Patents

Literature

479 results about "Piston Guide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

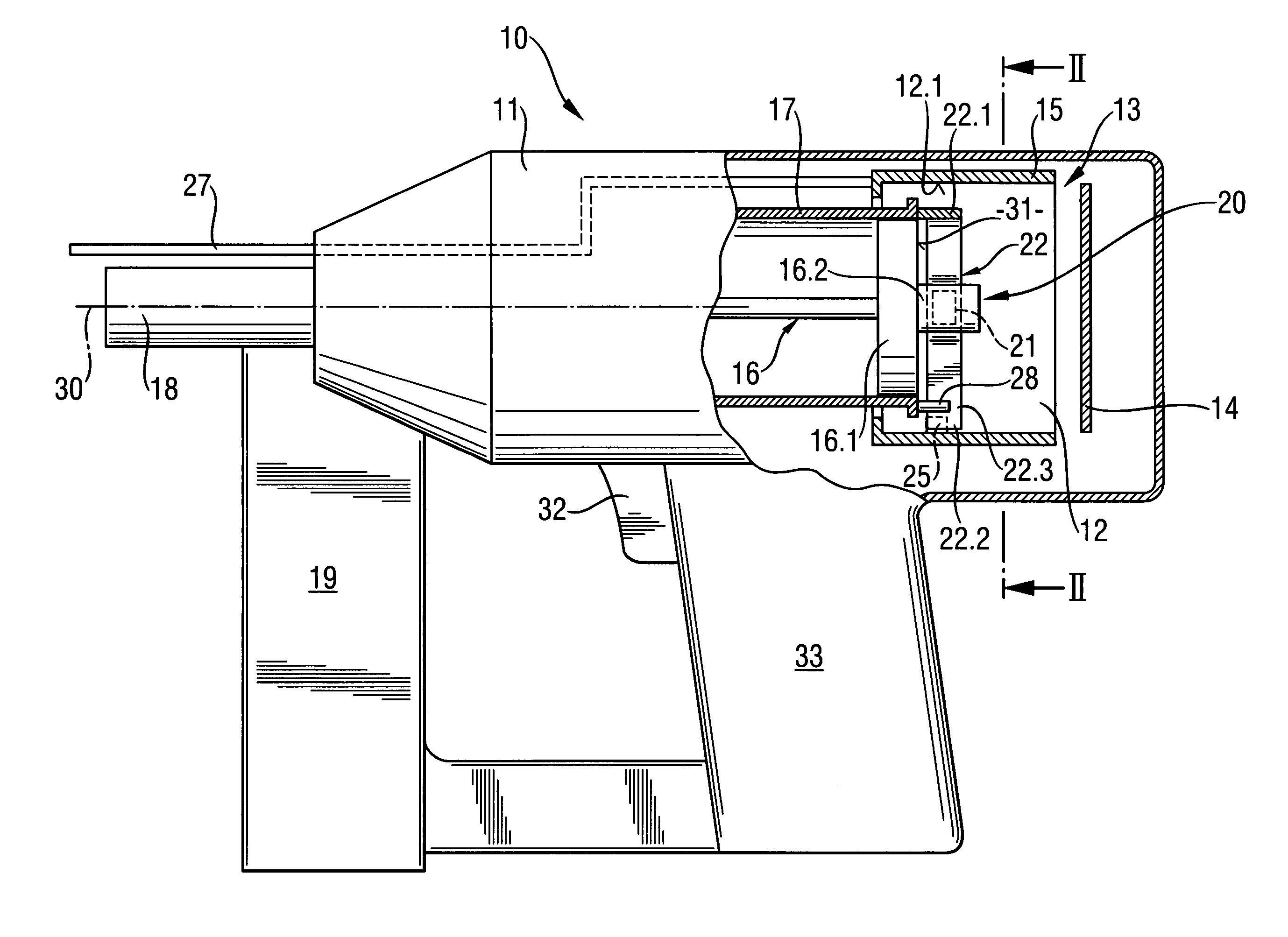

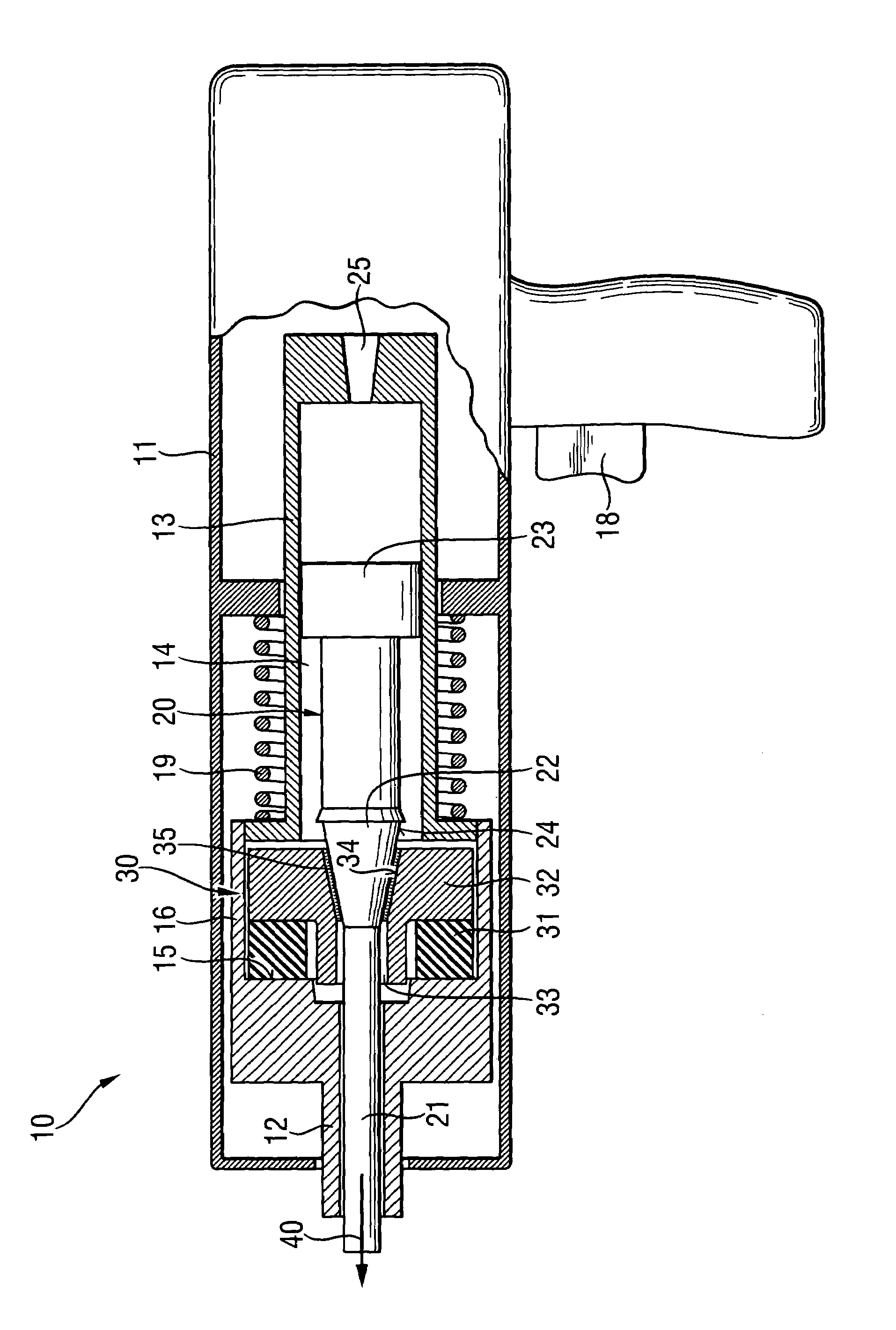

Setting tool

ActiveUS6938811B2Increase the pressing forceReliable returnStapling toolsNailing toolsPiston GuideEngineering

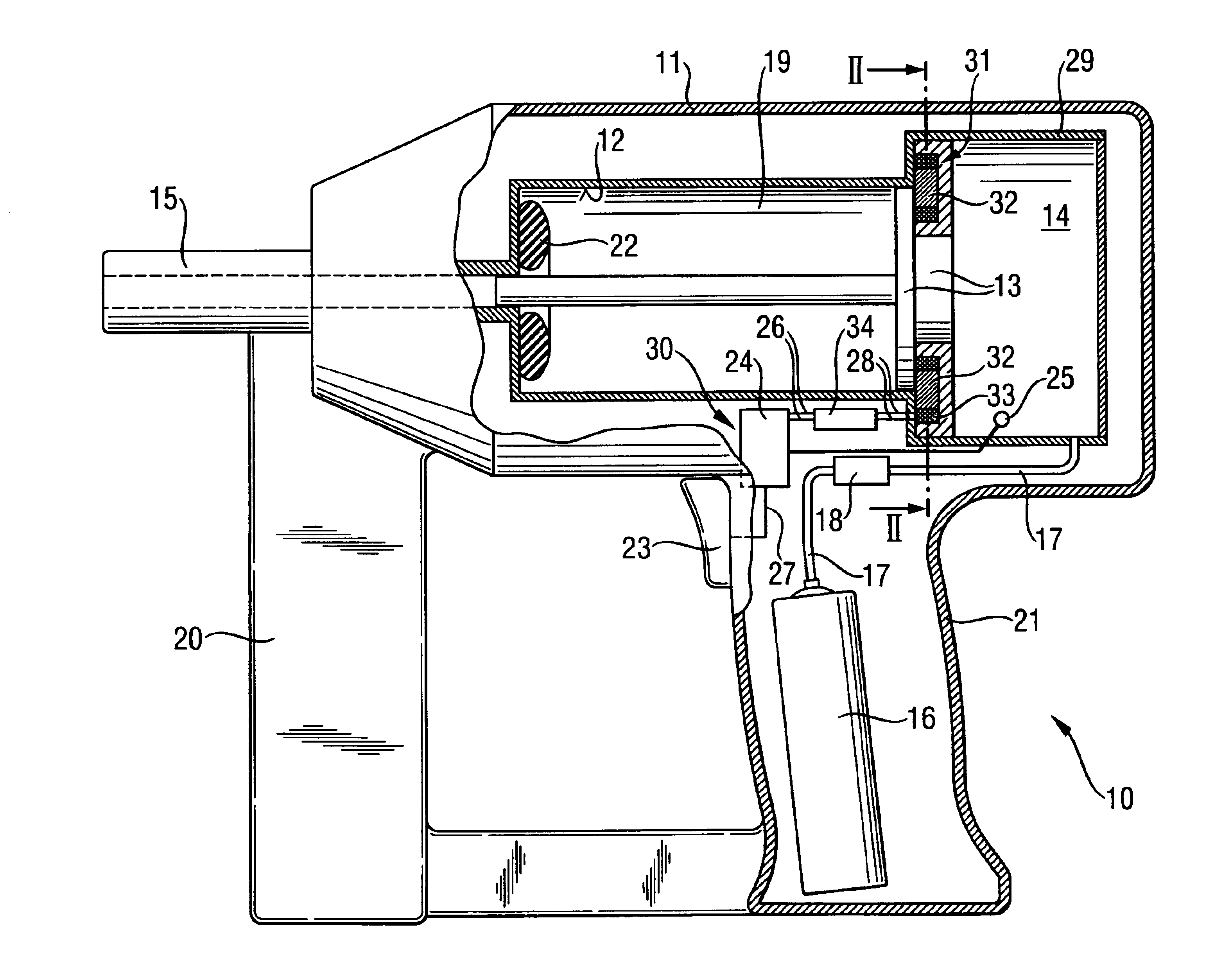

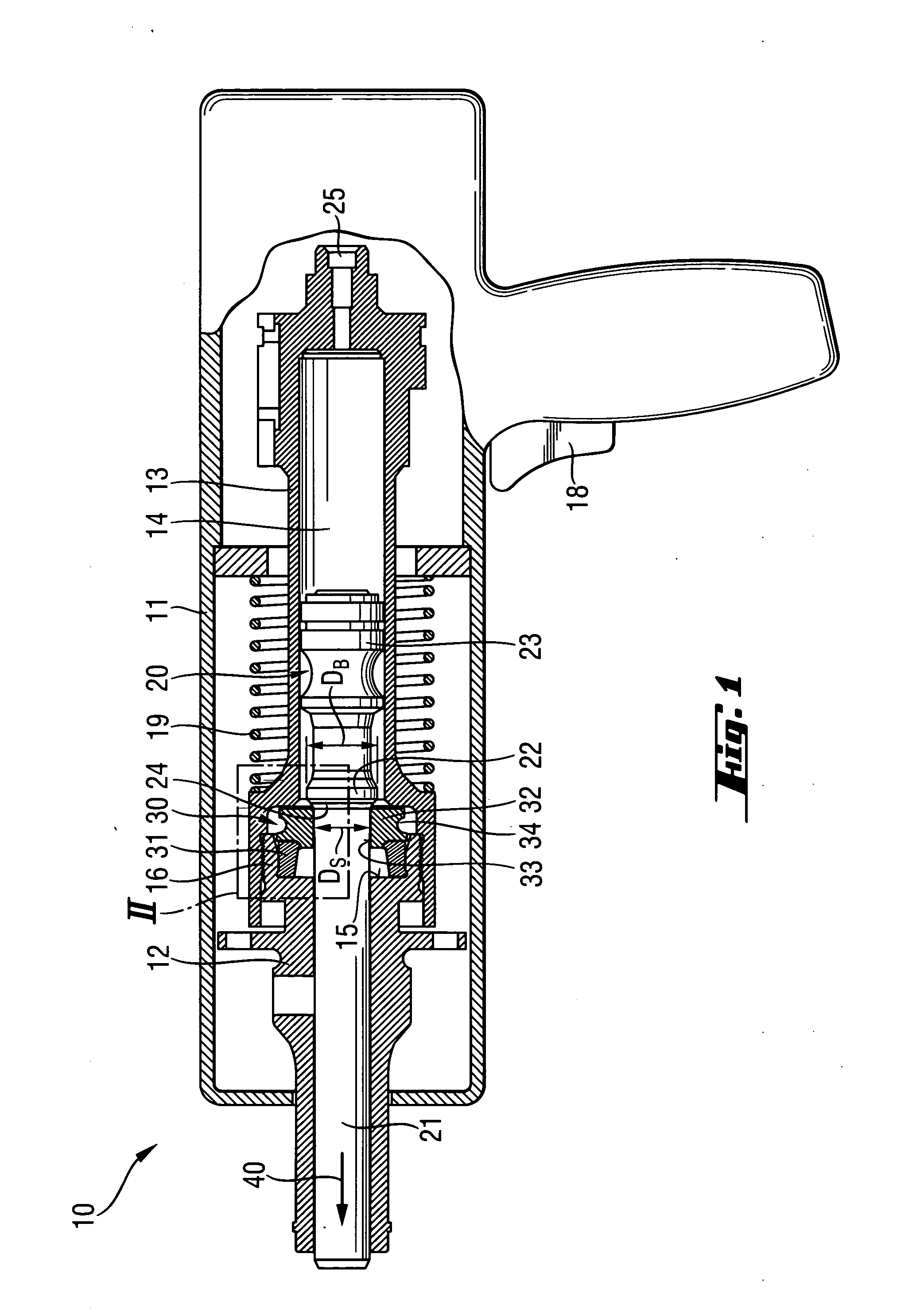

A setting tool for driving in fastening elements includes a drive piston (13) displaceable in a piston guide (11) between its initial (32) and setting positions, and device for returning the drive piston (13) in its initial position upon completion of a setting process and having an electromotive drive (30) and a transmission (20) for transmitting a motive actuating torque to the drive piston (13).

Owner:HILTI AG

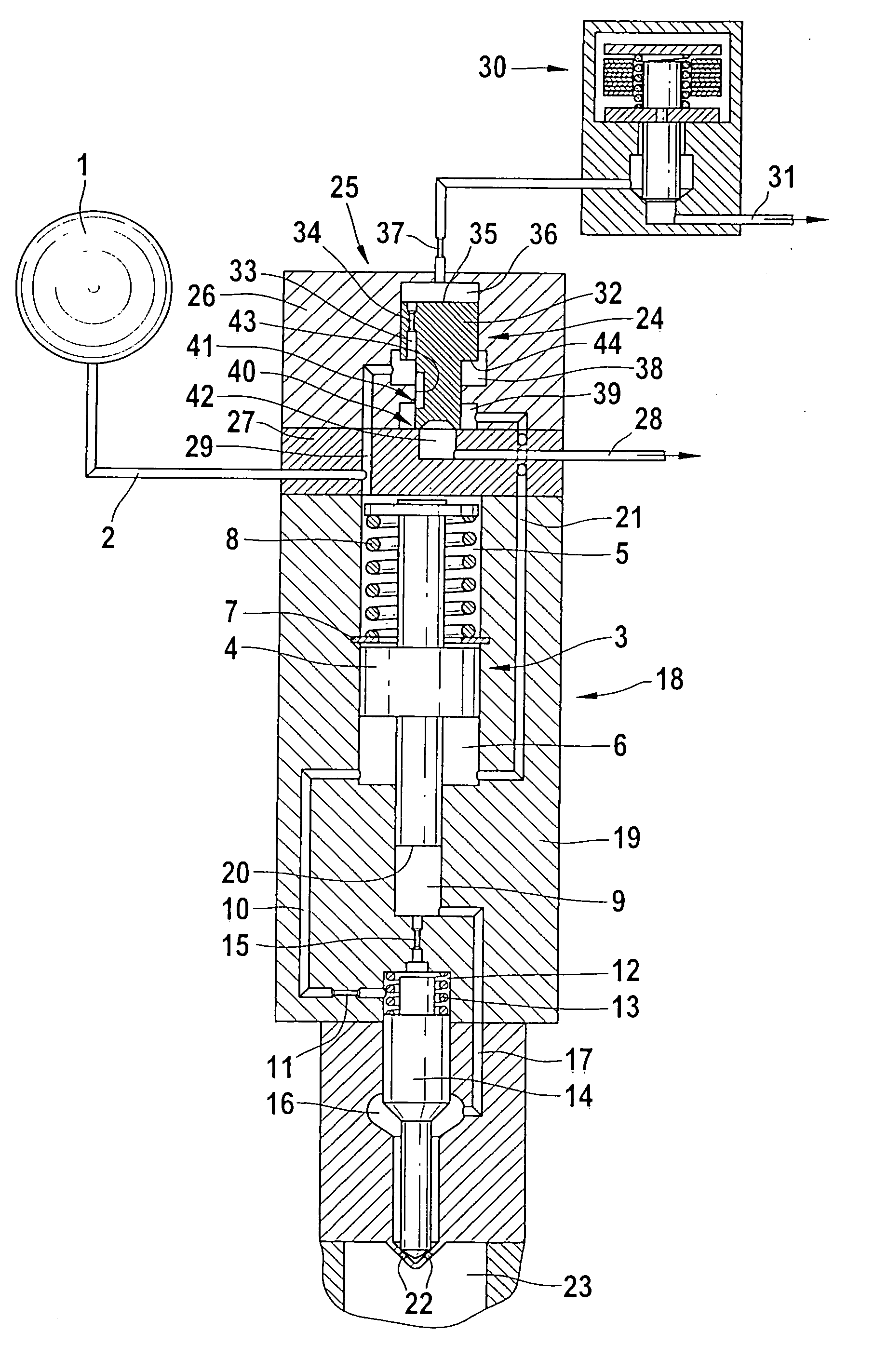

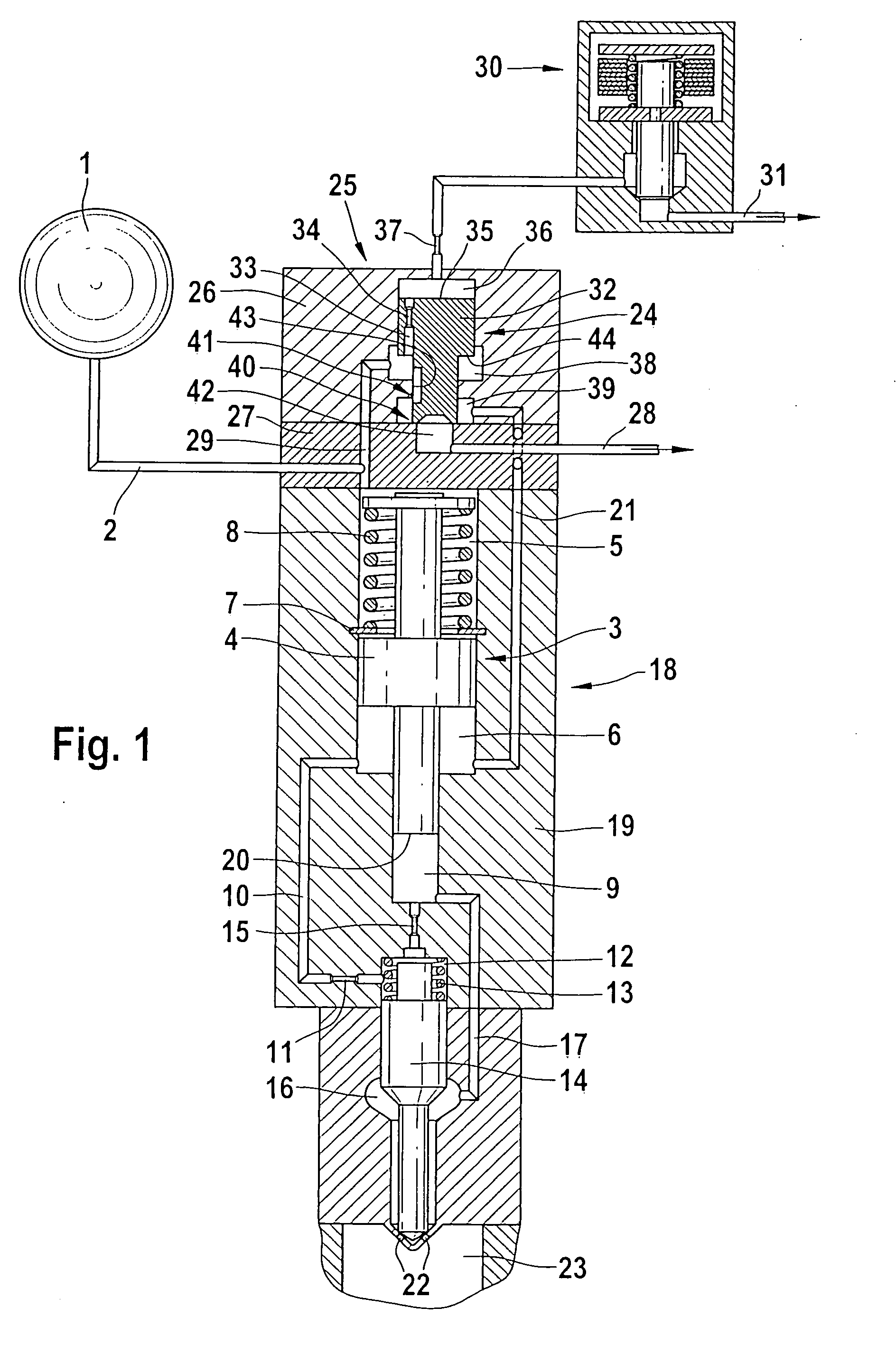

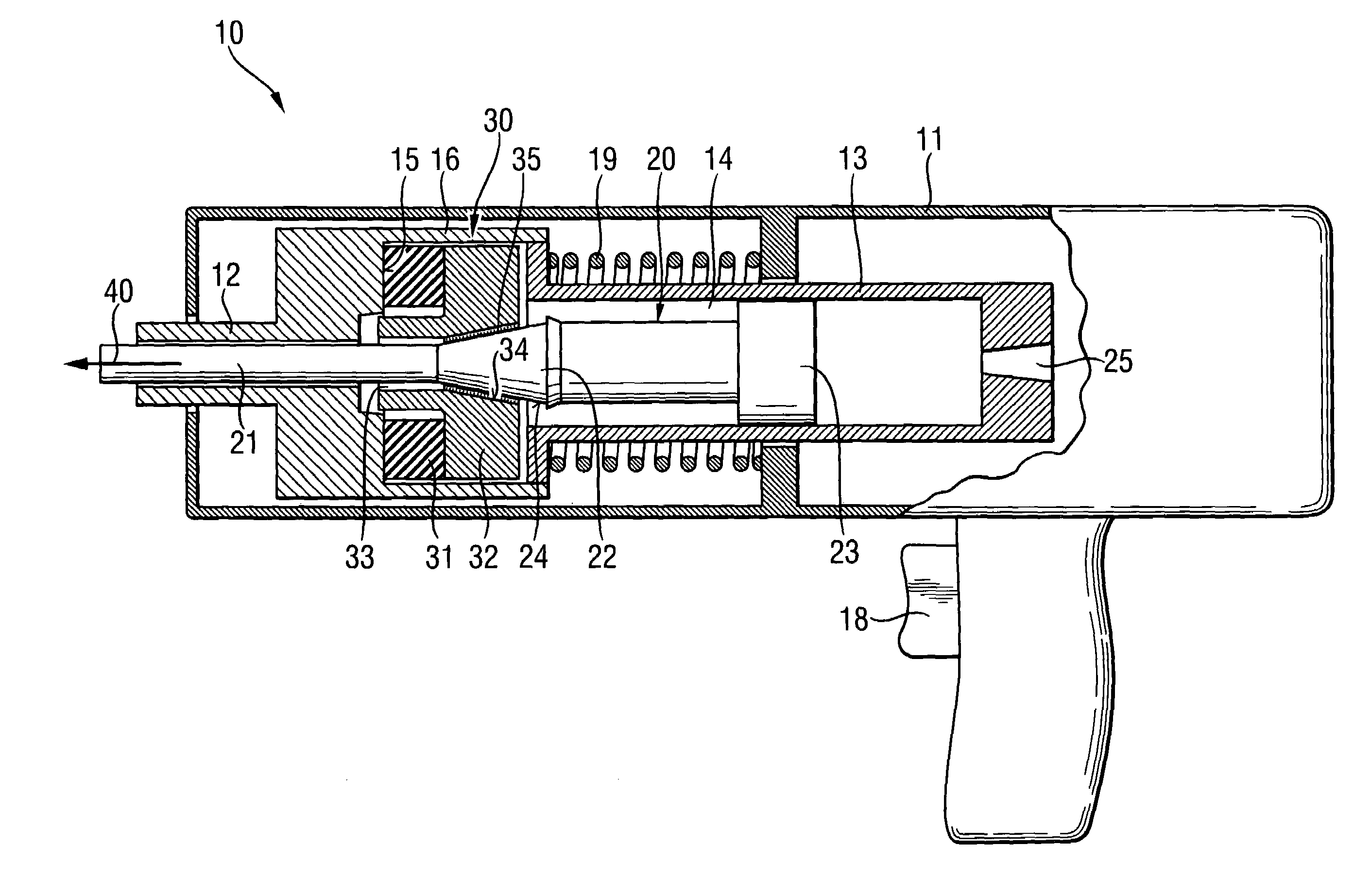

Fuel driven setting tool

ActiveUS6843401B2Drawback can be obviatedEfficient workStapling toolsNailing toolsPiston GuideEngineering

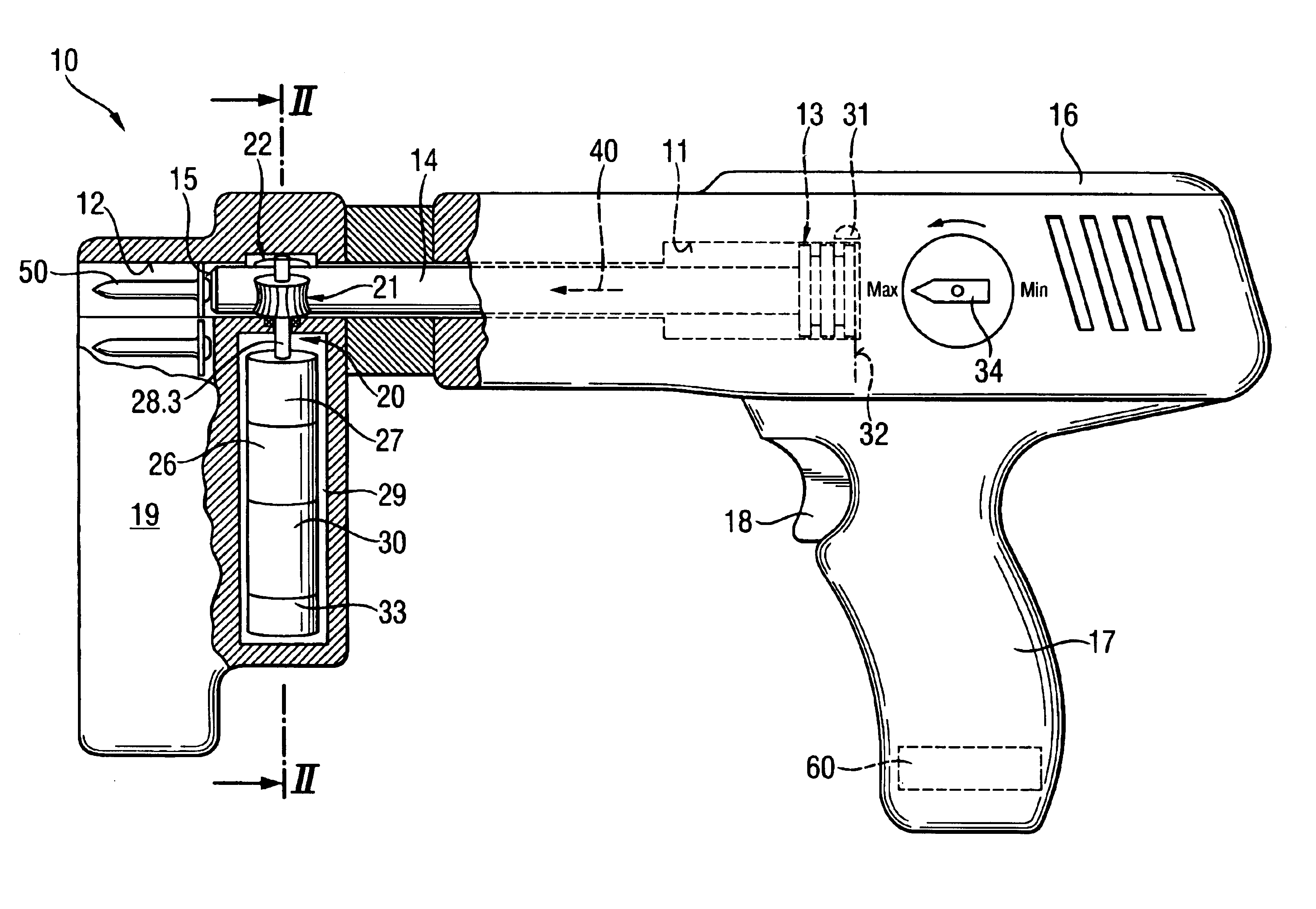

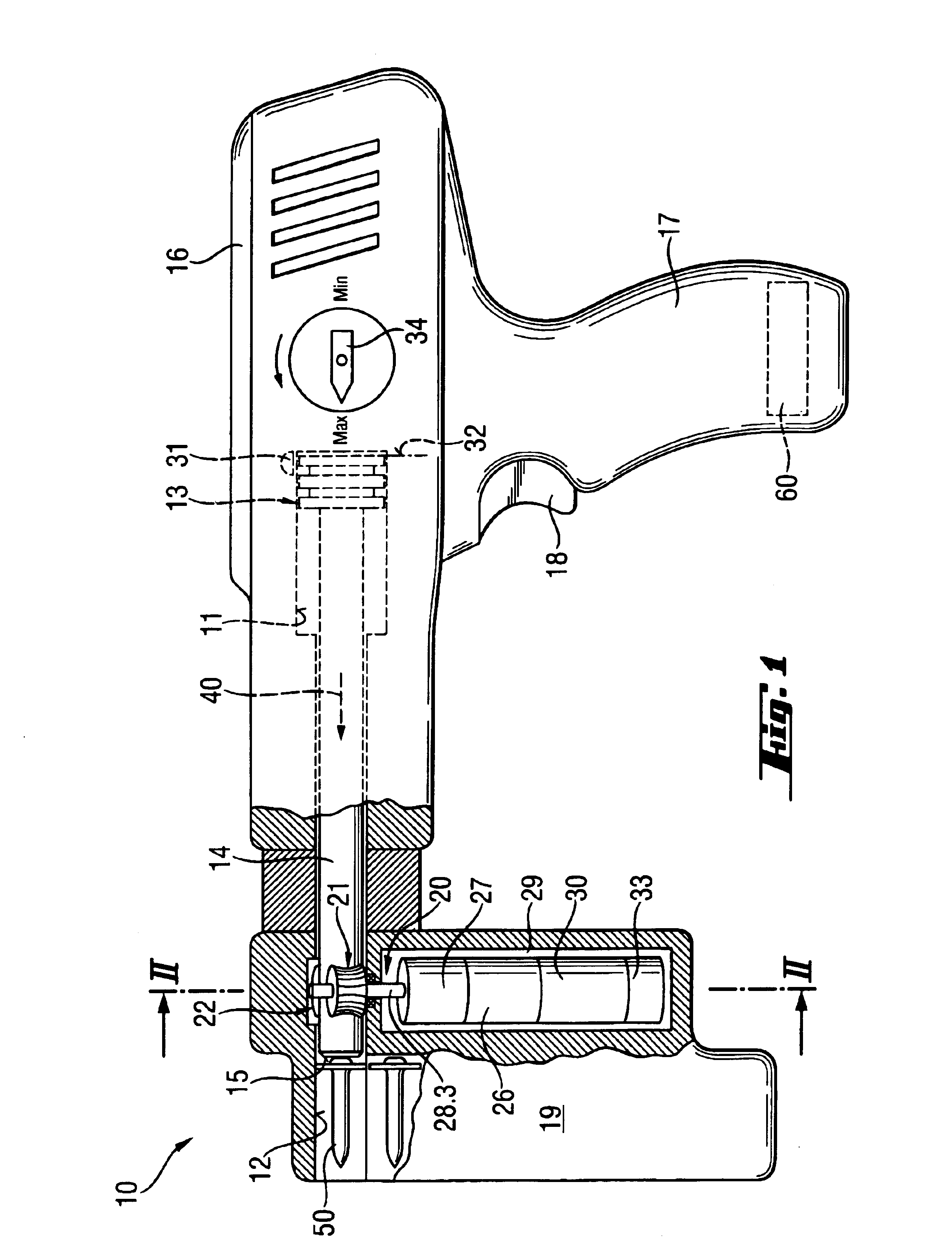

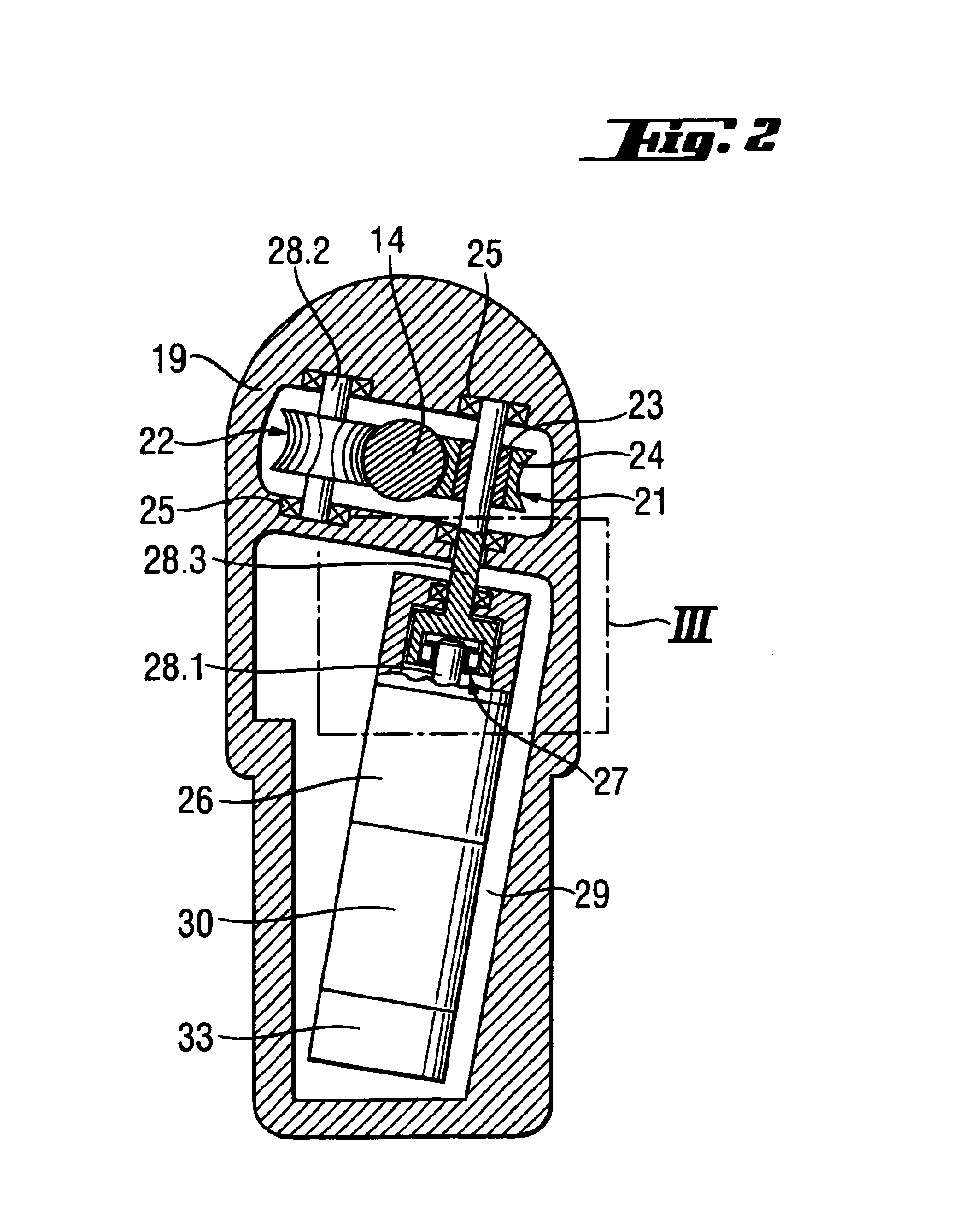

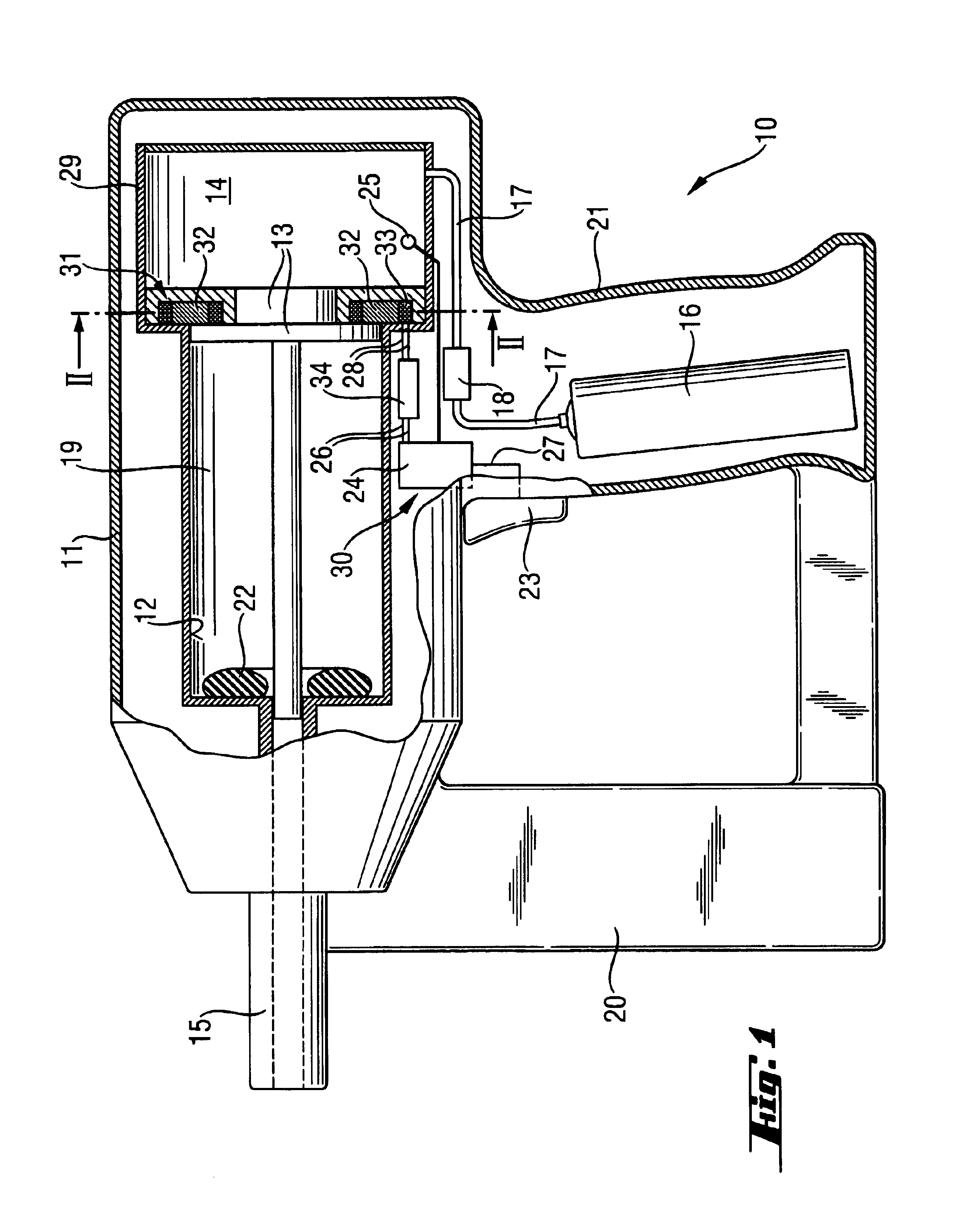

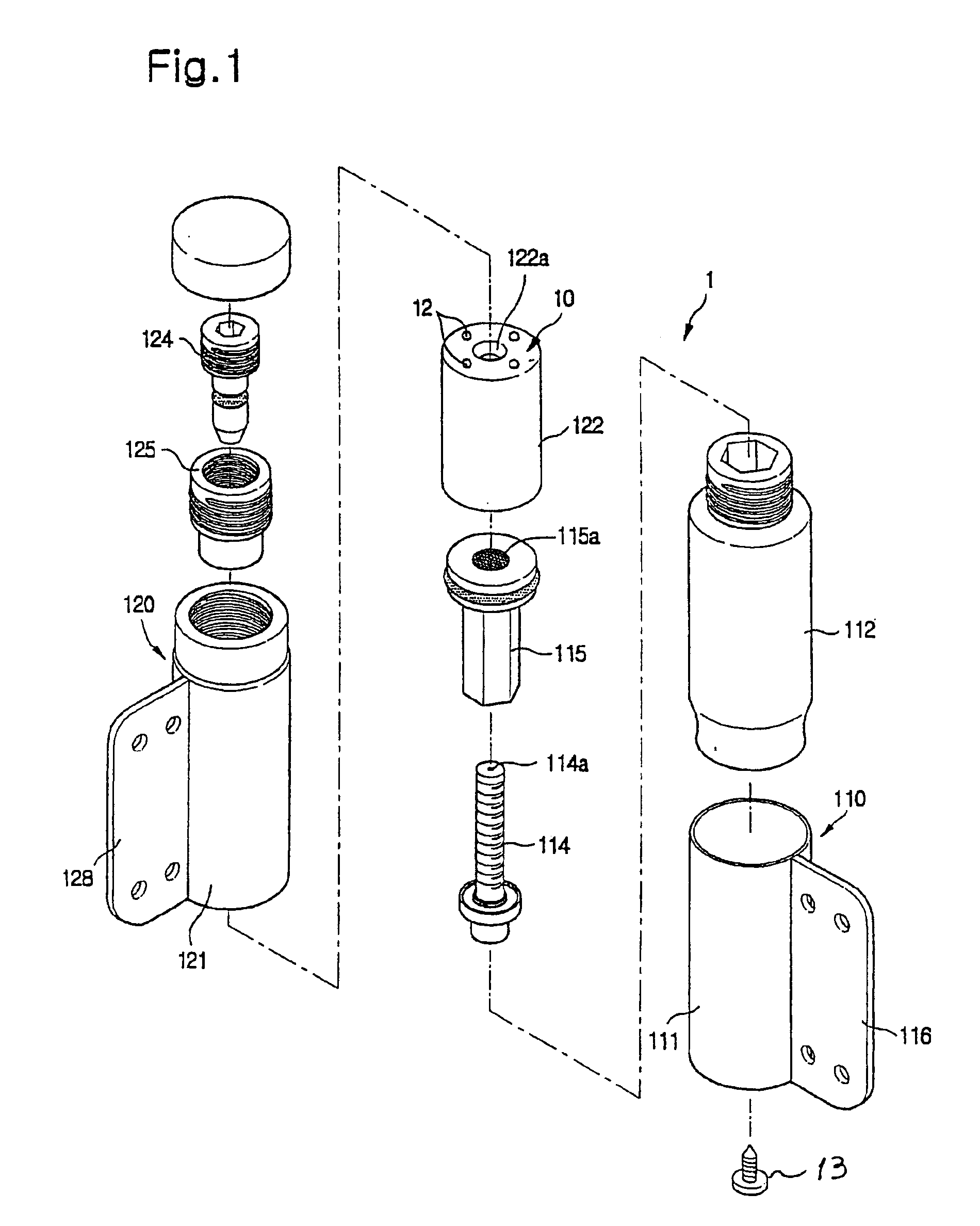

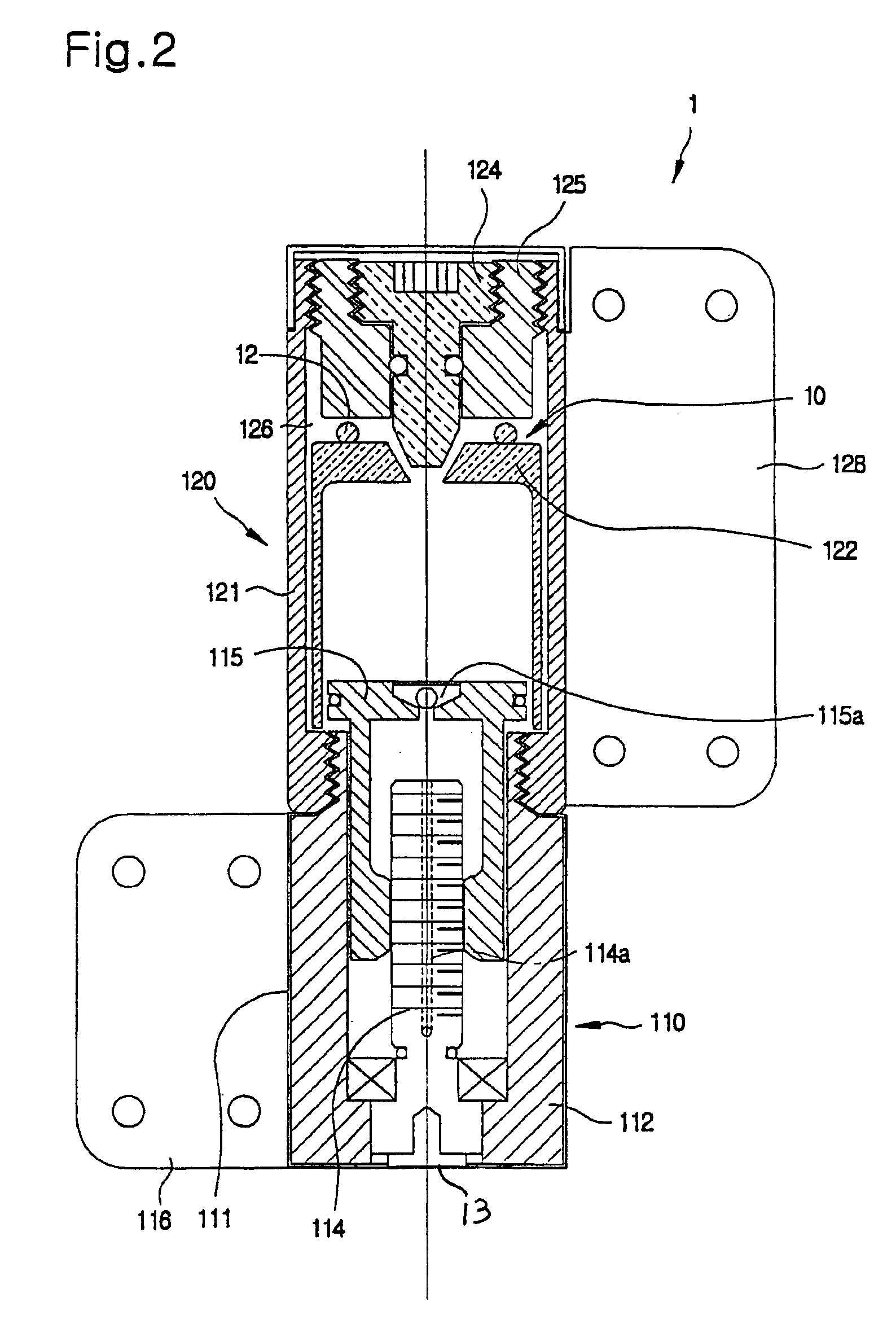

The present invention relates to a fuel-driven setting tool (10) for driving fastener elements such as nails, bolts, and pins into a substrate. The tool has a setting piston (13) guided in a piston guide (12) and displaceable using the combustion energy of a propellant and having a voltage source for supplying an electrical consumer on the setting tool (10). For improving a setting tool of this type, a generator device (30, 40) can be provided for transforming setting energy from the combustion of the propellant into electrical energy.

Owner:HILTI AG

Insertion instrument for joint sockets of prostheses

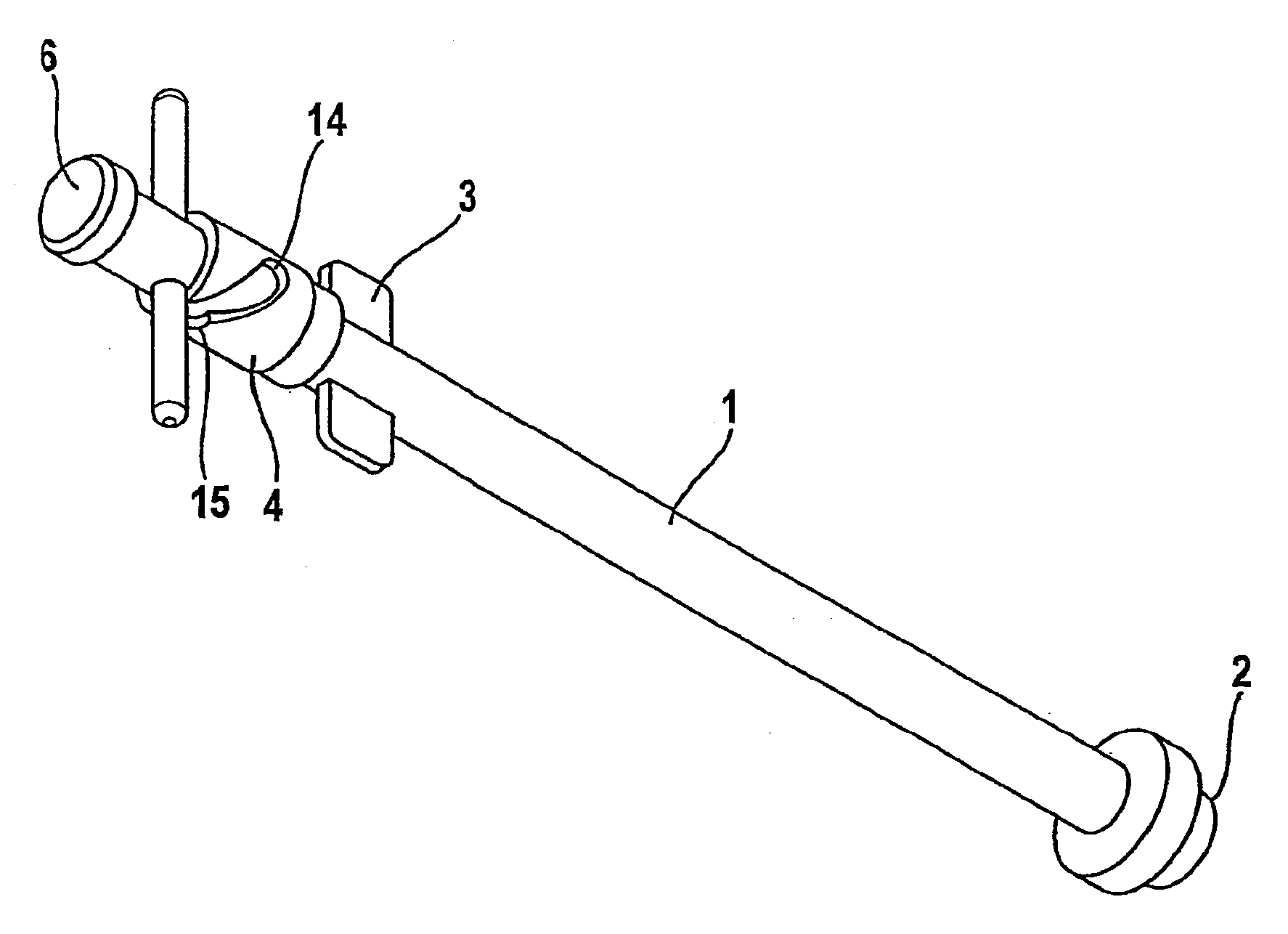

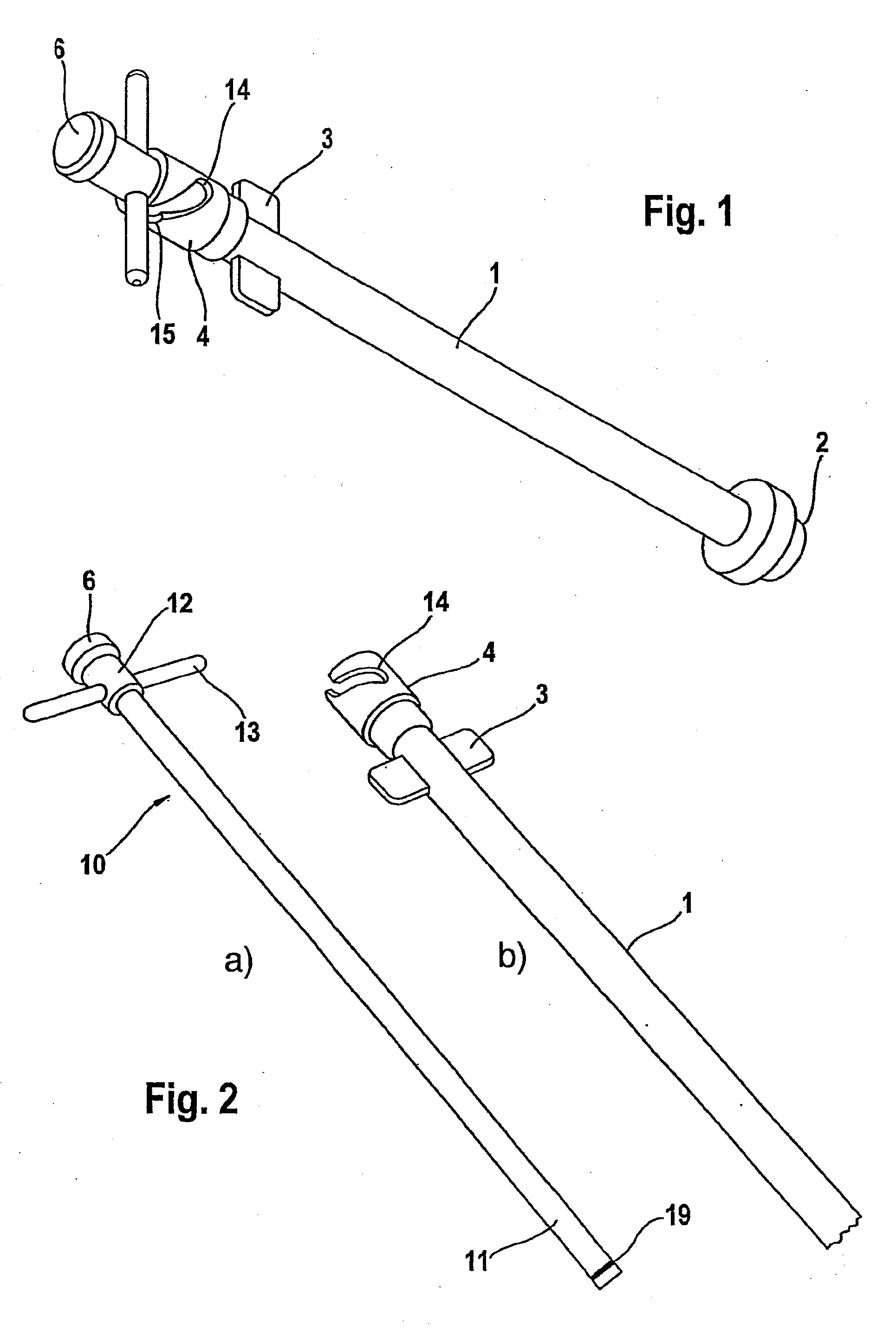

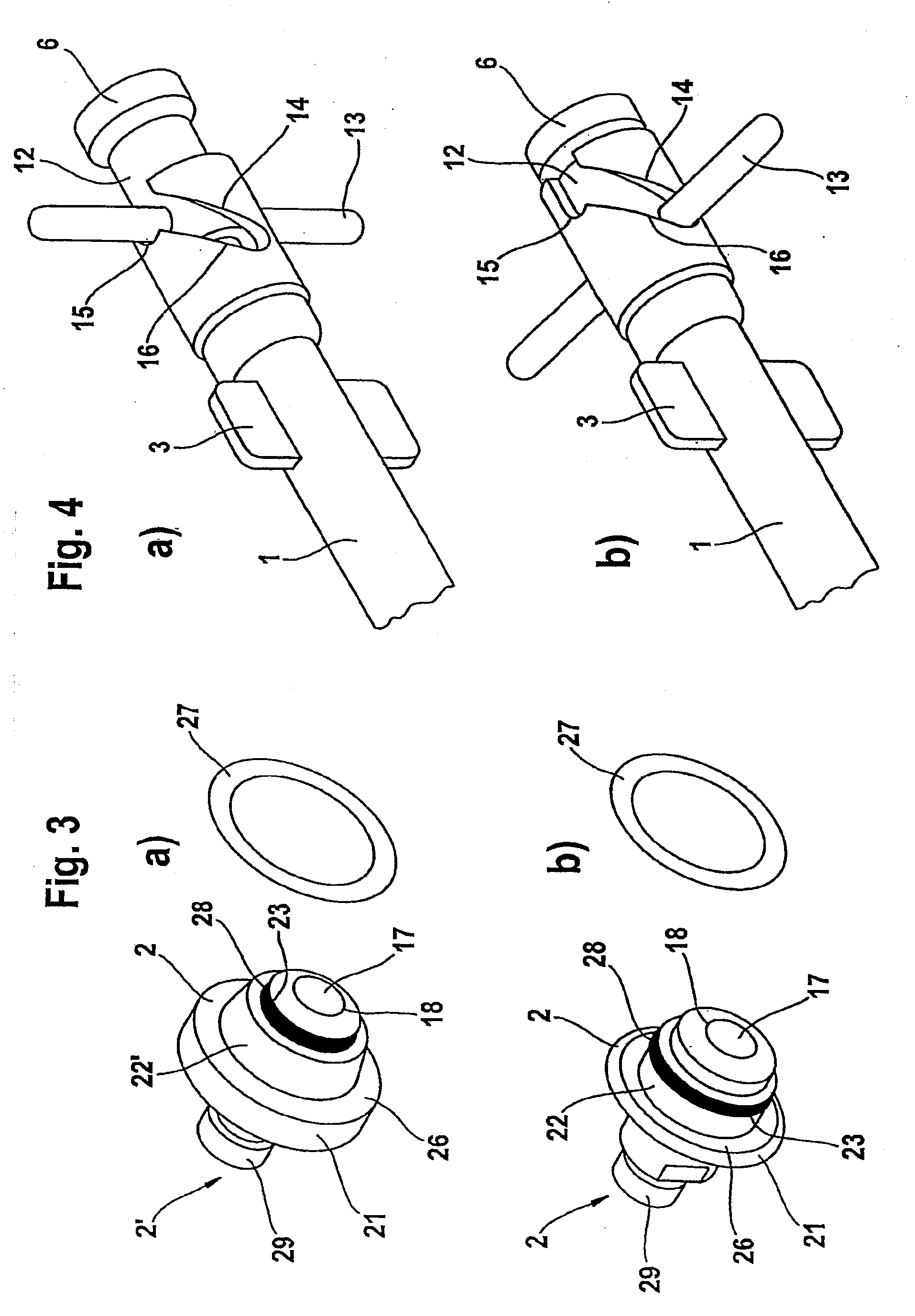

An insertion instrument comprising an elongate shaft, a suction head provided at the front end thereof for connection to a joint socket, a suction device with a piston guided in the shaft, a suction line opening out at the suction head, and an actuating element which is guided along a guiding track on the shaft. The guiding track can be helically shaped and have a locking arrangement, preferably in the form of a recess, for the actuating element in a suction position. Due to the helical shape of the guiding track, the actuating element executes a rotational and longitudinal movement during its displacement. The longitudinal movement produces a negative pressure in the suction line ensuring maintenance of the pressure, while the rotating movement causes rotation of the actuating element such that it reaches its locking position at the end of the guiding track, providing simplified handling of the instrument.

Owner:KELLER ARNOLD

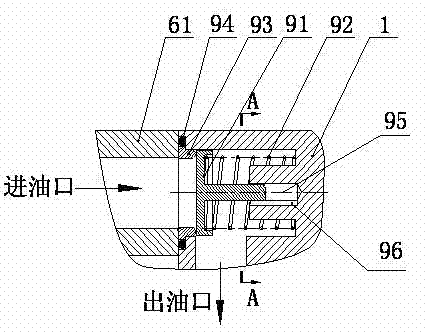

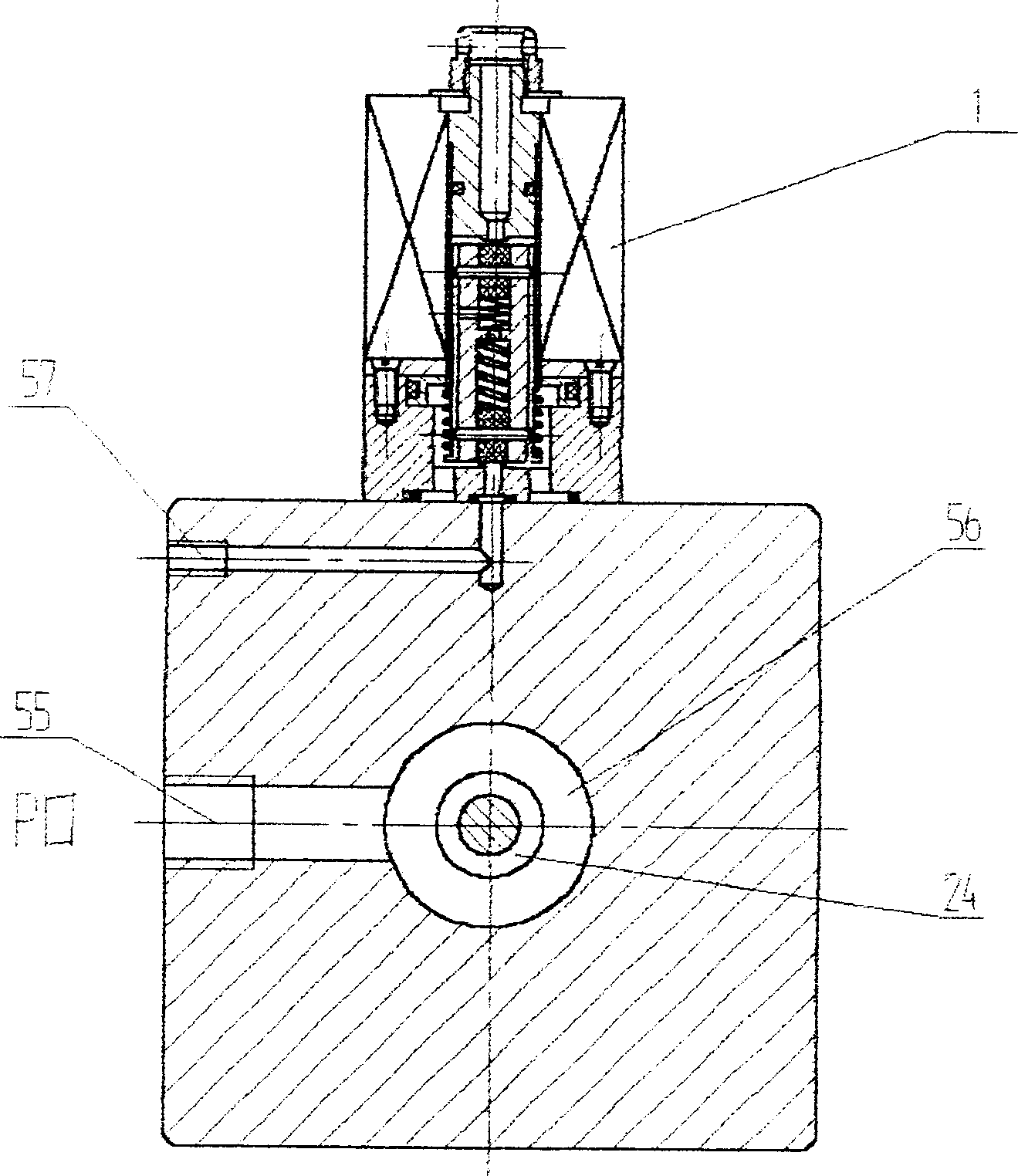

Apparatus for opening and closing door

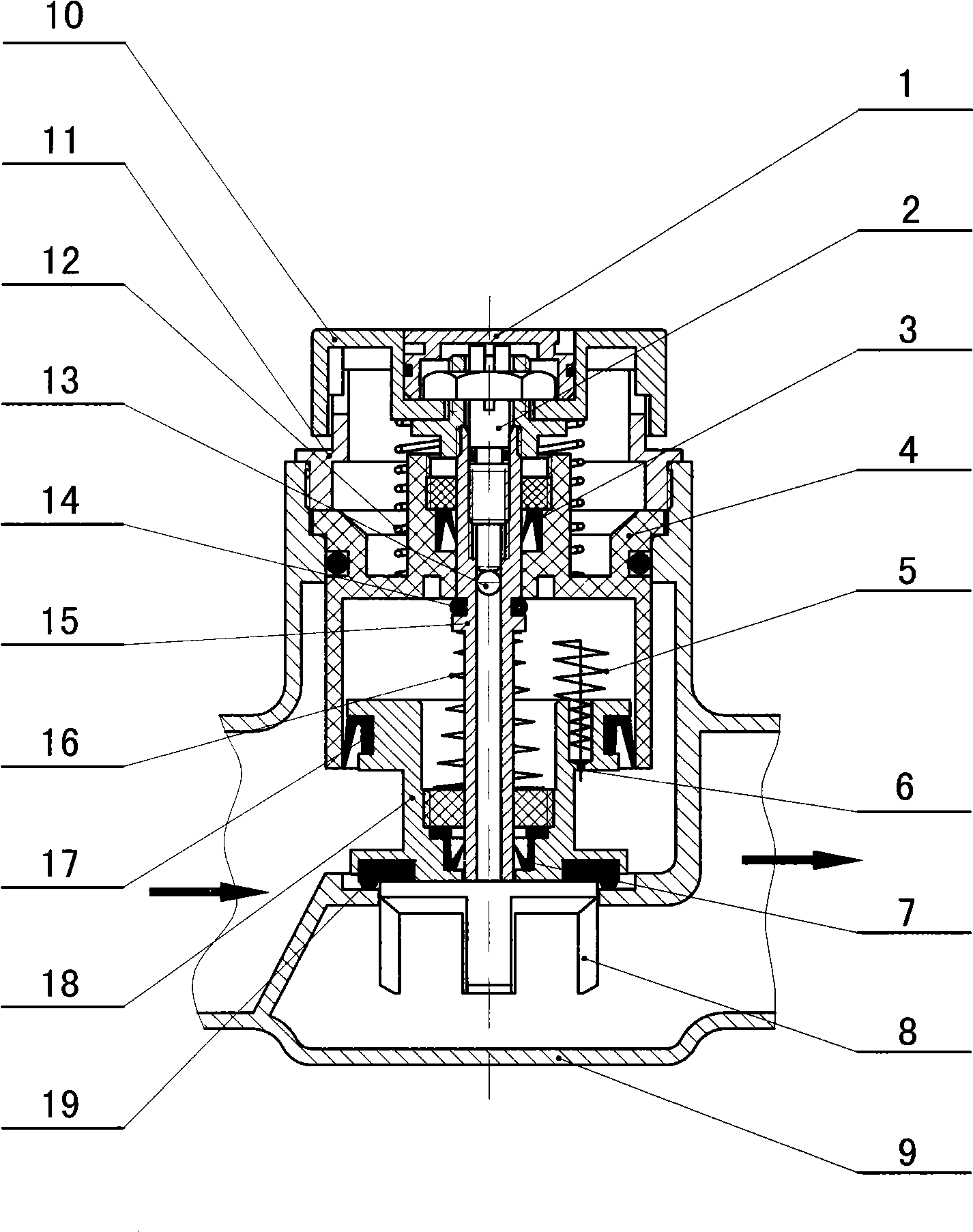

InactiveUS6854161B2Convenient amountSimple structureBuilding braking devicesSawing tools dressing arrangementsPiston GuideEngineering

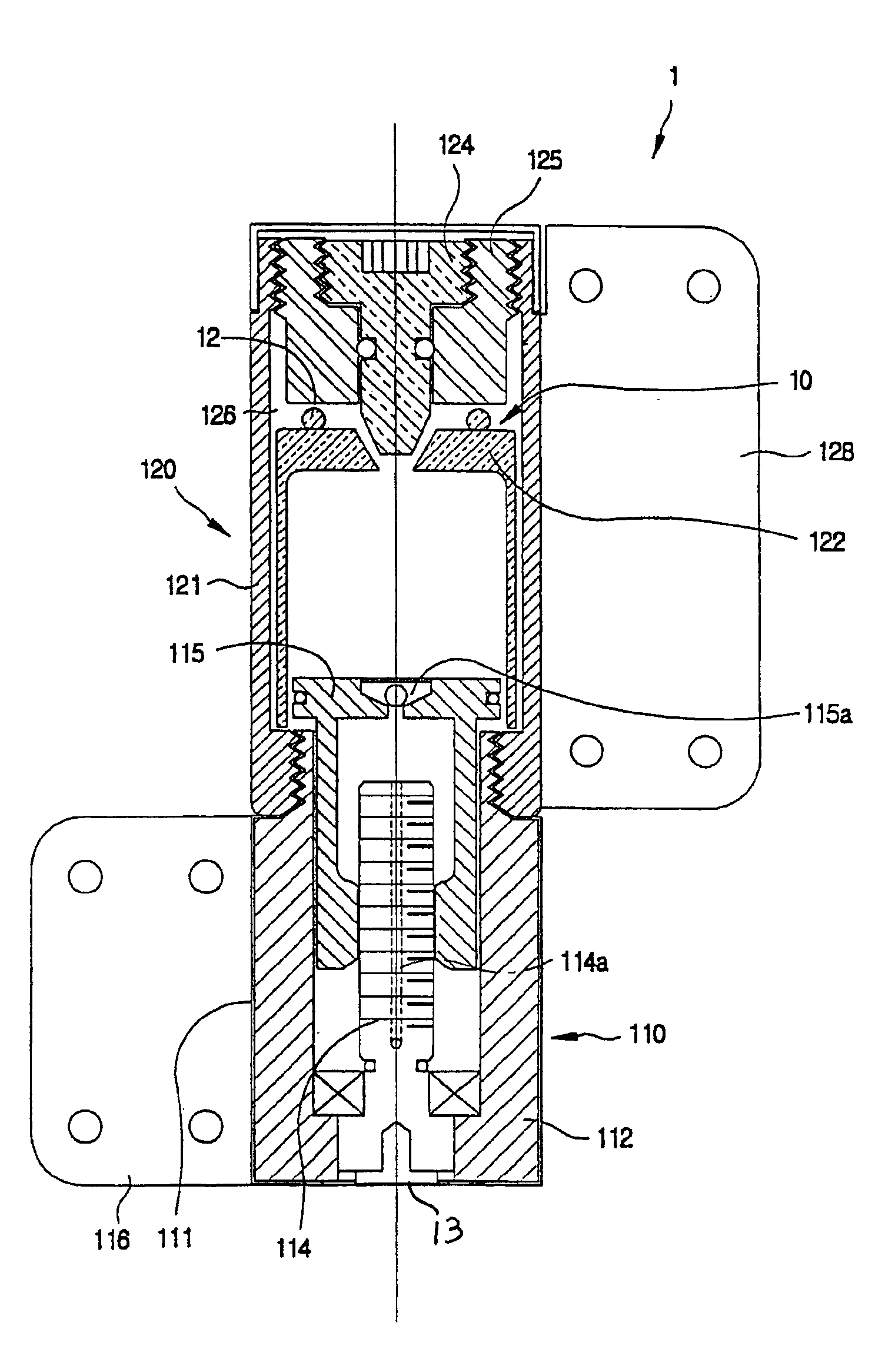

An improved apparatus for opening and closing a door including a hydraulic hinge and a spring-type hinge is provided. The hydraulic hinge includes a rotary member having a first housing, a piston guide placed inside the first housing, a rotary shaft disposed inside the piston guide and a piston screwed with the rotary shaft, and a fixed member having a second housing, a cylinder placed inside the second housing and having an oil outlet penetrating the cylinder for allowing oil to pass through the oil outlet, an outflow part formed on the top surface of the cylinder and having a plurality of support protrusions, a head mounted on the top surface of the cylinder and an adjusting bolt screwed with the head such an oil circulating passage is formed in the fixed member. The spring-type hinge includes a spring for closing an opened door by compressive tension and an elevation part rotatably elevated while being rotated, the elevation part having a spring fixing part formed on the top surface thereof for fixing the lower end of the spring.

Owner:JEONG CHAN IN

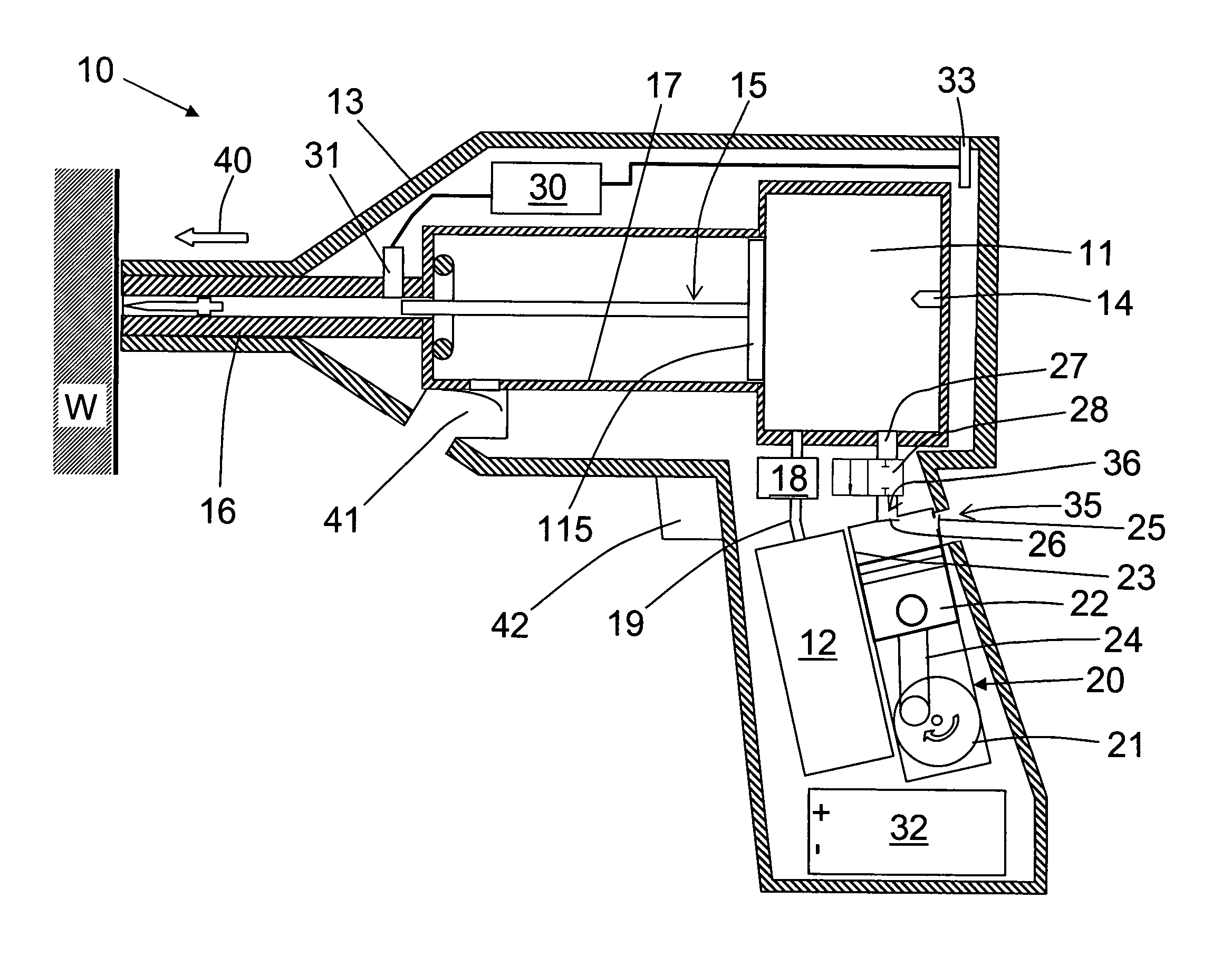

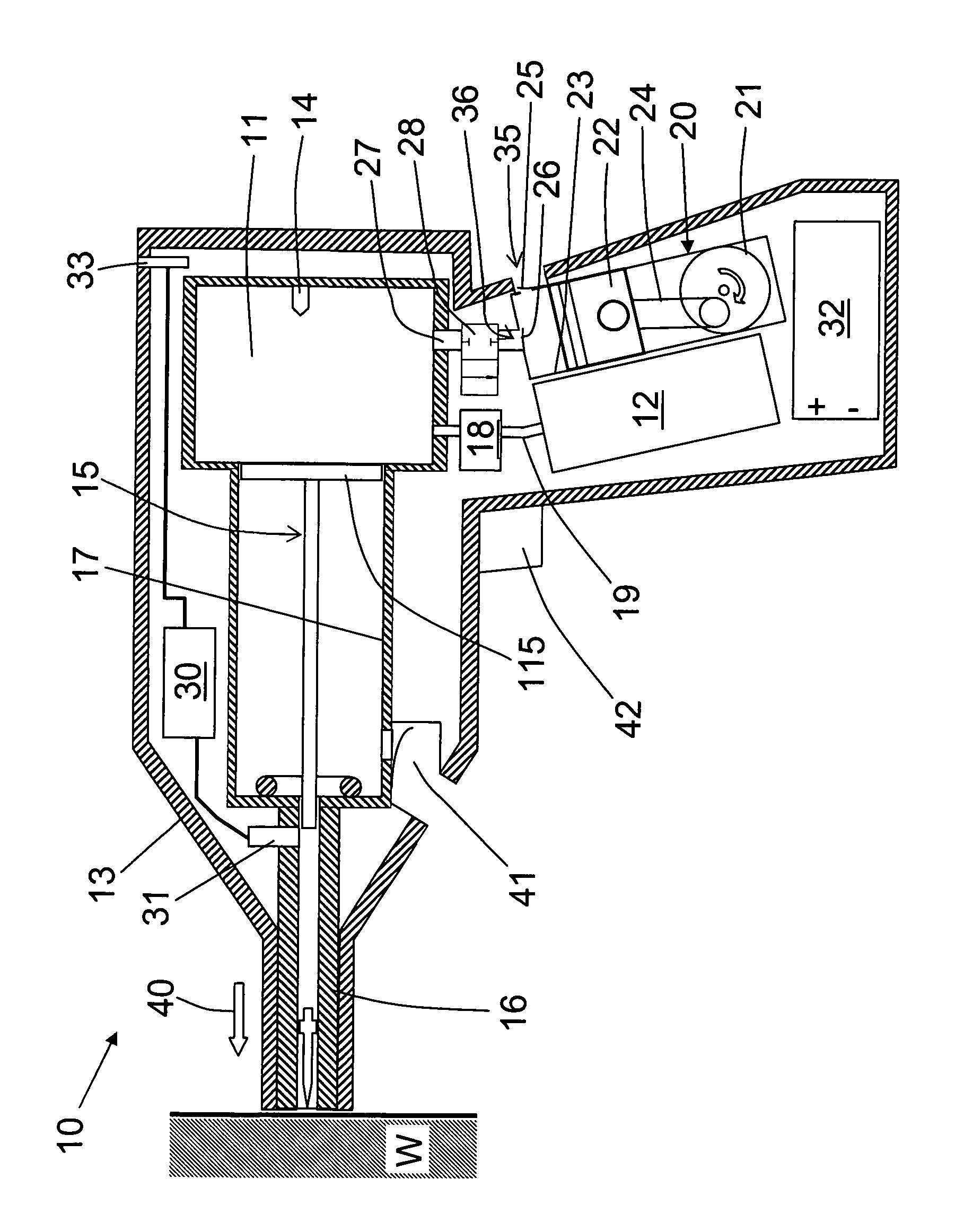

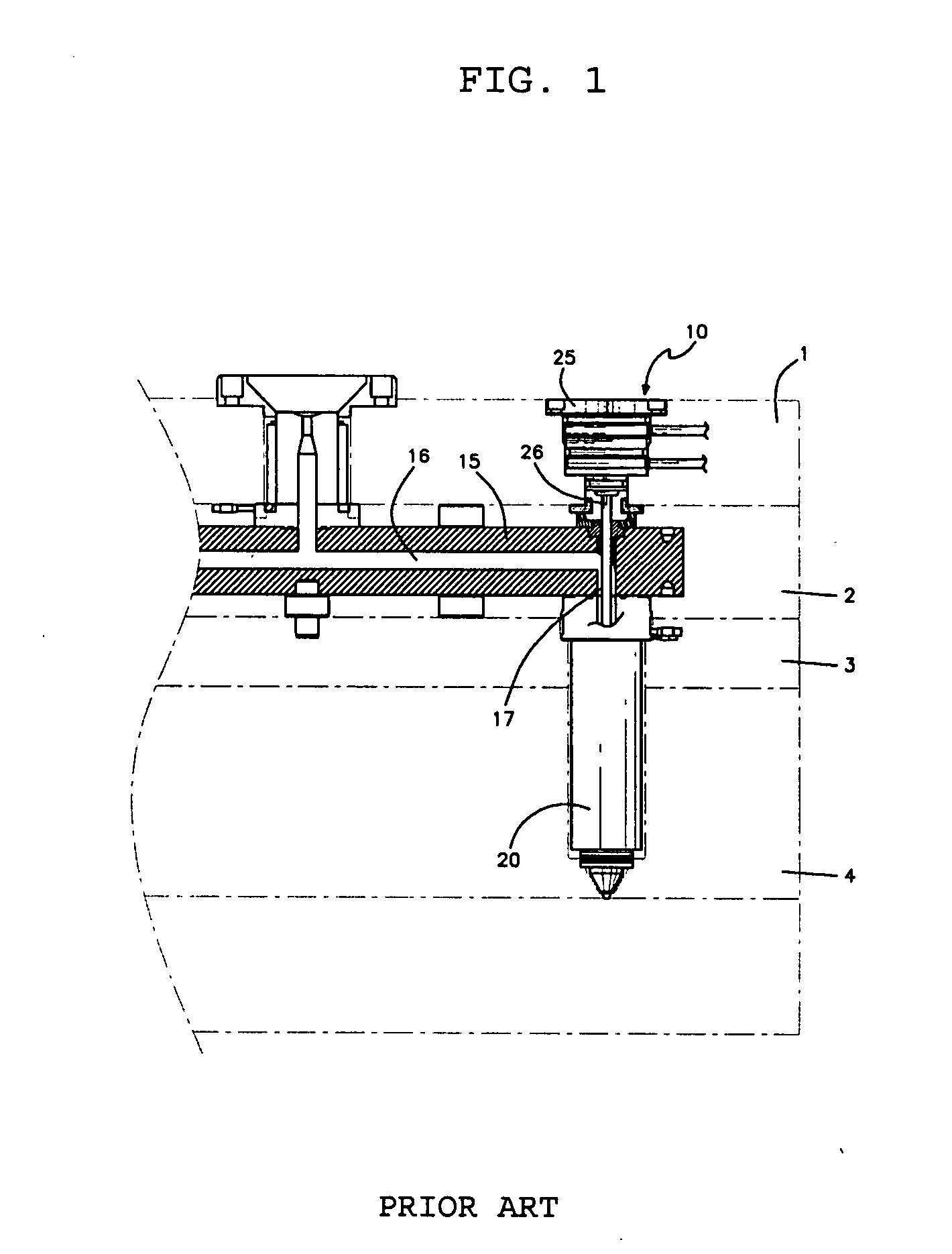

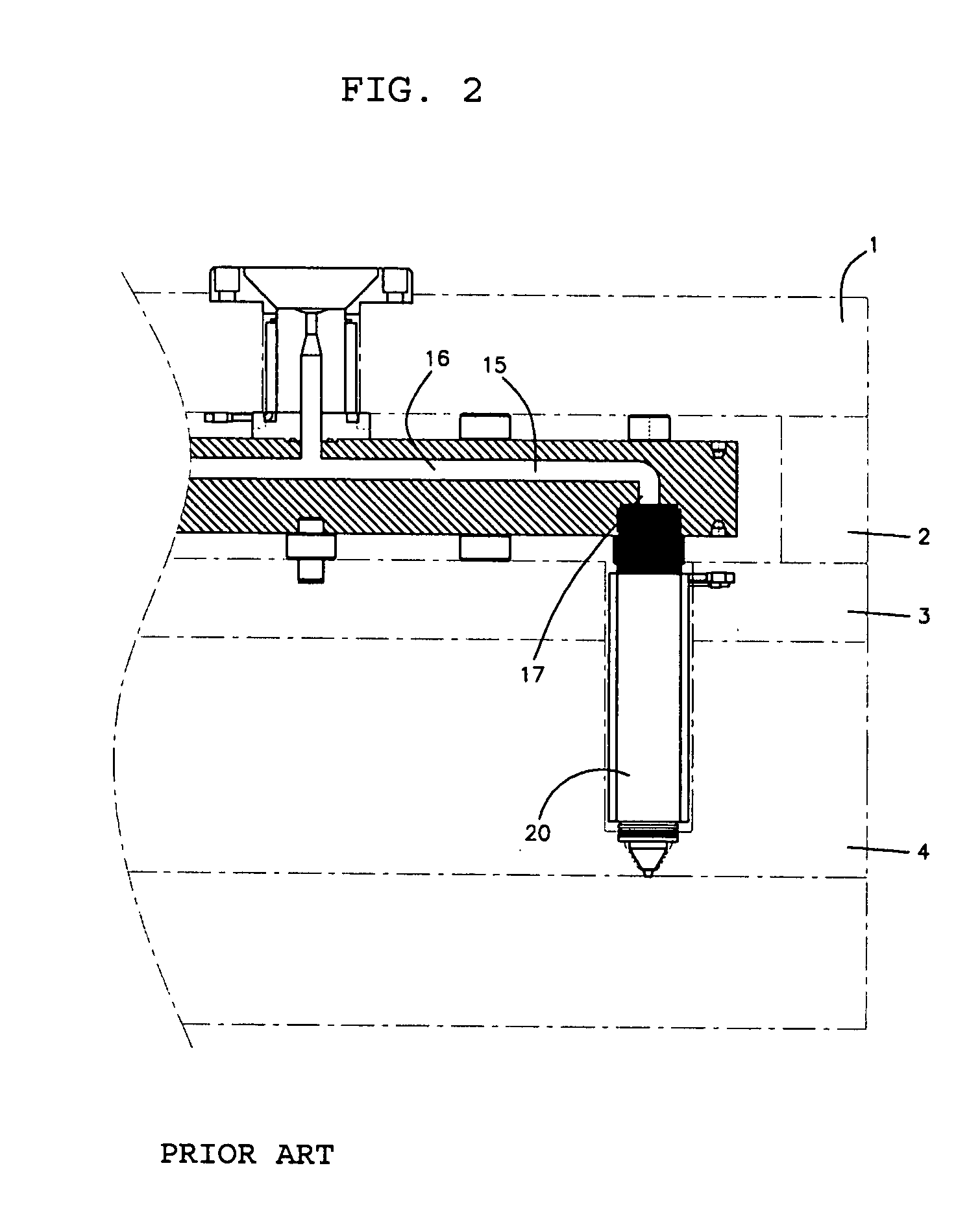

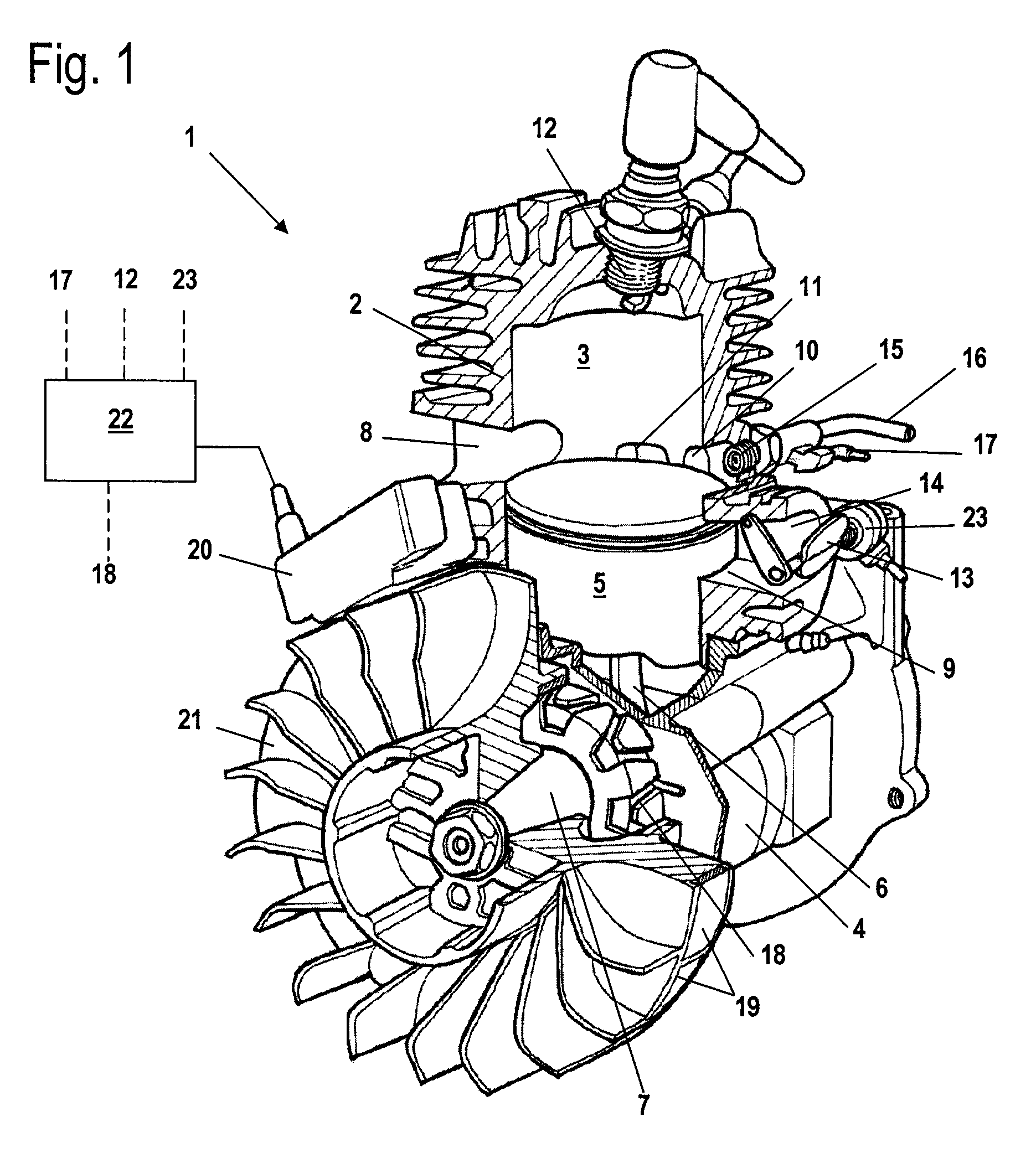

Combustion-engined setting tool

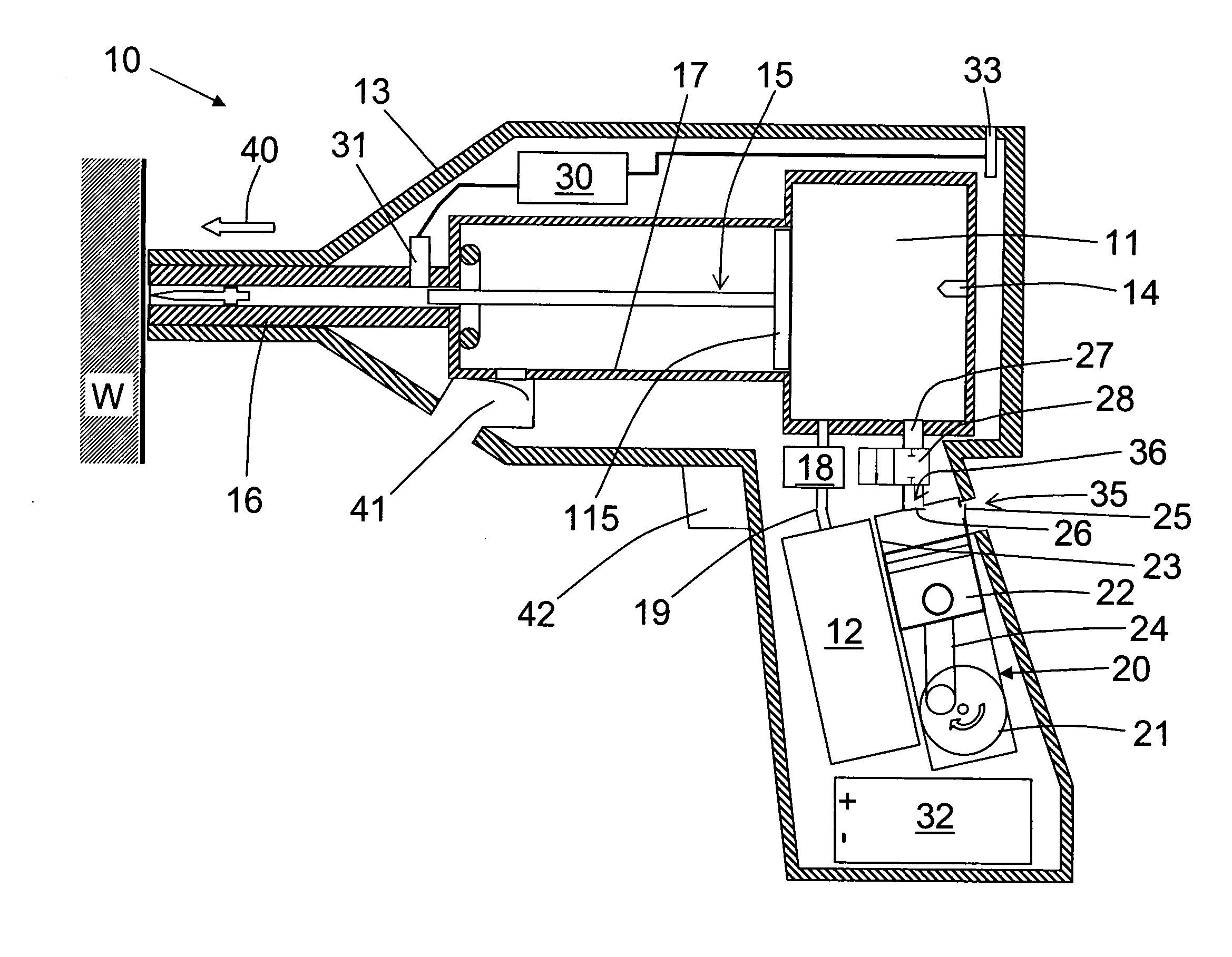

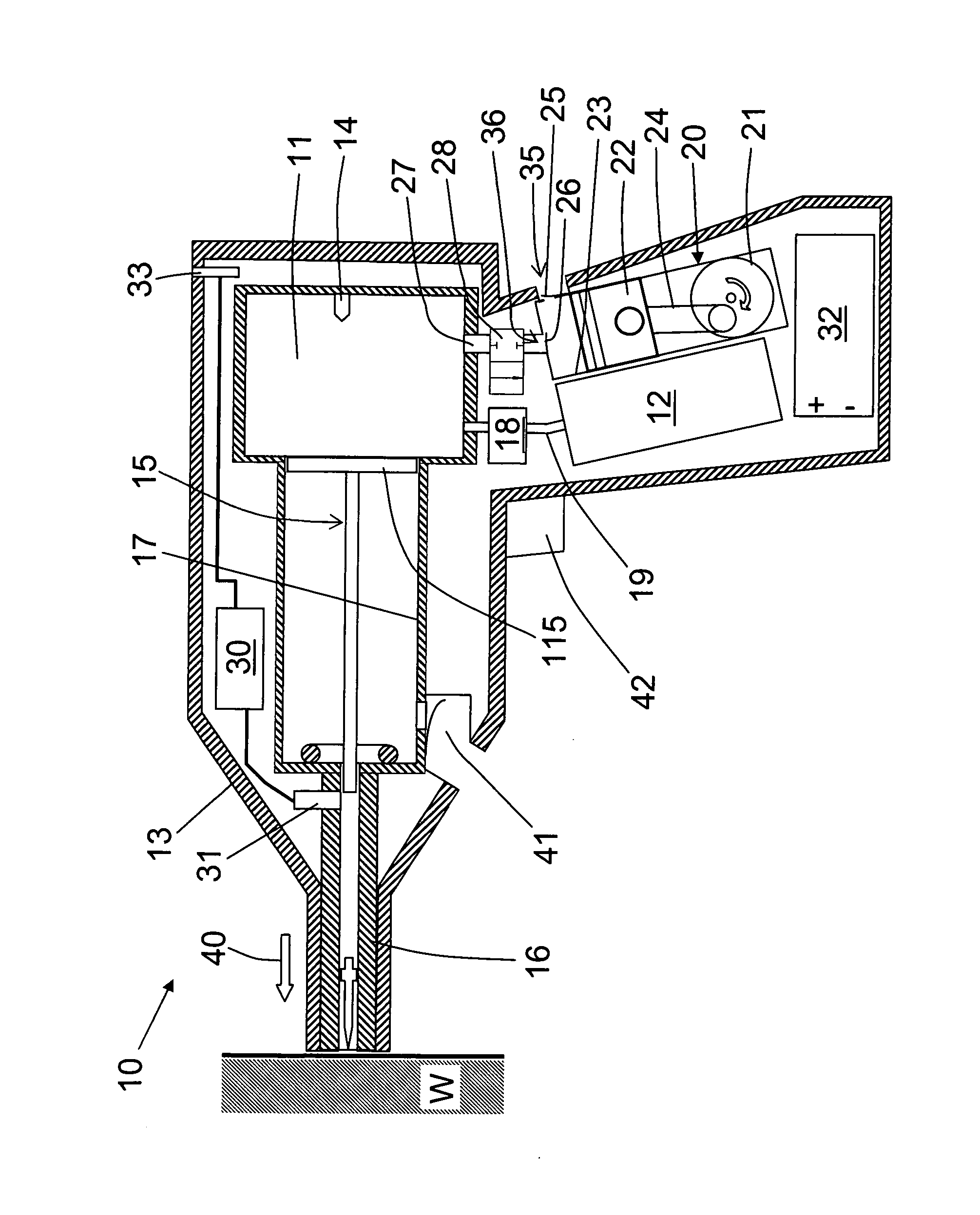

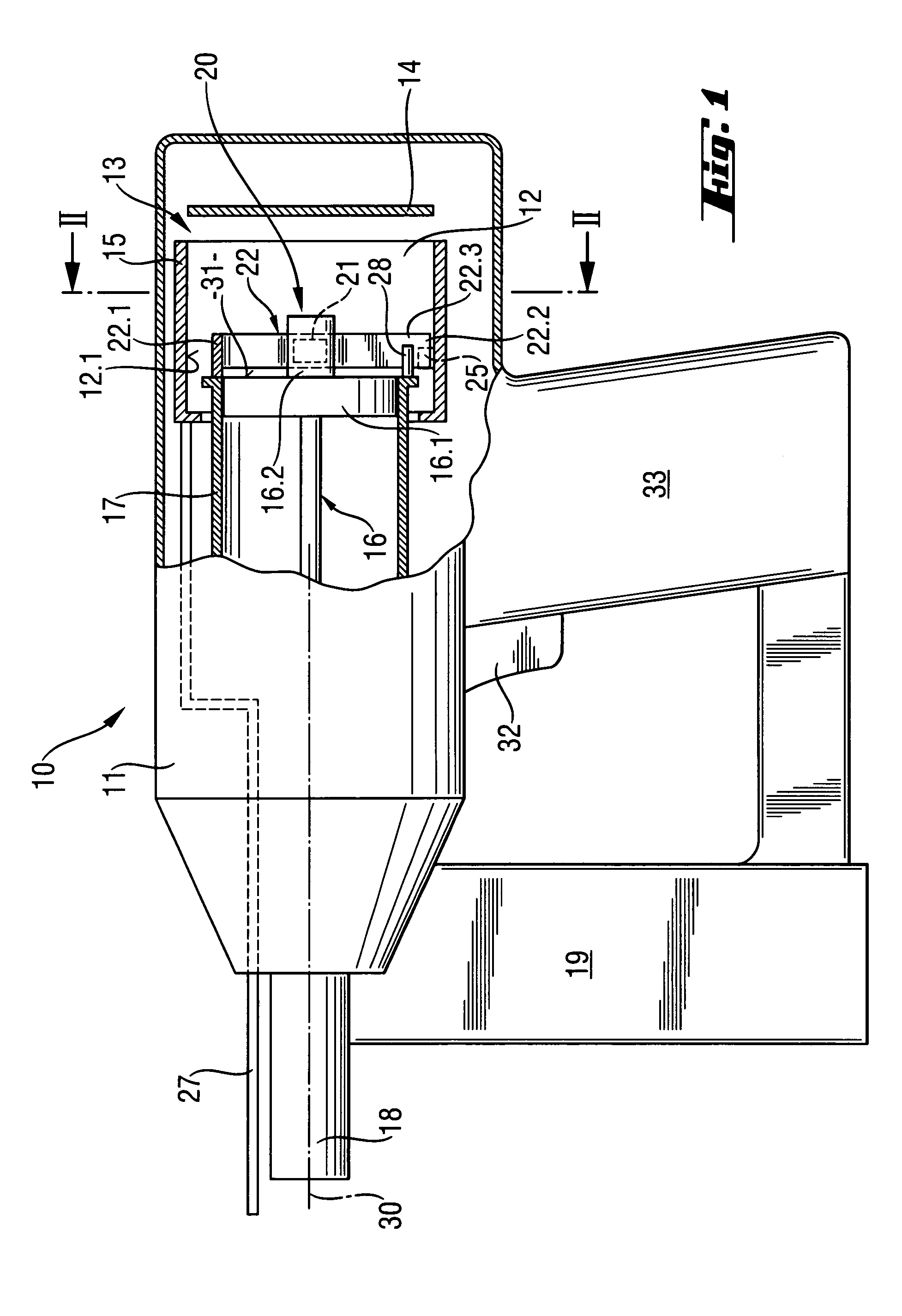

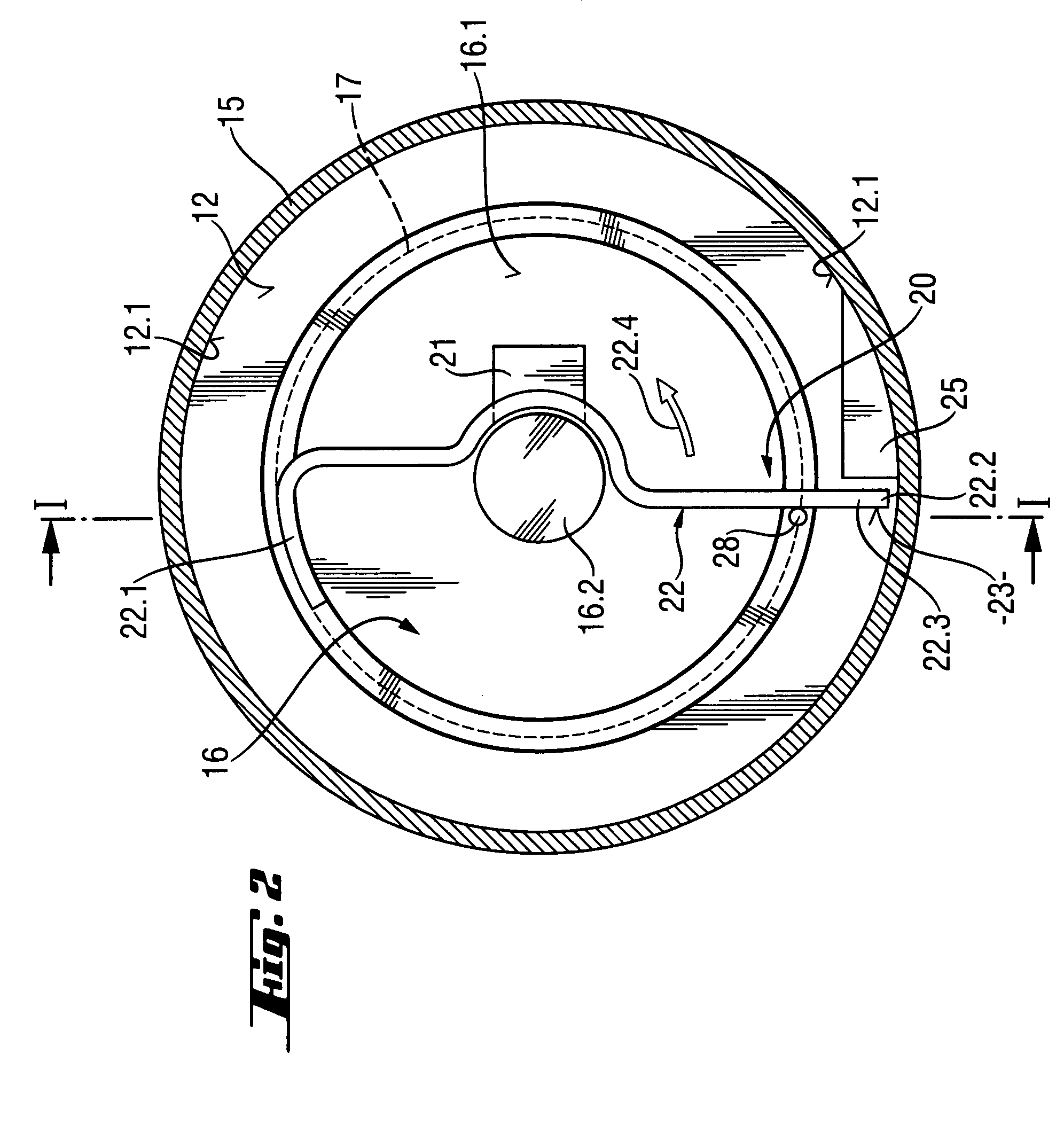

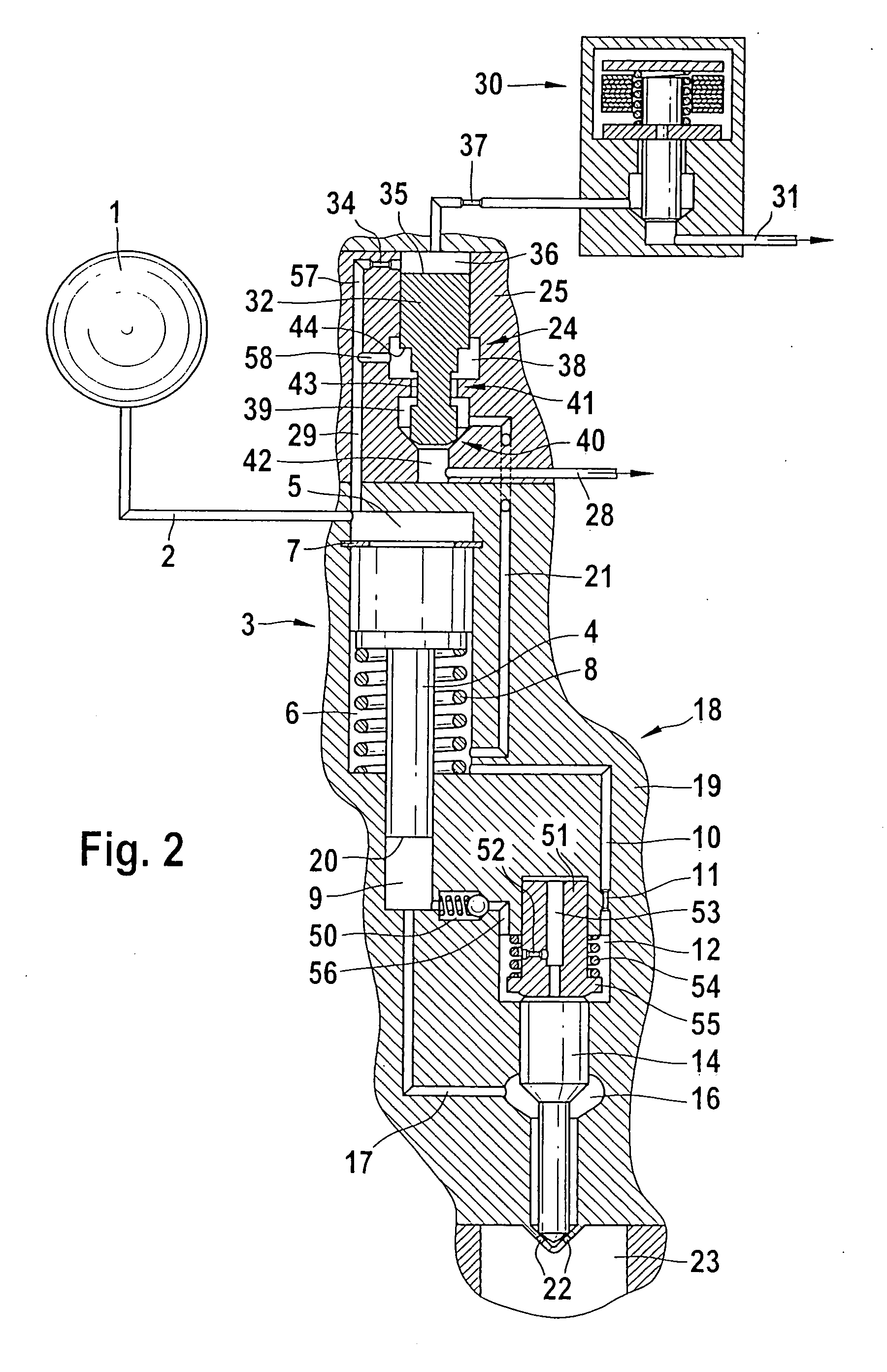

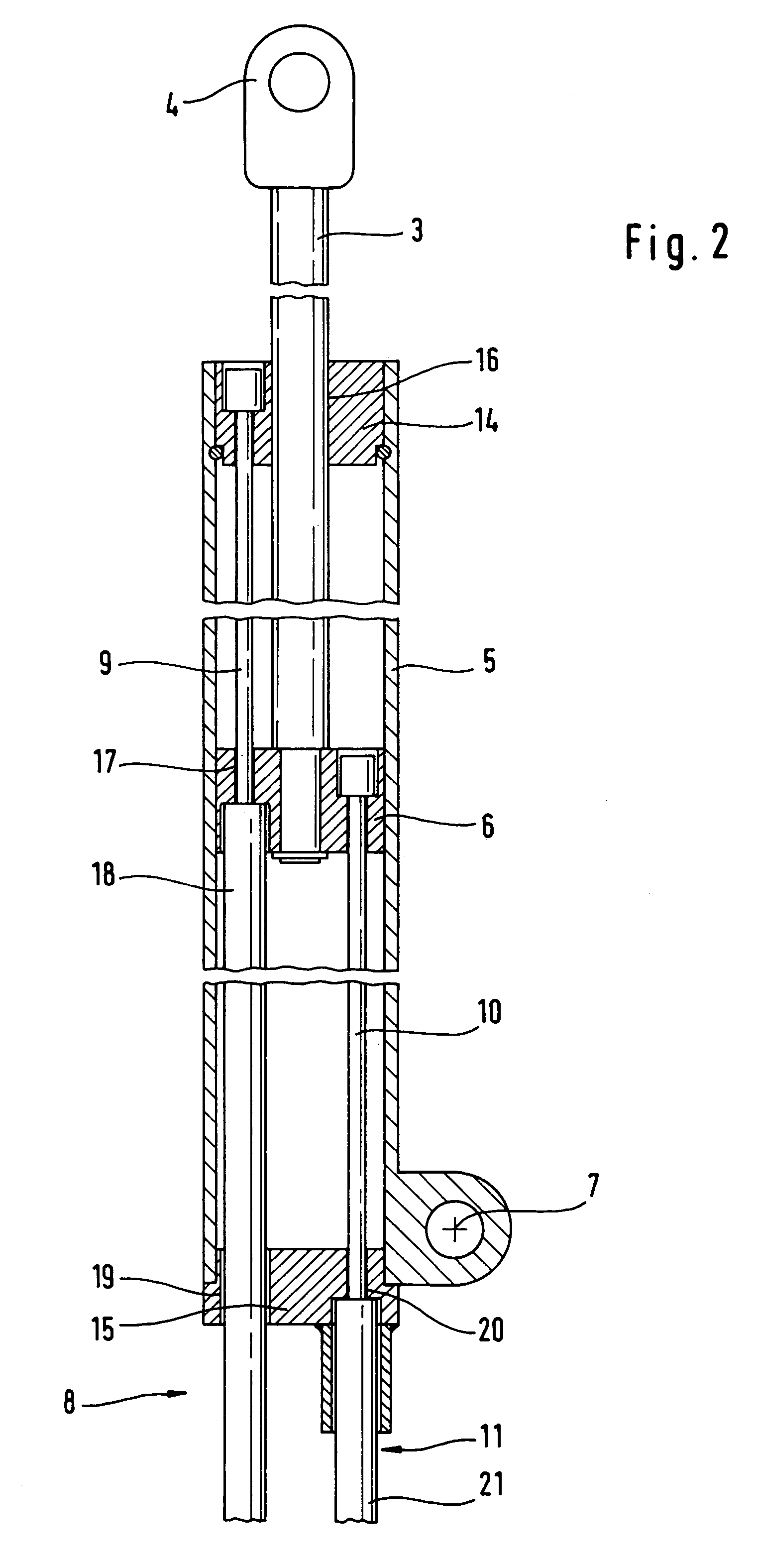

InactiveUS20090250499A1Guaranteed uptimeSave energyStapling toolsPiston pumpsCombustion chamberPiston Guide

A combustion-engined setting tool (10) for driving fastening elements in a workpiece includes a combustion chamber (11), a drive piston (15) displaceable in a piston guide (17) and driven by expanding gases produced in the combustion chamber (11), and a device for returning the drive piston (15) in its initial position as a result of pressure difference between chambers formed on opposite axial sides of the piston head (115), and including a pump (20).

Owner:HILTI AG

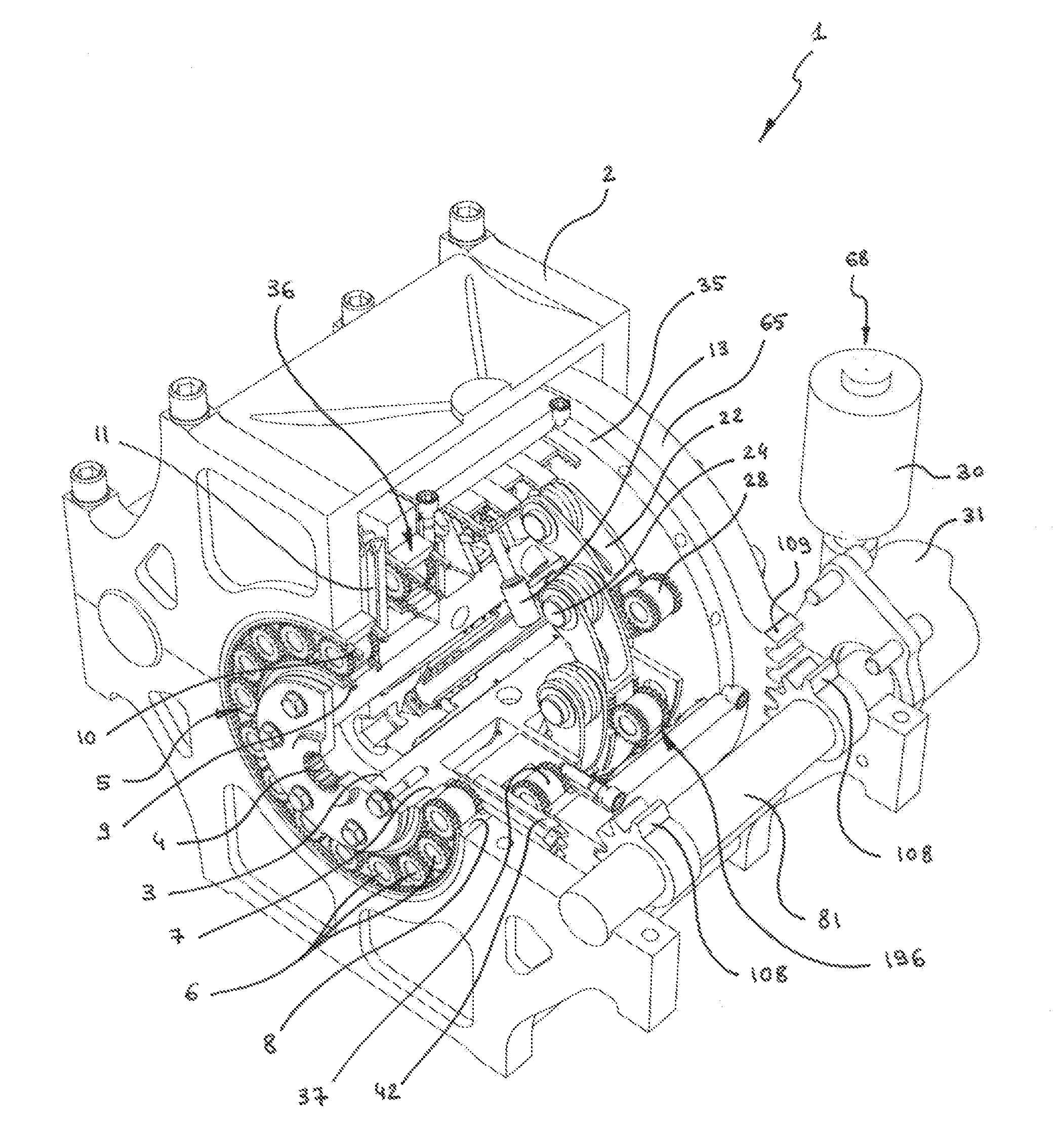

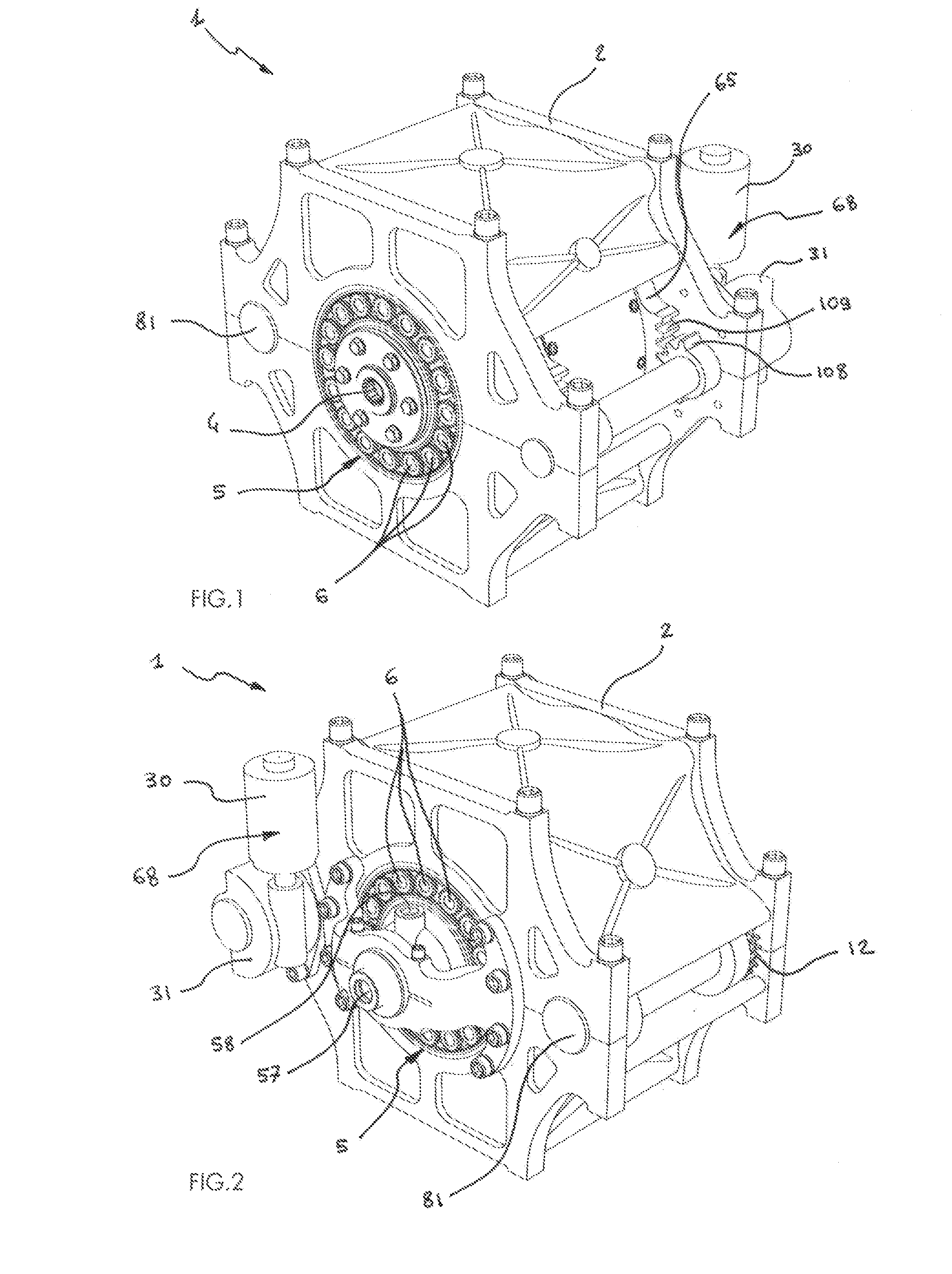

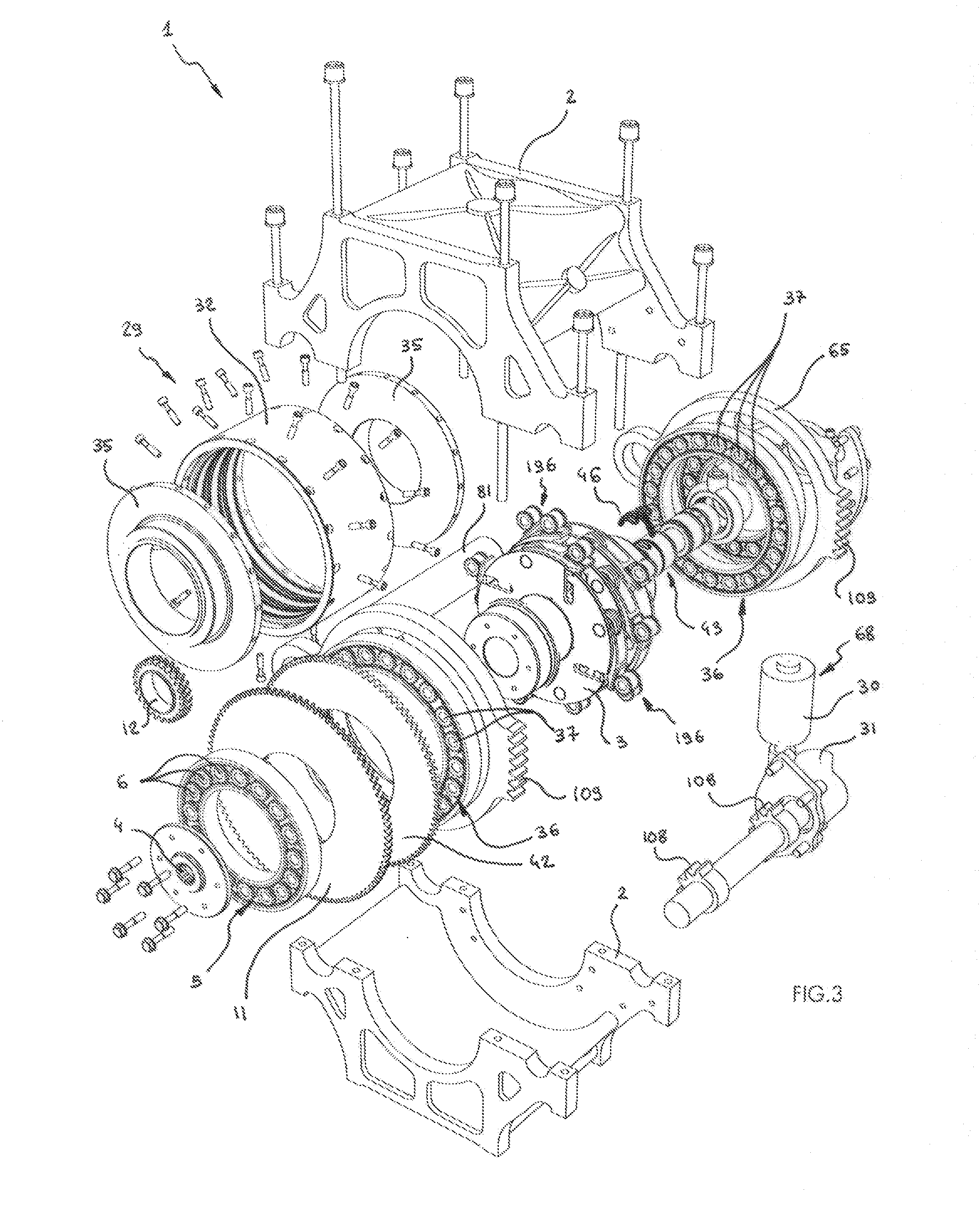

Hydraulic motor-pump with fixed or variable displacement

The fixed or variable displacement hydraulic motor-pump (1) includes a motor-pump central rotor (3) in which a hydraulic cylinder (14) is arranged, the rotor (3) being in sealed contact with an input-output spool valve (43) connecting the cylinder (14) with a motor-pump frame (2) while a hydraulic piston (13) moves in the cylinder (14) to push, using a hydraulic piston guided plunger (18), a tangential arm (22) articulated in the central rotor (3), and a tangential arm antifriction roller (28) on a motor-pump peripheral rotor (29) synchronized in rotation with the motor-pump central rotor (3).

Owner:RABHI VIANNEY

Combustion-engined setting tool

InactiveUS7980440B2Guaranteed uptimeSave energyStapling toolsPiston pumpsCombustion chamberPiston Guide

A combustion-engined setting tool (10) for driving fastening elements in a workpiece includes a combustion chamber (11), a drive piston (15) displaceable in a piston guide (17) and driven by expanding gases produced in the combustion chamber (11), and a device for returning the drive piston (15) in its initial position as a result of pressure difference between chambers formed on opposite axial sides of the piston head (115), and including a pump (20).

Owner:HILTI AG

Combustion-operated setting device

ActiveUS6971568B2Easy constructionAvoid displacementStapling toolsNailing toolsCombustion chamberPiston Guide

The present invention is directed to a combustion-operated setting device for driving fastening elements such as nails, bolts and pins into a substrate, with a combustion chamber (12) that has at least one combustion chamber outlet (13) in which a fuel gas mixture can be ignited for driving a driving piston (16) guided in a piston guide (17), and with a locking and unlocking mechanism (20) for unlocking the at least one combustion chamber outlet (13) in the starting position (31) of the driving piston (16) and for locking the at least one combustion chamber outlet (13) outside of the starting position (31) of the driving piston (16). The locking and unlocking mechanism (20) has a magnet (21) for detecting the driving piston (16) in the starting position (31).

Owner:HILTI AG

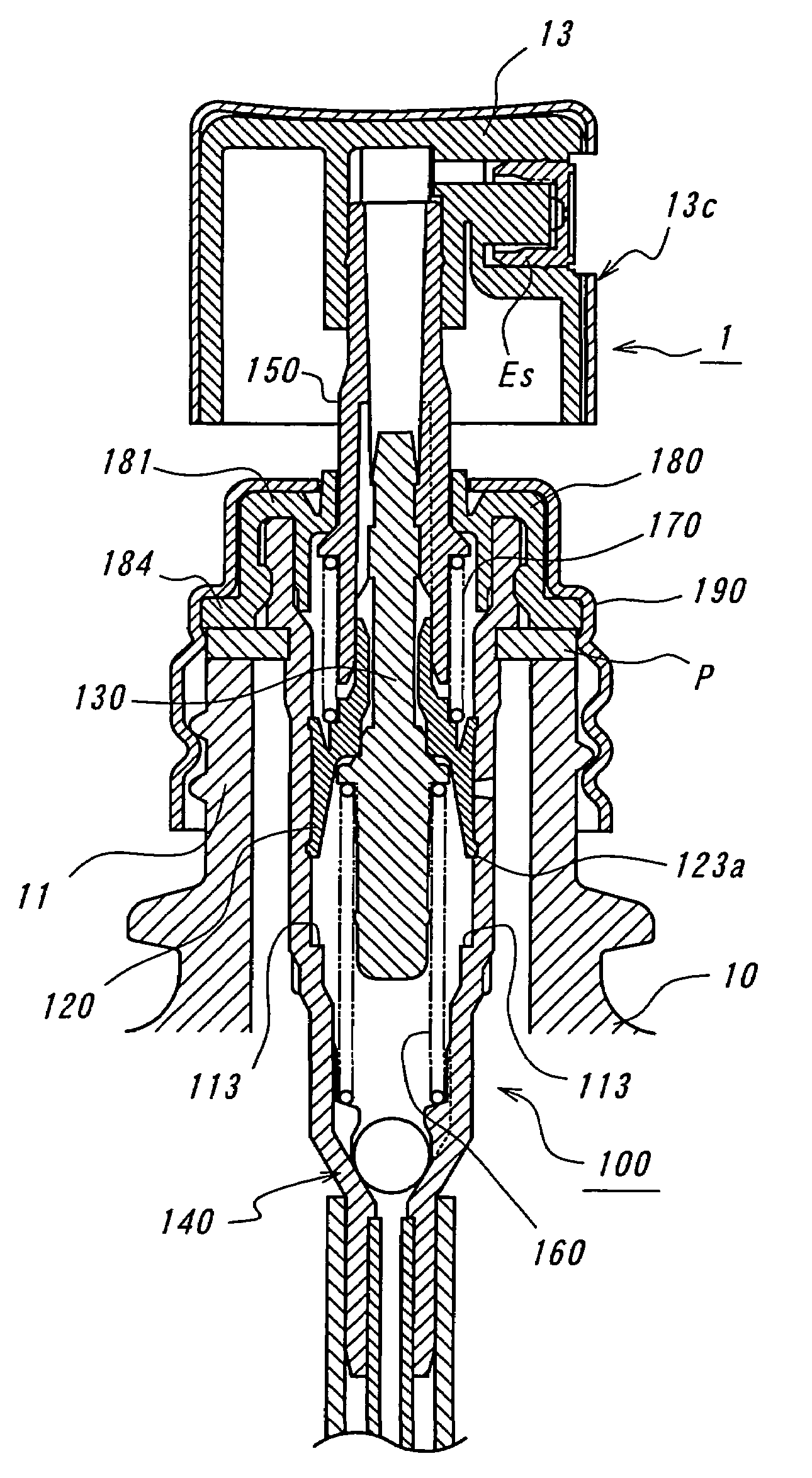

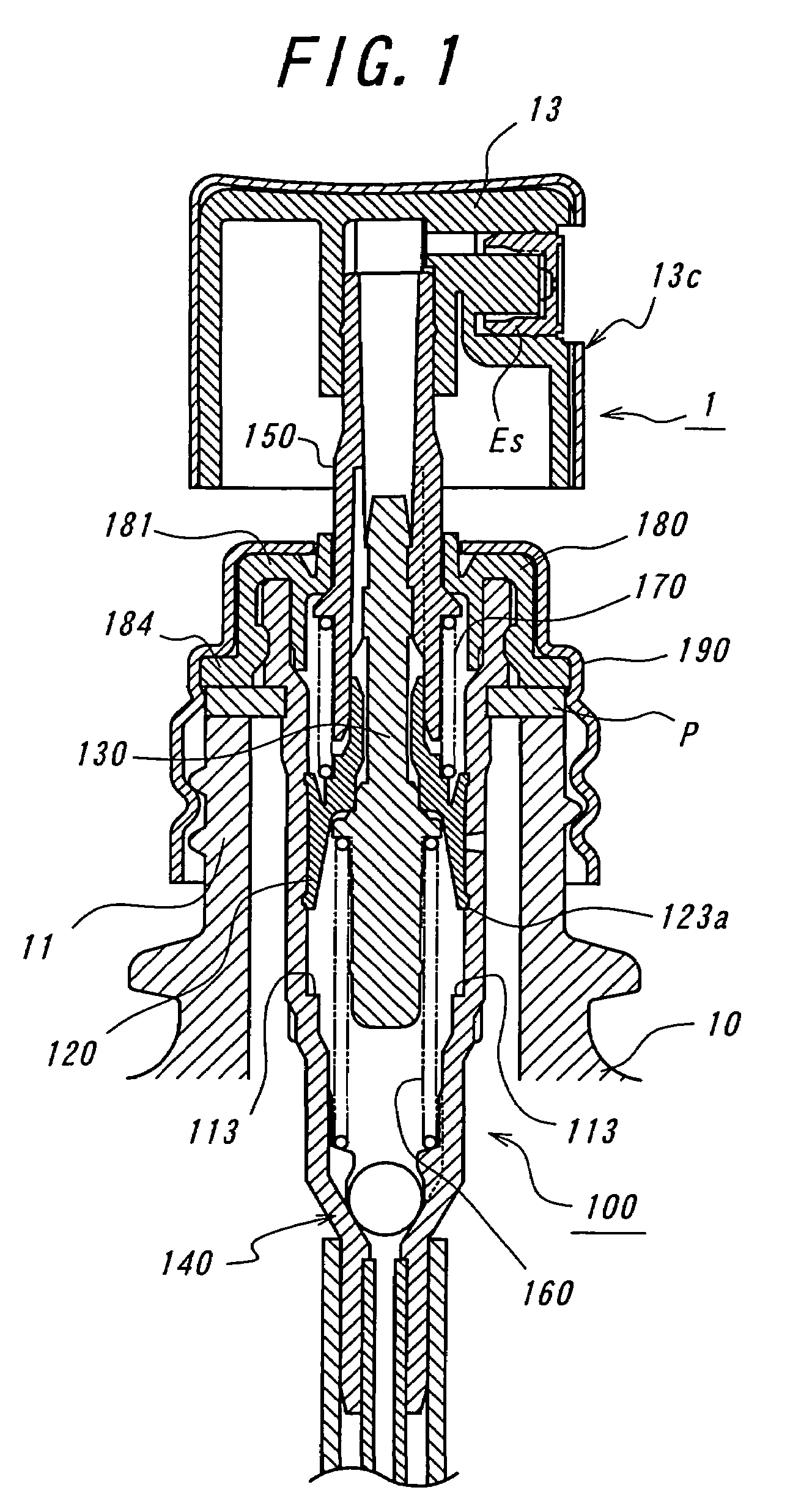

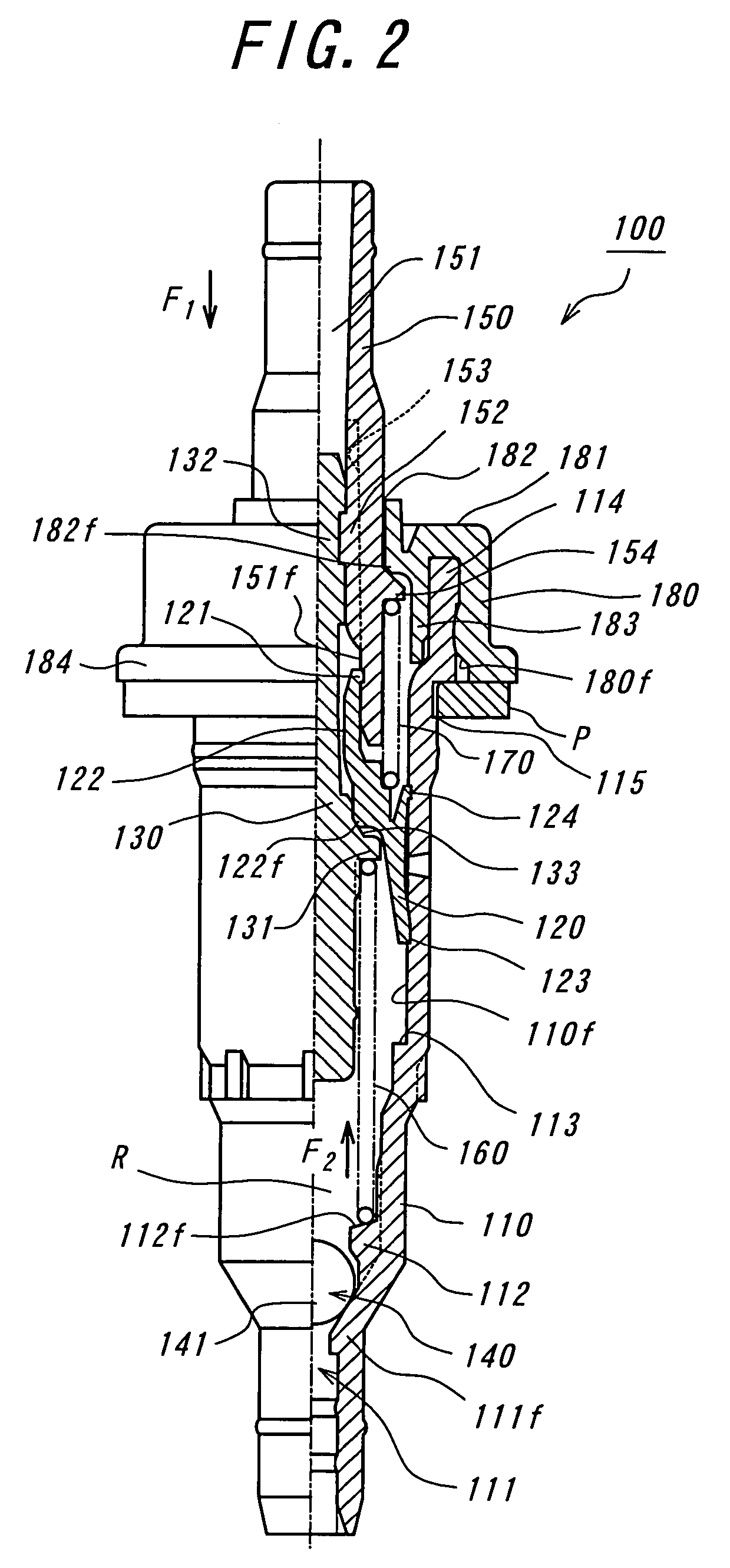

Fuel injector provided with provided with a pressure transmitter controlled by a servo valve

InactiveUS20060243252A1Pressure buildup can be assuredOptimization definitionSpray nozzlesFluid pressure injection controlCombustion chamberDifferential pressure

A fuel injector for injecting fuel into a combustion chamber of an internal combustion engine, including a pressure booster, whose booster piston separates a work chamber, subjected to fuel via a pressure reservoir, from a pressure-relievable differential pressure chamber. A pressure change in the differential pressure chamber is effected via an actuation of a servo valve, which opens or closes a hydraulic connection of the differential pressure chamber to a first low-pressure-side return. The servo valve has a piston guided between a control chamber and a first hydraulic chamber. On this servo valve piston, a hydraulic face that positions the servo valve piston constantly in the opening direction when system pressure is applied and a first sealing seat that closes or opens a low-pressure-side return are embodied.

Owner:ROBERT BOSCH GMBH

Brake master cylinder and manufacturing method therefor

InactiveUS20050044852A1Easy constructionReduce in quantityPiston ringsRotary clutchesMaster cylinderPiston Guide

In a brake master cylinder, when a first piston is pushed forward, first and second fluid chambers of a cylinder which are partitioned respectively by first and second cup seals supply brake fluids therefrom to first and second brake systems. Even when slightly inclined upon receiving a pushing force, the first piston is slidably guided along a first sleeve which is softer than the first piston, without coming into contact with the cylinder body. Since the first piston is not abrasively damaged, it does not occur that the first cup seal is injured at a slide guide portion thereof. Further, each of the first sleeve and a second sleeve is separated at one portion in the circumferential direction throughout the whole length thereof, so that by being inserted from an opening end of the cylinder, the sleeves can be fit respectively in sleeve recesses which are annually formed respectively at a first piston guide portion of a cylinder internal surface, which is bored in a cylinder body as one piece, and another portion between first and second piston guide portions of the cylinder internal surface.

Owner:ADVICS CO LTD

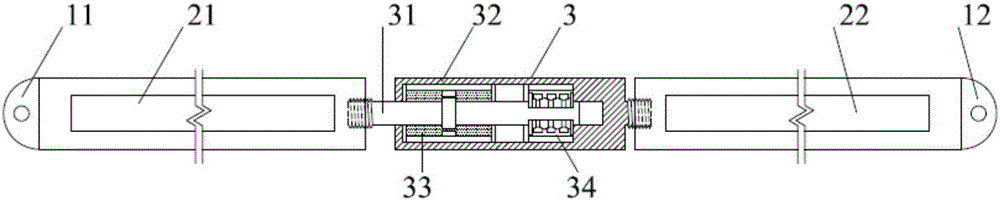

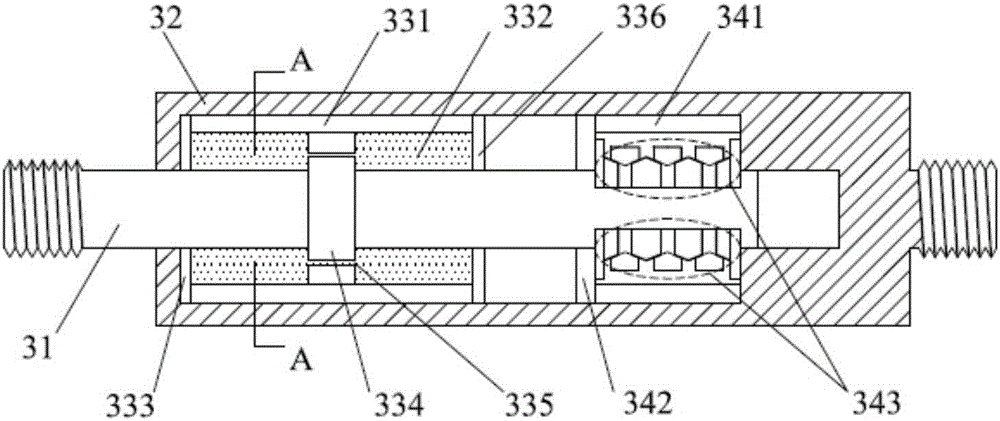

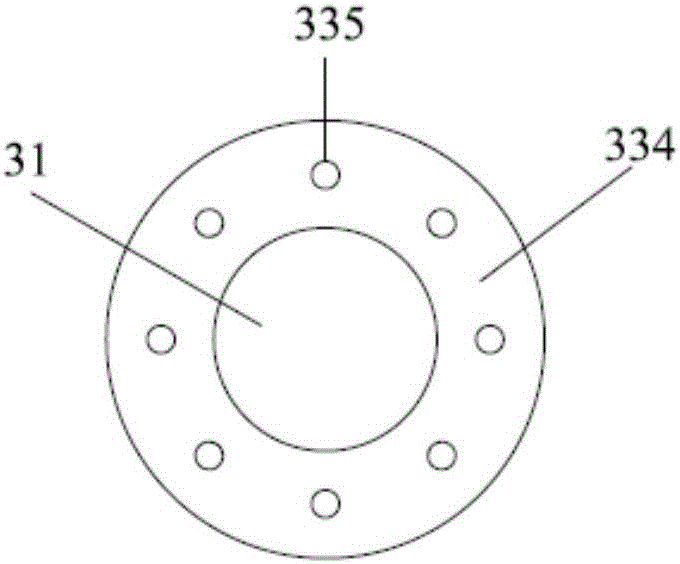

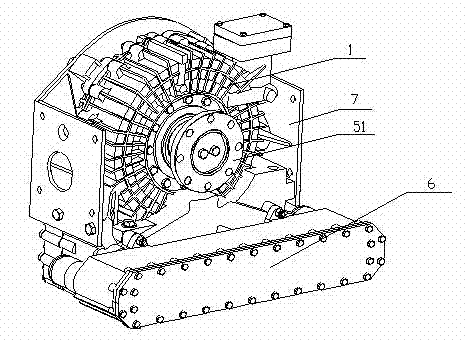

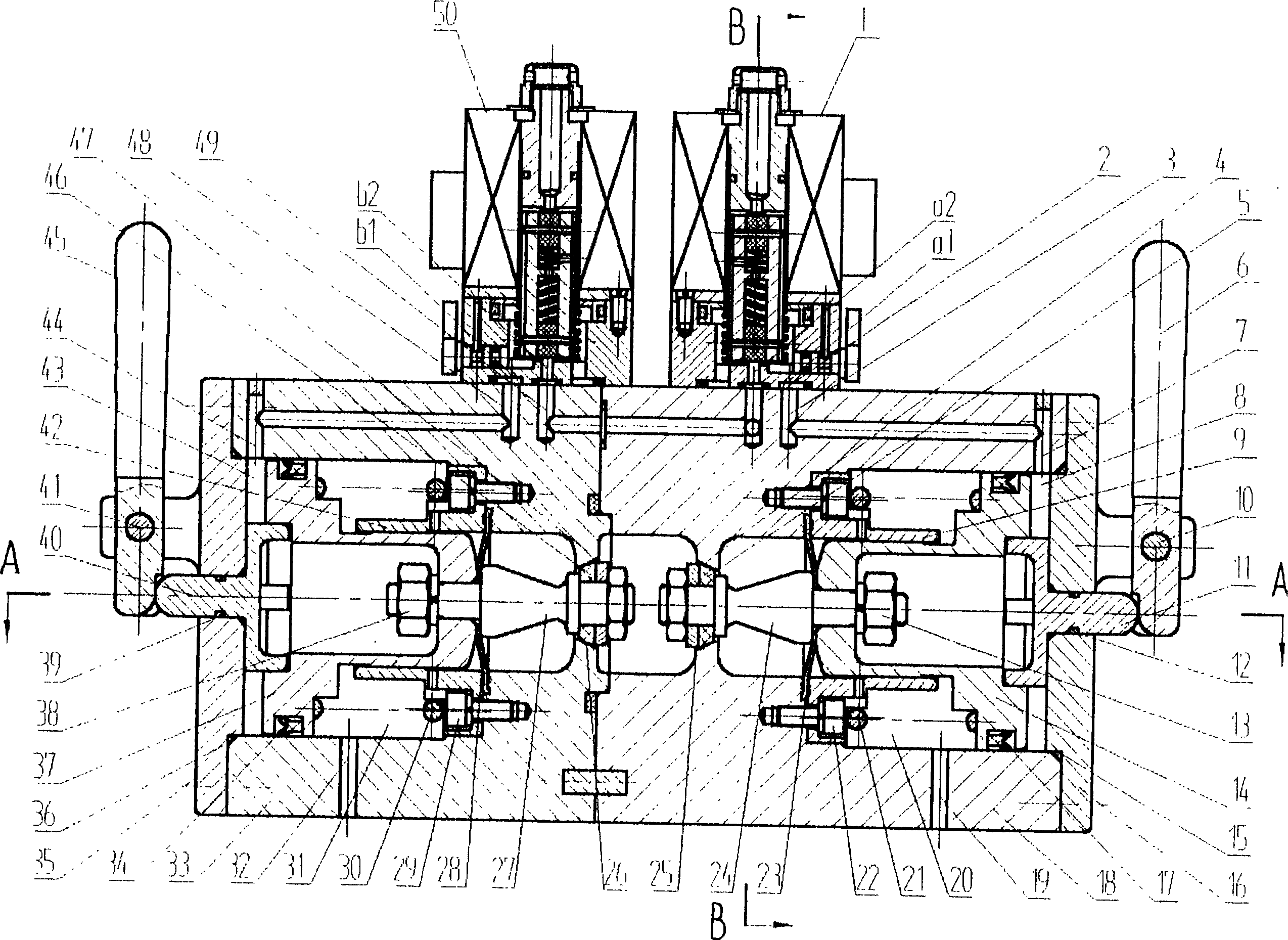

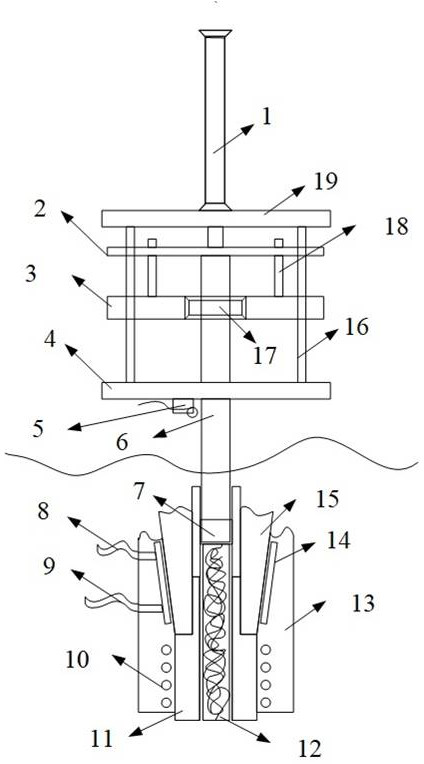

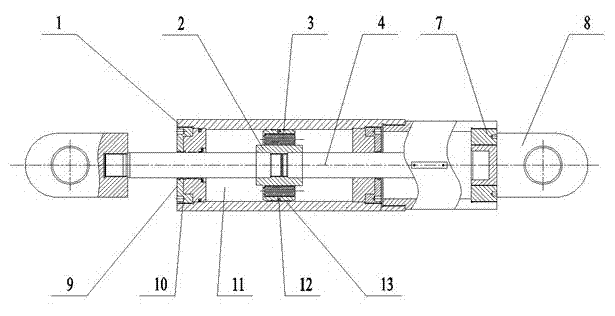

High-performance support component based on self-reset energy dissipation

ActiveCN106223507AAvoid replacementImprove the shortcomings of insufficient energy consumption at low frequenciesProtective buildings/sheltersShoresLoad resistancePiston Guide

The invention relates to a high-performance support component based on self-reset energy dissipation. The high-performance support component comprises a self-reset energy dissipation part (3) and main body support cylinders respectively mounted at two ends of the self-reset energy dissipation part (3), wherein end joints are further arranged on the main body support cylinders; and the self-reset energy dissipation part (3) comprises an outer cylinder (32) and a piston guide rod (31), a viscous damper cavity (33) and a shape memory alloy ring spring group cavity (34) are further arranged in the outer cylinder (32), one end of the piston guide rod (31) sequentially penetrates through the viscous damper cavity (33) and the shape memory alloy ring spring group cavity (34), the other end is fixedly connected with one main body support cylinder, and the other main body support cylinder is further fixedly connected to the outer cylinder (32). Compared with the prior art, the high-performance support component integrates important anti-earthquake functions such as lateral load resistance, bending resistance, self-reset and wide frequency domain energy dissipation, the disadvantage of insufficient energy dissipation of a viscous damper under low frequency and high temperature is improved, and the high-performance support component does not need to be replaced after the earthquake.

Owner:TONGJI UNIV

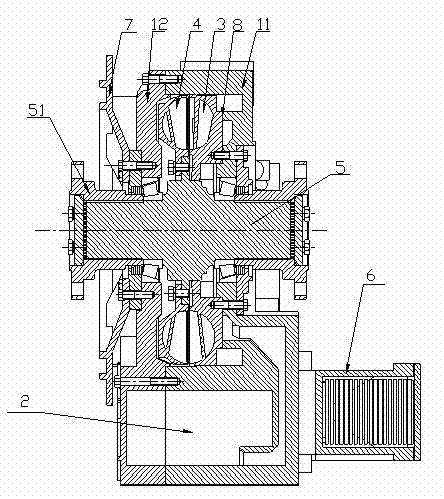

Hydraulic retarder

InactiveCN103047322APrevent movementIncrease the oil inlet speedLiquid resistance brakesPiston GuideEngineering

The invention discloses a hydraulic retarder. The hydraulic retarder comprises a hydraulic retarder shell, an oil storage tank, a stator, a rotor and a heat exchanger, wherein the oil storage tank, the stator and the rotor are all arranged in the hydraulic retarder shell, and the heat exchanger is fixedly arranged outside the hydraulic retarder shell; oil inlet holes a and oil outlet holes are arranged on the stator and along the periphery of the stator; and a second oil inlet channel is internally provided with a check valve, the check valve comprises a piston, a spring, a piston guide hole and an oil discharge groove, one end of the piston is pressed at the end part of the heat exchanger shell to block an oil inlet, the other end of the piston extends into the piston guide hole to be matched with the piston guide hole in a sliding mode, the spring is sheathed on the piston, one end of the spring is pressed on the piston, the other end of the spring is pressed on the hydraulic retarder shell, and the piston guide hole is communicated with an oil outlet by the oil discharge groove. When oil in the piston guide hole is compressed by the piston, the oil is discharged by the oil discharge groove, so that the counter-acting force is not generated to the piston to block the movement of the piston, the oil feeding speed of the retarder is enhanced, and the response time of the retarder is improved.

Owner:韦健全

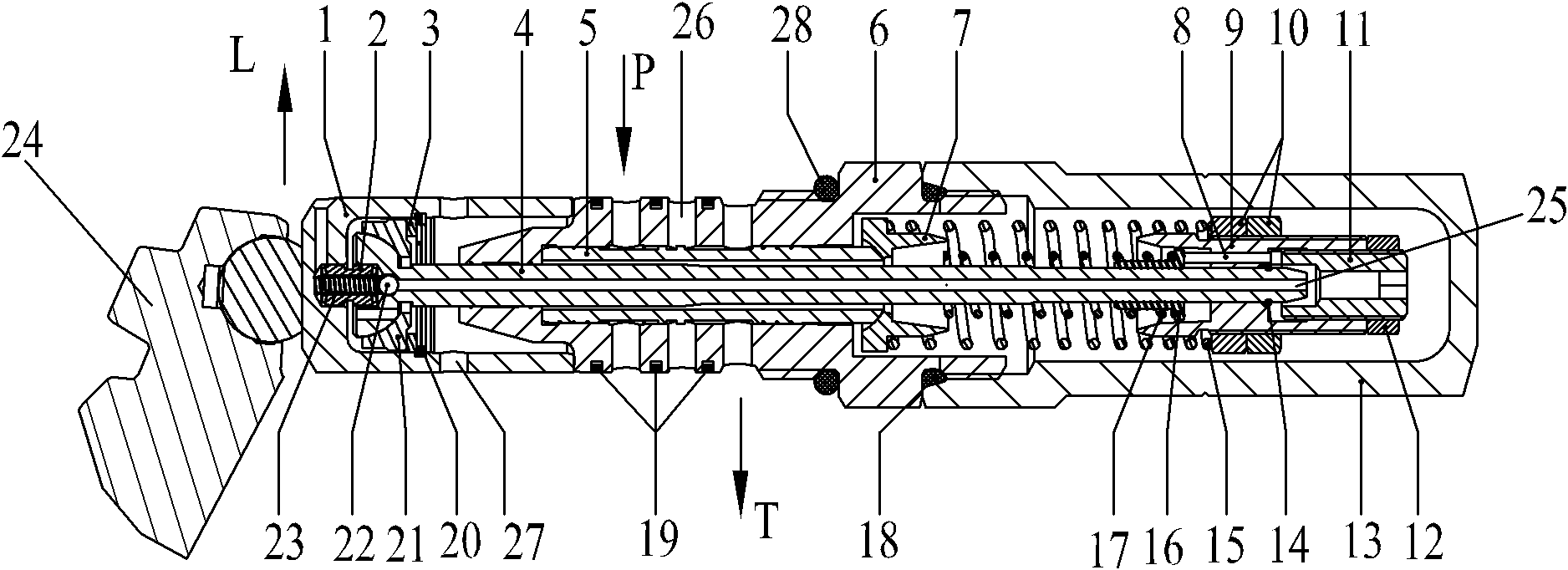

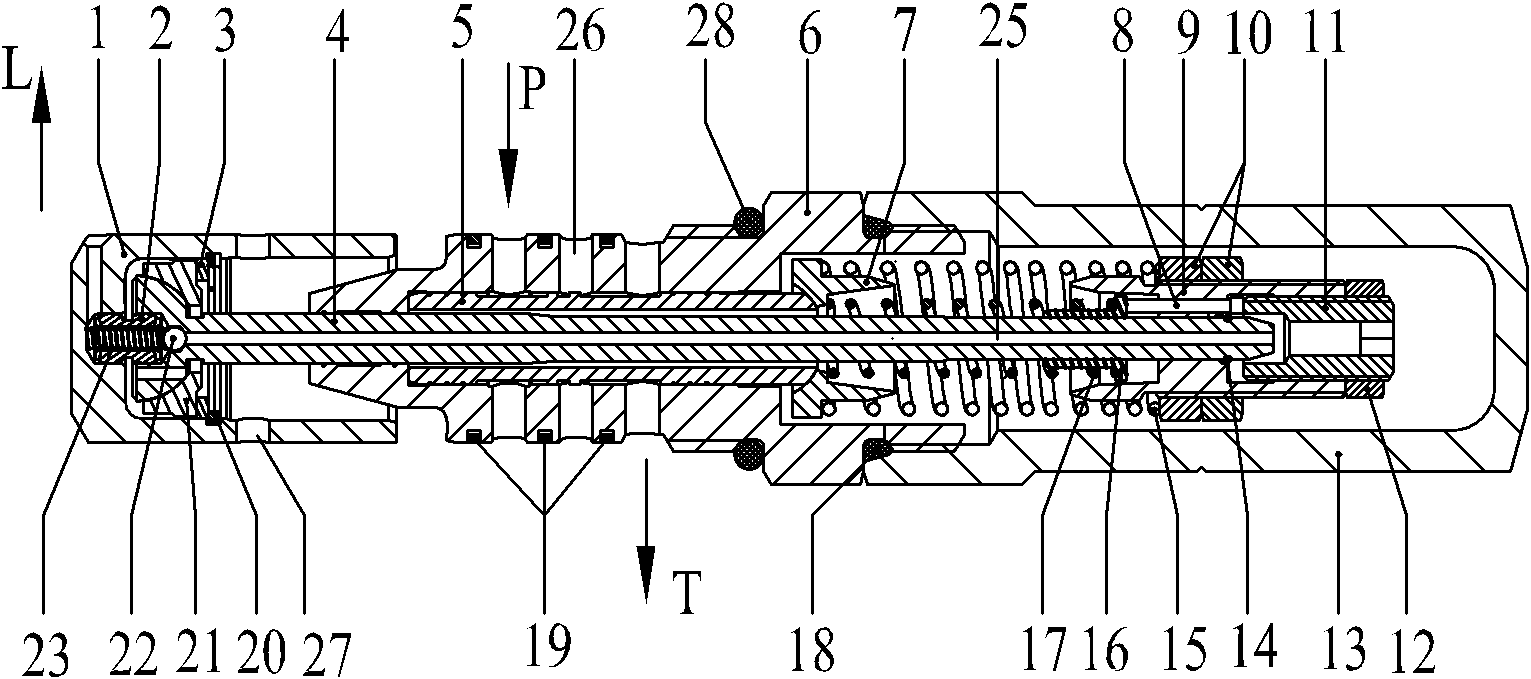

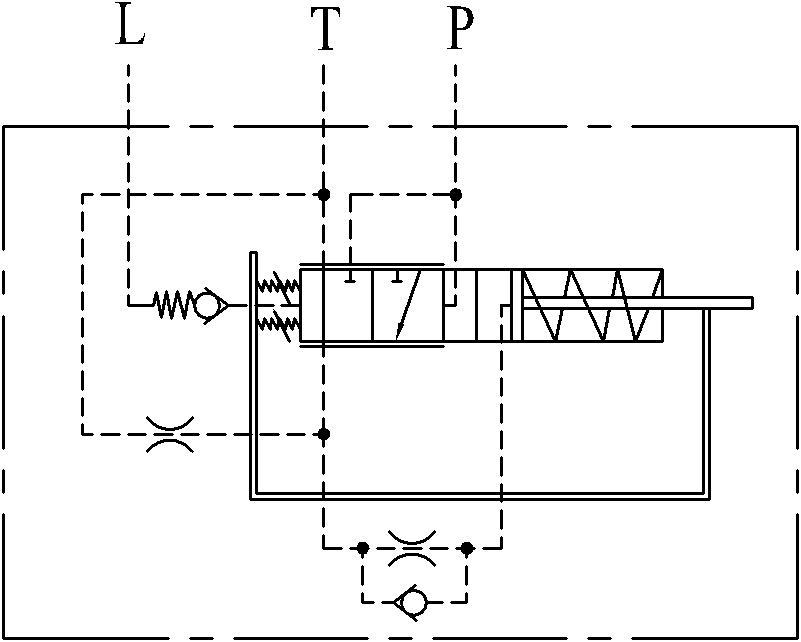

Three-position three-way hydraulic change valve

The three-position three-way water hydraulic reversal valve as directional control element of hydraulic system is formed from two symmetrically-connected inverted mouth cone valves with identical structure, each of them includes valve body with inverted mouth cone valve seat, value core, rubber diaphragm, cylinder piston, cylinder piston guide sleeve, reset spring and end cover. The rubber diaphragm can separate the internal space of the valve body into working cavity and cylinder cavity, the valve body as working cavity is equipped with external-connected working interface, an electromagnetic pilot is mounted on the valve body, and said rubber diaphragm can isolate the working main flow channel from cylinder cavity, so that it can prevent the working component in the cylinder from being corroded and worn.

Owner:HUAZHONG UNIV OF SCI & TECH

Friction stir additive device and additive manufacturing method

ActiveCN112496522AAchieve continuous supplyAchieve frictional heat generationNon-electric welding apparatusPiston GuideEngineering

The invention relates to the technical field of friction stir welding, in particular to a friction stir additive device and an additive manufacturing method. According to the friction stir additive device, hollow cavities which communicate with each other are formed in a stirring head and a knife handle, and the hollow cavity in the working end of the stirring head is provided with an opening; a wire is provided for the hollow cavities through a wire feeder; an extrusion part moves in the hollow cavities to extrude the wire, the wire is extruded into a bar to achieve friction heat production,and therefore, friction stir additive manufacturing is achieved, and continuous supply of materials during feeding can be achieved. By arranging a guide support to bear the extrusion part and providesliding support for an auxiliary plate, the auxiliary plate can be connected with a piston guide rod in a clamped mode, circumferential rotation of the piston guide rod is limited, and therefore, follow-up of a piston and the piston guide rod in the extrusion hollow cavity is avoided, and stability is improved.

Owner:安徽万宇机械设备科技有限公司

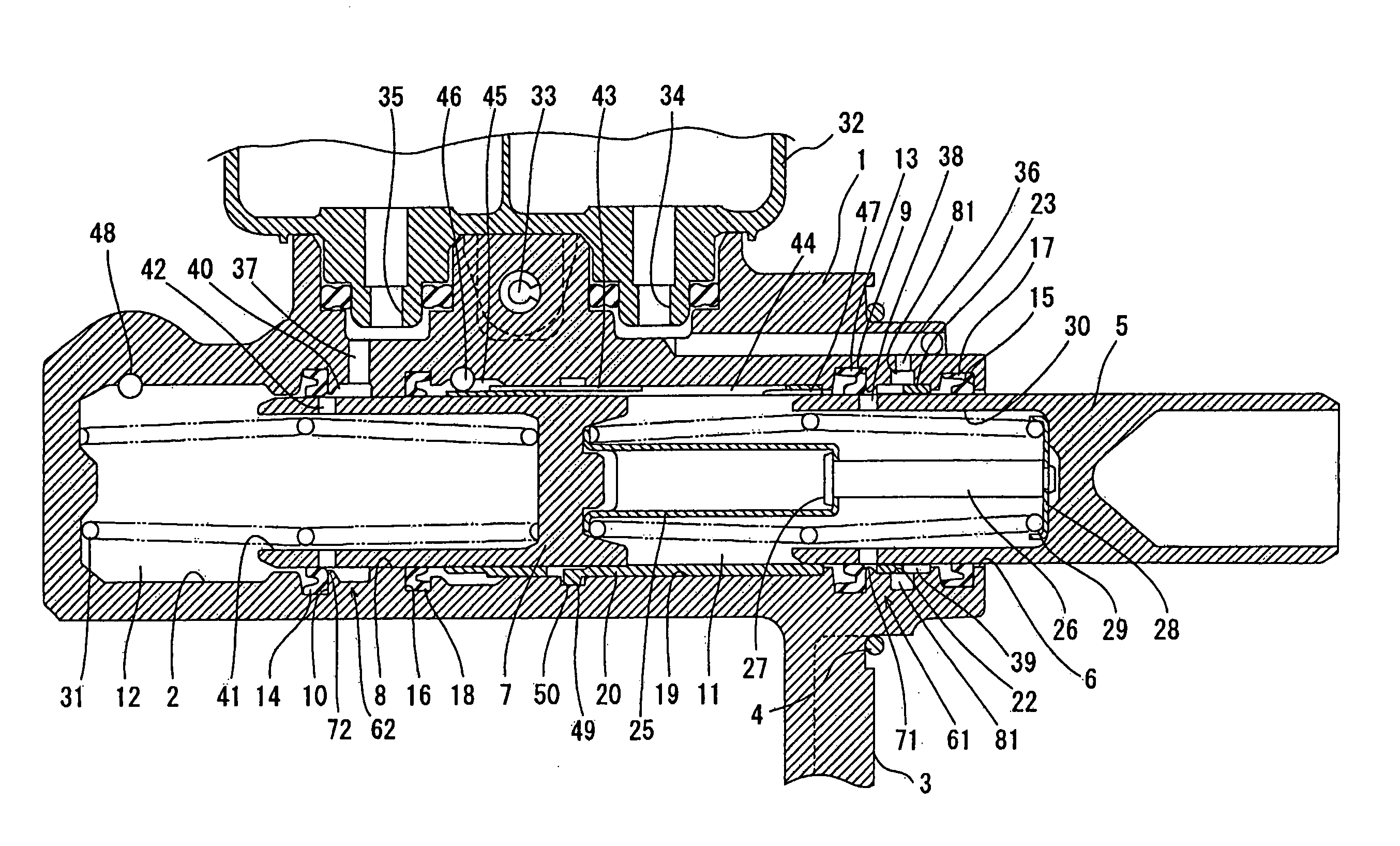

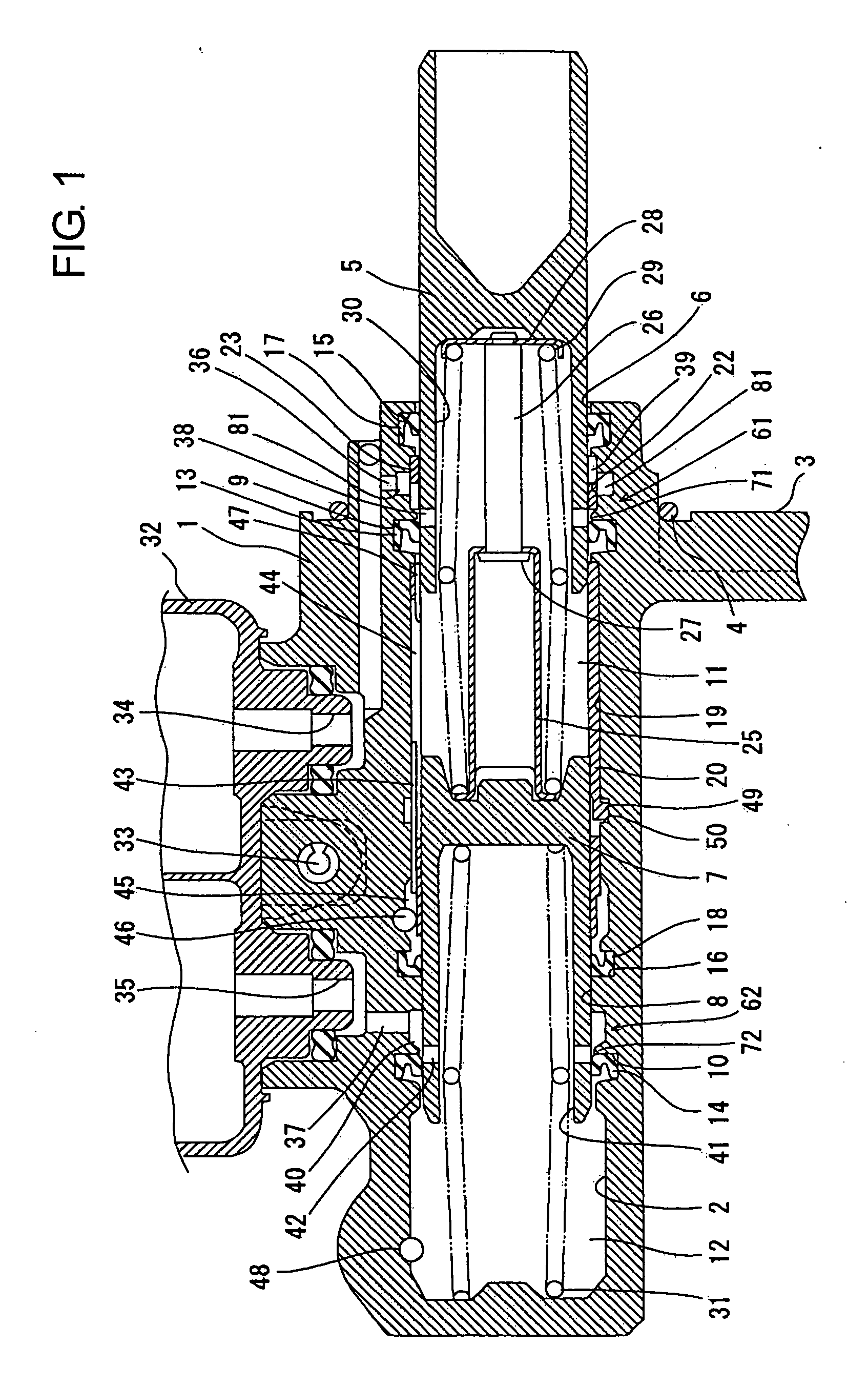

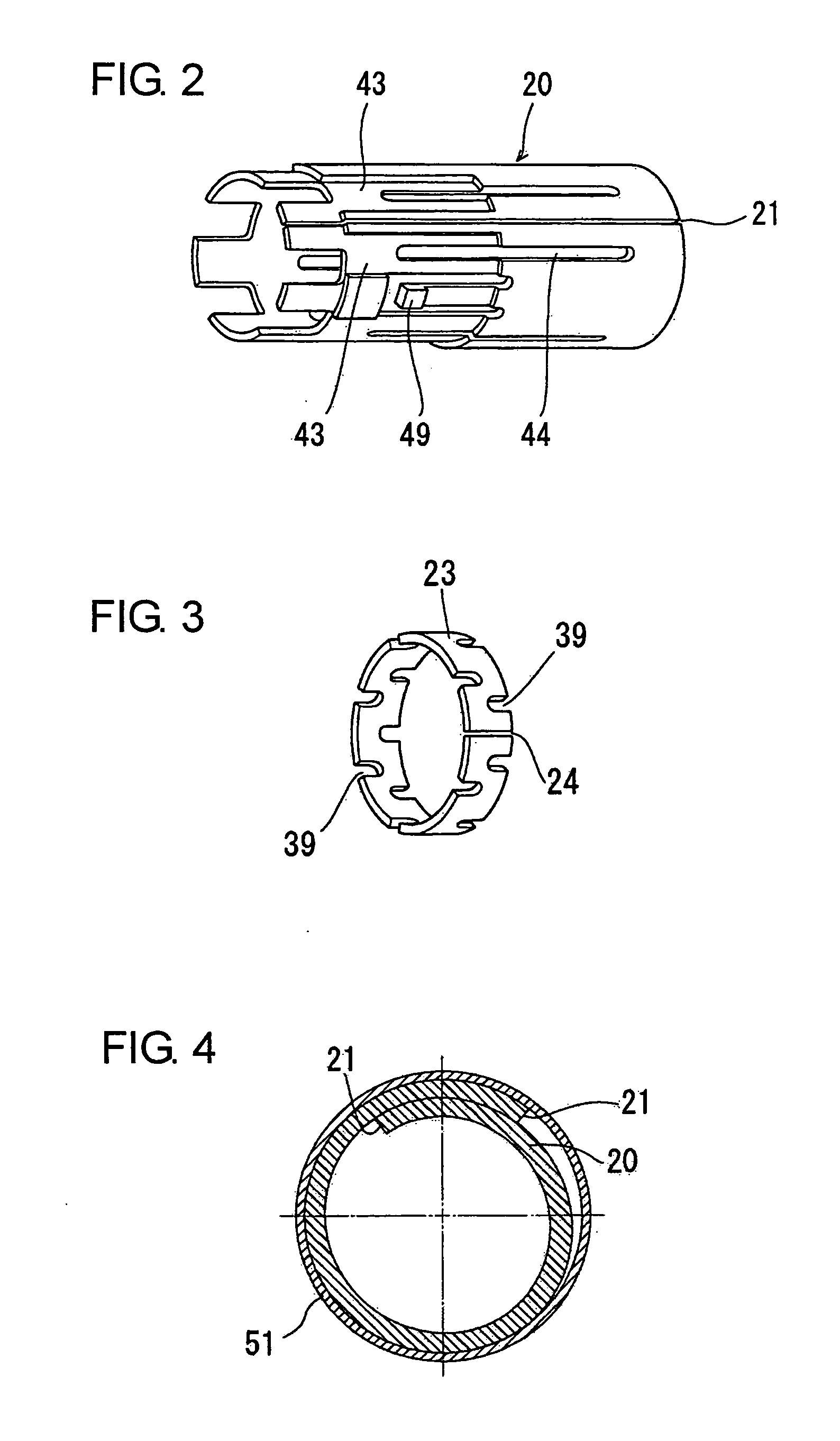

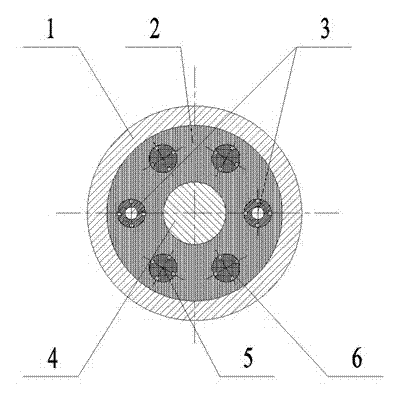

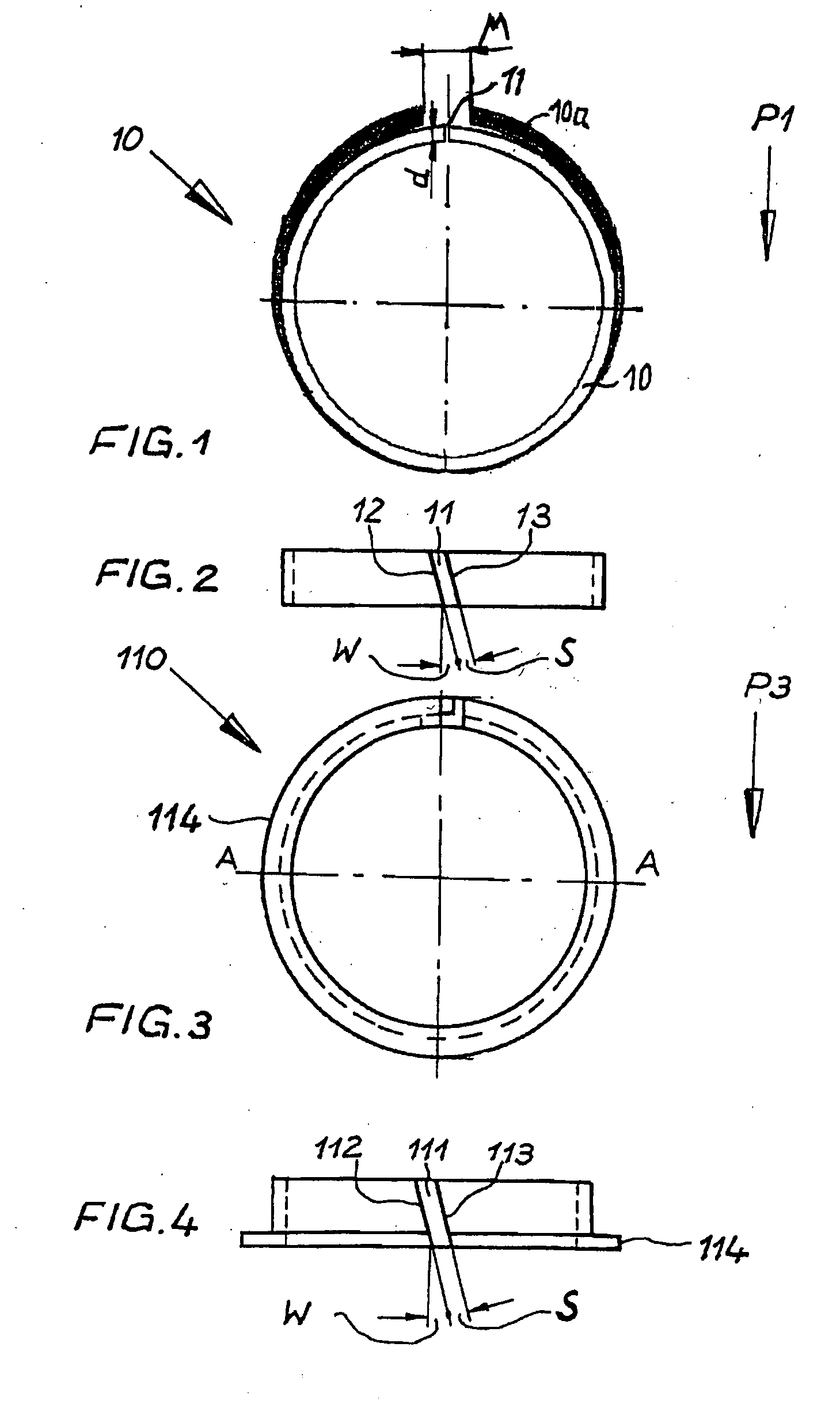

Electromagnetic reciprocating compressor with spring assembly mounted around piston

InactiveUS6015273AShorten the lengthReduce lateral forceEngine sealsPiston pumpsReciprocating motionPiston Guide

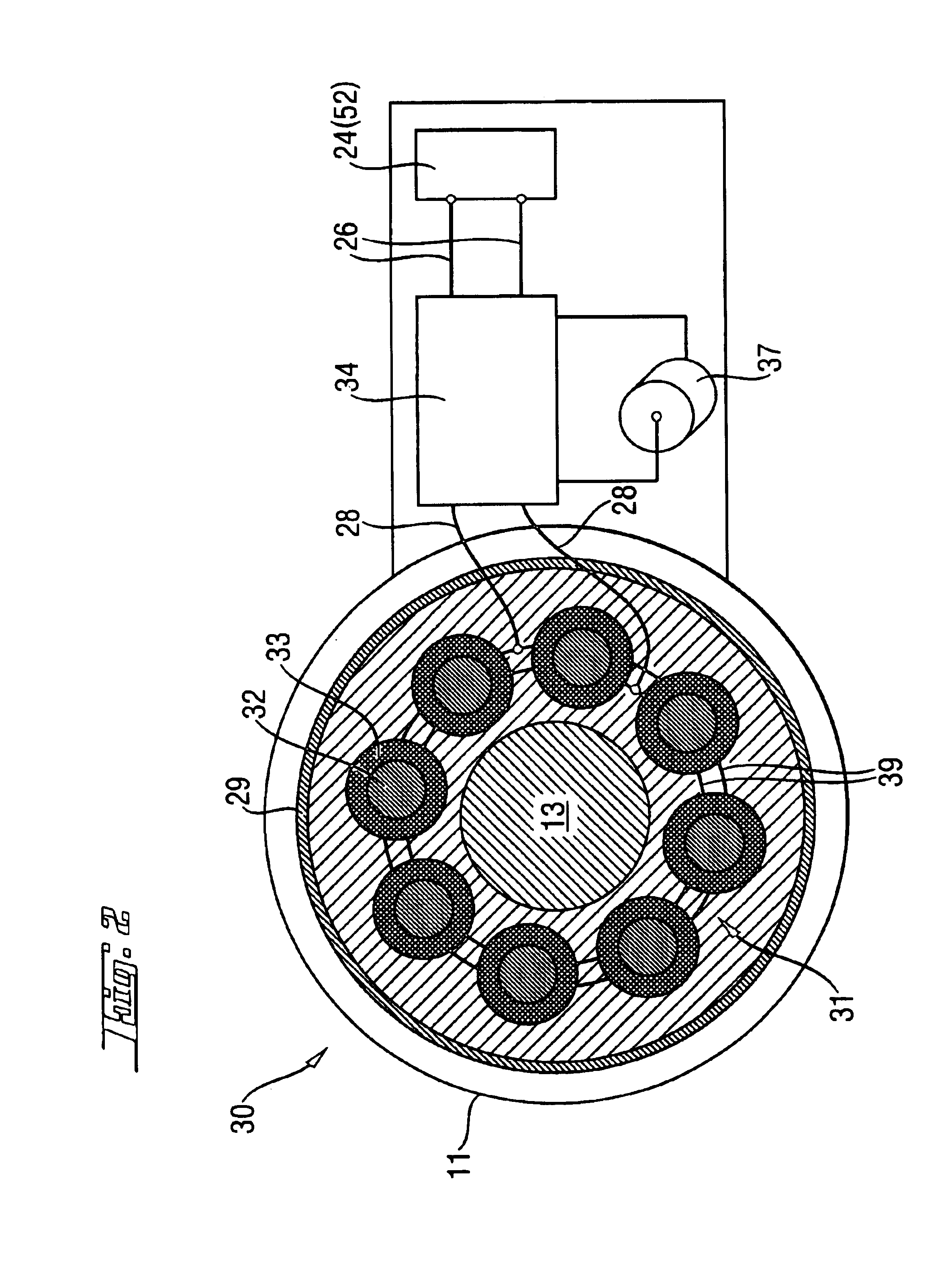

PCT No. PCT / GB95 / 02901 Sec. 371 Date Jul. 10, 1997 Sec. 102(e) Date Jul. 10, 1997 PCT Filed Dec. 8, 1995 PCT Pub. No. WO96 / 18037 PCT Pub. Date Jun. 13, 1996An electromagnetic reciprocating compressor has a body (1, 2), a piston (10) reciprocating in the body, and an electromagnetic drive (22, 23, 24) for the piston. The piston has a piston head (11) which slides in a cylinder (12) in the body to effect compression of fluid in the cylinder during operation of the compressor and, axially spaced from the piston head, a piston guide member (13) slidingly movable on a guide surface (14) provided by the body. The compressor has a compression spring arrangement (20) comprising at least one helical compression spring (20a, b) acting to drive the piston axially. The spring (20a, b) is mounted around the piston and is at least partly located within the cylinder during at least part of the piston stroke but is outside the working volume of fluid undergoing compression.

Owner:PEGASUS

Setting tool

ActiveUS7055727B2Service life of both the stop member and the setting piston is noticeably increasedAvoid interferenceStapling toolsNailing toolsPiston GuideStops device

Owner:HILTI AG

Anti-blockage descaling timing self-closed water saving device

InactiveCN101545556ALong water lifeOperating means/releasing devices for valvesFluid-delivery valvesWater savingPiston Guide

The invention relates to an anti-blockage descaling timing self-closed water saving device, which is a universal mechanical core device for manufacturing various domestic water saving faucets, toilet device flashing valves, a shower valve or other fluid self-closed water-saving products, and consists of a button, a timing pointer, a valve rod, a pressurizing hole spring cleansing pin, a cylinder, a piston assembly, a piston cup ring and a piston guide holder which are connected together. The device not only can prevent blockage and descale automatically, but also can satisfy construction installers and users to adjust the time delay self-closed time or water amount according to requirements on different water pressures and different water-saving amounts; and besides, the device is convenient and practical with zero fault, saves water and has long service life.

Owner:温州帝威斯感应洁具有限公司

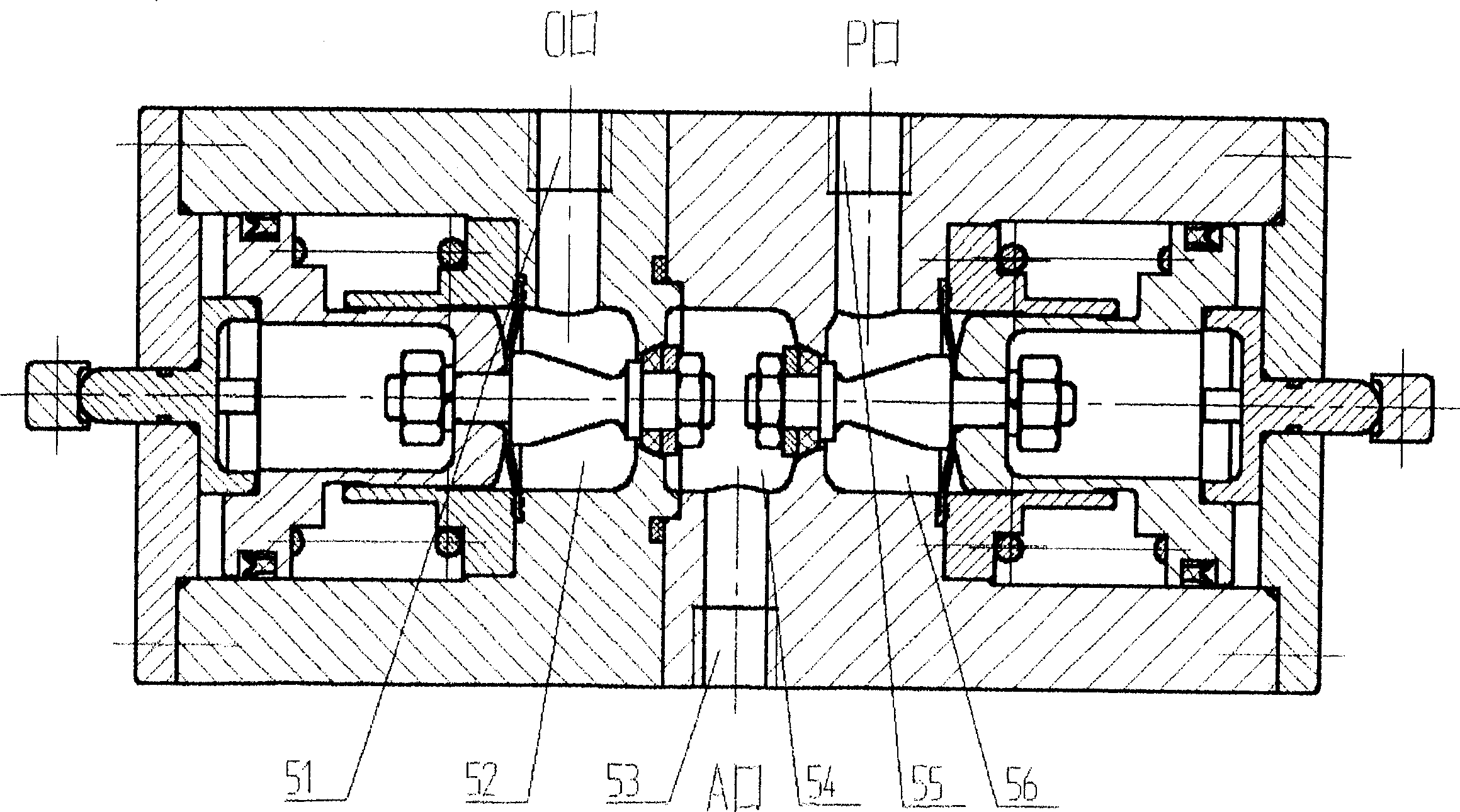

Sleeved viscous damper capable of damping variable parameters and design method thereof

ActiveCN102888903AOptimized vibration reduction (shock) effectSimple designShock proofingPiston GuideEconomic benefits

The invention relates to a sleeved viscous damper capable of damping variable parameters and a design method thereof. The sleeved viscous damper capable of damping variable parameters comprises a cylinder body of which two ends are sealed by end covers and in which a damping medium is filled, an axial clearance-free piston positioned in the cylinder body, a piston guide rod connected with the axial clearance-free piston, and a sleeved piece with a damping hole and a sleeved piece without a damping hole which are arranged in a sleeved mounting hole, wherein the axial end face of the axial clearance-free piston is provided with the sleeved mounting hole; and the axis of the sleeved piece with the damping hole is provided with a damping hole. The design method comprises the following steps of: determining a sleeved piece combination with the damping hole; mounting or replacing the sleeved piece with the damping hole; sealing the sleeved mounting hole which is not used; and finishing design of the variable parameters. The sleeved viscous damper is simple in structure and method and rapid in design. According to the method, a pore type viscous damper is developed and machined and is subjected to experimental operation, the efficiency can be improved, the material cost is reduced, and the economic benefits and social benefits are obvious.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

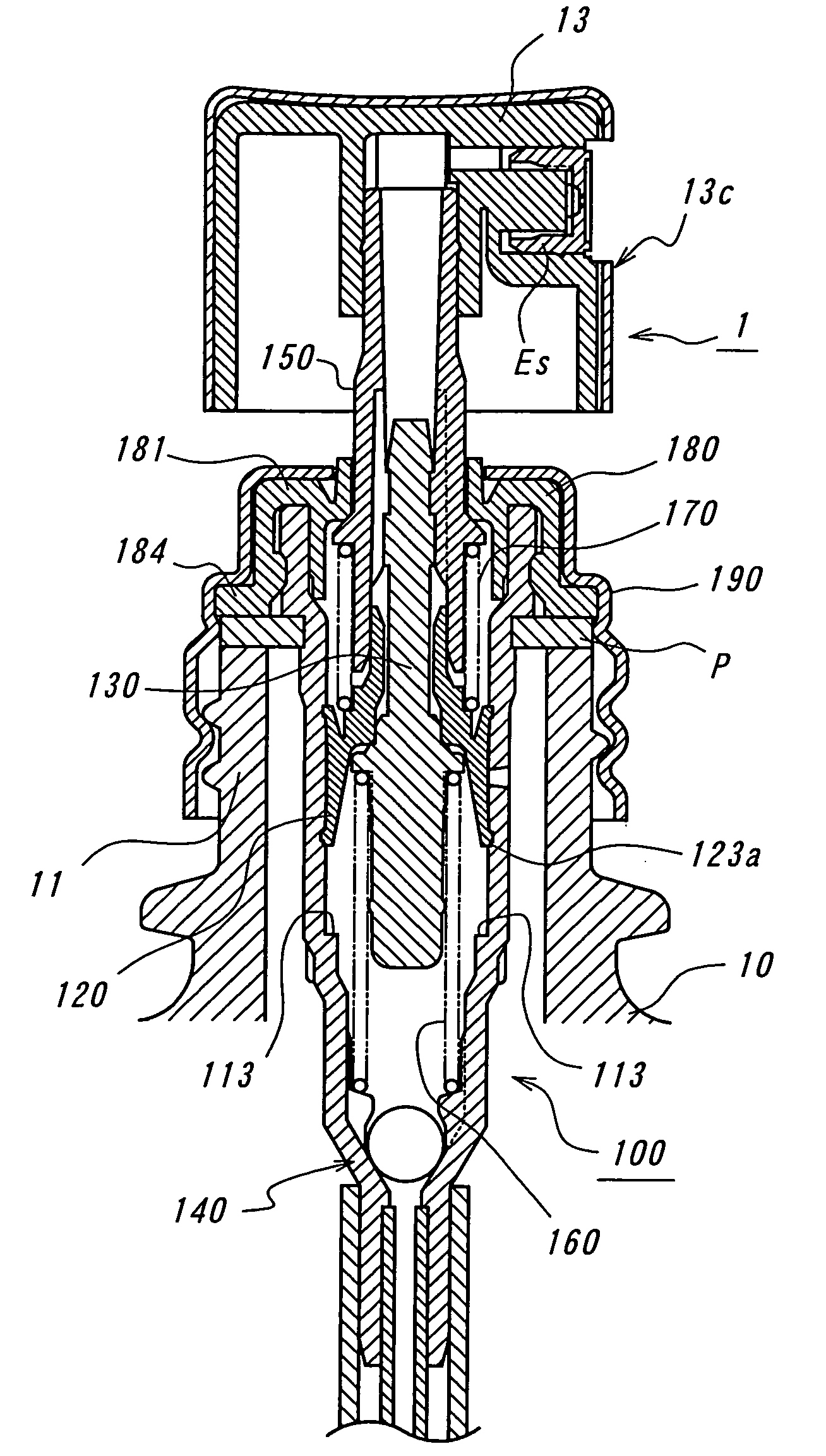

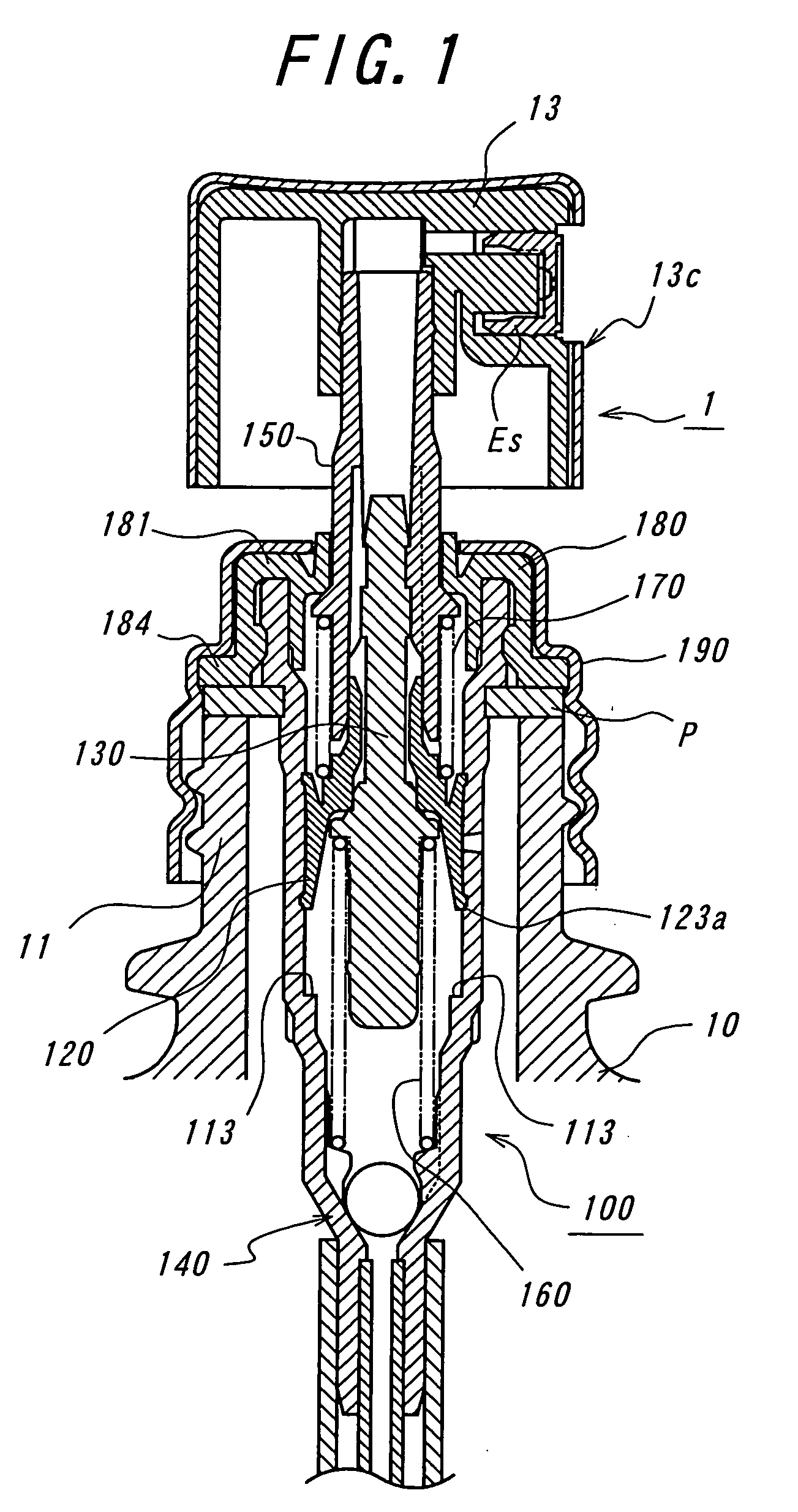

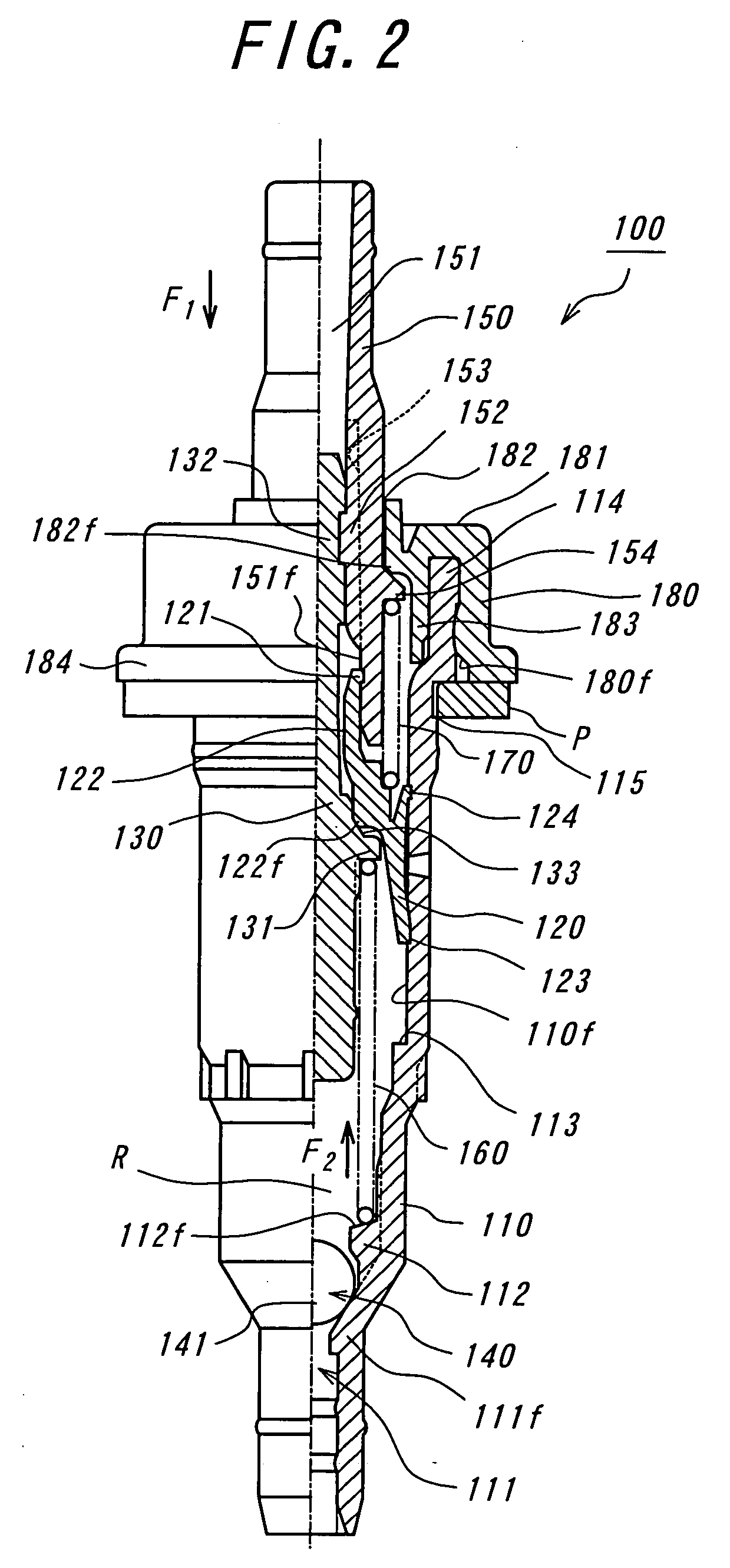

Pressure accumulator-type liquid spraying device

An accumulator-type liquid sprayer includes a piston arranged in a cylinder, a piston guide extending through a passage extending therethrough in an axial direction of the piston, so as to be engageable with, and disengageable from the piston, cooperating with the piston and the cylinder to form a space region for sucking and pressurizing a liquid, a check valve for opening a suction port of the cylinder during suction of the liquid, and a hollow stem slidably fitted with an outer side of the piston in a liquid-tight manner and engaging with an end portion of the piston guide. A first resilient member urges the piston guide against the piston for maintaining a closed state of the passage in the piston, and a second resilient member urges the piston against the piston guide for adjusting a spraying pressure of the liquid. A stopper is arranged in the cylinder, for positioning the piston before the content is sprayed to provide increased contact surface pressure so as to maintain the closed state of the passage. The piston has an end portion which can be brought into contact with the stopper, and which is formed with an annular recess extending along an outer peripheral edge of the end portion.

Owner:YOSHINO KOGYOSHO CO LTD

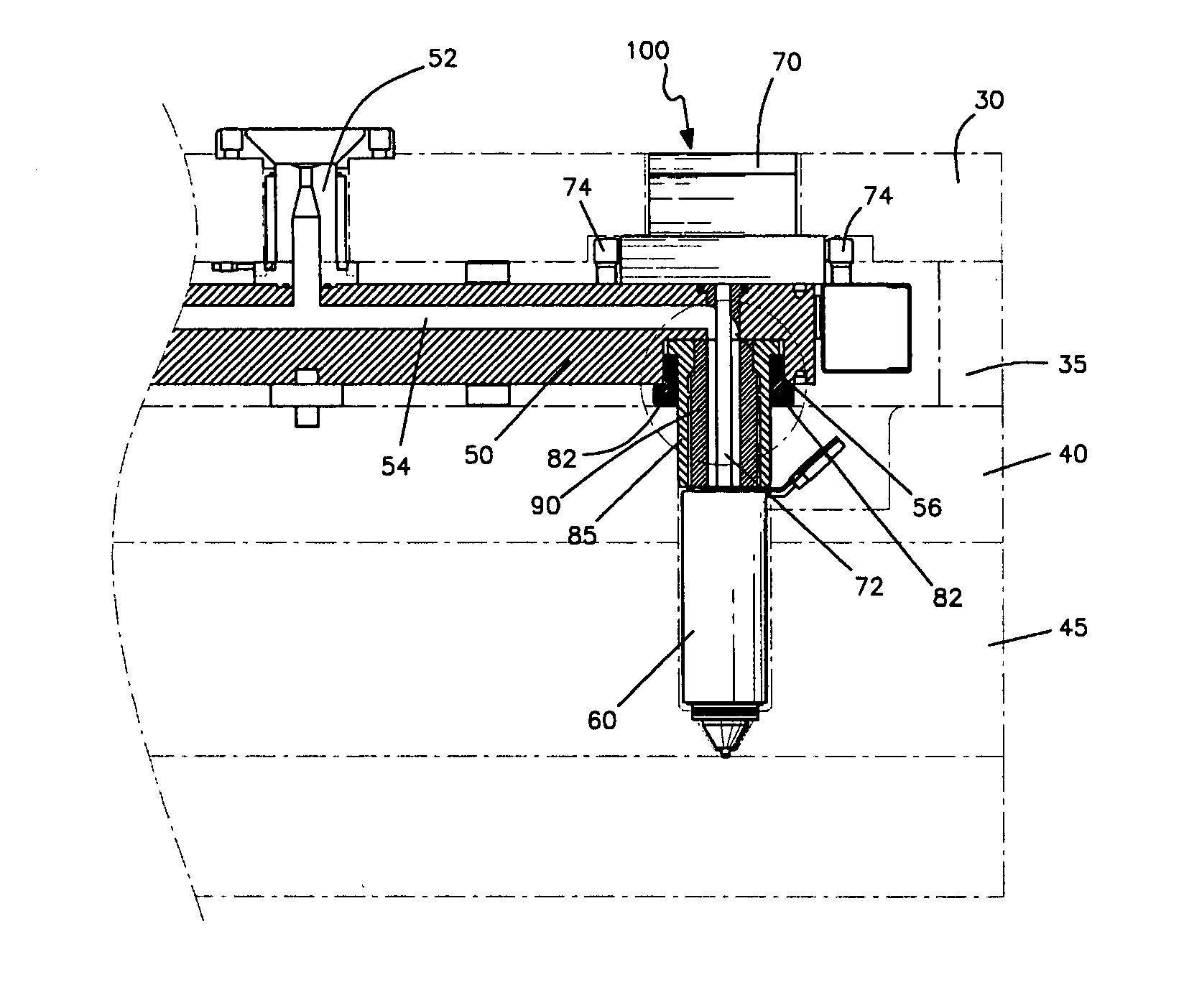

Hot runner system for injection molding machine

The present invention relates to a nozzle combining structure of a hot runner system for an injection molding machine capable of increasing durability of the nozzle. To achieve the object of the present invention, the present invention comprises a nozzle combining structure for a hot runner system for an injection molding machine comprising: a manifold having a resin injecting hole extending therethrough in its inner portion through which a resin flows and a nozzle seated groove formed in an outer peripheral surface of an end of the resin injecting hole, a nozzle being seated in the groove; a nozzle having a piston guide bushing formed at its upper end inserted into the nozzle seated groove of the manifold, for dispensing the resin injected from the resin injecting hole of the manifold through the piston guide bushing into a mold; a manifold guide bushing for surrounding and threadedly engaging with an upper portion of the piston guide bushing of the nozzle, the upper end of the manifold guide bushing having a diameter smaller than that of the nozzle seated groove of the manifold so that the upper end of the manifold guide bushing is inserted into the nozzle seated groove of the manifold; and a fastening bushing for receiving an outer surface of the manifold guide bushing and threadedly engaging with an inner circumferential surface defining the nozzle seated groove of the manifold so that the manifold guide bushing is fastened by the fastening bushing to the inner circumferential surface defining the nozzle seated groove of the manifold.

Owner:YUDO

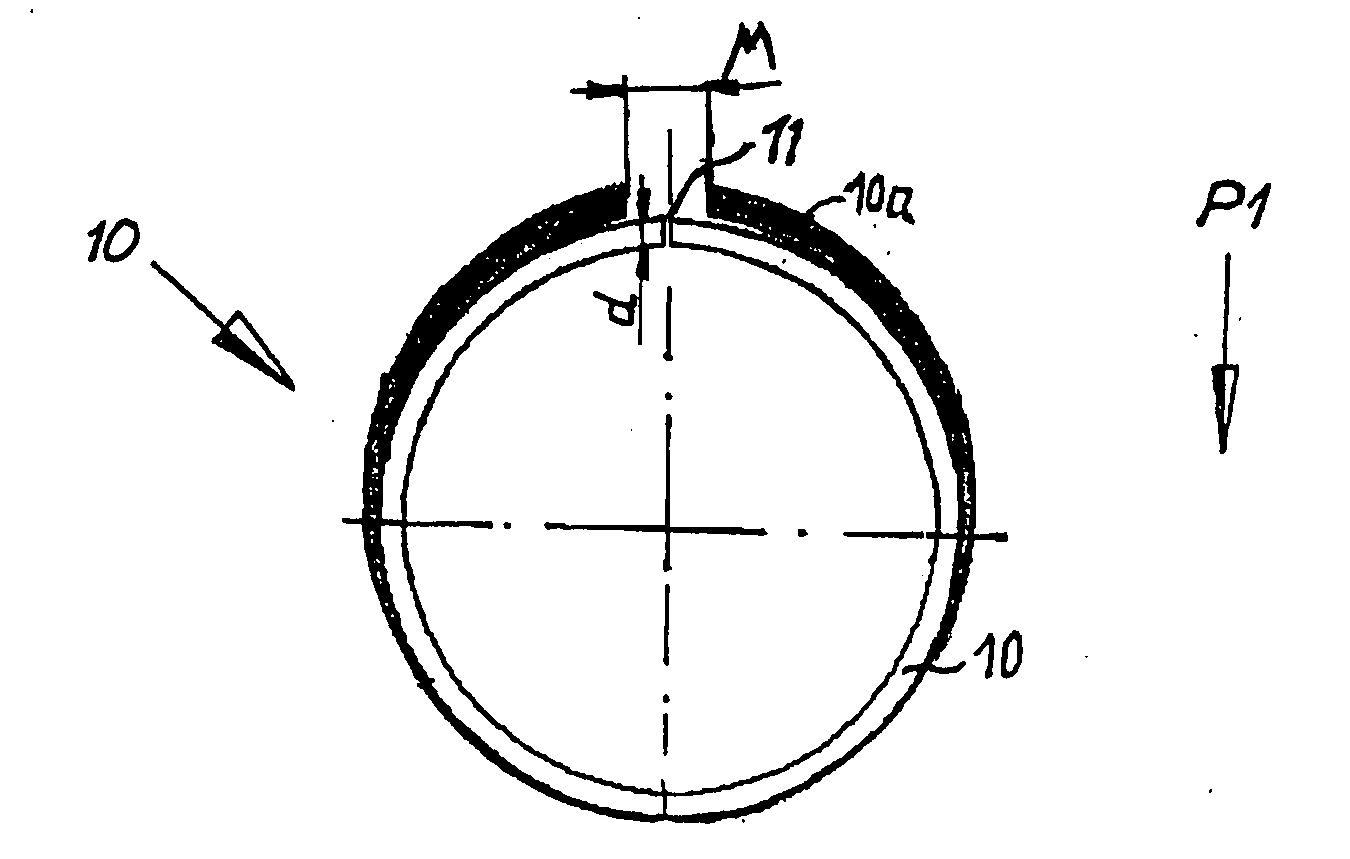

Insert for a cylinder sleeve or a cylinder of an internal combustion engine

ActiveUS20080150237A1Simple and cost-effectiveGood effectPiston ringsCylinder headsPiston GuideEngineering

An insert for a cylinder sleeve or a cylinder of an internal combustion engine is provided for narrowing the diameter of the cylinder sleeve or cylinder in the region of the upper dead center of a piston guided in the cylinder sleeve or cylinder. The insert is formed as an open, biased ring having a ring joint, which ring is held radially by means of its radial forces, which act outward, and axially by a recess in the cylinder sleeve or cylinder, in such a manner that the radial surface pressure is approximately the same on the circumference, whereby its ratio of ring wall thickness (d) to inside diameter (D) of the cylinder sleeve or the cylinder amounts to between 0.001 and 0.02.

Owner:MAHLE INT GMBH

Automatic assembly device and method of piston clamp spring

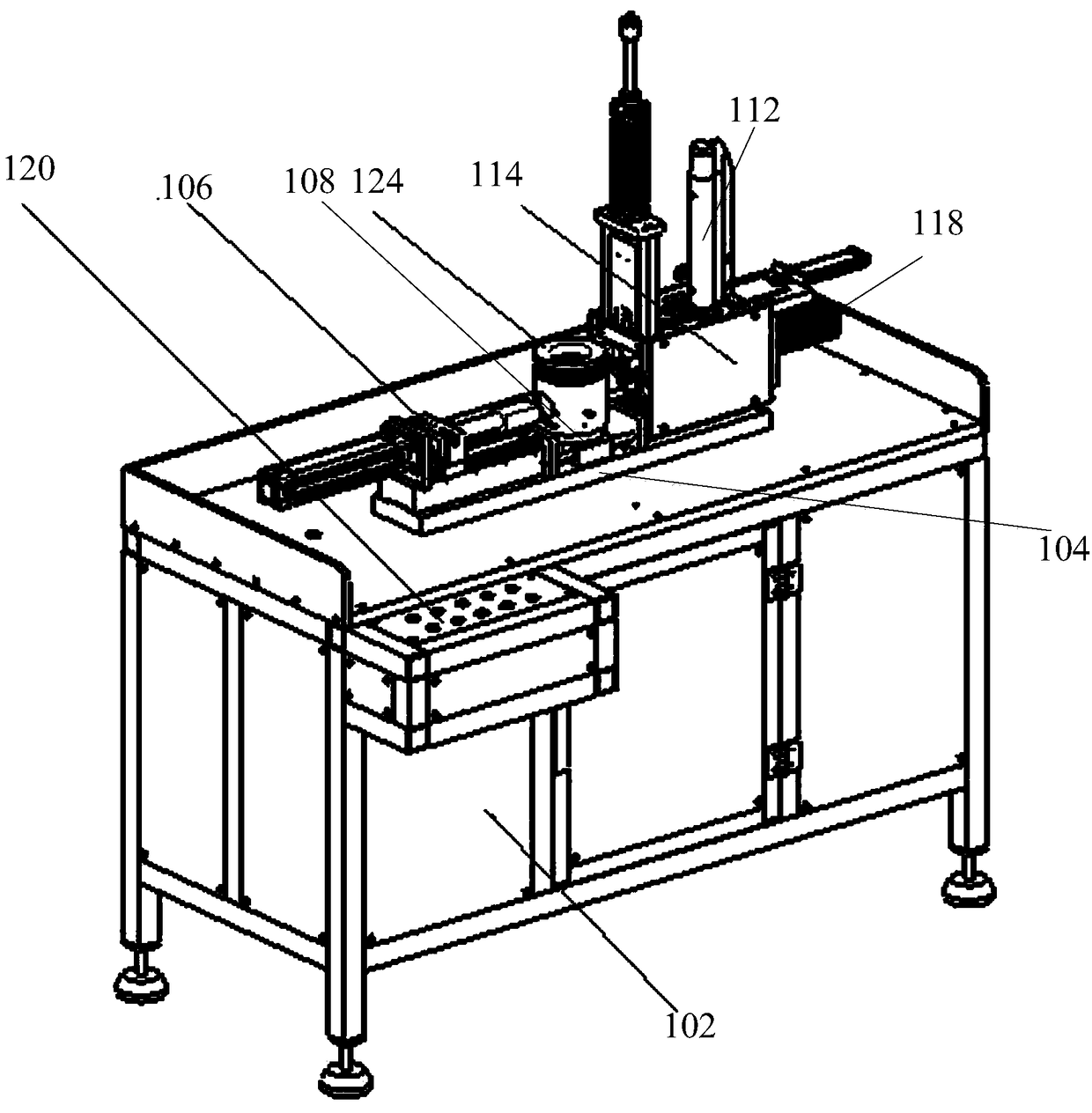

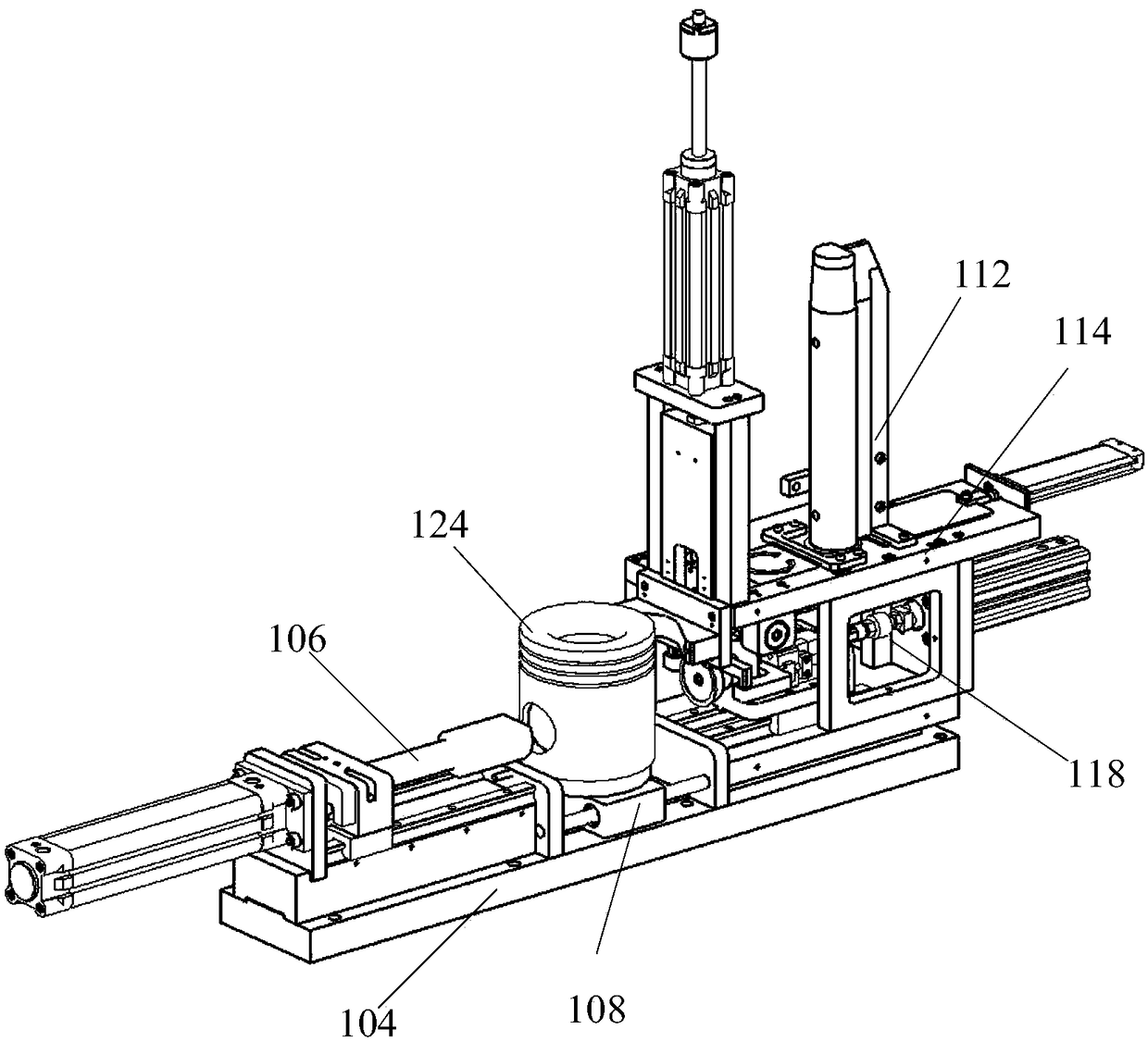

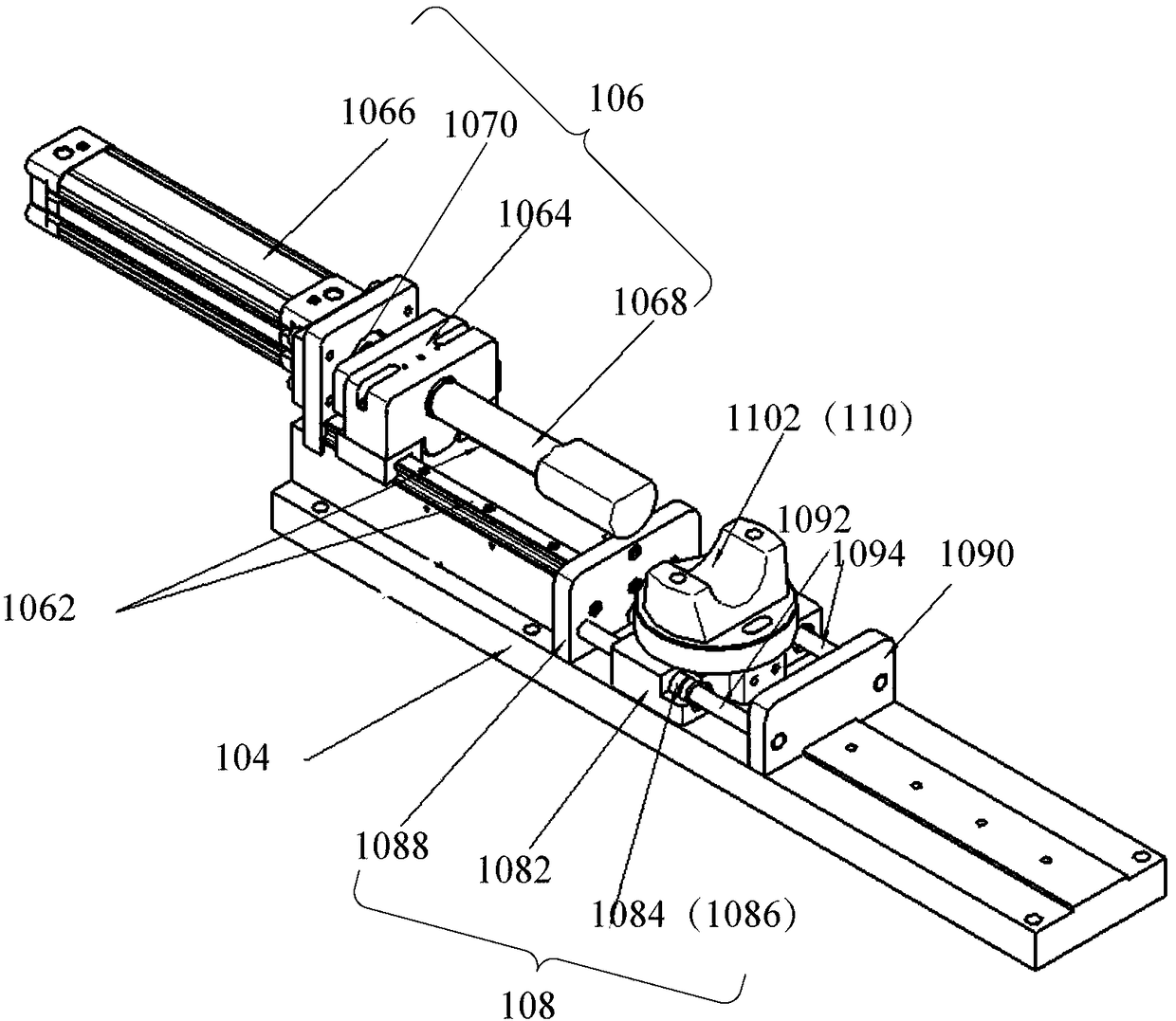

ActiveCN108544216AImprove continuityImprove the efficiency of automatic assemblyFinal product manufactureMetal working apparatusPiston GuideMaterial storage

The invention provides an automatic assembly device and method of a piston clamp spring. The device comprises a working bed body, a piston locating mechanism, a piston guide mechanism, a piston placement part, a clamp spring material storage part, a clamp spring feeding part, a clamp spring assembly mechanism and a controller. A reference mounting seat is arranged on the working face of the working bed body. The piston locating mechanism is installed on the reference mounting seat. The piston guide mechanism is arranged in cooperation with the piston locating mechanism and installed on the reference mounting seat. The piston placement part is arranged on the reference mounting seat and arranged adjacent to the piston locating mechanism, and the piston placement part is matched with the piston locating mechanism for locating a piston. The clamp spring material storage part and the piston placement part are arranged at intervals for storing and releasing a clamp spring. The clamp springmaterial feeding part is arranged adjacent to the clamp spring material storage part and connected with the piston placement part, and the clamp spring material feeding part comprises a working table,a clamp spring separation mechanism, a clamp spring turnover mechanism and a clamp spring horizontally moving mechanism. The clamp spring assembly mechanism is connected with the clamp spring feedingpart for assembling the clamp spring to the piston. Through the technical scheme, the automatic assembly of the clamp spring on the single side of the piston can be completed, using is convenient, the production efficiency is high, and the assembly quality is stable and reliable.

Owner:BINZHOU BOHAI PISTON CO LTD +1

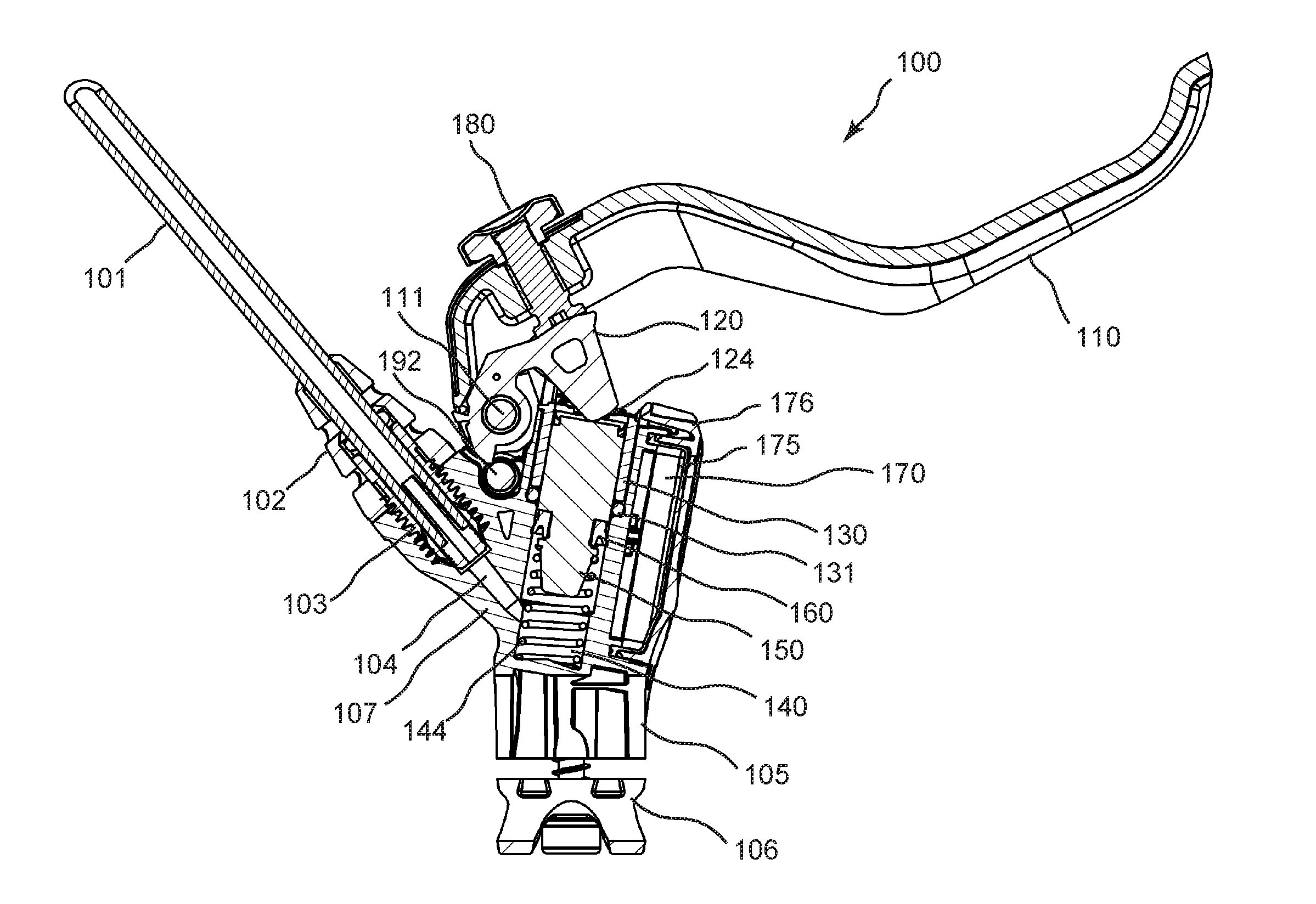

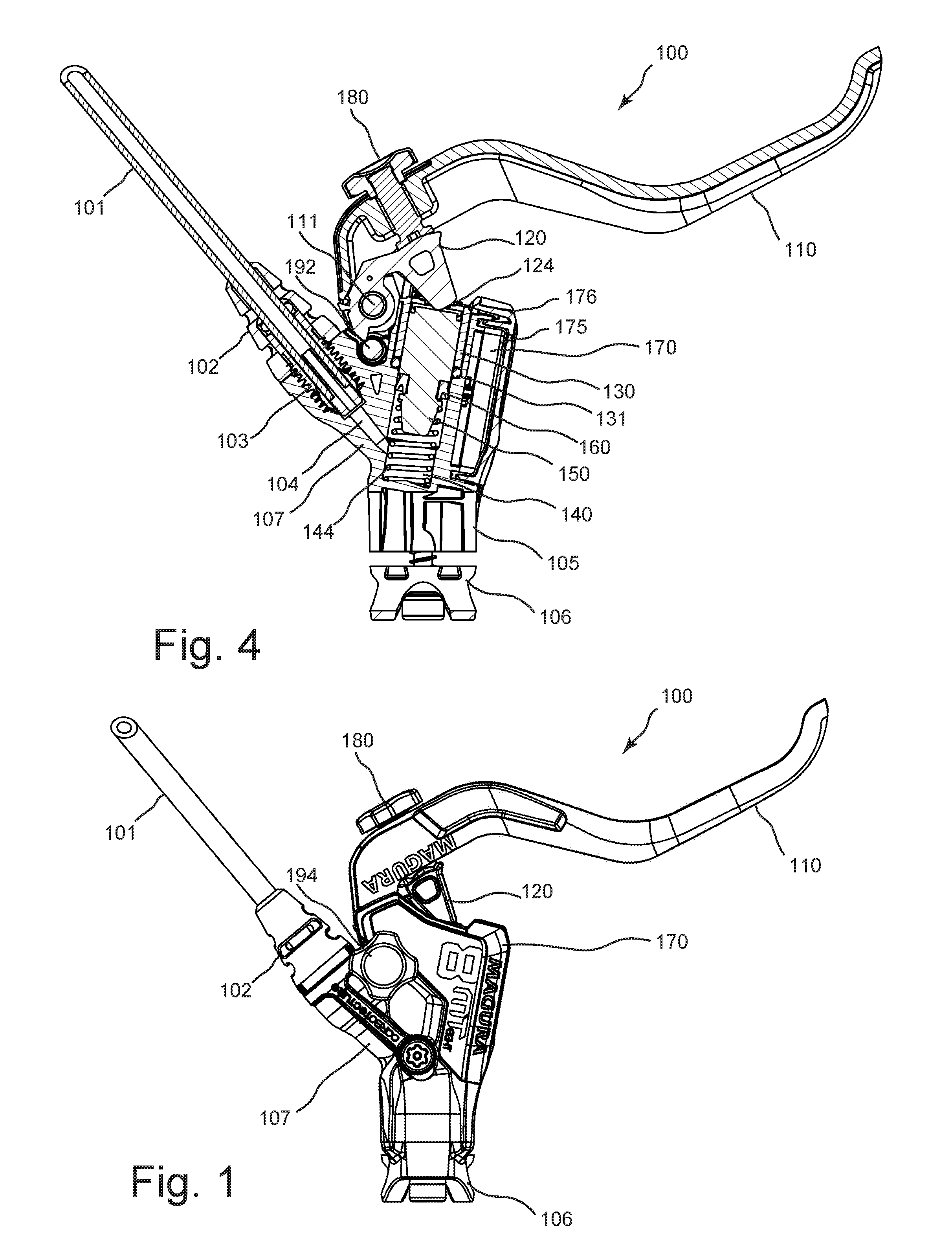

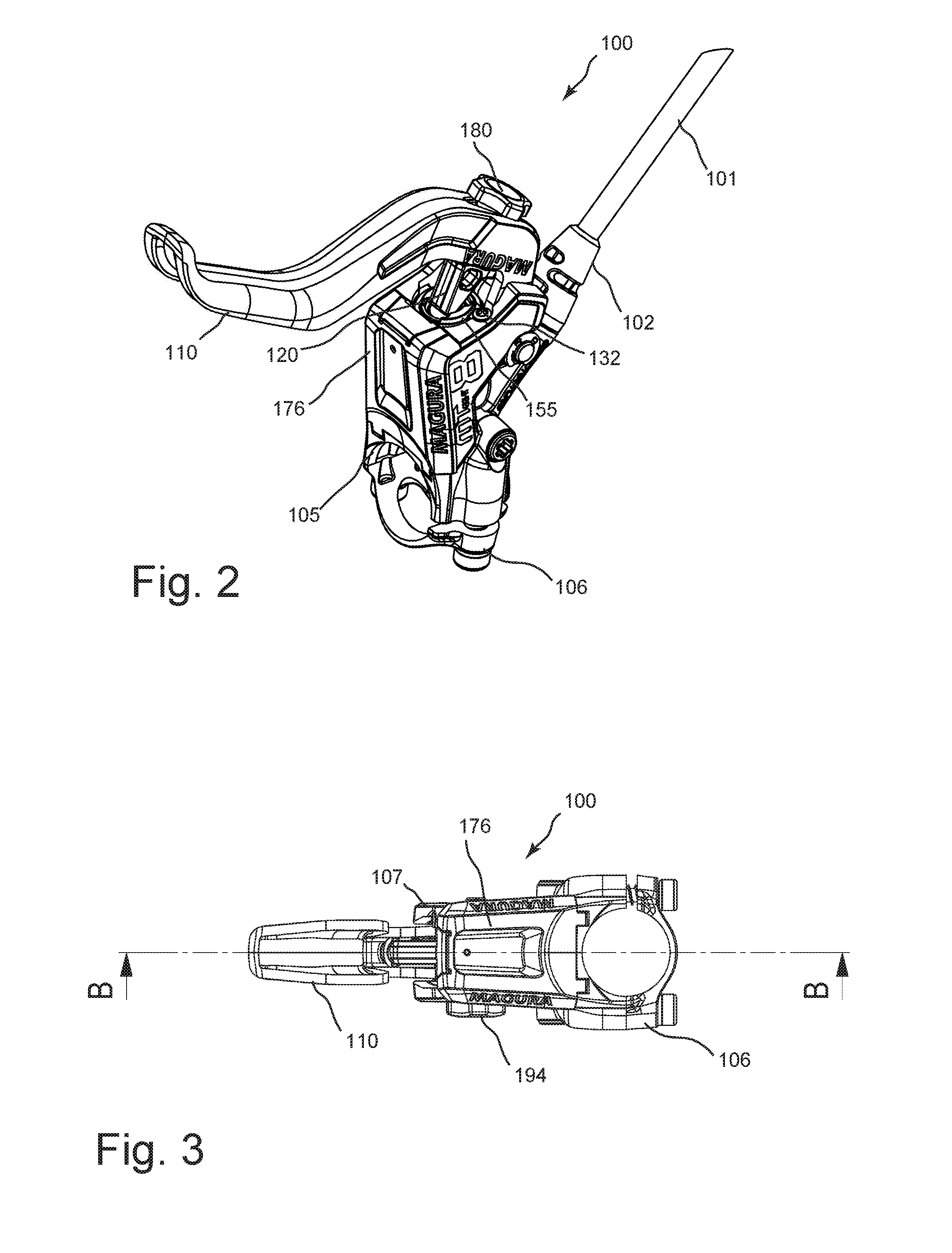

Master Cylinder Fitting

ActiveUS20160177976A1Ease of productionCompact dimensionsRotary clutchesCycle control systemsMaster cylinderPiston Guide

A master mounting for a hydraulic actuation member has a housing, which has a compensating chamber with an interior and a cylinder. The master mounting also has a piston guided in the cylinder. The cylinder and the compensating chamber are connected in at least one position of the piston by a communication channel. At least one overflow channel is disposed at least at the opening of the communication channel in the cylinder wall.

Owner:GUSTAV MAGENWIRTH GMBH & CO KG

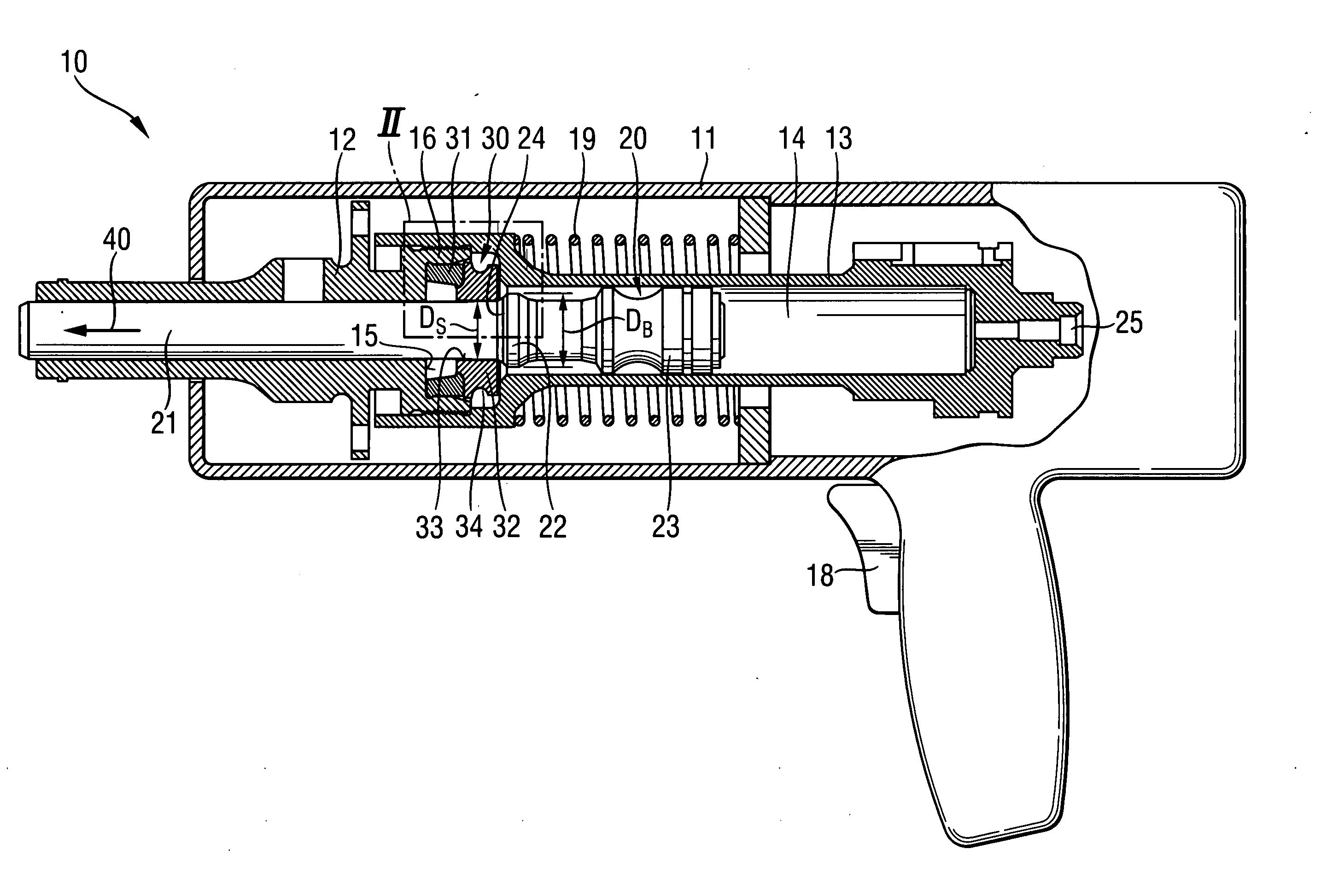

Setting tool

ActiveUS20050051594A1Improve deformationAvoid damageStapling toolsFree piston enginesPiston GuideStops device

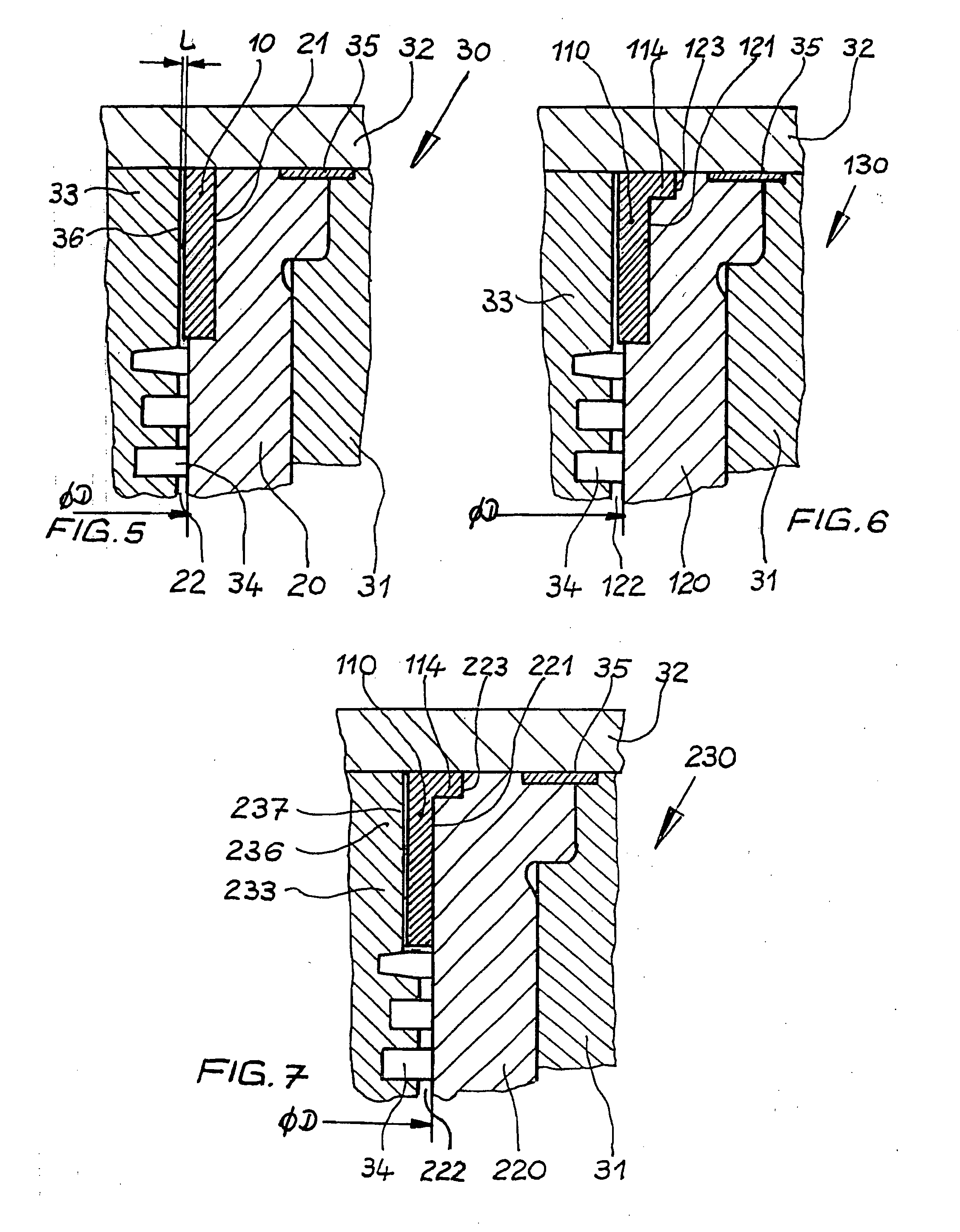

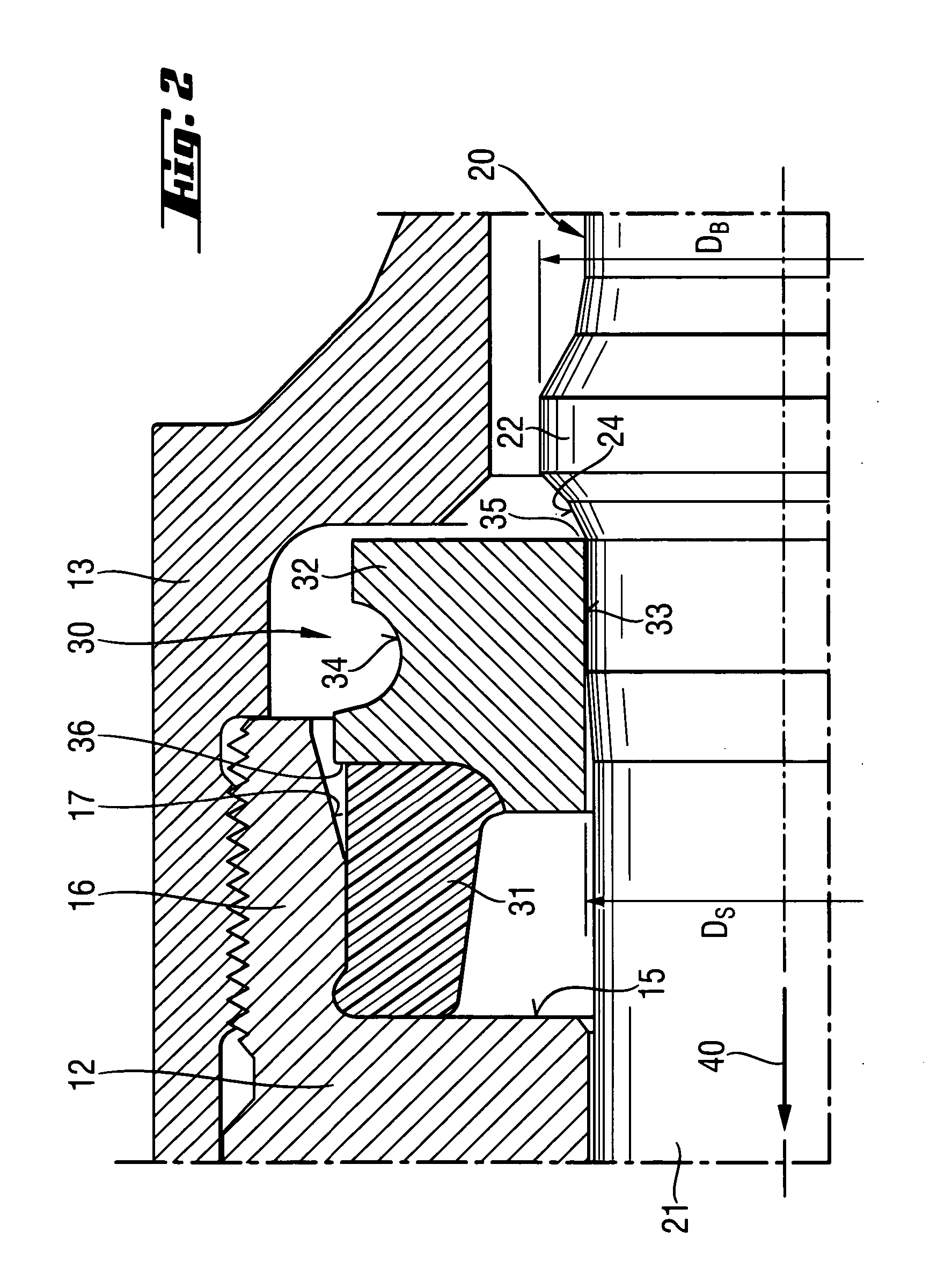

A setting tool for driving fastening elements and including a setting piston (20) axially displaceably arranged in the hollow chamber (14) of a piston guide (13), and a piston stop device (30) for the setting piston (20), arranged in setting direction end region of the hollow chamber (14) and having a damping element (31) supported against a stop (15), and a stop member (32) adjoining the damping element (31) in a direction of the hollow chamber (14) and operationally connectable with the piston band (22), and having a cylindrical bushing (33) for the piston stem (21), with the bushing (33) having an inner diameter (DS) that amounts to from 70% to 90% of a size of the maximal outer diameter (DB) of the prison band that has a conical surface engageable with the inner surface of the bushing.

Owner:HILTI AG

Device for opening and closing a vehicle body part

InactiveUS7506556B2Easy constructionSmall spacingGearingPower-operated mechanismBowden cablePiston Guide

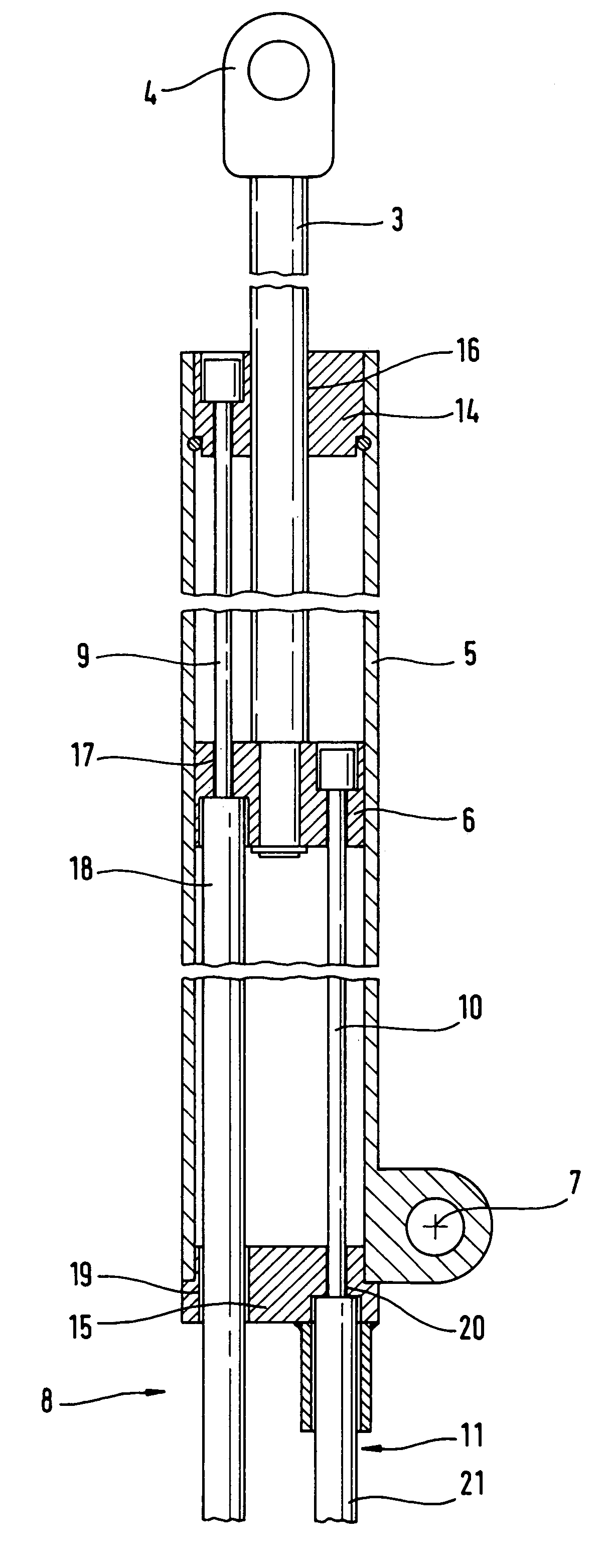

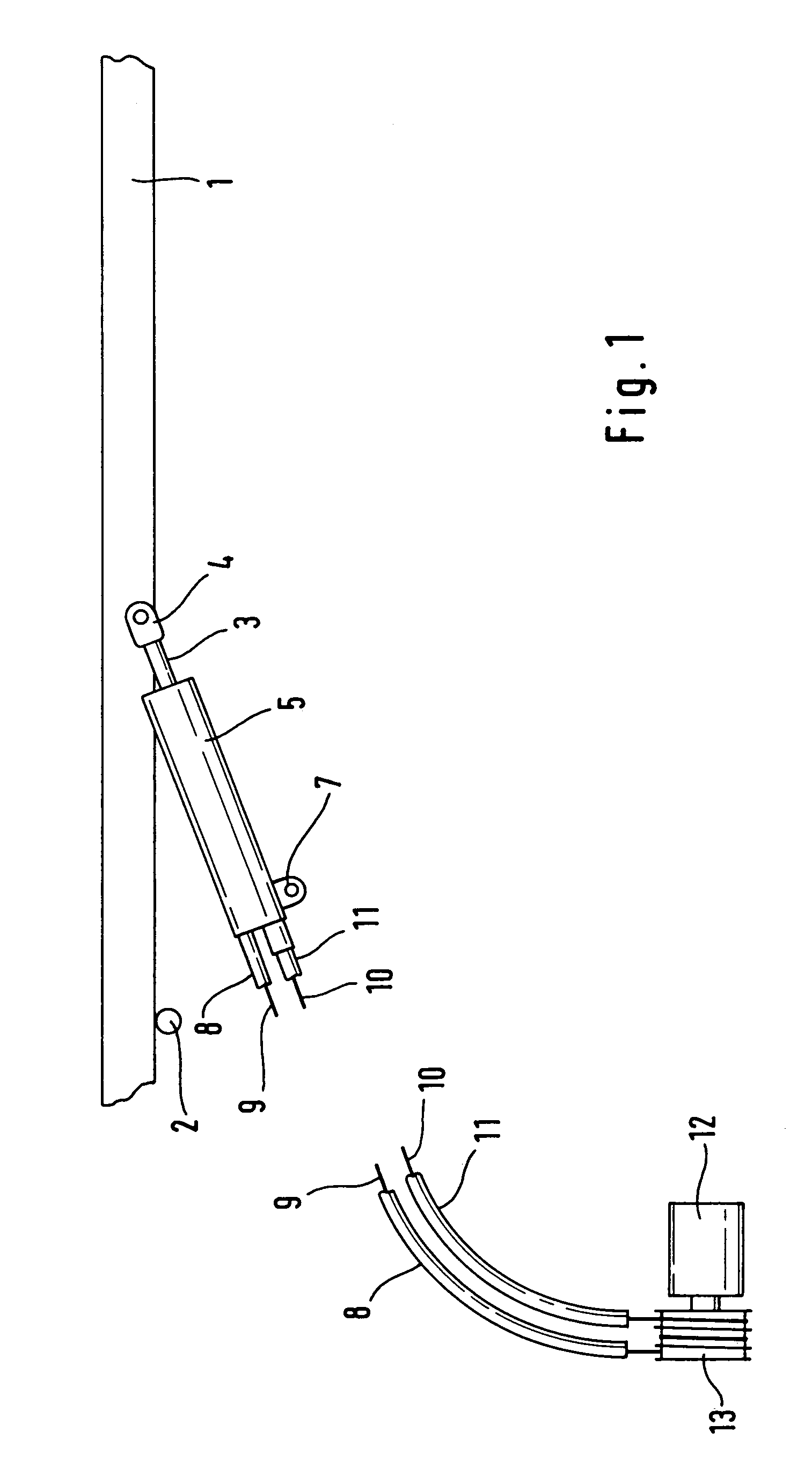

Apparatus for the motorized opening and closing of a motor vehicle body part which can be pivoted with respect to a vehicle body about a hinged lid axis includes a guide cylinder having a first end and a second end which can be coupled to the body at a pivot axis which is parallel to the hinged lid axis, a piston guided displaceably in the cylinder, and a piston rod having one end attached to the piston and an opposite end which protrudes from the first end of the cylinder and can be coupled to the pivotable body part at a distance from the hinged lid axis. A drive device drives first and second Bowden cables, which extend in parallel from the second end of the cylinder, to displace the piston in the cylinder. The first Bowden cable includes a sheath which is supported on the piston and a core which is fixed to the first end of the cylinder. The second Bowden cable includes a sheath which is supported on the second end of the cylinder and a core which is fixed to the piston.

Owner:STABILUS

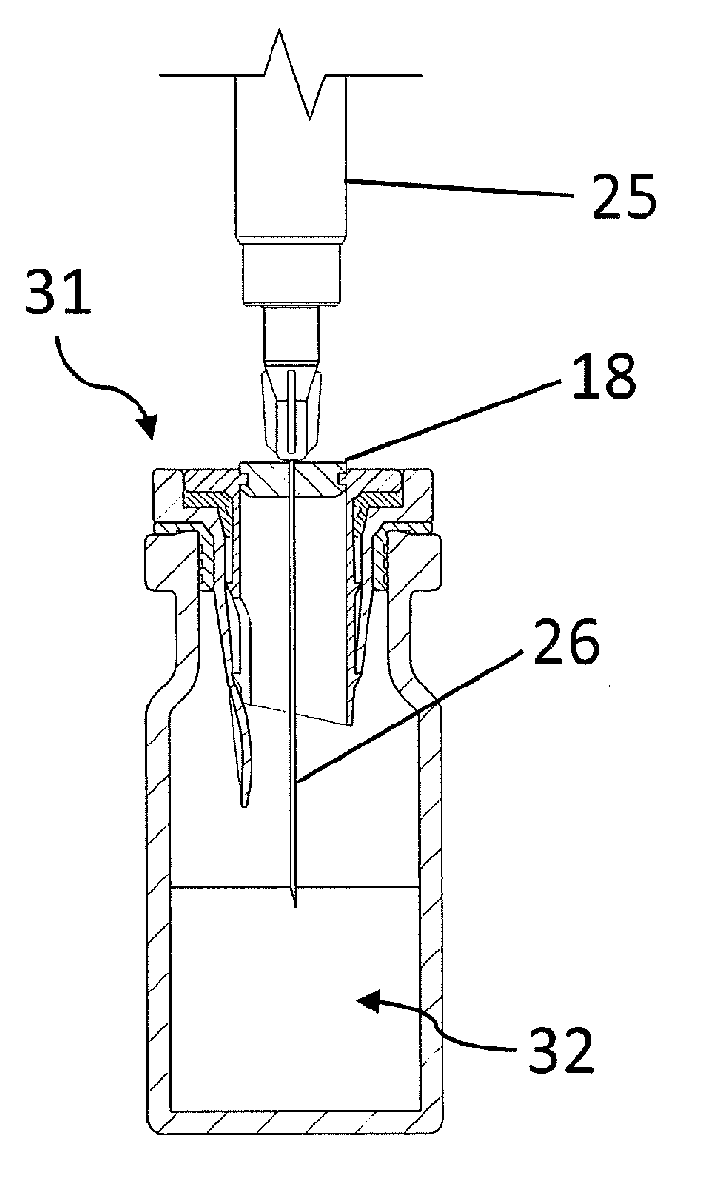

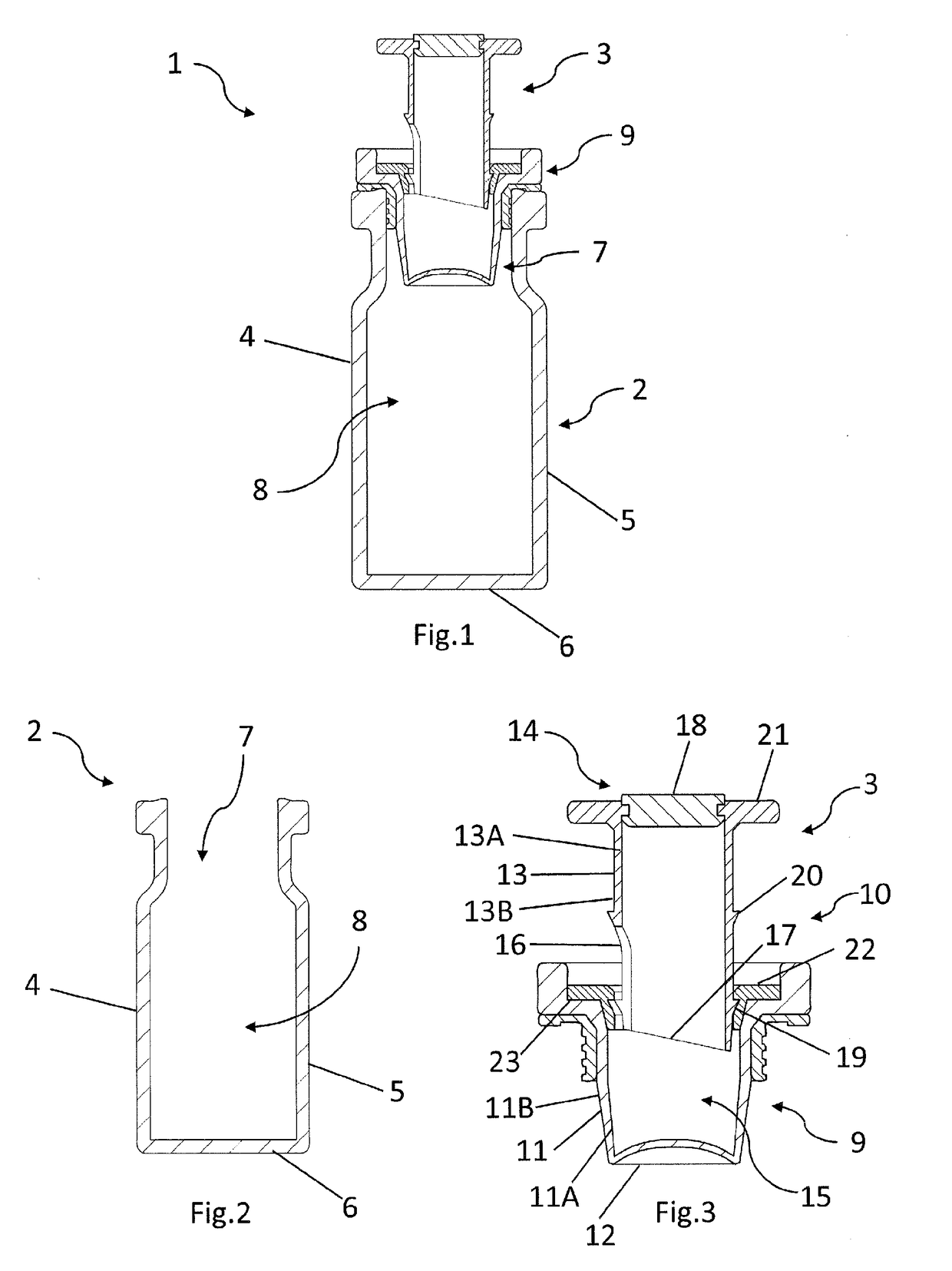

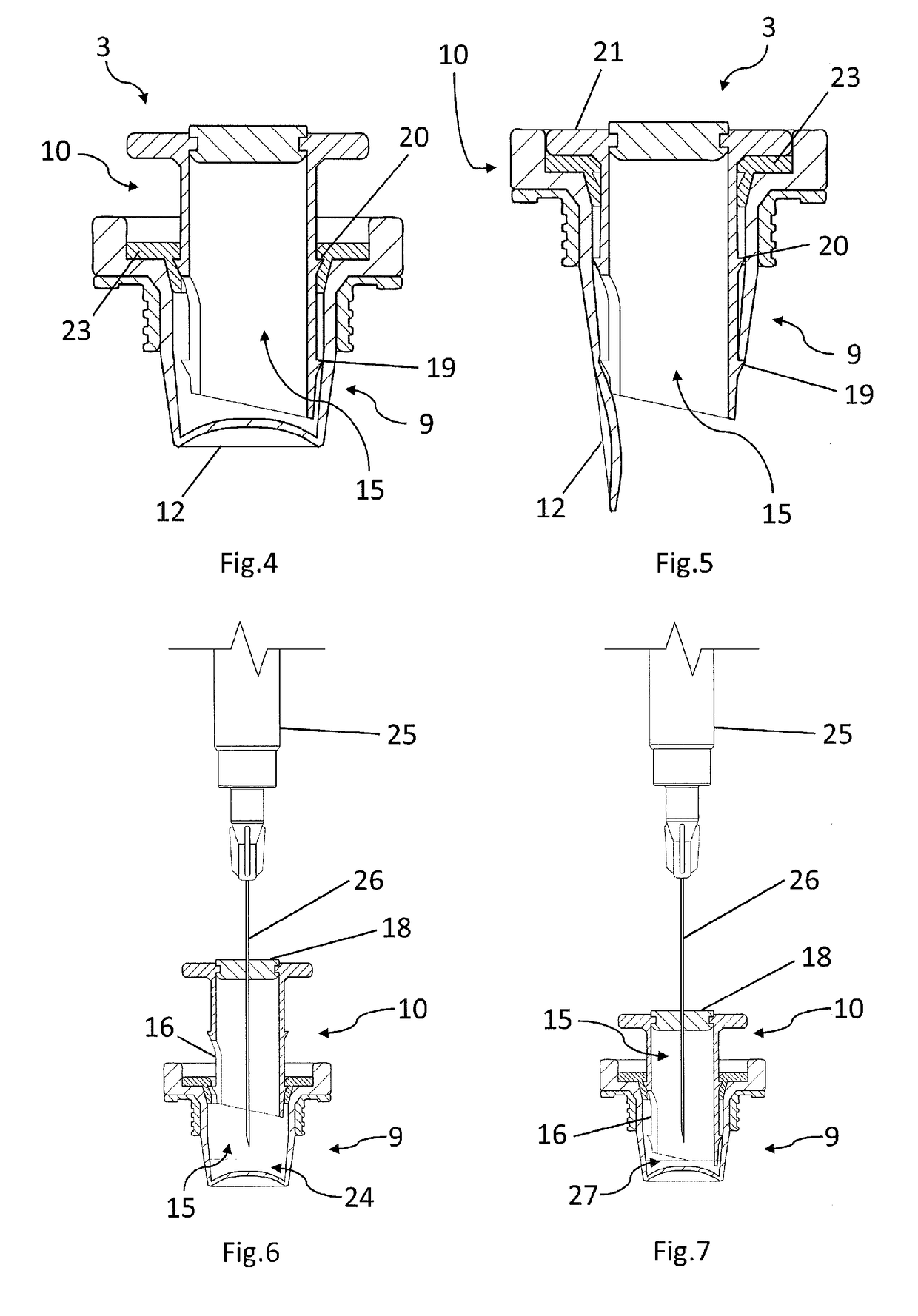

Container and closure

ActiveUS20170258683A1Keep sterileDeployment securityClosures with freeze-dryingPeptide/protein ingredientsActive agentPiston Guide

A closure for dispensing one or more active agents into a container comprises a sealed or sealable chamber having a breakable wall and a hollow piston slidably mounted in a piston guide. Said hollow piston comprises an outer wall having an end in the chamber and at least one ventilation aperture. Said end has a cutting formation. Said hollow piston is slidable in the piston guide between a ventilation position in which the at least one ventilation aperture allows ventilation of the chamber and a sealed position in which the at least one ventilation aperture is sealed to prevent ventilation of the chamber and a deployed position in which the cutting formation has broken through at least a portion of the breakable wall. The outer wall has a retaining formation which engages with the piston guide to releasably resist sliding of the hollow piston between the ventilation position and the sealed position and the deployed position. The hollow piston may have an outer wall, and said outer wall has an end within the chamber, facing the breakable wall, wherein the cutting end has a first edge having a cutting formation and a gap in said cutting formation.

Owner:EULYSIS UK

Accumulator-type liquid sprayer

Owner:YOSHINO KOGYOSHO CO LTD

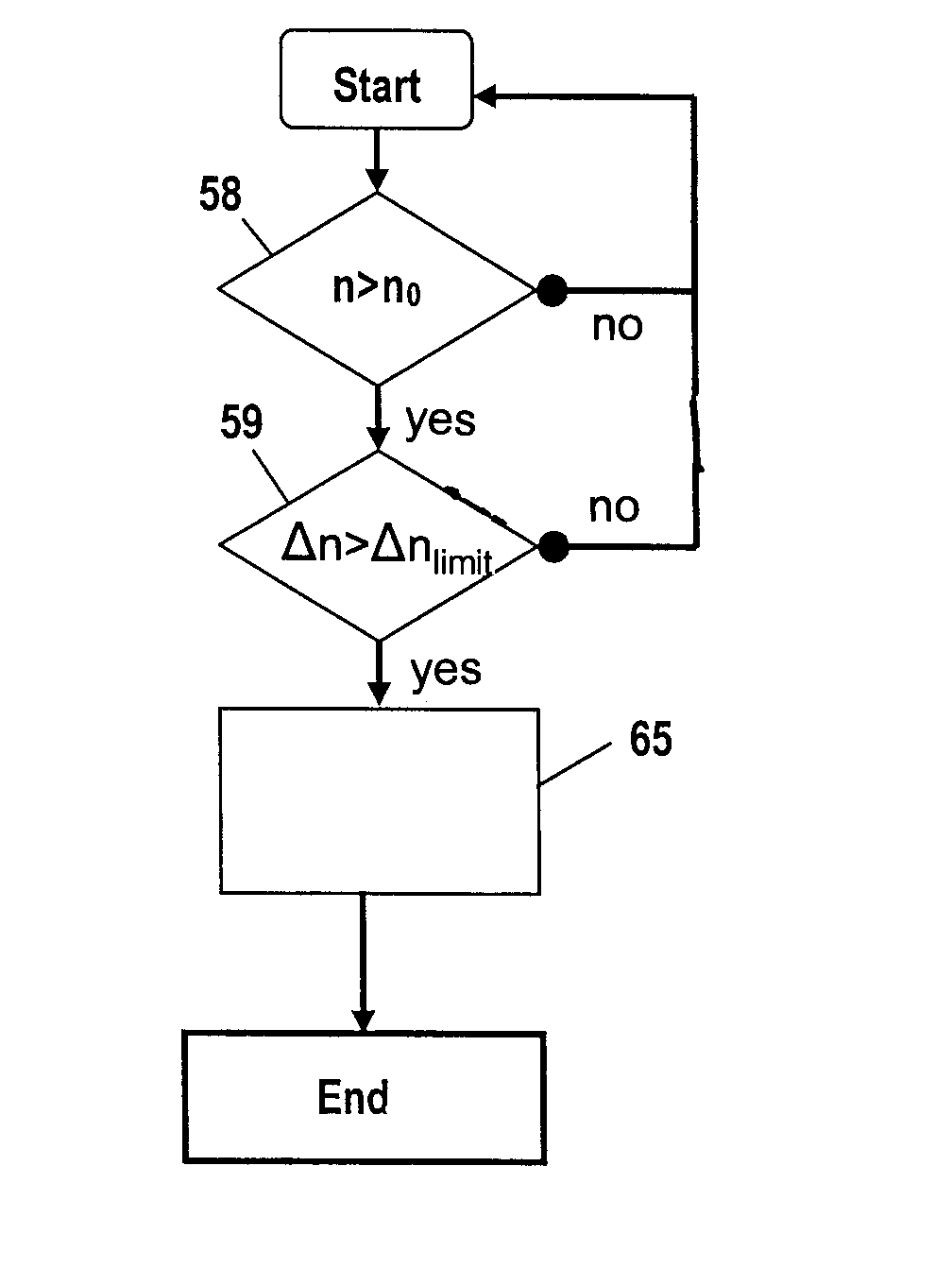

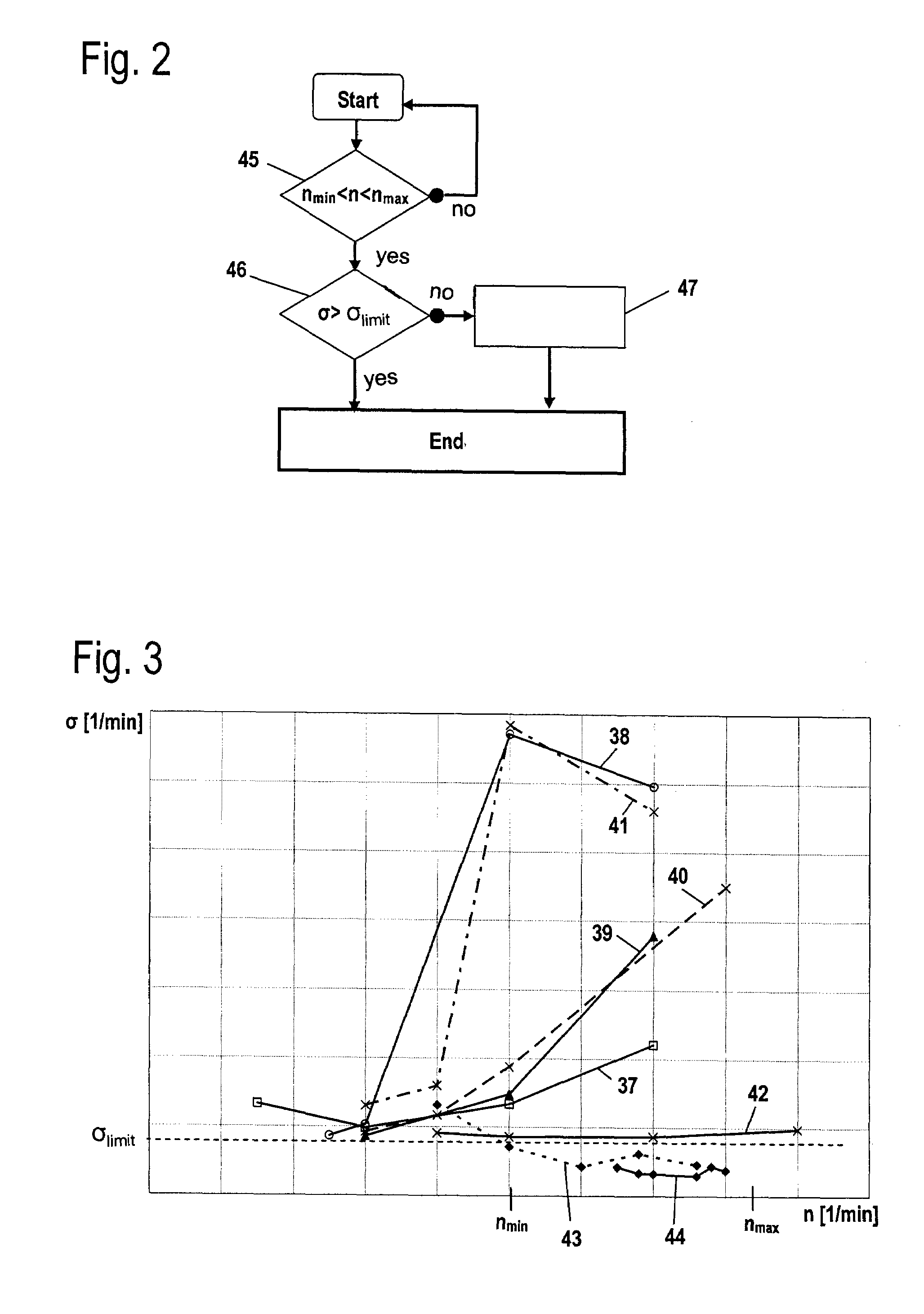

Method for operating an internal combustion engine by determining and counteracting a pre-ignition state

ActiveUS7637248B2Simple and fast determinationAnalogue computers for vehiclesElectrical controlExternal combustion enginePiston Guide

In a method for operating an internal combustion engine, wherein the internal combustion engine has a cylinder in which a combustion chamber is provided that is delimited by a reciprocating piston guided in the cylinder, wherein the piston is connected by a connecting rod to a crankshaft and wherein the internal combustion engine has a device for supplying fuel and a device for igniting the fuel / air mixture in the combustion chamber at least one engine speed value of the internal combustion engine is determined and evaluated. A pre-ignition state of the internal combustion engine is determined based on the result of the evaluation step.

Owner:ANDREAS STIHL AG & CO KG

Constant power valve

ActiveCN102425541AImprove efficiencyReduce energy consumptionPositive displacement pump componentsLiquid fuel engine componentsConstant powerCoupling

The invention relates to a constant power valve, which comprises a piston guide sleeve, wherein the outer wall of the piston guide sleeve is provided with a load pressure interface, a lateral middle hole and an oil discharging hole; a valve core is arranged in the piston guide sleeve; a piston rod is arranged in the valve core; a first spring seat is arranged in the end part of the piston guide sleeve which is correspondingly connected with a protective cap; the end part of the piston rod which correspondingly extends into the protective cap is provided with a reset adjusting spring; an adjusting piston is provided with a high-pressure oil inlet; the end part of the piston rod which correspondingly extends into the adjusting piston passes through a spherical seat and is correspondingly matched with the spherical seat; a hydraulic oil through hole which is distributed along the axis of the piston rod is formed in the piston rod, and can be communicated with a hydraulic oil outlet; the end part of the piston rod which correspondingly extends into the adjusting piston is provided with a shaft coupling; and a one-way valve spring is arranged in the shaft coupling, and is correspondingly matched with a steel ball for blocking the hydraulic oil through hole in the piston rod. The constant power valve has a compact structure, the efficiency of a hydraulic system is increased, and the energy consumption of the hydraulic system is lowered.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

Integral seal jack

InactiveCN101941657AImprove securityImprove reliabilityCylindersLifting devicesPiston GuideEngineering

The invention provides an integral seal jack. The jack consists of a cylinder body, a piston rod, a piston component and a cylinder port component, wherein the cylinder body consists of a base and a cylinder tube, and the base and the cylinder tube are welded together; the piston rod is a step bar one end of which is provided with a shoulder, and is sleeved in the cylinder tube; and the piston component is sleeved on the piston rod, is positioned by the shoulder of the piston rod, and is fixed on the piston rod through a nut. The integral seal jack is characterized in that the piston component consists of a piston, two piston guide parts and a piston seal component, and is an integral piston; the two piston guide parts are positioned on the front end and the rear end of the piston respectively; the piston seal component is positioned between the two piston guide parts; the piston seal component and the two piston guide parts are integrally cast on the piston; a stainless steel sleeve is welded on the inner wall of the cylinder tube; and a laser cladding layer is arranged on the outer surface of the piston rod. The integral seal jack has the advantages of simple structure, low cost, safety, reliability, good seal performance and low repair rate, and can remarkably improve the corrosion resistance effect of the jack.

Owner:中煤邯郸煤矿机械有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com