Solid edge gutter screen

a gutter screen and solid edge technology, applied in the field of gutter screens, can solve the problems of increasing the problem instead of solving, difficult installation, and significant risk that the installer will cut his hands on the edge of the gutter, so as to facilitate safe handling of the screen, prevent the fall of leaves and debris, and inhibit the sagging of the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

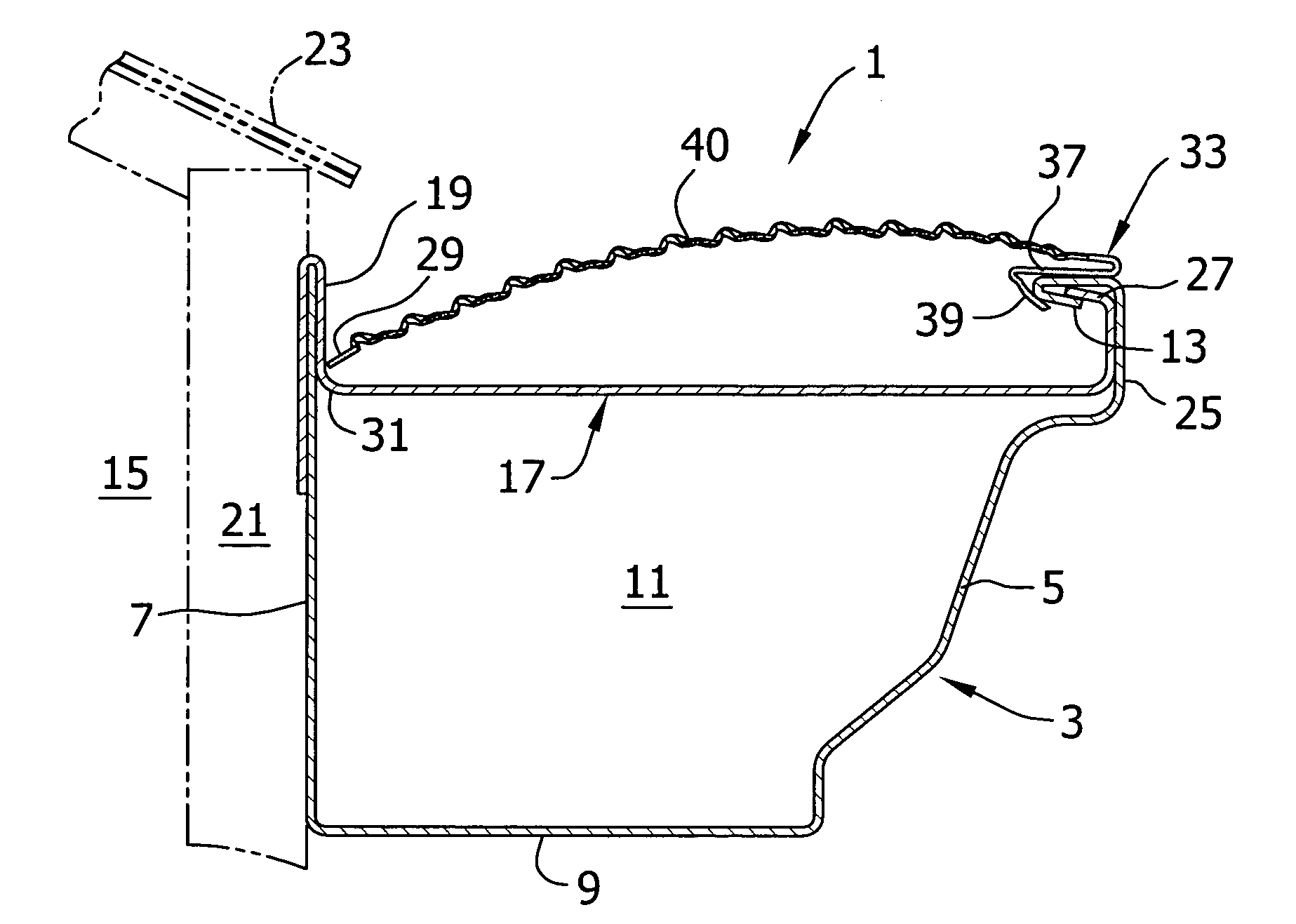

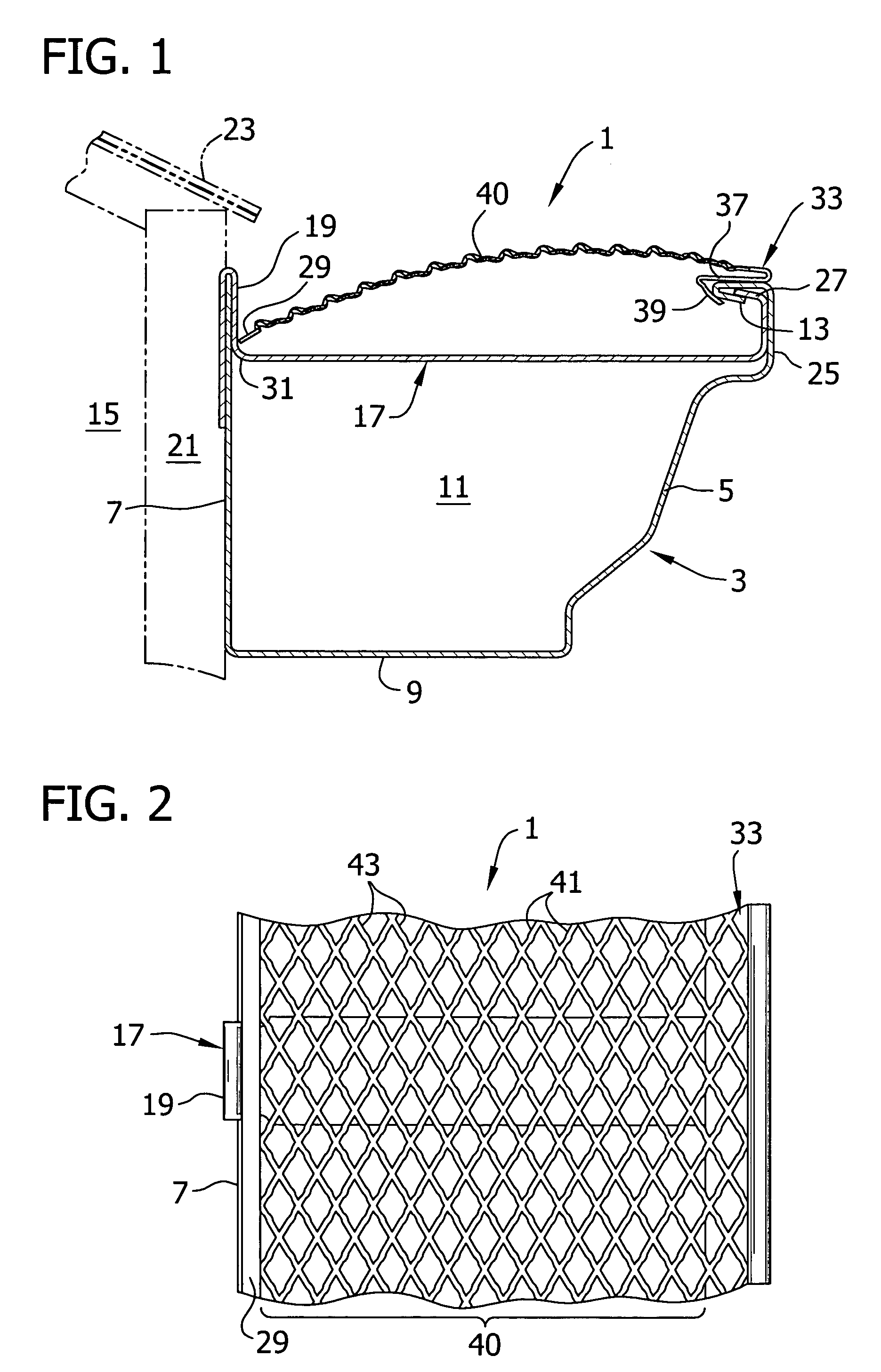

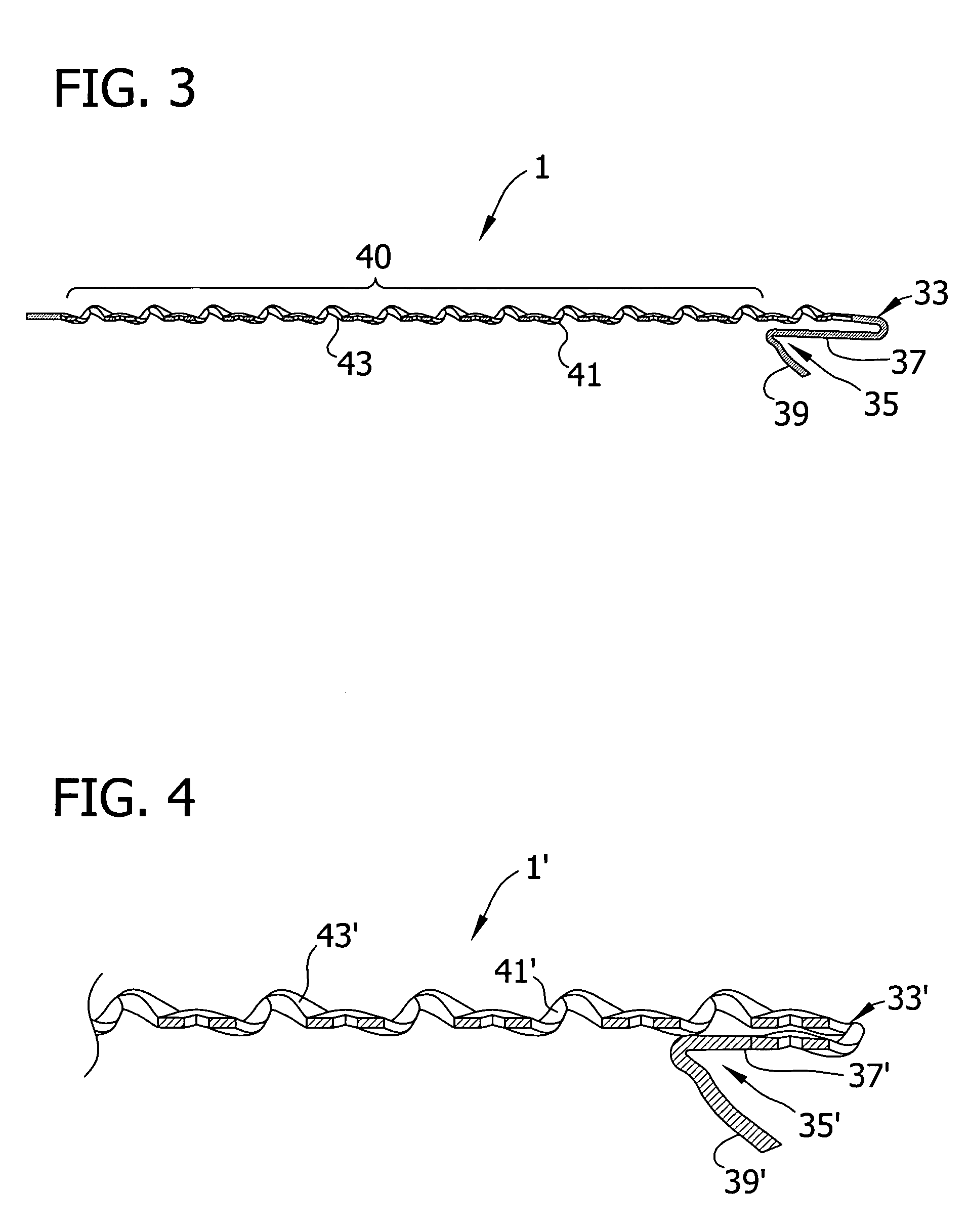

[0020] Now referring to FIGS. 1 and 2, a gutter screen of one embodiment of the present invention is designated in its entirety by the reference numeral 1. Gutter screen 1 is particularly adapted for covering a conventional rain gutter, such as indicated generally at 3, and preventing leaves, debris and the like from falling into the gutter. Note that the gutter screen is not made of hardware cloth or wire mesh.

[0021] As shown in FIG. 1, gutter 3 has a front wall 5, a back wall 7 and a bottom wall 9, which form a channel 11 for drainage of rainwater. Front wall 5 may be provided with a decorative and / or strengthening configuration, as shown. A conventional lip or flange 13 projects rearwardly from the front wall 5 and is spaced above the bottom wall 9 of the gutter 3. The flange 13 extends substantially continuously along the entire length of the gutter 3.

[0022] Gutter 3 is suitably attached to the outside wall 15 of a building by gutter hangers, one of which is shown and designat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com