Smoking article

A technology for smoking products and products, which is applied in the field of preparing smoking products, and achieves the effect of simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

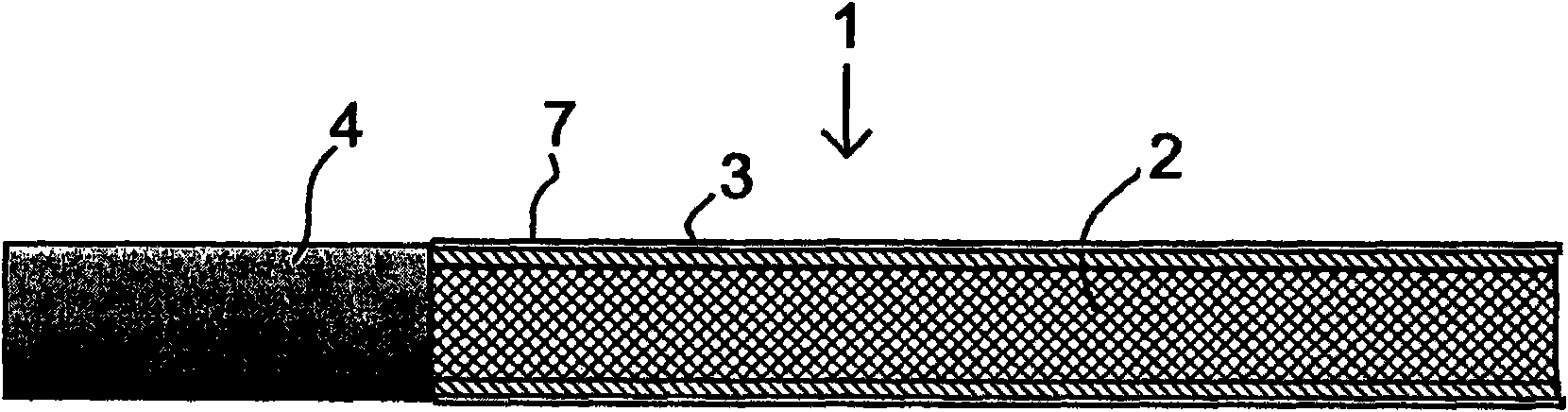

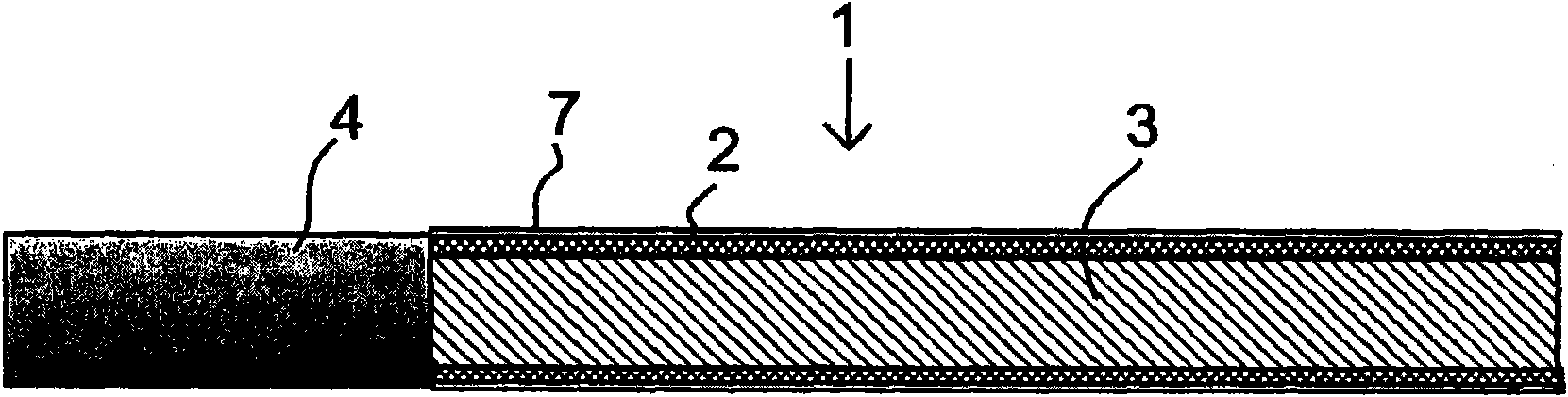

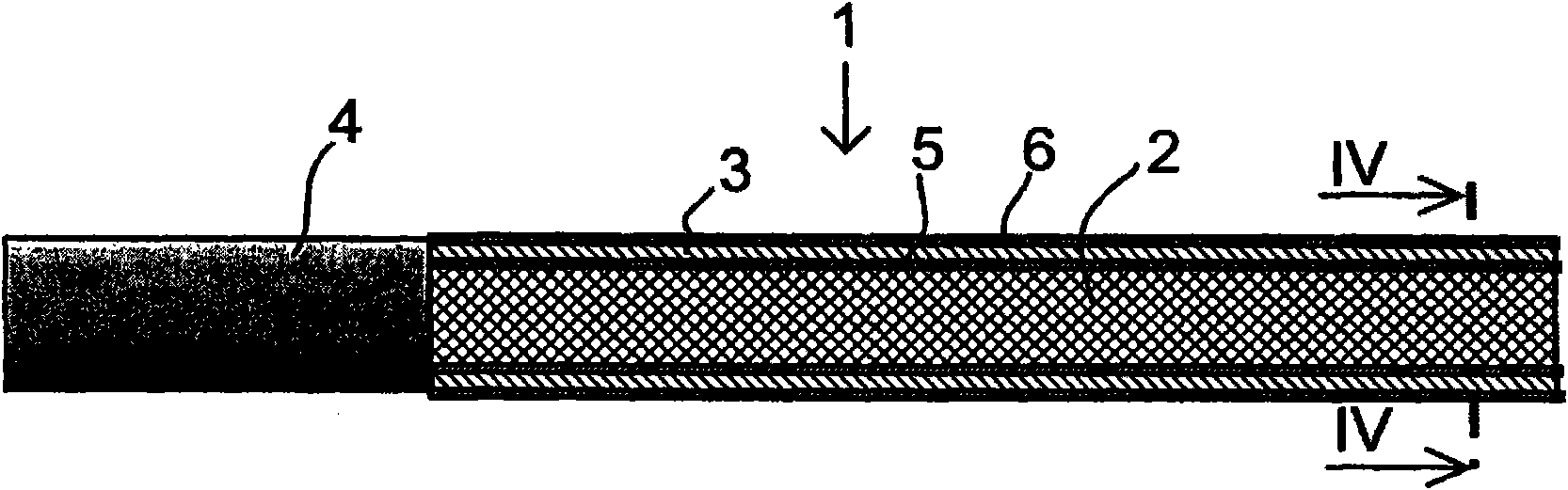

Image

Examples

Embodiment 1

[0079] In this experiment the effect of the heating chamber compound, starting material, on the exothermic reaction was tested. Weight ratios of different starting materials were used in the tests to establish their effect on heating rate, maximum temperature and temperature change over time. Heat tests were performed with the reaction of potassium permanganate and iron in weight ratios of 30 / 70 and 70 / 30. 1.0 g of the starting material mixture was used for this test. The reaction is carried out by placing the starting material in an aluminum or glass tube, whereupon the reaction is initiated by an electric fuse. The temperature was monitored by a thermocouple connected to the tube.

[0080] The tube is fitted inside the fine cut tobacco portion of a normal size cigarette in such a way that space is left for the fine cut tobacco. The inner diameter, outer diameter and wall thickness of the aluminum tube and glass tube are: Al 4.75mm, 4.05mm and 0.35mm; glass 5.06mm, 3.06mm ...

Embodiment 2

[0087] In this experiment the functionality of a smokeless smoking article was tested. Insulated glass tubes are used as the heating chamber structure. This structure is similar to that of Embodiment 1. The thickness of the thermal insulation layer formed by aluminum foil and fabric is 0.56mm.

[0088] 1.0 g of a mixture of potassium permanganate and iron (30 / 70) were introduced into the heating chamber.

[0089] Smoking articles are produced by placing a heating chamber in a rolling machine with paper, filter and fine cut tobacco and rolling the smoking article.

[0090] Reaction-initiating heat is introduced to the smoking article by a resistive wire that is heated by conducting electrical current to the wire.

[0091] After this test, the smoking article was visually inspected and it was observed that tar had separated from the tobacco onto the paper surface. Visible from the filter: The heating chamber reaction has separated components from the fine cut tobacco. No bu...

Embodiment 3

[0094] The test consists of analyzing the smokeless smoking articles according to the invention, regular cigarettes and commercial smokeless smoking articles for their volatile constituents: nicotine, carbon monoxide (CO) and tar. A smoking article according to Example 2 was used as a smokeless smoking article, and a Philip Morris "Gold" Marlboro was used as a regular cigarette. A smoking article under the Woodleaf Corporation trademark Aeros was used as a commercial smoke-free reference smoking article, based on a plastic tube already joined at both ends and containing a base comprising nicotine and tobacco flavour. The smoker cuts off the end of the plastic tube, and when the smoker inhales air through the tube, nicotine and tobacco flavor are released into the smoker's mouth and organs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com