Aqueous Urea Tank Structure for Construction Machine

a technology of aqueous urea and construction machines, which is applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of troublesome defrosting of aqueous urea, harmful nitrogen oxide in the exhaust gas emitted from the engine, etc., and achieve the suppression of damage to reduction of ammonia production, and suppression of corrosion and degradation of the aqueous urea tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

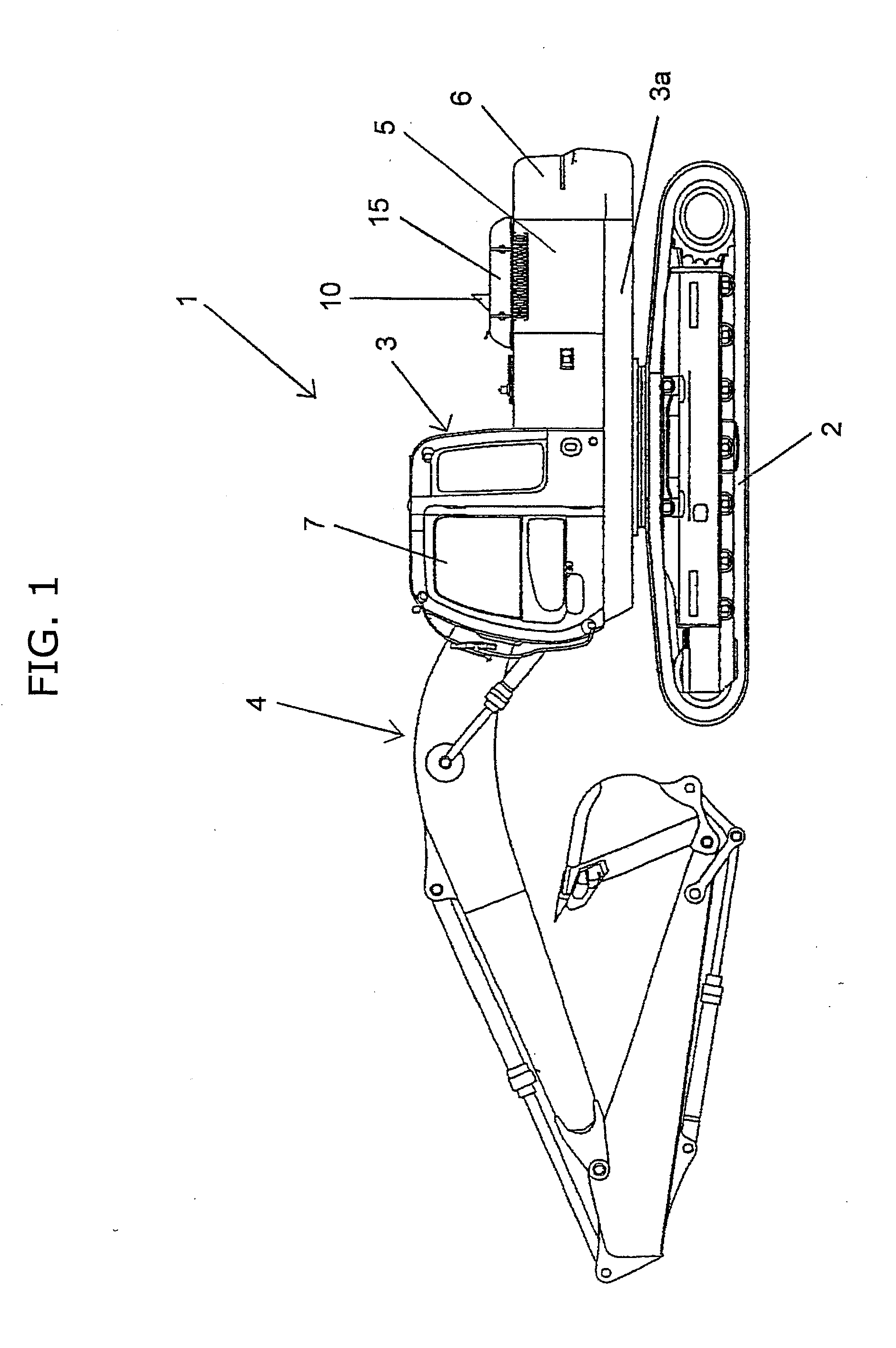

[0029]A first embodiment of an aqueous urea tank structure for a construction machine according to the invention is, for example, provided in a hydraulic excavator 1 as shown in FIG. 1. The hydraulic excavator 1 has a travel base 2, a revolving upperstructure 3 disposed on an upper side of the travel base 2 and having a slewing frame 3a, and a front work device 4 attached to the front of the revolving upperstructure 3 and revolving in an up / down direction. In addition, the revolving upperstructure 3 has a cab 7 in the front thereof and a counterweight 6 in the rear thereof. The revolving upperstructure 3 also has an engine room 5 between the cab 7 and the counterweight 6, and a vehicle body cover 15 disposed on an upper portion of the engine room 5. An exhaust port 10 through which exhaust gas emitted from an engine which will be described later is discharged to the outside is provided in the vehicle body cover 15.

[0030]The revolving upperstructure 3 has the engine which is not show...

second embodiment

[0046]FIG. 6 is a side view showing the configuration of a second embodiment of an aqueous urea tank structure for a construction machine according to the invention.

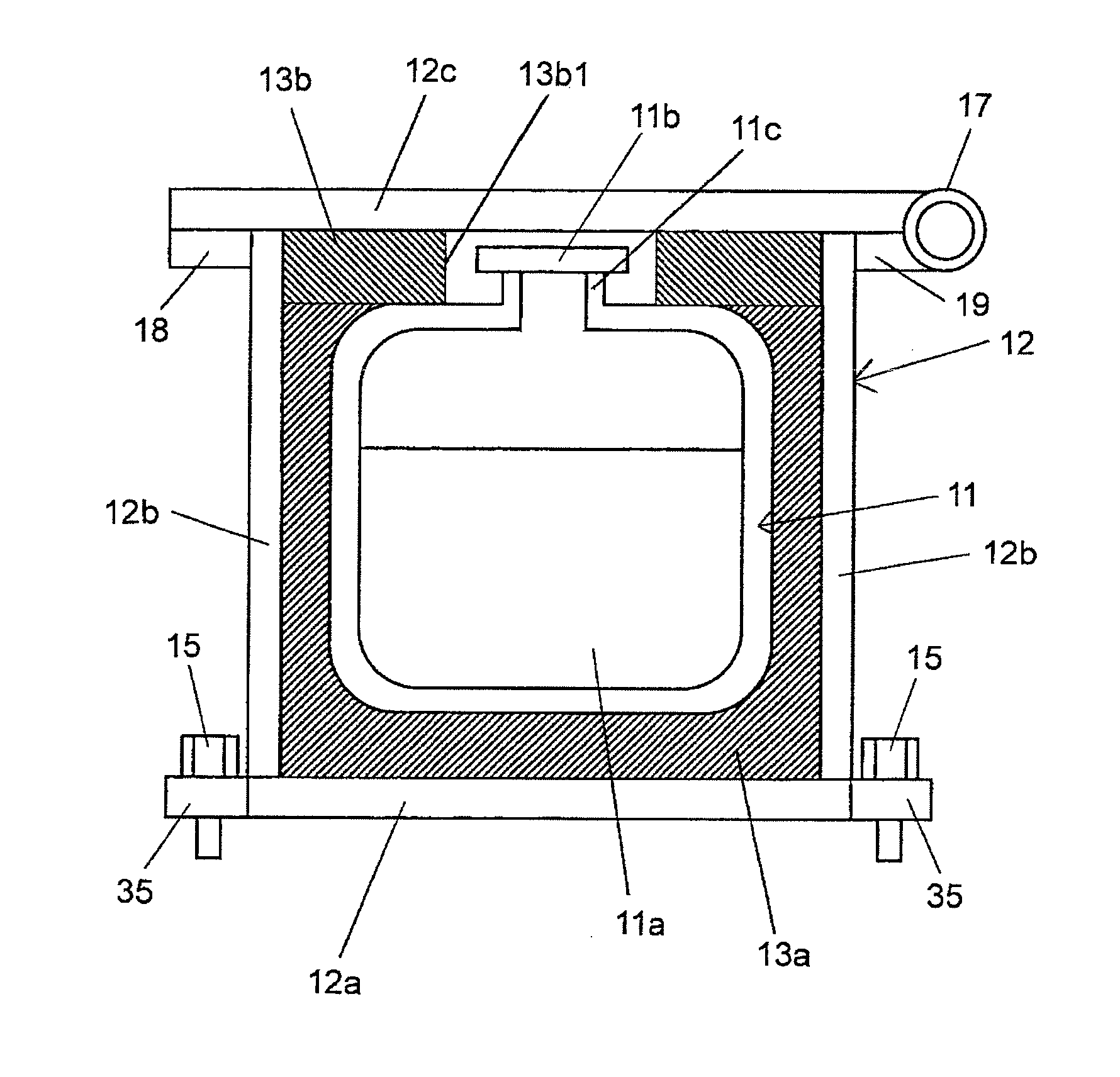

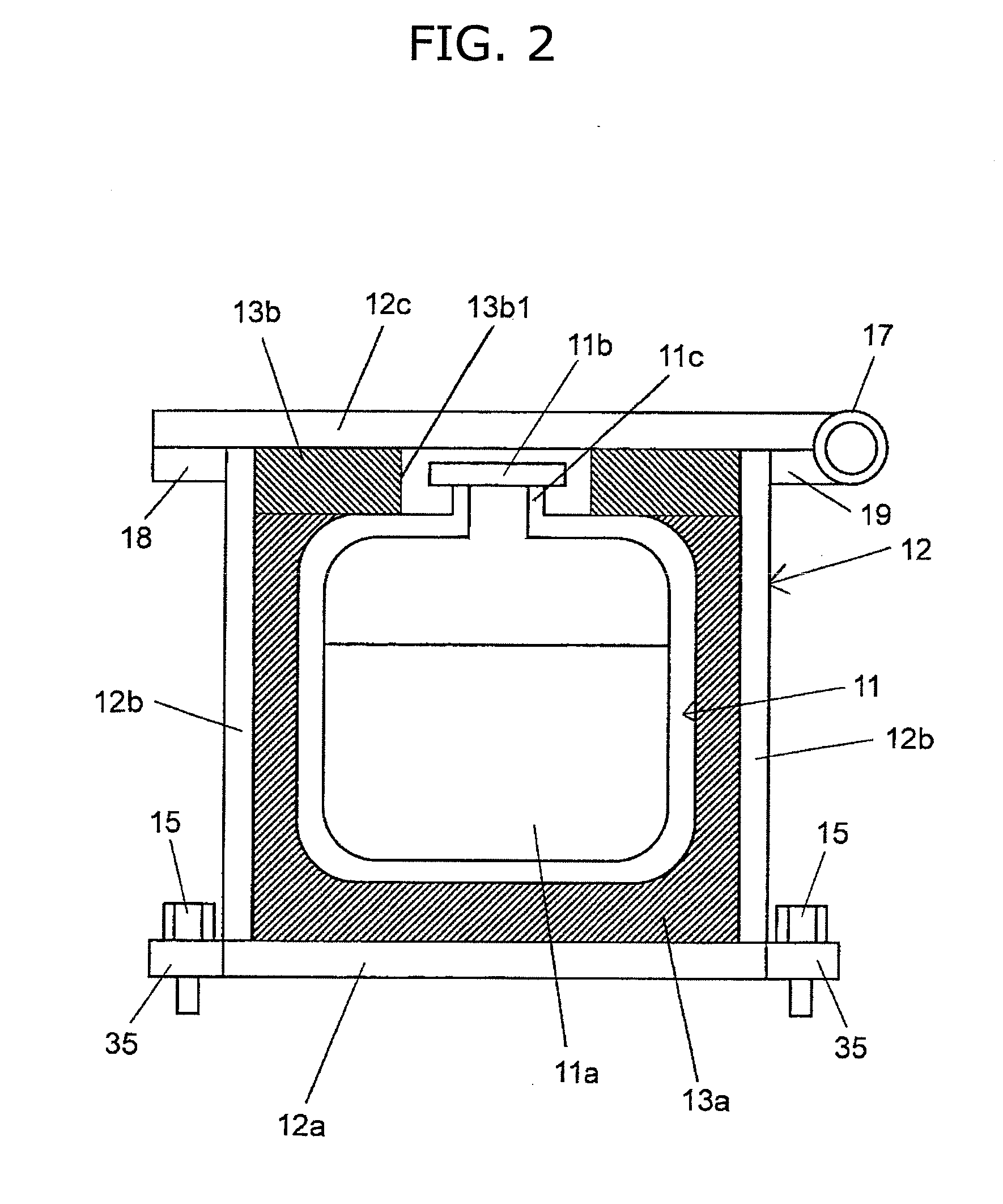

[0047]In the first embodiment, as shown in FIG. 2, the securing member includes the box 12, the heat insulating material 13a is laid between the box 12 and the lower portion and the side portions of the aqueous urea tank 11 so as to come into tight contact therewith, and the heat insulating material 13b is further inserted between the box 12 and the upper portion of the aqueous urea tank 11 so as to enclose the supply port 11c of the aqueous urea tank 11. The second embodiment of the invention is different from the aforementioned first embodiment in that heat insulating materials 13c, 13d1, 13d2 and 13e are disposed, for example, in some parts of a space between the box 12 and the aqueous urea tank 11 in the second embodiment as shown in FIG. 6.

[0048]In this case, the heat insulating material 13c is laid on the lower por...

third embodiment

[0052]FIG. 7 is a side view showing the configuration of a third embodiment of an aqueous urea tank structure for a construction machine according to the invention.

[0053]In the aforementioned first embodiment, as shown in FIG. 2, the heat insulating material 13a is laid between the box 12 and the lower portion and the side portions of the aqueous urea tank 11 so as to come into tight contact therewith, and the heat insulating material 13b is further inserted between the box 12 and the upper portion of the aqueous urea tank 11 so as to enclose the supply port 11c of the aqueous urea tank 11. The third embodiment of the invention is different from the first embodiment in that heat insulating materials are disposed, for example, in some parts of a space between the box 12 and the aqueous urea tank 11 in the same manner as in the second embodiment, and of the heat insulating materials, the heat insulating material provided on the bottom portion of the aqueous urea tank 11 is made of a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com