Patents

Literature

77results about How to "Achieve continuous supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

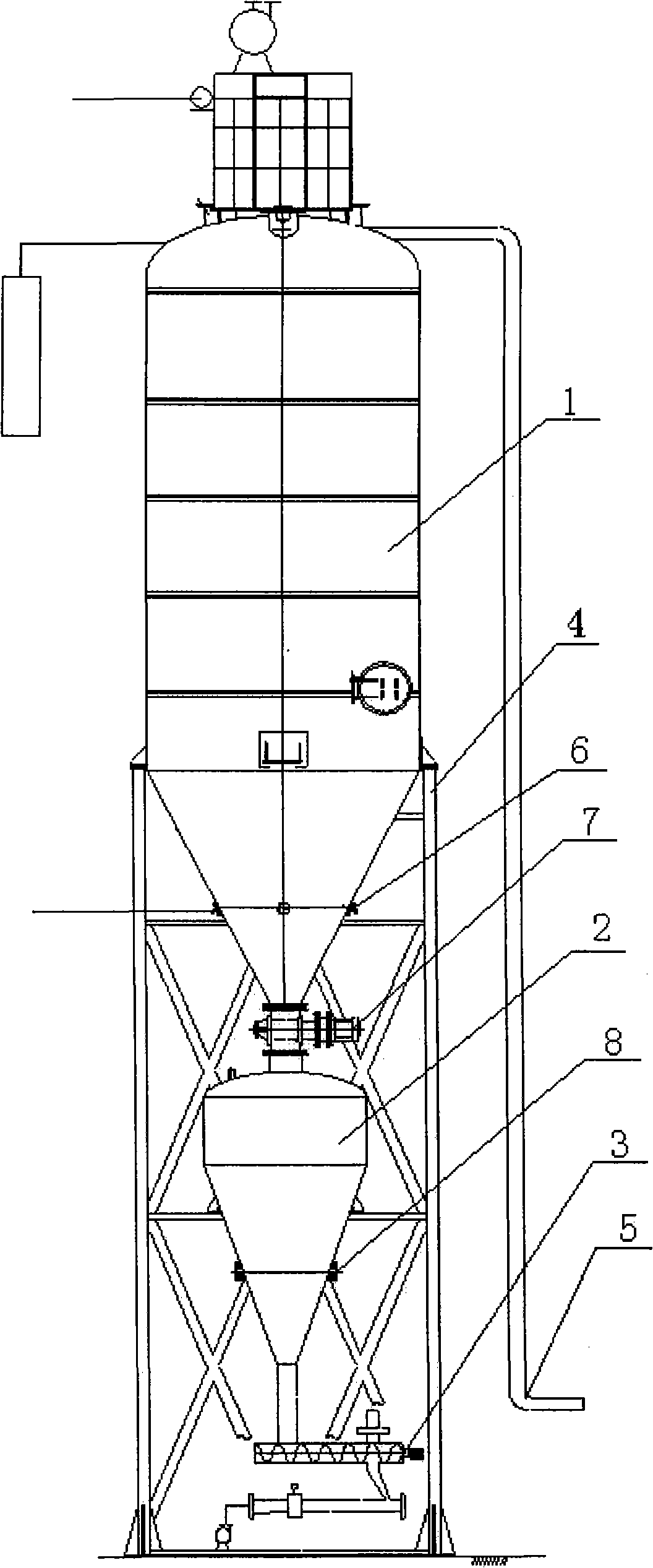

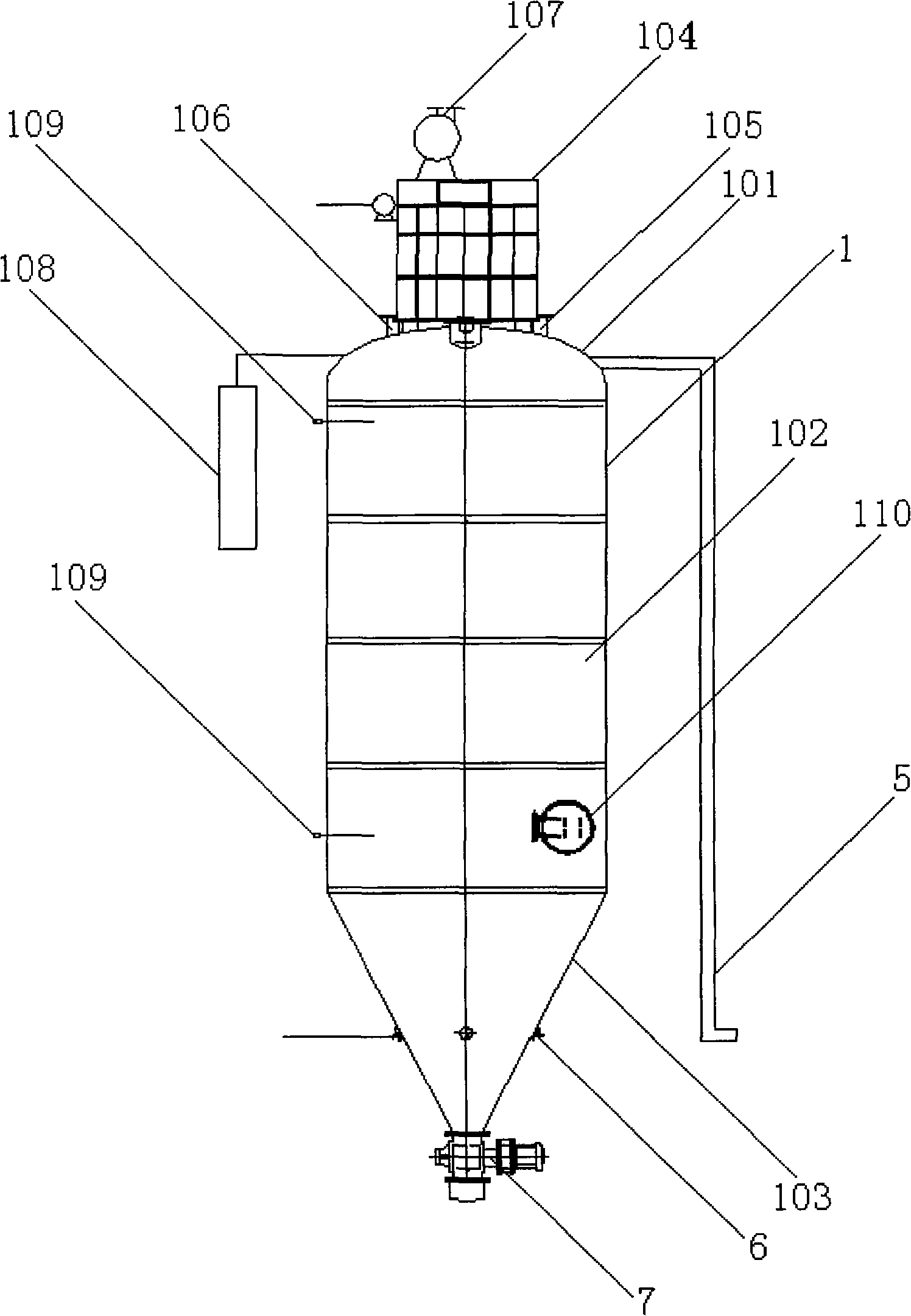

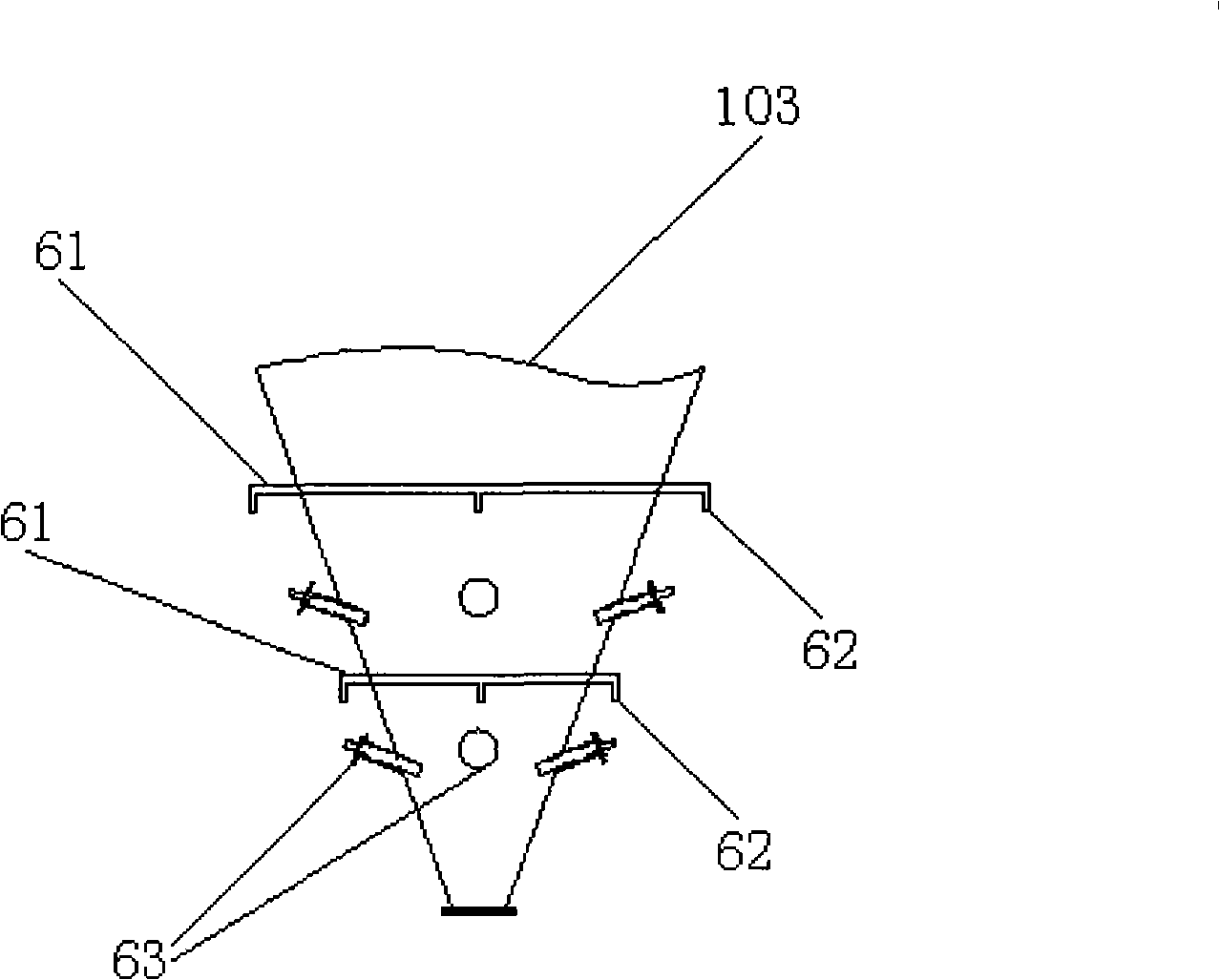

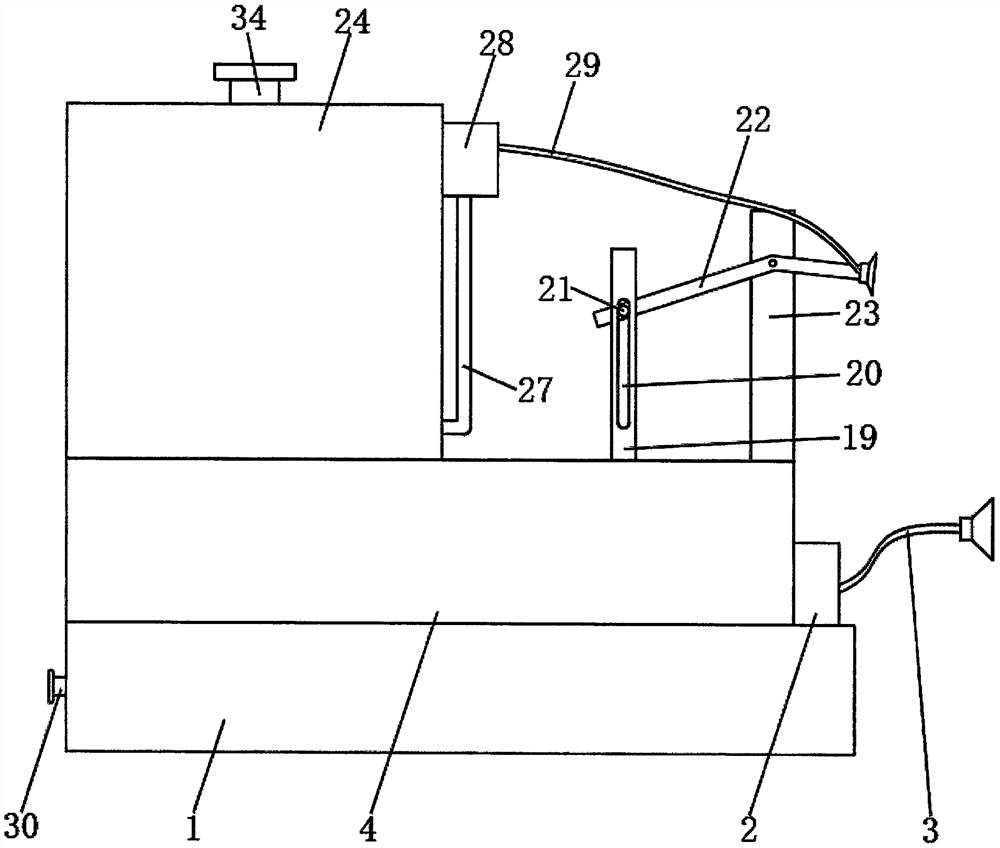

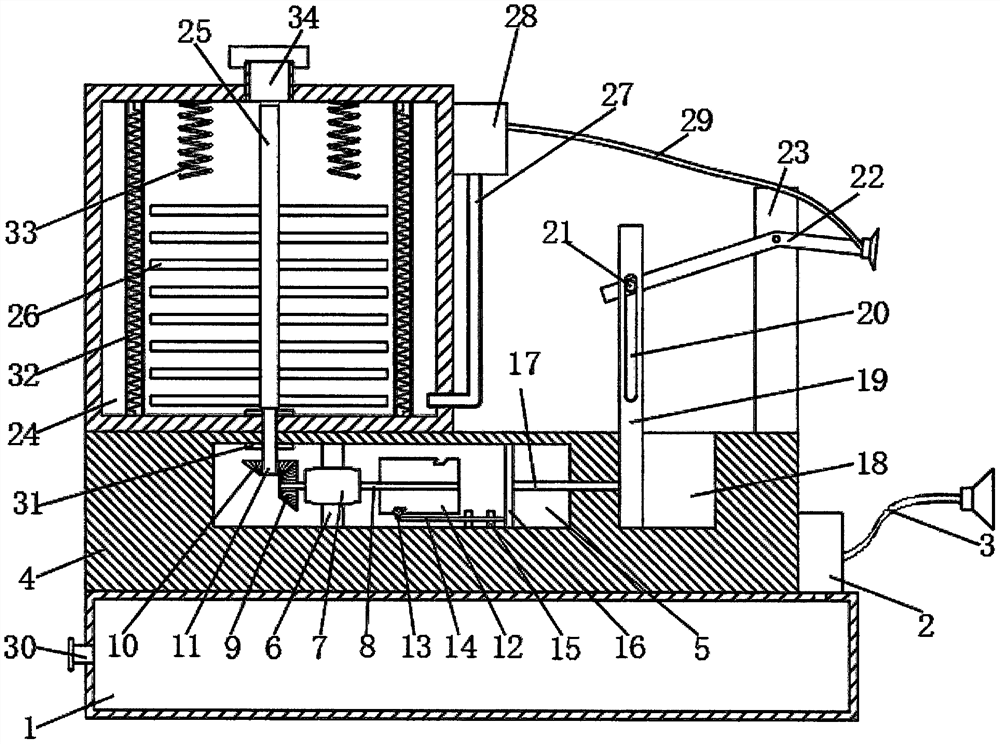

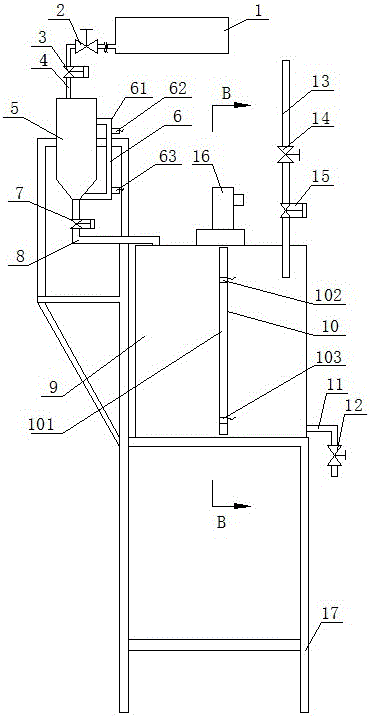

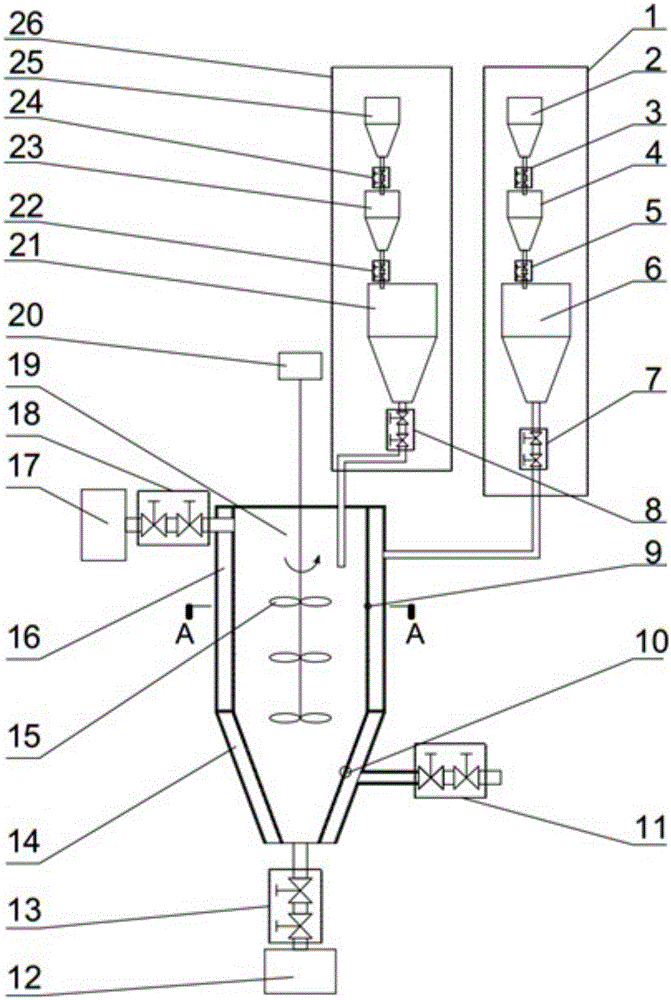

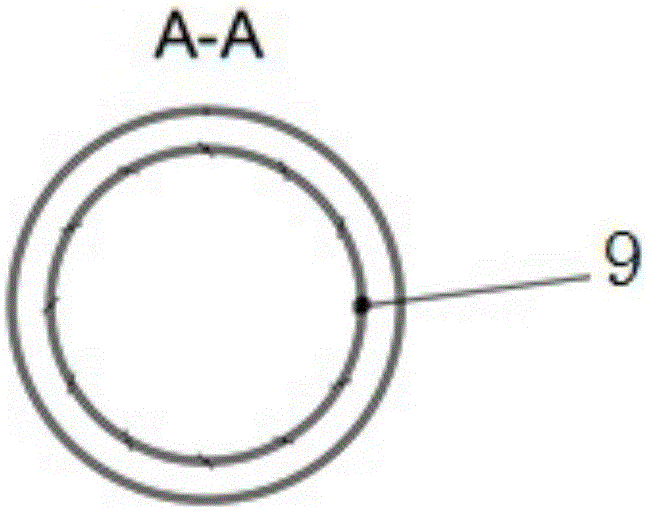

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

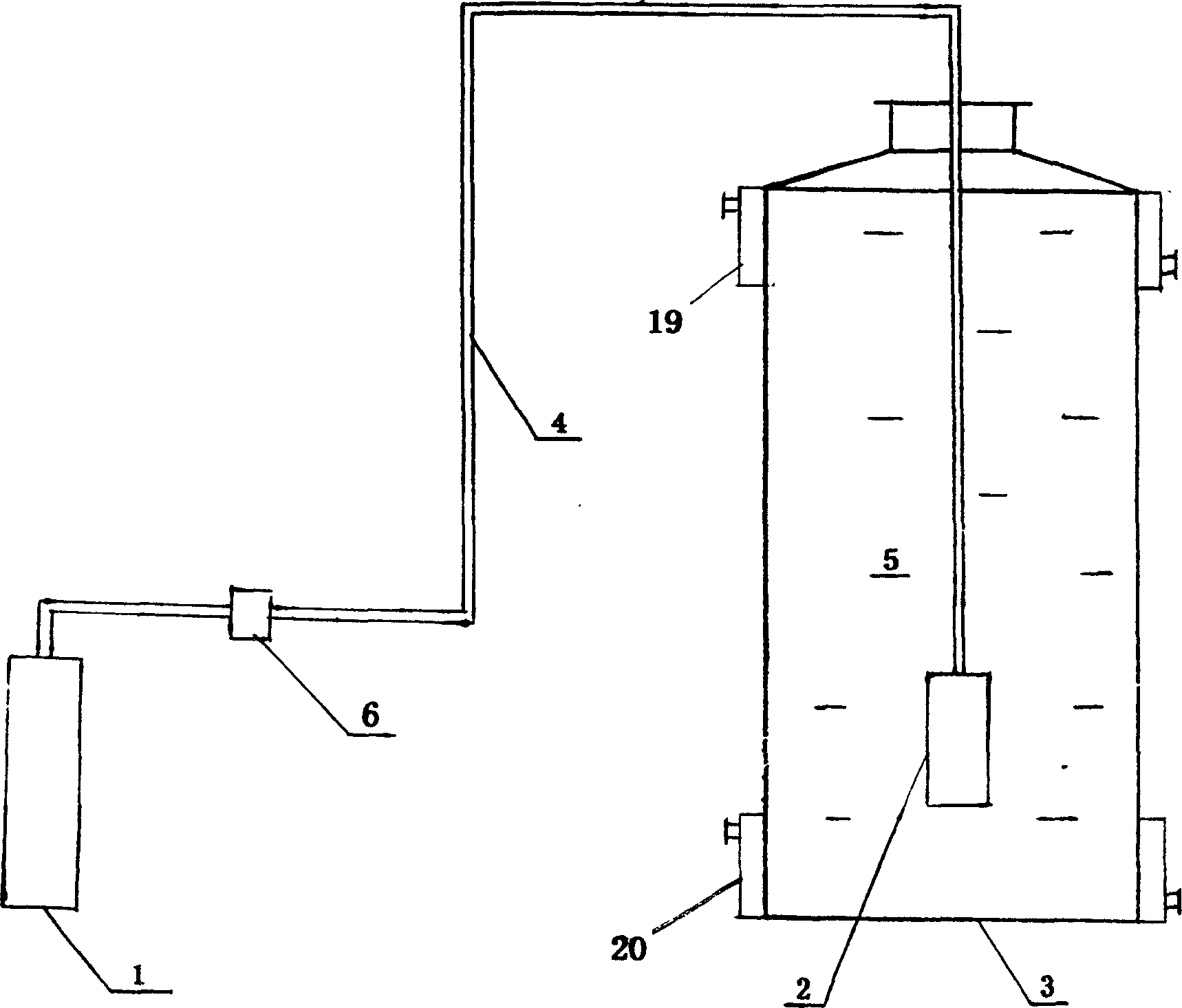

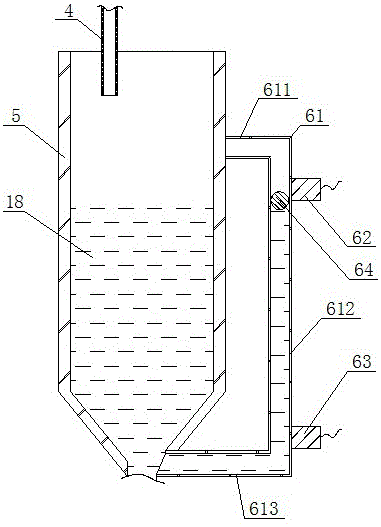

Ripening device with little oxygen suppled

InactiveCN1916154AAdjust dissolved oxygen contentAchieve continuous supplyAlcoholic beverage preparationGrape wineOxygen Consumptions

This invention relates to a micro-oxygenation device, which comprises an oxygen source, a vessel for containing liquid and a pipeline connecting the oxygen source and the vessel. A gas diffuser is set in the liquid in the vessel, which is made of wood material. Oxygen is introduced into the gas diffuser through the pipeline, where a certain pressure is maintained so that micro-oxygen can be introduced into the liquid through the gas diffuser. This invention can realize continuous introduction of micro-oxygen into the liquid in the vessel, thus simulating the condition of grape wine in traditional oak barrels. Therefore, during the breeding of grape wine in the vessel, the oxygen feeding amount and the oxygen consumption amount (by grape wine) can be maintained to be balance.

Owner:马荣昌

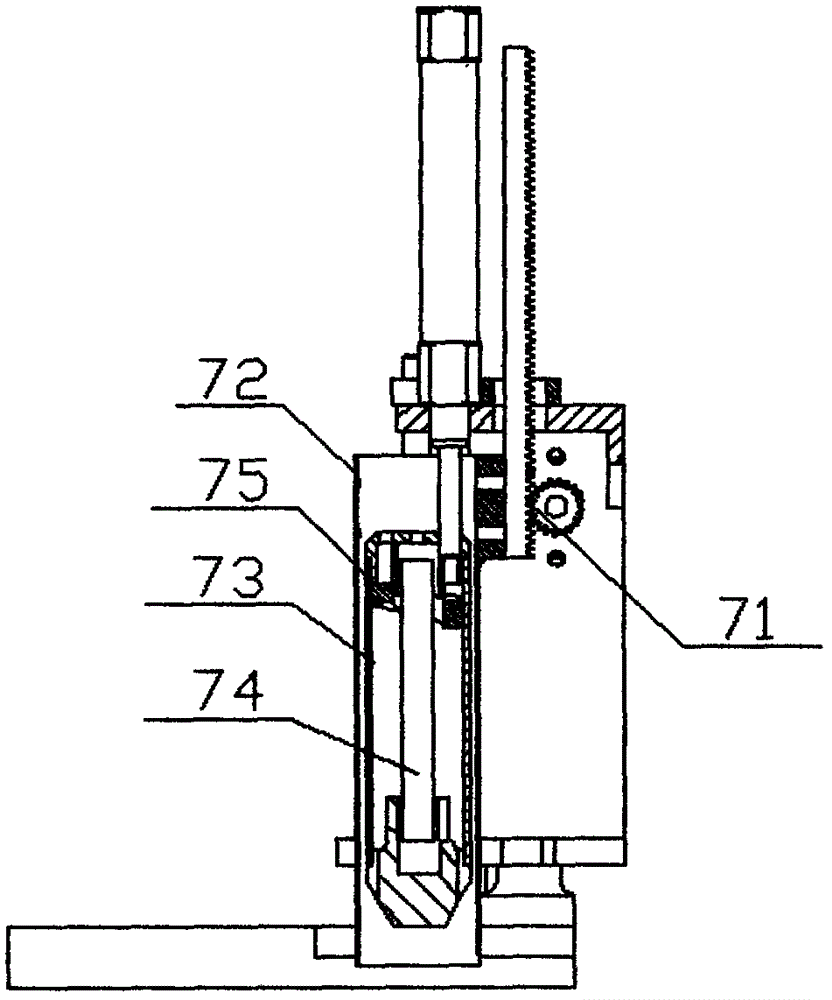

Friction stir additive device and additive manufacturing method

ActiveCN112496522AAchieve continuous supplyAchieve frictional heat generationNon-electric welding apparatusPiston GuideEngineering

The invention relates to the technical field of friction stir welding, in particular to a friction stir additive device and an additive manufacturing method. According to the friction stir additive device, hollow cavities which communicate with each other are formed in a stirring head and a knife handle, and the hollow cavity in the working end of the stirring head is provided with an opening; a wire is provided for the hollow cavities through a wire feeder; an extrusion part moves in the hollow cavities to extrude the wire, the wire is extruded into a bar to achieve friction heat production,and therefore, friction stir additive manufacturing is achieved, and continuous supply of materials during feeding can be achieved. By arranging a guide support to bear the extrusion part and providesliding support for an auxiliary plate, the auxiliary plate can be connected with a piston guide rod in a clamped mode, circumferential rotation of the piston guide rod is limited, and therefore, follow-up of a piston and the piston guide rod in the extrusion hollow cavity is avoided, and stability is improved.

Owner:安徽万宇机械设备科技有限公司

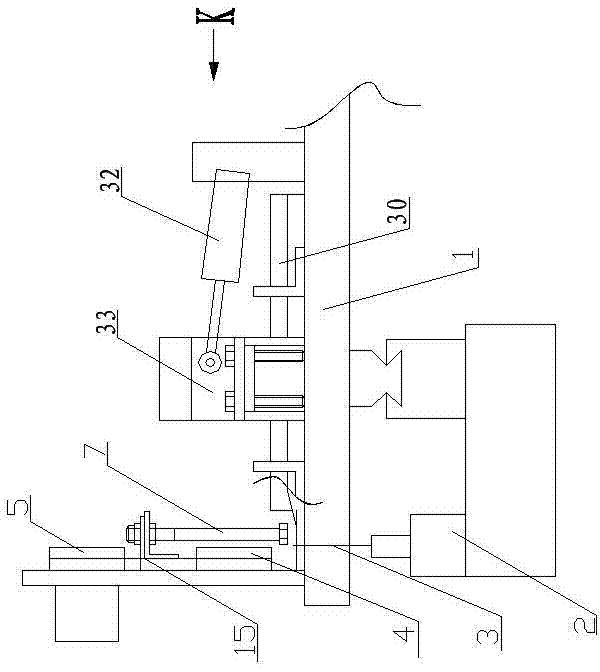

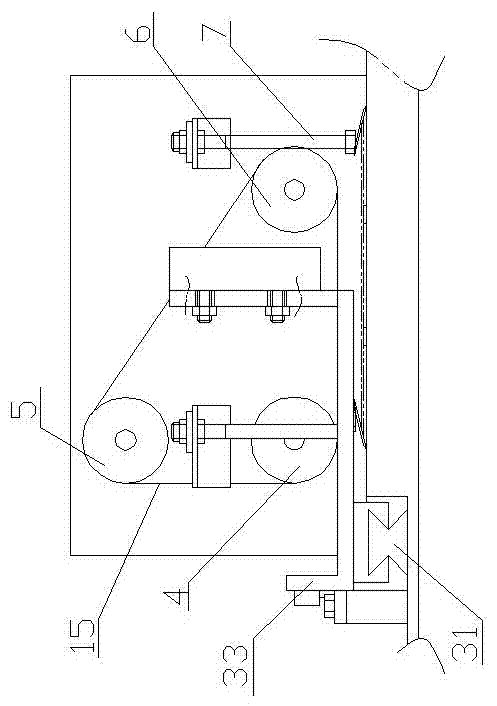

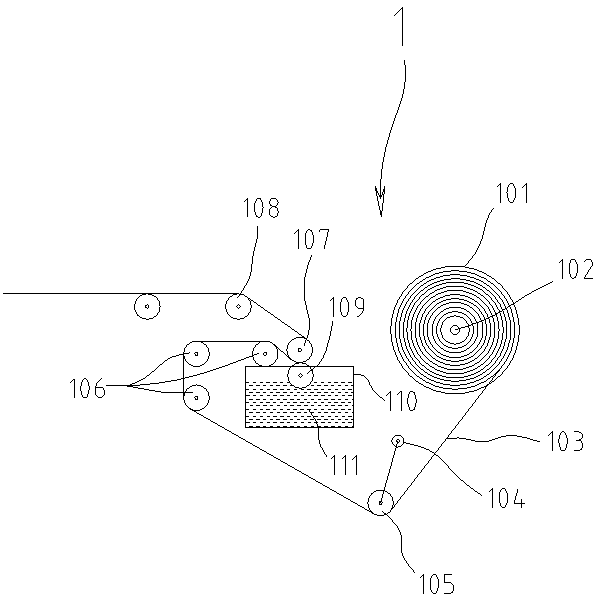

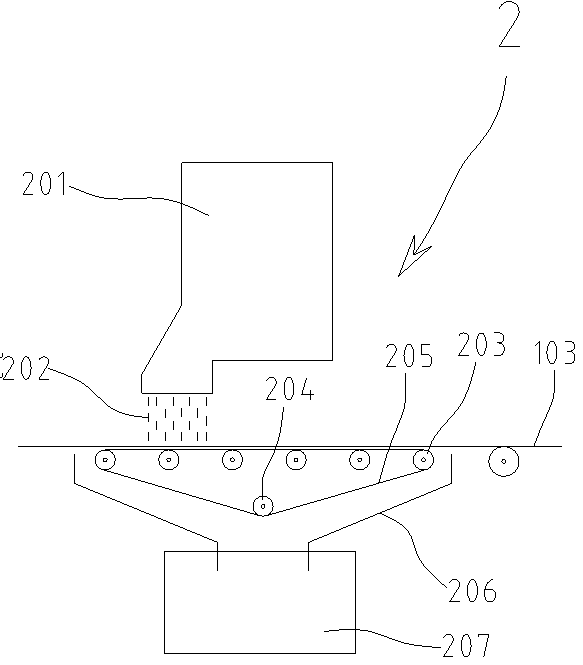

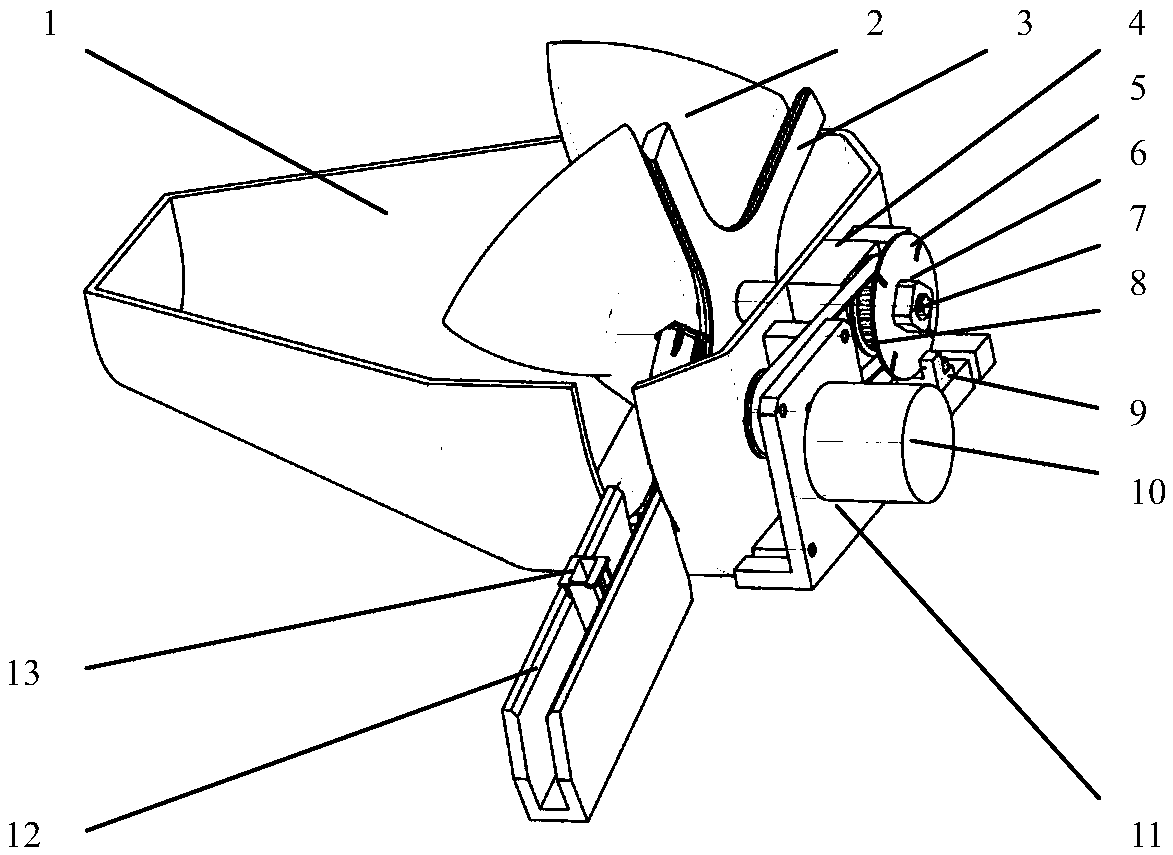

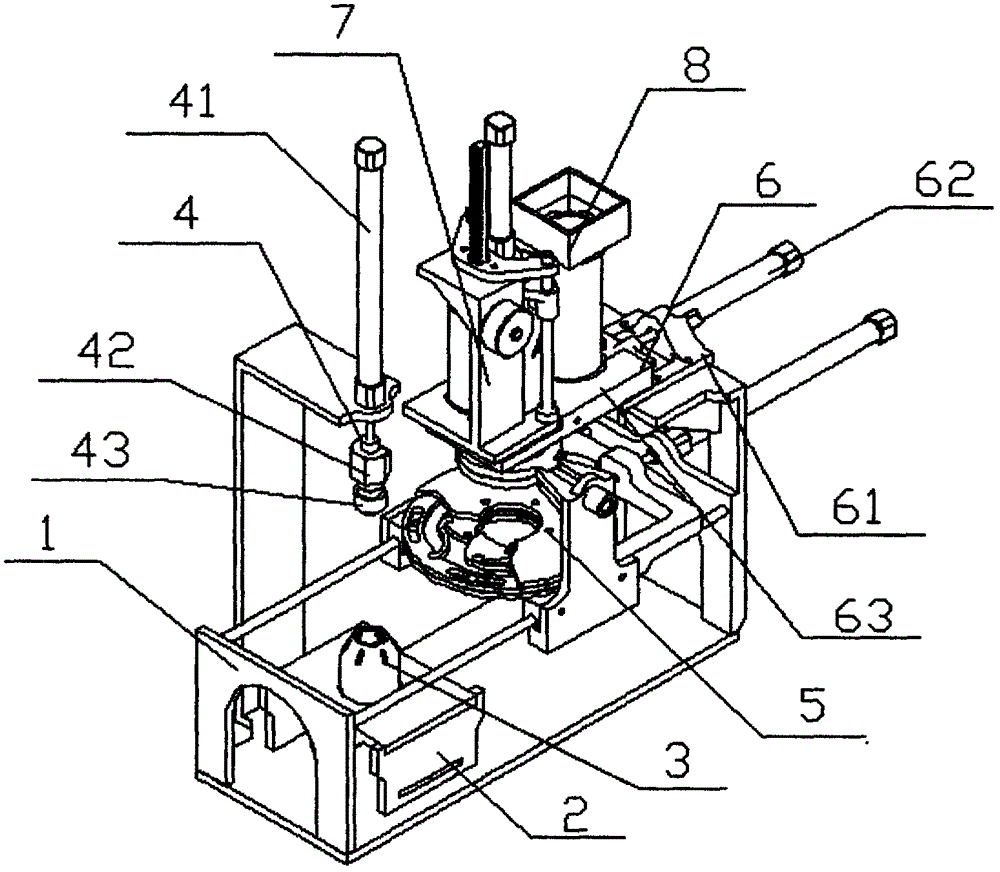

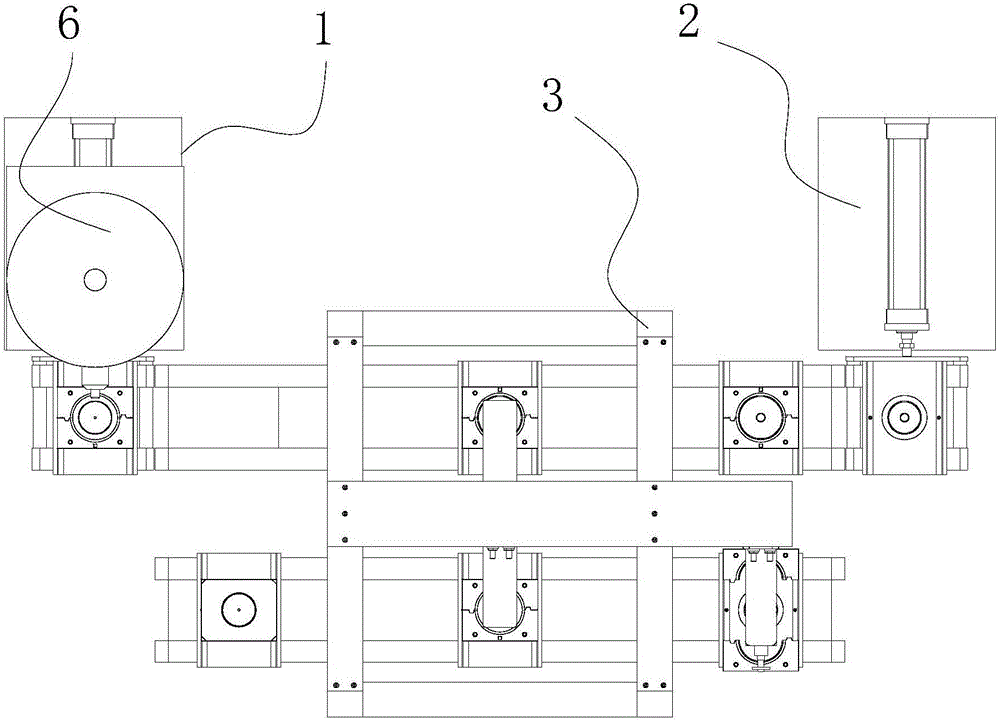

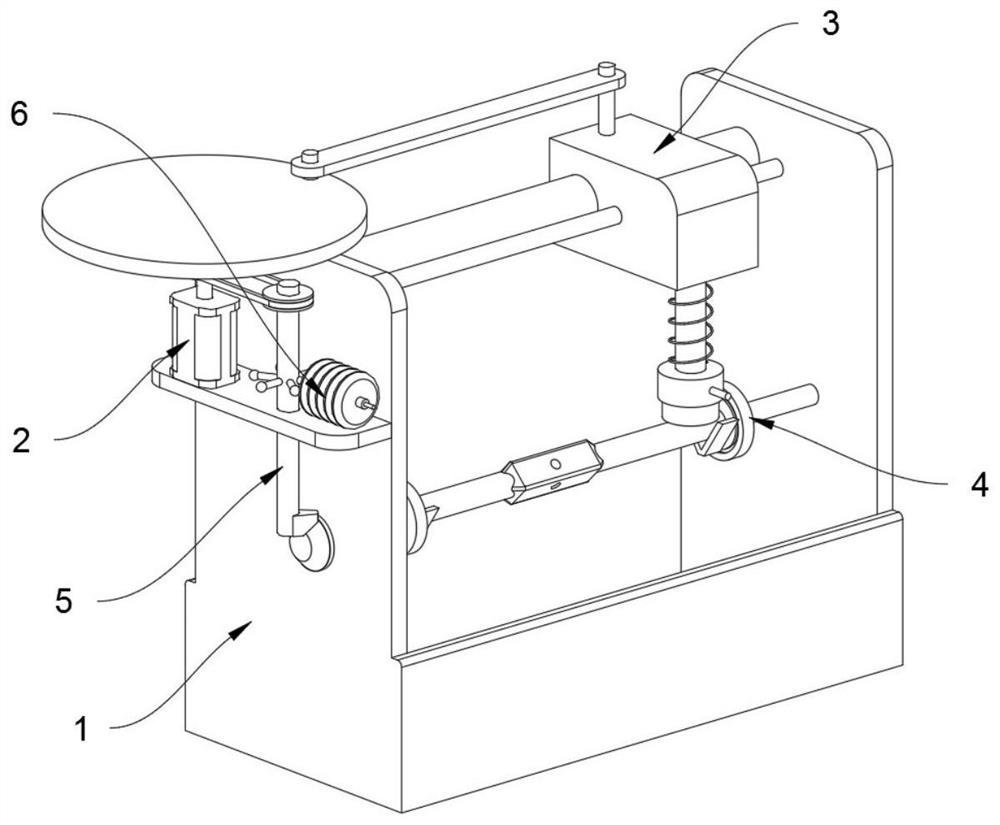

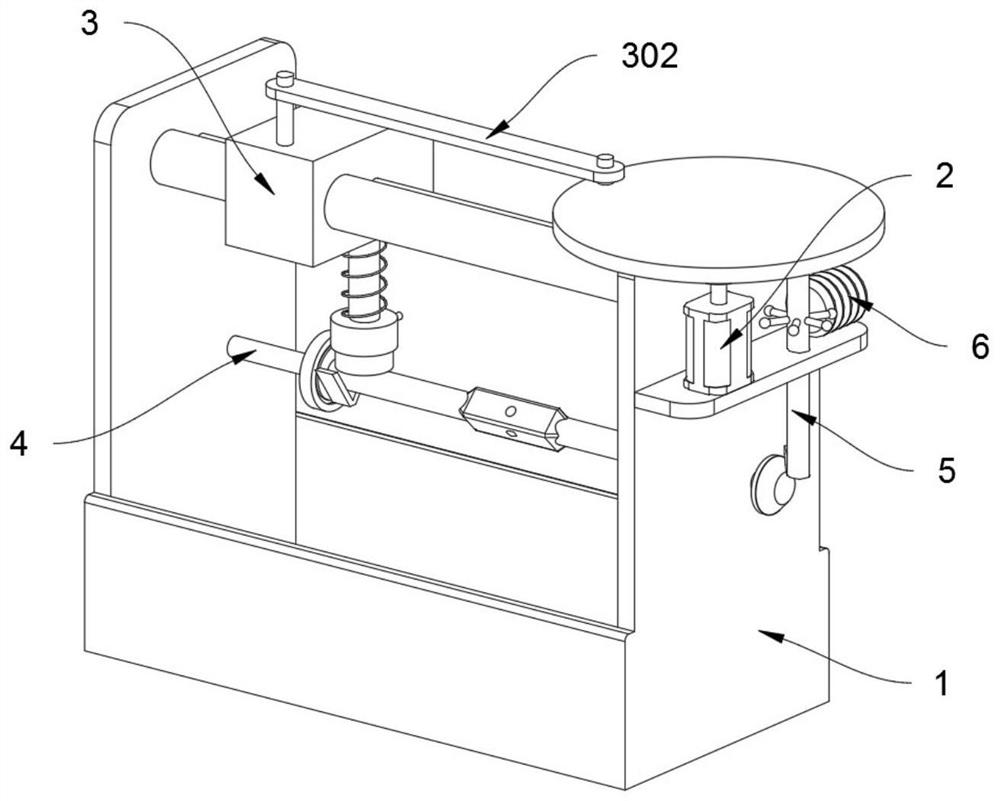

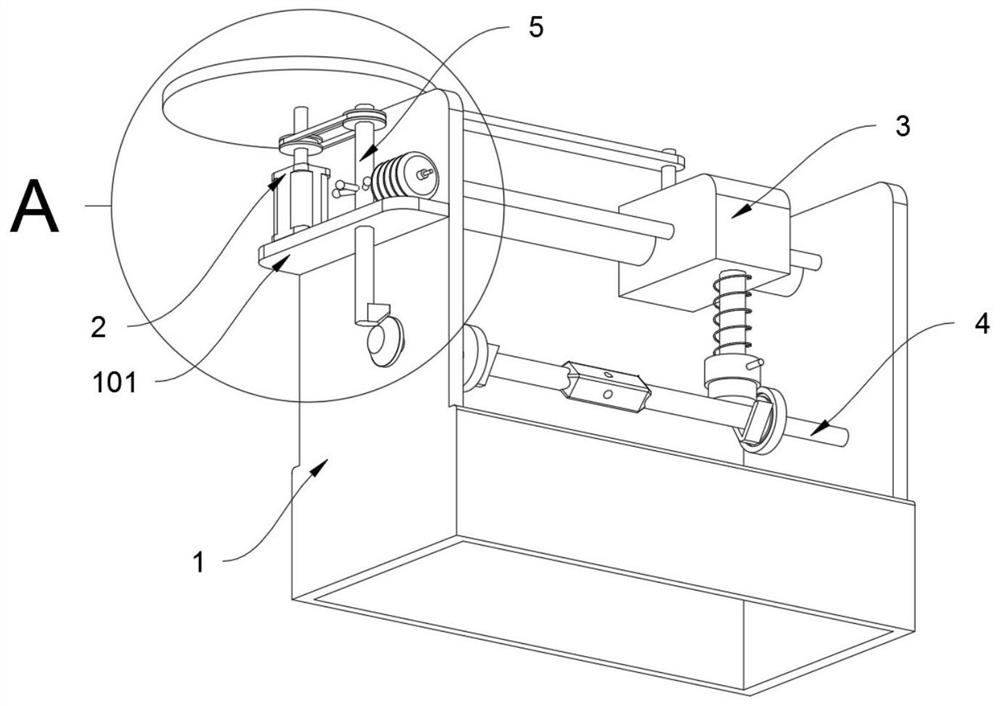

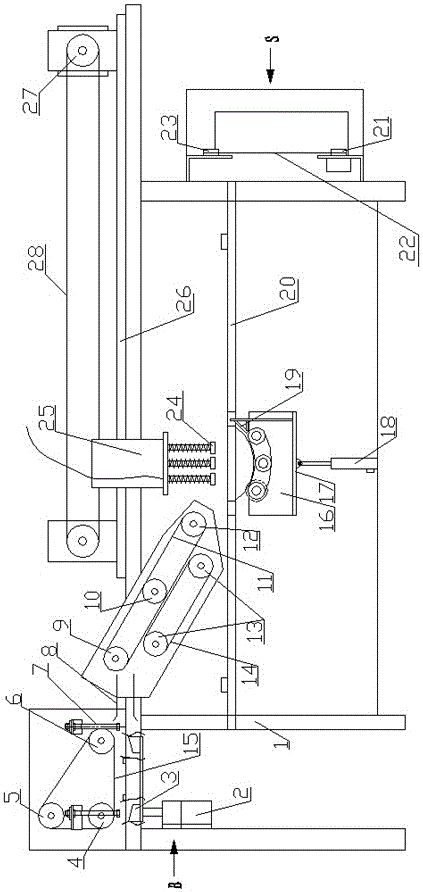

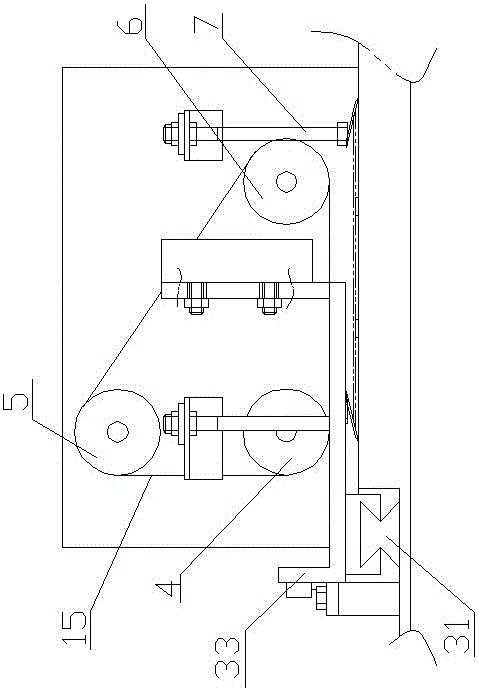

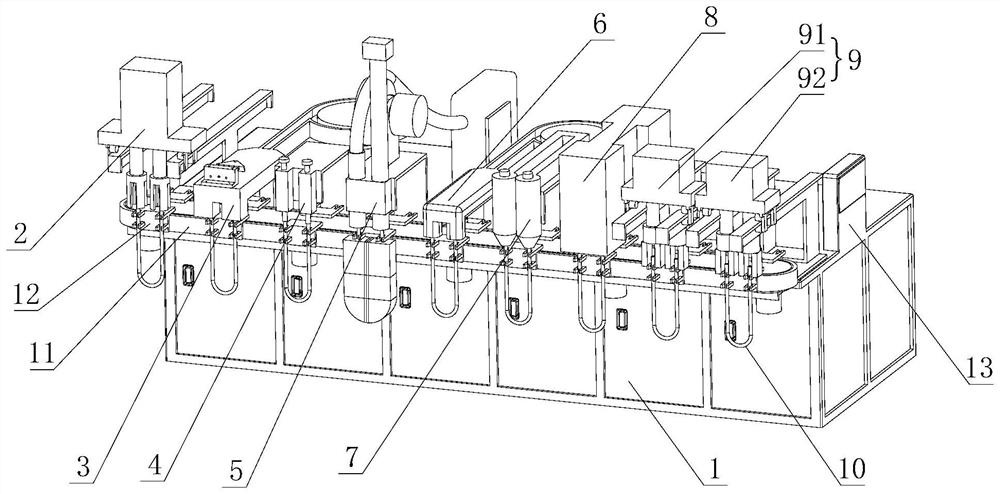

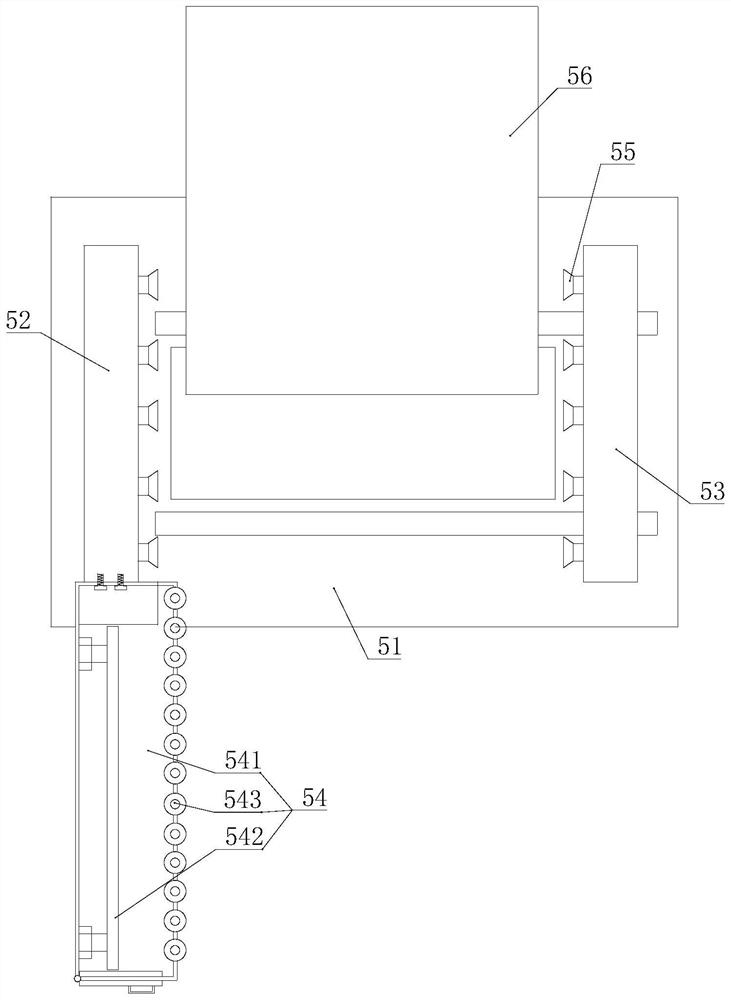

Transmission device for threading machine of handle of paper box

InactiveCN103042726AContinuous supplyAchieve continuous supplyBox making operationsPaper-makingPower apparatusPulley

The invention relates to a threading machine of a handle of a paper box, and in particular relates to a transmission device for the threading machine of the handle of the paper box. The transmission device for the threading machine of the handle of the paper box comprises a handle feeding mechanism, a handle cutting mechanism, a gasket feeding mechanism, a gasket conveying mechanism and a handle continuous feeding mechanism. A driving synchronous pulley in the gasket feeding mechanism is connected with a driven synchronous pulley through a gasket feeding synchronous belt. The gasket feeding synchronous belt is installed at one end of a traveling bracket which is placed on a slide rail. The other end of the traveling bracket is provided with an absorption device. A first-level handle feeding mechanism in the handle feeding mechanism comprises a driving synchronous pulley for handle feeding, a driven synchronous pulley for handle feeding and a driven feeding synchronous pulley. A feeding slide rail in the handle continuous feeding mechanism is provided with a feeding transmission bracket which is connected with a power device. A feeding bracket is installed below the feeding transmission bracket. The transmission device provided by the invention can continuously feed the handles and gaskets. The gaskets are not arranged continuously, and the gaskets can be continuously fed in small occupied space.

Owner:于颢明

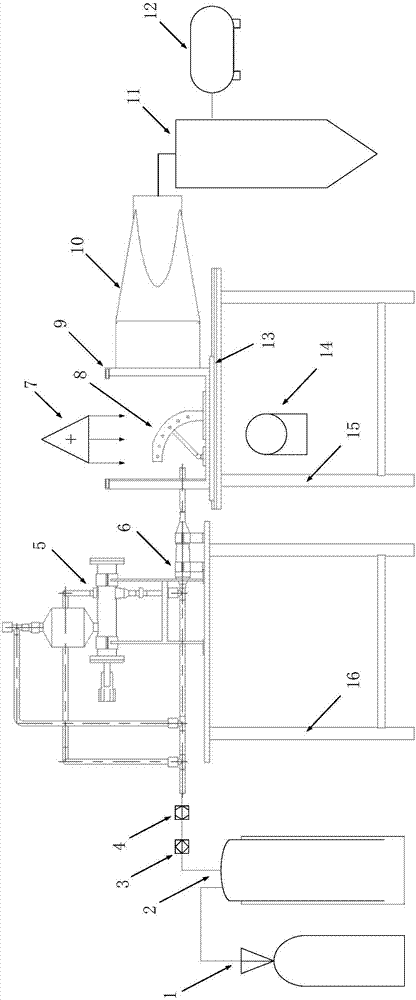

Continuous supersonic sand erosion test table and test method thereof

InactiveCN106950136AAchieve continuous supplyLow costInvestigating abrasion/wear resistanceUniform rotationEngineering

The invention discloses a continuous supersonic sand erosion test table and a test method thereof. The test table comprises a gas source device, a screw sand supply device, a sand blasting device, a test chamber, an exhaust tube and a cyclone separator. The gas supply device obtains high pressure gas flow through a high pressure gas storage tank, the screw sand supply device adopts a pressure container as a sand storage container, a motor drives a screw to rotate at a uniform speed, and the gas outlet of a feeding cylinder is provided with a gas flowing hole for assisting sand falling in order to avoid sand grain obstruction; and high quality gas flow is obtained from the Laval tube outlet of the sandblasting device to make the sand grains move along the axis in order to reduce sand grain and tube wall collision. The sand grains can be accelerated to a supersonic state only through room-temperature drying gas; the sand supply device has a good sealing property, can balance the pressure of the sand supply device in a high pressure environment, and has a good sand supply precision; and a gas source used in the invention has a low price and stable performances.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sandwich nori baking machine set capable of realizing continuous feeding

PendingCN107822010AAchieve continuous supplyAvoid wastingBaking ovenFood coatingEngineeringFeedback control

The invention relates to a sandwich nori baking machine set capable of realizing continuous feeding. The sandwich nori baking machine set capable of realizing continuous feeding comprises a lower layer nori roll feeding assembly, a first sandwich material feeding assembly, a second sandwich material feeding assembly, an upper layer nori roll feeding assembly, a backing assembly, and a cutting assembly; the upper layer and the lower layer nori roll feeding assemblies are used for continuous up and low nori roll feeding, and automatic coating of an adhesive; the sandwich material feeding assemblies are used for scattering sandwich materials into the middle parts of up layer and lower layer nori roll materials; sensing signal feedback control is adopted in rotating of the upper layer and thelower layer nori roll feeding assemblies; and the sandwich nori backing machine set is provided with a scattered material recovery device. The sandwich nori baking machine set is capable of realizingclean operation, is high in output, and is excellent in reliability.

Owner:LIANYUNGANG HAIGONG MASCH CO LTD

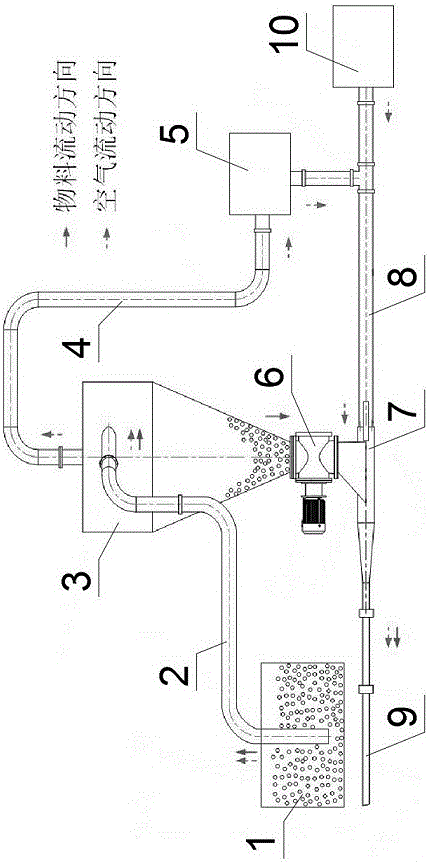

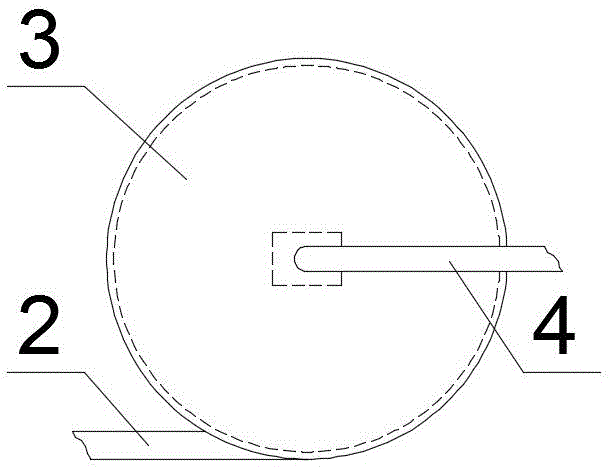

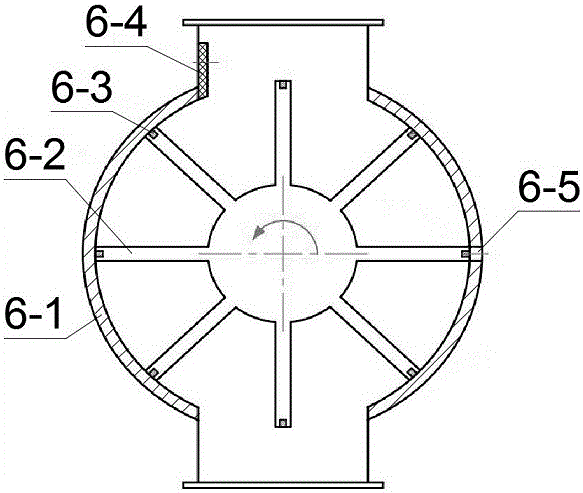

Feeding device for underground coal mine long-distance guniting system

ActiveCN106285720AAchieve continuous supplyReduce vibrationUnderground chambersTunnel liningProcess engineeringCoal

The invention discloses a feeding device for an underground coal mine long-distance guniting system. The feeding device comprises a stirring bin, a material suction pipeline, a cyclone collector, a cyclone air outlet pipeline, a vacuum pump, a blocking valve, an ejector, an ejector air inlet pipeline, a long-distance material conveying pipeline and a main air source air compressor. According to the feeding device for the underground coal mine long-distance guniting system, on the basis of the current situation that the underground air source is sufficient, after guniting materials are sucked and fed into the sealed cyclone collector through negative pressure produced through the vacuum pump, the materials and gas are separated, and the guniting materials enter the blocking valve so that automatic feeding can be achieved; and the materials are conveyed in a pneumatic conveying mode, surplus gas in the guniting materials is separated out and is pumped and supplemented into a main air source by the vacuum pump, and the air source can be sufficiently utilized; the guniting materials are subjected to pumping pressure conveying through the blocking valve, continuous feeding of the guniting materials is achieved, and pipeline vibration is reduced; and accordingly, long-distance conveying is achieved, the pipeline blockage failure rate is decreased, and the investment cost of underground auxiliary conveying and early-stage auxiliary engineering is reduced.

Owner:CHINA UNIV OF MINING & TECH

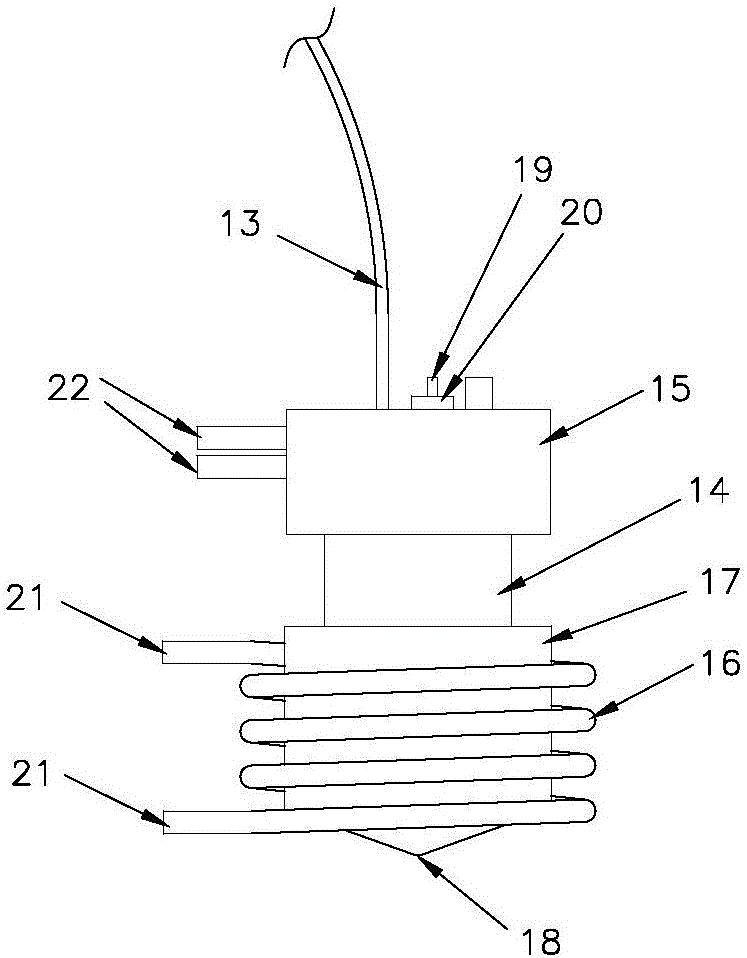

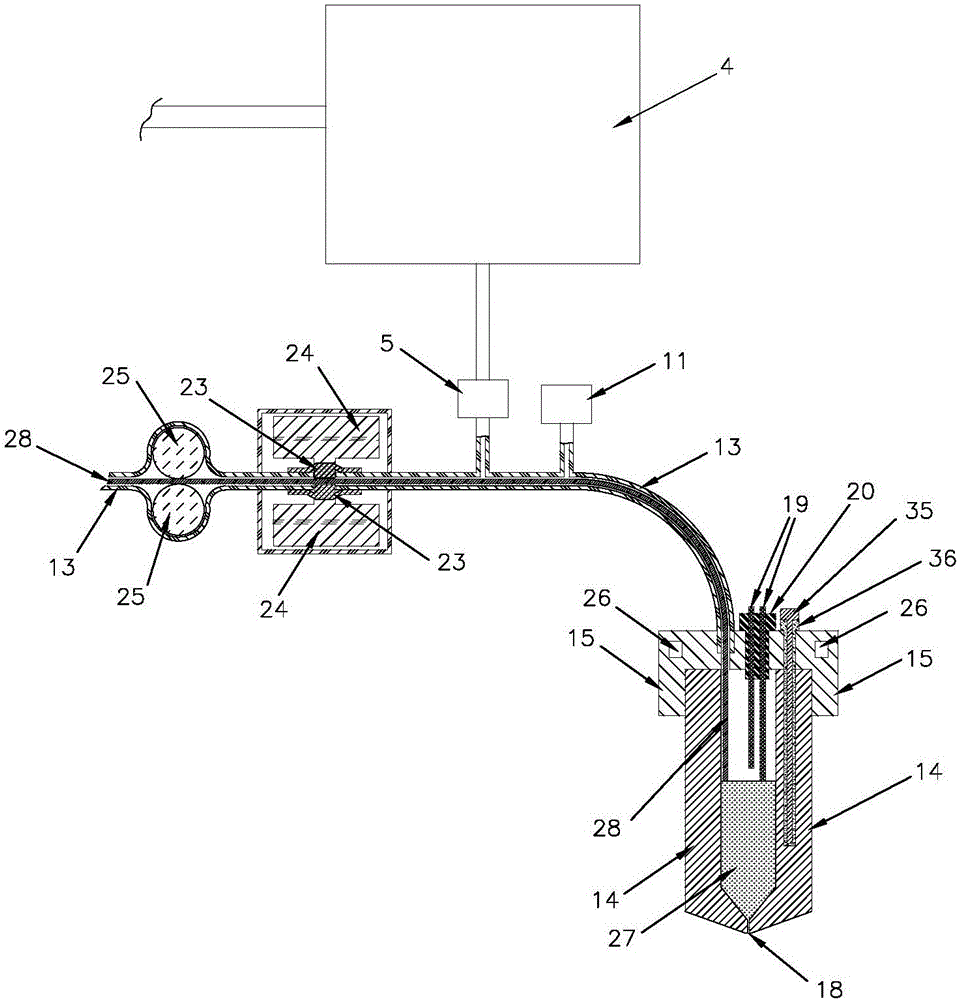

Liquid raw material generation device used for three-dimensional printing and control method of liquid raw material generation device

ActiveCN106180717AAvoid oozingAchieve continuous supplyAdditive manufacturing apparatusIncreasing energy efficiencyPressure senseProcess engineering

The invention discloses a liquid raw material generation device used for three-dimensional printing and a control method of the liquid raw material generation device. The device is mainly composed of a heating unit used for generating liquid raw materials, a first opening and closing device which is used for controlling internal space of the heating unit to communicate with the external atmosphere or a negative-pressure device, a second opening and closing device used for controlling solid raw materials to enter the internal space of the heating unit, an air pressure sensing device, a liquid level sensing circuit and a temperature sensing circuit. The device has the beneficial effects that the problem that liquid raw materials of an extrusion head leak from a solid raw material inlet in the current FDM three-dimensional printing technology is solved; continuous solid raw material supply in the three-dimensional printing process is achieved, and printing of large parts is facilitated; liquid drops can be generated, and continuous liquid raw material flow can also be generated; liquid raw material fluid can be flexibly controlled; real-time monitoring on parameters such the size and the temperature of the liquid raw materials in a heating cavity can be achieved; and high feasibility and practicability are achieved, and the application range is wide. The liquid raw material generation device and the control method have substantive progress.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

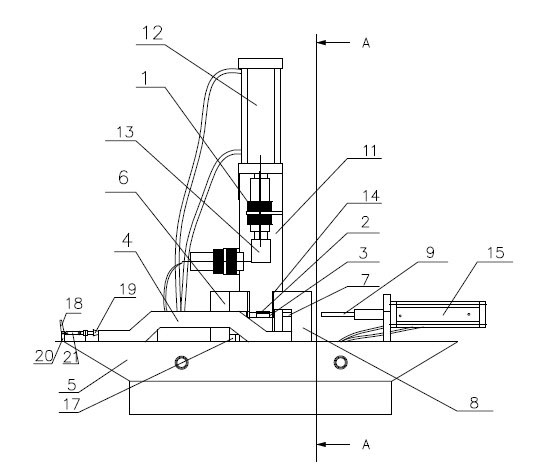

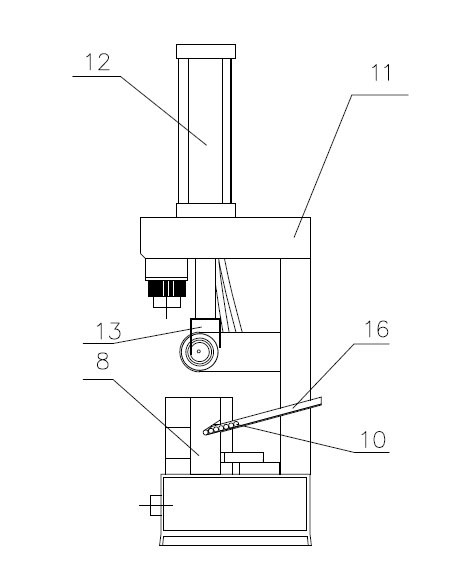

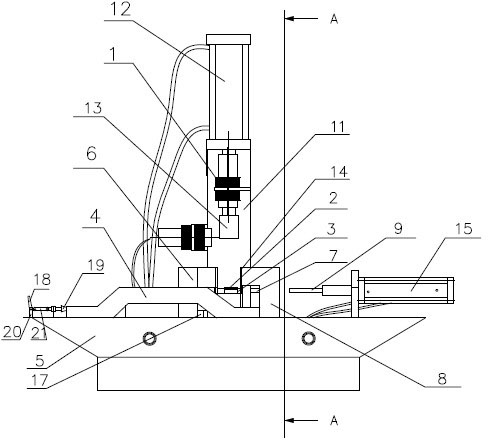

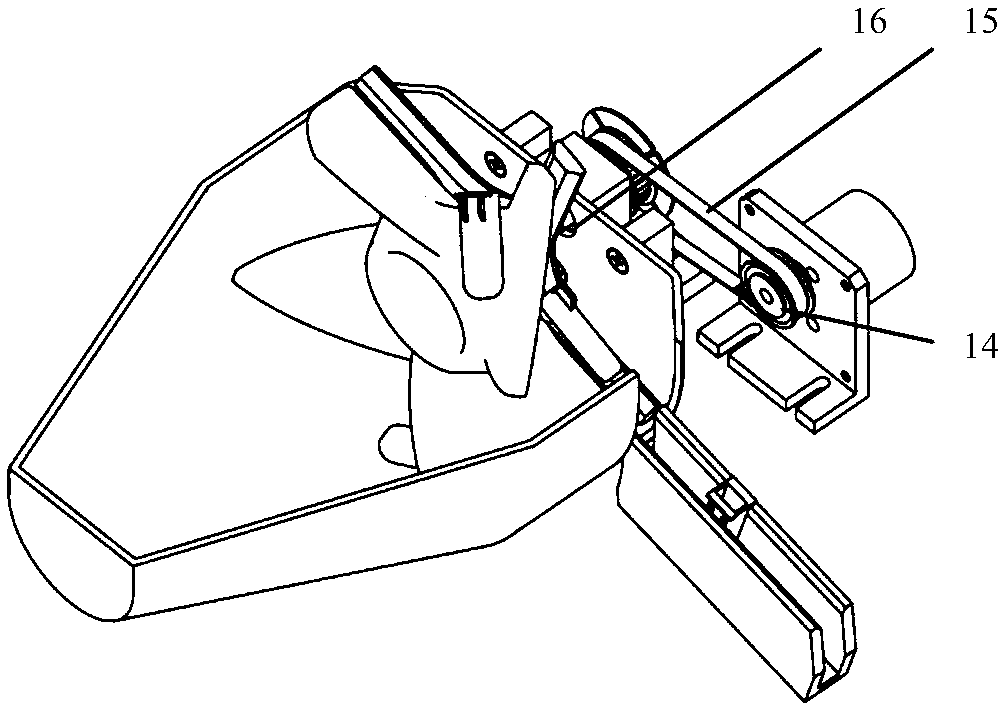

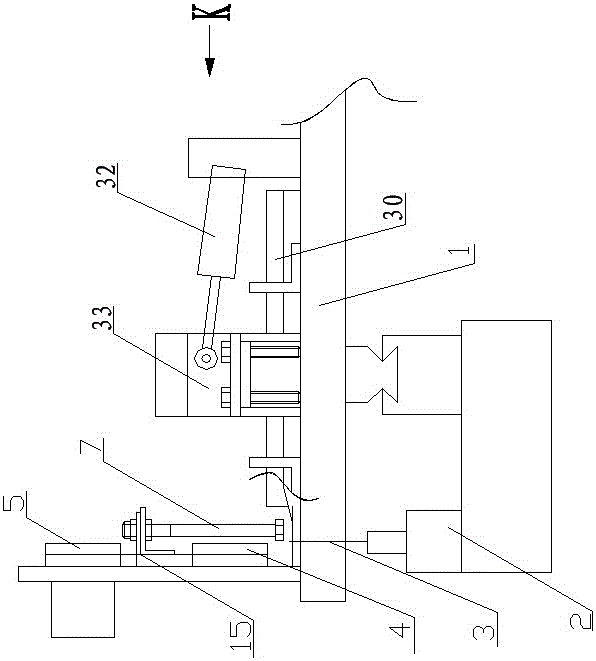

Device for assembling handle skeleton and balance weight block of vehicular door automatically

ActiveCN102489991AAchieve continuous supplyRealize automatic assemblyMetal working apparatusEngineeringMechanical engineering

The invention relates to equipment for installing finished pieces, in particular to a device for assembling a handle skeleton and a balance weight block of a vehicular door automatically. The device comprises a workbench (5) and a positioning block (6) which is arranged on the workbench (5) and used for fixing a handle skeleton (4), wherein a compacting device for compacting a balance weight block (2) and a pin positioning block (8) with a pin positioning groove (7) are arranged on the workbench (5). By the scheme, after the handle skeleton and the balance weight block are compacted and positioned by the positioning block and the compacting device, a pin in the pin positioning groove is jacked into a mounting hole of the handle skeleton and a pin hole of the balance weight block by a stamping rod, so that the handle skeleton and the balance weight block are assembled automatically, and the injury of personnel is avoided while the work efficiency is improved.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

Domestic sludge aerobic composting method and system thereof

PendingCN107089847AOptimizing dosageGuaranteed unobstructedBio-organic fraction processingClimate change adaptationSludgeSlag

The invention provides a domestic sludge aerobic composting method, which can solve the technical problems that the existing aerobic composting method is long in one-time composting period, and poor in sludge reduction effect. The method comprises the following steps: I. adding a conditioning agent for hardening and tempering, and then performing deep dehydration treatment to obtain a mud cake; II. crashing the mud cake to obtain mud cake particles; and III. composting and fermenting the mud cake particles. The composting method is characterized in that the conditioning agent contains a curing agent and a filtering aid, the addition quantity of each of the curing agent and the filtering aid is 10%-30% of solid content of sludge; the curing agent contains the following raw materials in percentage by mass: 5% -15% of incineration furnace slag, 50%-70% of carbide slag, and 20% -35% of desulfurization plaster, and the filtering aid is a porous biomass material. In addition, the invention further provides a domestic sludge aerobic composting system for realizing the method.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

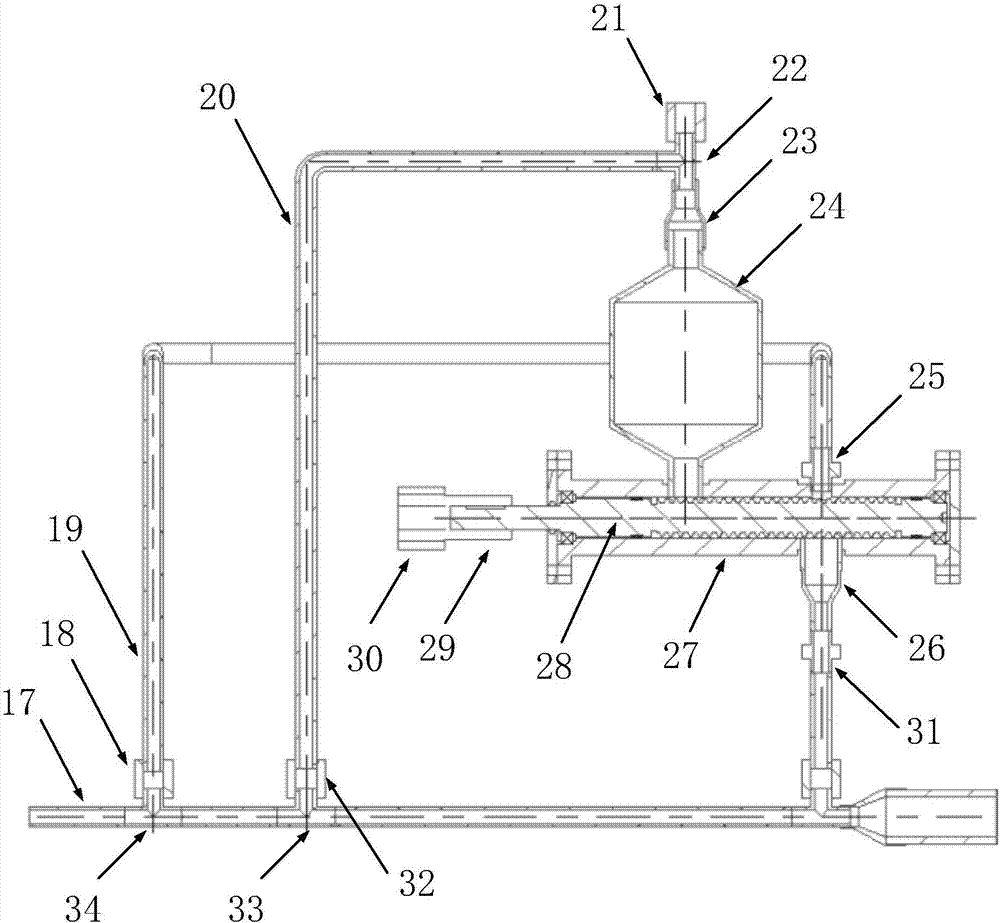

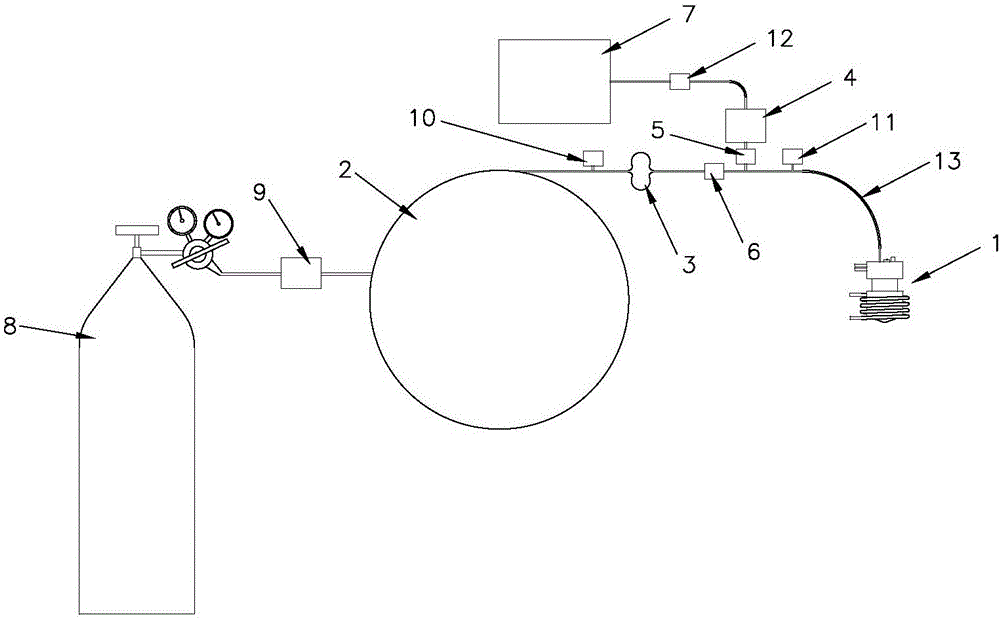

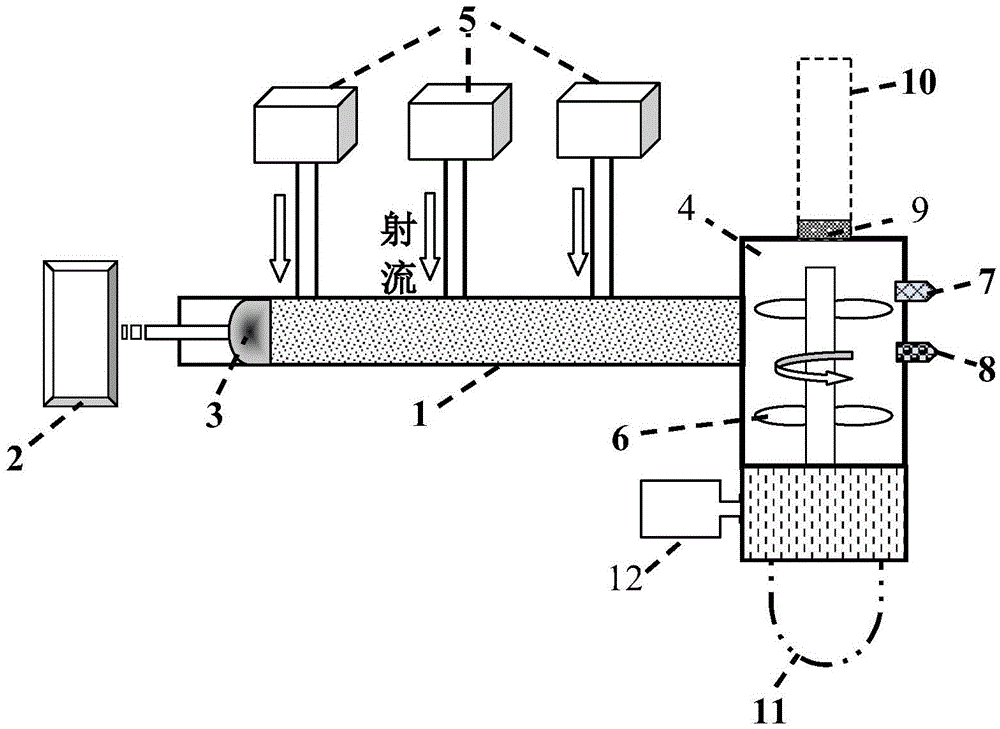

Experiment method and experiment device for decomposing hydrate

ActiveCN104897854APromote decompositionAchieve continuous supplyMaterial analysisDecompositionWater velocity

The invention discloses an experiment method and an experiment device for decomposing hydrate. The method comprises the following steps: loading hydrate sediment particles into a packing pipeline, pushing into a pressure chamber and spraying water into the pipeline, wherein the ratio of the water velocity to the advance velocity of the hydrate sediment particles has to ensure that the volume mixing ratio of water to the hydrate sediment particles is 7 to 3 or above; mixing the hydrate sediment particles in the pressure container with water to promote decomposition of hydrate; simultaneously measuring the temperature and pressure distribution in the pressure chamber; after the hydrate sediment particles in the pressure chamber are decomposed, enabling the gas and water to flow up to the outside through a filter screen; precipitating soil particles to the bottom of the pressure chamber, recording the quantity of the gas, water and soil particles; after decomposing of the hydrate sediment particles is finished, sucking the soil particles out of the pressure chamber; pulling a piston out of the pipeline and refilling the hydrate sediment particles; and repeating the steps to finish the experiment of decomposing the hydrate sediment particles in a way of mixing with water.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

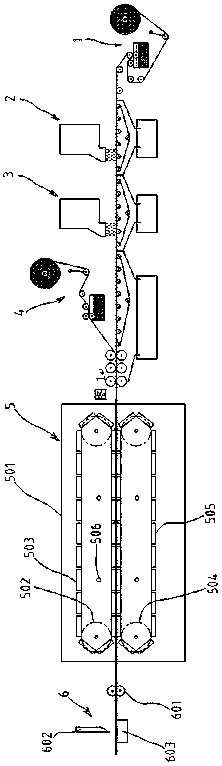

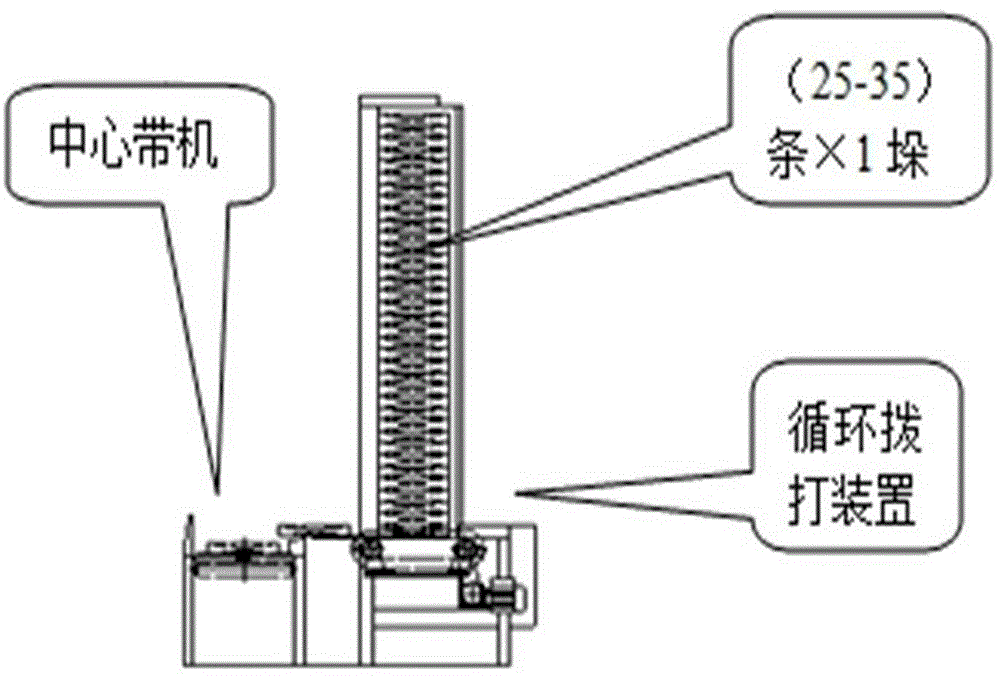

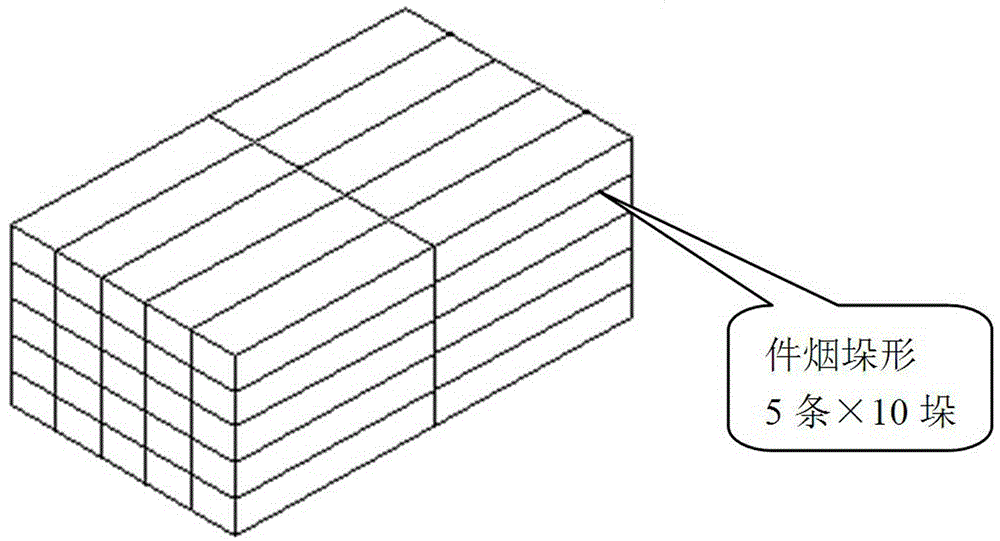

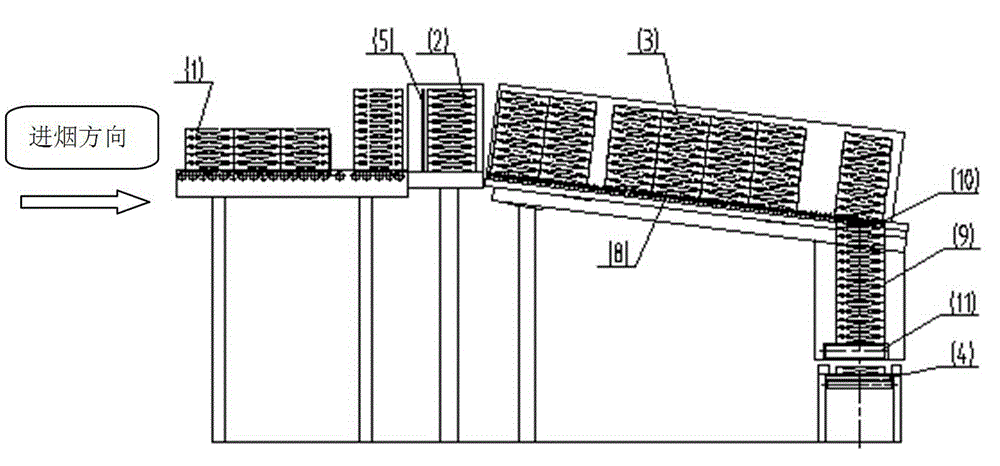

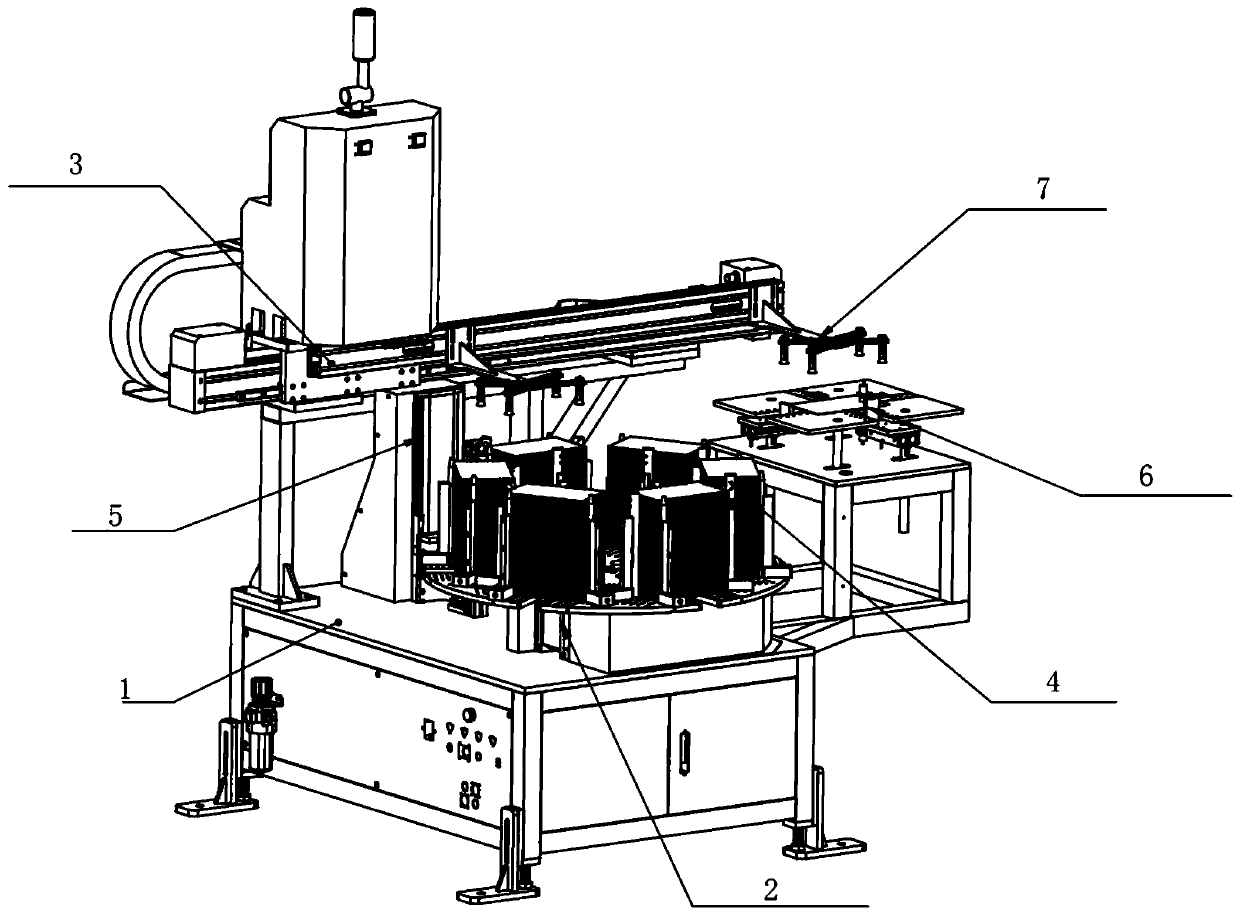

High-speed cigarette sorting unit

ActiveCN104590900AAchieve continuous supplyRealize stack conversionStacking articlesDe-stacking articlesCentral beltClockwise

The invention discloses a high-speed cigarette sorting unit. The high-speed cigarette sorting unit is characterized in that the upstream connecting opening is unpacking equipment and comprises a stack-shaped conversion device (1), a replenishment car (2), a dispensing machine (3), a central belt machine (4), and the like; the stack-shaped conversion device (1), the replenishment car (2) and the dispensing machine (3) are successively arranged in a clockwise direction, the central belt machine (4) is located under the end section of the dispensing machine (3); an unstacking mechanism (5) is arranged in the replenishment car (2), and the unstacking mechanism (5) reciprocates along a track (6) between the stack-shaped conversion device (1) and the sorting channel (7). The high-speed cigarette sorting unit has the beneficial effects that the sorting capacity is high, a stack shape is easily converted, goods can be automatically replenished, and the high-speed cigarette sorting unit has the compatibility of a plurality of brands, and is stable in performance and lower in cost.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

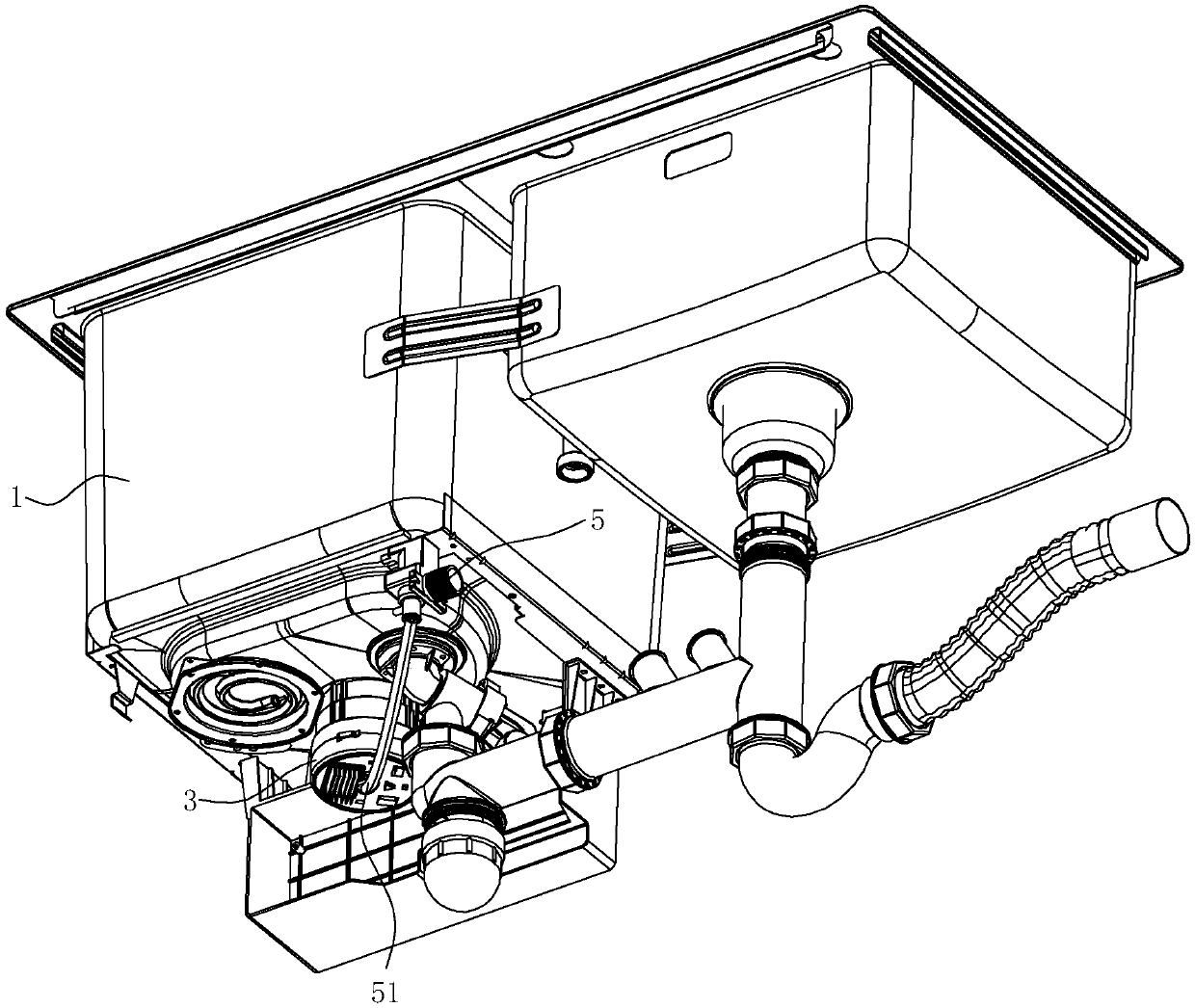

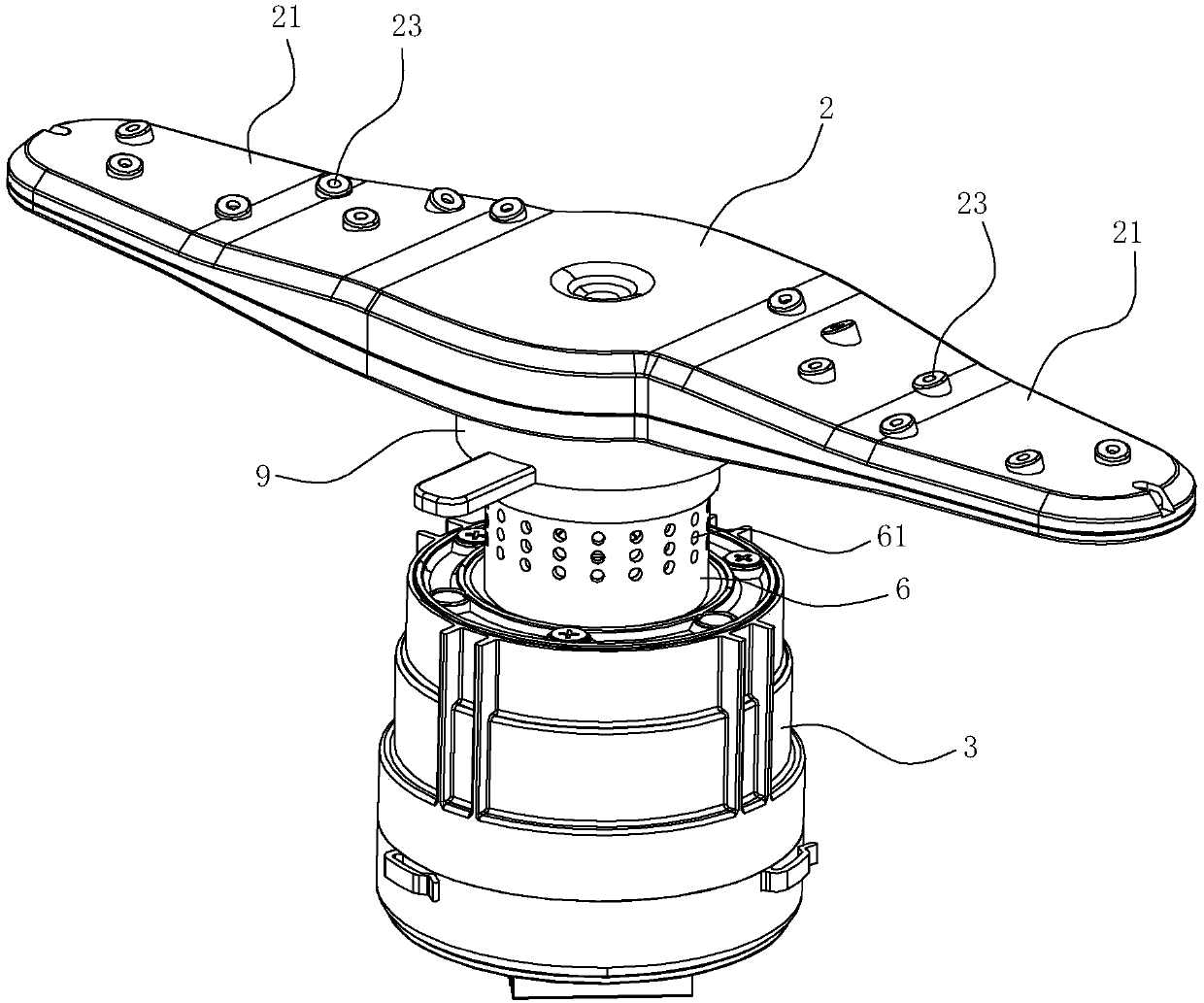

Cleaning machine

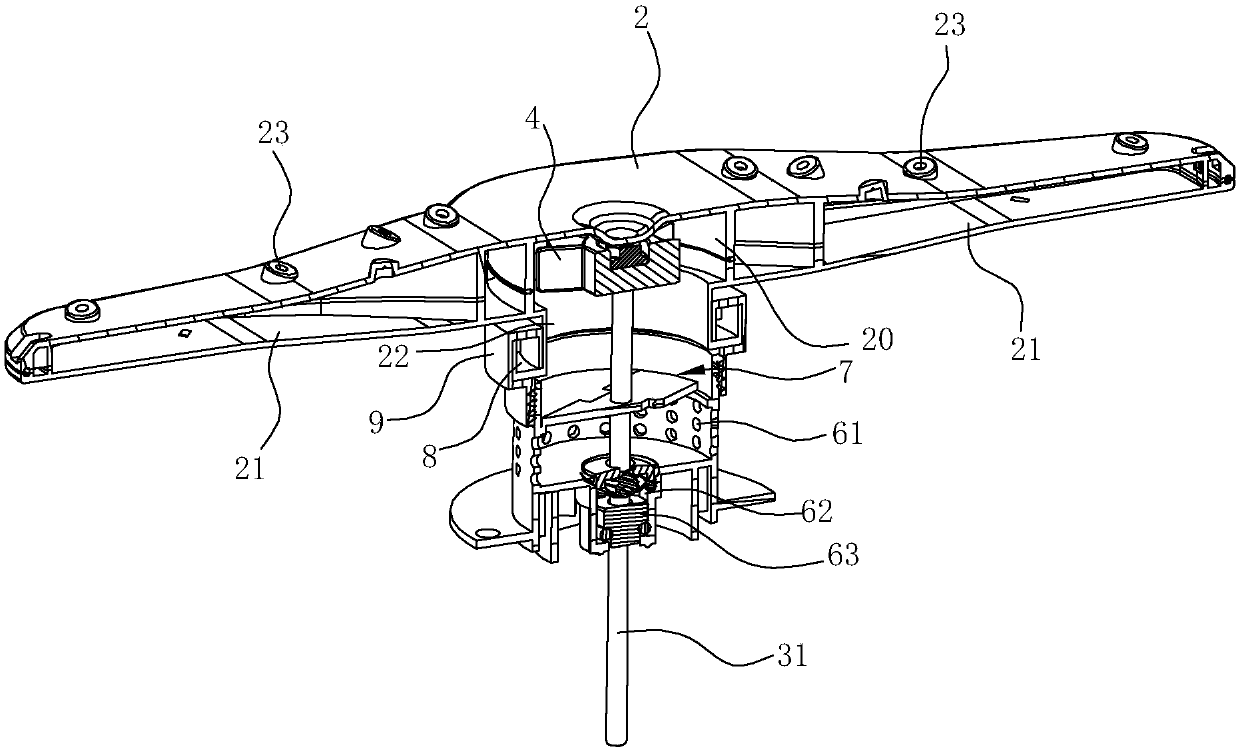

PendingCN110833369ARealize two-way rotationAchieve continuous supplyTableware washing/rinsing machine detailsImpellerElectric machinery

The invention relates to a cleaning machine. The cleaning machine comprises a water tank body, a spraying arm, a motor, a motor shaft, a centrifugal impeller, a water supply mechanism and a diversionpart; the centrifugal impeller is arranged in the spraying arm, and connected with the upper end of the motor shaft; the motor shaft is through vertically; furthermore, the lower end is connected withthe water supply mechanism; the diversion part is arranged below the spraying arm, and connected with a water inlet; multiple diversion holes are arranged on the outer circumferential wall of the lower part of the diversion part at intervals; and the upper part of the diversion part is provided with a valve assembly, which can close the lower end of the water inlet when the motor shaft inputs water into the spraying arm and open the lower end of the water inlet when the centrifugal impeller is started. When in use, the water inlet is closed through the valve assembly at first; the motor shaftinputs a little water into the spraying arm, so that the centrifugal impeller is immersed; after the centrifugal impeller is started, water supply of the motor shaft is stopped; under the action of negative pressure, a water flow continuously enters the diversion part, and drives the valve assembly to open the water inlet; therefore, continuous supply of the water flow is realized; due to positive and negative rotation of the motor, bidirectional rotation of the spraying arm can be realized; and thus, the cleaning effect is increased.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

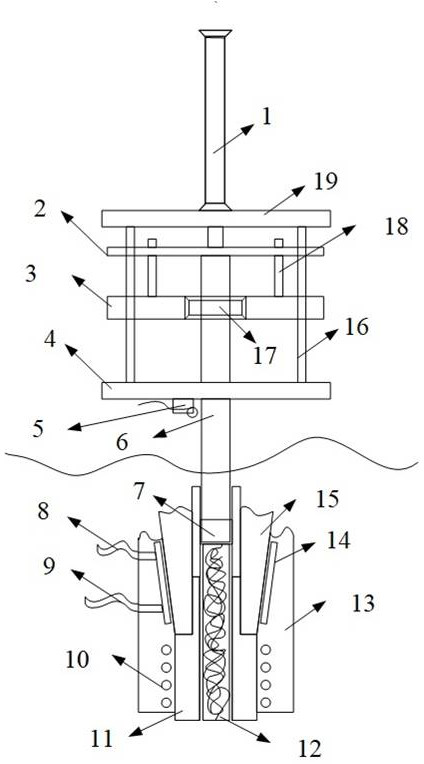

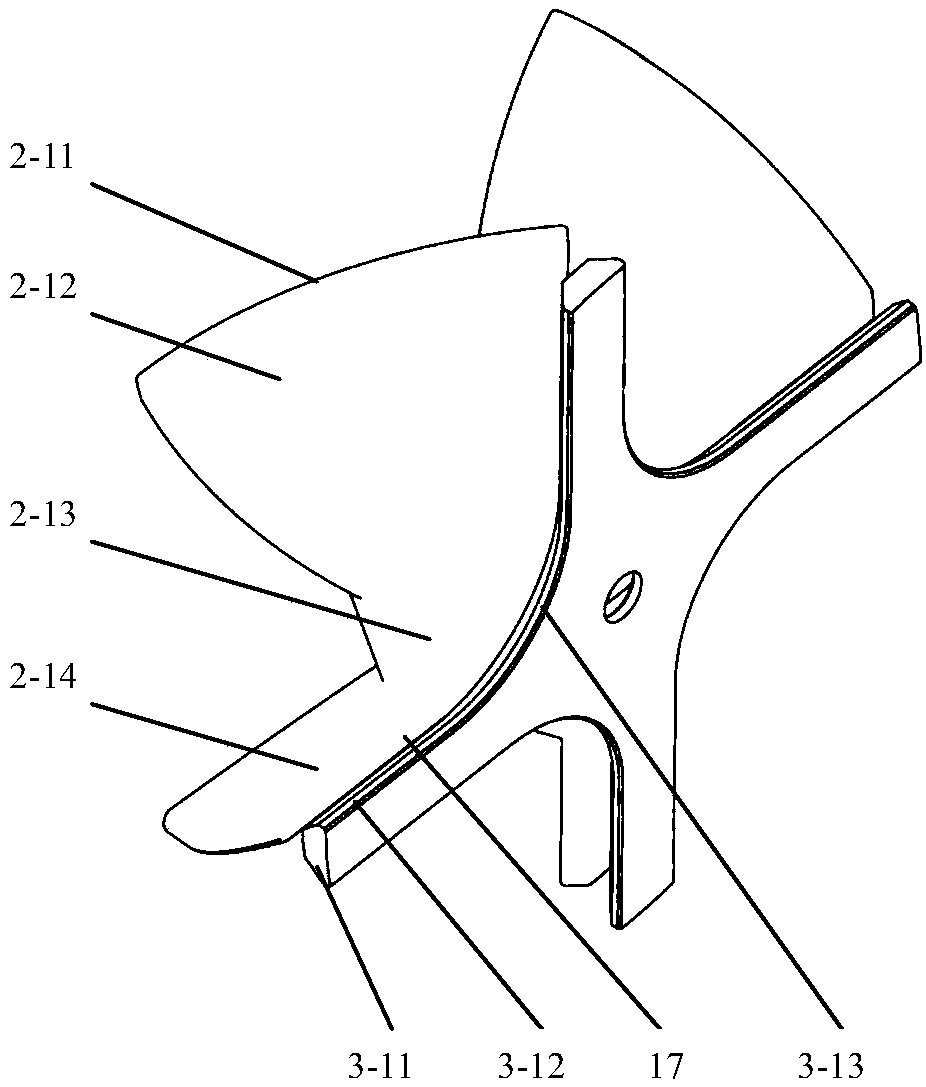

Solar mobile underwater ozone treatment machine

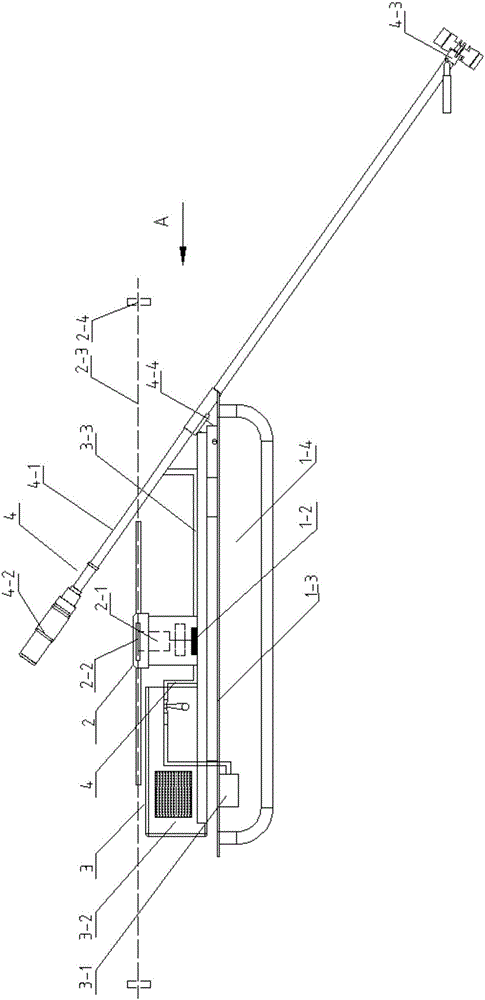

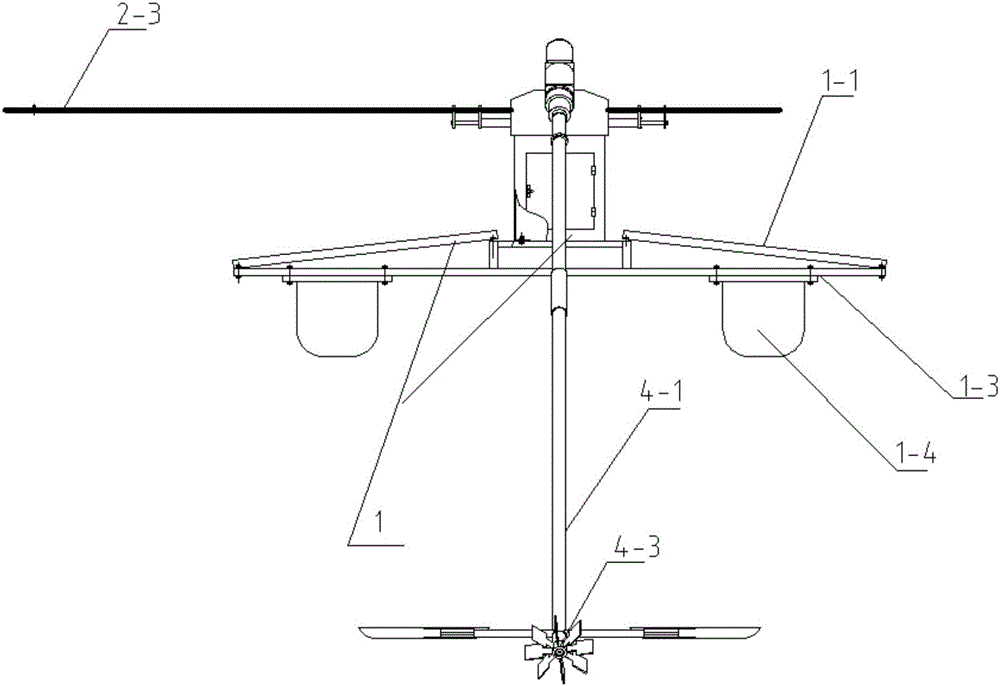

ActiveCN105712467AOxygenated organic matterKill germsSludge treatment by oxidationGeneral water supply conservationUnderwaterBottom water

The invention relates to a solar mobile underwater ozone treatment machine. The solar mobile underwater ozone treatment machine comprises a solar power device, a water walking device, an ozone generation system and a self-rotating spraying device, wherein the ozone generation system is arranged on a floating body and is used for conveying ozone to the self-rotating spraying device at the front end through a gas delivery pipe; the self-rotating spraying device comprises a hollow telescopic pole, the telescopic pole is obliquely downwards hinged and fixed to the floating body through a hinge ring, a disturbance motor is arranged at the head part of the telescopic pole and drives a transmission shaft in the telescopic pole to rotate, the transmission shaft drives a rotary disturbance head at the lower end to rotate, and the rotary disturbance head and a gas channel in the telescopic pole are arranged coaxially; under the combined action of ozone gas and disturbance performed by blades of the rotary disturbance head on water in the underwater area, improvement work for bottom mud and bottom water is completed.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Novel clinical delivery assist device for obstetrics and gynecology department

InactiveCN111821537AAchieve continuous supplyQuick configurationEnemata/irrigatorsRotary stirring mixersElectric machineryWastewater

The invention discloses a novel clinical delivery assist device for an obstetrics and gynecology department. The novel clinical delivery assist device comprises a waste water tank, wherein the upper surface of the waste water tank is fixedly connected with a negative pressure pump; a water outlet on the negative pressure pump runs through the inside of the waste water tank; a water inlet of the negative pressure pump is fixedly connected with a suction pipe; the upper surface of the waste water tank is fixedly connected with a sealing block; a hollow cavity is formed in the sealing block; an inner wall of the hollow cavity is fixedly connected with a ring I; the inner wall of the ring I is fixedly connected with a dual-shaft motor; and two ends of an output shaft on the dual-shaft motor are fixedly connected with shafts I. According to the novel clinical delivery assist device, through the cooperative use of the structures, the problems that shortage of a cleaning liquid easily occursin use due to the fact that preparation of the cleaning liquid cannot be easily completed quickly in an actual use process, and meanwhile, a doctor needs to manually align the cleaning liquid with a to-be-washed part for shaking washing, and the waste liquid after washing is also difficult to recover in time to cause inconvenience for use are solved.

Owner:谭桢

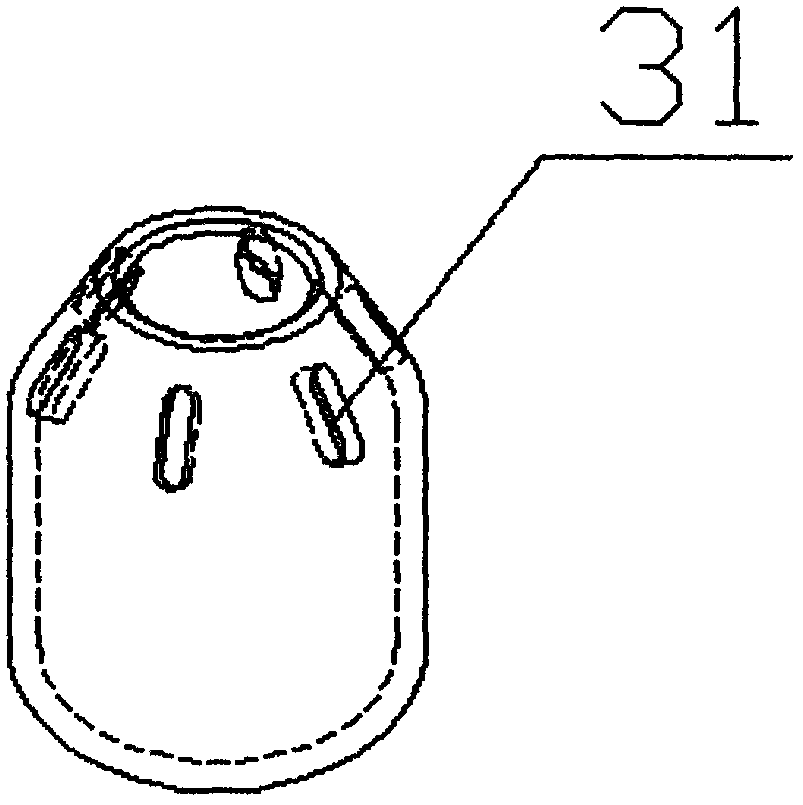

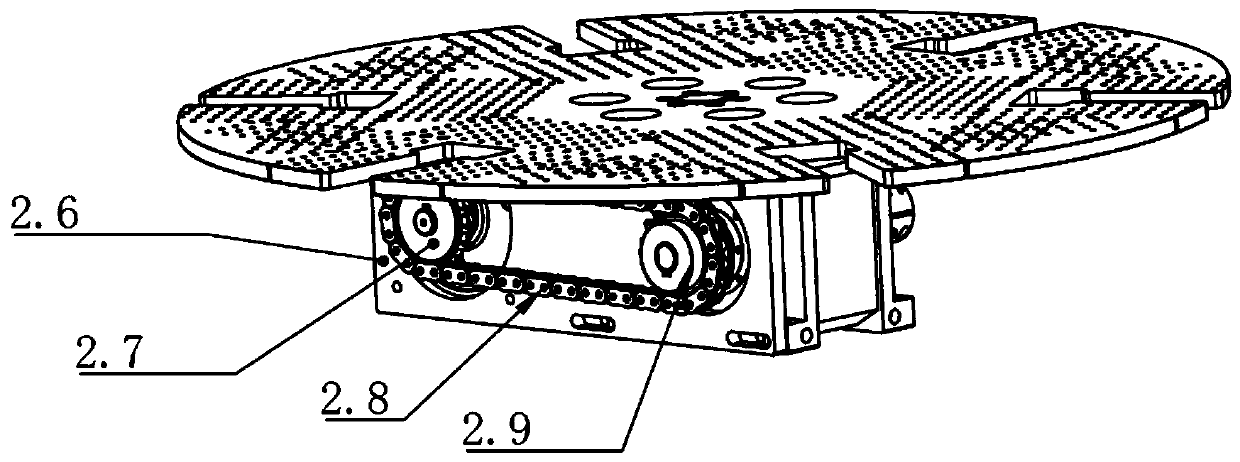

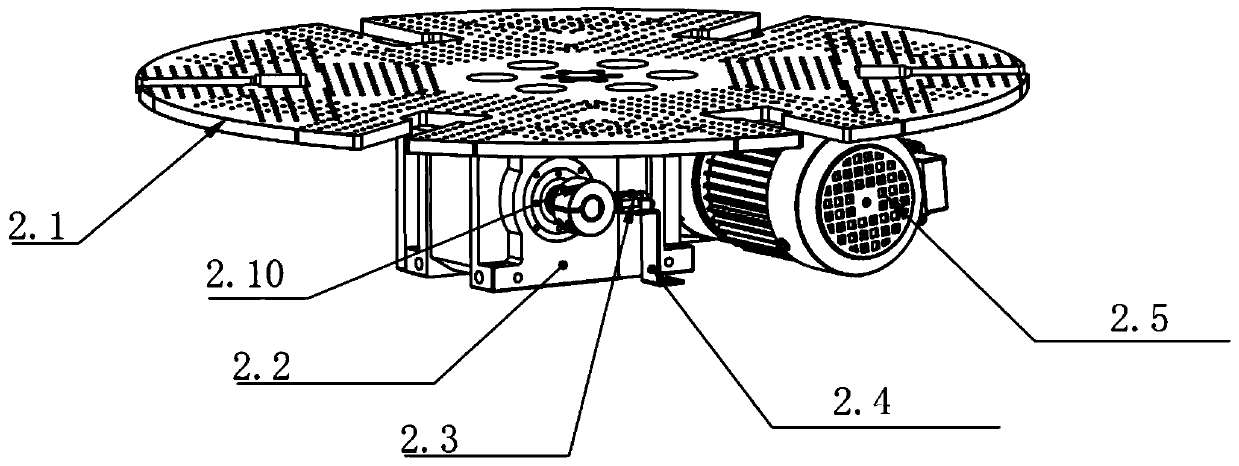

Reaction cup feeding mechanism

PendingCN109230386ASmooth slidingWell mixedConveyorsConveyor partsBiochemical engineeringCup feeding

The invention discloses a reaction cup feeding mechanism, which comprises a rotary bin, a main stirring wheel arranged in the rotary bin, an auxiliary stirring wheel arranged in the rotary bin and connected with one side of the main stirring wheel, a driving device arranged on the rotary bin, and connected with the other side of the auxiliary stirring wheel, a reaction cup outlet arranged at the side part of the rotary bin and a inclined chute arranged on the outlet of the reaction cup. The reaction cup feeding mechanism is matched with the auxiliary stirring wheel through the main stirring wheel, so that the mixing reaction cup can be conveniently mixed evenly, the reaction cup can be easily held up by the stirring wheel, continuous supply is realized, the occupied volume is small, and isconvenient for users to operate; an angle is formed between a main stirring wheel blade and the rotating shaft, and forms a cavity between the rotary bin, the number of the lifting reaction cup is increased, and the probability that the reaction cup is successfully fallen into the inclined chute is improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

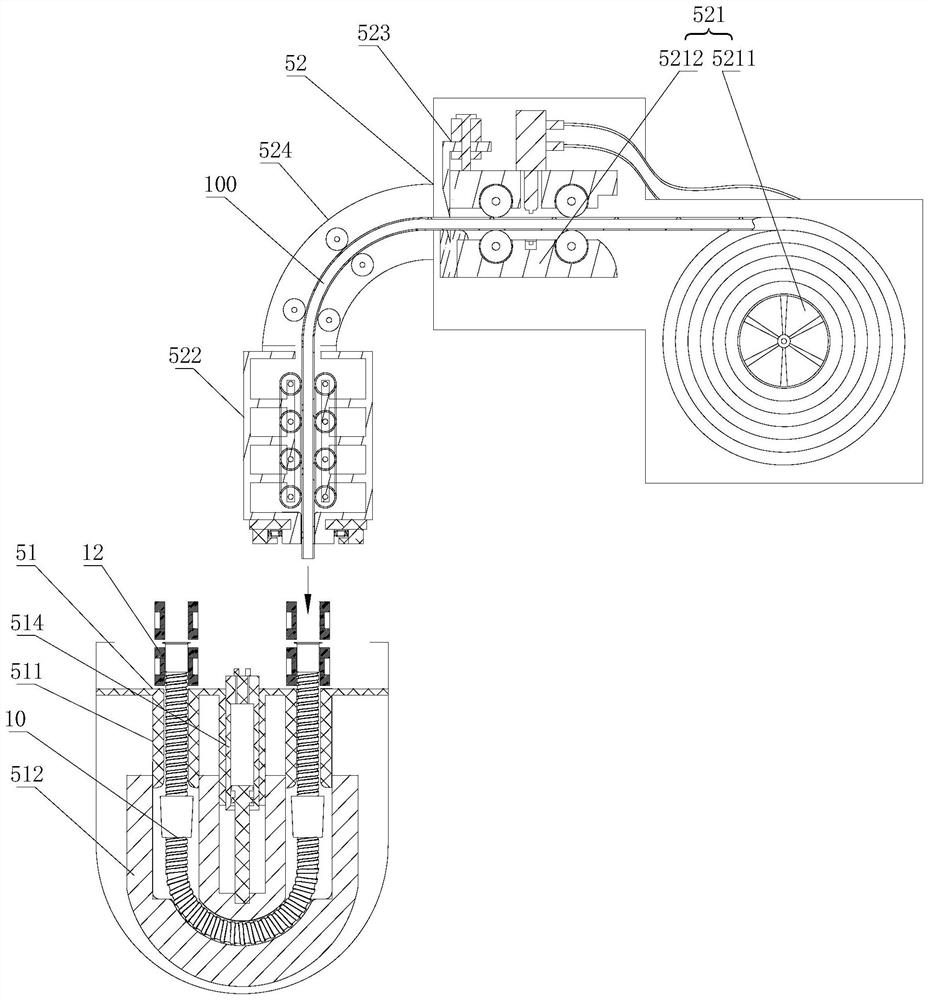

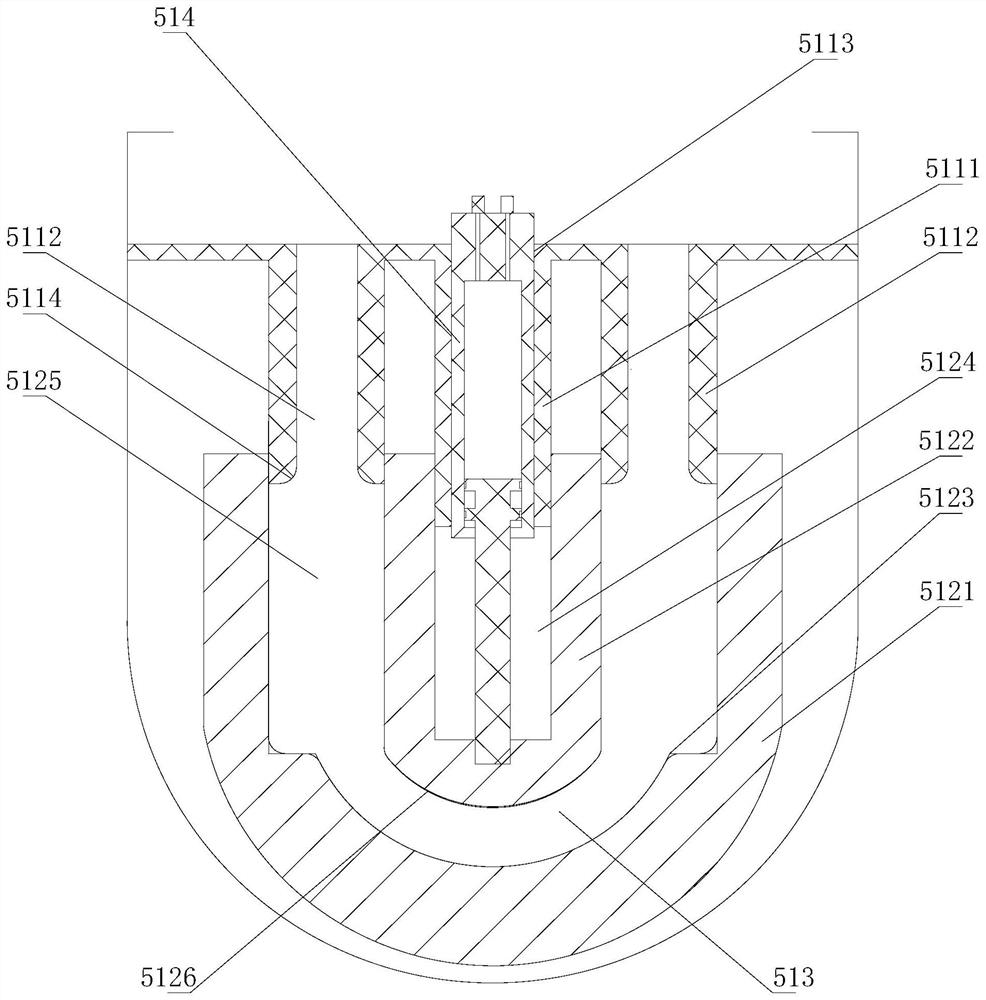

Thermal shrinkage type coin sorting packer

The invention relates to a thermal shrinkage type coin sorting packer comprising a coin sorter and a thermal shrinkage packer. The thermal shrinkage packer comprises a packer support, a tube film support, a tube film inner plunger, a tube film lifting device, a sealing device, a coin push-off device and a thermal shrinkage device; the thermal shrinkage device comprises a driving device, a thermal shrinkage outer tube connecting with the driving device, a thermal shrinkage inner tube located in the center inside the thermal shrinkage outer tube, a vertical heating device located in the center of the thermal shrinkage inner tube and a heat conducting plate which is arranged on the two sides of the upper end of the heating device and is connected with the thermal shrinkage inner tube; and air holes are formed in a lower cover of the thermal shrinkage inner tube. The thermal shrinkage type coin sorting packer has the advantages that the continuous supply of a tube film is achieved, the coin amounts of single package are adjustable, and the effect of thermal shrinkage packing is good.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

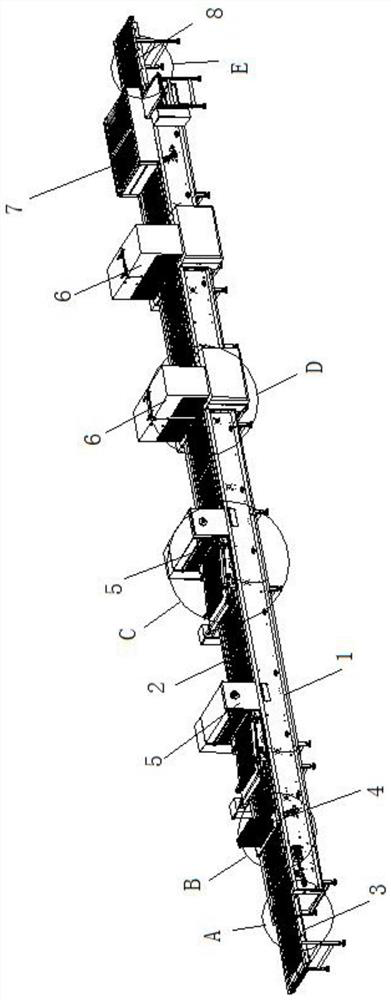

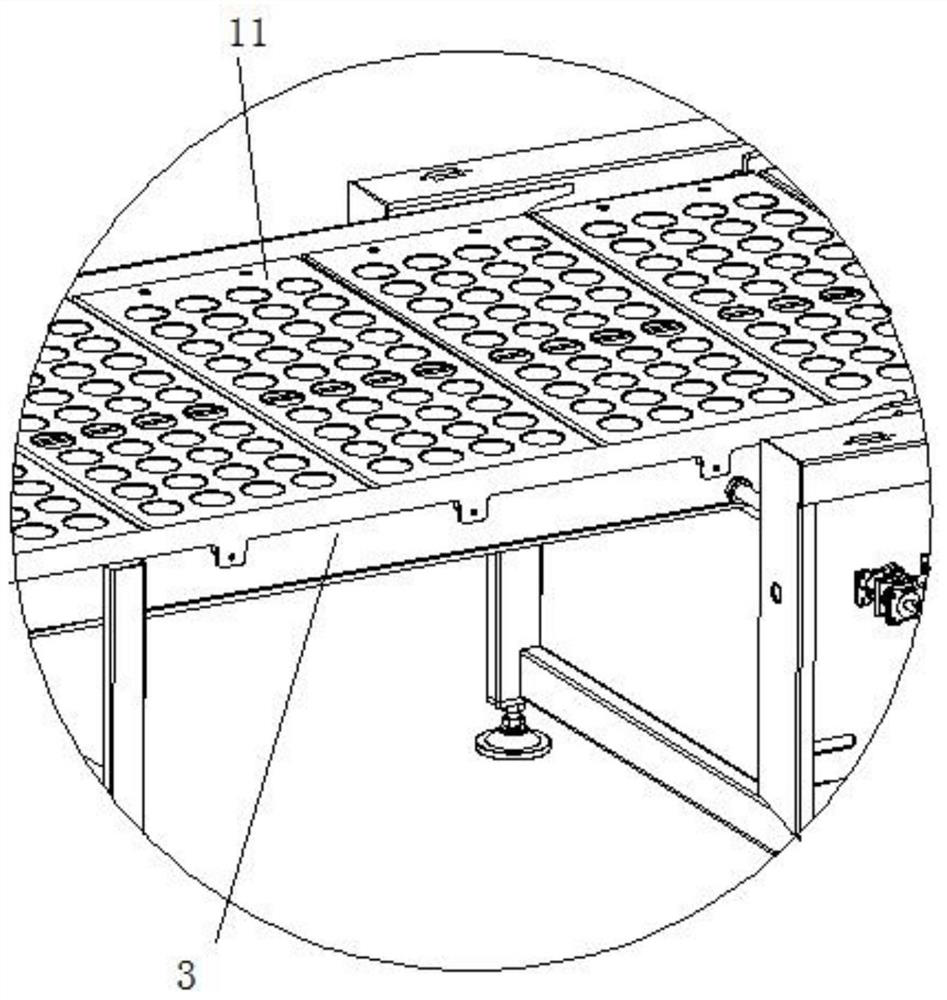

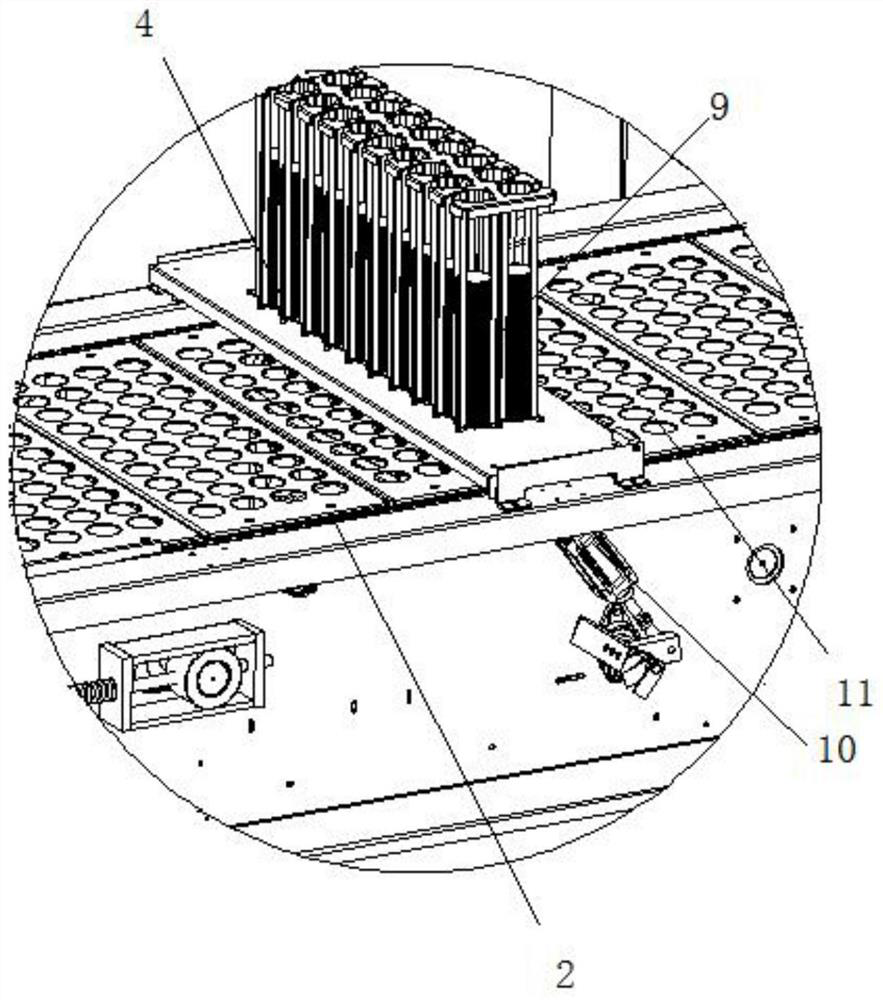

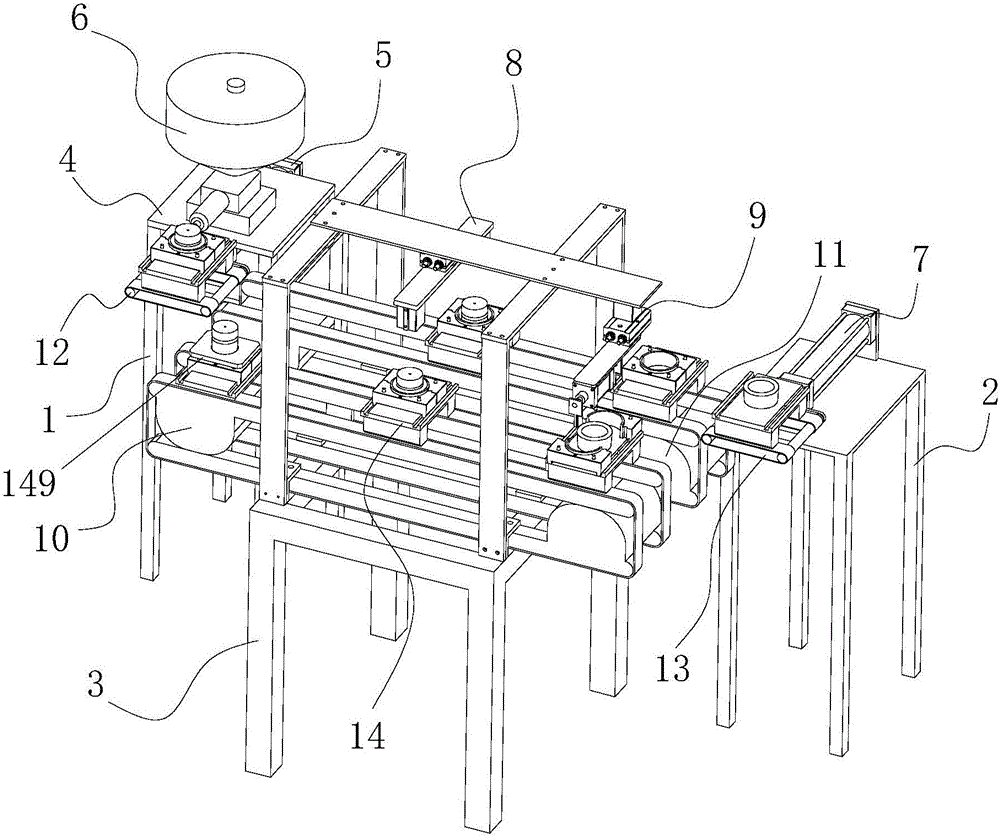

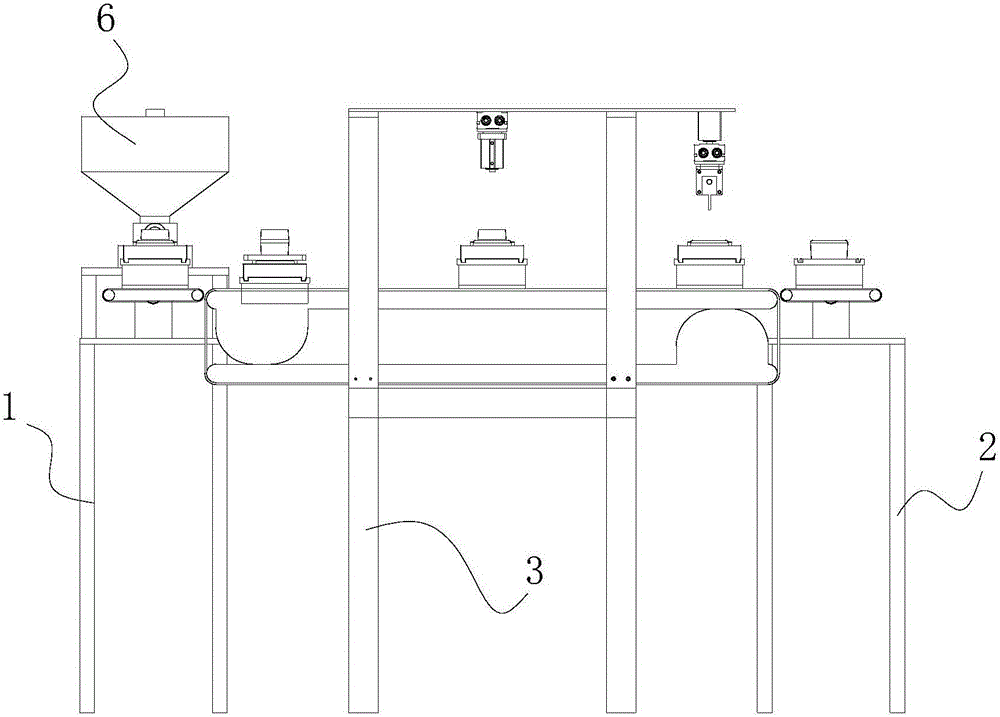

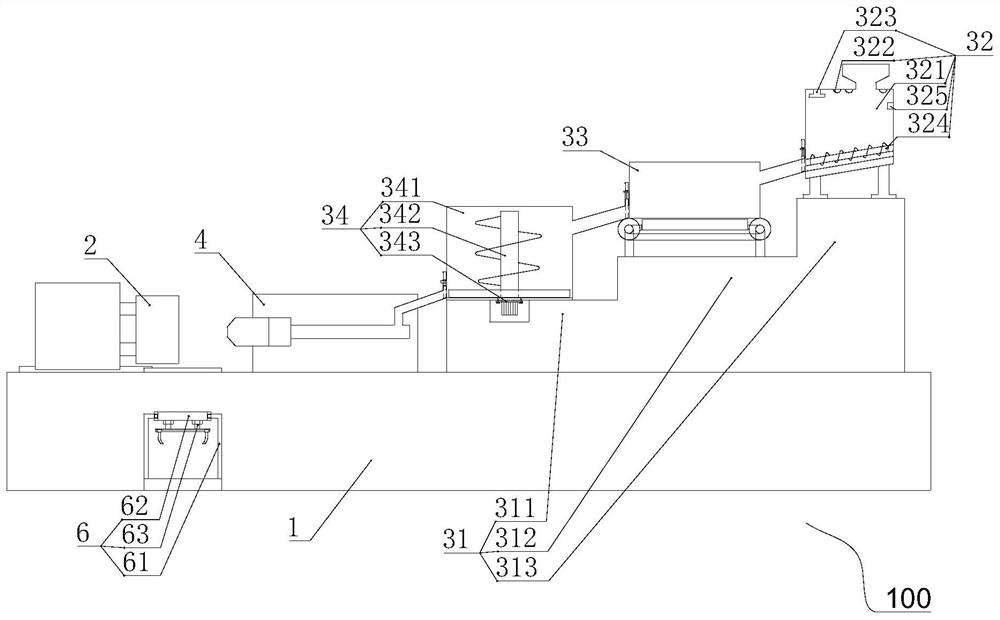

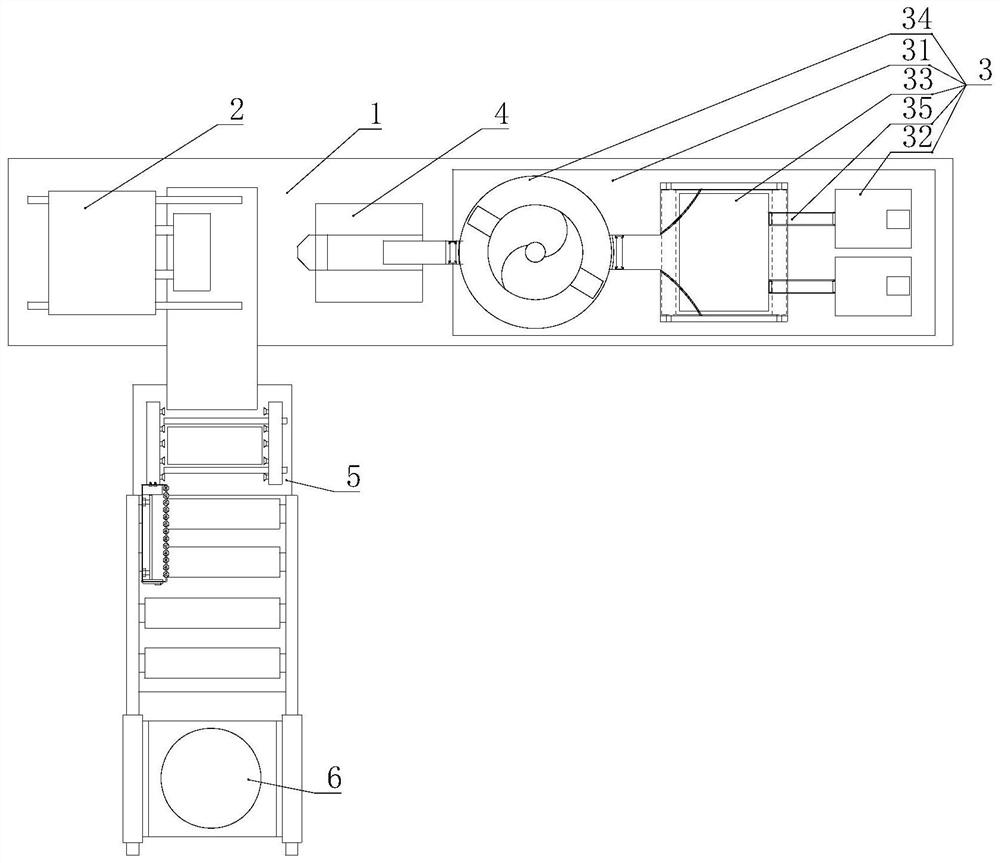

Full-automatic egg tart forming production line

PendingCN112568254ARealize automatic reclaimingEasy to operateDough shaping and cutting apparatusProduction lineMechanical engineering

The invention discloses a full-automatic egg tart forming production line which comprises a rack, a circulating conveying chain is erected on the rack, an aluminum support discharging station, a doughblank discharging station, a mold forming station and a tray removing station are sequentially arranged on the circulating conveying chain from the feeding end to the discharging end, the feeding endof the circulating conveying chain is a tray supplying station, and the discharging end of the circulating conveying chain is a tray discharging station. A flat plate placing frame in butt joint withthe circulating conveying chain is erected on the tray supplying station, the aluminum support discharging device is erected on the aluminum support discharging station, the dough blank discharging station comprises two quantitative slicing machines arranged in a spaced mode, two egg tart punch forming devices arranged in a spaced mode are erected on the mold forming station, and a tray removingdevice used after egg tart forming is erected on the tray removing station. A discharging frame is erected on the tray discharging station. The aluminum support discharging device, the quantitative slicing machines, the egg tart punch forming device and the tray removing device are integrated into a whole to form a production line, manual participation is not needed from aluminum support feeding,dough blank discharging and egg tart forming and stripping, and the automation strength is high.

Owner:王晓雅

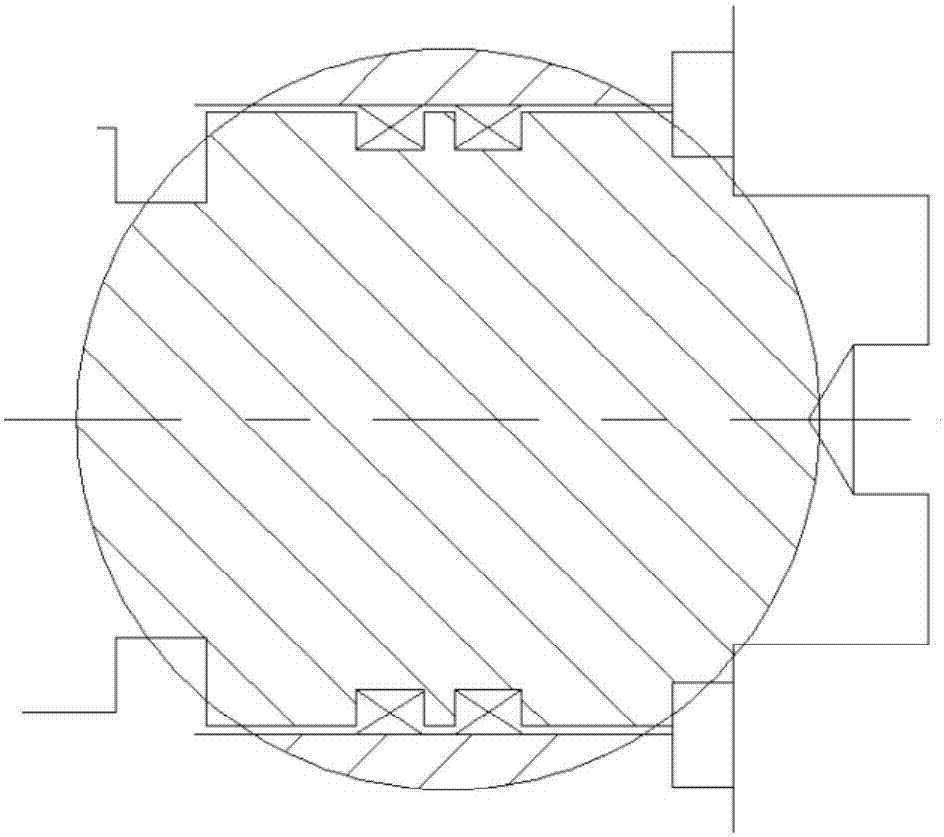

Full-automatic continuous cylinder molding device

The invention discloses a full-automatic continuous cylinder molding device, which comprises a left side support, a right side support, and a middle support. An adjusting support is mounted on the left side support; a pusher A is mounted on the left side support; a feeding mechanism is mounted on the adjusting support; a pusher B is mounted on the right side support; a mold core adjusting mechanism and a mold adjusting mechanism are mounted on the middle support; a conveying mechanism A and a conveying mechanism B are arranged on the middle support; the pusher A is connected with a feeding and conveying mechanism; the pusher B is connected with a discharging and conveying mechanism; a cylinder former comprises a locating seat, a locating plate, a half mold A, a half mold B, a mold core and locating pins; two sliding chutes are formed on the locating plate; the locating seat can move on the conveying mechanisms; the locating plate is mounted on the locating seat; the half mold A and the half mold B are mounted in the sliding chutes, and surround to form a mold cavity in the middle; and the mold core is located in the mold cavity. The full-automatic continuous cylinder molding device provided by the invention is high in automation degree, and can realize continuous feeding.

Owner:黄斌

Two-shaft multi-station automatic feeding method for stamping and feeding machine

PendingCN110732602AGuaranteed continuityImprove work efficiencyMetal-working feeding devicesMetal working apparatusMagnetic separatorMachine

The invention discloses a two-shaft multi-station automatic feeding method for stamping. The method comprises the steps that firstly, a whole stack of materials are prepared to a material preparationrotary table mechanism station; then, a material ejecting mechanism and a magnetic separator are used for conducting material ejecting and separating on the stack of materials together; then, a material taking jig on a two-shaft feeding transfer mechanism is used for grabbing, transferring and positioning the separated materials on a positioning table; a double-sheet detection system is used for detecting whether the phenomenon that two or more sheets of materials are stacked exists or not for the materials transferred to the positioning table; if that one sheet of materials exist currently isdetected, the feeding step continues, and the other shaft material taking jig on the feeding transfer mechanism is used for transferring the current materials on the positioning table to a stamping machine; and if that two or more sheets of materials are stacked is detected, the feeding step is stopped, and an alarm is given. The work continuity is effectively guaranteed, and the work efficiencyis improved; and manual operation is replaced, the automation degree of equipment is greatly improved, labor force is reduced, and productivity is improved. The invention further discloses a two-shaftmulti-station automatic feeding machine for stamping.

Owner:DONGGUAN ALFA AUTOMATION TECH CO LTD

Wax oil smearing device for chair legs

ActiveCN111644322ARealize reciprocating coatingAchieve continuous supplyLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention provides a wax oil smearing device for chair legs, and relates to the field of furniture processing. The problems that manual smearing is large in fatigue strength and low in efficiency,an existing smearing machine is high in manufacturing cost, and consequently the processing cost is increased are solved. The wax oil smearing device for the chair legs comprises a frame body; a driving motor is fixedly connected to the frame body, and a brushing structure is slidably connected to a sliding shaft of the frame body; and a table chair leg fixing structure is arranged on the frame body, and a transmission structure is rotationally connected to the frame body. According to the wax oil smearing device, a clamping head A and a clamping head B are each rotationally connected with aplacement seat which is of a V-shaped structure, thus in the using process, through arrangement of the placement seats which are each of the V-shaped structure, the temporary supporting effect can beexerted during fixing of the table chair legs, and the flexibility during placement of the table chair legs is improved, so that the smearing processing efficiency is improved.

Owner:临沂高新人才教育发展集团有限公司

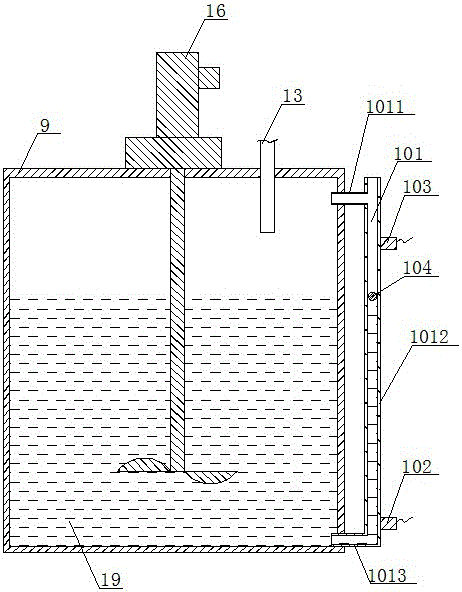

Full-automatic proportioning device and method of lubricating agent for thread throwing of ceramic fibers

PendingCN106823906AHigh precisionAvoid the lack of precision caused by manual proportioningTransportation and packagingRotary stirring mixersFiberWater pipe

The invention discloses an full-automatic proportioning device and method of a lubricating agent for thread throwing of ceramic fibers, belongs to the field of proportioning devices of lubricating agents for thread throwing of ceramic fibers, aims to solve the technical problem that the conventional lubricating agent for thread throwing of the ceramic fibers has the defects of low proportioning accuracy and impossibility in continuous production. The full-automatic proportioning device comprises a bracket, liquid level detection devices, a stirring device, a controller, a water tube, a liquid outlet tube, a lubricating agent container, a lubricating agent metering cup and an upper container, wherein the lubricating agent container, the lubricating agent metering cup and the upper container are arranged on the bracket; the lubricating agent metering cup and the upper container are provided with upper ports and lower ports which are arranged one above the other; the upper port of the upper container communicates with the water tube which is positioned above the upper port of the upper container; the lower port of the upper container communicates with the liquid outlet tube; the liquid outlet tube, the water tube and liquid delivery tubes are provided with switch valves; the lubricating agent metering cup and the upper container correspond to the liquid level detection devices respectively; the liquid level detection devices and the stirring device are connected with the controller. The method is used for preparing lubricating liquid by using the full-automatic proportioning device of the lubricating agent for thread throwing of the ceramic fibers.

Owner:山东红阳高温节能材料股份有限公司

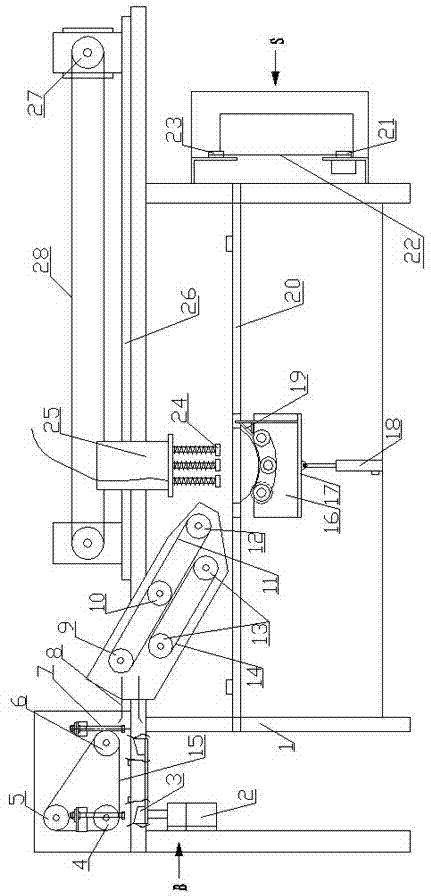

Transmission device for carton handle belt threading machine

InactiveCN103042726BAchieve continuous supplyReduce occupancyBox making operationsPaper-makingControl engineeringCarton

The invention relates to a threading machine of a handle of a paper box, and in particular relates to a transmission device for the threading machine of the handle of the paper box. The transmission device for the threading machine of the handle of the paper box comprises a handle feeding mechanism, a handle cutting mechanism, a gasket feeding mechanism, a gasket conveying mechanism and a handle continuous feeding mechanism. A driving synchronous pulley in the gasket feeding mechanism is connected with a driven synchronous pulley through a gasket feeding synchronous belt. The gasket feeding synchronous belt is installed at one end of a traveling bracket which is placed on a slide rail. The other end of the traveling bracket is provided with an absorption device. A first-level handle feeding mechanism in the handle feeding mechanism comprises a driving synchronous pulley for handle feeding, a driven synchronous pulley for handle feeding and a driven feeding synchronous pulley. A feeding slide rail in the handle continuous feeding mechanism is provided with a feeding transmission bracket which is connected with a power device. A feeding bracket is installed below the feeding transmission bracket. The transmission device provided by the invention can continuously feed the handles and gaskets. The gaskets are not arranged continuously, and the gaskets can be continuously fed in small occupied space.

Owner:于颢明

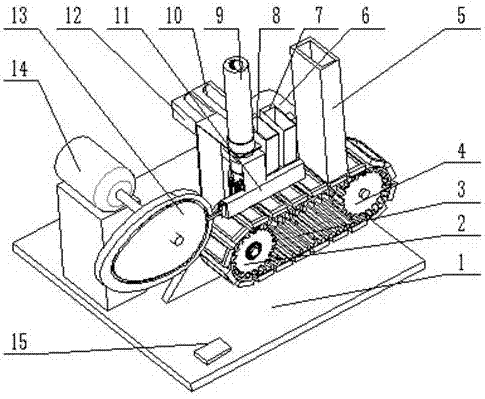

Crawler-type medical thinprep clamp automatic assembly robot

InactiveCN107186733AImplement automatic assemblyAchieve continuous supplyManipulatorHydraulic cylinderGear wheel

The invention relates to a crawler-type medical thinprep clamp automatic assembly robot, and belongs to the field of medical machines. The crawler-type medical thinprep clamp automatic assembly robot is composed of a rack, a gear set, a crawler set, gears, a base channel, sheet grooves, a rotating column, hydraulic cylinders, a rack set, a hydraulic cylinder base, a cam, stepping motors and a controller. The crawler-type medical thinprep clamp automatic assembly robot is characterized in that the controller, the hydraulic cylinder base, the stepping motor, the rotating column, the base channel, the stepping motor and the gear set are installed on the rack, the gears are installed on the stepping motors, the crawler set is installed on the gear set and the gears, the sheet grooves are fixed to the hydraulic cylinder base, the two hydraulic cylinders are installed on the hydraulic cylinder base, the rack set is fixed to the rotating column through a fixing plate on the rack set, one end of the rack is matched with a groove in the cam, and the cam is installed on one stepping motor. The crawler-type medical thinprep clamp automatic assembly robot has the beneficial effects that under cooperation of all devices, automatic assembling of a thinprep clamp can be achieved, continuous supply of a thinprep clamp base can be achieved through crawlers, downward pressing and rotating motions of a barrel can be achieved through the rotating column, and therefore assembly work is achieved.

Owner:柴传程

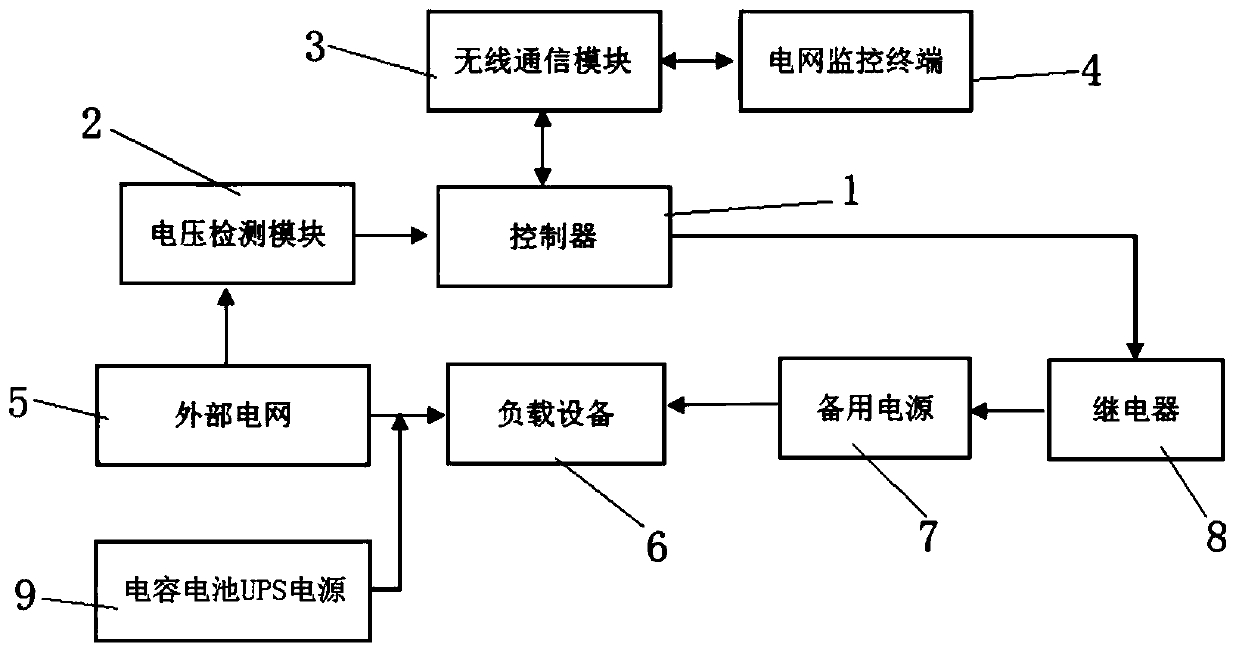

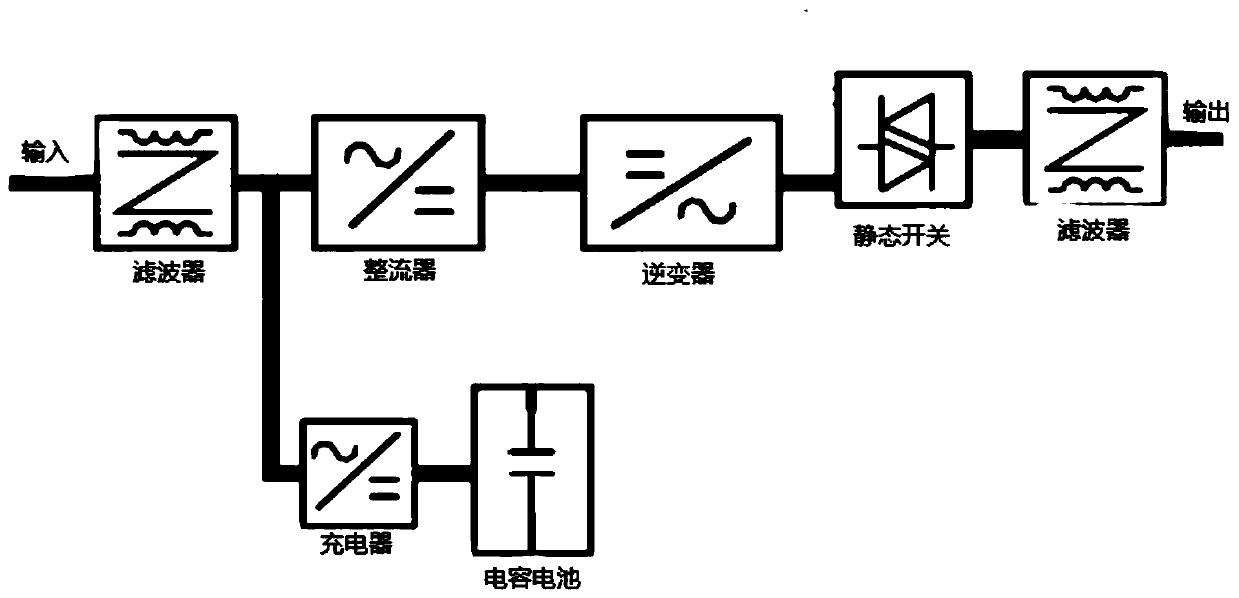

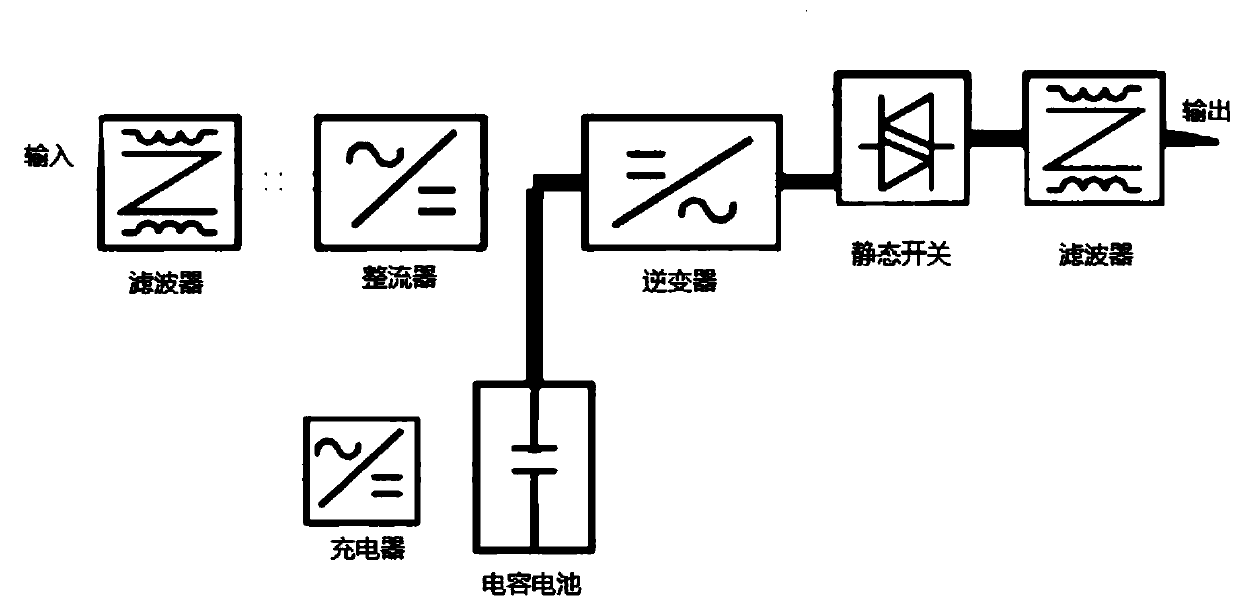

Instantaneous power-off prevention system based on capacitor battery and working method thereof

InactiveCN110380509ANo maintenanceWork lessEmergency power supply arrangementsCapacitanceStandby power

The invention discloses an instantaneous power-off prevention system based on a capacitor battery and a working method thereof. A controller input end is connected with a voltage detection module, a controller output end is connected with a relay, a controller is further connected with a grid monitoring terminal through a wireless communication module, the voltage detection module is connected with the external power grid, a relay output end is connected with a backup power supply, and the external power grid, the backup power supply and a capacitor battery UPS power supply are all connected with a load device. The working method includes steps that the required capacitance is calculated according to the power of most existing computers; the UPS uninterruptible power supply is made according to the capacitance; the uninterruptible power supply is connected with a computer, the UPS uninterruptible power supply is charged till the power is sufficient; whether a desktop computer is powered off is determined, if yes, the UPS uninterruptible power supply is started. The system is advantaged in that the system is safe and reliable, has high accuracy and has strong practicality.

Owner:STATE GRID CORP OF CHINA +2

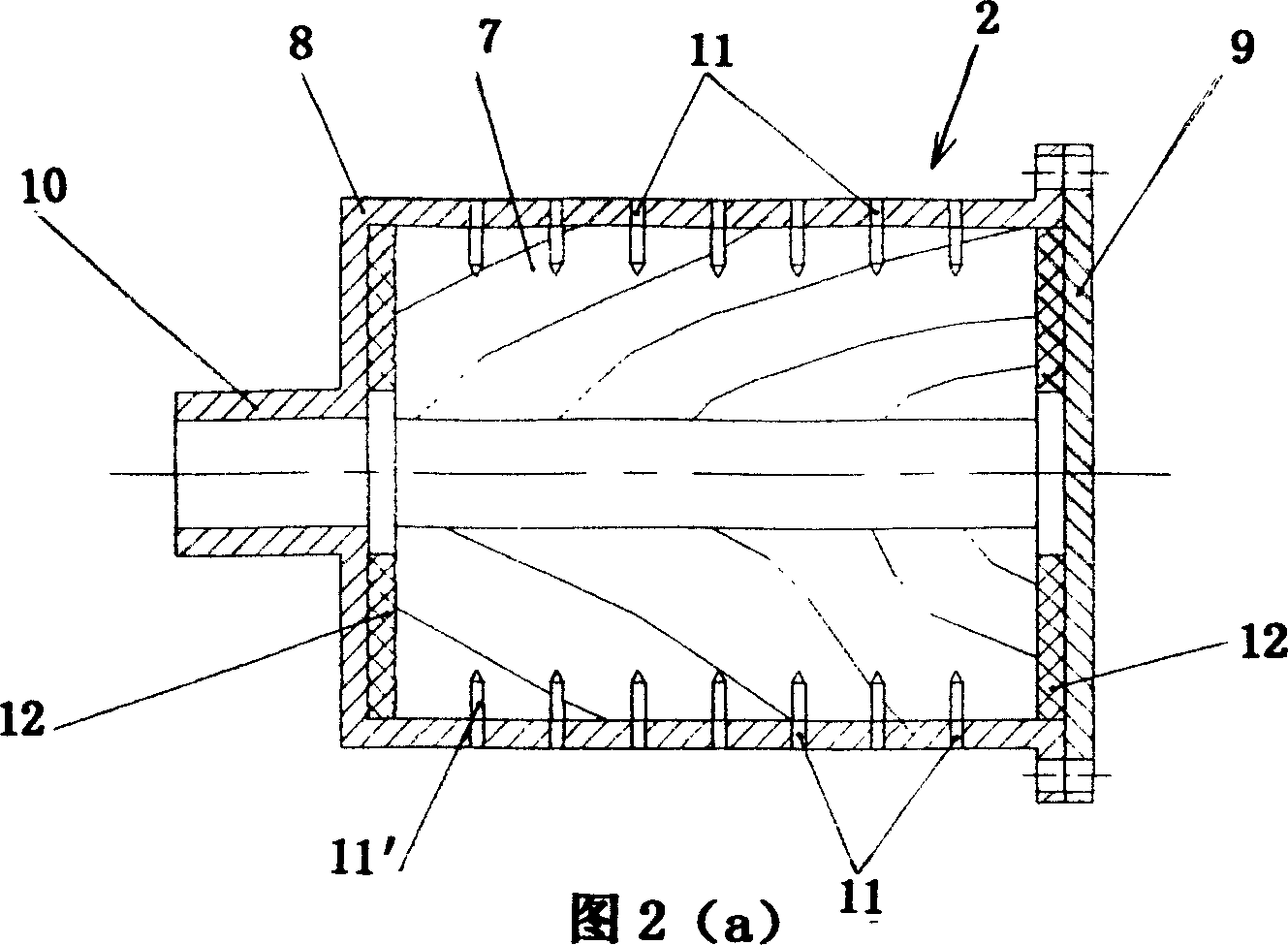

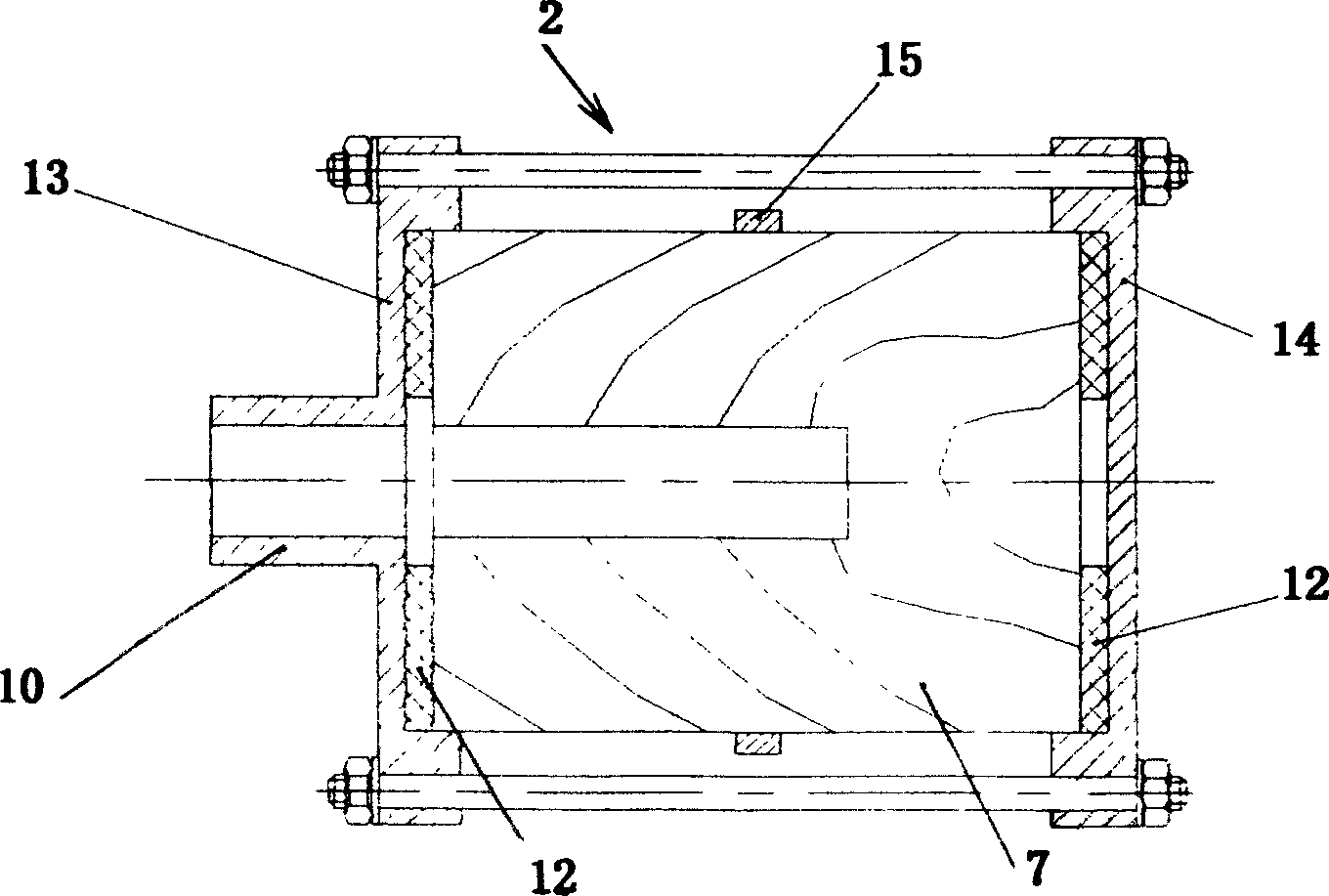

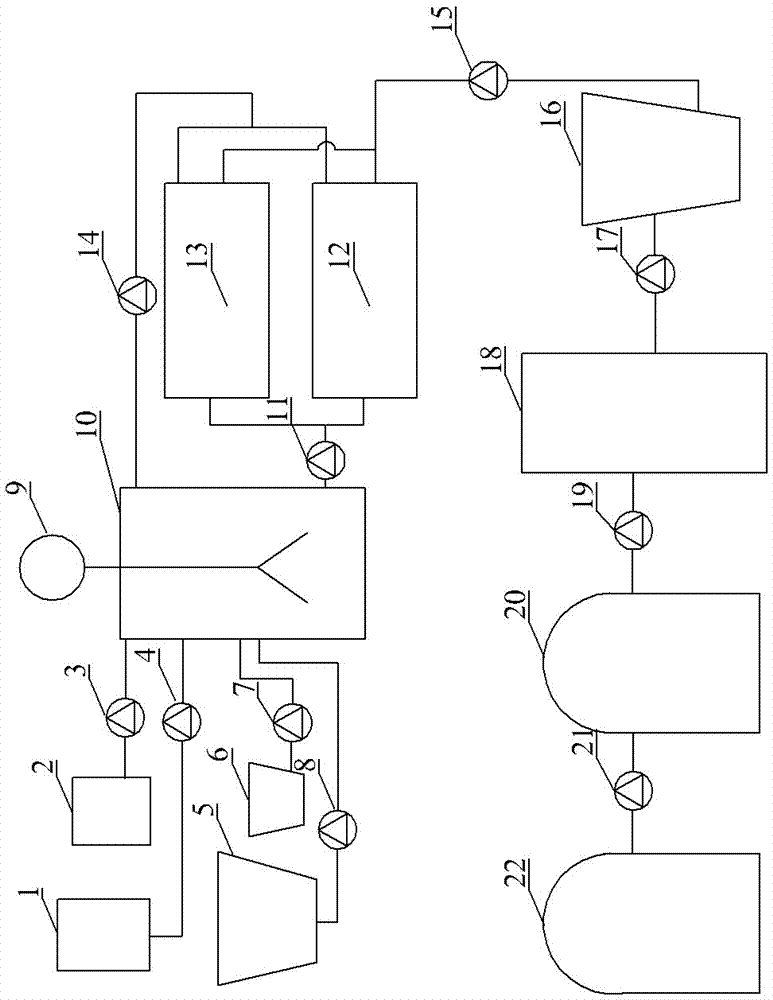

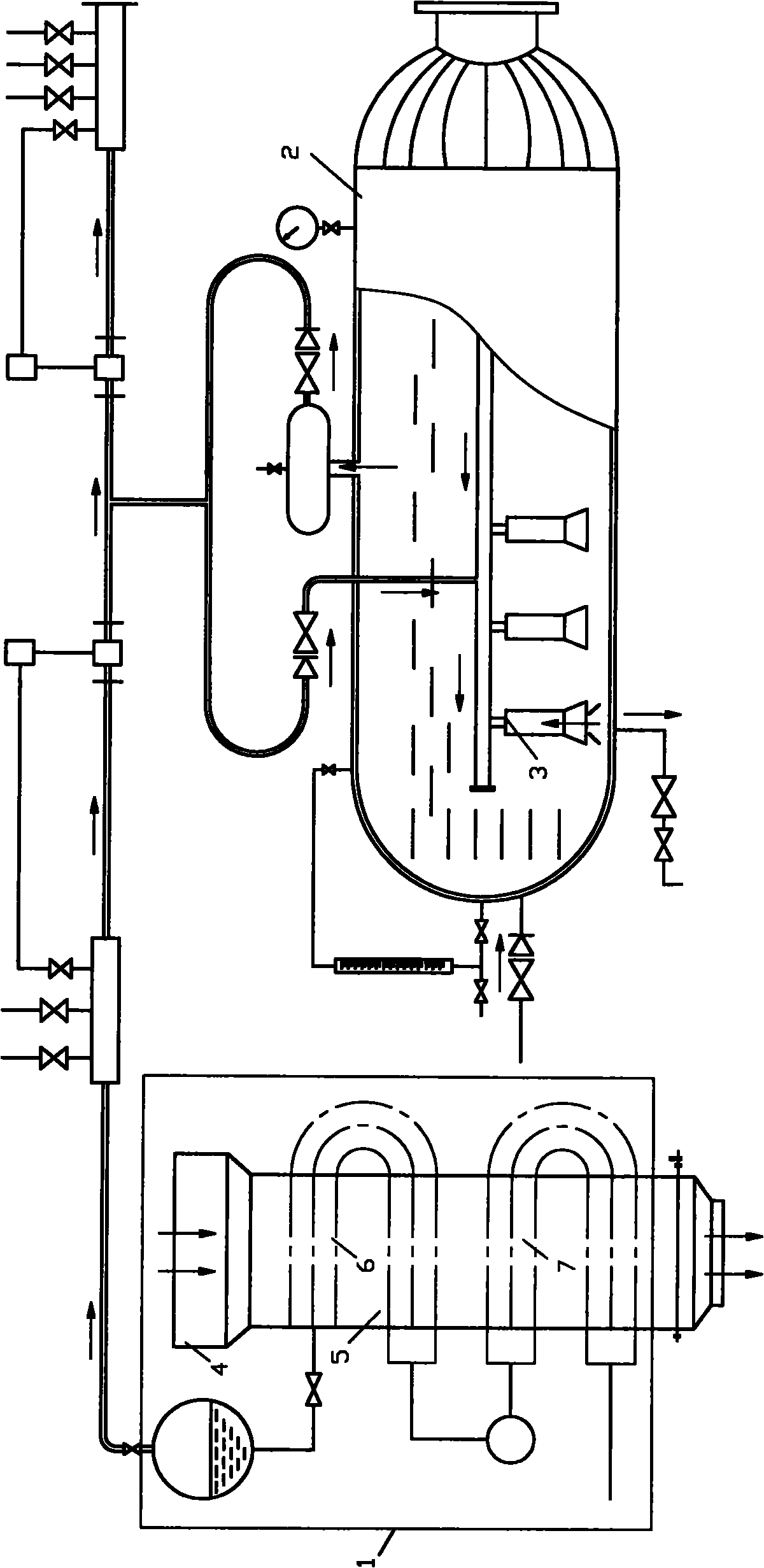

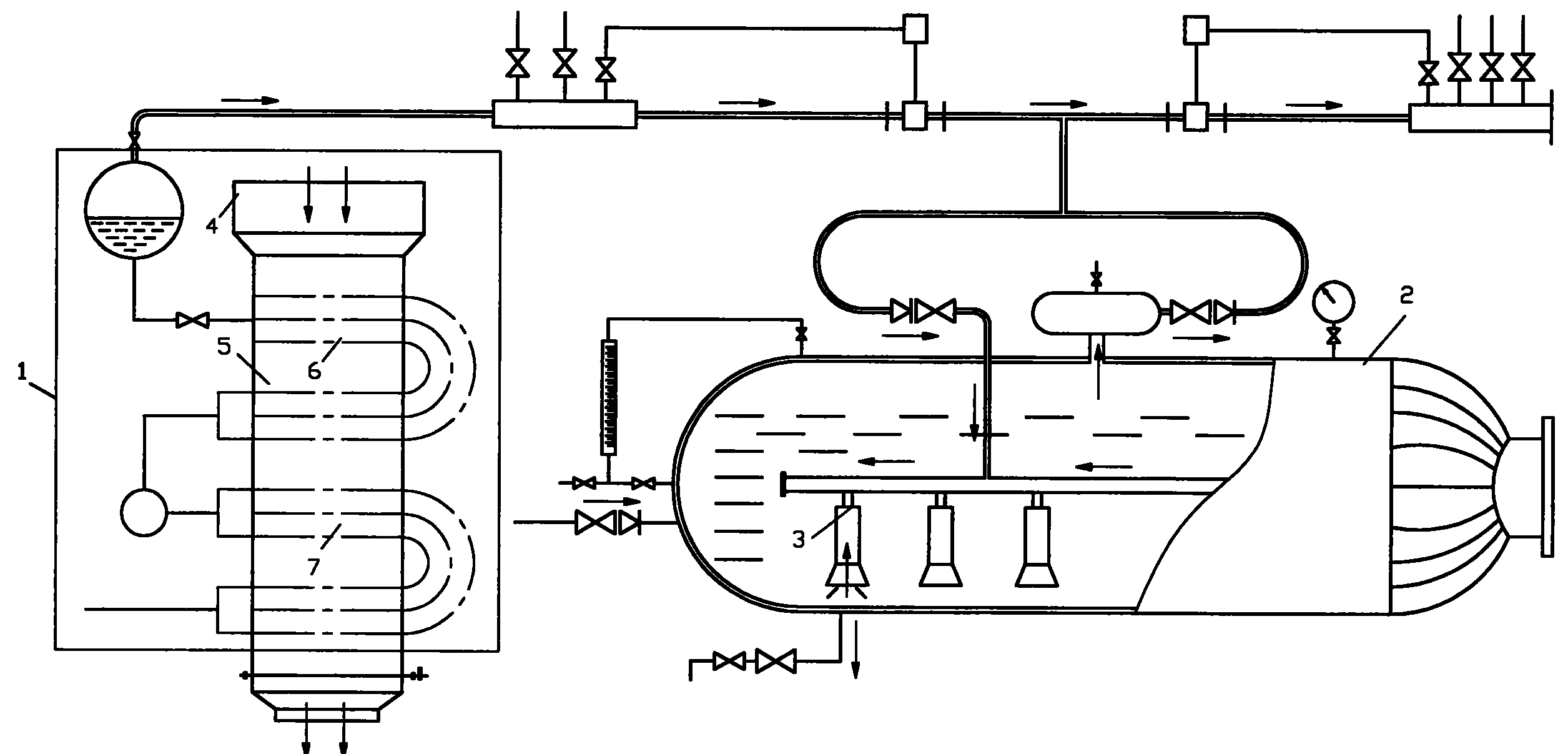

Heat energy recovery system of slag of magnesium reducing furnace

InactiveCN102042767AAchieve continuous supplyIncreasing energy efficiencyWaste heat treatmentSlagProcess engineering

The invention relates to a heat energy recovery system of slag of a magnesium reducing furnace, comprising a waste heat boiler (1) which is matched with deslagging equipment so as to utilize the waste heat of the slag to prepare heat steam. The heat energy recovery system is characterized by further comprising a steam heat storage device (2) which is internally provided with at least one steam nozzle (3); all the steam nozzles (3) extend out of the steam heat storage device (2) by a gas inlet pipeline and are respectively communicated with a steam outlet of the waste heat boiler (1); the deslagging equipment comprises a storage bin (4) and a discharging channel (5) communicated with the storage bin (4); and the discharging channel (5) is internally provided with a spiral discharging machine. The heat energy recovery system can be used for recycling the waste heat of the slag of the magnesium reducing furnace, and continuous supply of heat steam can be still realized under the condition that the slag is discharged at interval.

Owner:宁夏华亿镁业股份有限公司

Equipment for rapidly and continuously manufacturing droplet microspheres and application thereof

ActiveCN105032312AAccelerateIncrease production speedMicroballoon preparationMicrocapsule preparationMaterial supplyEngineering

The invention relates to equipment for rapidly and continuously manufacturing droplet microspheres and application thereof. The equipment comprises a dispersed phase feeding device, a continuous phase feeding device, a continuous phase pressure tank and a rotating stirring device. The top of the continuous phase pressure tank is communicated with the continuous phase feeding device. The bottom of the continuous phase pressure tank is provided with an unloading opening. The side wall of the continuous phase pressure tank is provided with a discharging opening, a dispersed phase inlet hole and a ventilation hole from top to bottom. The dispersed phase feeding device is communicated with the dispersed phase inlet hole, and the rotating stirring device is arranged in the continuous phase pressure tank. According to the equipment for rapidly and continuously manufacturing droplet microspheres and the application, continuous phases and dispersed phases are conveyed into the continuous phase pressure tank continuously to achieve rapid and continuous material supply, and rotating blades play a role in assisting in material supply, so that working efficiency is improved; liquid drops are brought into a discharge device through inlet air in an air chamber, and the droplet microspheres are prepared efficiently, rapidly and continuously.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Full-automatic metal double-buckle pipe assembling device

ActiveCN112719102AImprove penetration efficiencyImprove installation efficiencyMetal-working feeding devicesMetal working apparatusProduction lineTransmission belt

The invention relates to a full-automatic metal double-buckle pipe assembling device. The full-automatic metal double-buckle pipe assembling device comprises a rack and a conveying belt. A clamping and fixing mechanism is arranged on the conveying belt. A feeding module, a steel sleeve installing module, an inner steel sleeve expanding module, an inner pipe penetrating module, a core installing module, a buckling and pressing module, a detection module and a discharging module are sequentially arranged on the rack in the feeding direction of the conveying belt. A PLC control panel is further arranged on the rack. The full-automatic metal double-buckle pipe assembling device has the advantages that fixing and conveying of an outer pipe are achieved through the conveying belt, accordingly, the outer pipe can sequentially pass through the feeding module, the steel sleeve installing module, the inner steel sleeve expanding module, the inner pipe penetrating module, the core installing module, the buckling and pressing module, the detection module and the discharging module, automatic continuous assembling production of metal double-buckle pipes is achieved, and the work intensity of operators is relieved; and compared with existing manual assembling, the full-automatic metal double-buckle pipe assembling device has the characteristics that production personnel on a production line can be reduced by 80%, and the metal double-buckle pipes different in length can be assembled.

Owner:ZHEJIANG KAIYUE PLASTIC IND CO LTD

Automatic feeding, packaging and injection molding equipment and application method thereof

The invention discloses automatic feeding, packaging and injection molding equipment and an application method thereof. The automatic feeding, packaging and injection molding equipment comprises a mounting table, an injection mold, an automatic feeding device, an injection component and a receiving device; the injection mold is arranged on one side of the mounting table; the automatic feeding device comprises a mounting step, a dewatering and storing component, a weighing component, a mixing component and a conveying channel; the mounting step is arranged on the other side of the mounting table; the mounting step comprises a first step, a second step and a third step which are arranged from low to high; the mixing component, the weighing component and the dewatering and storage component are sequentially arranged on the first step, the second step and the third step; the injection component is arranged between the injection mold and the automatic feeding device; the receiving device comprises a base, a fixed frame, a movable frame, a bag storage component and a suction cup; the base is arranged on one side of the mounting table; the fixed frame and the movable frame are oppositelyarranged on the two sides of the base; the bag storage component is fixedly arranged on one side of the fixed frame; and the suction cup is arranged on the side, opposite to the movable frame, of thefixed frame.

Owner:太仓市冬鑫塑料制品有限公司

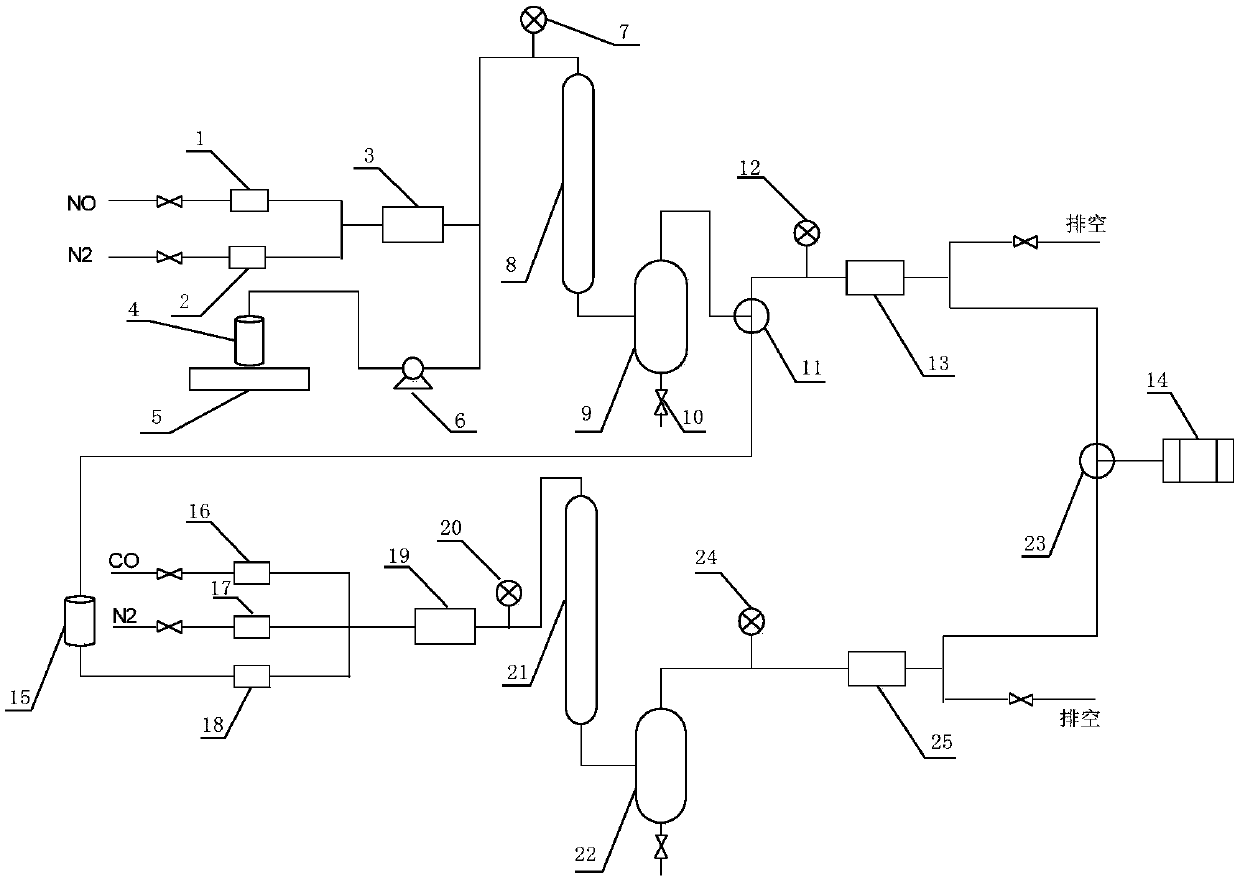

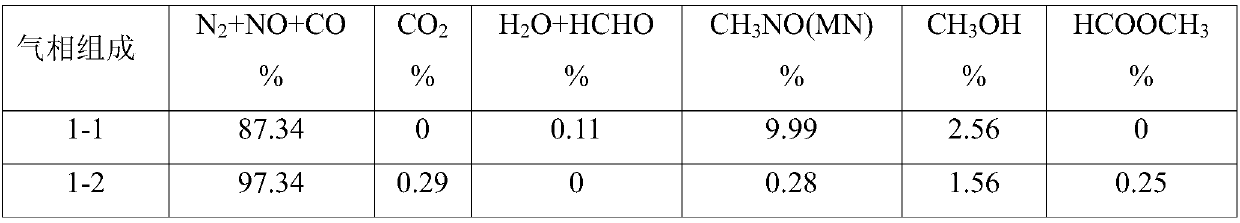

Device for continuously producing methyl nitrite gas and application of device

PendingCN110818568AAchieve continuous supplyChemical analysis using catalysisNitrous acid preparation ester preparationGas analysisMethyl nitrate

The invention provides a device for continuously producing methyl nitrite gas and an application of the device. The device comprises a methyl nitrite gas preparation system, a gas analysis system anda first fluid delivery control unit; the methyl nitrite gas preparation system is used for continuously producing methyl nitrite gas; the gas analysis system is used for obtaining the concentration ofthe methyl nitrite gas, wherein the methyl nitrite gas is from the methyl nitrite gas preparation system; and the first fluid delivery control unit is connected with the methyl nitrite gas preparation system and the gas analysis system, is used for making communication between the methyl nitrite gas preparation system and the gas analysis system to provide a to-be-analyzed gas sample for the gasanalysis system, and is also used for controlling product output of the methyl nitrite gas preparation system. According to the invention, stable supply of methyl nitrite gas is realized, the methyl nitrite gas preparation system and a catalytic reaction evaluation system taking methyl nitrite as a raw material are further connected in series, and stability and service life evaluation of a nitricacid reduction reaction for preparing methyl nitrite gas and supply of a stable gas source for a catalytic reaction are realized.

Owner:SHANGHAI HUAYI ENERGY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com