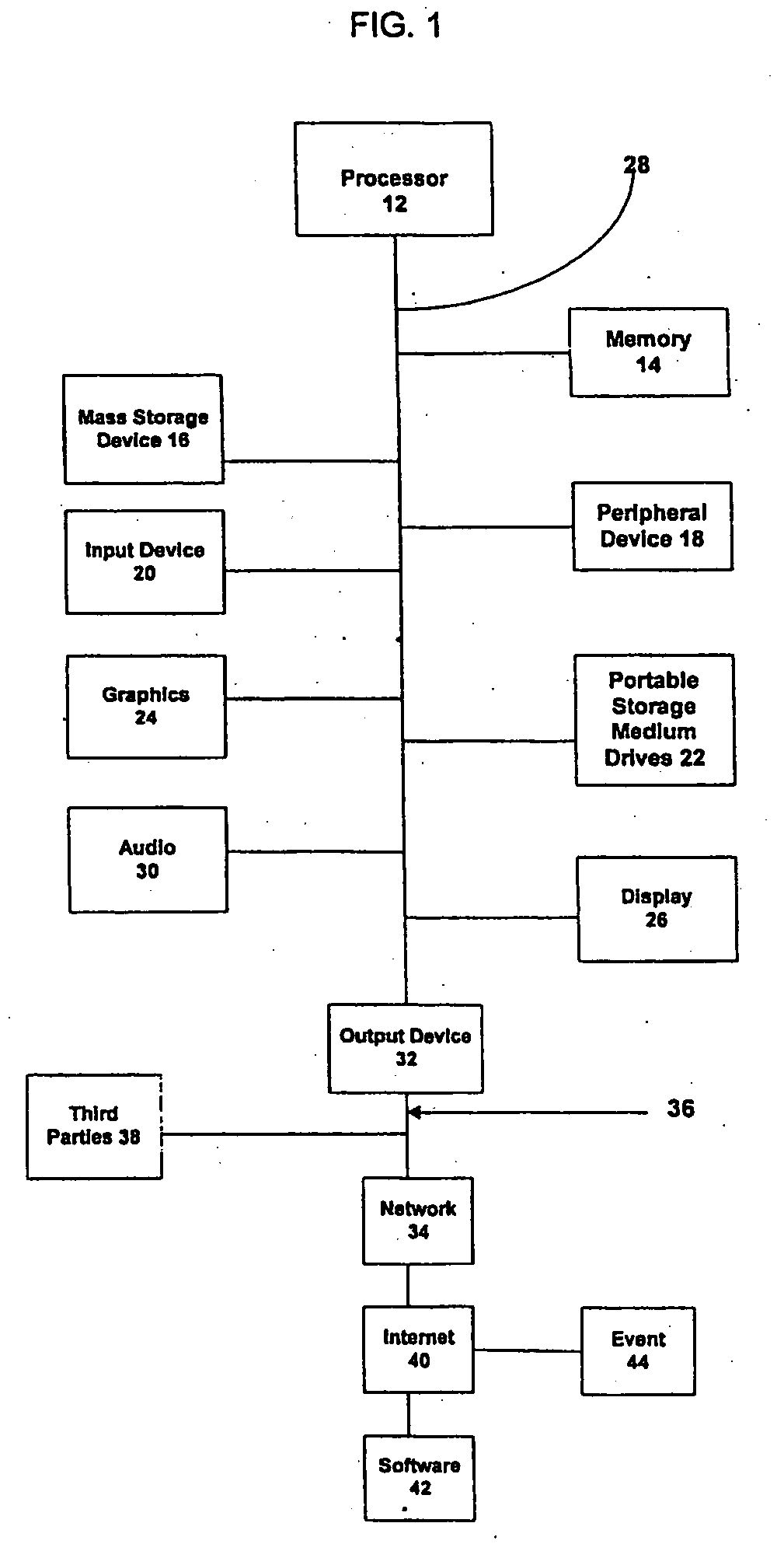

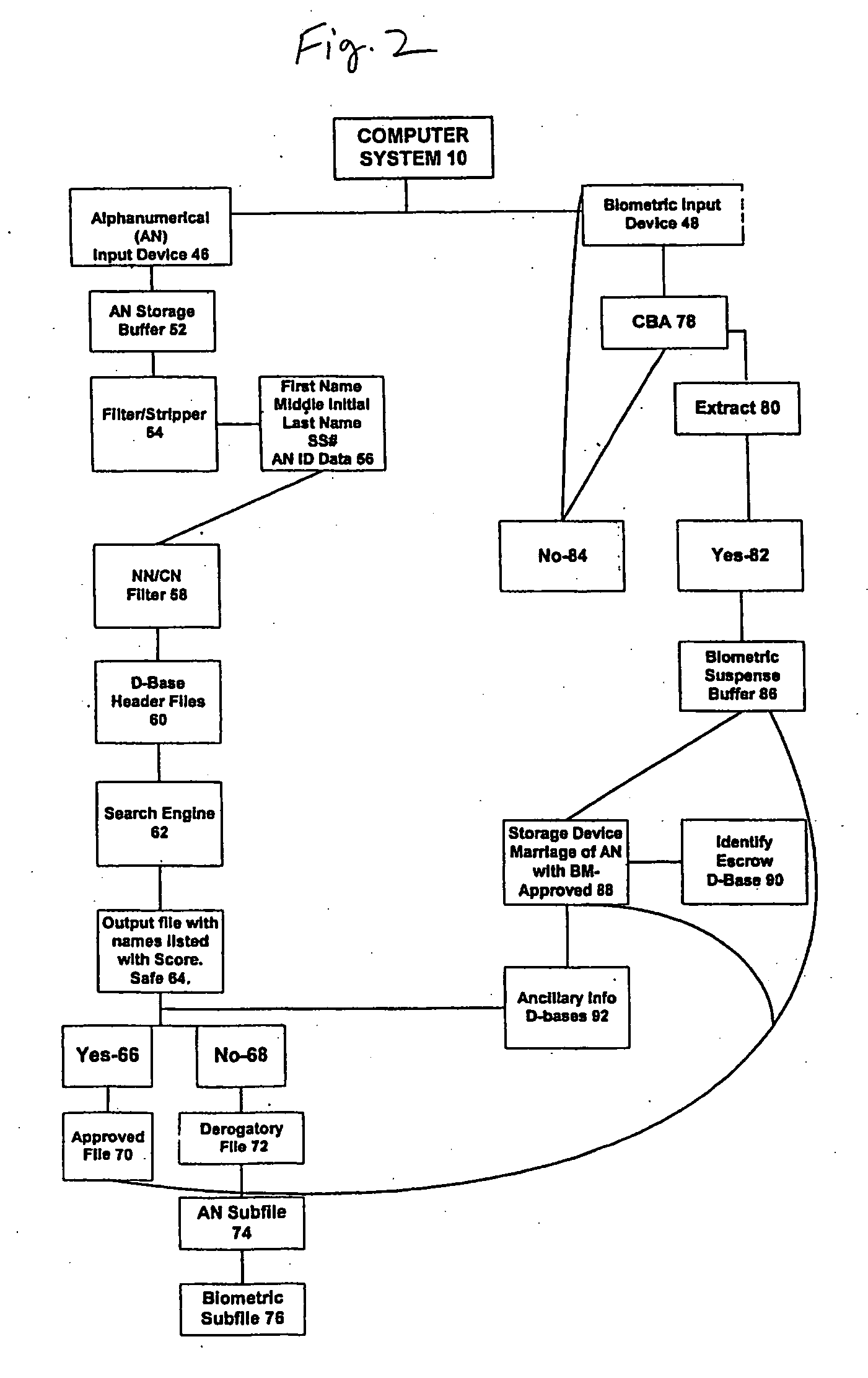

System and method for verification of identity

InactiveUS6871287B1Secure deliverySafe handlingFinanceDigital data processing detailsBiometric dataUser input

A system and method for the identification and verification of a user is provided. The disclosed invention has an enrollment system which includes (i) an alphanumeric input device; (ii) a biometric input device; (iii) a header file database having a plurality of identities; (iv) a search engine in communication with the header file database that searches the database for identifies that match alphanumeric data input by a user according to a predetermined first set of criteria; (v) a processor to score the set of identities matched by the search engine according to a predetermined second set of criteria, and determine that the user's input alphanumeric data based on the score is not suspicious; and (vi) an identity escrow database which receives an approved identity data signal based on the acceptability of the score, and is capable of receiving a biometric identity data signal input by the user to the biometric input device, the escrow database further capable of creating at least one subfile within the escrow database for each user comprising the approved identity data signal and the biometric data signal.

Owner:EDENTIFY INC

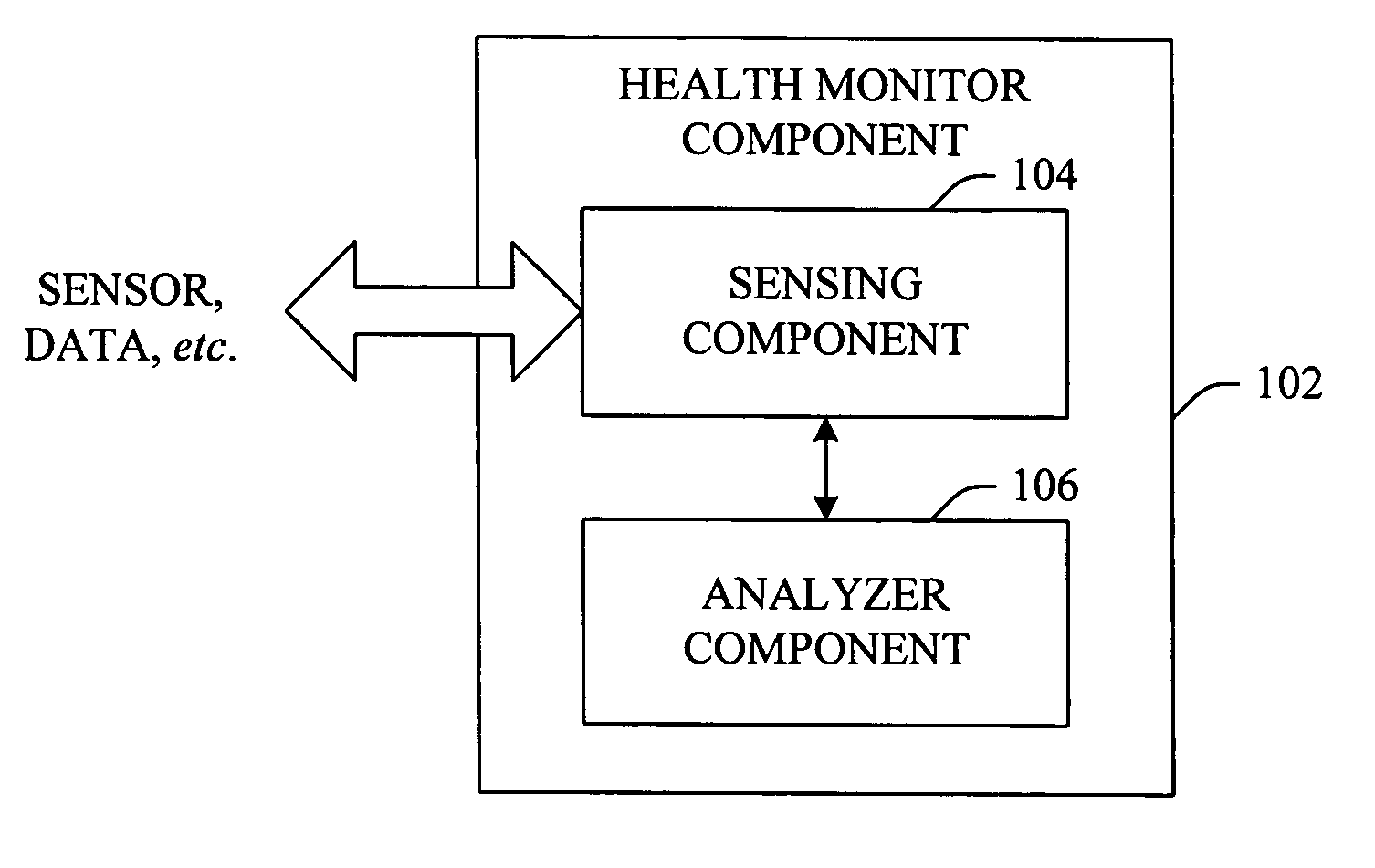

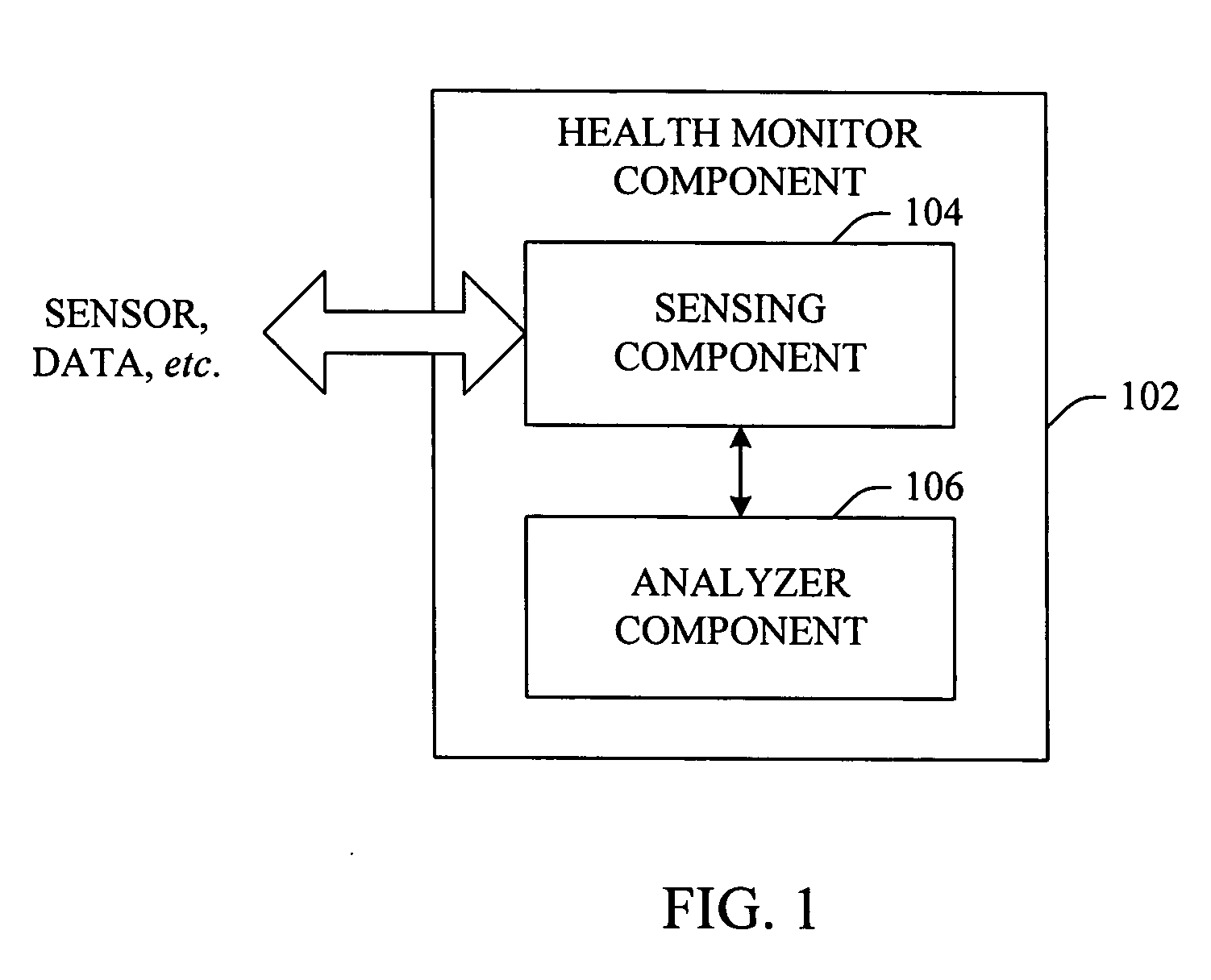

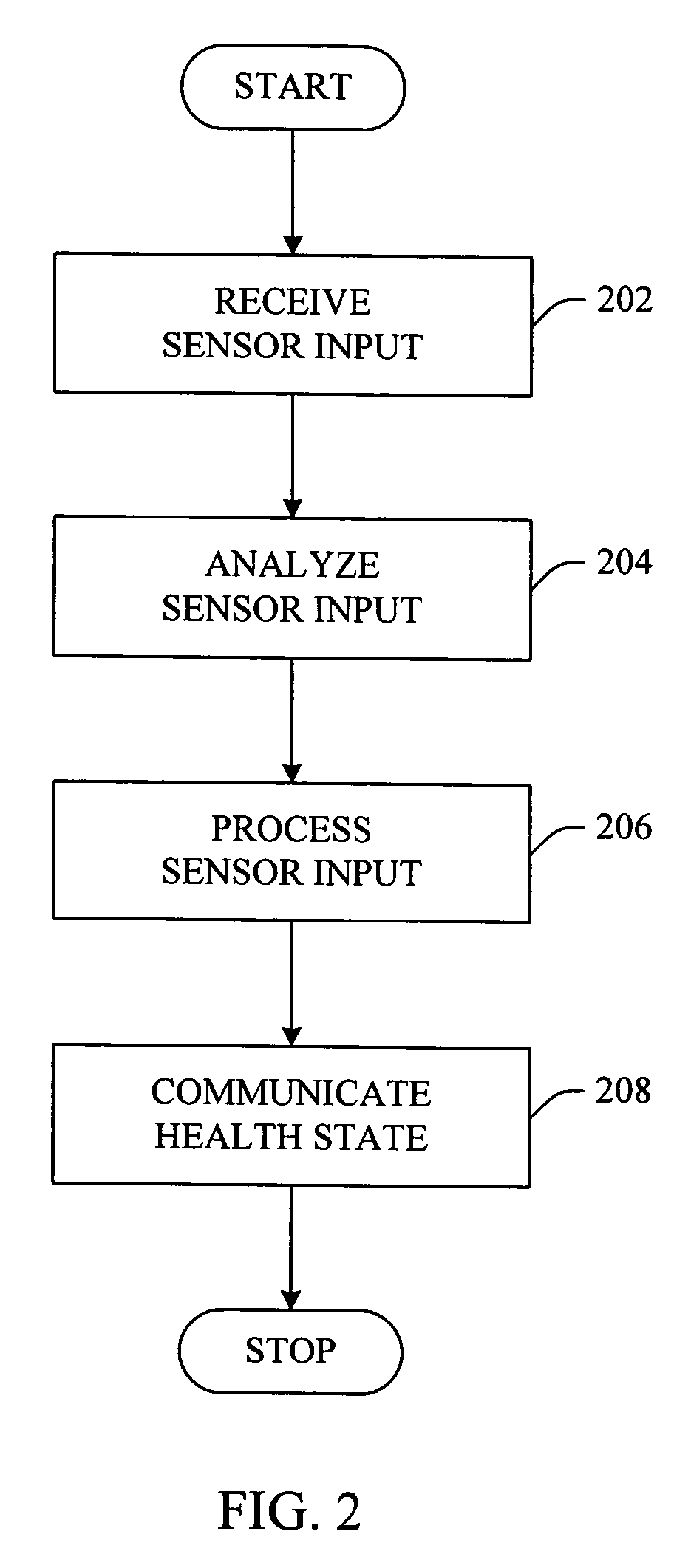

Health monitor

InactiveUS20070004969A1Safe handlingFunction increaseDiagnostic recording/measuringSensorsPreventive healthcareDriver/operator

A device and / or devices can be placed on an individual to continuously collect and / or transmit information regarding the health state of the individual. The monitor, for example, can transmit data to doctor(s), hospital(s), emergency personnel, as well as automatically initiate affirmative actions (e.g., call an ambulance). The invention can facilitate preventive medicine by monitoring the individual's day to day actions (e.g., eating habits, exercise, stress, sleep, allergy detection, heart rate, blood sugar). This monitored information can be employed to facilitate the individual in taking proactive steps to living a healthy life. The device can also be used to record a user reaction to an event and / or to broadcast information about oneself whether for health, business or social purposes. Additionally, the invention can be used as a driver monitor to facilitate safe handling of equipment (e.g., alcohol sensor).

Owner:MICROSOFT TECH LICENSING LLC

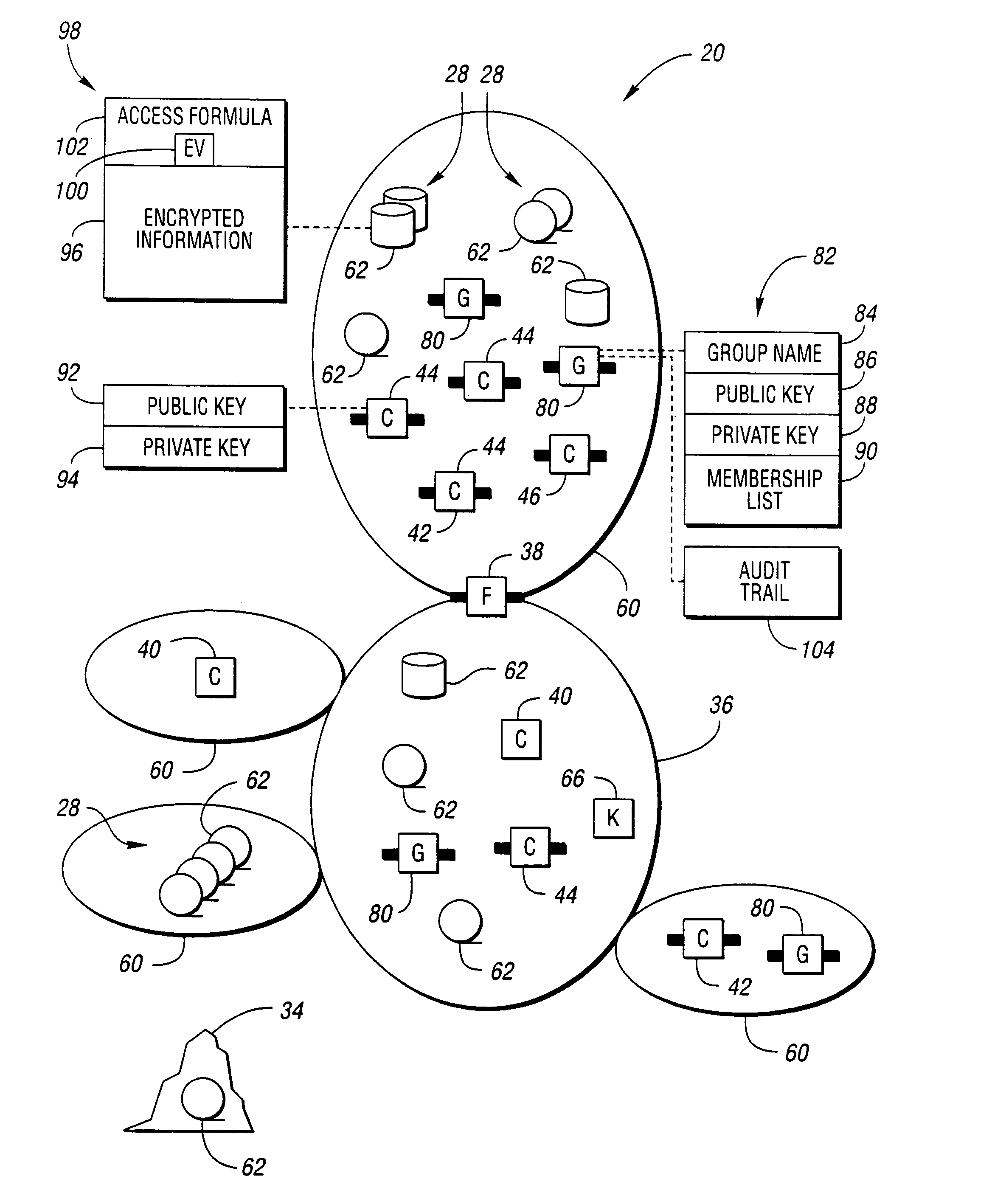

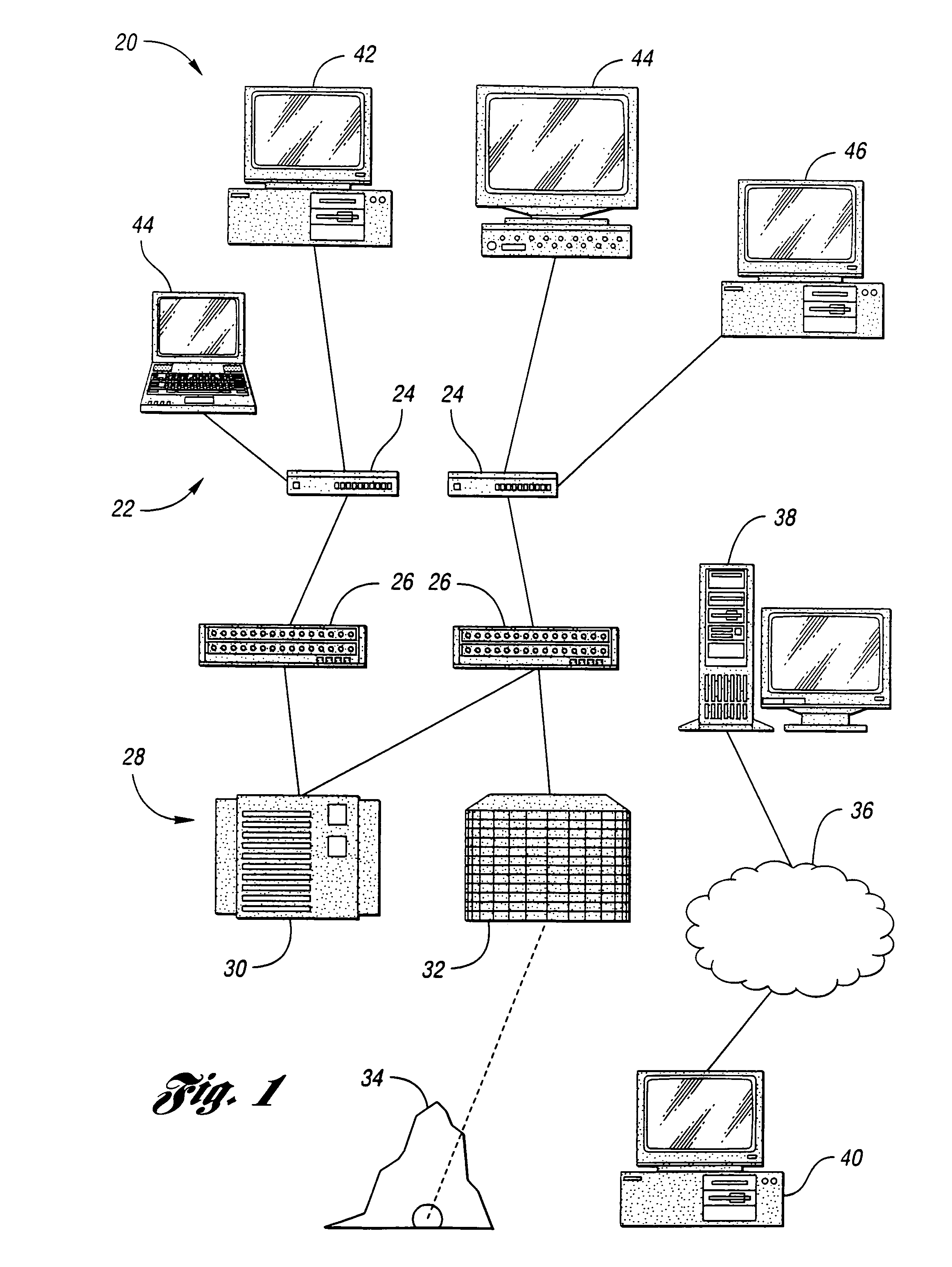

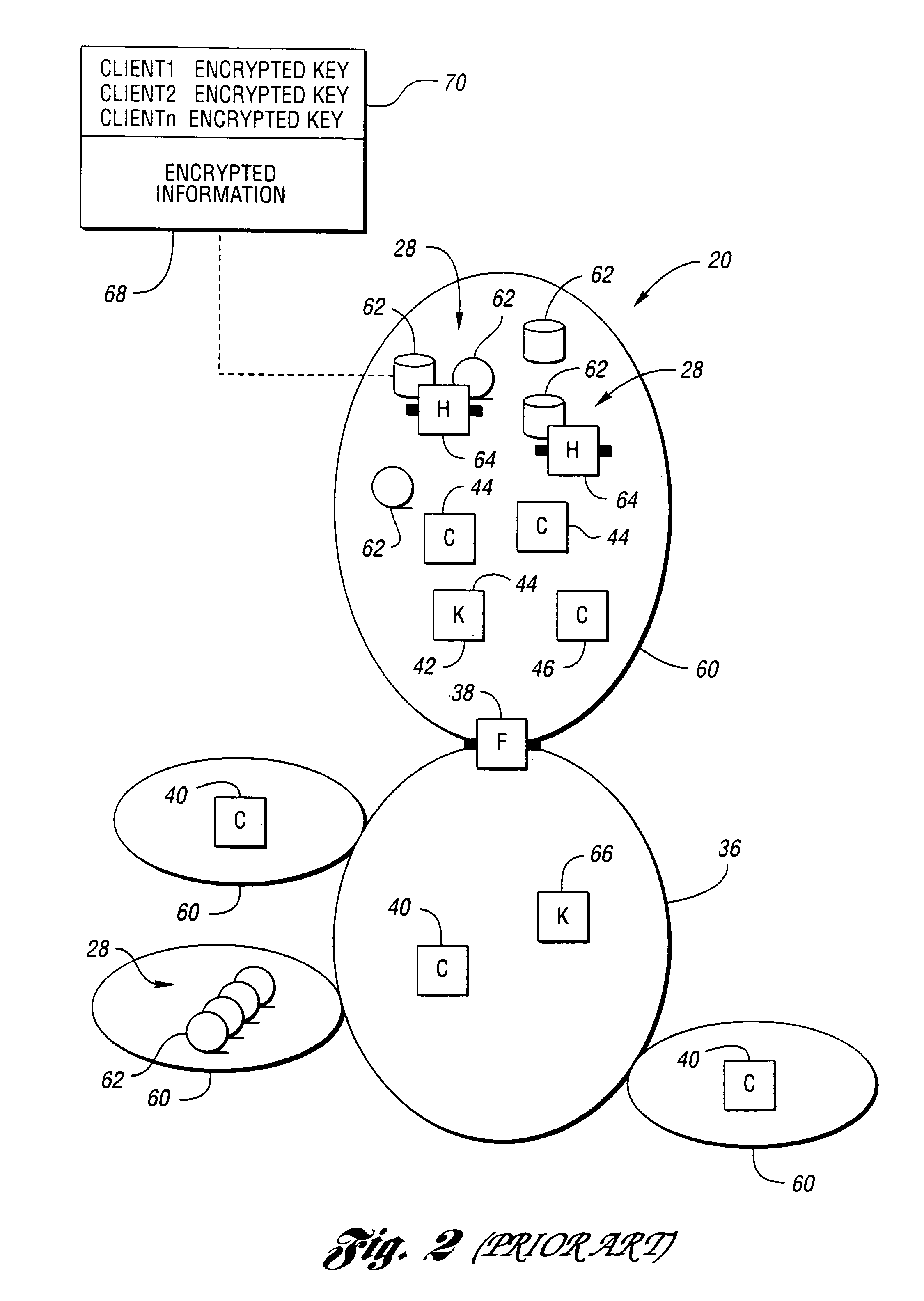

Method and system for secure information handling

InactiveUS6957330B1Safe handlingSafe storageKey distribution for secure communicationUser identity/authority verificationClient-sideSecurity information

Information that must remain secure is often stored on untrusted storage devices. To increase security, this information is encrypted by an encryption value prior to storing on the untrusted storage device. The encryption value itself is then encrypted. The encryption value is decrypted by correctly solving an access formula describing a function of groups. Each group includes a list of at least one consumer client. A requesting consumer client is granted access to the information if the requesting consumer client is a member of at least one group which correctly solves the access formula.

Owner:ORACLE INT CORP

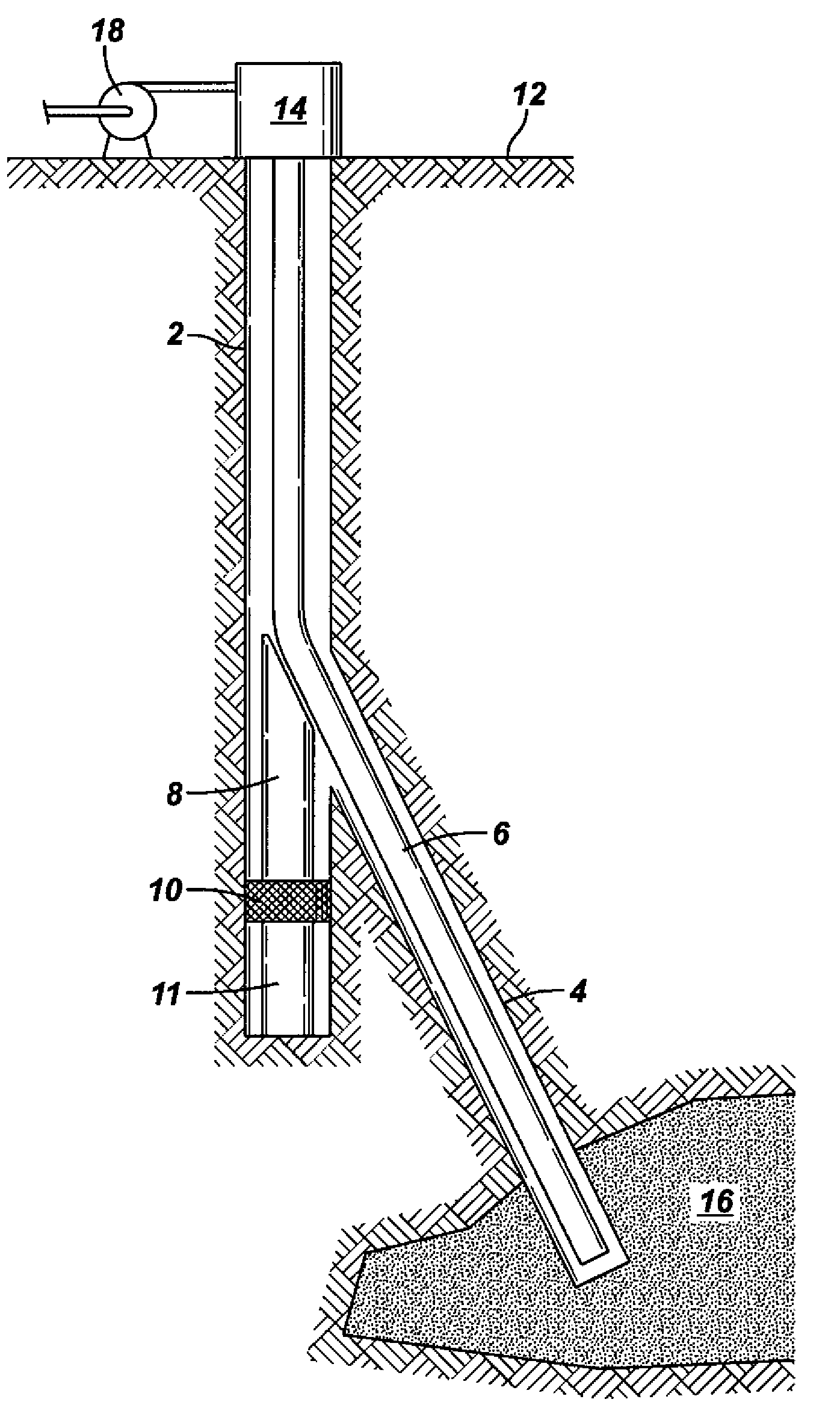

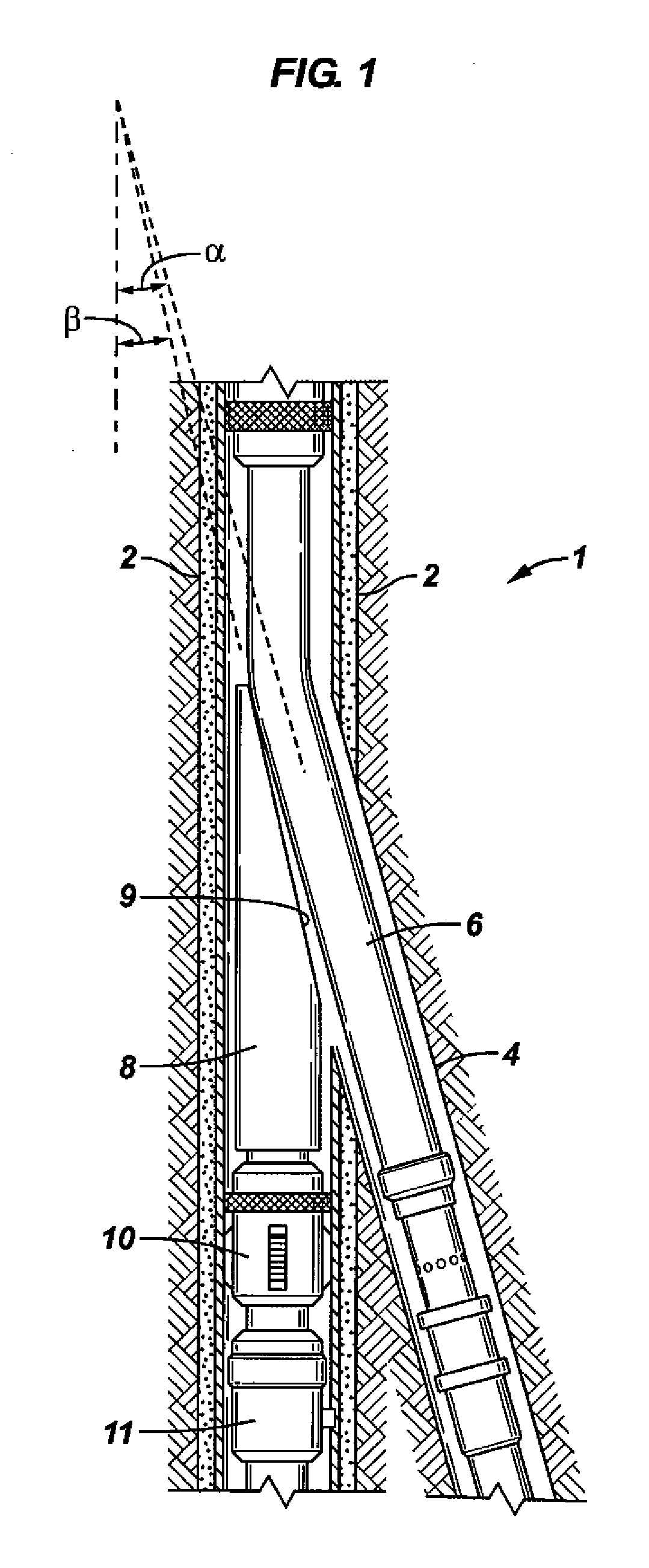

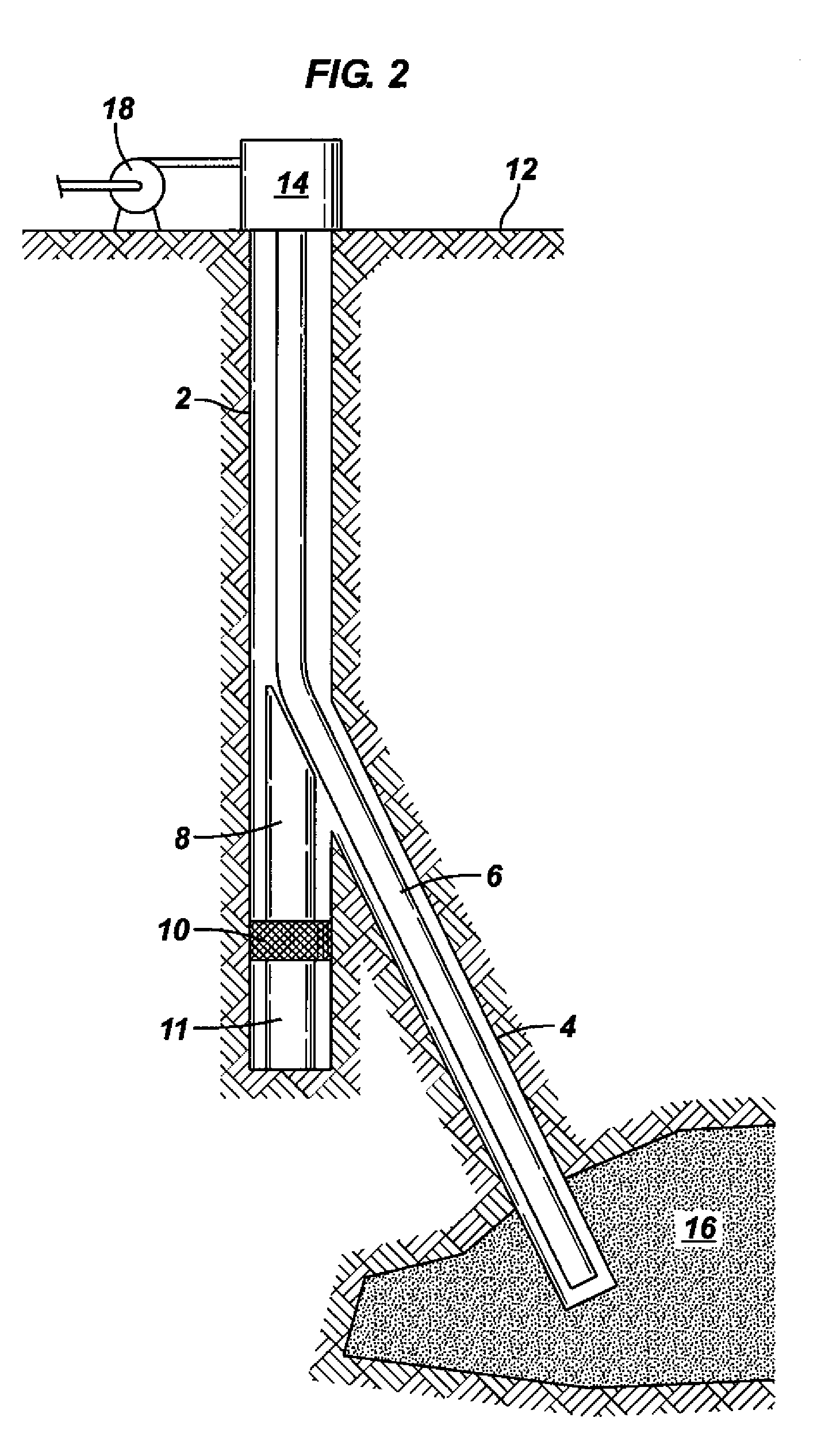

Degradable whipstock apparatus and method of use

InactiveUS20080105438A1Improve responseSafe handlingFluid removalDirectional drillingSubject matterHigh intensity

Whipstocks and deflectors comprising a degradable composition, and methods of using same are described. In one embodiment the degradable composition consists essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Methods of using degradable whipstocks in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. 1.72(b).

Owner:SCHLUMBERGER TECH CORP

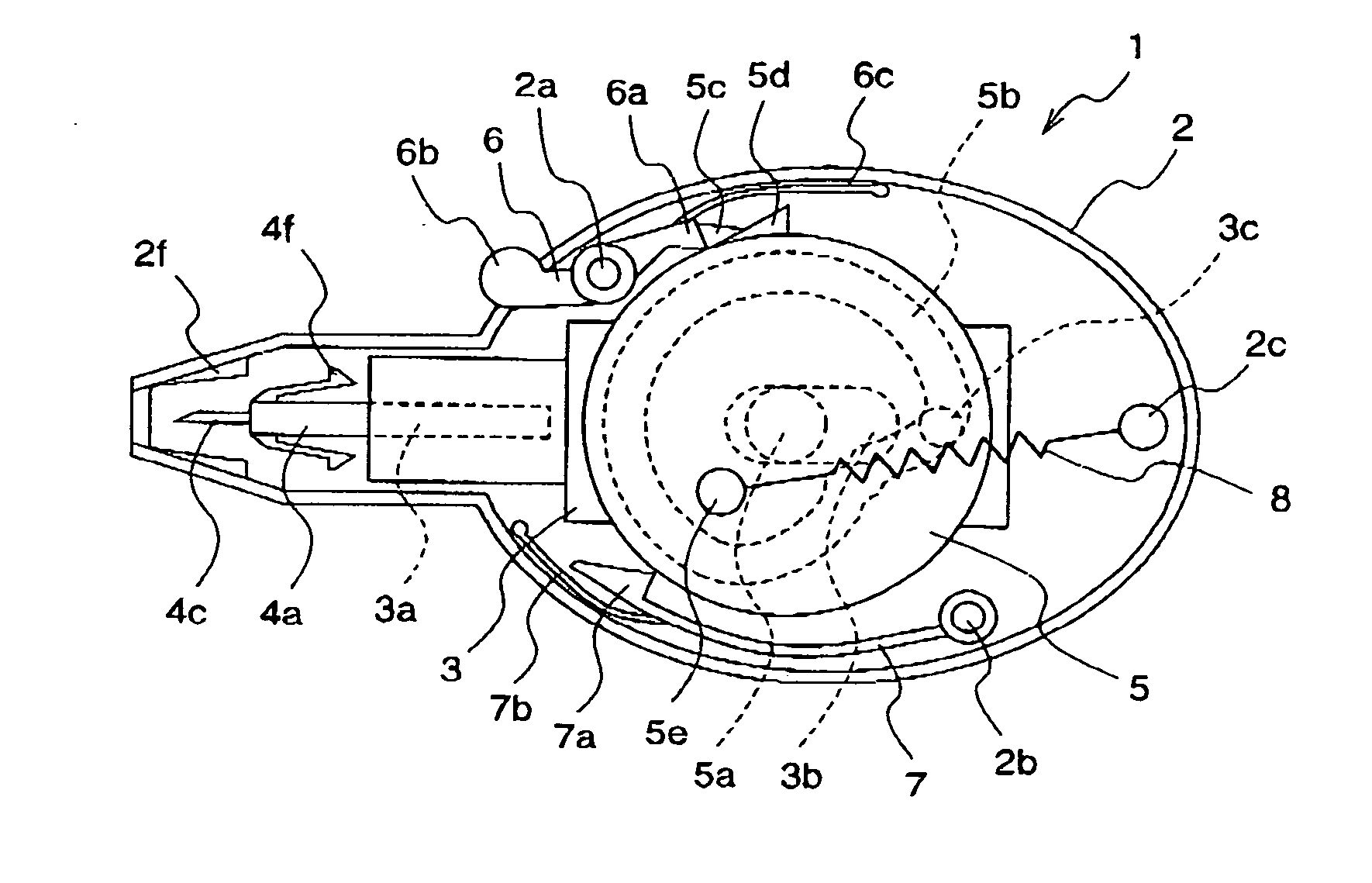

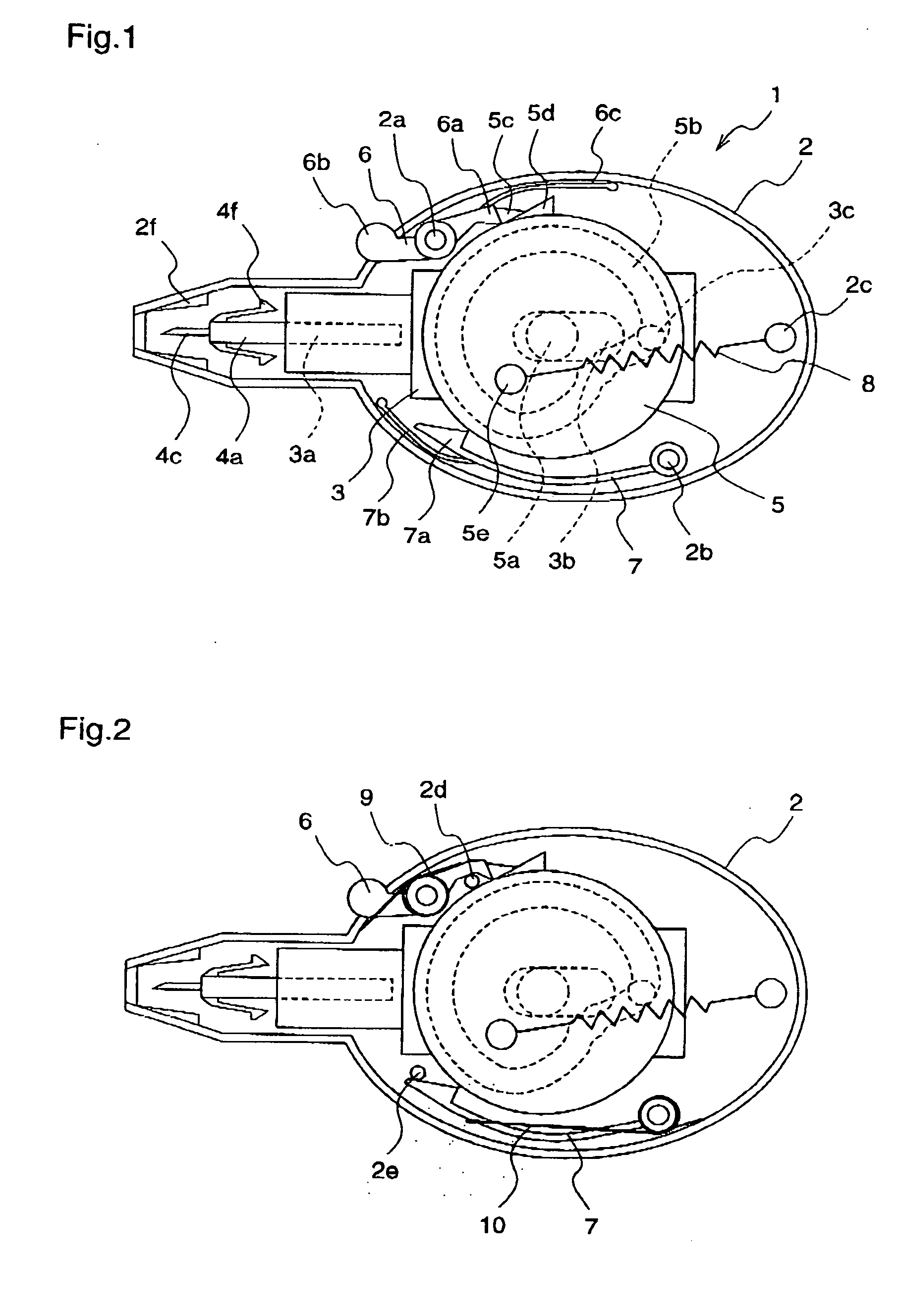

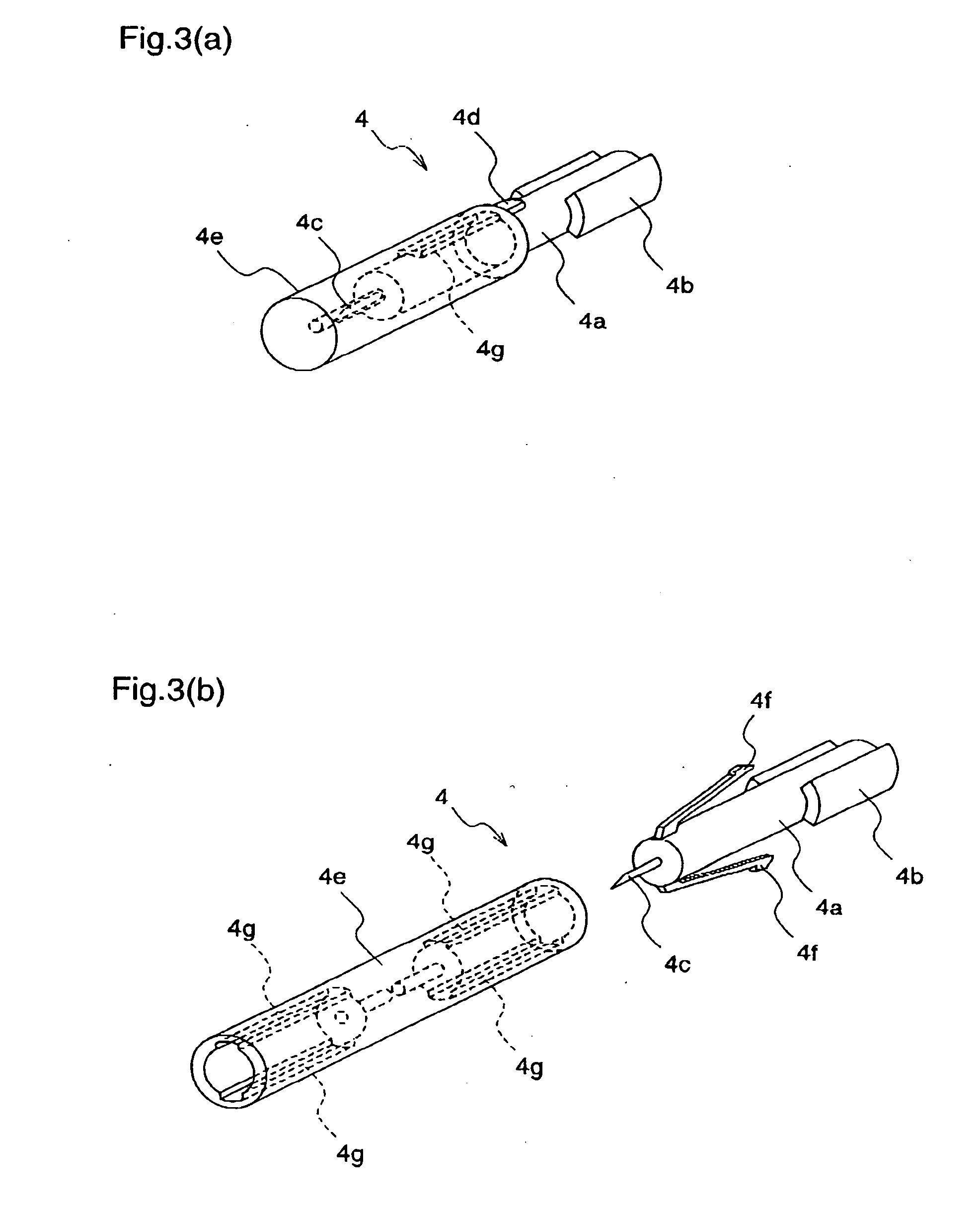

Lancet for blood collection and puncture needle unit

InactiveUS20050131441A1Safely discardedEasy to useSensorsBlood sampling devicesBlood collectionEngineering

A lancet comprises a slider having a puncture needle holding mechanism at its one end; a cam ring which has a continuous cam groove, is rotatable about a support shaft, and has a cam ring claw and an anti-return claw for restricting the rotation; a ring spring for applying a force to rotate the cam ring; a rotatable stopper arm for holding and releasing the rotation of the cam ring; and a rotatable ratchet for restricting the direction of rotation of the cam ring. A puncture needle unit comprises a puncture needle body which is integrally molded with a protrusion to be fitted to the lancet, a rotation stop rib, and a puncture needle; and a puncture needle cap which is lightly pressed into the puncture needle body.

Owner:PHC HLDG CORP

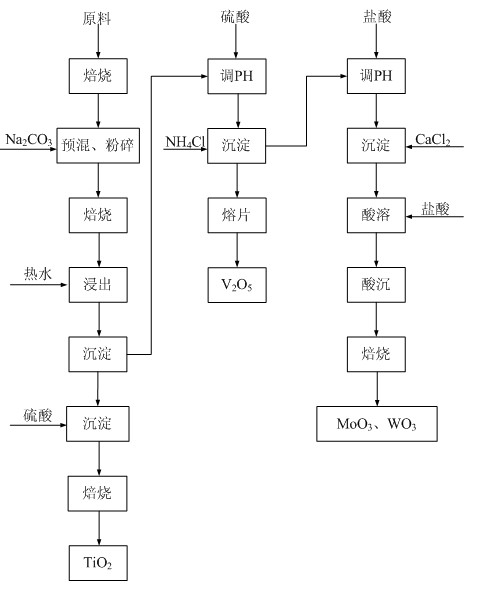

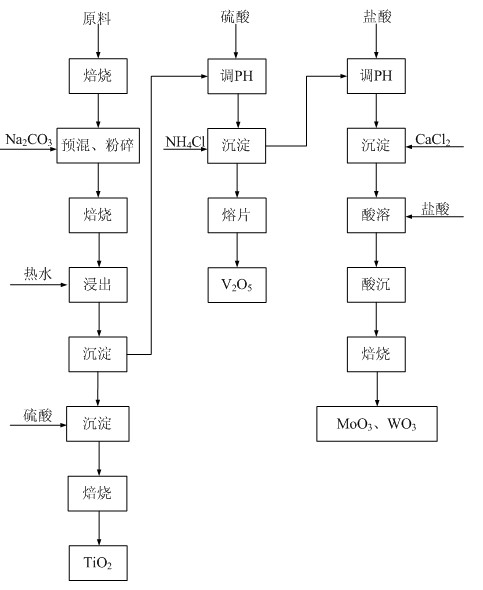

Method for recycling metal oxide from waste flue gas denitration catalyst

The invention discloses a method for recycling a metal oxide from a waste flue gas denitration catalyst, comprising the following steps of: crushing the waste flue gas denitration catalyst to carry out pre-roasting pretreatment at high temperature; adding Na2CO3 into the waste flue gas denitration catalyst according to the proportion, mixing, pulverizing and roasting at high temperature to obtain a sintering block; crushing the sintering block and putting the crushed sintering block into hot water, and stirring and lixiviating to obtain titanate; adding sulphuric acid into the titanate, filtering, water-washing and roasting to obtain TiO2; adding the sulphuric acid into the lixiviated filtering liquid to regulate a pH value to 8.0-9.0; adding excessive NH4Cl for vanadium precipitation; decomposing NH4VO3 obtained from filtering at high temperature to prepare a V2O5 product; adding hydrochloric acid into the filtering liquid subjected to the vanadium precipitation to regulate a pH value to 4.5-5.0; adding CaCl2 for molybdenum and tungsten precipitation; treating the CaM0O4 and CaWO4, obtained from filtering, with the hydrochloric acid and roasting to obtain MoO3 and WO3. The method of the invention has the advantages of simple process and apparatus, high recycling efficiency, good product technical data, large treatment capacity and the like.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

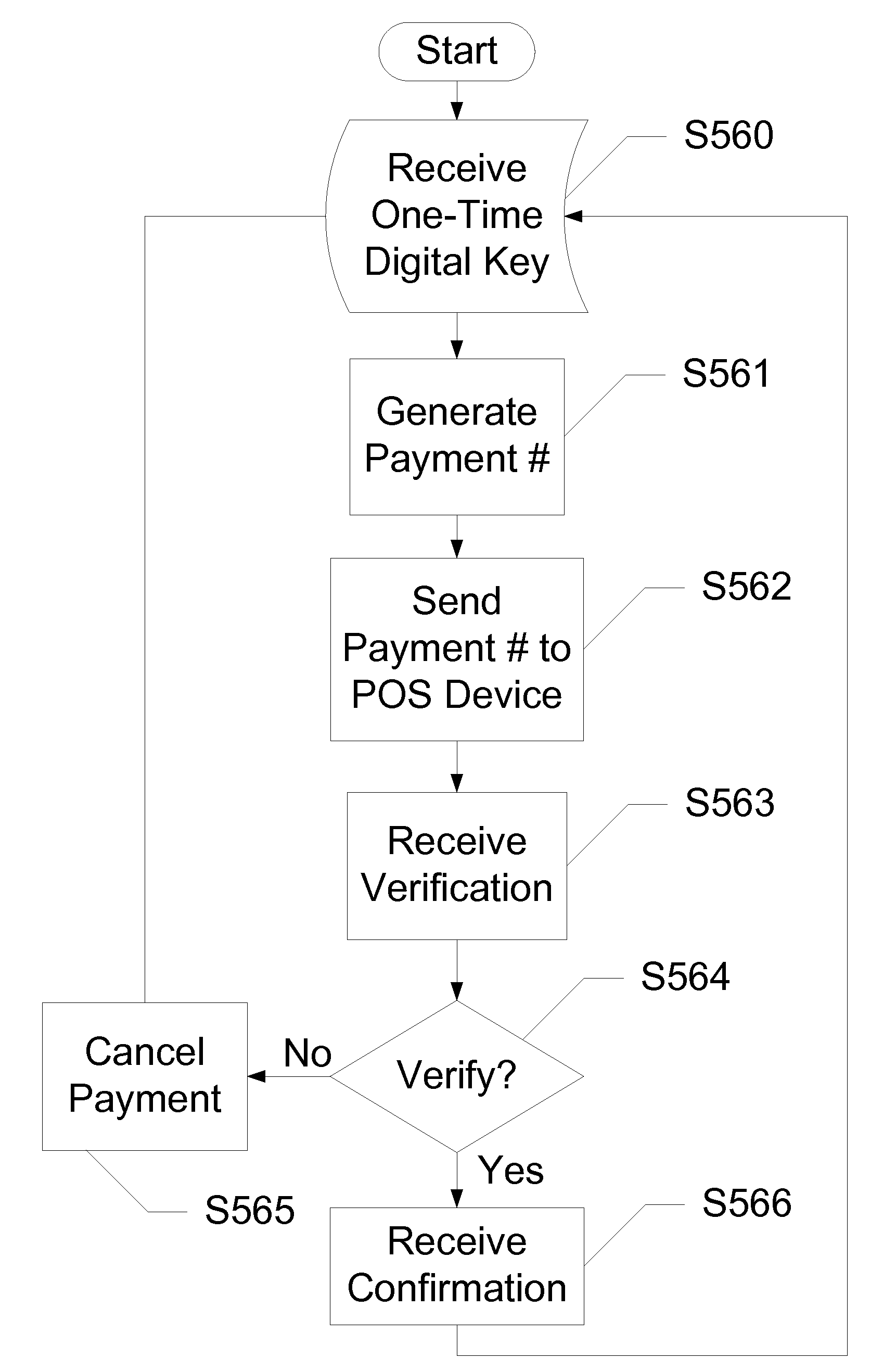

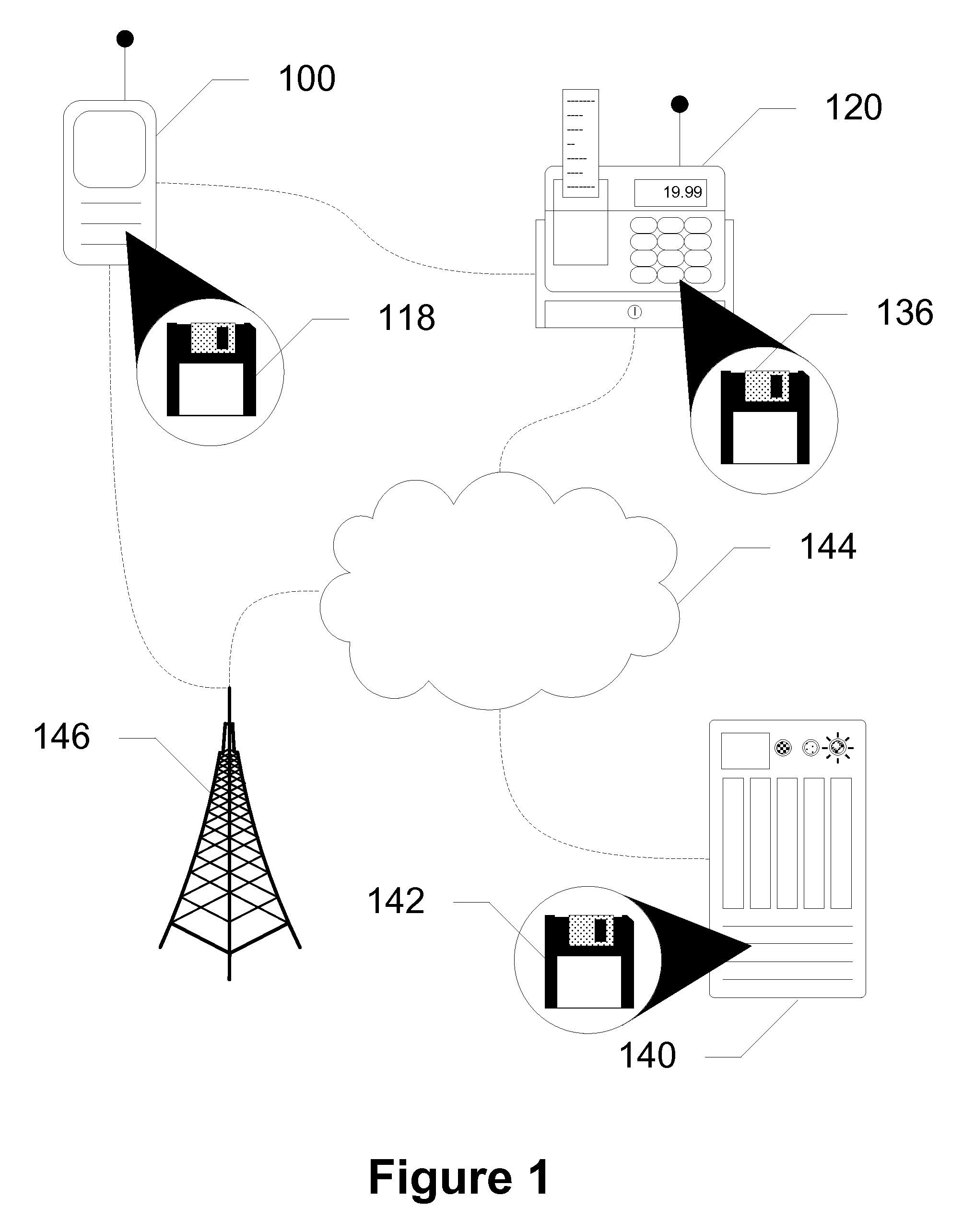

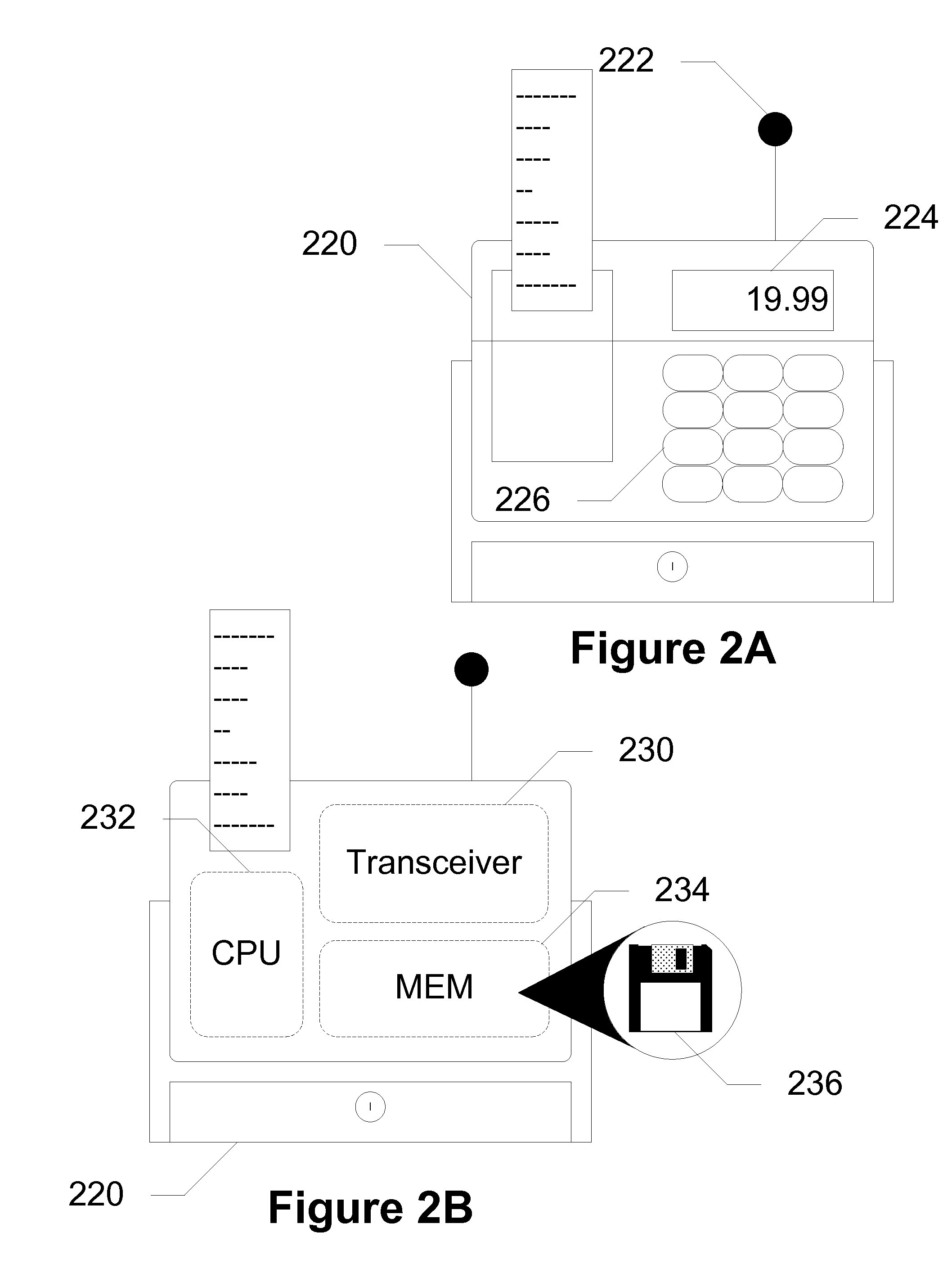

Secure Mobile-Based Financial Transactions

ActiveUS20110099079A1Limited in potentialSafe handlingHand manipulated computer devicesFinanceClient-sidePayment order

Devices, systems and methods are disclosed which relate to securing payments from a mobile communications device. In exemplary embodiments, a mobile communications device communicates with a payment server via a point-of-sale device to conduct a transaction. The mobile communications device uses a client payment logic to send payment information to the point-of-sale device. The point-of-sale device uses a vendor payment logic to forward the payment information to the payment server. The payment server verifies the payment information and sends confirmation to the point-of-sale device.

Owner:AT&T MOBILITY II LLC

Degradable compositions, apparatus comprising same, and method of use

InactiveUS8211247B2Improve responseSafe handlingDrilling compositionSealing/packingSubject matterDisplacement control

Owner:SCHLUMBERGER TECH CORP

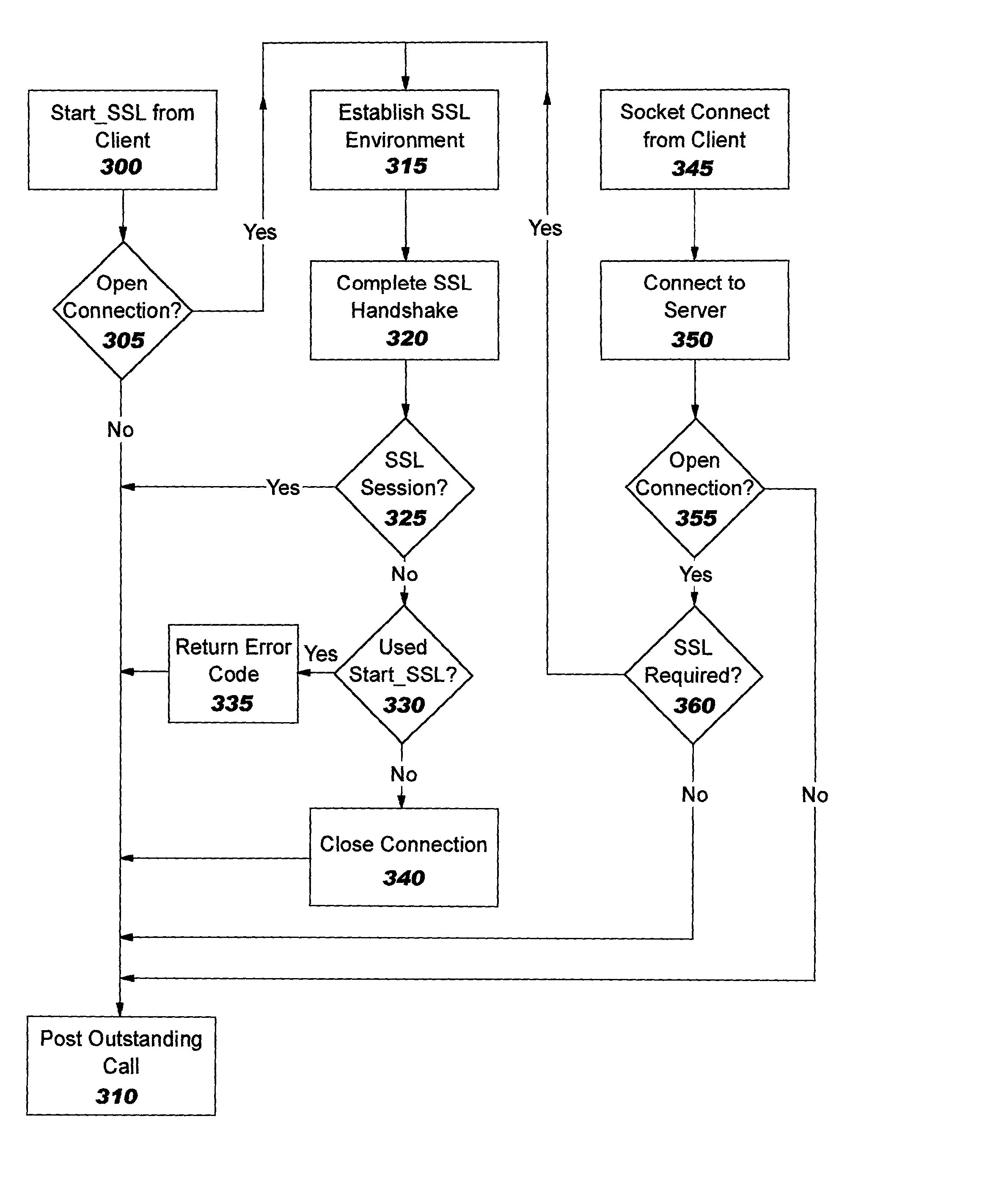

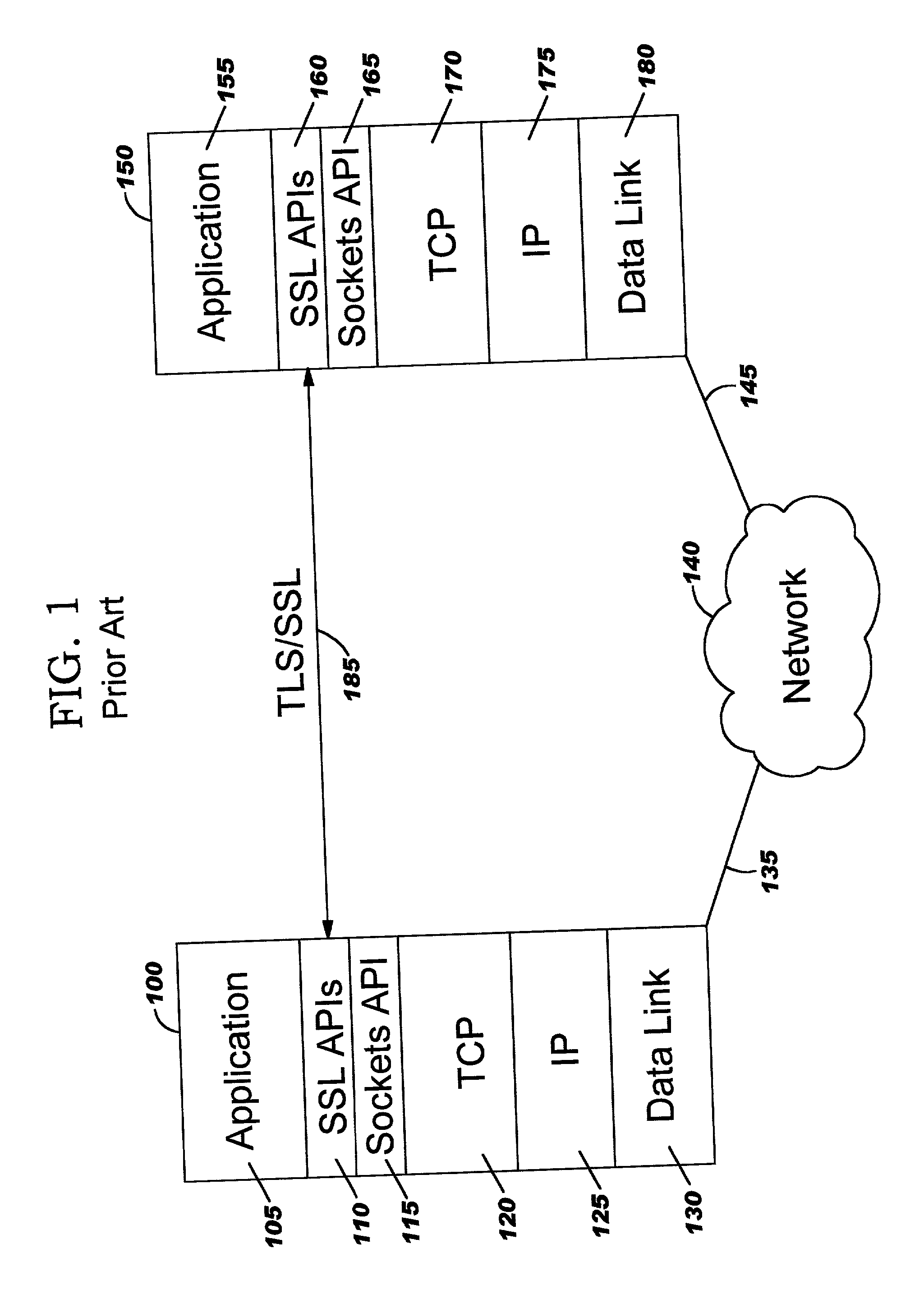

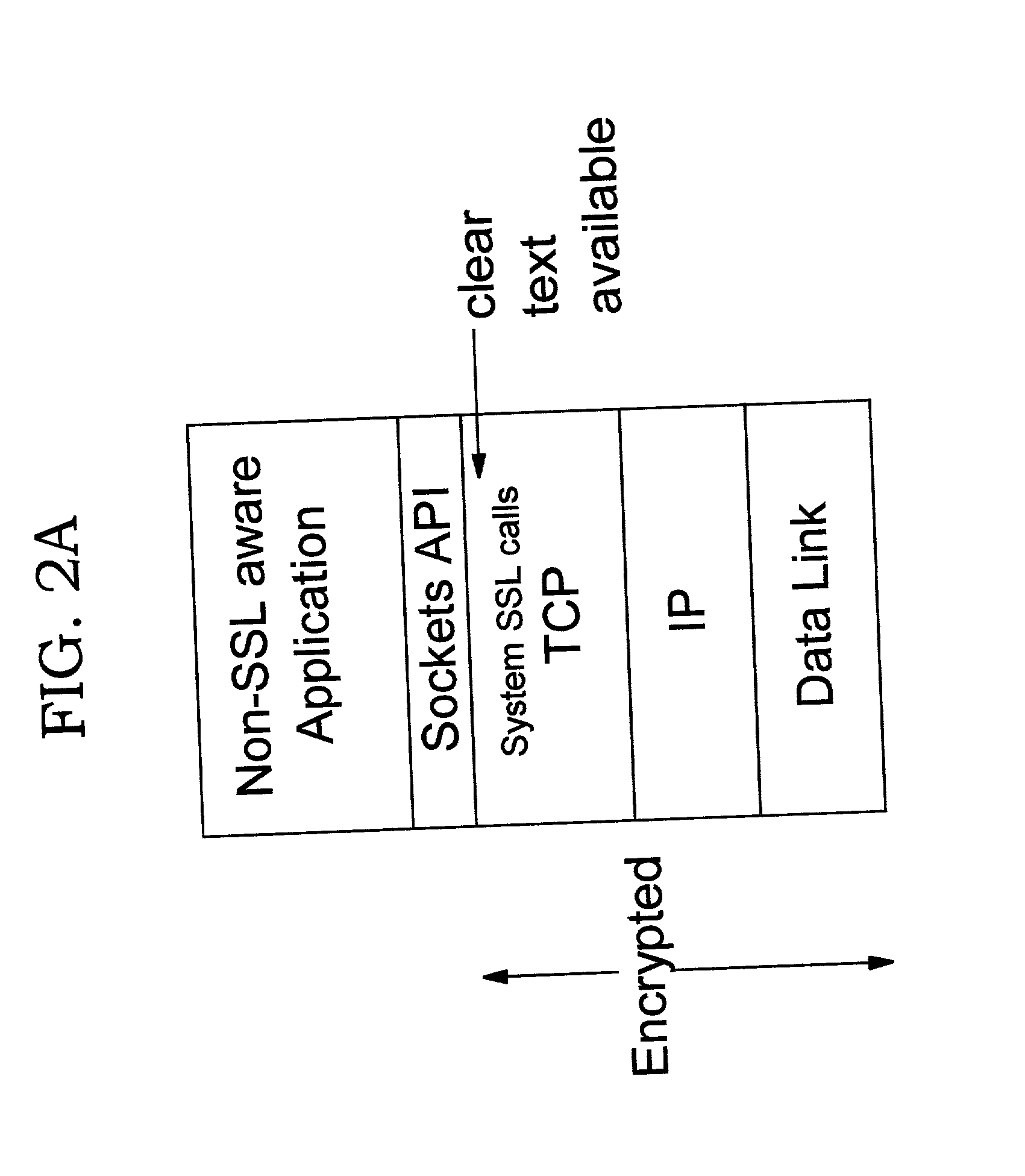

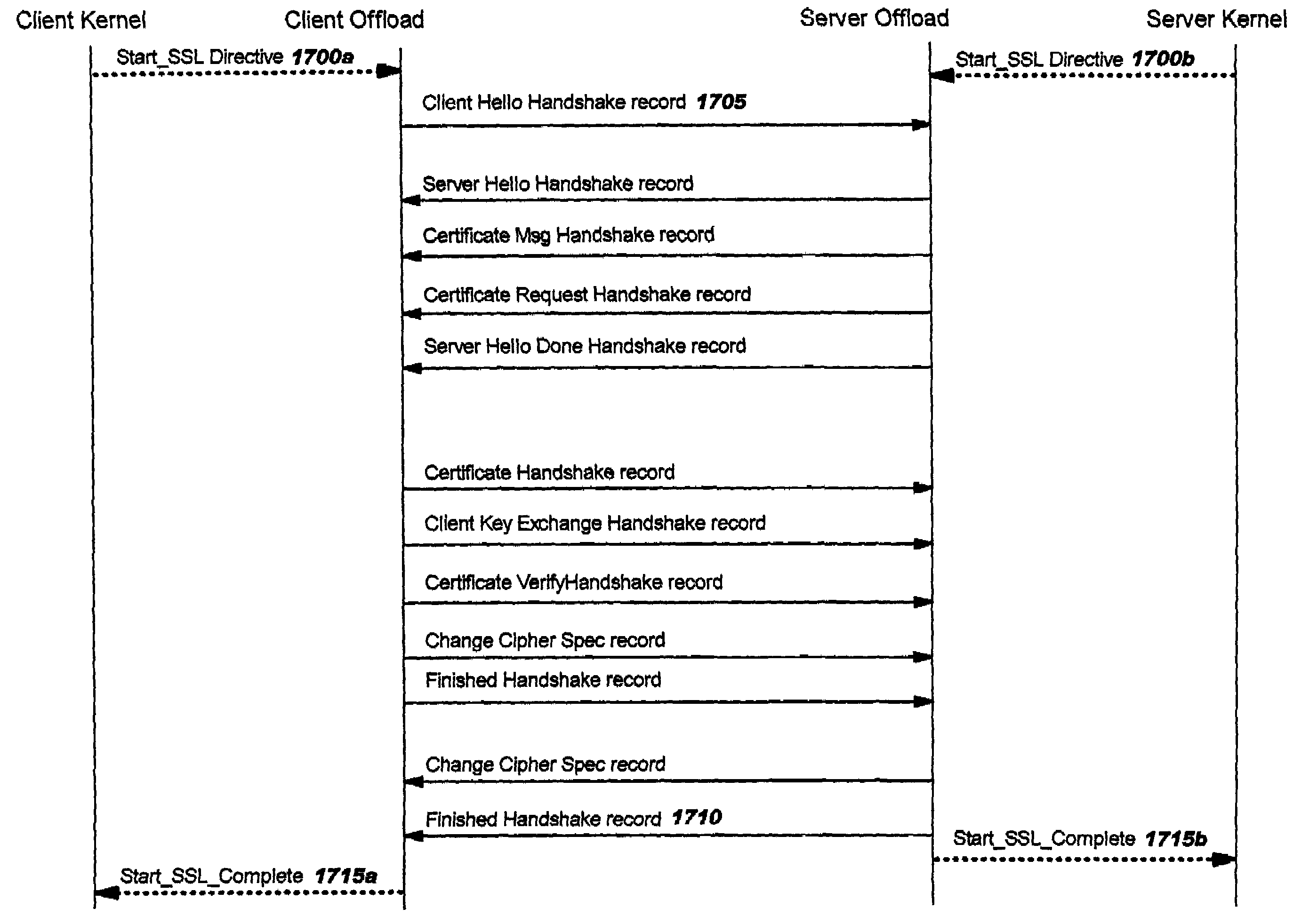

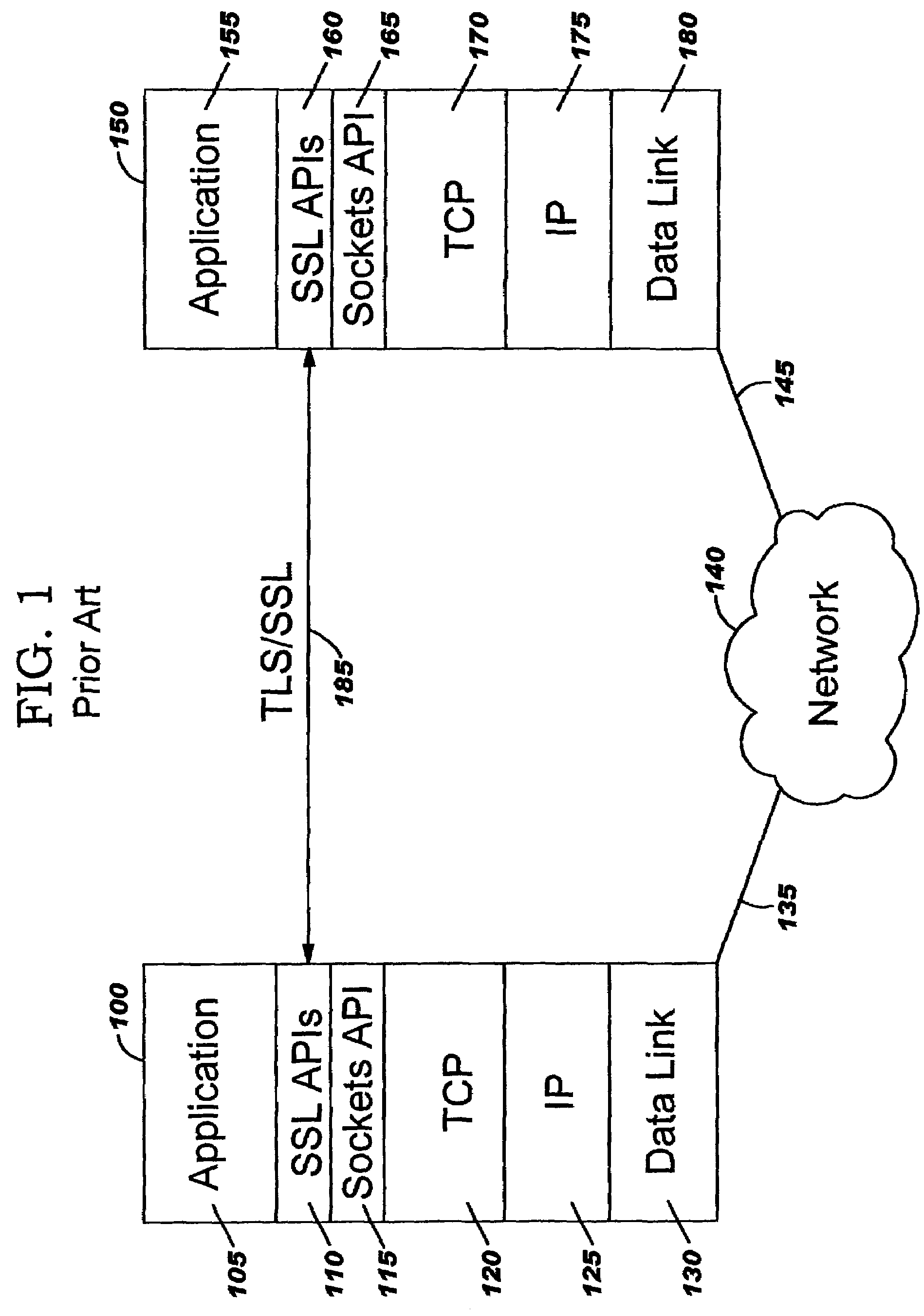

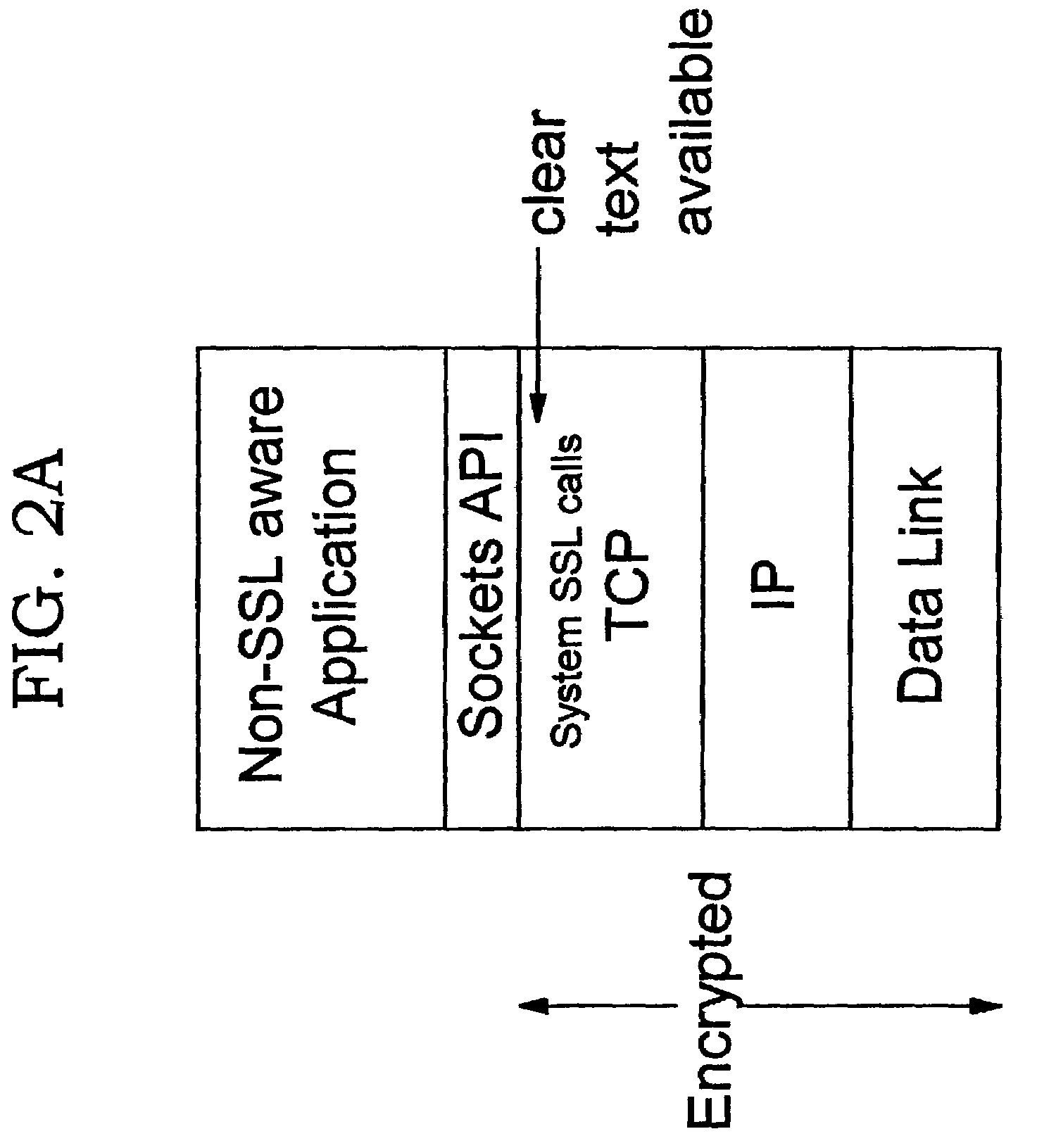

Offload processing for secure data transfer

InactiveUS20030105977A1Safe handlingMultiple digital computer combinationsProgram controlPlaintextSafe handling

Improvements in security processing are disclosed which enable security processing to be transparent to the application. Security processing (such as Secure Sockets Layer, or "SSL", or Transport Layer Security, or "TLS") is performed in (or controlled by) the stack. A decision to enable security processing on a connection can be based on configuration data or security policy, and can also be controlled using explicit enablement directives. Directives may also be provided for allowing applications to communicate with the security processing in the stack for other purposes. Functions within the protocol stack that need access to clear text can now be supported without loss of security processing capability. No modifications to application code, or in some cases only minor modifications (such as inclusion of code to invoke directives), are required to provide this security processing. Improved offloading of security processing is also disclosed, which provides processing efficiencies over prior art offloading techniques.

Owner:IBM CORP

System and method for verification of identity

InactiveUS20050216953A1Secure deliverySafe handlingDigital data processing detailsCharacter and pattern recognitionThird partyBiometric data

A system for verifying identities comprising an enrollment system having: (i) at least one alphanumeric input device; (ii) at least one biometric input device; (iii) at least one header file database having a plurality of identities; (iv) at least one search engine, said search engine in communication with said header file database such that said search engine first receives an alphanumeric data signal which has been input into said alphanumeric input device by the user, and then searches said database for identities that match the alphanumeric data according to a predetermined first set of criteria; (v) a processor to score the set of identities matched by said search engine according to a predetermined second set of criteria, said processor capable of determining the acceptability or unacceptability of said user's input alphanumeric data based on said score; and (vi) an identity escrow database which is in communication with said processor and receives from said unit an approved identity data signal based on the acceptability of the score, said escrow database additionally in communication with said biometric input device capable of receiving at least one biometric identity data signal input by the user to said biometric input device, said escrow database further comprising means for coupling the approved identity data signal and the biometric identity data signal to create at least one subfile within the escrow database for each user comprising the approved identity data signal and the biometric data signal. The present invention further comprises a verification system for verifying the identity of said user after the user has enrolled in the enrollment system. The verification system has means for processing a second input biometric data signal input by the user to the biometric input device to match the user's preexisting biometric data in said escrow database according to a predetermined third set of criteria. The verification system has an output device for transmitting to a third party whether or not a match was located within said escrow database for said user. The present invention further relates to a method and system for providing a warranty against the theft of a user's identity.

Owner:ELLINGSON JOHN F

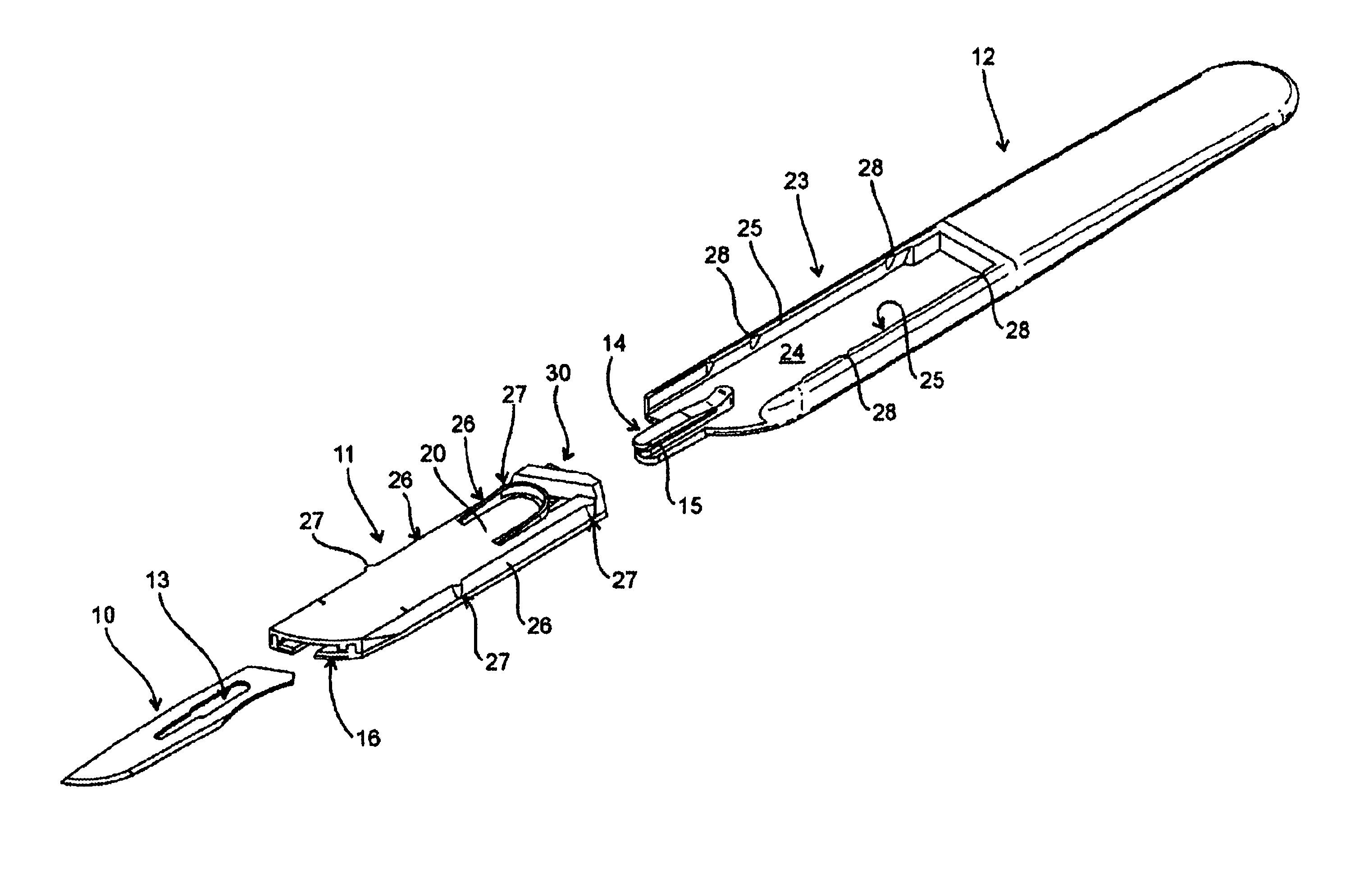

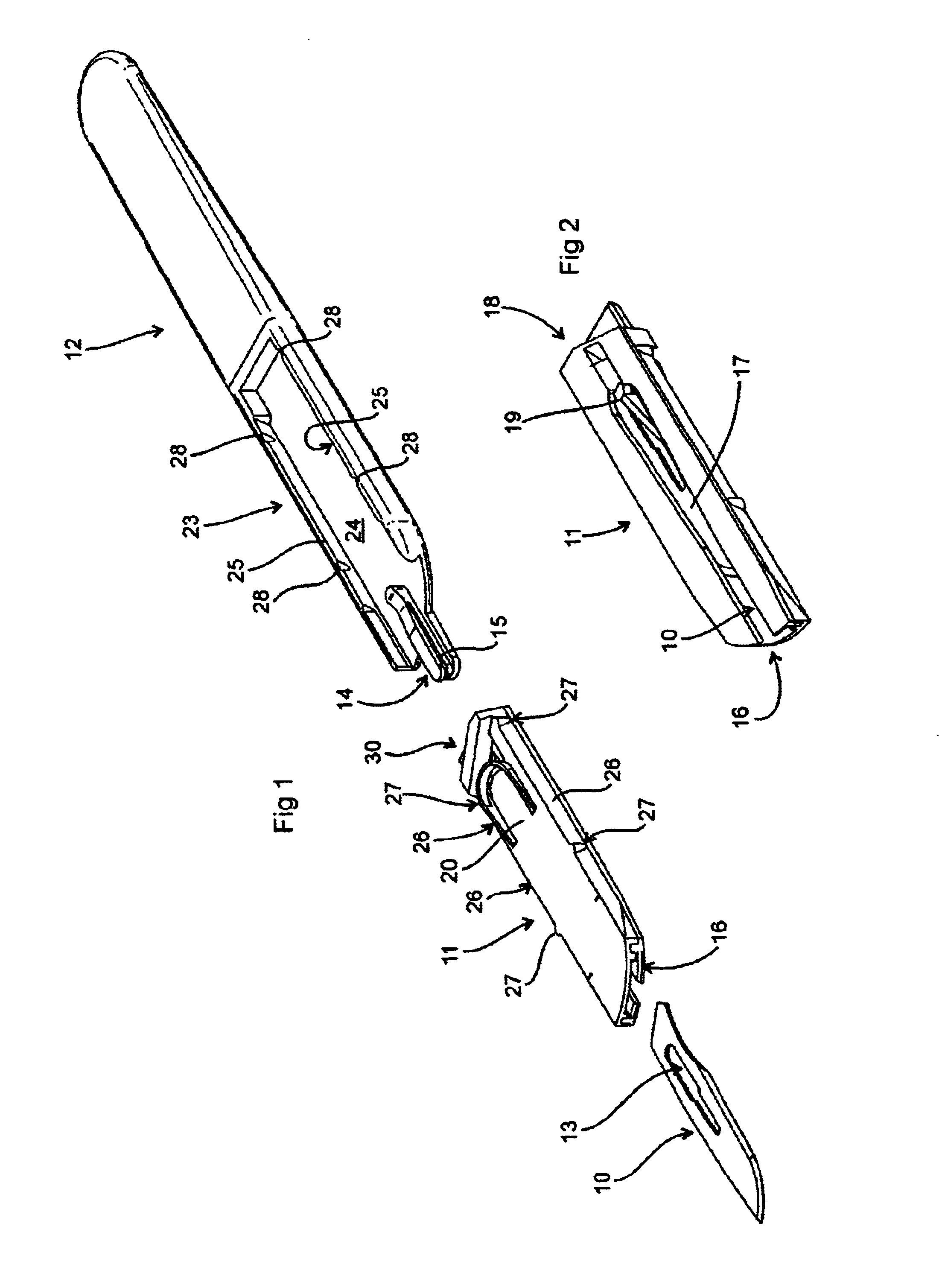

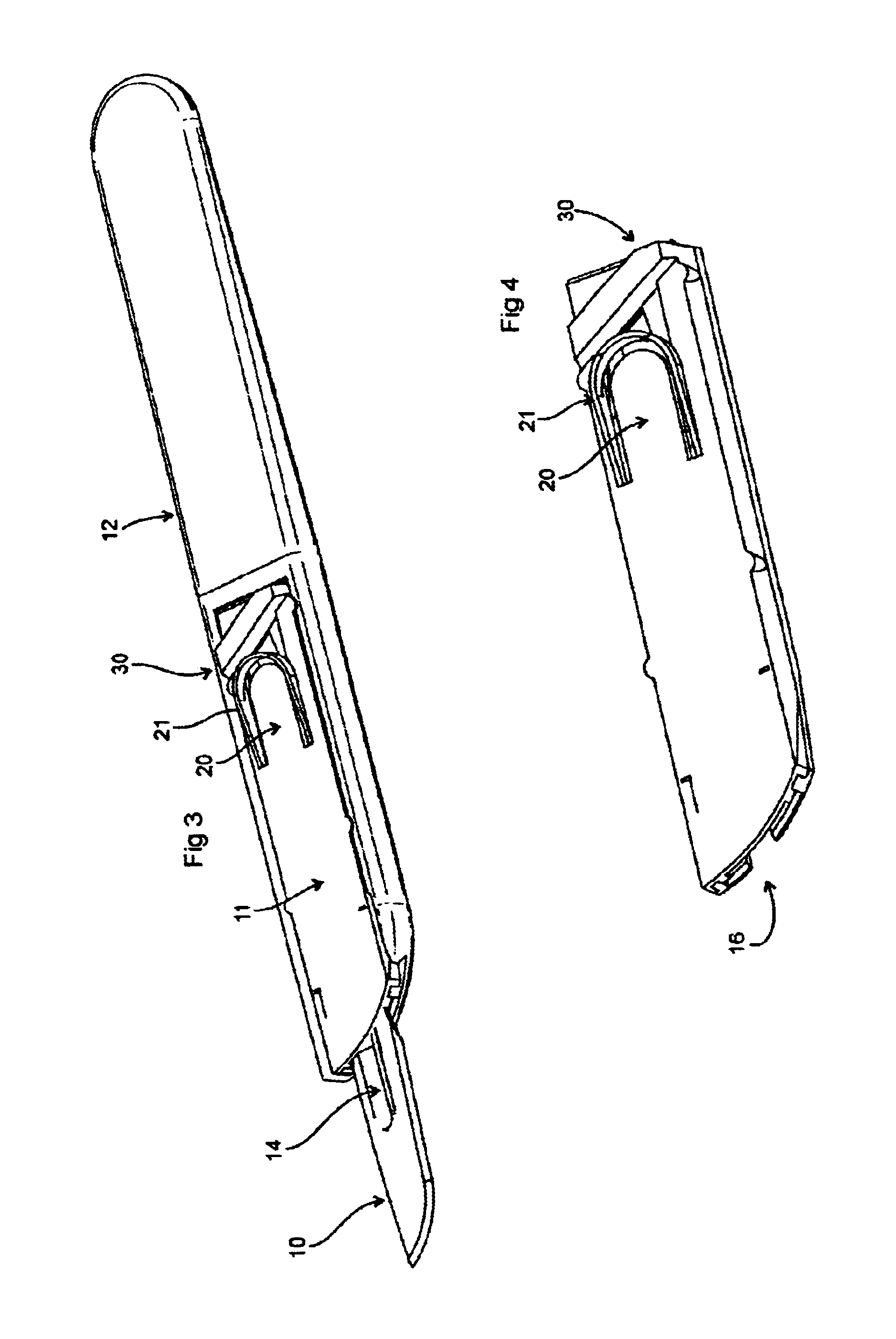

Surgical scalpel with retractable guard

InactiveUS6629985B1Safe handlingLittle risk of cuttingIncision instrumentsThrusting weaponsEngineeringSurgical department

A safety scalpel blade assembly comprising a scalpel blade, a guard which extends at least about the cutting edge of the blade, and releasable attachments device which releasably attach the blade to the guard as the assembly is being attached to the scalpel handle, thereby preventing the blade from cutting a person, but which releases the blade from the guard when the blade is attached to the blade carrier of the scalpel handle.

Owner:SOUTHMEDIC +1

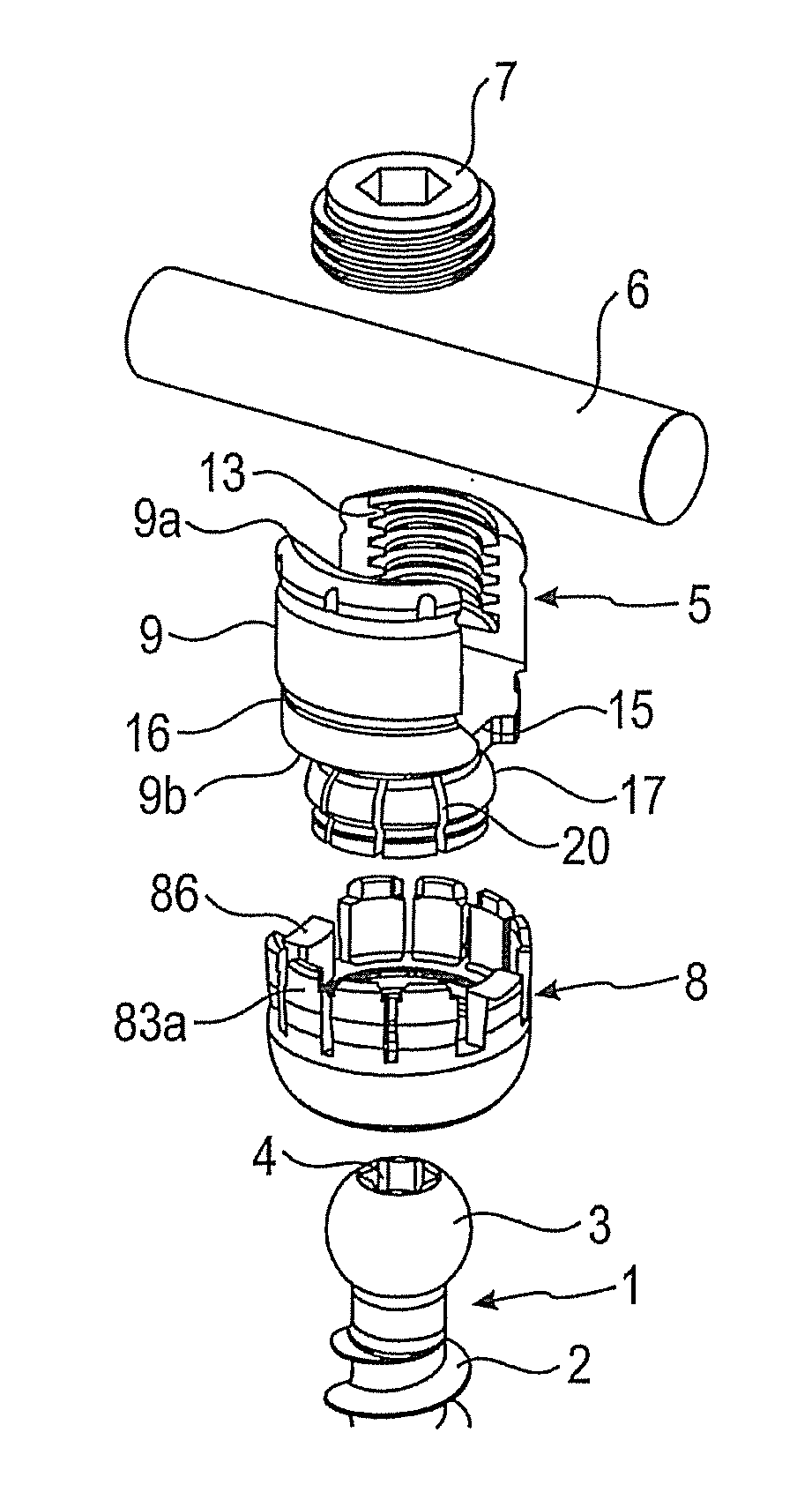

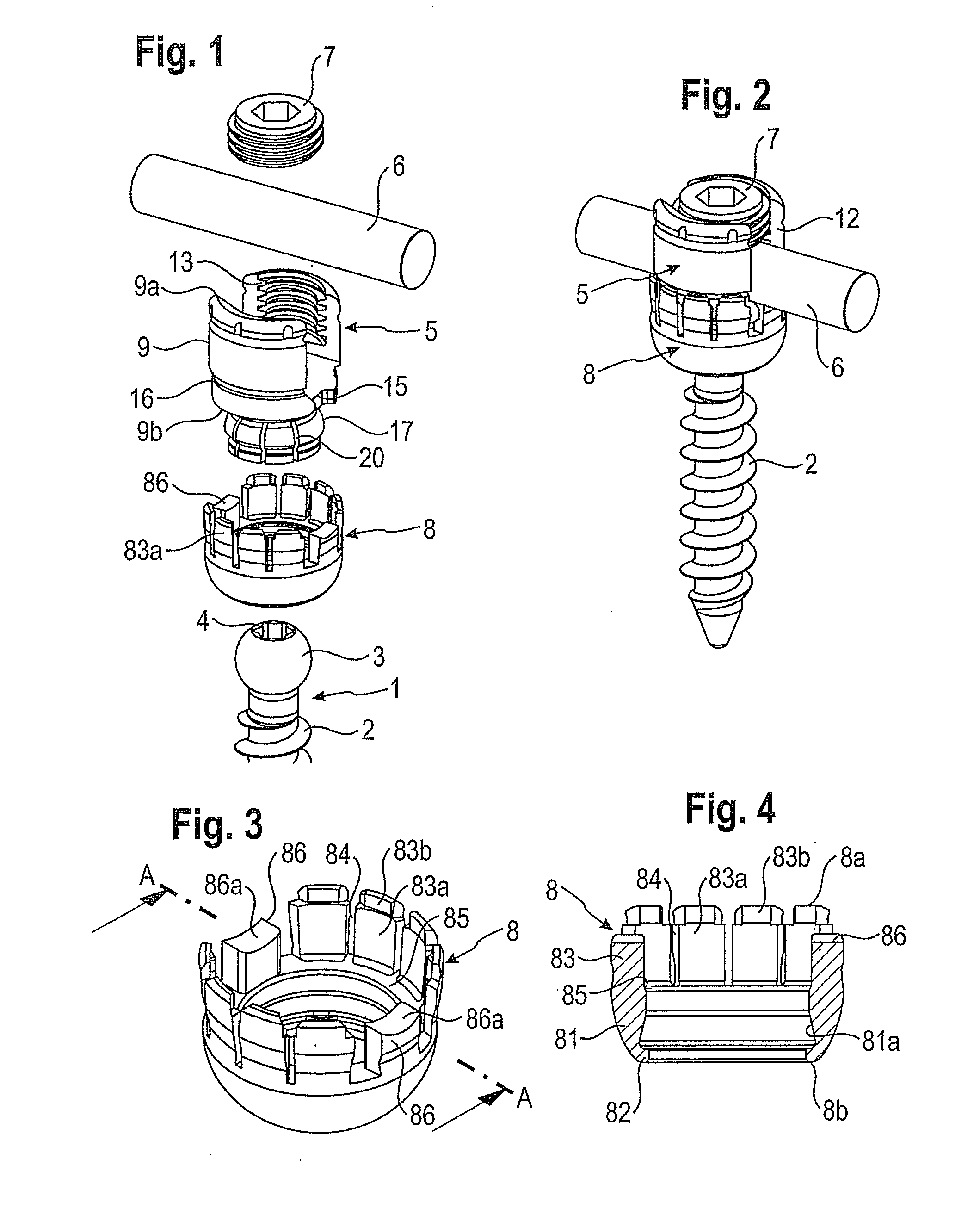

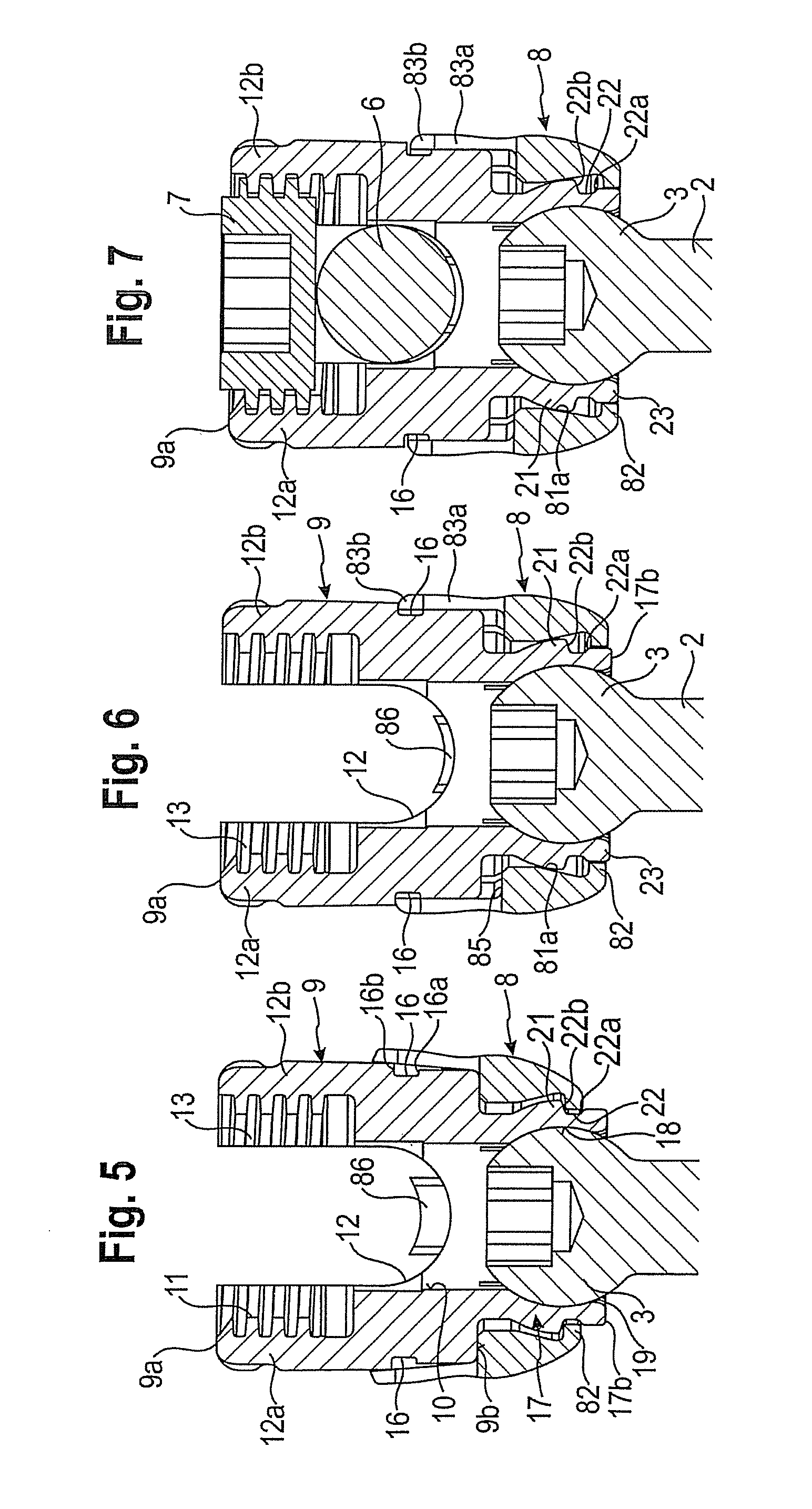

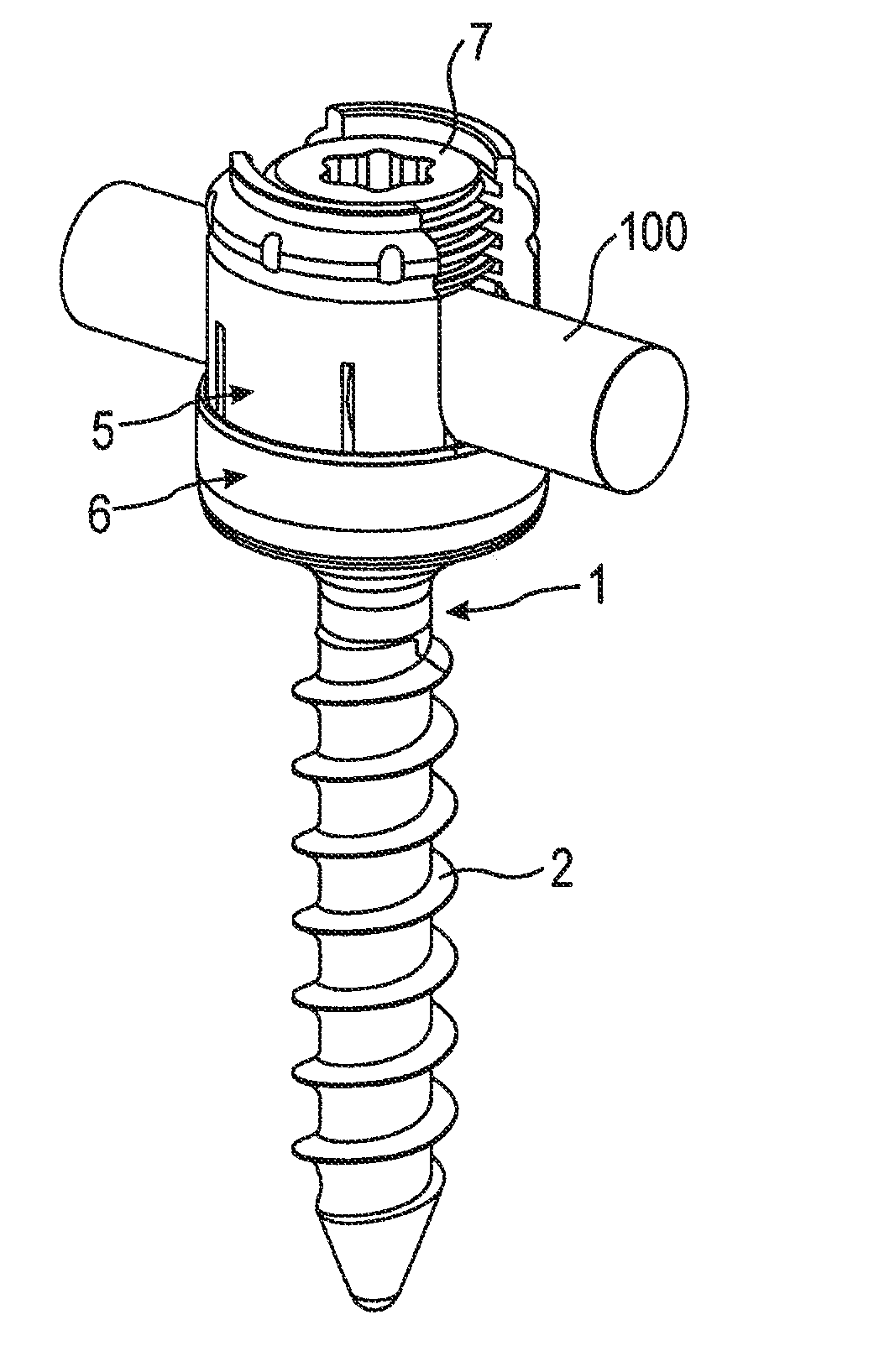

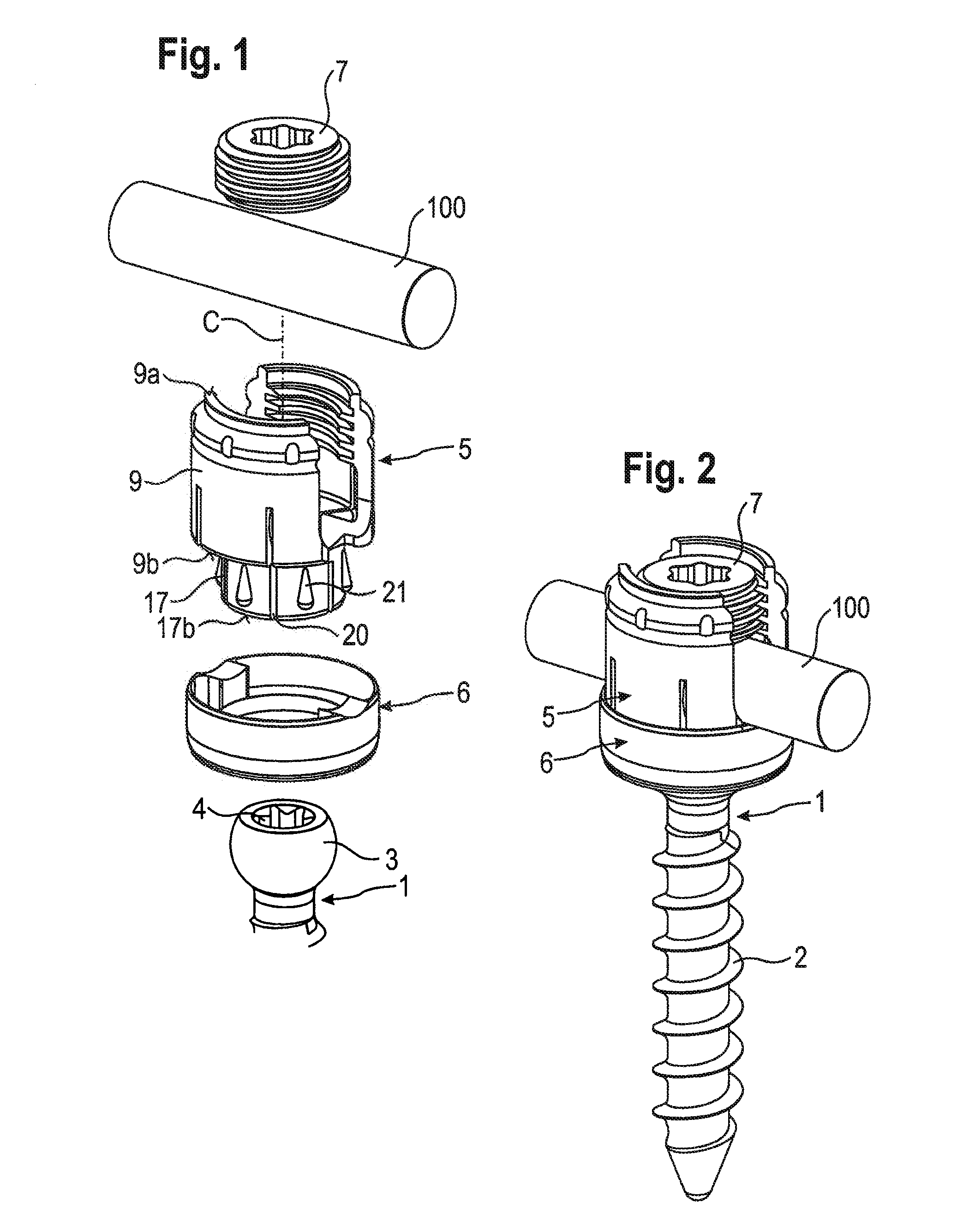

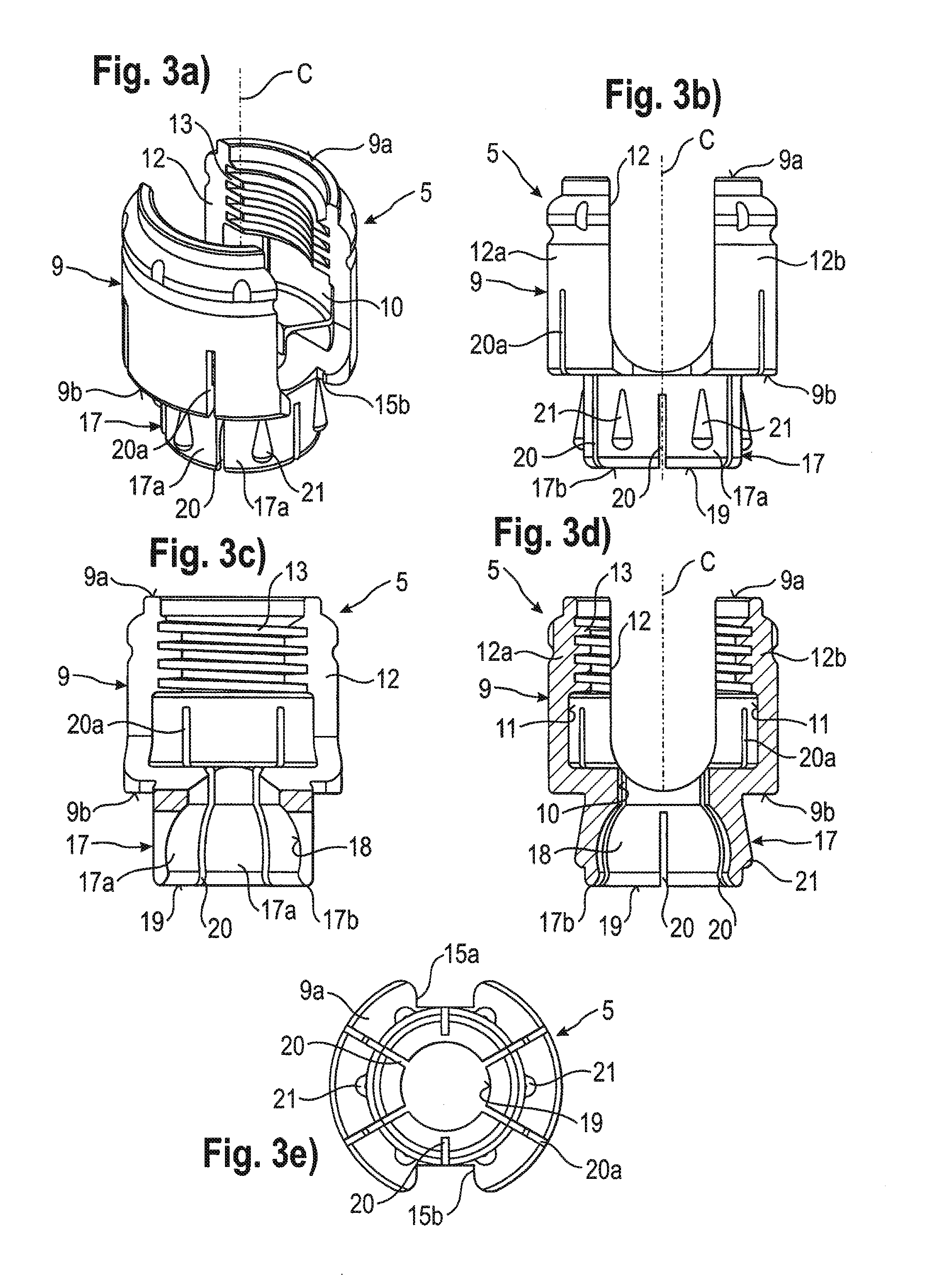

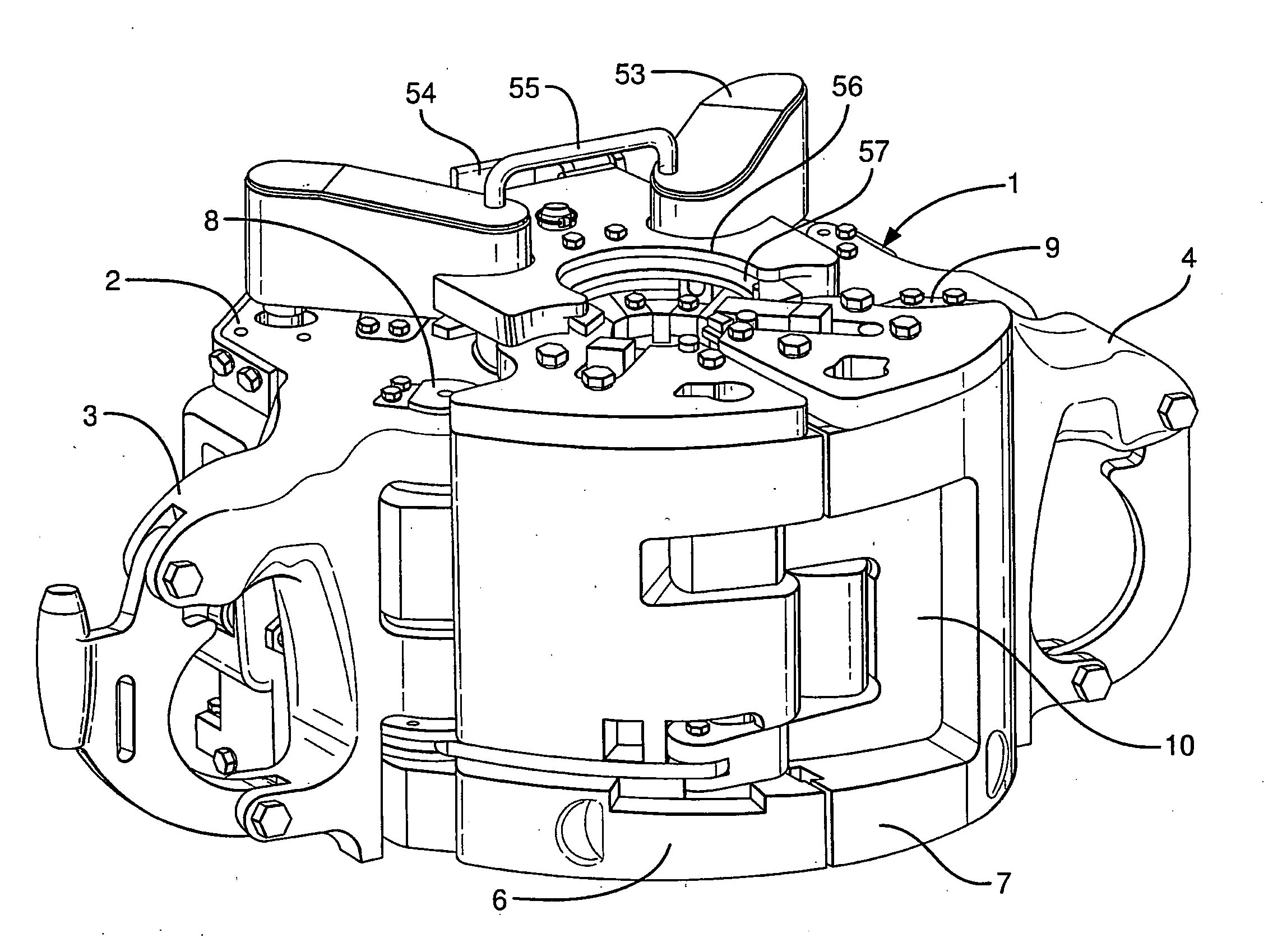

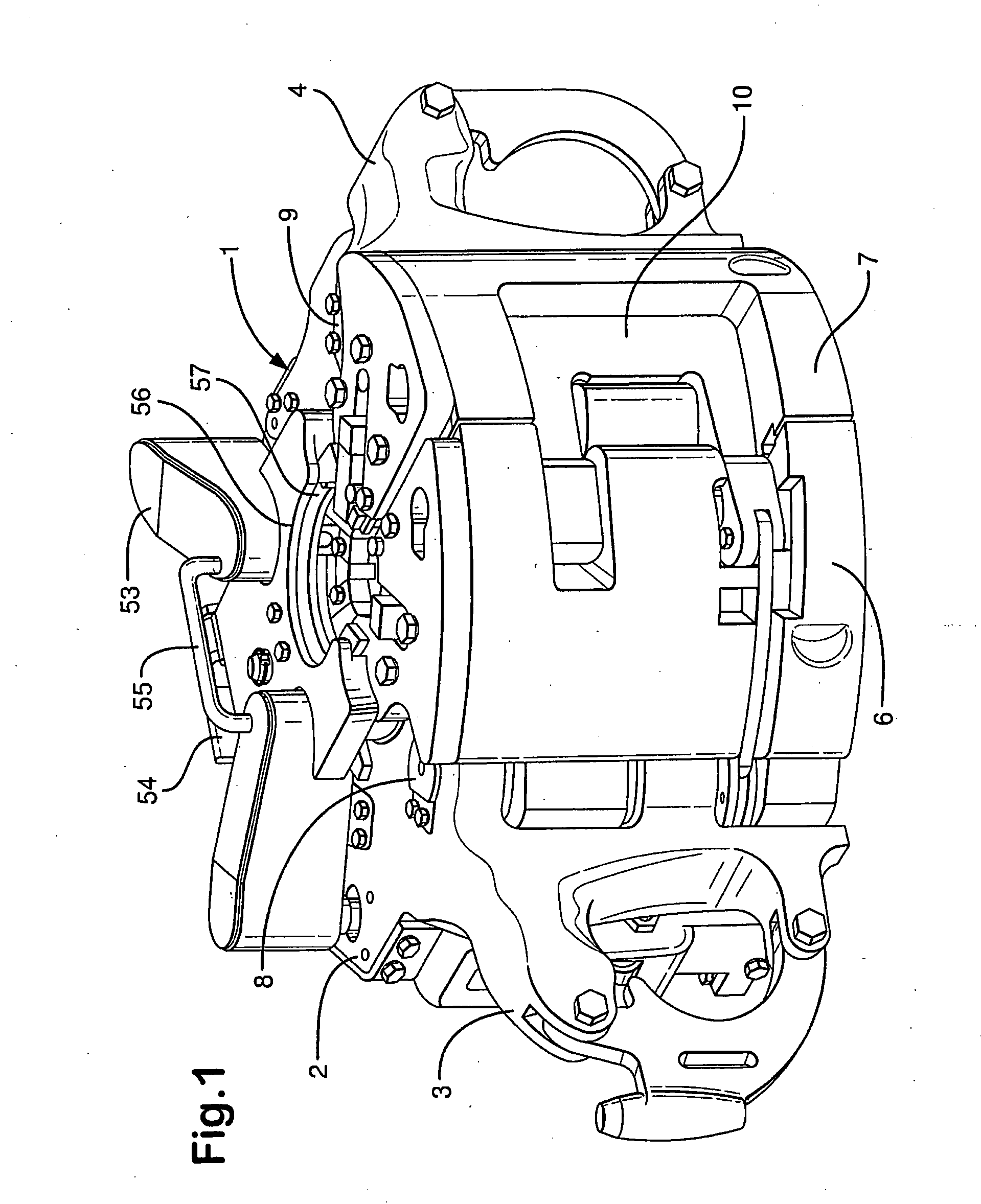

Receiving part for receiving a rod for coupling the rod to a bone anchoring element, bone anchoring device, method and tool for assembling the same

InactiveUS20110276098A1Easy to handleAssembly safetySuture equipmentsInternal osteosythesisBiomedical engineeringBone anchor

A receiving part for receiving a rod for coupling the rod to a bone anchoring element includes a receiving part body with a first end and a second end; a rod receiving portion with a channel for receiving a rod, and a head receiving portion for accommodating a head of a bone anchoring element, the head receiving portion having an open end at the second end of the receiving part body and being flexible so as to allow introduction and clamping of the head; and a locking ring configured to be positioned around the head receiving portion, wherein the locking ring can assume a first position with respect to the receiving part body in which the locking ring is latched to the receiving part body in a position where the head receiving portion is expandable to facilitate insertion of a head of a bone anchoring element, and wherein the locking ring can assume a second position with respect to the receiving part body in which the locking ring is latched to the receiving part body in a position where the locking ring compresses the head receiving portion, such that when a bone anchoring element has a head inserted in the head receiving portion, the bone anchoring element is held adjustably at a first angular position relative to the receiving part. A method for assembling a bone anchoring device includes inserting the head of the bone anchoring element into the receiving part body; and moving the locking ring and the receiving part body relative to each other until the locking ring assumes the second position with respect to the receiving part body.

Owner:BIEDERMANN TECH GMBH & CO KG

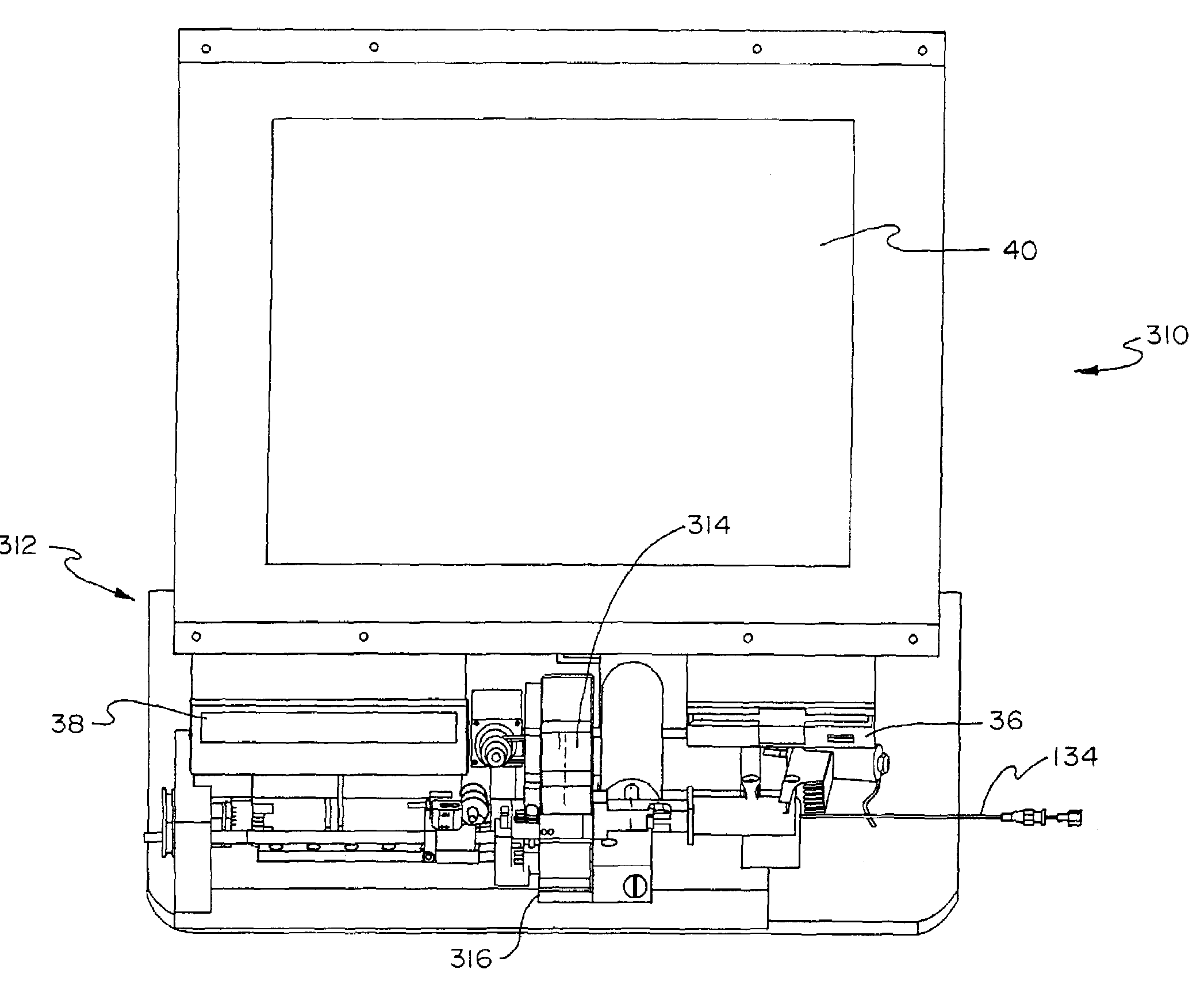

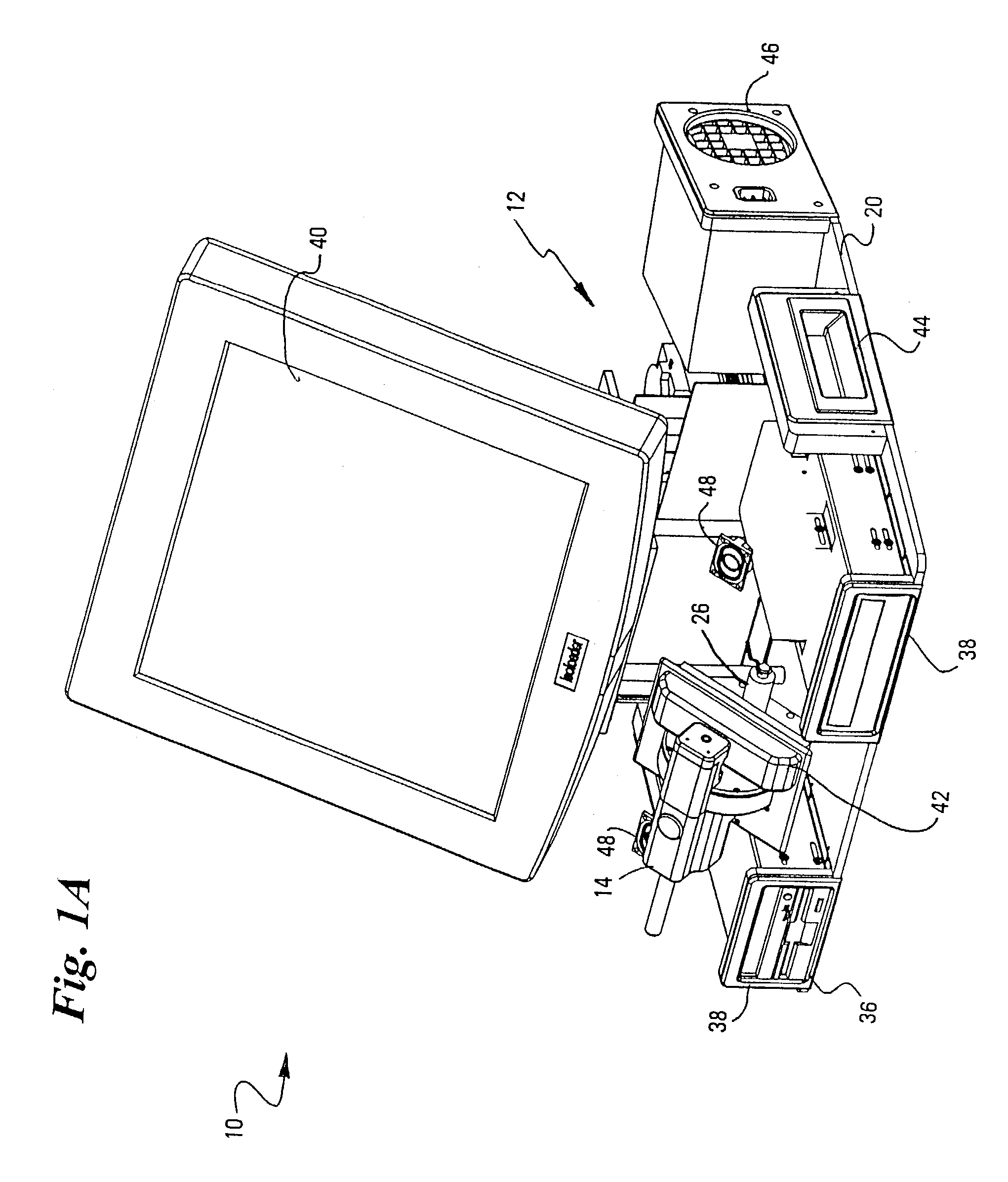

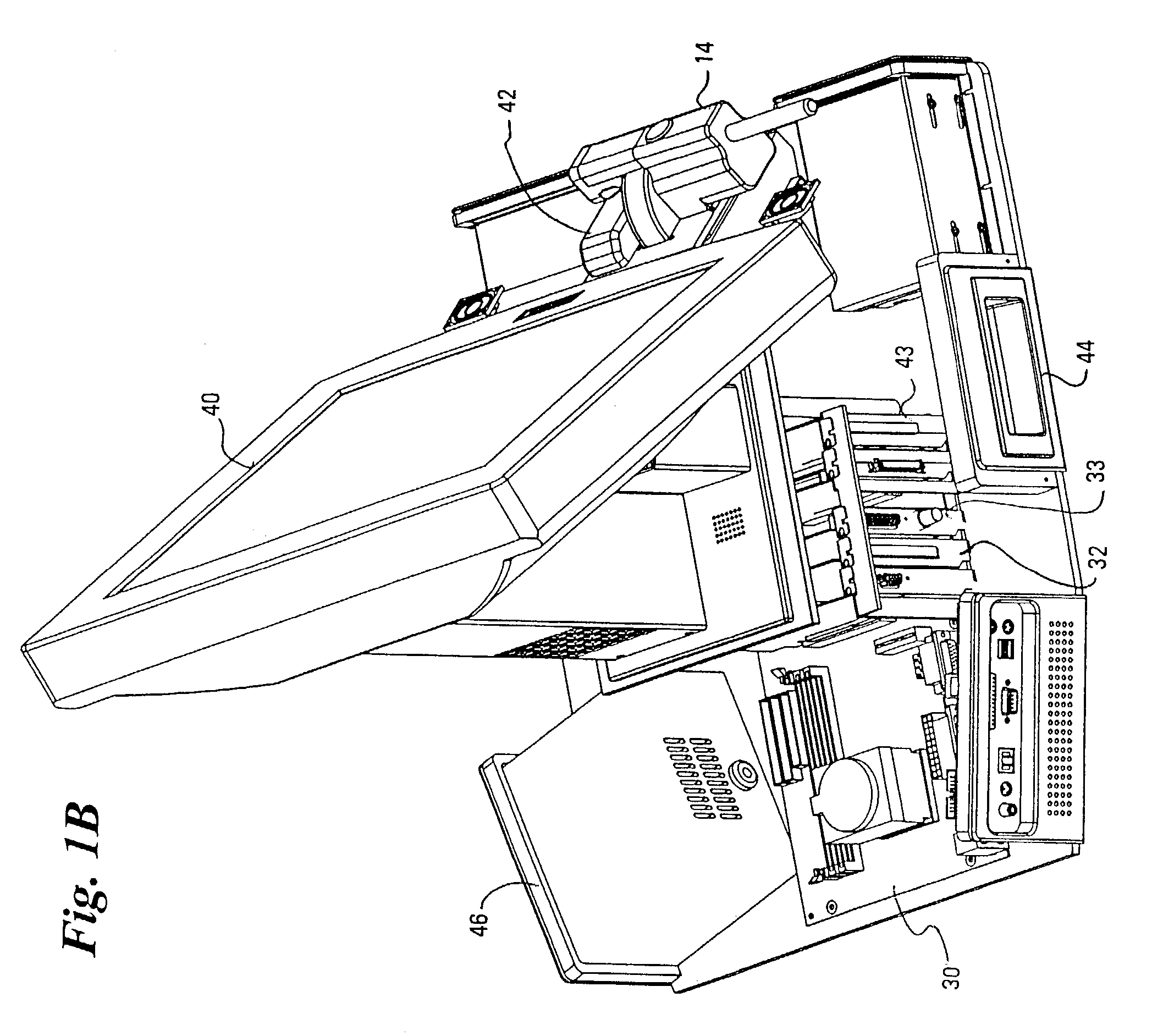

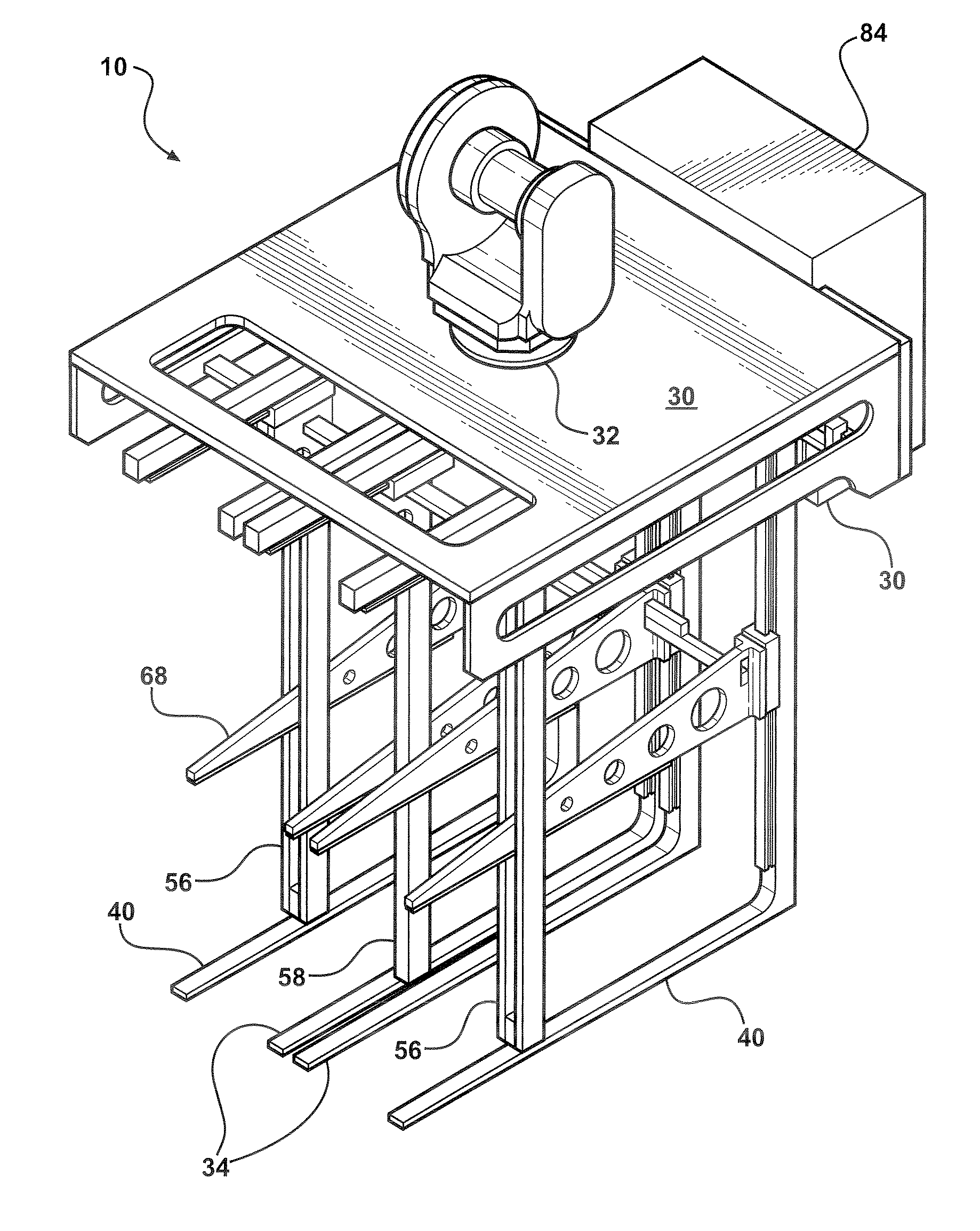

Automated radioisotope seed loader system for implant needles

InactiveUS7229400B2Minimize security issueSafe and efficientMedical devicesX-ray/gamma-ray/particle-irradiation therapyMovement controlAdemetionine

An automated system for loading low dose radioisotope seeds into a plurality of implant needles is comprised of a loading station into which a replaceable cartridge may be positioned. The cartridge is preloaded with a plurality of radioisotope seeds and a plurality of spacers. The cartridge has at least one aperture and preferably the radioisotope seeds and spacers are loaded around the periphery of a rotatable drum within the cartridge. The loading station has a cartridge receiving structure and an automated motion control system. When the cartridge is positioned in the cartridge receiving structure, the automated motion control system preferably drives a pair of stepper motors within the cartridge, one for rotating the rotatable drum and one for sliding a pushrod to selectively eject radioisotope seeds and spacers from the cartridge into each of a plurality of implant needles positioned so as to receive the radioisotopes seeds and spacers within the implant needle. In one embodiment, the implant needles are positioned tip first into the loading station, and once a predetermined arrangement of radioisotope seeds and spacers are loaded into the implant needle, a plug is positioned in the tip of the implant needle. Preferably, the automated system includes a computer processor having a touch screen user interface that is connected to and directs the operation of the automated motion control system to load the plurality of implant needles in accordance with a predetermined dose plan.

Owner:THERAGENICS CORP

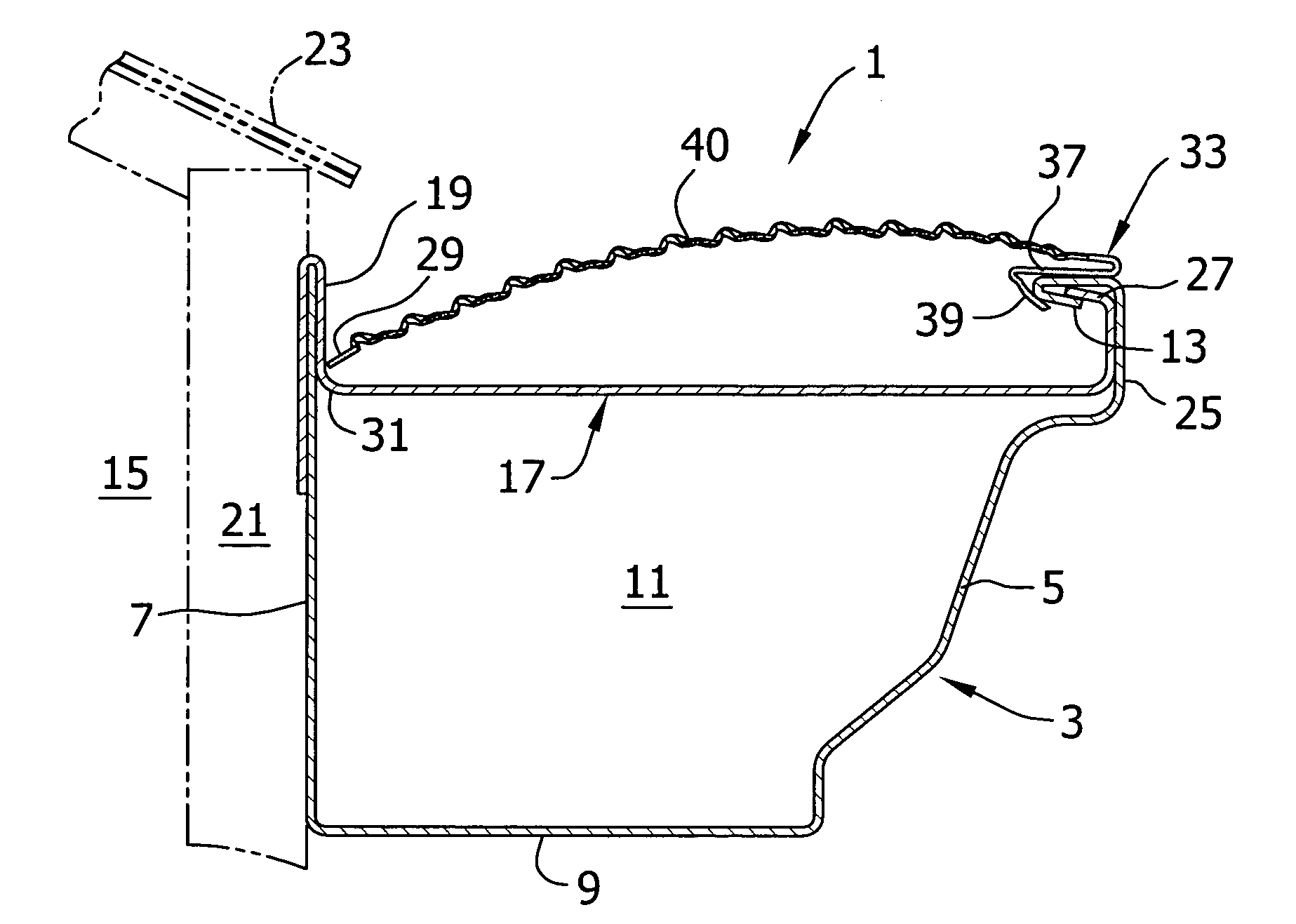

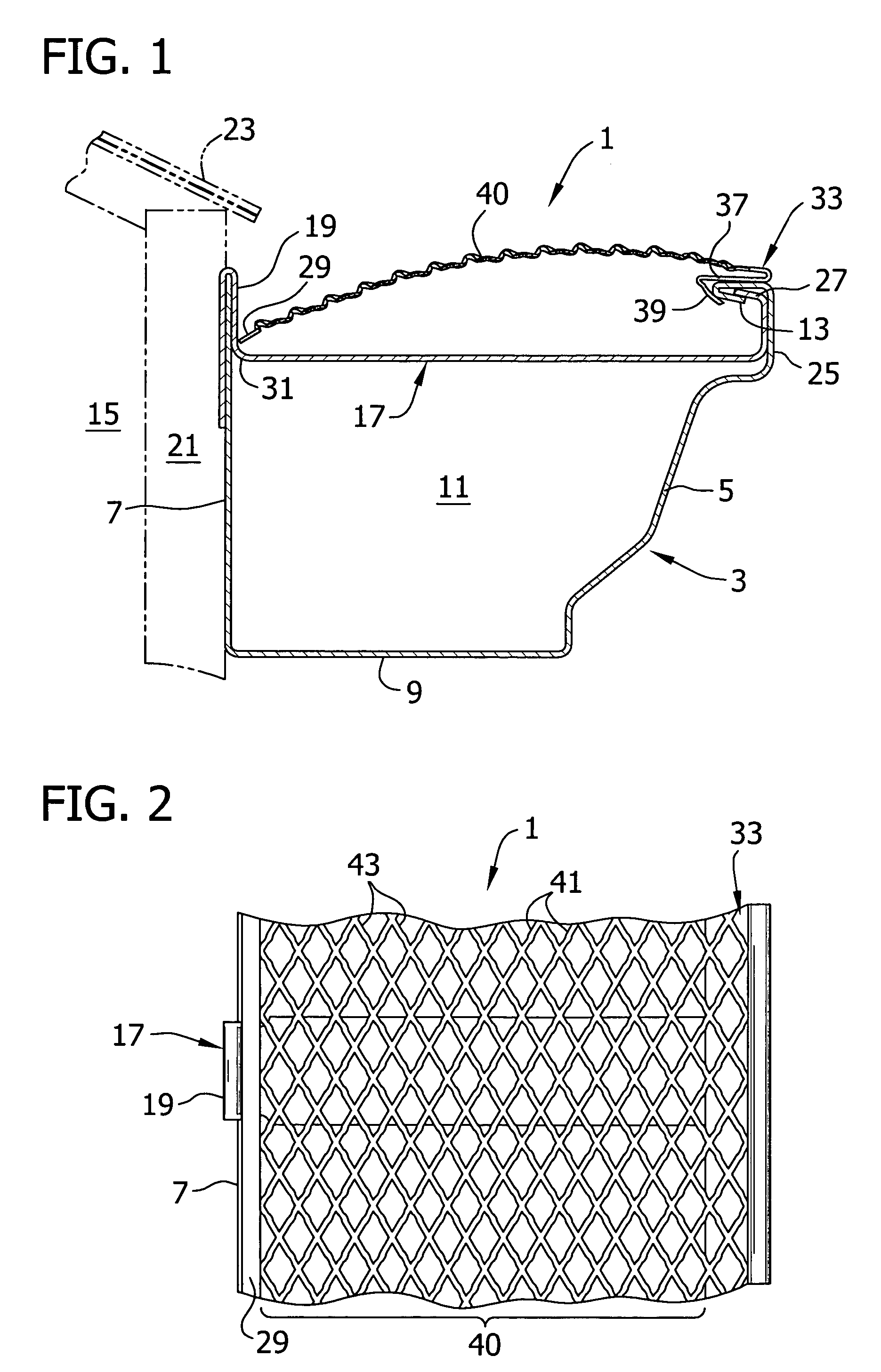

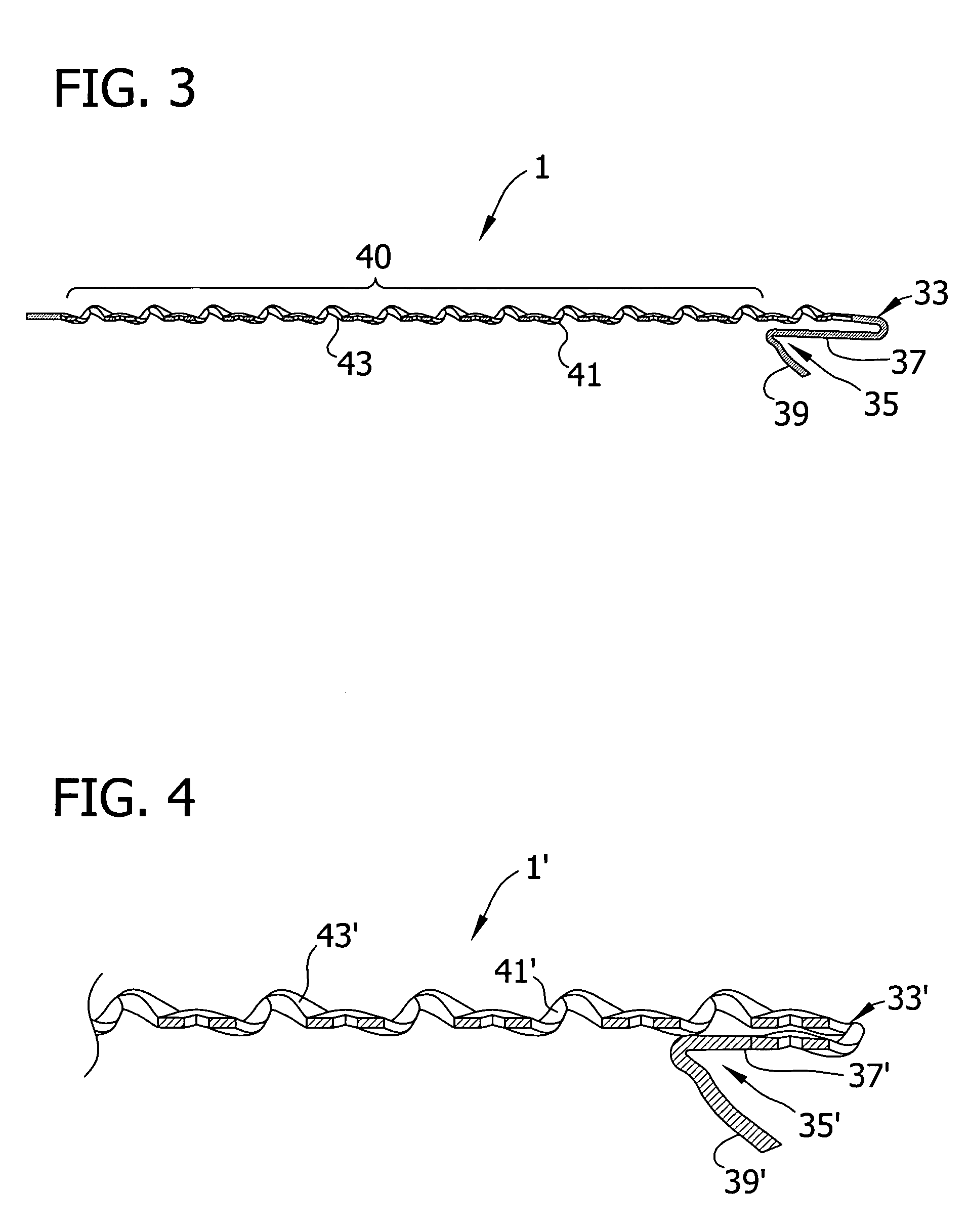

Solid edge gutter screen

A one-piece, integral metal gutter screen includes an expanded metal screen section for covering a gutter. A front edge margin is sized and shaped to engage the gutter, the front edge margin having no sharp edges. A rear edge margin is sized and shaped to engage at least one of a gutter hanger and a roof, the rear edge margin having no sharp edges. The gutter screen is formed of a single piece of elongate, flexible, resilient metal. The gutter screen includes strands and non-circular holes between the strands in at least the screen section. The strands and non-circular holes are sized and shaped to prevent leaves and debris from falling into the gutter. At least the front edge margin of the screen is solid, unperforated metal for facilitating safe handling of the screen and for ease of installation.

Owner:EALER JAMES E SR

Receiving part for receiving a rod for coupling the rod to a bone anchoring element and a bone anchoring device

ActiveUS20120179209A1Safe handlingImprove securitySuture equipmentsInternal osteosythesisBiomedical engineeringBone Anchors

A receiving part for coupling a rod to a bone anchoring element includes: a receiving part body with a rod receiving portion and a head receiving portion having an open end for introducing a head of a bone anchoring element, and a locking ring, wherein the head receiving portion includes a plurality of flexible wall portions, the flexible wall portions and the locking ring being configured to engage each other at circumferentially distinct pressure areas having positions corresponding to circumferentially separated projections on at least one of the flexible wall portions or the locking ring, and wherein the locking ring exerts a first force on at least one of the flexible wall portions at a corresponding pressure area, and exerts a second force less than the first force on the at least one flexible wall portion in a region circumferentially adjacent to the corresponding pressure area.

Owner:BIEDERMANN TECH GMBH & CO KG

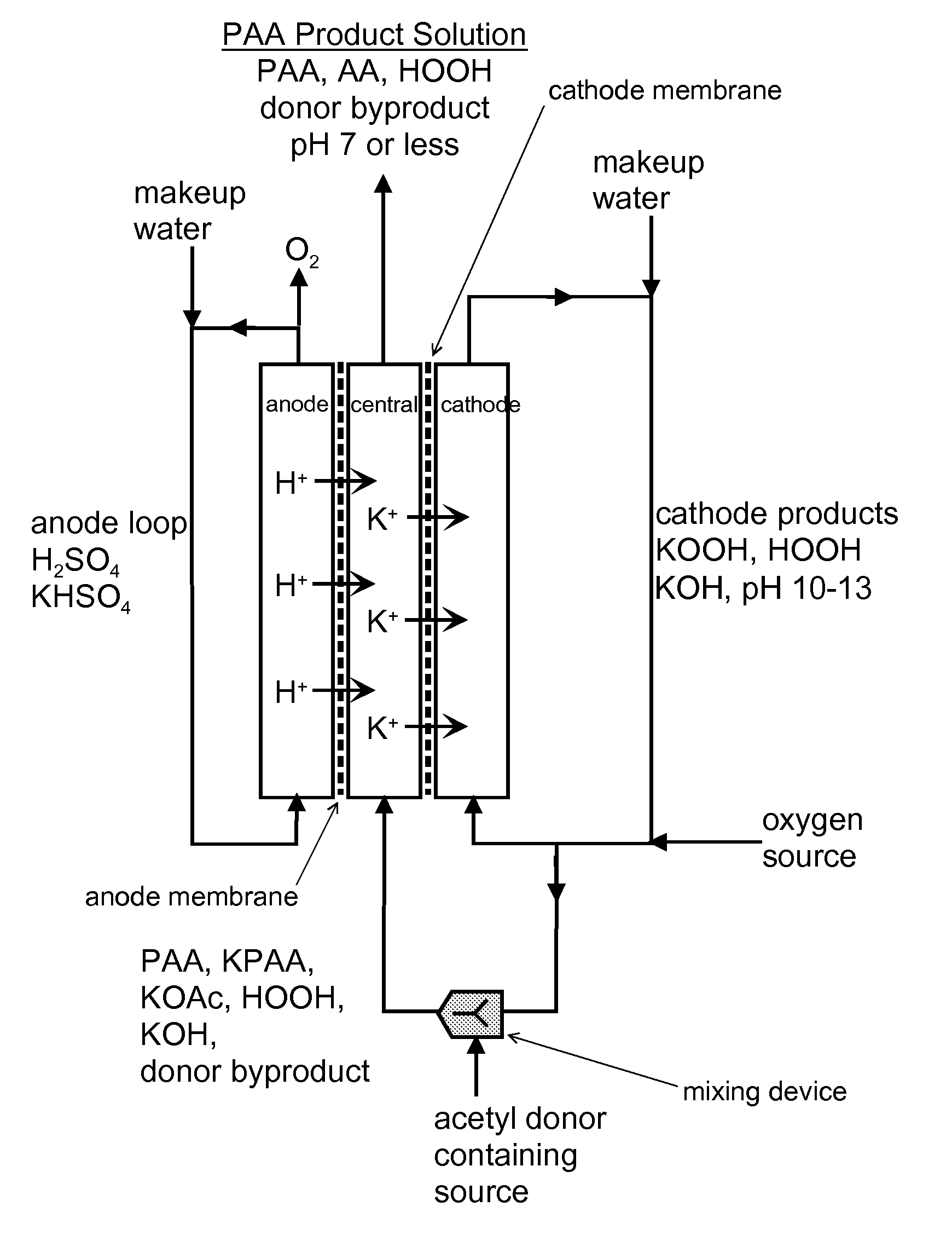

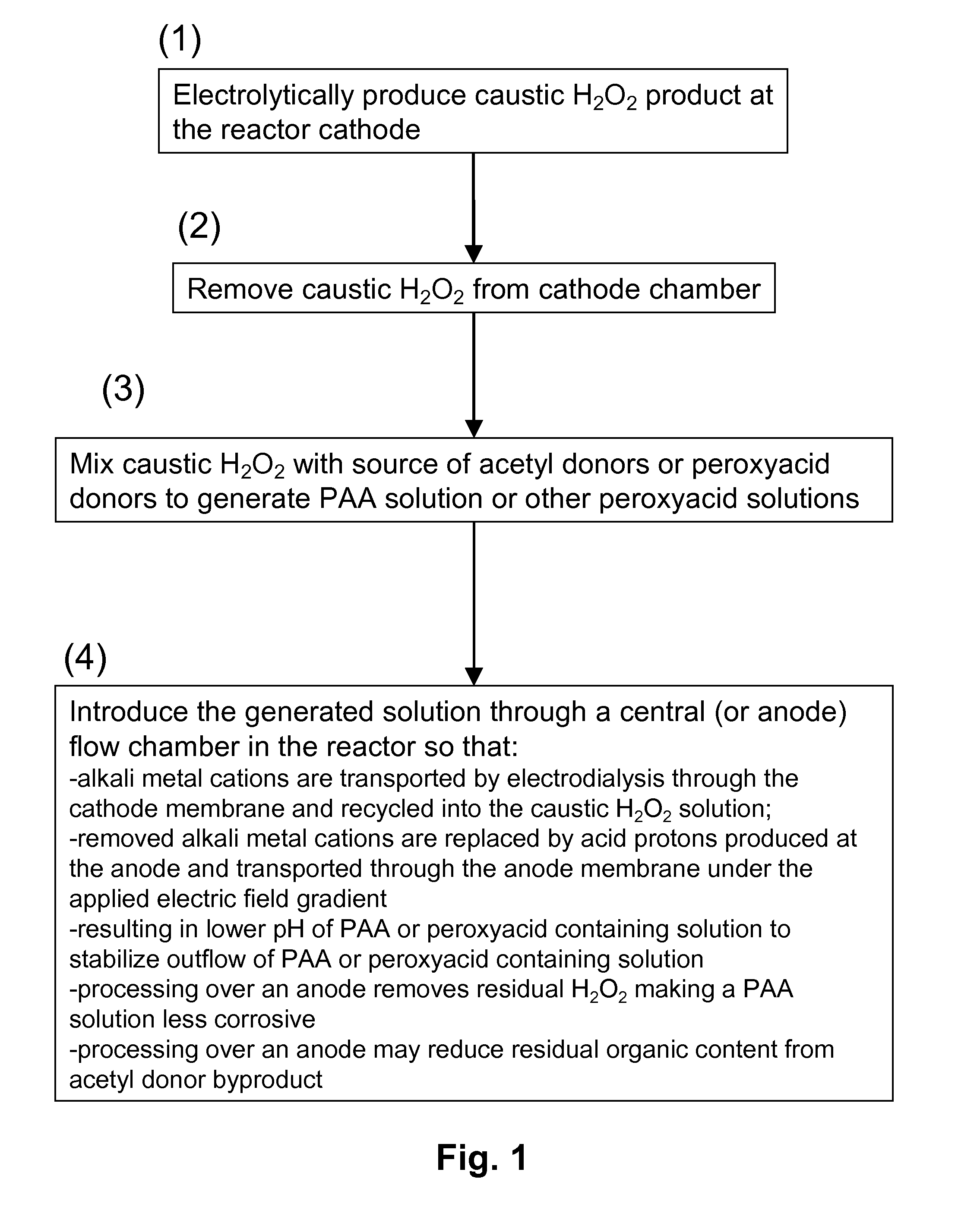

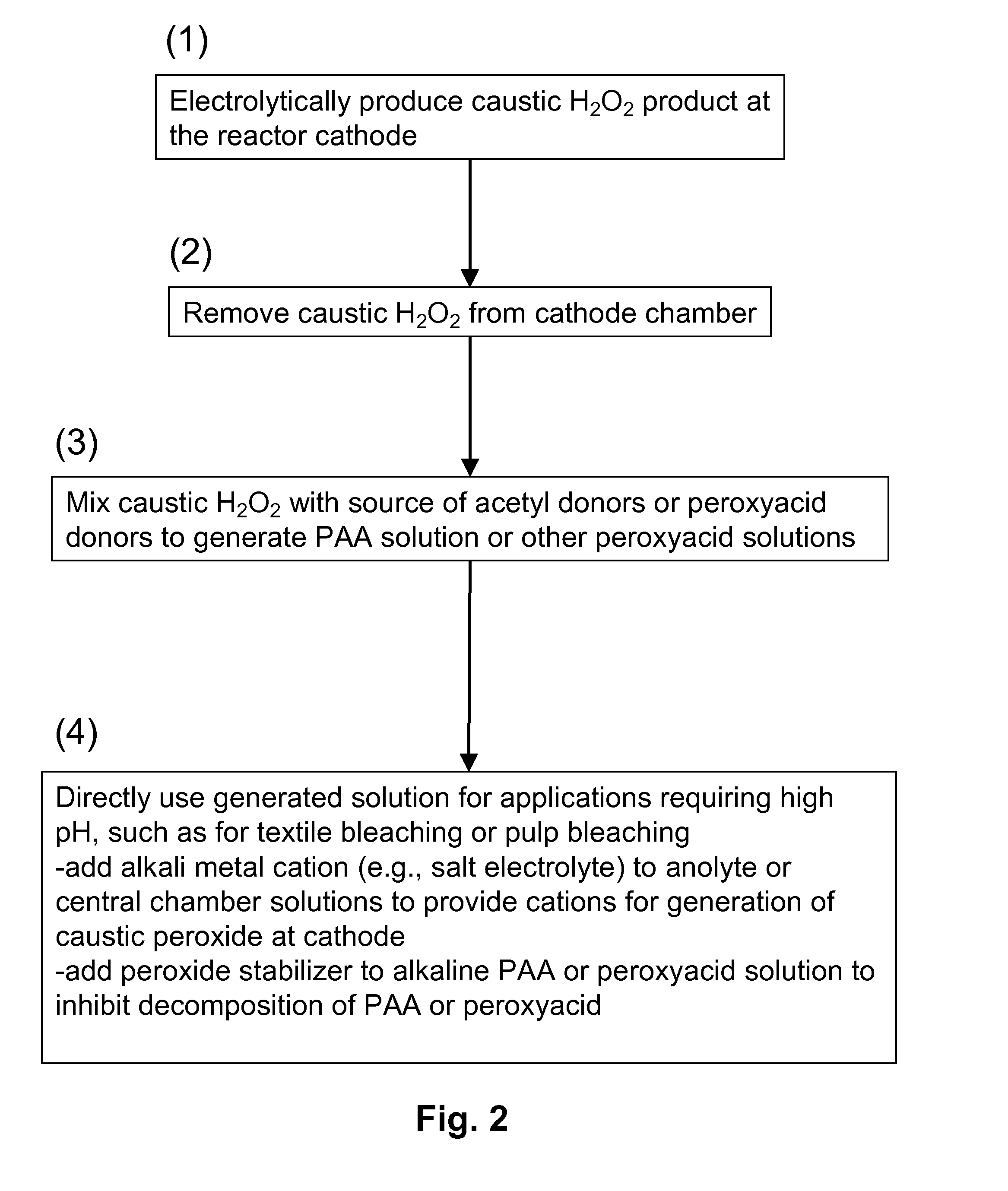

Production of Peroxycarboxylic Acids

InactiveUS20090314652A1Reduces concentration of hydrogen peroxideEasy to superviseCellsOrganic chemistryAcetic acidElectrolysis

Provided are various methods, systems and reactors for producing peroxycarboxylic acid compositions, such as non-equilibrium compositions of peracetic acid, for example. The methods and systems relate to electrolytic generation of hydrogen peroxide or peroxide ions in a reactor, wherein the generated materials are reacted with an acetyl donor to form peracetic acid. In an embodiment, a source of alkali metal ions is provided to an anode chamber such that the ratio of concentrations of the alkali metal ions to protons in the anode chamber of a reactor is greater than 1.

Owner:ELTRON RES

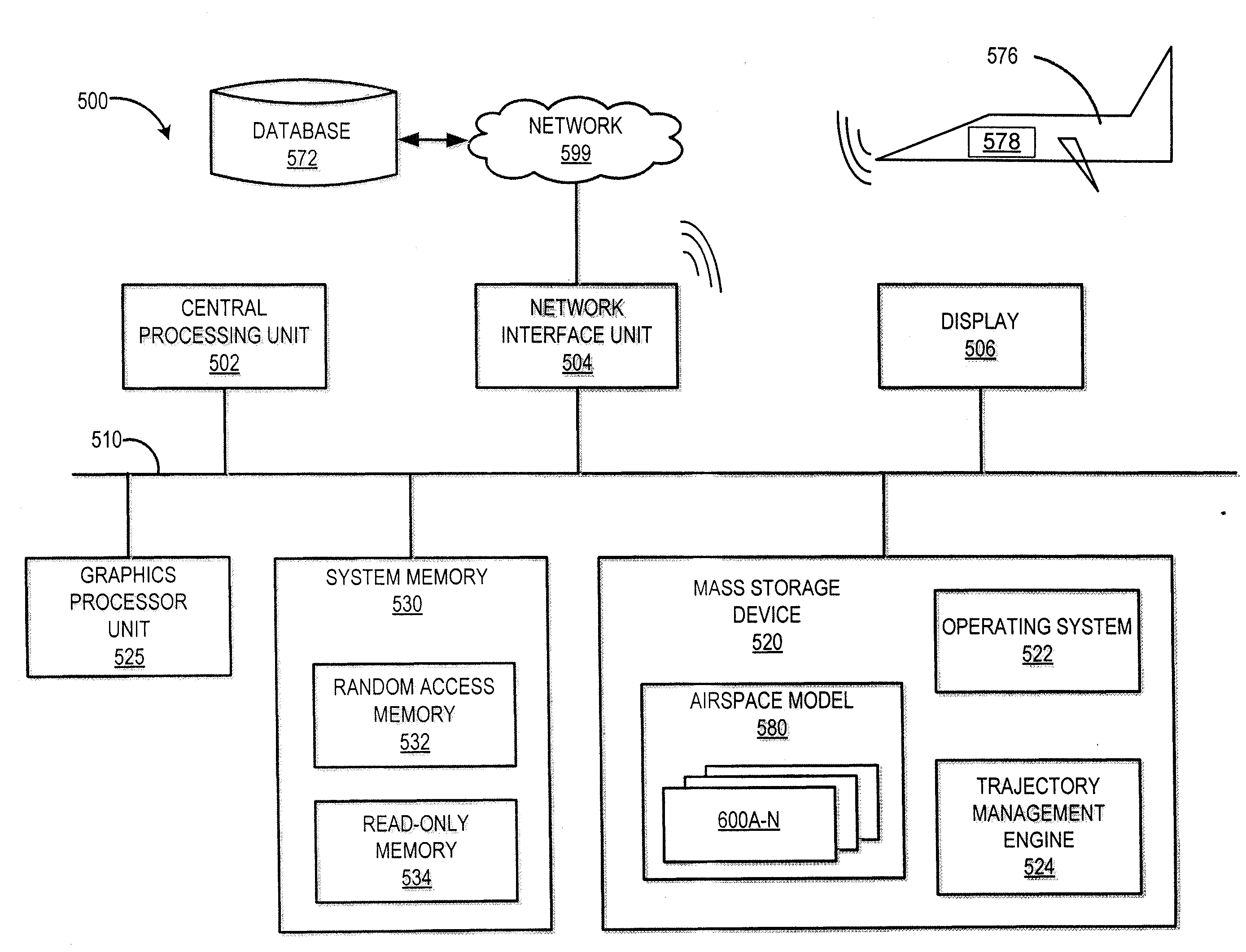

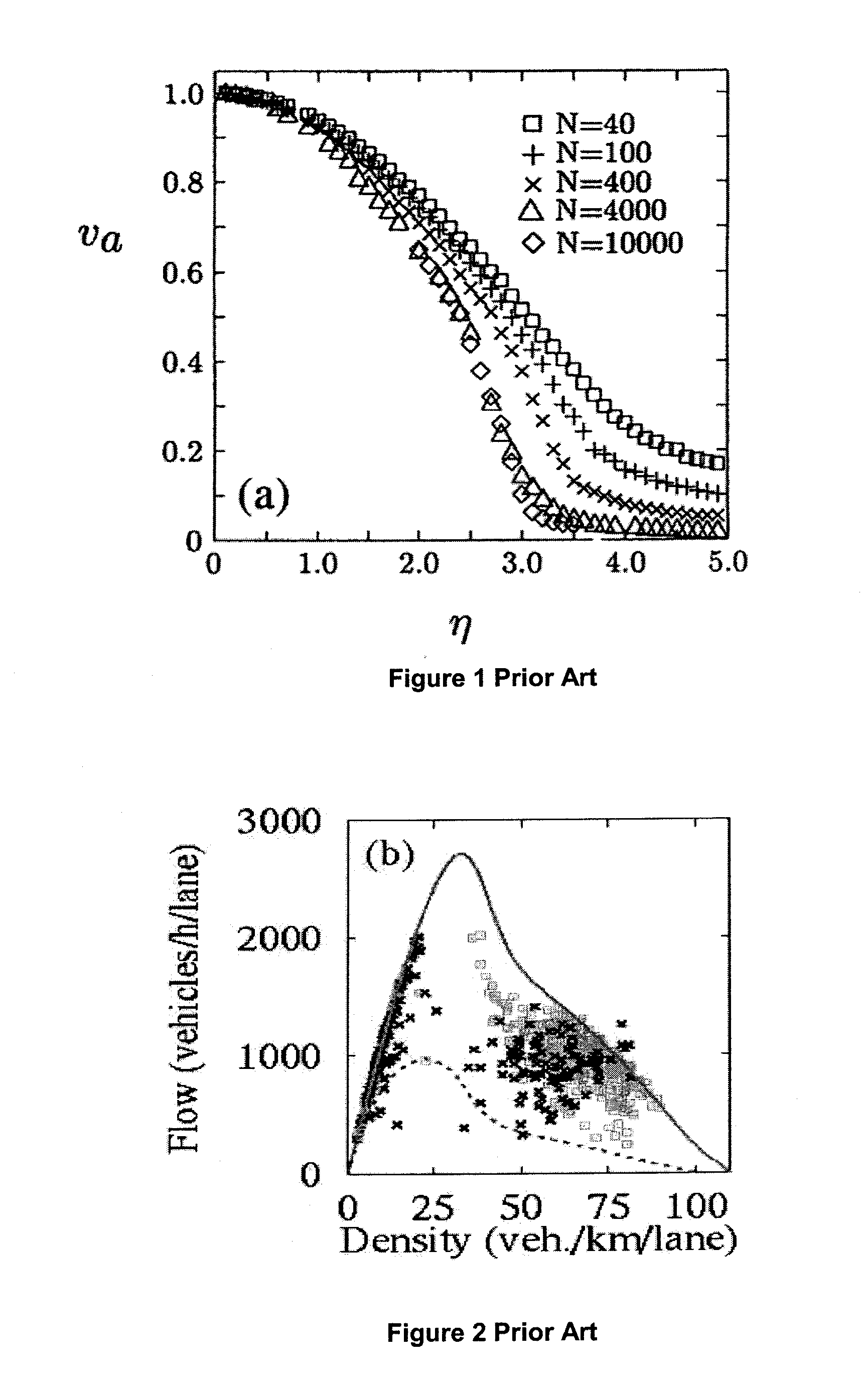

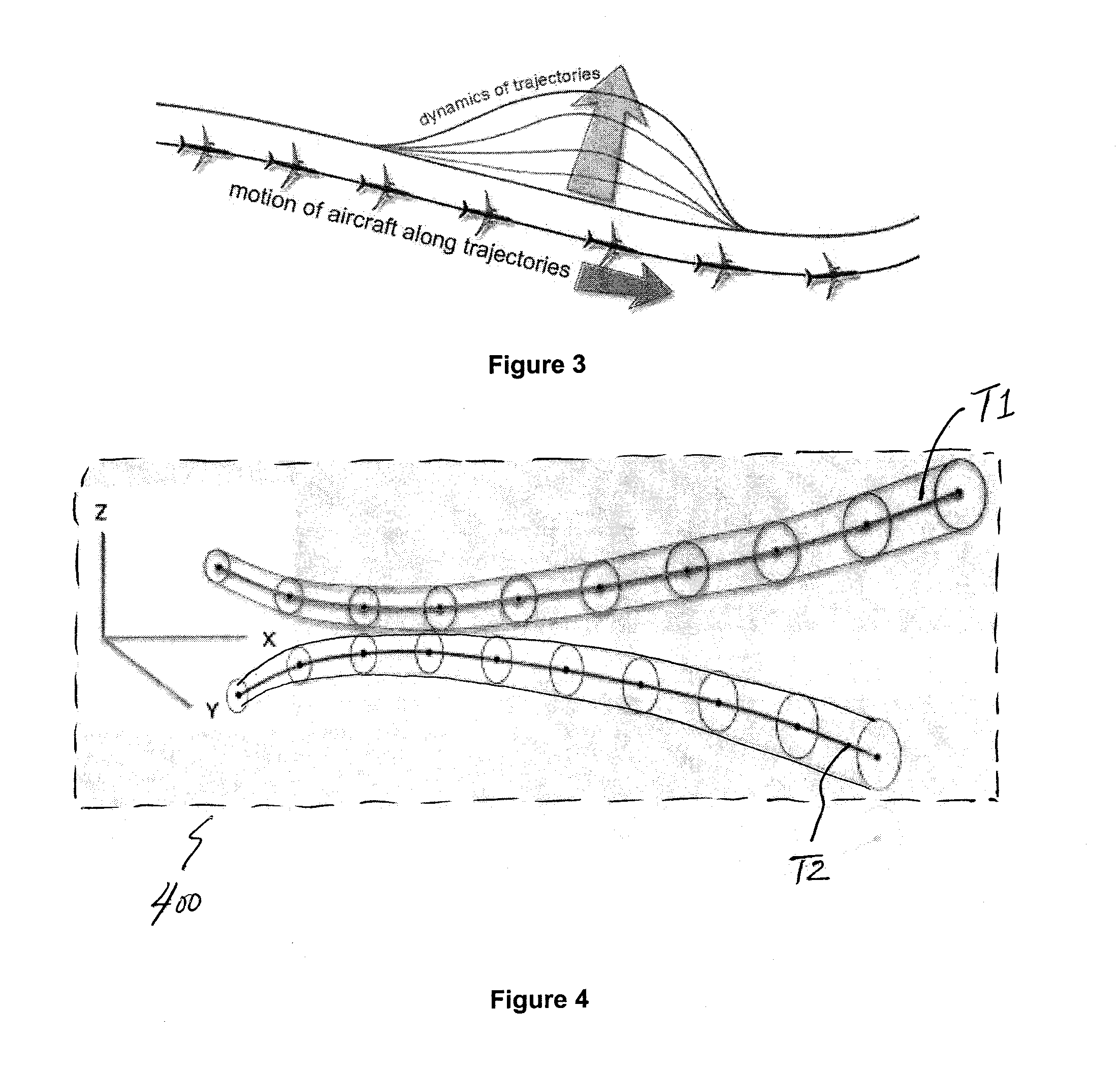

System and Method for Planning, Disruption Management, and Optimization of Networked, Scheduled or On-Demand Air Transport Fleet Trajectory Operations

ActiveUS20120191332A1Easy to manageOperational securityAnalogue computers for vehiclesAnalogue computers for trafficAviationFuel efficiency

Disclosed are algorithms and agent-based structures for a system and technique for analyzing and managing the airspace. The technique includes managing bulk properties of large numbers of heterogeneous multidimensional aircraft trajectories in an airspace, for the purpose of maintaining or increasing system safety, and to identify possible phase transition structures to predict when an airspace will approach the limits of its capacity. The paths of the multidimensional aircraft trajectories are continuously recalculated in the presence of changing conditions (traffic, exclusionary airspace, weather, for example) while optimizing performance measures and performing trajectory conflict detection and resolution. Such trajectories are represented as extended objects endowed with pseudo-potential, maintaining objectives for time, acceleration limits, and fuel-efficient paths by bending just enough to accommodate separation.

Owner:SMARTSKY NETWORKS

Offload processing for secure data transfer

InactiveUS7441119B2Safe handlingSpecial data processing applicationsSecuring communicationPlaintextData transmission

Owner:TREND MICRO INC

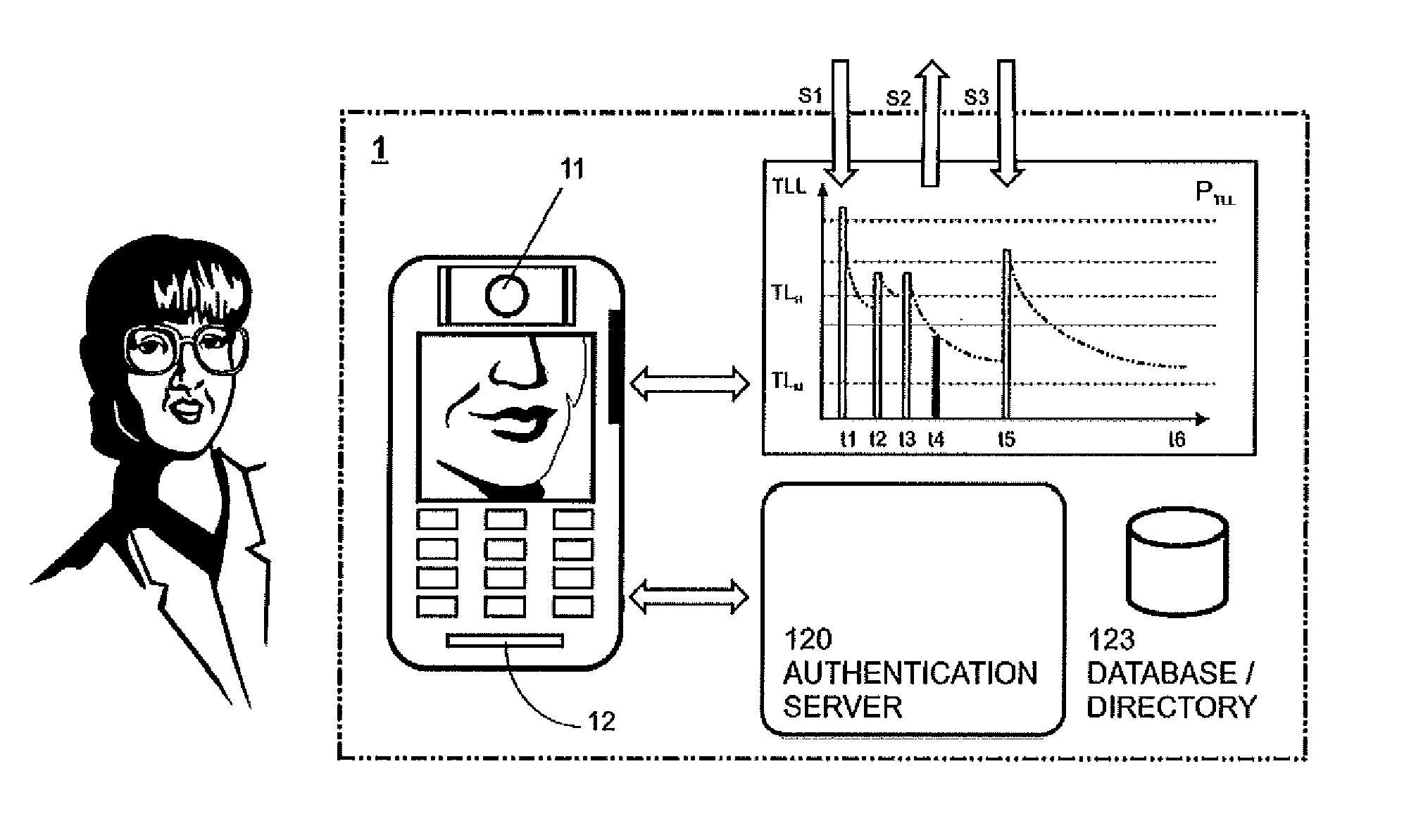

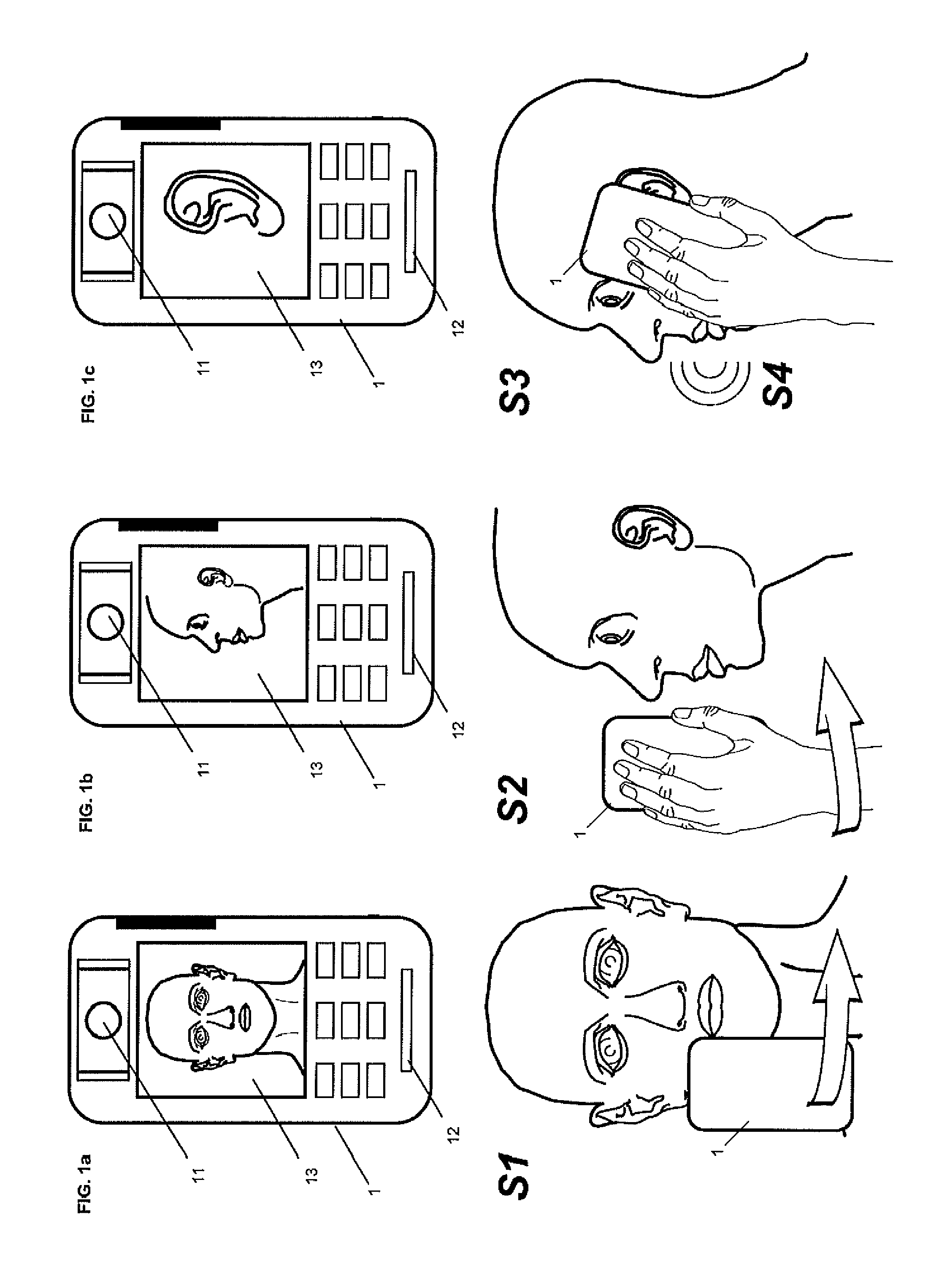

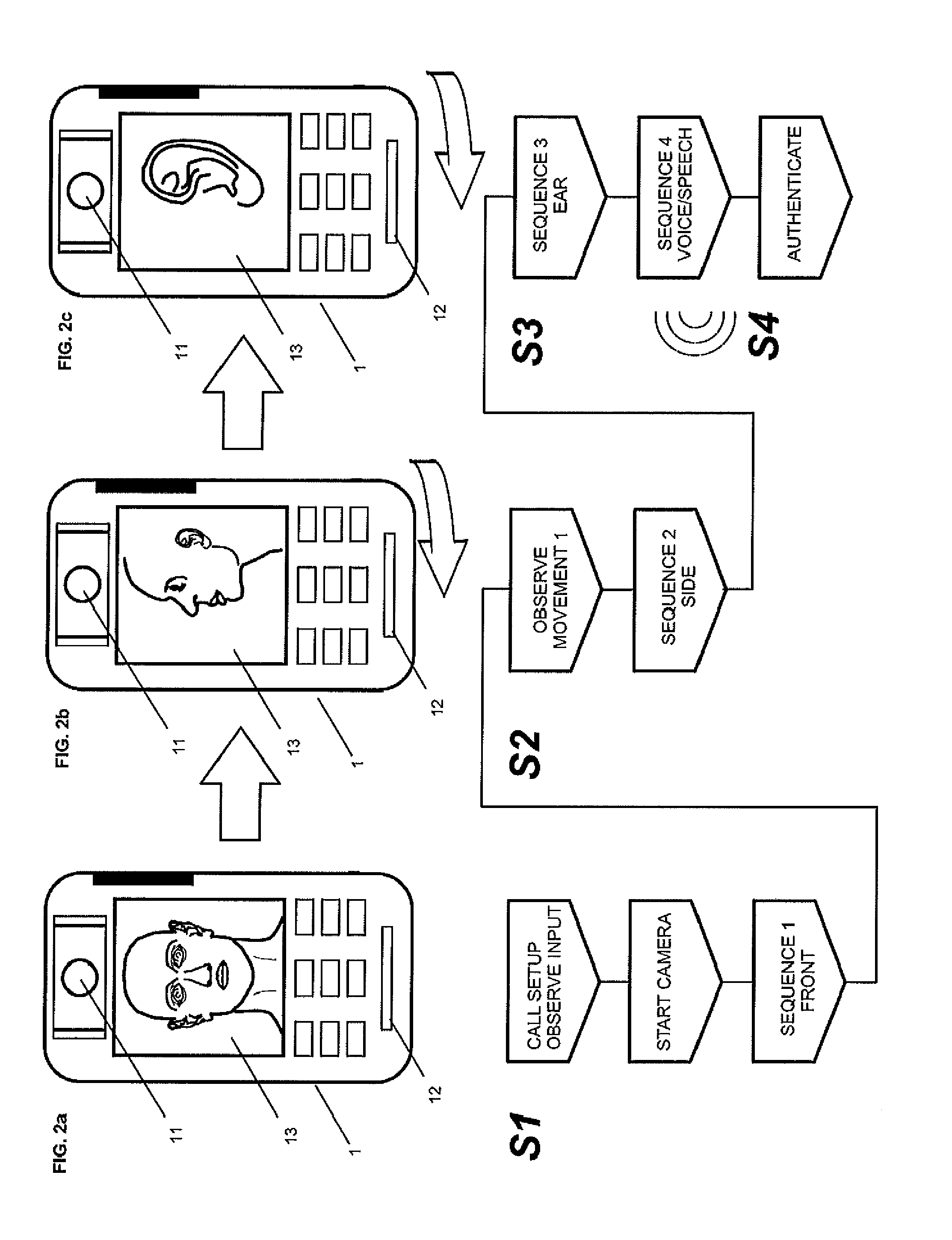

Method for sequential biometric authentication and mobile station

InactiveUS20130225129A1Not capture smallImprove security levelUnauthorised/fraudulent call preventionEavesdropping prevention circuitsBiometric dataDisplay device

A method of performing biometric authentication with a mobile station having a camera, front side display and integrated authentication server, or is connectable to an authentication server via a mobile communications network, includes:enrolling the user in a biometric system by capturing and storing biometric data relating to a plurality of characteristics of the user's head normally exposed to the mobile station during the process of accepting a call; activating the camera when initiating, receiving, or accepting a call and capturing optical information in one or a plurality of sequences at least between the setup or acceptance of the call and the start of the conversation and transferring the captured optical information to the authentication server; authenticating the user by comparing the optical information with the biometric data previously captured, by identifying and matching characteristics captured from different angles; and performing defined actions as a result of the authentication.

Owner:BIOMETRY COM

Degradable compositions, apparatus comprising same, and methods of use

InactiveUS20120080189A1Improve responseSafe handlingMaterial nanotechnologyFlushingSubject matterHigh intensity

Compositions, apparatus incorporating a composition, and methods of use are described, one composition embodiment consisting essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Compositions of the invention may exist in a variety of morphologies, including a reactive metal or degradable alloy processed into an alloy of crystalline, amorphous or mixed structure that may constitute the matrix of other composition, for instance a composite. Methods of using apparatus comprising a composition, particularly in oilfield operations are also described (e.g. flow and displacement control, sensors, actuators). This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

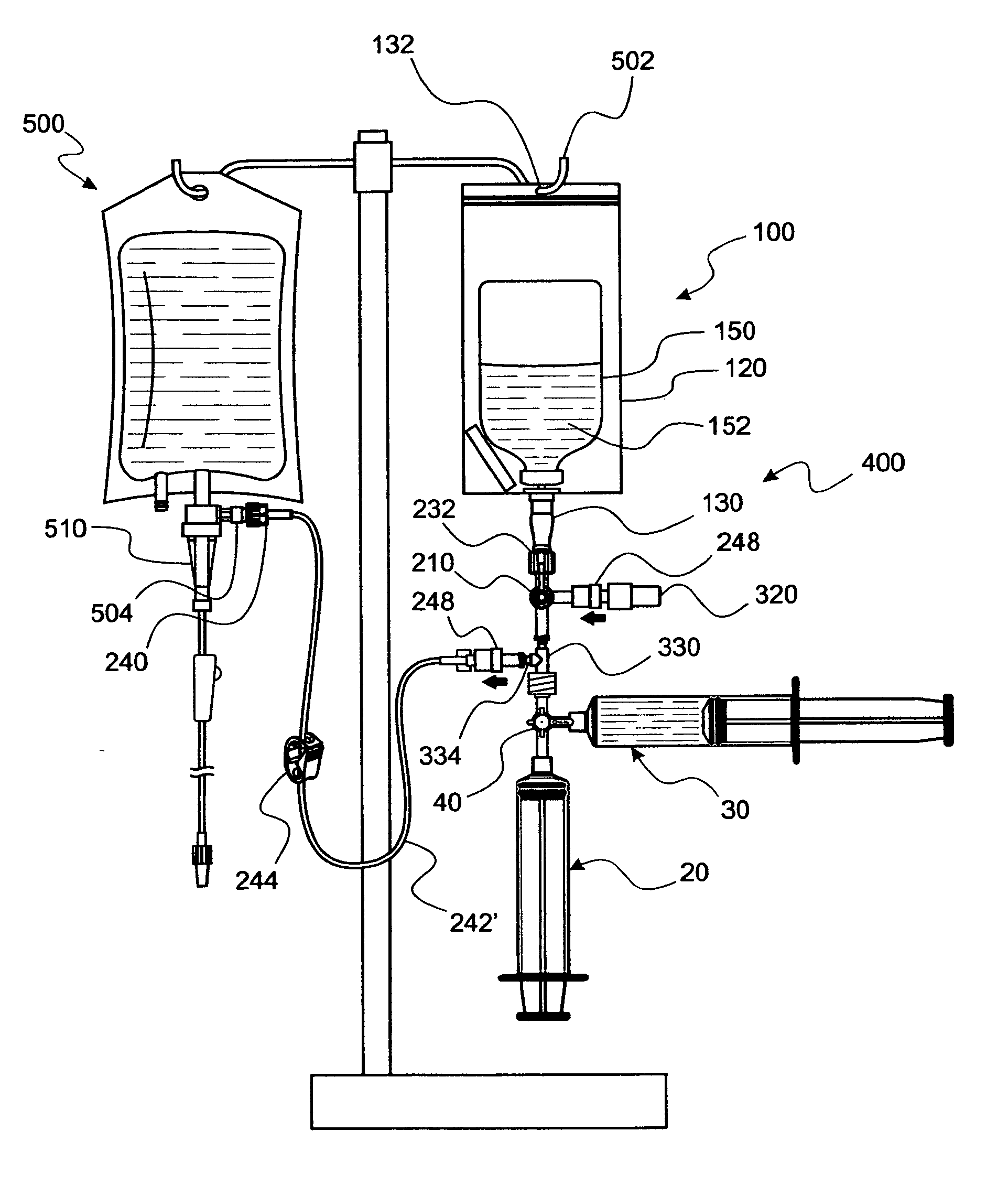

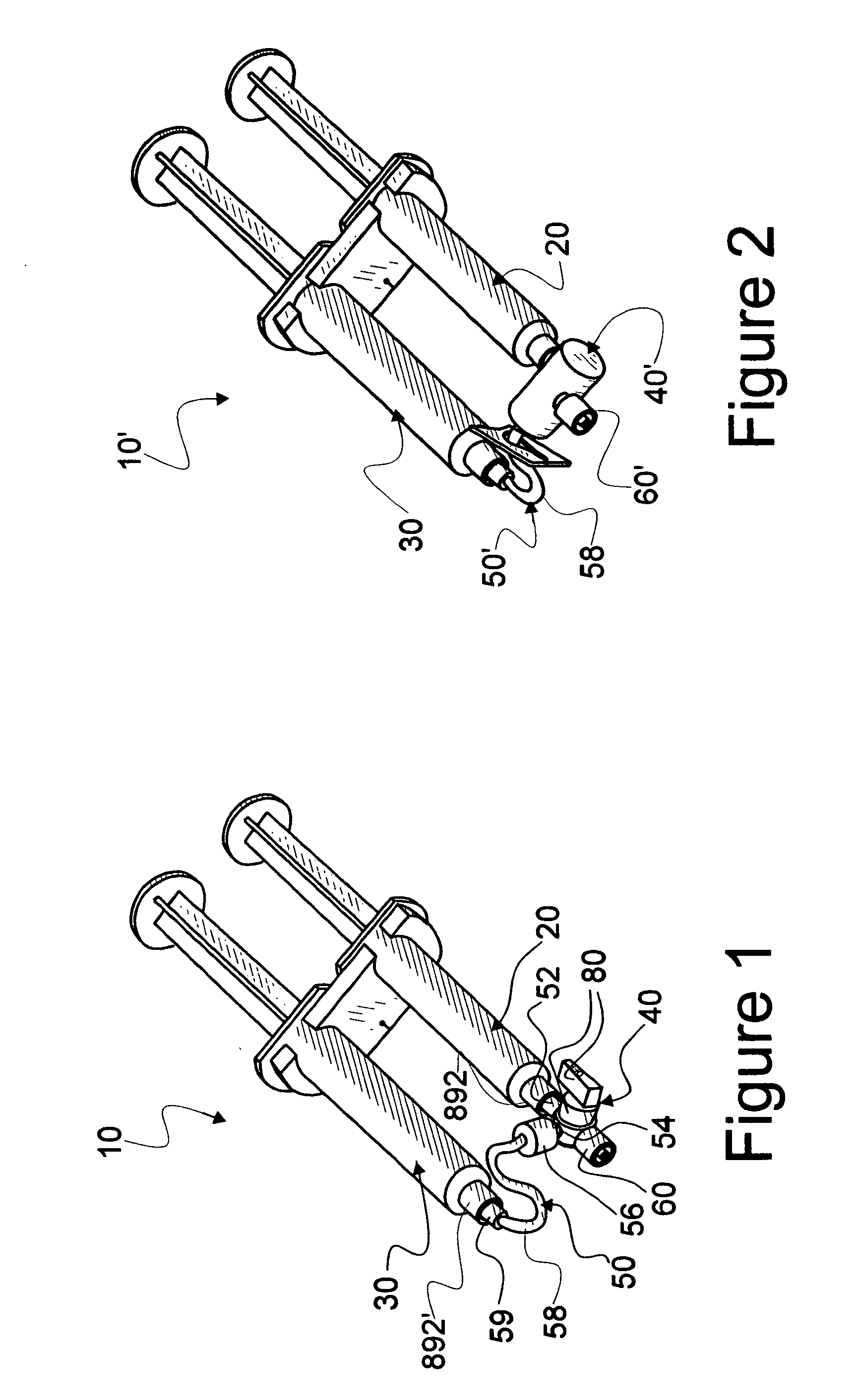

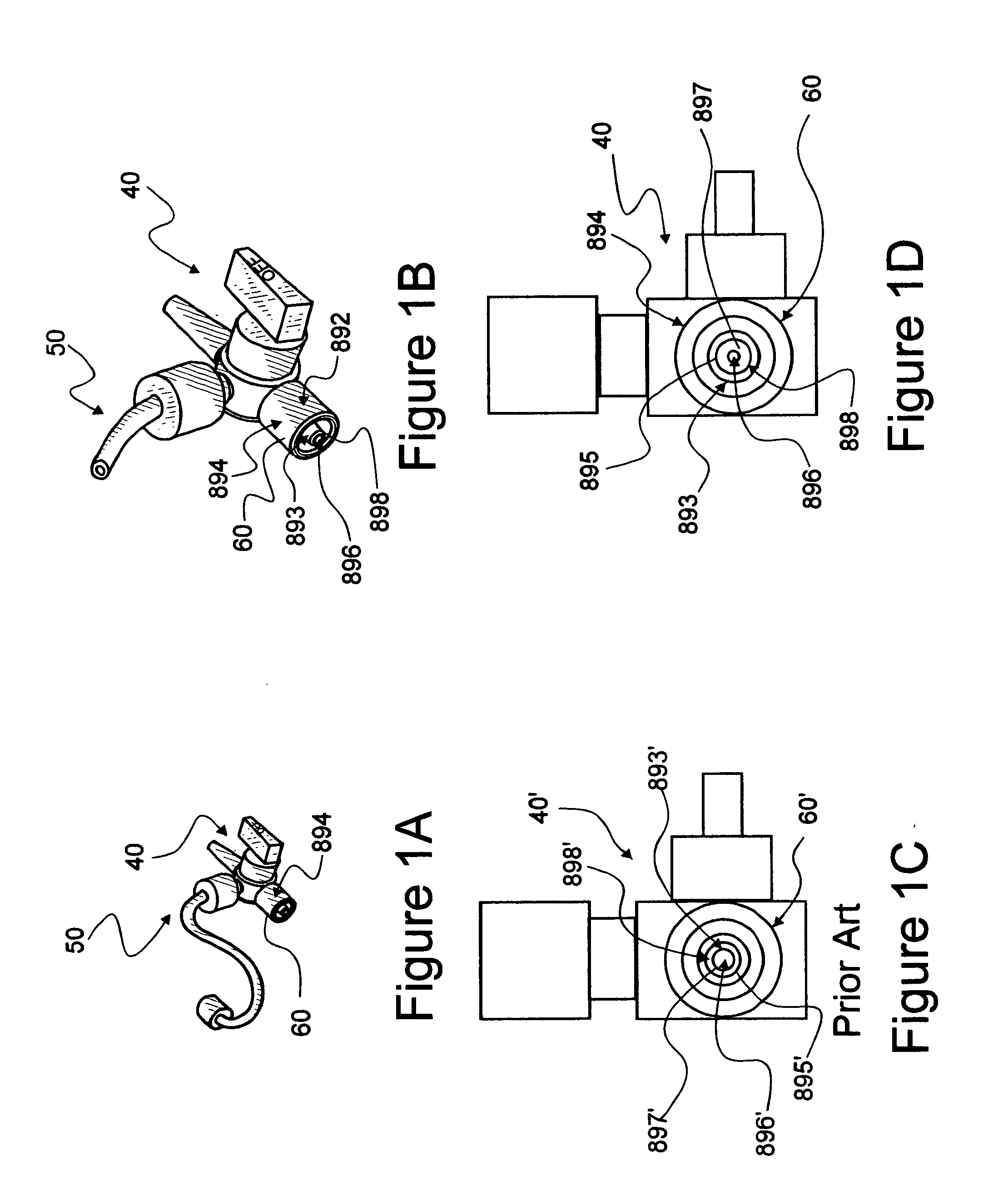

Vial transfer convenience IV kits and methods

InactiveUS20090306621A1Reduce disconnectionImprove securityInfusion devicesPharmaceutical containersEngineeringIntravenous therapy

Convenience kits designed to provide for closed, but selectable liquid transfer from a vial to a variety of IV containers and medical syringes. In particular, a kit for fully enclosing a vial for safety in hazardous drug transfer is disclosed. Generally, the kits contain unitized parts wherever reasonable to limit makes and breaks. Further, pathway determining kits provide selectable pathways for purging connections wish flushing solution where makes and breaks are made between various fluid pathway involved parts such that, when disconnections are made, flush solution is resident at the exposed interface. Also disclosed is a 3-way valve as part of a closed, switchable pathway controlling subsystem by which pathways are selected for reconstituting dry medicine in a vial, displacing a measured dose of liquid from a vial, exchanging gas into the vial for displaced liquid, delivering the measured dose to an IV container.

Owner:INTRAVENA

Smoking article

InactiveCN101925309AGood storage durabilitySimple structureTobacco treatmentCigar manufactureEngineering

Owner:STAGEMODE

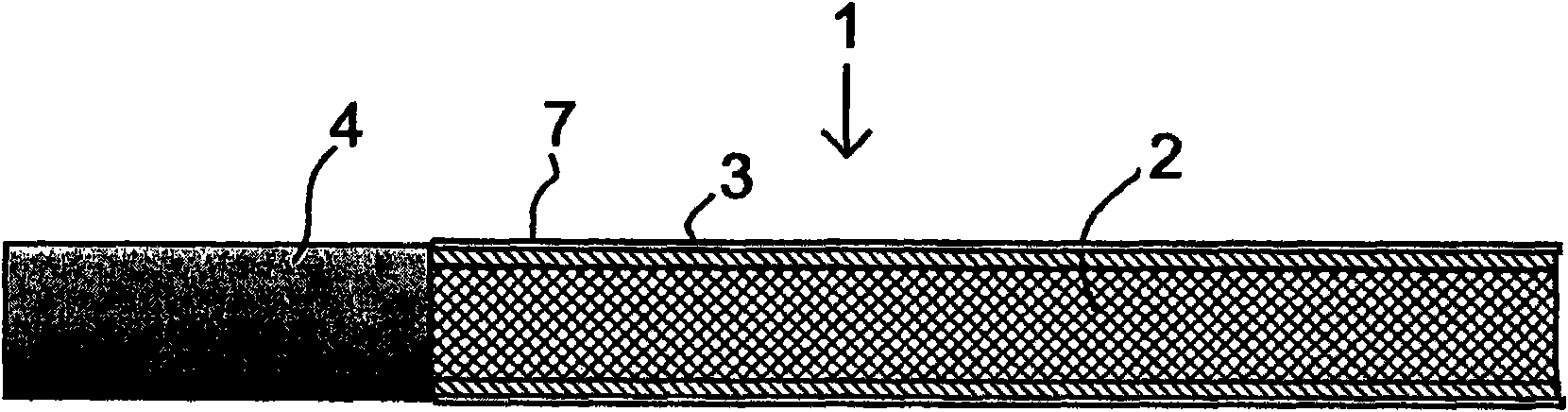

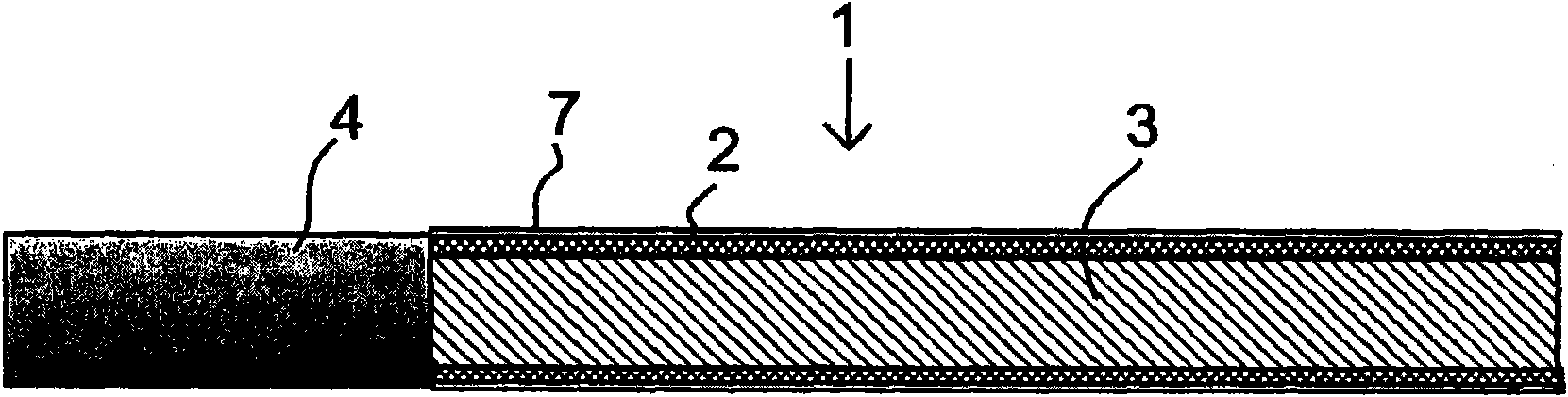

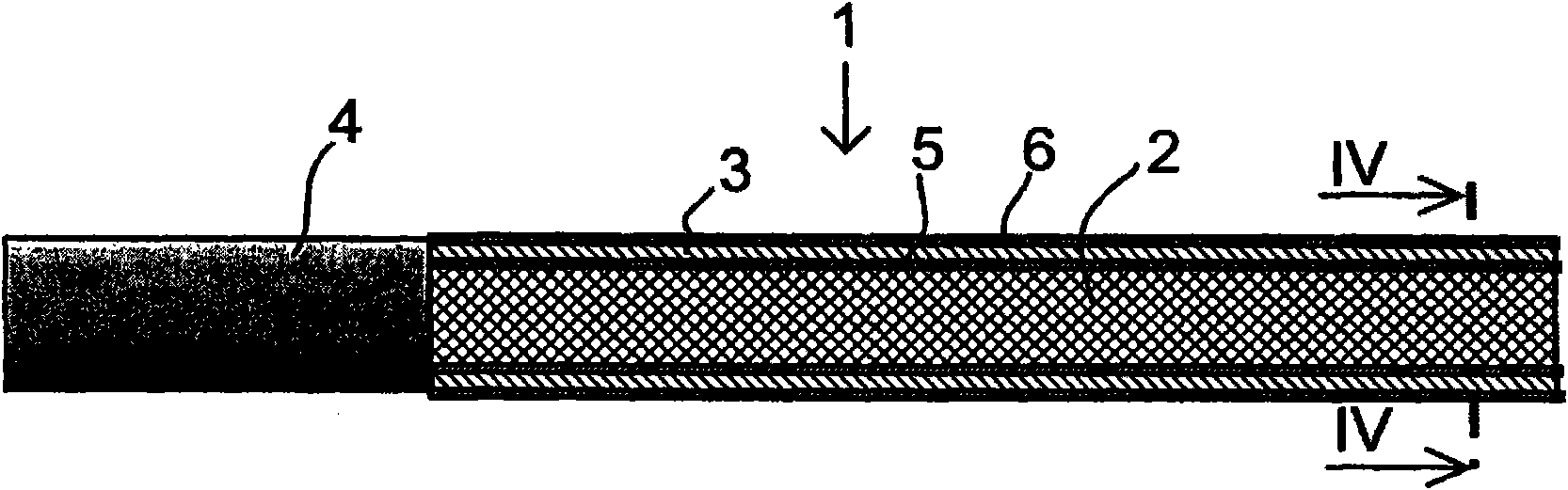

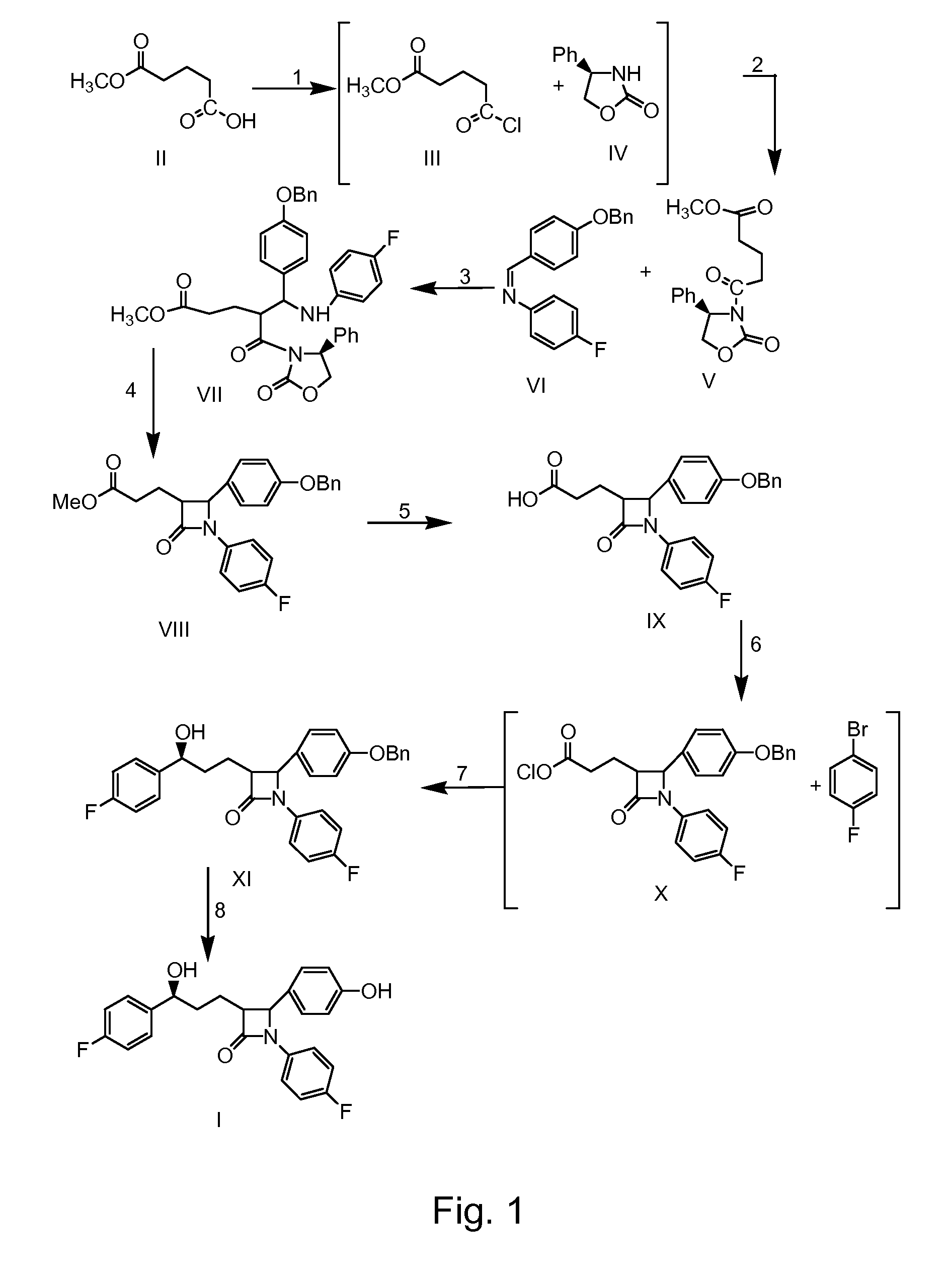

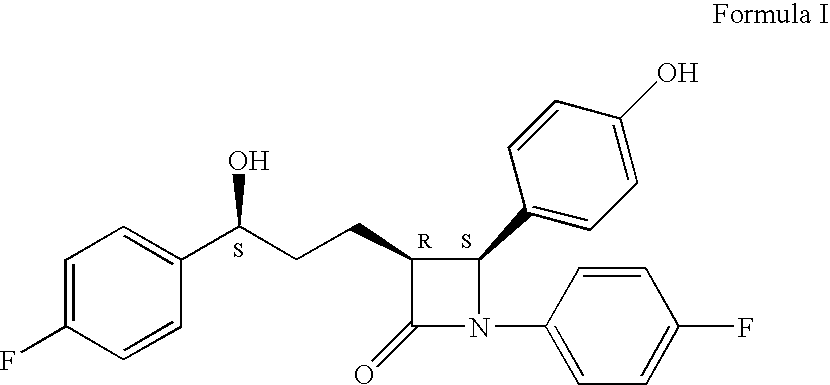

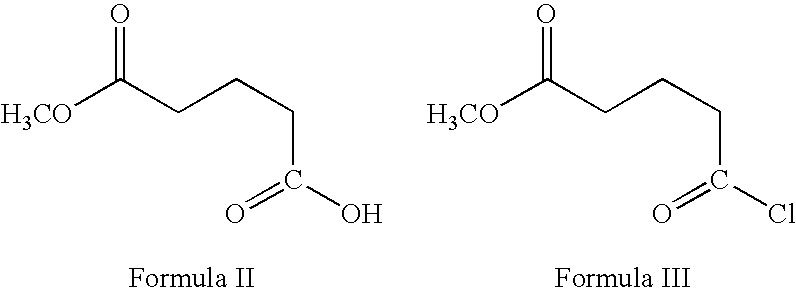

Preparation of ezetimibe

InactiveUS20070049748A1Improve scalabilitySafe handlingOrganic chemistryEzetimibeMedicinal chemistry

Owner:DR REDDYS LAB LTD +1

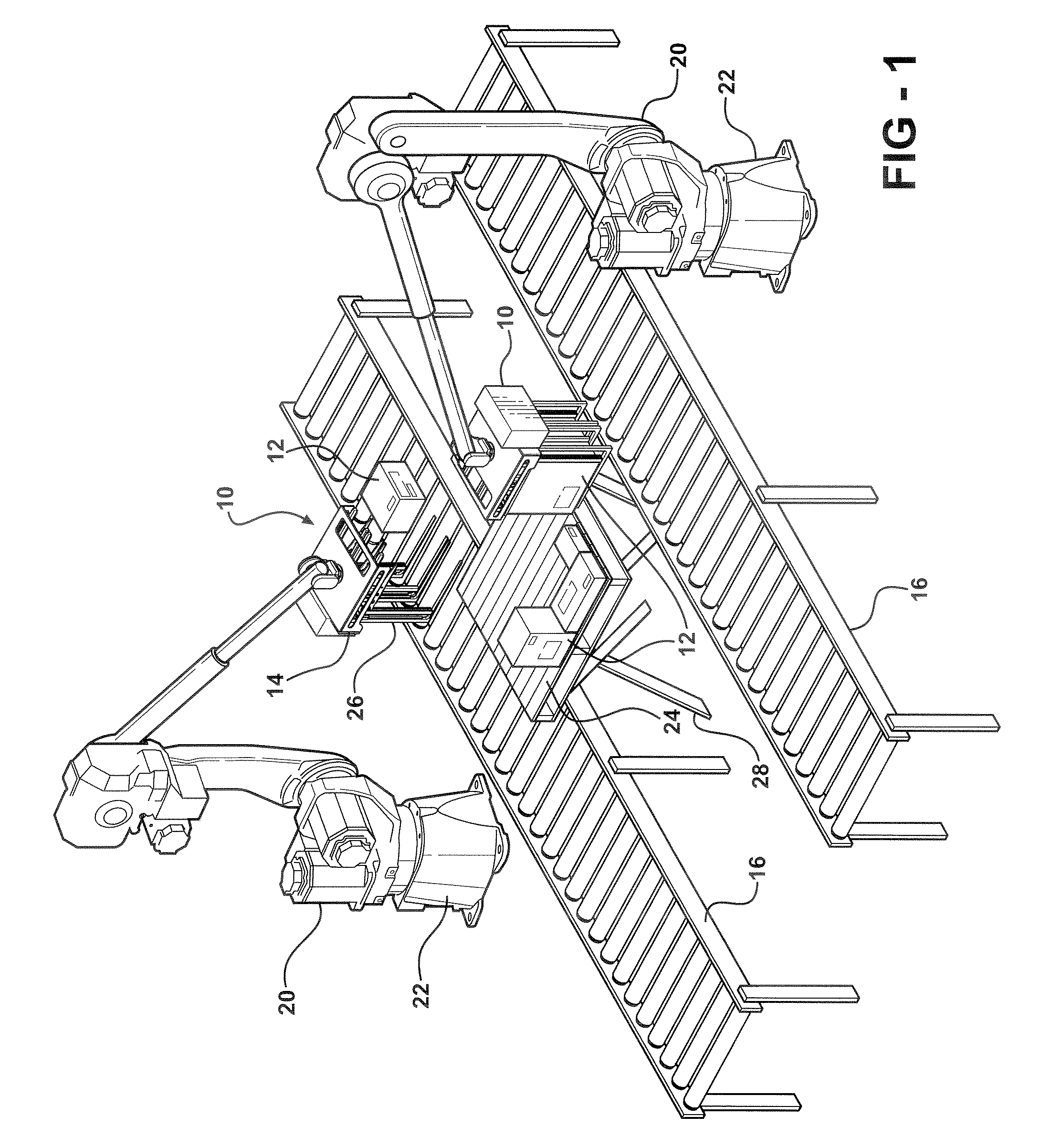

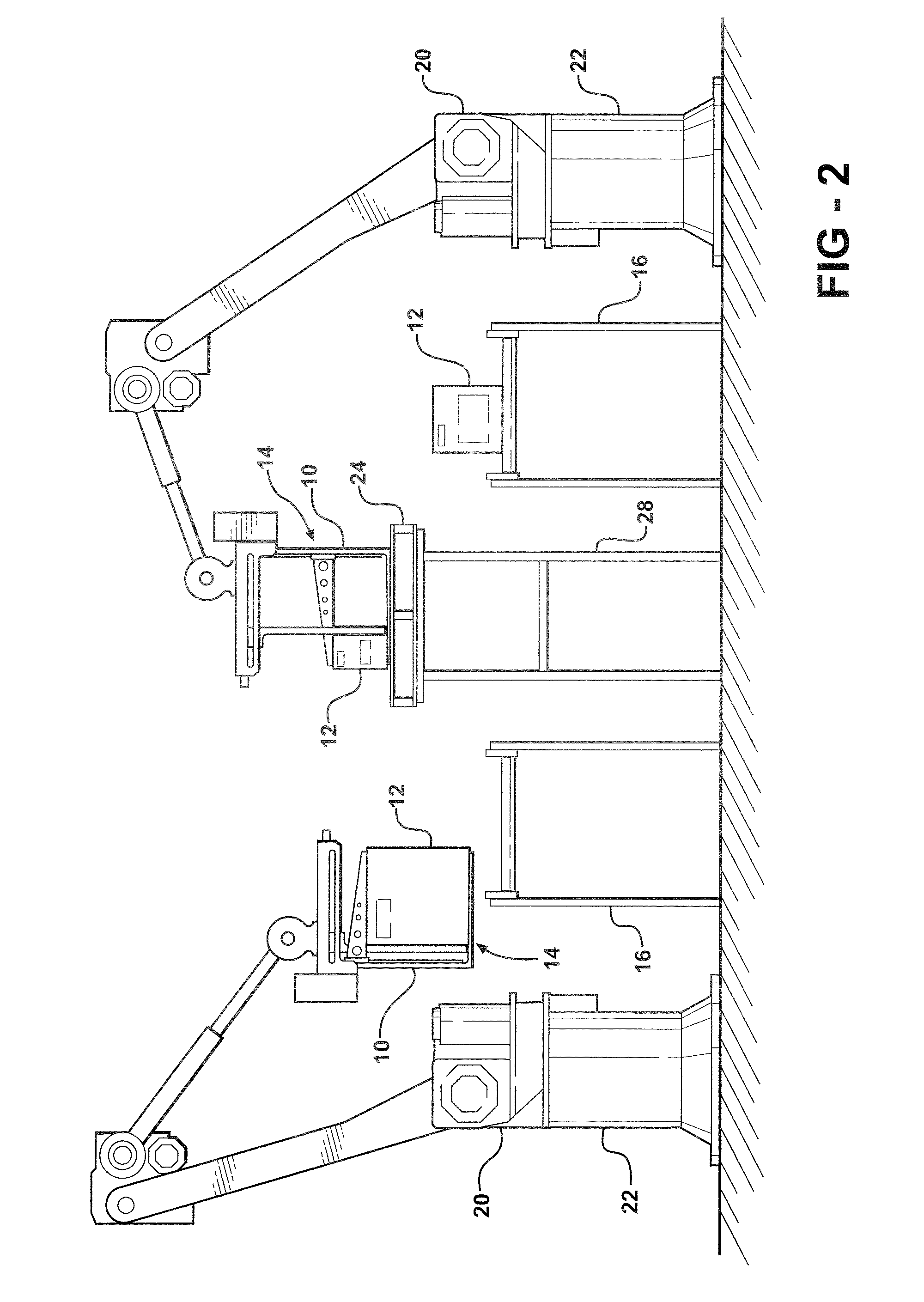

Apparatus and method for handling pipe

ActiveUS20090252589A1Safe handlingEasy to disassembleMeasuring points markingDrilling rodsMarine engineeringActuator

An apparatus for handling pipes, the apparatus, in certain aspects, having a body having a tapered surface and at least a first slip and a second slip slidable on the tapered surface, a slip actuator for setting said at least first slip and said second slip, said first slip and said second slip having interengaging elements such that upon actuation of said slip actuator, said first slip is set and said second slip is set by the interengaging elements transferring setting force from the slip actuator through said first slip to said second slip; and methods for using such an apparatus.

Owner:VARCO I P INC

Urea based composition and system for same

InactiveUS20030219371A1Safe handlingLow degreeGas turbine plantsFused electrolyte fuel cellsNitrogenNitrogen gas

A method and apparatus for generating energy from a composition comprising urea and water are described. The method in one embodiment includes: (a) reacting the urea with water to form ammonia; and (b) oxidizing the ammonia formed in step (a) to form water and nitrogen generating energy. The apparatus in one embodiment contains: (a) a first container for providing the composition; (b) a second container for reacting the urea with water to form ammonia, wherein the second container is connected to the first container by means for delivering the composition from the first container to the second container; (c) a third container for providing ammonia, wherein the third container is connected to the second container by means for delivering ammonia from the third container to the second container; and (d) a fourth container for oxidizing ammonia to form water and nitrogen generating energy, wherein the fourth container is connected to the second container by means for delivering ammonia from the second container to the fourth container. The method and apparatus are used to generate energy for use in stationary and mobile applications.

Owner:AMENDOLA STEVEN C

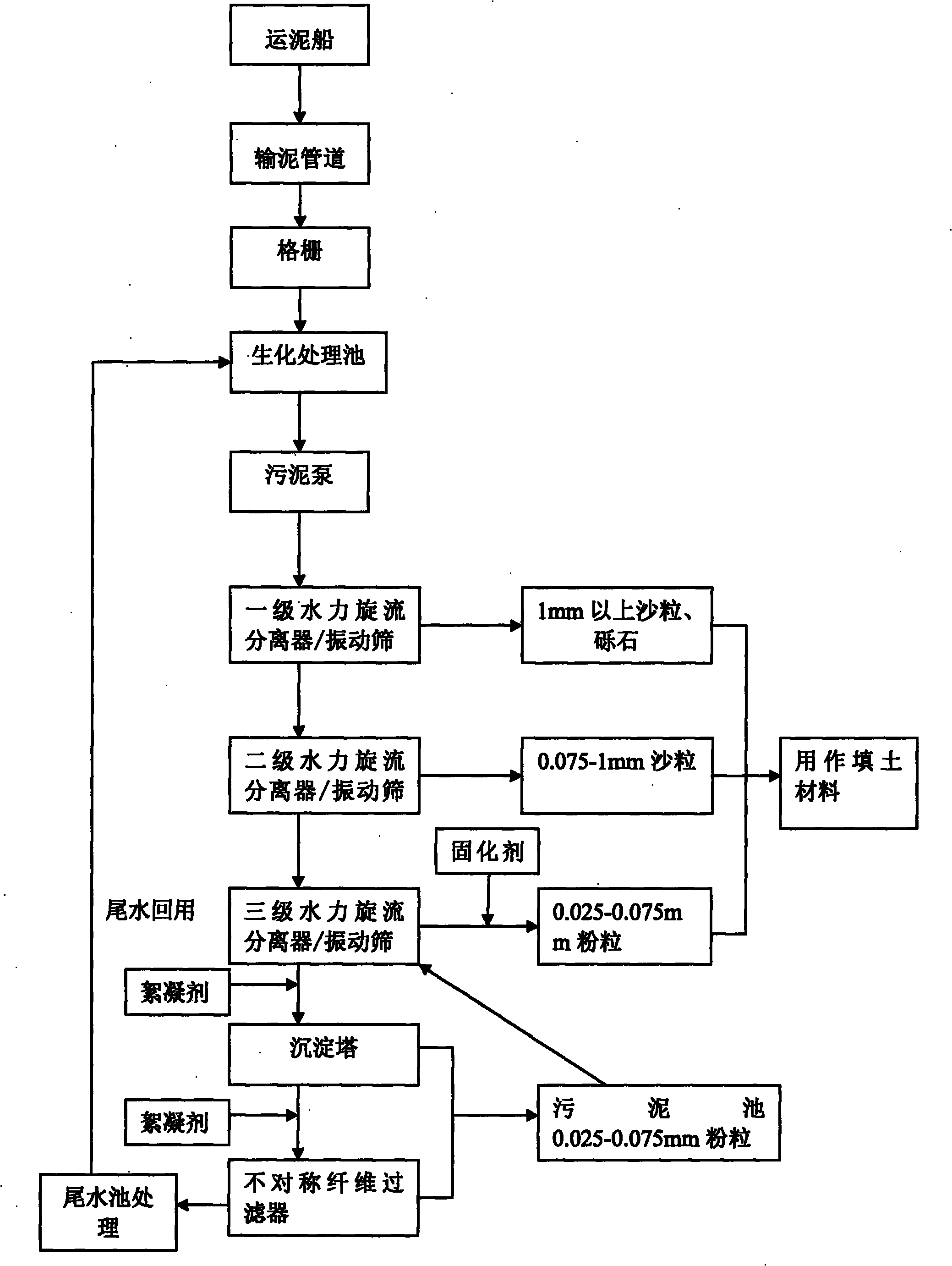

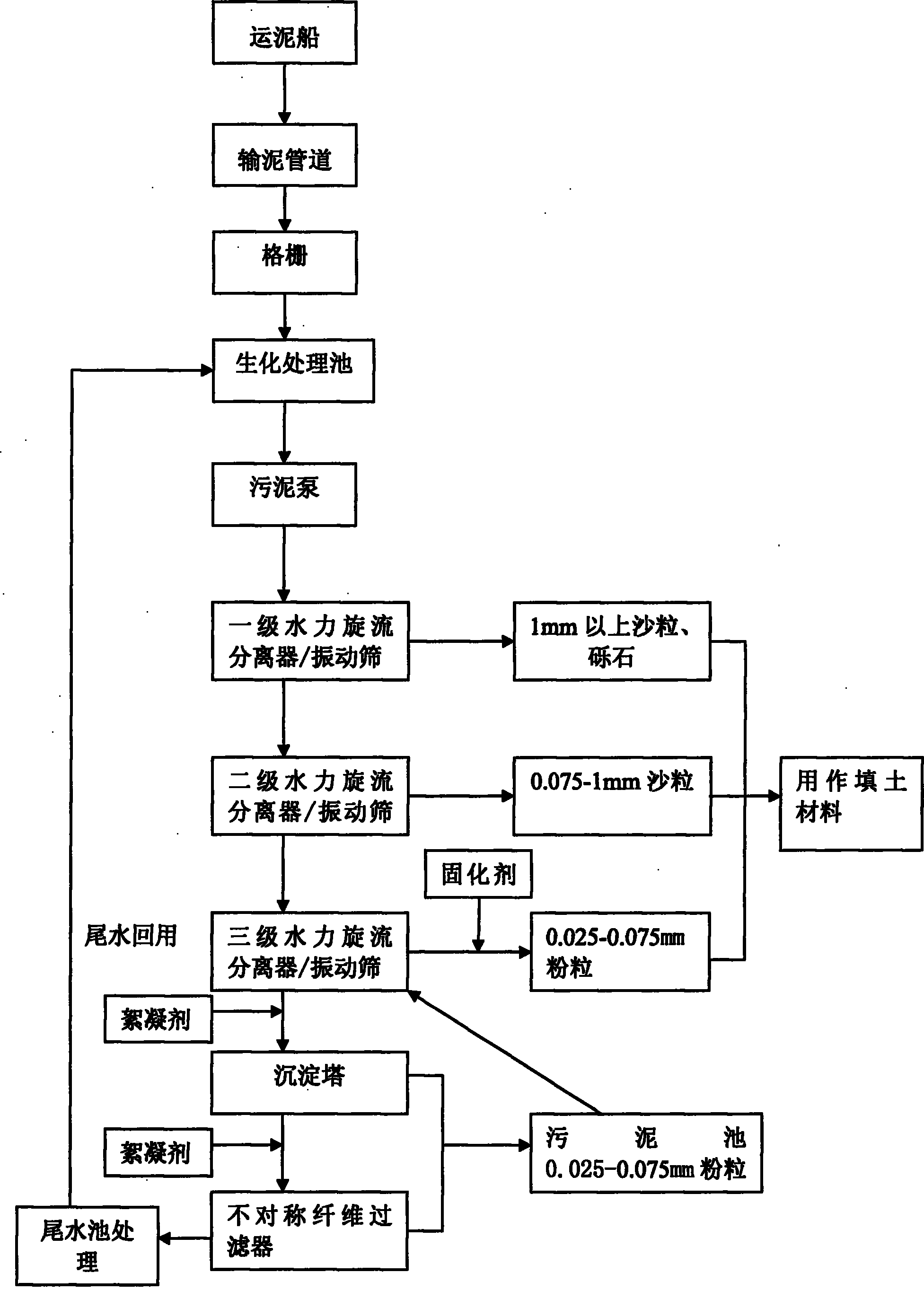

River surge silt harmless and recycling treatment method

InactiveCN101870546ALower redox potentialSmooth processSludge treatment by de-watering/drying/thickeningSolid waste managementFiberResource utilization

The invention provides a river surge silt d harmless and recycling treatment method. In the method, a dredger is utilized to suck silt, the silt is sent into a biochemical treatment pond from the ship through a silt transmission pipeline, compound enzyme is utilized to carry out bioremediation, gravels and sands with the particle size bigger than 1mm are filtered out by a primary hydrocyclone and a vibration screen, sands with the particle size of 0.075-1mm are filtered out by a secondary hydrocyclone and the vibration screen, powdery particles with the particle size of 0.025-0.075mm are filtered out by a third-level hydrocyclone and the vibration screen, powder particles are further separated out from outlet silt tail water through a sediment tower, sewage from the sediment tower is filtered by utilizing a fiber filter after flocculant is added into the sewage, and powdery particles are deposited from backflushing silt after being filtered by utilizing the sediment tower again, and the powdery particles are dehydrated by the third-level hydrocyclone and the vibration screen after entering a sludge pool and are cured by a curing agent after dehydration. The method has high resource utilization ratio, meets the requirements for the environmental protection, particularly carries out stage treatment on the silt, lowers the cost and enhances the efficiency.

Owner:GUANGZHOU BAOMINGLAI ENVIRONMENT SCI & TECH

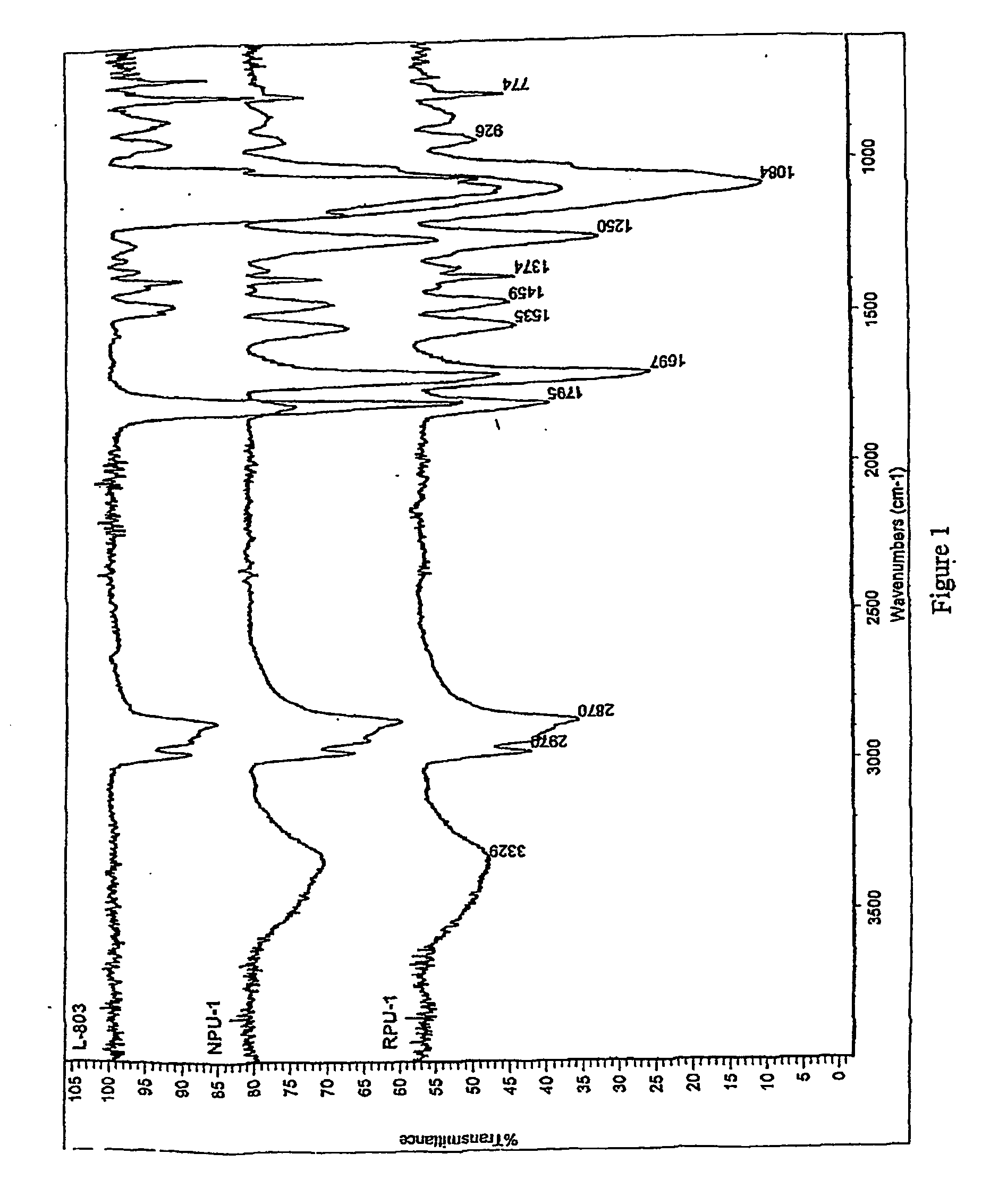

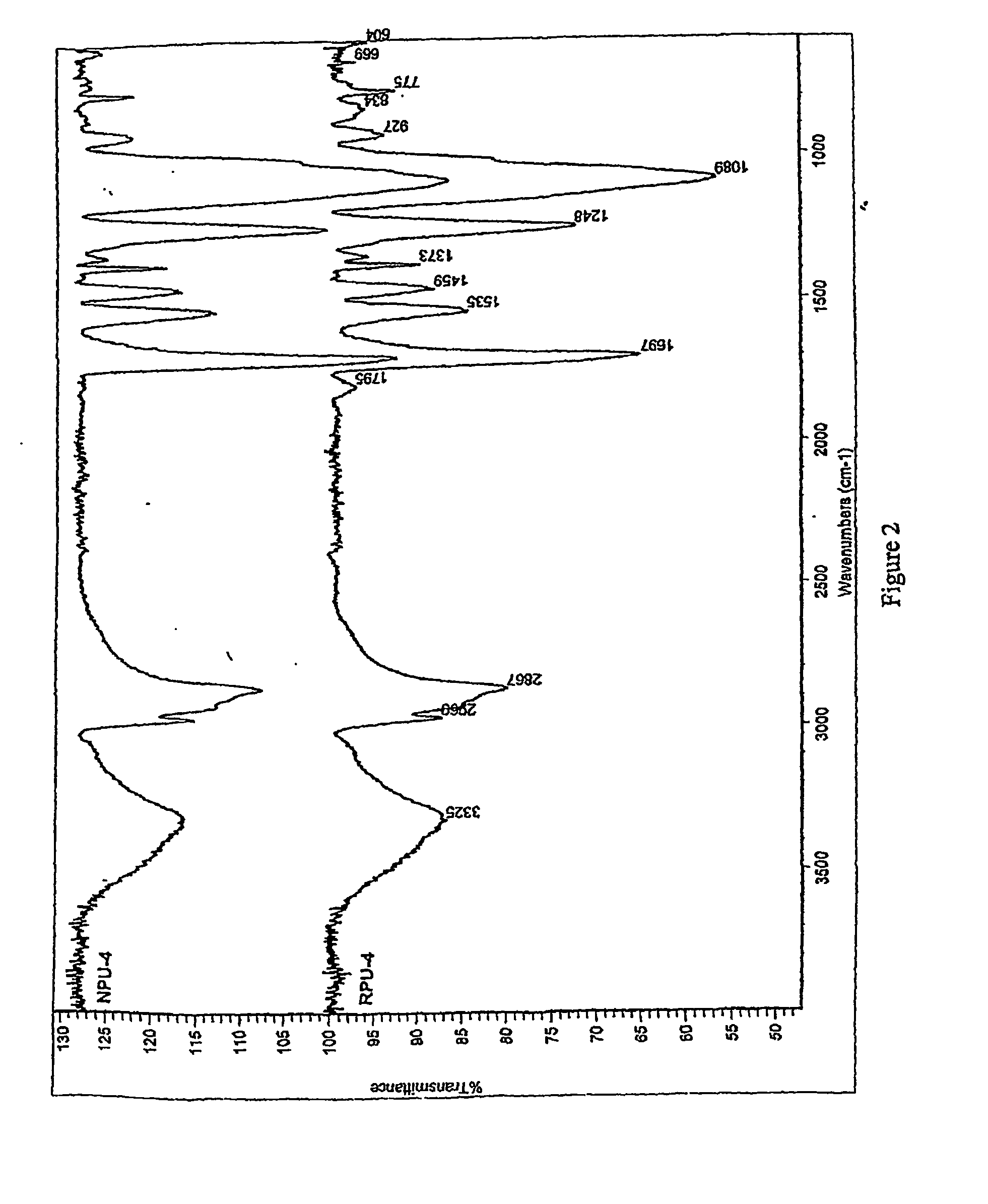

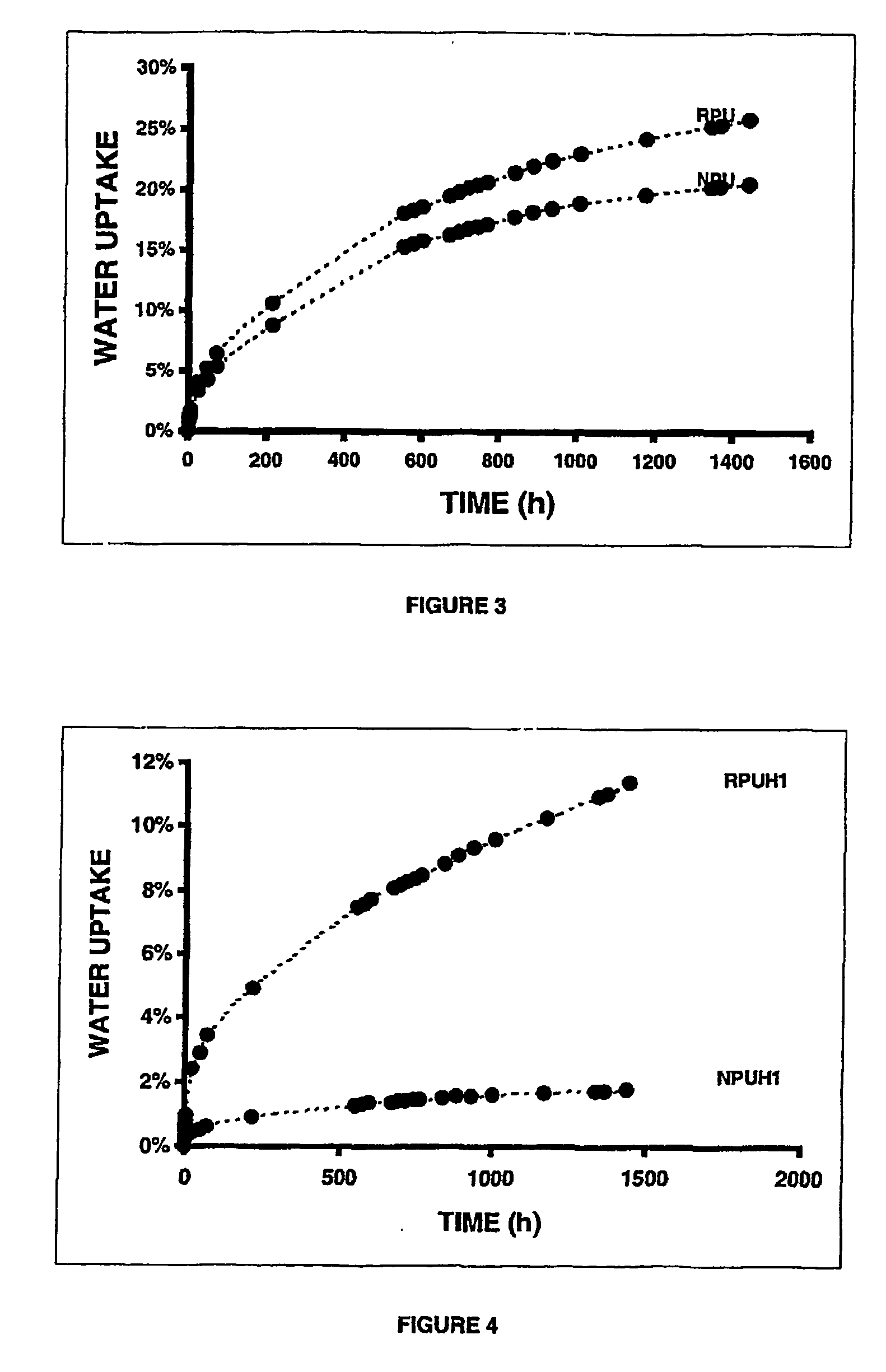

Nanocomposites based on polyurethane or polyurethane-epoxy hybrid resins prepared avoiding isocyanates

ActiveUS20070135588A1Beneficial physicochemical and mechanical propertyAvoid damageMaterial nanotechnologySynthetic resin layered productsNanometreAspect ratio

A fast curable non-isocyanate-based polyurethane- and polyurethane-epoxy network nanocomposite polymeric compositions are derived upon crosslinking a mixture comprising of natural or modified nano-clay [ionic phyllosilicate] with platelet thickness in the scale of A (˜1 nm) and aspect ratio (length / thickness) higher than 10 (nm)] preferably natural or modified montmorillonite with either a monomer(s) or oligomer(s) bearing at least one cyclocarbonate group or a mixture of the latter with an epoxy resin, with a hardener, which is a monomer or oligomer or mixtures therefrom, bearing primary and / or secondary amino groups. The use of the nanoclays reduces the gel time and increases the adhesion of the cured polyurethane and polyurethane / epoxy hybrid and also reduces its water absorption.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Mixed size product handling end of arm tool

InactiveUS7967354B2Safe handlingQuicker handling timeProgramme-controlled manipulatorGripping headsPalletRobot

A mixed size product end of arm tooling is used in conjunction with a robot to pick mixed size product and place the product onto a pallet or layers resting on top of a pallet. The end of arm tooling includes two center rails / forks mounted to a base. Two outer rails / forks are mounted to linear bearings that guide the outer rails / forks when moving inwardly or outwardly from the center rails for pre-sizing to the product. Pusher arms are formed of two outer pusher arms and one center pusher arm. These pusher arms are attached to linear bushings that guide the pusher arms forward and backward. The pusher arms push off the product simultaneously as the robot is withdrawing the rails.

Owner:FANUC ROBOTICS NORTH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com