Converting Process with Partial Pre-Oxidation of PGM Collector Alloy

a technology of collector alloy and converting process, which is applied in the direction of process efficiency improvement, manufacturing converters, recycling and recovery technologies, etc., can solve the problems of significant loss, low conversion efficiency, and limited application prospects, so as to reduce the volume of converter slag, reduce alloy melting time, and increase conversion capacity and/or throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

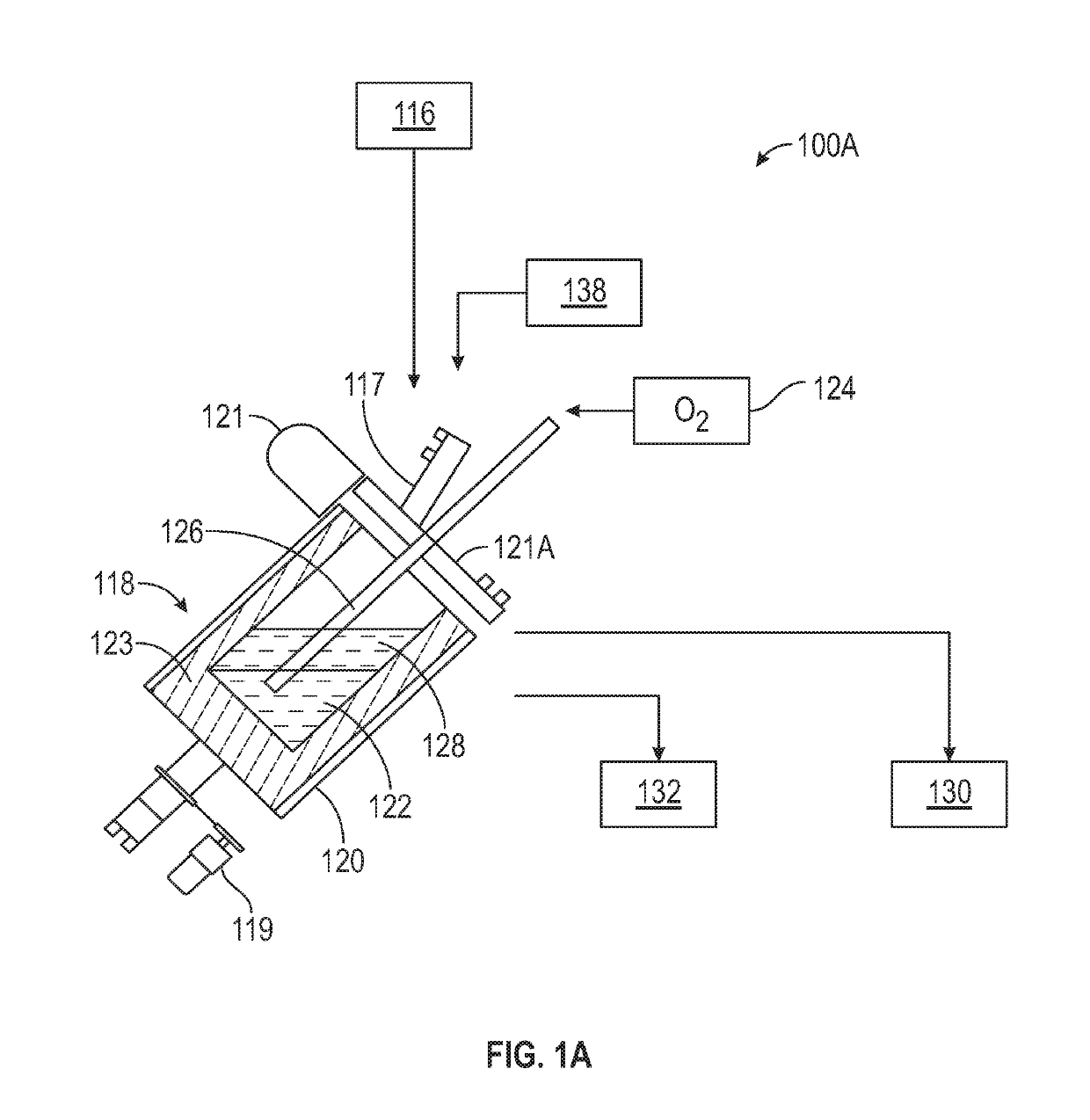

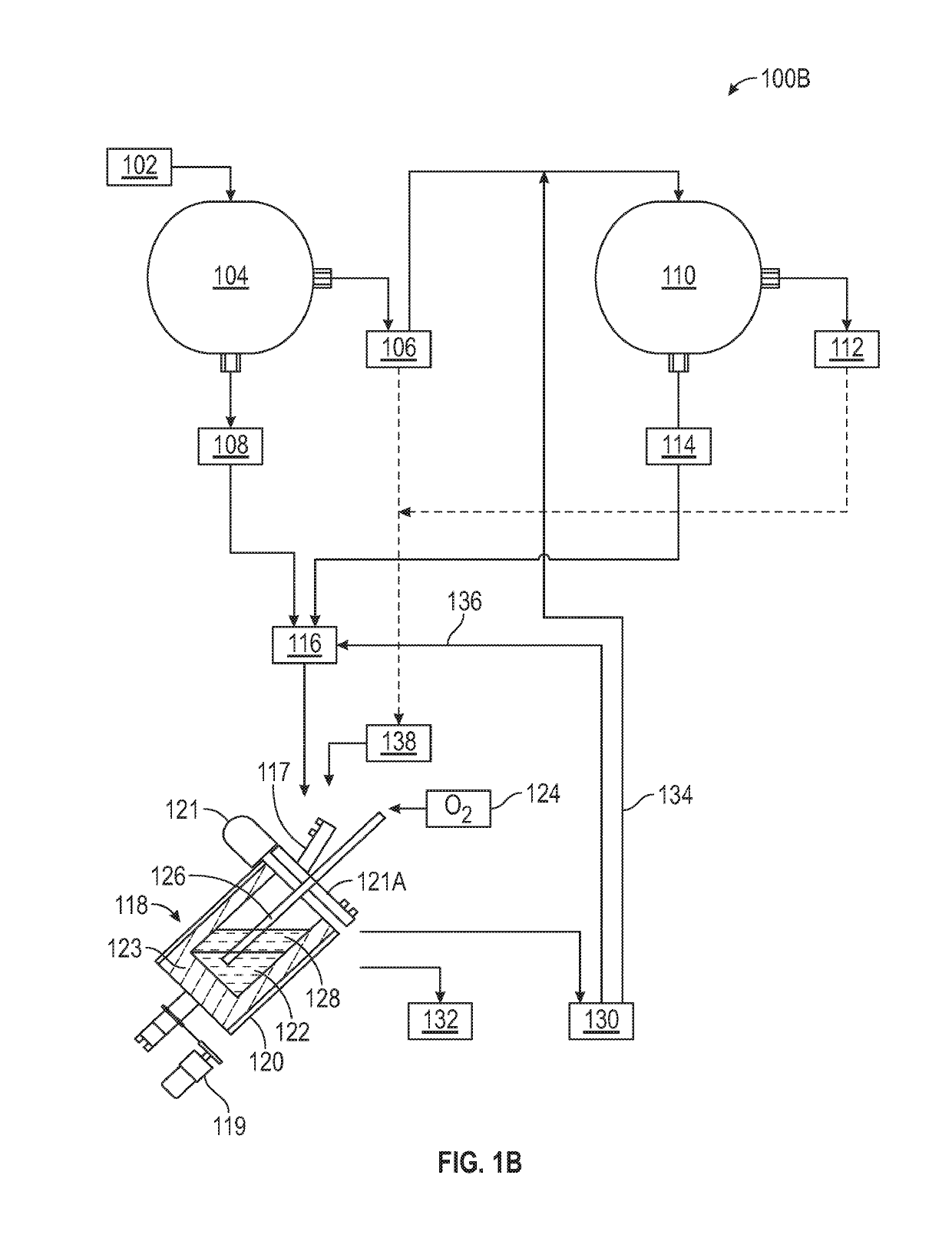

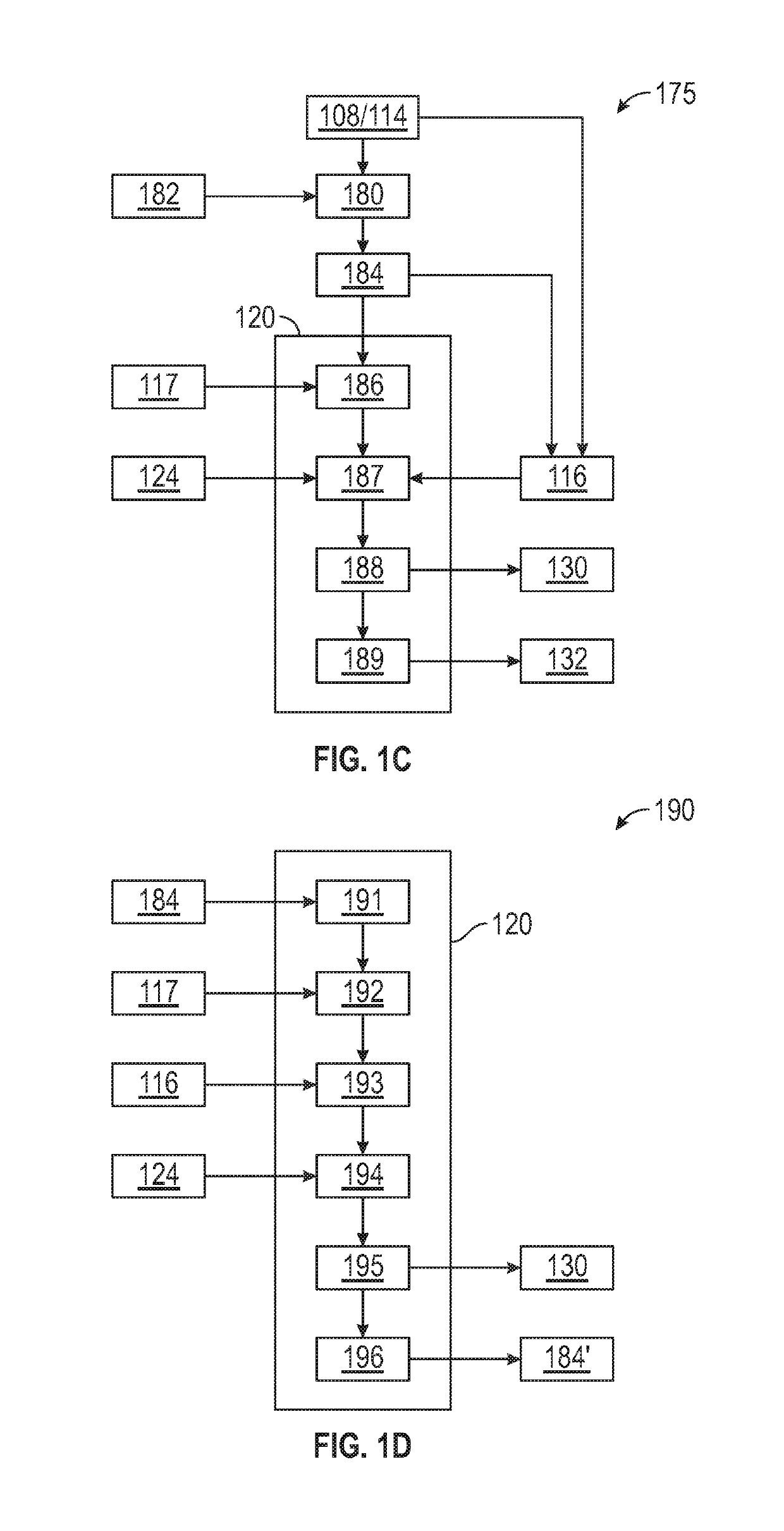

Image

Examples

embodiments listing

[0197]Accordingly, the present invention provides the following nonlimiting embodiments:

1. A process for converting platinum group metal (PGM) collector alloy, comprising the steps of:

[0198](a) introducing a converter feed into a pot of a converter holding a molten alloy pool (preferably comprising nickel), wherein the converter feed comprises:[0199](i) 100 parts by weight of a collector alloy comprising no less than 0.5 wt % PGM, no less than 40 wt % iron, and no less than 0.5 wt % nickel, (and preferably no more than 3 wt % sulfur and no more than 3 wt % copper), based on the total weight of the collector alloy; and[0200](ii) if an added flux material comprises more than 10 weight percent silica and more than 10 weight percent of calcium oxide, magnesium oxide, or a combination of calcium oxide and magnesium oxide, by weight of the added flux material, less than 20 parts by weight of the added flux material;

[0201](b) injecting oxygen-containing gas into the alloy pool to convert i...

embodiment 1

2. The process of embodiment 1, further comprising:

[0205]lining the pot with a refractory material; and

[0206]supplying a refractory protectant to the pot holding the alloy pool at a rate up to 20 parts by weight refractory protectant per hundred parts by weight of the collector alloy in the converter feed, preferably not more than 18 parts by weight per 100 parts by weight of the collector alloy, and more preferably at a rate between 5 and 15 parts by weight refractory protectant per 100 parts by weight of the collector alloy.

embodiment 2

3. The process of embodiment 2, wherein the refractory protectant is supplied to the pot (i) after initially melting the alloy pool and prior to commencing step (b), (ii) during one or both of steps (a) and (b), and / or (iii) after stopping one or both of steps (a) and (b) to tap the low-density layer in step (d), prior to resuming said one or both of steps (a) and (b).

4. The process of embodiment 2 or embodiment 3, wherein the refractory protectant is supplied to the pot together with the collector alloy introduced in step (a).

5. The process of embodiment 2 or embodiment 3, wherein the refractory protectant is supplied to the pot separately from the collector alloy introduced in step (a), preferably wherein the supply of refractory protectant to the pot is periodic.

6. The process of any of embodiments 2 to 5, wherein the refractory protectant comprises a component in common with the refractory material, preferably wherein the component in common comprises alumina.

7. The process of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com