Stimulation and injection system

a technology of injection system and injection tube, which is applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of system failure and inability to operate, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

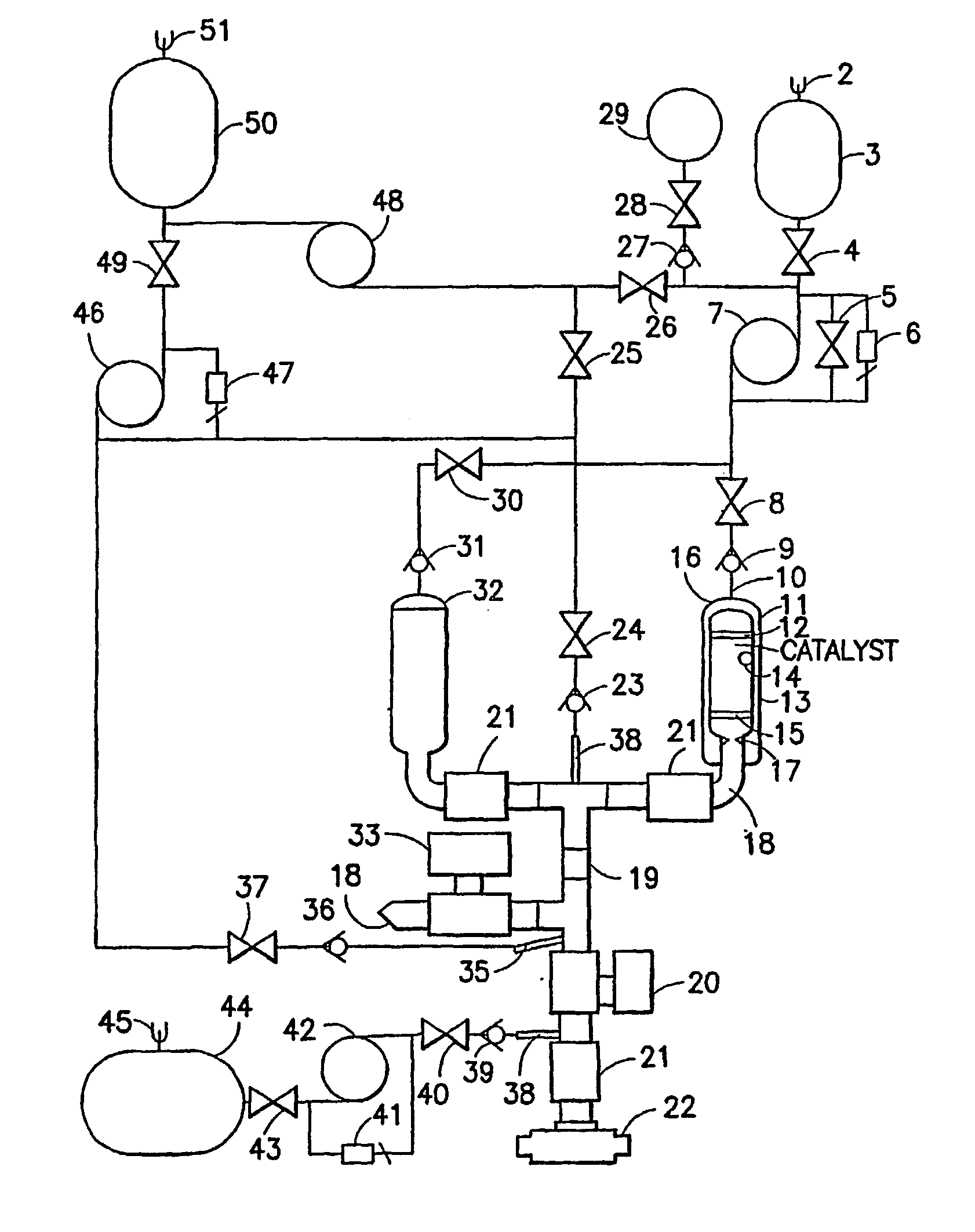

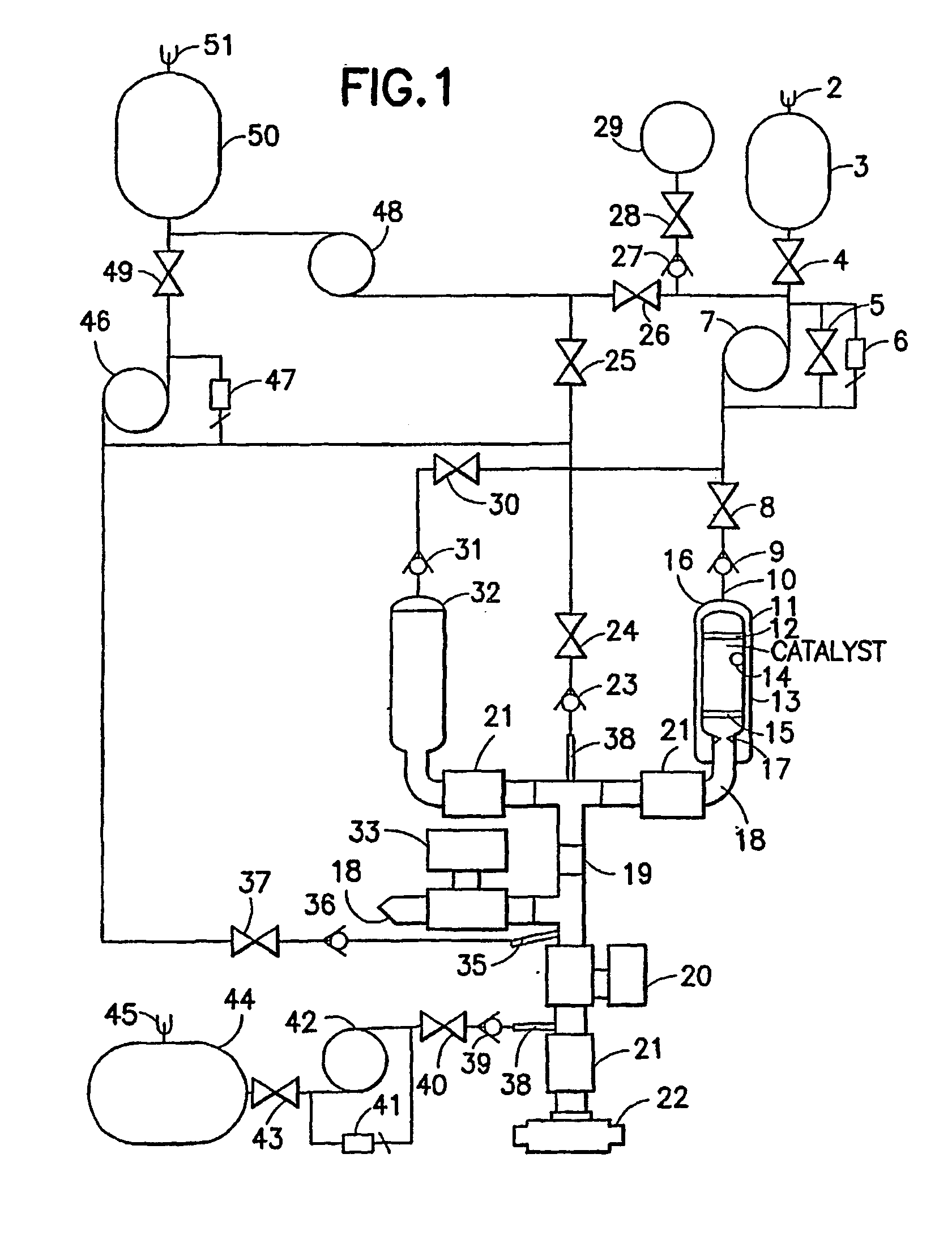

[0008] The present invention is directed to a system utilizing at least one vapor-containing stream generator to produce and inject a vapor-containing stream which can comprise steam, heated water, heated gas, and / or chemicals into underground formations, pumps, conduits or tanks. The system uses a vapor-containing stream drive with variable pressure and temperature, a steam drive with variable pressure and temperature, and chemical injection at variable pressures and temperature, which allows custom tailored cyclic drives.

[0009] The injection system has many applications due to the ability to inject heated vapor-containing streams at various temperatures and pressures. The injection system is ideal for solving paraffin problems as well as a heavy crude and gas depleted formations as well as in pumps, conduits or tanks. In addition the system is environmentally clean and easy to operate.

[0010] The pumps and vapor-containing stream generator and generator are present in a single lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com