Patents

Literature

60results about How to "Moderate temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

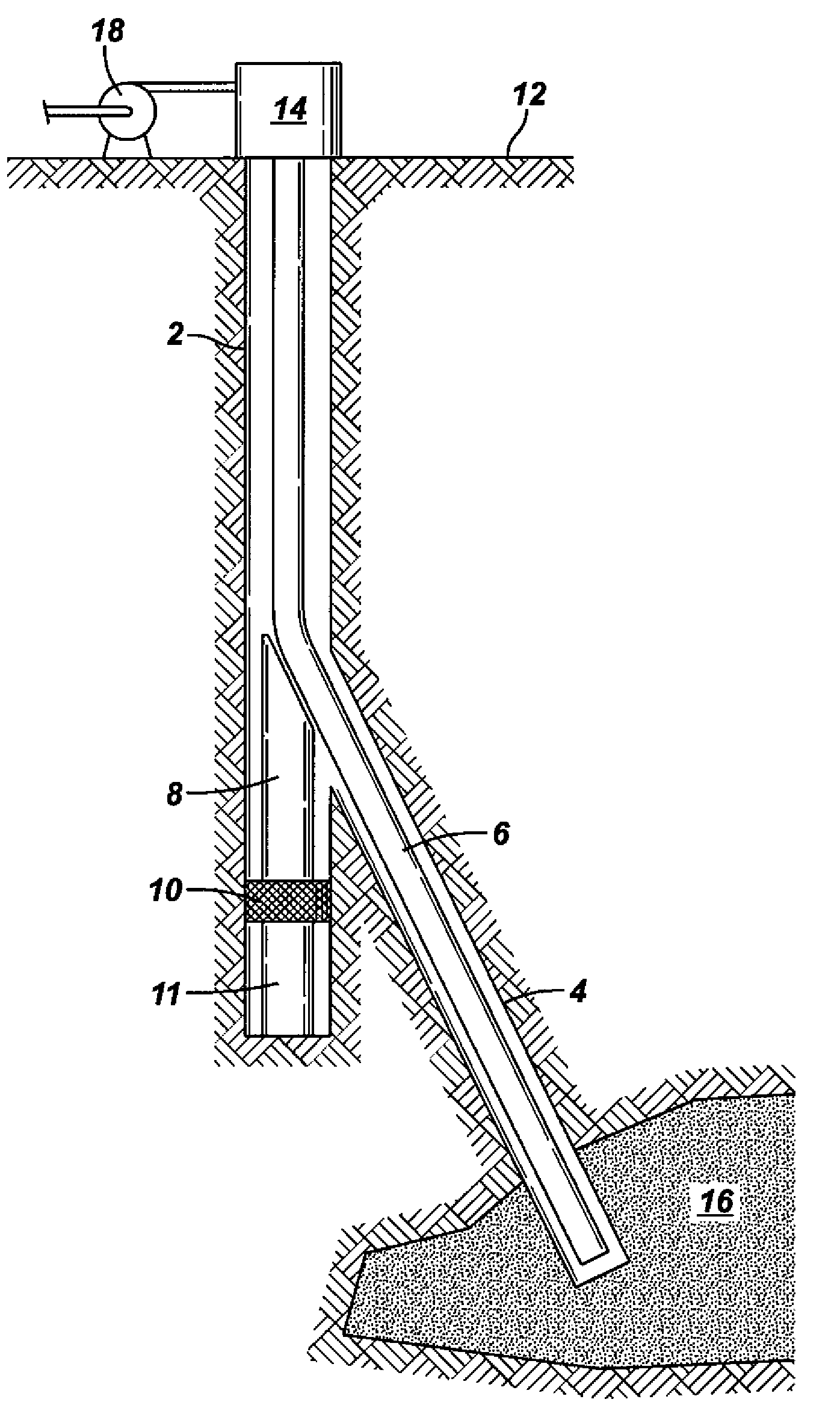

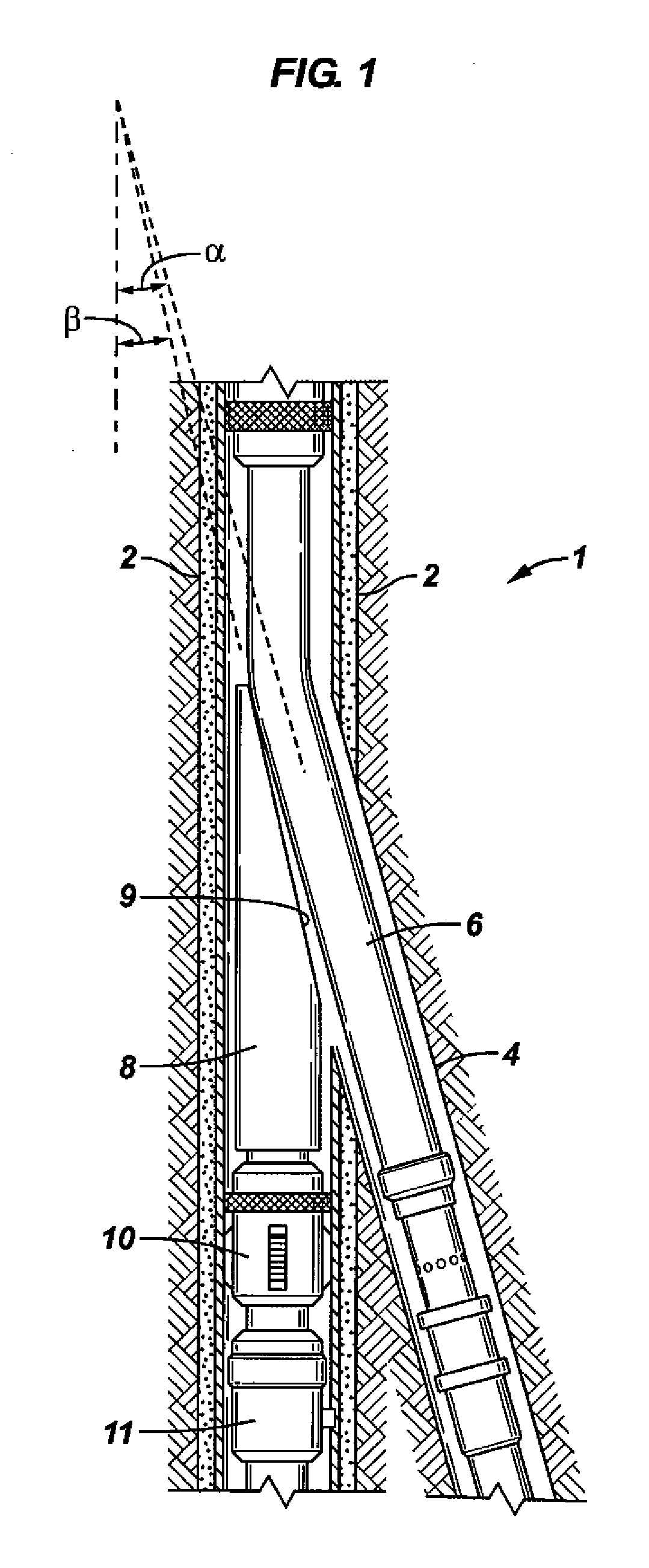

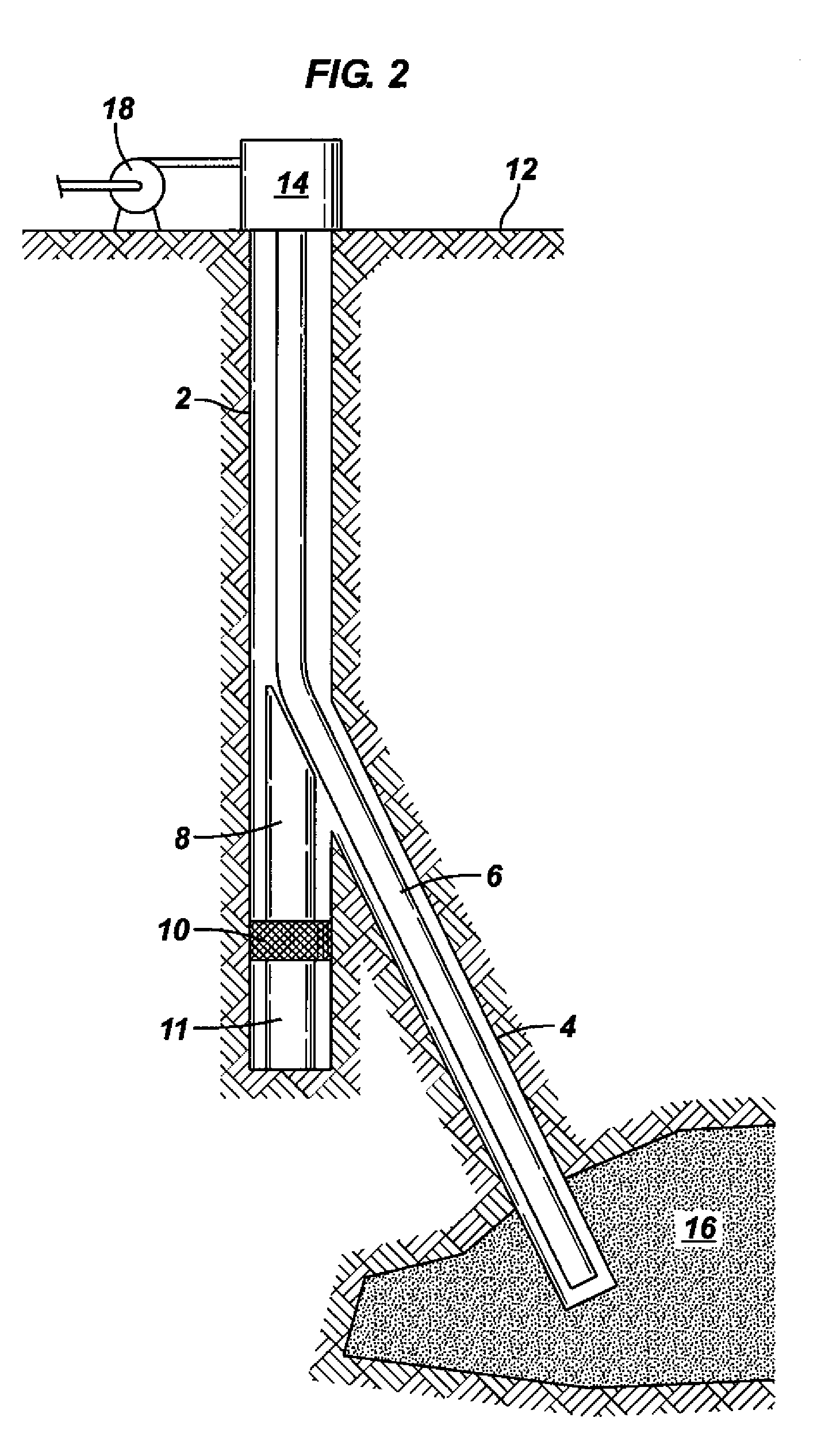

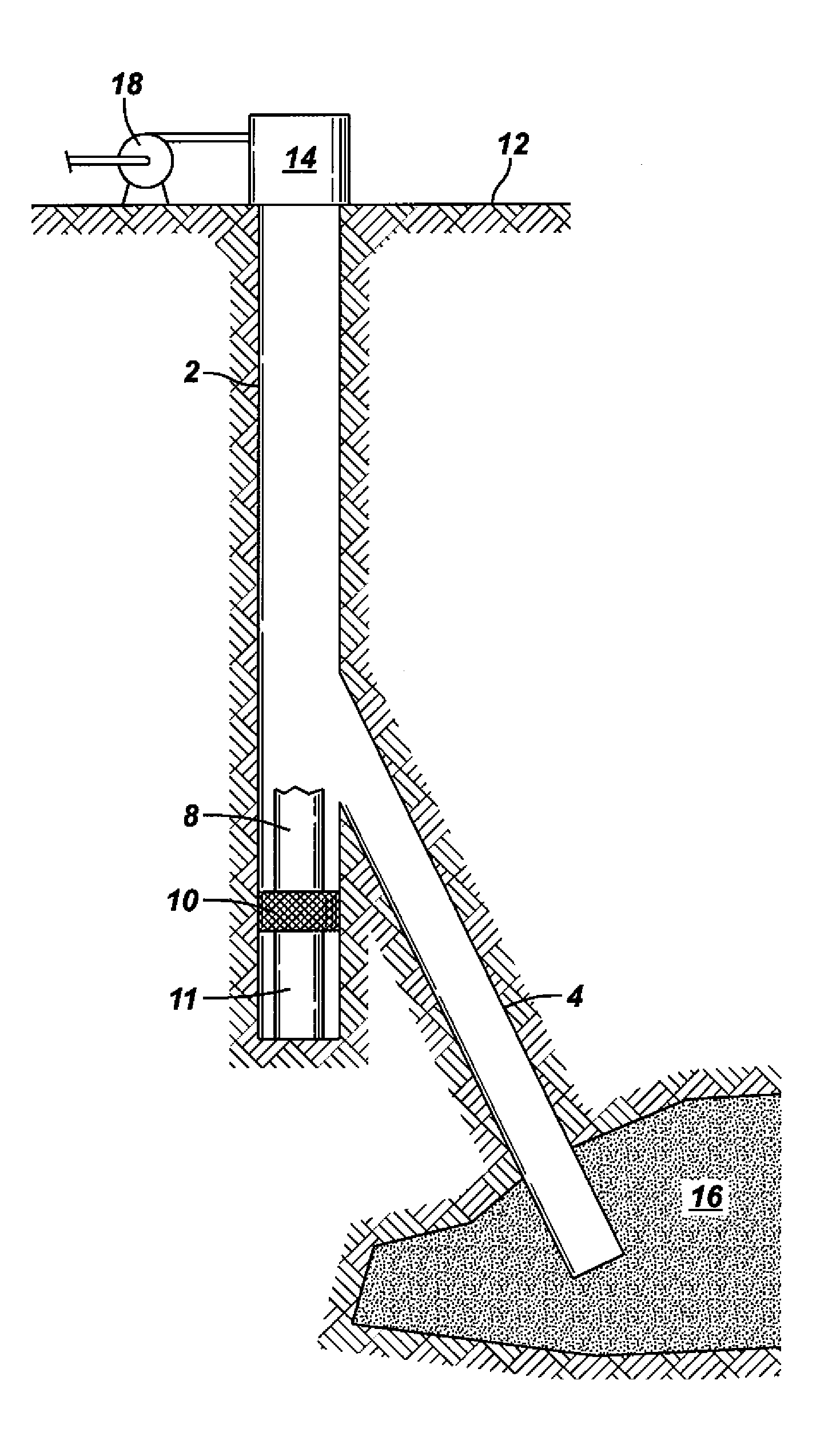

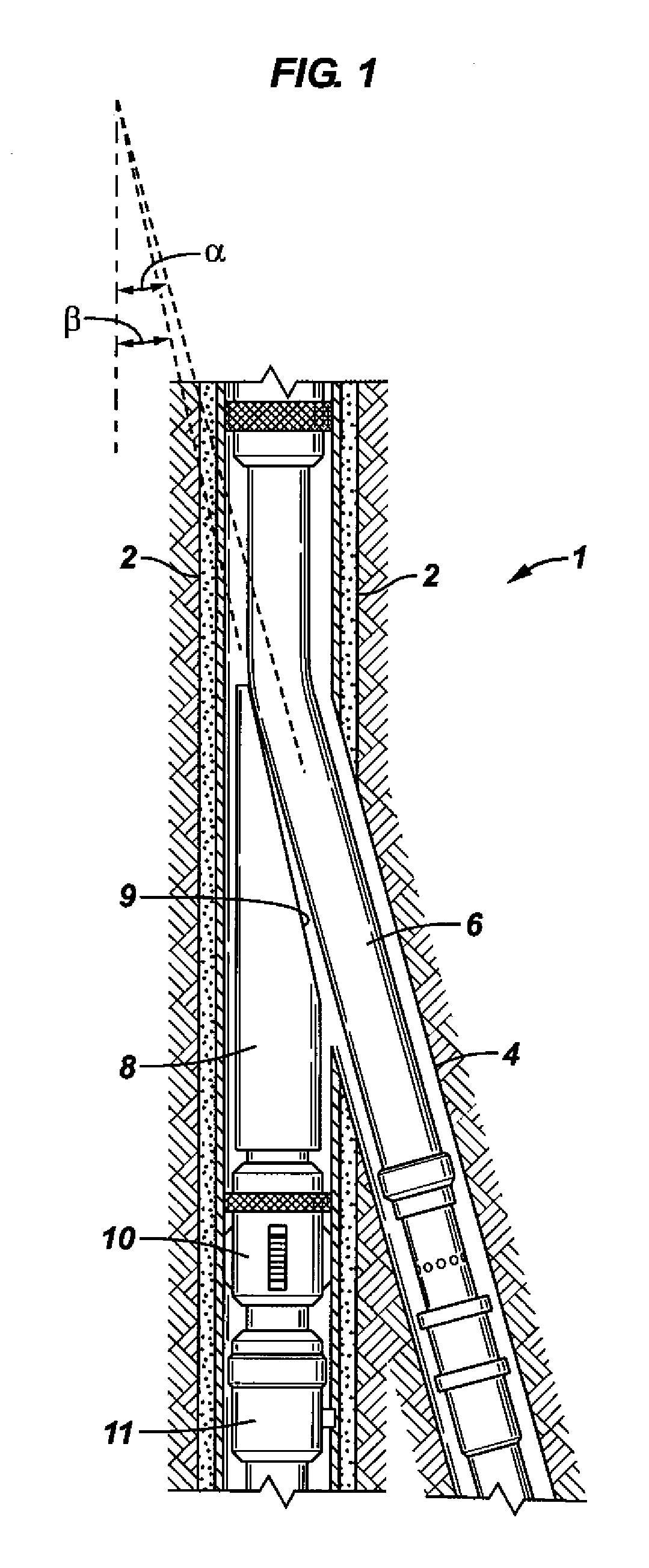

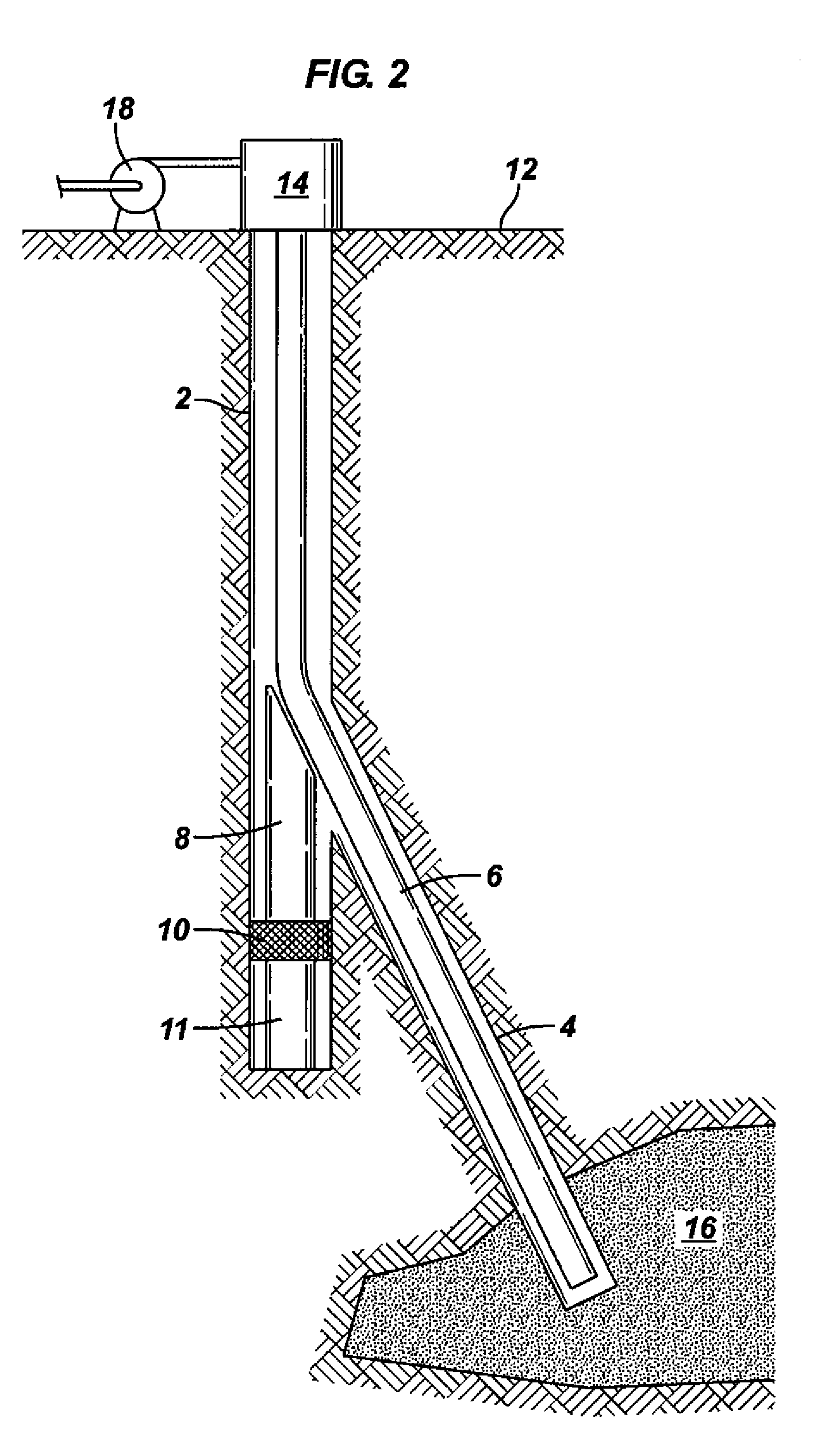

Degradable whipstock apparatus and method of use

InactiveUS20080105438A1Improve responseSafe handlingFluid removalDirectional drillingSubject matterHigh intensity

Whipstocks and deflectors comprising a degradable composition, and methods of using same are described. In one embodiment the degradable composition consists essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Methods of using degradable whipstocks in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. 1.72(b).

Owner:SCHLUMBERGER TECH CORP

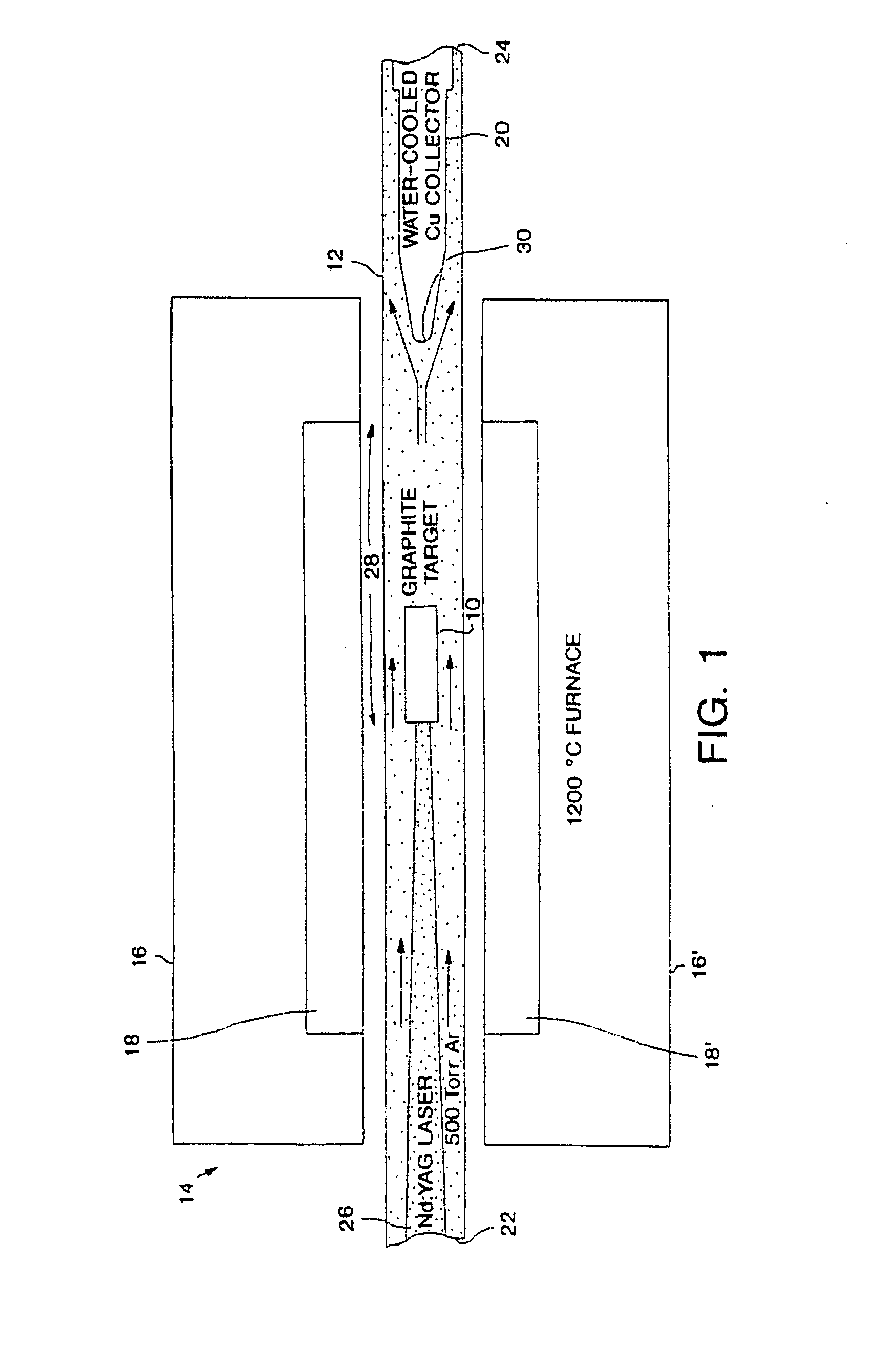

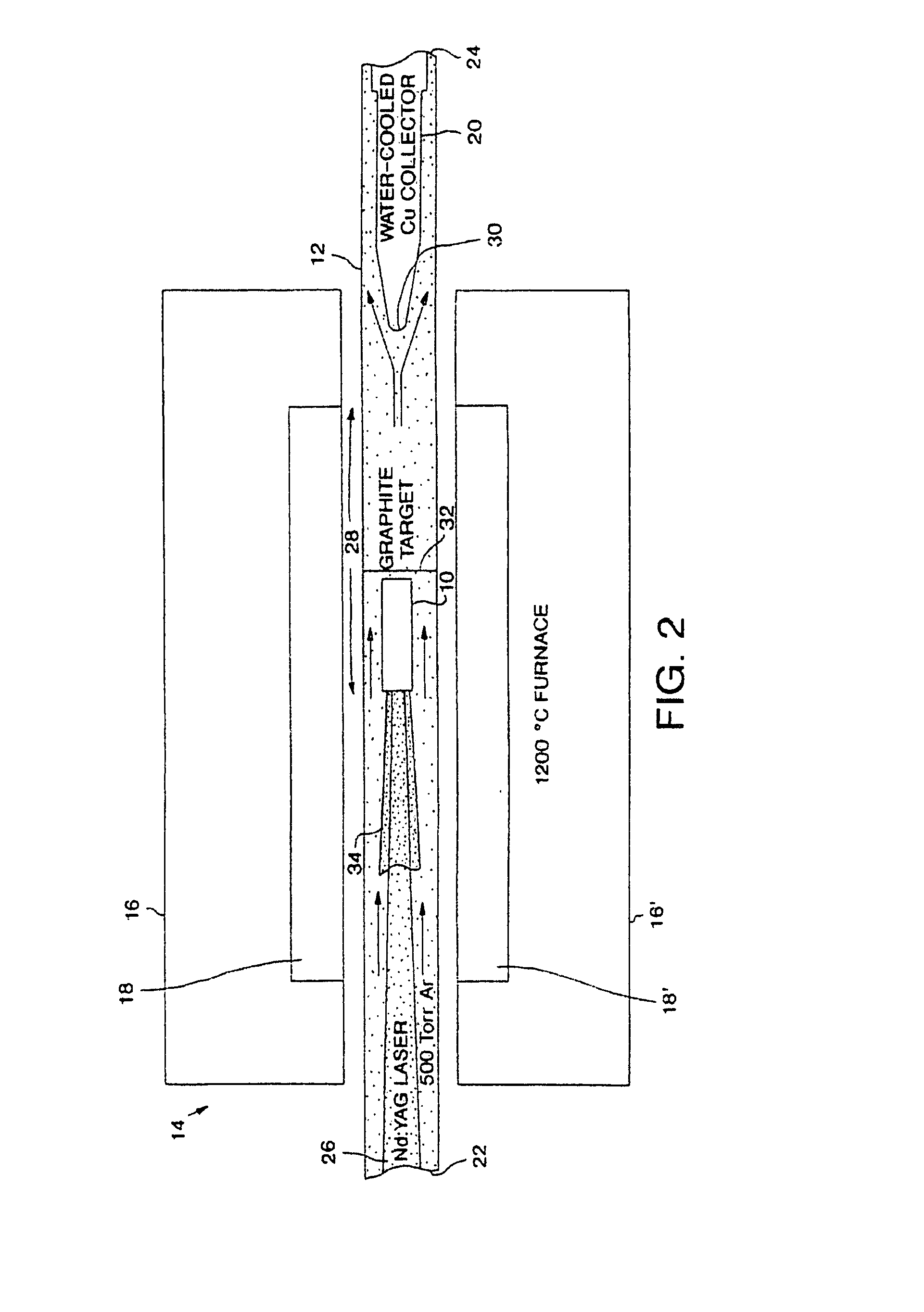

Fullerene nanotube compositions

InactiveUS20080063585A1High yieldModerate temperatureMaterial nanotechnologyFullerenesFullereneNanotube

This invention relates generally to a fullerene nanotube composition. The fullerene nanotubes may be in the form of a felt, such as a bucky paper. Optionally, the fullerene nanotubes may be derivatized with one or more functional groups. Devices employing the fullerene nanotubes of this invention are also disclosed.

Owner:RICE UNIV

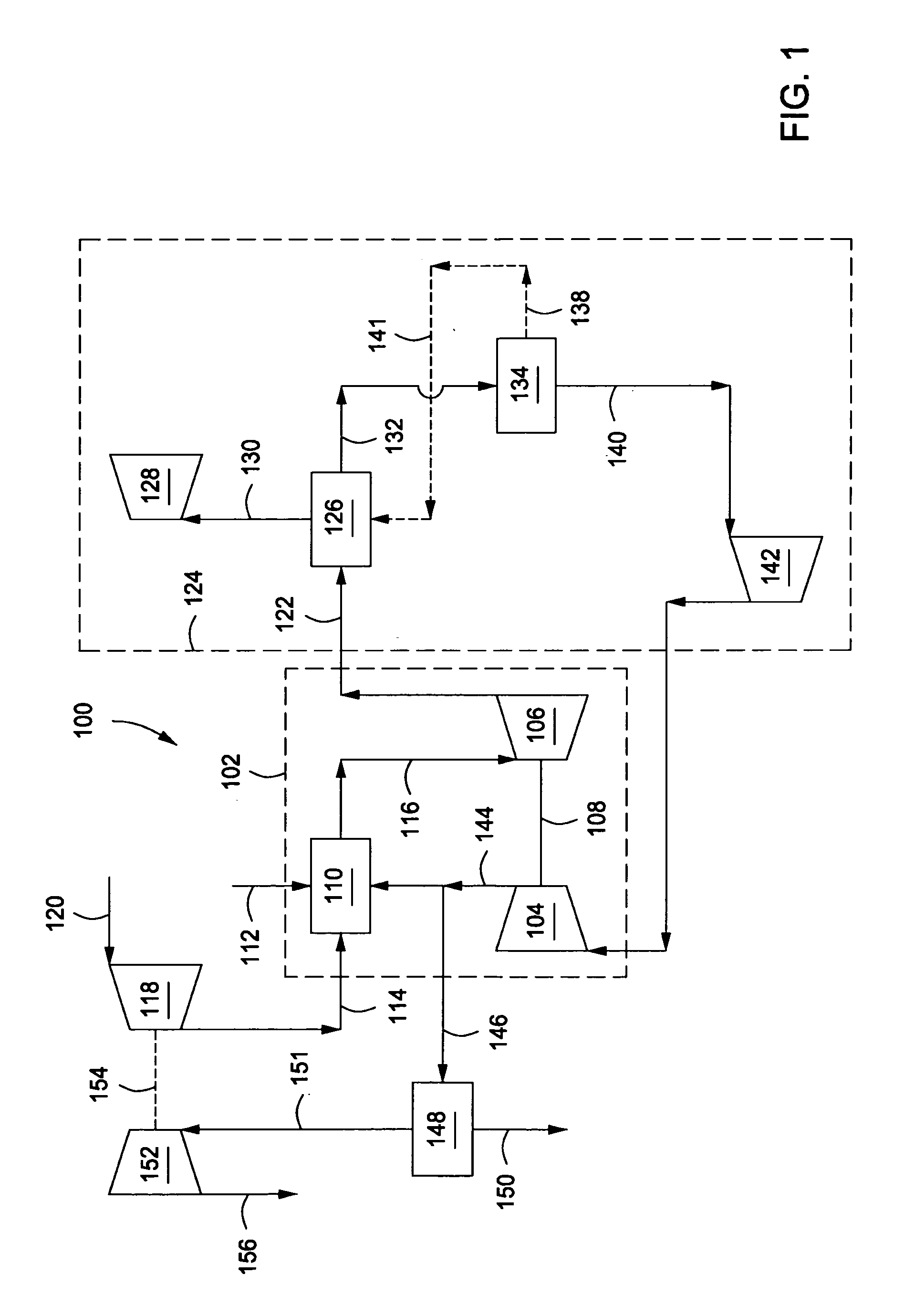

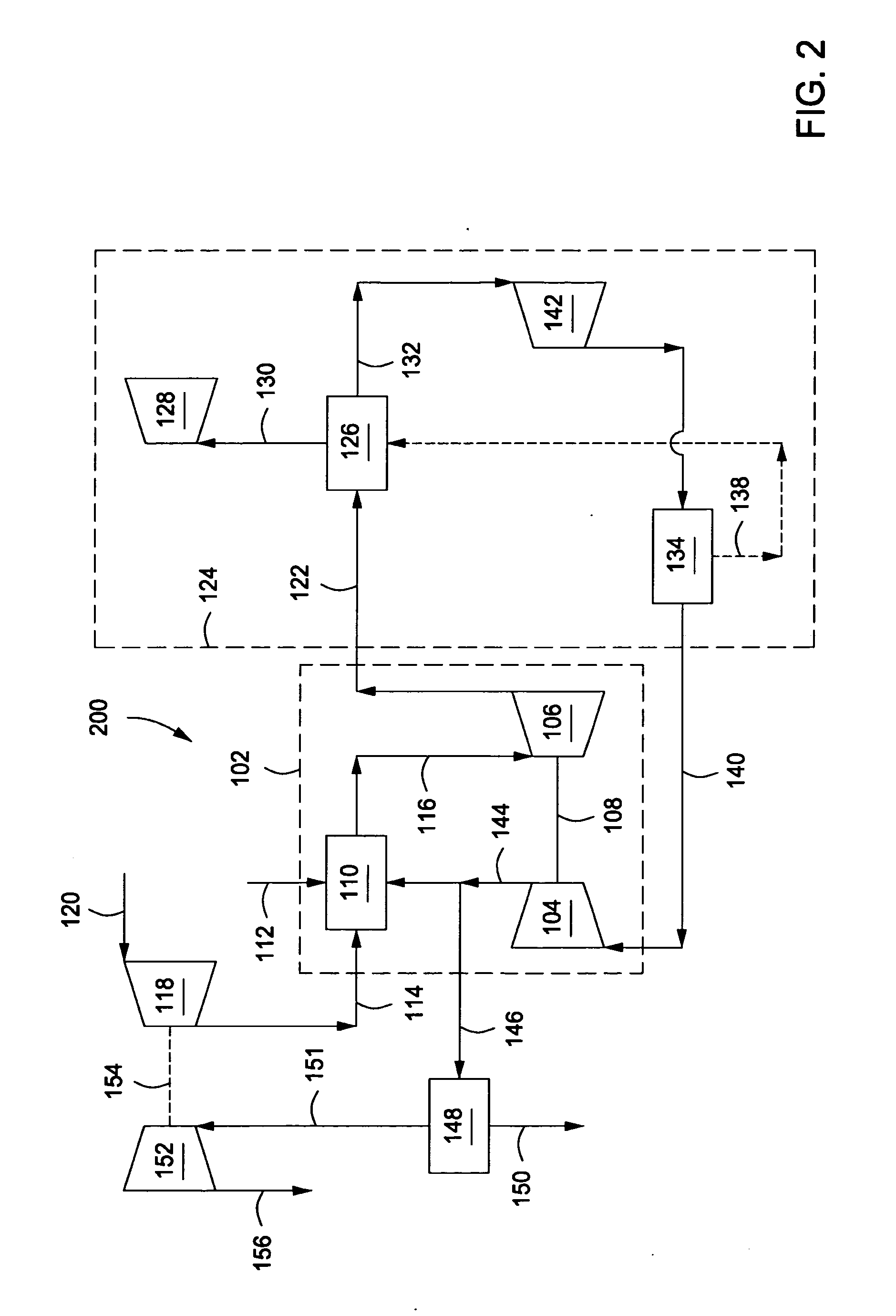

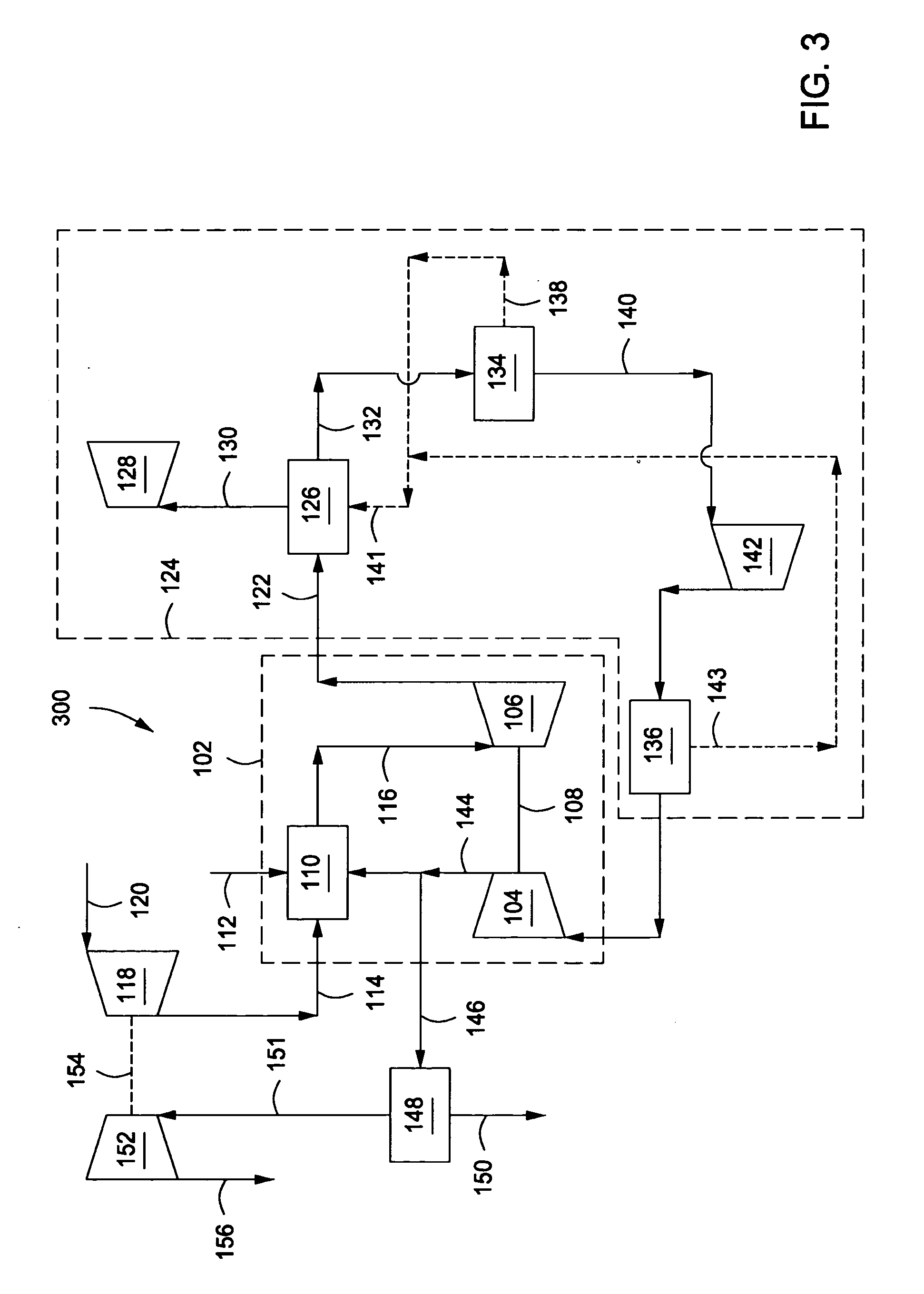

Low Emission Tripe-Cycle Power Generation Systems and Methods

Methods and systems for low emission power generation in hydrocarbon recovery processes are provided. One system includes a gas turbine system adapted to combust a fuel and an oxidant in the presence of a compressed recycle stream to provide mechanical power and a gaseous exhaust. The compressed recycle stream acts to moderate the temperature of the combustion process. A boost compressor can boost the pressure of the gaseous exhaust before being compressed into the compressed recycle stream. A purge stream may be tapped off from the compressed recycle stream and directed to a C02 separator which discharges C02 and a nitrogen-rich gas, which may be expanded in a gas expander to generate additional mechanical power.

Owner:OELFKE RUSSELL H +1

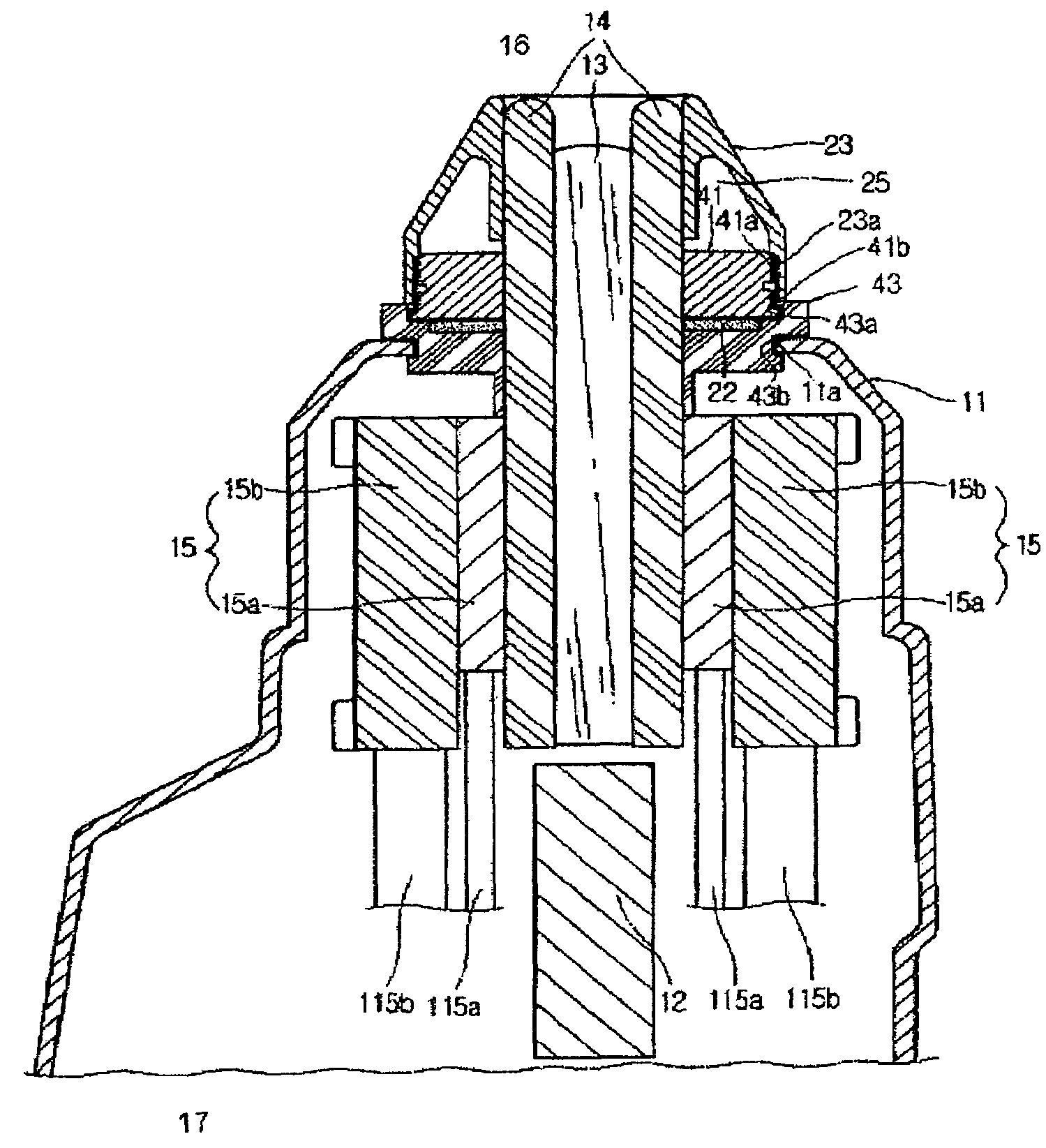

Degradable whipstock apparatus and method of use

InactiveUS8220554B2Improve responseSafe handlingFluid removalDirectional drillingSubject matterHigh intensity

Whipstocks and deflectors comprising a degradable composition, and methods of using same are described. A degradable composition may consist essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Methods of using degradable whipstocks in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. 1.72(b).

Owner:SCHLUMBERGER TECH CORP

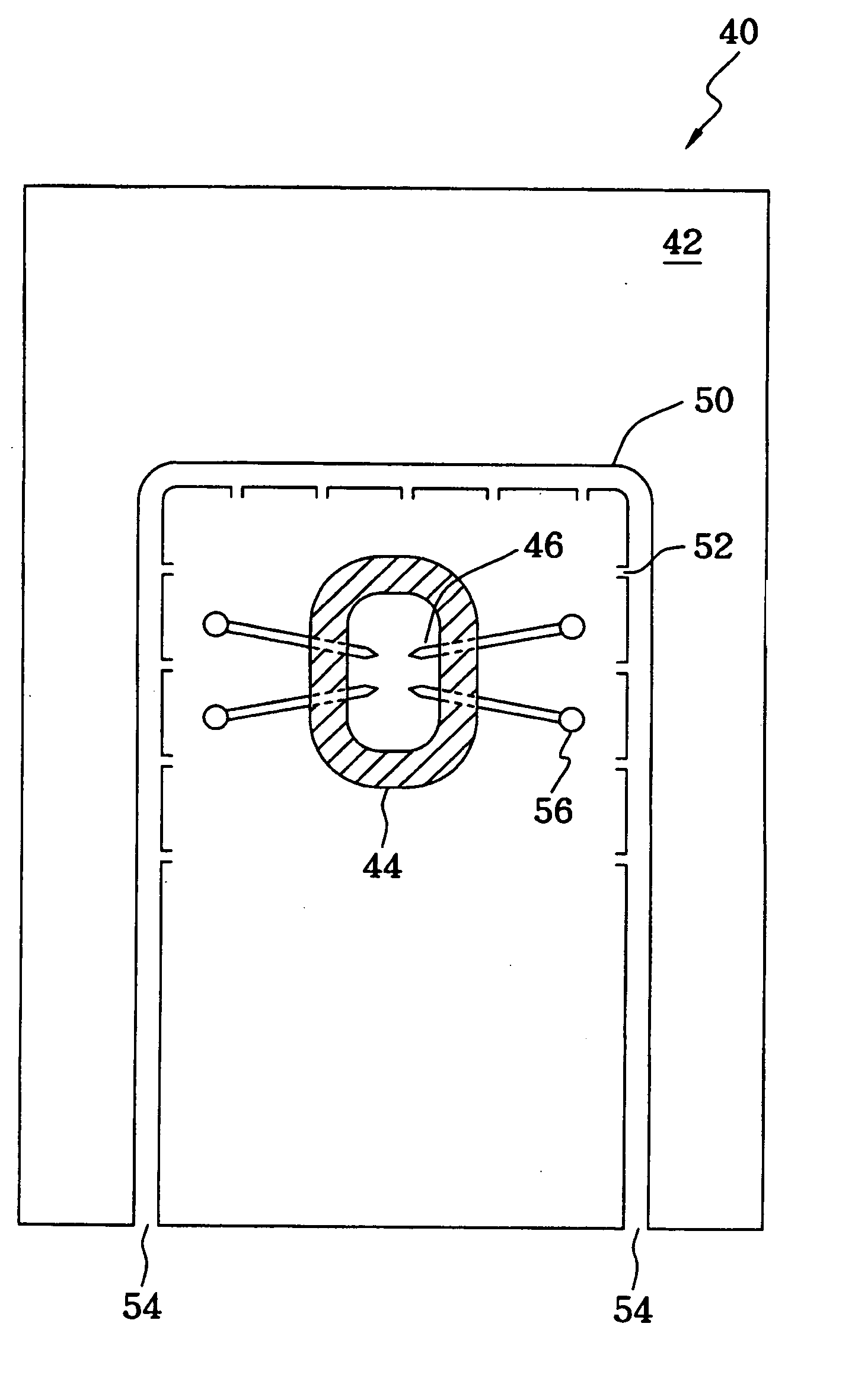

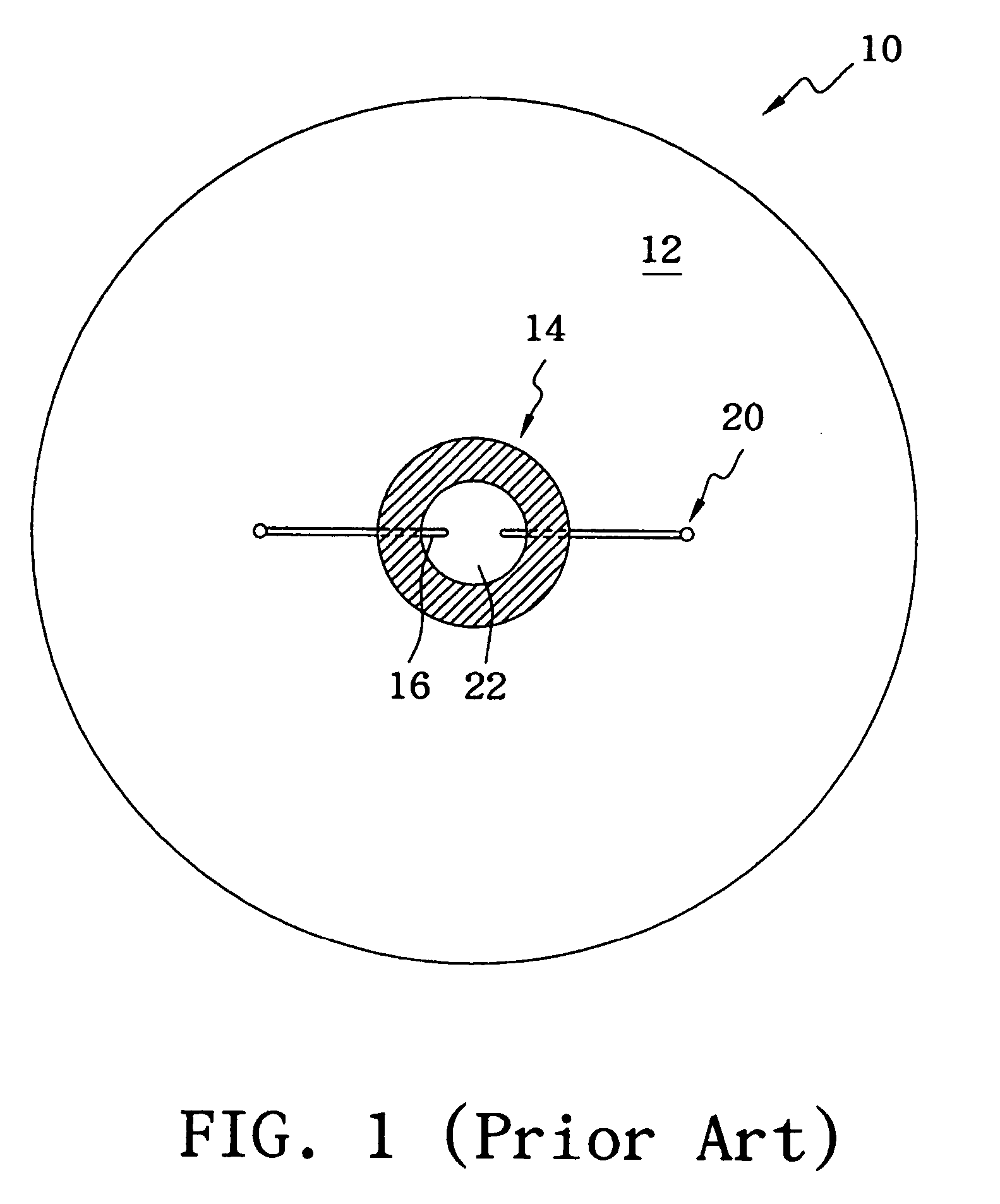

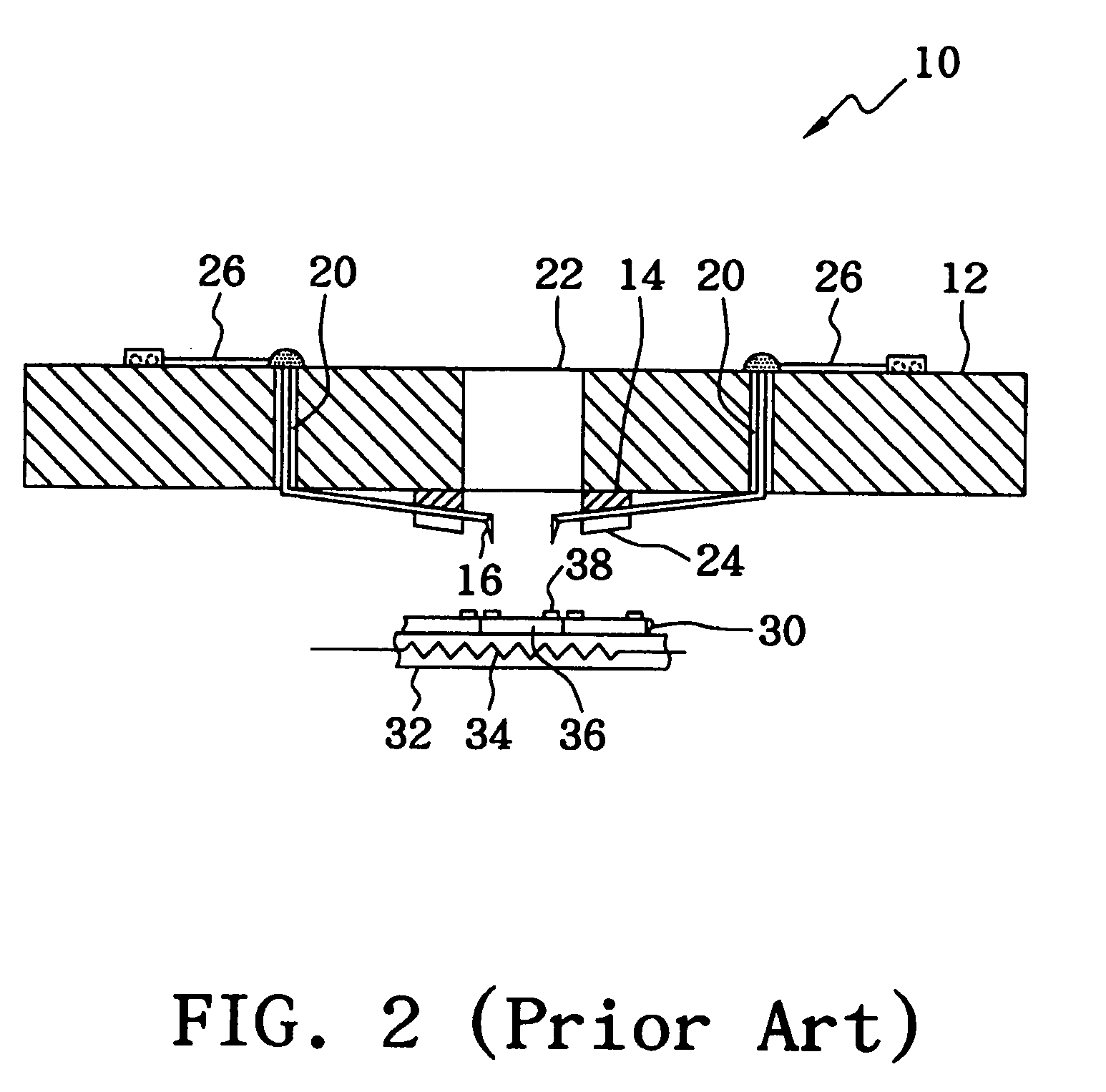

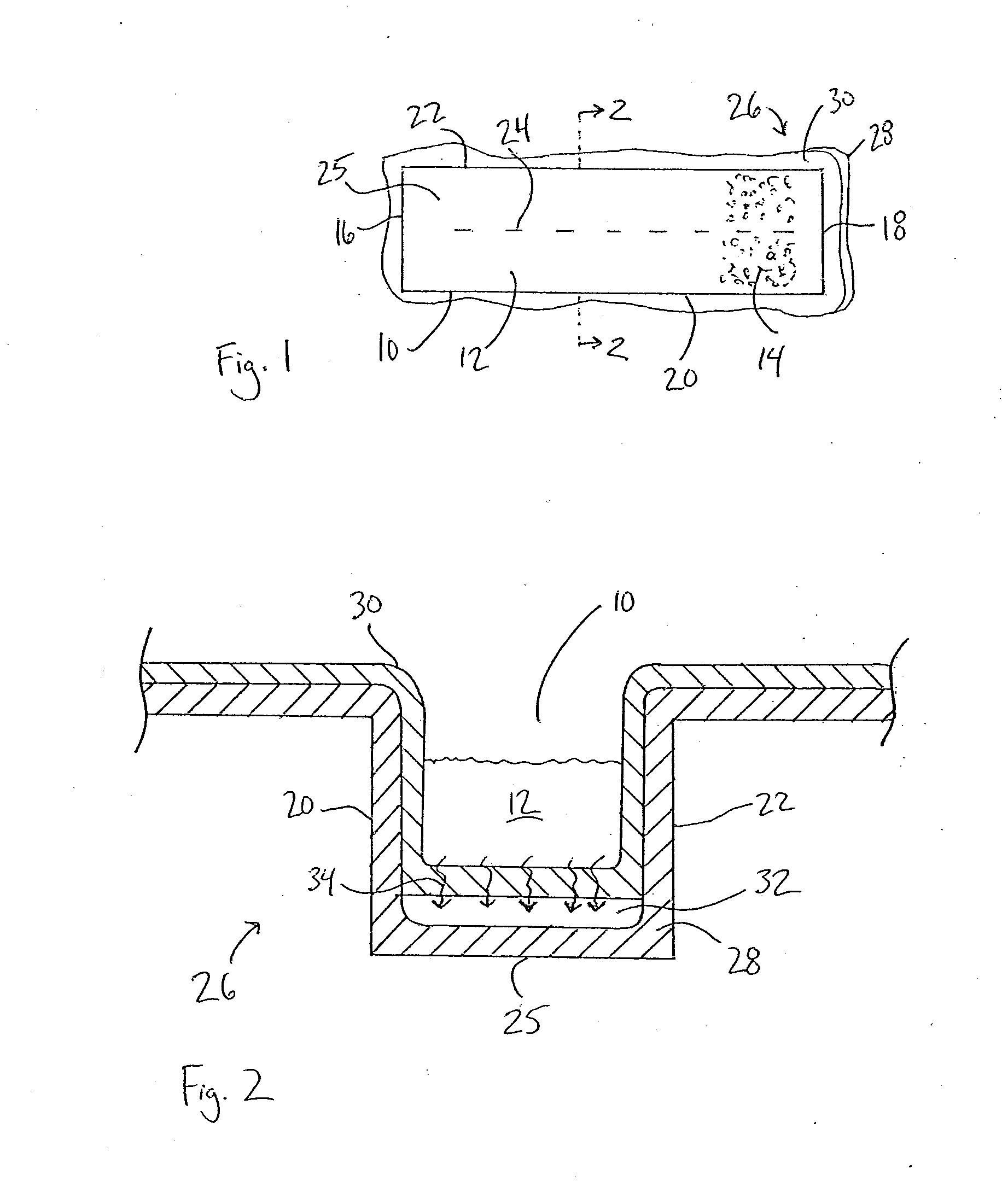

Probe card for testing a semiconductor

ActiveUS20040119463A1Moderate temperatureReduce impactElectrical measurement instrument detailsFault location by increasing destruction at faultProbe cardAdhesive

The present invention provides a probe card for testing a semiconductor. The probe card includes a circuit board, a cover, a circular supporter positioned on the circuit board, at least a probe needle fixed on the circular supporter by an adhesive, and a flow line positioned in the space formed between the circuit board and the cover. The present invention moderates the temperature of the probe card by introducing a fluid such as force-air or nitrogen into the flow line to carry heat into or out of the probe card.

Owner:STAR TECH INC

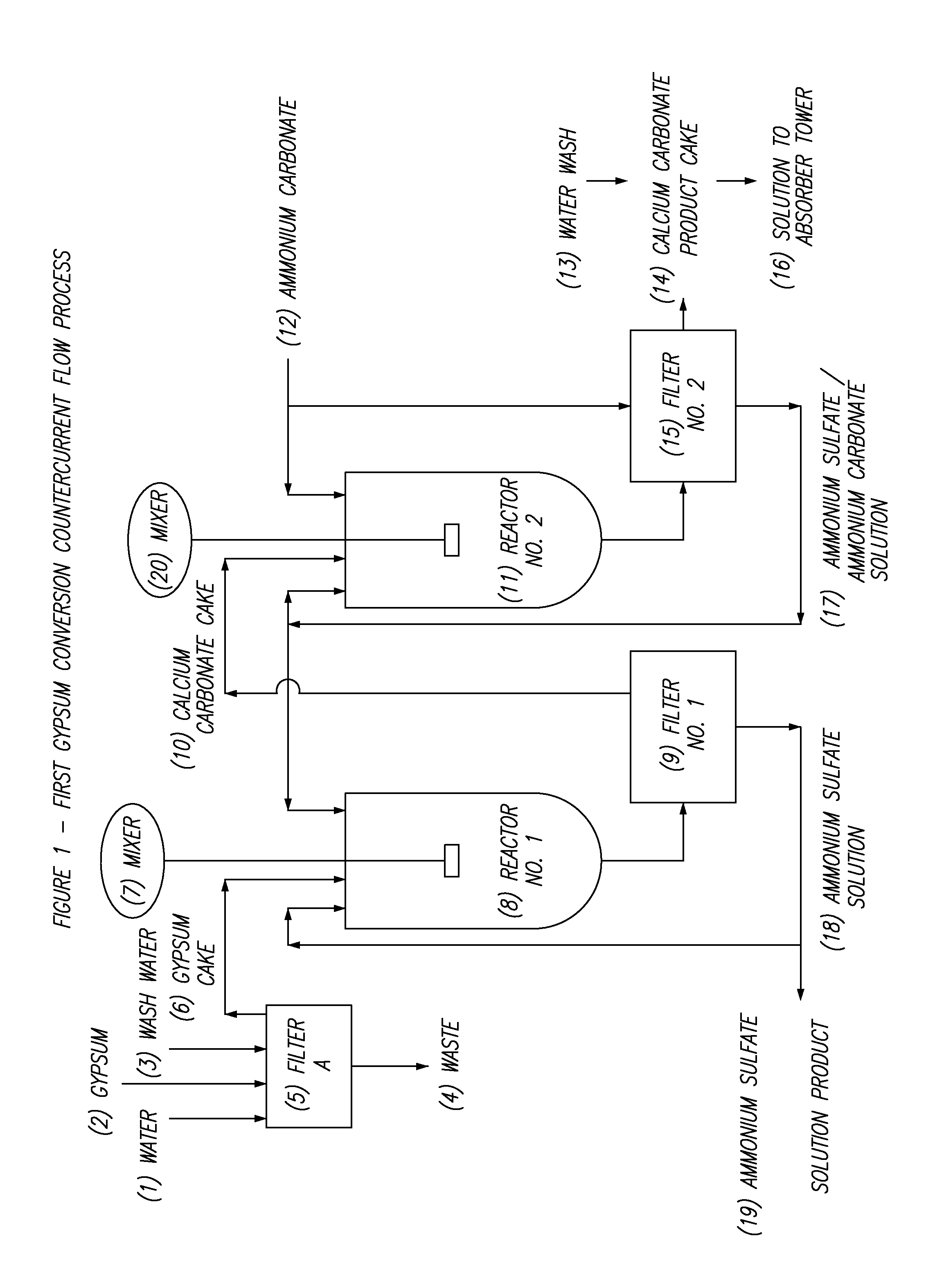

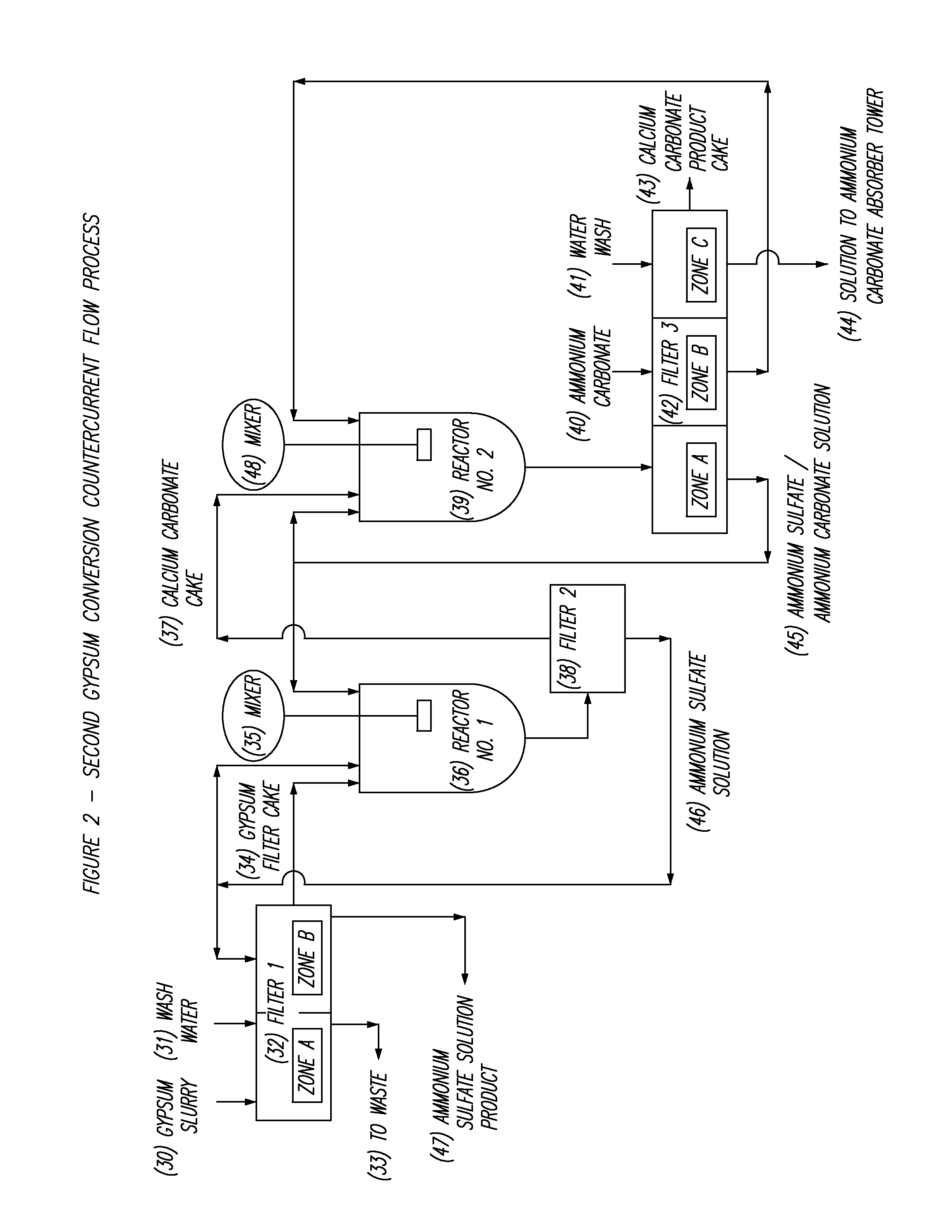

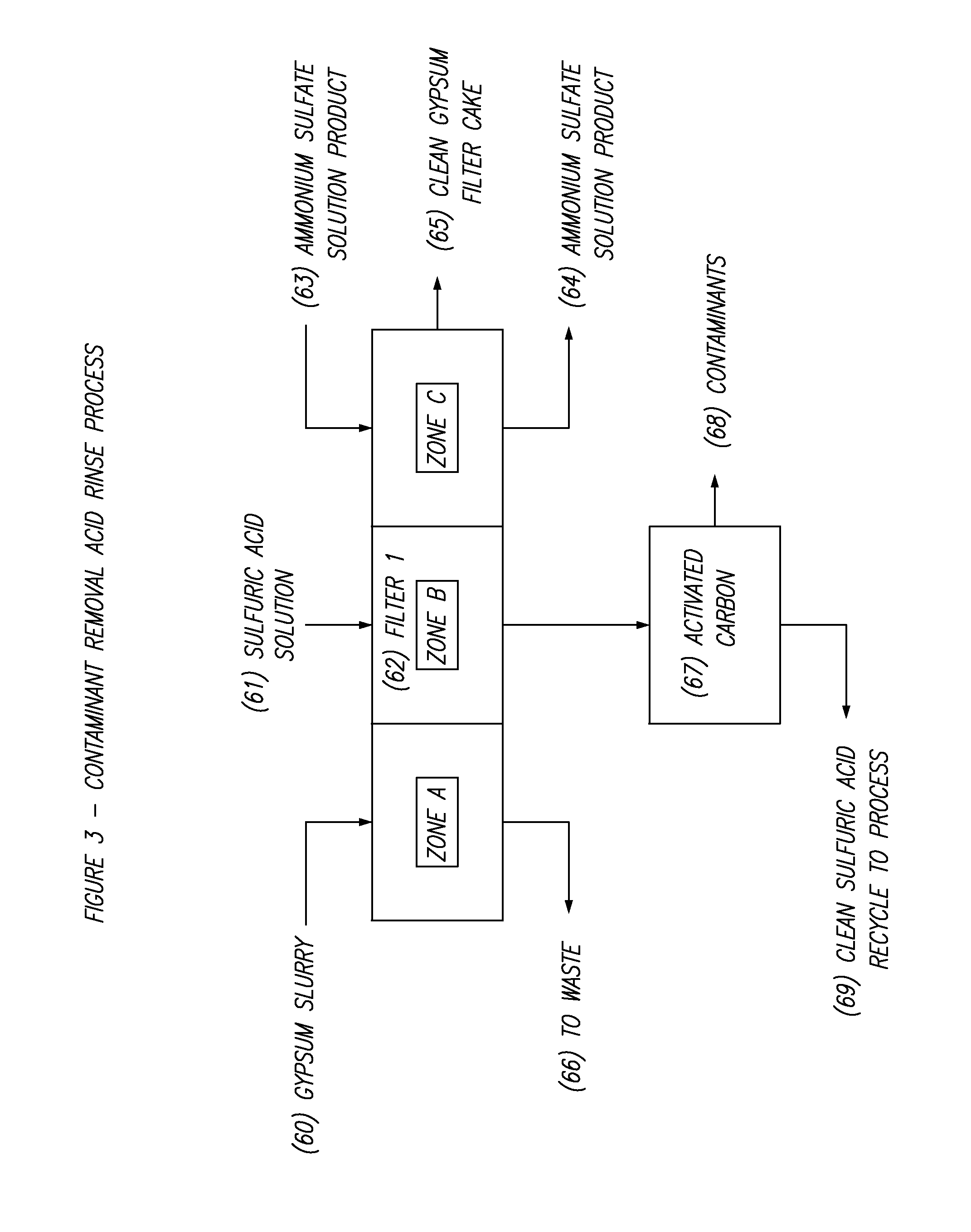

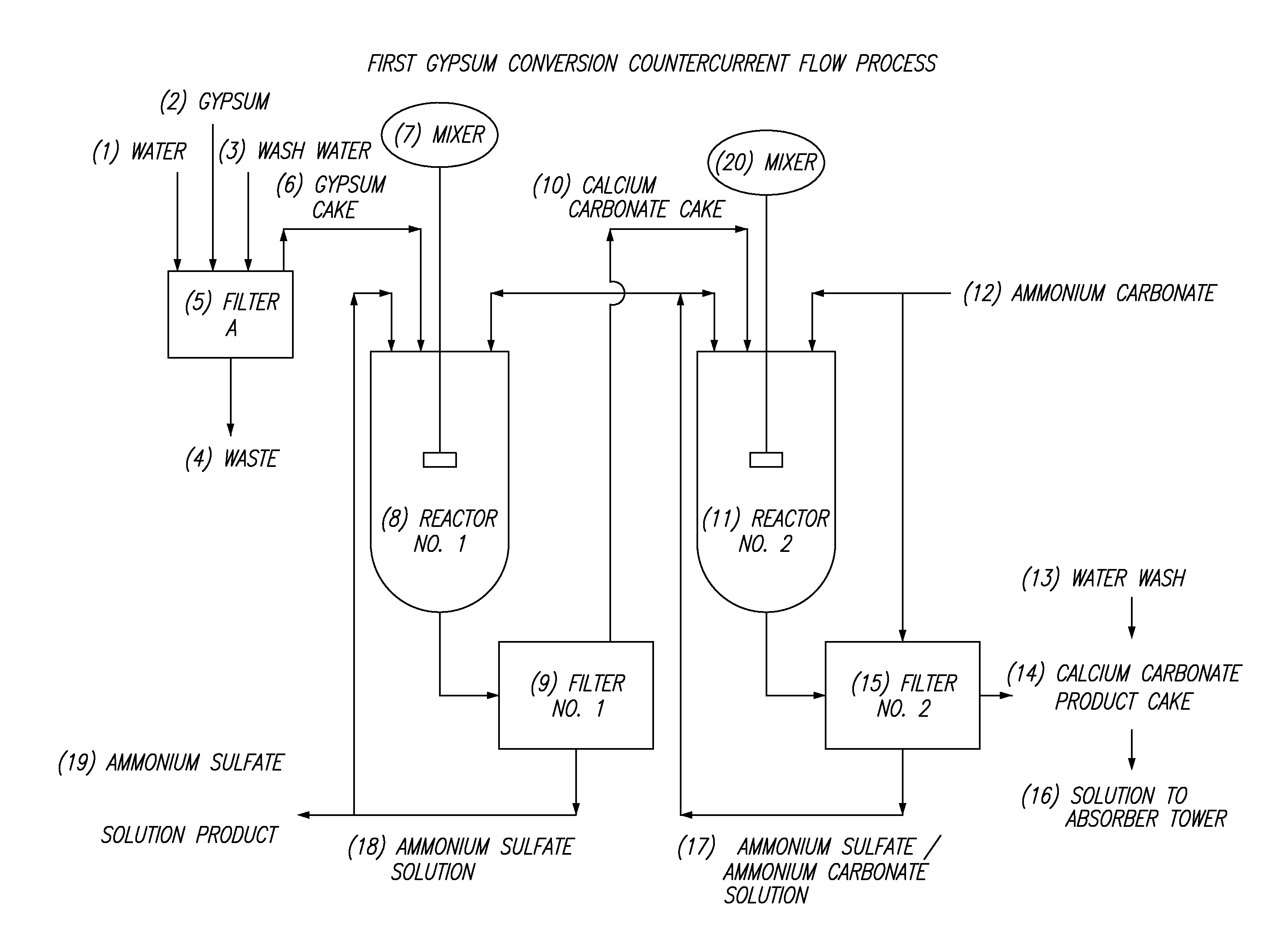

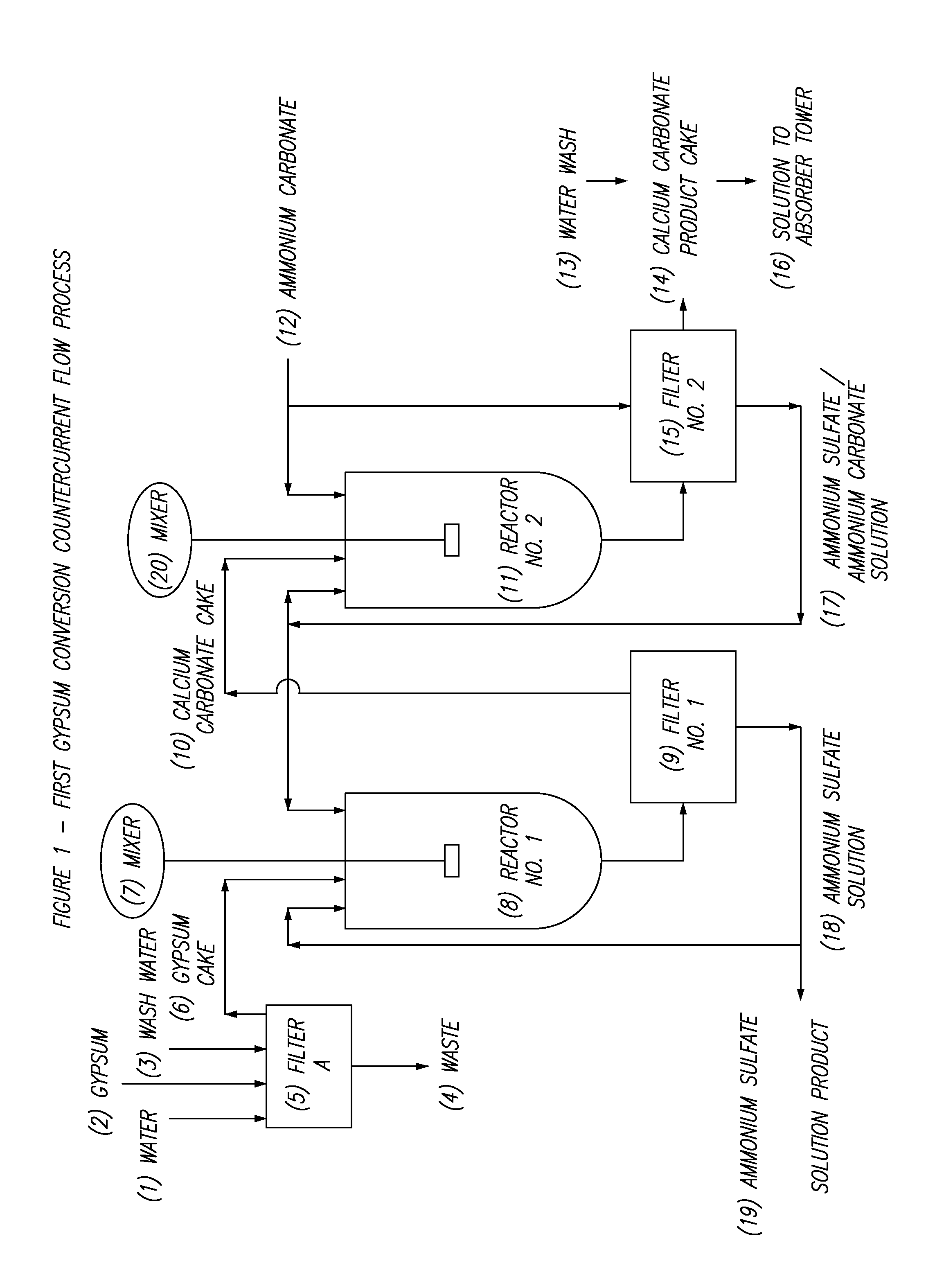

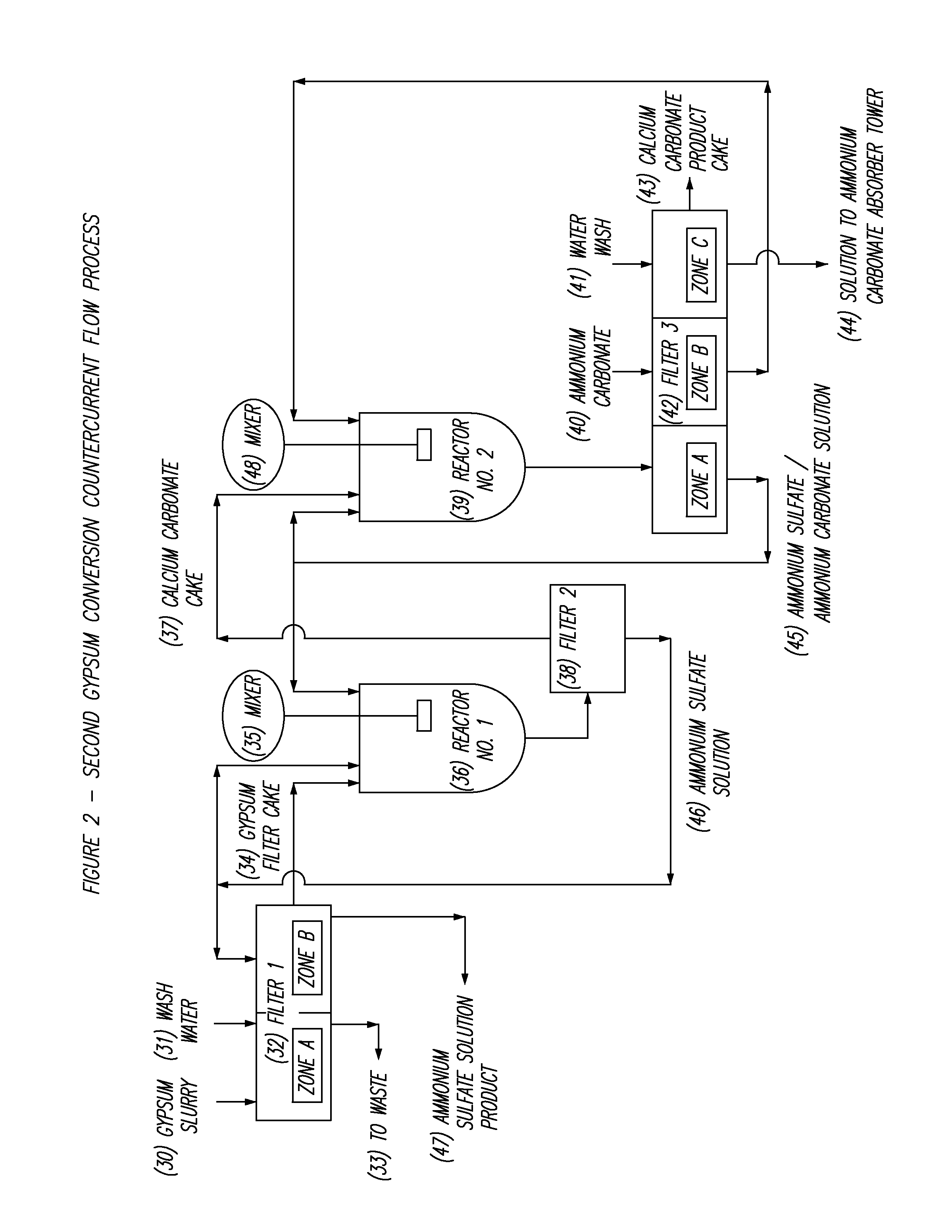

Process for converting fgd gypsum to ammonium sulfate and calcium carbonate

ActiveUS20140044619A1High yieldHigh purityCalcium/strontium/barium carbonatesMagnesium carbonatesSlurryNuclear chemistry

A continuous countercurrent flow process for converting FGD gypsum to ammonium sulfate and calcium carbonate including countercurrent flows with internal recycle of liquids to maximize the purity of reaction products while minimizing reaction times, and further include embodiments of the process that provide a yield of both ammonium sulfate and calcium carbonate to be 97 to 100%, and embodiments that provide for processes having a total time of reaction being 8 to 12 minutes, the invention further including processes for removing contaminants from the FGD gypsum employing an acid rinse process and / or a slurry tank reactor process.

Owner:SPARSTANE TECH

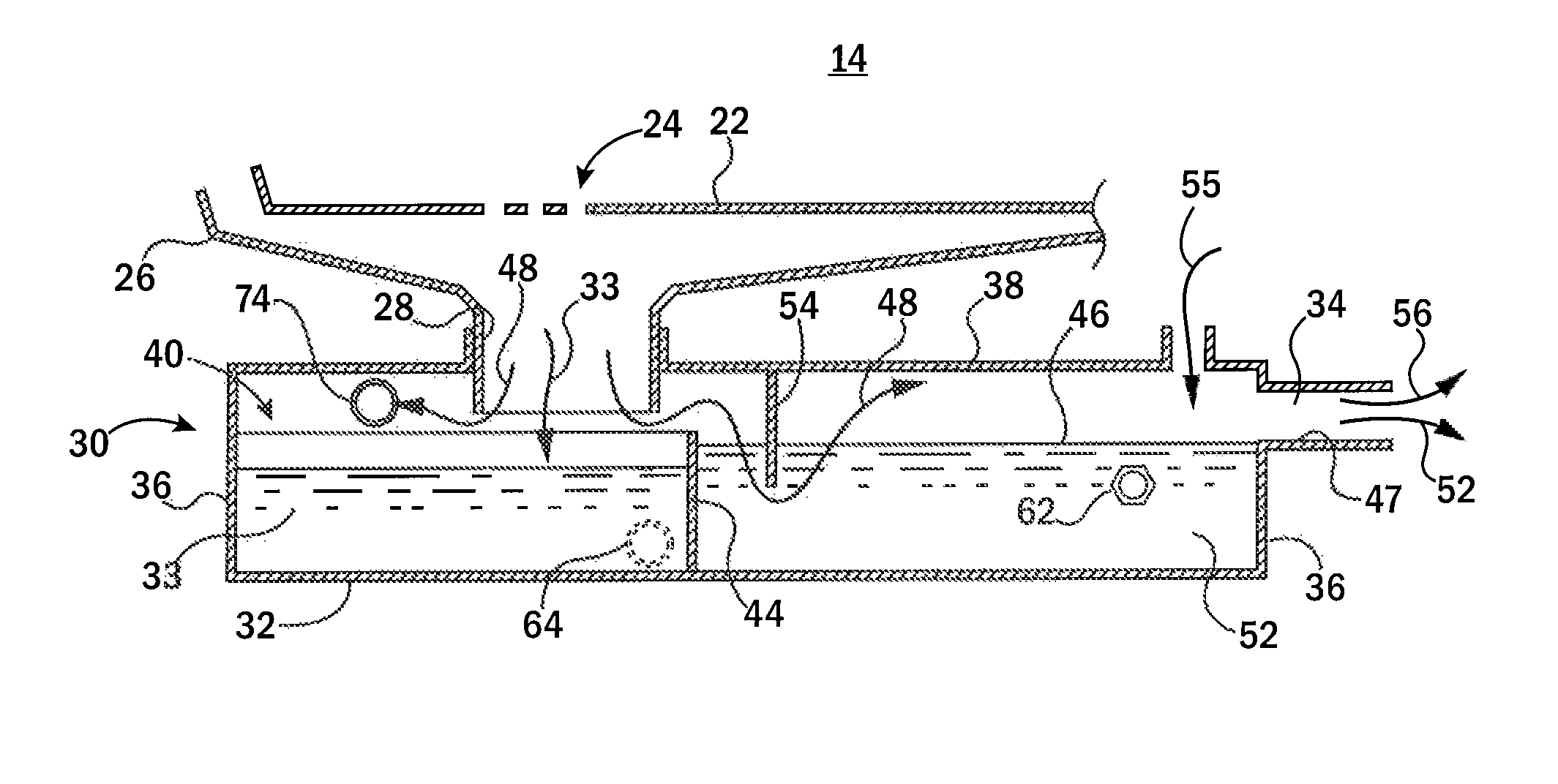

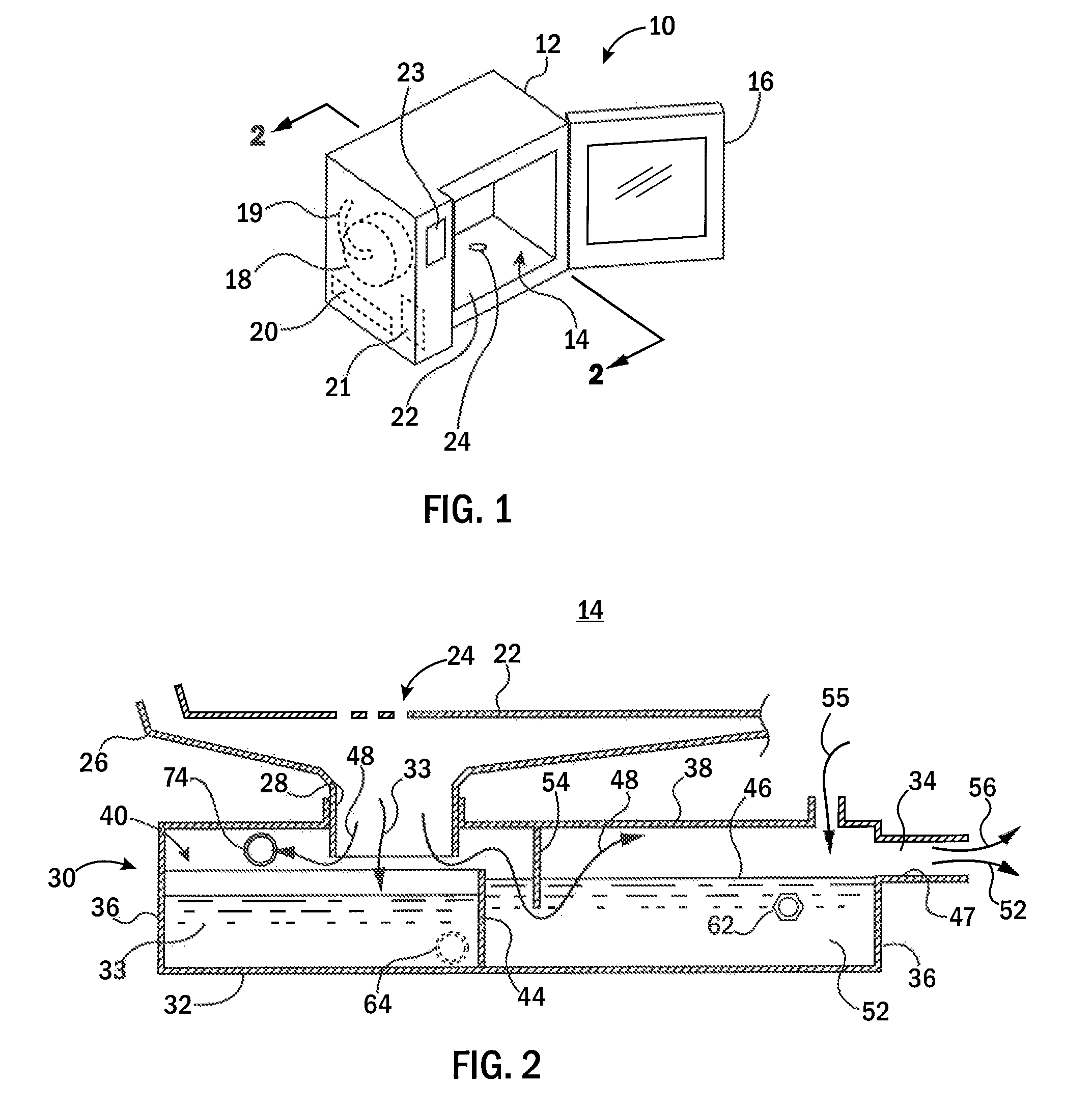

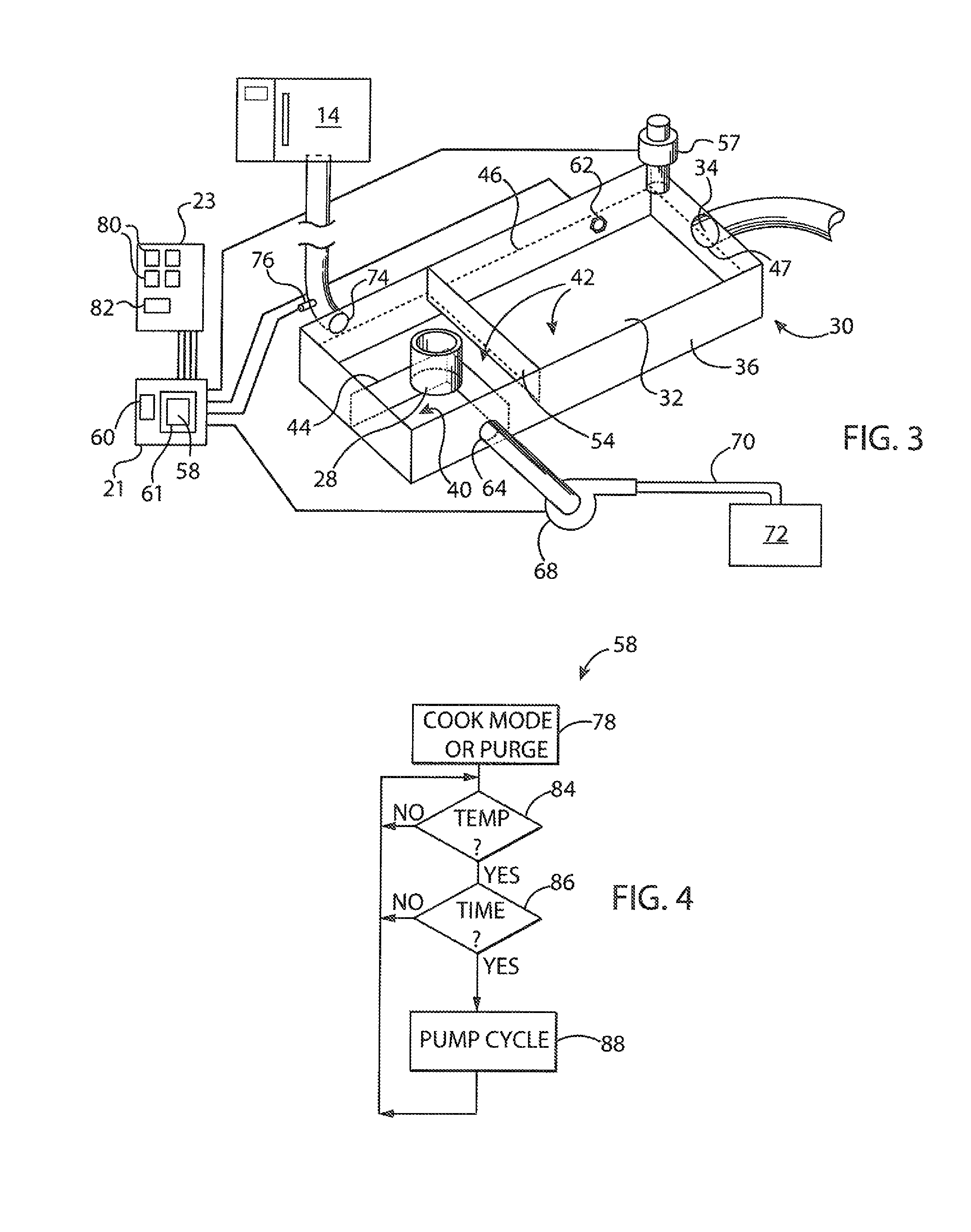

Grease handling apparatus for closed system oven

ActiveUS8997730B2Easy constructionEliminates and reduces height differentialStoves/ranges foundationsSelf-cleaning stoves/rangesOil and greaseSteam pressure

Owner:ALTO SHAAM

Warm-season turf establishment method

The invention provides a warm-season turf establishment method. The warm-season turf establishment method is mainly used for establishing a turf against a warm-season turf grass seeding method. According to the warm-season turf establishment method, various conditions required for seed germination of warn-season turf grass and growth of seedlings till the turf is formed can be ensured by controlling fertilizing amount and watering amount, utilizing control temperature, humidity and illumination of an agricultural plastic mulching film and applying a seedling stage film supporting technology. An effective method which can realize large-area application in production practices of garden afforestation, and can not only solve the difficult problems of turf establishment through the warm-season seeding method, but also reduce turf establishment cost is provided by preparing a place before the turf establishment, seeding, controlling the temperature and humidity during the germination stage, curing the seedlings in the film, controlling the temperature of the support film and the like.

Owner:LIAONING UNIVERSITY

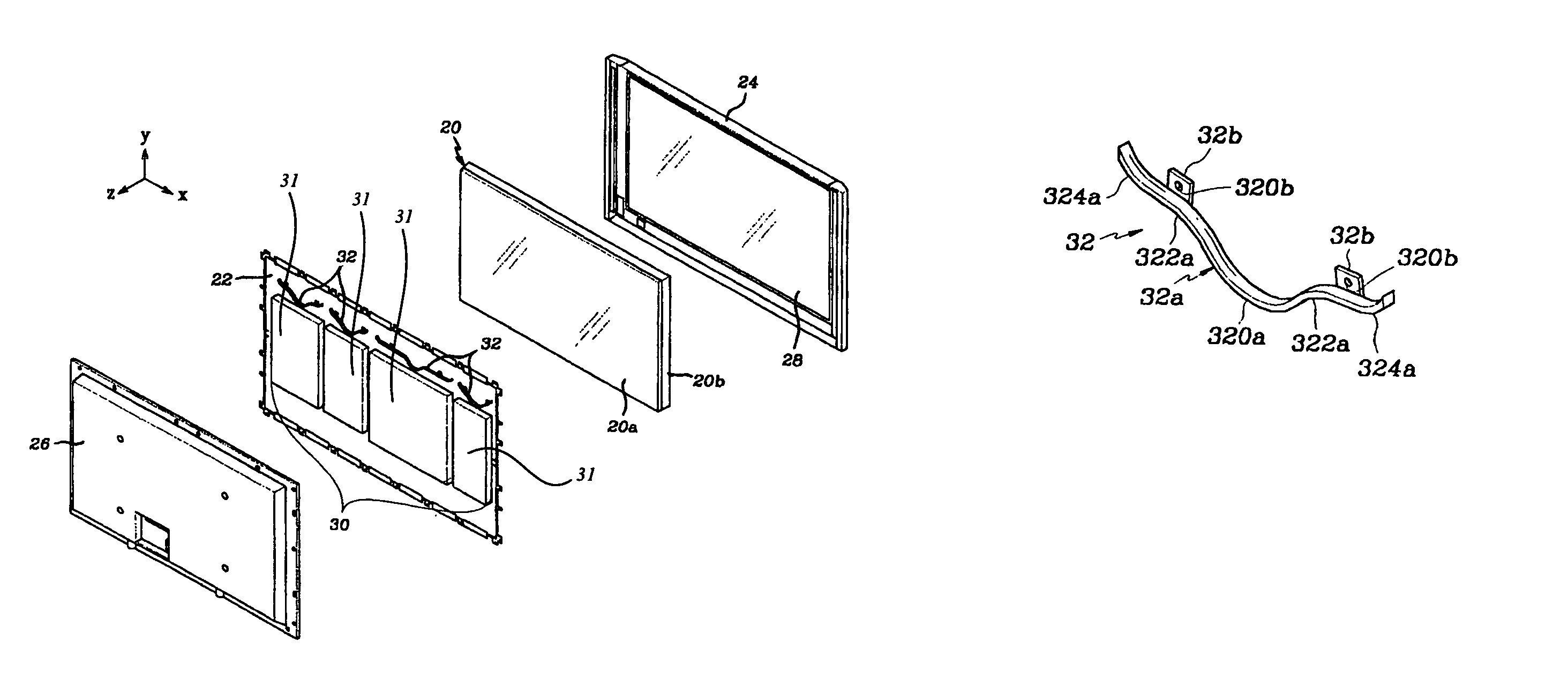

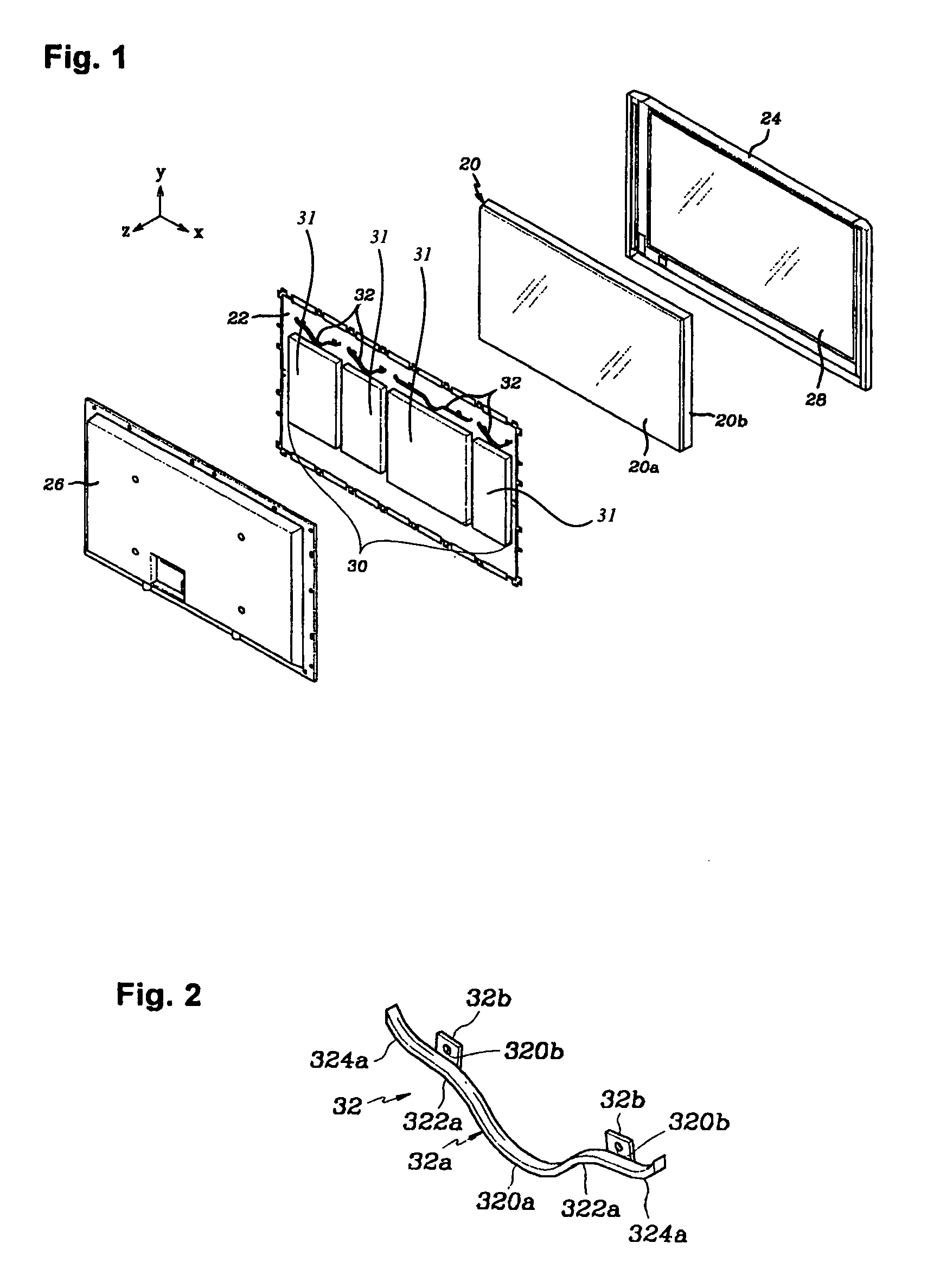

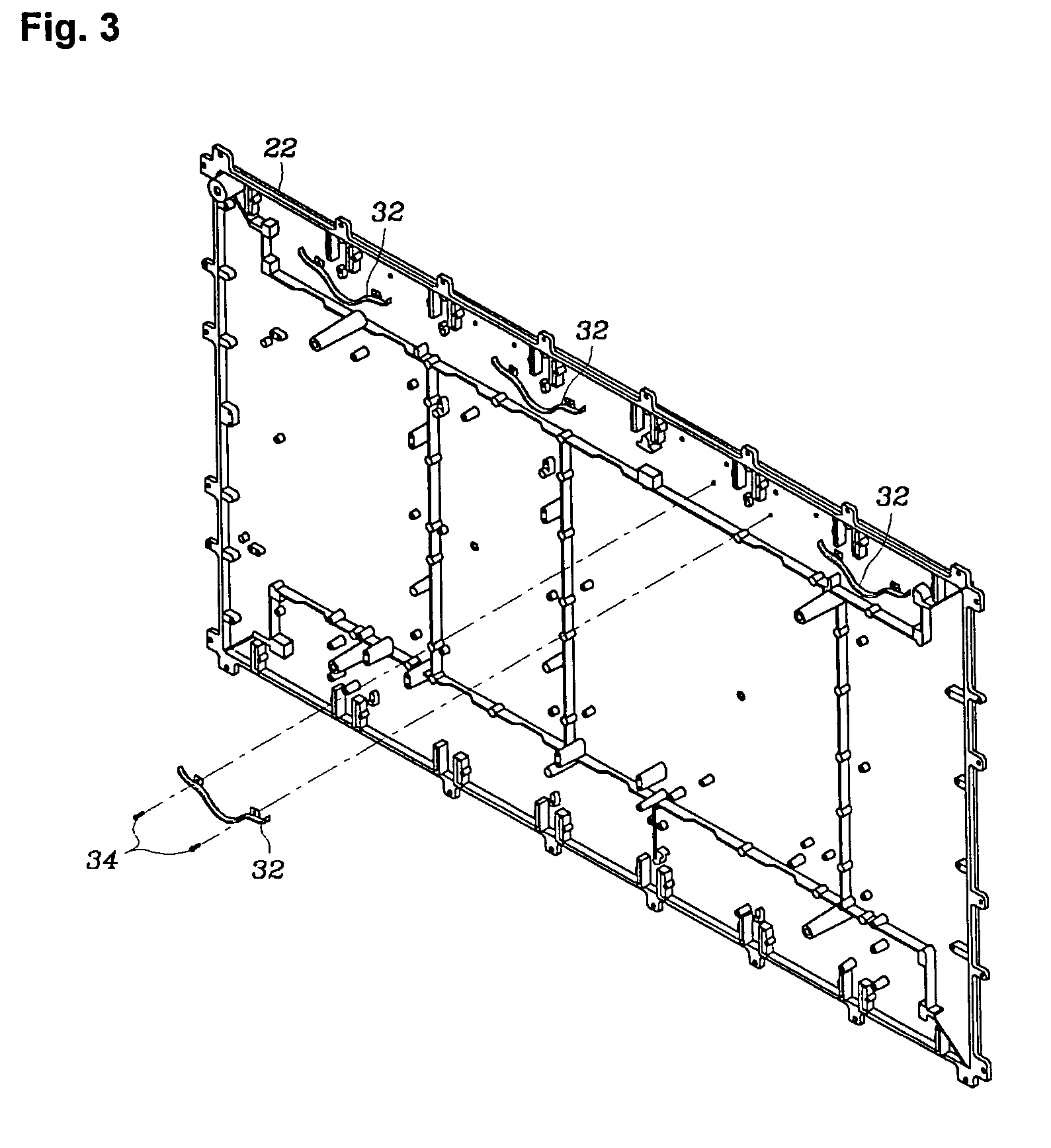

Passive apparatus that regulates a flow of heated air within a plasma display device

InactiveUS7038360B2Simple designEasy to manageTelevision system detailsCasings/cabinets/drawers detailsDisplay deviceEngineering

A plasma display device that uses a plasma display panel to enable use as an image device such as a television. The plasma display device includes a plasma display panel, a chassis base including a circuit assembly for driving the plasma display panel and regulating members mounted in a vicinity of the circuit assembly on a surface of the chassis base to which the circuit assembly is provided, said regulating members regulating the flow of air in the area of the chassis base.

Owner:SAMSUNG SDI CO LTD

Method for producing bubble aluminum alloy special-shaped member with even pore structure

The invention discloses a method used for preparing a foaming aluminum alloy special form part with an even hole structure. The method comprises the following steps: firstly, aluminum alloy is warmed up to melt, titanium hydride is added, the mixing is performed to lead the titanium hydride to being deconcentrated, and then calcium is added to aluminum alloy solution, to be mixed and to add the viscosity of molten mass, the molten mass after being mixed is cooled down, and a fabricated part is obtained; secondly, the fabricated part is put in a die assembly, and heated and warmed up, and insulated at temperature, to lead the foaming aluminum alloy fabricated part to perform secondary foaming in the die assembly, foaming aluminum alloy after foaming is cooled down, to obtain a foaming aluminum alloy product. Before warming up to the secondary foaming in the second step, the primary foaming aluminum alloy fabricated part and the die assembly are firstly preheated and insulated. Before adding viscosity agent calcium, the titanium hydride is added firstly, the viscosity of the aluminum alloy solution is lower, and the invention is in favor of the titanium hydride being uniformly dispersed in the aluminum alloy molten mass within the shortest time, and in favor of preparing the large sized foaming aluminum alloy special form part with the even hole structure.

Owner:SOUTHEAST UNIV

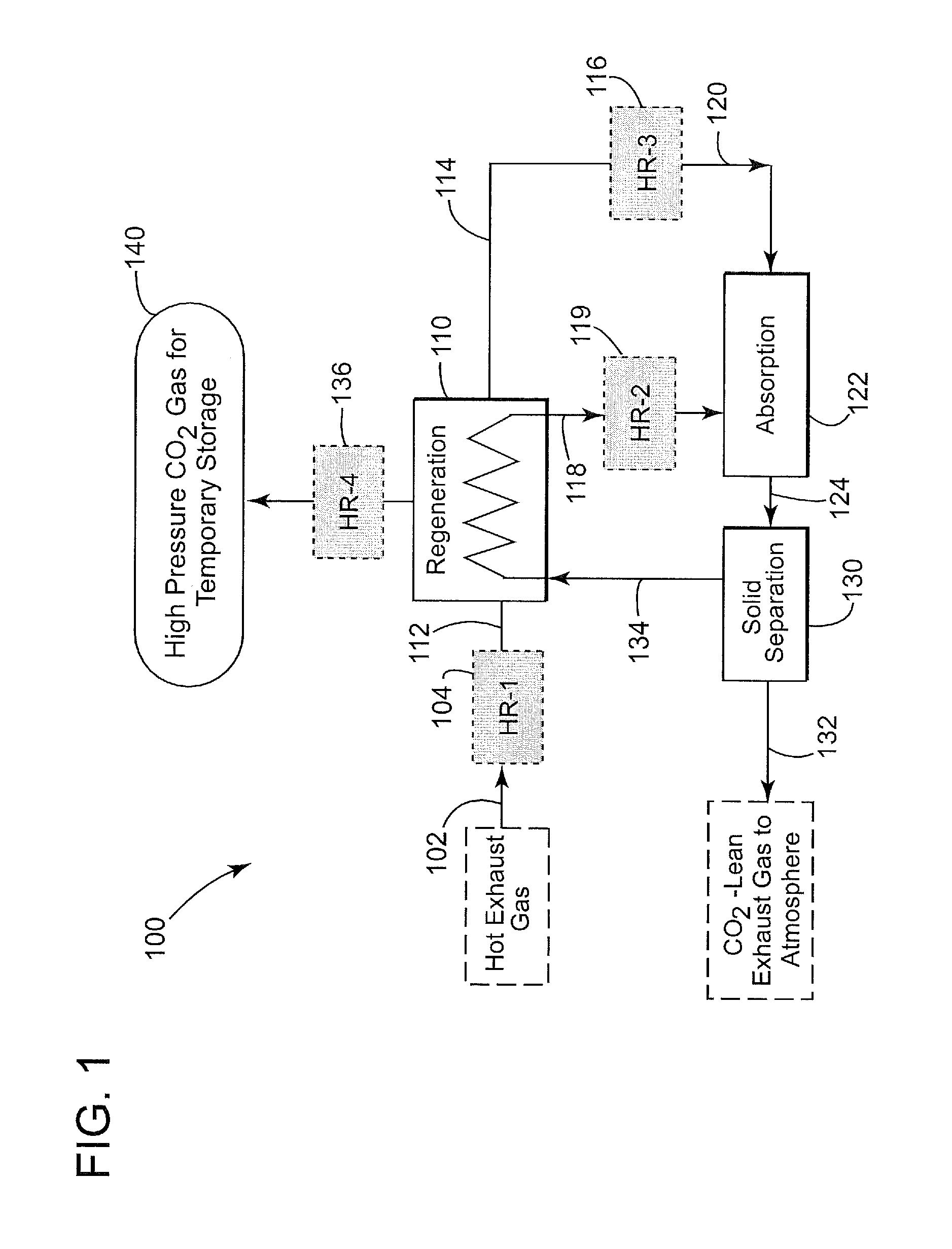

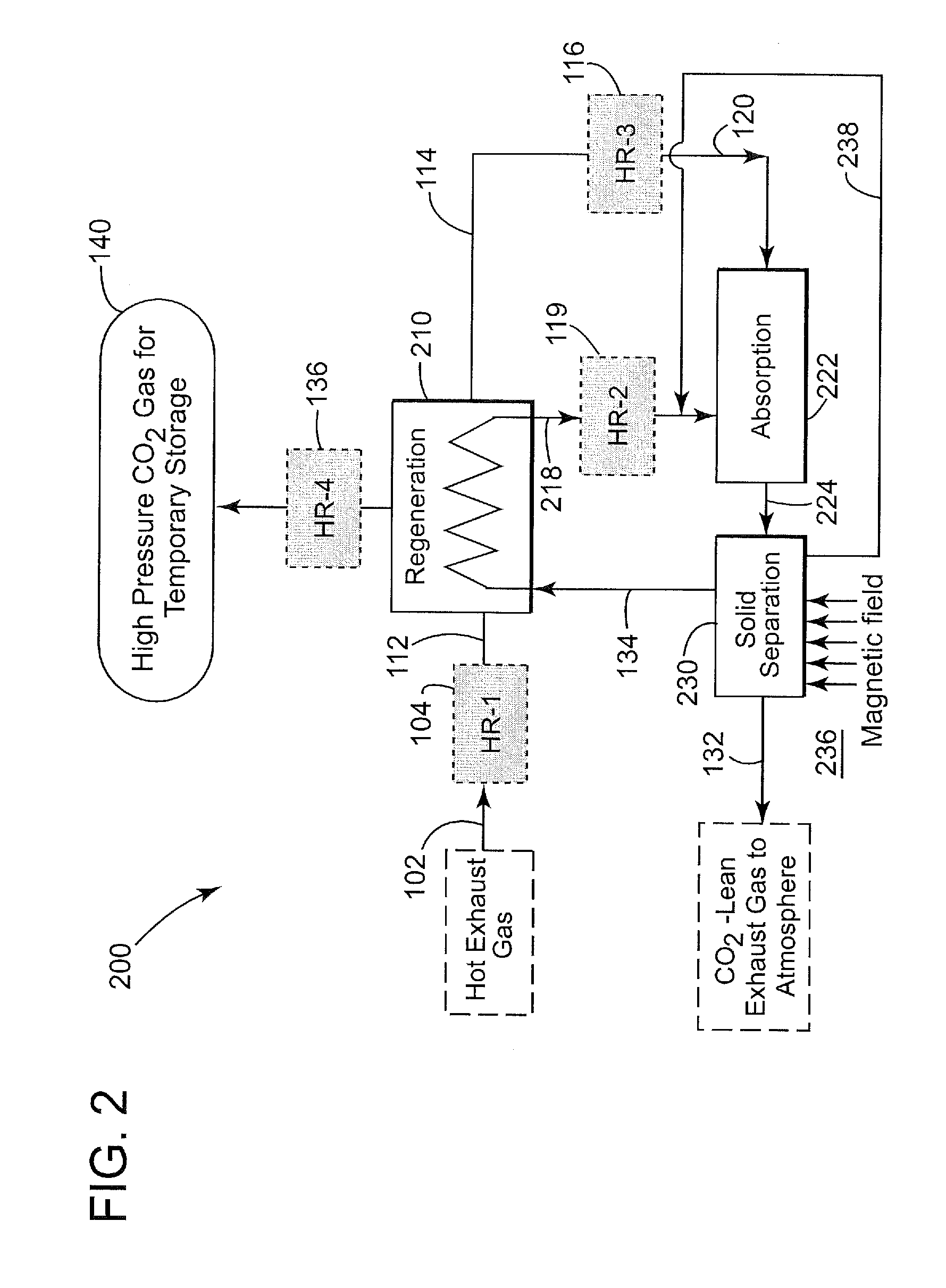

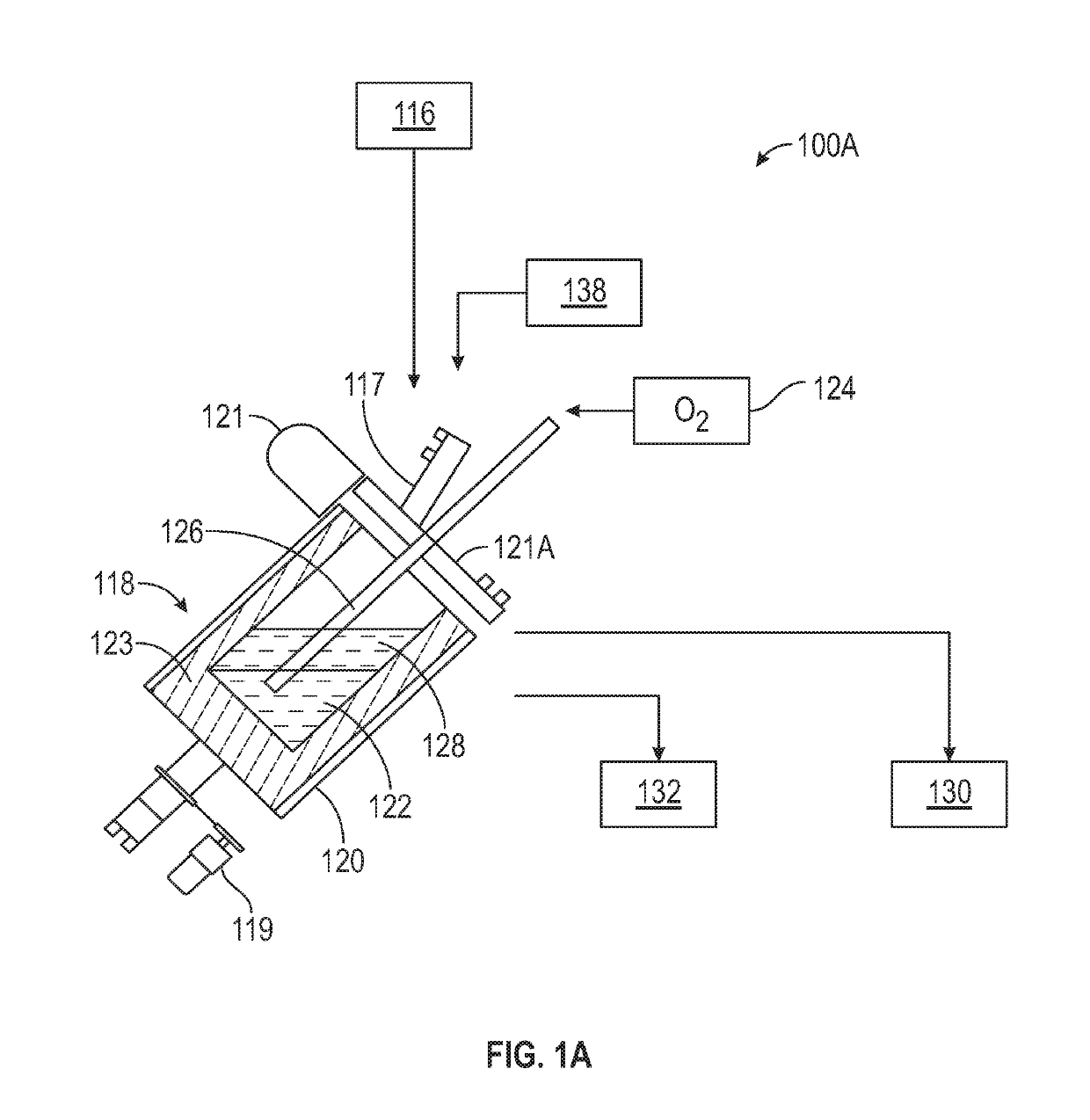

Process and system employing phase-changing absorbents and magnetically responsive sorbent particles for on-board recovery of carbon dioxide from mobile sources

ActiveUS9175591B2Moderate temperatureMaximize electrical energyGas treatmentExhaust apparatusOn boardSorbent

A method and system are described for the on-board treatment of a hydrocarbon-fueled internal combustion engine (ICE) exhaust gas stream to reduce CO2 emissions from the vehicle which include:a. contacting the exhaust gas stream with a CO2 sorbent capture agent on board the vehicle to produce a mixture containing modified CO2-containing sorbent and a treated exhaust gas stream with reduced CO2 content;b. separating the modified CO2-containing sorbent from the treated exhaust gas stream;c. passing the modified sorbent in heat exchange with heat from the ICE to release CO2 and regenerate the CO2 sorbent capture agent;d. recycling the regenerated CO2 sorbent for use in step (a);e. discharging the treated exhaust gas stream having a reduced CO2 content into the atmosphere;f. recovering and compressing the CO2 for temporary storage on board the vehicle.

Owner:SAUDI ARABIAN OIL CO

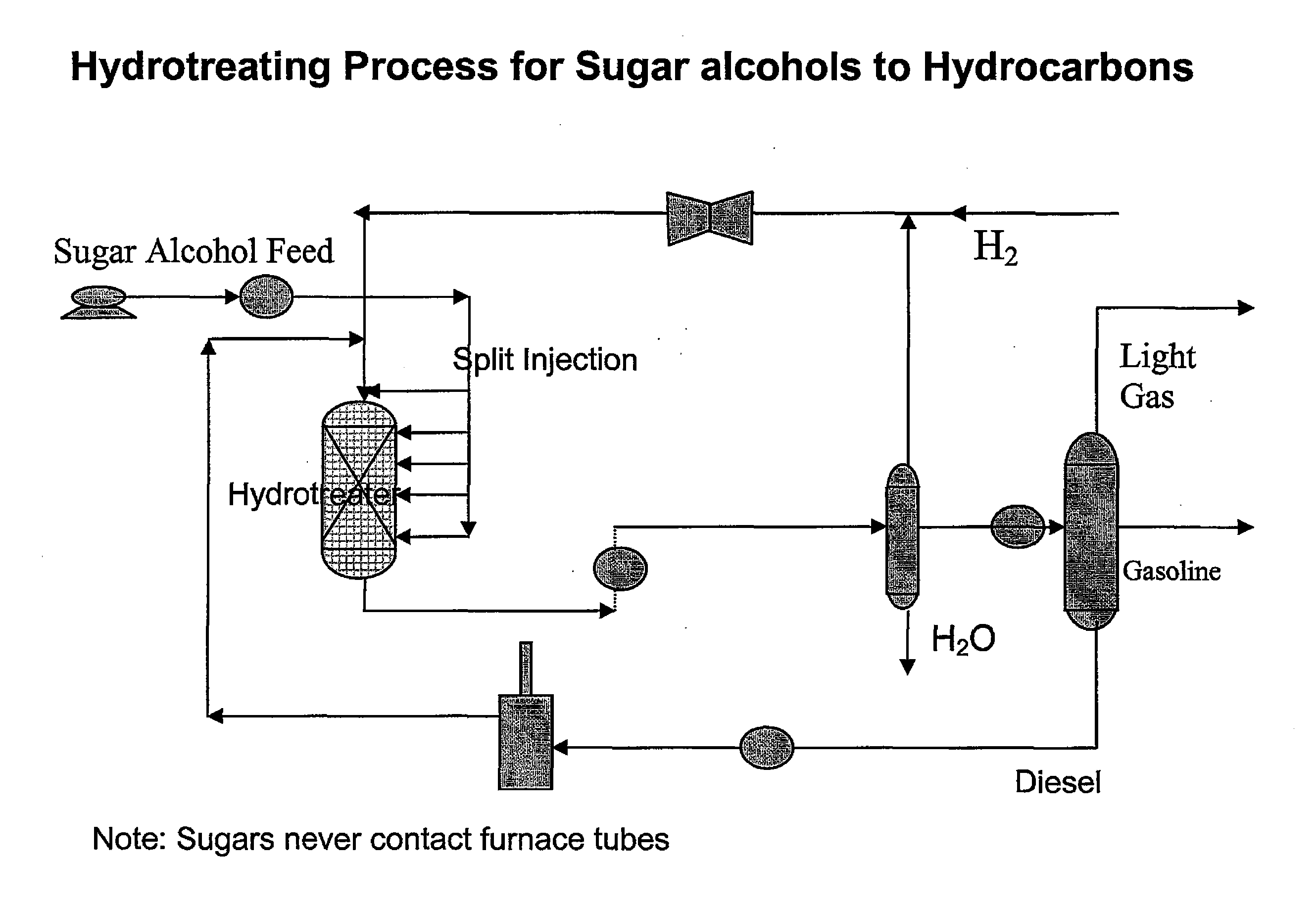

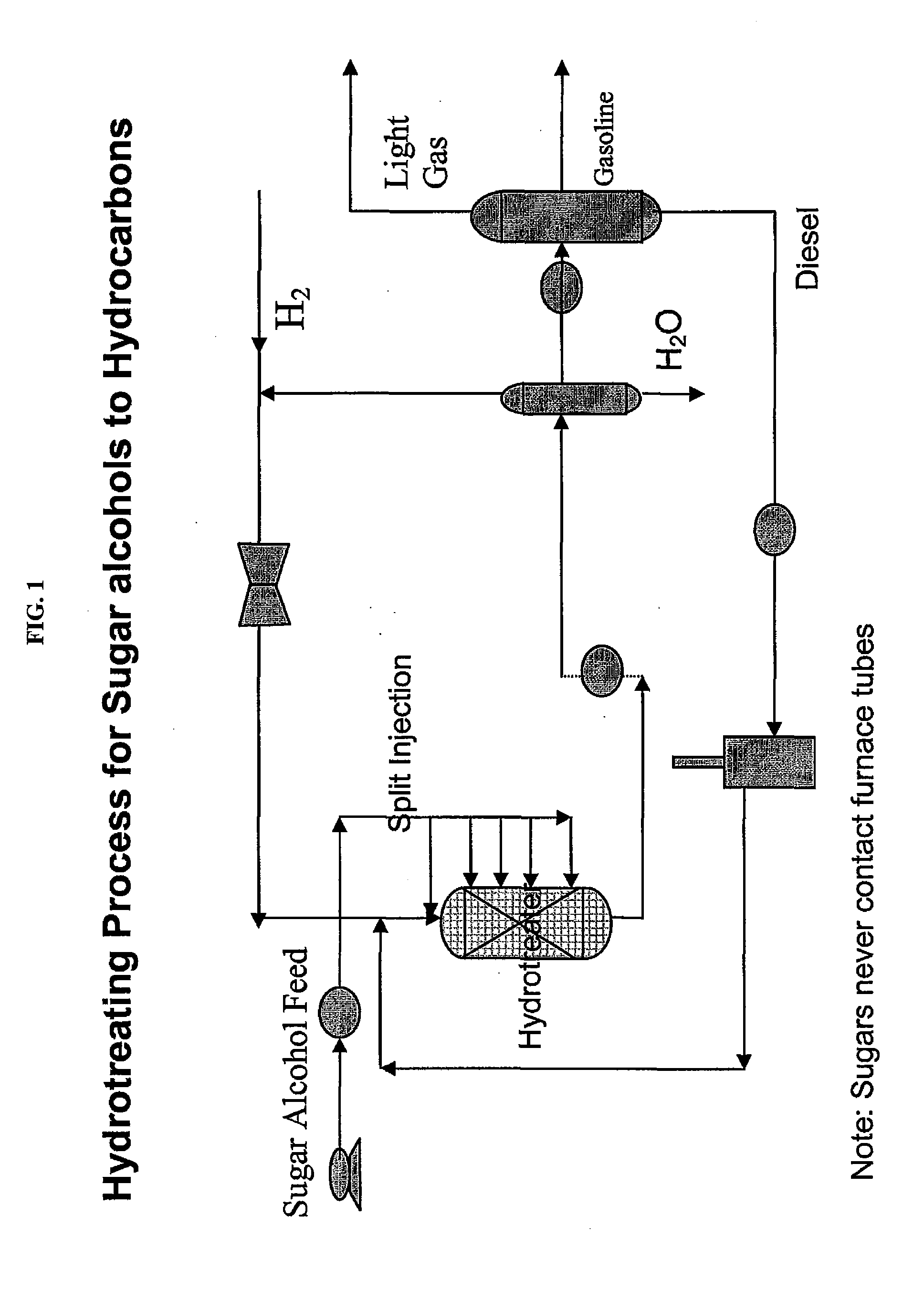

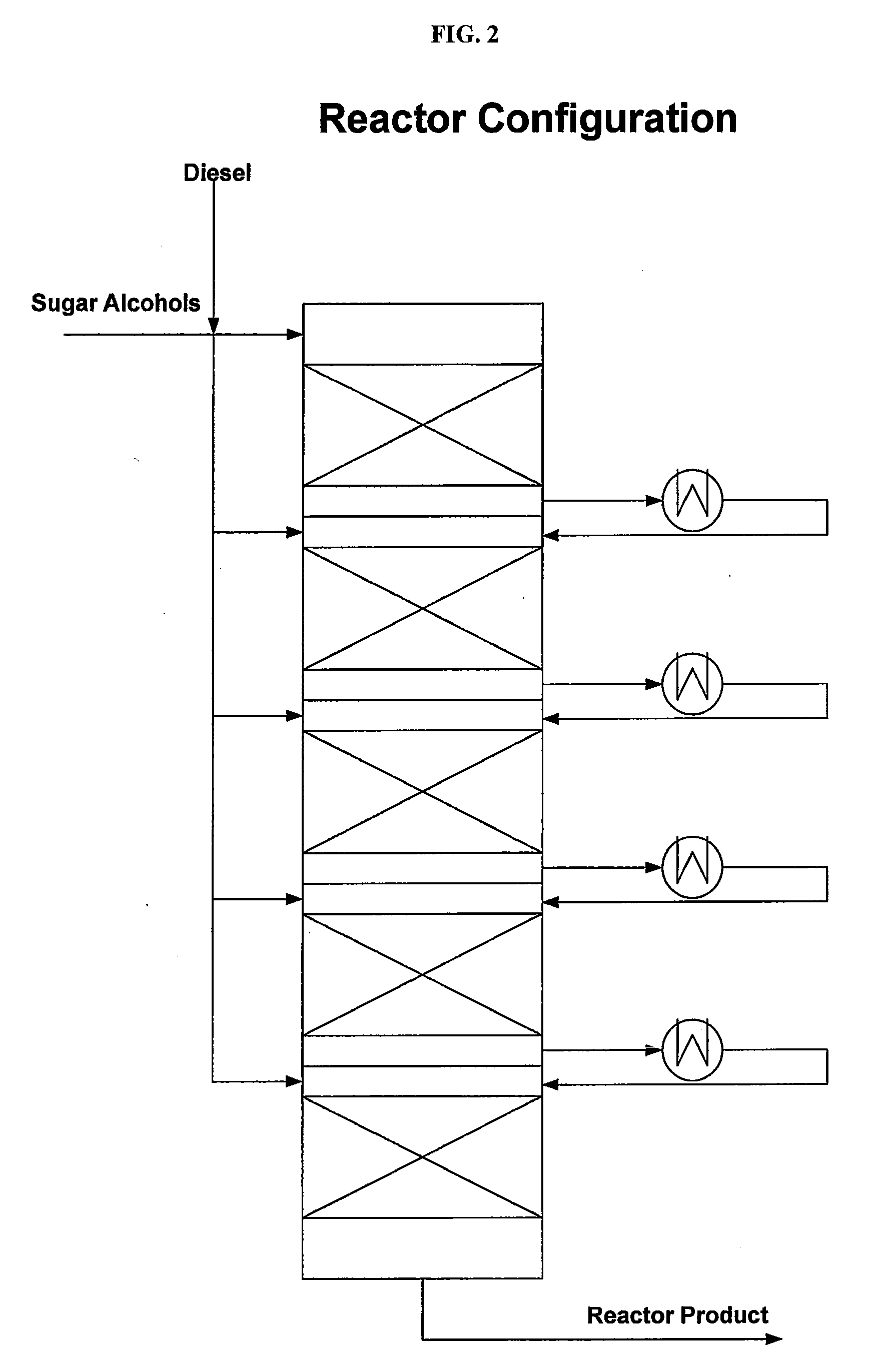

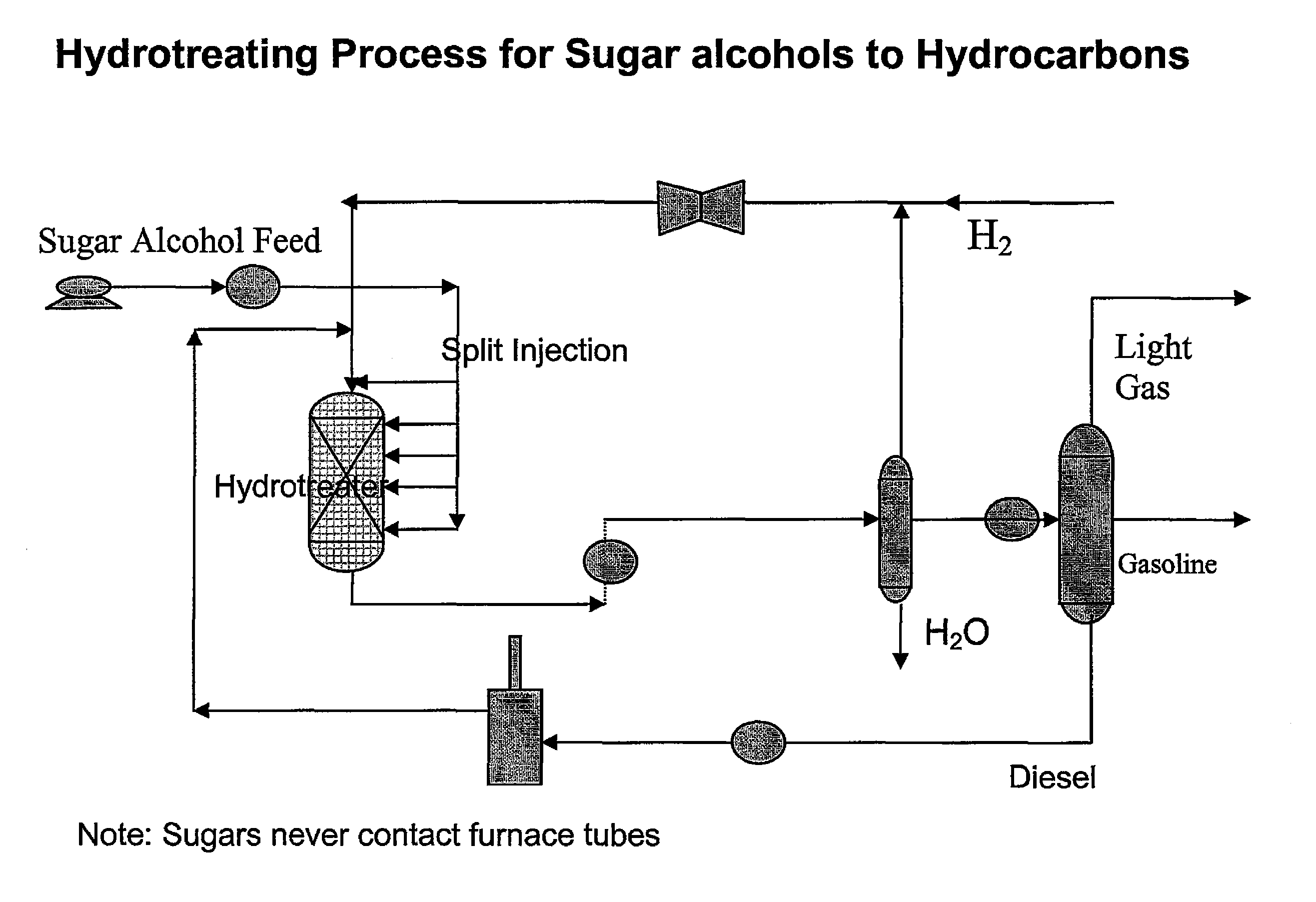

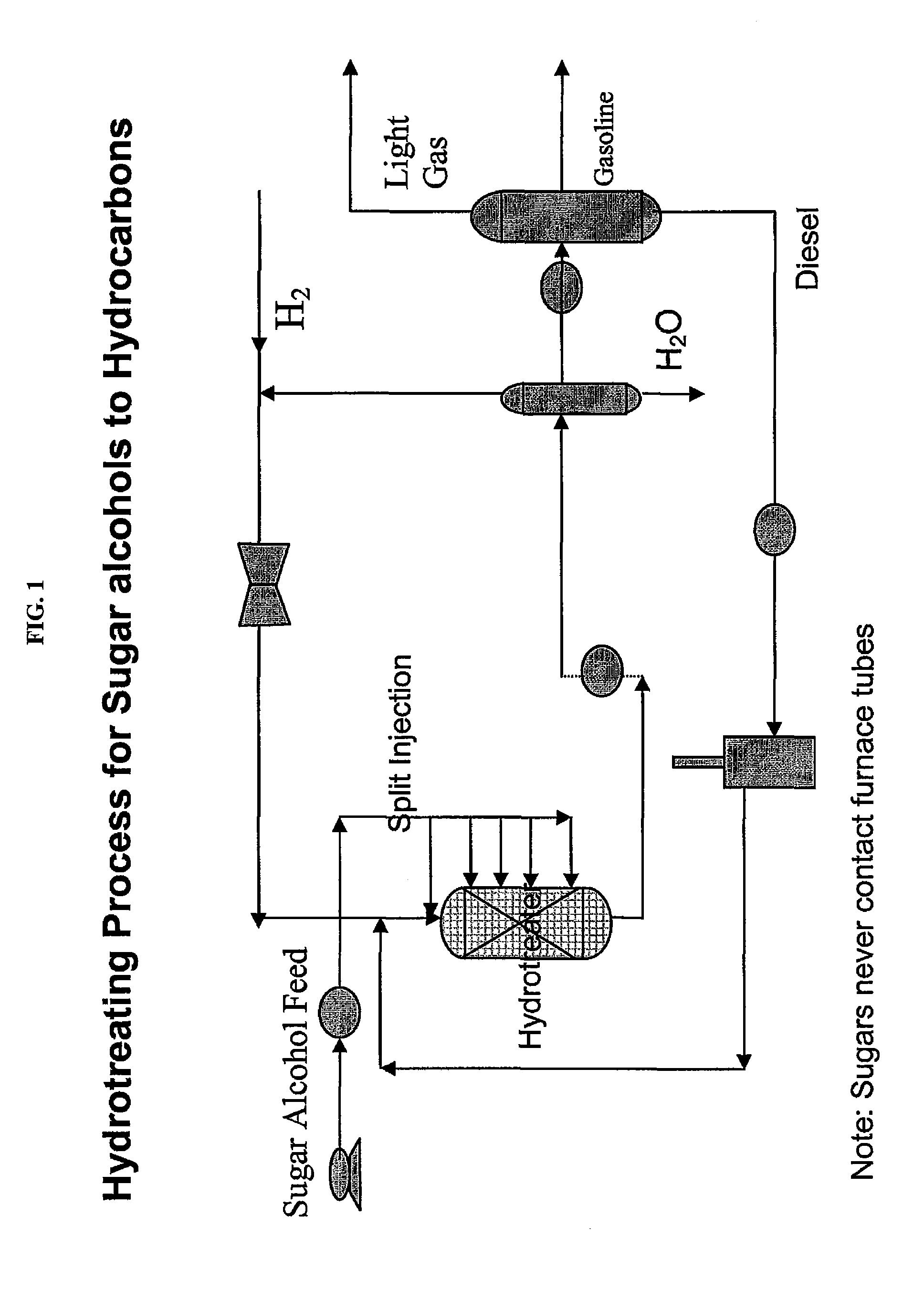

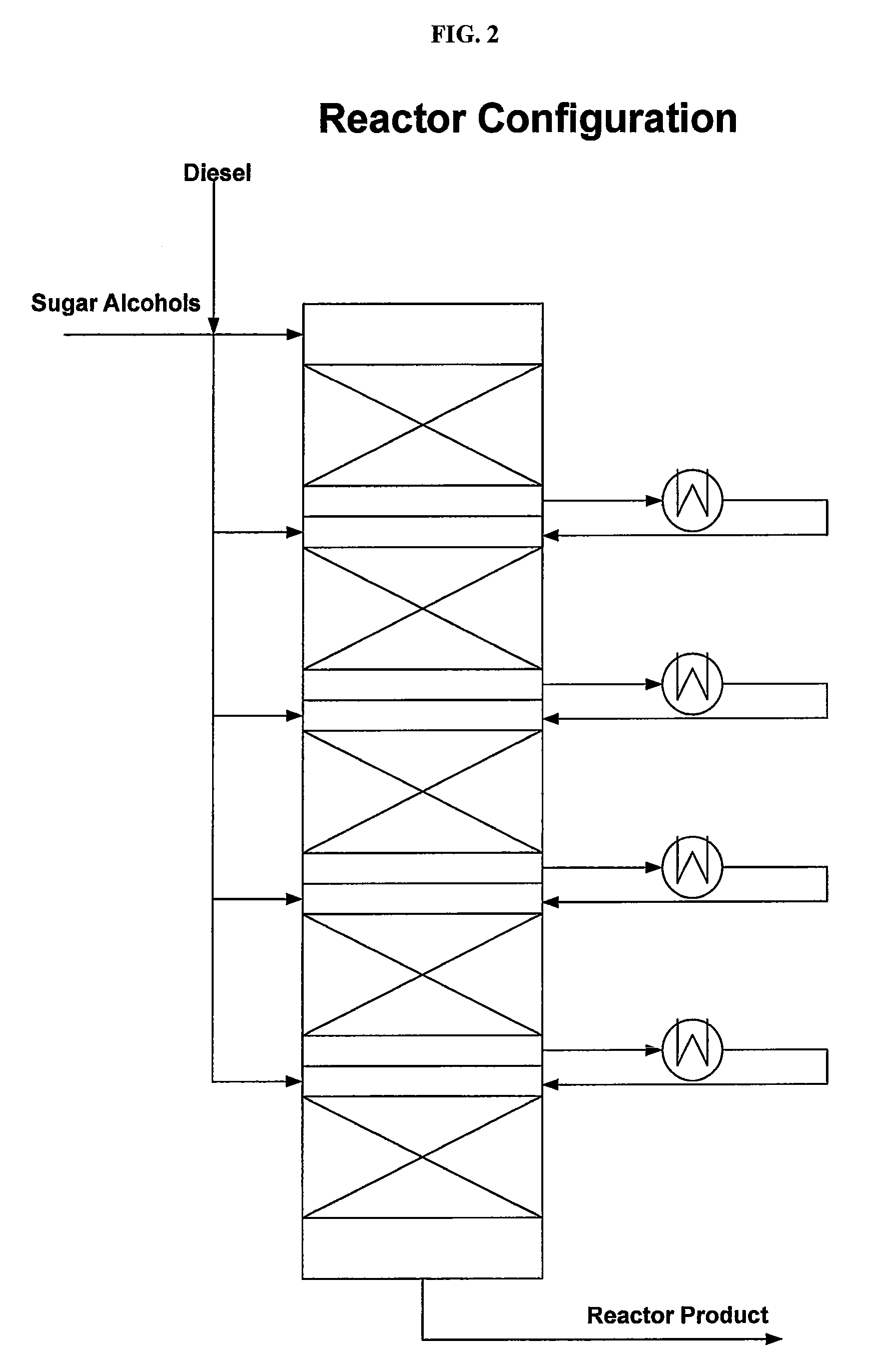

Sugar alcohol split injection conversion

ActiveUS20110087060A1Avoid damageReduces coke productionPhysical/chemical process catalystsBiofuelsAlkaneMultiple injection

A method of hydrotreating liquefied biomass feedstock with diesel feedstock to produce alkanes is demonstrated that prevents damage to the reactor catalyst, reduces coke production, and converts nearly all of the polyols to alkanes. In order to mitigate the potential coking issue and to moderate the temperature of the catalyst bed while maintaining high conversion for sugar alcohol to hydrocarbon via a hydrotreating process, a diesel feedstock is fed over the reactor catalyst with multiple injections of polyol feedstock along the reactor.

Owner:PHILLIPS 66 CO

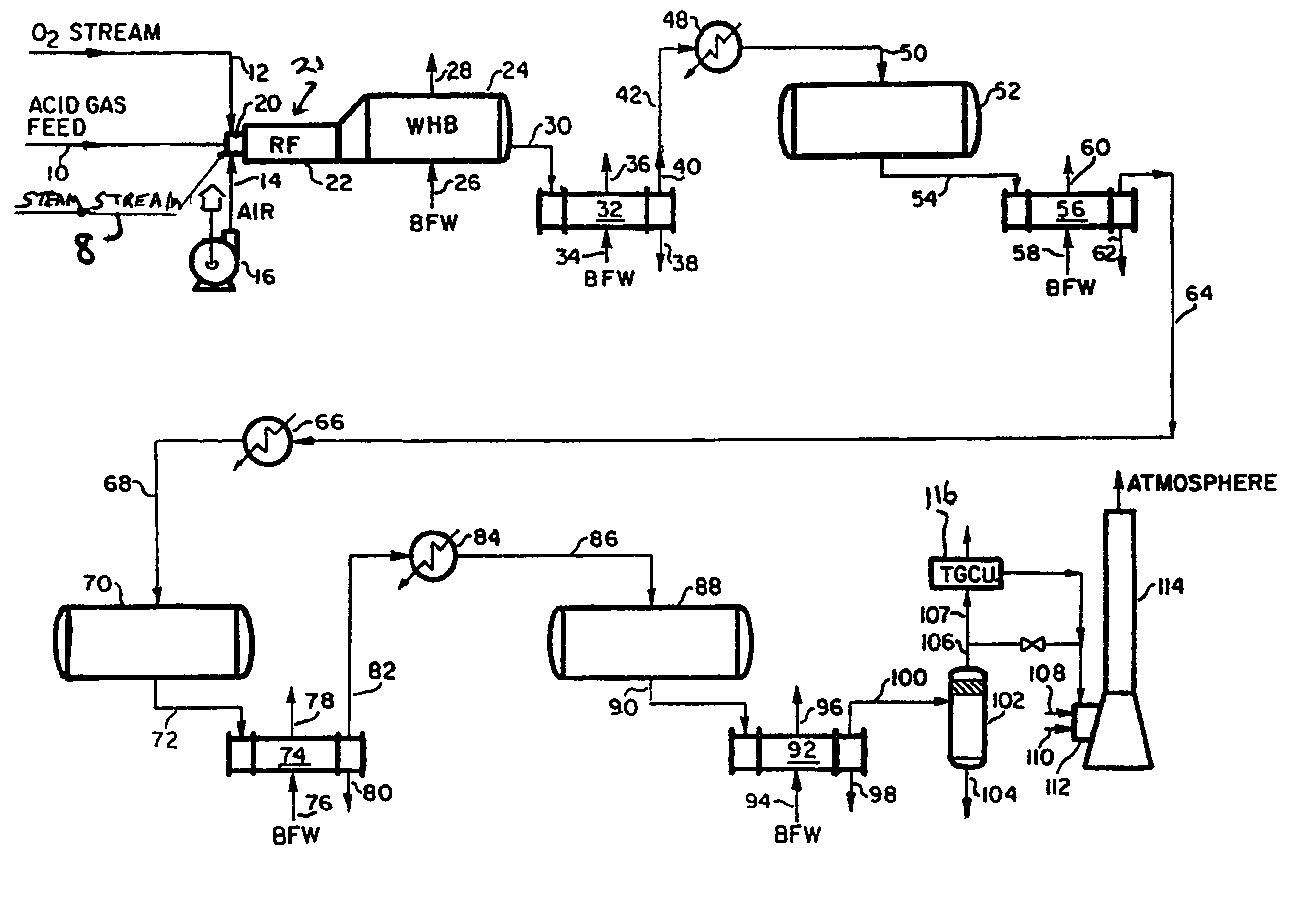

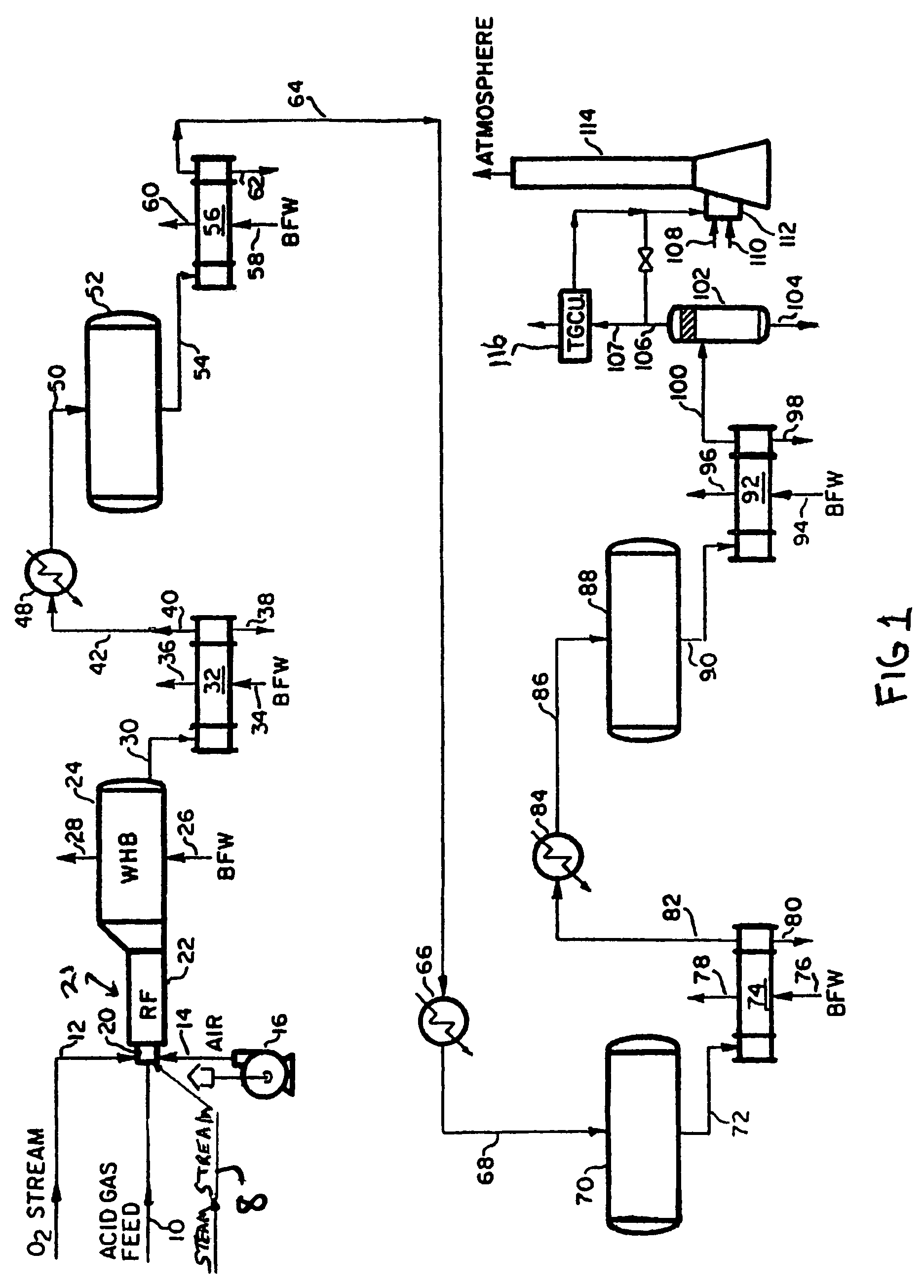

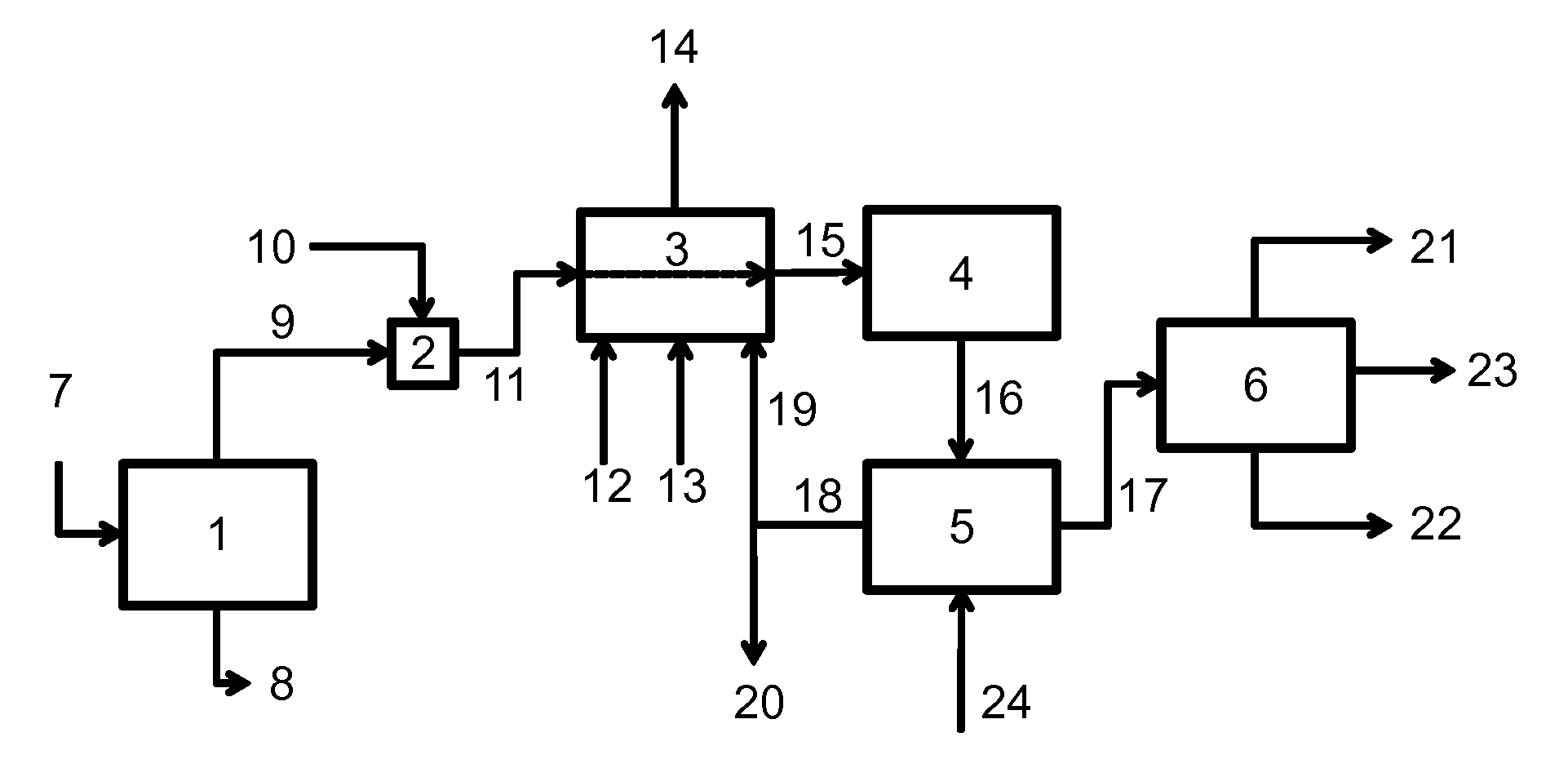

Steam modified Claus process

ActiveUS7597871B2Quantity minimizationMaximize feed rateSulfur preparation/purificationClaus processPhotochemistry

Disclosed is a method for treating a gas stream rich in hydrogen sulfide by providing one or more feed gas streams rich in hydrogen sulfide into a Claus reaction furnace, providing air into the Claus reaction furnace, providing supplemental oxygen into the Claus reaction furnace, and providing steam to the Claus reaction furnace, where the steam is in addition to any steam that may be present in gases that are recycled to the Claus reaction furnace. The components are then reacted at a temperature above about 2400° F. and at a pressure sufficient to cause hydrogen sulfide to be converted into sulfur.

Owner:AIR PROD & CHEM INC +1

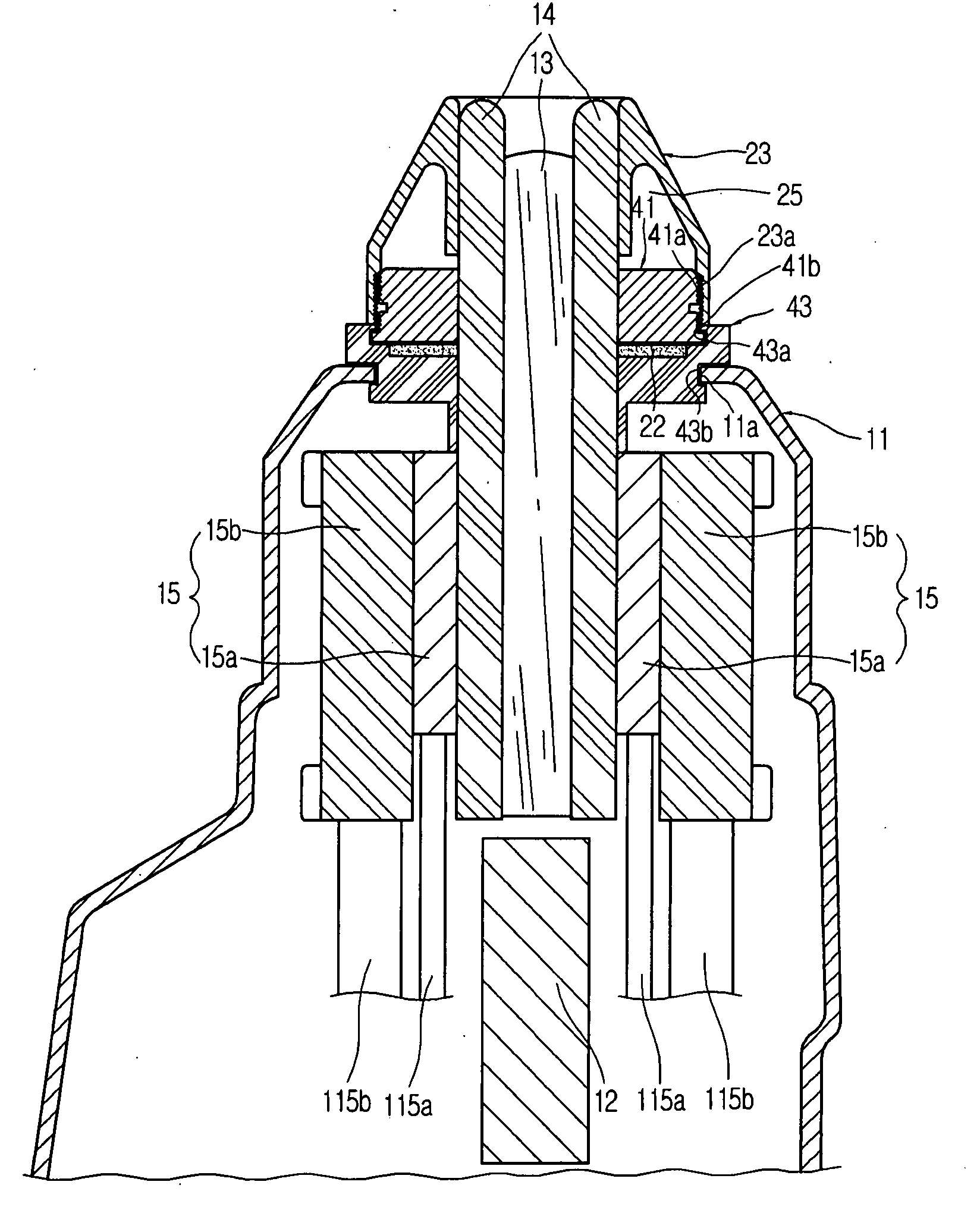

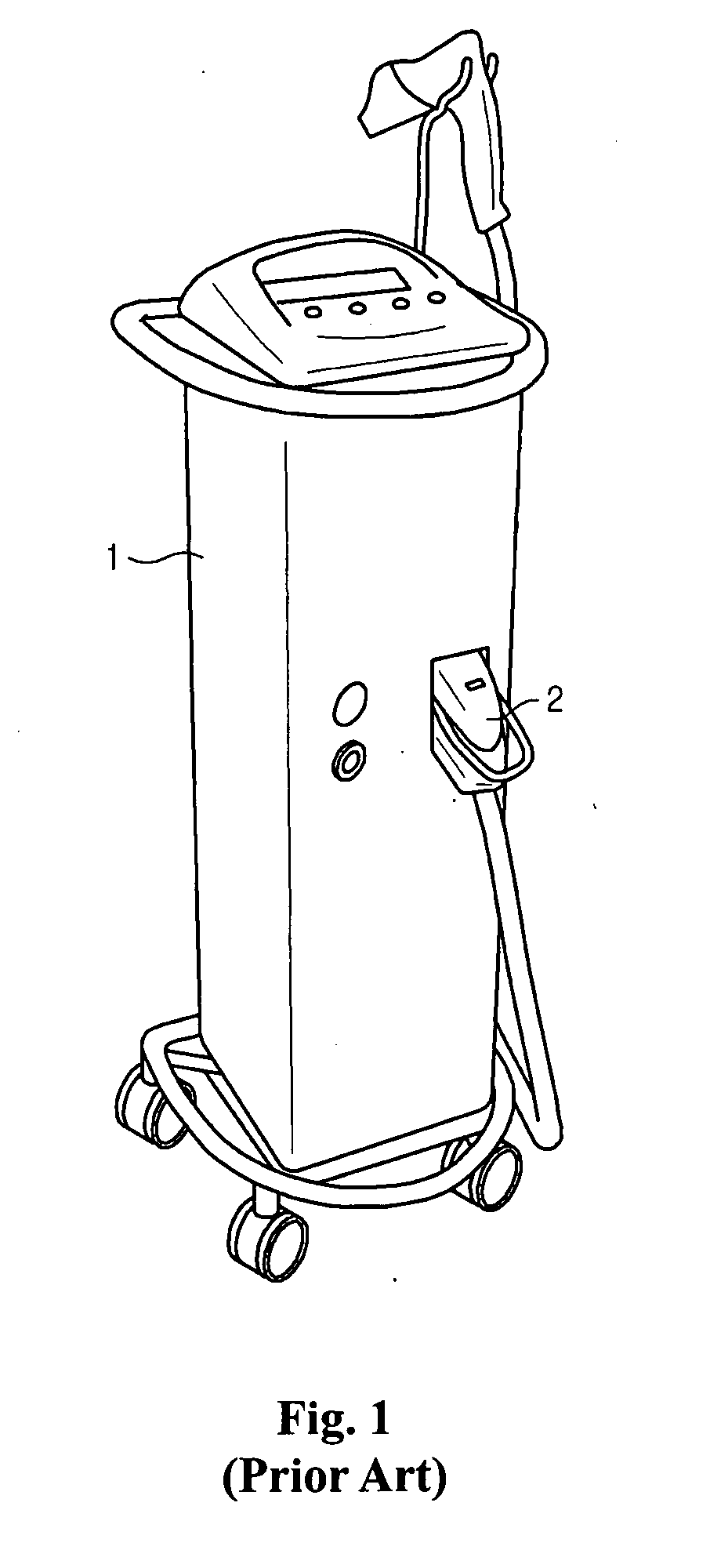

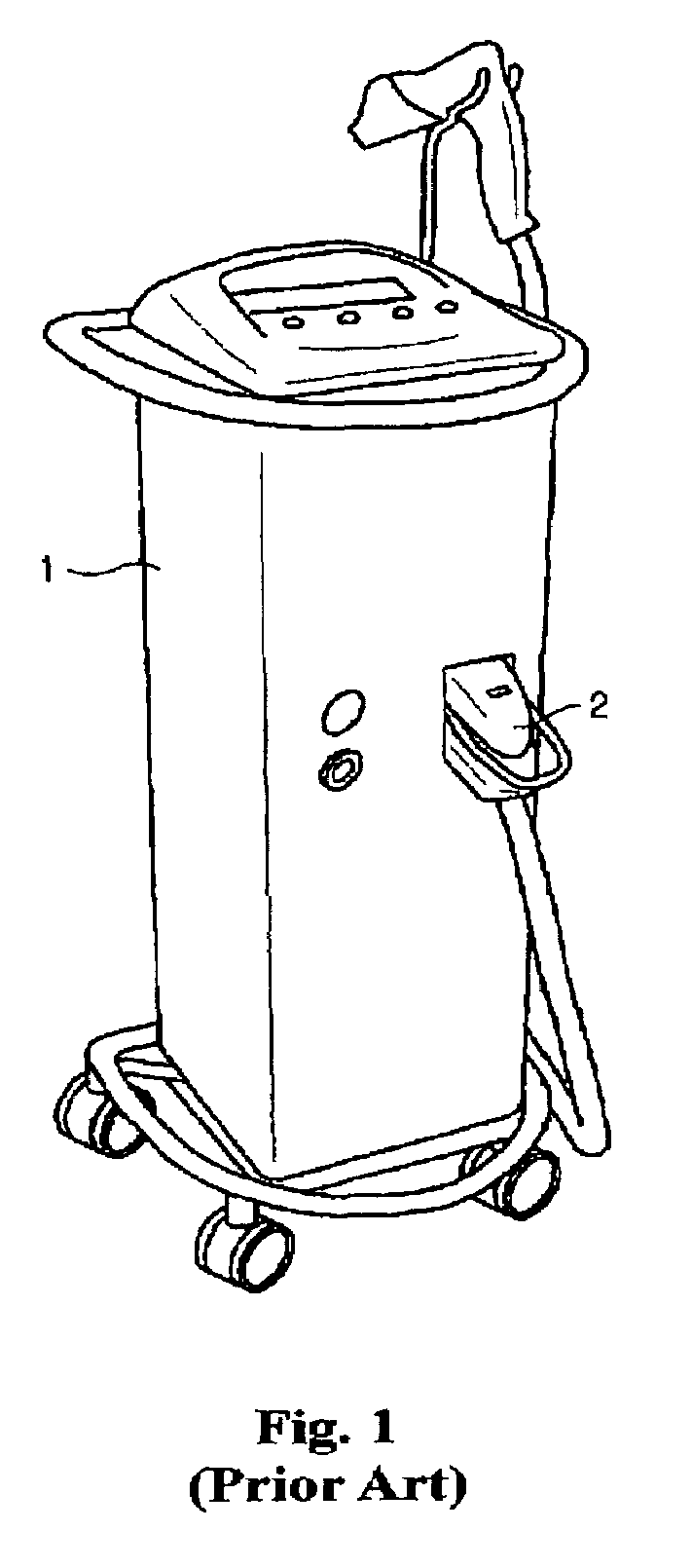

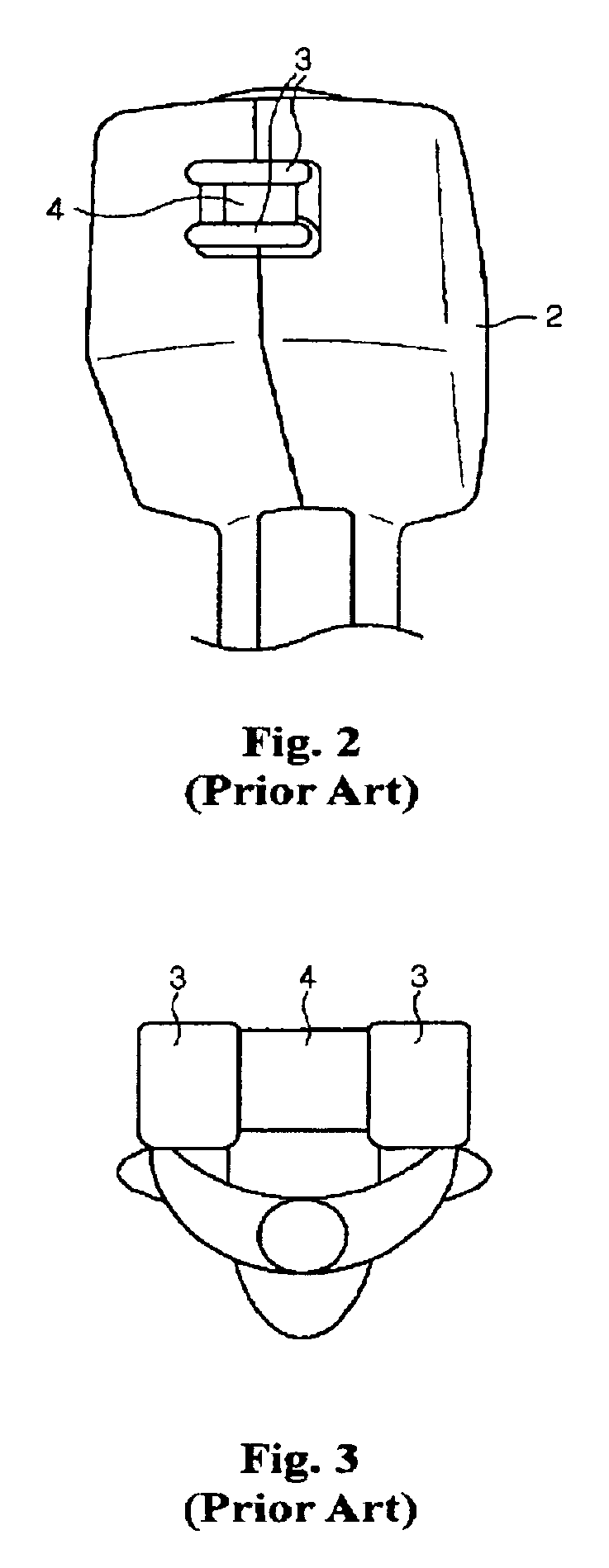

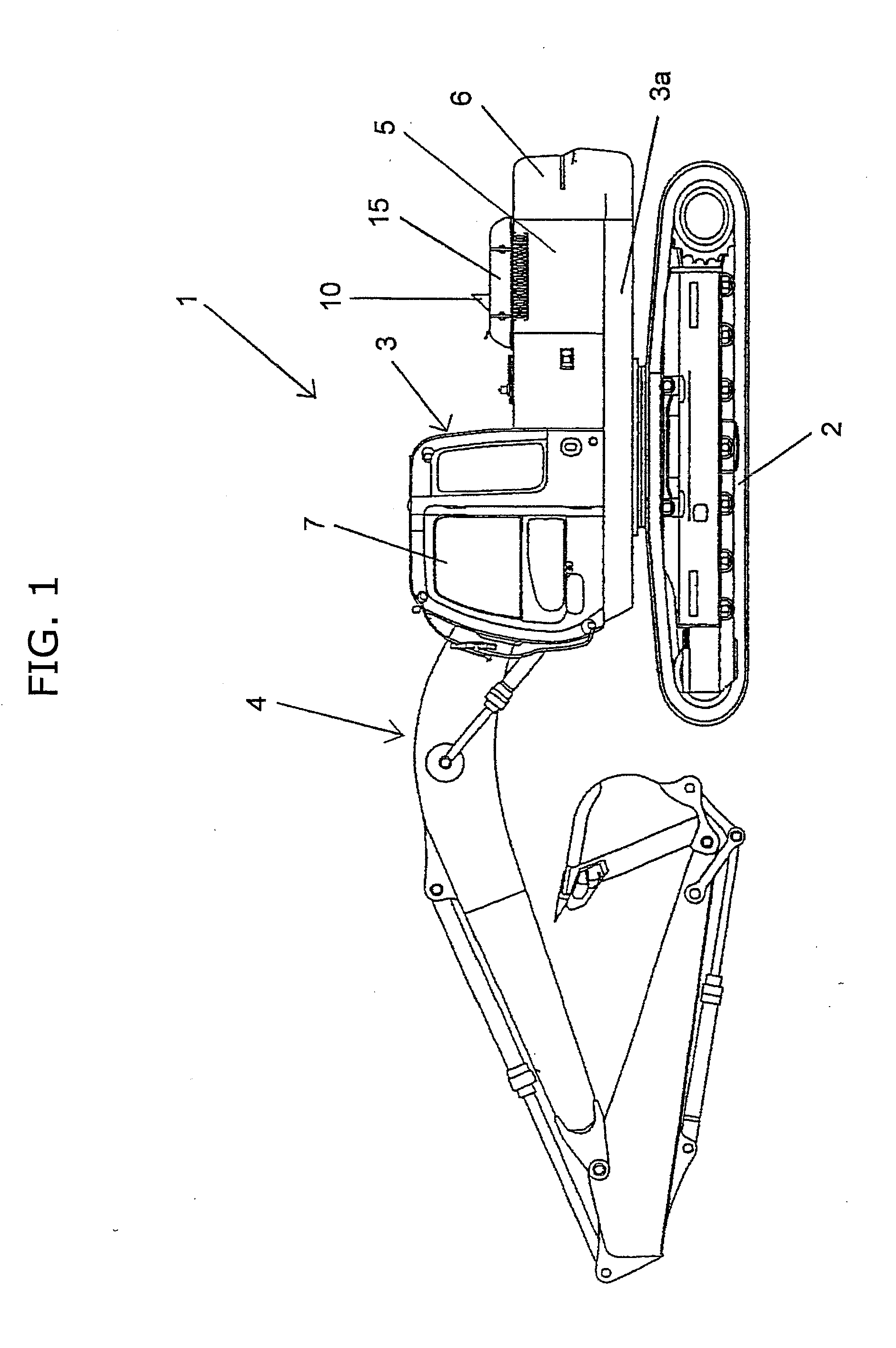

Applicator attachable to skin treatment device and skin treatment method using the same

ActiveUS20070203447A1Free from painEliminate unpleasant feelingElectrotherapySurgical instrument detailsSkin treatmentsSuction force

An applicator attachable to a skin treatment device that is capable of simultaneously applying RF energy and optic energy to a patient's skin, and a skin treatment method using the applicator are developed. The skin treatment device comprises: a housing, one or pair of electrodes arranged inside of the housing for generating the high frequency waves, a suction cavity formed in front of the electrodes while it is contacting to the patient's skin, opposite end installed to the housing and an lateral vacuum pocket that is connected to a flow pathway connected to a vacuum system for generating negative pressure inside the applicator. Thus, the patient's skin is lifted by suction force to place between the pair of electrodes for easily and effectively penetrating the laser beams in to the dermis.

Owner:JUN CORP

Aqueous curable binder composition

InactiveUS20130005870A1Binder viscosityGreat flexingOrganic detergent compounding agentsDextran coatingsEmulsionWater soluble carbohydrate

This invention is an aqueous curable binder composition useful as a thermosetting binder for a variety of applications, particularly for substrates that need to retain at least some flexibility. More particularly, the present invention relates to curable aqueous binder compositions comprising at least one water-soluble carbohydrate binder; at least one polyacid crosslinking agent; and one or more high acid polycarboxy emulsion copolymers, as latex modifiers.

Owner:KELLY MICHAEL D +1

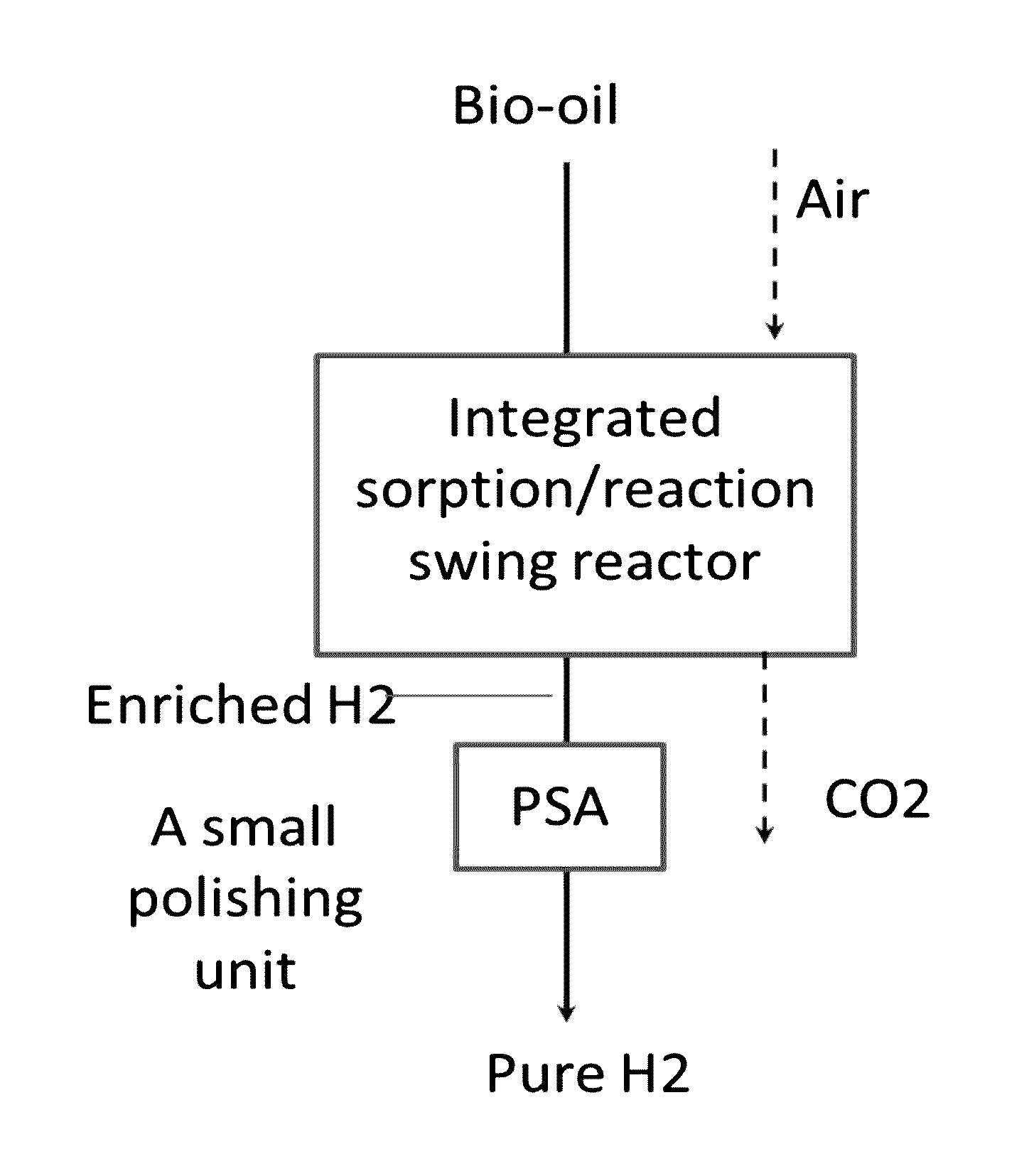

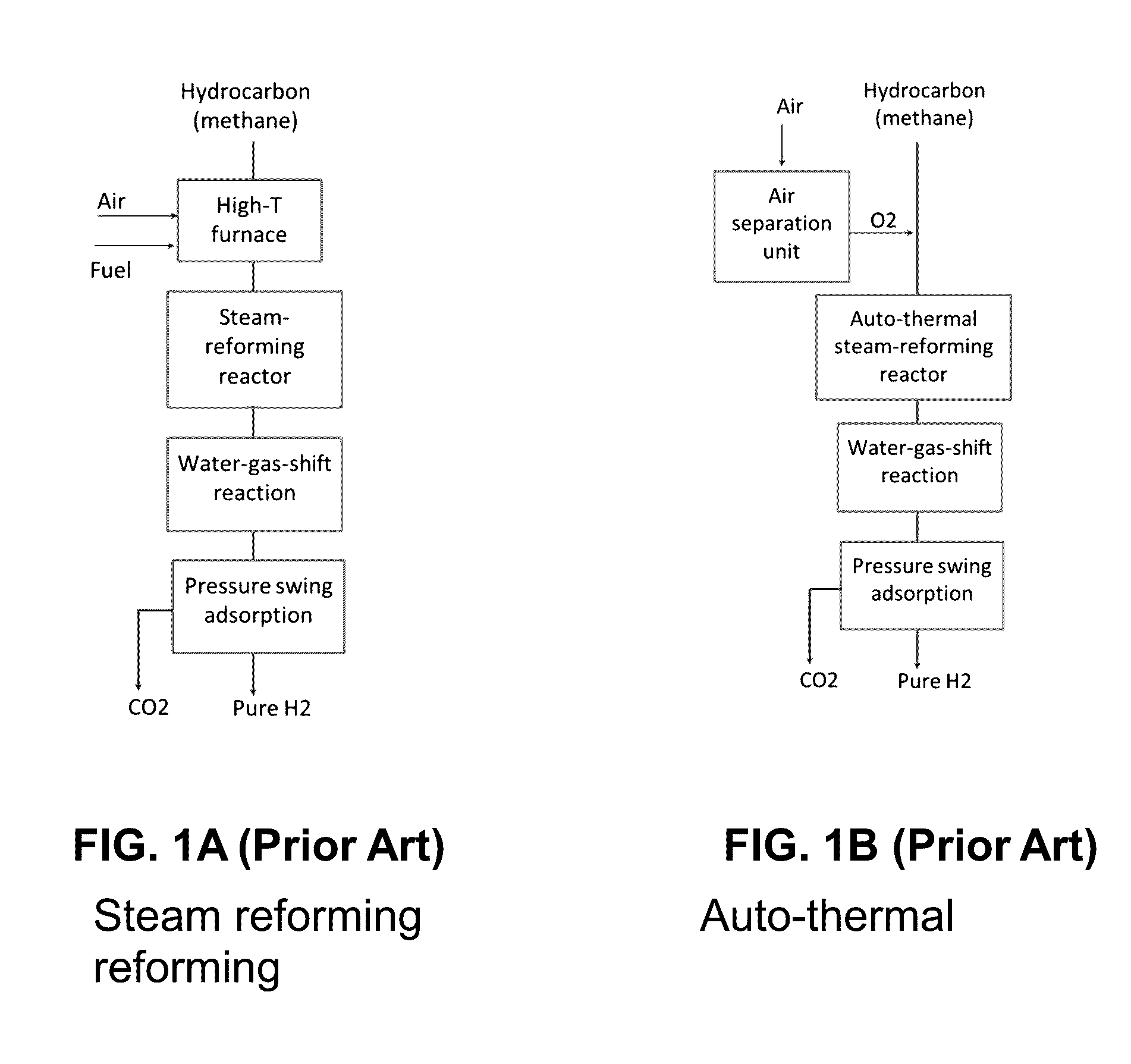

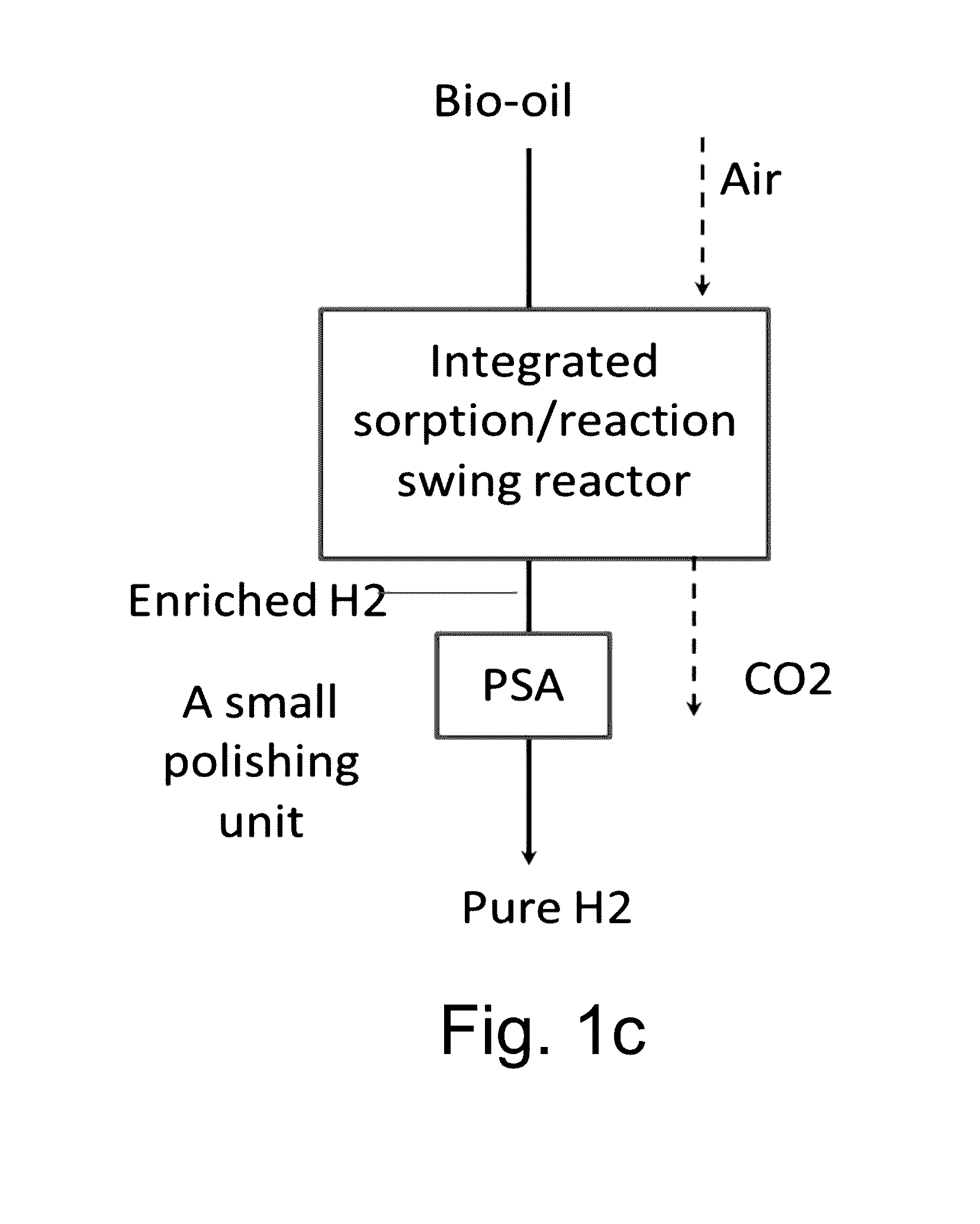

Reactor, CO2 sorbent system, and process of making H2 with simultaneous CO2 sorption

InactiveUS20160304344A1Increase productionReduce capacityProductsOther chemical processesSorbentAlkali metal

A reactor and process for production of hydrogen gas from a carbon-containing fuel in a reaction that generates carbon dioxide is described. The carbon-containing fuel can be, for example, carbon monoxide, alcohols, oxygenates bio-oil, oil and hydrocarbons. In preferred embodiments, the reactor includes a monolithic structure form with an array of parallel flow channels. Methods of using the reactor are also described. In the reactor apparatus of the present invention, the catalytic reaction for hydrogen formation is conducted in conjunction with a carbonation reaction that removes carbon dioxide that is produced by the reactor. The carbonation reaction involves reaction of the carbon dioxide produced from the hydrogen formation reaction with metal oxide-based sorbents. The reactor apparatus can be periodically regenerated by regeneration of the sorbent. A carbon dioxide sorbent system comprising a solid sorbent and a eutectic, mixed alkali metal molten phase is also described.

Owner:BATTELLE MEMORIAL INST PNNL

Cooling liquid for engines

The invention relates to the technical field of chemical engineering material, and particularly relates to a cooling liquid for engines. The cooling liquid comprises the components in parts by weight: 2-9 parts of tetramethyl orthosilicate, 50-85 parts of sorbitol, 1-5 parts of ammonium phosphomolybdate, 5-10 parts of octanoic acid, 350-500 parts of ethylene glycol, 3-5 parts of sodium citrate, 5-12 parts of citric acid, 200-400 parts of propylene glycol, 3-10 parts of 4-methyl 1H-benzotriazole, 9-13 parts of sebacic acid, and 7-11 parts of a cosolvent. The invention aims to provide the cooling liquid for the engines, wherein the cooling liquid is moderate in temperature and good in cooling effect.

Owner:汤彬

Applicator attachable to skin treatment device and skin treatment method using the same

ActiveUS7604630B2Eliminate feelingFree from painElectrotherapySurgical instrument detailsSkin treatmentsSuction force

An applicator attachable to a skin treatment device that is capable of simultaneously applying RF energy and optic energy to a patient's skin, and a skin treatment method using the applicator are developed. The skin treatment device comprises: a housing, one or pair of electrodes arranged inside of the housing for generating the high frequency waves, a suction cavity formed in front of the electrodes while it is contacting to the patient's skin, opposite end installed to the housing and an lateral vacuum pocket that is connected to a flow pathway connected to a vacuum system for generating negative pressure inside the applicator. Thus, the patient's skin is lifted by suction force to place between the pair of electrodes for easily and effectively penetrating the laser beams in to the dermis.

Owner:JUN CORP

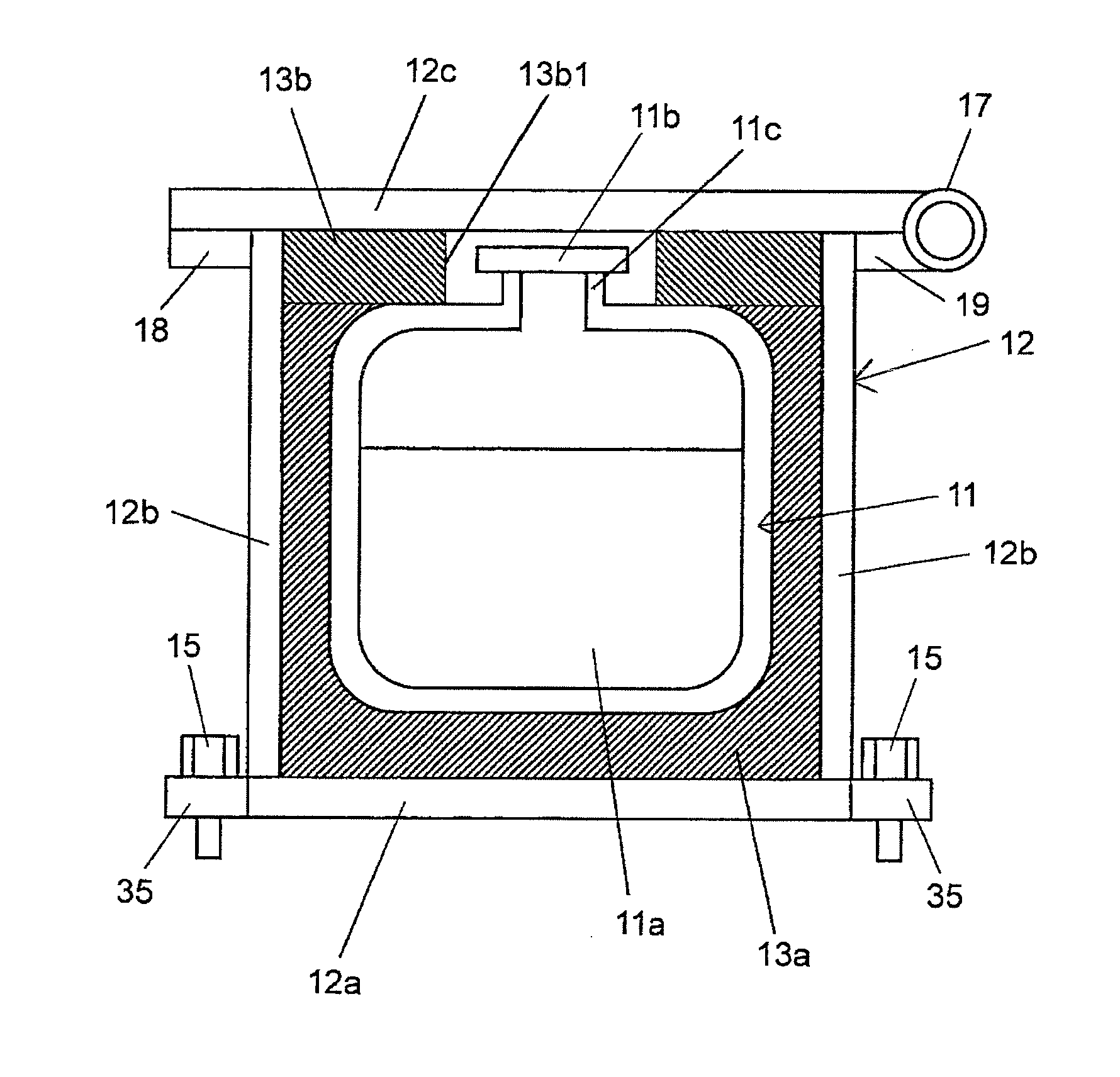

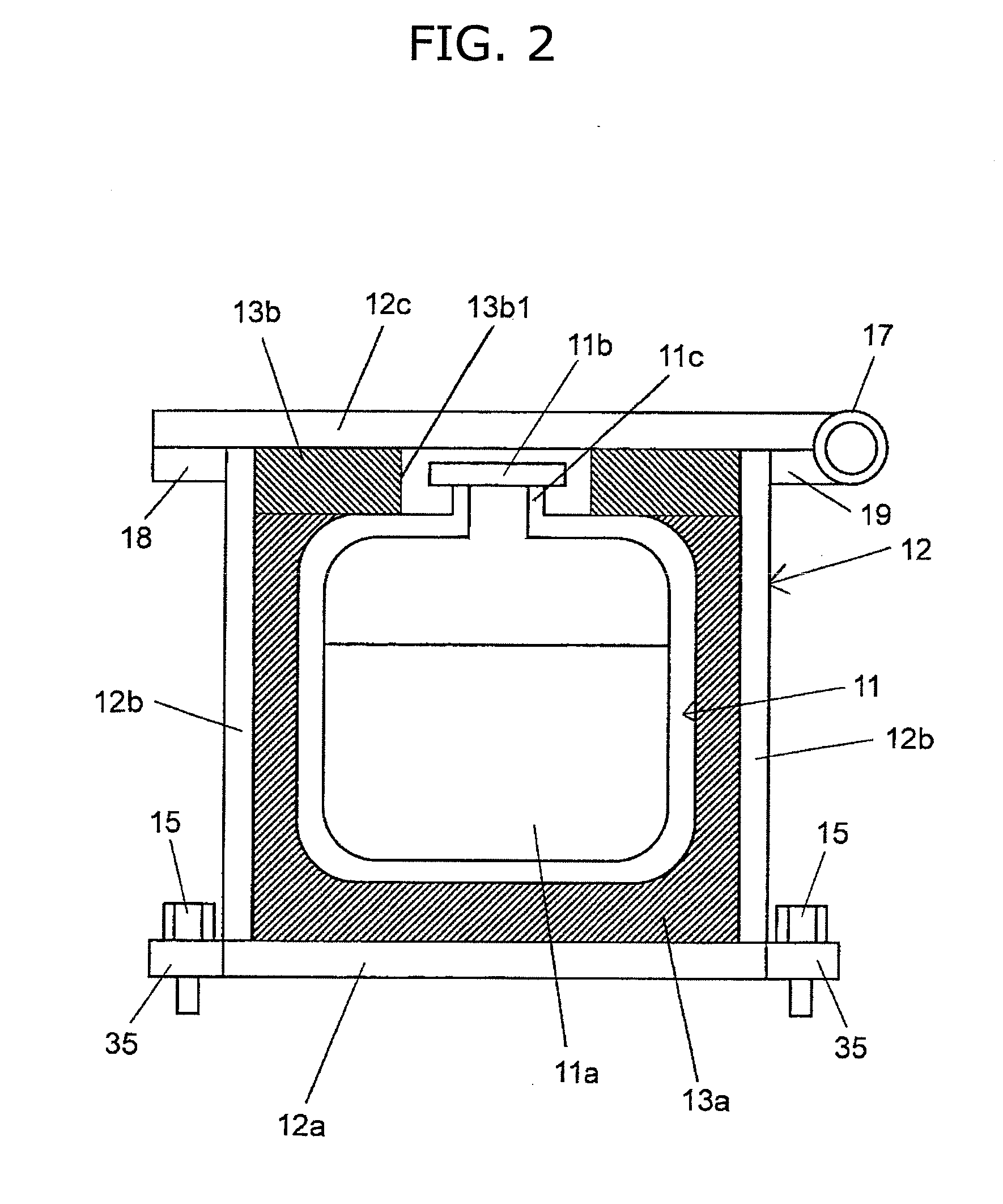

Aqueous Urea Tank Structure for Construction Machine

InactiveUS20130276922A1Reduce the amount requiredCorrosion and degradation of the aqueous urea tank by the ammonia can be suppressedInternal combustion piston enginesExhaust apparatusEnvironmental engineeringExcavator

An aqueous urea tank structure is provided for a construction machine, in which a temperature rise of the aqueous urea within the tank can be suppressed and the load applied to the tank due to vibration of a vehicle body can be reduced. The aqueous urea tank structure including an aqueous urea tank which is disposed within a revolving upperstructure of a hydraulic excavator to store aqueous urea that purifies the exhaust gas discharged from an engine, wherein the aqueous urea tank structure further includes a securing member which encloses the periphery of the aqueous urea tank to secure the aqueous urea tank within the revolving upperstructure, and heat insulating materials which are interposed between the securing member and the aqueous urea tank to hold the aqueous urea tank. The securing member contains a box.

Owner:NIHON KENKI CO LTD

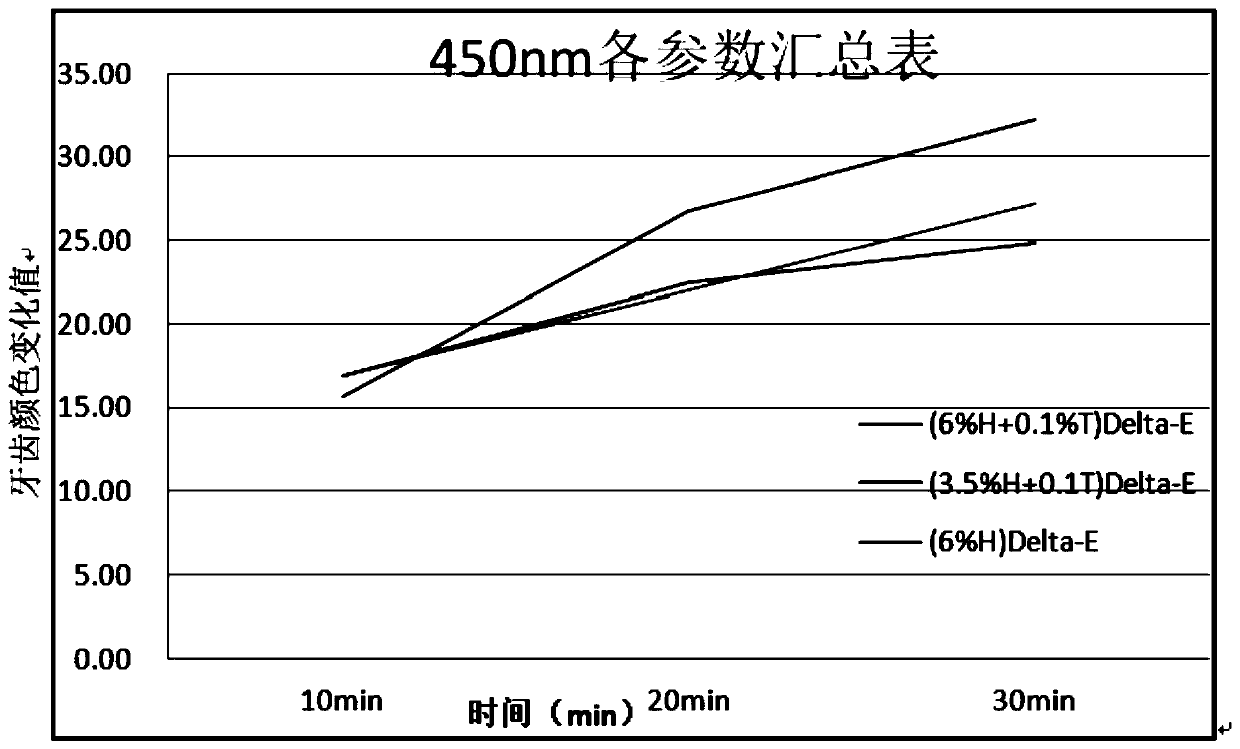

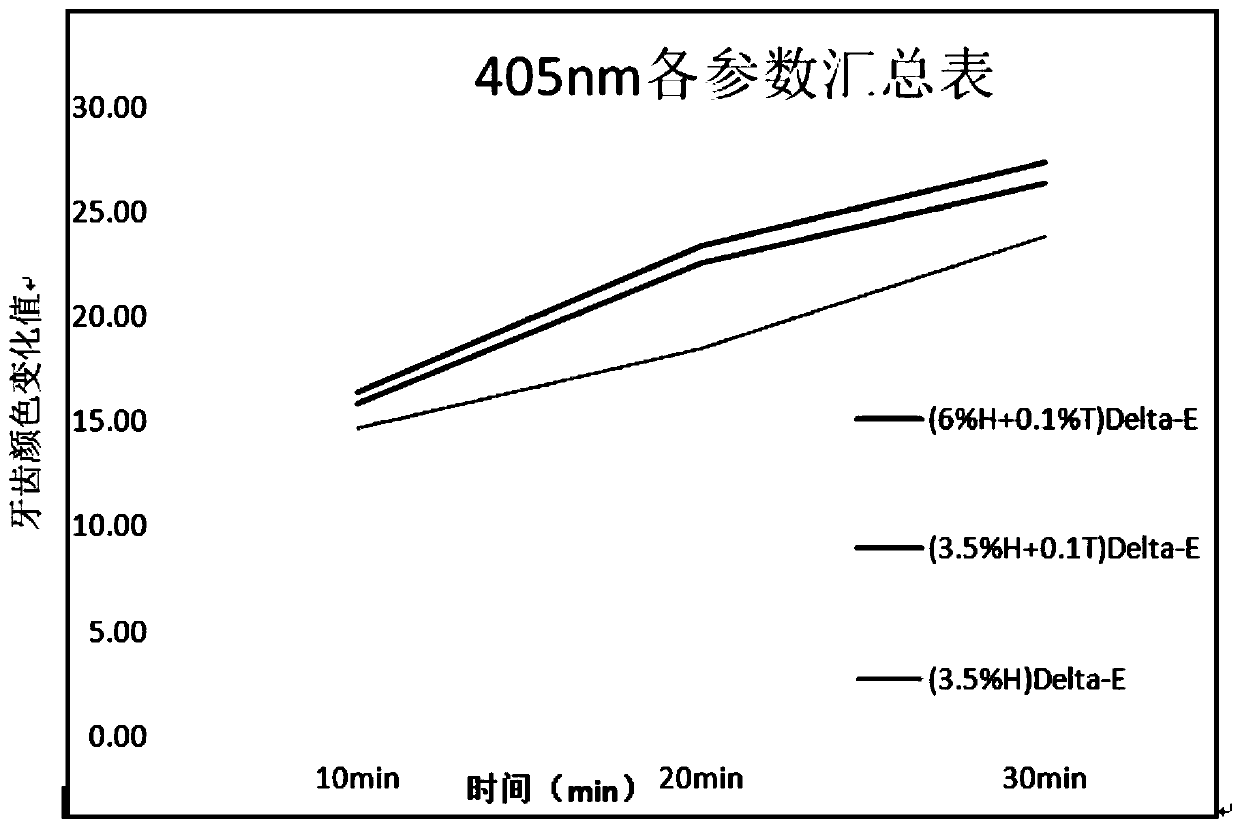

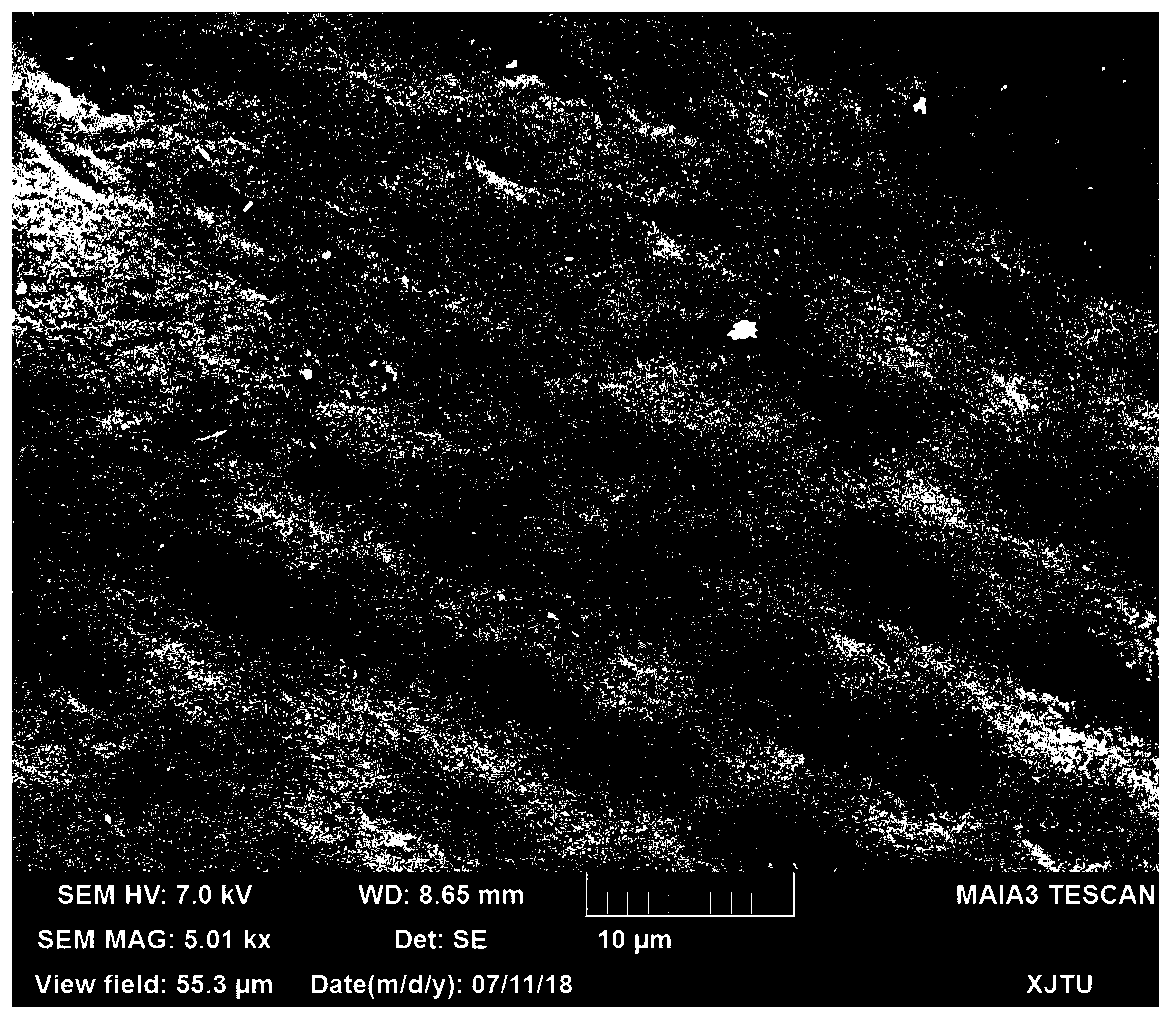

Tooth whitening gel and preparation method and use method thereof

InactiveCN109998933AEffective and safe whiteningReduce concentrationCosmetic preparationsToilet preparationsHigh concentrationTooth whitening

The invention provides a tooth whitening gel and a preparation method and a use method thereof. The problems are solved that a higher concentration of peroxide is used in order to achieve a better effect and a laser with a longer wavelength makes teeth uncomfortable or damaged in an existing tooth whitening method. The method adopts the low-concentration (3%-10%) peroxide as a main component of awhitening agent, and utilizes the catalysis of non-metal ion doped titanium dioxide with a large visible red shift, under the illumination of a blue laser source of 450+ / -10 nanometre or a purple laser source of 405+ / -5 nanometre, the peroxide is rapidly decomposed by photochemical catalysis, and the low-concentration peroxide can generate enough free radicals to achieve whitening of teeth.

Owner:西安蓝极医疗电子科技有限公司

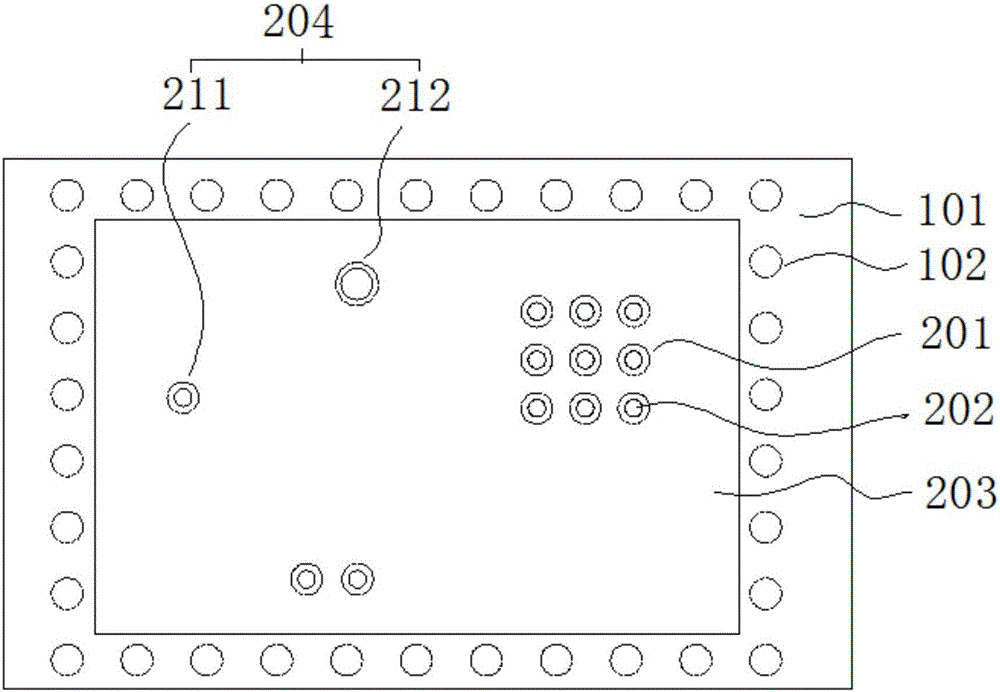

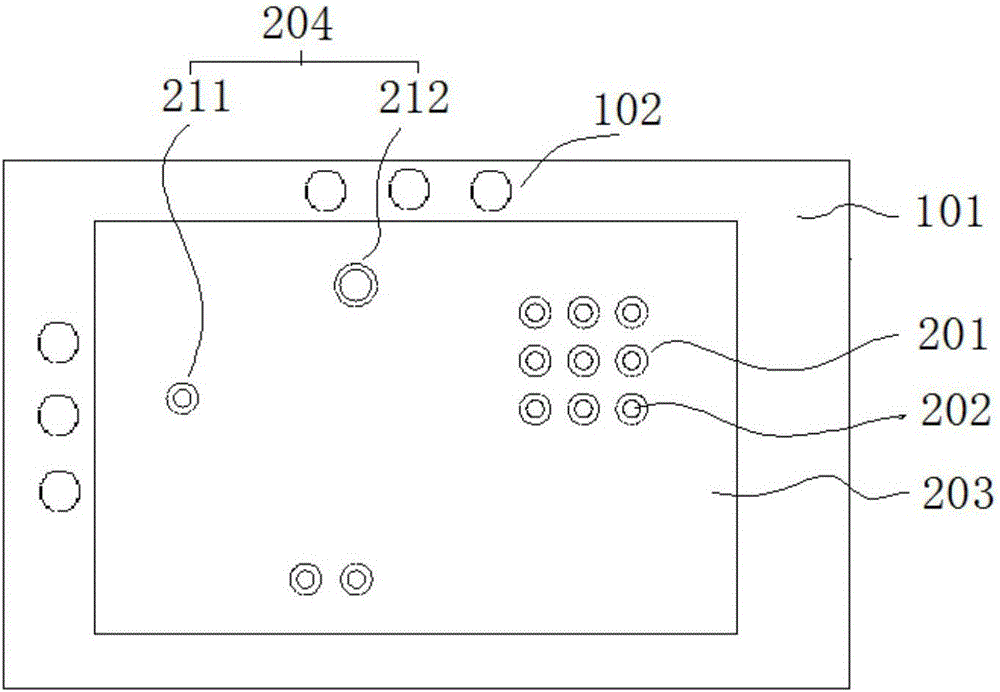

Backdrilling plug hole panel and machining method thereof

ActiveCN106132091AModerate temperatureSuitable timePrinted circuit aspectsPrinted element electric connection formationCopper platingEngineering

The invention discloses a backdrilling plug hole panel and a machining method thereof. Particularly, the machining method of the backdrilling plug hole panel comprises the following steps of (1) hole plating after backdrilling: carrying out backdrilling on plated through holes in a substrate, wherein a backdrilling segment is a non-plated through hole, and a remaining segment keeps the metallization characteristic; and carrying out thickening and copper plating on the plated through holes; (2) panel baking: baking the panel at 120-160 DEG C; (3) hole plugging: filling backdrilling holes with resin; and (4) solidification: carrying out solidification treatment on the resin for filling the backdrilling holes. According to the machining method, the moisture content of the substrate can be effectively reduced through panel baking before hole plugging, so that a cavity can be effectively avoided in resin hole plugging.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Process for converting FGD gypsum to ammonium sulfate and calcium carbonate

ActiveUS8758719B2High yieldQuick and high yieldCalcium/strontium/barium carbonatesAmmonium carbonates/bicarbonatesSlurryNuclear chemistry

Owner:SPARSTANE TECH

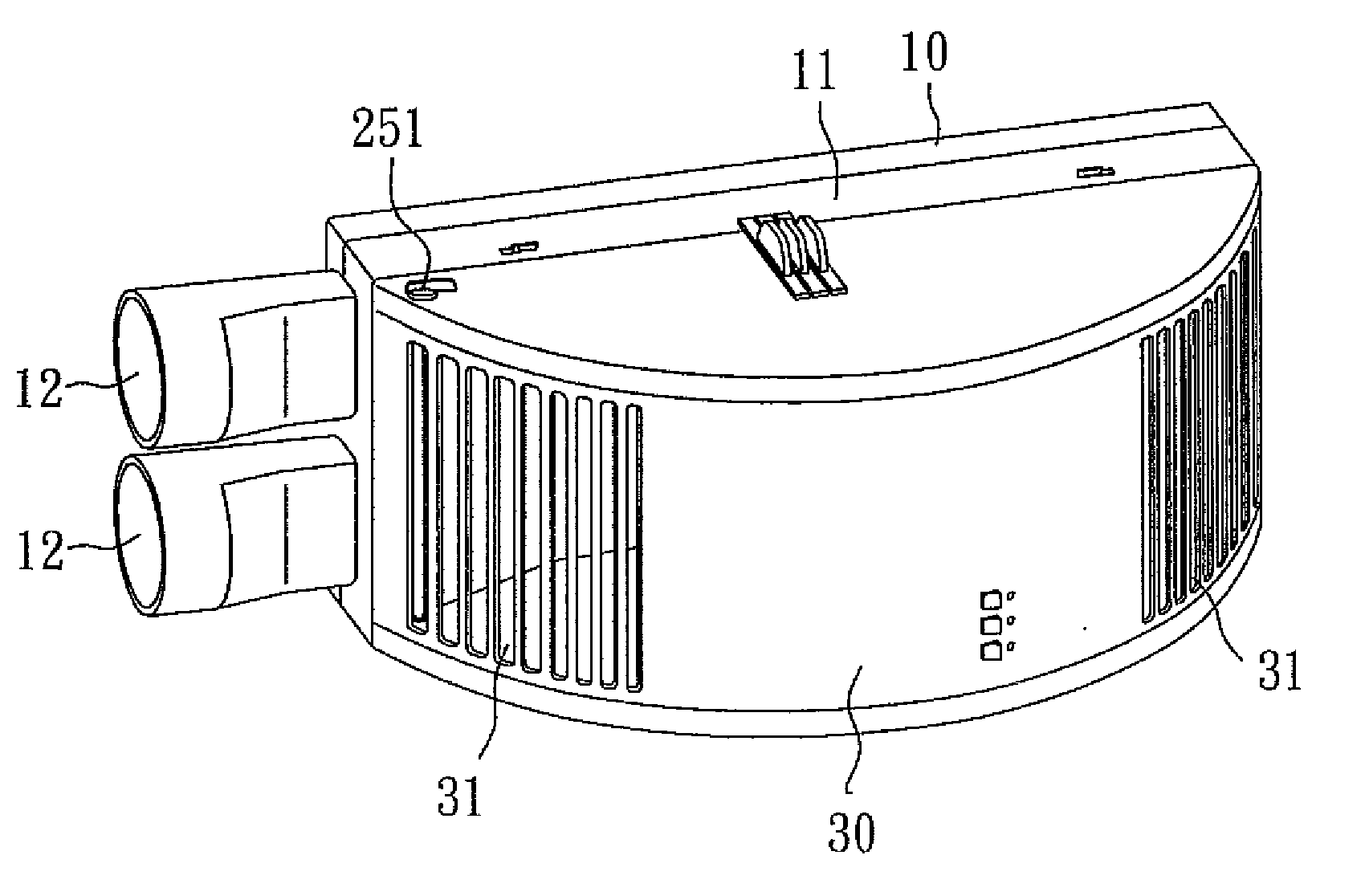

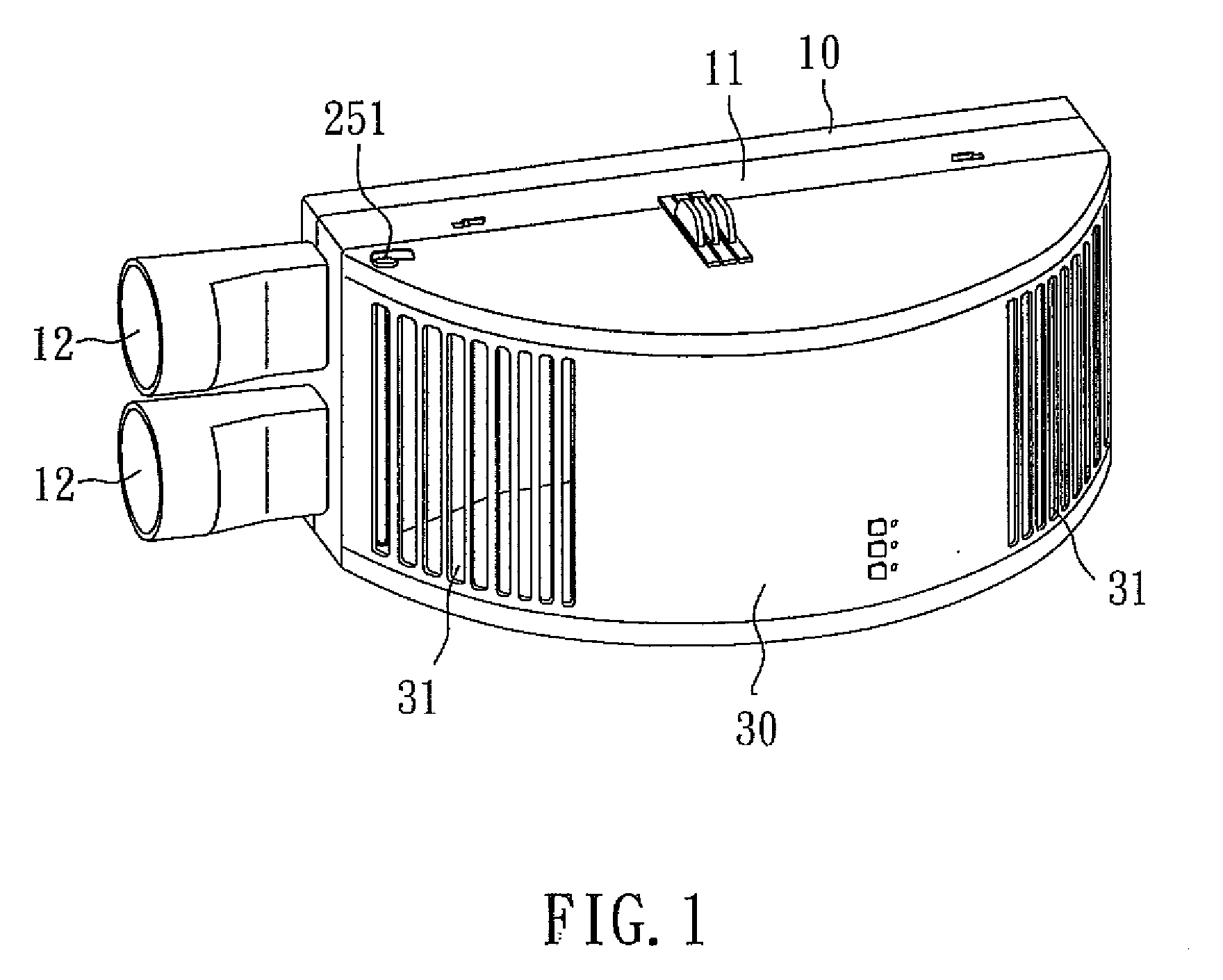

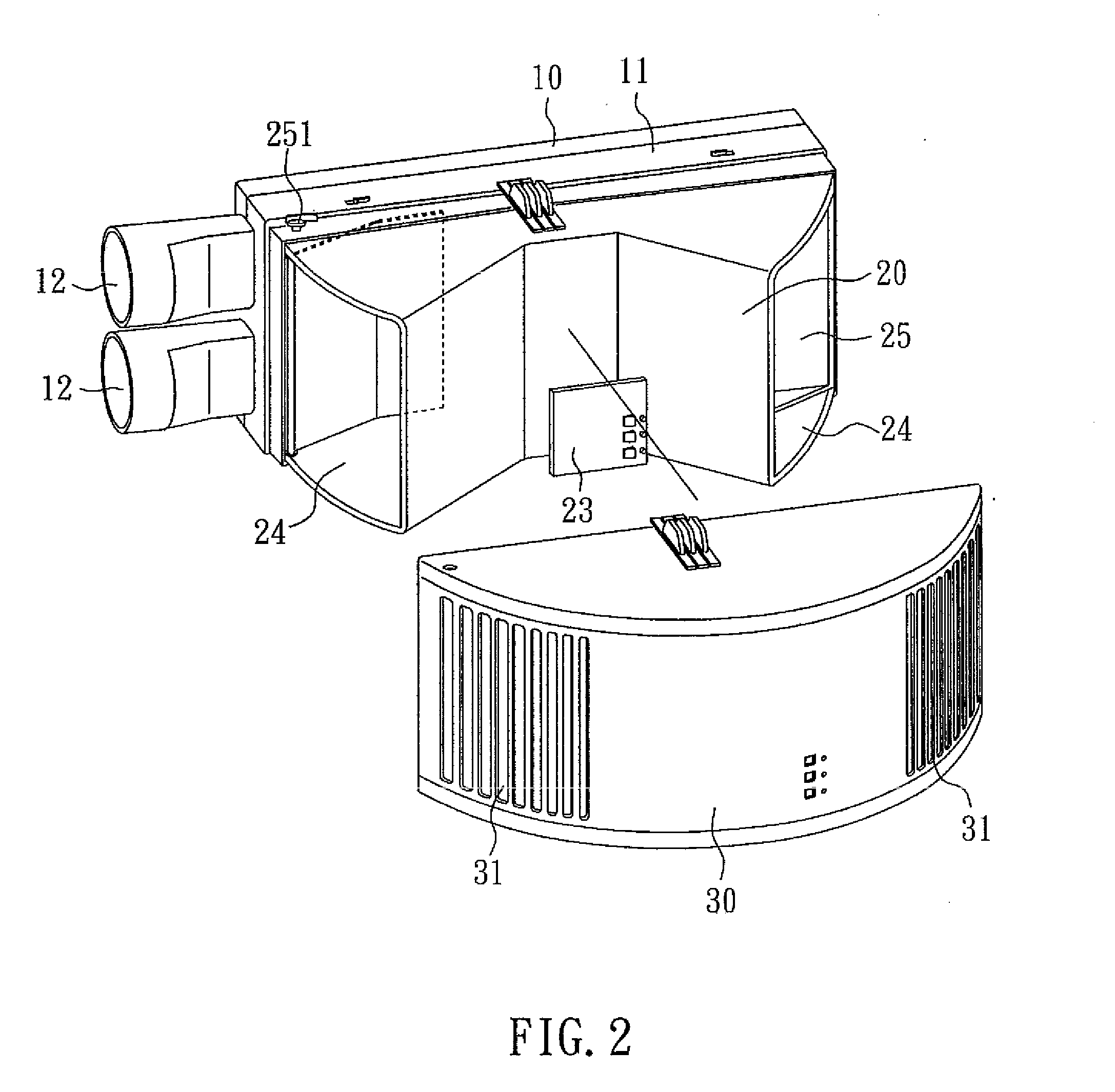

Air cleaner

InactiveUS20100035537A1Moderate temperatureCombination devicesDucting arrangementsAir filterEngineering

An air cleaner, which includes a casing having an enclosed air passage with a ventilation pipe for guiding in outdoor air, a windpipe affixed to one side of the casing for circulation of indoor air, a damper pivotally mounted in between the casing and the windpipe for controlling the passage the casing and the windpipe and flowing direction of air between the casing and the windpipe, and an air filter and a negative ion generator mounted in the windpipe for cleaning air passing through the windpipe.

Owner:EXTENIX CORP

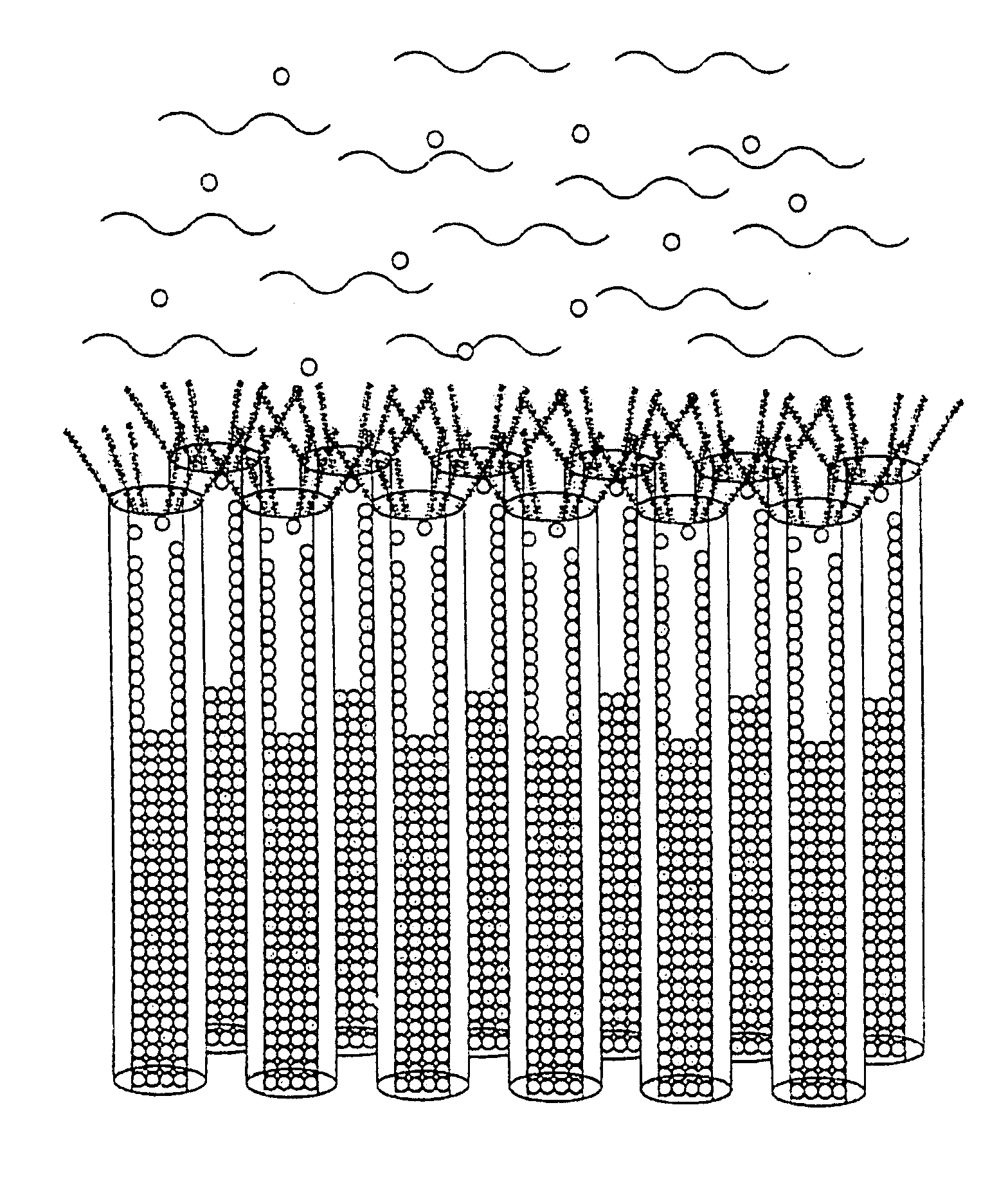

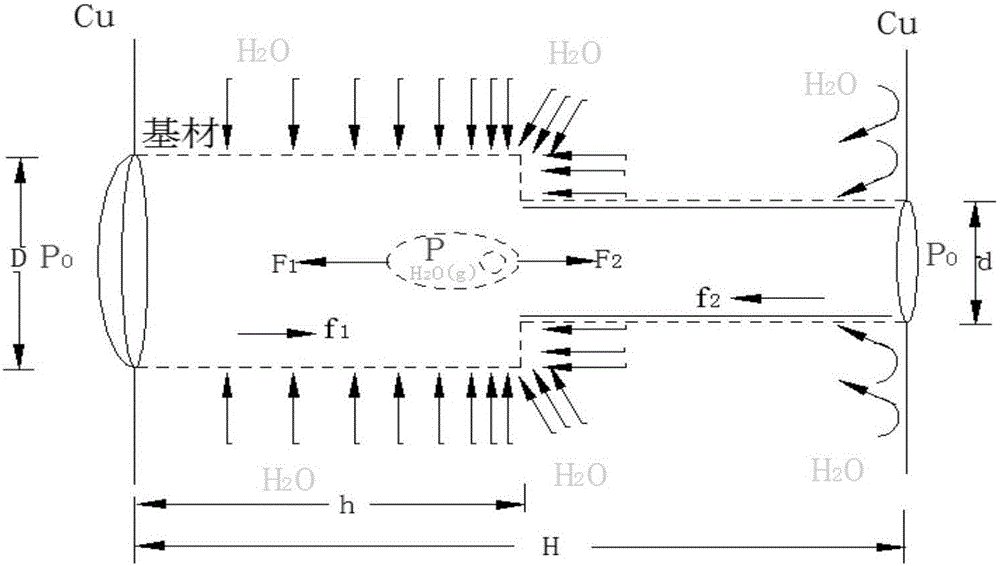

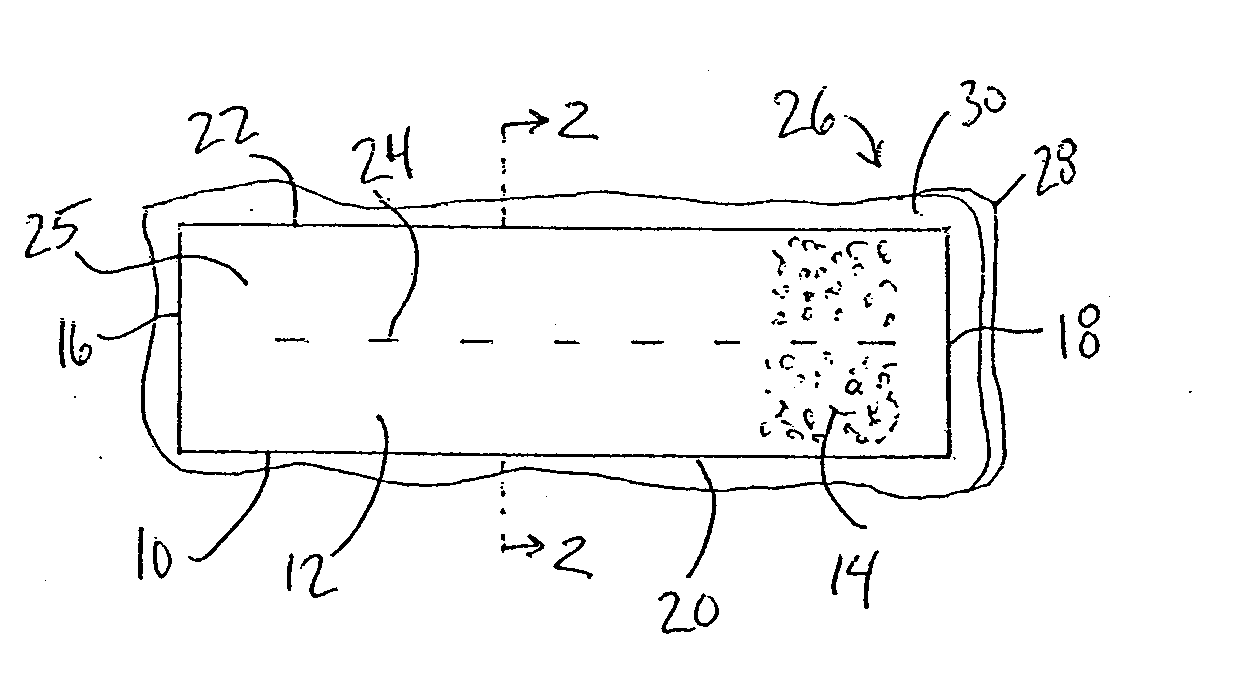

System for moderating the temperature of a medium for growing microalgae

InactiveUS20110318816A1Moderate temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeSunlight

A system is provided for moderating the temperature of a medium for growing microalgae and for distilling fresh water. In the system, the medium flows through a conduit having two ends and a bottom. As the sunlight passes into the medium, the algae grows and the medium is heated. For the system, an impermeable first liner is extended across the conduit to cover the bottom of the conduit. Further, a gas permeable / liquid impermeable second liner is extended across the conduit to cover the bottom of the conduit. With the second liner positioned on top of the first liner, vapor medium is only able to pass through the second liner. Also, a condensing mechanism is positioned between the first and second liners. Any vapor medium that passes through the second liner is condensed into fresh water. As a result, fresh water is distilled and the medium is cooled through condensation.

Owner:GENERAL ATOMICS

Converting Process with Partial Pre-Oxidation of PGM Collector Alloy

ActiveUS20190330720A1Lower the volumeShorten melting timeManufacturing convertersRecycling and recovery technologiesSlagSulfur

Converting process with partial pre-oxidation of PGM collector alloy. The process includes partially pre-oxidizing a raw alloy, introducing an initial charge of the partially pre-oxidized alloy into a converter pot, melting the initial charge, introducing converter feed to the pool, oxygen injection into the pool, tapping the slag, and tapping the PGM-enriched alloy. The collector alloy contains no less than 0.5 wt % PGM, 40 wt % iron, and 0.5 wt % nickel, and no more than 3 wt % sulfur and 3 wt % copper. The process can also include low- or no-flux converting; using a refractory protectant in the converter; magnetic separation of slag; recycling part of the slag to the converter; smelting catalyst material in a primary furnace to produce the collector alloy; and / or smelting the converter slag in a secondary furnace with slag from the primary furnace.

Owner:TECHEMET LP

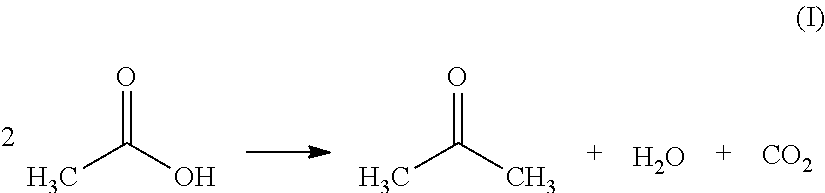

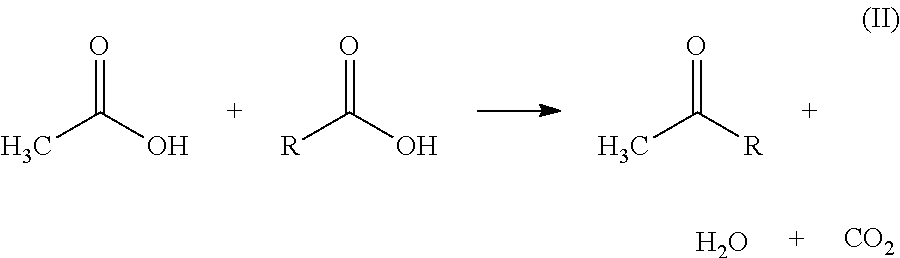

Process for reducing emissions of volatile organic compounds from the ketonization of carboxylic acids

ActiveUS8779208B2Efficiently and inexpensively destroyedReduce compoundingOrganic compound preparationCarbonyl compound preparation by condensationCombustionKetonic acids

Disclosed is a process for reducing the emission of volatile organic compounds that are produced during the ketonization of carboxylic acids to ketones. The ketonization of carboxylic acids produces a gaseous by-product stream containing carbon dioxide and volatile organic compounds. This gaseous by-product stream can be fed to a direct-fired furnace used to heat the ketonization reaction feed streams where the volatile organic compounds are destroyed by combustion in the furnace. The carbon dioxide stream further acts as a diluent for the fuel to the furnace.

Owner:EASTMAN CHEM CO

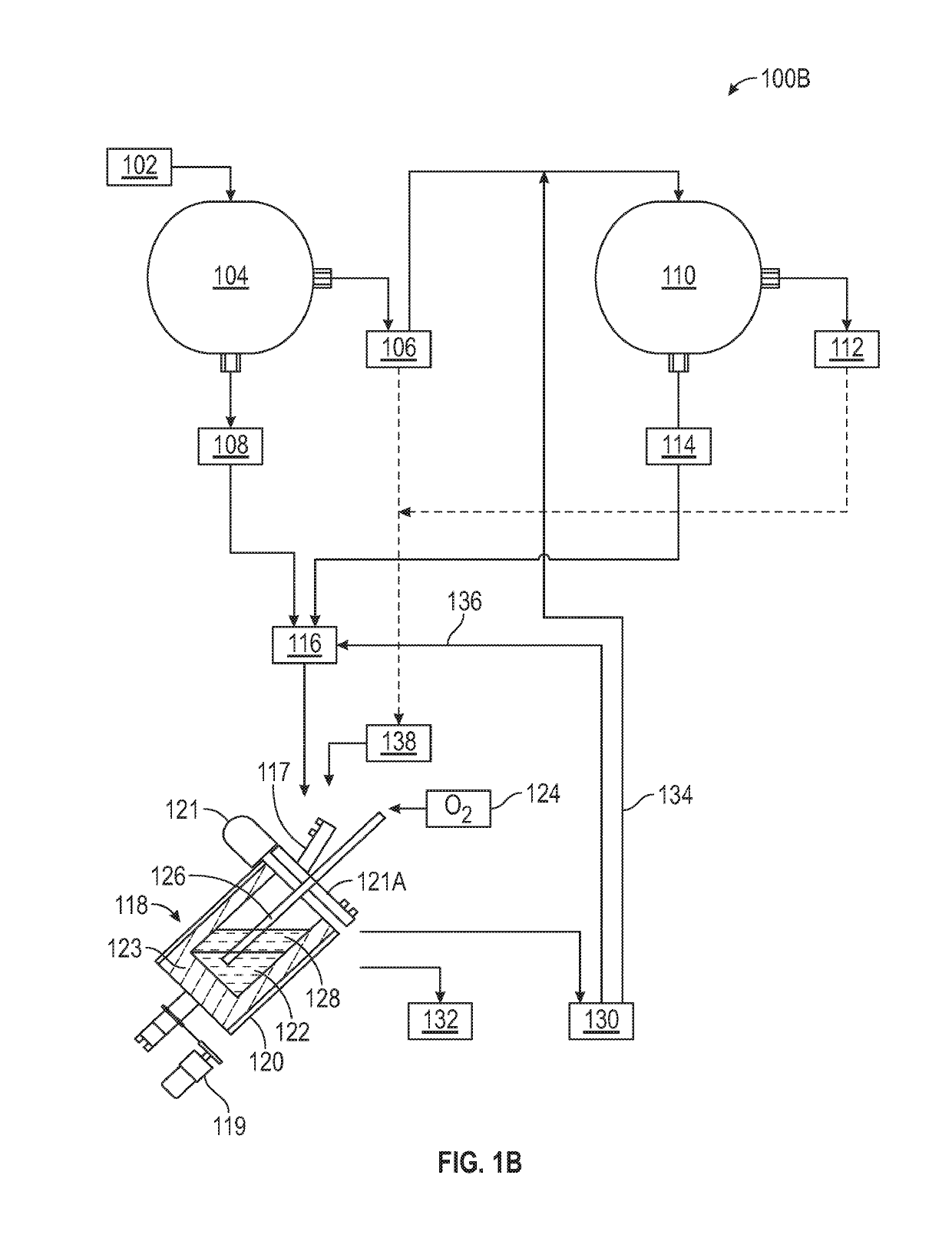

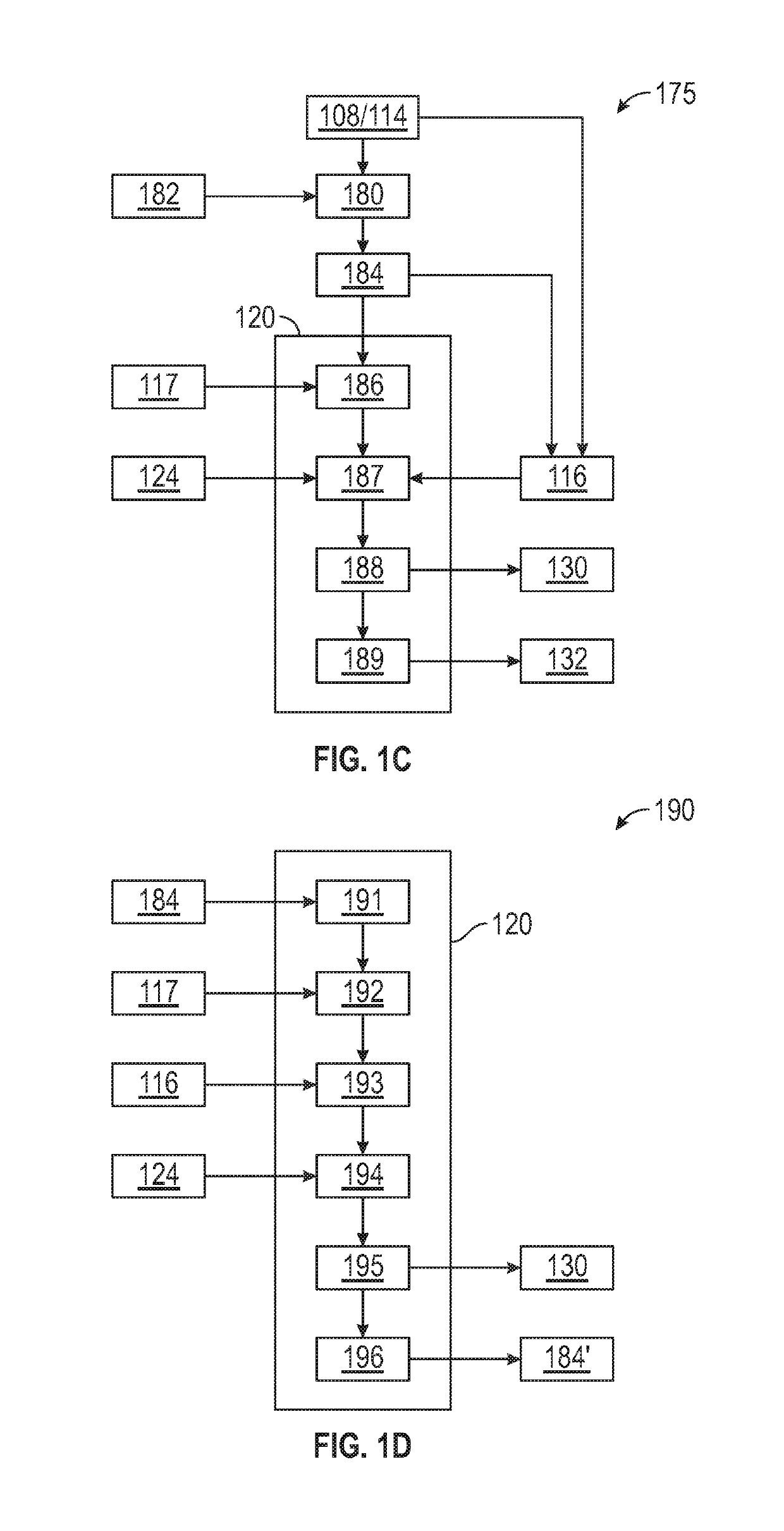

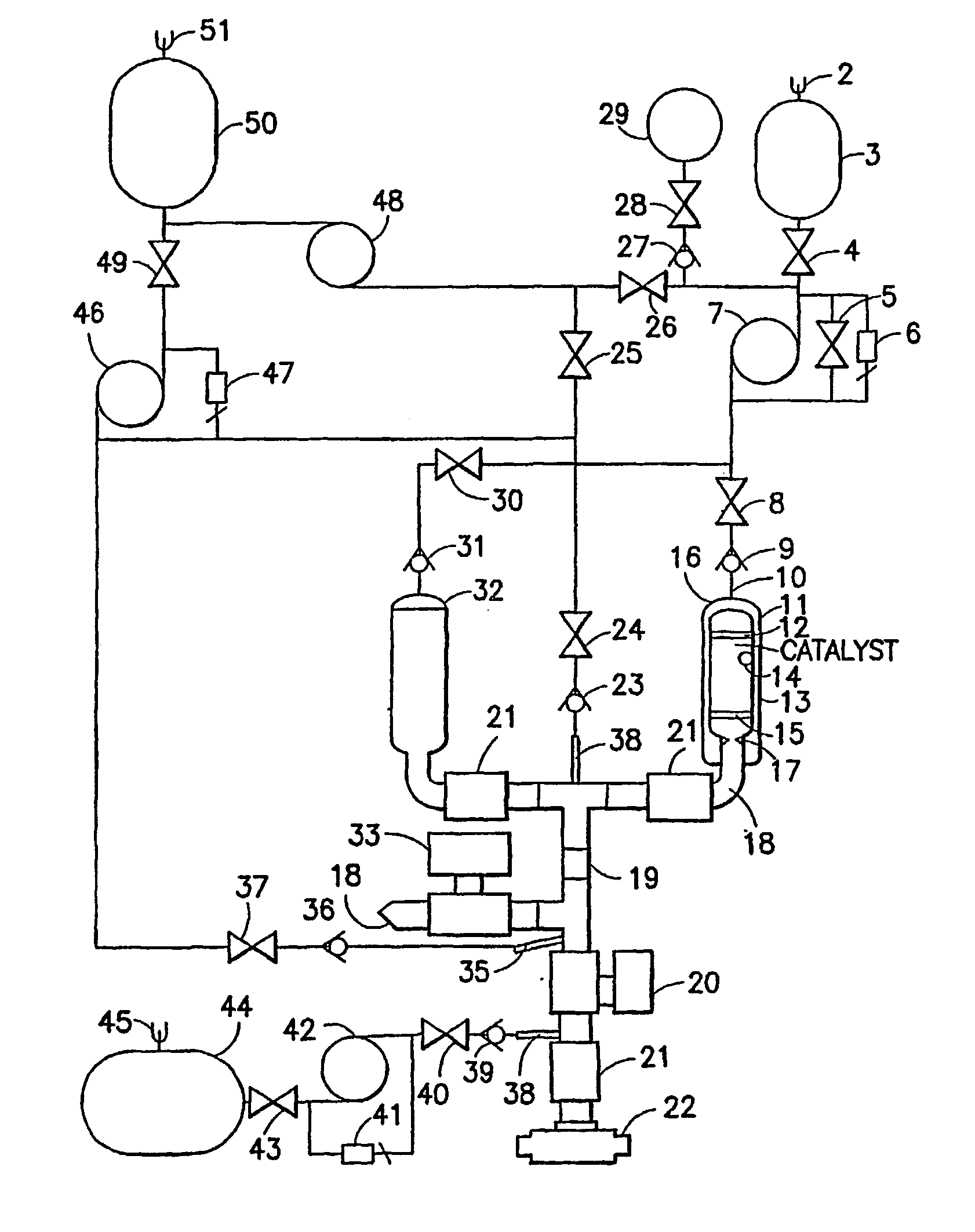

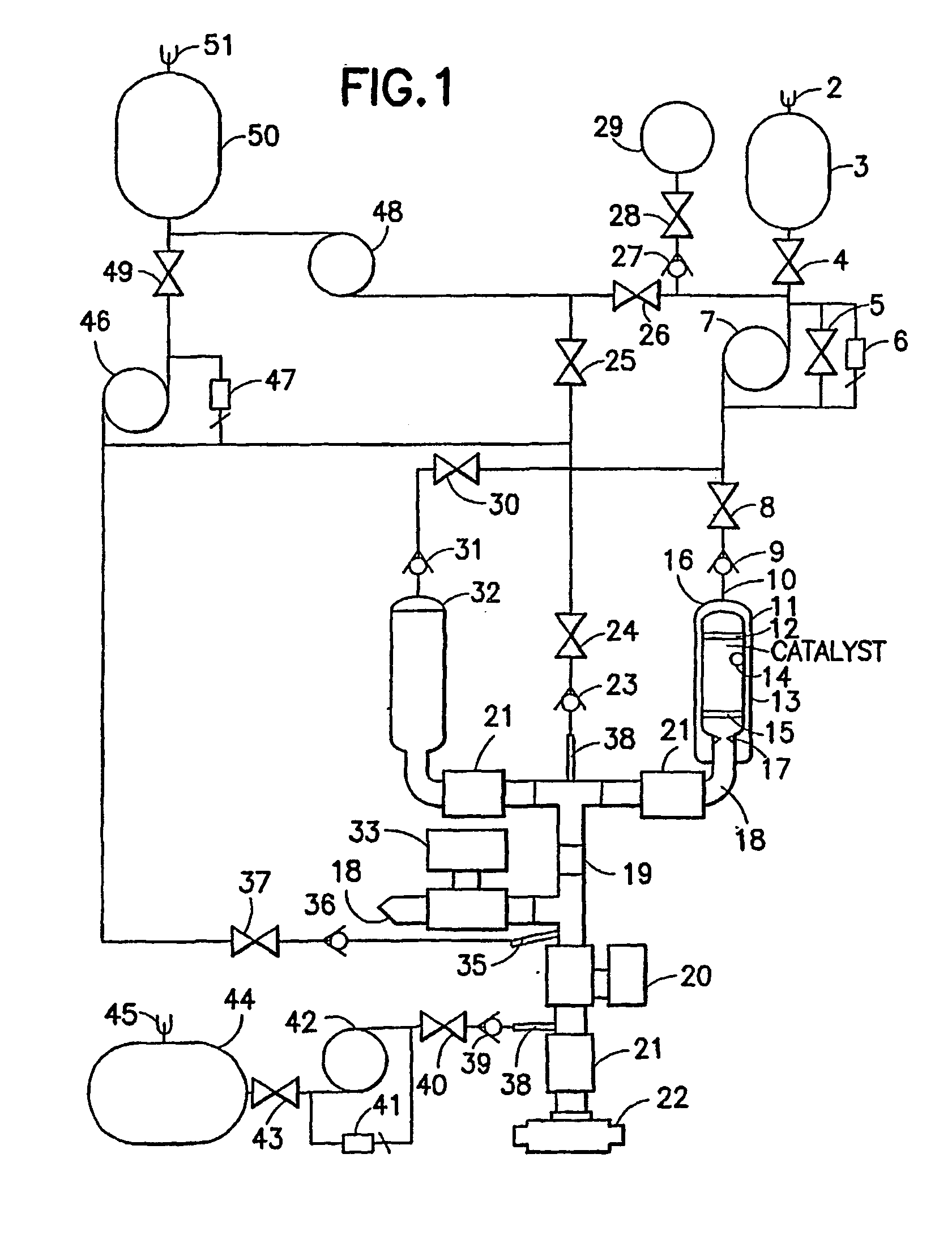

Stimulation and injection system

InactiveUS20070056738A1Improve efficiencyModerate temperatureCleaning apparatusInsulationLiquid hydrogenPeroxide

An apparatus for introducing a vapor-containing stream into underground geological formations, pumps, conduits or tanks comprising; at least one vapor-containing stream generator having a liquid hydrogen peroxide fuel introduction zone, a catalyst zone and a zone for creating a backpressure of a vapor-containing stream formed by the generator; a conduit for introducing the liquid hydrogen peroxide fuel with said liquid hydrogen peroxide having a concentration of from 7095 weight percent into the vapor-containing stream generator; means for directing the vapor-containing stream into the formation, pump, conduit or tank and means for introducing a fluid into the formations, pumps, conduits or tanks.

Owner:UNITED ENERGY CORP

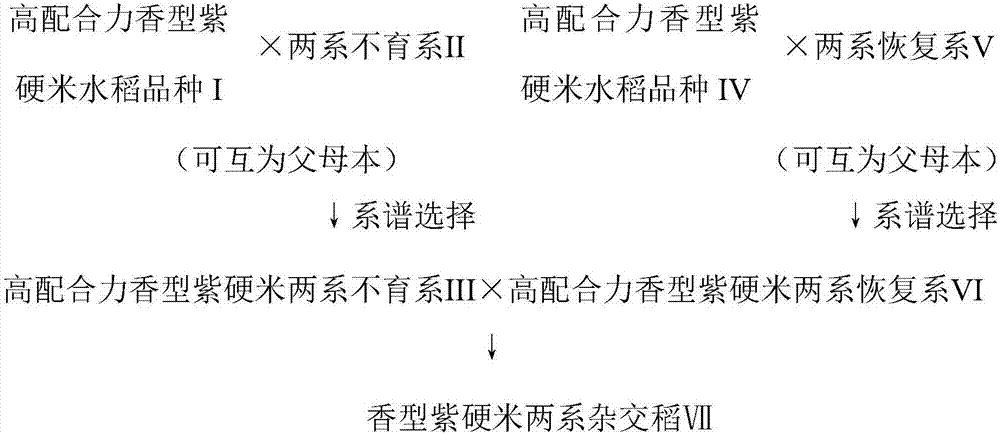

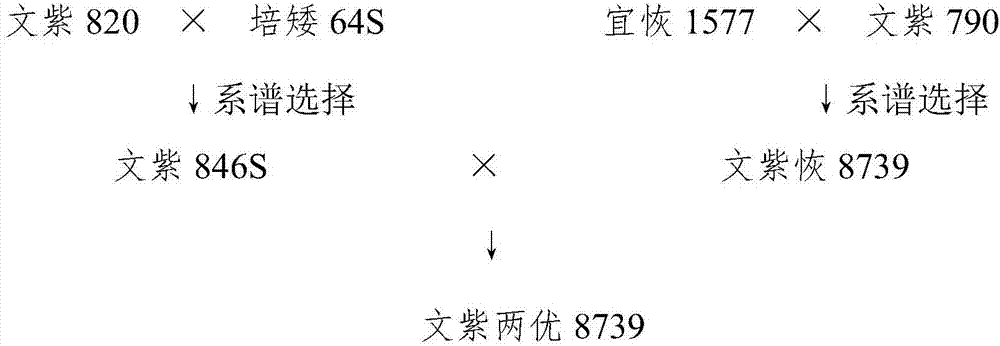

Method for breeding flavor-type purple hard rice two-line hybrid rice special for processing fragrant purple rice noodles

InactiveCN107318644AStrong fragranceLightly scentedPlant genotype modificationBiotechnologyOryza sativa

The invention discloses a method for breeding flavor-type purple hard rice two-line hybrid rice special for processing fragrant purple rice noodles. The method particularly comprises the following steps: screening a high-combining ability purple hard rice variety I and a high high-combining ability flavor-type purple hard rice variety IV, wherein the variety I and the IV have different genetic backgrounds and comprise purple rice genes P with a dosage effect and allelic fragrance genes a and allelic hard rice genes H; and respectively introducing the fragrance genes a, the purple rice genes P and the hard rice genes H in the two varieties into a two-line sterile line I and a two-line restoring line V, so as to respectively obtain a high-combining ability flavor-type purple hard rice two-line sterile line III and a high-combining ability flavor-type purple hard rice two-line restoring line VI, hybridizing and assembling, so as to obtain flavor-type purple hard rice two-line hybrid rice VII special for processing the fragrant purple rice noodles. The flavor-type purple hard rice two-line hybrid rice VII processed from the flavor-type purple hard rice bred by the method in the invention is fragrant and is high in yield and wide in adaptability, and seed coats are purple; and the rice noodles processed from the hybrid rice is boilproof, purple, has a slight fragrance and good taste and is low in fracture rate.

Owner:文山壮族苗族自治州农业科学院

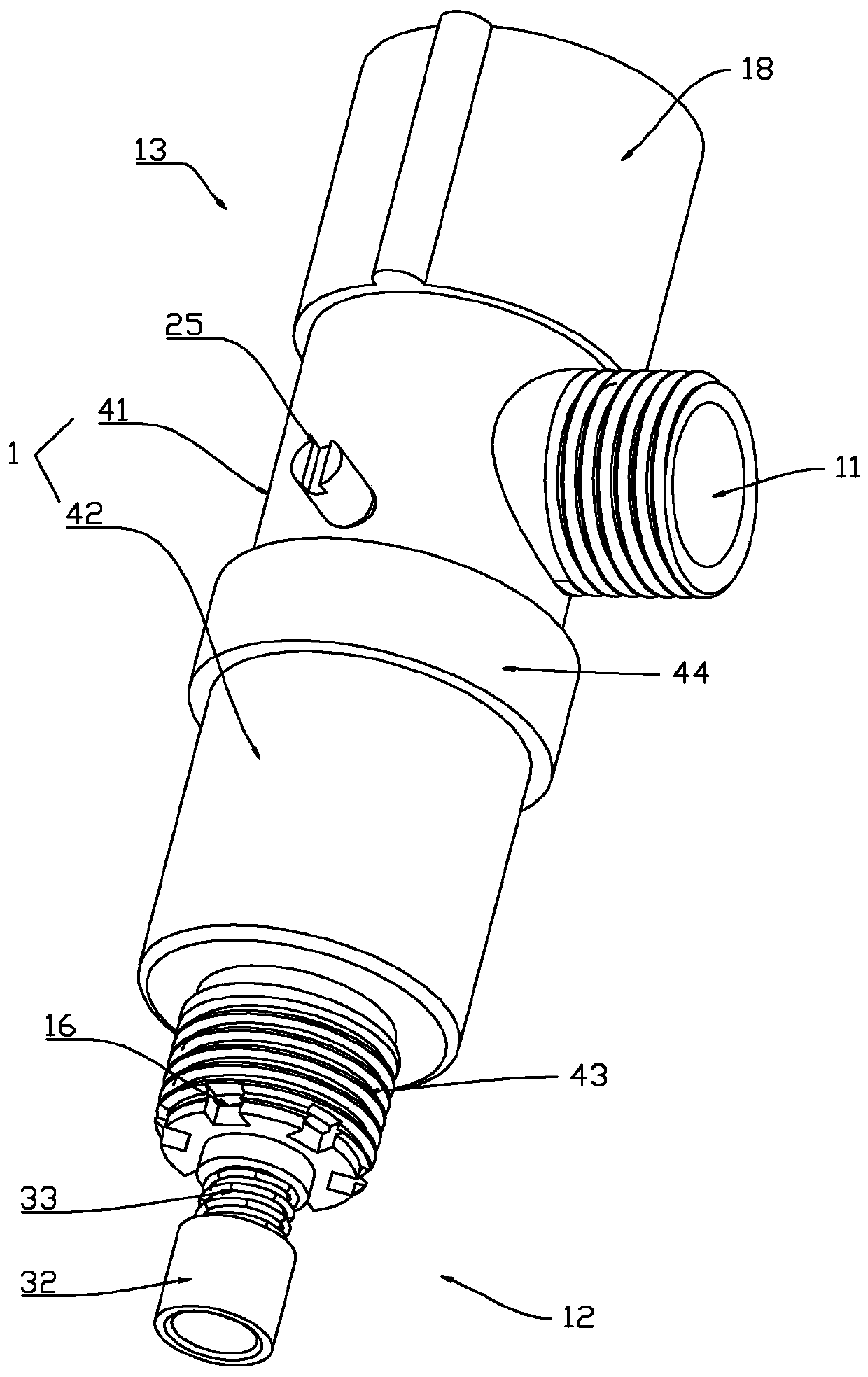

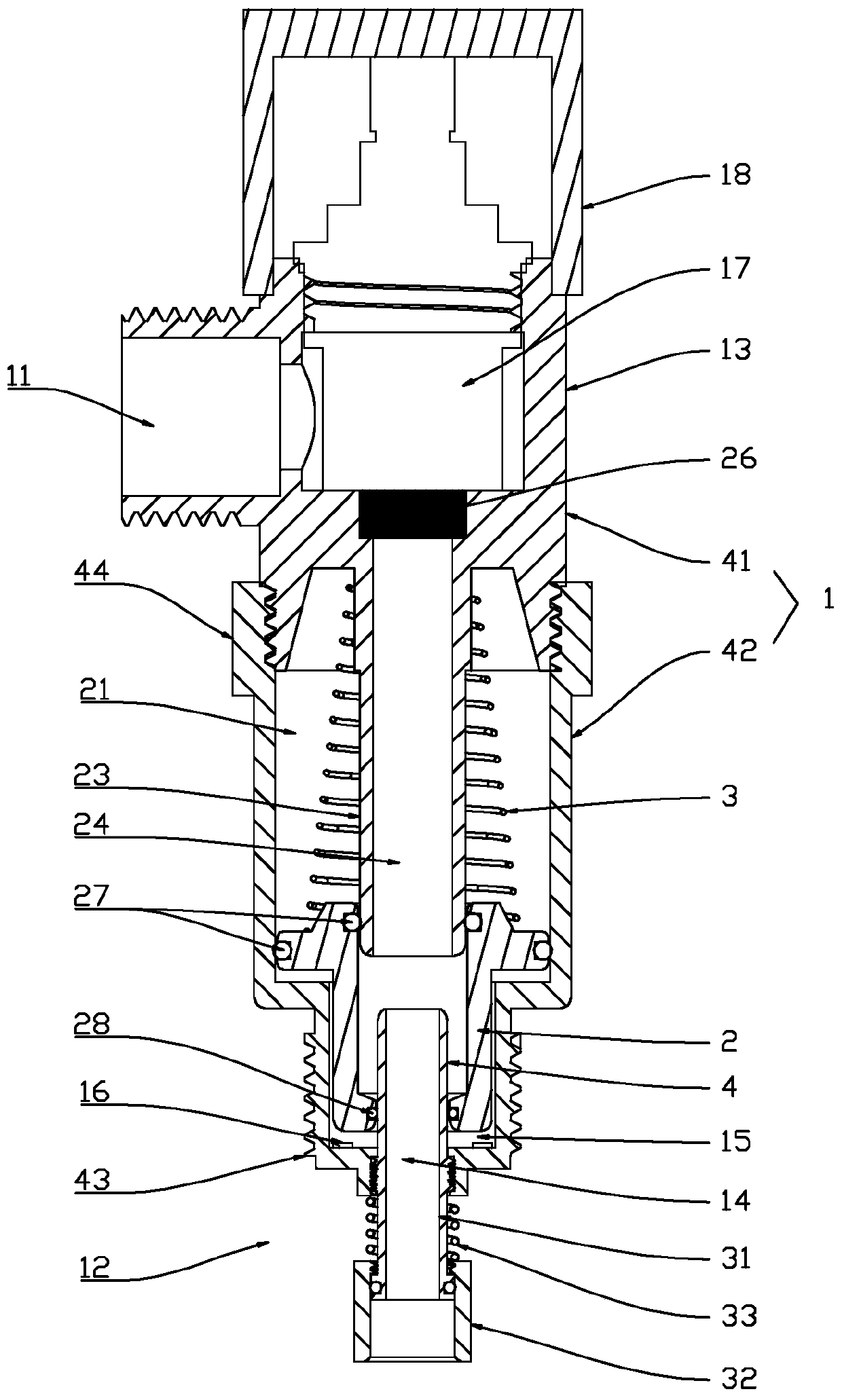

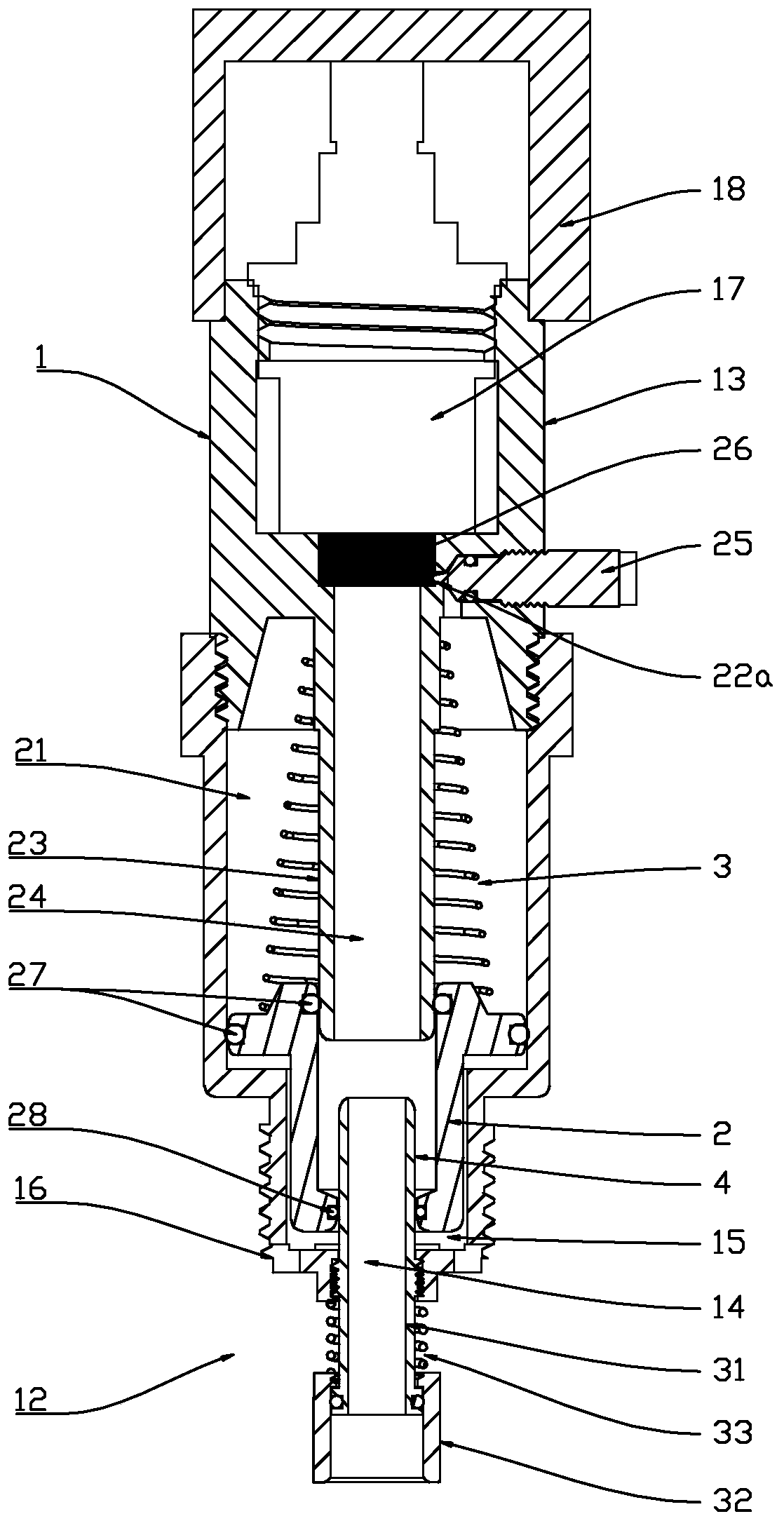

Delay water outlet valve for pipe-in-pipe and hot water discharge system thereof

PendingCN111550580AModerate temperatureReduce wasteFluid heatersOperating means/releasing devices for valvesPistonDomestic water consumption

The invention belongs to the technical field of domestic water, and particularly relates to a delay water outlet valve for a pipe-in-pipe and a hot water discharge system thereof. The delay water outlet valve for the pipe-in-pipe comprises a water heater, a liquid inlet valve and a pipe-in-pipe pipeline, the delay water outlet valve is arranged at the tail end of a branch of a pipe-in-pipe pipeline through a pipe-in-pipe joint, the delay water outlet valve comprises a valve body, the valve body is provided with a liquid outlet end and a pipe-in-pipe connecting end, the pipe-in-pipe connectingend is provided with an inner flow passage and an outer flow passage, and the liquid outlet end communicates with the inner flow passage and the outer flow passage through an inner cavity of the valvebody; the inner side of the pipe-in-pipe connecting end is provided with a delay sealing part separating the inner flow passage and the outer flow passage, the inner cavity of the valve body is provided with a damping piston and a first reset part providing elastic force, the damping piston is arranged on the outer side wall or the inner side wall of the delay sealing part, and the outer flow passage or the inner flow passage is sealed; and when an internal medium pushes the damping piston to separate the delay sealing part, the delay liquid outlet of the flow passage where the damping pistonis located is realized. The delay water outlet valve for the pipe-in-pipe and the hot water discharge system thereof have the advantages of small cold water emptying amount, high hot water outlet speed and the like.

Owner:陈奎宏

Sugar alcohol split injection conversion

ActiveUS8809604B2Avoid damageSpeed up the conversion processOrganic compound preparationBiofuelsAlkaneMultiple injection

Owner:PHILLIPS 66 CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com