Delay water outlet valve for pipe-in-pipe and hot water discharge system thereof

A technology of pipe-in-pipe and water outlet valve, which is applied in the direction of valve operation/release device, valve details, multi-way valve, etc., which can solve the problems of affecting the service life of springs, unsuitable water pipes, and unsuitable pipe-in-pipe medium, etc., to reduce Effect of waste, ease of operation, protection of equipment and discharge system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

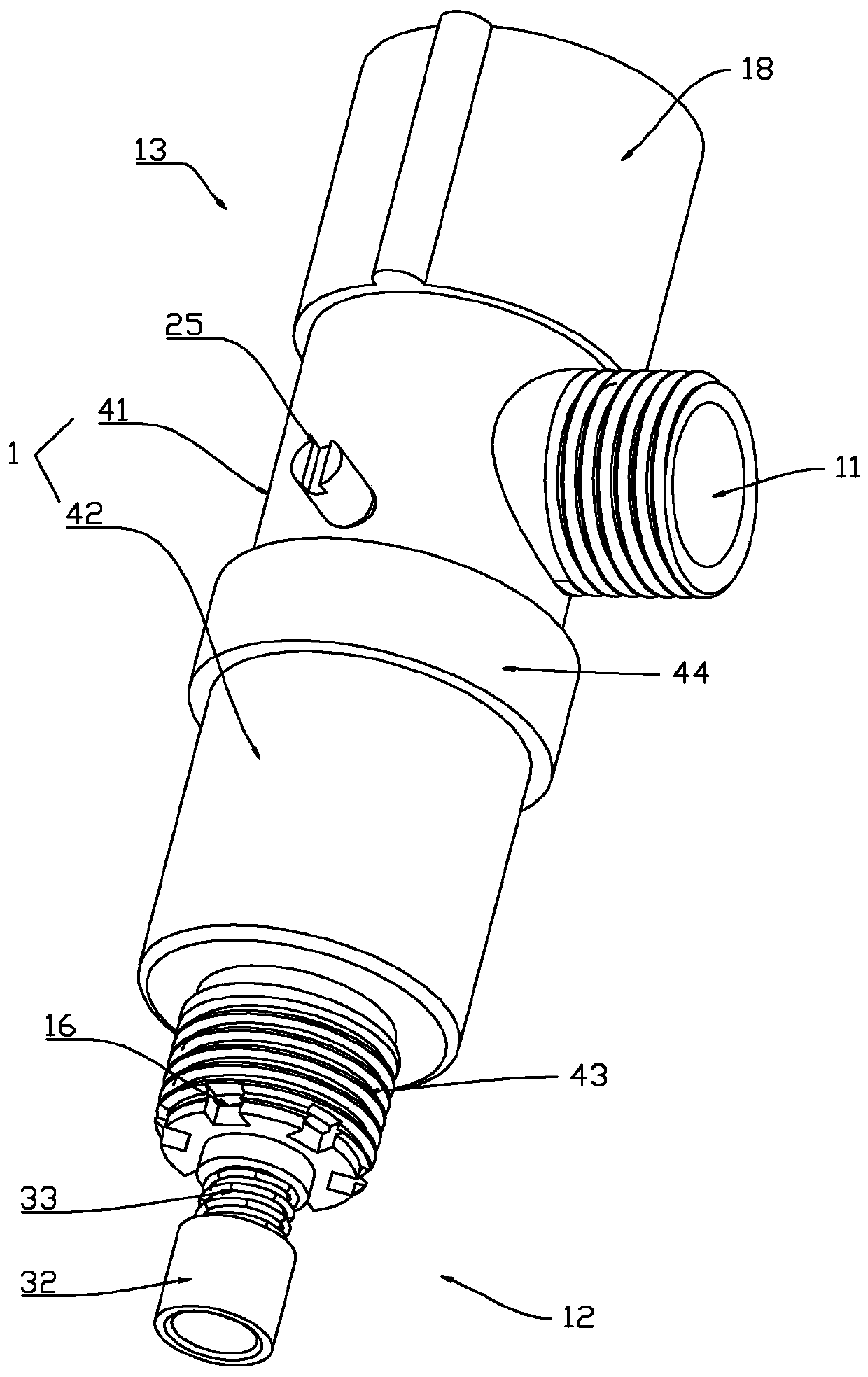

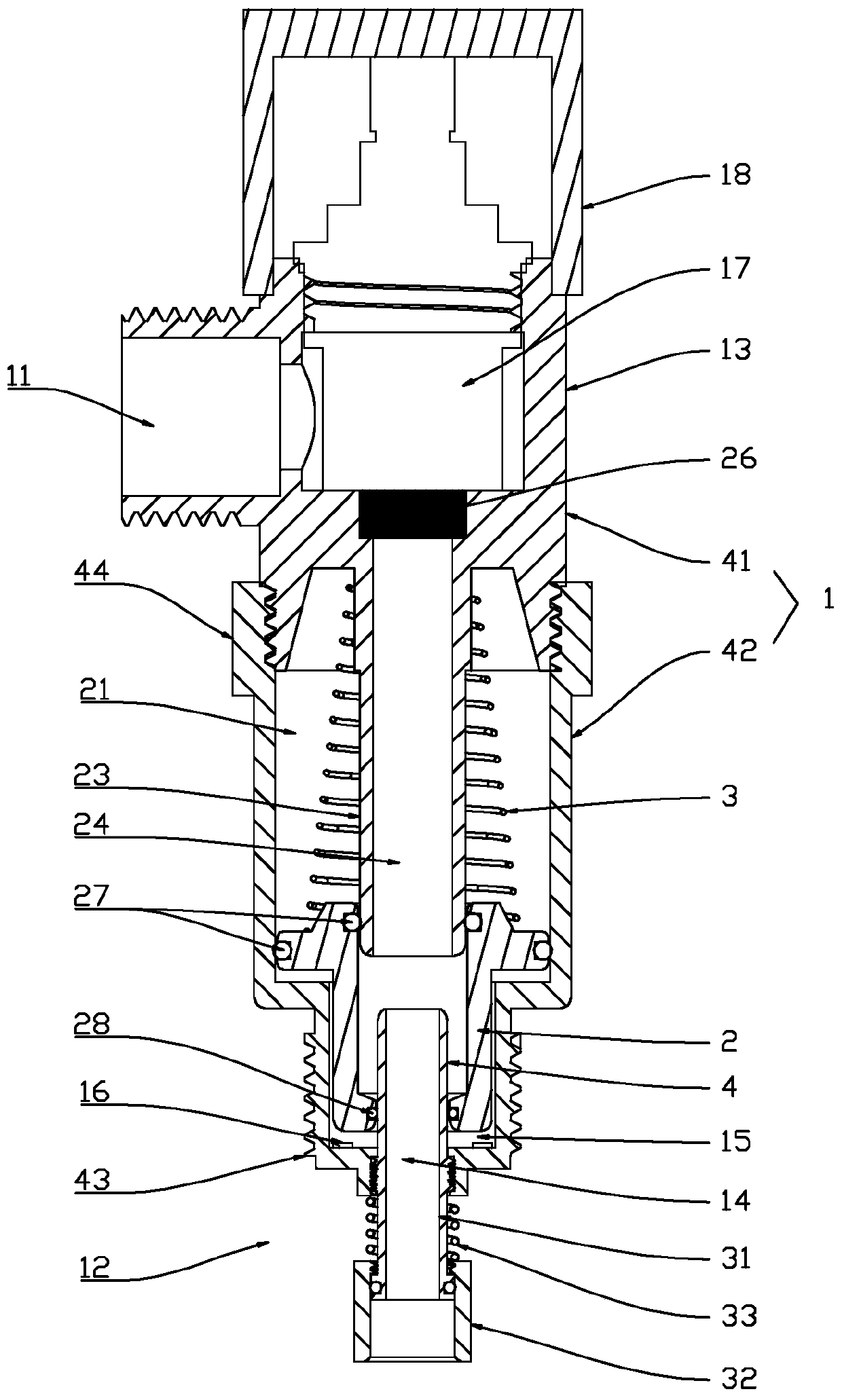

[0067] Such as Figure 1-3 As shown, a delayed water outlet valve for a pipe-in-pipe includes a valve body 1. The valve body 1 is provided with a liquid outlet end 11, a control end 13, and a pipe-in-pipe connection end 12, the pipe-in-pipe connection end 12 Generally, it is installed on the pipe-in-pipe pipe through a pipe-in-pipe joint, and realizes the delayed discharge of the pipe-in-pipe pipe. A control end 13 is provided between the pipe-in-pipe connection end 12 and the liquid outlet end 11. The control end 13 is provided with a control valve core 17 and a handwheel 18 that drives the control valve core 17 to rotate. The valve core 17 is common on the market The ceramic valve core, ball head valve core, etc., are driven by the handwheel 18 to achieve liquid discharge control. In addition, in order to achieve the same control effect, the liquid outlet 11 may be connected to an external control valve.

[0068] In order to facilitate the installation of the inner cavity part...

Embodiment 2

[0079] Such as Figure 4-6 As shown, this embodiment is basically the same as the first embodiment. The difference is that the piston guide rod 23 is separately arranged in the integrally formed valve body 1. Specifically, the piston guide rod 23 is axially opened with an intermediate flow The upper end of the channel 24 is provided with a mounting flange, the upper end of the mounting flange abuts against the through hole of the valve body 1 and the lower end abuts the first reset member 3. The other end of the first reset member 3 abuts against the damping piston 2, the sealing end of the damping piston 2 is provided with at least one return hole 52, and a water return sheet 53 is provided on the outside of the return hole 52. When the pressure of the inner flow channel is relatively high, the pressure relief and return flow can be achieved through the return hole 52.

[0080] Preferably, the damping adjustment channel of this embodiment is provided with a damping adjustment gr...

Embodiment 3

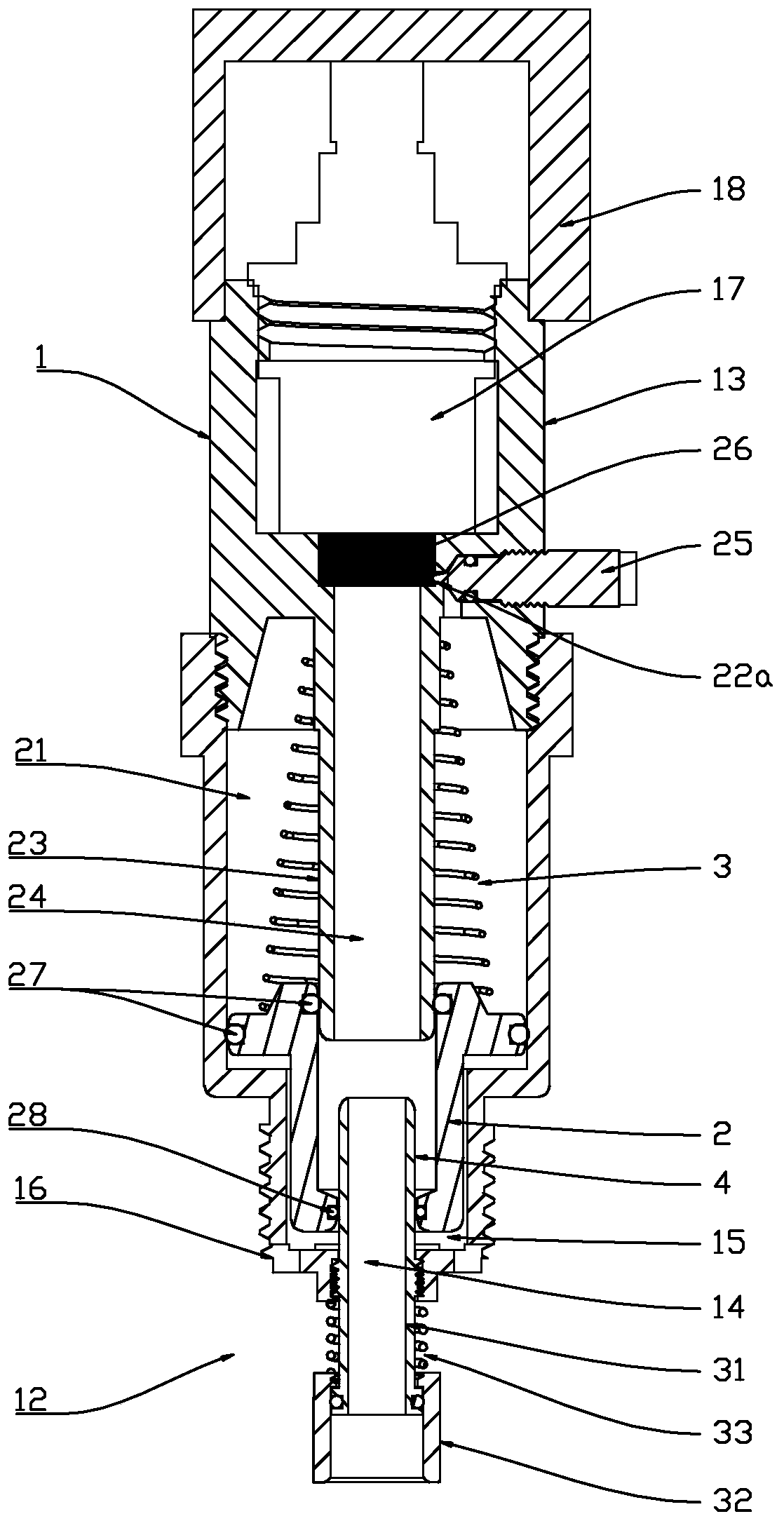

[0083] Such as Figure 7-9 As shown, this embodiment is basically the same as the first embodiment. The difference is that the piston guide rod 23 is separately arranged in the integrally formed valve body 1. Specifically, the piston guide rod 23 is axially opened with an intermediate flow The upper end of the channel 24 is provided with a mounting flange, the mounting flange is installed on the step surface of the valve body through the valve core, and a sealing gasket is provided between the mounting flange and the valve core. The lower end of the piston guide rod 23 is outwardly provided with a sliding convex ring, and the sliding convex ring is provided with a damping adjustment hole 22a. The sliding convex ring reduces the friction force by reducing the contact area with the damping piston 2; at the same time, the sliding convex ring can form a gap between the damping piston 2 and the piston guide rod 23 to facilitate the damping adjustment hole 22a to drain liquid .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com